Page 1

CME855A & CME1000A

INTRODUCTION

This manual is intended as a reference for the

installation of a Scotsman ice maker models

CME855 and the CME1000.

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

UTILITY CONNECTION LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

FOR THE INSTALLER: Environmental Limitations . . . . . . . . . . . . . . . . . . . . . . . . page 4

FOR THE INSTALLER: Machine & Bin Assembly . . . . . . . . . . . . . . . . . . . . . . . . . page 5

STACKING TWO UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

FOR THE PLUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

FOR THE ELECTRICIAN: Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . page 8

FOR THE INSTALLER: Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

INITIAL START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

ADJUSTMENT OF THE TIMER & SWITCH ASSEMBLY . . . . . . . . . . . . . . . . . . . . . page 12

REFRIGERATION SYSTEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

WATER SYSTEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

SERVICE SPECIFICATIONS: CME855A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

SERVICE SPECIFICATIONS: CME1000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

SERVICE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

REMOVAL AND REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

REFRIGERATION SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

LIQUID CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

A Service Parts List and the Wiring

Diagrams are located in the center of this

manual, printed on yellow paper.

October, 1994

Page 1

Page 2

SPECIFICATIONS

CME855A & CME1000A

Page 2

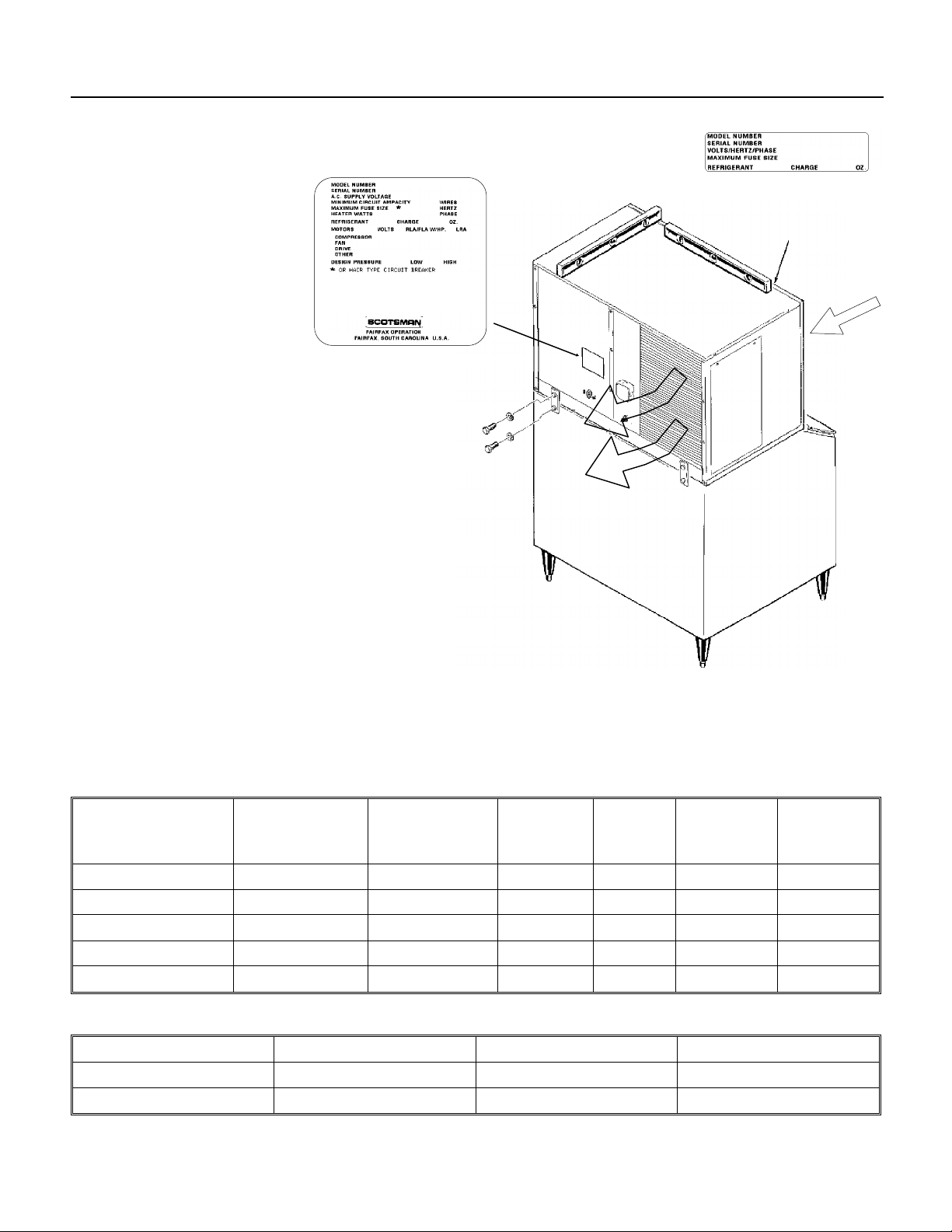

Always refer to the nameplate, located on the back

of the cabinet, for the:

••model number,

••serial number,

••basic electrical

requirements,

••minimum circuit ampacity,

••maximum fuse size,

••and refrigerant charge.

Serial Number

Plate Behind

Front Panel

A serial number plate with the model number,

serial number and refrigerant charge is located

behind the front panel, near the control box.

The unit comes from the factory with the correct

refrigerant charge. The refrigerant charge

information is for recharging, should that be

necessary.

All utility connections are made at the back of the

ice maker.

Before beginning installation, be sure that all of the

components necessary for complete assembly of

the ice system are available, and are the correct

components with regard to model, voltage, and

finish.

The CME855 or CME1000 will fit Scotsman bin

BH800 without needing a bin top. Other bins will

require a bin top.

Model Number Dimensions

W" x D" x H"

CME855AE-32A 42 x 24 x 27 208-230/60/1 R-404A 15.9 20 36 ounces

CME855AE-6A 42 x 24 x 27 230/50/1 R-404A 36 ounces

CME1000AE-32A 42 x 24 x 27 208-230/60/1 R-404A 19.9 20 42 ounces

CME1000AE-3A 42 x 24 x 27 208-230/60/3 R-404A 13.8 15 42 ounces

CME1000AE-6A 42 x 24 x 27 230/50/1 R-404A 42 ounces

* The system charge is in the machine. This number is for recharging purposes only. If the nameplate has a

different value, go by the nameplate. ** Or HACR type circuit breakers.

Basic Electrical Refrigerant

Type

Air Out

Min.

Circ.

Amps

Max.

Fuse** Size

Refrigerant

Charge*

Air In

Air Temperature Water Temperature Voltage

Minimum 50

Maximum 100

0

F. 400 F. -5%

0

F. 1000 F. +10%

December, 1994

Page 3

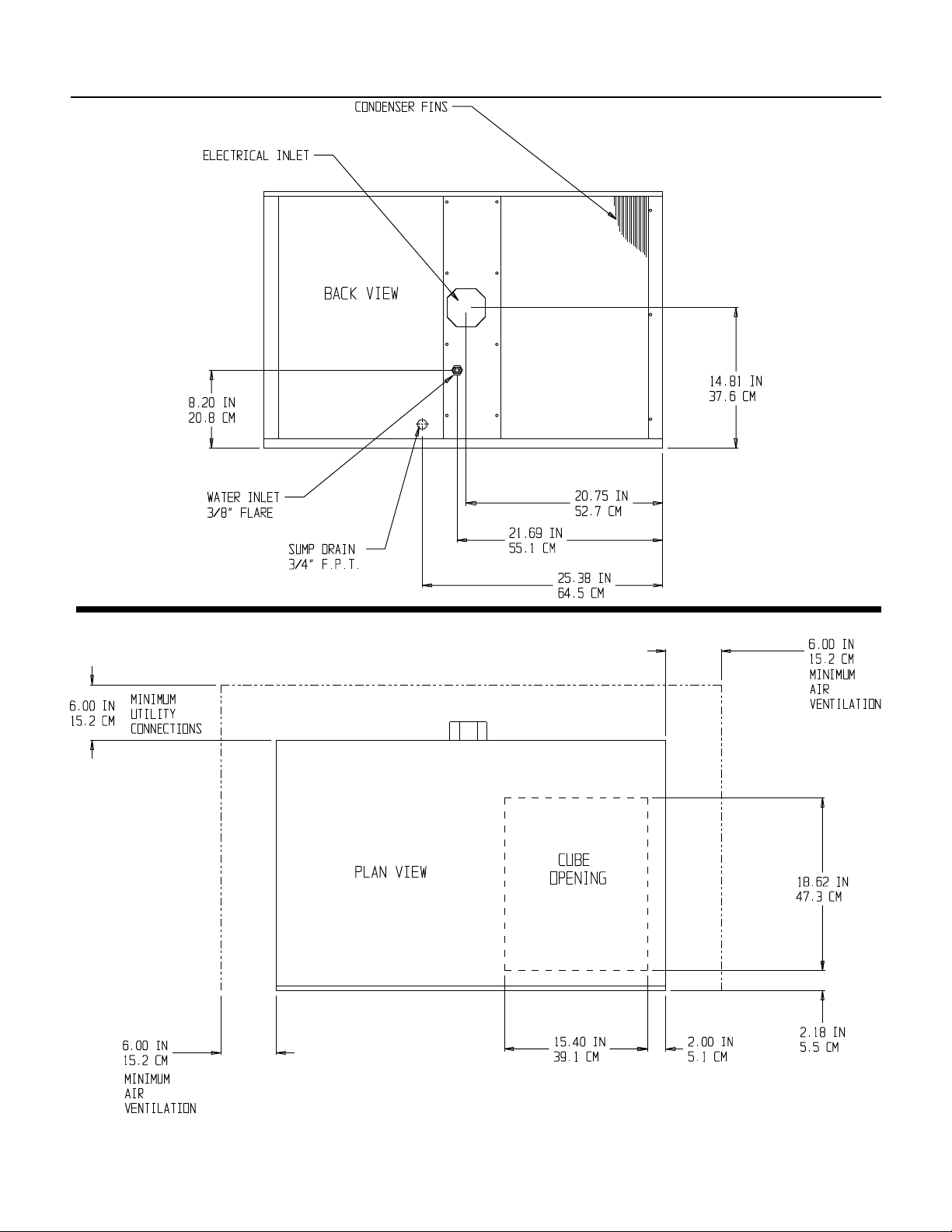

UTILITY CONNECTION LOCATIONS

CME855A & CME1000A

Page 3

October, 1994

Page 4

FOR THE INSTALLER: Environmental Limitations

CME855A & CME1000A

Page 4

Installation Limitations

The ice making portion of this ice system is

designed to be installed indoors, in a controlled

environment.

Minimum Maximum

Air Temp 50

Water Temp 40

Water Pressure 20 PSI 80 PSI

Voltage 197 253

Operating the ice machine outside of the above

limitations, or outdoors, is potentially damaging to

the machine; also it is misuse of the machine,

which may void the warranty.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL, NSF, and CUL.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

0

F. 1000F.

0

F. 1000F.

Water Limitations

An ice machine is a food manufacturing plant; it

takes a raw material, water, and turns it into a food

product, ice. The purity of the water is very

important in obtaining pure ice and in maximizing

product life. These general recommendations

should help keep the ice maker clean:

1. Filter the water used to produce ice. Water filters

vary greatly in ability and function. Install one that

filters out suspended solids to a dimension of 5

microns or smaller. The finer the filter the better,

but finer filters will clog sooner than course ones. It

may be necessary to add a course filter ahead of

the fine filter to prolong filter life.

2. Check with a water treatment specialist for a

water test, and recommendations regarding filters

and treatment.

Service Limitations

Some space on the sides, the back and the top

should be allowed for service and utility

connections.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

December, 1994

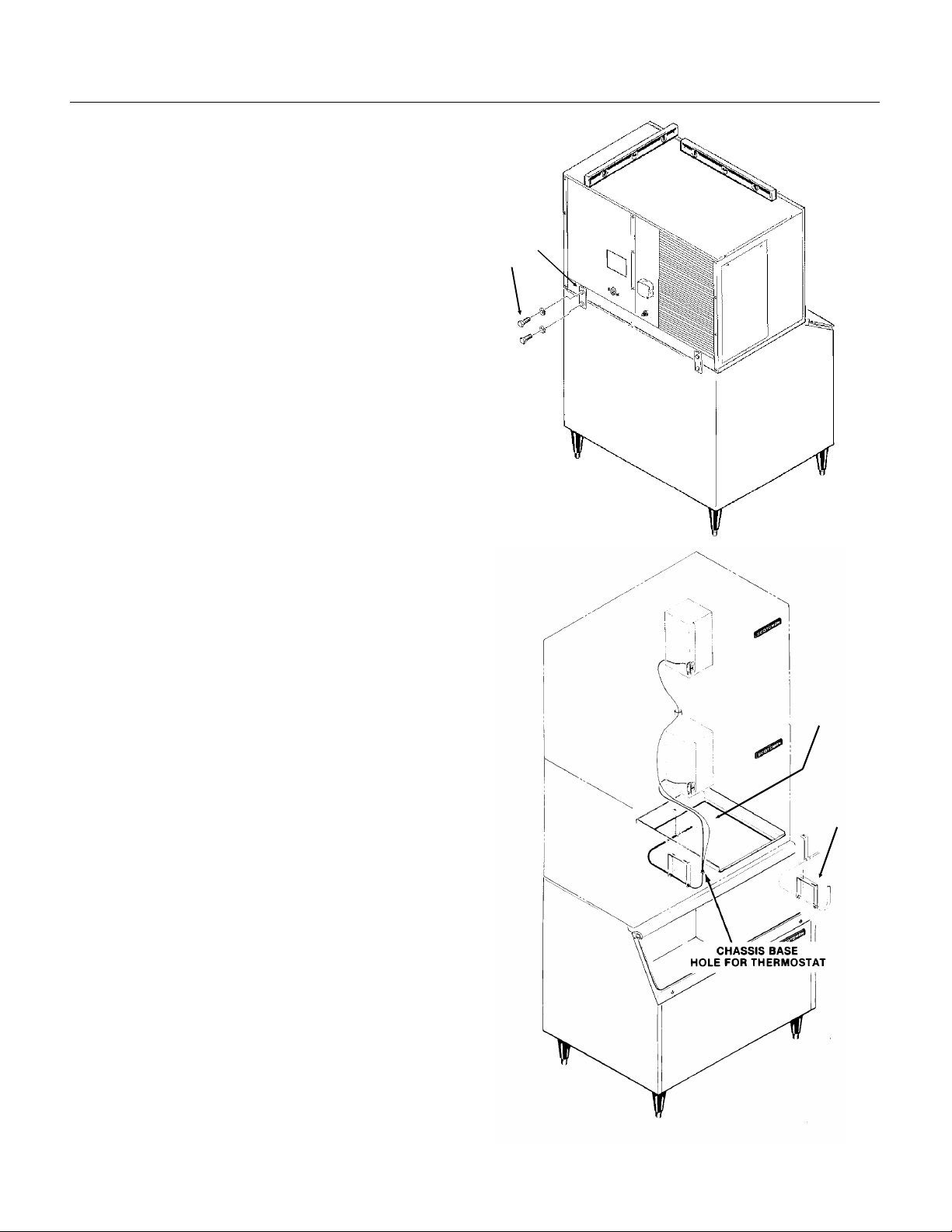

Page 5

Bin

Thermostat

Bracket

C ME 855A & CME1000A

FOR THE INSTALLER: Machine & Bin Assembly

Storage Bin:

Afte r u ncrat i ng the ice stor age bin , attach th e l egs

to th e bin:

1. Use a portion of the carton as a cushion, and tip

the stora ge bin on its back.

2. Scr ew the le g s i nto th e th r eade d ho l e s in the

bottom of the bin.

3. Turn th e leg levele rs all th e way in to p rep are

the bin and ice machine for lev eling.

4. Return the bin to th e uprigh t posit ion.

Ice Maker:

1. Arrange for proper ele ctric , wa ter and drain .

See instructio ns for th e plu mbe r and for the

electrician.

2. Position the ice st ora ge bin in the sele ct ed

INDOOR locat ion .

3. Level the bin , in bo th the fron t to rear an d side

to side directions.

4. Inspect the bin top mounting gasket which

should be flat, with no wrinkles, to pro vide a good

water seal whe n the cuber is installed on top of

the bin .

Fasten

Machine To

Bin

5. Install the modular cuber on top of the bin using

care to be sure a good se al is made betwee n th e

two cabinets, use of a mechanical lift is

recommended . Alig n the holes in the botto m back

of the cabinet to mate with the two mounting straps

on the top rear of the bin.

6. Use bolts and strap s found in the hard ware

package to se cure the ice mach ine to the ice

storage bin. When alignment and leveling are

completed, tigh ten th e bolts to secu re the

mounting straps.

7. Install the bin thermo sta t bra cke t. The bracket

is shipped in a cardb oa rd con ta ine r located in front

of the freezing compartment.

Mount the brac ket to the bo tt om of the ic e machine

with the plastic tube inserted up thru the ice

machine base from below. Se cure the brac ket to

the ice machine base using 3 thumbs crews from

the hardware packa ge.

Uncoil the bin thermost at cap tub e and insert it int o

the plastic tubing of the bracket to the end of the

meta l tubin g.

Bin

Thermostat

Capillary Tube

March 1995

Page 5

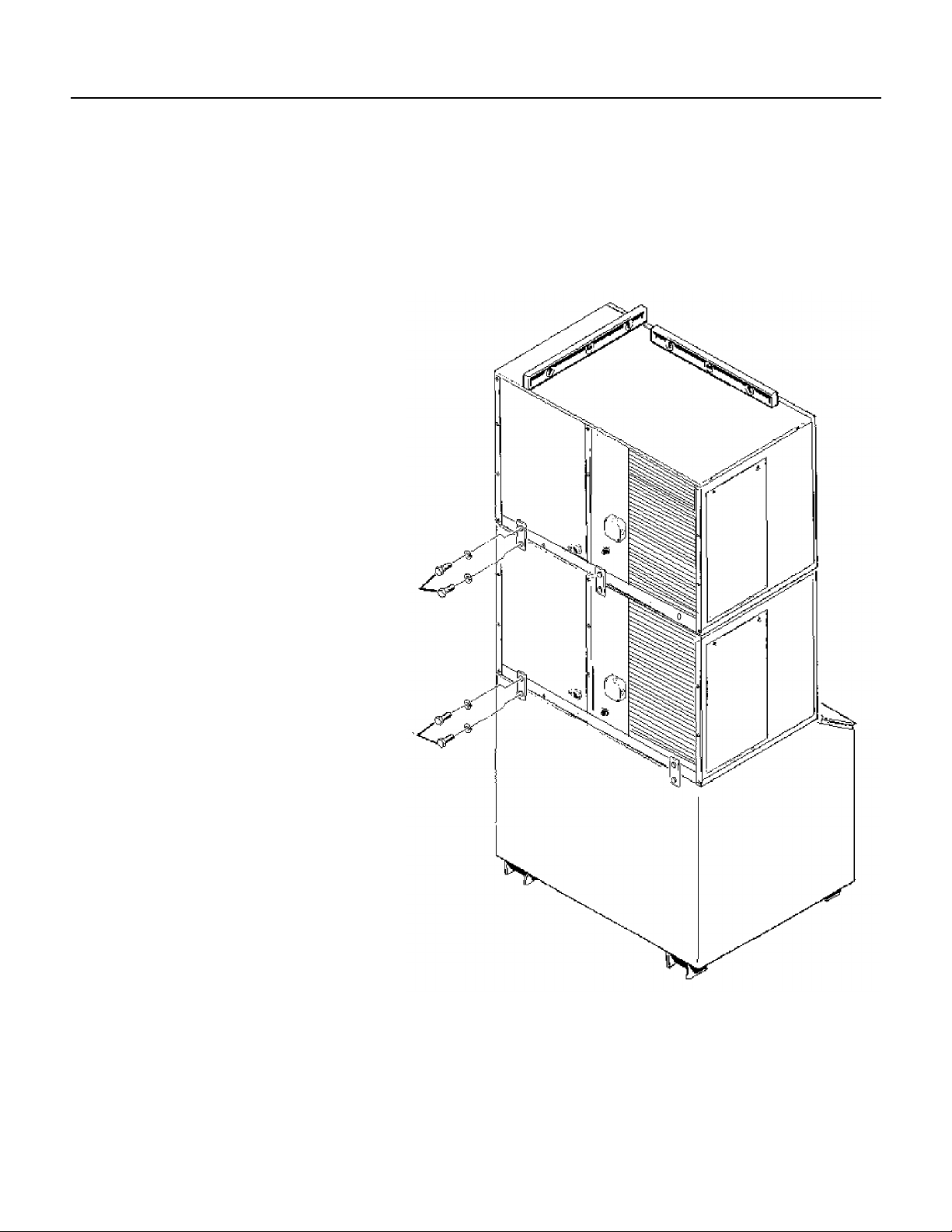

Page 6

STACKING TWO UNITS

CME855A & CME1000A

Page 6

To stack a 42" wide CME cuber onto a CME855A,

CME1000A, CM855 or CM1000 cuber:

A Heavy Duty Leg Kit is Recommended.

1. Remove the top panel from the lower unit.

2. Add a bead of food grade sealant (such as

Scotsman part number 19-0529-01) to the top

edges of the lower unit’s freezing compartment.

3. Lift the top unit onto the bottom machine (a

mechanical lift is recommended).

4. Align the two machine’s cabinets, and using the

bolts and straps from the hardware package,

fasten the two units together at the back.

Note: When placing a new unit on a CM855 or

CM1000, the outboard (right side viewed from the

back) threaded holes should be used.

5. Route the bin thermostat capillary tube from the

upper machine into the lower machine and into the

bin thermostat bracket, next to the capillary tube

from the lower machine.

FROM

HARDWARE

PACKAGE

FROM

HARDWARE

PACKAGE

STACKING TWO CME 42" AIR COOLED

December, 1994

Page 7

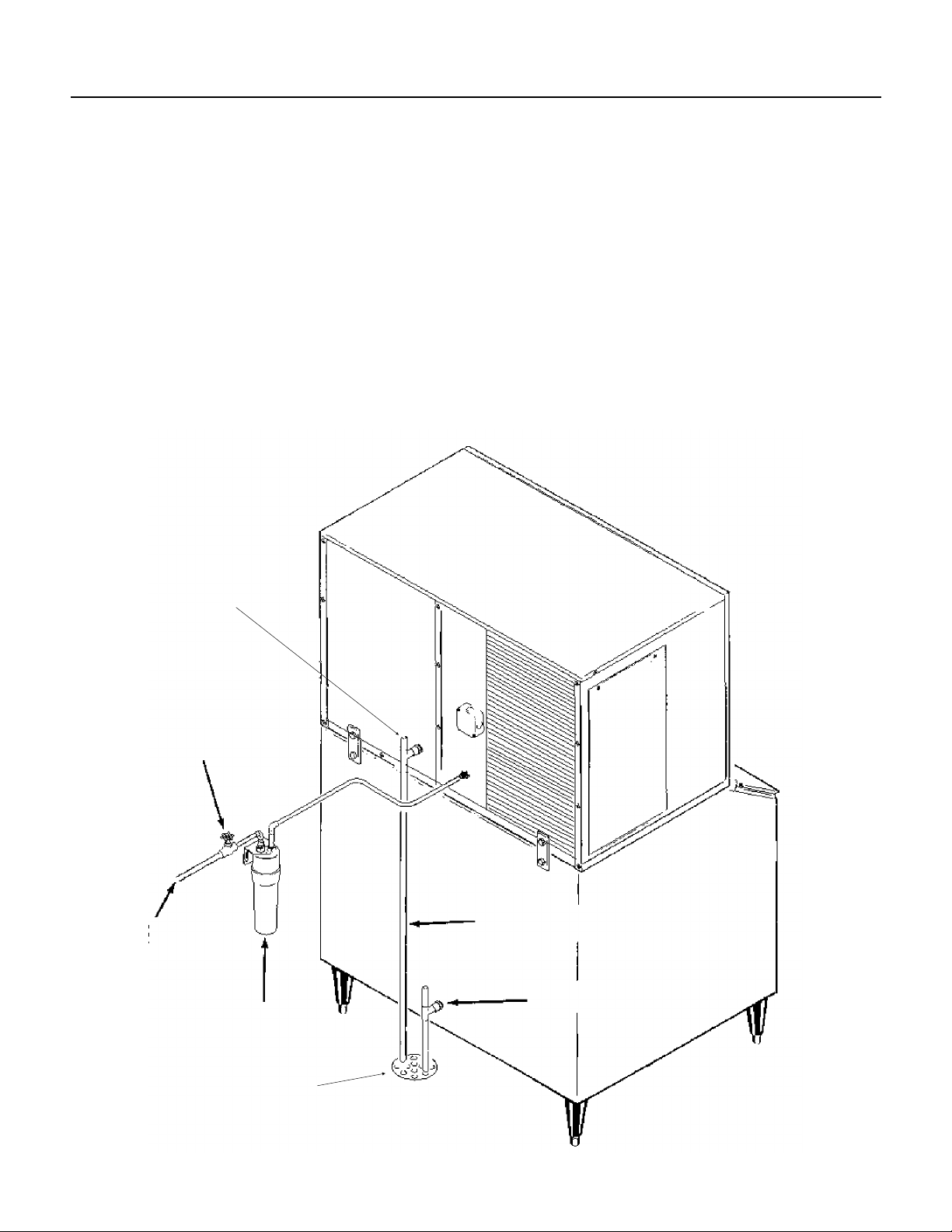

FOR THE PLUMBER

CME855A & CME1000A

Page 7

Water Supply

The recommended water supply line is a 3/8-inch

O.D. tubing with a minimum operating pressure of

20 PSIG and a maximum of 80 PSIG.

A separate water inlet is required for the

condenser water supply.

Connect to cold water supply line with standard

plumbing fittings, with shut off valve installed in an

accessible place between the water supply and

the cuber. In some cases a plumber will be

required.

CONFORM TO ALL LOCAL CODES

Drain Connections:

Connections: All drains are gravity type and must

have a minimum of 1/4 - inch fall per foot of

horizontal run. The drains to be installed must

conform with the local plumbing codes. Install a

vertical open vent on the ice machine reservoir

drain. The ideal drain receptacle is a trapped and

vented floor drain. The storage bin drain should be

insulated.

PLUMBING CONNECTIONS

RESERVOIR

DRAIN VENT

HAND SHUT OFF

HAND SHUT

OFF VALVE

VALVE

RESERVOIR DRAIN

BIN DRAIN VENT

POSITION OF

FILTER

FLOOR DRAIN

October, 1994

Page 8

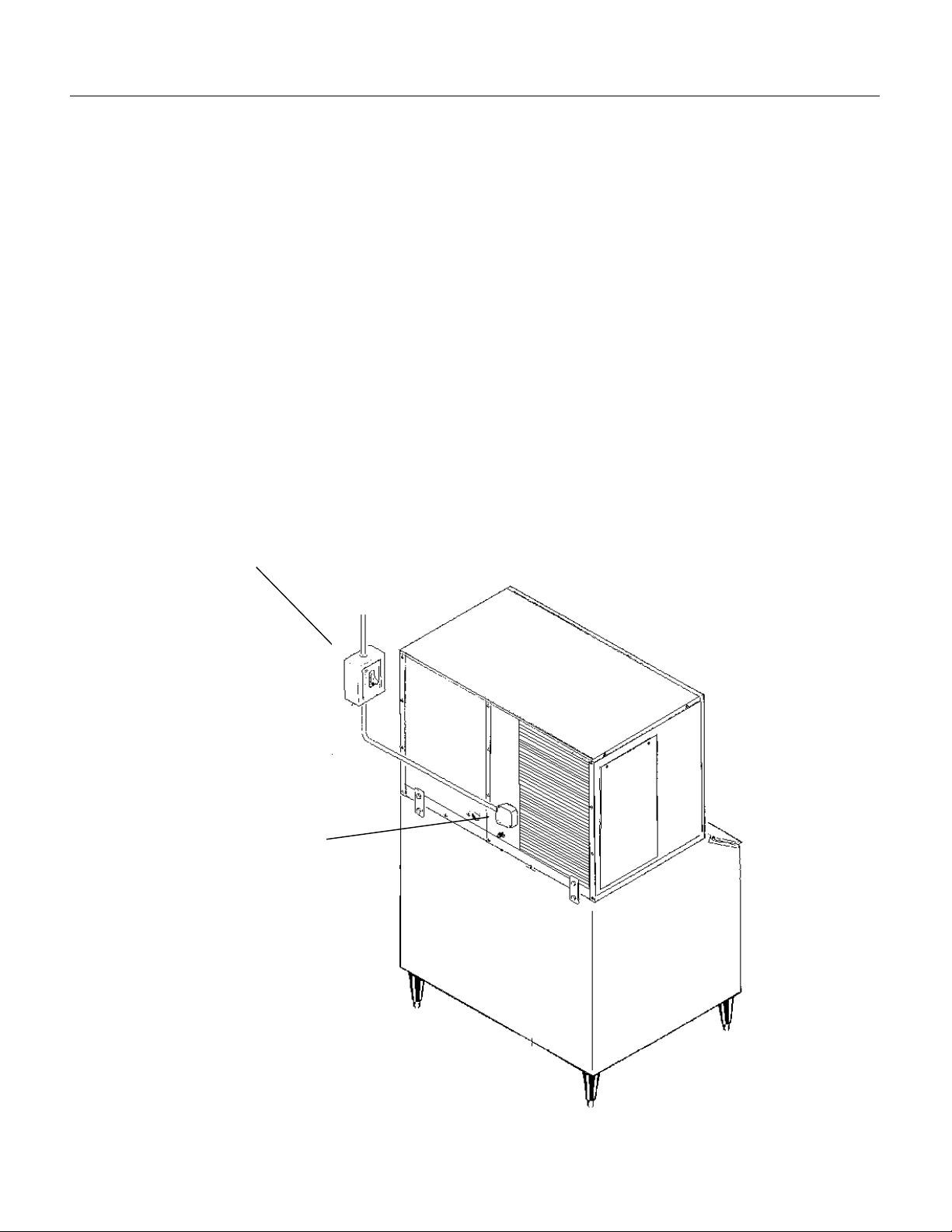

CME855A & CME1000A

FOR THE ELECTRICIAN: El ect ric al Connect ions

See the NAMEPLATE for curre nt requ ireme nts to

determine wire size to be used for electric al

hookup. The cuber requires a solid chassis to

chassis earth groun d wire. See Wiring Diag ram.

Be certain the cuber is connected to its own

electrical circuit and individ ually fus ed. Voltage

variation should no t exceed ten perce nt of the

nameplate rat ing , even under sta rtin g cond itio ns.

Low voltages can cause erratic ope rat ion and may

be responsible for seriou s dama ge to the ice

maker.

Electrical conn ection s are made at the rear of the

ice maker, inside the junction box.

FUSES or HACR

CIRCUIT BREAKERS

All external wiring shoul d conform to the

national, sta te and loc al electr ic al code

requirements. Usually an electrica l per mit and

services of a licensed electrici an wi ll be

required.

ELECTRICAL JUNCTION BOX

Cuber Electrical Conn ectio ns

January 1997

Page 8

Page 9

FOR THE INSTALLER: Final Check List

CME855A & CME1000A

Page 9

1. Is the ice maker cabinet in a room where

ambient temperatures are within the minimum and

maximum temperatures specified?

2. Is there clearance at the left side of the cabinet

and at the back and top for service and utility

connections?

3. Has water supply pressure been checked to

insure a minimum of 20 PSIG and a maximum of

80 PSIG operating pressure?

4. Is the cabinet level?

5. Check that any shipping material has been

removed from inside the cabinet.

6. Have all electrical and piping connections been

made?

7. Are the Master and

Compressor switches on OFF?

8. Has power been connected

to the ice maker?

9. Is the water supply line shut

off valve installed?

Power?

Final Check List

10. Check all refrigerant lines

and conduit lines, to guard

against vibration or rubbing

and possible failure.

11. Have the bin and cabinet

been wiped clean and

sanitized?

12. Has the Customer

Evaluation and Warranty

Registration form been properly

filled out? Check for correct

model and serial numbers from

Serial nameplate, then mail the

completed form to SCOTSMAN.

13. Has the owner been given

the name and telephone

number of the authorized

SCOTSMAN Service Agency

serving him?

Secure?

Supply?

Cabinet

Water

Filter?

Reservoir

Drain?

Bin Drain?

October, 1994

Page 10

INITIAL START UP

CME855A & CME1000A

Page 10

Ice Maker:

1. Remove screws and front panel.

2. Remove two screws and the control box cover.

3. Remove the evaporator cover.

4. Locate two toggle switches on the front of the

control box. Check that the Master ON/OFF switch

and the Compressor ON-OFF switch are in the

OFF position.

5. OPEN the water supply line shut off valve.

6. Inside the control box is the shaft of the timer

and the switch assembly. Rotate the shaft of the

timer and switch assembly clockwise to where the

actuator arm on the microswitch drops off outer

cam into cam slot. See Timer Cam Positions.

7. Move the Master ON/OFF switch to the ON

position.

TIMER CAM POSITIONS

ACTUATOR

CAM &

SHAFT

MICROSWITCH

8. Observe water fill cycle: Water pump operates

and water inlet solenoid valve OPENS, incoming

water flows from the valve through the tubing, the

reservoir fills and excess water drains out the

reservoir drain. At the end of the harvest cycle, the

water inlet solenoid valve will close and the water

fill cycle is complete. If the reservoir is not full,

advance the shaft of the timer clockwise into a new

harvest cycle; this opens the water valve again.

9. Check that the water cascades down over each

cube mold and into the reservoir.

10. When the reservoir is full, move the

compressor ON-OFF switch, to the ON position.

11. Check operation of the freezing cycle: The

compressor is operating. The ice making process

begins; feeling the metal parts of the evaporator

plate reveals cold temperature, very shortly ice

begins to form. Tubing will become frosted at the

top of the evaporator plate. After the first cycle,

freezing time will range between 10 and 17

minutes.

In moderate temperatures, CME855 average

complete cycle time is about 15 minutes, and

CME1000 average complete cycle time is about

12 minutes.

12. Check CUBE SIZE

FREEZE

PORTION

HARVEST

PORTION

The dimensions of the cubes are fixed by the size

and shape of the molds on the evaporator plate,

except that the thickness of the cube MAY need to

be adjusted at start up. There is only one size of

cube that is correct; adjusting the cube size control

to that size of cube will allow the ice maker to

produce ice at its most efficient size. The correct

size cubes will be fully formed at the edges; will

harvest off of the evaporators beginning with

individual cubes at the top of the evaporator, then

vertical strips for the balance; and will appear

similar to the illustration for ‘‘Correct Size Cube’’.

December, 1994

Page 11

INITIAL START UP

CME855A & CME1000A

Page 11

Adjust for the correct size if needed:

To produce SMALLER sized ice cubes:

Locate cube size control knob in the front of the

control box. Rotate this knob one eighth of a turn

counter clockwise. Observe size of the ice cubes

in the next ice cube harvest and adjust again if

needed, until the correct ice cube is achieved.

To produce LARGER ice cubes:

Locate cube size control on the front of the control

box. Rotate the knob one eighth of a turn

clockwise. Observe size of ice cubes in the next

cube harvest and adjust again if needed, until

correct the ice cube size is achieved.

13. Check Harvest Time. The machine must

harvest all cubes before returning to a freeze cycle.

Increase the harvest time if there is less than 15

seconds of harvest time after the last cube has

fallen into the bin.

Decrease the harvest time if there is much more

than 15 seconds of harvest time after the last cube

has fallen into the bin. Note: Harvest time is

dependent upon the water and air temperatures at

the ice machine. Do not adjust harvest time too

short, as this will cause a freeze up.

See the next page for detailed harvest time

adjustment instructions.

CUBES (ACTUAL SIZE)

TOO

THICK

1

⁄

"

1

4

CORRECT

SIZE

CUBE

Note: Optimum performance will be achieved when

the ice machine is adjusted to produce this size and

shape of cube. The typical batch weight at this

1

1

⁄

"

4

setting is between 8.25 and 9 pounds.

14. Check BIN THERMOSTAT

With the ice maker in the harvest cycle, hold ice

against the metal tube of the bin thermostat

bracket. The ice machine will shut off only at the

end of the harvest cycle.

Remove the ice and within a few minutes the ice

machine should restart.

15. Replace all panels, the machine is ready for

automatic operation.

16. Fill out and mail in the Customer Evaluation

and Warranty Registration Form.

Explain to the user the specifications, operation

and maintenance requirements of the ice machine.

Inform the user of the name and telephone

number of the local service contact.

TOO

THIN

October, 1994

Page 12

ADJUSTMENT OF THE TIMER & SWITCH ASSEMBLY

CME855A & CME1000A

Page 12

One complete revolution of the cam on the timer

represents eight minutes. If left as factory set, the

timed freeze cycle will be 5 minutes 15 seconds,

and the harvest cycle will be 2 minutes 45

seconds. Rotating the shaft of the timer cam

Clockwise will put the ice machine into the freeze

or harvest cycle.

ACTUATOR

TIMER CAM POSITIONS

MICROSWITCH

WARNING

Disconnect electrical power supply to ice maker

whenever adjustment procedures are performed.

To adjust the timer & switch assembly:

1. Remove front panel.

2. Remove control box cover.

A. To start the HARVEST CYCLE: Slowly rotate

the shaft of the timer and switch assembly,

clockwise until the actuator arm on the

microswitch initiates the harvest cycle. An audible

click can be heard, but in a noisy area, look at

the cam and switch to observe the event

B. To start the FREEZING CYCLE: Slowly rotate

the shaft of the timer and switch assembly

clockwise until the actuator arm on the

microswitch initiates the freezing cycle.

C. To adjust the length of the harvest cycle:

1. Loosen the adjustment screw on the cam and

rotate the shaft of the cam to move the cam. More

of a gap between the high and low portions will

yield more harvest time.

2. Tighten the set screw.

CAM &

SHAFT

HARVEST

PORTION

FREEZE

PORTION

TIMER ADJUSTMENT

MICROSWITCH

SHAFT OF

CAM

3. Replace the control box cover and front panel.

It is important that the length of the harvest cycle

allow enough time for all the ice cubes to fall from

the evaporator. Too short of a time will cause the

evaporator to freeze up and stop ejecting ice into

the bin. Too much time wastes ice making

capacity, energy and water. Adjustment of the

harvest cycle may require an adjustment of the

cube size control.

SET SCREW

December, 1994

Page 13

REFRIGERATION SYSTEM OPERATION

CME855A & CME1000A

Page 13

Suction

Line

Condenser

Hot Gas Valve

Hot

Gas

Line

Compressor

Drier

Refrigeration System Schematic

FREEZE CYCLE

The compressor forces the refrigerant into the

discharge tube. The refrigerant, now a very hot,

high pressure gas flows to the condenser. At the

condenser the refrigerant’s heat is transferred to

the air blowing thru the condenser. The refrigerant

changes from a gas to a liquid.

After the condenser, the now liquid refrigerant

flows thru the thermostatic expansion valve. The

thermostatic expansion valve liquid refrigerant thru

the refrigerant distributor and into the three

evaporators.

Inside the evaporators, the liquid refrigerant rapidly

expands, because it has moved from a high

pressure zone to one of much lower pressure. The

heat from the water going over the evaporators

keeps the refrigerant expanding, and the

refrigerant absorbs this heat. This causes the

evaporators and the water going over them to

loose heat.

Evaporators

Thermostatic

Expansion Valve

HARVEST CYCLE

The only change between freeze and harvest is

that a valve opens a path between the discharge

line and the evaporator inlet. This valve is called

the Hot Gas Valve. It allows hot discharge

refrigerant gas to flow directly from the compressor

to the evaporator inlet, warming the evaporators

and causing the ice cubes to release.

The refrigerant then flows into the suction line and

back to the compressor.

October, 1994

Page 14

WATER SYSTEM OPERATION

CME855A & CME1000A

Page 14

Evaporators

WATER SYSTEM SCHEMATIC

Drain

Inlet Water Valve

A fixed charge of water is brought into the reservoir

during the harvest cycle.

Water Manifold and

Distributors

Reservoir

Water Pump

A water pump, running continuously, forces the

water to the top of the evaporators, where it is

distributed through manifolds, and then cascades

down the evaporator surface by gravity.

As it flows across the refrigerated evaporators,

some of the water will be chilled enough to change

form, turn to ice and stay frozen to the evaporator.

Most of the water returns to the reservoir, to be

sucked back into the pump and re-pumped over

the evaporators.

Water is forced over the evaporators during the

freeze cycle to be changed into ice, and during the

harvest cycle to assist the release of the ice.

December, 1994

Page 15

COMPONENT DESCRIPTION

CME855A & CME1000A

Page 15

Compressor Contactor

The compressor contactor carries the compressor

line current. The compressor contactor coil has

power whenever the ice machine is making or

harvesting ice.

Cube Size Control

This reverse acting (closes on temperature fall)

thermostat determines how long the freezing cycle

will be. The cube size control closes it’s contacts

when the evaporator & suction line cools to the set

temperature. When the cube size control closes, it

connects power to the timer motor. A variation in

heat load (either ambient air or incoming water

temperature) will affect the efficiency of the

refrigeration system, and that will vary the length of

time it takes the evaporators to cool to the

temperature at which the cube size control is set to

close, which, in turn, will affect the overall cycle

time. See CUBE SIZE ADJUSTMENT BEFORE

attempting to adjust the control.

Relay

Hot Gas Solenoid Valve

The hot gas solenoid valve opens only during the

harvest cycle. When it opens, it diverts the hot

discharge gases so that they flow directly into the

evaporator plates, by-passing the condenser and

thermostatic expansion valve. The hot gases warm

the evaporators, releasing the ice cubes from the

ice cube molds. The hot gas solenoid valve is

installed in a branch of the discharge line, and

when the timer switches the ice machine into the

harvest cycle, the energized solenoid coil lifts the

valve stem within the valve body, allowing the hot

discharge gas to be diverted to the evaporators.

High Temperature Cut Out

This temperature sensor is located next to the hot

gas valve, on the outlet side.

Cut Out is 140

During normal operation, it does not affect the ice

machine, but it will shut the machine off if the hot

gas line overheats. It is an automatic reset.

o

F., Cut In is 110oF.

The multi-function, three pole, double throw, relay

plugs into a socket on the printed circuit board in

the control box. When the relay coil has power, the

machine is in a freeze cycle, and when power is

removed from the coil, the machine will be in the

harvest cycle.

The relay also by-passes the bin control during the

harvest and freeze cycles, preventing the ice

maker from shutting off in the middle of a cycle.

The bypass action allows only complete freeze

and harvest cycles; the only time that the ice

maker can shut off on bin control is as the end of

the harvest cycle.

Timer - Timer & Switch Assembly

The timer begins to turn when activated by the

cube size control. The outer surface, or large

diameter lobe of the timer cam, determines the

length of time for finish freezing of the ice cubes,

while the inner surface, or small diameter lobe,

determines length of the harvest cycle. The

single-pole, double throw microswitch on the timer

controls the power to the plug in relay coil, making

it either the freezing or harvest cycle. The

microswitch is actuated by the cams connected to

the timer motor. The timer cam can be adjusted to

vary the defrost time, as required. One complete

rotation of the cam will take eight minutes.

October, 1994

Page 16

COMPONENT DESCRIPTION

CME855A & CME1000A

Page 16

Electric Water Inlet Valve

The water inlet solenoid valve fills the reservoir

assembly with water. Excess water overflows out

the overflow standpipe located at the back of the

reservoir. This action fills and rinses the reservoir

during each harvest cycle. The flow rate is .75

g.p.m.

Water Distribution System

The water distribution system evenly supplies

water to all cells of the evaporator plates. The

water pump pumps water from the reservoir up the

vertical tygon tube to the tee. From there water is

channeled through the water manifold to the water

distributors, above each evaporator plate, and

from six holes within each distributor, water flows

to the cells of each side of the evaporator plates.

Gravity flow returns the unfrozen excess portion of

water to the reservoir for recirculation.

Reservoir

The reservoir, located below the evaporators,

stores the inlet water charge, and collects the

water that flows over the evaporator plates. Most

ice will be falling into the bin below the center

evaporator.

High Pressure Cut Out

This is a manual reset control that shuts down the

ice maker, should the discharge pressure ever

reach 450 PSIG.

WATER

DISTRIBUTION

SYSTEM

WATER

PUMP

EVAPORATOR

RESERVOIR

ELECTRIC WATER VALVE

December, 1994

Page 17

SERVICE SPECIFICATIONS: CME855A

CME855A & CME1000A

Page 17

When servicing a machine, it’s helpful to compare

that unit’s operating characteristics to those of a

new, clean, normally operating machine. What

follows is that type of information:

Numbers = Cabinet Air Temp/Water Temp.

70/50 90/70

Typical Cycle Time 14 - 15 minutes 17 - 18 minutes

Harvest Time (2

standard)

Typical Freeze Cycle Low Side

Pressure (end of cycle)

Typical Freeze Cycle Discharge

Pressure (end of cycle)

Typical Harvest Cycle Low Side

Pressure (peak)

Typical Harvest Cycle Discharge

Pressure (min)

2

⁄

minute

3

2

2

⁄

minutes

3

26 PSIG 32-32 PSIG

195 PSIG 255 PSIG

84 PSIG 107 PSIG

140 PSIG 180 PSIG

2 minutes

Typical Batch Weight

•• 8.25 - 9 lb.

Refrigerant Charge

•• 36 ounces of R-404A.

Hi Pressure Cut Out Point

•• 450 PSIG

Hi Temperature Cut Out Point

o

•• 140

F.

Typical Compressor Amp Draw

•• at 90/70: 5 min. into freeze: 9.9, in harvest 10.8

•• at 70/50: 5 min. into freeze: 8.9, in harvest 8.3

Compressor:

•• CS14K6E

Water Inlet Valve Flow Rate:

•• .75 g.p.m.

Cube Size Thermostat:

•• Cut in adjustable between 0

o

F. and 24oF.

Bin Thermostat:

••CI= 38.5

••CO= 33.5

o

F. to 43.5oF.

o

F. to 38.5oF.

Thermostatic Expansion Valve

••Not adjustable

October, 1994

Page 18

SERVICE SPECIFICATIONS: CME1000A

CME855A & CME1000A

Page 18

When servicing a machine, it’s helpful to compare

that unit’s operating characteristics to those of a

new, clean, normally operating machine. What

follows is that type of information:

Numbers = Cabinet Air Temp/Water Temp.

70/50 90/70

Typical Cycle Time 11 - 12 minutes 13 - 14 minutes

Harvest Time (2

standard)

Typical Freeze Cycle Low Side

Pressure (end of cycle)

Typical Freeze Cycle Discharge

Pressure (end of cycle)

Typical Harvest Cycle Low Side

Pressure (peak)

Typical Harvest Cycle Discharge

Pressure (min)

2

⁄

minute

3

2

2

⁄

minutes

3

25 PSIG 25 PSIG

190 PSIG 240 PSIG

84 PSIG 94 PSIG

155 PSIG 190 PSIG

2 minutes

Typical Batch Weight

•• 8.25 - 9 lb.

Refrigerant Charge

•• 42 ounces of R-404A.

Hi Pressure Cut Out Point

•• 450 PSIG

Hi Temperature Cut Out Point

o

•• 140

F.

Typical Compressor Amp Draw

•• 90/70: 5 min. into freeze - 11.5, harvest -13.3

•• 70/50: 5 min. into freeze - 10.7, harvest -11.8

Compressor:

•• CS18K6E

Water Inlet Valve Flow Rate:

•• .75 g.p.m.

Cube Size Thermostat:

•• Cut in adjustable between 0

o

F. and 24oF.

Bin Thermostat:

••CI= 38.5

••CO= 33.5

o

F. to 43.5oF.

o

F. to 38.5oF.

Thermostatic Expansion Valve

••Not adjustable

December, 1994

Page 19

CLEANING

CME855A & CME1000A

Page 19

A Scotsman Ice System represents a sizable investment of time and money in any company’s business. In

order to receive the best return for that investment, it MUST receive periodic maintenance.

Maintenance and Cleaning should be scheduled at a

minimum of twice per year.

CLEANING: ICE MAKER

1. Remove front panel.

2. Switch the Wash/Off/Ice switch to OFF.

3. Remove the front liner.

4. Remove and discard all ice from the storage bin.

5. Locate the reservoir drain and drain the

reservoir. If the reservoir doesn’t drain completely,

disconnect the pump hose attached to the water

distributors and place the end of the hose in a

bucket. Switch the Wash/Off/Ice switch to Wash,

and allow the pump to discharge the rest of the

water. Reattach the hose to the water distributors.

6. Mix 8 ounces of Scotsman Ice Machine Cleaner

with 1 gallon of warm (95

pour into the reservoir until full.

0

F. - 1150F.) water and

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water

or milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

13. Replace the front panel

14. Check the next batch of cubes to make sure all

of the acid taste is gone.

CAUTION

DO NOT use ice produced from the cleaning

solution. Be sure none remains in the bin.

15. Remove and discard all ice from the storage

bin, pour hot water into the storage bin to melt the

cubes and also clean out the bin drain.

16. The unit is now ready for continued automatic

operation.

7. Switch the Wash/Off/Ice switch to ‘‘wash’’. Let

the unit operate for 30 minutes, then switch the

unit off.

8. Drain the reservoir again (repeat step 5)

9. Switch the machine to ‘‘wash’’ and continue to

add fresh water to flush residual cleaner from the

system. Switch the Wash/Off/Ice switch off.

10. Sanitize the ice maker and bin, see ‘‘Sanitize

Water System’’.

11. Replace the front liner.

12. Switch the Wash/Off/Ice switch back on.

October, 1994

Page 20

CLEANING

CME855A & CME1000A

Page 20

SANITIZE WATER SYSTEM

1. Remove and discard all ice from the bin.

2. Remove front panel.

3. Drain the reservoir

4. Prepare 2 gallons of an approved sanitizer

solution in accordance with the instructions on the

package, or use the following instructions for use

of household bleach, if it meets local codes:

Mix a sanitizing solution of 1 ounce of household

bleach to 2 gallons of water.

5. Pour 1 gallon of the sanitizer into the ice maker

reservoir.

6. Move the Wash/Off/Switch switch to ‘‘Wash’’,

and allow the solution to circulate for a MINIMUM

of 5 minutes.

7. Move the Wash/Off/Switch switch to ‘‘Off’’.

8. Remove the drain plug and drain the reservoir.

9. Using a clean sponge and the remainder of the

sanitizer solution, wipe the interior of the

evaporator cover and the inside of the storage bin,

taking care to wipe all surfaces that are normally in

contact with ice.

SANITIZE ICE STORAGE BIN

This procedure is to be done monthly

1. Remove and discard all ice from the bin.

2. Switch the ice maker off.

2. Prepare 2 gallons of an approved sanitizer

solution in accordance with the instructions on the

package, or use the following instructions for use

of household bleach, if it meets local codes: Mix a

sanitizing solution of 1 ounce of household bleach

to 2 gallons of water.

3. Using clean rubber gloves and a clean cloth,

wipe all interior surfaces of the ice machine and

ice storage bin with the sanitizing solution.

Immerse any small parts in the sanitizing solution

and wash the parts, flushing the solution

thoroughly in, over and through all parts and

surfaces of the parts being cleaned.

4. Allow to air dry.

5. Switch the ice machine back on.

10. Replace the evaporator cover. Replace the

front panel.

11. Move the master switch to ON.

December, 1994

Page 21

SERVICE DIAGNOSIS

CME855A & CME1000A

Page 21

SYMPTOM POSSIBLE CAUSE PROBABLE CORRECTION

No ice, machine does not run 1. No electrical power 1. Restore power

2. Circuit breaker tripped or fuse

blown

3. High pressure control open. 3. Reset HPC, check fan motor

4. Bin Thermostat holding

machine off

5. High temp. cut out open 5. Hot gas valve leaks thru,

6. Timer switch open 6. Replace timer

7. Master switch open 7. Check or replace switch.

8. Circuit board open 8. Replace circuit board.

No ice, compressor does not run,

rest of ice machine does.

No ice, no water over evaporators 1. Water pump does not pump 1. Check/replace water pump

No ice, everything runs 1. Too much heat load 1. Check for slow leak thru of

Low ice production 1. Too much heat load. 1. Check condenser air inlet

1. Open contactor coil 1. Replace contactor

2. Thermostatic Expansion valve

clogged or does not open.

2. No water in reservoir 2. Check/replace water inlet valve.

2. Low on refrigerant 2. Check pressures, if low

3. Suction pressure too high 3. Defective compressor - replace

2. Compressor inefficient. 2. Replace compressor

3. Non condensable gasses in

refrigeration system.

2. Reset breaker or replace fuse,

check for electrical fault.

for proper operation, and

condenser coil for dirt.

4. Check bin thermostat.

replace hot gas valve

2. Check/replace TXV.

water inlet valve.

find/repair leak; weigh in charge.

temperature. Check water

temperature.

3. Check head pressure, if very

high, and no other reason is

suspected, replace refrigerant

charge.

October, 1994

Page 22

SERVICE DIAGNOSIS

CME855A & CME1000A

Page 22

SYMPTOM POSSIBLE CAUSE PROBABLE CORRECTION

Low ice production 4. High head pressure, a result of

a dirty condenser

5. Hot gas valve leaks thru 5. Replace hot gas valve

6. High discharge pressure 6. If possible, reduce condenser

No ice falling in bin, unit frozen up 1. Cube size control will not close 1. Check temp. of suction line,

2. Timer motor open 2. Replace timer

3. Plug in relay contacts open 3. Replace relay

4. Not enough time during the

harvest cycle to drop all ice

5. Cube size wrong 5. Adjust cube size

6. Hot gas valve restricted. 6. Replace hot gas valve.

7. Not enough water to help

harvest.

8. Head pressure too low 8. Check water reg./pressure

Ice maker stuck in harvest cycle 1. Relay coil open 1. Replace relay

2. Timer stuck in harvest cycle 2. Check for power to timer

3. Timer microswitch N.O.

contacts will not close.

Ice is mal-formed 1. Shortage of water 1. Check for restriction of water

2. Evaporator water passages

restricted.

3. Cube size set wrong 3. Adjust cube size control

Water overflows from reservoir

into bin.

1. Restricted sump drain 1. Repair drain

2. Inlet water valve lets in too

much water

4. Clean water circuit of

condenser

water inlet temperature.

cube size control will not close if

temp. too high. If temp. low

enough, replace cube size control

4. Adjust timer for more harvest

time

7. Check for restriction of water

supply.

control valve. Check for low

refrigerant charge.

motor, if power replace timer, if

no power to timer motor, replace

relay.

3. Replace timer.

supply. Check for leak.

2. Clean ice maker.

2. Replace valve

December, 1994

Page 23

REMOVAL AND REPLACEMENT

CME855A & CME1000A

Page 23

Disconnect electrical

power before beginning.

Cube Size Control

To remove the cube size control:

1. Remove front panel.

2. Remove cover from control box.

3. Trace capillary tube, from the cube size control

to the refrigerant suction line.

4. Remove the coiled capillary tube bulb from the

tube well on the suction line.

5. Remove electrical leads from the cube size

control.

6. Remove screws and the cube size control. To

replace the cube size control, reverse the removal

procedure. Be certain to re-insulate the cube size

control bulb.

Water Distributor Tubes And Manifold Tubes

To remove the water distributor tube and manifold

tube:

Inlet Water Solenoid Valve Assembly

To remove the inlet water solenoid valve assembly:

1. Shut OFF water supply to machine.

ELECTRICAL CORD

CONNECTION

INLET

FITTING

OUTLET

SOLENOID

VALVE

1. Pull out to unsnap catches and remove the front

panel.

2. Remove the evaporator cover.

3. Slide the water distributor tube to the front about

1/8-inch along the top of the evaporator plate, until

the water distributor tube can be unsnapped from

the flexible notch and lifted upward to the right

side.

4. Unsnap and disconnect water distributor tubes

from the water manifold section. To replace the

water distributor tubes and manifold tubes, reverse

the removal procedure.

BE SURE the notches in the water manifold tubes

properly engage the alignment keys in the tee. BE

SURE the water distributor tube is securely

fastened at the notch at both sides of the

evaporator plate.

Check identical attachment for the left water

distributor tube and notch; also, that the

distributor/manifold connections at the top center

of each evaporator plate is snug against the top of

the plate.

REMOVAL OF THE INLET WATER VALVE

2. Loosen and remove outlet water line from the

inlet water solenoid valve assembly.

3. Remove screws and pull the water solenoid

valve out to gain access.

4. Pull electrical cord connection from solenoid coil

terminals.

4. Remove inlet water fitting from the water

solenoid valve. To replace the inlet water valve

assembly, reverse the removal procedures.

October, 1994

Page 24

REMOVAL AND REPLACEMENT

CME855A & CME1000A

Page 24

Disconnect electrical

power before beginning.

Water Pump

1. Remove front panel.

2. Remove evaporator cover.

3. Unplug water pump electrical connection.

4. Remove thumb screw retaining pump to cross

brace.

5. Pull pump partially out of reservoir and remove

discharge hose.

ELECTRICAL

CONNECTION

Hot Gas Valve

1. Remove the side service panel, and top panel if

possible.

2. Discharge and recover the refrigerant from the

system.

3. Remove the electrical connections from the coil

of the valve

4. Cut out or unsweat the valve at the tubing

connections, remove the valve from the ice maker.

5. Install the new valve, wrap it in wet cloths or

other efficient heat sink material.

6. Sweat the tubing connections to the valve.

7. Connect the electrical wires to the terminals of

the valve coil.

8. Weigh in the nameplate charge.

9. Replace all panels removed for service.

10. Reconnect electrical power.

Thermostatic Expansion Valve

DISCHARGE

HOSE

PUMP

REMOVAL OF THE WATER PUMP

6. Reverse to reassemble.

7. Replace all panels.

8. Reconnect electrical power.

1. Remove the side service panel, and top panel if

possible.

2. Discharge and recover the refrigerant from the

system.

3. Locate the TXV sensing bulb on the suction line,

unwrap the insulation and remove the bulb from

the clamp.

4. Cut out or unsweat the old TXV from the tubing

connections.

5. Wrap the new TXV body in wet cloths or other

efficient heat sink material.

6. Sweat in the new valve. Do not overheat.

7. Re-attach the TXV bulb to the suction line in the

same place as the original. Be certain to

re-insulate.

8. Install a new HFC type drier.

9. Evacuate to at least 200 microns.

10. Weigh in the nameplate charge.

11. Replace all panels removed for service.

12. Reconnect electrical power, and restart

machine.

December, 1994

Page 25

REFRIGERATION SERVICE

CME855A & CME1000A

Page 25

This ice machine uses R-404A refrigerant and polyolester oil. Do NOT

use mineral oil in this refrigeration system.

••R-404A is a "Near Azeotrope" so liquid charging is required: See the

next page.

••When the system is serviced, a special liquid line drier is required. It is

included with replacement compressors.

••HP62 is not compatible with mineral oil, so these ice machines use

Polyolester oil. Polyolester oil absorbs water very easily. When one of

these refrigeration systems is opened for service, it must be re-sealed

as soon as possible (15 minutes maximum).

••Special leak detection equipment is required to locate small refrigerant

leaks. Usually a leak detector capable of detecting a Halongenated

refrigerant or HFC-134a will work. Check with the leak detector

manufacturer if in doubt.

Access Valves: To use the access valves:

••Remove the cap from the stem, use a 3/16" allen wrench to check

that the valve is CLOSED. The remove the core cap.

••Close the valve and replace the caps when the job is finished.

The valve must be closed and the caps must be on or the valve

will leak.

General Information:

Work on the refrigeration system should only be done when it is certain

that the system needs repair.

••Refrain from checking refrigeration pressures without reason.

Visual inspection of the water system, observation of the ice

formation, amp draw, voltage, and other techniques will lead to proper

diagnosis.

••If gauges must be used, don’t always check the high side pressure. If

the condenser is clean and seems to be operating correctly, it most

likely is.

••If gauges must be used, use very short hoses to minimize refrigerant

discharged into the air.

••Refrigerant should not be added except as a way to determine the

proper operation of the product. If the system was low on refrigerant,

there is a leak, and it must be found and repaired.

••This system has a critical charge, it must be recharged with the

correct amount of refrigerant as listed on the nameplate of the ice

machine, or performance will suffer.

••Anytime the refrigeration system has been opened, the dryer should

be replaced. Note: Only a HFC type dryer can be used.

••When brazing the tubing connections to components such as the

TXV, the component must be protected by heat sink material.

Recover, reclaim or recycle refrigerant . The method chosen is up to

the service company. Any refrigerant placed into a Scotsman ice machine

must meet ARI spec 700-88. Reclaim programs are available through

most refrigerant wholesalers.

Pressure-Temperature Chart for HP62

VAPOR VAPOR

TEMP. PRES. TEMP. PRESS.

(DEG F) (PSIG) DEG F) (PSIG)

-20 17 70 146

-18 18 72 150

-16 20 74 155

-14 21 76 161

-12 23 78 166

-10 24 80 171

-8 26 82 177

-6 28 84 182

-4 29 86 188

-2 31 88 194

0 33 90 200

2 35 92 206

4 37 94 212

6 39 96 219

8 41 98 225

10 43 100 232

12 46 102 239

14 48 104 246

16 50 106 253

18 53 108 260

20 55 110 268

22 58 112 275

24 60 114 283

26 63 116 291

28 66 118 299

30 69 120 307

32 72 122 316

34 75 124 324

36 78 126 333

38 81 128 342

40 85 130 351

42 88 132 360

44 91 134 370

46 95 136 379

48 99 138 389

50 102 140 399

52 106 142 409

54 110 144 420

56 114 146 430

58 118 148 441

60 123 150 452

62 127 152 464

64 132 154 475

66 136 156 487

68 141 158 499

October, 1994

Page 26

LIQUID CHARGING

CME855A & CME1000A

Page 26

Instructions for R-404A

In preparation for charging, the low side hose

should have a sight glass, and/or a restrictor

device (such as a "Charge Faster") installed in it

for metering liquid into the low side of the system.

1. After a thorough evacuation to at least 200

microns, shut off the manifold valves and switch

off the vacuum pump.

2. Place a drum of R-404A onto an electronic

scale.

3. Attach the charging hose to the drum.

4. Open the valve on the drum and purge the

charging hose.

5. Zero out the scale.

6. Shut the low side access valve at the ice

machine.

7. Open the discharge manifold valve full open.

8. Watch the scale, when the correct charge is

shown, shut the manifold valve.

Note: If all of the charge will not "go in" the

discharge side:

A. Shut the discharge access valve at the ice

machine.

B. Switch the machine on.

C. Open the low side access valve at the ice

machine.

D. Open the low side manifold valve and observe

the sight glass to be certain that only gas is

flowing into the system.

E. When the proper charge is indicated on the

scale, shut off the manifold valve(s).

9. Shut off the valve on the refrigerant drum.

10. Re-open the manifold valves until all liquid has

flowed out of the hoses.

11. Shut the low side access valve on the ice

machine.

12. Remove hoses from ice machine and replace

all caps.

Hose Connection Schematic for Liquid Charging

Allen

Wrench

Torque Stem to

6-8 ft. lb..

Torque Stem Cap to

8-12 ft. lb..

Torque

Core Cap to

7-12 ft. lb..

Access Valves

Note: There are no valve

cores in this valve.

December, 1994

Loading...

Loading...