Page 1

STATIM 2000S/5000S

C A S S E T T E A U T O C L A V E

• Operator’s Manual

• Benutzerhandbuch

• Manuel de l’utilisateu

• Manuale per l’operatore

• Manual del Operador

™

STATIM 2000S/5000S Operator’s Manual 95-108430 Rev 7.0.

Copyright 2009 SciCan. All rights reserved.

Page 2

Table of Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . 3

2. Important Information . . . . . . . . . . . . . . . 4

2.1 Disclaimers

2.2 Statim 2000S — Unit Overview

2.3 Statim 5000S — Unit Overview

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Environmental Considerations

3.2 Unit Placement

3.3 Connecting the Waste Bottle

3.4 Filling the Reservoir

3.5 Priming the Statim Pump

3.6 Setting the Time and Date

3.7 Language Selection

3.8 Assigning Unit Identifier Number

3.9 Shipping the Unit

4. Instructions for Use . . . . . . . . . . . . . . . 11

4.1 Statim 2000S — Cassette

4.2 Statim 5000S — Cassette

4.3 Statim 5000S — STAT-DRI Plates

4.4 Preparing and Loading Instruments

4.5 Instrument Weight Table

4.6 Selecting a Cycle

4.7 Running a Cycle

4.8 Stopping a Cycle

5. Maintenance . . . . . . . . . . . . . . . . . . . . . 20

5.1 Cleaning the Cassette

5.2 Cleaning the Water Reservoir Filter

5.3 Cleaning the Reservoir

5.4 Cleaning the Exterior Surfaces

5.5 Changing the Statim 2000S Air Filter

5.6 Changing the Bacteria Retentive Air Filters

5.7 Replacing the Cassette Seal

5.8 Maintaining Fluid Levels

5.9 Reading Water Quality

5.10 Preventative Maintenance Schedule

6. The Communication Port . . . . . . . . . . . 25

6.1 The RS232 Communication Port

6.2 Installing the Statim Data Logger

6.3 Installing Paper on the Internal Printer

6.4 Removing Internal Printer Paper Jams

6.5 Internal Printer Output Overview

7. Troubleshooting . . . . . . . . . . . . . . . . . . 35

8. Spare Parts List . . . . . . . . . . . . . . . . . . 39

9. Warranty . . . . . . . . . . . . . . . . . . . . . . . . 40

10. Test Protocol . . . . . . . . . . . . . . . . . . . 41

10.1 Type Test

STATIM Cassette Autoclave and Statim are registered trademarks and

STAT-DRI and DriTec logos are trademarks of SciCan Ltd. All other

referred to in this manual are the property of their respective owners.

For all service and repair inquiries:

In Canada 1-800-870-7777

United States: 1-800-572-1211

Germany: +49 (0) 821 56 74 56-0

International: (416) 446-4500

Email: techservice.ca@scican.com

Manufactured by:

SciCan

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

trademarks

11. Specifications . . . . . . . . . . . . . . . . . . . 43

11.1 Statim 2000S — Specifications

11.2 Statim 5000S — Specifications

EU Representative

SciCan GmbH

Kurzes Geländ 10

D-86156 Augsburg

GERMANY

Phone: +49 (0) 821 56 74 56-0

Fax: +49 (0) 821 56 74 56-99

SciCan Inc.

701 Technology Drive

Canonsburg, PA 15317

USA

Phone: +1 724 820 1600

Fax: +1 724 820 1479

Toll free: 1-888-632-6031

SciCan Medtech

Alpenstrasse

166300 Zug

SWITZERLAND

Phone: +41 (0) 41 727 7027

Fax: +41 (0) 41 727 702

Page 2

Page 3

1. Introduction

Statim 5000S

Statim 2000S

Congratulations on your selection of the STATIM®Cassette Autoclave. We are confident that

you have purchased the finest equipment of its type. The Statim is a compact, counter-top

unit that features a number of sterilizing cycles designed to meet your needs and suitability

for steam sterilization. The Statim “S” Cassette Autoclaves are fully compliant with EN13060.

The details of installing, operating and servicing your Statim are all contained within this

operator’s manual. To ensure years of safe, trouble-free service please read these instructions before operating this unit and keep them for future reference. Operational, maintenance and replacement instructions should be followed for the product to perform as

designed. Contents of this manual are subject to change without notice to reflect changes

and improvements to the Statim product.

The Statim is suitable for the sterilization of dental and medical instruments designed

to withstand steam sterilization. The Statim has not been designed to sterilize liquids, cloth

loads, biomedical waste or materials not compatible with steam sterilization.

The processing of such loads may result in incomplete sterilization and / or damage to the

autoclave. For more information about instrument suitability for steam sterilization, consult

the manufacturers’ reprocessing instructions.

Page 3

Page 4

2. Important Information

2.1 Disclaimers

Use only steam-process distilled water in your Statim. Deionized, demineralized, or specially

filtered water should not be used. Never use tap water.

Do not permit any person other than certified personnel to supply parts for, service or maintain your Statim. SciCan shall not be liable for incidental, special or consequential damages

caused by any maintenance or services performed on the Statim by a third party, or for the

use of equipment or parts manufactured by a third party, including lost profits, any commercial loss, economic loss, or loss arising from personal injury.

Never remove the cover of the unit and never insert objects through holes or openings in the

cabinetry. Doing so may damage the unit and / or pose a hazard to the operator.

All elements of this book are common to both Statim 2000S and Statim 5000S except when

noted.

IMPORTANT:

Follow local guidelines governing verification of the sterilization procedure.

Drying Performance

The Statim 2000S and 5000S have been designed to provide a complete sterilization

solution for your unwrapped and wrapped instrument needs: rapid sterilization balanced

with rapid drying, by using the SciCan Dri-Tec Drying Technology.

The Statim 2000S uses convection heat to dry instruments by utilizing the remaining heat

in the system after the sterilization phase. Heat is captured and released in the cassette to

rapidly dry a properly loaded Statim cassette.

The Statim 5000S uses heat generated by the sterilization phase which is absorbed by

the drying plates. The heat is transferred from drying plates directly to the load resulting in

accelerated, rapid drying of a properly loaded Statim cassette.

Please refer to this operator’s manual for instructions on the proper arrangement of

instruments in the cassette and the use of Stat-Dri plates (Statim 5000S). By carefully

following these directions on how to properly load the cassette chamber, rapid drying

of the load will be achieved.

Page 4

Page 5

2. Important Information Con’t.

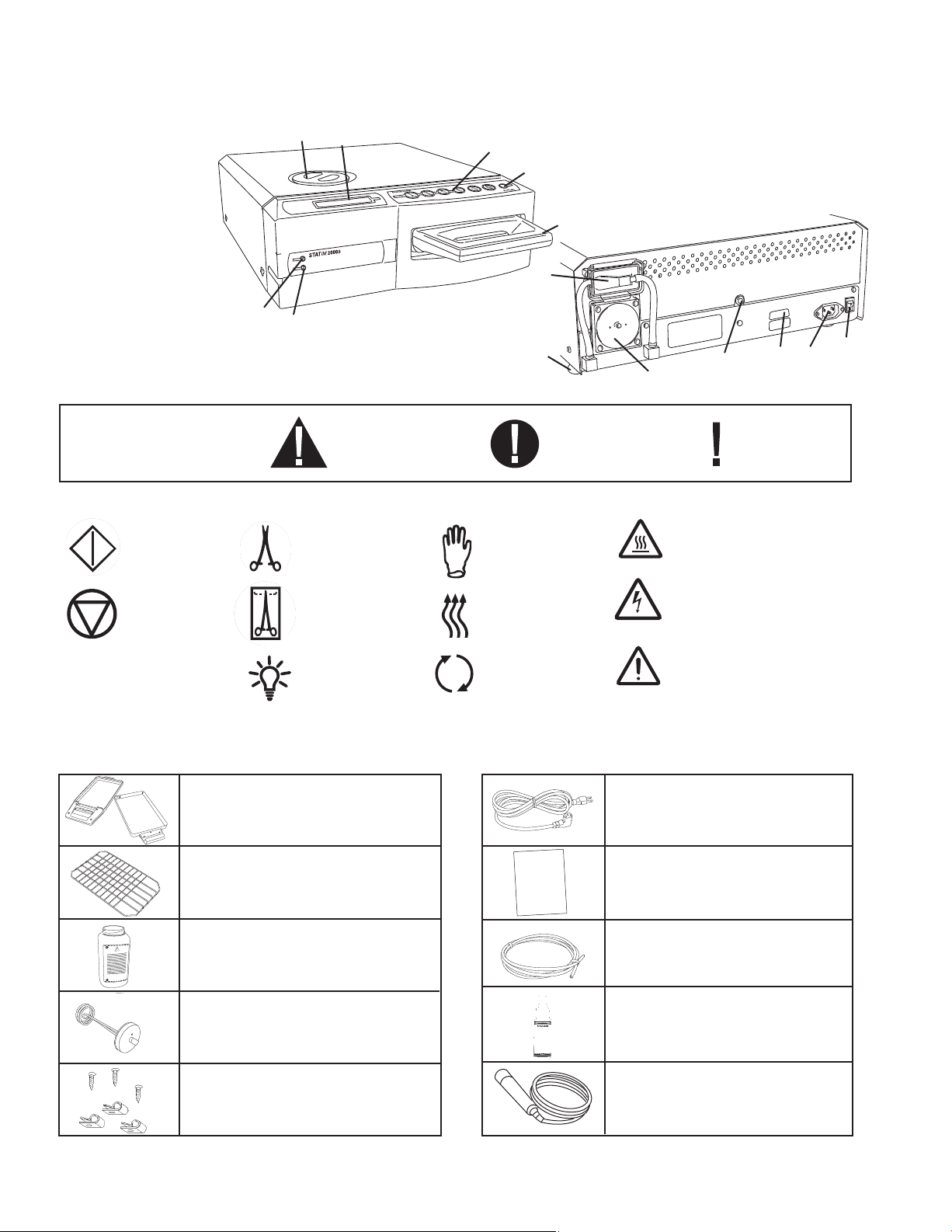

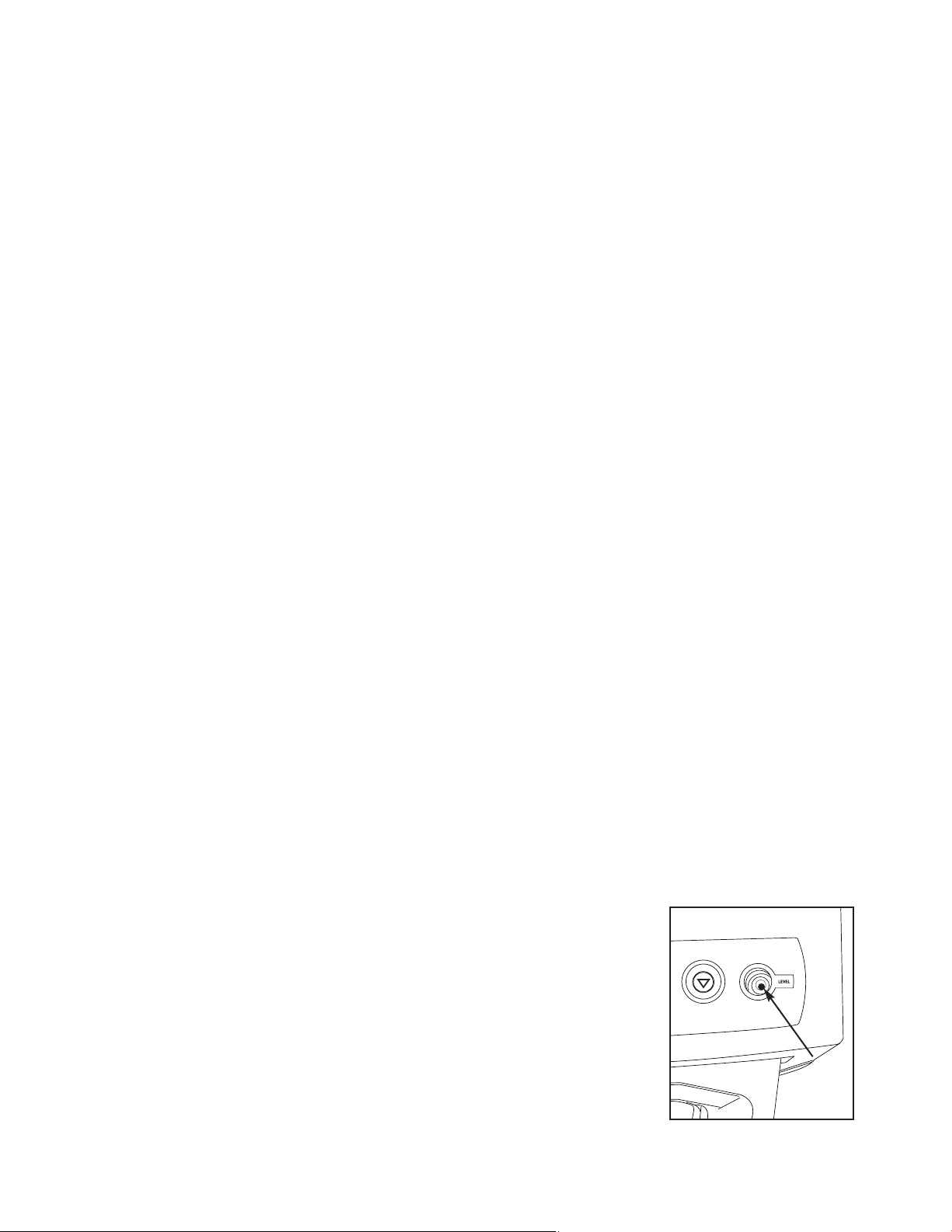

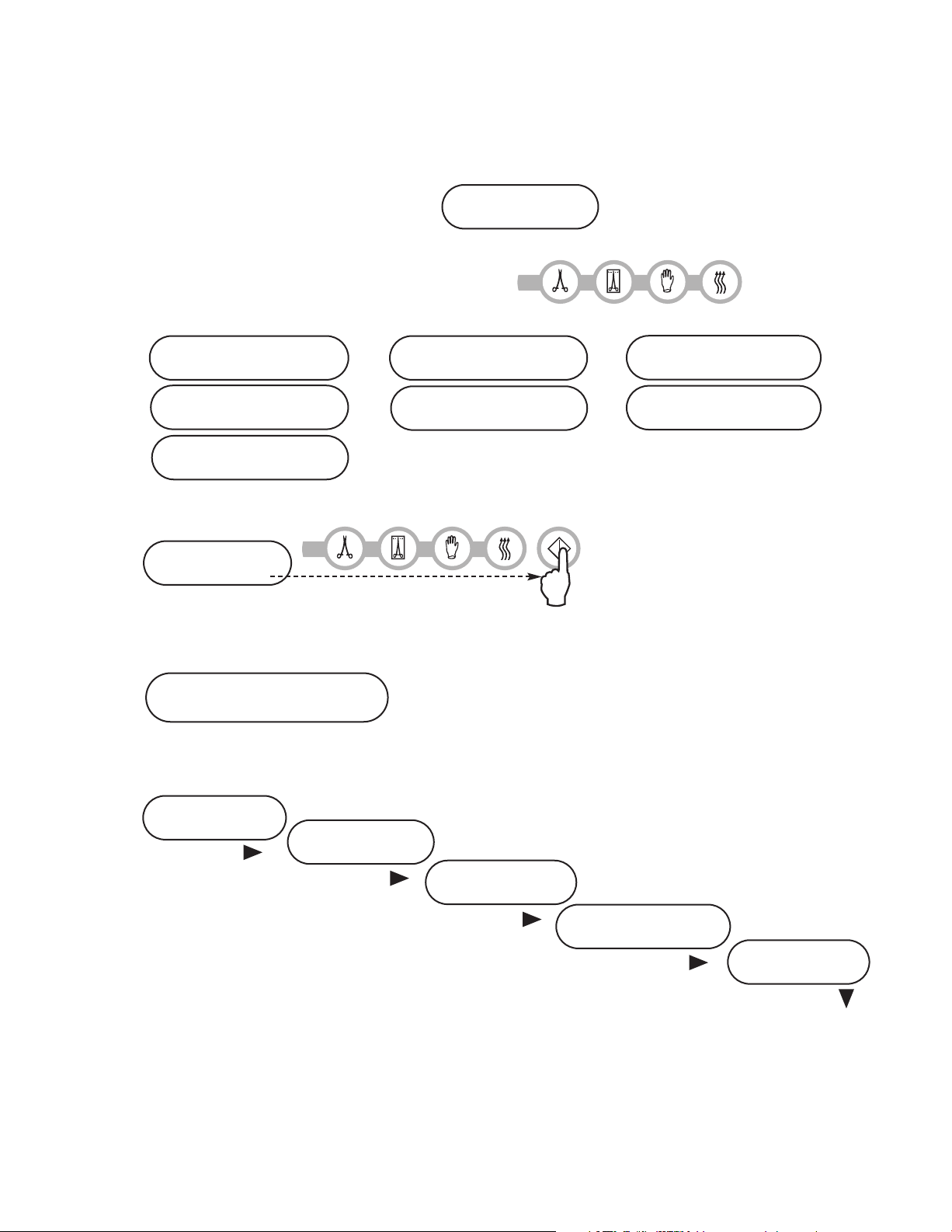

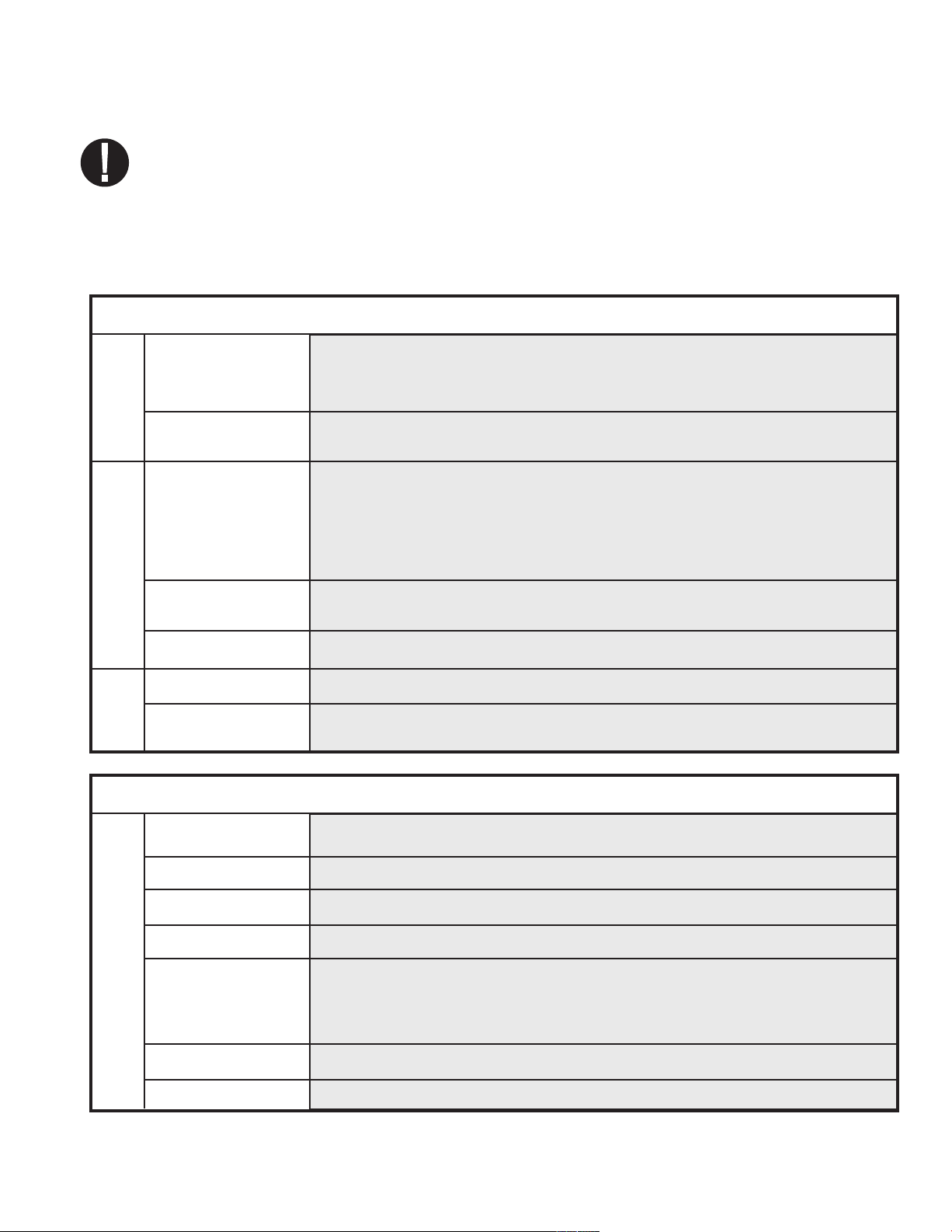

2.2 Statim 2000S — Unit overview

1

■■

level indicator

2

■■

keypad

3

■■

reservoir cap/

water filter

4

■■

LCD

5

■■

power indicator

6

■■

active indicator

7

■■

power switch

8

■■

power cable port

9

■■

leveler feet

10

■■

exhaust tube port

11

■■

compressor

12

■■

14

■■

3

■■

6

■■

5

■■

cassette

RS232 port

■■

4

13

■■

biological filter

■■

2

1

■■

12

■■

13

■■

9

■■

11

■■

10

■■

Figure 1

14

8

■■

■■

■■

7

The following symbols

appear in the margins

of this book.

The following symbols appear on the unit:

START

button

STOP

button

Steam distilled

water only

When you receive your Statim 2000S packing carton, the items listed below will be included.

If any of the items are missing, contact your dealer immediately so the situation can be corrected.

A potential hazard

to the operator.

UNWRAPPED

cycles

WRAPPED

cycles

Power

Indicator LED

RUBBER /

PLASTIC

cycles

Air dry only.

Active Indicator

LED

Cassette Tray and Lid

A situation which

may lead to a

mechanical failure.

Power Cord

Important

information

Caution: Hot Surface

and/or Hot Steam

Caution: Risk of electrical

shock. Disconnect supply

before servicing

Caution: Refer to

manual for details

Unwrapped Instrument

Rack

Waste Bottle

Bottle Lid Fitting

Tube Mounting Hardware

Operator’s Manual

Exhaust Tube

Stat-Dri

P.C.D. + 20 SciCan

Sterilization Emulators

Page 5

Page 6

2. Important Information Con’t.

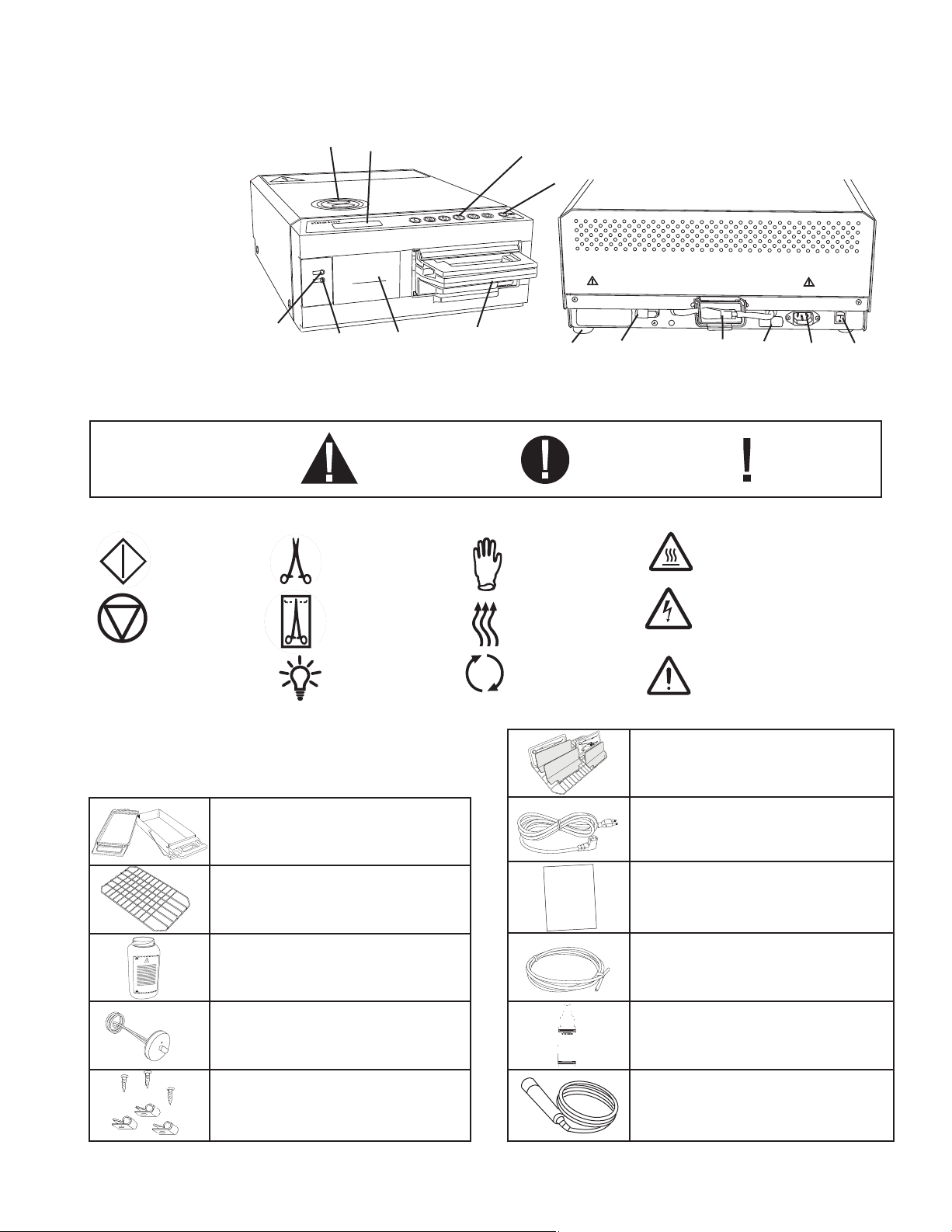

2.3 Statim 5000S — Unit overview

1

■■

level indicator

2

■■

keypad

3

■■

reservoir cap/

water filter

4

■■

LCD

5

■■

power indicator

6

■■

active indicator

7

■■

power switch

8

■■

power cable port

6

9

■■

leveler feet

10

■■

exhaust tube port

11

■■

biological filter

12

■■

optional internal printer (not on all models)

The following symbols

appear in the margins

of this book.

The following symbols appear on the unit:

START

button

STOP

button

■■

3

■■

4

■■

5

■■

A potential hazard

to the operator.

UNWRAPPED

cycles

WRAPPED

cycles

12

■■

13

■■

13

■■

2

■■

■■

cassette

RUBBER /

PLASTIC

cycles

Air dry only.

1

9

■■

10

■■

14

■■

RS232 port (not on all models)

A situation which

may lead to a

mechanical failure.

Figure 2

11

■■

14

■■

Caution: Hot Surface

and/or Hot Steam

Caution: Risk of electrical

shock. Disconnect supply

before servicing

■■

Important

information

7

■■

8

Steam distilled

water only

When you receive your Statim 5000S packing carton,

the items listed below will be included. If any of the

items are missing, contact your dealer immediately

so the situation can be corrected.

Power

Indicator LED

Cassette Tray and Lid

Unwrapped

Instrument Rack

Waste Bottle

Bottle Lid Fitting

Tube Mounting Hardware

Active Indicator

LED

Caution: Refer to

manual for details

Drying Enhancement Plates

Power Cord

Operator’s Manual

Exhaust Tube

Stat-Dri

P.C.D. + 20 SciCan

Sterilization Emulators

Page 6

Page 7

3. Installation

3.1 Environmental Considerations

There are several factors that may affect the performance of your Statim.

Please review these factors, and select a suitable location in which to install the unit.

• Temperature and Humidity

Avoid installing your Statim in direct sunlight or close to a heat source

(e.g. vents or radiators). The recommended operating temperatures are

15-25˚C with humidity of 25-70%.

• Spacing

The vents and openings on the Statim should remain uncovered and unobstructed. Leave a

minimum of 50 mm between the top, sides and back of the unit and any

wall or partition.

• Venting

The Statim should be operated in a clean, dust free environment.

• Work Surface

The Statim should be placed on a flat, level, water-resistant surface.

Never install and operate the unit on a sloped surface.

• Electromagnetic Environment

The Statim has been tested and meets applicable standards for electromagnetic emissions.

While the unit does not emit any radiation, it may itself be affected by other equipment which

does. We recommend that the unit be kept away from potential sources of interference.

• Electrical Requirements

Use properly grounded and fused power sources with the same voltage rating as indicated

on the label at the back of your Statim. Avoid multiple outlet receptacles. If using a surge

suppressor power bar, plug in one Statim only.

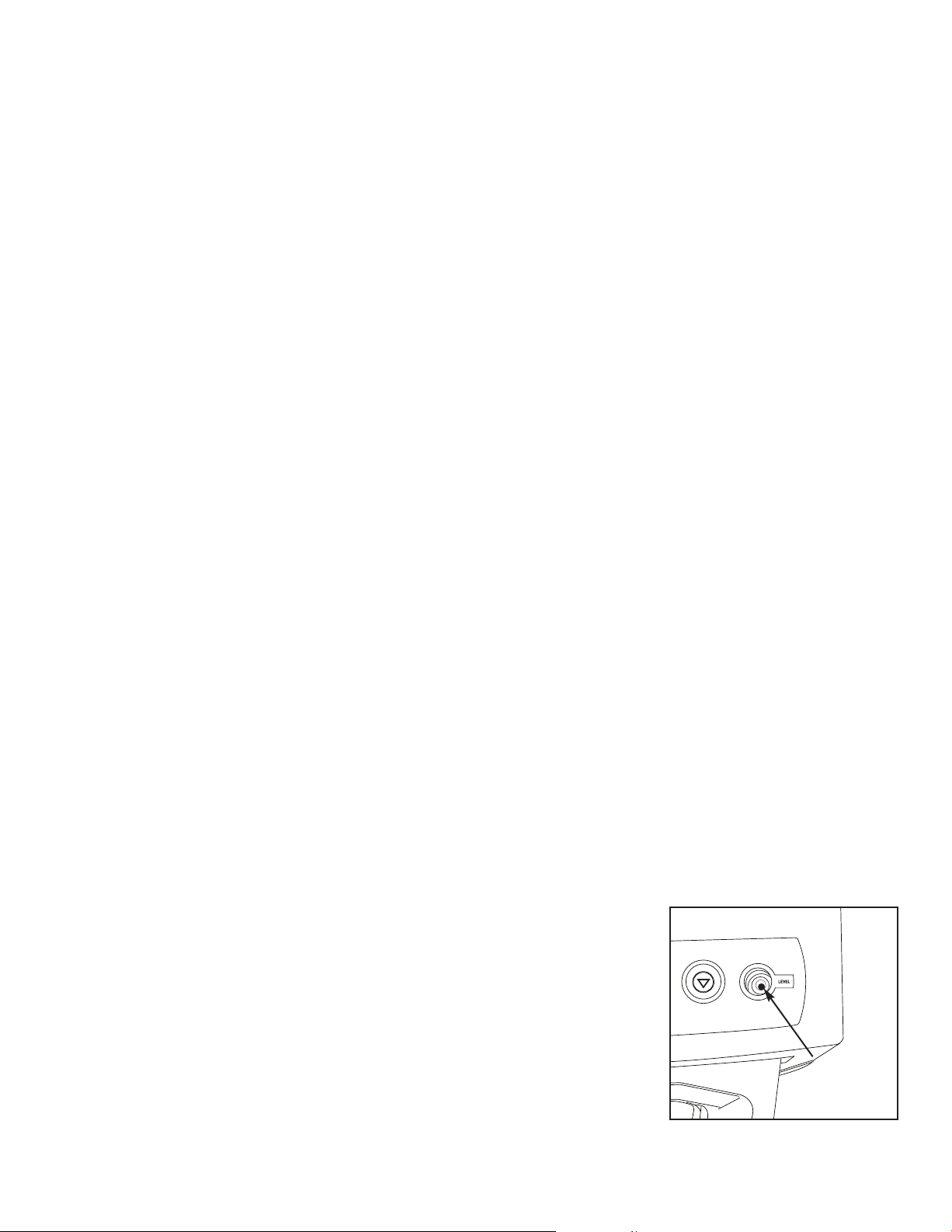

3.2 Unit Placement

When placing the unit on a counter top, ensure the following:

1

■■

• The level indicator bubble

balanced in the front right quadrant of the target. This will

ensure that the unit drains properly. Adjusting the three leveler feet will help you move the bubble if necessary.

on the front panel should be

• The unit should be stable and all four feet should be securely in contact with the counter surface.

This will prevent the unit from moving freely.

Page 7

1

■■

Figure 3

Page 8

3. Installation Con’t.

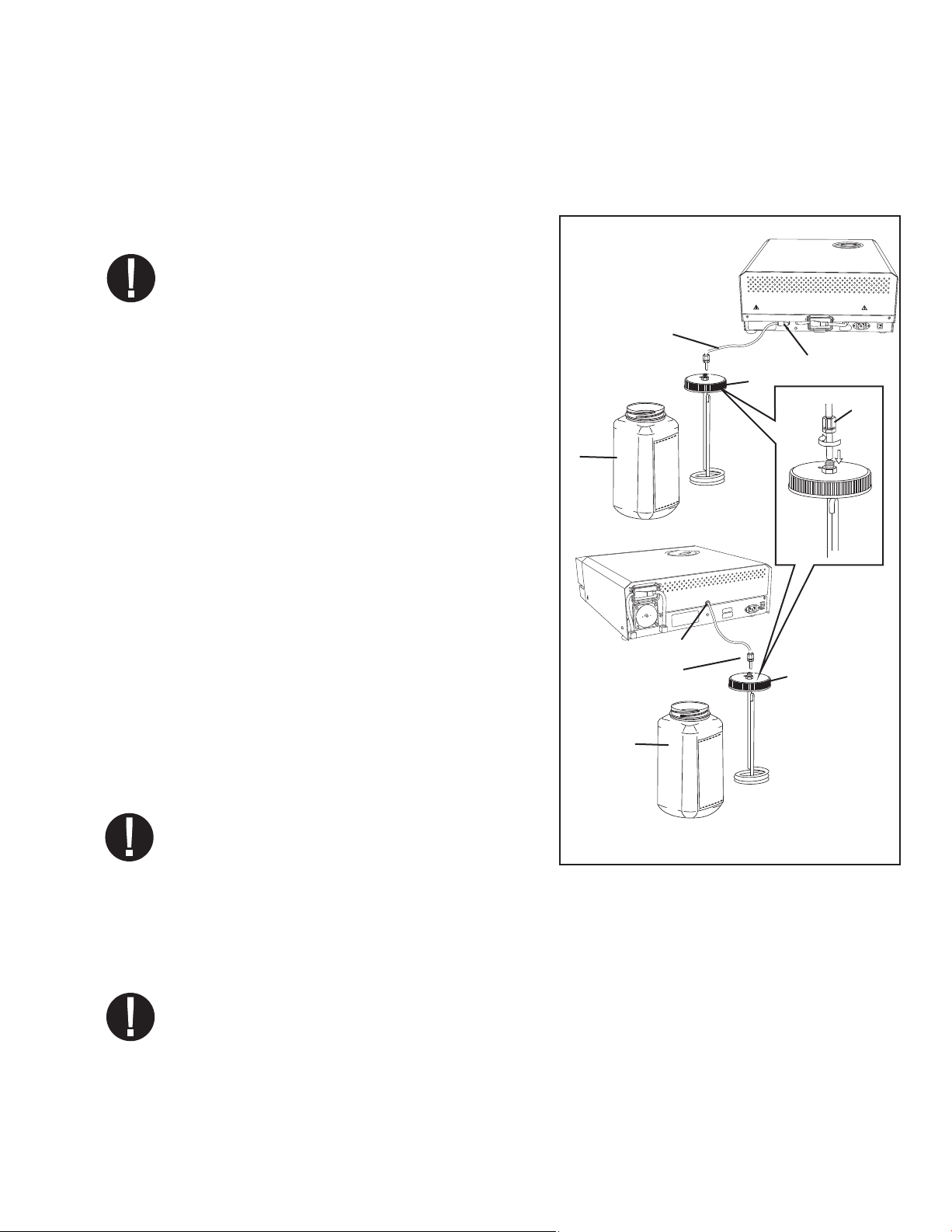

3.3 Connecting the Waste Bottle

2

The waste bottle

to steam and then drained from the cassette. To connect the waste bottle to the

Statim, follow these steps (see figure 4):

■■

is used to collect the wastewater after it has been converted

3

■■

1. Insert the exhaust

on the back of the unit and connect tightly.

2. Cut the tube to length and slide the waste

5

■■

bottle fitting

3. Place the free end of the tube into the hole in

the lid of the waste bottle and hand-tighten

the fitting. Do not coil the exhaust tube.

4. Unscrew the lid and copper condenser coil

assembly from the waste bottle. The lid and

coil should come out together.

5. Fill the waste bottle with water to the MIN line

and replace the lid and copper condenser

assembly. Empty the waste bottle often to

avoid unpleasant odors and discoloration of

the contents. (A low-level disinfectant, prepared according to the manufacturer’s

instructions, may be added to the waste

bottle to remedy this situation). As a minimum, empty the waste bottle each time

you refill the reservoir.

into place.

tube into the fitting

■■

4

■■

5000S

3

■■

4

■■

6

■■

5

■■

6

2

■■

2000S

■■

2

■■

■■

4

3

■■

6

6. Place the waste bottle near the unit. Store

the bottle below the unit. The tube can be

routed through a hole, (8 mm in diameter)

in the counter-top and secured with the

provided nylon clamps.

Figure 4

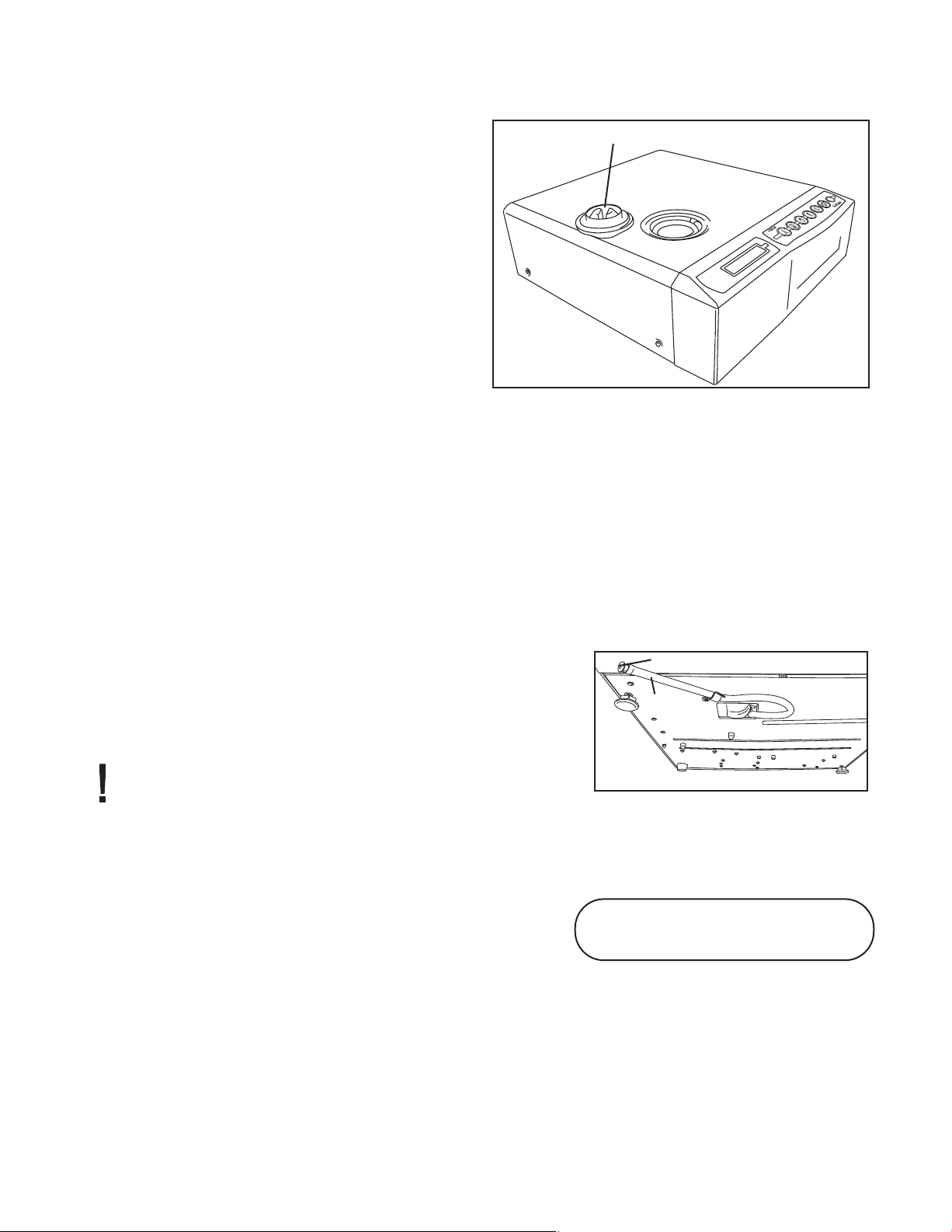

3.4 Filling the Statim Reservoir

When filling the reservoir, ensure you only use steam processed distilled water containing

less than 5 ppm total dissolved solids (having conductivity of less than 10 µS / cm). The

impurities and additives in other water sources will cause an error reading on the LCD. If

you have a water conductivity meter (available from SciCan, order number 01-103139S)

check each new water container before filling the reservoir. To fill the reservoir, follow these

steps (see figure 5):

Page 8

Page 9

3. Installation Con’t.

1. Remove the reservoir cap

2. Pour steam-process distilled water into

the reservoir until almost full (a maximum of 4L). Use a funnel to avoid

spillage.

3. Replace and secure the cap.

3.5 Priming the Statim Pump

To prime the Statim pump,

follow these steps:

1. Move the unit to the edge of the work surface. The front leveler feet should be

approximately 12 mm from the edge.

2. Lift the front left corner of the unit upward and remove the drain tube

the clip located on the underside of the unit.

■■

2

■■

2

Figure 5

3

■■

from

3. Pull the drain tube outward so the free end can be positioned over a water container.

4. Fill the reservoir with steam-process distilled water.

4

■■

5. Remove the plug

tube into a container for 30 seconds. When the water flows in a steady stream, replace

the stopper.

6. Lift the front left corner of the unit upward and reinsert

the tube into the clip on the underside of the unit.

Push the excess length of tubing back into the space

provided.

Make sure the plug in the drain tube is secured.

from the end of the drain tube and allow water to drain from the

4

■■

3

■■

Figure 6

3.6 Setting the Time and Date

To set the time and date, follow these steps and watch the blinking cursor on the LCD:

1. Power the Statim OFF.

2. Press and hold the UNWRAPPED cycle button.

3. While pressing the UNWRAPPED cycle button,

power the Statim ON. The LCD display reads:

14:23 11/15/2006

HH:MM DD/MM/YYYY

Display when setting the Date / Time

4. Use the cycle buttons to select and change the selected field’s value. To increase a

field’s value, press the UNWRAPPED cycle button. Hold the button down to increase the

value.

5. To decrease the value, press the WRAPPED cycle button.

Page 9

Page 10

3. Installation Con’t.

6. To select the next field, press the RUBBER AND PLASTICS cycle button.

7. To save changes and return to the regular operating mode, press the STOP button.

8. To quit without making changes, power the Statim OFF.

3.7 Language Selection

The messages displayed on the LCD can be changed to a number of different languages. To

change the current language selections, follow these steps:

1. Turn the power switch at the back of the unit OFF.

2. Press and hold the WRAPPED cycle button.

3. While depressing the WRAPPED

cycle button, turn the power switch at

the back of the unit to ON.

4. Press the UNWRAPPED cycle button to scroll to the next language selection.

5. Press the WRAPPED cycle button to scroll to the previous language.

6. When the desired language is displayed, press the STOP button to save the selection

and return to the regular operating mode.

Display when scrolling through languages

3.8 Assigning Unit Identifier Number

1. Power the Statim OFF.

2. Press and hold the RUBBER / PLASTIC cycle button.

3. While pressing the RUBBER / PLASTIC cycle button, power the Statim ON.

4. Using the cycle buttons, select a maximum of 3 digits to be used as the unit’s identifier. The

UNWRAPPED button will increase the selected value and the WRAPPED cycle button will

decrease it. Use the RUBBER / PLASTIC to move to the next digit.

5. To save changes and return to the regular operating mode, press the STOP button.

Display when assigning unit number

ENGLISH

STATIM 2000 S2S2R601

#323

3.9 Shipping the Unit

Before you move the unit, you will need to drain the reservoir. To do so, follow these steps:

1. Place a water container below the unit.

2. Using the drain tube (see section 3.5 Priming the Pump, Figure 6) empty the contents of

the reservoir into the water container.

3. Remove any remaining water from the reservoir with a non-linting, absorbant towel.

4. Screw-in the three leveler feet found underneath the unit.

5. Repack the unit in the original packing materials and include all accessories originally

included with the unit.

6. Specify heated and insured shipping.

Page 10

Page 11

4. Instructions For Use

4.1 Statim 2000S — Using the Cassette

When removing the cassette after a cycle, exercise caution as the metal areas will be hot

and the cassette may contain hot steam.

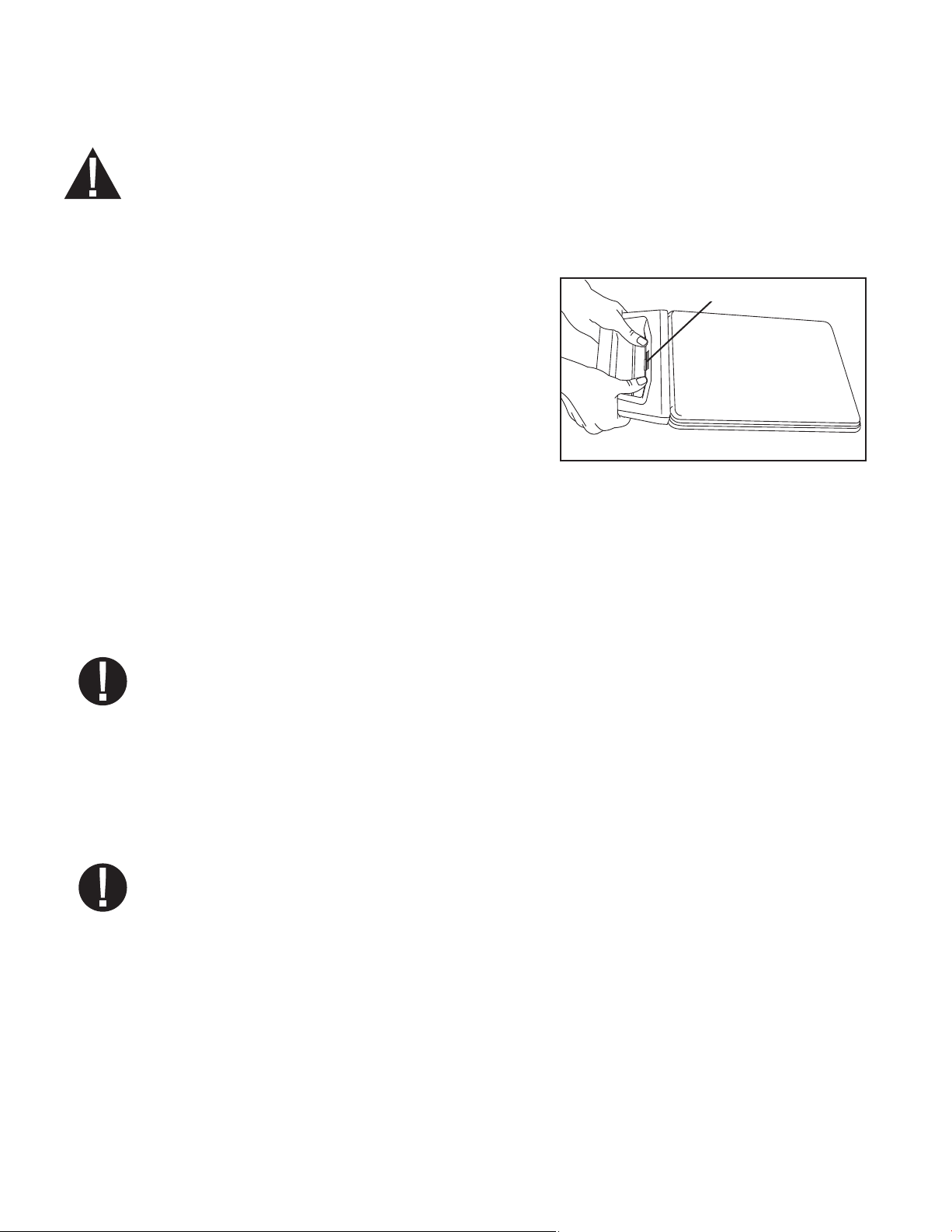

• To open the cassette:

1. Hold the cassette handle with your thumbs facing inward on the cassette latch.

2. Push downward on the cassette latch.

3. Raise the cassette lid upwards and disengage the

hinge.

4. Rest the lid on its outer surface.

cassette latch

• To close the cassette:

1. Align the hinge tab on the cassette lid with

the hinge slot on the rear of the bottom tray.

2. As you begin to close the lid, the hinge tab and slot will engage.

• Inserting the cassette into the Statim 2000S:

1. Place the end of the cassette into the unit.

”

2. Gently push inward until you hear a “click

Never push the cassette into the Statim with force as the interior components could

be damaged.

sound.

• Removing the cassette:

Figure 7

1. Grasp the handle with two hands and pull away from the unit.

2. Pull the cassette clear of the unit and set down on a firm surface.

• Disengaging the cassette

When not in use, the cassette should be disengaged. To disengage the cassette, grasp the

1

handle and pull the cassette out until there is a 15 mm to 20 mm (

the front of the Statim 2000S and the cassette handle.

/2 to 3/4") gap between

• STAT-DRI

Treatment of the interior surfaces of the cassette with the Stat-Dri drying agent, provided with

your unit, will enhance the drying process. (Replacement bottles are available from SciCan,

order number 2OZPLUS, 8OZPLUST, 32OZPLUS).

Page. 11

Page 12

4. Instructions For Use Con’t.

4.2 Statim 5000S — Using the Cassette

When removing the cassette after a cycle, exercise caution as the metal areas will be hot

and the cassette may contain hot steam.

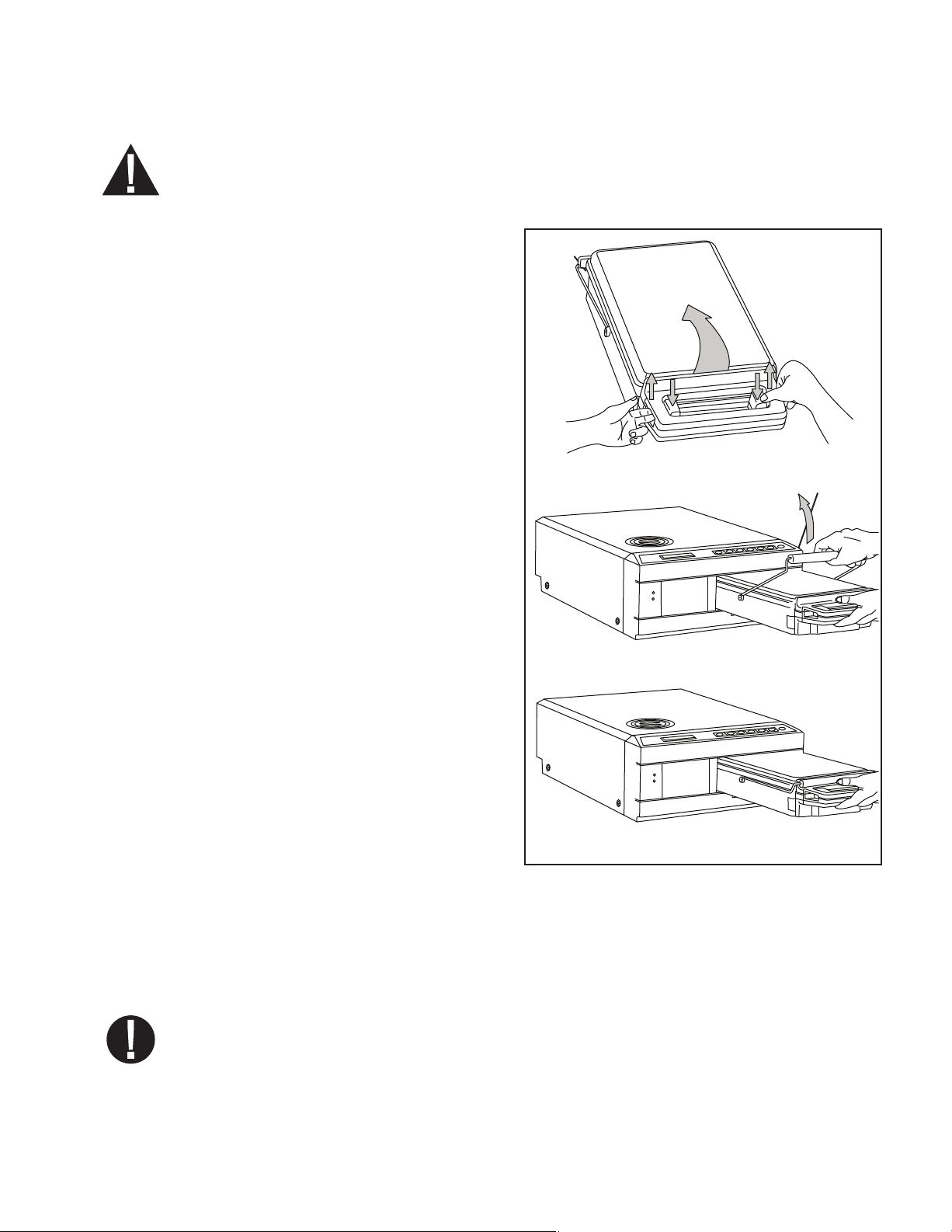

• To open the cassette:

1

1. Push the carry handle

open position.

2. Put your hands on either side of the cas-

sette handle.

3. Insert your forefingers in the slots and

place your thumbs on the thumb pads.

4. Press down with your thumbs and

pull up with your forefingers until

the lid opens.

5. Raise the cassette lid and disengage

from the tray. Rest the lid on its

outer surface.

■■

into the

■■

1

1

■■

• To close the cassette:

1. Align the hinge tab on the lid with the

hinge slot on the tray.

2. As you begin to close the lid, the hinge

tab and slot will engage.

3. Place the carry handle into the

closed position.

• Inserting the cassette into the

Statim 5000S:

1. Hold the cassette handle in one hand

and the carry handle in the other as

shown in Figure 8.

2. Place the end of the cassette into the unit and drop the carry handle into its

closed position.

3. Gently push the cassette inward until you hear a click sound.

Never push the cassette into the Statim with force as the interior components could

be damaged.

Figure 8

Page 12

Page 13

4. Instructions For Use Con’t.

• Removing the cassette:

1. Grasp the cassette handle with one hand and pull out from the unit.

2. As the cassette emerges from the unit, grasp the carry handle with your free hand and lift

it upwards.

3. Pull the cassette clear from the unit and set down on a firm surface.

• Disengaging the cassette

When not in use, the cassette should be disengaged. To disengage the cassette, grasp the

handle and pull the cassette out until there is a 15 mm to 20 mm (

the front of the Statim 5000S and the cassette handle.

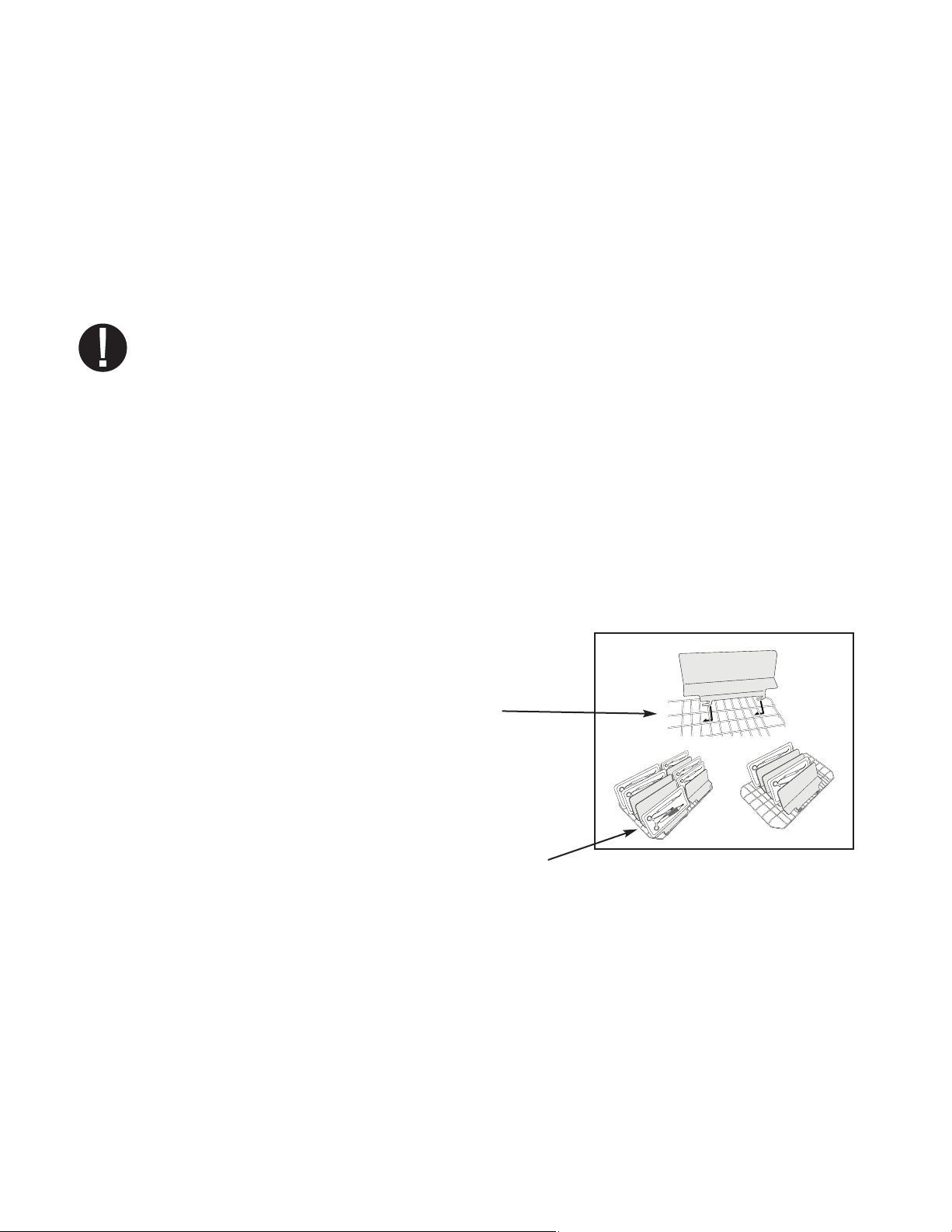

4.3 Statim 5000S — STAT-DRI Plates

The Statim 5000S cassette uses STAT-DRI plates to enhance the drying process

for wrapped instruments. The adjustable plates are designed for the unwrapped instruments

rack and eliminate the need for a separate wrapped instrument rack.

Up to ten plates can be arranged along the length of the rack. Each unit is shipped

with five STAT-DRI plates. Additional plates may be ordered from SciCan (SciCan

part number 01-103935).

1

/2 to 3/4") gap between

To install and adjust a STAT-DRI plate, follow these steps:

1. Hold a plate over the desired position, tilted slightly forward with the tabs down.

2. Insert the tabs between the mesh of the

unwrapped instrument rack.

3. Each tab has an elongated slot. Slide the plate until

the wire is at the end of each slot.

4. Release the plate to the resting position.

5. Prepare and load instruments for sterilization.

4.4 Preparing and Loading Instruments

Before loading any instruments into the Statim, consult the manufacturer’s reprocessing

instructions.

• Clean Instruments

Clean and rinse all instruments before loading them into the cassette. Disinfectant residues

and solid debris may inhibit sterilization and damage the instruments, the cassette, and the

Statim. Lubricated instruments must be wiped thoroughly and any excess lubricant should

be removed before loading.

Page 13

Page 14

4. Instructions For Use Con’t.

• Unwrapped Instruments

Arrange unwrapped instruments on the instrument rack in the tray so that they

do not touch one another. This ensures that steam reaches all surfaces and will promote

drying.

Instruments must not be stacked or piled in the cassettes, as this will impede the sterilization

process.

• Wrapped Instruments (single wraps)

Place the instruments into single layer autoclave bags according to the manufacturer’s

instructions. Orient the instrument rack in the cassette to ensure that wrapped instruments

rest approximately 6 mm / 0.25" above the cassette base. Place the wrapped instruments

on the rack and arrange them to avoid overlap. Ensure that all wrapped loads are dry before

handling and /or storage to maintain sterility.

The use of cloth wraps in the Statim is not recommended.

SciCan recommends the use of paper / paper and plastic / paper autoclave bags

manufactured in accordance to EN 868. Loosely pack instruments in the bags to allow

steam penetration to all instrument surfaces.

The wrapped instrument rack for the Statim 5000S is designed to hold a maximum of

12 autoclave bags. Care must be taken to ensure that the combined weight of the loaded

bags does not exceed 1.5 kg (3.3 lbs).

The unwrapped instrument rack fitted with a maximum of 10 Stat-Dri plates will hold

10 autoclave bags.

• Rubber and Plastic Instruments

The following materials can be sterilized in the Statim:

nylon, polycarbonate (Lexan™), polypropylene, PTFE (Teflon™), acetal (Delrin™),

polysulfone (Udel™), polyetherimide (Ultem™), silicone rubber, and polyester.

When loading rubber and plastic instruments in the tray, leave a space between the

instruments and the cassette walls. This ensures that steam reaches all surfaces, and

will promote drying.

The following materials cannot be sterilized in the Statim:

polyethylene, ABS, styrene, cellulosics, PVC, Acrylic (Plexiglas™), PPO (Noryl™), latex,

neoprene, and similar materials.

Use of these materials may lead to instrument or equipment damage. If you are unsure of

your instrument’s material or construction, do not load into your Statim until you have

checked with the instrument manufacturer.

Page 14

Page 15

4. Instructions For Use Con’t.

• All Instruments

The Statim is NOT intended for sterilizing textiles, liquids or biomedical waste. Instruments

will remain sterile after a successful cycle until the cassette is disengaged from the unit.

Unwrapped instruments, once exposed to ambient or external conditions, cannot be maintained in a sterile state. If sterile storage is desired, wrap the instruments to be sterilized in

autoclave bags, according to the instrument manufacturer’s instructions. Then allow the

wrapped cycle to run until the air-dry phase is complete.

Best Practice: Allow instruments (wrapped or unwrapped) to dry completely prior to

handling. Wrapped or pouched instruments must not touch each other to promote drying

and enable effective sterilization.

SciCan recommends the final user carefully choose the most appropriate sterilization cycle

according to the recommendations of their leading infection control authorities and local

regulatory guidelines / recommendations.

• Routine Monitoring

Chemical process indicators suitable for steam sterilizers should be included in or on each

package or load being sterilized. In addition, the weekly use of biological indicators, which

allow you to ascertain whether the instruments have been exposed

to sterilization conditions, is recommended.

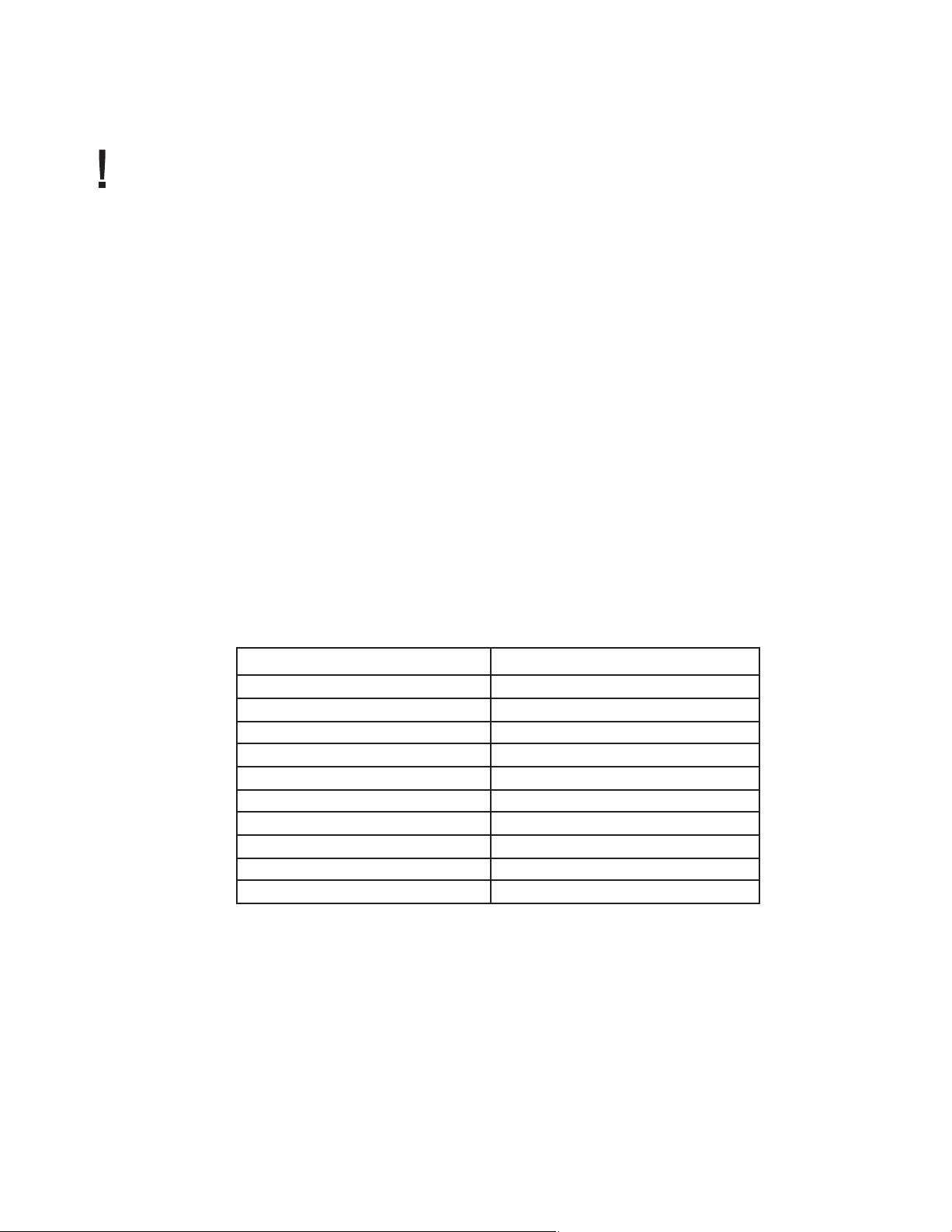

4.5 Instrument Weight Guide

Instrument

Scissors

Dental scalers

Forceps

Dental handpiece

Wrapped instrument rack

Unwrapped instrument rack

Suction cannula

Plastic mouth mirror

Impression tray

Plastic x-ray positioning ring

NOTE: The above weights are to be used as reference only. For exact weights of your

instruments, consult the manufacturer’s specifications.

Typical Instrument Weight

30 g / 0.96 oz

20 g / 0.64 oz

15 g / 0.48 oz

40 to 60 g / 1.29 to 1.92 oz

260 g / 8.35 oz

225 g / 7.23 oz

10 g / 0.32 oz

8 g / 0.25 oz

15 to 45 g / 0.48 to 1.45 oz

20 g / 0.64 oz

Page 15

Page 16

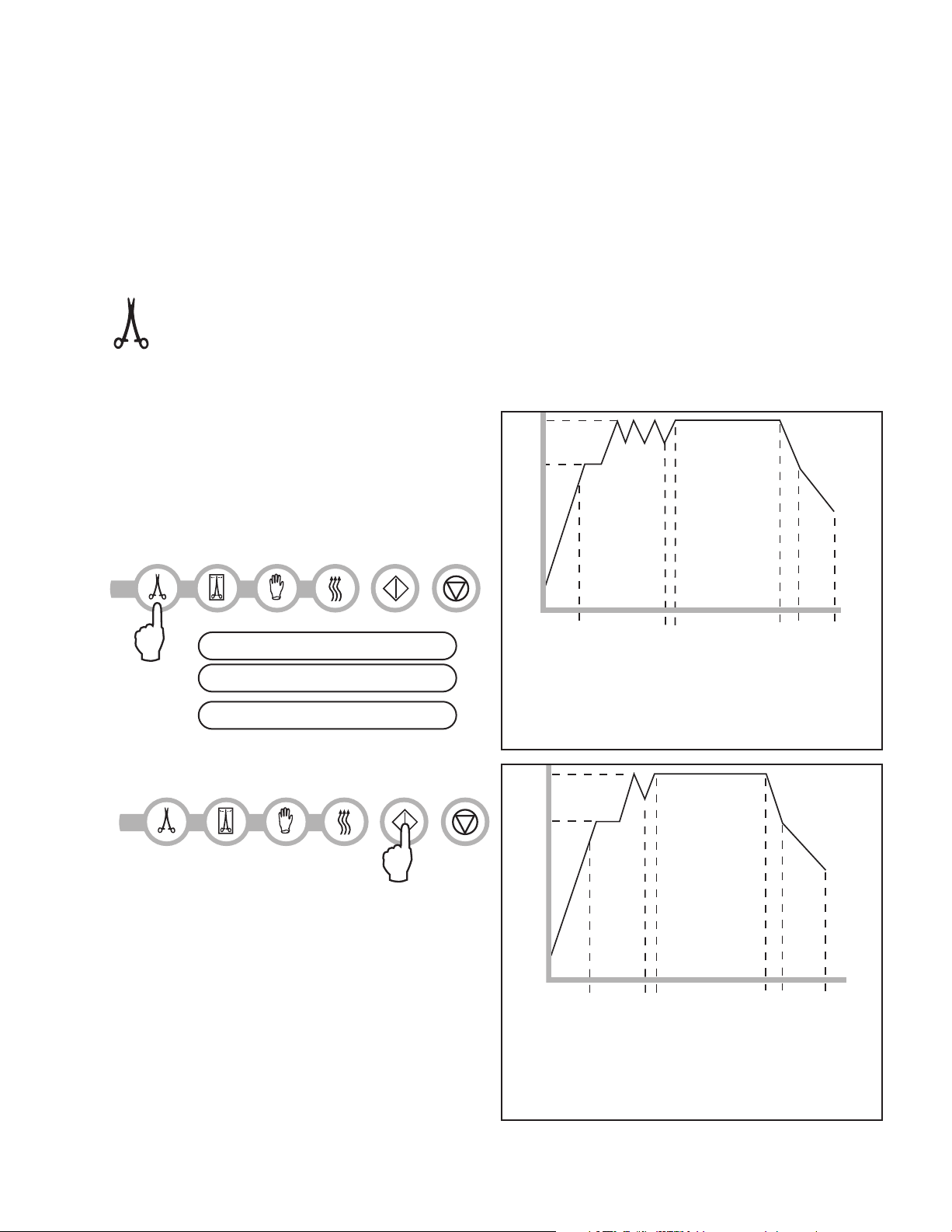

4. Instructions For Use Con’t.

A

B

C

D

E

F

D Sterilizing

134˚C / 304 kPa 138˚C / 341 kPa

E Venting

F Air Drying

3.5 min / 18 min

A 100˚C / 101 kPa

B 3 purges (Conditioning)

peak at 133˚C / 295 kPa

vent to 115˚C / 169 kPa

C Pressurizing

(Type S)

A

B

C

D

E

F

D Sterilizing

134˚C / 304 kPa 138˚C / 341 kPa

E Venting

F Air Drying

3.5 min

A 100˚C / 101 kPa

B 1 purge (Conditioning)

peak at 133˚C / 295 kPa

vent to 115˚C / 169 kPa

C Pressurizing

(Type N)

4.6 Selecting a Cycle

The Statim 2000S and 5000S have seven sterilization cycles, each designed to

sterilize using the parameters specified. Each cycle can be selected by pressing

the UNWRAPPED, WRAPPED or RUBBER / PLASTIC cycle buttons.

The types of instruments, sterilization requirements and a graph depicting each cycle characteristics are described over the following pages.

1. Unwrapped Cycles

The Statim 2000S and 5000S feature two 134˚C type S and one 134˚C type N

UNWRAPPED sterilization cycles. At the end of the cycle’s sterilization phase, air drying will

commence for one hour.

Air-drying can be interrupted at any

time by pressing the STOP button.

To select one of these cycles:

Press the UNWRAPPED

cycle button to scroll through the available

cycles.

HOLLOW UNWRAPPED (S) 134˚C / 3.5 min

HOLLOW UNWRAPPED (S) 134˚C / 18 min

SOLID UNWRAPPED (N) 134˚C / 3.5 min

Once the desired cycle has been

selected, press the START button.

The unit memory remembers the last

cycle run and then displays this first when

the unit is powered on.

Page 16

Page 17

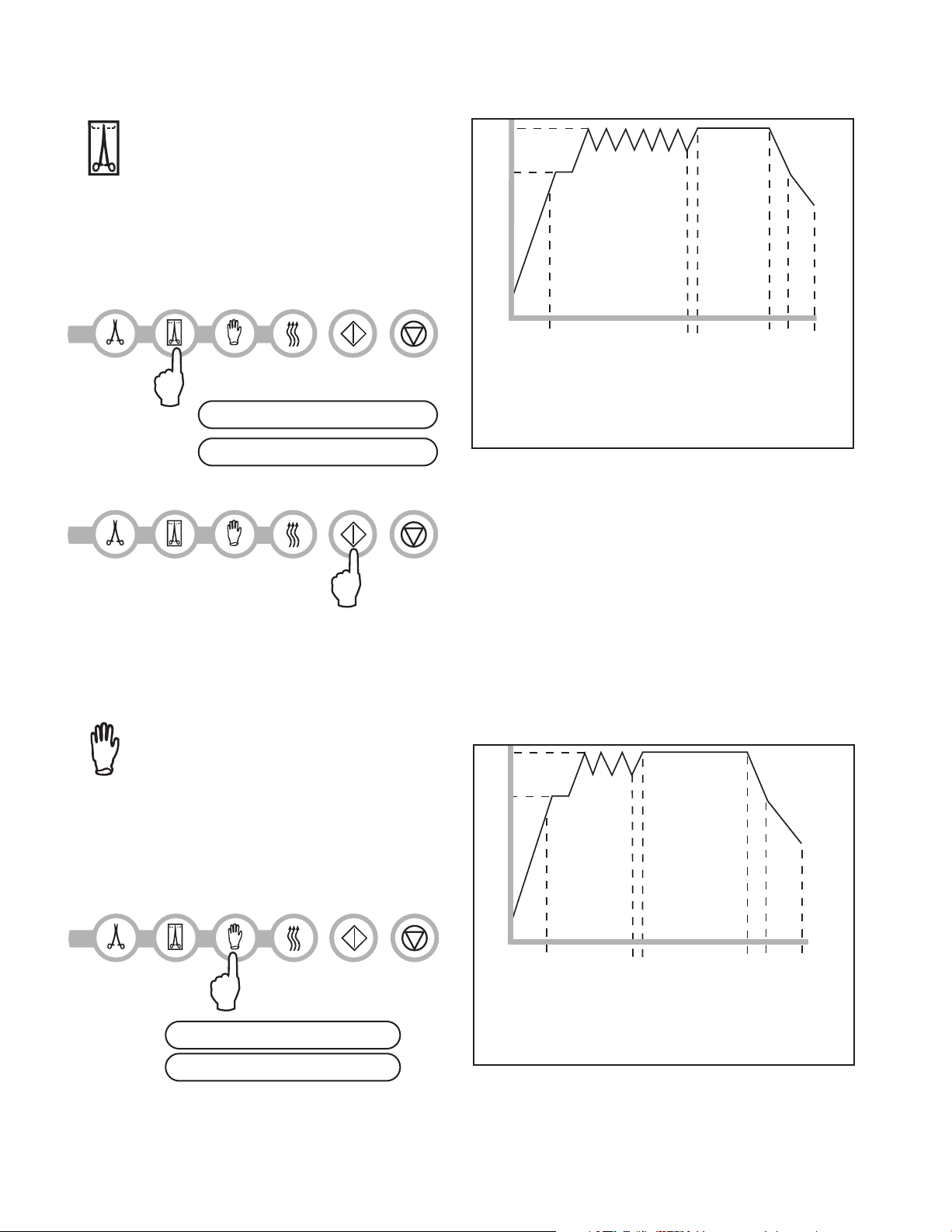

4. Instructions For Use Con’t.

A

B

C

D

E

F

D Sterilizing

134˚C / 304 kPa 138˚C / 341 kPa

E Venting

F Air Drying

3.5 min /

18 min

A 100˚C / 101 kPa

B 6 purges (Conditioning)

peak at 133˚C / 295 kPa

vent to 115˚C / 169 kPa

C Pressurizing

A

B

C

D

E

F

D Sterilizing

121˚C / 205 kPa -

124˚C / 225 kPa

E Venting

F Air Drying

15 min / 30 min

A 100˚C / 101 kPa

B 3 purges (Conditioning)

peak at 120˚C / 199 kPa

vent to 110˚C / 143 kPa

C Pressurizing

2. Hollow Wrapped Cycles

The Statim 2000S and 5000S

feature two WRAPPED 134˚C type S

sterilization cycles.

To select one of these S Cycles:

Press the WRAPPED button to

scroll through the available cycles.

HOLLOW WRAPPED (S) 134˚C / 3.5 min

HOLLOW WRAPPED (S) 134˚C / 18 min

Once the desired cycle has been selected, press the START button.

The unit remembers the last cycle run and then displays this first when the unit

is powered on.

A Process Challenge Device (PCD) is available for validation of HOLLOW WRAPPED (S)

134˚C/3.5 min cycle.

3. Rubber and Plastics Cycle

The Statim 2000S and 5000S feature two

121˚C type S sterilization cycles.

To select one of these S Cycles:

Press the RUBBER / PLASTIC button

to scroll through the available cycles.

RUBBER / PLASTIC (S) 121˚C / 15 min

RUBBER / PLASTIC (S) 121˚C / 30 min

Page 17

Page 18

4. Instructions For Use Con’t.

Once the desired cycle has been selected, press the START button.

The unit remembers the last cycle run and then displays this first when the

unit is powered on.

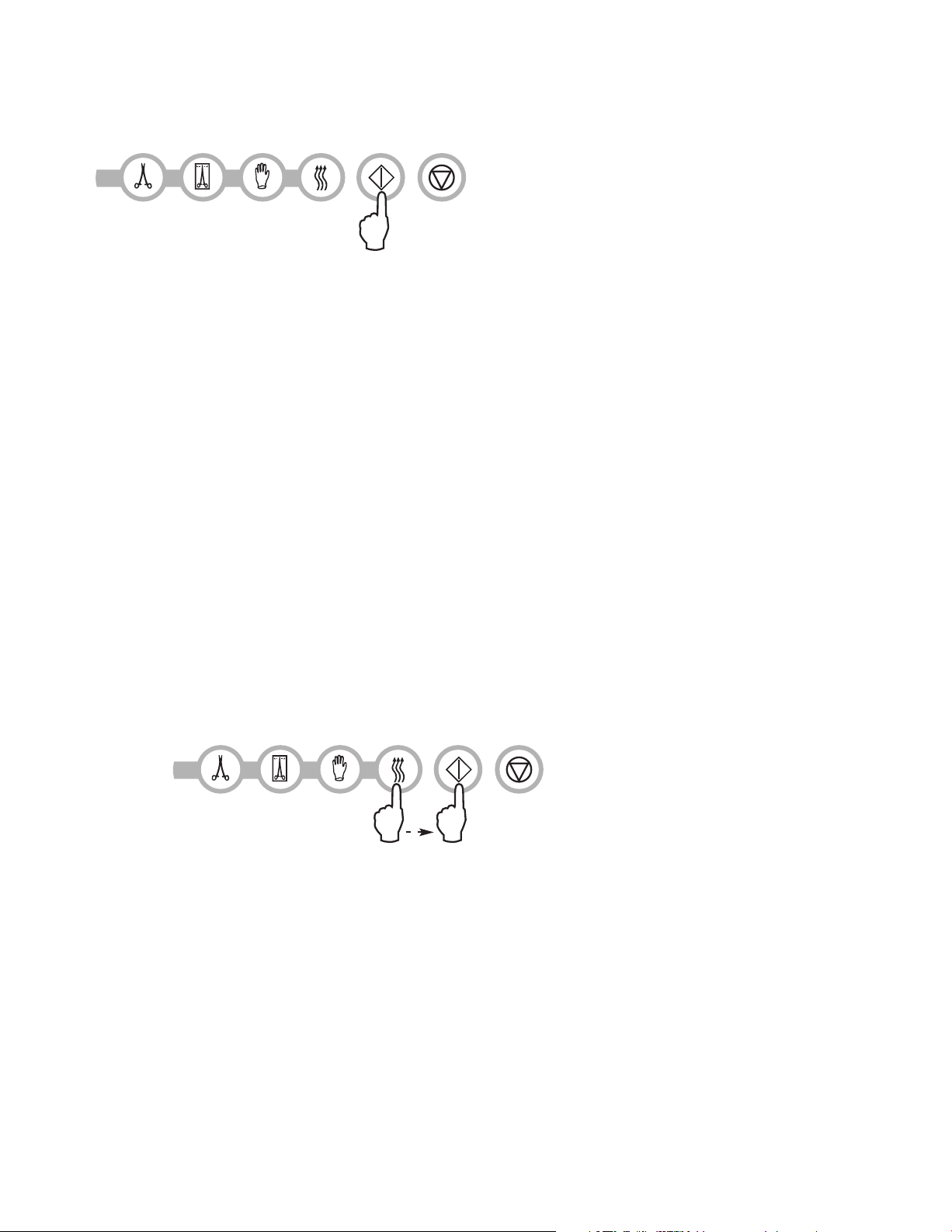

4. Air Dry Only Cycle

This is not a sterilization cycle.

The Air Dry Only Cycle starts automatically after each sterilizing cycle and runs for

60 minutes.

Air drying may be interrupted by pressing the STOP button. To ensure that the contents of

the cassette are dry, the cycle should run for the full 60 minutes. Dryness is important for

unwrapped instruments for corrosion prevention. For wrapped instruments, a dry wrap is

required to maintain sterility.

If the STOP button is pressed during the air drying stage of the sterilization cycle, and the

cassette has not been removed from the autoclave, the Air Dry Only cycle may be used to

promote further drying. If the cassette has been removed from the autoclave, it may NOT

be reinserted for the Air Dry Only cycle. If the cassette contains wrapped instruments and

the wraps are not dry when the cassette is opened, the instruments must be handled in an

aseptic manner for immediate use or resterilized.

To start, press the Air Dry Only Cycle button, then press the START button.

When started independently, this cycle will run for 1 hour.

Page 18

Page 19

4. Instructions For Use Con’t.

4.7 Running a Cycle

To operate each cycle, follow these steps and watch the LCD .

1. Turn the power switch

at the back of the unit to ON.

The LCD display reads:

2. Press the appropriate cycle button on the

keypad to scroll through the available cycles

The display will read either:

14:23 11/15/2006

SELECT A CYCLE

HOLLOW UNWRAPPED

(S) 134˚C / 3.5 min

HOLLOW UNWRAPPED

(S) 134˚C / 18 min

SOLID UNWRAPPED (N)

134˚C / 3.5 min

HOLLOW WRAPPED (S)

or or

134˚C / 3.5 min

HOLLOW WRAPPED (S)

134˚C / 18 min

RUBBER / PLASTIC (S)

121˚C / 15 min

RUBBER / PLASTIC (S)

121˚C / 30 min

As the button is released the display reads:

Cycle you selected

PRESS START

The unit’s cycle counter is displayed at the start, after the start button is depressed.

Cycle you selected

CYCLE NUMBER 000000

The amber indicator light comes on. To indicate that the cycle is in progress, the following messages are displayed as the cycle runs.

Cycle you selected

WARMING UP

CONDITIONING

110˚C 143 kPa

125˚C 232 kPa

As the cycle is running,

various sounds will be heard.

This is the normal functioning of the unit.

PRESSURIZING

STERILIZING

136.8˚C 330 kPa 3:29

VENTING

108˚C 134 kPa

Page 19

Page 20

4. Instructions For Use Con’t.

The buzzing noise during the air drying stage is the compressor operating. The air drying

phase of the cycle may be interrupted at any time by pressing the STOP button. The display will read:

PLEASE WAIT

CYCLE COMPLETE

When the automatic 60-minute air drying stage is finished the display reads:

REMOVE CASSETTE

CYCLE COMPLETE

If a sterilization cycle is successful the reminder tone sounds and the amber light flashes

until the STOP button is pressed or the cassette is removed from the unit.

4.8 Stopping a Cycle

To stop a cycle press the STOP button. If the STOP button is pushed, the cassette is

removed, or the unit detects a problem while operating, the cycle will stop and the

amber active light will flash. Once a cycle has been stopped, the STOP button must

be pressed before another cycle can be started. The display reads any of the

following messages:

CYCLE FAULT xxx

NOT STERILE

or

CASSETTE REMOVED

NOT STERILE

If the display shows the message, CYCLE FAULT or NOT STERILE, the cassette contents

are not sterile! See section 7. Troubleshooting for more information.

If the air drying stage of the cycle is interrupted, do not store wrapped instruments that were

in the cassette unless they are dry.

Page 20

Page 21

5. Maintenance

5.1 Cleaning the Cassette

Keeping the Statim cassette clean is good clinical practice and assists in the function of the

unit. SciCan recommends that the interior surface be cleaned at least once a week. Use

dishwashing soap or a mild detergent that does not contain chlorine. Scrub the inside of the

cassette with a cleaning pad designed for use with Teflon™ coated surfaces. After scouring,

rinse thoroughly with water to remove all traces of the detergent. Cleaning the inside of your

cassette is very important if you regularly sterilize lubricated instruments. Coating the entire

inside surface with STAT-DRI drying agent induces water to form an even coat on the inside

surface, without beading. The water in contact with the hot cassette surfaces also evaporates much more efficiently. Spotting is minimized and instruments dry much better. STATDRI should be applied every 10 cycles, and after every cassette cleaning.

5.2 Cleaning the Water Reservoir Filter

This water reservoir filter should be cleaned at least once a week or when required. The filter

can easily be removed and cleaned by placing the filter upside down under running water to

wash away the particles until clean, and then placed back into the reservoir opening. If a

replacement water reservoir filter is required, order part number 01-109300S.

5.3 Cleaning the Reservoir

Check the reservoir for dirt or particles. The reservoir may be cleaned by draining followed

by cleaning and rinsing with steam process distilled water ONLY. Use of chemicals or cleaning agents is not reccommended and could cause the unit damage.

5.4 Cleaning the Exterior Surfaces

Use a soft cloth moistened with soap and water to clean all exterior surfaces. Do not use

harsh cleaning chemicals or disinfectants.

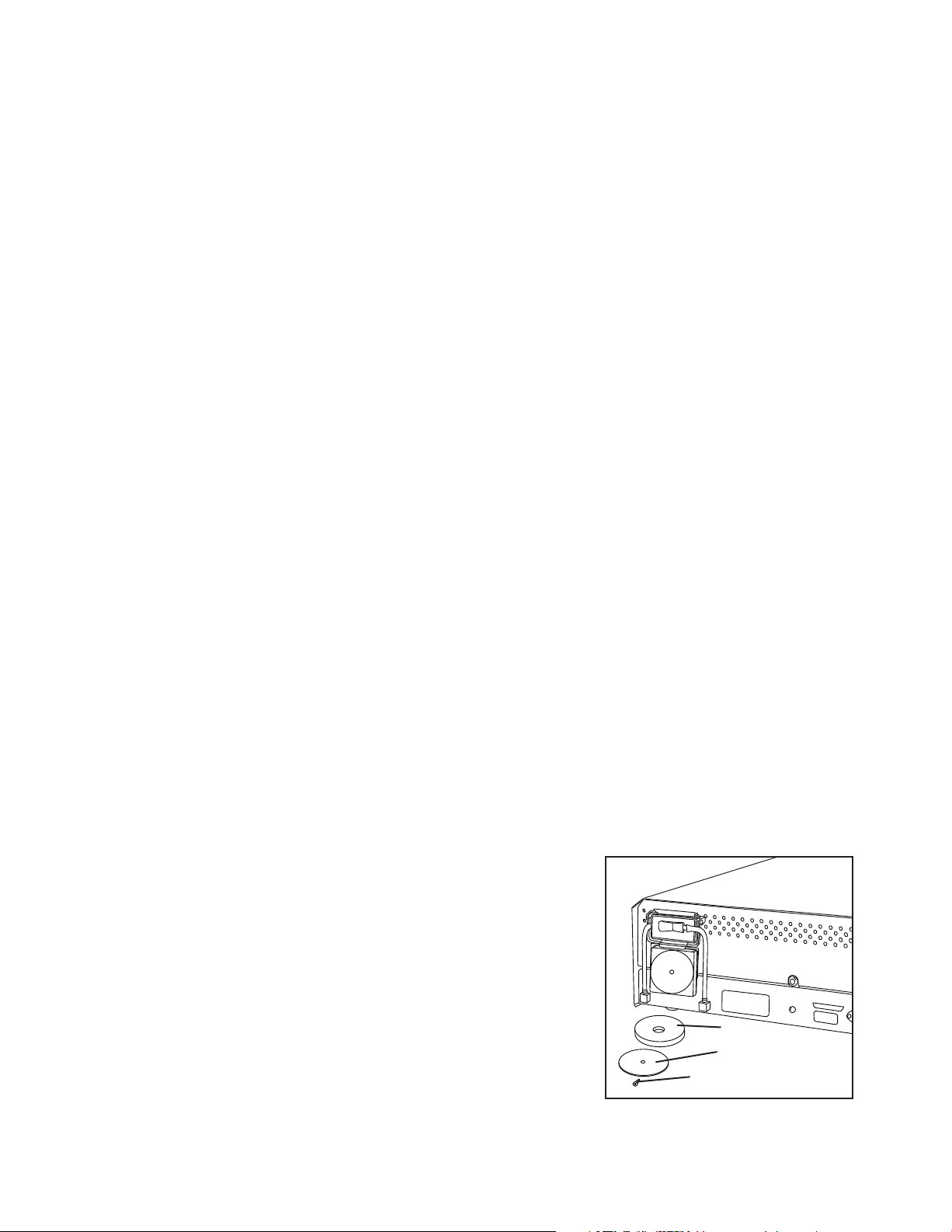

5.5 Changing the Statim 2000S Air Filter

The filter should be replaced every six months in order to maintain an adequate supply of

clean air during the air drying cycle.

To change the filter, follow these steps:

1. Turn the power switch at the back of the unit OFF.

4

■■

2. Remove and discard the old foam air filter

4

■■

3. Install the new filter

4. Secure the filter plate

using the screw

the disassembly procedure.

■■

(SciCan part no. 01-100207S).

2

■■

to the back of the compressor

1

retained during

.

■■

4

■■

2

■■

1

2000S

Figure 10

Page 21

Page 22

5. Maintenance

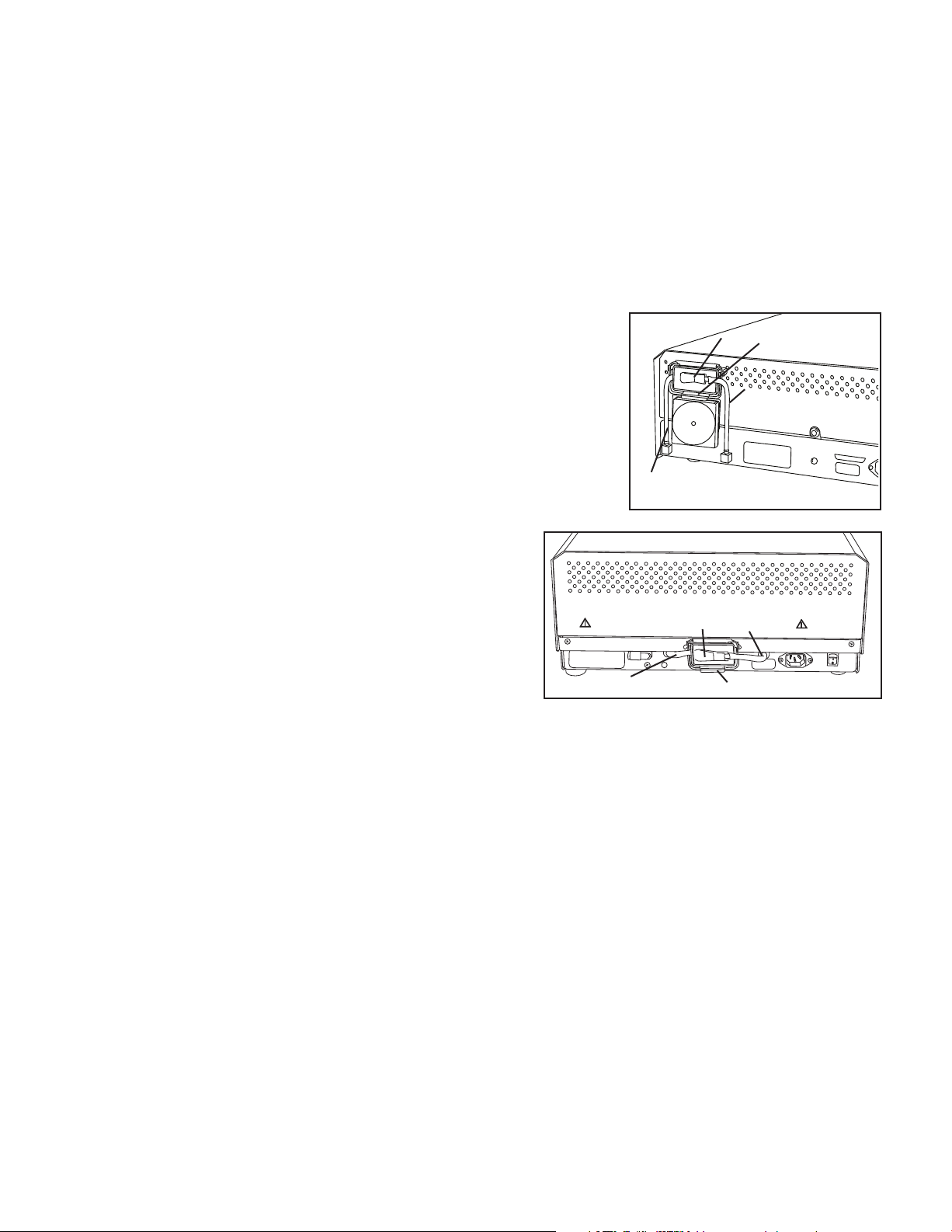

5.6 Changing the Bacteria Retentive Air Filters

The filters should be replaced every six months or after 500 cycles to maintain

an adequate supply of clean air during the air drying cycle.

To change the bacteria retentive air filter on the Statim 2000S and 5000S,

follow these steps:

1. Power the Statim OFF.

2. Disconnect tube A

retentive filter

the filter bracket

from the bracket, note the orientation of the

arrow mark on the filter.

3. When the filter is free of the bracket, carefully discon-

nect tube B

4. Before installing the replacement

bacteria retentive filter

no. 01-102119S) check that the arrow mark

on the filter matches the direction

of the arrow on the bracket. Push the left

hand filter fitting into tube B

1

■■

2

■■

and remove the filter from

3

■■

. As you remove the filter

4

■■

from the filter.

from the bacteria

2

■■

(SciCan order

4

■■

.

■■

2

■■

3

■■

1

■■

4

2

■■

1

■■

2000S

Figure 11

5000S

5. Gently press the replacement filter into

3

■■

the filter bracket

the filter should be facing out and pointing to

the left.

6. Re-connect tube A

. The arrow mark of

1

■■

to the right hand filter fitting.

■■

4

■■

3

Figure 12

5.7 Replacing the Cassette Seal

To ensure optimum performance of your Statim cassette autoclave, change the

cassette seal every 500 cycles or every six months, whichever comes first. Replacement

seals are available from SciCan (order number 01-100028S for Statim 2000S and 01101649S for Statim 5000S).

To change the cassette seal, follow these steps:

Place the cassette lid and the new seal on a clean work surface. Examine the position

of the old seal in the cassette lid and arrange the new seal in the same orientation,

next to the lid.

Page 22

Page 23

5. Maintenance con’t.

Remove the old seal and discard. Clean any residue out of the

seal channel and flush out the channel with distilled water.

Lubricate the new seal with the liquid seal lubricant provided.

Insert the rounded edge of the seal under the round lip of

the lid. Align the holes in the new seal with the holes in the lid.

NOTE: At every corner and at the holes in the lid, two square nibs

should be visible. The nibs should fit flush with the lid’s outer surface.

Ensure the seal is completely inserted. Feel around

the periphery to ensure the seal is securely in place.

NOTE: During a cycle, steam may appear between the lid

and the tray. If this persists, remove the cassette and check

that the seal is correctly installed.

Figure 13

Be careful. The metal parts will be hot, and the cassette may contain hot steam.

5.8 Maintaining Fluid Levels

Use only steam-process distilled water containing less than 5 ppm total dissolved

solids (having conductivity of less than 10 µS / cm) in the Statim. To fill the reservoir, remove

the cap from the top of the unit and fill the reservoir. We recommend using

a funnel to minimize spills. Each time you refill the reservoir, empty the waste bottle

and refill with water to the MIN line. Empty the waste bottle often to avoid unpleasant odors

and discoloration of the contents. (A low-level chlorine-free disinfectant,

prepared according to the manufacturer’s instructions, may be added to the waste

bottle to remedy this situation).

5.9 Reading Water Quality

1. Power up unit while pressing the STOP button to access the User Setup menu.

2. Using the UNWRAPPED and WRAPPED buttons, scroll to Water Quality and select it by

pressing the RUBBER AND PLASTIC button.

>Water Quality

CD=XXluS / yyy / z.z ppm

CD=conductivity XX= micro S. value

yyy= engineering value z.z= parts per million value

Page 23

Page 24

5. Maintenance con’t.

5.10 Preventative Maintenance Schedule

To ensure trouble-free performance, both the operator and the dealer must follow

a preventative maintenance schedule. NOTE: Please refer to your National, Regional, State

or Safety laws for any additional reoccurring user testing that may be required.

The schedules below describe the necessary actions.

Water Reservoir • Replace water as needed.

• For opthalmic use, drain at the end of every workday, leave empty, and refill at the start

of the next workday.

Daily

Weekly

Waste Bottle • Empty the waste bottle every time you refill the water reservoir.

• Fill the bottle with water, up to the MIN line marking.

Cassette • Wash the interior of the cassette with dishwashing soap or a mild detergent that does not

contain chlorine.

• Scrub the inside with a cleaning pad designed for use with Teflon™-coated surfaces.

• After removing all traces of the detergent, treat interior surfaces of the cassette with

the STAT-DRI™ Plus drying agent to enhance the drying process. Order more STATDRI™ Plus from SciCan quoting 2OZPLUS, 8OZPLUST, or 32OZPL US.

Biological and/or • Check the filter for dirt and moisture. Replace if dirty. Call for service if wet.

Air Filter

Operator

Every

Once a year

Water Filter • Check the water reservoir filter every week and clean if necessary. Replace only if necessary.

Cassette Seal • Replace every 500 cycles or six months (whichever is first), or whenever necessary.

Biological and/or • Replace every 500 cycles or six months (whichever is first).

Air Filter

6 months

Technician

Cassette • Check the tray, lid and seal for damage. Replace if necessary.

Biological Filter • Inspect the biological filter for moisture.

Solenoid Valve • Inspect the valve and clean if dirty. Replace the plunger if defective.

Pump • Clean the filters, replace if dirty.

Check Valve • Remove the exhaust tube from the back of the unit during the air drying phase. Check for

air coming from the fitting.

• Remove the air compressor tube from the check valve inlet while running a cycle. Make

sure no steam is leaking from the valve. Replace if there are any leaks.

Water Reservoir • Check the reservoir for dirt. Clean and rinse with steam process distilled water if necessary.

Calibration • Calibrate the unit.

Page 24

Page 25

6. The Communication Port

6.1 The RS232 Communication Port

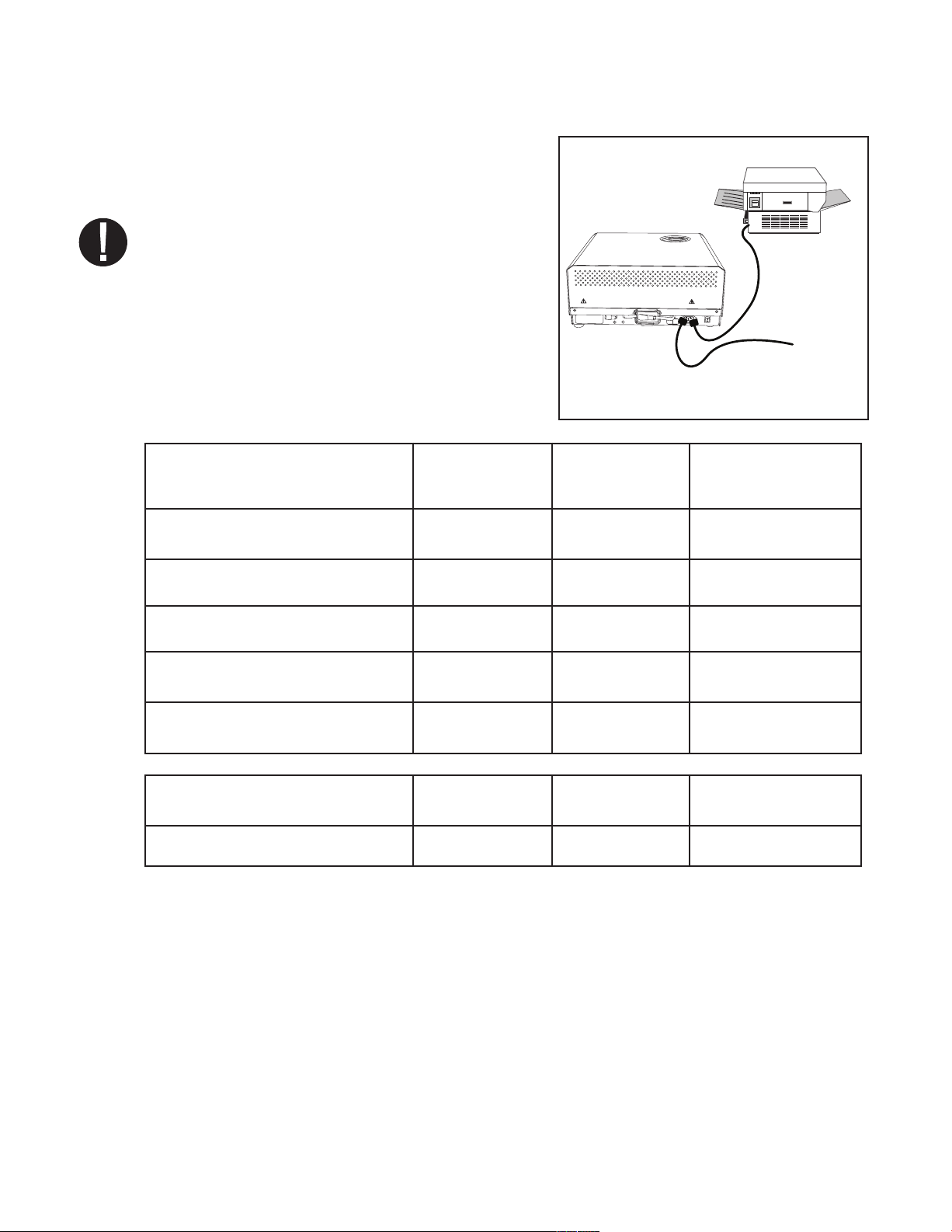

All Statim units that do not have an internal

printer will have an RS232 communication

port that will allow you to connect to an external

printer or to a SciCan Data Logger. For printing,

you will need to purchase a recommended printer

(see list below) from your local computer or electronics store. For data storage, you can

purchase SciCan’s USB Data Logger to record

and store cycle information onto a mass storage

device (MSD) such as a USB Flash Drive or SD

memory card.

Printer Model End Of Line Serial Port Printer user °

CR/LF Bitrate character

Epson

TM-U220D (C31C515603) CR/LF 9600 248 [0xF8]

Citizen

IDP-3110-40 RF 120B CR 9600 N/A

Printer

Data

Logger

OR

Star Micro

SP212FD42-120 CR 9600 210 [0xd2]

Star Micro

SP216FD41-120 CR/LF 9600 210 [0xd2]

Star Micro

SP512MD42-R CR/LF 9600 210 [0xd2]

SciCan Data Logger End Of Line Serial Port Printer user °

CR/LF Bitrate character

For Mass Storage Device* N/A 9600 32 [0xd2]

* Due to a variety of software programs/viewers that can be used to view the data files stored

on a mass storage device such as a USB memory stick, we recommend the above settings.

For your Statim to communicate to a specific device, you must enable this function through

the User Setup menu. Follow the instructions in section 6.2 Installing the

SciCan Data Logger below to enable communication to either an external printer or

the SciCan Data Logger.

Page 25

Page 26

6. The Communication Port con’t.

6.2 Installing the SciCan Data Logger

SciCan’s USB Data Logger can record and store cycle information onto a mass storage

device (MSD) such as a USB Flash Drive or SD memory card.

These instructions are for units with a 9-pin communication (RS232) port located at

the back of the unit.

Follow the steps below before connecting the Data Logger.

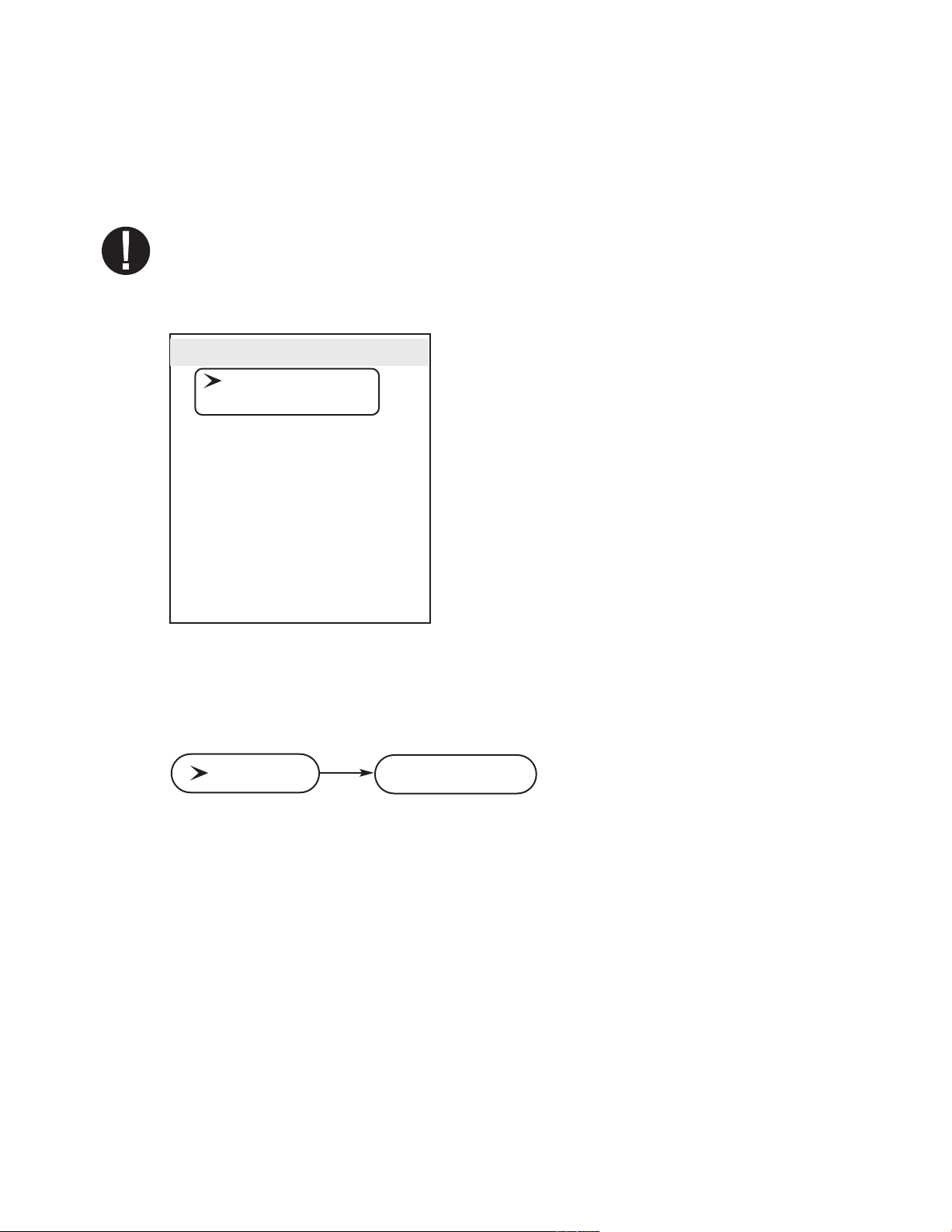

User Mode

Time/Date Setup

Language Setup

Unit ID Setup

Water Quality

Last Printout

RS232

End Of Line CR/LF

Serial Port Bitrate

Printer user ° char

Save and Exit

Exit

User Setup Menu

To install the SciCan Data logger, access

the user setup menu by powering up the

unit while pressing the STOP button.

Follow the instructions below to complete installation steps.

STEP 1

Selecting the USB Flash/MSD Option

RS232

1. Power up unit while pressing the STOP button to access the User Setup menu.

2. Using the UNWRAPPED and WRAPPED buttons, scroll to RS232 and select it by pressing the RUBBER AND PLASTIC button.

3. From the RS232 menu, use the UNWRAPPED and WRAPPED buttons to scroll down to

the USB/FLASH MSD option and press the RUBBER AND PLASTIC button to select and

return to the User Setup menu.

USB/Flash MSD

Page 26

Page 27

6. The Communication Port con’t.

Setting the Serial Port Bitrate to 9600

Serial Port Bitrate

1. From the User Setup menu, use the UNWRAPPED and WRAPPED buttons to scroll to

the Serial Port Bitrate menu and select it using the RUBBER AND PLASTIC button.

2. From the Serial Port Bitrate menu, use the UNWRAPPED and WRAPPED buttons to

scroll down to 9600 and press the RUBBER AND PLASTIC button to select and return to

the User Setup menu.

9600

Setting the Printer user Character; (example: 134°C)

Printer user ° char

1. From the User Setup menu, use the UNWRAPPED and WRAPPED buttons to scroll to

the Printer user ° char menu and select it using the RUBBER AND PLASTIC button.

2. From the Printer user ° char menu, using the UNWRAPPED button to increase the displayed value by one, and the WRAPPED button to increase that value by ten, enter the

value 32 [0x20] and press the RUBBER AND PLASTIC button to accept and return to the

User Setup menu.

32 [0x20]

Save and Exit

Save and Exit

A Save and Exit must be performed after the above settings are completed. If this is not

done, the information will revert to its prior settings.

1. From the User Setup menu, use the UNWRAPPED and WRAPPED buttons to scroll to

Save and Exit.

2. Select it by pressing the RUBBER AND PLASTIC button.

The LCD will display time and date

information and a sequence of

messages:

HH:MM DD/MM/YYYY

“MSD NOT DETECTED”/”INSERT

MSD/FLASH”/”SELECT A CYCLE”

Page 27

Page 28

6. The Communication Port con’t.

Step 2

Selecting the Time and Date

Time/Date

Note: If the time and date were set according to section 3.6, this does not have to be per-

formed again.

1. Power up unit while pressing the STOP button to access the User Setup menu.

2. Using UNWRAPPED and WRAPPED buttons, scroll to Time/Date Setup and press the

RUBBER AND PLASTIC button to select it.

3. From the Time/Date Setup menu, set the time and date using the UNWRAPPED and

WRAPPED buttons to change the displayed values and the RUBBER AND PLASTIC button to select. Press the STOP button when completed.

HH:MM DD/MM/YYYY

Step 3

Setting Unit ID

Unit ID

Note: If the unit ID was set according to section 3.8, this does not have to be

performed again.

1. Power up unit while pressing the STOP button to access the User Setup menu.

001

2. Using the UNWRAPPED and WRAPPED buttons, scroll to the Unit ID Setup and press

the RUBBER AND PLASTIC button to select it.

3. From the Setup Unit ID menu, use the UNWRAPPED and WRAPPED buttons to change

the displayed values and the RUBBER AND PLASTIC button to select and move to the

next digit. Press the STOP button when completed.

Step 4

Connecting the SciCan Data Logger

1. Ensure that both the Statim unit and the SciCan Data Logger are off.

2. Connect the SciCan Data Logger to the Statim unit by using the serial cable.

3. Power up the SciCan Data Logger

4. Power up the Statim unit.

5. The LCD will display the following

sequence of messages:

6. Insert USB Flash Drive or SD memory card

7. After a few seconds the LCD will display

the following sequence of messages:

REMOVE MSD/SELECT A CYCLE

HH:MM DD/MM/YYYY

“MSD NOT DETECTED”/”INSERT

MSD/FLASH”/”SELECT A CYCLE”

HH:MM DD/MM/YYYY

USB/FLASH DETECTED/SAFELY

Page 28

Page 29

6. The Communication Port con’t.

6.3 Installing Paper on the Internal Printer

Use only paper approved for use with the optional internal printer on the Statim 5000S. The

use of any other paper will damage the printer and will void the warranty. Thermal paper is

available from SciCan (SciCan order no. 01-101657S).

Do not operate the printer without paper. If you run out of thermal paper, or if you do not wish

to use the printer, turn it

Never pull the paper backwards through the printer.

This will damage the printer mechanism.

To install the paper into the printer, follow these steps:

OFF.

1. Power the Statim 5000S

2. Open the printer door

3. Power the printer

4. Unroll some paper from the thermal paper roll

paper cutting template included with each box.

5. Move the paper roll arm

so the paper strip feeds from the top of the roll and then carefully insert

it into the paper feed slot

If the paper does not feed from the top, the heat sensitive side of the paper will not be in contact with the print head and the printer will not print.

6. With one hand, continue to gently feed the paper strip into the paper feed slot. With the

other hand, press the paper advance button until the paper feeds by itself.

Keep the paper straight when feeding it into the printer or it may jam. Do not force the paper

into the slot! If the paper will not feed into the slot, pre-cut the end of the roll again and reload

the paper.

ON.

ON.

1

■■

by pushing on the top half of the door.

3

■■

and trim the corners using the

4

■■

into the loading position. Place the paper roll

5

■■

until it stops.

3

■■

on the arm

Page 29

Page 30

6. The Communication Port con’t.

7. Continue to press the paper advance but-

6

■■

ton

paper exit slot on the front of the printer.

Then, move the paper roll

the operating position and close the printer

door

ate.

until the paper feeds through the

3

■■

and arm into

1

■■

. The printer is now ready to oper-

■■

■■

5

2

When you see a red line on one side of the

paper, it is time to replace the roll.

If a paper jam occurs, and the paper cannot be

removed by pressing the paper advance button

6

■■

, do not pull the paper backwards through

the printer.

Never put a utensil or tool into the paper exit

slot. For full instructions on how to remove

paper jams, see section 6.4 Removing Internal

Printer Paper Jams.

3

■■

To replace the paper roll

steps:

1. With scissors, cut the paper between the

roll and the paper feed slot

2. Remove the roll from the arm and discard

the unused portion.

3. Press the paper advance button

the paper that remains in the printer out of the slot

at the front of the printer.

, follow these

5

■■

.

6

■■

to feed

■■

■■

■■

4

4

6

■■

3

Figure 15.1

5

■■

2

■■

6

■■

■■

3

Figure 15.2

■■

1

4. Install the new thermal paper roll by following the

instructions described in this section.

Page 30

Page 31

6. The Communication Port con’t.

6.4 Removing Internal Printer Paper Jams

If paper jams in the printer and cannot be removed

6

■■

by pressing the paper advance button

er must be disassembled. Do not pull the paper

backwards through the printer and never put utensils or tools into the paper exit slot.

When paper is jammed in the printer, follow

these steps to remove the jam:

, the print-

■■

7

8

■■

1. Power the Statim 5000S OFF and unplug the

unit.

2. Using scissors, cut the paper between the

5

■■

roll and the paper feed slot

3

3. Remove the paper roll

4

■■

roll arm

loading position.

4. Using a #1 Phillips screwdriver, remove the

three screws

remove the cover.

5. Note the orientation of the exposed printed

wiring board and the paper roll arm

bled on the printer door

6. Gently lift the printed wiring board upwards and away from the printer door. Exercise

care while handling the board. The printer is integral to the wiring board. Do not place

strain on the connections of the ribbon cable soldered to the board. Do not remove the

connector of the flexible cable from the connector header on the board. The paper drive

mechanism on the underside of the wiring board is now exposed.

and leave the arm in the

7

■■

from the printer cover

■■

■■

.

from the paper

4

■■

1

.

8

■■

and

assem-

■■

1

10

■■

■■

11

12

■■

13

■■

■■

9

■■

10

■■

15

Figure 16

14

■■

■■

4

7. Using a pair of tweezers or fine needle-nosed pliers, carefully remove the paper

from the mechanism.

When the paper is removed, reassemble the printer:

1. Carefully snap the paper roll holder, in the loading position, back into the clips on the

1

■■

printer door

.

Page 31

Page 32

6. The Communication Port con’t.

2. Place the printed wiring board back into position on the printer door. Note the alignment

9

■■

of the mounting holes

door. The black plastic printer body rests between the locating ribs

the printer door.

3. Ensure that the flexible cables

and the wiring board.

4. Place the printer cover on the printer door. Ensure that the flexible cables are not

pinched between the cover and the door. The power button and the paper advance button must protrude through the openings in the cover and operate freely.

5. Using a #1 Phillips screwdriver, secure the printer cover to the printer door with

the three screws retained during the disassembly procedure. Do not over-tighten these

screws.

6. Plug your Statim 2000S / 5000S into the wall receptacle. Reconnect the printer if it was

previously disconnected. Turn the power switch to the ON position.

in the wiring board and the mounting bosses

11

14

■■

■■

,

are not pinched between the printer door

13

■■

on the printer

10

■■

on the inside of

7. Press the printer power button to the ON position. Load paper into the printer following

the procedures in section 7.3 Installing Paper on the Internal Printer.

Page 32

Page 33

6. The Communication Port con’t.

6.5 Cycle Printout Overview

1. Model: STATIM 2000 software:

S2S2R410

2. Unit Identifier: autoclave has

been set up as number 323

3. Cycle counter: the number of

cycles having been run on the

unit = 9

1.

2.

3.

4.

5.

6.

4. Time / Date: 1:38 pm 14th

April, 2003

5. Cycle Name: SOLID

UNWRAPPED (N)

6. Cycle Name cont’d – parameters: 134˚C /

3.5 min – 1P

7. Cycle clock: starting at 0:00

8. Warm up complete: start of

the conditioning phase is 2:07

(see cycle graph – ‘A’ phase

complete, start of ‘B’ phase)

9. Peek Temp. / Press. & Time of

conditioning purge: for each

purge (number of lines based

on cycle selection – this is a

one purge cycle – activity

within ‘B’ phase )

10. Lowest Temp. / Press. & Time

of conditioning purge: for each

purge (number of lines based

on cycle selection – this is a

one purge cycle – activity

within ‘B’ phase )

7.

8.

9.

10

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

.

Page 33

Page 34

6. The Communication Port con’t.

11. Start Time of Pressurization: 3:21(start of ‘C’ phase)

12. Start Time of Sterilization: 4:12 (start of ‘D’ phase)

13. Temp. / Press. & Time at start of sterilization (‘D’ phase)

14. Min. Temp. / Press during the sterilization phase (lower limits of ‘D’ phase)

15. 135.1˚C 308 kPa

16. Max. Temp. / Press during the sterilization phase (upper limits of ‘D’ phase)

17. 136.7˚C 323 kPa

18. Temp. / Press. & Time of end of sterilization phase (end of ‘D’ phase)

19. Time Venting started: 7:43 (start of ‘E’ phase)

20. Sterilization was successfully completed

21. Time Air Drying started: 8:07 (start of ‘F’ phase)

22. Cycle was stopped by user

23. Drying cycle aborted prior to completion, load may not be dry

Page 34

Page 35

7. Troubleshooting

Problem

Unit does not power ON.

There is water under the machine.

Solution

Check that the unit is plugged into a properly

grounded outlet and that the power cord is firmly

seated at the rear of the machine.

Try another circuit. Power unit OFF for 10 seconds

and then power ON again.

Check the condition of the line circuit

breaker or fuse.

Check that water was not spilled when refilling the

reservoir. Make sure the plug in the exhaust tube is

secured. Remove and reinsert the cassette .

Attempt another cycle.

Be careful. The metal parts will be hot, and the cassette will contain hot steam.

The cassette is leaking. If water drips from the underside of the unit during operation, check the cassette

seal for misalignment or damage and replace the seal

if required.

Instruments do not dry.

Be careful. The metal parts will be hot, and the cassette will contain hot steam.

Attempt another cycle. If it still leaks attempt another

cycle using a different cassette if possible.

If the leak persists, turn the unit OFF, remove and

unload the cassette, unplug the unit, and call

your dealer.

Best drying occurs when the cycle continues to completion. Allow the cycle to finish. Make sure the instruments are loaded correctly in the cassette. Refer to

section 4.4 Preparing and Loading Instruments.

Check the unit leveling.

Clean the inside of the cassette and treat with Stat-Dri

drying agent. Refer to section 5.1 Cleaning the

Cassette. Examine the exhaust tube (tube to the

waste bottle) for kinks.

Page 35

Page 36

7. Troubleshooting con’t.

If kinked, straighten the tube. If the tube cannot be

straightened, remove it from the push-in fitting

attached to the Statim. Depress the collar on the fitting and with the other hand pull firmly on the tube.

Once the tube is free of the fitting, cut the damaged

section of tubing away using a sharp instrument. Be

sure that you leave enough tube to reach the unit

when you re-attach the tube to the exhaust fitting. If

the tube is too short to remove a section, contact your

SciCan dealer fora replacement.

Make sure the compressor is working. To check,

remove the exhaust tube from the waste bottle.

Start the Air Drying Only Cycle, and place the free

end into a glass of water. If there is not a strong,

steady flow of bubbles, the compressor is not

functioning properly. Contact your SciCan dealer.

Cycle interrupted — NOT STERILE,

Cycle aborted — NOT STERILE and

CYCLE FAULT messages.

Wait a few minutes and attempt another cycle before

proceeding to the next solution. Remove the cassette. Be careful. The metal parts will be hot and the

cassette will contain hot steam. Inspect the cassette

to ensure that the holes in the back of the seal are

perfectly aligned, and that the flexible lip of the seal is

completely free. Check the exhaust tube for kinks or

obstructions. If kinked, straighten the tube. If the

tube cannot be straightened, remove it from the pushin fitting attached to the Statim. Depress the collar on

the fitting and, with the other hand pull firmly on the

tube. Once the tube is free of the fitting, cut the damaged section of tubing away using a sharp instrument.

Be sure that you leave enough tube to reach the unit

when you re-attach the tube to the exhaust fitting. If

the tube is too short to remove a section, contact your

SciCan dealer for a replacement.

Check that the Statim has not inadvertently been

exposed to any electrical interference.

Refer to the Installation section dealing with

Environmental Considerations. (Section 3.1)

Try running another cycle. If the problem persists,

record the cycle fault message number and contact

your dealer.

Page 36

Page 37

7. Troubleshooting con’t.

Excessive steam issuing from the front

of the machine.

Message WATER QUALITY IS NOT ACCEPTABLE. Machine will not start.

Message REFILL RESERVOIR,

Machine will not start.

Remove and reinsert the cassette. Attempt another

cycle. Remove and check the cassette seal for misalignment or damage. Replace the seal if required.

Be careful as the metal parts will be hot and the cassette will contain hot steam.

If the leak persists, turn the unit OFF, remove and

unload the cassette and contact your SciCan dealer.

You have used water which is not steam-process distilled or is improperly distilled.

Empty the reservoir and refill with steam-process distilled water containing less than 5 ppm total disolved

solids (having conductivity of less than 10 µS / cm).

If you have the water conductivity meter, check the

quality of the water before refilling the reservoir.

Refer to the steps described in section 3.9 Shipping

the Unit to empty the reservoir.

The level of the water in the reservoir is low. Refill the

reservoir. Refer to the steps described in section 3.4

Filling the Reservoir.

Message PRINTER FAULT displayed on

LCD Printer is not printing.

The printer does not work.

The printer appears to work, but nothing is

printed on the paper.

Time and date are incorrect.

Check for a paper jam. If the paper is jammed, follow

the paper removal procedures outlined in section 6.4.

Power unit OFF for 10 seconds and then power

ON again. If the paper is still jammed, follow the disassembly procedures outlined in section 6.4

Removing

Make sure that the printer cable is connected securely

with the connector on the back of the Statim

and the

ered ON. Power unit OFF for 10 seconds and

then power ON again.

Ensure that the paper is loaded properly (refer to section 6.3 Installing Paper on the Internal Printer). Check

to see that the paper leaves the paper roll from the top

of the roll. This means that the treated surface of the

coated thermal paper will be in contact with the thermal

print head.

The time and date have not been set. See section

3.6

Paper Jams.

Statprinter

Setting the Time and Date.

. Make sure that the printer is pow-

Page 37

Page 38

7. Troubleshooting con’t.

Message MSD NOT CONNECTED <>

INSERT MSD/FLASH

Message MSD/FLASH FULL <>

REPLACE MSD

Message Missing lines of

Data on MSD/FLASH

Check the serial cable connection.

Check the power connection.

Ensure the lower red LED is lit.

Check that the Mass Storage Device is properly

inserted.

Repeat the instructions for Installing the SciCan

Data Logger on your Statim.

The MSD is full. Export the data.

Refer to the STATIM screen to confirm successful

sterilization.

Reset the Data Logger by unplugging its power, disconnecting the MSD and waiting 10 seconds. Then

re-connect the power adapter and insert the MSD into

the Data Logger.

If the problem persists, contact the SciCan Service

Center.

Message: The file or directory in the

MSD is corrupted or unreadable.

Refer to the STATIM screen to confirm successful

sterilization.

The MSD may have been unplugged while data was

being written to it. The MSD should not be unplugged

until after “SAFELY REMOVE MSD <> MSD/FLASH

DETECTED” is displayed.

The corrupted files or directories may be lost.

Reformat the MSD on your computer.

Page 38

Page 39

8. Spare Parts List

01-100204S

01-100724S

01-100735S

01-100780S

01-100782S

01-100812S

01-100834S

01-101649S

01-101657S

01-101658S

01-101709S

01-101755S

01-101757S

01-101766S

01-101768S

01-101769S

01-101779S

01-106030S

01-106071S

01-104093S

01-101783S

01-101970S

01-102119S

01-103139S

01-103475S

01-103557S

01-103865S

01-103945S

01-104343S

01-104472S

01-104696S

01-104697S

01-104698S

01-104699S

Exhaust Tube

Condenser Bottle w / o

Condenser

Waste Water Bottle Fitting

Bumper

Push-In Fitting (2000S)

Condenser Bottle

Cassette Lid (2000S)

Cassette Seal (5000S)

Thermal Paper (Box of 10 rolls)

Cassette Handles

Mesh Rack (5000S)

Push-In Fitting (5000S)

Cassette Lid w / Box (5000S)

Power Cord UK

Power Cord Switzerland

Power Cord Italy

Power Cord Europe

Cassette Lid Handle (2000S)

Extended Cassette Lid

Handle (5000S)

Exhaust Tube 3 m long

Reservoir Cap and Filter

Data Cable (5000S)

Filter Biological

Conductivity Meter

Tray (2000S)

Power Cord Repl. Denmark (det.)

Seal Lubricant

Rack-Tray Unwrapped

Instr. Kit (2000S)

Plug - Drain Tubing (5000S)

Extended Cassette Handles

(5000S)

Handpiece Adapter

Adapter Cassette Seal (2000S)

Adapter Cassette Seal (5000S)

Seal Insert

01-100207S

01-104700S

01-104702S

01-104704S

01-104786S

01-100028S

01-106438S

01-108340S

01-109300S

01-100008A

01-100271A

01-101613S

01-101614S

01-103923

01-103935

01-104104

01-104499

01-104701

01-104703

01-106101

01-106102

01-106653

01-210000

01-106325

2OZPLUS

8OZPLUST

32OZPLUS

99-108332

01-108341

Compressor Filter (2000S)

Adapter Cassette O-Ring Kit

Adapter Cassette Lid (2000S)

Adapter Cassette Lid (5000S)

Instrument Holder - 4 mm

(5000S)

Cassette Seal (2000S)

Cassette Lid, Extended (2000S)

Statim PCD – spare parts

Water Reservoir Filter Kit

ACCESSORIES

Kit Cassette Final (2000S)

Kit Tray Cassette w / Mesh

(2000S)

Cassette Complete (5000S)

Tray Complete (5000S) with Box

Condenser Additional Bottle

STATDRI Plates (5000S)

Extended Length Cassette

(5000S)

Extended Cassette Instrument

Rack (5000S)

Adapter Cassette (2000S)

Adapter Cassette (5000S)

Handpiece Adapter Kit (2000S)

Handpiece Adapter Kit (5000S)

Mesh Tray (2000S)

Kit Printer (5000S)

Container Endoscope

Complete (5000S)

STAT-dri 2 oz.

STAT-dri 8 oz.

STAT-dri 32 oz.

Chemical Emulator

134˚C/3.5 min

Statim PCD Final Assembly Kit

Page 39

Page 40

9. Warranty

Limited Warranty

For a period of one year, SciCan guarantees that the Statim 2000S / 5000S, when manufactured by SciCan in new and unused condition, will not fail during normal service due to

defects in material and workmanship that are not due to apparent abuse, misuse, or accident.

The one year warranty will cover the performance of all components of the unit except consumables such as the cassette seal, the compressor filter and the microbiological filter, provided that the product is being used and maintained according to the description in the

user’s manual.

A two-year warranty will be applied specifically to the water pump, steam generator, and

printed circuit board (PCB) provided that the product is being used and maintained according

to the description in the user’s manual.

In the event of failure due to such defects during this period of time, the exclusive remedies

shall be repair or replacement, at SciCan’s option and without charge, of any defected

part(s) (except gasket), provided SciCan is notified in writing within thirty(30) days of the

date of such a failure and further provided that the defective part(s) are returned to SciCan

prepaid.

This warranty shall be considered to be validated, if the product is accompanied by the original purchase invoice from the authorized SciCan dealer, and such invoice identifies the item

by serial number and clearly states the date of purchase. No other validation is acceptable.

After one year, all SciCan’s warranties and other duties with respect to the quality of the

product shall be conclusively presumed to have been satisfied, all liability therefore shall terminate, and no action or breach of any such warranty or duty may thereafter be commenced

against SciCan.

Any express warranty not provided hereon and any implied warranty or representation as to

performance, and any remedy for breach of contract which, but for this provision, might arise

by implication, operation of law, custom of trade or course of dealing , including any implied

warranty of merchantability or of fitness for particular purpose with respect to all and any

products manufactured by SciCan is excluded and disclaimed by SciCan. If you would like

to learn more about SciCan products and features, visit our website at www.scican.com.

Page 40

Page 41

10. Test Protocol

KaVo GENTLEforce 7000C

Kavo – Gentle Power Lux 25 LPA

W&H-Trend LS, WD-56

W&H-Trend HS, TC-95RM

KaVo Super-Torque LUX/640 B

KaVo-INTRAmatic LUX3, 20 LH

NSK-PANA Air

NSK-ATL118040

NSK – Ti-Max

STAR-430 SWL

Sirona-T1 Classic, S 40 L

Sirona-T1 Control, TC3

Midwest-Tradition

Bein – Air - Bora L

W&H – WS-75

W&H – WA-99 LT

W&H – TA-98 LC

B & L Ophthalmology instruments

Gimble irrigating cannula 30g E4894

Lasik cannula E4989

Gillis irrigating-aspirating cannula E4932

Nichamin hydrossection cannula 26g E4421 H

Irrigating-aspirating handpiece MVS 1063C

R

udolf Medizintechnik GmbH Endoscope accessories

Trocar sleeve, arthroscopy, 2 rotating stop cocks,

1.7 mm dia x 104 mm length #10-0008-00

Trocar sleeve, hysteroscopy diagnostic sheath, 1 fixed

stop cock, 2.7 mm dia x 302 mm length #10-0049-00

A

lcon ophthalmic handpiece

NeoSonix Phaco handpiece

M

iltex medical instruments

Frazier needle 26-778

Yeoman biopsy forceps with rotating shaft 28-304

Kerrison rongeur 18-1994

Frazier-Ferguson tube 19-570

Yankauer suction tube 2-104SS

Menghini biopsy needle 13-150

Becton Dickinson

Needle, 30G1

M

edical Workshop

Hockeystick Forceps, membrane peeling mw-1925

D

ental instruments

—

—

—

—

/ / 18

UN

UN

/ / /

/ /

HOLLOW / UNWRAPPED (S) 134˚C / 3.5 min