Page 1

TDE470 Service Manual

TDE470

Purpose of this ma nu al: To provide de ta iled

installation and operation instructions; to give

insights into how the machine works; to list

possible cause s for problems; and to suggest

procedures for s pecific type s of service .

The TDE470 is an ice make r an d dispe nse r

combined into one cabinet. The refrigeration

system is air cooled, using R-134 a as a refrig era nt.

The control system uses elec tric ey es as a bin

control and a water leve l sensor as the water

safety control. As ice is made, it fills a pla st ic

storage bin. When ice is needed , a motor rot at es a

stainless stee l van e inside th e storage bin and

sweeps the ice int o the spo ut .

Table of Contents

Specifications: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

To The Installer: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

For The Electrician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

For The Plumbe r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Optional Kits: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

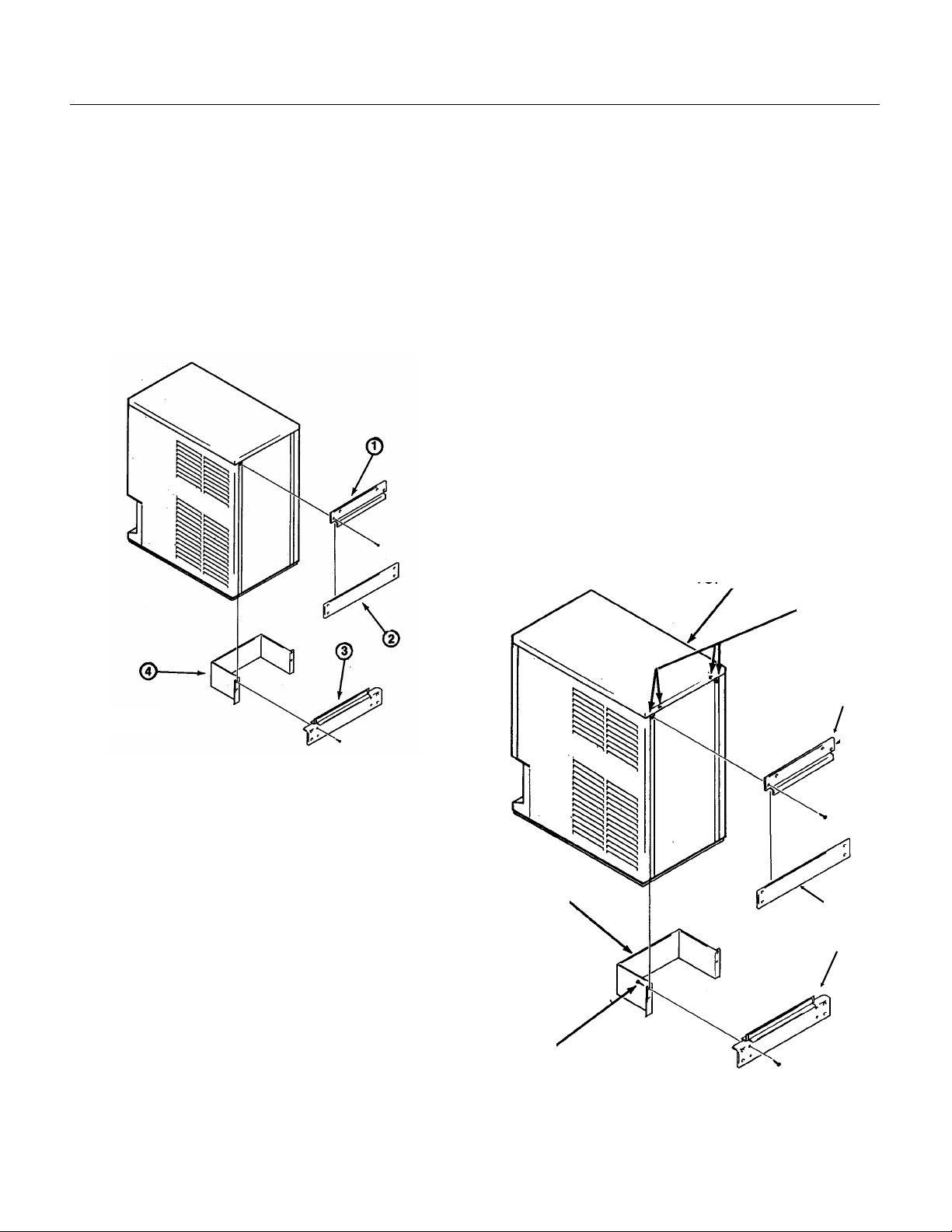

Wall Mount Kit (KWB1): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Final Check List & Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

User Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Component Loca tio n & Functio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Refrigerat ion Syst em Op era tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

Water System Operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Electrical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

Maintenance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 15

Dispense Area Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Auger and Bearing Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Inspection: A ug er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Service Diagnosis: Circu it Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 23

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 24

Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25

Bearings, Water S eal an d Aug er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 26

Bearing Replac ement: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 27

Refrigerat ion Syst em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 28

Gear Reducer Remo val . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Auger Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 30

A Parts List and Wiring Diagram are located in the center of this m anual, on yellow paper.

February 1995

Page 1

Page 2

TDE470

Specifications:

The standard finish for this machine is painted

enamel. A stainless ste el p anel kit may be inst alle d

at the field leve l to chang e the fin ish to stainless

steel. The kit numbe r is : SPKFD4 70

Scotsman ice machines, like the TDE4 70 , are

designed to be installe d ind oors, in a controlle d

environment. The minimum a nd maximu m

operatin g cond itio ns are:

••Minimum Air Temperature: 50

••Maximum Air Temperatu re: 100

••Minimum Water Temperature: 40

•• Maximum Water Temperature: 100

o

F.

o

F.

o

F.

o

F.

••60 Hz voltage may vary betwee n 104 and 126

volts.

••Water Pressu re may va ry between 20 and 80

psi.

Operatin g the mac hin e ou tsid e thes e con dit ions

constitu tes misuse and voids the warrant y.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance . They meet or ex cee d the

standards of UL, NSF and CUL.

Scotsman assu mes no liability or res po nsib ility of

any kind for pro duct s ma nufa ct ured by Scotsman

that have been altered in any way, including the

use of parts and/of other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Model Number Dimensions

W" x D" x H"

TDE470AE-1A

TDE470AE-6A

14 x 23

14 x 23

3

⁄4 x 277⁄

3

⁄4 x 277⁄

Basic

Electrical

115/60/1 12 lb. 470 lb./24Hr 14 oz. 14.6 20

8

230/50/1 12 lb. 14 oz. n/a n/a

8

Bin

Capacity

February 1995

Ice Making

Capacity

Page 2

Refrigera nt

Charge

(R134a)

Min.

Circuit

Ampacity

Max

Fuse Size

Page 3

To The Installer:

TDE470

A pro fe ssio na l insta llat ion of any produ ct is critic al

to the long term satisfaction of the user. The

TDE470 is designed to be installed either on a

counter, or, usin g a wall hanging kit, hung from a

wall. Another opt ion is a kit to increa se the ca bin et

height which will allow taller containers to be

placed under the spout. Determine the location

from the anticip ated use and any optio ns plann ed

for.

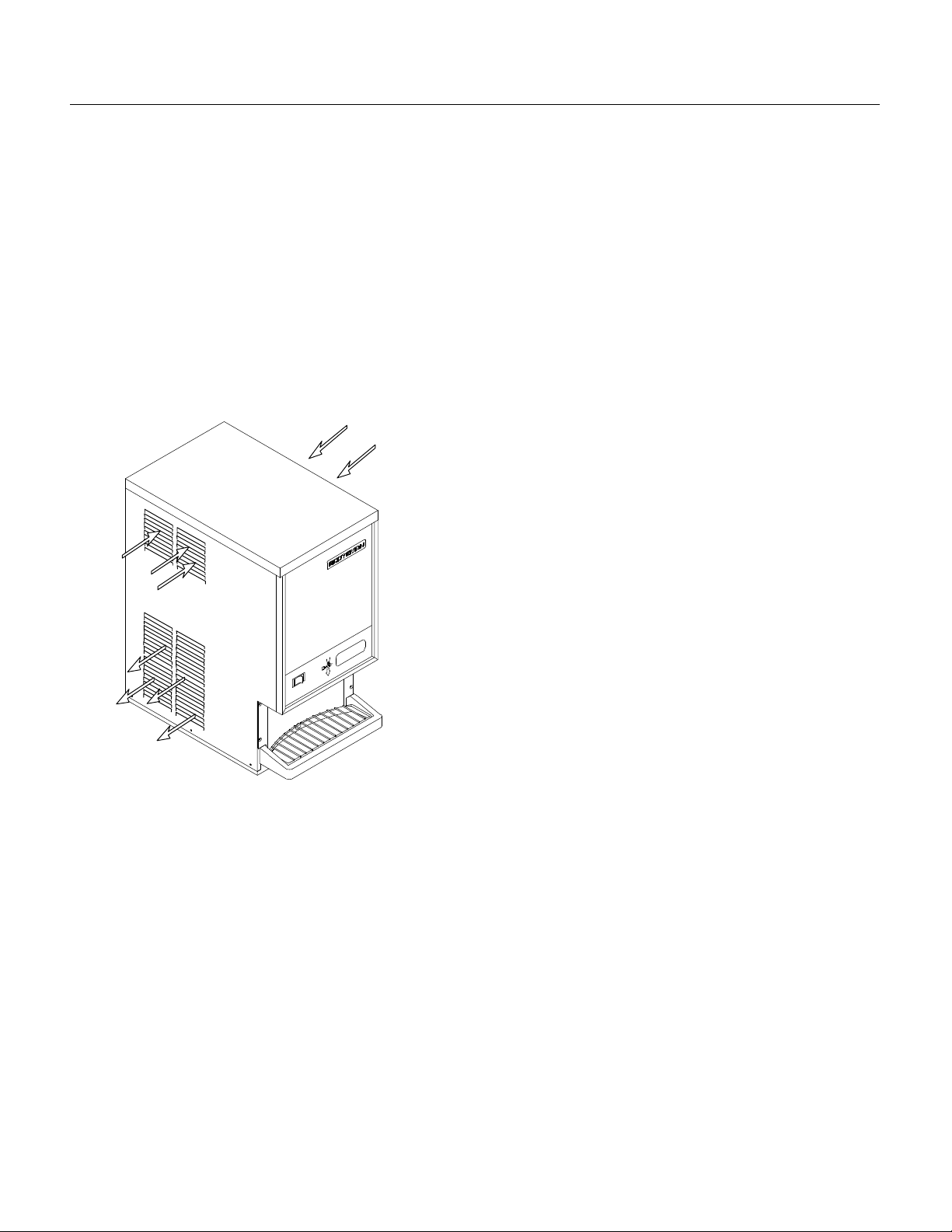

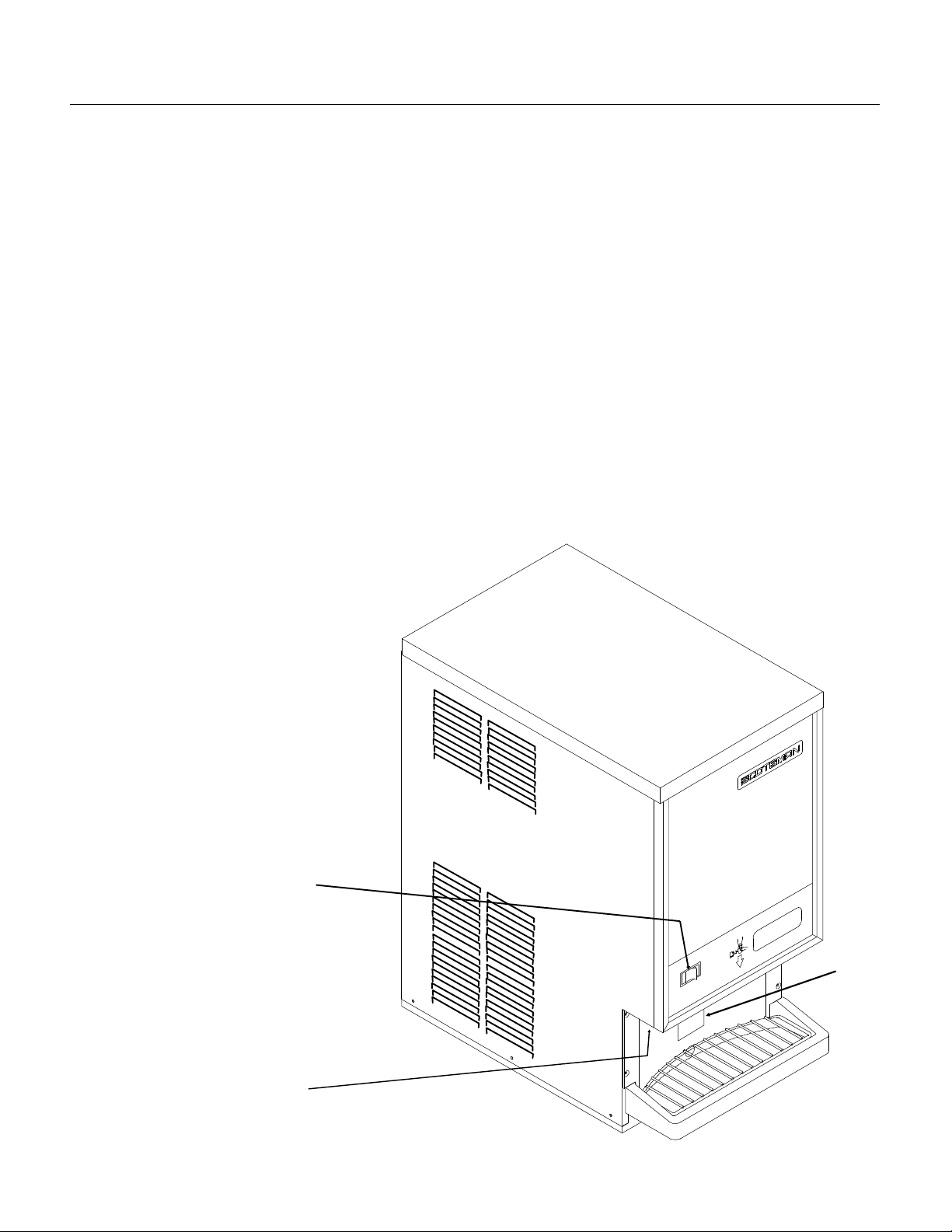

This machine is air cooled and blows air out the

lower left side of the cabinet. Do not install the

machine whe re the side to side air flo w might be

blocked.

Cooling Air Flow

Cooling

Air Flow

Water Quality:

The quality of the water supplie d to the mach ine

will directly affe ct th e purity of the ice and the

reliability of the machin e. While th e condit ion of the

water supplied to a building is normally ou t of the

control of the user, wate r can be trea te d at the

point of use.

There are two major typ es of water impurities:

suspended solids (those that are carried along

with the water and may be filtered out) and

dissolved solids (those that are part of the wate r

and have to be treated). A wate r filt er is alwa ys a

good idea, but does require regular maint enan ce

to change the cartridg e. In some wat er condit ions,

water treat men t may be require d. Genera lly this

means a polyphosphate feeder of some kind.

Water sof te ners are not rec omme nd ed for the

TDE470.

General Installation:

Place the machin e in its fina l location. Remo ve the

top, right and left side panels:

1. Remove two screws at the bac k of the top panel.

2. Pull up on the back of the top panel and remove

it.

Warm Air

Exhaust

The machine will require electrical power, water

and a drain. Follow all loc al codes . Rou gh in the

utilities befo re pla cing the mach ine into posit ion

(see For The Electrician and For The Plumbe r).

3. Remove screws from the sides (to p and bottom)

of the side panels an d fro m the spla sh pa ne l.

4. Pull the side panels back and of f the machin e.

Plumbing co nnections may be ma de thru hole s in

the ba c k of the c abine t or thru th e base.

••Route the sink drain to the back of th e cabinet.

Route the bin drain to the back panel.

••Route the electrical power cord from the

junction box inside the cabinet. thru the back

panel .

••Route the inlet water line thru the back panel or

base to the fla re fit ting inside the cabin et .

Install the sta inle ss steel panel kit (if us ed) n ow.

Install the back pa nel o f the sta inle ss steel panel

kit now (if used).

After all plumbing and interna l wiring has been

done, replac e th e side and bac k panels .

Level the unit front to back and left to right.

The machine does not require sealing to the

counter due to the gasket on the base.

February 1995

Page 3

Page 4

TDE470

For The Electrician

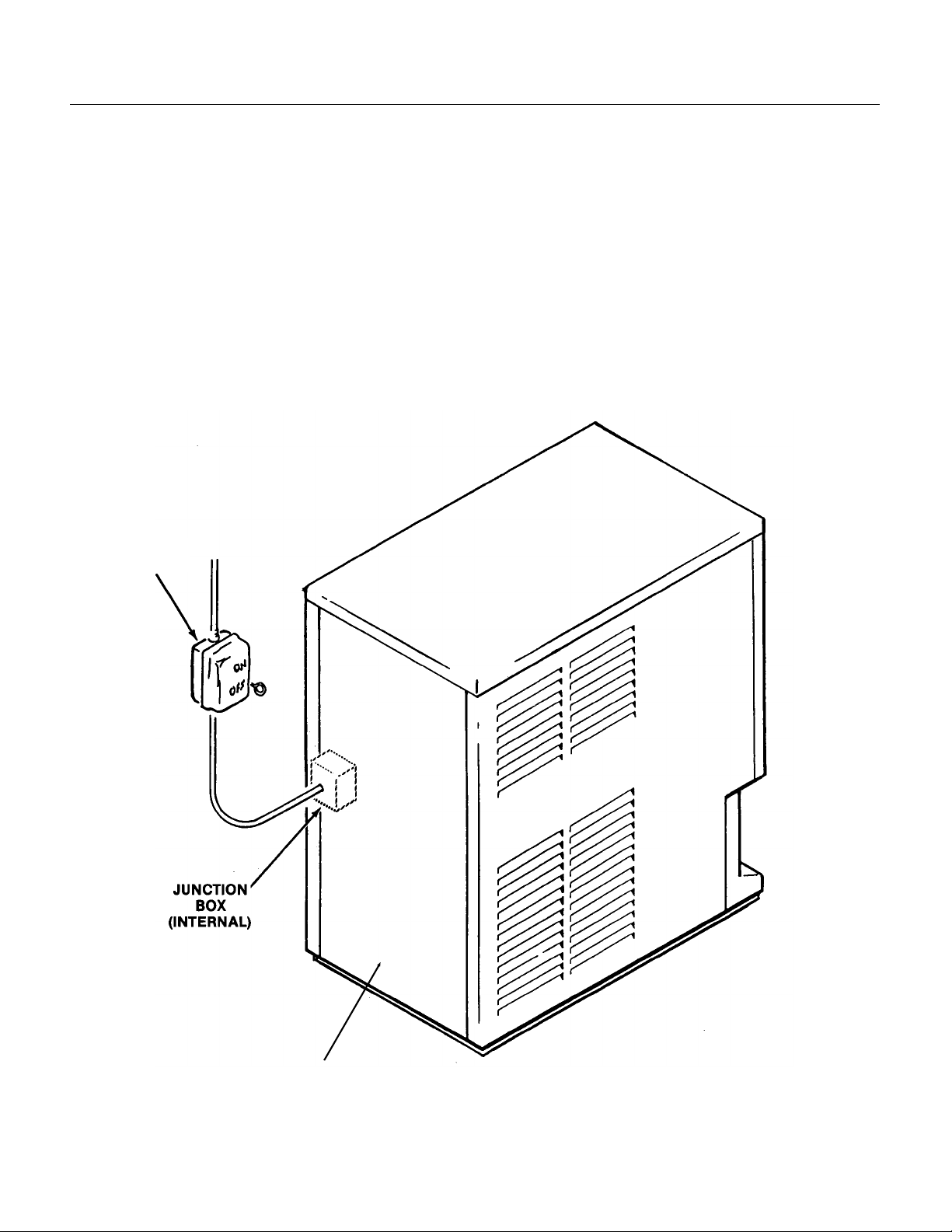

Electrical conn ection s:

Check the nameplat e for v olt age and curre nt

requiremen ts . An ele ct rical c ord is not supplie d.

Connect the TDE470 to a separate electrical

circuit. Wiring to the machin e must confo rm to all

codes. A licensed electrician may be required in

some situations.

Remove the back panel to make the ele ct rical

connection . The electrical connectio n is made on

the terminal strip in the junction box inside the

machine. Replace the back panel when the

electrical conn ect ions are complete.

FOLLOW ALL APPLICABLE LOCAL,

STATE AND NATIONAL CODES

This Unit MUST BE GROUNDED

Electrical

Power

Remove Back Panel To

Expose Junction Box

February 1995

Page 4

Page 5

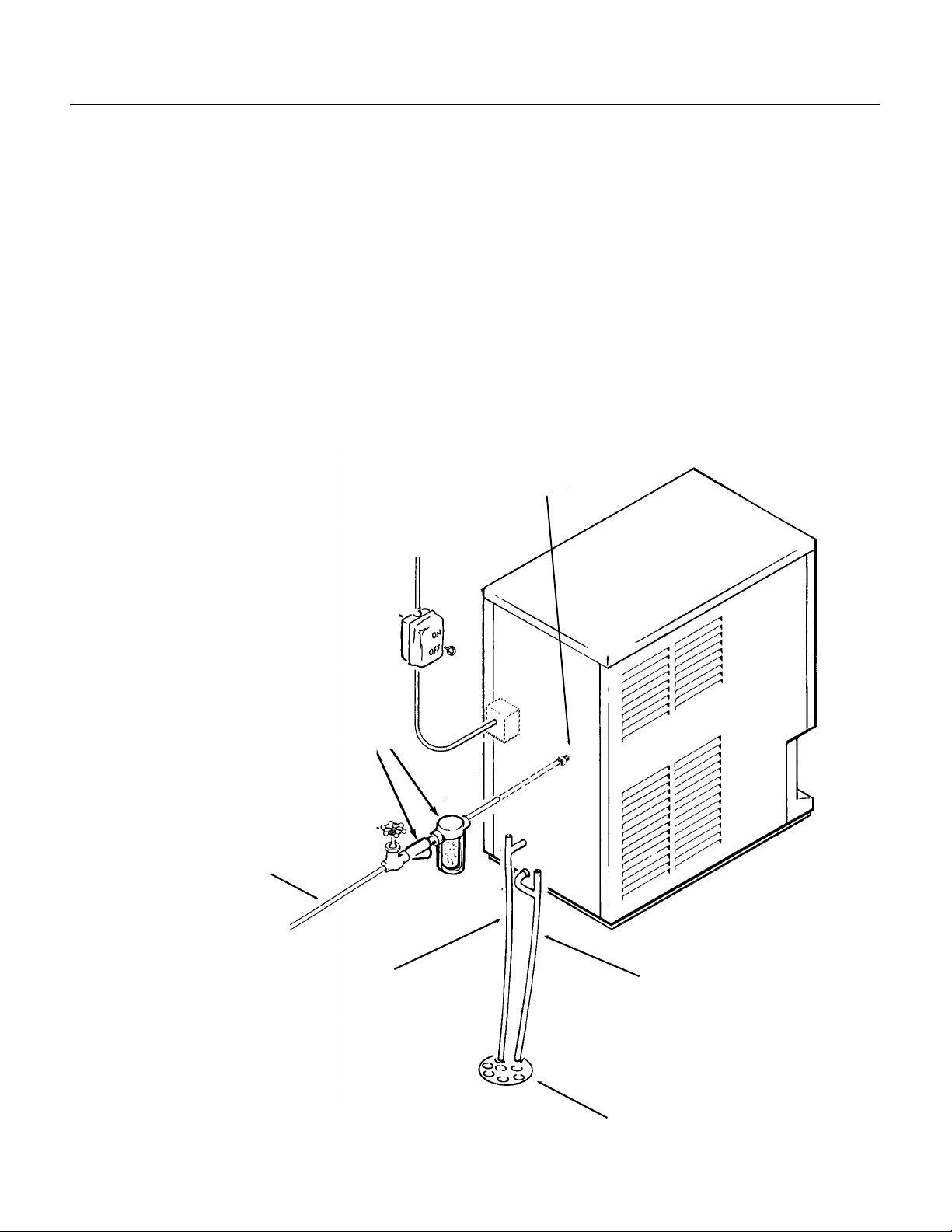

For The Plumber

Drains:

The dispenser req uire s a gravity drain. The pitch

on the drain tubes must be at least 1/4 inch fall per

foot of horizont al run . On long horizo ntal runs, a

vent at the back of the cabinet will improve

draining, and is recommended.

There are two dra ins to connect : A sin k dra in, a

plastic tube; and the bin drain, a

5

⁄8" plastic tube.

Install rigid tubing bet wee n the mach ine and the

building drain. Rout e the dra ins sepa rat ely to the

building drain.

7

⁄8"

TDE470

Water supply:

Connect cold, pota ble wate r to the machine. A

hand valve ne ar th e lo ca tio n is recomme nded . A

water filter is also a good idea.

Follow all local codes.

Strainer or

Filter

FOLLOW ALL APPLICABLE LOCAL,

STATE AND NATIONAL CODES

Water Inlet Fitting

(Inside Cabinet)

Water Supply

Bin and

Reservoir

Overflow Drains

Sink Drain

Building Drain

(Typical)

February 1995

Page 5

Page 6

TDE470

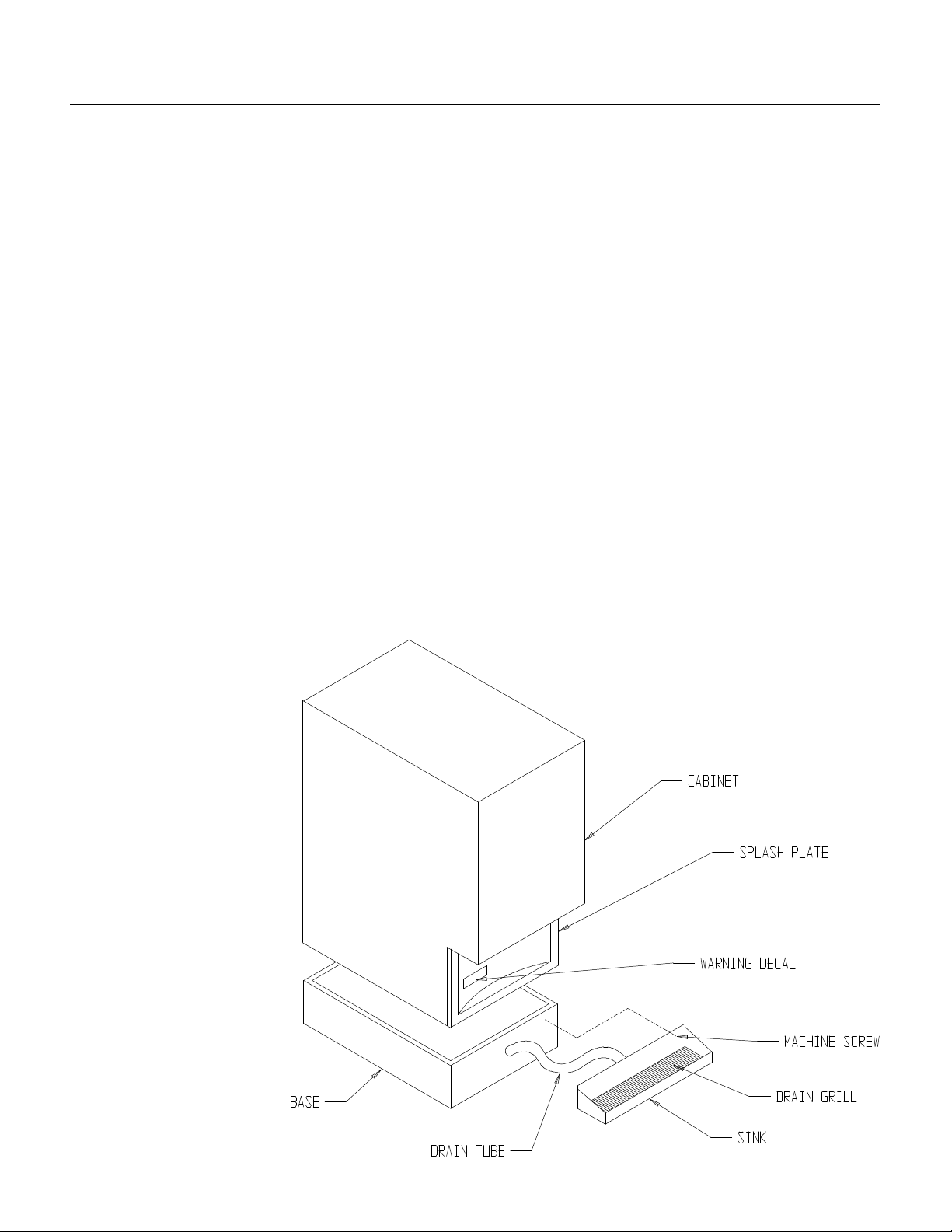

Optional Kits:

Sink Exten sio n (KDE 1A ename l or K DE1 A-SS

stainless steel):

If installe d, follo w the se st ep s, if no t go to st ep 2.

••A. Unplug or disconnect electrical powe r.

••B. Remove top and right side panels .

••C. Shut off water supply and dis con nect wate r

inlet tube.

•• D. Drain reservoir.

2. Unplug or disconnect electrical power. Remove

splash panel from the dispenser’s cabinet. Save

the screws for re-assemb ly.

3. Remove the Touch-Free sensor from the spla sh

panel. Save the hard ware for re-a sse mbly.

4. Loosen hose clamp at sink drain.

5. Remove screws holding sink to dispenser

cabinet.

6. Remove the original sink from the cabin et .

7. Carefully lay the dispenser on its left side.

8. Remove the gasket from the base of the

dispenser.

16. Cente r and att ach the ice deca l on spla sh

pane l wi t h the op ening ov er the

portion of the sensor holder.

17. Install spla sh pan el to the dispe ns er cab ine t

with 4 sheet metal screws (from step 2).

18. Place the warnin g stic ker abou t 2

ice decal.

19. Install grill.

20. Pour water in sin k and check fo r drain ag e or

leaks.

21. Replace all panels, and recon nect any ut ilitie s.

1

⁄2" x 1 1⁄2" raised

1

⁄2" lef t of the

9. Place the sink extension base against the

bottom of the d is pen se r. The fla nge of the

dispenser base fits in the

slots in the sink ext en sion

base.

10. Secure the sink

extensio n ba se to th e

dispenser with 3 screws on

each side.

11. Ret urn the dispe ns er to

an upright position.

12. Attach t he d rain fitting,

drain top and o-ring (o-ring

goes under the sink) to the

sink from the kit.

13. Place the new sink and

drain on the dispenser.

Attach sink drain tube and

secure with a hose clamp.

14. Secure sink to cabine t

with 2 machine screws.

15. Install sen so r hold er in

new splash panel using

hardware saved in step 3.

February 1995

Page 6

Page 7

Wall Mount Kit (KWB 1):

Wall

Brackets

TDE470

Contents:

1. Top Case Hanger Brac ket : A tt ac he s to th e f rame

of th e dispenser.

2. Top Wall Bracket: Mounts to the wall an d

enga ges th e top cas e hang er br acke t to supp o rt

the dispenser.

3. Bottom W all Bra cke t: Moun ts to the wall and

spaces the base of the disp enser away from the

wall.

4. Bottom Fittin gs Cover: Fastened to the bott om

Top Wall Bracket:

1. Hold the bracket on the wall where it will be

mounted .

2. Mark on the wall the positions of the holes in the

bracket.

3. If needed, drill pilot holes for the faste ners.

4. Secure the bracket to the wall with fasten ers of

suffic ien t stre ngth to hold up the TDE 47 0.

Bottom Wall Bracket:

1. Lift up and hang the dispenser from the top wall

bracket.

2. Position the bott om wall bra cke t so that the

molding on the dispe nser bas e bott oms in th e

channel of the wall bracket.

3. Secure the bracket to the wall.

Bottom Fitting Cover:

1. Connect electric al po wer, wat er inle t, bin drain

and sink drain of the dis pense r thru the botto m of

the ca se.

Top Panel

wall bracket to hide the utility con nect ion s.

Installation: Check building wall for the strength

required to sup po rt a machine of the TDE4 70’ s

weight and size. Note that if at least 6" of space is

not left above the machine , cleaning and most

service of the machine will require remov al of the

machine from th e wall moun ts. All utilities are to be

routed thru the base. The back panel is not used

when the machine is hung from the wall.

Top Case Hanger Bracket

1. Remove top panel.

2. Remove back cover an d save th e 4 screws for

mounting the bracket.

3. Drill out the holes (as marked in the illustration )

in the back of the frame with a 3/16" drill bit.

4. Place top hang er bra cke t on the inside of th e

frame and fasten to the frame with the four screws

removed in step 2.

Enlarge Holes

Top Case

Bracket

Bottom

Cover

Secure With

Screws

2. Secure bottom fitting cover to the bottom wall

bracket with the four sheet metal screws provided

in this kit.

February 1995

Page 7

Page 8

TDE470

Final Check List & Initial Start Up

1. Is the machine loca te d ind oo rs where the

temperature limitations are not exceeded?

2. Is there at least 6" clearance on both sides of

the cabinet for ad equa te air flow?

3. Is the water supply adequate, and has a shut off

valve been inst alle d?

4. Is the cabinet level?

5. Have all of the electrical and drain connections

been made?

Initial Start Up

1. Remove 2 screws at the back of the top panel

and remove the top panel.

2. Remove screws and the side panels.

3. Open the water su pply s hut of f valve .

4. Watch the water fill the reserv oir. Check that it

flows in and fills the reservo ir near to the mark

molded into the side of the reservoir. Check that

the float shuts off the water flow when the tank is

full. Check for leak s. Tighten hose clamp s as

needed.

5. Plug the unit in or switch on the electrical power.

After about 15 se con ds the machin e sh ould start.

6. Let the machine operate, listen for any unusual

noises. If needed, reposition tubing & panels to

eliminate vibrat ion.

After the unit has been operating for about 10

minutes, there sho uld be enough ice in the bin to

test the dispense system.

7. Using a container, place in in front of the glass

sensor and below the ice chute. See that ice is

dispensed (the bin drive motor cont inues to run as

long as the cont ain er is in pla ce).

8. Move the water switch (rocker switch on the

front panel) to ON. Pla ce the contain er in fro nt of

the gla s s se nsor and under th e i ce chut e. Both

water and ice should be dispensed.

9. Pour water into the sink and ch eck that th e drain

does not leak but drains the water rapidly.

10. Explain to the user th e mainte na nc e

requirements and operation of the machine.

1 1 . Fill out the W arra nt y Regis tra tio n and

Customer Evaluation form. Mail it to Scotsma n.

12. Leave the service man ual wit h the owner/user

and explain who shou ld be calle d if service is

needed.

February 1995

Page 8

Page 9

User Operation

Glass

Sensor

The TDE470 is an automa tic ice ven ding machine.

All it requires is coo l air, clea n water an d an

adequate supply of electrical power.

To Vend Ice:

Place a container in front of the Touch Free sensor

and below the ice spout. Hold it th ere until t he

container is full of ice. Do NOT overf ill t he

container or a bu ild up of ice in the sin k or a bac k

up of ice in the spout will occur.

To Vend Ice and Water.

Switch the W ater Switch to ON. Place a container

in front of the Touch Free sensor and b elo w the ice

spout. W ater an d ice will be dispense d into the

container be low th e spou t. Note : Th e water is NOT

cooled, it is the same te mpe rat ure as the build ing

supply water.

Daily Maintenance: Pour hot water into the sink to

flush out any debris or build up. Wipe the cabinet

off, wash the sink and grill to keep minerals from

accumulating.

TDE470

Caution:

Unless the touch free senso r is

de-activa ted by pushing the

Cleaning Swit ch in, ice and/ or wat er

may be dispense d during clean ing .

The Cleaning Switch is a button,

located to the left of the ice chute,

that temporarily shuts off the sensor

for c l eanup of the sp l a s h pane l .

Pushing the butto n in will disab le th e

sensor for 2 minute s, push ing the

button in again will return the sensor

to normal operation.

Water

Switch

Touc h Fre e

Disable

Switc h

February 1995

Page 9

Page 10

Bin Cover

TDE470

Component Location & Function

Evaporator. This is a vertical cylinde r full of wat er

and refrigerated. Also in the cylin der is a slowly

rotating auger. The auger force s th e ice up the

evaporato r walls and comp ress es it at the to p. The

resulting flake d ice then falls by gra vity into the ice

storage bin.

Water Reservoir. The water reservoir contains the

inlet float valve and the wate r level senso r. The

float valve controls the flow of water into the

reservoir, and the water level sensor will s top the

ice maker if the water su pply fails .

Ice Storage Bin. The ice sto rag e bin is an

insulated plastic contain er that is open at the top

and has a spout at the bottom. There is a rotating

ice va ne inside the b in that cause s the ice to be

swept over the spou t and disp en se d. The va ne is

rotated by a gear motor at the top of the bin.

Bin Cover. The bin co ver not only ke eps dirt from

the ice storage bin, it also is the support for the

dispense gear r educ er and the loc ation of the

electric eye bin controls.

Condenser. The TDE4 70 uses

an air cooled condenser. It blows

air out, away from the fan motor.

The heat removed fro m the wate r

is exhausted from the condenser.

Compressor. The re frig era tion

system compressor provides the

force to move the refrigerant

around th e sy stem .

Auger Drive. The auger drive is

a direct drive gear reduc er.

Compressor

Auger Drive

Water Reservoir

Evaporator

Ice Storage

Bin

Condenser

February 1995

Page 10

Page 11

Refrigeration System Operation

The TDE470 uses a f orce d d raf t condenser,

capillary tube and herme tic co mpre sso r. The

system uses R-134a as a refrige rant. High

pressure, high temp era tu re ref rigerant is forced

thru the conden ser whe re it loo se s eno ugh heat to

condense. The high pressure liquid ref rigerant

then passes thru the capilla ry tu be which ca use s a

pressure drop in the evaporator. As the high

pressure liqu id refrigeran t mov es int o the

evaporator’s area of low pressure, the warm water

and low pressure ca use the refrig erant to

evaporate and absorb heat from the metal walls of

the e vap o rator. After the re fr i g e rant ha s fl owed thru

the evaporato r it goes back to the co mpre sso r thru

the suction lin e as a low press ure vap or. At the

compresso r the cycle is repeated.

The TDE470 uses a low side pressu re co nt rol as a

safety, it will shut the system down if the suction

pressure is to o low for reliab le op era tio n.

TDE470

System Character i stics:

••Typical Low Side Pressure:

13 - 14 PSIG

••Typical Discharge Side Pressu re:

135 - 175 PSIG

••System Refrigerant Charge:

14 ounces of R-134a

Evaporator

Compressor

Capillary Tube

Dryer

Refrigeration System Schematic

Air Cooled

Condenser

February 1995

Page 11

Page 12

Sink Drain

TDE470

Water System Operation:

The water system consist s of a float valve,

reservoir and water dispense solenoid valve. The

water level in th e reservo ir t ank is the same lev el

as that inside the ev apora to r. Building water supply

flows to both th e flo at va lve and the sole no id. The

float valve will open to add water to the reservoir

as water flows out to the eva porator. The solen oid

will only open if the water switch is close d and the

touch free senso r initia te s an ice dispe ns e.

Evaporato r

Electric Eyes

Ice

Dispensi ng

Vane

Inside the evaporator there is a water seal. This

seal is the type that has a rotating half and a

station ary ha lf. The are a whe re t he two se als

touc h are smo oth flat surfa ces . Wh en the aug er i s

installed in the evapora to r, it forces the rotating

half of the sea l aga inst the stationary half. The

station ary half is spring-loaded and prov ides a firm

pressure ag ainst the auger portio n of the seal.

Water Level

Sensor

Float Valve

Water Seal

Inner Bin

Bottom

Water and Ice

Dispensing Spout

Water Dispensing

Soleno i d Valv e

Sink

Bin and

Reservoir

Overflow

Drain

Water Inlet

Connection

Water System Sch ematic

February 1995

Page 12

Page 13

Mechanical Operation

TDE470

General:

The TDE470 makes, sto res an d dispe ns es ice. It

also dispense s wate r. The ice making portion of

the machine pro du ces flake d ice at abou t 32

The ice falls thru a chute into the dispensing bin.

Above the cylindrical bin is a disp ense drive mot or

and electric eyes. The drive moto r is connecte d to

an ic e van e i n the bin . W he n the user ho lds a

container in front of the glass sensor and below

the ice chute, the dispense driv e motor rotates the

vane and the ice. The re is a slot in the ba se of th e

bin, located just above the vend spout and glass

filler lever. When the ice moves over that slot,

some of the ice on the bottom of the bin falls thru

the slot, into the chute and fills the container .

ON/OFF Control:

Flaked ice is produced by the ice maker until ice

builds up between the electric eye s. When the

electric eyes can no longer "see" each othe r, they

send a signal to the control board to shut the

machine off. The ref rige ration compressor stops

but the auger drive motor will continue to operate

for about 2 minutes to clear the evaporator of ice.

o

F.

Ice Vending

Dispensing takes place when the touch free

sensor’s infrare d be am boun ces back to the

sensor from a container pla ced direc tly in fro nt of

it, and under the ice chute.

When the beam is reflected back, it sign als the

circuit board to connect power to the dispense

drive motor, and ice is then move d over the slot in

the base of the bin, where it falls by gravity thru the

chut e in t o the con ta i ner.

If the Wat er swit ch is On , wat er is also dispens ed

at the same time.

Dispensing continues until the beam is no longer

refl ecte d ba c k to t he se nsor.

Water Control:

Because water is such an important requirement

for making ice, a water le vel sens or ha s been

placed in the rese rvoir. If the wat er su pp ly to th e

machine should fail, the water leve l sensor will

send a signal to the control board to shut down the

machine.

Refrigeration:

The refrigeration system uses a hermetic

compresso r (spec ifica lly design ed for R-134a ),

forced draft air cooled cond enser, capillary tube

and vertical flaked ice evaporat or. Inside the

evaporator is a slowly rotatin g auger. The auger is

supported by bearings at each end, and there is a

face-type wat er se al above the botto m bearing.

The auger is driven by a 1/10 HP direct drive gear

reducer. The auger drive mot or has a spee d

operated switch on it that will keep the compres sor

from operating if the auger motor is not tu rnin g at

full speed.

Water System

Water flows from the buildin g supply to the

reservoir and to the elect ric sole noid valv e. W at er

from the reservoir is used to make ice. W a te r the

flows thru the sole no id is disp ensed.

Touch Free Senso r

The bin, sink and res ervo ir ove rf lo w all have

drains.

February 1995

Page 13

Page 14

TDE470

Electrical Sequence

Refer the wiring diagram as needed.

The "Power" light on the board glows whenev er

there is power to the machine (and the master

switch is ON).

If the machine is switched off at the maste r switch ,

but is otherwise ready to go, switching the mast er

switch to ON does the following:

••The bin empty and power lights on the circuit

board glow.

•• There is a 15 second delay

••If there is enough water in th e reservo ir, th e

circuit board will allow the mach ine to start up.

Start up consists of:

••The compressor contactor coil receives power

from the circuit board.

••The contactor is energized, connec tin g power to

the compresso r, and the comp res sor st arts.

••The auger motor receive s powe r f rom the circu it

board and starts.

•• As ice goes past th e ice level sen so rs, th e bin

empty light will stay on and the machine will

continu e to run, unle ss th e ice st ays between

the sensors for more than 15 secon ds (bin full).

At that point , the bin empt y ligh t go es out, and

the machine shuts down.

Other reasons for shut down:

••Low water level (as sensed by the thermistor in

the reservoir).

••Excessive auger mo tor amp draw, measu red by

the circuit board.

••If the auger motor amp draw become s

excessive twice in an hour, the auger moto r is

shut down and the circuit board must be

manually reset. If th is condition occurs it mea ns

that the drive train is in need of cleaning.

maintenanc e or repair.

Shut Down consists of:

••The compressor contactor opens

••The compressor stops

•• The auger motor is run by the circuit board for 2

more minutes, clea ring out ice in the

evap o rator , and then

••The auger motor no longer receives power from

the circuit board, and the auger motor stops.

After a 6 minute delay, If the ice level senso r is

clear (bin empty ) f or more than 15 seco nd s, th e

machine will start up again.

Another purpose of the circuit board is to turn the

machine of f if there is not enoug h water in th e

machine.

••When the water level in the reservo ir f alls

below the tip of the water lev el sen so r, the

machine will "shut down"

••After a 6 minute delay, if the water refills the

reservoir, the mac hine will start up again.

Separate from the circuit board:

••If the high pressure control (cut out switch)

opens, the compressor will sto p immediately

(through the contactor ). It must be manually

reset.

••The master switch is the manual control for the

complete machine, but it is not a service

disconnect.

Ice Vending

••When a user places a con ta ine r in fron t of the

Touch Free ice senso r and belo w the ic e

delivery chute, the circuit board connects po wer

to the bin drive motor and ice is disp ense d for

as long as the container is present. If the user

does not remove the con tainer, ice will be

dispensed for 60 seconds and then stop.

••When a use r places a container in front of the

Touch Free water senso r, an d below the wat er

spout, the circuit board connect s power to the

water solenoid valve and water is dispensed. If

the user does not remo ve the cont ain er wat er

will be dispensed for 90 seconds and then stop.

Splash panel cleaning:

A switch , loc at ed to the left of the spout, may be

pushed to disable the Touch-Free sensor for

splash panel clea nin g. It automat ica lly rese ts af ter

2 minutes, or, if pushed wit hin the 2 minutes ,

resets the circuit board to enable the Touch Free

sensors.

February 1995

Page 14

Page 15

Maintenance:

Although the ice in this dis pe nser is comple tel y

untouched, the water and ice vending systems will

need to be periodically sa nit ized and

de-mineralized. The air cooled condenser will also

need to be kept clea n.

Schedule the sanitation, cleaning and

de-mineralization on a regular basis to keep the

ice clean and the machine operating efficiently.

Sanitation and Cleaning

Water System:

This ice machine requires periodic sanitation and

de-mineralization.

1. V end all ice fro m the mach ine .

TDE470

12. Repeat step s 3-11, except substitu te a locally

approved san itizing solu tion for the cleaner. A

possible sanitizing solu tio n may be obtained by

mixing 1 ounce of household bleach with 2 gallons

of clean, warm (95

o

F.-115oF.) water.

2. Remove top and right side panels .

3. Unplug or disconne ct electrical power.

4. Shut off water supply.

5. Drain reservoir.

6. Mix 8 ounces of Scotsman Ice Machine Cleaner

and 3 qu a rts of hot (95

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of wat er or

milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

7. Pour the water into the reservoir.

8. Wait 15 minutes fo r the cleaner to disso lve the

minerals inside the evaporator.

9. Plug in the machine or reconnect electrical

power.

10. A s the machin e opera tes, pou r i n the balan ce

of the cleaning solution.

11. Reconn ec t water supply, operate the machin e

for 15 more minutes, then switch it off.

o

F. -115oF.) potable wat er.

13. Unplug or disconnect electric al power.

14. Remove bin top, pour in warm pot able wat er to

melt out any ice.

15. Pull out the vane and bin bottom from the bin.

16. Thoroughly wash the bin’ s in te rior, bin top

interior, spout, ice vane and bin bott om with the

sanitizing solu tio n. Pour some down th e bin drain .

17. Reasse mble the bin bo tt om, van e and bin

cover .

18. Wash the sink are a with the sanit izin g solu tio n

and pour sanitizing solutio n down th e sink drain .

19. Replace all pane ls and reco nnect wate r and

electrical power.

Air Cooled Condenser:

1. Disconnect electrical power.

2. Remove top panel

3. Remove right and lef t side panels.

4. Use pressurized air to blo w the lint fro m t he

outside of the conde ns er in to ward s the fan moto r.

A vac uu m cleaner ho se place d on near the fan

motor should pick up most of the dust. Che ck fo r

interior dirt. If needed , use coil cle aner to

de-grease the condens er.

5. Replace all panels and reconne ct electrical

power .

February 1995

Page 15

Page 16

TDE470

Dispense Area Sanitation

The dispense area is made up of the spout, sink,

grill and splash panel. It require s periodic cleanin g

and sa ni tatio n.

1. The spout may be removed by taking ou t the

two mounting screws. Wash and sanitize it.

2. The sink grill may be removed for was hin g and

sanitizing .

3. The sink should be flushe d with ho t wat er and

wiped clean with sanitizer.

4. The splash pan el req uire s sp ecial attent ion to

clean it.

••Push and release th e Clea nin g Swit ch located

to the left of the ice spout . This dis ables th e

Touch Free Se ns or so th e sp lash panel may be

cleaned without vendin g ice or wat er.

••Wash the splash panel and wipe with sanitizer.

••Re-push the clean switch or allow 2 minutes to

pass for the Tou ch Free system to reset .

February 1995

Page 16

Push Touch Free Sensor

Disable Butto n Befor e

Wiping Splash Panel

Pour Hot Water Into Sink

Regularly To Keep Drain

Line Open

Page 17

Auger and Bearing Inspection

Breaker

Water

Seal

While in most are as regular in-place clea nin g with

Scotsman Ice Machin e Cleaner will be adequate to

keep the interior of the evaporator free of

excessive minera l build up, some wat er co nd itio ns

may require more intense methods. In addition,

the auger bearings req uire physical inspe ctio n to

determine that they are not wearing . This physical

inspection is reco mmen ded twic e per year for the

top bearing and once per year for th e auger and

both bearings.

TDE470

Snap Ring

Auger & Bearings

Cap

Cap Screw

Whenever the auger is remove d, repla ce men t of

the water seal is reco mmen ded.

If a bearing requires replacement, the other

bearing must also be replac ed.

1. Unplug or disconne ct electrical power.

Rotating parts hazard.

Disconnect Electrical

Power Before Begin ning.

2. Shu t off th e w ater sup pl y.

3. Remove top panel.

4. Remove right side panel.

5. Drain the evapora to r and reserv oir.

6. Rem ove foa m cap on top of eva po r ator.

7. Remove 2 permagum plugs from the side of the

evapora tor .

8. Remove 2 screws (screwh eads were cov ered

by the permagum).

9. Pull up on the pull ring to remove the auger . If it

is difficult to pull:

Breaker

Screws

Bottom

Bearing

Washer

Top Bearing

Set

Auger

A. Remove the breaker co ver by takin g the snap

ring out.

B. Unscrew the auger bolt.

C. Use threaded rod or a slide hammer puller and

screw into the auger, slide the weight quic kly up

against the stop to remove the auger.

If the auger still will not move, bearin g replac ement

is mandatory. See Bearing Removal and

Replaceme nt .

Coupling

Adapter Stan d

February 1995

Page 17

Page 18

TDE470

Inspection: Auger

The auger is made of stainless ste el. It has a

polished surface that may be either sh inn y or dull,

but must be smooth. After removal, allow t he au ger

to dry to inspect for sca le. If mine ral scale is found

on the auger’s surf a ce , clea n of f th e auge r with ice

machine clea ne r and a scrub bing pad.

Remove the wate r seal an d cle an of f th e shou lde r

of th e auger.

Bearings: The top bearing should sp in f ree ly with

no rough spots. If it feels rough when spun by

hand, replace it. There should be minima l rust or

dirt. If in doubt, rep lac e the bearin g.

Note: The top bearing u sed in th e TDE 470 is a

"directional" bea ring . Not e which way th e inner

race is configure d and inst all int o t he brea ke r. The

breaker is also availa ble as a replacement part

with the top bearing already installed.

The bottom bearing must be removed from the

evaporator when replacing the water seal.

Remove bin cover.

Remove the thre e bolts holdin g the

evap or ator to the

gear motor adapte r

and lift the

evaporator up

slightly. Tap the water

seal and bo ttom

bearing out from the

top down. Check the

bottom bearing the

same way as the top.

Repl ace the w ater

seal and install a

new bearing set if

needed.

Outer

Race

To replace the water seal:

1. Remove old rota ting half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shou l der of the au ger wh er e the rotat ing ha lf of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auge r, rubber side toward

the auger. Push up until seated against the

sealant . Do not allo w any se alant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the botto m of the evapo rat or

until the bottom of the seal is inside the evaporator

abou t 1/4".

5. Push the bottom be arin g again st th e wat er se al

until the bottom bearing is insid e the evaporator

abou t 1/16" .

6. Rep lace the evap orato r o n th e adap te r, and

re-attach the stand using the original bolts.

7. Attach the auger to th e top bearing

and br eaker.

8. Return the auger to the evaporator

and slide it down until the splines touch

Inner Race

Wider on Top

Side

Open

Side s

the coupling.

9. Rotate the auger unt il the couplin g

splines alig n with the auge r.

10. Push the auger down, and rotate

the breaker u ntil the screw holes line

up with the pilot hole s in th e evapo rat or.

11. When the auger is comple tely

seated, reinst all th e break er scre ws.

12. Replace permagum and foam top.

Sealant

Here

Rubber

Smooth

Side

13. Switch on the water supply.

14. Check bin cover fo r elec trica l

grounds and switc h on the electrica l

power.

15. Observe ope rat ion . The unit should

make minimal noise while prod ucing

ice. Catch first 2 minutes of ice and

discard it.

16. Repla ce the bin cov er an d all

panels.

Water Seal

February 1995

Page 18

Page 19

Inspection:

Photo-Electric Eyes

The photo electric eyes used to "see" the ice build

up in the top of the bin cove r mu st be clean to get

a good "look" at the ice. If clou ded by mine ral

scale, the eyes will cause the ice machine to shut

off and sta y of f .

To clean the photo-electric ey es.

1. Remove the top panel.

2. Pull both of the photo-elec tric ey es out of thei r

rubber grommets.

3. Was h both eyes with a clea n cloth dipp ed in

Scotsman Ice Machine Cleaner.

4. W a s h the eye s off with clean wa ter.

5. Replace the eyes in the grommets

6. Replace the top pa nel

TDE470

Clean Photo-El ectric

Eyes

Water Level Sensor

The water level sens or may not sh ut the ice

machine off when the rese rvoir go es dry if there is

a film of mineral scale on the pro be tip.

1. Remove the top panel.

2. Remove the reservo ir cover .

3. Pull the water lev el pro be up and out of the

reservoi r.

4. Carefully wip e the tip of th e probe with a clean

cloth. Ice machine cleaner may be needed.

Note: The tip is made of glass.

5. Reinsert the water level sensor in the reservoir.

6. Replace the reserv oir cov er an d the top panel.

Coupling

Use the grease ze rk on the sid e of the coupling to

add greas e once pe r y ear.

Clean Water Level

Sensor

Wate r

Reservoir

That concludes no rmal main te nance . If the fan

motor has an oil plug, it may be oiled aft er 10

years of operat ion .

February 1995

Page 19

Page 20

TDE470

Service Diagnosis

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

No ice is dispense d. No ice in bin due to:

••No electrical power

••Overuse

••Water sup pl y turned off

••Bin controls dirty

••Water sensor dirty

••Control system malfunction

••Auger drive motor open

•• Centrifugal switch op en

••Auger does not turn

•• No refrigeration

Ice in bin, but will not dispens e:

Drive motor does not turn

••Vend system does not work

••Dispense motor open

••Dispense output sha ft broken

Ice in bin, motor tu rns va ne .

Ice jammed up

••Users held cup against

dispens e spout and jammed

unit.

••Bin bottom slot not over spout

••Ice will not slide down bin wall,

bin out of round.

••Sink heigh t too small for

container us ed

••Wet ice in the bin from high

water level or hig h suctio n

pressure

Check/re sto re po wer

Recheck ice needs vs. mach ine

capacity.

Check water filter/hand valve/float

valve

Check & clean bin control (electric

eyes)

Check & clean water sensor

Check control system

Check auger drive motor

Check centrifugal switch

Check coupling & gear reducer

Check refrigeration system

Check/replace vend system

Check that clea ning switch has

been released.

Check/replace dispense motor

Check/replace output shaft

Advise owner/manager to instru ct

users.

Check bin bott om positio n

Check bin int erio r wall f or rou gh

texture or out of ro und.

Install sink ext ension ki t

Check water level, check suction

and discharge pressures

February 1995

Page 20

Page 21

TDE470

Service Diagnosis

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

Unusual noiseMineral scale in evaporator Clean water system with ice

machine cle aner.

Auger coupling dry Grease co upling

Auger couplin g worn Replace co up ling and adapt er

stand.

Bearings worn Replace bearings and water seal.

Gear motor loose on frame Tighten bolts, check gromme ts

Low water level Check water level in reservoir

Tubing vibrating Check tubing for contact

Tooth on a gear missing Check gears in auger drive

Compressor to o loud Replace co mpre sso r

Gear noise Check gear motor for oil lea k

No water is dispensed Water Switch in Off po sit ion S witch to ON

Water switch open Replace switch

Water soleno id plu gg ed up Clean inlet scree n of solen oid

Water soleno id coil open Replace solenoid

Vend system does not work Check/re pla ce vend syste m

Water turne d off Re store water su ppl y

Water drips from spout Melting ice in chute Some water dripp ing is normal

Water soleno id leaks thru Replace solenoid

Ice jammed in spout Clear ice jam, check for cause

Ice will not stop dispens ing Vend syst em does no t work Check/re pla ce ve nd syste m

Water leaks from cabinet Evaporator water seal worn or

cracked

Tubing to evaporator leaks Replace tubing/fittings

Drain leaks Check drain tub es and fittings

External drain restricted Clean out drain

No refrigerat ion Ge ar mot or do es not turn Check moto r

Centrif ug al swit ch does not close Check switch

Fan motor does not t urn Check fan motor

Lack of refrigerant Add refrigerant, if problem is

Compressor does not pump Check/replace start capacitor

Replace se al an d bearin gs

redu ced , l oc ate leak a nd repair it .

Check/replace start relay

Check/re place compre sso r

February 1995

Page 21

Page 22

2 - Reset Button

TDE470

Service Diagnosis: Circuit Board

1

3

Circuit Board Lig ht

Identificati on

Explanation of Indicator Light or Reset Position On

Board

Will be On after the

machine must be clea ned and/ or ins pe cte d for drive train

maintenance and manually reset.

This button must be pushed if the auger moto r has overload ed

twice.

On at all times when the master switc h is ON and machine is

connected to electric al power.

On when ice level is low (unit mak ing ice). 4 Bin Empty,

Normal 6 minute off/de lay st art . To pre ven t short cycling, the

machine will not restart after any shut off (ex cpet power to the

board) until 6 minutes have passed.

Too much current has been drawn thru th e auger moto r. This

light is ON for the 30 minutes that must pass bef ore the mach ine

will automatically restart.

After the first Auger Motor Error, the next 60 minutes of operation

are monitore d, and this ligh t will be ON. If anothe r Aug er Mot or

Error occurs, the mac hin e shuts down.

On when water level is low in the reservo ir. 8 No Water ,

second auger motor trip, indicating that the

1 Auger Motor

2 Auger Motor Reset

3 Power,

5 Off Timer,

6 Auger Motor Error,

7 Auger Motor Timer,

4

5

6

7

8

Name and Meaning of

Light or Reset

Overload, ON =

Trouble

Button

ON = Normal

ON = Needs Ice

ON = Unit cycling off

ON = Trouble

ON = Trouble

ON = Trouble

February 1995

Page 22

Page 23

Electrical System

Bin and Water Level Sensors

There are two indica to r light s on the control bo ard .

The Bin Empty light glows when there is no ice

between the electric eyes.

The Wat er Le ve l light only glows when there is a

lack of water in th e reservoir.

If no lights, check for mis -alig nme nt of the electric

eyes or dirty eyes. Clean and or adjust as needed.

To check the electrical sys te m, first check th e lights

on the circuit board.

1. Remove the top panel.

2. Remove the right side pan el.

3. Remove the control box cover.

If the problem is that the machin e will not sta rt, and

the bin empty ligh t is glowin g and the water lev el

light is not, the gearmot or sho uld be che cke d. The

auger motor must start, and the switch on top the

motor close, or the comp ressor will not receive any

electrical power.

TDE470

February 1995

Page 23

Page 24

TDE470

Removal and Replacement

Panels:

1. Remove two screws at the bac k of the top panel.

2. Lift up at the back and push the top panel

forward to release it.

3. Remove 3 screws at the top, 3 screws at the

bottom and 1 screw at the front edge of each side

panel.

4. Push each side panel to the rea r to rele ase the

panel from the cabinet frame.

Dispensing System

The dispensing syst em consist s of the vend

switch, dispense motor, dispense vane, bin bottom

and bin.

Electrical Shoc k Haz ard

Disconnect electrical

power before beginning.

Dispense Va ne

1. Disconnect electrical power.

Dispense Drive

Motor

Bin Top

Dispense Gear Motor

1. Disconnect electrical power.

2. Remove top panel.

3. Remove one screw holding ground strap to

cabinet frame.

4. Cut off two dispe ns e mot or wire nuts.

5. Remove screws holding disp ense driv e gear

motor to the bin top.

6. Pull gear motor off the bin top.

7. Unscrew the output shaf t extension from the

gear motor.

8. Remove screws hold ing the mountin g bra cke t to

the gear motor.

9. Reverse to reas semb le, be certain that the new

wire nuts are secure and that th e groun d strap is

reattached.

2. Remove top panel.

3. Remove four thumb screws ho ldin g bin cover to

bin.

4. Lift bin cover off bin. Se t asid e.

5. Grasp the ice vane and pull it stra igh t up.

6. Reverse to reassemble.

Bin Bottom.

Perform steps 1-5 above (to remo ve th e dispe nse

vane) .

1. Lift bin bottom out of the dispense bin.

2. W h en repla cing, be sure tha t th e slot on the bin

bottom is over the dispense chute (at the front).

February 1995

Page 24

Page 25

Water System

Water Level

Sensor Slot

TDE470

The water system consist s of the reserv oir and

inlet water valve.

Reservoir.

1. Shu t off th e w ater sup pl y.

2. Remove the top panel.

3. Remove the right side pan el.

4. Drain the water res ervo ir and evaporator.

5. Disconnect inlet and outlet tubes from the

reservoir.

6. Remove screws holding reservoir to its

mounting bracket.

7. Remove reservo ir f rom th e machine.

8. Reverse to reassemble.

Float Valve

1. Shu t off th e w ater sup pl y.

2. Remove the top panel.

3. Remove the reservo ir cover .

4. Remove the water inle t tu be.

Va lve Plunger

1. After the valv e has been removed from the

reservoi r, remo ve the nut holdin g th e valve to its

mounting bracket.

2. Pull out the cotter pin to release the inte rna l

valve plunger.

Note: Do not replac e the pl ung er if the valve’s seat

is damaged. Rep lace the valve.

Inlet Water Valve.

1. Disconnect electrical power.

2. Shu t off th e w ater sup pl y.

3. Remove the top panel.

4. Remove the right side pan el.

5. Remove wire harness fro m inlet water va lve .

6. Remove tube connecting outlet of the valve to

the dispense tub e.

7. Rotate the valve to unscrew it from its inlet fitting.

8. Reverse to reassemble.

5. Push in the mounting tabs at the back of the

reservoir and lif t the valve ou t of the rese rvoir tank .

6. Replace with a new valve or replace the valve

plunger.

Plunger

Valve

February 1995

Page 25

Page 26

Snap Ring

Cap

Bolt

Washer

Water Seal

TDE470

Bearings, Water Seal and Auger

1. Disconnect electrical power.

Rotating parts hazard.

Disconnect Electrical

Power Before Begin ning.

2. Shu t off th e w ater sup pl y.

3. Remove the top panel.

4. Remove the side panels .

5. Drain the reservoir and evaporator.

6. Remove foam cap from the top of the

evapora tor .

7. Remove the two permagu m plugs from th e side

of th e evap orator.

8. Pull up on the ring to lift the auger out of the

evapora tor .

If the auger will not lift out:

1. Remove snap ring hold ing bearing cover t o

breaker.

2. Remove bearing cov er.

1. Remove three cap screws ho ldin g evaporat or to

the ad apte r s tand .

2. Lift evaporator up slightly an d tip the botto m out

to expose the splined end of the auger.

3. Remove snap ring hold ing bearing cover t o

breaker.

4. Remove bearing cov er.

5. Unscrew bolt holding bearing to auger.

6. Screw a length of threaded rod or a shoulder

screw into the auger.

7. Tap on the end of the thr eaded r od to push th e

auger out of the bottom of the evaporator.

8. Replace the bearings and water seal. Replace

the auger if the splines are dama ge d. Repla ce the

evaporator if more than 1/3 of the vertical rifle

grooves are gone. Sand or hone and sand the

inside of the evaporat or if mine ral build up is heavy.

3. Unscrew bolt holding bearing to auger.

4. Thread in a threa de d rod and weig ht or

slide-hammer puller into the auger.

5. Use the threade d rod & weight or slide hamme r

puller to remove the auger .

Or

1. Remove three cap screws ho ldin g evaporat or to

the ad apte r s tand .

2. Lift evaporator up slightly an d tip the botto m out

to expose the splined end of the auger.

3. Use a plastic mallet or dead-blow hammer to tap

the bottom of the auger and force the auger up. Do

NOT damage the splin es of the auge r or the auger

will have to be replaced.

If the auger is "frozen" to the botto m bearing , do

not force the bottom bearing thru the evaporator.

Top Bearing

Breaker

Auger

Coupling

February 1995

Page 26

Page 27

Bearing Replacement:

TDE470

Top Bearing Replacement

If the inner race is secure , us e an arbor press to

push the top bearing out of the breaker. If the inner

race has separa ted fro m t he bearing , rep lace the

breake r.

Insert a new bearing in the brea ker, check for

orientation :

The top of the bearing has a wider inne r race an d

a narrower outer race than the bottom.

Replace the "O" ring in the breaker.

Push the bearing in, push on ly on the out er race .

Water Seal & Bottom Bearing Replacement:

1. Remove old rota ting half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shou l der of the au ger wh er e the rotat ing ha lf of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auge r, rubber side toward

the auger. Push up until seated against the

sealant . Do not allo w any se alant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the botto m of the evapo rat or

until the bottom of the seal is inside the evaporator

abou t 1/4".

5. Push the bottom bearing against the

water seal until the bottom bearing is

inside the evapora tor abo ut 1/16".

6. Rep lace th e evap or a tor on the ad ap ter,

and re-attach the stand using the original

bolts.

Inner Race

Wider on Top

Side

7. Attach the auger to th e top be arin g and

breaker.

8. Return the auger to the eva porat o r an d

slide it down until the splines touch the

coupling.

Sealant

Here

Rubber

Smooth

Side

Outer

Race

Water Seal

Open

Sides

9. Rotate the auger until th e couplin g

splines align with the auger.

10. Pu sh the auger dow n, and r otat e the

breaker until the screw holes line up with

the pilot holes in the ev apora to r.

1 1. When the auger is comp let ely se at ed,

reinstall the breaker screws.

12. Replace perma gu m and foa m top.

13. Switch on the water supply.

14. Check bin cover for electrical groun ds

and switch on the electrical power.

15. Observe opera tio n. The unit should

make minimal noise while producing ice.

Catch firs t 2 minute s of ice and discard it.

16. Replace the bin co ver and all panels.

February 1995

Page 27

Page 28

TDE470

Refrigeration System

This ice machine uses R-134 a as the refrige ran t.

This refrigera nt has no chlorine , and th ere fore

requires polyolester type ref rige ran t o il. This oil

requires specific service pro cedures.

General Service

A HFC type liquid line drier is required. "Standard"

driers may not take out enough moist ure and may

affect th e oil addit ive s.

The time that the refrigera tio n sys tem is open to

the air must not exceed 15 minutes. The oil will

rapidly absorb moisture from the air, and the

contact time must be kept to a minimum.

A spe cia l o r very sensitive elect ron ic leak det ect or

will be needed to locate refrigerant leaks. Many

are on the market that will sense R-134a.

The access va lves must be in the close d posit ion

before the hose caps are removed . Do not remo ve

the hose caps before checking the position of the

valve. Use a 3/16" allen wrench to open and close

the valve.

Stem Cap

Torque Stem

to 6-8 ft. lb.

Access Valve

As with any other ref rige ran t, do not pla ce

pressurize d air or oxy gen int o the ref rige rat ion

system.

Note: The refr igera tion system uses an HFC

type refrigerant and MUST use an HFC type

drier .

Torque to 8-12 ft. lb.

Fitting Cap

Torque to 7-12 ft. lb.

Temperatu re Pre ssure Chart, Sele cte d Points

Temperatu re in

0

F. PSIG of R-134a

-102.0

-6 3.7

-4 4.6

-2 5.5

06.5

17.0

27.5

38.0

48.6

59.1

10 12.0

12 13.2

14 14.4

16 15.7

18 17.1

20 18.4

25 22.1

30 26.1

31 26.9

32 27.8

33 28.6

34 29.5

35 30.4

40 35.0

45 40.0

50 45.4

75 78.7

90 104.3

110 146.4

120 171.1

130 198.7

150 262.8

Evacuation to 200 microns is recommen ded.

February 1995

Page 28

Page 29

Gear Reducer Removal

TDE470

1. Disconnect electrical power.

Electrical Shoc k Haz ard

Disconnect electrical

power before beginning.

2. Shu t off th e w ater sup pl y.

3. Remove the top and side panels .

4. Remove the control box cover.

5. Remove the centrifugal switch co ver on the top

of the auger drive motor.

6. Disconnect the electrical wires from the

centrifugal switch.

7. Drain the evapora to r and reserv oir.

8. Disconnect the water inlet tube from the

evaporator.

9. Remove the three screws holdin g th e

evaporator to the adapter stand.

10. Lift the evaporato r u p hi gh enough fo r the

auger to clear the adapter stand.

11. Remove th e mou nt ing bolt s ho ldin g the ge ar

reducer to the cabin et frame .

12. Trace auger driv e motor wires b ack to the

control box.

13. Disconnect the drive motor wires from the relay

on the circuit board.

14. Pull the wires back to the auger drive moto r.

15. Pull the gear reducer out the side of the

cabinet to remo ve it fro m t he mach ine.

Note: If there is evidence of water near the output

shaft of the gear reducer, it would be a wise

precaution to pull the auger from the evaporator

and check the bearing s.

16. Rebuild or replace the gear reducer.

Motor Cover &

Bearing

Fan

Stator

Rotor

Rotor

Bearing

Shaft Seals- 2,

back to back

E-Clip

Woodru ff Ke y

Output Gear

Gear Reducer Components

Gear Case

February 1995

Page 29

Page 30

TDE470

Auger Drive Motor

The windings or top bearing & cover may be

replaced without removing the evaporator or gear

reducer fro m the ma chin e.

1. Disconnect electrical power.

Electrical Shoc k Haz ard

Disconnect electrical

power before beginning.

2. Shut off water supply.

3. Remove top panel.

4. Remove right side panel.

5. Drain the reservoir and evaporator.

6. Disconnect the reserv oir ou tle t tube from th e

bottom of the reservoir.

7. Remove screws holding reservoir mounting

bracket to the cabinet.

8. Lift the reservoir up & away from the top of the

auger drive motor.

9. Remove the 4 bolts holding the auger motor

cover to the gear reducer case.

10. Lift the plastic switch housin g off the auger

drive motor.

If the rotor needs to be removed:

1. Run a screw into the top of the rotor.

2. Grasp the screw with a grip pliers.

3. Pull and/or tap on the pliers to pull the rotor &

bearing out of the gear reducer.

4. Inspect the bearin g and inp ut seal. Rep lace

them if worn.

Note: When the rotor is re-inst alled, be certain that

the bearing is fully seate d in the gear cas e.

Gear Reducer Rebuild

1. After the gear reducer has b ee n removed, the

internal components may be inspected and/or

replaced . Remo ve all bolts hold ing the two cas e

halves together.

2. Tap against the roll pins at each end of the gear

cases to split them.

3. Pry the case halves apart.

4. Check the internal condition of the gear reducer.

If rusty or wate r is prese nt , rep lac e the comp let e

assembl y. The oil should be black and the prop er

oil level is 1/8" from the top of the biggest gear

(with all gears installed). Check the input seal.

The gears may be replaced individually.

1 1 . Hold the cent rif u gal s witch and remov e the

screw holding it to the rot or of the motor.

12. Lift the centrifugal switch up and off the motor.

13. Lift the motor co ver up and off the motor.

14. Pull the fan up and off the rotor.

If the windin gs are to be rep lace d, remov e th e lef t

side panel and control box cov er.

1. Locate the auger drive motor wires plugge d into

a relay on the circuit board.

2. Disconnect the auger motor’s wires and pull

them back to the auger drive motor.

3. Lift the auger mot or wind ing s of f the gear

reducer.

February 1995

Page 30

Loading...

Loading...