Page 1

Page 1

Page 1

SERVICE MANUAL

TC 180

Electronic

counter nugget

ice dispenser

MS 1000.59 REV. 09/2001

Page 2

Page 2

Page 2

TABLE OF

CONTENTS

2

3

Table of contents page

Specifications

GENERAL INFORMATION AND INSTALLATION

Introduction

Unpacking and Inspection

Location and levelling

Electrical connections

Water supply and drain connections

Final check list

OPERATING INSTRUCTIONS

Start up

Operational checks

PRINCIPLE OF OPERATION (How it works)

Water circuit

Refrigerant circuit

Mechanical system

Operating pressures

Components description

ADJUSTMENT, REMOVAL AND REPLACEMENT PROCEDURES

Wiring diagram

Service diagnosis

MAINTENANCE AND CLEANING INSTRUCTIONS

General

Icemaker

Cleaning instructions of water system

5

5

5

5

6

6

7

8

17

18

11

11

12

13

14

20

20

20

Page 3

Page 3

Page 3

SPECIFICATIONS

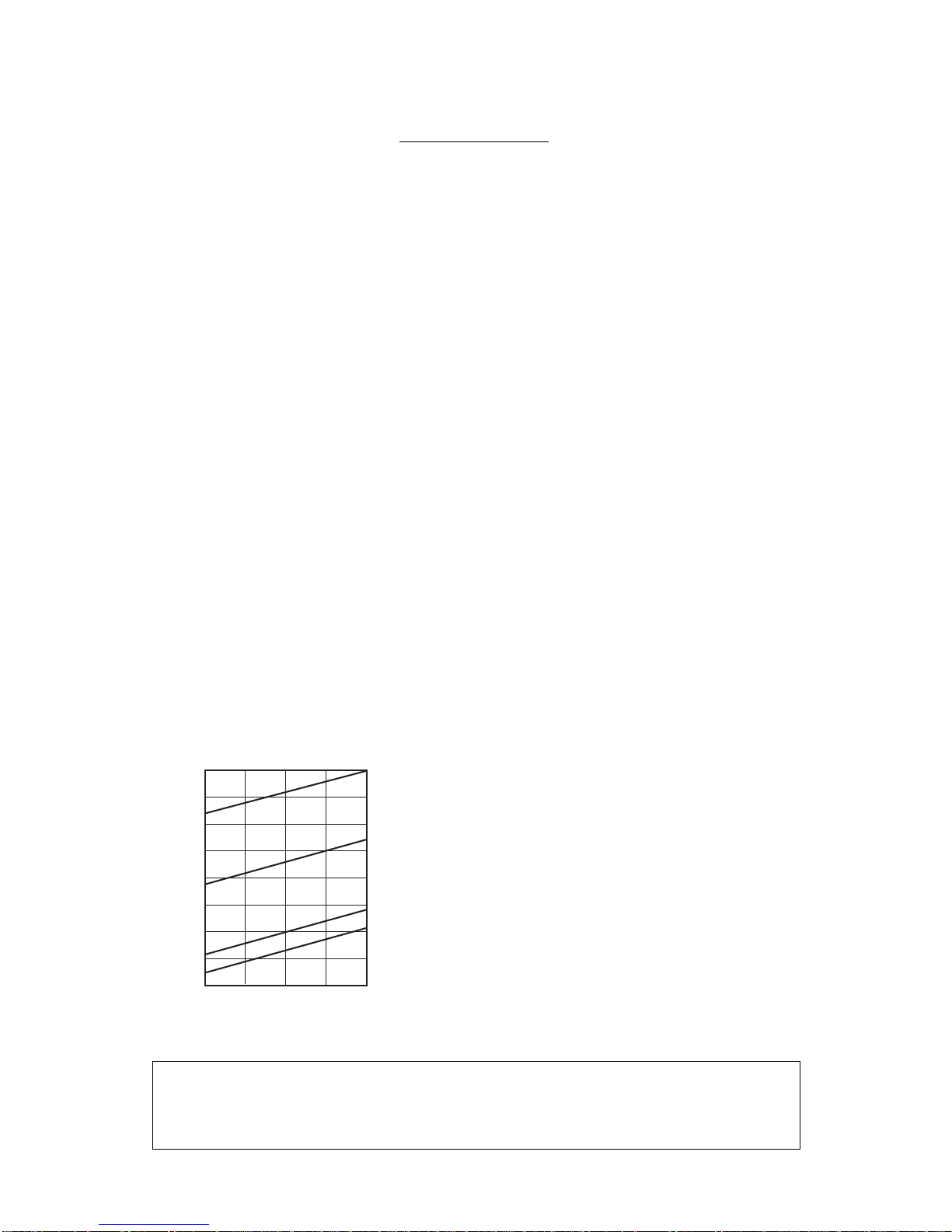

ice making capacity

ELECTRONIC COUNTER NUGGET DISPENSER TC 180

Important operating requirements:

MIN MAX

- Air temperature 10°C (50°F) 40°C (100°F)

- Water temperature 5°C (40°F) 35°C (100°F)

- Water pressure 1 bar (14 psi) 5 bars (70 psi)

- Electr. voltage

variations fromvoltage

rating specified

on nameplate -10% +10%

NOTE. The daily ice-making capacity is directly related to the condenser air inlet temperature, water

temperature and age of the machine.

To keep your SCOTSMAN NUGGET DISPENSER at peak performance levels, periodic maintenance

checks must be carried out as indicated on page 21 of this manual.

32

38

10

21

150

140

130

120

110

100

90

80

70

Kg.

32

10 °C

27

21 15

°C

o

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

Page 4

Page 4

Page 4

Start Electric power cons.

Amps Kwh per 24 HR

Basic electr. Amps Watts Nr. of wires Amps fuse

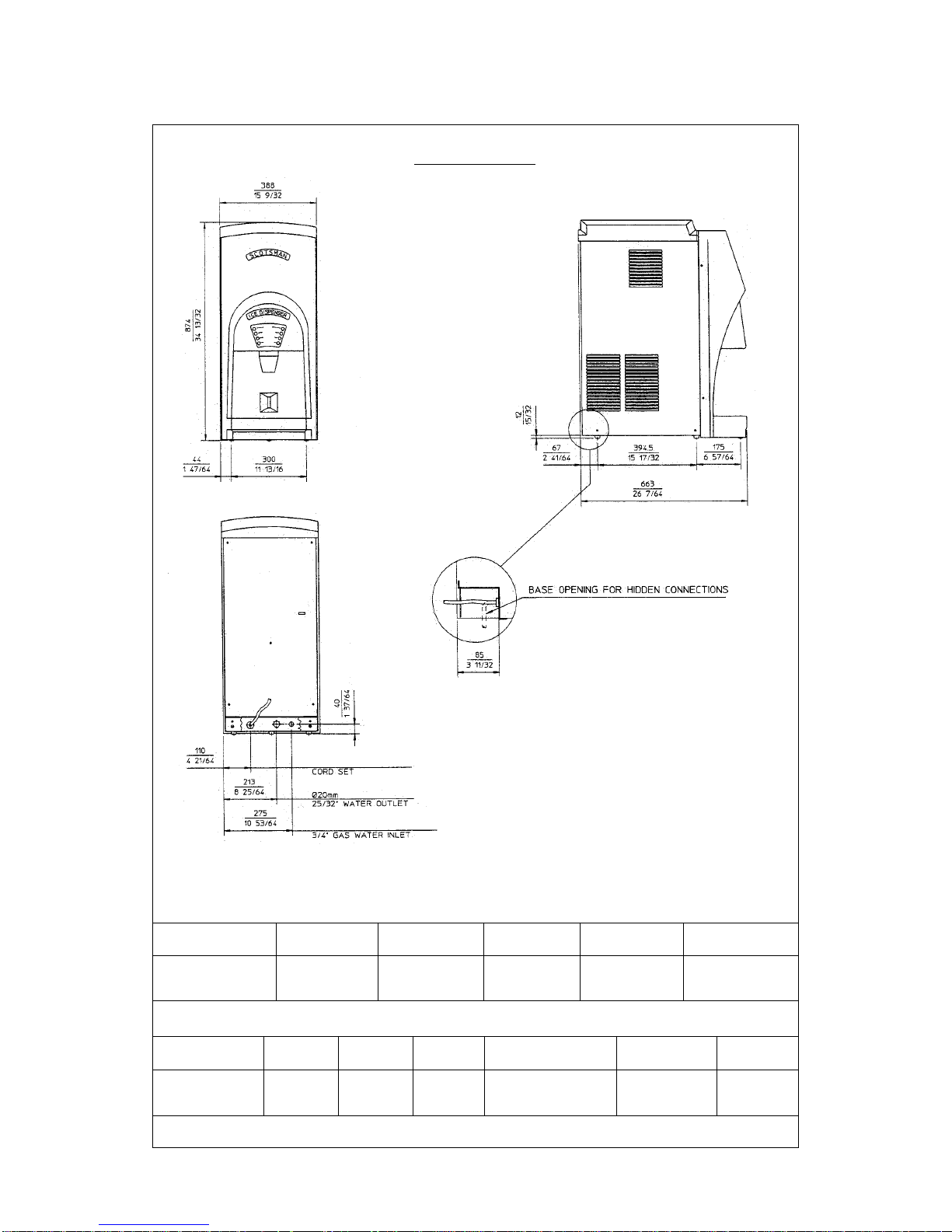

SPECIFICATIONS

Model Cond. unit Finish Comp. HP

Ice bin

cap

Water req.

lt/24 HR

TC 180 - MACHINE SPECIFICATIONS

230/50/1 3.2 17 550 13 3 x 1.5 mm

2

10

TC 180 AS Air S. Steel 3/8 5 Kg. 150

Page 5

Page 5

Page 5

GENERAL INFORMATION AND INSTALLATION

A. INTRODUCTION

This manual provides the specifications and the

step-by-step procedures for the installation, startup and operation, maintenance and cleaning for

the SCOTSMAN TC 180 counter nugget ice

dispenser.

Their ice making systems are thoroughly tested

providing the utmost in flexibility to fit the needs

of a particular user.

NOTE. To retain the safety and performance

built into this icemaker, it is important that

installation and maintenance be conducted

in the manner outlined in this manual.

B. UNPACKING AND INSPECTION

1. Call your authorized SCOTSMAN Distributor

or Dealer for proper installation.

2. Visually inspect the exterior of the packing

and skid. Any severe damage noted should be

reported to the delivering carrier and a concealed

damage claim form filled in subjet to inspection of

the contents with the carrier’s representative

present.

3. a) Cut and remove the plastic strip securing

the carton box to the skid.

b) Cut open the top of the carton and remove

the polystyre protection sheet.

c) Pull out the polystyre posts from the

corners and then remove the carton.

4. Remove the top and sides panels of the unit

and inspect for any concealed damage. Notify

carrier of your claim for the concealed damage

as stated in step 2 above.

5. Remove all internal support packing and

masking tape.

6. Check that refrigerant lines do not rub against

or touch other lines or surfaces, and that the fan

blades move freely.

7. Check that the compressor fits snugly onto

all its mounting pads.

8. Use clean damp cloth to wipe the surfaces

outside of the cabinet.

9. See data plate on the rear side of the unit

and check that local main voltage corresponds

with the voltage specified on it.

CAUTION. Incorrect voltage supplied to

the icemaker will void your parts

replacement program.

10. Remove the manufacturer’s registration card

from the inside of the User Manual and fill-in all

parts including: Model and Serial Number taken

from the data plate.

Forward the completed self-addressed

registration card to SCOTSMAN EUROPE

factory.

C. LOCATION AND LEVELLING

WARNING. This Ice Dispenser is designed

for indoor installation only. Extended

periods of operation at temperature

exceeding the following limitations will

constitute misuse under the terms of the

SCOTSMAN Manufacturer’s Limited

Warranty resulting in LOSS of warranty

coverage.

1. Position the unit in the selected permanent

location.

Criteria for selection of location include:

Min Max

Air Temperature 10°C40°C

Water Temperature 5°C35°C

Water pressure 1 bar 5 bar

Voltage -10% +10%

(Compared to the nameplate)

Service access: adequate space must be left for

all service connections through the rear of the ice

maker.

This machine is air cooled and sucks air through

the left side panel and blows air out the rear side

of the top panel. Do not install the machine where

the left side air flow might be blocked. A minimum

clearance of 15 cm is required.

It is important that the machine be installed in a

location where it has enough space around it to

be accessible for service, and minimum of 150

mm be allowed at the left and upper side for air

circulation. Try to avoid hot, dirty and crowded

locations.

NOTE. It is imperative to do not place on top

of the machine any sort of goods and leave

the upper lowers open for proper air exhaust.

D. ELECTRICAL CONNECTIONS

See data plate for current requirements to

determine wire size to be used for electrical

connections. All SCOTSMAN icemakers require

a solid earth wire.

All SCOTSMAN ice machines are supplied from

the factory completely pre-wired and require

only electrical power connections to the wire

cord provided at the rear of the unit.

Make sure that the ice machine is connected to

its own circuit and individually fused (see data

plate for fuse size).

Page 6

Page 6

Page 6

The maximum allowable voltage variation should

not exceed -10% and +10% of the data plate

rating. Low voltage can cause faulty functioning

and may be responsible for serious damage to

the overload switch and motor windings.

NOTE. All external wiring should conform to

national, state and local standards and

regulations.

Check voltage on the line and the ice maker’s

data plate before connecting the unit.

E. WATER SUPPLY AND DRAIN

CONNECTIONS

GENERAL

When choosing the water supply for the ice flaker

consideration should be given to:

a) Length of run

b) Water clarity and purity

c) Adequate water supply pressure

Since water is the most important single ingredient

in producting ice you cannot emphasize too

much the three items listed above.

Low water pressure, below 1 bar may cause

malfunction of the ice maker unit.

Water containing excessive minerals will tend to

produce scale build-up on the interior parts of the

water system while too soft water (with too lo

contents of mineral salts), will produce a very

hard flaker ice.

PLUMBING CONNECTIONS MUST

CONFORM TO ALL APPLICABLE CODES

CONNECT TO POTABLE WATER ONLY

The model TC 180 has the possibility to have the

water connections through the bottom base or

through the rear bottom side of the machine. In

this second case it is necessary to remove the

rear bottom small panel.

WATER SUPPLY

Connect the 3/4" GAS male of the water inlet

fitting, using the flexible tube supplied to the cold

water supply line with regular plumbing fitting

and a shut-off valve installed in an accessible

position between the water supply line and the

unit.

If water contains a high level of impurities, it is

advisable to consider the installation of an

appropriate water filter or conditioner.

WATER DRAIN

The recommended drain tube is a plastic or

flexible tube with 18 mm (3/4") I.D. which runs to

an open trapped and vented drain. When the

drain is a long run, allow 3 cm pitch per meter

(1/4" pitch per foot).

Install a vertical open vent on drain line high point

at the unit drain connection to ensure good

draining.

The ideal drain receptacle is a trapped and

vented floor drain.

NOTE. The water supply and the water drain

must be installed to conform with the local

code. In some case a licensed plumber and/

or a plumbing permit is required.

F. FINAL CHECK LIST

1. Is the unit in a room where ambient

temperatures are within a minimum of 10°C

(50°F) even in winter months?

2. Is there at least a 15 cm (6") clearance

around the unit for proper air circulation?

3. Is the unit level?

4. Have all the electrical and plumbing

connections been made, and is the water supply

shut-off valve open?

5. Has the voltage been tested and checked

against the data plate rating?

6. Has the water supply pressure been checked

to ensure a water pressure of at least 1 bar

(14 psi).

7. Check all refrigerant lines and conduit lines

to guard against vibrations and possible failure.

8. Has the owner/user been given the User

Manual and been instructed on the importance of

periodic maintenance checks?

9. Has the Manufacturer’s registration card

been filled in properly? Check for correct model

and serial number against the serial plate and

mail the registration card to the factory.

10. Has the owner been given the name and the

phone number of the authorized SCOTSMAN

Service Agency serving him?

Page 7

Page 7

Page 7

OPERATING INSTRUCTIONS

START UP

After having correctly installed the ice maker and

completed the plumbing and electrical connections, perform the following “Start-up” procedure.

A. Open the water supply line shutoff valve and

give power by moving the main switch, on the

power supply line, to the ON position.

The GREEN LED will glow to signal that unit is

under power.

NOTE. Every time the unit is put under power,

after being kept for sometime in shut-off

conditions (electrically disconnected) the 2nd

RED LED will blink for 3 minutes (Fig.1).

FIG. 2

FIG. 1

B. Elapsed the 3 minutes - stand by period - the

unit starts operating with the activation in

sequence of the following assemblies:

GEAR MOTOR

COMPRESSOR

FAN MOTOR kept under control by the condenser

temperature sensor which has its probe within

the condenser fins

with the switching off of the 2nd RED LED

(Fig. 2).

C. Elapsed 2 or 3 minutes from the compressor

start up, observe that flaker ice begins dropping

off the ice spout to fall into the storage bin.

Page 8

Page 8

Page 8

NOTE. If, after ten minutes from the

compressor start-up, the evaporating temperature has not dropped down to a value

lower than -1°C (30°F) the evaporating temperature sensor detects such an abnormal

situation and stops consequently the unit

operation.

In this circustance, the 3rd warning YELLOW

LED will blink (Fig.3).

After having diagnosed and eliminated the

cause of the poor evaporating temperature

(insufficient refrigerant in the system or

inoperative compressor or evaporator sensor)

it is necessary to push the RE-SET BUTTON

that protrudes through the hole of the control

box cover.

The unit, before resuming the total operation,

will go through the usual 3 minutes STAND-

BY period.

OPERATION CHECKS UPON THE UNIT

START UP

D. Remove service panels and if necessary

install the refrigerant service gauges on the

corresponding Service valves to check both the

HI and LO refrigerant pressures.

NOTE. The condenser temperature sensor,

which is located within the condenser fins,

keeps the head (condensing) pressure

between two preset valves.

In case of condenser clogging such to prevent

the proper flow of the cooling air or, in case

the fan motor is out of operation, the

condenser temperature rises and when it

reaches 70°C (160°F) the condenser temperature sensor shuts-off the ice maker with the

consequent light-up of the 2nd RED

WARNING LIGHT (Fig.4).

After having diagnosed the reason of the

temperature rise and removed its cause, it is

necessary to proceed as per the previous

“NOTE” to start up again the operation of the

ice maker.

FIG. 4

FIG. 3

Page 9

Page 9

Page 9

After this, open the water supply line shutoff

valve to fill up again the float reservoir, the 5th

YELLOW LED goes off while the 2nd RED LED

starts blinking.

After 3 minutes the unit resumes its total operation

with the immediate start-up of the gear motor

and, 2 seconds later, of the compressor.

F. Check for the correct operation of the

electronic eye for the ice bin level control, by

placing one hand between the sensing “eyes”

located in the ice spout, to interrupt the light

beam.

This interruption will cause an immediate

extinguishing of the 1st RED LED and after

about 6 seconds causes the shutoff of the unit

with the simultaneous lighting of the 6th YELLOW

LED signalling the full bin situation (Fig.6).

Allow the resumption of the light beam previously

interrupted and after about 6 seconds the flaker

will resume - through the 3 minutes STAND-BY

period - the ice making process with the

extinguishing of the YELLOW LED.

E.

Check for the correct CUT-OUT and

CUT-IN of the float reservoir water level sen-

sors by shutoff the valve on the water supply line.

This will cause a gradual decrease of the water

level in the float reservoir and as soon as the level

gets below the sensors, the flaker stops to operate and the 5thYELLOW warning LED will glow

to signal the shortage of water (Fig.5).

NOTE. The water level sensor detects the

presence of sufficient water in the float

reservoir and confirms it to the micro

processor by maintaining a low voltage

current flow between the two sensors using

the water as conductor.

WARNING. The use of de-mineralized

water (water with no salt content) having

an electrical conductivity lower than 30

µS, will cause the ability of the water

sensors to vanish with the consequent

CUT-OUT of the flaker operations and the

glowing of the YELLOW LED of shortage

of water, even though that water is indeed

in the reservoir.

FIG. 6

FIG. 5

Page 10

Page 10

Page 10

H. CHECK OF THE DISPENSING

OPERATING MECHANISM

There are two different versions of dispensing

label; one with just ICE and CONTINUOUS push

buttons and a second with ICE/WATER + ICE/

WATER and CONTINUOUS push buttons.

To check for the correct operation of the

dispensing mechanism:

a) Select first the Dispensing Mode by

pushing the proper switch;

b) Place a glass or a carafe in front of the two

Optical Dispensing Devices.

c) The dispensing drive motor and/or the

water solenoid valve starts to operate with ice

and/or water discharged through the bottom

plastic spout.

The drive motor and/or the water solenoid valve

remains in operation as per setting dispensing

time unless the glass or carafe is removed.

Push the CONTINUOUS switch and check again

for the dispensing mechanism operation as per

steps above.

The drive motor and/or the water solenoid valve

now remains in operation till the glass or carafe

is removed.

I. If previously installed, remove the refrigerant

service gauges and re-fit the unit service panels

previously removed.

J. Instruct the owner/user on the general

operation of the ice machine and about the

cleaning and care it requires.

NOTE. The ICE LEVEL CONTROL (INFRA-

RED SYSTEM) is independent of the tempe-

rature however, the reliability of its detection

can be affected by dirt and scale sediment

which may deposit directly on the light source

and on the receiver.

To prevent any possible ice maker

malfunction, due to negative affection of the

light detector, it is advisable to follow the

instructions for the periodical cleaning of

the light sensor elements as detailed in the

MAINTENANCE AND CLEANING PROCEDURES.

G. SETTING OF THE DISPENSING

SELECTOR

Setting of the dispensing time

It's possible to modify the dispensing time to 5, 10

or 15 seconds.

To modify the original setting time (5 seconds):

a) Push and old the 4th switch "CONTINUOUS" for 10 seconds till the first 3 lights start

to blink

b) Push the 1st switch (ICE) for 5 seconds

Push the 2nd switch (ICE+WATER) for 10 seconds

Push the 3st switch (WATER) for 15 seconds

Setting of resume mode (default)

To modify the original resume mode (ICE) push

for 5 seconds the desired switch ICE,

ICE+WATER or WATER.

Page 11

Page 11

Page 11

PRINCIPLE OF OPERATION

WATER CIRCUIT

The water enter in the machine through the water

inlet fitting (which incorporates a strainer and it is

located at the rear side of the cabinet) and then

it goes to the water reservoir flowing through a

float valve.

NOTE. The presence of the water in the float

reservoir is detected by a system of two

sensors which operates in conjunction with

the P.C. Board. The two sensors use the

water as a conductor to maintain a low voltage

current flow between them. In case the water

used is very soft (de-mineralized) or the float

reservoir gets empty the current flow between

the sensors become so weak or is no longer

maintained that, as consequence, the P.C.

Board shutoff the flaker operation with the

simultaneous glowing of the YELLOW LED

signalling “Shortage of water”.

The float reservoir is positioned at the side of the

freezing cylinder at such an height to be able to

maintain a constant water level around the freezer

auger. In fact, the water flows from the reservoir

into the bottom inlet of the freezing cylinder to

sorround the stainless steel auger which is

vertically fitted in the center of the freezer.

In the freezer the incoming water gets chilled into

soft (slush) ice which is moved upward by the

rotating action of the auger. The stainless steel

auger that rotates counter-clockwise within the

freezer, is powered by a direct drive gear motor

and carries the ice upward along the refrigerated

freezer inner walls and by doing so the ice gets

progressively thicker and harder.

The ice, being costantly lifted up, meet the tooth

of the ice breaker which is fitted on the top end of

the auger, where it gets compacted, cracked and

forced to change from vertical into horizontal

motion to be discharged out, through the ice

spout, into the storage bin.

By running the ice maker, i.e. by putting the unit

under power, starts the automatic and continuous

icemaking process which would not stop until the

ice storage bin gets filled-up to the level of the

control “eyes” located on the sides of the ice

spout. As the ice level raises to interrupt the light

beam running between the two infrared lamps,

the unit stops after six seconds, with the

simulteneous glowing of the YELLOW LED

signalling the “Full Bin” situation.

NOTE. The interruption of the light beam

between the two light sensors is immediately

signalled by the extinguishing of the 1st RED

LED located on the front of the P.C. Board.

After about 6" of steady interruption of the

light beam the unit stops and the “Full Bin”

YELLOW LED glows.

The six seconds of delay prevent the unit

from stopping for any undue reason like the

momentarily interruption of the light beam

caused by the flakes that slides along the ice

spout before dropping into the bin.

As some ice gets scooped out from the storage

bin, the light beam between the two sensors

resumes and immediately the 1st RED LED

lights-up; six seconds later the ice machine

restarts the ice making process and the YELLOW

LED goes off.

REFRIGERANT CIRCUIT

The hot gas refrigerant discharged out from the

compressor reaches the condenser where, being

cooled down, condenses into liquid.

Flowing into the liquid line it passes through the

drier filter, then it goes all the way through the

capillary tube where it looses some of its pressure

so that its pressure and temperature are lowered.

Next, the refrigerant enters into the evaporator

coil wrapped around the freezer inner tube.

The water being constantly fed at the interior of

the freezer inner tube, exchange heat with the

refrigerant circulating into the evaporator coil,

this cause the refrigerant to boil-off and evaporate, thereby it changes from liquid into vapor.

The vapor refrigerant then passes through the

suction accumulator and through the suction line

where the refrigerant exchanges heat with the

one flowing into the capillary tube (warmer) before

being sucked into the compressor to be

recirculated.

The refrigerant heat pressure is kept between

two pre-set values 9÷10 bar -125÷140 psig by

the condenser temperature sensor which has its

probe located within the condenser fins - in air

cooled versions.

This condenser temperature sensor, when

senses a rising of the condenser temperature

beyond the pre-fixed limit, changes its electrical

resistance and send a low voltage power flow to

the MICRO-PROCESSOR of the P.C. Board

which energizes, through a TRIAC, the Fan

Motor in ON-OFF mode.

FREEZER

FLOAT TANK

FLOAT VALVE

WATER INLET LINE

ICE SPOUT

FREEZER

WATER

FEED LINE

Page 12

Page 12

Page 12

When the opposite situation occures, i.e. the

condenser temperature gets below the pre-fixed

limit, the temperature sensor changes again its

electrical resistance reducing therefore the

current flow to the P.C. Board to cause a temporary stop of the Fan Motor.

NOTE. In case the condenser temperature

probe senses that the condenser temperature has rised to 70°C (160°F) for one of the

following abnormal reasons:

CLOGGED CONDENSER

FAN MOTOR OUT OF OPERATION

AMBIENT TEMPERATURE HIGHER THEN

43°C (110°F)

it causes the total and immediate SHUTOFF of the machine in order to prevent the

unit from operating in abnormal and

dangerous conditions. When the ice maker

stops on account of this protective device,

there is a simultaneous glowing of the 2nd

RED LED, warning the user of the Hi Temperature situation. After having eliminated

the source of the excessive condenser temperature, to restart the ice machine it is

necessary to push the RE-SET button that

protrudes through the control box cover.

The 2nd RED LED starts blinking and

three minutes later the flaker unit resume its

normal operating mode.

ACCUMULATOR

CAPILLARY TUBE

COMPRESSOR

DISCHARGE LINE

CONDENSER

SUCTION LINE

FAN MOTOR

EVAPORATOR

FIG. 7

The refrigerant suction or Lo-pressure sets - in

normal ambient conditions (21 °C) - on the value

of 1 bar (14 psig) after few minutes from the unit

start-up.

This value can vary of 0.1 or 0.2 bar (1.5÷3 psig)

in relation to the water temperture variations

influencing the freezer cylinder.

NOTE. If, after ten minutes from the unit start

up, no ice is made and the evaporating

temperature detected by the evaporator

sensor results to be higher than -1°C (30°F)

the ice maker stops and the 3RD WARNING

YELLOW LED blinks.

MECHANICAL SYSTEM

The mechanical system of the SCOTSMAN

Nugget Ice Dispenser consists basically of a

gear motor assembly which drives, through a

ratched coupling, a worn shaft or auger placed

on its vertical axis within the freezing cylinder.

The gear motor is made of a single phase electric

motor with a permanent capacitor. This motor is

directly fitted in the gear case through which it

drives - in counter clockwise rotation at a speed

of 9.5 r.p.m. - the freezer auger being linked to it

by the ratched coupling.

NOTE. In the event the gear motor will tend

to rotate in the wrong direction (counterclockwise) or not rotating at all the unit will

stop immediately with the glowing of the

3RD WARNING YELLOW LED on account

of the intervention of the Electromagnetic

Safety Device - based on Hall Effect principle.

After having diagnosed and eliminated the

source of the failure, to restart the unit it is

necessary to press the RE-SET push button

or switch OFF and ON the power line main

disconnnect switch (Fig. 7).

The RED LED will start blinking and after

3 minutes the ice maker will resume its total

operations by running first the gear motor

and then the compressor.

Page 13

Page 13

Page 13

When the gear motor rotating speed is slowed

below 1300 r.p.m. from the normal speed of

1400 r.p.m. the Electromagnetic Safety Device

transmits an electrical signal to the

MICROPROCESSOR to stop immediately the

unit operations like it occures for the wrong

rotation, with the lighting-up of the 3RD YELLOW

WARNING LED. This to relieve from the

excessive load all the electrical and mechanical

components of the entire Drive System and

extend their durability.

NOTE. After having diagnosed and eliminated

the source of the gear motor slow rotation to

restart the unit it is necessary to press the

RE-SET push button or switch OFF and ON

the power line main switch.

NOTE. Any time the machine stops in alarm

the front four LED's start to blink.

REFRIGERANT METERING DEVICE:

capillary tube

OPERATING PRESSURES

(With 21°C ambient temperature)

D

ischarge pressure: 9 ÷ 10 bar (125 ÷ 140 psig)

Suction pressure: 1 bar (14 psig)

REFRIGERANT CHARGE (R 134 A): 370 gr

NOTE. Before charging the refrigerant system

always check the type of refrigerant and

quantity as specified on the individual ice

machine dataplate.

The refrigerant charges indicated are relatives

to averages operating conditions.

Page 14

Page 14

Page 14

COMPONENT DESCRIPTION

A. EVAPORATOR TEMPERATURE

SENSOR - BLUE 2 POLES CONNECTOR

- MANUAL RESET

The evaporator sensor probe is inserted into its

tube well, which is welded on the evaporator

outlet line. It detects the temperature of the

refrigerant on the way out from the evaporator

and signals it by suppying a low voltage current

flow to the P.C. Board Micro-Processor.

According to the current received, the microprocessor let the ice maker to continue its

operations or not. In case the evaporating temperature, after 10 minutes from the unit start-up,

does not go below -1°C (30°F) the evaporator

sensor signal reaching the microprocessor is

such to stop immediately the unit operation, with

the 3rd Warning YELLOW LED that blinks.

B. WATER LEVEL SENSOR - RED TWO

POLES CONNECTOR - AUTOMATIC

RESET

This sensor system consist of two small stainless

steel rods vertically fitted on the inner face of the

reservoir cover and electrically connected to the

low voltage circuit of the P.C. Board. When the

cover of the reservoir is positioned in its place the

tips of both the rods dip into the reservoir water

and detects and signals its presence by supply

power back to the P.C. Board.

NOTE. In the event of shortage of water in

the reservoir or, in case the water used is too

soft (de-mineralized) to cause greater

resistence to the current flow (conductivity

lower than 30 µS) this sensor system causes

the shutoff of the machine, to protect it

from running with an interrupted or inadequate

water supply.

In this situation the 5th YELLOW LED will

glow to warn of the machine shutoff and the

reason why.

C. CONDENSER TEMPERATURE SENSOR

- BLACK TWO POLES CONNECTOR MANUAL RESET

The condenser temperature sensor probe,

located within the condenser fins detects the

condenser temperature variations and signals

them by supplying current, at low voltage, to the

P.C. BOARD.

In relation to the different current received, the

micro processor of the P.C. BOARD supplies,

through a TRIAC, the power at high voltage to

the fan motor so that it can cool the condenser

and reduce its temperature.

In the event the condenser temperature rises

and reaches 70°C the current arriving to the

micro processor is such to cause an immediate

and total stop of the machine operation with the

glowing of the 2nd RED WARNING LED.

NOTE. To restart the unit after the shutoff

caused by the hi condenser temperature, it

is necessary to push the RE-SET button

(after having remedied to the causes of unit

stoppage) or to switch OFF and ON the

power line main disconnect Switch.

D. GEAR MOTOR ROTATION AND SPEED

SENSOR - RED FOUR POLES

CONNECTOR - MANUAL RESET

This safety device is housed on top of the Drive

Motor and detects - based on Hall Effect principle

- the rotating speed and rotating direction of the

drive Motor.

Should the rotating speed drop below

1300 r.p.m. the magnitude measured by this

device is such to signal to the microprocessor to

stop the unit and light-up the 3rd YELLOW LED.

The same reaction occures when the drive motor

will tend to rotate in the wrong direction

(counterclockwise) or it doesn't rotate at all.

NOTE. To restart the unit after the shutoff

caused by this safety device, it is necessary

first to eliminate the cause that has generated

the intervention of the device and then press

the RE-SET push button or switch OFF and

ON the power line main disconnect switch.

E. ICE BIN LEVEL LIGHT CONTROL - BLACK

FOUR POLES CONNECTOR AUTOMATIC RESET

The electronic ice bin level control, located into

the ice spout, has the function to stop the operation

of the ice machine when the light beam between

the light source and the sensor gets interrupted

by the flake ice which accumulates in the spout.

When the light beam is interrupted the 1st RED

LED located in the front of the P.C. BOARD goes

off; in case the light beam gets interrupted for as

long as 6 seconds, the ice machine stops with the

glowing-up of the 6th YELLOW LED to monitor

the full ice bin situation.

The 6 seconds of delay prevents that any

minimum interruption of the light beam due to the

regular ice chuting through the ice spout may

stop the operation of the unit.

As soon as the ice is scooped out (with the

resumption of the light beam between the two

infrared sensor of ice level control) the RED LED

lights up and after 6 seconds the ice machine

resume its operation with the simultaneous

extinguishing the 6th YELLOW LED.

F. ICE/WATER OPTICAL DISPENSING

DEVICE - BLUE FOUR POLES CONNECTOR

Located on the front of the dispensing area it

consists of the combination of an infrared

Transmitter and Receiver.

When a glass or a carafe is placed in front of the

Infrared sources, the optical device transmits a

signal to the PC Board that is equivalent to

activate the dispensing drive motor which, in

Page 15

Page 15

Page 15

turn, put in rotation a dispensing vane that pushes

the ice towards a rectangular opening located in

the bottom of the storage bin.

Elapsed the dispensing time (5, 10 or 15 seconds

according to the setting) or after have removed

the glass/carafe, the infrared resume its original

condition switching off the dispensing drive motor.

G. FRONT DISPENSING SELECTOR/

DISPLAY - BLACK SIX POLES CONNECTOR

Placed in the upper front part of the dispensing

area it is used to select, according to the version

of the machine:

a) Ice (first switch)

or

a) Ice (first switch)

b) Ice and water (second switch)

c) Water - not chilled - (third switch)

It is also possible to set up for "continuous"

dispensing operation just pushing the fourth switch

before or after the selection of the dispensed

product.

Once completed the dispensing selector/display

resumes its original dispensing setting mode.

NOTE. It is possible to modify the original

resume mode (default) by pushing for 5

seconds the corresponding switch (all

machines are supplied from the factory in the

ICE dispensing mode).

It is also possible to modify the dispensing

time controlled by the PC Board to 5, 10 or 15

seconds by:

a) Push and olt the 4th switch "continuous"

for approximately 10 seconds till the first 3

lights start to blink

b) Pushing the 1st switch (ICE) is equivalent

to 5 seconds

Pushing the 2nd switch (ICE+WATER) is

equivalent to 10 seconds

Pushing the 3rd switch (WATER) is equiva-

lent to 15 seconds.

H. P.C. BOARD (Data processor)

The P.C. BOARD, fitted in its plastic box located

in the right side of the unit, consists of two separated

printed circuits one at high and the other at low

voltage, protected by three fuses, integrated with

a RE-SET button. Also it consists of six aligned

LEDS monitoring the operation of the machine

and of input terminals for the leads of the sensor

probes as well as input and output terminals for

the leads of the ice maker electrical wires.

The P.C. BOARD is the brain of the system and

it elaborates, through its micro processor, the

signals received from the sensors in order to

control the operation of the different electrical

components of the ice maker (compressor, gear

motor, etc.) as well as the dispensing of the ice

and water.

The six LEDS, placed in a row in the front of the

P.C. BOARD, monitor from right to left the

following situations:

RED LIGHT

Empty storage bin

RED LIGHT

ON all the time

- Unit shut-off due to a too hi-condensing

temperature > 70°C

Blinking

- 3 minutes start up delay time

YELLOW LIGHT

ON all the time

- Unit shut-off due to the wrong rotation

direction of gear motor

- Unit shut-off due to the too lo speed

of gear motor

Blinking

- Unit shut-off due to a

too hi-evaporating temp.

>-1°C after 10 min of operation

GREEN LIGHT

- Unit under electrical power

YELLOW LIGHT

- Unit shut-off due to a too lo-water level into

float tank

YELLOW LIGHT

- Unit shut-off at full storage bin

Page 16

Page 16

Page 16

I. FLOAT RESERVOIR

The float reservoir consists of a plastic water pan

on which is fitted a float valve with its setting

screw. The float valve modulate the incoming

water flow to maintain a constant water level in

the reservoir, level that corresponds to the one in

the freezing cylinder to ensure proper ice

formation and fluidity.

On the inner side of the reservoir cover are fitted

the two water level sensors which detects the

presence or the shortage of water in the reservoir.

NOTE. It is very important to make sure of the

correct fitting of the cover on the reservoir in

order to enable the sensor to efficiently control

the water situation avoiding undue shutoff

interventions.

J. FREEZING CYLINDER (EVAPORATOR)

The freezing cylinder is made of a stainless steel

vertical tube on which exterior is wrapped around

the cooling coil with the evaporating chamber

and in its interior is located the auger which

rotates on its vertical axis and it is maintained

aligned by the top and bottom bearings. A water

seal system is located in the bottom part of the

freezer while at the top end is fitted the ice

breaker.

The water constantly flowing into the cylinder

bottom part, freezes into ice when in contact with

the cylinder inner walls. The ice is then lifted up

by the rotating auger and compacted and forced

out by the ice breaker.

K. ICE BREAKER

The ice breaker is made by several rectangular

openings where the ice is forced to pass through.

By undergoing this, the ice looses its excess of

water content so it drops into the bin in hard dry

bits of ice.

In the ice breaker it is housed the top bearing

which is made of two rolls bearings positioned to

withstand the auger axial and radial loads. This

bearing is lubricated with a food grade - water

resistant grease.

NOTE. It is advisable to check the conditions

of both the lubricant grease and the bearings

every six months.

L. DRIVE GEAR MOTOR

This motoreducer is made of a single phase

electric motor with permanent capacitor directly

fitted on a gear box.

The drive motor rotor is kept aligned on its

vertical axis by two ball bearings permanently

lubricated. The gear case contains a train of

three spur gears the first one of which is in fiber

to limit the noise level. All the three gears are

encased in case bearings and are covered by

lubricant grease (MOBILPLEX IP 44).

Two seal rings, one fitted on the rotor shaft and

the other on the output shaft keep the gear case

sealed.

Hovewer, the interior can be inspected and

serviced by unbolting the two halves of the

aluminium gear case housing.

The gear reducer output shaft is connected to the

freezer auger by a ratched coupling which is

made of two toothed halves that engages

themselves only if turned in the correct direction

namely, conterclockwise.

M. FAN MOTOR (Air cooled version)

The fan motor is controlled through the P.C.

BOARD and the TRIAC by the condenser temperature sensor. Normally it operates to draw cooling

air through the condenser fins.

In cold ambient situation, the fan motor can run

at intermittance as the condenser pressure must

be kept between two corresponding head

pressure values.

N. COMPRESSOR

The hermetic compressor is the heart of the

refrigerant system and it is used to circulate and

retrieve the refrigerant throughout the entire

system. It compresses the low pressure

refrigerant vapor causing its temperature to rise

and become high pressure hot vapor which is

then released through the discharge valve.

O. ICE DISPENSER DRIVE MOTOR

Located on the upper side of the storage bin, it

turn by a milled shaft the dispensing vane placed

inside the round storage bin.

By rotating, the dispensing vane pushes the ice

towards the bottom rectangular opening so to

force the nugget ice to go through the bottom

outlet spout.

P. STORAGE BIN

Round shaped it is located in the front of the ice

machine and has the main reason to store the

nugget ice produced by the evaporator till it

reaches its maximum level controlled by an

infrared optical system. In its bottom is placed the

ice spout as well as the water drain hole.

Inside the ice spout opening is also located the

water outlet tube connected to the solenoid valve.

Q. DISPENSING WATER SOLENOID VALVE

Energized and controlled by the PC Board, it

allows a metered quantity of not chilled water to

be dispensed through the same opening of the

ice.

Page 17

Page 17

Page 17

WIRING DIAGRAM

AIR AND WATER COOLED

230/50/1

B - WHITE

G - GREY

N - BLACK

A - BLUE

M - BROWN

GV - YELLOW GREEN

Page 18

Page 18

Page 18

SYMPTON POSSIBLE CAUSE SUGGESTED CORRECTION

Unit will not run Blown fuse in P.C.Board Replace fuse & check for cause of

No LED lighted-up blown fuse

Master switch in OFF position Turn switch to ON position

Inoperative P.C.Board Replace P.C.Board

Loose electrical connections Check wiring

6th Yellow LED glows Inoperative or dirty ice level control Replace or clean ice level control

5th Yellow LED Shortage or too soft water See remedies for shortage of water

glows or install a mineral salt metering

device

2nd LED glows High head pressure Dirty condenser. Clean

Inoperative fan motor. Replace

3rd Yellow LED blinks

Too hi evap. temperature Check and charge refrigerant system

Shortage or lack of refrigerant

3rd Yellow LED glows Gear motor tends to run on reverse Check gear motor capacitor

Too low gear motor rotating speed Check rotor bearings, freezer

bearings and interior of freezer for

scores. Replace whatever worn or

damaged.

No rotation of gear motor Check for power to drive motor

(16 A fuses)

Check for stator winding

Gear motor starts and stop Check for correct operation of drive

after a while motor magnetic sensor

Check for correct magnetic capacity

of magnetic cylinder

Compressor cycles intermittently Low voltage Check circuit for overloading

Check voltage at the supply to the

building. If low, contact the power

company

Non-condensable gas in system Purge the system

Compressor starting device with Check for loose wires in starting

loose wires device

Low ice production Capillary tube partially restricted Blow charge, add new gas & drier,

after evacuating system with vacuum

pump

Moisture in the system Same as above

Low water level in the freezer Adjust to approx 20 mm below ice

spout

Shortage of refrigerant Check for leaks & recharge

Pitted or stained auger surface Clean or replace auger

SERVICE DIAGNOSIS

Page 19

Page 19

Page 19

SYMPTON POSSIBLE CAUSE SUGGESTED CORRECTION

Wet ice Ambinet temperature too high Move unit to cooler location

High water level in the freezer Lower to approx. 20 mm below

ice spout

Faulty compressor Replace

Machine runs but makes no ice Water not entering in the freezer Air look in feed line to freezer.

Clogged feed line to freezer. Clean it

Gear stripped Check and repair

Moisture in the system Purge, replace drier and re-charge

Water leaks Water seal leaking Replace water seal

Water feed line to freezer leaking Check and fasten hose clamp

Float valve not closing Check and adjust float valve

setting screw

Excessive noise or chattering Mineral or scale deposit on auger Remove and manually polish auger

and inner freezer walls and inner walls of freezer barrel

using emery paper

Low suction pressure

Add refrigerant to rise suction pressure

Water feed line to freezer clogged Vent and clean it

Low water level into freezer Adjust to approx. 20 mm below

ice spout

Gear motor noise Worn rotor bearings Check and replace

Shortage or poor lubricant in gear Check for proper lubricant opening

case gear case.

Top of gears must be covered

with lubricant

Gear case bearings and gear Check and replace worn parts

racers worn out

Shortage of water

Strainer at water inlet fitting clogged

Remove strainer and clean

Float reservoir water nozzle Remove float valve and clean

clogged-up nozzle

SERVICE DIAGNOSIS

Page 20

Page 20

Page 20

MAINTENANCE AND CLEANING INSTRUCTION

A. GENERAL

The periods and the procedures for maintenance

and cleaning are given as guides and are not to

be construed as absolute or invariable.

Cleaning, especially, will vary depending upon

local water and ambient conditions and the ice

volume produced; and, each icemaker must be

maintened individually, in accordance with its

particular location requirements.

B. ICEMAKER

The following maintenance should be scheduled

at least two times per year on these icemakers.

1. Check and clean the water line strainer.

2. Remove the cover from the float reservoir care to do not damage the two water sensors and depress the float to make sure that a full

stream of water enters into the reservoir.

3. Check that the icemaker is levelled in side to

side and in front to rear directions.

4. Check that the water level in the water

reservoir is below the overflow but high enough

that it does not run out of the spout opening.

NOTE. The float must close positively the

incoming water flow when the rubber housed

in the setting screw, is perpendicular to the

water nozzle.

5. Clean the water system, water reservoir

and the interior of freezing cylinder using a

solution of SCOTSMAN Ice Machine Cleaner.

Refer to procedure C cleaning instructions and

after cleaning will indicate frequency and procedure to be followed in local areas.

NOTE. Cleaning requirements vary

according to the local water conditions and

individual user operation.

6. If required, polish the two sensor rods

secured to the float reservoir cover, heavy scale

sediment on them can be removed with the help

of a bit of SCOTSMAN Cleaner plain.

7. With the ice machine and fan motor OFF

clean condenser using vacuum cleaner, whisk

broom or non metallic brush taking care to do not

damage the condenser temperature sensor.

8. Check for water leaks and tighten drain line

connections. Pour water into the sink to be sure

that drain line is open and clear.

9. Check the ice level control sensor to test

shut-off. Put your hand between the light source

and the receiver on the upper side of the storage

bin so to cut off the light beam for at least 6

seconds.

This should cause the immediate extinguishing

of the 1st RED LED located in the front face of

P.C. Board and, 6 seconds later, the total stopping

of the ice maker with the simultaneous light up of

the 6th Yellow LED.

Within few seconds from the removal of the hand

from between the sensor lights the ice maker

resume its operation.

NOTE. The ice level control uses devices

that sense light, therefore they must be kept

clean enough so they can “see”.

Every month clean/wipe the sensing “eyes”

with a clean soft cloth.

10. Check for refrigerant leaks and for proper

frost line, which should frost as far as approx. 20

cm (8") from the compressor.

When doubtful about refrigerant charge, install

refrigerant gauges on corresponding Schräder

valves and check for correct refrigerant pressures.

(See Operating pressure at page 19 of this

manual).

11. Check that fan blades move freely and are

not touching any surfaces.

12. Remove the ice spout cover, unloose the

bolt securing the casting ice sweep and remove

it; then inspect the top bearing, wipe clean of all

grease and apply a coating of food grade water

proof grease P/N 263612.00.

NOTE. It is recommended to use only food

grade and waterproof grease to lubricate the

freezer top bearing.

13. Turn the ice dispensing spout and remove it.

Wash and sanitise it.

14. Remove the sink grill for washing and

sanitising.

C. CLEANING INSTRUCTIONS OF WATER

SYSTEM

1. Switch OFF the Master disconnect switch

on the power line.

2. Remove the top panel and later the top

cover of storage bin with the dispensing drive

motor.

3. Remove all ice stored in the bin to prevent it

from getting contaminated with the cleaning

solution.

Page 21

Page 21

Page 21

4. Shut close the water shutoff valve on water

line.

5. Remove the left side panel to gain access to

the water reservoir.

6. Remove the float reservoir cover and with a

piece of copper wire jump the two water level

sensors.

7. Remove the right service panel and unloose

the drain plug from the water purge tube so to

drain out all water from the freezer. Then re-plug

the purge tube.

CLEANING

8. Prepare the cleaning solution by diluting in

a plastic container two liters of warm water (45°50°C) with a 0,2 liters of SCOTSMAN Ice Machine

Cleaner.

WARNING. The SCOTSMAN Ice Machine

Cleaner contains Phosphoric and

Hydroxyacetic acids. These compounds

are corrosive and may cause burns if

swallowed, DO NOT induce vomiting.

Give large amounts of water or milk. Call

Physician immediately. In case of external

contact flush with water. KEEP OUT OF

THE REACH OF CHILDREN

9. Pour the cleaning solution into the water

reservoir till reaches the proper level.

10. After 15 minutes switch ON the Master

switch to start the unit.

11. Wait till the machine starts to discharge ice,

then continue to slowly pour the cleaning solution

into the water reservoir taking care to maintain

the level just below the overflow.

NOTE. The ice made with the cleaning

solution is slushy and coloured also, it may

tend to loose fluidity creating some resistence

in being elevated and extruded; this situation

can be heard by the creacking noise made by

the ice.

Should this occure it is recommended to stop

for few minutes the ice machine in order to

allow the ice in the freezer to partially melt.

12. When all the cleaning solution has been

used up, open the water shutoff valve to allow

new fresh water to flow into the reservoir. Let the

unit to continue to run until the ice resumes the

normal colour and hardness.

13. Stop the icemaker and pour warm water on

the ice deposited into the storage bin to melt it up.

NOTE. DO NOT use ice produced with the

cleaning solution. Be sure none remains in

the bin.

SANITATION

14. Pour into the water reservoir 1 cc. (approx

20 drops) of Scotsman Sanitiser (Antialgae P/N

264000.02) then switch the unit ON.

15. Left the unit running for approx 10 minutes

then remove the copper wire used to jump the

two sensors for the water level and place back

correctly the cover on the float reservoir.

NOTE. DO NOT use ice produced with the

sanitising solution.

16. With a sponge moisted with a sanitising

solution, wipe clean all the bin interior surfaces.

REMEMBER. To prevent the accumulation

of undesirable bacteria it is necessary to

sanitise the interior of the storage bin with an

anti-algae disinfectant solution every week.

Loading...

Loading...