Page 1

• Operator’s Manual

STATIM® 900J AUTOCLAVE

95-110106 JP EN R2. Copyright © 2017 SciCan Ltd. All rights reserved. .

Page 2

STAT IM 900J Operator’s Manual

Table Of Contents

1. Introduction ........................... 3

2. Important Information ........... 4

2.1 Disclaimers

2.2 Unit Overview

3. Installation ............................. 6

3.1 Environmentall Considerations

3.2 Unit Placement

3.3 Connecting The Waste Bottle

3.4 Filling The Statim Reservoir

3.5 Priming The Statim 900J Pump

3.6 Language Selection

3.7 Setting the Time and Date

3.8 Preparing The Unit For Use

3.9 Shipping The Unit

4. Instructions For Use ............ 10

4.1 Using The Sterilization

Chamber Drawer

4.2 Preparing and Loading

Instruments

4.3 Instrument Mass Guide

4.4 Selecting A Cyle

4.5 Running A Cycle

4.6 Stopping a Cycle

4.7 Biological Indicators

4.8 Chemical Indicators

5. Maintenance .......................19

5.1 Cleaning the Chamber

5.2 Cleaning The Exterior Surfaces

5.3 Preventative Maintenance

Schedules

5.4 Spare Parts List

6. Troubleshooting

Problems ............................. 22

7. The Communication Port .... 24

7.1The RS232 Communication Port

7.2 Installing the SciCan Data Logger

7.3 Cycle Printout Overview

8. Warranty ............................... 30

9. Statim 900J

Specifications ......................31

STATIM is a registered trademark

of SciCan Ltd. STAT-DRI and

Infection Control Specialist

trademarks of SciCan Ltd. All other

trademarks referred to in this manual

are the property of their respective

owners.

For all service and repair inquiries:

In Canada: 1-800-870-7777

International: (416) 446-4500

Email: techservice.ca@scican.com

Manufactured by:

SciCan Ltd.

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

Your

are

2

Controlled Medical Device (Class II)

Approval No. 222AABZ100071000

DMAH:

AJMD K.K.

Hisamatsu Rotary Bldg.

4-7 Hisamatsu-cho, Nihonbashi

Chuo-ku Tokyo 103-0005

Tel: 03-5614-0733

Fax: 03-5614-0734

Page 3

STAT IM 900J Operator’s Manual

1. Introduction

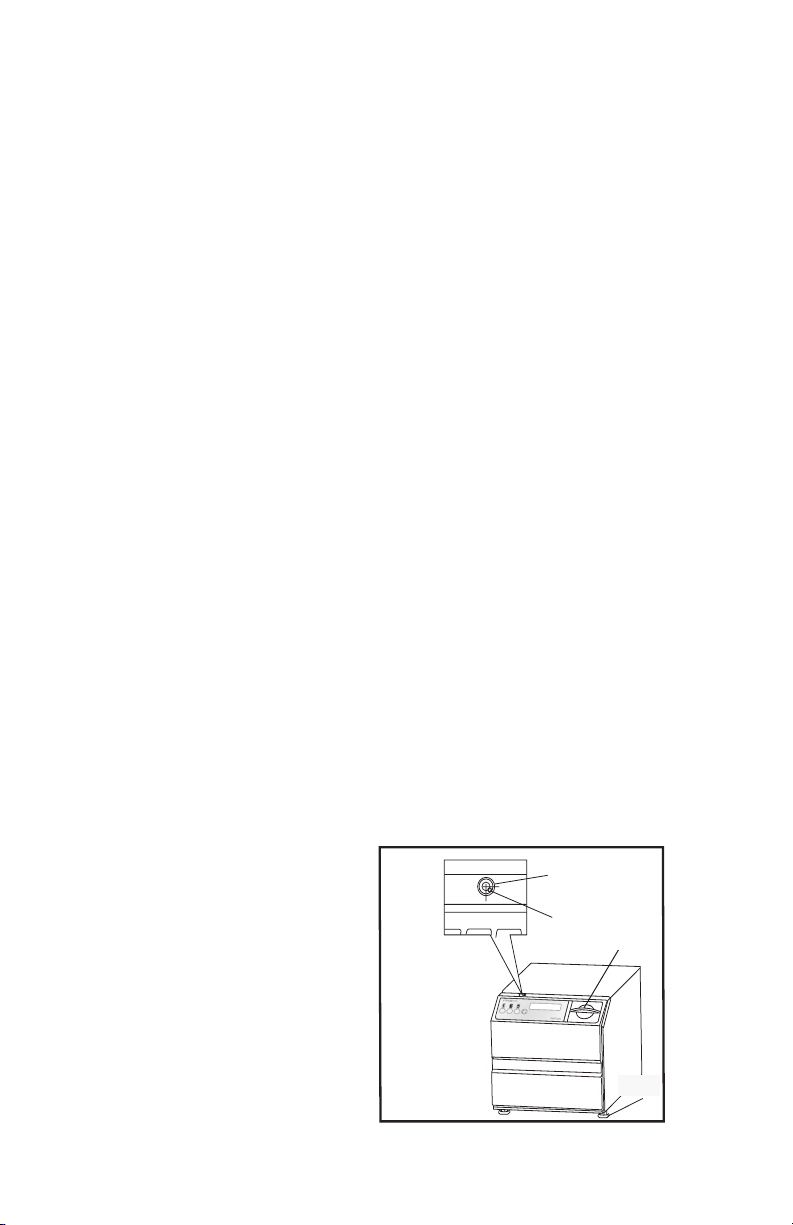

Figure 1

The STATIM® 900J autoclave has been designed expressly for the rapid

sterilization of instruments intended for immediate use. This allows you to

sterilize instruments between patients. To decrease instrument turn-around

time, the Statim 900J does not have a post-sterilization drying cycle. Quick

drying and cooling of the load at the end of the cycle is achieved through

evaporation after the automatic opening of the sterilization chamber drawer.

Because of the unique operation of the Statim 900J, once the instruments are

exposed to ambient conditions, their continued sterility cannot be assured. It is

recommended to use these instruments immediately after they are comfortable

to the touch. The Statim 900J has three sterilization cycles:

The Solid Instrument Cycle is used to sterilize solid metal instruments. The

sterilization phase of this cycle is at 134°C for 3.5 minutes. For a detailed

description of this cycle, please see page 14.

The Hollow or Wrapped Instrument Cycle is used to sterilize dental handpieces.

The sterilization phase of this cycle is at 134°C for 5 minutes. For a detailed

description of the cycle please see page 15.

The Rubber or Plastic Instrument Cycle is used to gently sterilize rubber and

plastic instruments. The types of materials appropriate for this cycle are outlined

in Preparing and Loading Instruments. The sterilization phase of this cycle is at

121°C for 15 minutes. For a detailed description of this cycle please see page

15.

3

Page 4

STAT IM 900J Operator’s Manual

2. Important Information

2.1 Disclaimers

Use only steam-process distilled water in your Statim. Specially filtered

water should not be used. Never use tap water. Usage of any water other than

steam-process distilled water may damage the unit and void the warranty.

Do not permit any person other than certified personnel to supply parts for,

service or maintain your Statim. SciCan shall not be liable for incidental,

special or consequential damages caused by any maintenance or services

performed on the Statim by a third party, or for the use of equipment or parts

manufactured by a third party, including lost profits, any commercial loss,

economic loss, or loss arising from personal injury.

Never remove the cover of the unit and never insert objects through holes or

openings in the cabinetry. Doing so may damage the unit and / or pose a hazard

to the operator.

IMPORTANT: Follow local guidelines governing verification of the sterilization

procedure.

4

Page 5

STAT IM 900J Operator’s Manual

1. Reservoir cap

2. Liquid crystal display (LCD)

3. Keypad

4. Level indicator

5. Drawer

6. Sterilization chamber

7. Power switch

8. Power cord

9. Leveller feet

10. Waste bottle (condenser)

and coil assembly

TM

11. Teflon

exhaust tube

5

4

3

2

12. Exhaust fitting 13. Drain Tube

The following symbols

appear in the margins

of this book

A potential

Hazard to

the operator.

Rubber /

The following

symbols appear

on the unit

Plastic cycle

Multifunction

button

13

7

8

6

14. Communications port

A situation which

may lead to a

mechanical failure.

Hollow or Wrapped

Instrument cycle

Solid Instrument

cycles

10

1

Figure 2

Important

Information.

Caution: Hot

Surface and / or

Hot Steam

Caution: Risk of

electrical shock.

Disconnect supply

before servicing

14

12

9

11

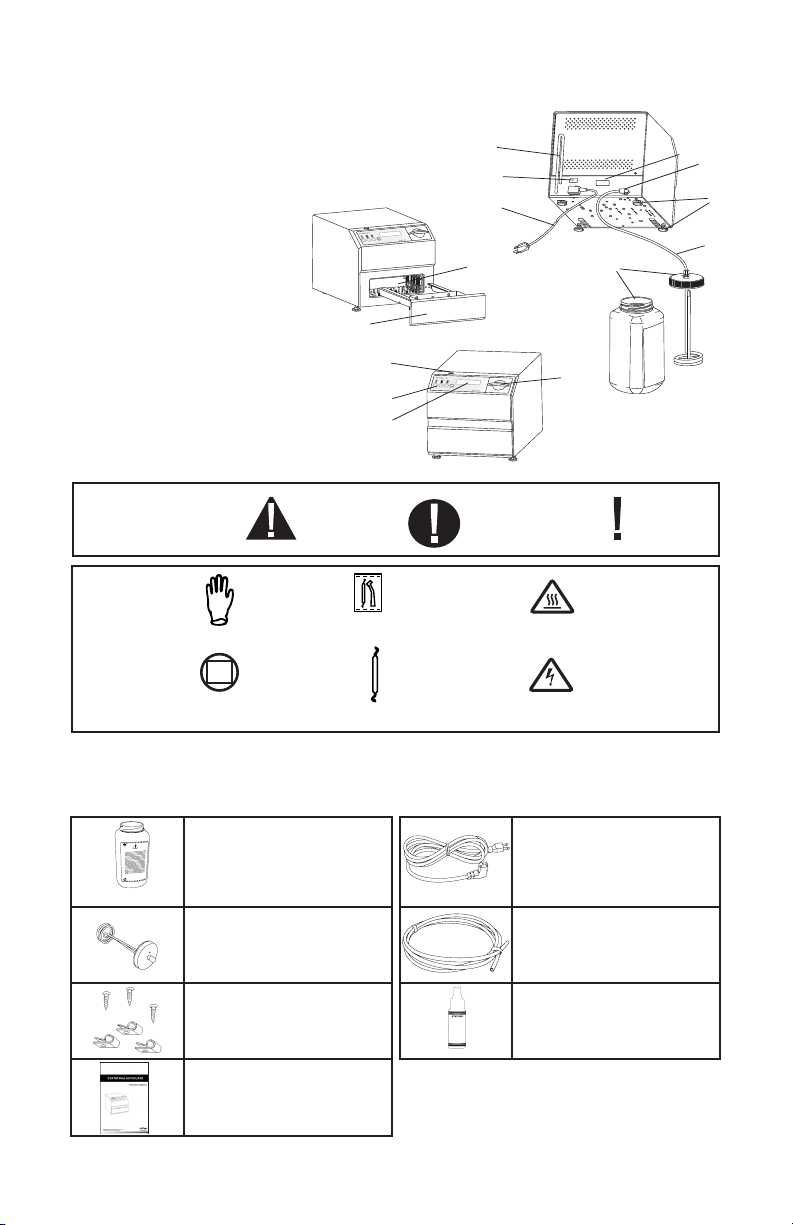

When you recieve your Statim 900J packing carton, the items listed below will be

included.If any of the items are missing, contact your dealer immediately so the

situation can be corrected.

Waste Bottle

part number 01-100724S

Bottle Lid Fitting

part number 01-100735S

Tube Mounting Hardware

Power Cord

part number 01-101763S

Exhaust Tube

part number 01-100204S

Stat-Dri

part numbers: 2OZPLUS,

32OZPLUS, 8OZPLUS,

8OZPLUS (with trigger)

Statim 900J

Operator’s Manual

part number 95-110106

5

Page 6

STAT IM 900J Operator’s Manual

3. Installation

3.1 Environmental Considerations

There are several factors that may effect the performance of your

Statim. Please review these factors, and select a suitable location in

which to install the unit.

• Temperature and Humidity

Avoid installing your Statim in direct sunlight or close to a heat source

(e.g. vents or radiators). The recommended operating temperature is

between 15 ˚C to 25 ˚C (59 ˚F to 77 ˚F) with humidity of 25 % to 70 %.

• Spacing

The vents and openings on the Statim should remain uncovered and

unobstructed. Leave a minimum of 50 mm / 2 " between the top, sides

and back of the unit and any wall or partition.

• Venting

The Statim should be operated in a clean, dust-free environment.

• Work Surface

The Statim should be placed on a flat, level, water-resistant surface.

Never install and operate the unit on a sloped surface.

• Electromagnetic Environment

The Statim has been tested and meets applicable standards

for electromagnetic emissions. While the unit does not emit any

radiation, it may itself be affected by other equipment which does.

We recommend that the unit be kept away from potential sources of

interference.

• Electrical Requirements

Use properly grounded and fused power sources with the same voltage

rating as indicated on the label at the back of your Statim. Avoid

multiple outlet receptacles. If using a surge suppressor power bar, plug

in one Statim only.

3.2 Unit Placement

To stabilize the Statim 900J, follow these steps:

1. Align the bubble (1)

in the level indicator

(2) on the front panel

to the right front quadrant

(or 4 o’clock) of the target

by adjusting the four

leveller feet (3). This will

ensure that the Statim 900

functions properly.

2. Ensure that all four feet are

in contact with the surface,

and that the Statim 900J

does not rock.

1. Bubble

2. Level indicator

3. Leveller feet

4. Reservoir

cap

6

Figure 3

2

1

4

3 (4x)

Page 7

STAT IM 900J Operator’s Manual

3. Installation

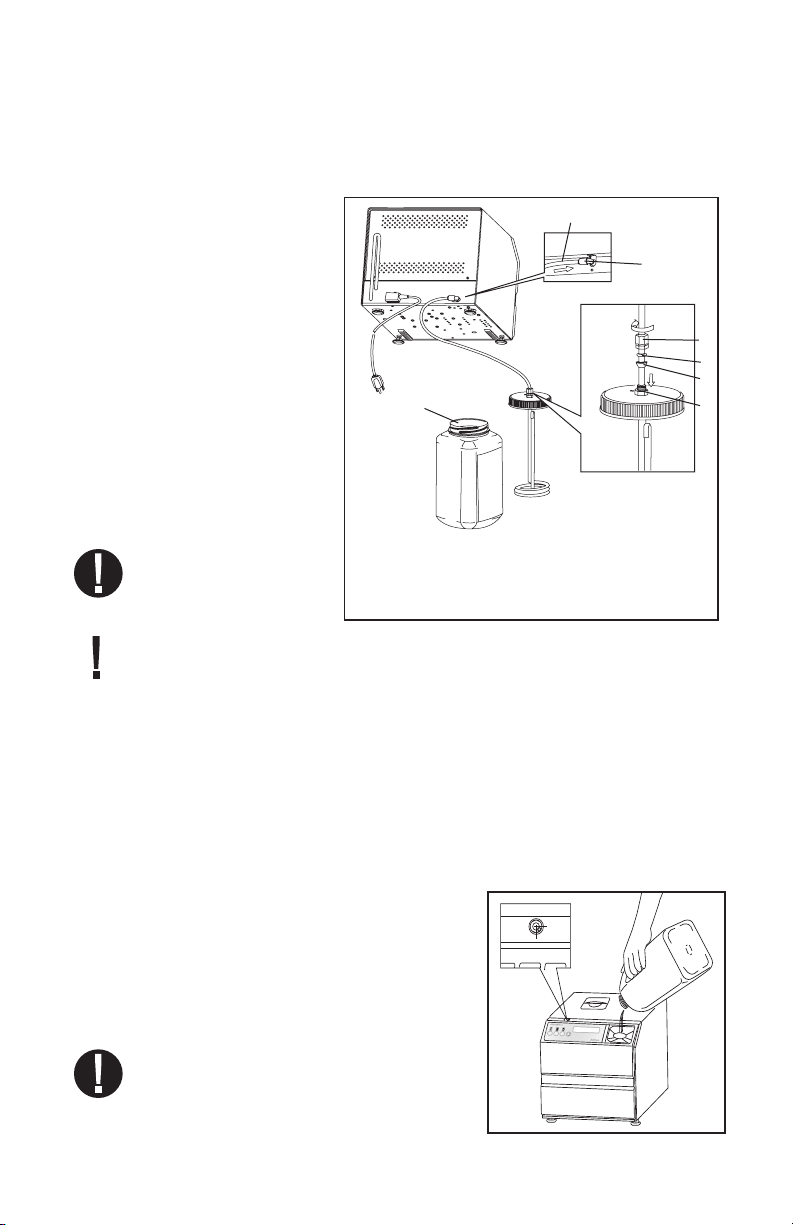

3.3 Connecting the waste bottle

To connect the waste bottle (1), follow these steps:

1. Insert one end of the

Teflon™ exhaust tube

(2) into the exhaust

fitting (3) on the back of

the Statim 900J. Push

the tube into the fitting

as far as it will go to

ensure that the tube is

connected tightly.

2. Cut the tube to length

and slide the nut, ring

and cone onto the tube.

Place the free end of

the tube into the fitting

in the lid of the waste

bottle and hand tighten.

Do not coil the exhaust

tube.

3. Place the waste bottle

near the Statim 900J.

We recommend that

you keep it in a cabinet

below the unit. For convenience, the tube can be routed through a hole, 7

mm (5/16") in diameter, drilled through the counter-top and secured with the

nylon clamps provided.

4. Unscrew the lid with the copper condenser coil assembly from the waste

bottle. The lid and coil should come out together. Fill the waste bottle with

water to the “MIN” line and replace the lid and copper condenser assembly.

5. If required, a low-level disinfectant prepared according to instructions on

the disinfectant packaging may be added to the waste bottle. This may help

prevent unpleasant odours or discoloration of the waste water if it is not

changed regularly.

1

1. waste Bottle

2. Teflon™ exhaust tube

3. exhaust fitting

2

4. nut

5. ring

6. cone

7. threaded nut

Figure 4

3

4

5

6

7

3.4 Filling the Statim Reservoir

To fill the reservoir, follow these steps:

1. Remove the reservoir cap from the top of

the Statim 900J and pour only steamprocess distilled water into the reservoir

until nearly full (a maximum of 3 litres).

Never use tap water. We recommend using

a funnel when filling the reservoir to avoid

spills. Pour slowly when filling the top portion

of the reservoir. Use only steam processed

distilled water containing less than 5 ppm

total dissolved solids (having conductivity of

less than 10 μS / cm).

7

Figure 5

Page 8

STAT IM 900J Operator’s Manual

3. Installation

2. Replace the reservoir cap to ensure that nothing other than steam-process

distilled water enters the reservoir.

3. Empty the waste bottle and refill to the MIN indicator.

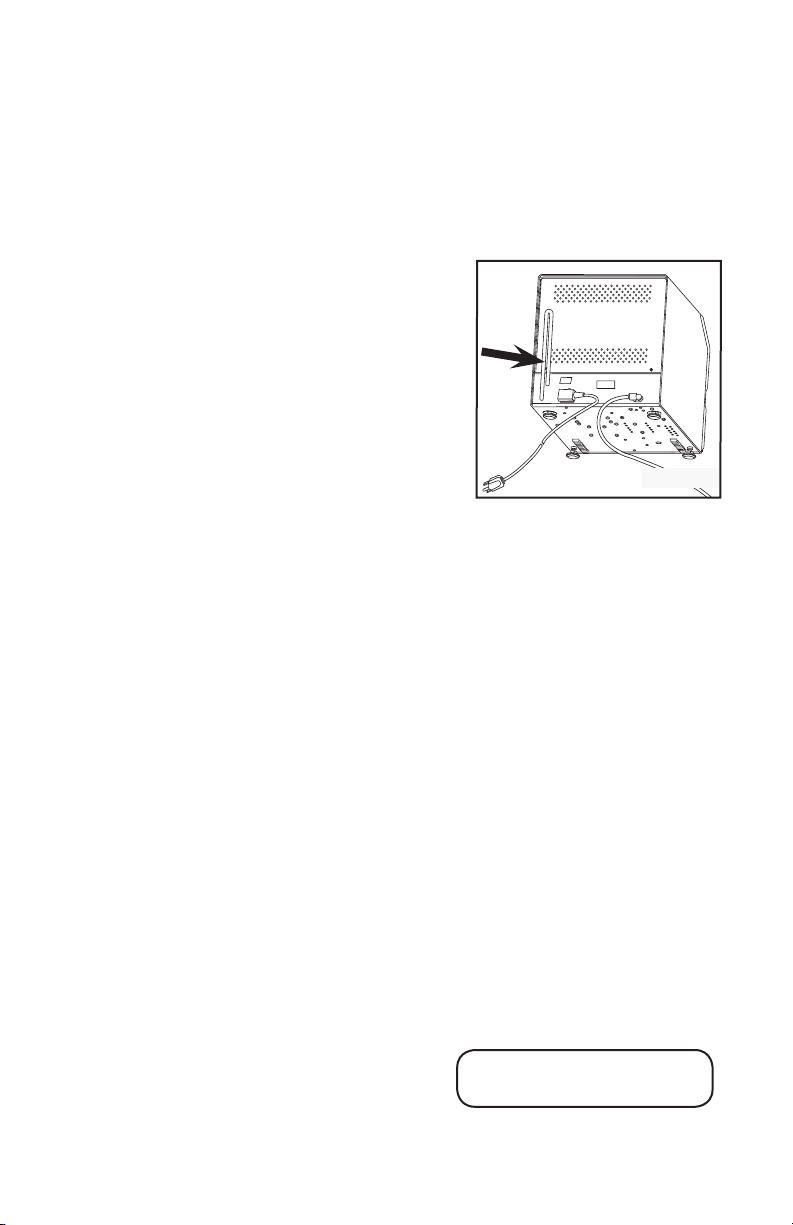

3.5 Priming the Statim 900J pump

To Prime the Statim 900J pump follow

these steps:

1. Carefully turn the Statim 900J sideways,

and locate the drain tube beside the

power switch, on the back of the unit.

Gently pull the tube out as far as possible

so the free end can be positioned over a

water container.

2. Remove the stopper from the end of the

drain tube and allow water to drain from

the tube into a container for at least

30 seconds.

3. Replace the stopper, and feed the tube back into the unit until secure.

4. Plug the power cord into the power cord receptacle on the back of the unit.

5. Plug the power cord into a standard, grounded, wall outlet.

Figure 6

3.6 Language Selection

To set the language feature for the Statim 900J, follow these steps. Watch the

blinking cursor on the LCD.

1. Turn the Statim 900J power switch OFF.

2. Press and hold down the Hollow or Wrapped Instrument Cycle button on

the front of the Statim 900J, and turn the power switch at the back of the

unit ON. Release the Solid Instrument Cycle button. The current language

selection will appear.

3. To scroll to the next language press the Hollow or Wrapped Cycle button.

To scroll to the previous language press the Solid Instrument Cycle button.

4. When the desired language feature is indicated on the LCD, press

the MULTIFUNCTION button shown to save the change and return to

normal operation.

3.7 Setting the Time and Date

To set the time and date, follow these steps and watch the blinking cursor

on the LCD:

1. Power the Statim OFF.

2. Press and hold the Solid Instrument cycle button.

3. While pressing the Solid Instrument cycle button, power the Statim ON.

The LCD display reads:

14:23 06/22/2007

HH:MM DD/MM/YYYY

8

Page 9

STAT IM 900J Operator’s Manual

3. Installation

4. Use the cycle buttons to select and change the selected field’s value. To

increase a field’s value, press the Solid Instrument cycle button. Hold the

button down to increase the value.

5. To decrease the value, press the Hollow or Wrapped Instrument cycle

button.

6. To select the next field, press the RUBBER AND PLASTICS cycle button.

7. To save changes and return to the regular operating mode, press the

MULTIFUNCTION button.

8. To quit without making changes, power the Statim OFF.

3.8 Preparing Unit for Use

Once the unit is installed and before any instruments are sterilized, run two

Hollow or Wrapped instrument cycles (See section 4.5 Running a Cycle). Clean

the drawer and the instrument basket using a soft cloth to wipe the inside

surfaces and rinse thoroughly with tap water. Once the instrument basket and

sterilization chamber are clean and dry, coat the interior surfaces with Stat-Dri.

3.9 Shipping the Statim 900J

If you must ship the Statim 900J, follow these instructions:

1. Drain the water from the reservoir. Carefully turn the Statim 900J backwards.

Locate the drain tube beside the power switch on the back of the unit.

Release the drain tube from the clip.

2. Remove the stopper from the end of the drain tube and allow for the water

to drain freely from the reservoir. When the water no longer drips from the

drain tube replace the stopper and secure the drain tube under the clip.

9

Page 10

STAT IM 900J Operator’s Manual

4. Instructions for Use

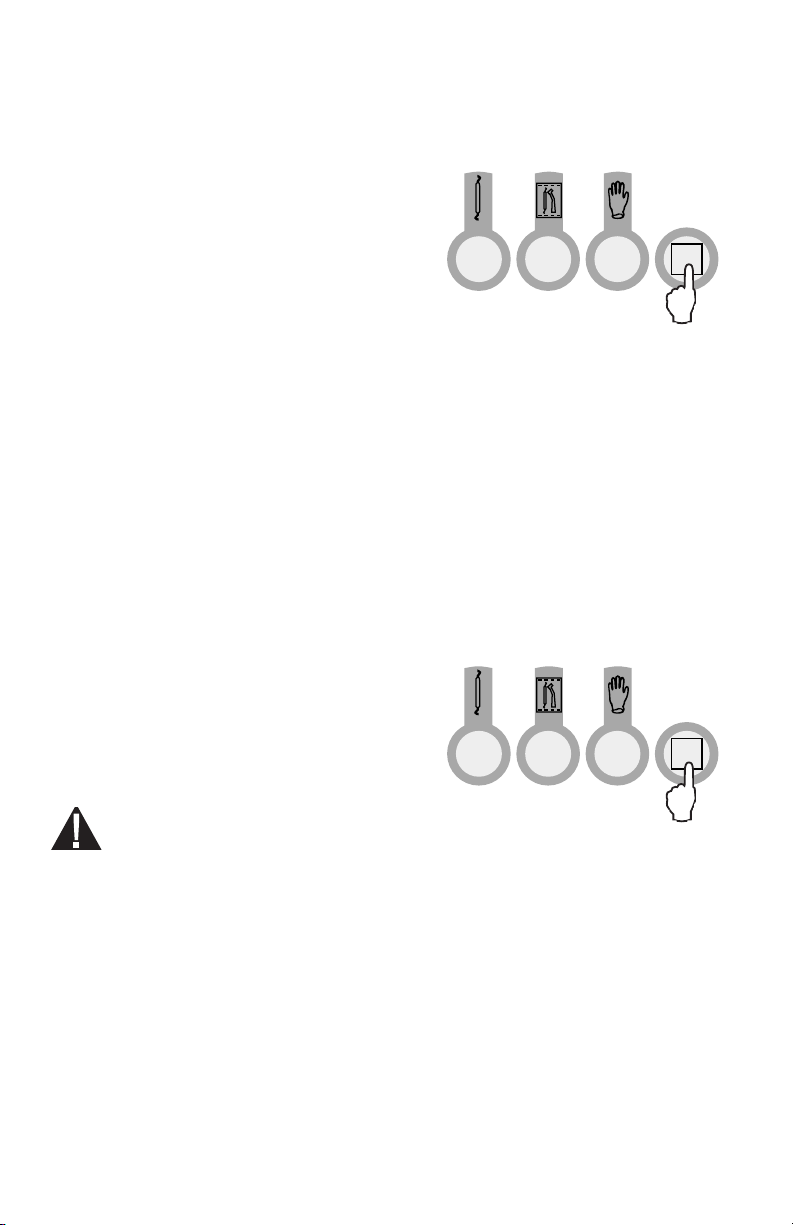

4.1 Using The Sterilization Chamber Drawer

The Statim 900J keypad has four buttons.

The first three buttons will initiate one

of the three different sterilization cycles.

These cycles are described in detail

in section 4.4 Selecting A Cycle. The

fourth button on the keypad, the

MULTIFUNCTION button, opens and

closes the Sterilization Chamber Drawer.

Instrument

• To open the Sterilization Chamber Drawer:

Solid

Cycle

Handpieces /

Hollow

Instrument

Cycle

1. Press the MULTIFUNCTION button and the drawer will open automatically.

2. Lift the instrument basket from the sterilization chamber.

3. Load instruments to be sterilized into the instrument basket. Ensure you

follow the instrument manufacturer’s reprocessing instructions to ensure you

do not damage the instruments.

4. Replace the instrument basket into the sterilization chamber.

5. Press the MULTIFUNCTION button and the drawer will close automatically,

or press one of the sterilization cycle buttons and the drawer will close and

the selected sterilization cycle will begin automatically.

• To Remove The Sterilization Chamber Drawer:

To remove the sterilization chamber drawer, follow these steps:

1. Open the drawer by pressing the

MULTIFUNCTION button on

the keypad.

2. Turn the unit power switch to OFF.

3. Locate the green latch inside the

front opening of the machine near the

top right hand side. Push the latch to the

right and gently pull the drawer out of the unit.

Be careful. The instruments and the metal parts of the drawer may be hot.

Rubber

& Plastic

Cycle

• To Replace The Sterilization Drawer:

To replace the sterilization chamber drawer, follow these steps:

1. Center the drawer into the opening.

2. Rest the rear ends of the drawer on the front rollers in the opening.

3. Tilt the front of the drawer upwards and push the drawer into the unit. Level

the drawer and continue to push until the drawer clicks into the intermediate

position. Lift and push the drawer past the position where the green latch is

engaged by the drawer.

4. If installed properly, the drawer cannot be removed without pushing

the green latch.

5. Turn the power ON and close the drawer by pressing the MULTIFUNCTION

button.

10

Page 11

STAT IM 900J Operator’s Manual

4. Instructions for Use

4.2 Preparing and Loading Instruments

Before loading any instruments into the Statim, consult the instrument

manufacturer’s reprocessing instructions.

• Clean Instruments

Clean and rinse all instruments before loading them into the cassette.

Disinfectant residues and solid debris may inhibit sterilization and damage the

instruments, the sterilization chamber, and the Statim. Lubricated instruments

must be wiped thoroughly and any excess lubricant should be removed before

loading.

• Solid Instruments

Arrange unwrapped instruments in the instrument basket so that they do not

touch one another. This ensures that steam reaches all surfaces.

Instruments must not be stacked or piled in the instrument basket as this will

impede the sterilization process.

The Statim 900J provides cycles to sterilize instruments for both immediate and

future use.

• Immediate use

Use the Solid Instrument cycle only if the instruments are going to be used

immediately following sterilization. Handpieces should be sterilized in the Hollow

or Wrapped instrument cycle even for immediate use. Since the item is not

wrapped for processing, the sterilized item should be used immediately (as soon

as it cools off) and must be protected from re-contamination during transport to

the point of use. The rapid timing of the Solid Instrument cycle (about 6 minutes)

is sufficient to sterilize instruments between patients.

• Hollow or Wrapped Instruments

If the instruments are going to be stored for future use, place the instruments

into autoclave bags according to the instrument manufacturer’s instructions.

Pouch each instrument individually. Place one pouch on the bottom rack and

another one on the top rack of the basket. The Statim 900J unit does not

have an active drying process and handling of wet pouches will compromise

the sterility of the instruments. Following sterilization, the wet pouches may

be allowed to dry within the drawer of the unit or can be transported to the

cabinet in the basket and allowed to dry in the basket prior to further handling.

Care should be taken that the basket and contents remain protected from recontamination during this drying period. The use of cloth wraps in the Statim is

not recommended.

SciCan recommends the use of plastic / paper autoclave bags such as SPS™,

Medi-Plus™ and Chex All II™. Steri-Stik™ paper / paper may also be used. The

use of cloth wraps in the Statim is not recommended. Loosely pack instruments

in the bags to allow steam penetration to all instrument surfaces.

Care must be taken to ensure that the combined weight of the loaded bags does

not exceed 1.0 kg (2.2 lbs).

11

Page 12

STAT IM 900J Operator’s Manual

4. Instructions for Use

• Rubber and Plastic Instruments

The following materials CAN be sterilized in the Statim:

nylon, polycarbonate (Lexan™), polypropylene, PTFE (Teflon™), acetal

(Delrin™), polysulfone (Udel™), polyetherimide (Ultem™), silicone rubber, and

polyester. When loading rubber and plastic instruments in the instrument basket,

leave a space between the instruments and the chamber walls. This ensures that

steam reaches all surfaces.

The following materials CANNOT be sterilized in the Statim:

polyethylene, ABS, styrene, cellulosics, PVC, Acrylic (Plexiglas™), PPO (Noryl™),

latex, neoprene, and similar materials. Use of these materials may lead to

instrument or equipment damage. If you are unsure of your instrument’s material

or construction, do not load into your Statim until you have checked with the

instrument manufacturer.

• All Instruments

The Statim is NOT intended for sterilizing textiles, liquids or biomedical waste.

Unwrapped instruments, once exposed to ambient or external conditions,

cannot be maintained in a sterile state. If sterile storage is desired, wrap the

instruments to be sterilized in autoclave bags, according to the instrument

manufacturer’s instructions. Then allow the wrapped cycle to run. At completion

of cycle, handle load aceptically

Best Practice: Allow instruments (wrapped or unwrapped) to dry completely

prior to handling. Wrapped or pouched instruments must not touch each other

to promote drying and enable effective sterilization.

SciCan recommends the final user carefully choose the most appropriate

sterilization cycle according to the recommendations of their leading infection

control authorities and local regulatory guidelines / recommendations.

• Routine Monitoring

SciCan recommends that chemical process indicators suitable for steam

sterilizers be used in routine monitoring of the Statim 900J. Of the many brands

on the market, it is important to choose the correct type. Use only indicators

designed for steam sterilization at 134°C for the Solid Instrument and Hollow or

Wrapped Instrument cycles, and indicators designed for steam sterilization at

121°C for the Rubber or Plastic Instrument cycle. Use at least one indicator for

each load processed. Follow the indicator manufacturer’s instructions closely.

Cycle Biological

Solid

Instruments

Hollow or

wrapped

instruments

Rubber & Plastic

Instruments

Indicator

Attest™

1261

Attest™

1261

Attest™

1262

Incubation

Period

24 Hours Place the indicator in the center of

24 Hours Place the indicator in the center of

48 Hours Place the indicator in the center of

Test Pack

the unloaded instrument basket.

the unloaded instrument basket.

the unloaded instrument basket.

12

Page 13

STAT IM 900J Operator’s Manual

4. Instructions for Use

For detailed instructions on how to handle, use and dispose of both the

biological and chemical indicators, please consult the product literature

accompanying the 3M Attest™ biological indicators or contact the manufacturer

directly.

To use the indicators with the Statim 900J, follow these steps:

1. Place the appropriate biological indicator in the Statim 900J chamber.

2. Process the load in the sterilizer according to your usual practice.

3. Ensure that the message “Cycle Complete” is displayed on the LCD after

the cycle is finished.

4. Recover the biological and / or chemical indicator and process further

according to the literature that accompanied the indicator.

At the first indication of a potential sterilization failure:

1. Do not process any more instruments until favourable test results have

been returned.

2. Ensure the correct indicator type was chosen.

3. Ensure the chamber was not overloaded. Consult the earlier portion of this

section for proper loading instructions.

4. If the results do not change, do not process any more instruments within the

Statim 900J and contact your SciCan dealer for further assistance.

Because the turnaround time for the 3M Attest™ is up to 48 hours, it is

recommended that the tests be conducted so that the incubation period occurs

during a period of planned downtime such a the last cycle before a weekend.

4.3 Instrument Mass Guide

Instrument Typical Instrument Mass

Scissors 30 g (0.96 ozt)

Dental Scalers 20 g (0.64 ozt)

Forceps 15 g (0.48 ozt)

Dental handpiece 40 to 60 g (1.3 to 1.9 ozt)

Unwrapped instrument rack 225 g (7.23 ozt)

Suction cannula 10 g (0.32 ozt)

Plastic mouth mirror 8 g (0.3 ozt)

Impression Tray 15 to 45 g (0.48 to 1.5 ozt)

Plastic x-ray positioning ring 20 g (0.64 ozt)

NOTE: The above weights are to be used as reference only. For exact weights

of your instruments, consult the manufacturer's specifications.

13

Page 14

STAT IM 900J Operator’s Manual

AB DEC

A Warming up

B Conditioning

C Pressurizing

D Sterilizing

E Venting

4. Instructions for Use

4.4 Selecting a Cycle

The Statim 900J Autoclave has been designed expressly for the rapid

sterilization of instruments intended for immediate use. This allows you to

sterilize instruments between patients. Quick drying and cooling of the load

at the end of the cycle is achieved through evaporation after the automatic

opening of the sterilzation chamber drawer. Because of the unique operation

of the Statim 900J, once the instruments are exposed to ambient conditions,

their continued sterility cannot be assured. It is recommended to use these

instruments immediately after they are comfortable to the touch. Each cycle can

be selected by pressing the Solid Instrument, Hollow or Wrapped Instrument, or

Rubber / Plastic buttons.

The types of instruments, sterilization requirements and a graph depicting each

cycle characteristics are described over the following pages.

The Statim 900J has three sterilization cycles, each designed to sterilize a

specific type of instrument. The instruments will remain sterile after a successful

cycle until the drawer is opened. The types of instruments, sterilization

requirements, and a graph depicting each cycle are described over the next few

pages. Consult the Instrument Mass Guide in Section 4.3 for information on how

to make up an appropriate load for the masses specified for individual cycles.

1. Solid Instrument Cycle

The Solid Instrument Cycle is used to sterilize solid metal instruments free from

deep cavities or holes, such as pliers, burrs, scalers and forceps.

The maximum recommended load for the Solid Instrument Cycle is 1.0 kg.

To select this cycle, press the Solid Instrument Cycle button. The cycle then

starts automatically. This cycle is illustrated in the graph below. During the

sterilizing phase of this cycle, the temperature in the chamber is maintained at

a minimun of 134ºC for 3.5 minutes. See Preparing and Loading Instruments

before running this cycle.

SOLID 134°C / 3.5 min

14

Page 15

STAT IM 900J Operator’s Manual

A B C E D

A Warming up

B Conditioning

C Pressurizing

D Sterilizing

E Venting

ABCED

A Warming up

B Conditioning

C Pressurizing

D Sterilizing

E Venting

4. Instructions for Use

2. Hollow or Wrapped Instrument Cycle

The Hollow or Wrapped Instrument Cycle is used to sterilize dental handpieces.

The maximum recommended load for the Handpiece cycle is 1.0 kg.

To select this cycle, press the Hollow or Wrapped Instrument Cycle button.

The cycle then starts automatically. This cycle is illustrated in the graph below.

During the sterilizing phase of this cycle, the temperature in the chamber is

maintained at a minimum of 134ºC for 5 minutes. See Preparing and Loading

Instruments before running this cycle.

HOLLOW OR WRAPPED 134°C / 5 min

3. Rubber or Plastic Instrument Cycle

The Rubber or Plastic Instrument Cycle is used to sterilize instruments

constructed of the materials listed under the heading Rubber or Plastic

Instruments in Preparing and Loading Instruments. The maximum recommended

load for the Rubber or Plastic Instrument Cycle is 0.1 kg.

To select this cycle, press the Rubber or Plastic Instrument Cycle button. The

cycle then starts automatically. This cycle is illustrated in the graph below.

During the sterilizing phase of this cycle, the temperature in the chamber is

maintained at a minimum of 121ºC for 15 minutes. See Preparing and Loading

Instruments before running this cycle.

RUBBER / PLASTIC 121°C / 15 min

15

Page 16

STAT IM 900J Operator’s Manual

4. Instructions for Use

4.5 Running a Cycle

To operate each cycle, follow these steps and watch the LCD:

Turn the power switch at the back of

the unit ON. The LCD display reads:

Selecting the MULTIFUNCTION

button changes the position

STATIM 900J R1.11

SELECT A CYCLE

PRESS TO CLOSE

if the drawer

is fully open

of the drawer

or

Selecting a cycle will close

the door and start that cycle.

SELECT A CYCLE

PRESS TO OPEN

SELECT A CYCLE

PRESS TO OPEN

if the drawer

is closed

if the drawer

is ajar

Select the apropriate cycle

button on the keypad located

beside the LCD.

As the drawer closes, the display reads

SOLID INSTRUMENTS

134ºC for 3.5 mins

HOLLOW OR WRAPPED

INSTRUMENTS 134ºC for 5 mins

Solid

Instrument

Cycle

Hollow or

Wrapped

Instrument

Cycle

Rubber

& Plastic

Cycle

RUBBER AND PLASTICS

121ºC for 15 mins

and the cycle begins. Messages change throughout the cycle. For example,

if the SOLID INSTRUMENT CYCLE is selected, the following LCD messages

would be displayed:

SOLID INSTRUMENTS

WARMING UP

SOLID INSTRUMENTS

WARMING UP 96ºC

SOLID INSTRUMENTS

CONDITIONING 110ºC

16

Page 17

STAT IM 900J Operator’s Manual

4. Instructions for Use

SOLID INSTRUMENTS

PRESSURIZING 130ºC

STERILIZING

134ºC 212 kPa 3:15

SOLID INSTRUMENTS

VENTING 115ºC

After venting is complete, the drawer will open automatically and the instruments

may be removed. The display reads:

SOLID INSTRUMENTS

CYCLE COMPLETE 6:02

Be careful. The instruments and metal parts of the drawer will be hot. Hot steam

will escape as the drawer opens.

This message is displayed for 30 minutes as a reminder of a successfully

completed cycle. When sterilized instruments are removed press the

MULTIFUNCTION button to clear the CYCLE COMPLETE message, and prepare

the machine for the next cycle. This ensures that the CYCLE COMPLETE

message is not displayed when a new load of unsterilized instruments is placed

in the chamber.

After 30 minutes the LCD message will automatically change to:

SELECT A CYCLE

PRESS TO CLOSE

Once exposed to a non-sterile environment at the end of a complete cycle, the

continued sterility of the chamber contents can no longer be assured. Therefore,

the Statim 900J should only be used for the prevention of cross-contamination,

unless other steps are taken to ensure continued sterility.

17

Page 18

STAT IM 900J Operator’s Manual

4. Instructions for Use

4.6 Stopping a Cycle

To stop a cycle, press the MULTIFUNCTION button. If the MULTIFUNCTION

button is pushed, or the unit detects a problem while operating, the cycle will

stop and the amber active light will flash. Once a cycle has been interrupted, the

MULTIFUNCTION button must be pressed before another cycle can be started.

The display reads the following message:

BUTTON PRESSED

PLEASE WAIT

If the display shows the message, CYCLE FAULT or NOT STERILE, the chamber

contents are not sterile! See section 6. Troubleshooting for more information.

18

Page 19

STAT IM 900J Operator’s Manual

5. Maintenance

5.1 Cleaning the Chamber

It is good clinical practice to keep your Statim 900J sterilization chamber clean.

We recommend that the interior surface of the chamber be cleaned at least once

a week with dishwashing soap or mild detergent that does not contain chlorine.

Remove the drawer from the unit to make cleaning easier. See, section 4.1.

Afterwards, rinse thoroughly to remove all traces of soap. After the chamber is

clean treat the entire inside surface with Stat-Dri. Stat-Dri causes water to form

an even coat on treated surfaces, without beading. The water in contact with

the hot chamber surfaces evaporates more efficiently. Spotting is minimized and

instruments dry faster. Stat-Dri is available from your dealer or from SciCan.

Cleaning the inside of the chamber is very important if you regularly sterilize

lubricated instruments.

5.2 Cleaning the Exterior Surfaces

Use a soft cloth moistened with a mild cleaning solution or mild disinfectant to

clean all outer surfaces. Do not use solvents or harsh chemicals.

5.3 Preventative Maintenance Schedules

To ensure trouble-free performance, both the operator and the dealer must

follow a preventative maintenance schedule.

NOTE: Please refer to your National, Regional, State or Safety laws for any

additional reoccurring user testing that may be required.

19

Page 20

STAT IM 900J Operator’s Manual

5. Maintenance

The schedules below describes the necessary actions.

Operator

Daily Chamber Wash the interior of the sterilization chamber

Unit After a week or period of extended non-use,

Water Reservoir Drain Daily

Waste Bottle Empty the waste bottle every time you refill

technician

Once Chamber Check the drawer, lid and seal for damage.

a year Replace if necessary.

Solenoid Valve Inspect the valve and clean if dirty.

Replace the plunger if defective.

Pump Clean the filters, replace if dirty.

Water Reservoir Check the reservoir for dirt. Clean and

Calibration Calibrate the unit

with a chlorine-free dishwashing detergent

or soap. Rinse thoroughly with water.

run the first cycle with an empty load.

the reservoir. Fill with tap water up to MIN

line. You can also add some chlorine-free

disinfectant.

rinse with steam process distilled water if

necessary.

20

Page 21

5. Maintenance

5.4 Spare Parts List

01-100204S Exhaust Tube

01-101561S Packaging

01-101565S Condenser Bottle

01-101582S Replacement Cap

STAT IM 900J Operator’s Manual

01-103636S Wire Basket

01-104343S Plug - Drain Tubing

01-101562S Statim 900J Drawer

2OZPLUS Stat Dri Plus 2oz.

32OZPLUS Stat Dri Plus,

8OZPLUS Stat Dri Plus,

8OZPLUST Stat Dri Plus, 8oz.

Complete

bottle w/sprayer

32oz. bottle

8oz. bottle

bottle w/trigge

21

Page 22

STAT IM 900J Operator’s Manual

6. Troubleshooting Problems

Problem Solution

Unit Does not Power

ON.

Drawer does not

open / close when a

cycle button or the

multifunction button

is pressed.

Water under

the Machine

Cycle aborted,

message “NOT

STERILE”

and “CYCLE

FAULT” message

Message “CYCLE

FAULT 12”

Check that the unit is plugged into a properly

grounded outlet, that the power cord is firmly seated

at the rear of the machine, and that the power switch

is ON.

Check the condition of the line circuit breaker or fuse.

The drawer may not be installed properly. Push the

drawer further into the unit assuring that it is past

the position where the green latch is engaged by the

drawer.When installed properly the drawer may not be

pulled out of the unit without pushing the green latch.

See, section 4.1, Using the Sterilization Chamber

Drawer

Check that water was not spilled when refilling the

reservoir. We recommend that you use a funnel when

filling your Statim 900J .

Make sure the plug in the drain tube is secured. If the

leak persists, unload the chamber, unplug the unit,

and call your dealer.

Wait a few minutes and attempt another cycle before

proceeding.

Check the exhaust tube for kinks or obstructions. Try

another cycle. If the problem persists, record the cycle

fault message number and contact your dealer.

Do not attempt another cycle. There is an internal

electrical problem. Turn the unit off, unload the

sterilization chamber and call your dealer.

Be careful. The instruments and metal parts of the

drawer will be hot. Hot steam will escape as the

drawer opens.

Excessive steam

is issuing from the

front of the unit

Open and close the drawer. Attempt another cycle.

Be careful. The instruments and metal parts of the

drawer will be hot. Hot steam will escape as the

drawer opens.

If the leak persists, unload the chamber, unplug the

unit, and call

your dealer.

22

Page 23

6. Troubleshooting Problems

Problem Solution

STAT IM 900J Operator’s Manual

Message “WATER

QUALITY IS NOT

ACCEPTABLE”.

Machine will not start

Message “REFILL

RESERVOIR” and

“EMPTY WASTE

BOTTLE”. Machine

will not start.

Inadvertently, you have used water which is not

steam-process distilled or is improperly distilled. Drain

the reservoir and refill with steam-process distilled

water To drain the unit, use the drain tube at the

back of the machine. Refer to the steps described in

Shipping the Statim 900J.

The level of water in the reservoir is low. Refill the

reservoir, using steam-process distilled water and

empty the waste bottle. Refer to the steps described

in Maintaining the Statim 900J.

23

Page 24

STAT IM 900J Operator’s Manual

7. The Communication Port

7.1 The RS232

Communication Port

All Statim units that do not have an

internal printer will have an RS232

communication port that will allow you

to connect to an external printer or to a

SciCan Data Logger. For printing, you

will need to purchase a recommended

printer (see list below) from your local

computer or electronics store. For data

storage, you can purchase SciCan’s

USB Data Logger to record and store

cycle information onto a mass storage

device (MSD) such as a USB Flash Drive

or SD memory card.

Printer

OR

Data Logger

Figure 5

Printer Model End Of

Epson

TM-U220D (C31C515603) CR/LF

Citizen

IDP-3110-40 RF 120B

Star Micro

SP212FD42-120

Star Micro

SP216FD41-120

Star Micro

SP512MD42-R

SciCan Data Logger End Of Line

For mass storage device* N/A 9600 32 [0xd2]

* Due to a variety of software programs/viewers that can be used to view the

data files stored on a mass storage device such as a USB memory stick, we

recommend the above settings.

For your Statim to communicate to a specific device, you must enable this

function through the User Setup menu. Follow the instructions in section 7.2

Installing the SciCan Data Logger below to enable communication to either an

external printer or the SciCan Data Logger.

Line

CR/LF

CR

CR

CR/LF

CR/LF

CR/LF

Serial Port

Bitrate

9600

9600

9600

9600

9600

Serial Port

Bitrate

Printer user °

character

248 [0xF8]

N/A

210 [0xd2]

210 [0xd2]

210 [0xd2]

Printer

user °

character

24

Page 25

STAT IM 900J Operator’s Manual

7. The Communication Port

7.2 Installing the SciCan

Data Logger

SciCan’s USB Data Logger can record and store cycle information onto a mass

storage device (MSD) such as a USB Flash Drive or SD memory card. These

instructions are for units with a 9-pin communication (RS232) port located at the

back of the unit.

User Setup Menu

To install the SciCan Data logger,

User Mode

Time/Date Setup

Language Setup

Unit ID Setup

Water Quality

Last Printout

RS232

End of Line CR/LF

Serial Port Bitrate

Printer User º Char

Save and Exit

Exit

access the user setup menu

by powering up the unit while

pressing the MULTIFUNCTION

button. Follow the instructions

below to complete installation

steps.

STEP 1

Selecting the USB Flash/MSD Option

RS232

1. Power up unit while pressing the MULTIFUNCTION button to access the

User Setup menu.

2. Using the Solid Instrument or Hollow or Wrapped Instrument Cycle buttons,

scroll to RS232 and select it by pressing the Rubber and Plastic Cycle

button.

3. From the RS232 menu, use the Solid Instrument or Hollow or Wrapped

Instrument Cycle buttons to scroll down to the USB/FLASH MSD option and

press the Rubber and Plastic Cycle button to select and return to the User

Setup menu.

25

USB/Flash MSD

Page 26

STAT IM 900J Operator’s Manual

7. The Communication Port

Setting the Serial Port Bitrate to 9600

Serial Port Biterate

1. From the User Setup menu, use the Solid Instrument and Hollow or

Wrapped Instrument Cycle buttons to scroll to the Serial Port Bitrate menu

and select it using the Rubber and Plastic Cycle button.

2. From the Serial Port Bitrate menu, use the Solid Instrument or Hollow or

Wrapped Instrument Cycle buttons to scroll down to 9600 and press the

Rubber and Plastic Cycle button to select and return to the User Setup

menu.

Setting the Printer user Character; (example: 134°C)

Printer User º Char

1. From the User Setup menu, use the Solid Instrument or Hollow or Wrapped

Instrument Cycle buttons to scroll to the Printer user ° char menu and select

it using the Rubber and Plastic Cycle button.

2. From the Printer user ° char menu, using the Solid Instrument cycle button

to increase the displayed value by one, and the Hollow or Wrapped

Instrument Cycle button to increase that value by ten, enter the value 32

[0x20] and press the Rubber and Plastic Cycle button to accept and return

to the User Setup menu.

Save and Exit

9600

32 [0x20]

Save and Exit

A Save and Exit must be performed after the above settings are completed. If

this is not done, the information will revert to its prior settings.

1. From the User Setup menu, use the Solid Instrument or Hollow or Wrapped

Instrument Cycle buttons to scroll to Save and Exit.

2. Select it by pressing the Rubber and Plastic Cycle button.

The LCD will display time

and date information and

a sequence of messages:

If the time and date need to be adjusted, refer to section 3.7, Setting The Time

and Date.

HH:MM DD/MM/YYYY

"MSD NOT DETECTED"/"INSERT

MSD/FLASH"/"SELECT A CYCLE"

26

Page 27

STAT IM 900J Operator’s Manual

7. The Communication Port

Step 2

Selecting the Time and Date

HH:MM DD/MM/YYYYTime/Date

Note: If the time and date were set according to section 3.7, this does not have

to be performed again.

1. Power up unit while pressing the MULTIFUNCTION button to access the

User Setup menu.

2. Using Solid Instrument or Hollow or Wrapped Instrument Cycle buttons,

scroll to Time / Date Setup and press the Rubber and Plastic Cycle button

to select it.

3. From the Time / Date Setup menu, set the time and date using the Solid

Instrument or Hollow or Wrapped Instrument Cycle buttons to change the

displayed values and the Rubber and Plastic Cycle button to select. Press

the MULTIFUNCTION button when completed to save your selection.

Step 3

Setting Unit ID

001UNIT ID

1. Power up unit while pressing the MULTIFUNCTION button to access the

User Setup menu.

2. Using the Solid Instrument or Hollow or Wrapped Instrument Cycle buttons,

scroll to the Unit ID Setup and press the Rubber and Plastic Cycle button to

select it.

3. From the Setup Unit ID menu, use the Solid Instrument or Hollow or

Wrapped Instrument Cycle buttons to Change the displayed values and the

Rubber and Plastic Cycle button to select and move to the next digit. Press

the MULTIFUNCTION button when completed to save your selection.

Step 4

Connecting the SciCan Data Logger

1. Ensure that both the Statim unit and the SciCan Data Logger are OFF.

2. Connect the SciCan Data Logger to the Statim unit by using the serial cable.

3. Power up the SciCan Data Logger

4. Power up the Statim unit.

5. The LCD will display the following

sequence of messages:

6. Insert USB Flash Drive or SD memory card

7. After a few seconds the LCD will display the

following sequence of messages:

27

HH:MM DD/MM/YYYY

"MSD NOT DETECTED"/"INSERT

MSD/FLASH"/"SELECT A CYCLE"

HH:MM DD/MM/YYYY

USB/FLASH DETECTED/SAFELY

REMOVE MSD/SELECT A CYCLE

Page 28

STAT IM 900J Operator’s Manual

7. The Communication Port

7.3 Cycle Printout

Overview

1. Model: STATIM 900J

software: SJ00R604

2. Unit Identifier: autoclave

has been set up as

number 000

3. Cycle counter: the number of

cycles having been run on the

unit = 6

4. Time / Date: 4:10 pm

Dec. 4, 2007

5. Cycle Name: SOLID

INSTRUMENT CYCLE

6. Cycle Name: Cycle name

parameters 134 C for 3.5 min.

7. Cycle clock: starting

at 0:00

8. Warm up complete:

start of the conditioning

phase is 1:35 (see cycle

graph – ‘A’ phase

complete, start of

‘B’ phase)

9. Start Time of Pressurization:

2:40 (start of ‘C’ phase)

10. Start Time of Sterilization:

3:14 (start of ‘D’ phase)

11. Temp. / Press. & Time at start

of sterilization (‘D’ phase).

12- 17 Cycle pararmeters at 30

second intervals.

18. Temp. Press. & Time of end

of sterilization phase (end of D

phase.)

19. Time venting start 6:44 (start

of E phase.)

20. Sterilization was successfully

completed.

1. Statim 900J SJ00R604

2. Unit # : OOO

3. CYCLE NUMBER 00006

4. 16:10 04/12/2007

5. SOLID INSTRUMENTS

6. 134 C for 3.5 min.

7. CYCLE START 0:00

8. CONDITIONING 1:35

9. PRESSURIZING 2:40

10. STERILIZING 3:14

11. 136.5 C 227kPa 3:14

12. 135.7 C 220kPa 3:44

13. 136.4 C 226kP a 4:14

14. 136.5 C 227kPa 4:44

15. 135.9 C 221kPa 5:14

16. 136.4 C 227kPa 5:44

17. 135.9 C 221kPa 6:14

18. 136.4 C 226kPa 6:44

19. VENTING 6:44

20. CYCLE COMPLETE 6:59

28

Page 29

STAT IM 900J Operator’s Manual

8. Limited Warranty

For a period of one year, SciCan Ltd. guarantees that the STATIM 900J, when

manufactured by SciCan Ltd. in new and unused condition, will not fail during

normal service due to defects in material and workmanship that are not due to

apparent abuse, misuse, or accident. In the event of failure due to such defects

during this period of time, the exclusive remedies shall be repair or replacement,

at SciCan Ltd.’s option and without charge, of any defected part(s) (except

gasket and filters), provided SciCan Ltd. is notified in writing within thirty(30)

days of the date of such a failure and further provided that the defective part(s)

are returned to SciCan Ltd. prepaid.

This warranty shall be considered to be validated, if the product is accompanied

by the original purchase invoice from the authorized SciCan Ltd. dealer, and

such invoice identifies the item by serial number and clearly states the date of

purchase. No other validation is acceptable. After one year, all SciCan Ltd.’s

warranties and other duties with respect to the quality of the product shall

be conclusively presumed to have been satisfied, all liability therefore shall

terminate, and no action or breach of any such warranty or duty may thereafter

be commenced against SciCan Ltd.

Any express warranty not provided hereon and any implied warranty or

representation as to performance, and any remedy for breach of contract which,

but for this provision might arise by implication, operation of law, custom of

trade or course of dealing, including any implied warranty of merchantability

or of fitness for particular purpose with respect to all and any products

manufactured by SciCan Ltd. is excluded and disclaimed by SciCan Ltd. If

you would like to learn more about SciCan Ltd. products and features, visit our

website at www.scican.com.

29

Page 30

STAT IM 900J Operator’s Manual

9. Statim 900J Specifications

Machine Dimensions Length 384 mm (15.1 inches)

Width 293 mm (11.5 inches)

Height 282 mm (11.1 inches)

Chamber Size Length 190 mm (7.5 inches)

Width 90 mm (3.54 inches)

Height 53 mm (2.1 inches)

Reservoir Capacity Usable volume: 3.0 litres (102 fl.oz.)

Weight (Without water) 13 Kg / 29 lbs

Maximum Operating Pressure 49.5

Power Consumption 100 V, 50 / 60 Hz, 1200 W

30

Page 31

STAT IM 900J Operator’s Manual

31

Loading...

Loading...