INTRODUCTION

CME1056

This product manual contains the information

needed for the setup, installation, initial start up,

sanitation and maintenance of this ice machine.

Keep it for future reference.

Be certain that the information applies to the

model in question. If no model is listed, the

information applies to all models.

TABLE OF CONTENTS

Specifications ,,,,,,,,,,,,,PAGE2

Air Cooled Layout ,,,,,,,,,,,PAGE3

Water Cooled Layout ,,,,,,,,,PAGE4

Pre-Installation ,,,,,,,,,,,,,PAGE5

Location & Assembly ,,,,,,,,,PAGE6

Cabinet Panel Removal: ,,,,,,,,PAGE7

Stacking: Requires Kit ,,,,,,,,,PAGE8

Stacking ,,,,,,,,,,,,,,,,PAGE9

Bin Thermostat: Installation ,,,,,,PAGE10

This manual is organized in the same way as the

expected use of the machine, it begins with

specifications, goes thru unpacking and setup,

shows where everything is; continues with initial

start up, then describes how it works. After that is

the sanitation section, followed by service diagnosis

and repair.

CM Cubed™ Cuber Performance Raised

to a Higher Power.™

™

Technicians Only: Harvest Cycle Operational

Sequence ,,,,,,,,,,,,,,,PAGE23

Sanitation and Cleaning ,,,,,,,,PAGE24

Additional Maintenance ,,,,,,,,PAGE25

Additional Maintenance: Ice Sensors and Water

Level Sensor ,,,,,,,,,,,,,,PAGE26

Additional Maintenance: Air Filter Replacement

,,,,,,,,,,,,,,,,,,,,,PAGE27

Additional Maintenance: Condenser , , PAGE 28

Service Diagnosis: Controller Diagnostic Light

Analysis ,,,,,,,,,,,,,,,,PAGE29

Plumbing - Air Cooled ,,,,,,,,,PAGE11

Plumbing - Water Cooled ,,,,,,,PAGE12

Electrical ,,,,,,,,,,,,,,,,PAGE13

After Utility Connections ,,,,,,,,PAGE14

Component Description and Function , PAGE 15

AutoIQ Controller ,,,,,,,,,,,PAGE16

How To Operate The Controller ,,,,PAGE17

Initial Start Up ,,,,,,,,,,,,,PAGE18

Adjustments ,,,,,,,,,,,,,,PAGE19

How This Machine Works ,,,,,,,PAGE20

How This Machine Works ,,,,,,,PAGE21

Technicians Only: Freeze Cycle Operational

Sequence ,,,,,,,,,,,,,,,PAGE22

Parts Lists and Wiring Diagrams are Located in the Center of this Manual

Service Diagnosis ,,,,,,,,,,,PAGE30

Service Diagnosis: Components,,,,PAGE31

PTCR Diagnosis ,,,,,,,,,,,,PAGE32

Operational Characteristics: CME1056 PAGE 33

Removal and Replacement: Water Level Sensor

,,,,,,,,,,,,,,,,,,,,,PAGE34

Removal and Replacement: Fan Blade and/or Fan

Motor,,,,,,,,,,,,,,,,,,PAGE35

Access Valves ,,,,,,,,,,,,,PAGE36

Before Calling for Service ,,,,,,,PAGE37

May 2000

Page 1

CME1056

Specifications

This ice machine is designed to be installed

indoors, in a controlled environment. It will operate

satisfactorily under a wide variety of conditions. Do

NOT operate the machine in temperatures it has

not been designed for. Do NOT operate the

machine above or below the voltage limits for the

particular model. Do NOT operate the machine

with too little or too much water pressure.

Operational Limits

Minimum Maximum

Air Temperature 50oF. 100oF.

Water Temperature 40oF. 100oF.

Water Pressure 20 psi 80 psi

Voltage (60 Hz model) 198 253

Voltage (50 Hz model) 207 253

Inlet water flow required is 2.7 GPM.

All models will fit a standard, 30" wide Scotsman

Ice Storage Bin. Some examples are:

BH550

•

• HTB555

Note: Slope front bins must have an internal baffle.

Scotsman BH550 and HTB555 have the required

baffle. Baffle must be approximately in the position

shown in the diagram on page 5.

Basic Information

In addition, there may be other bins that can be

used, check Scotsman’s sales literature for

application information.

Kits:

BH800 bin: Add kit KBT23

•

BH900 bin: Add kit KBT22

•

ID200 or ID250 Dispenser: Add adapter kit

•

KBT44. Do not deploy the CME1056’s

thermostat.

Lancer 30” wide dispenser. Add adapter kit

•

KSTAT-MD

Cornelius ED200 dispenser requires adapter

•

kit from Cornelius. Do not deploy the

CME1056’s thermostat.

Other combinations may be available. See

•

Scotsman product literature for more

information.

Stacking two CME1056s together requires

•

stacking kit: KSCME6-MD (cannot stack any

other model with a CME1056).

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any parts and/or other components not

specifically approved by Scotsman.

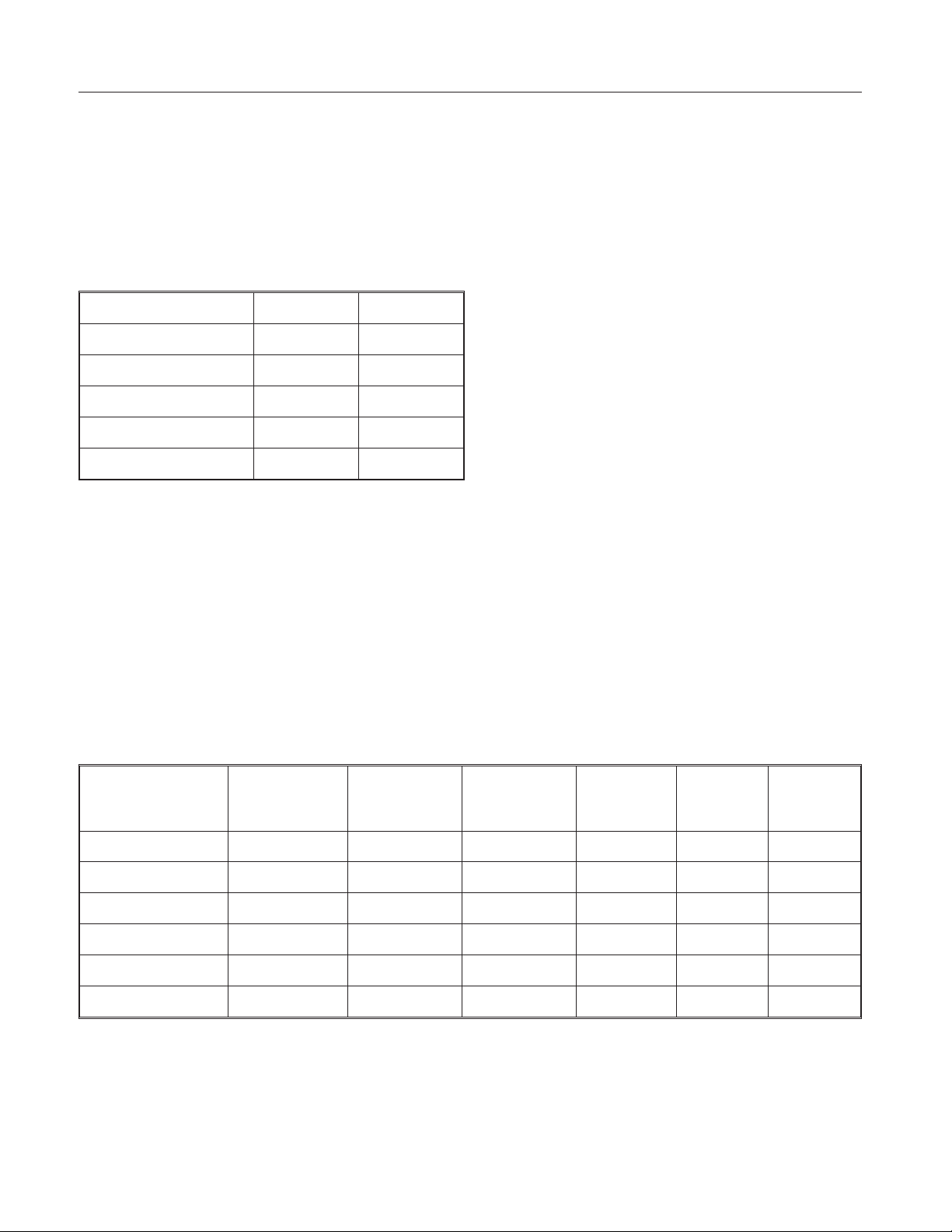

Dimensions

Model Number

CME1056AS-32F 30½x24x28 208-230/60/1 Air Cooled 18.75 20 44 ounces

CME1056WS-32F same 208-230/60/1 Water Cooled 17.25 20 28 ounces

CME1056AS-3F same 208-230/60/3 Air Cooled 13.63 15 44 ounces

CME1056WS-3F same 208-230/60/3 Water Cooled 12.13 15 28 ounces

CME1056AS-6F same 230/50/1 Air Cooled 44 ounces

CME1056WS-6F same 230/50/1 Water Cooled 28 ounces

W"xD"xH"

(w/o bin)

Basic

Electrical

Condenser

Type

May 2002

Page 2

Minimum

Circuit

Ampacity

Maximum

Fuse Size

Refrigeran

t Charge

(R-404A)

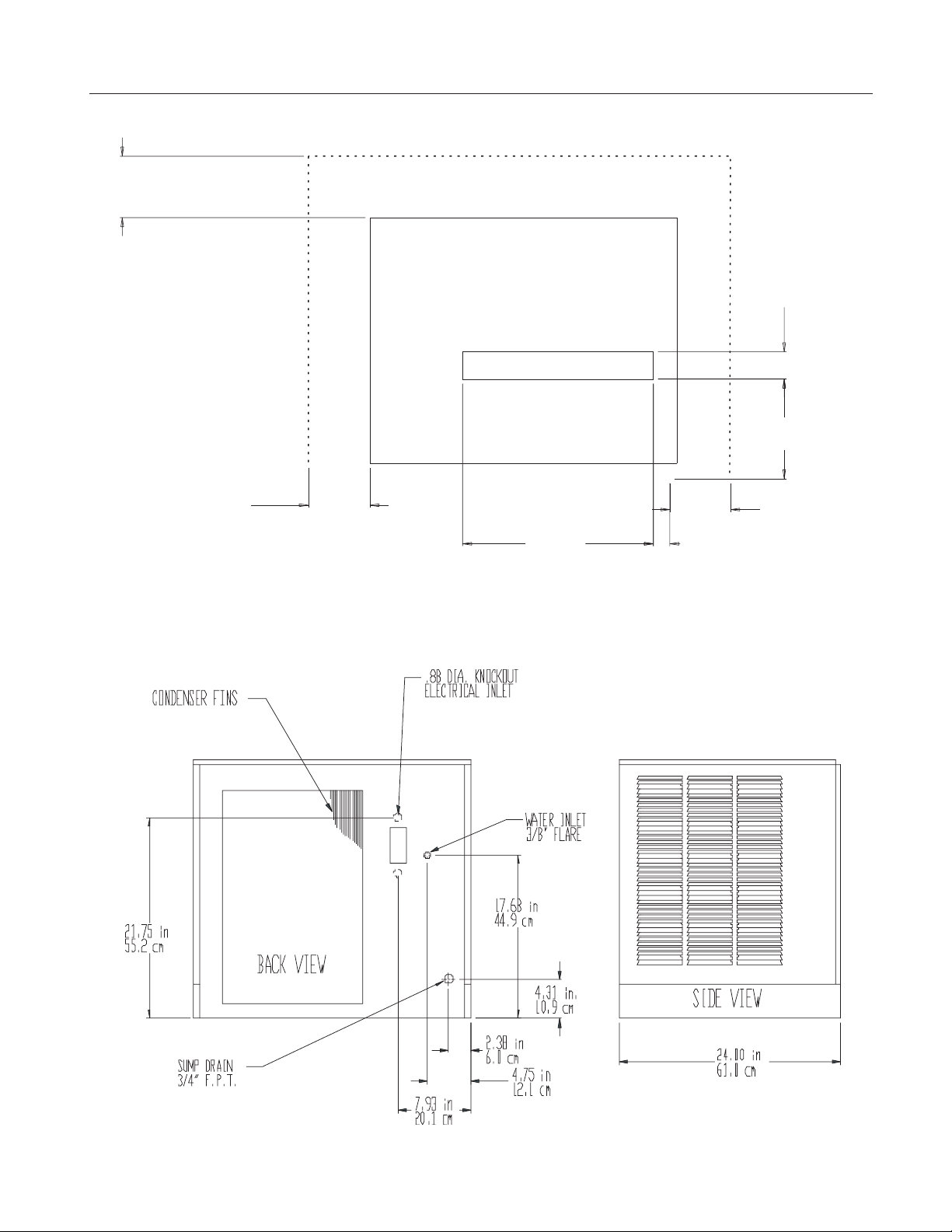

Air Cooled Layout

CME1056

6.00 in

15.2 cm

MINIMUM FOR

UTILITY CONNECTIONS

6.00 in

15.2 cm

MINIMUM FOR

AIR VENTILATION

PLAN VIEW

18.70 in

47.5 cm

OPENING

ICE

1.63 in

4.1 cm

2.70 in

6.9 cm

9.85 in

25.0 cm

6.00 in

15.2 cm

MINIMUM FOR

AIR VENTILATION

ICE

OPENING

January 2003

Page 3

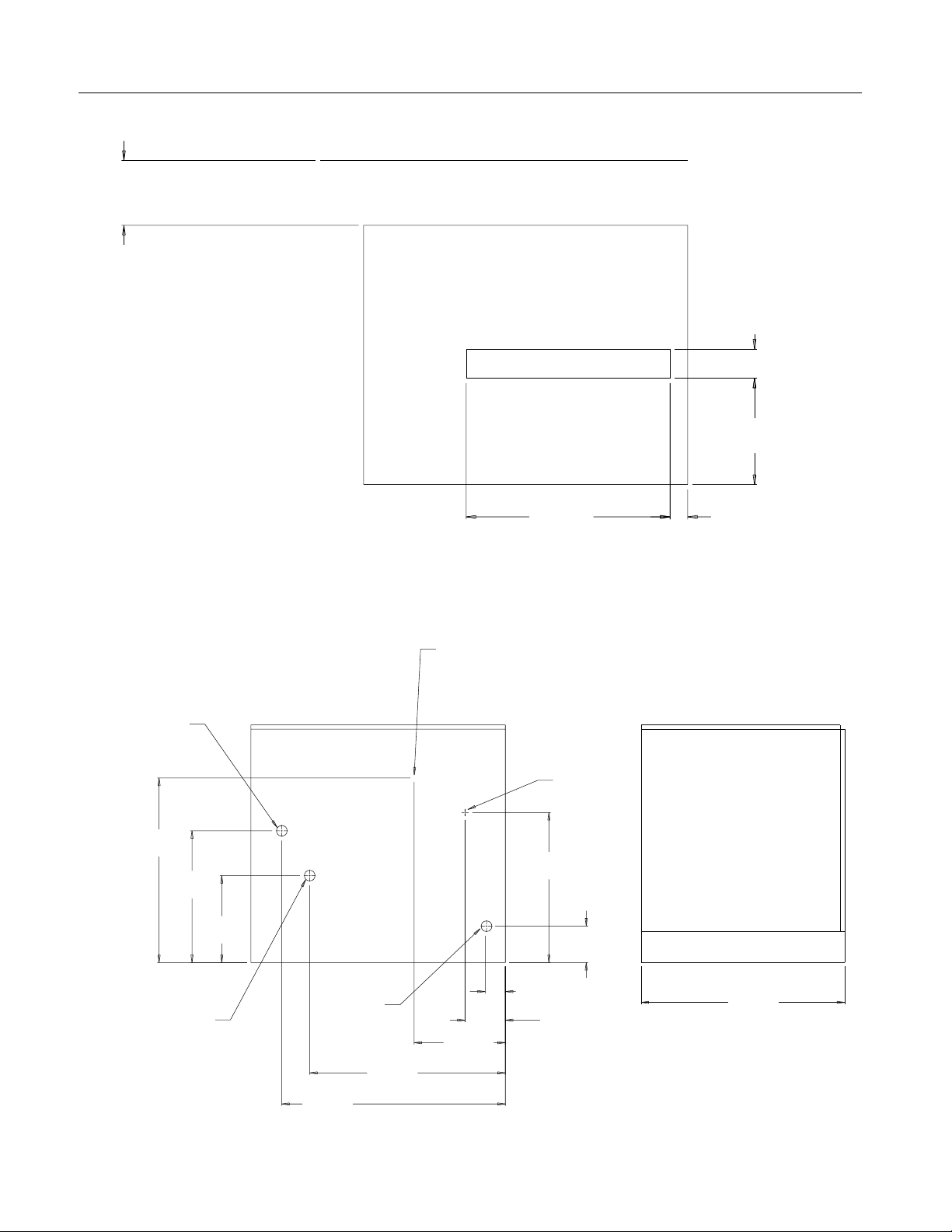

CME1056

Water Cooled Layout

6.00 in

15.2 cm

MINIMUM FOR

UTILITY CONNECTIONS

PLAN VIEW

18.70 in

47.5 cm

OPENING

ICE

2.70 in

6.9 cm

9.85 in

25.0 cm

1.63 in

4.1 cm

ICE

OPENING

CONDENSER INLET

3/8" F.P.T.

21.75 in

55.2 cm

15.53 in

39.4 cm

CONDENSER DRAIN

1/2" F.P.T.

10.25 in

26.0 cm

BACK VIEW

SUMP DRAIN

3/4" F.P.T.

26.35 in

66.9 cm

23.06 in

58.6 cm

.88 DIA. KNOCKOUT

ELECTRICAL INLET

10.75 in

27.3 cm

17.68 in

44.9 cm

2.38 in

6.0 cm

WATER INLET

3/8" FLARE

4.31 in.

10.9 cm

4.75 in

12.1 cm

SIDE VIEW

24.00 in

61.0 cm

May 2000

Page 4

Pre-Installation

Other Applications:

Check Scotsman sales information for

recommendations regarding applications.

Do not place Air Cooled models where the noise

from the fan will be objectionable.

Check the nameplate for electrical requirements.

The nameplate is located on the back of the ice

machine. While the model and serial number are

on the nameplate, a serial number plate is

located at the front of the machine, near the purge

valve.

Water:

There is no such thing as pure water. All water

contains some impurities. There are two ways

water carries the impurities: suspended and

dissolved. Suspended solids can be filtered out.

Dissolved solids must be diluted or treated. Water

filters are recommended to remove suspended

solids. Some filters also have treatment in them for

dissolved solids. Check with a water treatment

service for a recommendation.

Cube Ice machines use more water than what

ends up in the bin as ice. While most water is used

during ice making, a portion is designed to “rinse"

out the water system to keep hard water scale

from clogging up the machine. That water rinse,

combined with water filters, prolongs the times

between needed water system cleaning.

Note: All Scotsman CM

described in this manual, feature Scotsman’s

AutoIQ™ control system and ReliaClean™ water

system cleaning process.

3

models, like those

CME1056

Nameplate on Back Panel

Serial Number Plate, Remove

Front Panel to Locate

Note: Slope front bins must have an internal baffle.

Scotsman HTB555 and BH550 have the required

baffle. Baffle must be approximately in the position

shown in the diagram.

Baffle

Service Technicians: All models covered here

come set from the factory at a “standard” water

rinse, which is compatible with typical water

conditions. They may be adjusted to “Minimum" or

“Maximum" water rinse after start up. If the prior

ice machine worked acceptably well with the local

water conditions, leave the machine at the factory

setting. If severe water conditions are present, and

water filters do not solve the problem acceptably,

adjust the machine to use more water. If water

conditions are excellent, adjust the machine to use

less water. See the Adjustments section.

Note: Water use adjustments are customer

convenience adjustments; they are NOT factory

defects and are NOT covered by warranty.

May 2000

Page 5

12.0"

4.0"

Side View

CME1056

Location & Assembly

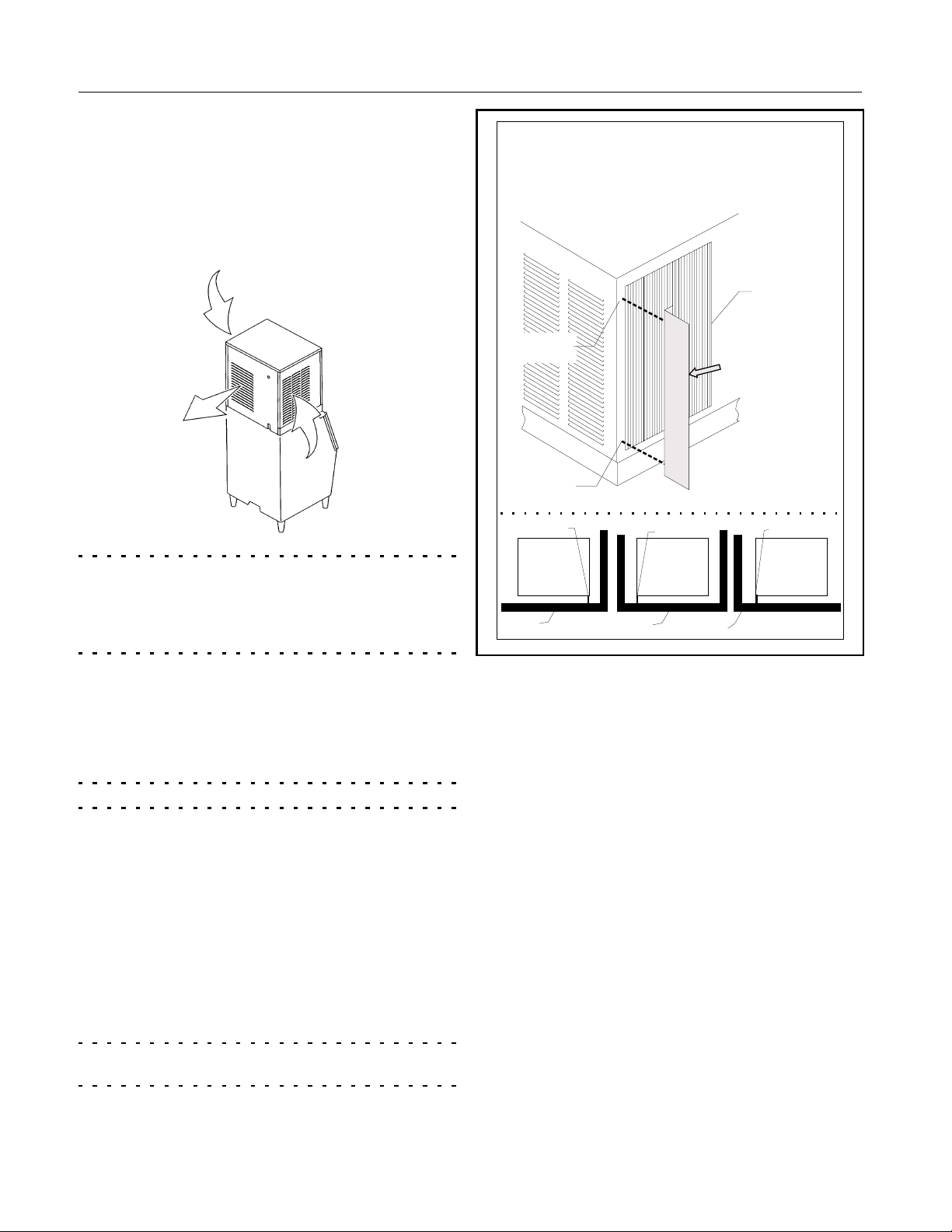

Air cooled models take room temperature air in

from the sides and discharge warm air out the

back. Do not place them where the heat and noise

will be objectionable.

A 6 inch MINIMUM clearance on the back, and

both sides is required for the basic operation and

service of the air cooled model.

Airflow is in

the sides and

out the back

Remove Air Baffle from its

Shipping Position.

Use baffle for

In-The-Corner Applications

Back View of Ice

Machine

Attach Air

Baffle Here

Attach Air

Baffle Here

Air Cooled

Condenser

Outlet

Air

Baffle

Note: A six inch side clearance with zero top

clearance will NOT provide enough air exchange

space for optimum performance. 12 inches side

clearance is required when there is no top

clearance.

Unpacking and Assembly:

Begin with unpacking the ice storage bin. Remove

the carton, and using part of the carton as a

cushion, tip the bin on its back to remove the skid

and attach the legs or casters.

Note: Stacked applications may not use casters.

Return the bin to an upright position. Check the bin

top gasket for gaps and tears, fill any in with food

grade sealant prior to placing the ice machine on

the bin.

Level the top edge of the bin front to back and

left to right.

If the ice machine has not been unpacked, do so

now. Remove the carton from the skid. After

removal of the shipping straps, lift the ice machine

off the skid directly onto the bin.

Baffle Position

Ice Machine

Top View

Wall

Baffle

Ice Machine

Top View

Wall

Wall

Baffle

Ice Machine

Top View

17-2632-01 Rev. A.

Air cooled models come equipped with a baffle

that can be used when the machine is installed

in a corner.

The purpose of the baffle is to limit air

recirculation. This can occur in a corner when the

hot air from the back of the machine is re-drawn

back into the machine from the nearest side of the

machine.

Install the air baffle as shown. Place the baffle:

•

On the left rear corner when the left wall and

back wall are between 6 and 18 inches from

the unit.

•

On the right rear corner when the right wall

and back are between 6 and 18 inches from

the unit.

Note: The machine is heavy! Use a mechanical

hoist if necessary.

Secure the ice machine to the bin with the

hardware provided (two metal straps and 4 bolts).

May 2000

Page 6

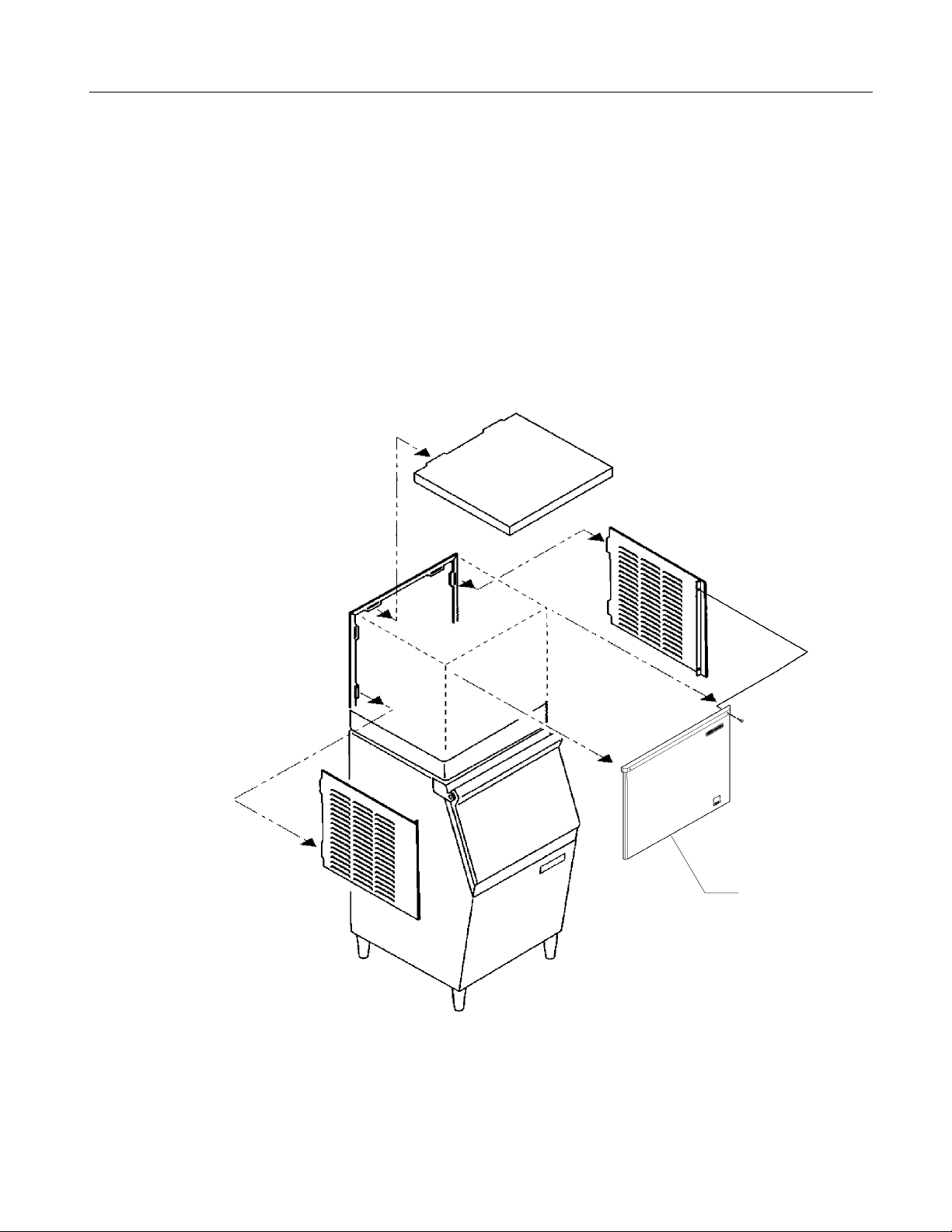

Cabinet Panel Removal:

Note: The top panel holds the upper edges of the

side panels in place.

1. Remove the front panel by removing the two

screws connecting the top edge of the front panel

to the machine, then pull out at the bottom.

2. Lift up at the front edge and push the top panel

back until it releases from the tabs connecting it to

the back panel.

3. Remove the screws at the front edge of the left

side panel, and pull forward until it releases from

the tabs connecting it to the back panel.

CME1056

May 2000

Page 7

Remove The

Front Panel

First

CME1056

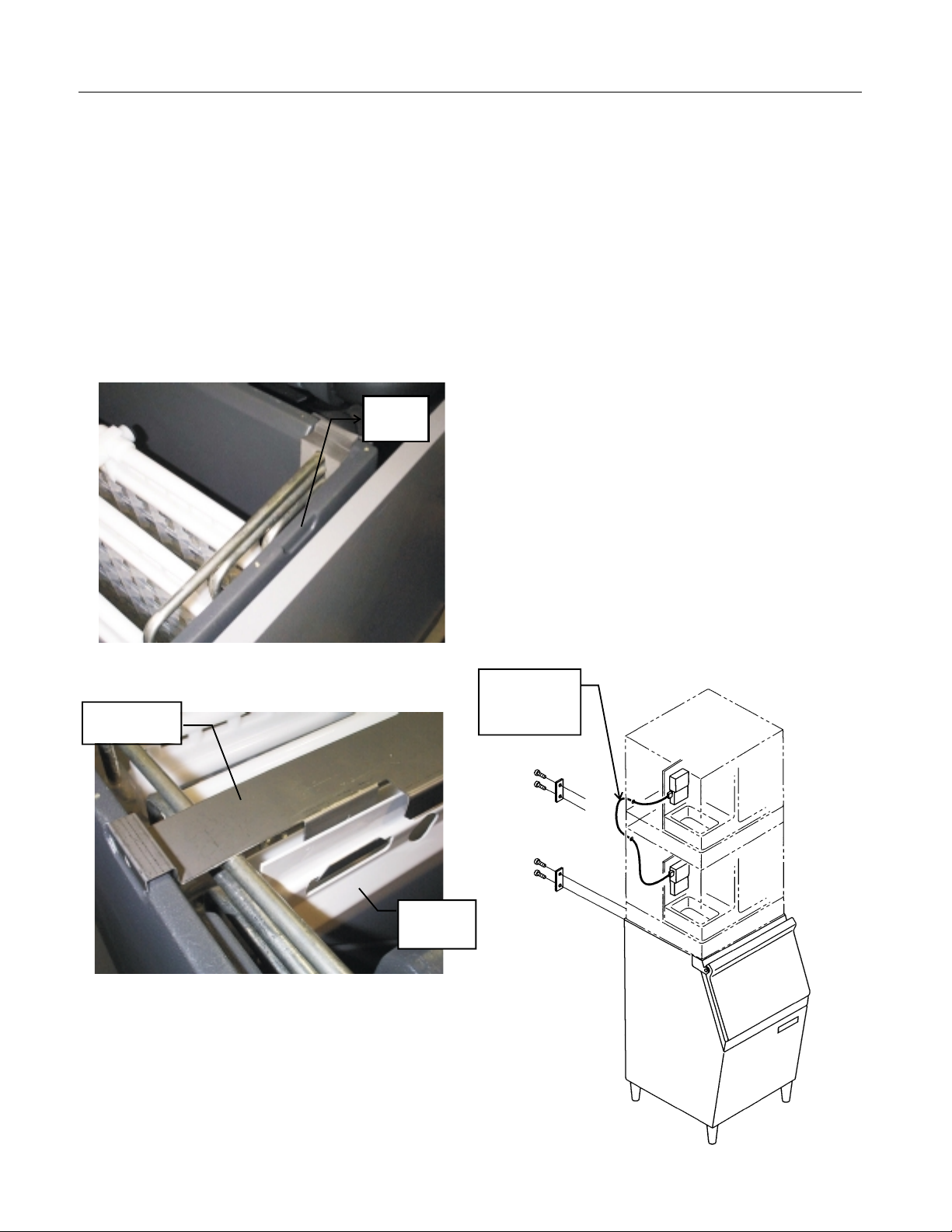

Stacking: Requires Kit

Only like models may be stacked. Begin after the

bottom unit has been placed on the ice storage bin

and secured. Stacking requires heavy duty leg kits.

Casters are NOT recommended.

Bottom Machine:

1. Remove front, side, and top panels.

2. Hang the plastic shield from the tabs on the

stainless steel bracket.

3. Locate the two notches on the sides of the top

edge of the freezing compartment.

Notch

Upper Machine:

8. Knock out 1 hole in the lower left (viewed from

the front) corner of the upper unit’s back panel.

Lower Unit:

9. Knock out 1 hole in the upper left (viewed from

the front) corner of the lower unit’s back panel.

10. Position the strain reliefs over the wrapped

portion of the stacking kit wire harness.

11. Route the Stacking Kit wire harness from the

back to the top and bottom machines thru the

holes made in steps 8 and 9.

The harness is marked which end goes to which

machine.

Push the strain reliefs into place from the back of

the machines.

Follow local codes for 24 volt wire

12.Route wire harness in lower ice machine to the

controller. Connect to terminal #7. Plug the two

free wires onto thermostat terminals #1 and #2

4. Place the bracket over the notches of the

freezing compartment.

Bracket

Shield

5. Secure bracket to freezing compartment with

screws from the kit (from the sides).

6. Locate gasket material in kit. Place a layer of

gasket material on the top edge of the plastic

freezing compartment.

Routing of

Harness

7. Place the top ice machine onto the bottom one.

Secure together with hardware from the top

machine. Remove front and left side panels.

May 2000

Page 8

Stacking

CME1056

Top Machine:

13. Route the wire to the controller. Connect to

terminal 7.

Bottom Machine

14. Route the bulb of the thermostat thru the base

of the unit into the bin.

15. Mount the bulb of the thermostat to the bracket

from the kit.

16. Install the bin thermostat bracket onto the

bottom of the machine.

17. Pull back excess cap tube and coil up in the

machine.

18. Connect wires from harness to thermostat

terminals.

Both Machines:

19. Return all panels and covers to their normal

positions.

20. Complete the balance of the installation.

March 1999

Page 9

CME1056

Bin Thermostat: Installation

The bin control is a thermostat. Its bulb must be

deployed after the ice machine has been placed

on the bin or dispenser.

Before starting, remove the left side panel and any

baffle in the bin.

1. Locate bin thermostat bulb.

2. Route bulb thru routing hole (located between

the compressor and the reservoir).

Routing Hole

5. Fasten the bracket to the bottom of the ice

machine with the two 3-pronged knobs supplied

with the unit.

6. Pull back into the ice machine any excess

capillary tubing.

7. Return the baffle to the bin and continue with

the installation.

3. Locate bin thermostat bracket.

4. Carefully position the thermostat bulb on the

bracket.

Bin Thermostat Altitude Correction Table

CW Turns of Range Screw (under plastic cover)

Feet Turns Feet Turns

2000 55

4000 160

6000 250

o

o

o

8000 340

9000 385

10000 405

o

o

o

Use This Table to Adjust Thermostat

Insert Tip

May 2000

Page 10

Plumbing - Air Cooled

CME1056

All models require an adequate potable water

supply and a gravity drain. The recommendations

for tubing are:

Water supply to be

•

Drain to be

•

3

" OD.

4

3

" OD.

8

Note: When replacing a prior ice machine, do not

take a short cut and reuse the old inlet and drain

system. INSTALL A NEW SYSTEM.

Supply:

Air cooled models have 1 water supply connection,

3

" male flare at the back of the cabinet. Connect

a

8

to cold potable water that has adequate pressure.

Note: Using water supply tubing smaller than

3

"

8

will cause severe operational issues.

Water Filters:

The water filters must flow at least 2.7 GPM or they

will cause severe operational issues. Check with

the filter manufacturer. When replacing a prior ice

machine, do NOT assume that the water flow

capacity of the filter will be adequate.

All Drain Tubing Material must be RIGID.

Flexible tubing will eventually cause a restricted

drain.

Drain:

Air cooled models have 1 gravity drain connection,

3

" FPT fitting at the back of the cabinet. Use only

a

4

RIGID TUBING. Flexible tubing may be easily

kinked or become cracked.

The drain tube must be vented at the back of the

cabinet. Use an 18" high vent.

The ice storage bin will have a drain out the back or

base, depending upon the model.

The drain for the ice machine and the ice storage

bin must be SEPARATE or the ice machine’s drain

water may run into the bin and MELT THE ICE.

Insulation is recommended for the ice machine

reservoir and bin drains.

Follow all applicable codes

Water Inlet

System

Vent this

Drain

Bin Drain

Water IN

Water OUT

May 1999

Page 11

Plumbing Connections

CME1056

Plumbing - Water Cooled

All models require an adequate potable water

supply and a gravity drain. The recommendations

for tubing are:

Water supply to be

•

Drain to be

•

3

" OD.

4

3

" OD.

8

Note: When replacing a prior ice machine, do not

take a short cut and reuse the old inlet and drain

system. INSTALL A NEW SYSTEM.

Supply:

Water cooled models have TWO water supply

3

connections, a

AND an additional

" male flare for POTABLE water

8

3

" FPT condenser inlet

8

connection, both at the back of the cabinet.

Connect both to cold water w/adequate pressure.

Note: Using water supply tubing smaller than

3

"

8

will cause severe operational issues.

Water Filters:

The water filters must flow at least 2.7 GPM to the

potable water inlet or they will cause severe

operational issues. Check with the filter

manufacturer.

When replacing a prior ice machine, do NOT

assume that the water flow capacity of the filter will

be adequate.

All Drain Tubing Material must be RIGID.

Flexible tubing will eventually cause a

restricted drain.

Drain:

Water cooled models have TWO gravity drain

3

connections, a

" FPT fitting ANDa½“FPT

4

fitting. Use only RIGID TUBING. Flexible tubing

may be easily kinked or become cracked.

The reservoir drain must be vented at the back of

the cabinet. Use an 18" high vent. Do NOT vent

the condenser drain.

The ice storage bin will have a drain out the back

or base, depending upon the model.

The drain for the ice machine and the ice storage

bin must be SEPARATE or the ice machine’s drain

water may run into the bin and MELT THE ICE.

Insulation is recommended for the ice machine

reservoir and bin drains.

Follow all applicable codes

Water Inlet

System

Do NOT Vent the

Condenser Drain

Bin Drain

Potable

Water IN

Water OUT.

VENT THIS

DRAIN

May 2000

Page 12

Plumbing Connections

Loading...

Loading...