Page 1

STATCLAVE™G4 - Chamber Autoclave

Operator’s Manual

95-115362 CA EN R3

Page 2

Manufacturer’s Information and Customer Service Information

For all ser vice and repair inquiries:

Canada: 1-800-870-7777

techservice.ca@scican.com

Manufactured by:

SciCan Ltd.

1440 Don Mills Road,

Toronto, ON M3B 3P9

Canada

Telephone: (416) 445-1600

Fax: (416) 445-2727

Toll fre e: 1- 800-667-7733

STATCLAVE G4 Operator’s Manual, Copyright 2019 SciCan Ltd. All rights reserved.

Page 3

Quick Start Guide

1. Switch the autoclave ON.

3. Ensure BOTH drainage tubes are connected at the back.

2. Ensure BOTH reservoirs are filled with high quality distilled water.

IMPORTANT! Never Use Tap Water.

More informati on IN SECTION 4.

4. Pull up on the door latch to open the door.

More informati on in SECTION 2.3

5. Insert the load.

CAUTION! Hot Chamber.

More informati on in SECTION 5.

7. Select a cycle.

More informati on in SECTION 1.7

6. Close and latch the door.

8. Press the START icon.

More informati on in SECTION 7.

Page 4

1. Your STATCLAVE 3

1.1 Checking the Package Contents 3

1.2 Important Information About Using Your STATCLAVE 4

1.3 Operating Principles, Key Features and Safety

Devices 5

1.4 Unit Overview 7

1.5 Touchscreen Overview 8

1.6 Using the Operation Screens 8

1.7 Unlocking the Door 9

9. Storing, Retrieving and Printing

Sterilization Records 45

9.1 Retrieving Cycle Information Using the Touchscreen 45

9.2 Retrieving Cycle Information Using the Web Portal 45

9.3 Retrieving Cycle Information Using

the USB Data Back Up 46

9.4 Connecting to a Printer 47

9.5 Adjusting your Print Settings 47

9.6 External Printer Specifications 47

2. Set Up 10

2.1 Installing Your STATCLAVE 10

2.2 Connecting and Powering Your STATCLAVE 11

2.3 Connecting Your STATCLAVE’s Water

Draining System 11

2.4 Connecting your STATCLAVE to a Network 13

3. Getting Started 15

4. Filling the Water Reservoirs 17

4.1 Manual Filling Using Reservoir Top 18

4.2 Manual Filling Using Quick Connector at Unit Front 19

4.3 Automatic Filling Using a VistaPure Specialized

Water Filtration System with Accumulation Tank 20

4.4 Automatic Filling Using External Water Tank

and Auxiliary Pump 21

5. Loading Instruments 22

5.1 Using the Chamber Rack 23

5.2 Wrapped Instruments 24

5.3 Unwrapped Instruments 26

5.4 Rubber and Plastic 27

5.5 Textiles and Surgical Packs 27

5.6 Using Biological and Chemical Indicators 27

6. Using Your STATCLAVE 28

6.1 Running a Cycle 28

6.2 Stopping a Cycle 30

6.3 Using the Delayed Start 31

6.4 Emergency Door Opening 32

6.5 Running a Bowie-Dick Test 33

6.6 Running a Vacuum Test 35

6.7 Using the Custom Cycle 35

10. Maintenance Procedures 48

10.1 Preventative Maintenance Message 48

10.2 Preventative Maintenance Schedule 48

10.3 Cleaning the Door Seal and Door Plate 49

10.4 Cleaning and Disinfecting the External Surfaces 49

10.5 Cleaning the Sterilization Chamber, Rack and Trays 49

10.6 Draining the Reservoirs for Cleaning 50

10.7 Cleaning the Water Reservoirs and Reservoir Filters 51

10.8 Cleaning the External Water Reservoir Tank 52

10.9 Cleaning the Chamber Filters 52

10.10 Replacing the Bacteriological Filter 53

10.11 Replacing the Door Seal 53

10.12 Using On-Screen Instructions 53

10.13 Enabling Remote Access for a Technician 54

10.14 Preparing the Unit for Shipping 54

11. Troubleshooting 55

12. Ordering Spare Parts and Accessories 58

13. Limited Warranty 59

14. Specifications 60

APPENDIX A – Software Icons 61

APPENDIX B – Software Screens 62

APPENDIX C – STATCLAVE Cybersecurity Statement 64

7. Sterilization Cycles 37

8. Using and Changing Settings 38

8.1 Setting Up Load Traceability with User ID, PIN,

and Process Enforced Function 40

8.2 Setting Drying Time 42

8.3 Setting the Stand-By Mode 42

8.4 Setting Up and Using Your STATCLAVE Web Portal 43

8.5 Registering for STATCLAVE Online Access 44

Page 5

1. Your STATCLAVE

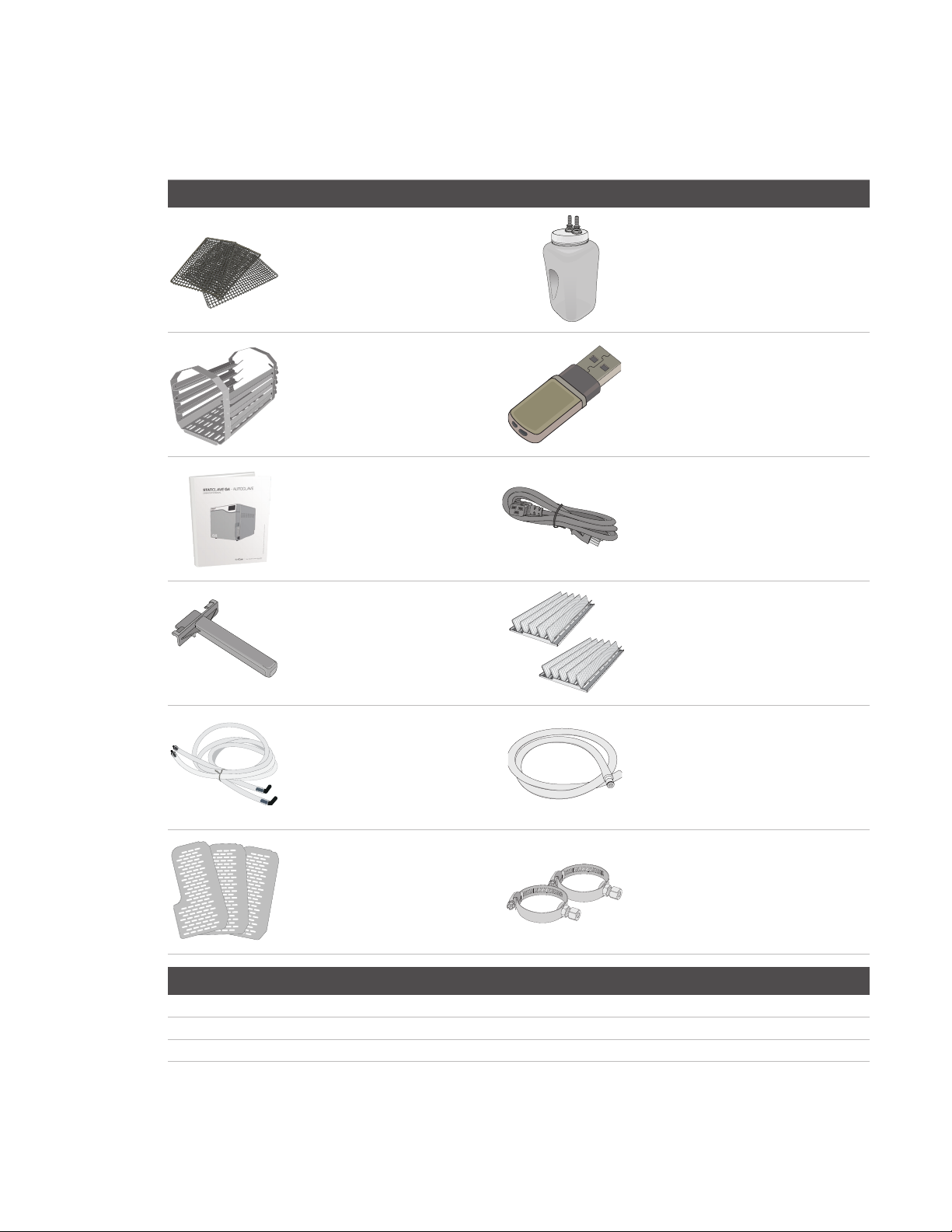

1.1 Checking the Package Contents

When you receive your STATCLAVE, the items listed below will be included. If any of the items are missing, contact your dealer

immediately.

Included with your STATCLAVE

1 Chamber rack 1 USB Memory stick

1 Operator’s manual 1 Power cord

4 Stainless steel wire

instrument trays

1 Tray extractor with door

unlocking pin (in handle)

1 Waste bottle

2 Pouched instrument racks

The following terms appear in this manual:

CAUTION! A potential hazard to the operator or end patient

IMPORTANT! A situation that may affect the functioning of the unit.

TIP Additional information that may be helpful.

2 Long silicone tubes

with elbow connectors

3 Drying plates Direct-to-drain hardware

3

1 Reservoir drain tube

(for use when cleaning reservoirs)

Page 6

1.2 Important Information About Using Your STATCLAVE

Intended Use

The STATCLAVE G4 is a dynamic air removal (pre-vacuum) table-top steam sterilizer intended for use by a health care provider

to sterilize medical products by means of pressurized steam.

It is suitable for the sterilization of dental and medical instruments that are validated to be sterilized by steam. The STATCLAVE

G4 has not been designed to sterilize liquid loads, pharmaceutical products, bio-medical waste or materials not compatible

with steam sterilization. The processing of such loads may result in incomplete sterilization and / or damage to the autoclave.

For more information about instrument suitability for steam sterilization, consult the instrument manufacturers’ reprocessing

instructions.

Get to Know Your STAT C L AVE: Read this Manual

The details of installing, using and maintaining your STATCLAVE are all in this manual. Please read this manual before operating

the unit and keep it for future reference. Users should follow the operating instructions and maintenance schedule described

in this manual. Contents of this manual are subject to change without notice to reflect changes and improvements to the

STATCLAVE product.

Water Quality

High quality distilled water is recommended for use in your STATCLAVE. Deionized, demineralized, or specially filtered water

can also be used. Never use tap water.

User Qualifications

The operation and maintenance of this unit should be restricted to trained and authorized personnel.

Repair and Modifications

Do not permit any person other than certified personnel to supply parts, service or maintain your STATCLAVE. SciCan shall

not be liable for incidental, special or consequential damages caused by any maintenance or services performed on the

STATCLAVE by a third party, or for the use of equipment or parts manufactured by a third party, including lost profits, any

commercial loss, economic loss, or loss arising from personal injury.

Never remove unit panels. Never insert objects through holes or openings in the cabinetry (unless explicitly instructed as in the

emergency door opening procedure, for example). Doing so may damage the unit and / or pose a hazard to the operator.

WiFi Compliance

This device has been tested and found to comply with the limits for a Class B digital device pursuant to the Federal

Communications Commission’s Part 15 Subpart B. The total radiated energy from the main antenna connected to the wireless

card conforms to the FCC limit of the SAR (Specific Absorption Rate) requirement regarding 47 CFR Part 2 Section 1093, when

the autoclave was tested. The transmission antenna for the wireless card is located in the front fascia.

CAUTION! Follow your local guidelines governing the verification of a sterilization procedure.

4

Page 7

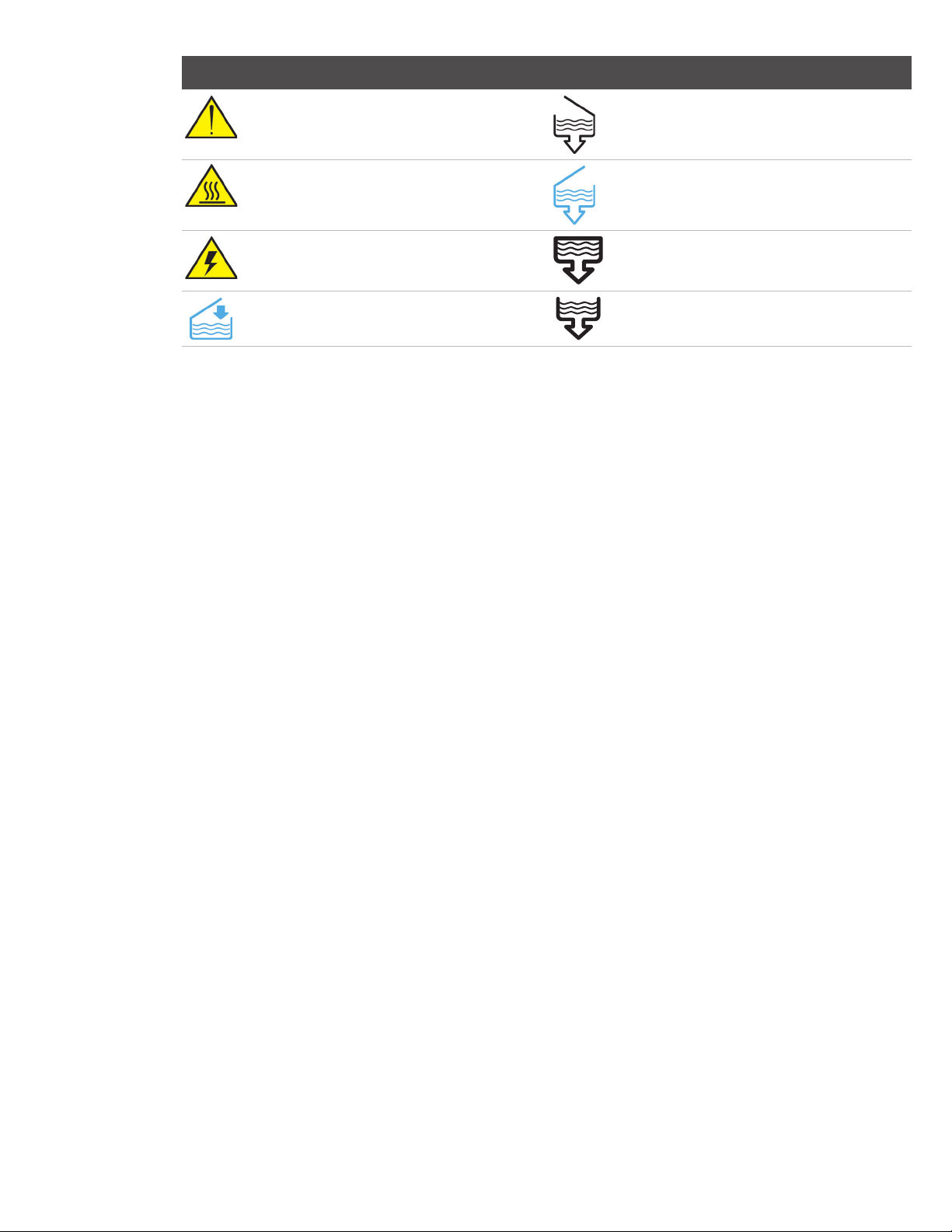

Pay close attention to the following symbols that appear on the unit:

Caution: A potential hazard to the operator

Caution: Hot surface

Caution: Danger of electric shock.

Disconnect power supply when servicing unit.

Clean water fill Exhaust drain

1.3 Operating Principles, Key Features and Safety Devices

The STATCLAVE is a dynamic air removal (pre-vacuum) table-top steam sterilizer that uses steam to sterilize wrapped and

unwrapped instrument loads typically used in dental and medical offices. It has six validated sterilization cycles with optimized

drying for fast, effective instrument processing. An additional custom cycle can be configured using one of three temperature

settings but this cycle must be validated by the user.

How it Works

The STATCLAVE uses a pre- and post-vacuum to condition the load at the beginning and end of each cycle.

› The pre-vacuum draw removes the air from the chamber before sterilization begins. This ensures more efficient steam

penetration into every load.

› The post-vacuum draw at the end of the cycle pulls the moist air from the chamber while heater bands warm the

chamber walls to speed drying.

› Finally, fresh, filtered air is drawn into the chamber to eliminate condensate and cool the chamber. This reduces the

cooling time and ensures the load is dry the moment you open the door.

Venturi reservoir drain

Clean water drain

Condenser drain (only used for shipping and

servicing)

Why Connect It

STATCLAVE’s WiFi-enabled G4 technology can connect and send cycle data to a smart device or computer, allowing staff

to focus on the most important thing in a dental practice, the patients. Maintenance reminders, instructions and the option

for automatic user interface software updates keep your STATCLAVE in good working order. Should your unit experience an

error, G4 technology connects it to specialized technicians who can provide remote support that can minimize unnecessary

downtime.

5

Page 8

Other Features

Closed-door drying

Ensures your wrapped and pouched loads finish dry and ready to store.

Deep chamber

Holds up to 4 large and 4 small IMS cassettes or up to 20 pouched loads.

Reservoir fill options

Includes front and top options, as well as an autofill port at the back.

Chamber preheating

Programmable chamber preheating and unit Stand-by mode ensure the STATCLAVE is warm and ready when you need it.

Delayed start option

Every cycle features a delayed start option to help coordinate sterilization with your work flow or even start the day with a clean

instrument load.

Water quality sensor

Protects the unit from the long-term damage of unsuitable water.

Motor-less door latching mechanism

Provides improved reliability over motorized door locks.

Flip-top water reservoir

Makes the STATCLAVE easy to fill and clean.

Read-at-a-glance, colour touchscreen

Offers real-time monitoring of all the important sterilization parameters.

Easy-to-use emergency door opening

Simple procedure to open the door and retrieve instruments in the event of a power loss.

Programmable features

Automate your test cycles to be completed BEFORE the start of your work day.

Low water indicator

Know when there is not enough water to run a full cycle - before you start it.

Space-saving design

Front venting and recessed connections at the back allow the unit to fit snugly into compact steri-centres.

Door monitoring system

Tells you if the door is properly closed.

Safety Devices

Overheat thermostats

Band heater safety thermostats and steam generator safety thermostat protect the unit.

Pressure relief valve

Chamber pressure relief valve protects the unit and users.

Pressure or vacuum relief on power failure

Automatic pressure or vacuum relief protects users when the power is interrupted.

Electronics protection

Controller board fuses protect the unit’s electronics.

6

Page 9

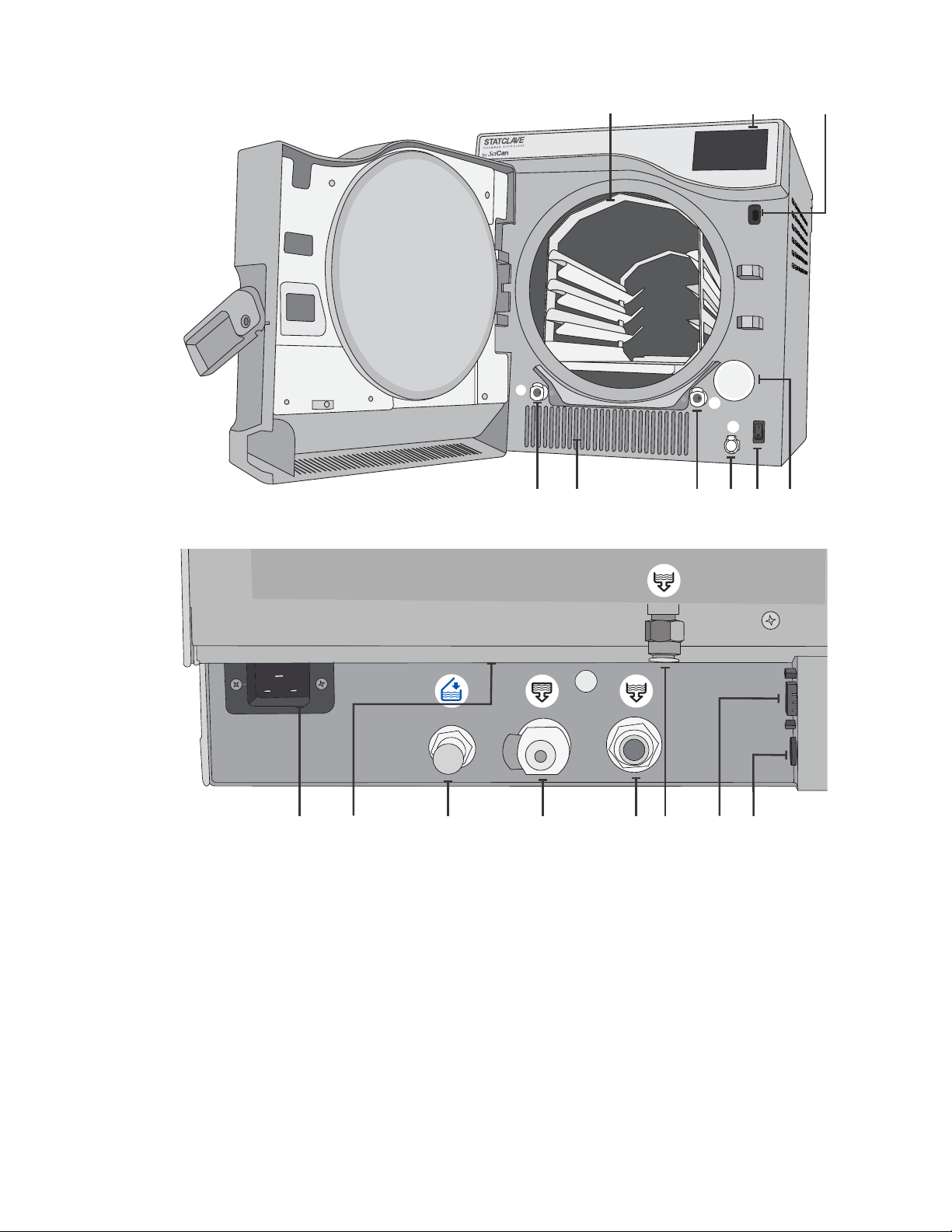

1.4 Unit Overview

7

31

42

8

5126

9

10

1. Venturi reservoir drain quick-connect (OUT)

2. Warm air exhaust

3. Clean water reservoir drain quick-connect (OUT)

4. Clean water reservoir fill quick-connect (IN)

5. Power switch

6. Bacteriological filter

(bacteria-retentive air filter)

7. Chamber rack

8. Touchscreen

9. USB port

11

7

15

13

10. Power cord input

11. Ethernet port (not visible)

12. Auto fill port for clean water reservoir

13. Condenser drain port (to drain for shipping)

14. Overflow drain port for reservoirs

15. Exhaust drain port

16. RS232 port

17. Power port for external fill pump (optional)

14

16 17

Page 10

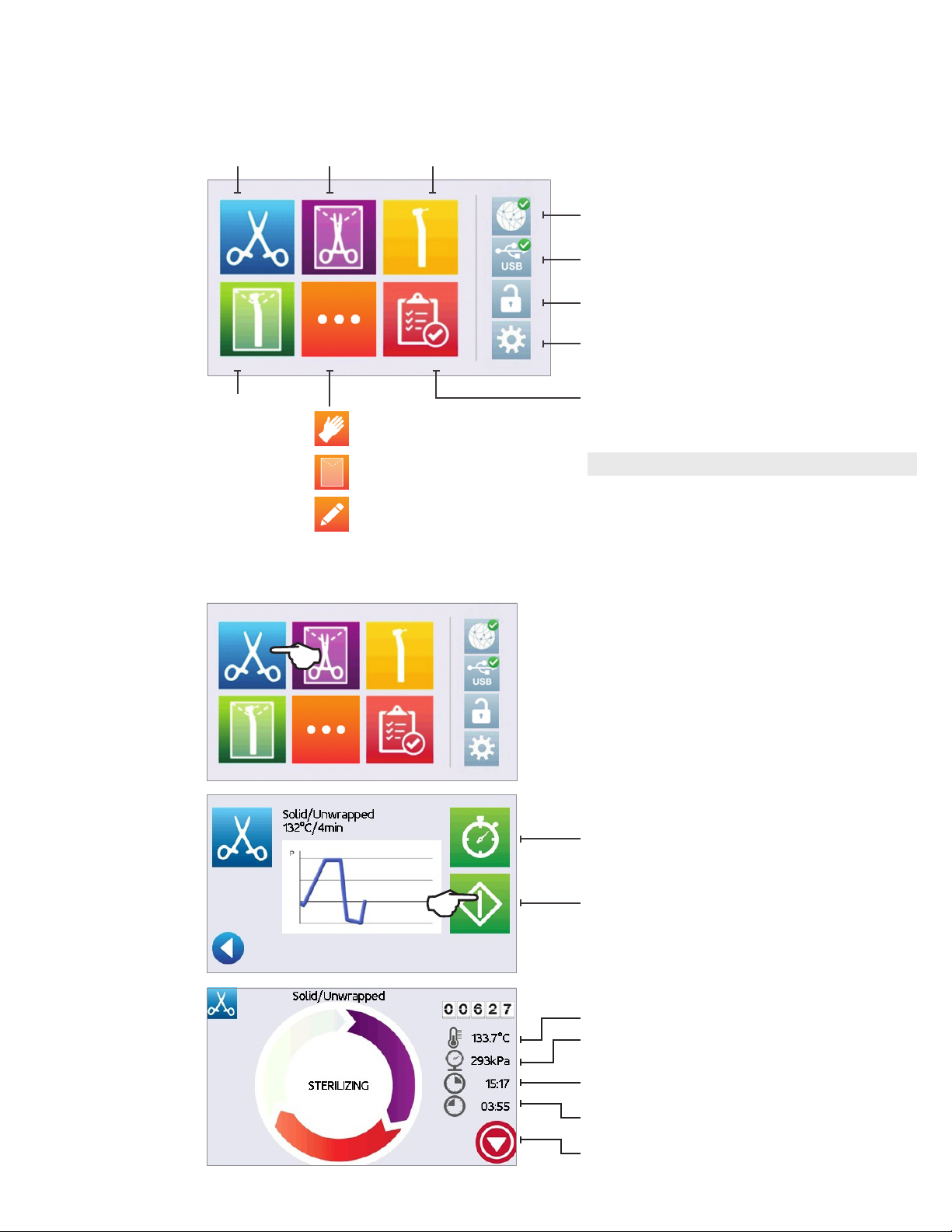

1.5 Touchscreen Overview

Home Screen

Solid /

Unwrapped

Solid /

Wrapped

Hollow /

Unwrapped

System icons:

Connectivity: Access network and Internet.

USB: View cycle history.

Door Lock: Unlock door.

Settings: Access settings menu.

Hollow /

Wrapped

Rubber & Plastic

Textiles/Porous

Custom Cycle

1.6 Using the Operation Screens

Test Cycles

Complete cycle information in Section 7

More inf ormati on on ico ns and sof twar e scree ns in Ap pendi ces A and B .

1. Select a cycle.

2. Press START.

Delayed start

More information in Section 6.3

Start

3. Cycle in progress.

Current chamber temperature

Current chamber pressure

Total time elapsed in the cycle - seen on cycle

screen for entire cycle

Appears during STERILIZATION and DRYING to show

time remaining

Stop

8

Page 11

1.7 Unlocking the Door

The STATCLAVE will lock the chamber door when you select a cycle.

To unlock the door, go to the home screen and follow these steps:

1. PRESS lock icon.

2. PRESS unlock icon.

3. PRESS the back icon.

4. Lock icon is now changed to unlocked.

9

Page 12

2. Set Up

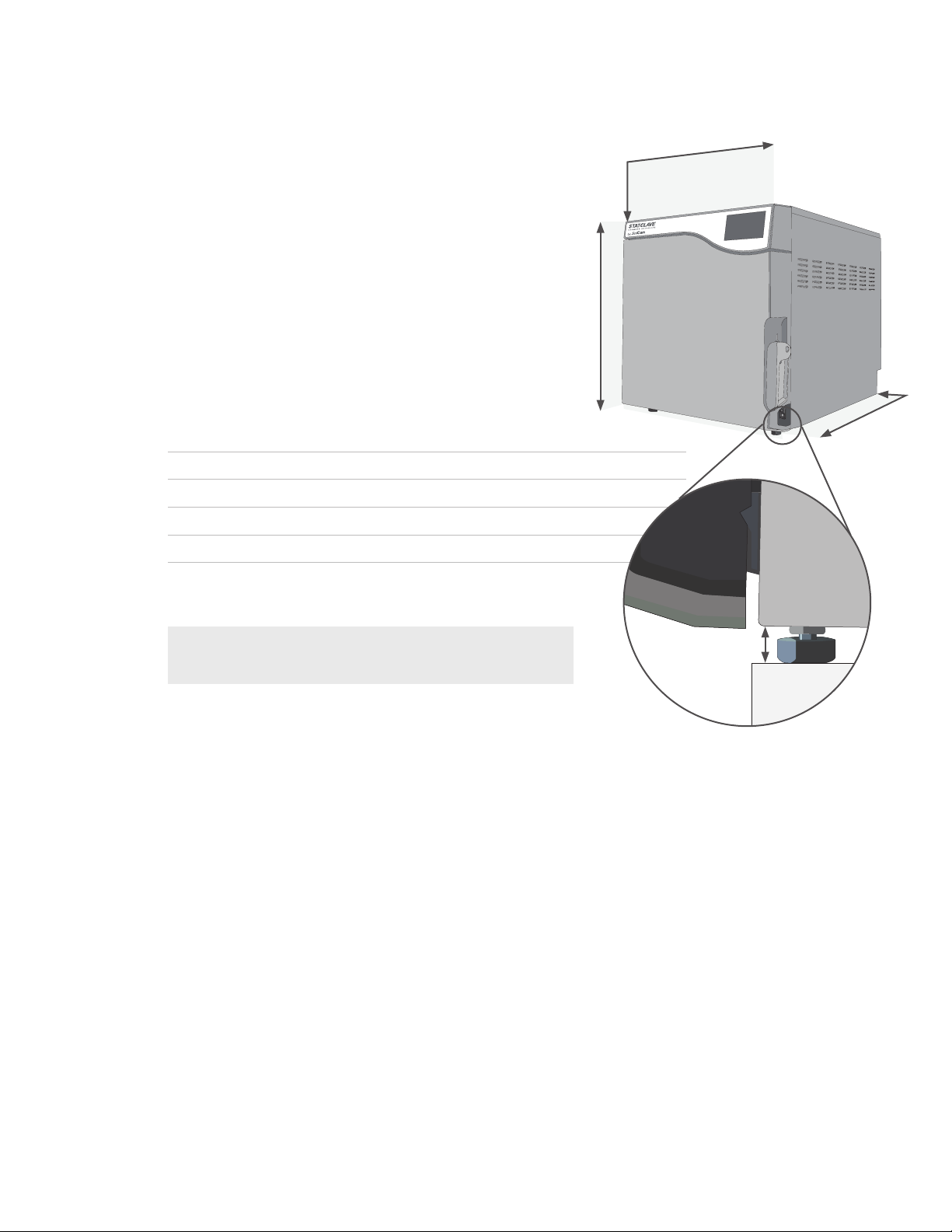

2.1 Installing Your STATCLAVE

› Place the STATCLAVE on a flat level surface

to support a 175 lbs (79.5 kg) load

.

strong enough

› Allow for at least 7” (180 mm) of space ABOVE the unit

to enable access to the reservoirs. If there is less than

7” (180 mm) above the unit, use a screwdriver to remove

the front hinge of the clean water reservoir so that the

reservoir panel can slide in and out of position from the front

of the unit.

› On the right side of the unit, allow for at least 2” (50 mm) of

space for ventilation.

› The unit vents warm air from below the door. Ensure the

door overhangs the level surface.

Unit Dimensions and Operating Environment

Height with front legs retracted 19” / 483 mm

Height with front legs fully extended 19.5” / 495 mm

Width 17.75” / 450 mm

Depth 25” / 635 mm

Weight (empty) 136 lbs/ 61.7 kg

Weight (with full reservoirs and full load) 175 lbs/ 79.5 kg

19”-

19.5”

17. 5 ”

7”

2”

25”

IMPORTANT! To improve drainage, ensure the unit is tilted

toward the back. Use the leveling feet to ensure the front of

the unit is 1” (25 mm) from the level surface.

Temperature and Humidity

Avoid installing your STATCLAVE in direct sunlight or close to a heat source such as vents or radiators. The recommended

operating temperatures are between 5˚C-40˚C / 41˚F-104˚F with a maximum humidity of 80%.

Electromagnetic Environment

Your STATCLAVE has been tested and meets applicable standards for electromagnetic emissions. While your unit does not

emit any radiation, it may itself be affected by other equipment that does. We recommend that your unit be kept away from

potential sources of interference.

1” gap

10

Page 13

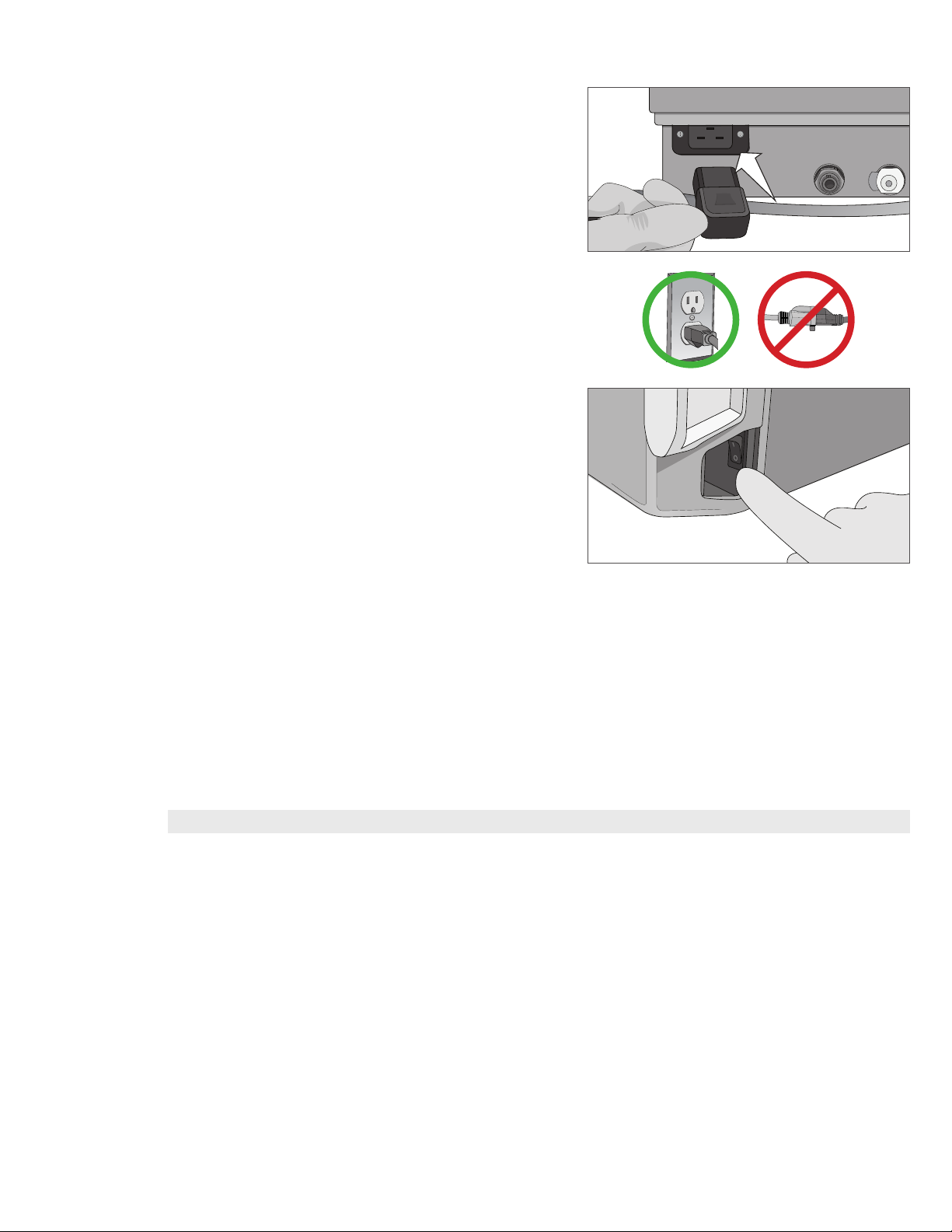

2.2 Connecting and Powering Your STATCLAVE

1. Ensure the power switch at the front right of the unit is in

the OFF position and connect the power cord supplied

to the power port at the back of the unit.

2. Connect directly to a power source.

Don’t use an extension cord.

3. Turn ON the power switch located at the front right of

the unit.

Electrical Connections

To power your unit, use properly grounded and fused power sources with the same voltage rating as indicated on the serial

number label at the back of your STATCLAVE.

› DO use an outlet that is protected by a 15A breaker.

› DO use a dedicated circuit, single phase 120 V~ 60Hz, 12A or 208-240 V~60Hz, 12A, depending on the voltage rating

indicated on the serial number label at the back of your unit.

Unit Electrical Characteristics:

› Protection class 1 device.

› Maximum power consumption of the autoclave is 1,440 Watts for 120V and 2,250-3,000 Watts for 208-240V.

2.3 Connecting Your STATCLAVE’s Water Draining System

IMPORTANT!

The STATCLAVE uses water from the Venturi reservoir to generate vacuum draws at the beginning and end of each cycle. For

the unit to operate, BOTH the clean water reservoir and the Venturi reservoir must contain the minimum required water levels.

When the chamber releases steam it travels through the condenser and drains from the condenser exhaust tube. Excess water

in both the Venturi reservoir and the clean water reservoir drains from the reservoir overflow tube. BOTH elbow fittings at the

back of the unit must be connected to a water draining system.

For the unit to function, BOTH reservoirs must be full and BOTH drain tubes must be connected.

11

Page 14

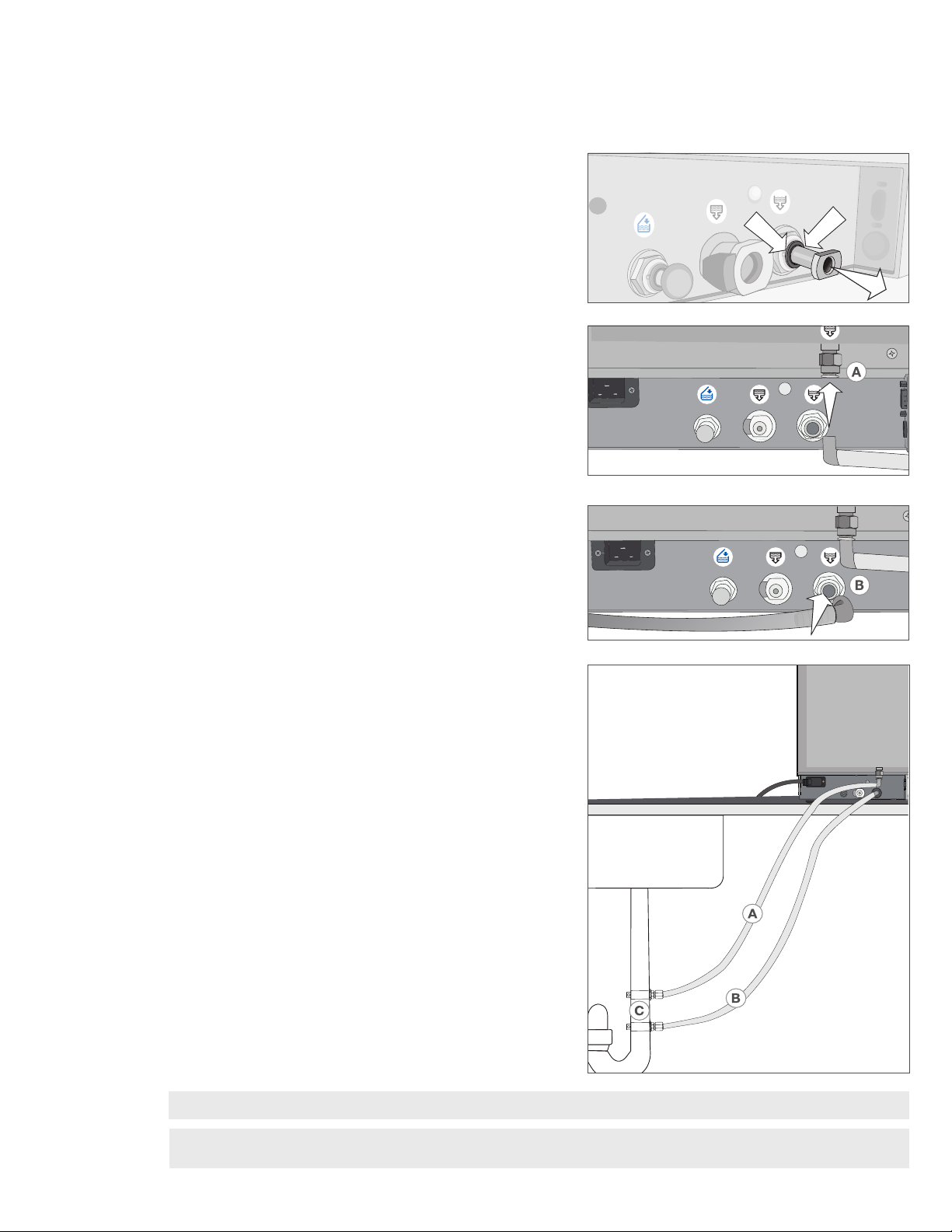

Connecting Directly to a Drain

Any new central drain point installation should be done by a technician. The drain points (C) must be located on the upper

portion of vertical drain pipe ABOVE the P-trap.

For direct-to-drain connections, you will need to use the direct-to-drain hardware (provided with the unit).

1. The unit is shipped with plugs in its ports. To remove a

plug, apply even pressure to the Inner Ring holding it

down on either side of the plug and pull out the plug.

2. Insert one elbow connector with silicone tube to the

metal exhaust port (A).

3. Insert the other elbow connector with silicone tube to

the plastic reservoir overflow

drain port (B).

4. Connect the exhaust tube with elbow fittings (A) to the

port installed on the drain pipe (C).

5. Connect the reservoir overflow tube (B) to the remaining

port on the drain pipe (C).

IMPORTANT! Avoid excess sagging in the lines; cut both tubes to measure.

IMPORTANT! Tubes should not be kinked, bent or otherwise obstructed. The connection point to the central drain

must be lower than the autoclave’s support surface otherwise the reservoirs may not drain correctly.

12

Page 15

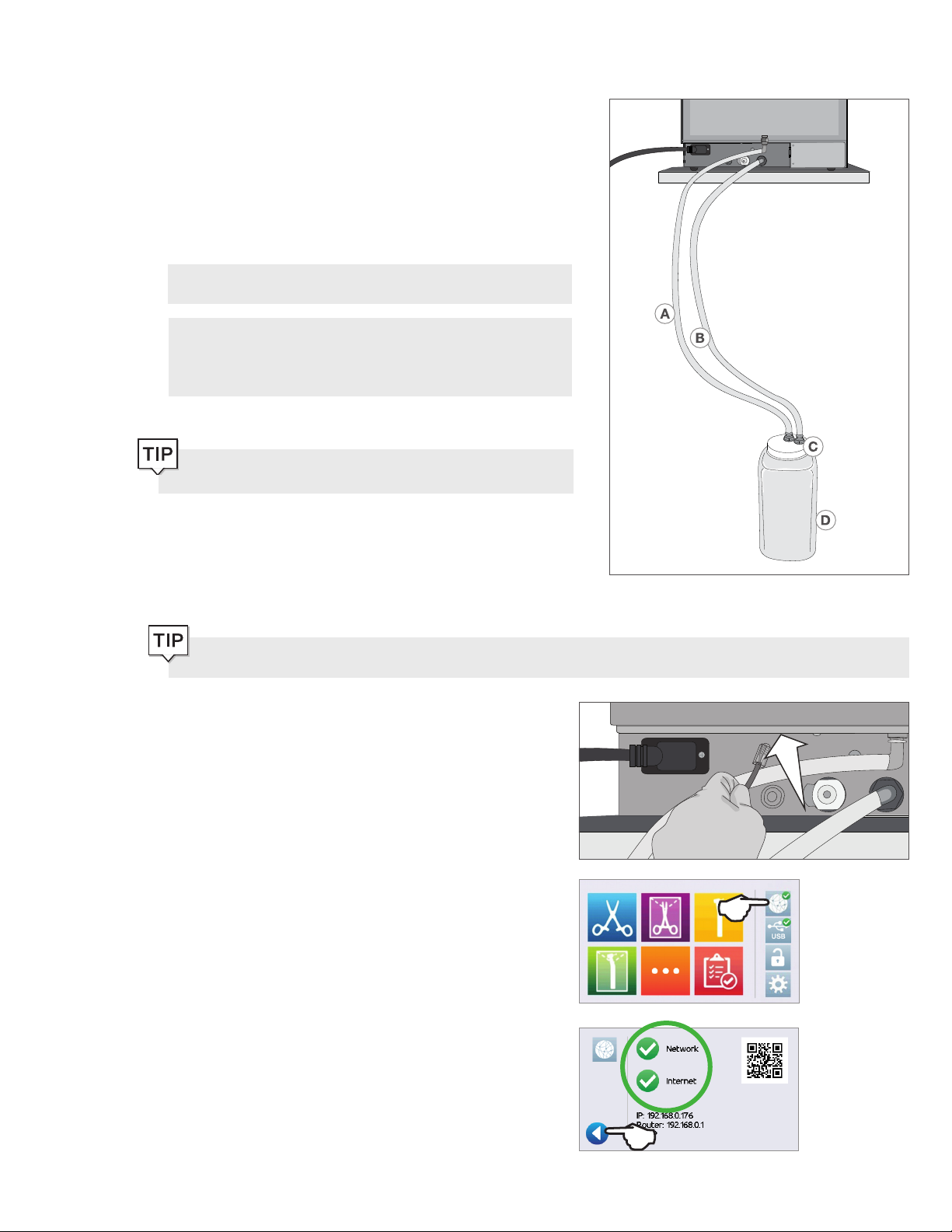

Connecting the Waste Bottle

The unit is shipped with a waste bottle in case a direct-to-drain installation is not possible. To use the waste bottle, follow these

steps:

1. Set the waste bottle (D) on the ground or in the

cabinetry below the unit.

2. Connect the exhaust tube (A) to a port on the waste

bottle cap (C).

3. Connect the reservoir overflow tube (B) to a port on the

waste bottle cap (C).

IMPORTANT! Avoid excess sagging in the lines; cut both

tubes to measure.

IMPORTANT! Tubes should not be kinked, bent or

otherwise obstructed. The waste bottle must be lower than

the autoclave’s support surface otherwise the reservoirs

may not drain correctly.

Add a small amount of water to the empty waste bottle to

give it stability.

2.4 Connecting your STATCLAVE to a Network

Connecting to a Wired Network

Do you want to drain the unit prior to shipping or cleaning? For instructions on how to completely drain both

reservoirs for cleaning or shipping, see Sections 10.6 and 10.14.

1. Connect Ethernet cable to port at back of unit.

2. From the home screen select the CONNECTIVITY icon.

3. Confirm that the unit is connected to both the Network

and Internet and press the back icon to return to

the home screen.

13

Page 16

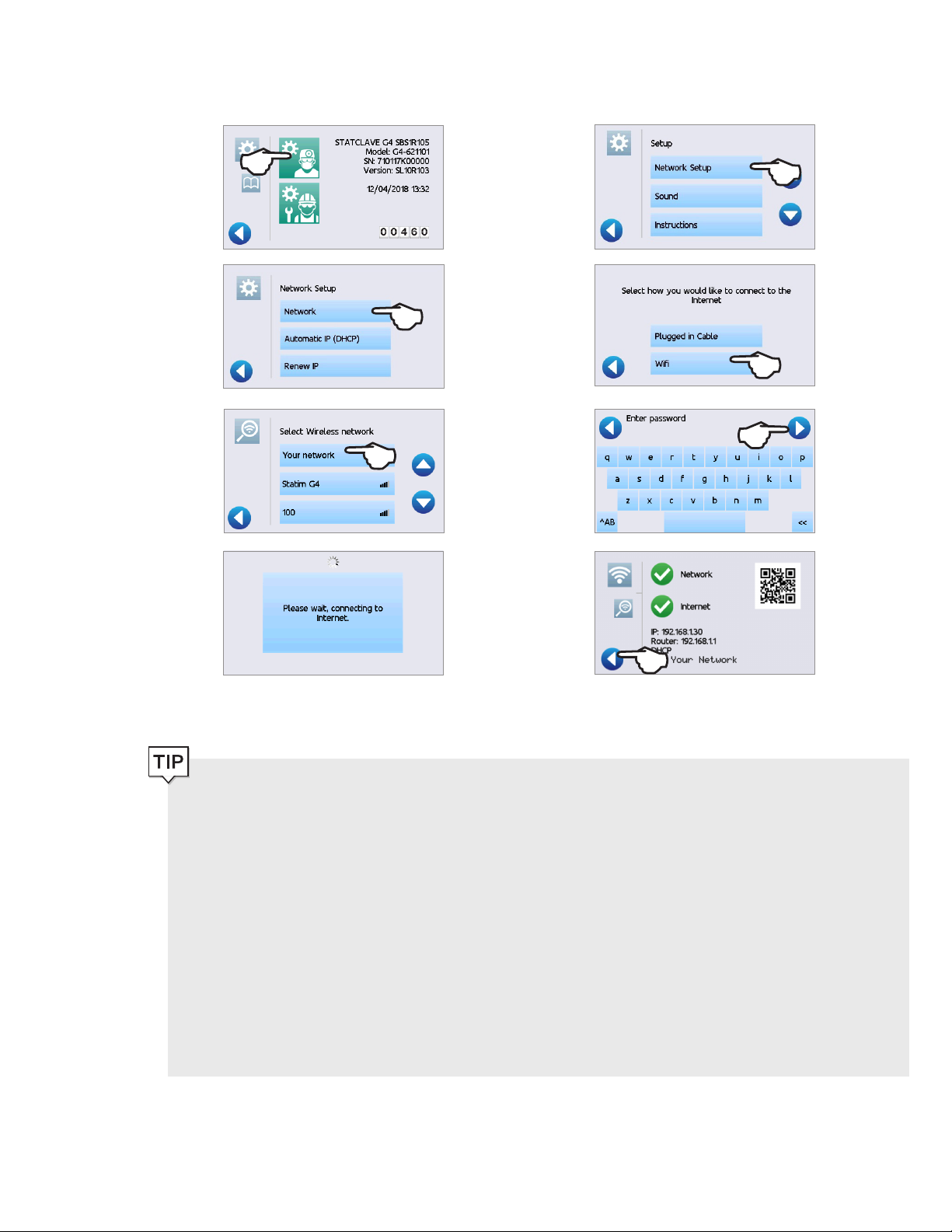

Connecting to a Wireless Network

From the unit’s home screen, select the SETTINGS icon, then follow these steps:

1. 2.

3. 4.

5. 6.

7. 8.

Data Security and WiFi

Ensuring your WiFi® connections are secure is an important element of safeguarding your organization’s data. A WiFi

network using WPA2™ provides both security (you can control who connects to it) and privacy (the transmissions

cannot be read by others) for communications as they travel across your network. For maximum security, your

network should include only devices with the latest in security technology – WiFi Protected Access® 2 (WPA2).

Tips for securing your network

Change the network name (SSID) from the default name.

Change the administrative credentials (username and password) that control the configuration settings of your Access

Point/Router/Gateway.

Enable WPA2-Personal (aka WPA2-PSK) with AES encryption.

Wireless transmission considerations

To comply with Federal Communications Commission and Industry Canada Radiofrequency exposure compliance

requirements, the antenna used for this transmitter has been installed to provide a separation distance of at least 20

cm from all persons and must not be co-located or operating in conjunction with any other antenna or transmitter.

(The transmission antenna for the wireless card is located in the front fascia.)

For the STATCLAVE Cybersecurity Statement, see Appendix C.

14

Page 17

3. Getting Started

Preparing Your STATCLAVE for Use

Once the STATCLAVE has been correctly installed, and before using it for the first time, make sure BOTH the clean water and

Venturi reservoirs contain distilled water. The STATCLAVE uses water from the Venturi reservoir to generate vacuum draws at

the beginning and end of each cycle. Both reservoirs must contain the minimum required water levels for the unit to function.

IMPORTANT! DON’T run the STATCLAVE without the chamber rack in place.

1. Power on the unit.

2. Follow the screen prompts to connect your STATCLAVE

using either WiFi or an Ethernet cable connection. This

will automatically set the time and date for your unit.

If you do not wish to connect your STATCLAVE at this time, Press the FORWARD icon and select a language. Then

press the FORWARD icon and the SKIP icon to scroll to the end of the introduction. You must Agree or Disagree

with the Privacy Policy to get to the home screen. (For more information on the Privacy Policy screen see Section 8.

Using and Changing Settings.)

From the home screen, select the SETTINGS icon then the USER icon and then the GENERAL button to access

the menu for time, date, country, and time zone. (See Section 8 Using and Changing Settings)

(SciCan recommends connecting and registering your STATCLAVE. To do this at a later time, see Section 8.5

Registering for STATCLAVE Online Access.)

15

Page 18

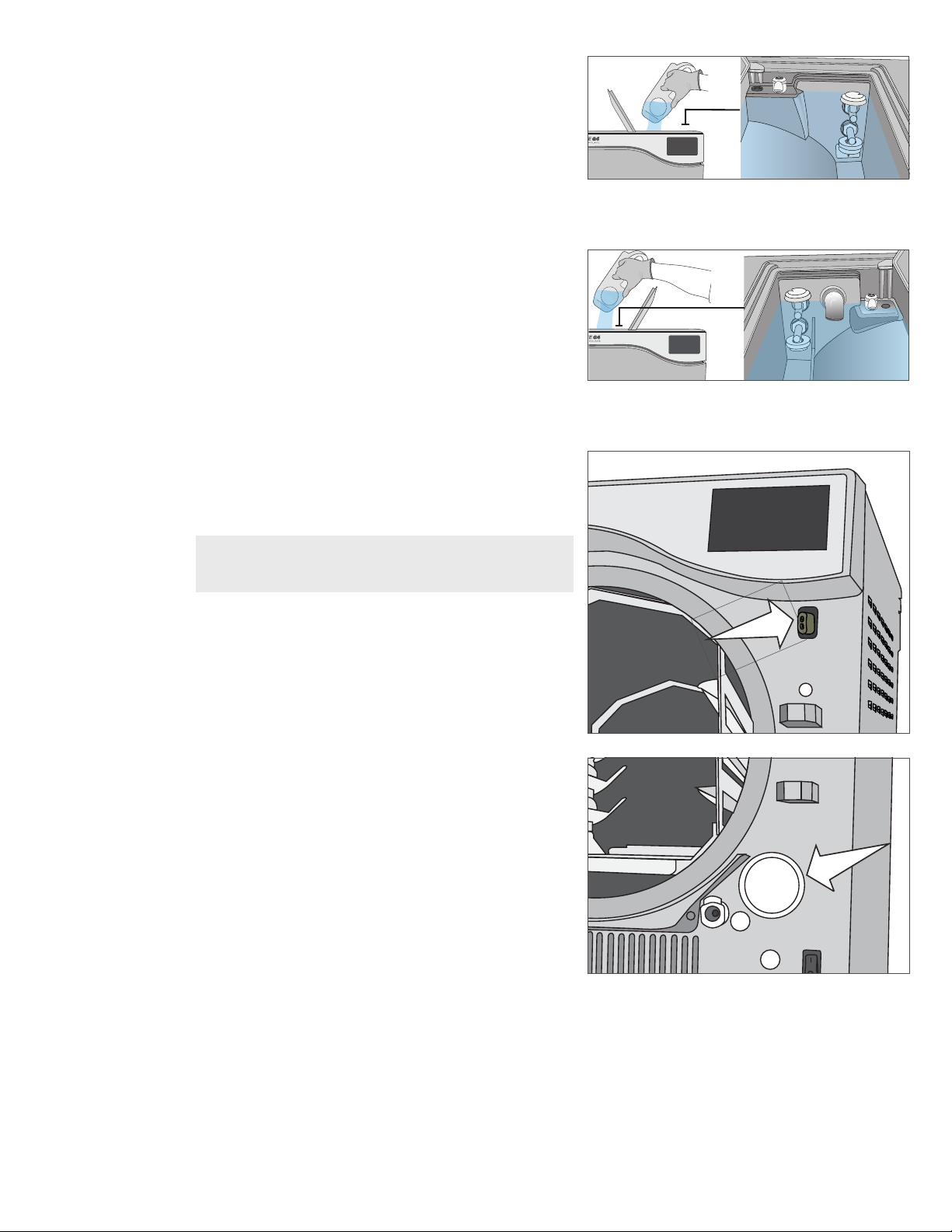

3. Open the clean water reservoir located on the top right

of the unit. Using a large container, fill with distilled water

to the maximum fill level line or until you hear 3 BEEPs.

(For more fill options see Section 4. Filling the Water

Reservoirs.)

4. Open and fill the Venturi reservoir to the maximum fill

level.

5. Open the door, plug the USB storage device into the

USB port.

CAUTION! Hot Chamber.

The unit’s Stand-by mode is preset to maintain a hot

chamber.

6. Make sure the bacteriological filter is securely in place.

7. Check your national and local guidelines for any

additional protocols and tests required before using

your unit.

16

Page 19

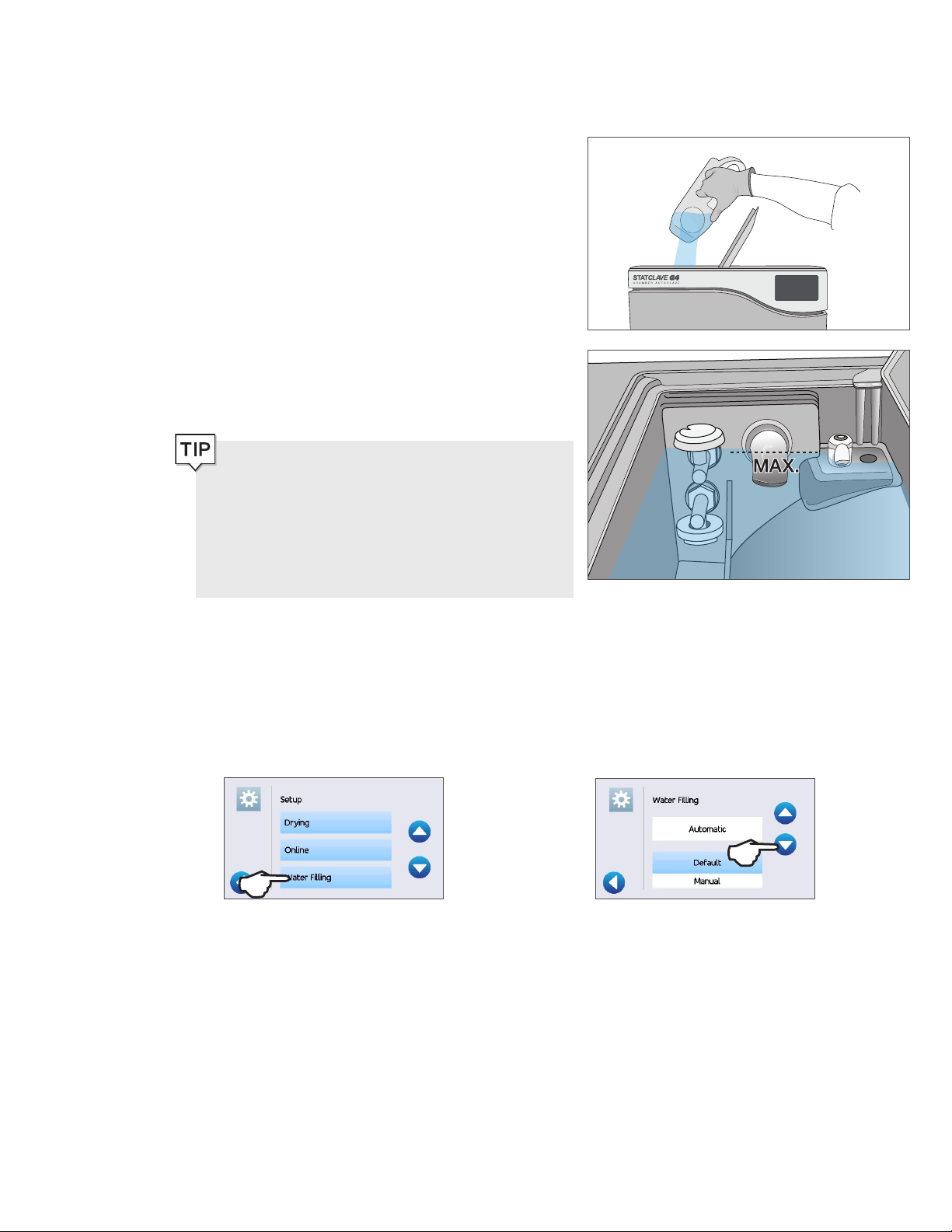

4. Filling the Water Reservoirs

Normal operation of the STATCLAVE requires a minimum amount of distilled water in BOTH the clean water reservoir and

Venturi reservoir.

To fill the Venturi reservoir:

1. Open the Venturi reservoir lid located on the top left of

the unit.

2. Fill it with distilled water to the maximum fill line

indicated in the reservoir.

When filling the Venturi reservoir for the first time,

you will need to add an additional

0.5 US gal / 2 L of water. This will fill the steam cooling

system’s condenser. To do this, simply fill the Venturi

reservoir to the maximum fill line and wait as the

Venturi reservoir water fills the condenser, then top up

the Venturi reservoir to the maximum fill line again.

Setting the water reservoir filling mode

Your STATCLAVE’s default filling option is MANUAL. If you are manually filling the reservoir, you do not need to change the

unit’s fill option settings.

If you are connecting your STATCLAVE to an external filling device such as a VistaPure specialized water filtration system or

external water tank and auxiliary pump, make sure your unit is set to the AUTOMATIC filling mode.

To change this setting from the home screen, select SETTINGS then USER and then follow these steps:

1. 2.

To fill the clean water reservoir, there are four different methods:

› Manual filling using RESERVOIR TOP.

› Manual filling using the FRONT QUICK CONNECTOR.

› Automatic filling using VISTAPURE SPECIALIZED WATER FILTRATION SYSTEM with accumulation tank.

› Automatic filling using an EXTERNAL WATER TANK AND AUXILIARY PUMP.

17

Page 20

4.1 Manual Filling Using Reservoir Top

1. With the unit powered ON, flip open the clean water

reservoir lid located on the top right of the unit.

2. Using a large container, fill with distilled water to the

maximum fill line or until you hear three BEEPs.

When adding water for the first time, the reservoir may

take up to 1 US gal / 4 L.

3. With the door open, select any cycle from the LCD’s

home screen to view the pre-cycle information screen.

4. The clean water level check mark will turn yellow when

the minimum water level is reached and green when the

reservoir is filled to the maximum level.

You can start a cycle if water level icons are either yellow or green.

If your unit is not directly connected to the drain, empty the waste bottle regularly or each time you are filling the

clean water reservoir.

18

Page 21

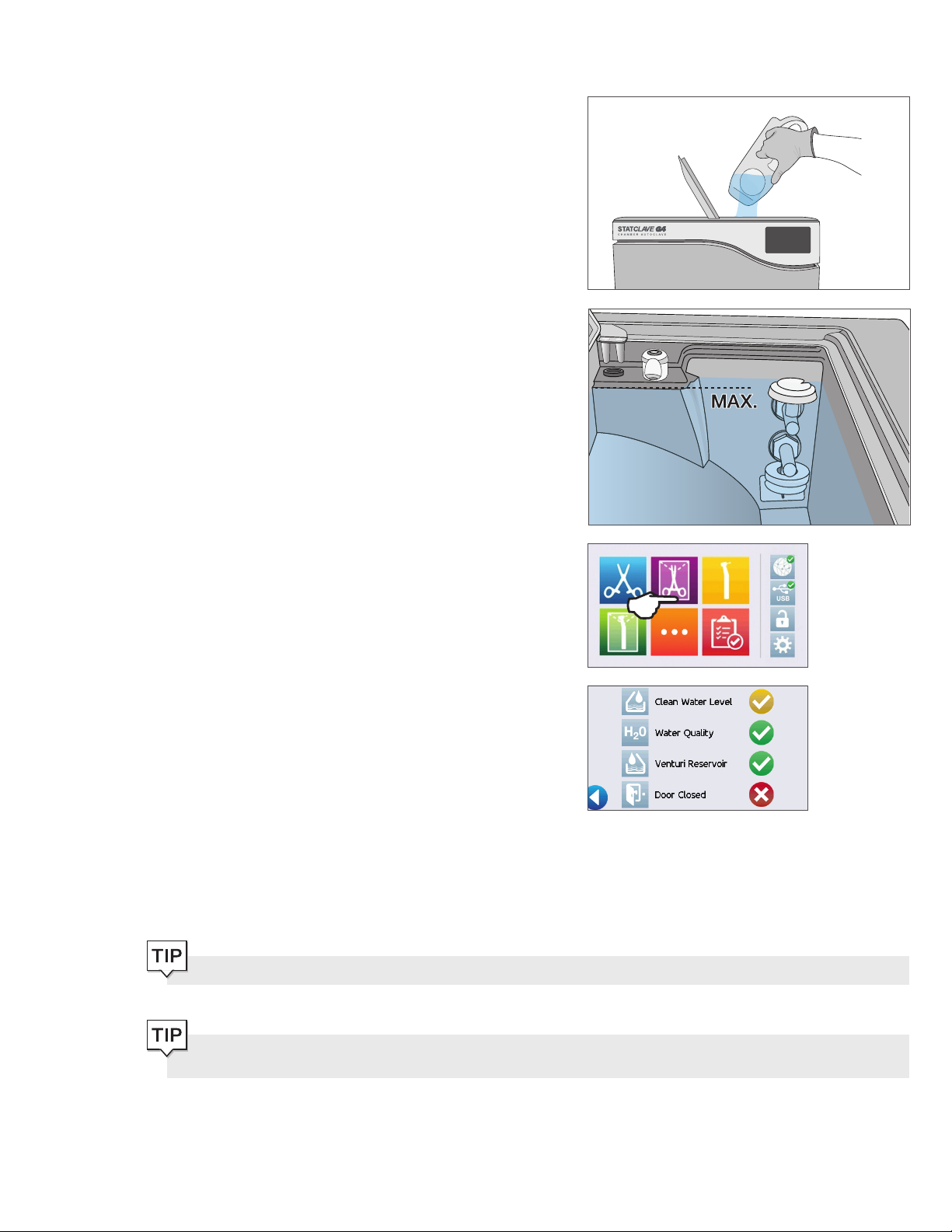

4.2 Manual Filling Using Quick Connector at Unit Front

The front fill quick connector is for the refilling of the clean water reservoir. The Venturi reservoir does not have a front fill quick

connector because it is only filled on installation or after cleaning.

1. To use this method, you will need the manual fill

container (0.5 US gal / 2 L) with quick connect and

tubing (sold as an accessory).

2. Fill the accessory container with distilled water, keeping

it horizontal.

3. With the unit powered ON, connect the tube’s quick

connector to the unit’s clean water fill port at the front.

4. Hold or place the manual fill container at a level higher

than the unit’s fill port and loosen the cap on the

container to allow water to flow into the tank.

5. With the door open, access the LCD’s home screen

and select any cycle to view the pre-cycle information

screen.

6. The clean water level check mark will turn yellow when

the minimum water level is reached.

You can start a cycle if water level icons are either yellow or green.

7. Repeat this procedure a second time to fill the water

reservoir to max level. (Each fill takes 4 minutes.)

Continue until the clean water level

and you hear three

If your unit is not directly connected to the drain, empty the waste bottle regularly or each time you are filling the

clean water reservoir.

BEEPs.

indicator turns green

19

Page 22

4.3 Automatic Filling Using a VistaPure Specialized Water Filtration System

with Accumulation Tank

When connecting your STATCLAVE to an external filling device such as a VistaPure specialized water filtration system, make

sure your unit is set to the AUTOMATIC filling mode. (See Section 4. Setting the water reservoir filling mode.)

1. Remove the plug from the automatic fill port (A) at the

back of the unit.

2. Connect the water filtration system’s Teflon tube (or

other suitable tube) to the automatic fill port (A) at the

back of the unit.

3. Ensure the tube runs freely from the water filtration

system. It should not be sharply bent, crushed or

obstructed in any way.

4. Open the valve on the water filtration system (C) to

fill the accumulation tank.

5. Open the accumulation tank’s (B) valve to facilitate the

flow of water to the STATCLAVE.

6. Go to the home screen and select any cycle to activate

the filling system.

IMPORTANT! Before you activate the AUTOMATIC filling mode, make sure the external tank has been filled with high

quality distilled water. Also remember to open the tap on the external tank or filtration system, if required.

IMPORTANT! When selecting an automatic filling option, it is best to use a direct-to-drain waste connection. Use of

an external waste bottle will require careful monitoring and frequent emptying.

High quality distilled water with a conductivity of 6.4 ppm / 10 µS/cm or less is recommended.

20

Page 23

4.4 Automatic Filling Using External Water Tank and Auxiliary Pump

When connecting your STATCLAVE to an automatic filling system such as an external water tank and auxiliary pump, make

sure your unit is set to the AUTOMATIC filling mode. (See Section 4. Setting the water reservoir filling mode.)

An input hose can be connected to the STATCLAVE from

an external tank that uses an automatic water pump to feed

the internal tank automatically when it reaches the MIN level.

Be sure to monitor the water level of your external tank. The

STATCLAVE unit does not monitor the water level in the

external tank and the auxiliary water pump should not run dry.

To use this method, you will need the STATCLAVE automatic

fill pump (sold as an accessory) and an external tank with a

minimum diameter opening of 2” (50mm) through which you

can insert the pump.

To connect the automatic fill pump to the STATCLAVE,

follow these steps:

1. Remove the plug from the automatic fillport(A) at the

back of the unit.

2. Connect the fitting at the end of the pump’s tubing to

the automatic fill port (A).

3. Connect the automatic fill pump’s power source to the

power connection (B) located at the back of the unit.

4. Fill the external tank (C) with distilled water.

5. Place the submersible automatic fill pump (D) in the

external tank.

6. Go to the home screen and select any cycle to activate

the filling system.

21

Page 24

5. Loading Instruments

Before loading any instruments into the STATCLAVE, consult the instrument manufacturer’s reprocessing instructions to

confirm instruments can tolerate steam sterilization temperatures.

The following material can typically be sterilized with steam:

› Stainless steel surgical/generic instruments

› Carbon steel surgical/generic instruments

› Rotating and/or vibrating instruments driven by compressed air (turbines) or

mechanical transmission (counter-angles, tooth scalers)

› Glass articles

› Mineral-based articles

› Articles made of heat-resistant plastic

› Articles made of heat-resistant rubber

› Heat-resistant textiles

› Medical textiles (gauze, pads, etc.)

CAUTION! DON’T use the STATCLAVE to sterilize liquids or pharmaceutical products.

This may result in incomplete sterilization and/or damage to the autoclave.

Clean Instruments Before Sterilization

It is important to clean, rinse and dry all instruments before loading them into the autoclave. Disinfectant residues and solid

debris may inhibit sterilization and damage both the instruments and the STATCLAVE. Lubricated instruments must be wiped

thoroughly and any excess lubricant removed before loading.

STATCLAVE LOAD CAPACITIES

Load Type Capacity per Tray Capacity per Pouch Rack Total Capacity*

Solid Items 1. 5 kg 3 kg 6 kg

Rubber and Plastics 0.5 kg Not applicable 2 kg

Dental Handpieces 1.5 kg 3 kg 6 kg

Textiles and Packs Not applicable Not applicable 2 kg

* Load capacities listed here are for the total weights of instruments and cassettes or containers not supplied with the unit.

DON’T include the weight of the chamber rack, trays, pouch rack or drying plates that are supplied with the unit when calculating

your instrument load weights.

22

Page 25

5.1 Using the Chamber Rack

IMPORTANT! DON’T run the STATCLAVE without the chamber rack in place.

Inserting the Rack

Push the rack into the chamber until it locks into position at the

back. The front of the chamber rack should be flush with the

chamber flange.

CAUTION! Hot Chamber.

Using the Rack

1. Tray Configuration

2. Pouch Configuration

3. Cassette Configuration

23

Page 26

5.2 Wrapped Instruments

If you plan to store your instruments after sterilization, wrap them according to the instrument manufacturer’s instructions,

select the appropriate wrapped cycle and allow it to run to completion. Unwrapped instruments, once exposed to ambient or

external conditions, cannot be maintained in a sterile state.

› DO ensure to use only sterilization wraps and

pouches that have been cleared for your market.

IMPORTANT! To ensure optimal drying when using pouches, SciCan recommends the use of the STATCLAVE

pouch racks supplied with your unit.

Using Pouches

1. Position pouches with the paper side towards the tall

support on the pouch rack. This will optimize drying.

2. Arrange pouches 2 per row to a maximum of 10

pouches to a rack.

3. Load one pouch rack on the bottom rail and the other

on the second from top rail.

› DON’T use 100% cellulose sterilization wraps as

these may require longer drying times.

CAUTION! Instruments in pouches or wraps that are not completely dry must be used immediately or reprocessed.

› DO use the STATCLAVE pouch racks supplied with your

unit to position pouches on their sides.

› DO always check that pouches are placed correctly: with

the paper side against the rack’s tall supports.

› DO package instruments individually. If you are placing

more than one instrument in the same pouch, ensure they

are made of the same metal.

› DO always use the tray extractor tool provided to remove

the pouch rack from the unit.

24

› DON’T stack pouches or wraps. Instead, use the

pouch rack to keep pouches vertical. This will

promote drying and enable effective sterilization.

› DON’T store pouched or wrapped loads that are

wet. If the wraps on the wrapped load are not dry

when the load is removed, the instruments must be

handled in an aseptic manner for immediate use or

re-sterilized.

Page 27

Using Wrapped Cassettes and Containers

Drying plates must be used when processing wrapped cassettes to ensure air flow around cassettes and to promote proper

drying.

For wrapped loads, place a chemical indicator inside each of the wrappings.

Inserting drying plates

1. Remove the wire trays from the unit and insert the

drying plates into each of the slots in the base of the

rack.

2. The three plates should sit vertically, evenly placed in

the rack with the taller end pointing up and at the back

of the chamber.

3. Place cassettes vertically into the unit to optimize

drying.

When Using Wrapped Cassettes:

› DO ensure you always use suitably porous material (sterilization paper, muslin napkins, etc.) and close the wrapping

with adhesive tape designed for use in autoclaves.

› DO ensure there is space for sufficient air flow between cassettes when loading more than one wrapped cassette per

row.

› DO always use adhesive tape designed for autoclaves or heat-sealing machines. Using staples, pins or other fasteners

could compromise the sterility of the load.

› DO be sure to insert wrapped cassettes with the flat side down to avoid tearing the wrap.

25

Page 28

Using Rigid Sterilization Containers

The STATCLAVE is capable of processing re-usable rigid sterilization containers, which can be used as an alternative to

wrapping cassettes. These provide a convenient way to organize and store instruments, and cut down on the waste involved

with using paper wraps. Check the sterilization container manufacturer’s instructions to determine its suitability for pre-vacuum

steam sterilization.

When Using Rigid Sterilization Containers:

› DO ensure drying plates are used and that the rigid

sterilization containers are placed vertically in the rack

to promote proper drying. (See Inserting drying

plates, above.)

› DO ensure there is space for sufficient air flow

between the rigid sterilization containers when loading

more than one container per row.

5.3 Unwrapped Instruments

Unwrapped instruments are also referred to as Immediate Use Instruments because once exposed to ambient or external

conditions, they cannot be maintained in a sterile state. If you plan to store your instruments after sterilization, wrap them

according to the instrument manufacturer’s instructions, select the appropriate wrapped cycle and allow it to run to completion.

› DO use the trays provided with your unit to hold

unwrapped instruments.

› DO always use the trays with the chamber rack provided.

› DO always use the tray extractor provided to remove trays

from the sterilization chamber.

› DO arrange instruments made of different metals

(stainless steel, tempered steel, aluminum, etc.) on

different trays or keep them well separated from

each ot h e r.

› DO arrange receptacles upside down to prevent water

from pooling inside.

› DO ensure objects on trays are always arranged with

some distance between them ensuring they will remain

in the same position for the entire sterilization cycle.

› DO ensure that hinged instruments are sterilized in

an open position.

› DO position cutting instruments (scissors, scalpels, etc.)

so that they do not come into contact with each other

during sterilization.

› DON’T load the trays beyond their maximum indicated

limit. (See STATCLAVE Load Capacities chart at the start

of Section 5. Loading Instruments)

› DON’T stack trays or put them in direct contact with the

sterilization chamber walls.

26

Page 29

5.4 Rubber and Plastic

The following materials CAN be sterilized in the STATCLAVE:

› Nylon, polycarbonate (Lexan™), polypropylene, PTFE

(Teflon™), acetal (Delrin™), polysulfone (Udel™),

polyetherimide (Ultem™), silicone rubber, and polyester.

When loading rubber and plastic tubing on the tray, make sure

they do not touch the chamber walls. This ensures that steam

reaches all surfaces, and will promote drying.

› DO arrange receptacles upside down to prevent water

from pooling inside.

› DO process dental impression trays on the top tray to

optimize drying.

› DO process on the top tray any items with shapes that

could collect water.

Additional tips for rubber and plastics:

Arrange the tubing on the tray so that ends are not obstructed or crushed.

DON’T bend or wind tubes. Allow tubes to lie as straight as possible.

IMPORTANT! DON’T attempt to sterilize the following materials in the STATCLAVE:

Polyethylene, ABS, styrene, cellulosics, PVC, Acrylic (Plexiglas™), PPO (Noryl™), latex, neoprene, and similar

materials.

Use of these materials may lead to instrument or equipment damage. If you are unsure of your instrument’s material

or construction, do not sterilize it in your STATCLAVE until you have checked with the instrument manufacturer.

5.5 Textiles and Surgical Packs

Carefully wash and dry textile materials (or porous materials

in general), such as smocks, napkins, caps and other, before

treating these in the autoclave. Do not use detergents with a

high content of chlorine and/or phosphates and do not bleach

with chlorine-based products. These substances can damage

the tray supports, trays and any metal instruments that may be

present in the sterilization chamber.

5.6 Using Biological and Chemical Indicators

Use chemical process monitors suitable for autoclaves/steam sterilizers at the indicated cycle temperatures and times in

or on each package or load being sterilized. For biological indicator usage and frequency, follow the indicator manufacturer’s

instructions and your local regulations, guidelines and standards.

27

Page 30

6. Using Your STATCLAVE

6.1 Running a Cycle

Once the autoclave has been correctly installed and before using your STATCLAVE for the first time, make sure BOTH the clean

water reservoir and Venturi reservoir are full. Refer to Section 4. Filling the Water Reservoirs for detailed instructions.

1. Power on the unit

The main switch is located below the

door handle.

2. Ensure both reservoirs are full

You will not be able to start a cycle if the reservoir levels are

below the minimum fill lines.

3. Open the door

The LCD should display the UNLOCKED icon. Pull up

on the handle to disengage the manual latch and open

the door. If the door will not open, press the LOCK

icon to go to the door lock status screen and press the

UNLOCK icon.

CAUTION! Hot chamber.

The unit’s Stand-by mode is preset to maintain a hot chamber.

To avoid burns, take care not to touch the chamber, rack or door with bare hands.

4. Load the instruments

Refer to Section 5. Loading Instruments for detailed

instructions

28

Page 31

5. Close the door

Close the door by locking the handle into position.

When you close the door, you will hear the sound of the

vacuum system adjusting chamber pressure to seal the

door. This is a normal operating sound.

6. Select the cycle

From the LCD, select the cycle you want to run. To

learn more about the available cycles, see Section 7.

Sterilization Cycles.

Press the icon to see the cycle name and parameters.

If User PIN ID has been enabled, you will be prompted to enter your User ID and PIN before your cycle selection is

accepted.

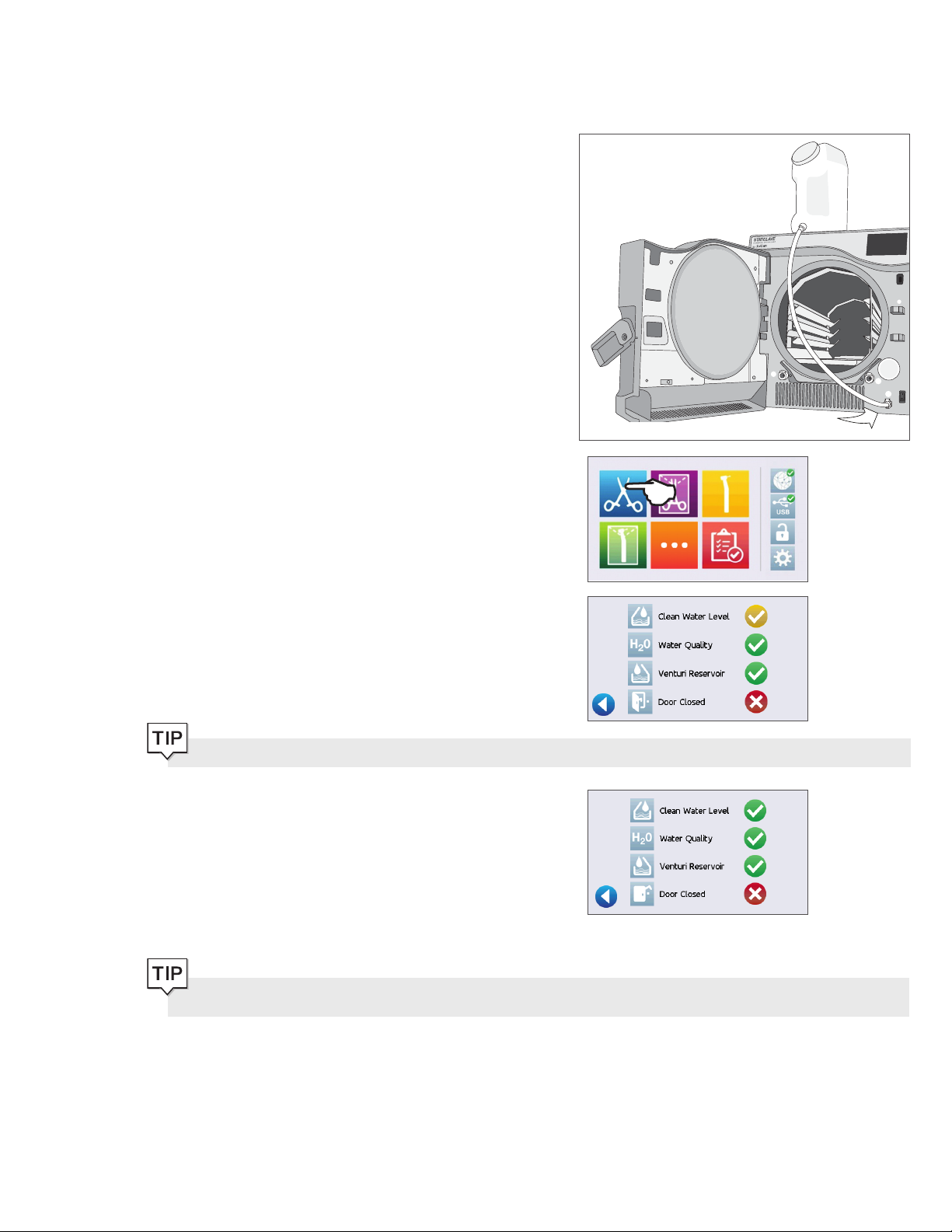

If there is a problem with the door lock or water, a PRECYCLE SCREEN will appear:

Clean water level low. Add water.

There is a water quality problem. Press icon to view detail.

Venturi water reservoir level low. Add water.

There is a problem locking the door. Check for instruments

jamming the door.

7. Press the START icon

If the chamber is cold, warming up can take up to 12

minutes.

Allow the cycle to run to completion.

IMPORTANT! When the drying stage is finished, the display will show the cycle is complete.

8. Cycle is complete.

When the cycle is complete, press the STOP icon to

release the load.

29

Page 32

9. Remove the load

Open the door. Remove the trays or pouch racks using

the tray extractor provided with the unit.

CAUTION! The metal parts will be hot.

6.2 Stopping a Cycle

CAUTION!

If the screen displays a CYCLE FAULT code or a NOT STERILE message, the contents are not sterile. See Section

11 Troubleshooting for more information.

If the wraps on the wrapped instruments are not dry when the load is removed, the instruments must be handled in

an aseptic manner for immediate use or re-sterilized.

To stop a cycle BEFORE sterilization is complete, press the

STOP icon at the bottom right of the touchscreen:

1. If you stop the cycle before sterilization is complete,

the unit will remind you that the load is NOT STERILE.

2. Press the STOP icon to continue.

To stop a cycle DURING the drying phase, press the STOP

icon at the bottom right of the touchscreen:

1. If you stop the load during the drying phase, the unit

will remind you to CHECK FOR DRYNESS.

2. Press the STOP icon to continue.

30

Page 33

Opening the door after pressing STOP

Once a cycle has been stopped, the STOP button must be pressed before another cycle can be started. To start a new cycle

or to open the door:

1. Press the STOP icon to continue.

2. Press the LOCK icon.

3. Press the UNLOCK icon.

Press the BACK icon to return to the home screen.

If Process Enforced usage is enabled, you will be prompted to enter your User ID and PIN before opening the

door. A non-registered user can open the door by pressing the SKIP icon.

6.3 Using the Delayed Start

1. Select any cycle.

2. Press the DELAYED START icon.

3. Enter the number of hours and minutes for the delayed

start.

Press the FORWARD icon to begin the countdown.

Press the BACK icon to stop and reset countdown.

The LCD will remain in countdown mode until the cycle

begins.

31

Page 34

6.4 Emergency Door Opening

The STATCLAVE is equipped with a safety mechanism that automatically regulates the chamber pressure when the unit loses

power. (The unit will take approximately 2 minutes to depressurize. Without power, the door lock will remain engaged.)

To unlock the door without power, follow these steps:

1. Remove the emergency door unlocking pin located

in the handle of the tray extractor supplied with your

STATCL AVE

2. Insert the emergency door unlocking pin into the small

hole on the side of the unit’s handle. Push the pin into

the hole as far as it goes to trigger the door release.

3. Remove the emergency door unlocking pin from the

hole in the door handle.

4. Pull up on the handle to open.

CAUTION! Risk of Injury.

Do not force the door handle. If the unit is locked due to a cycle fault, do not force the door handle. Power OFF the

unit and allow it to cool for 10 minutes before attempting again.

32

Page 35

6.5 Running a Bowie-Dick Test

The BOWIE-DICK test is used to ensure proper air removal is occurring in a pre-vacuum autoclave. Complete air removal is

important because pockets of cool air remaining in the chamber can compromise sterilization. The Bowie-Dick test runs a

cycle at 134°C / 273°F for 3.5 minutes to evaluate the correct air removal.

To perform a Bowie-Dick test, you will need a Bowie-Dick device or test pack. These are NOT supplied with your STATCLAVE.

To perform the test, follow the instructions provided by the test pack manufacturer.

Generally, the process is as follows:

1. Open the unit’s chamber door to insert a Bowie Dick

test pack. (Position pack at centre back.)

2. Close and lock the door.

3. From the home screen, select the TESTS icon.

4. To run a Bowie Dick Test, press the BD icon.

5. Press the START icon.

Allow the test to run to completion.

6. Press the STOP icon to release the load.

Follow the test manufacturer’s instructions to interpret

the test results.

If the unit passes the test, it is ready for use. If the unit fails,

check the test manufacturer’s instructions and repeat the test.

33

Page 36

Presetting your Bowie-Dick test

To schedule a Bowie-Dick test before the start of the next working day, use the delayed start function.

1. At the end of the working day, select the Bowie-Dick

test.

2. Press the DELAYED START icon.

3. Enter the number of hours and minutes for the delayed

start.

Press the FORWARD icon to begin the countdown.

4. Press the BACK icon to CANCEL.

The Bowie-Dick test will finish faster when the unit starts with a warm chamber. Set your test to start at least 15

minutes after your unit has begun to warm the chamber.

NOTE: The STATCLAVE’s default setting is to keep the chamber temperature at Stand-by HIGH from 7:00 a.m. to

8:00 p.m.

34

Page 37

6.6 Running a Vacuum Test

The vacuum test checks the autoclave’s plumbing system for leaks and should be done on a regular basis in accordance to

your local guidelines. Run this test with the rack and empty trays in the chamber.

IMPORTANT! Vacuum tests must be conducted when the unit is cool. Running a vacuum test on a hot chamber

may cause the test to fail.

1. From the home screen, select the TESTS icon.

2. To run a Vacuum Test, press the V icon.

3. Press the START icon.

Running a vacuum test can take a minimum of 45 minutes. When the test is complete, the screen will display a CYCLE

COMPLETE message. If the test has failed, see Section 11 Troubleshooting.

Presetting your vacuum test

To schedule a vacuum test before the start of the next working day, use the delayed start function. The process is the same as

described in the section above for the Bowie-Dick test.

IMPORTANT! When using the delayed start with your vacuum test...

Make sure the vacuum test is scheduled at a time when the chamber is cold. A warm chamber may cause the vacuum

test to fail. Set your vacuum test to start at least 1 hour before your unit begins to warm the chamber. NOTE: The

STATCLAVE’s default setting is to keep the chamber temperature at Stand-by HIGH from 7:00 a.m. to 8:00 p.m.

6.7 Using the Custom Cycle

The custom cycle offers a choice of three sterilization temperatures and allows users to adjust the sterilization time and drying

time of each to create a unique cycle.

› Custom cycle 121C/250F: sterilization time adjustable from 20 to 30 minutes, drying from 0 to 60 minutes.

› Custom cycle 132C/270F: sterilization time adjustable from 4 to 18 minutes, drying from 0-60 minutes.

› Custom cycle 134C/273F: sterilization time adjustable from 4 to 18 minutes, drying from 0-60 minutes.

CAUTION! Custom cycles have NOT been validated and have NOT been cleared by any regulatory authority. The

user is responsible for validating the sterilization efficacy of a custom cycle.

35

Page 38

The custom cycle’s default cycle is 132C/270F for 4 minutes with 25 minutes of drying. To adjust the settings of this cycle,

select SETTINGS then USER and follow these steps:

1. From the Setup menu, scroll to Custom Cycle and

select.

2. From the Custom Cycle menu, press Cycle temperature.

3. Select one of the three sterilization temperature options.

Press the BACK icon to save your change.

4. From the Custom Cycle menu, press Sterilization time.

IMPORTANT! Each temperature option comes pre-set with a minimum sterilization time and drying time. Follow

the instrument manufacturer’s instrument reprocessing instructions when setting time and temperature. Failure to

do so could result in damage to the instruments and/or autoclave.

5. Adjust how long the cycle will hold the sterilization

temperature. Press BACK to save your change.

6. Press Drying time to adjust the amount of drying. Press

BACK to save your change, then press BACK again to

exit the Custom Cycle settings.

7. To confirm your changes, select the Custom Cycle icon

from the home screen and check the cycle description

at the top of the start screen. If it is incorrect, return to

the Custom Cycle settings and re-enter your selections.

36

Page 39

7. Sterilization Cycles

The STATCLAVE features 6 validated sterilization cycles with optimized drying for the fast, effective sterilization of the various

types of loads used in a medical or dental environment. An additional custom cycle can be configured using one of three

temperature settings but this cycle must be validated by the user.

The table below describes load types and corresponding sterilization requirements. Load size requirement details are listed in

Section 5. Loading Instruments.

NOTE: When selecting a sterilization cycle, choose according to the load you are sterilizing and the instrument manufacturer’s

reprocessing instructions.

STERILIZATION CYCLE INFORMATION

Cycle Load Type and Weight Sterilization Temperature and Time

Solid /

Unwrapped*

IUSS CYCLE* for unwrapped solid instruments (mirrors,

explorers), hinged instruments (hemostats) on trays.

Maximum Load: 6 Kg / 13.2 lbs

Solid /

Wrapped

Single wrapped IMS cassettes with solid instruments, rigid

sterilization containers with solid instruments or singlepouched solid instruments on a pouch rack.

Maximum Load: 6 Kg / 13.2 lbs

Hollow /

Unwrapped*

Hollow /

Wrapped

IUSS CYCLE* for unwrapped dental handpieces on trays.

Maximum Load: 6 Kg / 13.2 lbs

Single-pouched dental handpieces on a pouch rack

or a combination load (wrapped cassettes with solid

instruments and wrapped pouches with solid instruments

or dental handpieces).**

Maximum Load: 6 Kg / 13.2 lbs

Textiles / Porous Tex ti le s

Maximum Load: 2 Kg / 4.4 lbs

132˚C / 270˚F for 4 minutes

132˚C / 270˚F for 4 minutes

132˚C / 270˚F for 4 minutes

132˚C / 270˚F for 4 minutes

132˚C / 270˚F for 4 minutes

Rubber & Plastic IUSS CYCLE* for unwrapped solid or hollow

121 ˚C / 250˚F for 20 minutes

instruments constructed of metal, rubber and plastic.

Maximum Load: 2 Kg / 4.4 lbs

Custom

†

Maximum Load: 2 Kg / 4.4 lbs 121 ˚C / 250˚F from 20-30 minutes

Maximum Load: 6 Kg / 13.2 lbs 132 ˚C / 270˚F from 4-18 minutes

Maximum Load: 6 Kg / 13.2 lbs 134 ˚C / 273˚F from 4-18 minutes

*Immediate Use Steam Sterilization cycle.

**When running combination loads, drying times may need to be extended.

†

Custom cycles have NOT been validated and have NOT been cleared by any regulatory authority. The user is responsible for

validating the sterilization efficacy of a custom cycle.

37

Page 40

8. Using and Changing Settings

The STATCLAVE user menu provides you with access to settings that can be adjusted or changed. The chart below

offers an overview of where these settings can be found within the menu structure and tells you what you can do with each

button. Functions such as setting up load traceability, User IDs and PINs, setting drying times and Stand-by mode are

explained in more detail later in this chapter.

To access this menu from the home screen, select SETTINGS then USER. Use the UP and DOWN arrows to navigate

the menu. Press on a button to make a selection. Press the BACK button to move to a previous screen when navigating the

menus. After changing a setting, press the BACK button to save your selection.

USER SETUP BUTTONS SUBMENU BUTTONS WHAT TO DO WITH IT

General

Language

Unit No.

Printer

Time

Date

Set Time Zone

Time Update

Time 12/24

Date Format

Country

Units

Printer Type

Baud Rate

End of Line CR/LF

Enter values.

Enter values.

Select zone.

Select automatic or manual.

Select 12-hour or 24-hour format.

Select how date is displayed.

Type name to select country.

Select metric or imperial.

Select from language list.

For users with multiple units.

Select serial or no printer.

For printer adjustments.

For printer adjustments.

Printer user ° char

Enforced

Process

User

Screensaver

Screen

Network Setup

Sound

Instructions Water Reservoir Filters

LCD Contrast

Cycle Run

Network

Automatic IP (DHCP)

Renew IP

Button Beep

Beep Volume

For printer adjustments.

Select ON, OFF or DOCUMENTATION.

Create User ID and PIN. Up to 20 users.

Adjust the time delay for the screensaver.

Adjust LCD readability.

Select circle or chart graphic to display

during a cycle.

Select WiFi or wired connection.

Network connection.

Network connection.

Turn the beep ON or OFF.

Adjust sound.

Slide show on how to clean the filters.

38

Page 41

Solid/Unwrapped 132°C/4 min

Adjust drying time. (0 to 60 minutes)

Drying

Online

Solid/Wrapped 132°C/4 min

Hollow/Unwrapped 132°C/4 min

Hollow/Wrapped 132°C/4 min

Textiles/Porous 132°C/4 min

Rubber & Plastic 121°C/20 min

Online Access

Privacy

Intro

Adjust drying time. (0 to 60 minutes)

Adjust drying time. (0 to 60 minutes)

Adjust drying time. (0 to 60 minutes)

Adjust drying time. (0 to 60 minutes)

Adjust drying time. (0 to 60 minutes)

Enter an email address to receive

notifications.

Agree: Your unit will send cycle data and unit

errors to SciCan. It will also receive automatic

software updates to the user interface.

Disagree: Your unit will NOT send any cycle

information but it will receive automatic

software updates to the user interface.

Select ON then use the power switch to

turn the unit OFF. The start-up screen and

connection wizard will begin when the unit is

next powered ON.

Water Filling

Stand-by

Custom Cycle

Remote Access

Notifications

Auto / Manual

Stand-by On/Off

Stand-by Start

Stand-by End

Cycle temperature

Sterilization time

Drying time

Use to generate a token that can be sent

to a technician who can access your unit

re mote ly.

Enter email addresses (max. 4) to which unit

can send notifications.

Select auto when using an external auto fill

system. Default is manual.

Select high, low or off. Default is high.

Enter time value. Default is 07:00.

Enter time value. Default is 20:00.

Select from 3 temperature options.

Adjust the custom cycle’s sterilization hold

time.

Adjust the custom cycle’s drying time.

39

Page 42

8.1 Setting Up Load Traceability with User ID, PIN, and Process Enforced Function

The Process Enforced function keeps track of who has started and who has removed a load from your STATCLAVE. It does

this by prompting users to enter a PIN at the start of a cycle, when they STOP or CANCEL a cycle, and when they REMOVE a

load. Using Process Enforced does not restrict any functions, it is simply a means of tracking which of the registered users was

operating the unit. To use the Process Enforced feature, you must first assign User IDs and PINs.

To set up a User ID and PIN, select SETTINGS then USER and follow these steps:

1. Scroll to PROCESS and select.

2. Select USER.

3. From the SETUP PIN screen, you can assign up to 20

user IDs. Select one of the User icons to assign a PIN to

a user ID.

4. Using the keypad, assign a PIN of up to four digits.

Press EN to save.

5. Press the FORWARD icon to accept the new PIN.

6. Press the BACK icon to return to the User IDs.

To make a correction, select the User ID you want to change. On the next screen select Change password.

40

Page 43

To turn Process Enforced Usage ON, OFF or to activate DOCUMENTATION mode, select SETTINGS then USER and

follow these steps:

1. Scroll to PROCESS and select.

2. Select ENFORCED.

3. Use the arrows to select one of the following:

ON, OFF or DOCUMENTATION.

4. Press the BACK icon to save your change and return to

the main menu.

Any user can stop a cycle and remove the load even with the Process Enforced feature ON. However, the cycle

data will record that an unregistered user has stopped the cycle and/or opened the door.

Using Process Enforced Documentation mode:

This mode activates the process enforced usage function along with the additional documentation function that generates a

report with information about the cycle and the load type.

When starting a cycle with Process Enforced Documentation

mode turned ON, you will be prompted to identify the general

contents of the load to be processed by selecting from a list as

well as whether a biological indicator and chemical indicator

are included.

If the unit is connected to a label printer, you can select to print

tracking labels for your biological indicator/spore tests.

41

Page 44

At the end of the cycle, you will be prompted to report

whether the indicators have passed and whether the load is dry

(as applicable).

Biological indicator/spore test results are available at a different time than chemical indicators but you still have the option to

add the BI/spore test results to the documentation report when these results are available.

On the home screen, the STATCLAVE will indicate a result

is pending by displaying a document icon over the settings

icon (see image at right).

Pressing this icon will lead you to a screen that allows you to

input the BI/spore test results.

CAUTION! Instruments in pouches or wraps that are not completely dry must be used immediately or reprocessed.

8.2 Setting Drying Time

Use this setting to lengthen or shorten drying times on selected cycles. The default drying times for each cycle are pre-set to

provide optimal drying of a standard load. Loads must always be checked for dryness.

To change drying times, select SETTINGS then USER and follow these steps:

1. Scroll to DRYING and select.

2. Select the cycle whose drying time you would like to

change.

8.3 Setting the Stand-By Mode

Using this setting will reduce the warm-up time between cycles by keeping the chamber at a temperature that is optimal for

your office’s level of use.

› STAND-BY LOW: For low to average use. Provides a balance between keeping the chamber at 70°C and using a

minimum of electricity.

› STAND-BY HIGH: For high use. Optimizes your STATCLAVE for speed by keeping the chamber at 120°C. This is the

unit’s default setting.

› STA N D - BY OFF: For infrequent use. In this setting, the wait time will be longer (up to 12 minutes from a cold start).

42

Page 45

To change this setting and to modify the amount of time the unit is in Stand-by, select SETTINGS then USER and

follow these steps:

1. Scroll to STAND-BY and select.

2. Use the arrows to select Stand-by HIGH, LOW or OFF.

3. If HIGH or LOW is selected, you will be prompted to

enter a START and END time for the Stand-by mode.

Once you have entered the END time, press EN

to save and press the BACK icon to return to the

previous menu.

The STATCLAVE G4’s default setting is to maintain the unit at Stand-by HIGH from 7:00 a.m. to 8:00 p.m. For this

feature to function correctly, your unit must be set to the correct time, date and country.

Press SETTINGS to verify that your unit is set to your local time and date.

To update this information, from the SETTINGS screen, select USER and GENERAL.

Select the item (TIME, D ATE, COUNTRY) you would like to update and enter the correct values.

8.4 Setting Up and Using Your STATCLAVE Web Portal

The web portal provides a direct connection to the STATCLAVE on your local area network. It is protected by your firewall and

not accessible to outside users (unless they have a Remote Access Code. For more information, see Section 10.13 Allowing a

technician to access your STATCLAVE from a remote location).

The web portal displays real-time cycle information and has an archive of sterilization records unique to this unit. From the web

portal, you can print reports, set up email notification and search cycle history.

To access your web portal, follow these steps:

1. Press the connectivity icon.

2. The connectivity screen displays information about

your STATCLAVE’s Internet connection, including its

IP address.

3. Type the IP address displayed on the touchscreen into

the browser of any web enabled device to access your

unit’s web portal.

To set up your web portal, follow the instructions

available on the portal’s HELP tab.

Using a por table device? Scan QR Code to easily access

your unit’s web portal.

43

Page 46

8.5 Registering for STATCLAVE Online Access

From the home screen, select SETTINGS then USER and follow these steps:

1. Scroll to ONLINE and select.

2. Select ONLINE ACCESS.

3. To use ONLINE ACCESS, you must agree to the Privacy

Policy. Then press FORWARD.

4. Enter your email.

A confirmation email will be sent to your inbox.

If you did not receive a confirmation email, check your spam folder.

To cancel, scroll to privacy in the STATCLAVE’s user menu and disagree.

44

Page 47

9. Storing, Retrieving and Printing Sterilization Records

The STATCLAVE’s internal memory is capable of storing data on every cycle, whether successful or incomplete, for the lifetime

of the unit. You can access this information through the unit’s touchscreen, through the web portal, by using a USB storage

device or by connecting a printer.

9.1 Retrieving Cycle Information Using the Touchscreen

You can always see the last five successful cycles and the last five incomplete cycles, whether you have a USB storage device

attached to the unit or not.

1. Press the USB icon.

2. Press on a cycle information button to see its details.

The unit will record the last five successful cycles and the last five incomplete cycles (incomplete cycles will

be identified with a CF number). If you select a cycle from the list, it will display cycle information in a format similar

to how it would be printed.

9.2 Retrieving Cycle Information Using the Web Portal

Use the STATCLAVE Web Portal to access all the cycle information stored on your STATCLAVE from your computer. If your

STATCLAVE was not connected to a network during the initial installation, follow the instructions in Section 2.4 Connecting your

STATCLAVE to a network.

45

Page 48

9.3 Retrieving Cycle Information Using the USB Data Back Up

The USB storage device can be used to transfer cycle information stored in the unit to a computer. Best practice suggests this

should be done once a week. To transfer data using the USB port, follow these steps:

1. Insert the USB storage device into the USB port.

2. Press the USB icon.

3. Press the COPY icon.

4. Press OK to copy cycle data to the USB device inserted.

IMPORTANT! Data stored in the internal memory of the STATCLAVE can only be copied once. Data that has been

previously transferred will not be re-saved onto a new USB storage device. You can access previously transferred

information from your STATCLAVE G4’s Web Portal.

When the activity light on the USB storage device stops blinking or the USB icon on the LCD turns from a flashing green to a

solid grey, remove the USB storage device and transfer the information to your computer.

IMPORTANT! If you select the USB storage device icon from the main menu, you will only be able to view the last

five complete cycles and the last five incomplete cycles. To view all the cycles stored on the USB storage device, you

must connect the device to your computer.

46

Page 49

9.4 Connecting to a Printer

Some users may prefer to have a printed record generated

after every cycle. To use an external printer you must connect

it to the STATCLAVE’s RS232 port using the serial printer cable

supplied with your printer. Once the printer is connected,

enabled and its settings correctly adjusted (see below), it will

automatically print a record of each cycle.

To connect the printer, power on the printer and from the home screen, select SETTINGS then USER and follow these

steps:

1. Scroll to PRINTER and select

2. Select PRINTER TYPE.

3. Use the arrows to scroll to SERIAL PRINTER option

and select. Press the BACK icon to save.

9.5 Adjusting your Print Settings

The STATCLAVE allows for several printer adjustments. To access these settings, select SETTINGS then USER and follow

these steps:

1. Select PRINTER.

2. Use the arrows to scroll through the settings.

Use the table below or your printer’s operator manual to make

the correct adjustments to your printer’s Baud Rate, End of

Line CR/LF and Printer User Char.

9.6 External Printer Specifications

Recommended Printer End Of Line CR/LF Serial Port Bitrate Printer user ° char

Epson TM-U220D (C31C515603) CR/LF 9600 248 [0xF8]

Under normal storage conditions, a thermal document will remain legible for a minimum of 5 years. Normal storage conditions

of thermal documents include avoiding direct sunlight, filing in office temperatures below 25 degrees Celsius and moderate

humidity (45% - 65% relative humidity) and not next to incompatible materials including plastic, vinyl, hand lotion, oil, grease,

alcohol-based products, carbonless paper and carbon paper.

47

Page 50

10. Maintenance Procedures

Regular maintenance will ensure the safe and efficient operation of your STATCLAVE. Before performing any of the cleaning

and maintenance procedures described in this chapter, power OFF the unit and disconnect it from its power source.

CAUTION! Hot Surfaces.

The STATCLAVE chamber’s Stand-by mode maintains an optimal operating temperature during working hours.

Unless this feature is disabled (See Section 8.3 Setting the Stand-by Mode), the chamber will remain hot between

cycles throughout the work day. Make sure the STATCLAVE is properly cooled before accessing the chamber to

perform any maintenance.

› DO always use SciCan replacement parts.

› DON’T use abrasive cloths, metal brushes or metal-cleaning products, whether solids or liquids, to clean the device or

sterilization chamber.

10.1 Preventative Maintenance Message

Frequency: Message will appear every 6 months or 500 cycles.

When a maintenance message appears, you have 2 options:

OPTION 1: OK OPTION 2: REMIND LATER

Press OK to clear the message. You can continue

to use your STATCLAVE or perform the required

maintenance. When you press OK, the maintenance

notification counter will restart the counter,

regardless of whether or not you have performed the

maintenance.

10.2 Preventative Maintenance Schedule

What you should do

Daily

Weekly

Monthly or every 100 cycles

Every 6 months or 50 0 cycles

(Message appears at these intervals)

What the technician should do

Every year or 1,000 cycles

If you press REMIND LATER, the message will repeat

24 hours later.

Wipe the door gasket clean with a damp, lint-free cloth.

Clean external surfaces with a damp, lint-free cloth.

Clean the chamber and, if applicable, the waste bottle.

Disinfect external surfaces.

Drain and clean both water reservoirs and water reservoir filters.

Inspect and clean the 3 chamber filters

Clean the external distilled water tank - if installed

Clean the chamber rack and trays

Perform all the cleaning tasks listed in the monthly schedule (above).

Replace the bacteriological filter

Replace the door seal

A complete maintenance of the autoclave including testing of the pressure

relief valve and the power failure pressure/vacuum relief valve (by a

SciCan-approved technician) is recommended.

48

Page 51

10.3 Cleaning the Door Seal and Door Plate

Frequency: Daily

CAUTION! Hot Chamber.

The unit’s Stand-by mode is preset to maintain a hot

chamber. Turn the unit off and allow adequate time for it to

cool before performing maintenance.

1. Using a clean, lint-free cloth dampened with water, wipe

the door seal and door plate.

10.4 Cleaning and Disinfecting the External Surfaces

Frequency: Clean daily. Disinfect weekly.

1. Clean all of the STATCLAVE’s external parts using

OPTIM wipes or a clean, lint-free cloth dampened with

water and, if needed, a mild detergent.

2. Dry the surfaces and remove any residue before

powering ON the unit.

10.5 Cleaning the Sterilization Chamber, Rack and Trays

IMPORTANT! When cleaning the chamber, be careful not to damage the temperature probe on the inside back wall

of the chamber.

CAUTION! Hot Chamber.

The unit’s Stand-by mode is preset to maintain a hot chamber. Turn the unit off and allow adequate time for it to cool

before performing maintenance.

Frequency: Monthly or every 100 cycles

1. Remove the sterilization trays and the rack from the

chamber. (Pull the rack out to disengage it).

2. Use a clean, lint-free cloth dampened with water to

clean the chamber and the chamber flange. Wipe dry.

3. Use a clean, lint-free cloth dampened with water to

clean the STATCLAVE rack and trays.

49

Page 52

10.6 Draining the Reservoirs for Cleaning

IMPORTANT! Before shipping or servicing the unit, drain all water from the unit using these 3 ports. See Section

10.14 Preparing the Unit for Shipping.

Use the waste bottle or arrange an empty 4-litre (1 gallon) container on the floor near the autoclave and insert the free end of

the silicone drain tube (supplied with your STATCLAVE).

To drain CLEAN WAT E R reservoir:

1. Open the unit door to connect the drain tube to the

CLEAN WATER reservoir’s front draining port.

Drain the reservoir completely.

2. Empty the container.

To drain Venturi reservoir:

1. Open the unit door to connect the drain tube to the

Venturi reservoir’s front draining port.

Drain the reservoir completely.

2. Empty the container.

50

Page 53

10.7 Cleaning the Water Reservoirs and Reservoir Filters

Frequency: Monthly or every 100 cycles.

To avoid accidental cross-contamination, always start with the clean water reservoir and complete steps 1-6 BEFORE cleaning

the Venturi reservoir.

Follow the draining instructions in Section 10.6 to drain the reservoirs completely.

1. Using a soft bristle brush, scrub the corners and loosen

any deposits.

2. Wipe the reservoir’s surfaces using OPTIM wipes or a

clean, lint-free cloth dampened with water.

Rinse the reservoir’s surfaces with distilled water and

drain it using the front drain tube (See Section 10.6

Draining the Reservoirs for Cleaning).

3. Remove the reservoir filter by pulling up on the filter’s

tab.

4. Rinse the filter under running water and dry it before

re-installing.

5. Repeat these steps to clean the Venturi reservoir.

6. Once you have cleaned both reservoirs, fill them with

distilled water and run one empty cycle.

The Venturi reservoir is connected to the back panel condenser. The water level in the Venturi reservoir may drop

as it tops up the condenser. Wait a few minutes and add more water to fill the Venturi reservoir.

CAUTION! To avoid cross contamination, be sure to use a different cloth and container with solution to wipe the

internal surfaces of each reservoir.

51

Page 54

10.8 Cleaning the External Water Reservoir Tank

Frequency: Monthly or every 100 cycles.

1. Disconnect the external tank from the autoclave and close the tank valve.

2. Fill the tank with a solution of distilled water and alcohol (10%), such as isopropyl.

3. Allow the solution to sit for 30 minutes.

4. Drain the tank and discard the solution.

5. Fill the tank with water and drain it to remove any residual alcohol solution.

6. Reconnect the tank to the autoclave and refill it with distilled water.

10.9 Cleaning the Chamber Filters

CAUTION! Hot Chamber.