Page 1

Statim 7000

Field Training Manual

Page 2

Table of Contents

Table of Contents 2

Packaging & Accessories 3

Installation 4 – 6

User Setup 7 – 12

Service Setup 13 – 22

Cover Removal 23 – 25

Armature Removal 26

Rear Cover Removal 27

Chassis Parts 28 – 30

Cassette 31 – 33

Error Codes 34 – 38

Water Conductivity Circuit Calibration 39

Validation Thermocouple Calibration 40 – 41

2

Page 3

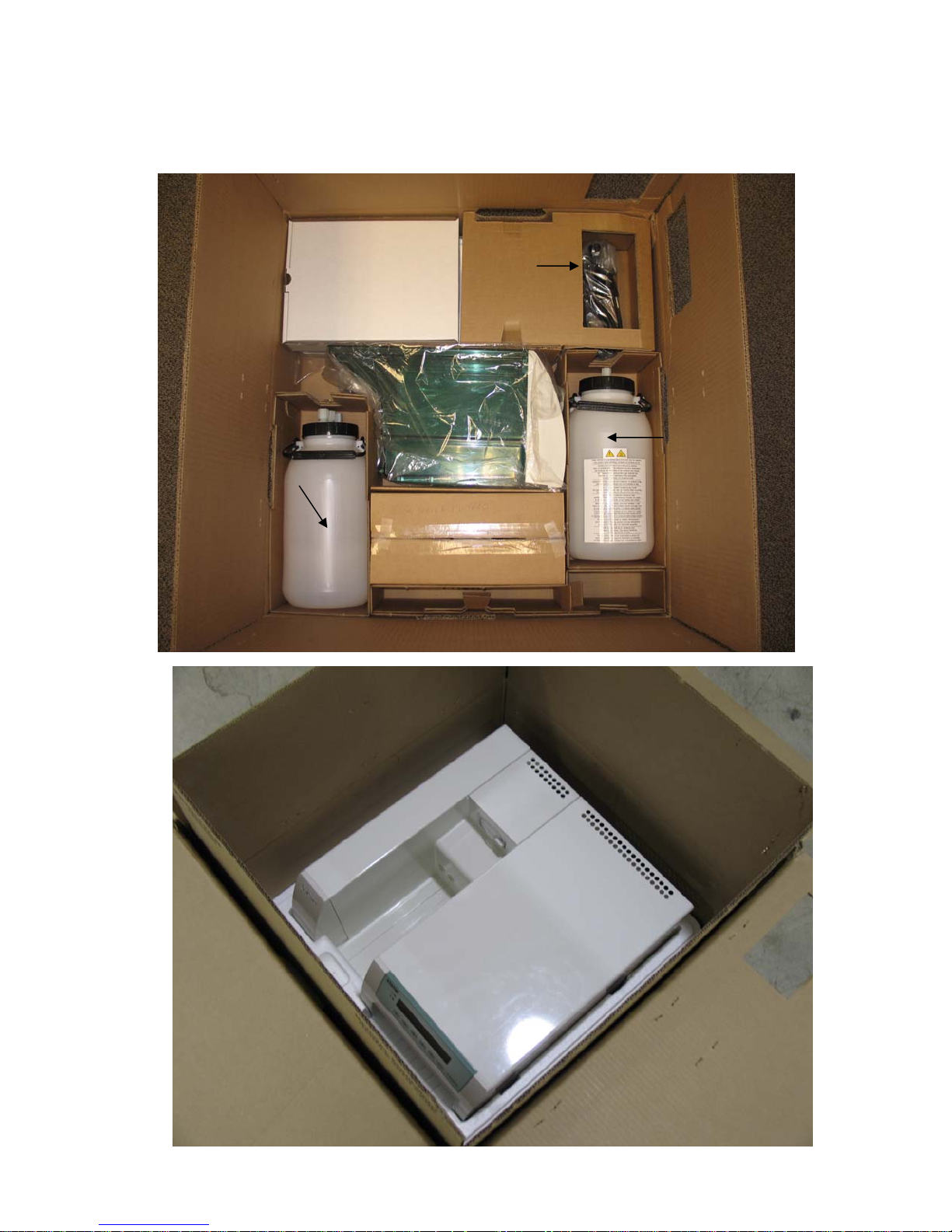

Packaging & Accessories

Exhaust Tubings

Stat-Dri Power Cord

Op Manual

O-ring Lube

Cassette (on bottom of box)

Condenser Bottle

Statim 7000

Water Reservoir

2 Water Filters

Waste Bottle

3

Page 4

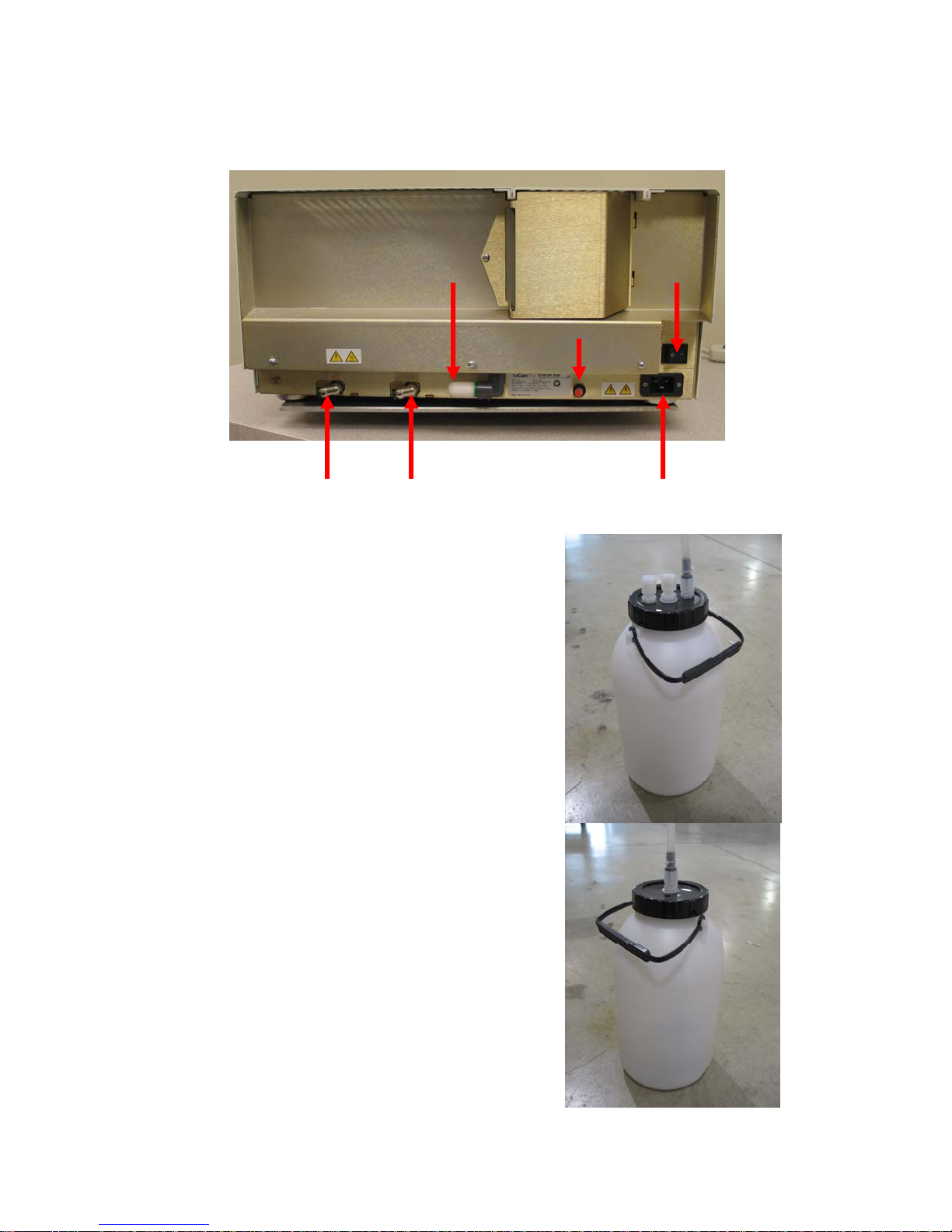

Statim 7000 Installation

Connect the Power Cord and the Exhaust Tubings to the rear of the Statim.

Push In Fitting Push In Fitting Power Cord Connection

Connect the Exhaust Tubings to the large fittings

on the Condenser Bottle & the small tubings to the

small fitting on the Condenser & Waste Bottles.

Drain Tube

Power Switch Air Filter

Condenser Bottle

Waste Bottle

4

Page 5

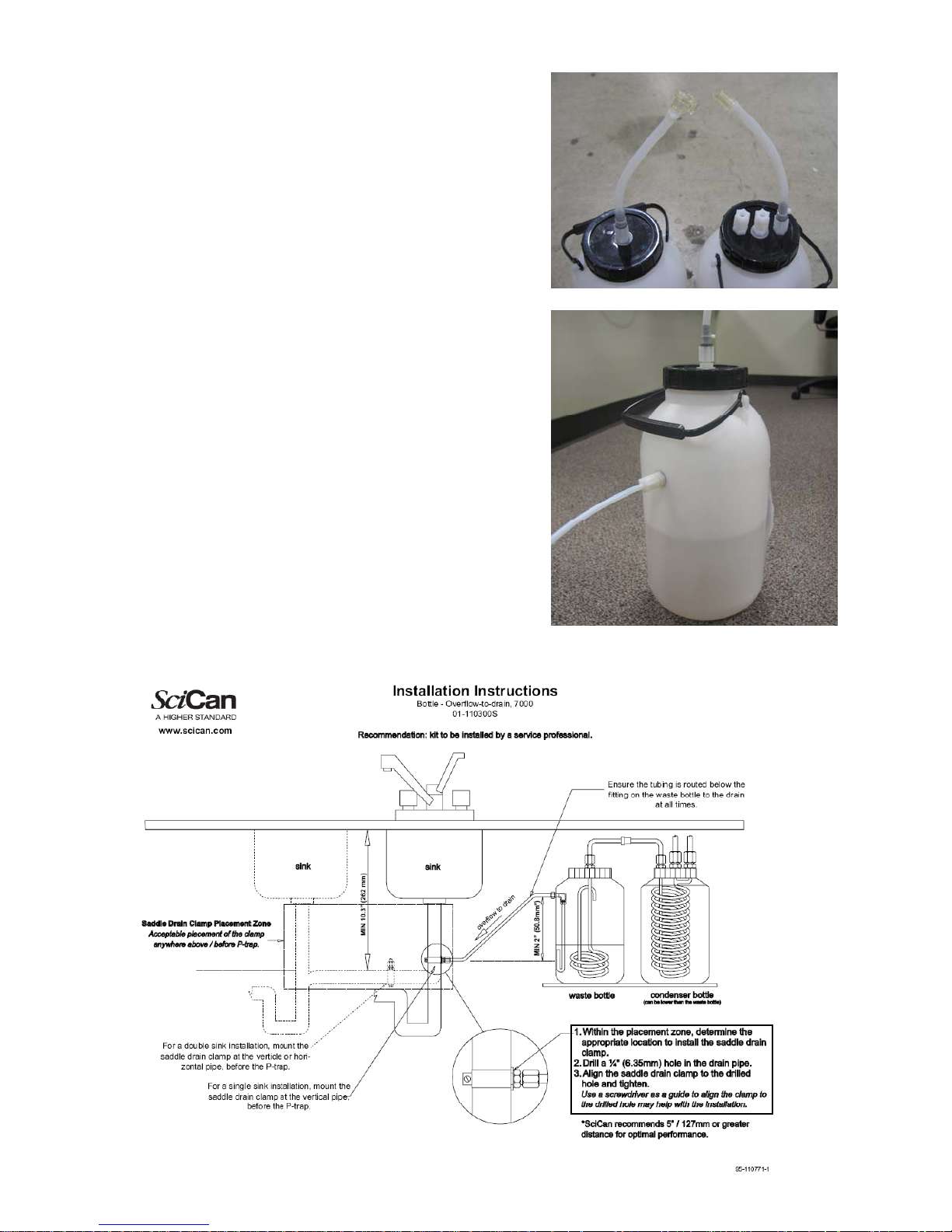

Connect bottle together using Quick Disconnect

Coupling.

Direct to Drain Waste Bottle

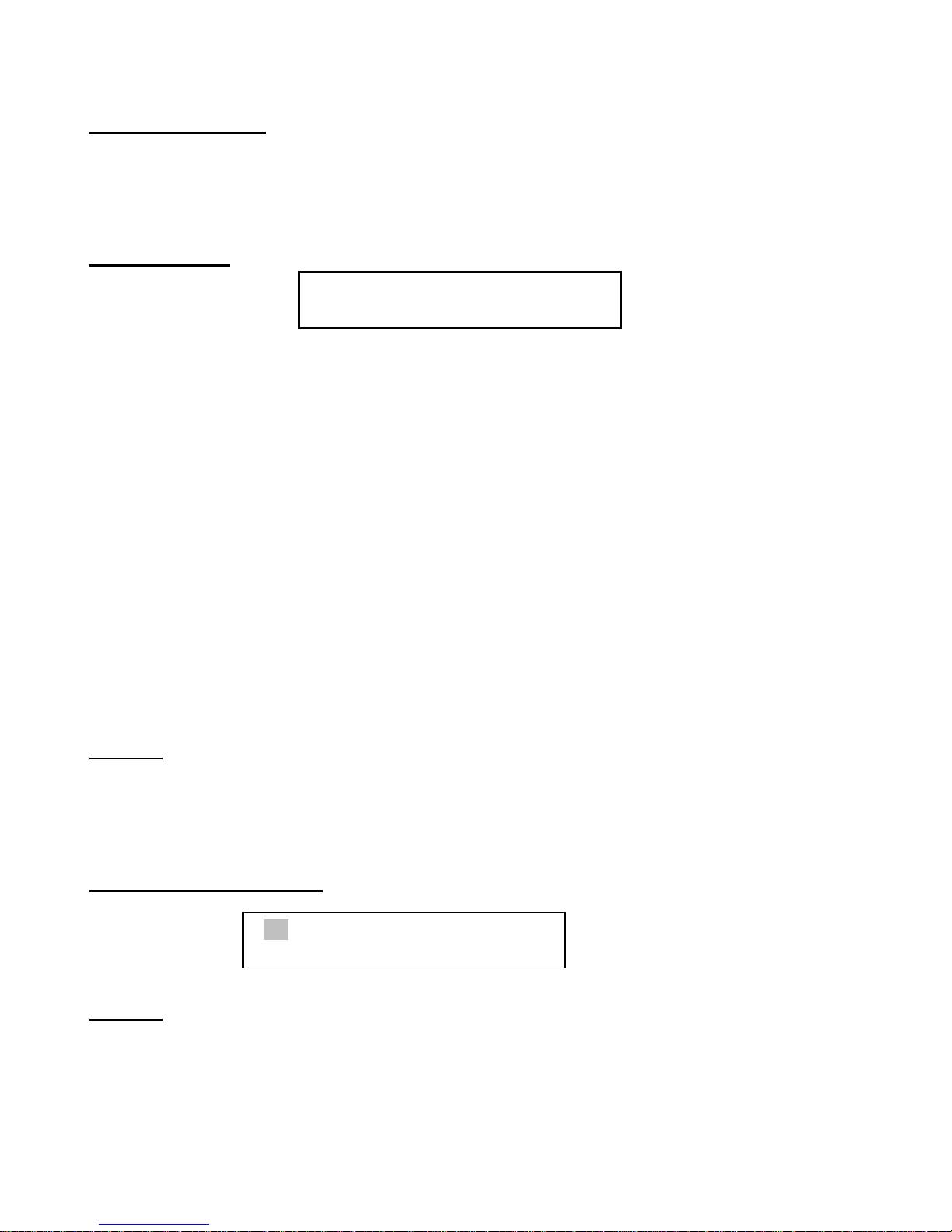

Direct to Drain Waste Bottle Installation Instructions

5

Page 6

Insert Water Filter or Bypass Cartridge.

Insert Water Reservoir

Note: The Biological Filter is accessible behind the Water Reservoir.

Biological Filter

6

Page 7

Statim 7000 User Setup

User setup mode – To initially setup your Statim

Hold down the Stop button and turn the unit ON.

If unit is already ON.

Hold down the Stop Button and the Air Dry Only Button simultaneously.

Initial Display

>Time/Date Setup

Language Setup

Unit ID Setup *

Drying – Unwrapped

Drying – Wrapped

Drying – R&P

Drying - Extra

Water Quality

Last Printout *

RS232 *

End of Line CR/LF *

Serial Port Bit rate *

Printer user º char *

Steri. End buzzer

Air Filter Warning

Water Filter

Replace Filter

Save and Exit

Exit

* Only used when Statim is connected to a Printer or Data Logger

Keypad:

Unwrapped Select next item in the menu

Wrapped Select previous item in the menu

Rubber and Plastics Enter the indicated sub menu selection

Stop Exit menu to normal mode of operation

Time/Date Setup Mode – Set the proper time and date

Keypad:

Unwrapped Increase current field (the flashing value on the display)

Wrapped Decrease current field (the flashing value on the display)

Rubber and Plastics Select next field

Stop Save & exit menu to normal mode of operation

18:00 04/10/2008

HH:MM MM/DD/YYYY

7

Page 8

Language Setup – Display information in your desired language

N. A. ENGLISH

Available Languages

N. A. English (North American English)

U. K. English (United Kingdom English)

Francais (French)

Deutsch (German)

Espanol (Spanish)

Italiano (Italian)

Dansk (Danish)

Portugues

Nederlands

Japanese

Svenska (Swedish)

Polski (Polish)

Magyar (Hungarian)

Cesky (Czech)

Norsk (Norwegian)

Islenska (Iceland)

Slovencina (Slovak)

Eesti (Estonian)

Lietuviu K. (Lithuanian)

Slovenian (Slovenia)

Romana (Romanian)

Keypad:

Unwrapped Select next language

Wrapped Select previous language

Stop Save & exit menu to normal mode of operation

Unit ID Setup – Associate unit with an ID number (Used with Printer)

Keypad:

Unwrapped Decrease current field (the flashing value on the display)

Wrapped Increase current field (the flashing value on the display)

Rubber and Plastics Select next digit

Stop Save & exit menu to normal mode of operation

Unit # :

000

8

Page 9

Drying – Unwrapped – Set Unwrapped Cycle drying time between 0 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying - Unwrapped

Time: 12 minutes

Drying – Wrapped – Set Wrapped Cycle drying time between 10 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying - Wrapped

Time: 12 minutes

Drying – R&P – Set Rubber & Plastics Cycle drying time between 0 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying – R&P

Time: 12 minutes

Drying – Extra – Sets drying time between 1 & 30 minutes for Air Dryer Only Cycle

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying – Extra

Time: 12 minutes

9

Page 10

Water Quality – Display detected water quality

>Water quality

CD= x.xuS/NNN/y.yppm

Screen Representation

x.x Water conductivity in uS (micro-Siemens)

NNN Water conductivity in ADC (Analog to Digital converter) counts (0…255)

y.y Water quality in ppm (parts per million)

Keypad:

Rubber and Plastics Return to main menu

Stop Exit menu to normal mode of operation

Last Printout – Printer reprints last cycle and unit returns to normal mode of operation

(Used with Printer)

RS232 – To select which serial device to attach (Used with Printer)

Serial Printer

Keypad:

Unwrapped Move to next option, second line shows the new value

Wrapped Move to previous option, second line shows the new value

Rubber and Plastics Save and return to main menu

Stop Exit menu to normal mode of operation without saving

>RS232

N/A

USB FLASH/MSD

End of Line CR/LF – Configure the printout layout (Used with Printer)

Available options:

- No line terminator is sent after each line. To be used with printer that accepts only

CR A <CR> is sent at the end of the line. To be used with printers that advance to

CR/LF A <CR><LF> is sent at the end of the line. To be used with printers that translate

Keypad:

Unwrapped Select next option. Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Save & exit to main menu

Stop Exit and return to normal mode of operation

>End Of Line CR/LF

CR/LF

CR

This only needs to be set if a serial printer is attached to the serial port.

20 characters per line and automatically advances to next line. Should be used

with the STATprinter.

beginning of next line when a CR is received.

advance to beginning of next line only when LF is received.

10

Page 11

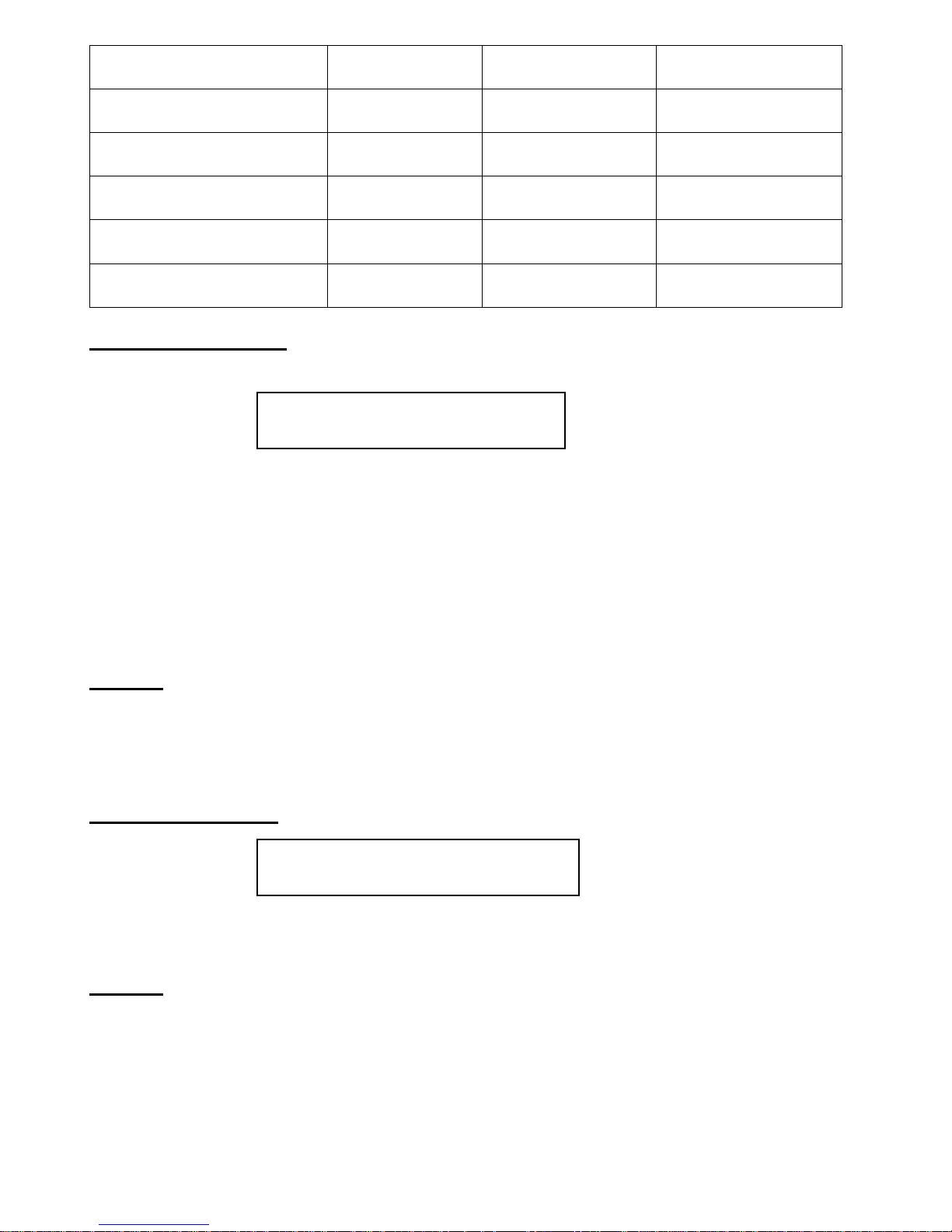

SciCan Suggested

[

External Printers

Epson

End Of Line

CR/LF

Serial Port Bit

Rate

Printer user ° char

CR/LF 9600 248 [0xF8]

TM-U220D (C31C515603)

Citizen

CR 9600 N/A

IDP-3110-40 RF 120B

Star Micro

CR 9600 210 [0xd2]

SP212FD42-120

Star Micro

CR/LF 9600 210 [0xd2]

SP216FD41-120

Star Micro

CR/LF 9600 210 [0xd2]

SP512MD42-R

Serial Port Bit Rate – Choose bit rate for device connected to the serial port

(Used with Printer)

Serial Port Bit Rate

9600

19200

57600

115200

1200

2400

4800

If USB FLASH/MSD is selected as the RS232 device, a Serial Port Bit Rate selection of 9600 will

be required for the Data Logger to be operational.

Keypad:

Unwrapped Select next value

Wrapped Select previous value

Rubber and Plastics Save & Return to main menu

Stop Exit without saving and return to normal mode of operation

Printer user ° char – Setting to print a °C sign (Used with Printer)

32 decimal value for selected char-default 32

20 hex value for the selected char-default 20

Keypad:

Unwrapped Increase value by one

Wrapped Increase value by ten

Rubber and Plastics Select and return to main menu

Stop Exit without saving and return to normal mode of operation

Printer user ° char

0x20]

32

11

Page 12

Steri. End buzzer – Set length of time buzzer will sound a end of sterilization

15s

30s

Max

Keypad:

Unwrapped Select next value

Wrapped Select previous value

Rubber and Plastics Save & Return to main menu

Stop Save & exit menu to normal mode of operation

>Steri. End buzzer

0s

Air Filter Warning – Reset warning indicator when Air Filter is replaced.

Yes, Reset

>Air Filter Warning

Do not Reset

Water Filter – Set Statim for Water Filter or Water Bypass Cartridge

Not Installed

>Water Filter

Installed

Replace Filter – Reset Statim when Water Filter is replaced.

Yes, replace

>Replace Filter

Do not replace

Save and Exit

Upon selection, current settings are saved and unit restarts in normal mode of operation

– Saving settings and return to normal mode of operation

Exit – Exit menu without saving settings

Upon selection, current settings are discarded, not saved and unit restarts in normal mode of

operation

12

Page 13

Statim 7000 Service Setup

Service setup mode – To enter the Service Setup Mode, turn power switch ON while

holding down Unwrapped and Wrapped buttons.

The Service Setup Mode is password protected; a password must be entered to continue. The

default password is Unwrapped, Wrapped, Rubber and Plastics, Stop buttons pressed in this

order. If the password has been changed the backdoor password is, Unwrapped, Wrapped,

Unwrapped, Wrapped buttons pressed in this order.

* Only used when Statim is connected to a Printer or Data Logger

Keypad:

Unwrapped Select next item in the menu

Wrapped Select previous item in the menu

Rubber and Plastics Enter the indicated sub menu selection

Stop Exit menu to normal mode of operation

>Calibration

Time/Date Setup

Language Setup

Unit ID Setup *

Set cycle counter

Conductivity Setup

Water.Cnd Tmp. Comp

Last Printout *

Stored CF Printouts *

Clear CF Printouts *

Display last CF#

Devices Test On/Off

Temperature Offset

Validation Offset

Repeater mode

RS232 *

End of Line CR/LF *

Serial Port Bitrate *

Printer user º char *

Factory default

Drying – Unwrapped

Drying – Wrapped

Drying – R&P

Drying - Extra

Air Filter Warning

Water Filter

Replace Filter

Steri. End buzzer

Upgrade Firmware

Change Password

Backup NVRAM

Restore NVRAM

Save and Exit

Exit

Production Cycle

13

Page 14

Calibration – Select calibration to run chamber and validation thermocouple calibration cycles

only.

Note: See page 38 for validation thermocouple calibration procedure.

Time/Date Setup Mode – Set the proper time and date

Keypad:

Unwrapped Increase current field (the flashing value on the display)

Wrapped Decrease current field (the flashing value on the display)

Rubber and Plastics Select next field

Stop Save & exit menu to normal mode of operation

18:00 07/09/2008

HH:MM MM/DD/YYYY

Language Setup – Display information in your desired language

Available Languages

N. A. English (North American English)

U. K. English (United Kingdom English)

Francais (French)

Deutsch (German)

Espanol (Spanish)

Italiano (Italian)

Dansk (Danish)

Portugues

Nederlands

Japanese

Svenska (Swedish)

Polski (Polish)

Magyar (Hungarian)

Cesky (Czech)

Norsk (Norwegian)

Islenska (Iceland)

Slovencina (Slovak)

Eesti (Estonian)

Lietuviu K. (Lativan)

Keypad:

Unwrapped Select next language

Wrapped Select previous language

Rubber and Plastics If Repeater mode is ON, this key will scroll through all the available

Stop Save & exit menu to normal mode of operation

N. A. ENGLISH

Slovenian (Slovenia)

Romana (Romanian)

display messages of the chosen language.

14

Page 15

Unit ID Setup – Associate unit with an ID number (Used with Printer)

Unit # :

000

Keypad:

Unwrapped Decrease current field (the flashing value on the display)

Wrapped Increase current field (the flashing value on the display)

Rubber and Plastics Select next digit

Stop Save & exit menu to normal mode of operation

Set cycle counter – Adjust the recorded number of cycles ran

Cycle Number

000000

Keypad:

Unwrapped Decrease current digit

Wrapped Increase current digit

Rubber and Plastics Select next digit

Stop Save & exit menu to normal mode of operation

Conductivity Setup – To display detected water quality and adjust low and high thresholds.

CD= x.xuS/NNN/y.yppm

L R H=HH.H G=G.GG

Screen Representation

x.x Water conductivity in uS (micro-Siemens)

NNN Water conductivity in ADC (Analog to Digital converter) counts (0…255)

y.y Water quality in ppm (parts per million)

L “L” is displayed when water level switch is activated, "-" when the switch is

R “R” is displayed when water reservoir reed switch is activated, "-" when the

HH.H High value threshold (Bad water threshold) default 10uS

Values larger than this trigger “Bad water quality” error

G.GG Water conductivity circuit gain default 1.00

Note: Statim 7000 does not use the conductivity reading to trigger the “No Water, Refill

Reservoir” message. There is a float sensor for that.

Keypad:

Unwrapped Increase current field

Wrapped Decrease current field

Rubber and Plastics Move to next field

Stop Exit menu to normal mode of operation

Note: To perform Water Conductivity Circuit Calibration see page 37.

not active

water reservoir reed switch is not activated.

15

Page 16

Water Cnd Tmp Comp - To enable or disable water conductivity temperature compensation

Off

Keypad:

Unwrapped Select next option Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, to normal mode of operation

>Water Cnd Tmp Comp

On

Last Printout – Printer reprints last cycle and unit returns to normal mode of operation

(Used with Printer)

Stored CF Printouts – Printer prints saved cycle fault printouts and unit returns to normal

mode of operation. (Used with Printer)

The saved CF printouts are sent to the printer or data logger only when either one is attached and

configured. The following types of errors are saved:

CF’s

Water quality or Water level low errors

Cycle interrupted due to errors (##)

Clear CF Printouts – Reset Cycle Fault printout list (Used with Printer)

Yes

Keypad:

Unwrapped Select next option Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, to normal mode of operation

>Clear CF Printouts

No

Display last CF# - Show the last Cycle Fault that occurred

Screen Representation

## Last recorded CF number

(######) Cycle counter number for last CF

Keypad:

Rubber and Plastics Return to main menu

Stop Exit to normal mode of operation

>Display last CF#

## (######)

16

Page 17

Devices Test On/Off – Toggle the unit’s devices on or off

>Devices Test On/Off

Pump Off

Valve Off

Compressor Off

Yellow LED Off

Extra 1L Off

Extra 2L Off

Valve 2 Off

Fan Off

Keypad:

Unwrapped Select next option. Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Toggle On/Off selected device

Stop Return to main menu

Chamber Temperature Offset – View the offset of the chamber thermocouple

>Temperature Offset

##

Screen Representation

## Offset value

Keypad:

Rubber and Plastics Return to main menu

Stop Exit to normal mode of operation

Validation Offset – View the offset of the validation thermocouple

Screen Representation

>Validation Offset

##

## Offset value

Keypad:

Rubber and Plastics Return to main menu

Stop Exit to normal mode of operation

Repeater mode – Enable or disable unit to run cycles continuously

On

Keypad:

Unwrapped Select next option. Second line shows new value

Wrapped Select previous option. Second line shows new value

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, to normal mode of operation

>Repeater mode

Off

17

Page 18

RS232 – To select which serial device to attach (Used with Printer)

>RS232

N/A

Serial Printer

USB FLASH/MSD

Keypad:

Unwrapped Move to next option, second line shows the new value

Wrapped Move to previous option, second line shows the new value

Rubber and Plastics Save and return to main menu

Stop Exit menu to normal mode of operation without saving

End of Line CR/LF – Configure the printout layout (Used with Printer)

This only needs to be set if a serial printer is attached to the serial port.

Available options:

- No line terminator is sent after each line. To be used with printer that accepts only

20 characters per line and automatically advances to next line. Should be used

with the STATprinter.

CR A <CR> is sent at the end of the line. To be used with printers that advance to

beginning of next line when a CR is received.

CR/LF A <CR><LF> is sent at the end of the line. To be used with printers that translate

advance to beginning of next line only when LF is received.

Keypad:

Unwrapped Select next option. Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Save & exit to main menu

Stop Exit and return to normal mode of operation

SciCan Suggested

External Printers

Epson

TM-U220D (C31C515603)

Citizen

IDP-3110-40 RF 120B

Star Micro

SP212FD42-120

Star Micro

SP216FD41-120

Star Micro

SP512MD42-R

>End Of Line CR/LF

CR/LF

CR

End Of Line

CR/LF

CR/LF 9600 248 [0xF8]

CR 9600 N/A

CR 9600 210 [0xd2]

CR/LF 9600 210 [0xd2]

CR/LF 9600 210 [0xd2]

Serial Port Bit

Rate

Printer user ° char

18

Page 19

Serial Port Bit Rate – Choose bit rate for device connected to the serial port

(Used with Printer)

If USB FLASH/MSD is selected as the RS232 device, a Serial Port Bit Rate selection of 9600 will

be required for the Data Logger to be operational.

Keypad:

Unwrapped Select next value

Wrapped Select previous value

Rubber and Plastics Save & return to main menu

Stop Exit, without saving, and return to normal mode of operation

Serial Port Bit Rate

9600

19200

57600

115200

1200

2400

4800

Printer user ° char – Setting to print a °C sign (Used with Printer)

dd decimal value for selected char-default 32

hh hex value for the selected char-default 20

Keypad:

Unwrapped Increase value by one

Wrapped Increase value by ten

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, and return to normal mode of operation

Printer user ° char

dd [0xhh]

Factory default – Reset to factory default settings

Yes, Reset NVRAM!

This function resets the NVRAM to factory default settings. The chamber and voltage calibration

offsets and conductivity settings will be reset. The cycle counter will not be reset.

Keypad:

Unwrapped Select next option. Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Save and return to main menu

Stop Exit, without saving, and return to normal mode of operation

>Factory default

No

19

Page 20

Drying – Unwrapped – Set Unwrapped Cycle drying time between 0 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying - Unwrapped

Time: 12 minutes

Drying – Wrapped – Set Wrapped Cycle drying time between 10 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying - Wrapped

Time: 12 minutes

Drying – R&P – Set Rubber & Plastics Cycle drying time between 0 & 30 minutes

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying – R&P

Time: 12 minutes

Drying – Extra – Sets drying time between 1 & 30 minutes for Air Dryer Only Cycle

Keypad:

Unwrapped Increase time by one minute

Wrapped Decrease time by one minute

Rubber and Plastics Save and return to main menu

Stop Save & exit menu to normal mode of operation

>Drying – Extra

Time: 12 minutes

20

Page 21

Air Filter Warning – Reset warning indicator when Air Filter is replaced.

>Air Filter Warning

Do not Reset

Yes, Reset

Water Filter – Set Statim for Water Filter or Water Bypass Cartridge

>Water Filter

Installed

Not Installed

Replace Filter – Reset Statim when Water Filter is replaced.

>Replace Filter

Do not replace

Yes, replace

Steri. End buzzer – Set length of time buzzer will sound a end of sterilization

15s

30s

Max

>Steri. End buzzer

0s

Upgrade Firmware – Not used at this time.

Change Password – Change the password required to access the service menu

The unit will query for a 4 key password

Type New Password

****

The unit will require that the user re-enter the same 4 key password

Type New Password

****

The unit will confirm that the password has been changed or if changing the

password failed, the unit will again query for a new 4 key password

Password Changed

In case the changed password is lost a backdoor password can be used: Unwrapped, Wrapped,

Unwrapped, Wrapped in this order.

21

Page 22

Backup NVRAM – Saves a copy of the unit’s current settings

Yes

Keypad:

Unwrapped Select next option Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, to normal mode of operation

>Backup NVRAM

No

Restore NVRAM – Restores the previously saved unit settings into the NVRAM

Yes

Keypad:

Unwrapped Select next option Second line shows the new value

Wrapped Select previous option. Second line shows the new value

Rubber and Plastics Select and return to main menu

Stop Exit, without saving, to normal mode of operation

>Restore NVRAM

No

Save and Exit – Saving settings and return to normal mode of operation

Upon selection, current settings are saved and unit restarts in normal mode of operation

Exit – Exit menu without saving settings

Upon selection, current settings are discarded, not saved and unit restarts in normal mode of

operation

Production Cycle – For manufacturing use only

22

Page 23

1. With the unit off, unplug the power

cord from the wall outlet and remove

the cassette and reservoir from the

unit.

Statim 7000 Cover Removal

2. Remove the water filter or water bypass

cartridge (if the unit is using distilled

water) from the reservoir area.

3. Remove the eight screws across the

bottom front of the unit using a Philips

screw driver.

4. Push the cover forward from the back

a little to loosen it, until it stops.

5. Detach the LCD/keypad by reaching

up inside the cover through the

armature opening to feel for a plastic

tab located directly behind the Rubber

and Plastics key.

23

Page 24

6. Push this tab to the left to unlock the

LCD/keypad from the cover.

7. Place the LCD/keypad on top of the

armature so that it is out of the way

as you remove the cover.

8. Release the cover retention clip by

reaching inside the cover though the

LCD opening and lift up on the tap

located on the left most side of the

opening. Slide cover forward.

24

Page 25

9. Push the cover all the way forward to

slide it off from the front.

10. To replace the cover. Place the cover

back on to the unit about 1 inch away

from the back. Once the chassis hooks

engage with the cover, push the cover

towards the back until the back of the

cover is in line with the back of the

chassis

11. Replace the LCD panel

12. Insert the 8 screws that were originally

removed.

25

Page 26

Armature Removal

Removed 2 screws in lower left and right corners

of Armature and loosen alignment screw in top

center of Armature.

Armature is mounted on 2 rails which will allow

the Armature to slide easily. Slide Armature

forward and remove using two hands. There are

no connections to the Armature.

Armature Screw

Armature Alignment Screw

Armature Screw

26

Page 27

Rear Cover Removal

Remove 3 screws from bottom of rear cover.

Remove 3 screws from top of rear cover.

Disconnect black and white wires from Fan

Disconnect Biological Filter Tubings

Biological Filter Tubings

Screw Screw

Screw Screw

Fan Wires

Screw

Screw

27

Page 28

Statim 7000 Chassis Parts

Thermocouple Validation

Reservoir Inlet

01-110493S

01-110515S

Armature Microswitch

Biological Filter

01-102119S

Armature

01-110496S

01-110502S

PCB RFID Board

01-110483S

28

Page 29

Reservoir Inlet Assembly

01-110493S

Water Filter Ports

Water Reservoir Port

Sensor Reservoir

01-110492S

Compressor

01-110478S

Pump

01-110471S

29

Page 30

Solenoid Chamber

Valve 2

01-110527S

Push In Fitting

01-110503S

Plug Drain Tubing

Auxiliary Heater

01-104343S

01-110474S

Solenoid Validation

Valve 1

01-110528S

Line Filter

01-110505S

Boiler

01-110472S

Air Filter

01-101652S

Power Switch

01-110504S

30

Page 31

Perforated Rack

Statim 7000 Cassette

Steam Deflector

Outlet Coupling O-Ring Seals

Exhaust Duct

Exhaust Duct Screen

Outlet Coupling

Inlet Coupling

Inlet Coupling O-Ring Seals

31

Page 32

Cassette Complete 7000 Internal Dimensions:

Part #01-110288S 13.7" x 8.6" x 2.5"

Cassette Lid 7000

Part #01-110290S

Cassette Tray 7000

Part #01-110289S

Cassette Lid Handle

Part #01-110329S

Cassette Tray Handle

Part #01-110330S

Cassette Seal Kit (not shown)

Part #01-110327S

Cassette Inlet Coupling

Part #01-110291S

Cassette Outlet Coupling

Part #01-110292S

Cassette Coupling Seal Kit

Part #01-110296S

(Includes o-rings & gaskets for both couplings)

Cassette Perforated Rack

Part #01-110294S

Cassette Lid

Cassette Tray

Cassette Lid

Handle

Cassette Tray

Handle

Inlet Coupling

Outlet Coupling

Cassette Perforated

Rack

32

Page 33

Cassette Tray Exhaust Duct

Part #01-110297S

Cassette Steam Deflector

Part #01-110825S

Filter Exhaust Duct Insert

Part #01-106848S

Cassette Steam Deflector Clip

Part #01-110824S

Cassette Tray

Exhaust Duct

Cassette Steam

Deflector

Filter Exhaust

Duct Insert

Cassette Steam

Deflector Clip

33

Page 34

Statim 7000 Error Codes

Cycle Fault

Number

Cycle Fault #1 The Cassette temperature

Cycle Fault #3 The Cassette has failed to

Cycle Fault #4 The Cassette has failed to

Cycle Fault #6 The software has detected a

Cycle Fault #7 If chamber temperature drops

Cycle Fault #8 The software has detected a

Cycle Fault #10 The cassette temperature has

Cycle Fault #11 The cassette temperature has

Cycle Fault #12 This indicates a problem with

Description of Fault Suggested steps for Correction of Fault

failed to reach 95°C within a

time-out period.

pressurize and achieve a

temperature of 110°C within a

time-out period.

achieve sterilization

conditions within a timeout

period of the chamber first

reaching 110°C.

Validation Thermocouple

temperature 5°C greater than

the chamber during the

sterilizing phase of a cycle.

below the sterilization

temperature (134°/121°C) by

more than 3°C, CF 7 is

posted.

Validation Thermocouple

temperature 5° less than the

chamber during the sterilizing

phase of the cycle.

failed to drop to 115°C during

the Unwrapped or Wrapped

Cycle or 110°C during the

Rubber and Plastics Cycle in

the purge conditioning stage.

failed to drop to 102°C within

a timeout period during the

venting cycle.

the temperature measuring

system.

May be caused by a large cassette leak in

conjunction with an extremely large load or

a blown Thermal Fuse caused by weak

water pump delivery.

May be caused by a faulty Cassette Seal,

a damaged Cassette, or a faulty Solenoid

Valve (failed to close).

May be caused by a faulty Cassette Seal,

a damaged Cassette, or a faulty Solenoid

Valve (failed to close).

Check for kinked or pinched exhaust tubing

and for visible steam leaks from the

Cassette Seal, Lid or Tray. Check the

exhaust Solenoid Valves and make sure

the plunger is not sticking. Recalibrate

Validation Thermocouple.

May be caused by a faulty Cassette Seal,

a damaged Cassette, a faulty Solenoid

Valve (failed to close), a leaky Pressure

Relief Valve or a leaky Check Valve.

Check for a clogged Filter Screen in the

Exhaust Duct in the Cassette Tray. Check

the Solenoid Valves for debris and make

sure the plunger is not sticking. Recalibrate

the Validation Thermocouple.

Check for a clogged Filter Screen in the

Exhaust Duct in the Cassette Tray, a

kinked or pinched Exhaust Tubing from

center elbow fitting or a faulty Solenoid

Valve (failed to open).

Check for a clogged Filter Screen in the

Exhaust Duct in the Cassette Tray, a

kinked or pinched Exhaust Tubing from

center elbow fitting or a faulty Solenoid

Valve (failed to open).

Check for a disconnected, broken or faulty

thermocouple lead or a defective PCB.

34

Page 35

Cycle Fault #14 The steam temperature

raised above the high

threshold.

Cycle Fault #15 The cassette temperature

raised above the high

threshold during the

sterilization phase of the

cycle or above 138.6°C

during conditioning or

pressurizing phase of the

cycle.

Cycle Fault #16 The Boiler temperature

went above a threshold

value.

Cycle Fault #17 Auxiliary Heater

overheated.

Cycle Fault #18 Ambient temperature to

high.

Cycle Fault #19 The Validation

Thermocouple calibration is

invalid.

Cycle Fault #20 The cassette temperature

raised above 138.6°C

during the Drying phase of a

cycle.

Cycle Fault #25 The software has failed to

detect a need to pump

water within 90 seconds of

the state of a cycle.

Check for faulty PCB or defective Solid

State Relay.

Check for a clogged Filter Screen in the

Exhaust Duct in the Cassette Tray, a

kinked or pinched Exhaust Tubing from

center elbow fitting or a faulty Solenoid

Valve (failed to open).

Replace Water Filter

Check for a weak Water Pump or a faulty

PCB causing constant power to the Boiler.

Check for a faulty Auxiliary Heater, a

defective Solid State Relay or PCB.

Ambient temperature (as sensed by the

PCB cold junction temperature sensor)

increased over a preset threshold. This

may be caused by a failed cool down fan, a

failed Auxiliary Heater PCB or a defective

main PCB.

This occurs when a new PCB or

Microprocessor is installed. This may also

happen when the unit has been subjected

to a strong static discharge corrupting the

memory. Calibrate the Validation

Thermocouple.

Check for a clogged Filter Screen in the

Exhaust Duct in the Cassette Tray, a

kinked or pinched Exhaust Tubing leading

to the Condenser Bottle or a faulty

Solenoid Valve (failed to open). A faulty

Auxiliary Heater, Auxiliary Heater PCB or

Solid State Relay.

Check for a blown Thermal Fuse caused

by a weak Water Pump, constant power to

the Water Pump caused by a defective

PCB or a faulty Boiler.

35

Page 36

Cycle Fault #26 The sterilization phase has

failed to start within 3

minutes of the cassette

reaching sterilization

temperature.

CF26 is displayed when it

occurred in 3 consecutive

cycles (Cycle Interrupted is

displayed for the first two

cycles). CF26 counter is

reset whenever a

successful cycle is

completed.

Cycle Fault #27 The temperature of the

Boiler failed to drop below a

set-point temperature

(150°C) in a timeout period.

Cycle Fault #32 No water pumped to the

boiler while executing the

Water Filter priming.

Cycle Fault #79 Error in communication with

the RFID adapter or

Cassette Seal RFID tag.

Cycle Fault #80 Auxiliary Heater heating

element did not reach a

target temperature in a

specified period of time.

Cycle Fault #81 Auxiliary Heater

superheated steam did not

reach a target temperature

in a specified period of time.

Cycle Fault #82 Unit failed to cool down in a

specified period of time.

Cycle Fault #90 Corrupted or not initialized

chamber calibration value.

Cycle Fault #98 Main PCB not

communicating with

Auxiliary Heater PCB.

May be caused by improper Validation

Thermocouple calibration, weak Water

Pump or faulty Solenoid Valve.

May be caused by a weak Water Pump, a

defective float switch (does not detect

insufficient water in the water reservoir) or

a faulty Boiler.

May be leaking Water Filter, leaking Water

Reservoir connection or faulty Water

Pump.

Make sure cassette is completely inserted

and try another cycle.

May be defective Cassette Seal or RFID

adapter.

Check fuses on Auxiliary Heater PCB

May be a defective Auxiliary Heater,

Auxiliary Heater PCB, Solid State Relay or

main PCB.

Check to see that Biological Filter is

installed correctly.

Check fuses on Auxiliary Heater PCB

May be a defective Auxiliary Heater,

Auxiliary Heater PCB, Solid State Relay or

main PCB.

May be a defective Auxiliary Heater,

Auxiliary Heater PCB, Solid State Relay,

main PCB or Compressor.

This occurs when a new PCB or

Microprocessor is installed. This may also

happen when the unit has been subjected

to a strong static discharge corrupting the

memory. Unit requires chamber calibration.

May be Microprocessor not installed

properly, defective main PCB or Auxiliary

Heater PCB.

36

Page 37

“No

Configuration

EEPROM”

Message: Printer

No communication between

EEPROM and

Microprocessor.

Printer is not printing. Check for paper jam or defective Printer.

Fault (if optional

printer is

installed)

“Cycle Aborted” This error message is

displayed on the printout

only, followed by the

message “Not Sterile”, as a

result of the operator

pressing the STOP button

to stop the cycle or as a

result of any other abnormal

cycle termination, including

Cycle Fault errors.

“Stop Button

Pressed”

The operator pressed the

STOP button to stop the

cycle. The LCD shows the

message “Not Sterile”.

“ Cycle

Interrupted”

This message is displayed

when the sterilization phase

has failed to start within 3

minutes of the cassette

reaching the sterilization

temperature. If it occurs in 3

consecutive cycles CF26 is

displayed. Also this

message is generated if a

bad water conductivity or no

water condition was

detected for a while before

water conductivity level

turns back to normal. Also

this message is displayed if

the unit lost power before

the cycle ended.

May be Microprocessor or EEPROM not

installed properly. Replace Microprocessor

kit.

Check for loose Power Cord connection at

the back of the Statim and at the wall

outlet.

Check for low water level in the Water

Reservoir.

Go to User Menu and check the water

quality.

If CF 26 appears run a Validation

Thermocouple calibration.

37

Page 38

“Press Stop To

Reset”

“Order Water

Filter Expiring

Soon”

“Water Filter

Expired Replace

Water Filter”

“Refill

Reservoir/Empty

Waste Bottle”

“LUBRICATE

CASSETTE

COUPLING

O-RINGS”

This message is displayed

for all error faults. The user

must press the Stop button

on the keypad to reset the

unit: otherwise the user will

be unable to initiate another

cycle.

This message is displayed

when the water quality

reaches 8uS or the filter is

within 6 days of the average

usage time for this unit.

This message appears

when the Water Filter has

been in use for 60 days or

water quality is above 10uS.

The Water Filter must be

replaced otherwise the user

will be unable to initiate

another cycle.

This message appears

when the Water Reservoir is

low on water or the Water

Filter is clogged.

This message appears

every 250 cycles.

Order Water Filter Cartridge part #SCWF1

(single cartridge) or part #SCWF6

(package of 6 cartridges). Replace Water

Filter Cartridge when Water Filter Expired

message appears.

Replace Water Filter Cartridge part#

SCWF1 (single cartridge) or SCWF6

(package of 6 cartridges)

Check to see that the Water Reservoir is

full.

Go to Device Test and run the Water Pump

for 5 to 10 seconds.

Replace the Water Filter.

Check Float Switch.

Used Q-Tips & Lubricant provided with

Statim and replacement seals to lubricate

o-rings.

38

Page 39

Statim 7000

Water Conductivity Circuit Calibration

1. Disconnect conductivity sensor wires (J4-3 & J4-4).

2. Using a wire, short together the float pins (J4-5 & J4-6).

3. Turn power switch ON while holding down Unwrapped and Wrapped buttons to enter

Service Mode.

4. The Service Mode is password protected, enter password to continue, default

password is: Unwrapped, Wrapped, Rubber and Plastics and Stop buttons pressed in

this order.

Keypad function at this time:

Unwrapped Key: Select next item in the menu

Wrapped Key: Select previous item in the menu

Rubber and Plastics Key: Enter current selection

5. Toggle through the menu selections using the keypad to reach Conductivity Setup

and press the Rubber and Plastics key.

6. Display should be similar to the example below.

CD=xx.xuS/NNN/y.yppm

L R H=HH.H G=G.GG

Screen Representation

x.x Water conductivity in uS (micro-Siemens)

NNN Water conductivity in ADC (Analog to Digital converter) counts (0…255)

y.y Water quality in ppm (parts per million)

L “L” is displayed when float switch is activated, "-" when the float switch is not

active

R “R” is displayed when the Water Quality Sensor is active, "-" when the Water

Quality Sensor is not active.

HH.H High value threshold (Bad water threshold) default 10uS

Values larger than this trigger “Bad water quality” error

G.GG Water conductivity circuit gain default 1.00

Note: Statim 7000 does not use the conductivity reading to trigger the “No Water, Refill

Reservoir” message. There is a float sensor for that.

7. By pressing the Rubber and Plastics Key the selection moves between H and G.

8. Select “G” Water conductivity circuit gain (flashing value on the display), by pressing

the Rubber and Plastics Key.

9. Adjust G.GG value so the conductivity in ADC counts (NNN) shows 186±1 count.

Note: When the NNN value is 186±1 the G.GG value will be approximately 1.00.

10. Press Stop Key to exit the Water Conductiv ity Mode and save displayed setting and

enter normal mode of operation, “Select a Cycle” screen.

Keypad functions in Conductivity Setup screen:

Unwrapped Key: Increase current field (flashing value on the display)

Wrapped Key: Decrease current field (flashing value on the display)

Rubber and Plastics Key: Move to next field

Stop Key: Exit

39

Page 40

Statim 7000

Validation Thermocouple Calibration

1. Turn power switch ON while holding down Unwrapped and Wrapped keys to enter Service

Mode.

2. The Service Mode is password protected, enter password to continue, default password

is: Unwrapped, Wrapped, Rubber and Plastics and Stop keys pressed in this order. If the

password has been changed the backdoor password is, Unwrapped, Wrapped,

Unwrapped, Wrapped buttons pressed in this order.

Keypad function at this time:

Unwrapped Key: Select next item in the menu

Wrapped Key: Select previous item in the menu

Rubber and Plastics Key: Enter current selection

3. Toggle through the menu selections using the keypad to reach Calibration and press the

Rubber and Plastics key.

4. Display should be similar to the example below.

25.5 FE 24.1 F9

1.4

Screen Representation

25.5 Validation thermocouple reading

FE Validation thermocouple hexadecimal offset compared with chamber reading

24.1 Chamber temperature in °C

F9 Chamber thermocouple hexadecimal offset

1.4 Difference between validation thermocouple and chamber thermocouple in

°C

5. Start a Validation thermocouple self-calibration cycle. Press and hold the Unwrapped key

and at the same time press the Start key.

40

Page 41

6. The Validation thermocouple self-calibration will start by entering the heating up phase and

the screen will change for the Voltage Reading calibration.

Voltage Calibration

V=VVV VCAL=CCC

Screen Representation

VVV = Voltage measured by unit

CCC = Voltage calibration offset

Keypad function at this time:

Unwrapped Key: Increase current field

Wrapped Key: Decrease current field

Rubber and Plastics Key: Select and return to main menu

Stop: Exit, without saving, to normal mode of operation

7. VCAL value should be adjusted so that the VVV value is the same as the line voltage

measured by the reference voltmeter connected to the power line (same power outlet

where the Statim power cord is plugged in). Calibration should be done within ±2%.

8. This calibration phase lasts at least 30 seconds and it ends either by pressing the Rubber

and Plastics button or automatically when the unit moves to the Conditioning phase. When

the Voltage Reading calibration phase ends the screen moves to the main calibration

screen.

Note: The Validation thermocouple hexadecimal offset will change to 00 and the character

“*” will appear after the 00. The display should be similar to the example below. The 00* on

the display indicates the Validation thermocouple calibration cycle is running. This

calibration will take approximately 6 minutes. Note: If there is no cassette in the unit,

the water quality is unacceptable or the water level is low the Validation

thermocouple calibration cycle will not run.

25.5 00* 24.1 F9

1.4

9. Allow the Validation thermocouple self-calibration to complete. The temperature within the

chamber will rise to sterilization temperature. Wait until the sterilization phase of the

calibration cycle ends automatically. The 00* value will change to a new offset value. The

unit will vent automatically. After the unit has vented press the Stop key to end the

calibration cycle.

25.5 FF* 24.1 F9

1.4

10. Press the Stop button to end the Validation thermocouple self-calibration cycle.

41

Loading...

Loading...