SciCan Statim 2000,Statim 5000 Technical Training Manual

Statim 2000 & 5000

Technical

Training Manual

Table of Contents

Statim 2000 & 5000 Specifications 3

2000 Keypad 4

5000 Keypad, Installation & Language Selection 5

Display 6

Statim 2000 Unwrapped Cycle Description 7

Statim 2000 Wrapped Cycle Description 8

Statim 5000 Unwrapped Cycle Description 9

Statim 5000 Wrapped Cycle Description 10

Cassette Operation, Care & Maintenance, Seal Replacement 11

Statim 2000 & 5000 Cover Removal 12

Steam Flow Chart 13

Sequence of Operation 14

No Power PCB Revision 2.4-2.92 & 6.4 15

Pump, Solenoid & Compressor Testing 16

Pump Filter Cleaning Instructions 17

Thermal Fuse Location 18

Probe Bracket 19

Microswitch Location 20

Solenoid Valve 21

Boiler Calibration 2000 & 5000 Rev. 2.4-2.9 22

Boiler Calibration 2000 & 5000 Rev. 6.x & Adapter Boards with 44-pin Microprocessor 23

Water Testers 24

Water Quality Problems 25

Water Quality Check Revision 4XX or 5XX Software 26

Control Box Connections 27

Water Pump Filters Tech Service Bulletin 28

QA Supply Water Tester 29

2

Statim 2000 & 5000 Specifications

The Statim 2000 & 5000 are tabletop steam sterilizers, which are designed to sterilize instruments and

handpieces between patients.

Statim 2000 Statim 5000

External Size (LgthxWdthxHgth) External Size (LgthxWdthxHgth)

17 3/4" x 16 1/4" x 6" 21 3/4" x 16 1/4" x 7 1/2"

Cassette Internal Dimensions Cassette Internal Dimensions

11" x 7" x 1 1/2" 15" x 7" x 3"

Reservoir Capacity Reservoir Capacity

4 Liters 4 Liters

Approximately 40 Cycles Approximately 15-18 Cycles

Weight Without Water Weight Without Water

46 Pounds 72 Pounds

Power Consumption Power Consumption

1300 Watts 1300 Watts

Printer Printer

Not Available Type: Thermal Paper

Print: 20 Characters Per Line

Speed: 1 Line Per Second

Capacity: 80 Cycles Per Roll

Cycle Time Cycle Time

Unwrapped: 6 Minutes* Unwrapped: 9 Minutes*

Wrapped: 12-15 Minutes* Wrapped: 15-18 Minutes*

Rubber & Plastics: 20 Minutes* Rubber & Plastics: 40 Minutes*

Heavy Duty Unwrapped: 12 Minutes*

Warranty Warranty

1 Year Parts (Excluding Seal) 1 Year Parts (Excluding Seal)

1 Year SciCan Labor 1 Year SciCan Labor

*Cycle times will vary depending on load size in cassette.

3

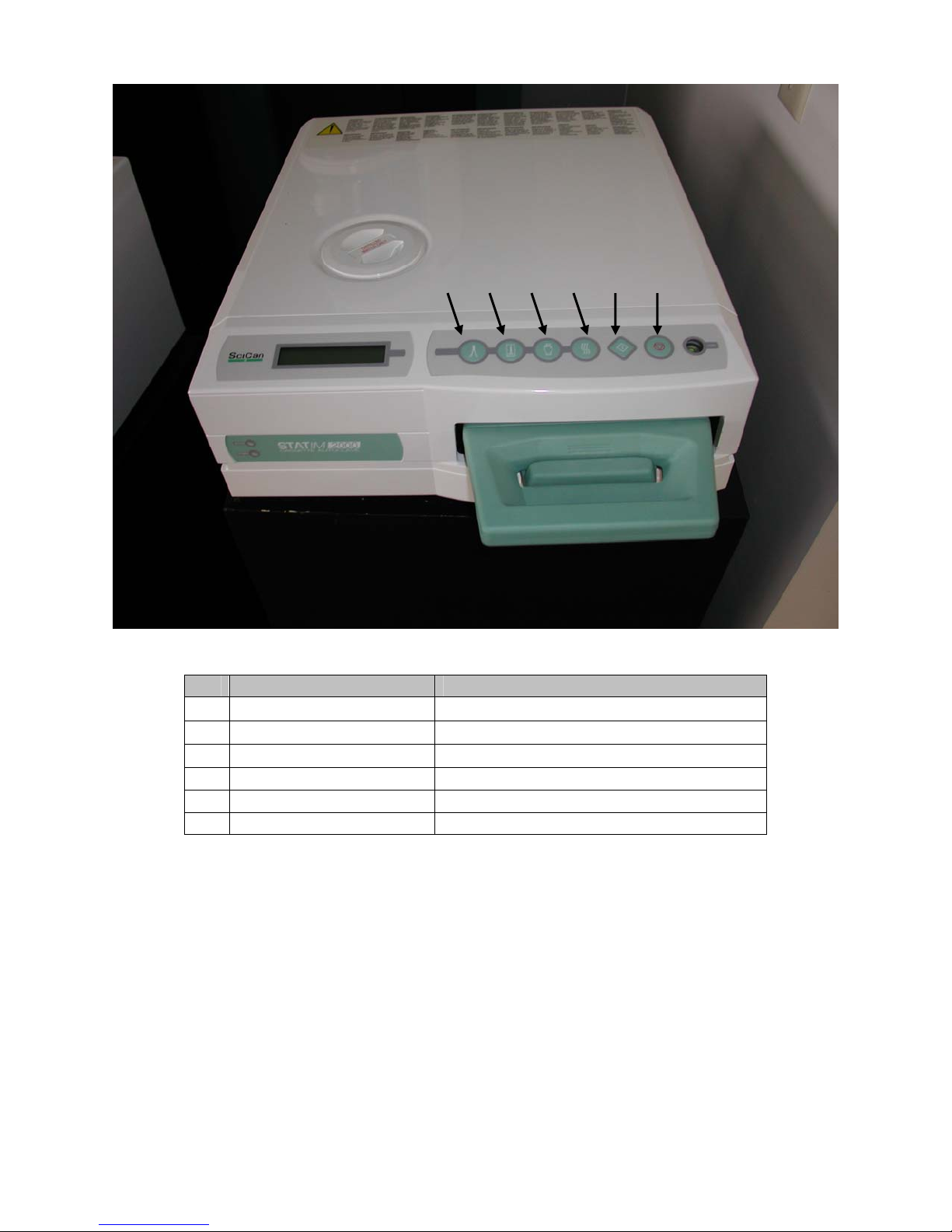

2000 Keypad

4

Cycle Sterilization Time & Temperature

1 Unwrapped Instruments

2 Wrapped Instruments

3 Rubber & Plastics

3.5 Minutes 135°C

10 Minutes 135°C

15 Minutes 121°C

4 Air Dry Only 60 Minutes

5 Start

6 Stop

4

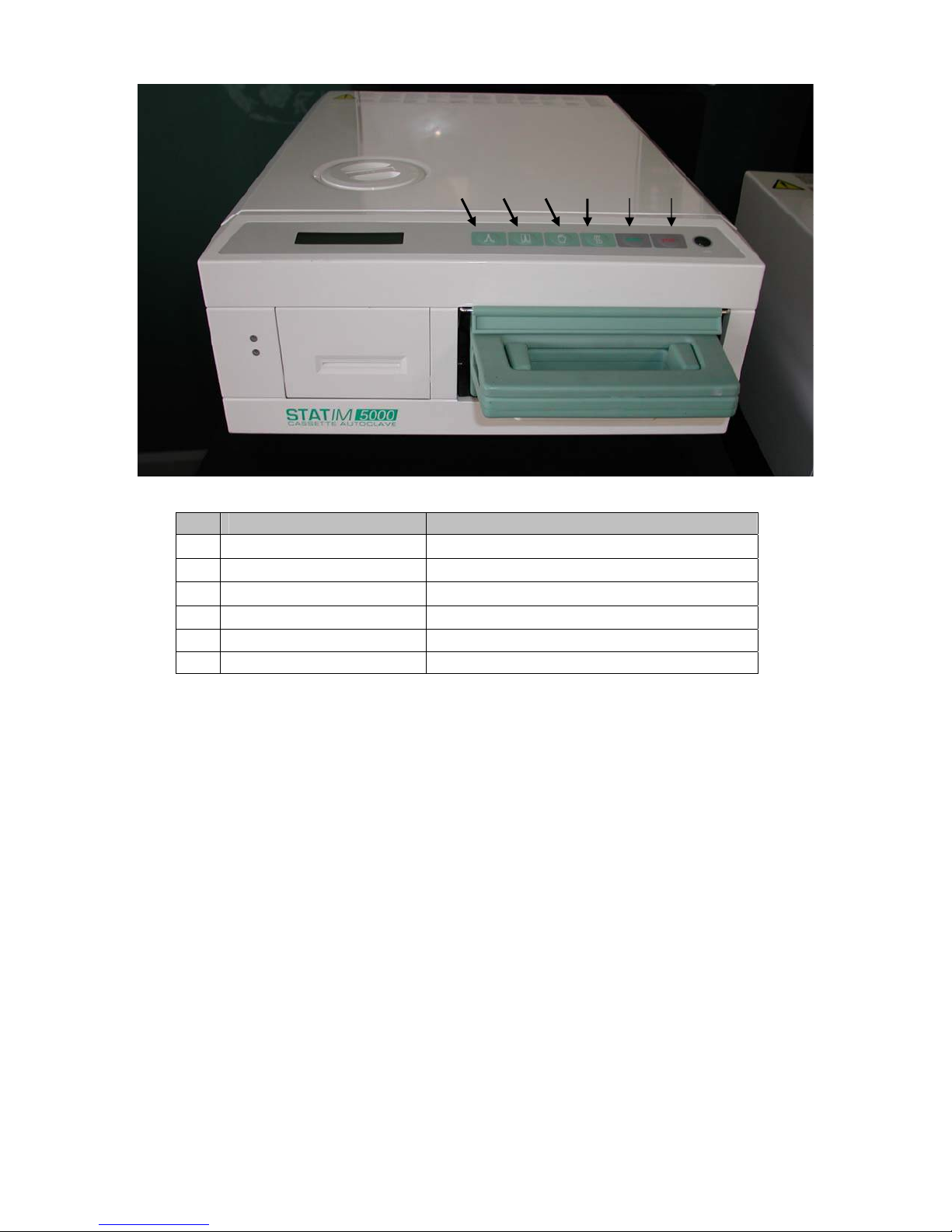

5000 Keypad, Installation & Language Selection

Cycle Sterilization Time & Temperature

1 Unwrapped Instruments

2 Wrapped Instruments

3 Rubber & Plastics

4 Heavy Duty Unwrapped

3.5 Minutes 132°C

6 Minutes 132°C

20 Minutes 121°C

6 Minutes 132°C

5 Start

6 Stop

Installation

Adjust the bubble level, located in the right front corner of the Statim, so the bubble is in the 4 or

5 o’clock position.

The waste bottle should be placed below the Statim.

Install the exhaust tubing as short as possible with no complete loops and no dips below the

waste bottle.

Make sure the mesh rack in the cassette, is positioned so there is a gap underneath for airflow.

Cassettes need to be treated with Stat-Dri Plus when water begins to cling to the cassette lid.

Do not stack bags in the cassette.

All the above will help to enhance drying in the Statim cassette.

Selecting a Language

Turn the Statim OFF.

Hold down the wrapped instrument button and turn the Statim ON. Release the wrapped button

when the display appears.

Press and release the wrapped button or the unwrapped button to scroll through the languages.

You are looking for N A English (North American English).

When N A English appears on the display press the stop button.

5

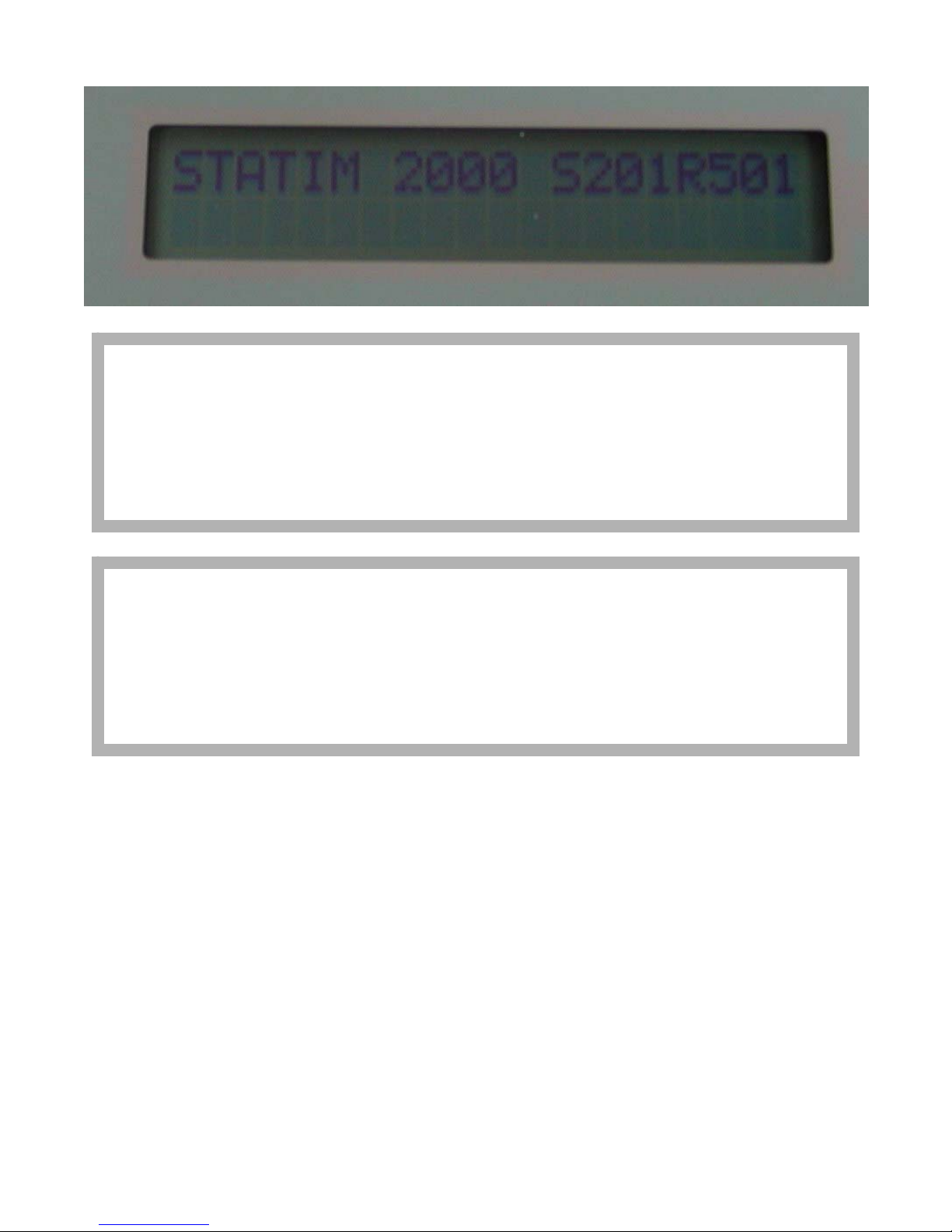

Display

Statim 2000 S201R501

Select A Cycle

When the Statim is turned ON the display will show Statim and model 2000 or 5000 then the

software number. The last three digits of the software number (501) are the software revision.

The revision number is required to answer numerous questions concerning the Statim. The

display will change to Select A Cycle after approximately 5 seconds. To see the software

revision number again the Statim will need to be turned OFF and then back ON. This display is

for a Statim 2000, with revision 501 software.

Units manufactured from 1990 thru 1994 may say Select A Program with no software number

when turned ON.

When using the Troubleshooting Guide there are three sets of error codes.

Statims that say “Select A Program” when turned ON, use original Statim error codes on page 17

in the troubleshooting guide.

Statims with software revision 2XX when turned ON, use 2XX error codes page 3 in the

troubleshooting guide.

Statims with software revision 5XX when turned ON, use 5XX error codes page 10 in the

troubleshooting guide.

For units with revision 4XX software most troubleshooting will be done using 2XX codes.

6

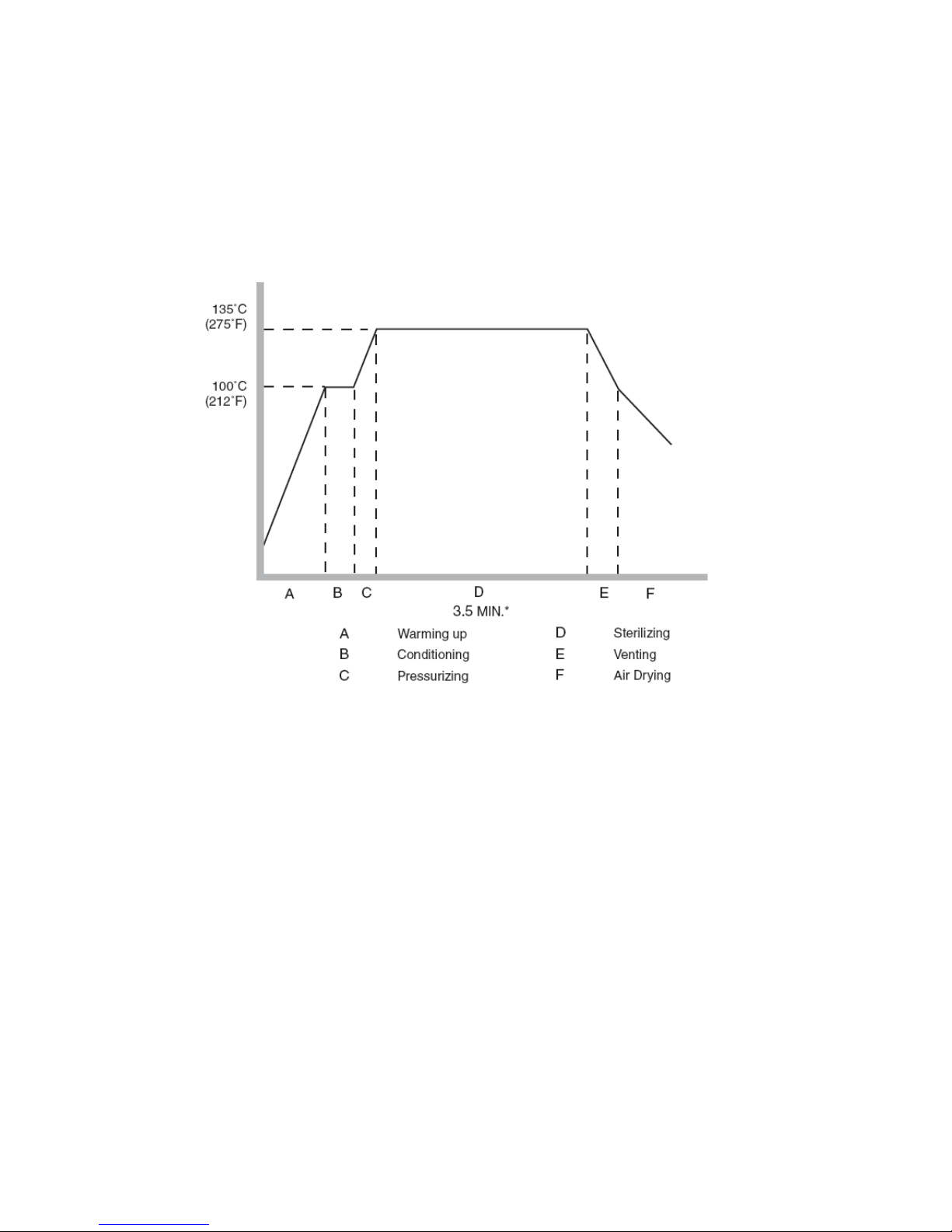

Statim 2000 Unwrapped Cycle

Temperature rises to approx 102°C. Solenoid closes (new units 30 second delay after reaching

102°C before Solenoid closes). Unit then pressurizes to 135°C. Unit goes into sterilization for

3.5 minutes. Unit then depressurizes to 103°C, air-drying starts (on units with 4XX and 5XX

software the air compressor will turn ON while unit is still venting). This feature is to prevent

deposits from collecting in the boiler. The compressor turning ON during venting will remove

moisture from the boiler. The operator is unable to remove the cassette from the Statim until the

Stop button is pressed.

7

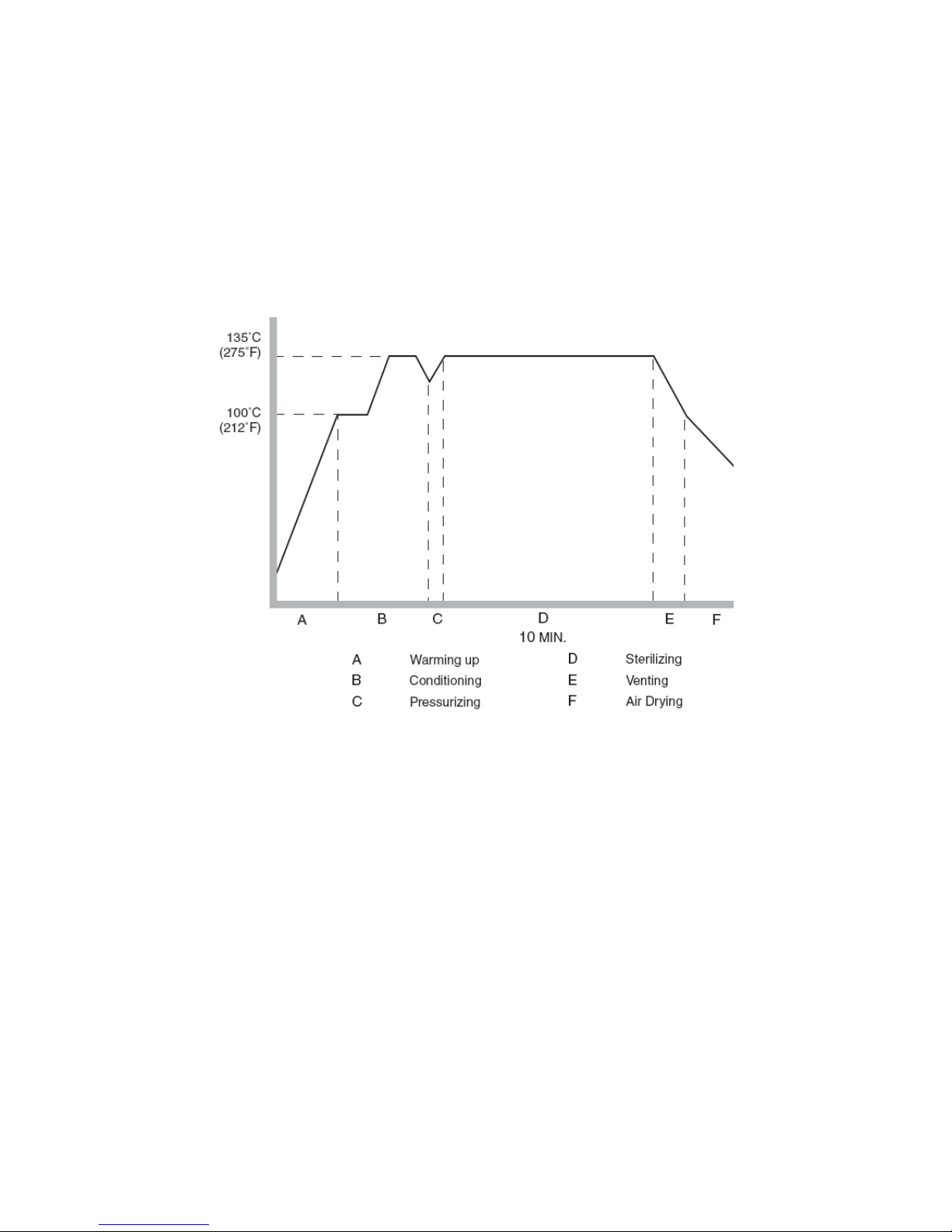

Statim 2000 Wrapped Cycle

Temperature rises to approx 102°C. Solenoid closes (new units 30 second delay after reaching

102°C before Solenoid closes). Unit then conditions to 135°C. Unit will hold at 135°C for

approximately 30 seconds, then the Solenoid opens and the unit depressurizes to 115°C. This

depressurization is to remove air from the bags. The Solenoid then closes and the unit

pressurizes to 135°C. The unit goes into sterilization for 10 minutes. Unit then depressurizes to

103°C and air-drying starts (on units with 4XX and 5XX software the air compressor will turn

ON while unit is still venting). This feature is to prevent deposits from collecting in the boiler.

The compressor turning ON during venting will remove moisture from the boiler. The operator

is unable to remove the cassette from the Statim until the Stop button is pressed.

8

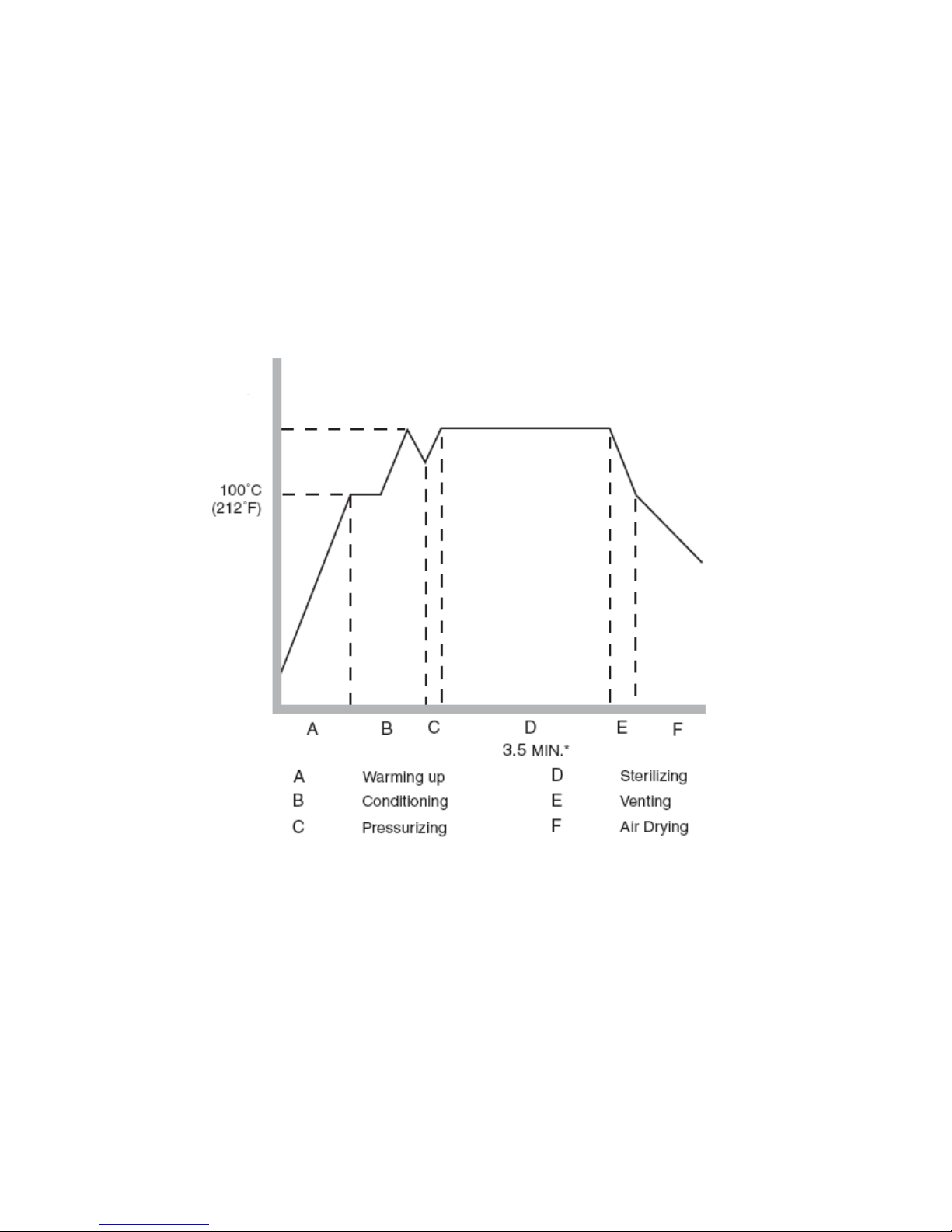

Statim 5000 Unwrapped Cycle

Temperature rises to approx 102°C. Solenoid closes (new units 30 second delay after reaching

102°C before Solenoid closes). Unit then conditions to 132°C. The Solenoid opens and the unit

depressurizes to 115°C. This depressurization is to remove air from the large chamber. The

Solenoid then closes and the unit pressurizes to 132°C. The unit goes into sterilization for 3.5

minutes. Unit then depressurizes to 103°C and air-drying starts (on units with 4XX and 5XX

software the air compressor will turn ON while unit is still venting). This feature is to prevent

deposits from collecting in the boiler. The compressor turning ON during venting will remove

moisture from the boiler. The operator is unable to remove the cassette from the Statim until

the Stop button is pressed.

Note: Heavy Duty Unwrapped Cycle operates the same as the Unwrapped Cycle with a sixminute sterilization time.

132ºC

(270ºC)

9

Loading...

Loading...