Page 1

HYDRIM® L110w G4

INSTRUMENT WASHER

Operator’s Manual

Manuel de l’utilisateur

HYDRIM L110w G4 Operator’s Manual 95-113645 CA ML R2 Copyright 2013 SciCan Ltd. All rights reserved.

Page 2

Table of Contents

1. Introduction ......................1

2. Important Information ..............2

3. Disclaimers ......................3

4. Installation Instructions.............4

5. Instructions for Use ...............9

5.1 Instrument Reprocessing

Recommendations ..................9

5.2 Cycle Description Chart .............10

5.3 Hints and tips for best cleaning results . 11

5.4 Recommended load congurations ....12

5.5 Baskets and Accessories............14

5.6 Touchscreen Overview .............15

5.7 Set up menu overview ..............16

5.8 - 5.22 Setup menu options ...........17

5.23 Connecting to a network ............22

5.24 Connecting to a wireless network .....22

5.25 Activating the HYDRIM L110w G4.....23

5.26 Interrupting / aborting a cycle ........24

5.27 Additional user

and setup menu functions ...........25

5.28 Opening the Door in

Case of Power Failure ..............26

5.29 Storing and Retrieving

Cycle Information ..................27

5.30 Printer / Data Logger Setup ..........29

6. Care and Maintenance ...........30

6.1 Replacing the HIP™

Cleaning Solution .................30

6.2 Relling the Water Softener

Salt Reservoir...................... 32

6.3 Cleaning the HYDRIM L110w G4 .....32

6.4 Filter and Wash Arm Maintenance ....33

6.5 Preparing the unit for shipping .......33

6.6 Annual maintenance ...............34

7. Troubleshooting .................36

8. Specications ..................38

9. Serial Number Plate .............38

10. Warranty ......................39

HYDRIM and STATIM are registered trademarks of SciCan Ltd. BRAVO,

HIP, and SysTM are a trademarks of SciCan Ltd. All other trademarks referred

to in this manual are the property of their respective owners.

For all service and repair inquiries:

In Canada 1-800-870-7777

United States: 1-800-572-1211

Germany:

International: (416) 446-4500

Email: techservice.ca@scican.com

Manufactured by:

+49 (0)7561 98343 - 0

SciCan Ltd.

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

EU Representative

SciCan GmbH

Wangener Strasse 78

88299 Leutkirch GERMANY

Tel.: +49 (0)7561 98343 - 0

Fax: +49 (0)7561 98343 - 699

SciCan Inc.

701 Technology Drive

Canonsburg, PA 15317 USA

Phone: +1 724 820 1600

Fax: +1 724 820 1479

Toll free: 1-800-572-1211

SciCan Medtech

Alpenstrasse 16

CH-6300 ZUG SWITZERLAND

Phone: +41 (0) 41 727 7027

Fax: +41 (0) 41 727 7029

Page 3

1. Introduction

Thank you for selecting the HYDRIM L110w G4 instrument washer. The HYDRIM

complements the STATIM® and BRAVO™ autoclaves by quickly and hygienically

preparing soiled instruments for sterilization. To ensure years of safe, trouble-free service,

carefully review this Operator’s Manual before operating the unit. The HYDRIM L110w G4

is suitable only for the applications listed in this manual. Using the HYDRIM for other

purposes may be dangerous. The manufacturer cannot be held responsible for damage

caused by improper use.

Operational, maintenance and replacement instructions must be followed for the product

to perform as designed. All trademarks referred to in this manual are the property of their

respective owners. Contents of this manual are subject to change without notice to reect

changes and improvements to the HYDRIM product.

The HYDRIM L110w G4 should only be installed and serviced by a qualied contractor

as it is an Installation Category 2 device. Before connecting the unit, the installer should

check that the voltage and frequency of the electrical supply correspond with the details

in the installation instructions. The unit must only be plugged into a grounded outlet.

Please note that this unit is completely isolated from the electrical supply only when it is

unplugged or the circuit breaker is turned OFF. This must be done before any repair work

is carried out.

The HYDRIM L110w G4 uses HIP™ Cleaning Solution exclusively. The unit will not

perform as described if other detergents / cleaning products are used. Other detergents /

cleaning products may damage the unit, the instruments, cause excessive foaming, and

void the warranty. Do not use solvents in this unit. Do not allow small children or

unauthorized personnel access to this unit or its controls.

1

Page 4

2. Important Information

The following symbols appear in this book.

Caution, there is a potential hazard to the operator.

This situation may lead to a mechanical failure.

This is important information.

2

Page 5

3. Disclaimers

Do not permit any person other than authorized personnel to supply parts for service or

maintenance for your HYDRIM. SciCan is not liable for incidental, special or consequential

damages caused by any maintenance or services performed on the HYDRIM by unauthorized

personnel, or for the use of equipment or parts manufactured by a third party, including lost prots,

any commercial loss, economic loss, or loss arising from personal injury.

Never remove any unit panels and never insert objects through holes or openings in the cabinetry.

Doing so may damage the unit and/or pose a hazard to the operator.

If the unit is used in a manner other than that specied, the protection provided by the equipment

may be impaired.

Cleaning solutions may irritate. Avoid contact with eyes, skin and mouth.

Never sit, stand or lean on the open door. The unit may tip forward causing injury.

Always turn the unit OFF before adding softener salt, adding solutions or performing routine

maintenance to the unit.

The owner shall not allow any personnel other than the trained and authorized personnel

to operate the unit.

SciCan recommends leaving the unit turned ON at all times, in particular over times when no staff

is in the ofce or when no water shut-off mechanism is installed. Leaving the unit turned ON will

activate the drain pump if water is leaking into the chamber as a result of any faulty circumstance.

For further information or questions about the HYDRIM L110w G4, contact your authorized dealer.

3

Page 6

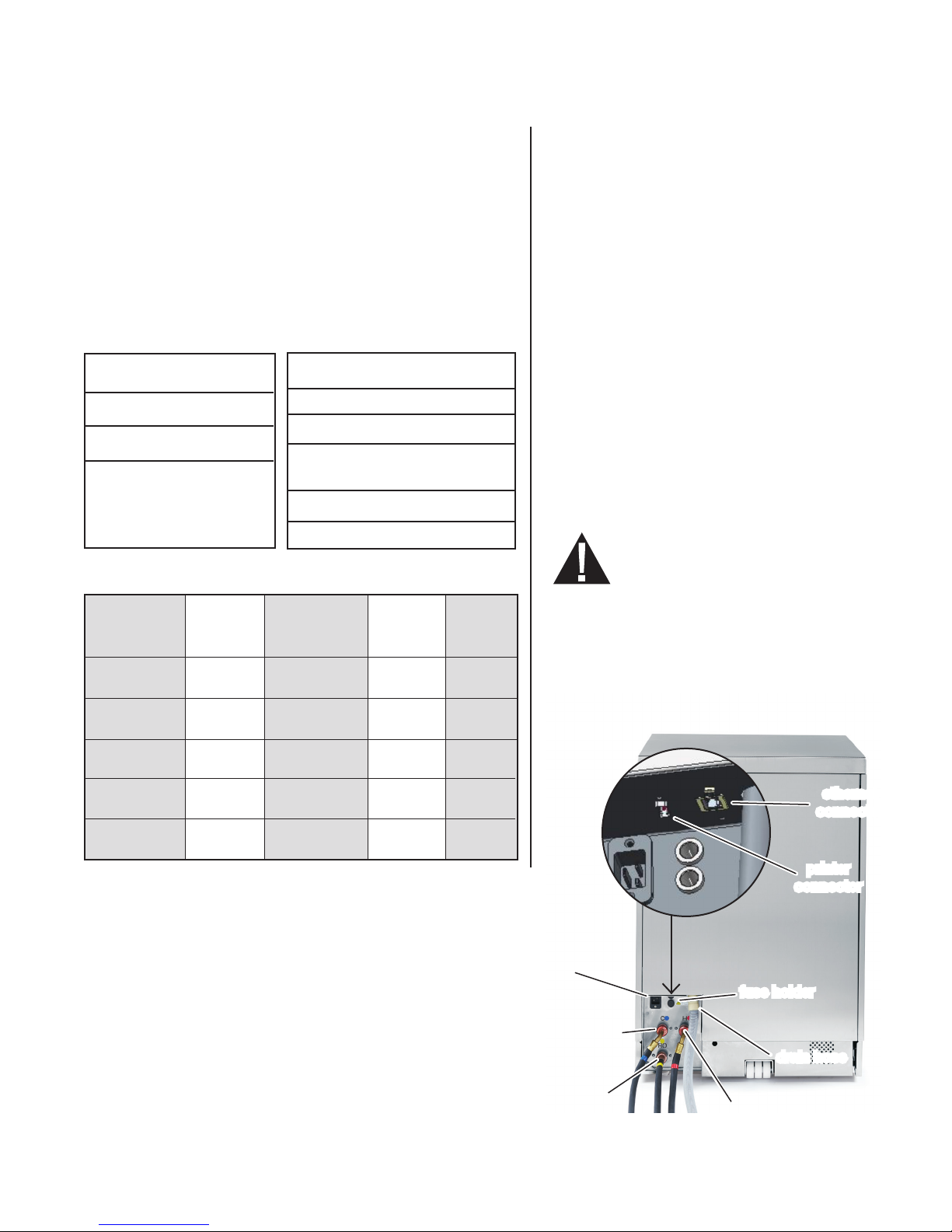

4. Installation Instructions

To open the wash chamber door, plug in the unit,

turn it on and press the unlock symbol.

Alternatively, remove the screw in the kickplate

and pull the ring. See section 5.28.

Tools and supplies required for installation:

• Slot screwdriver

• Channel locks

Specications:

Voltage: 208 – 240 V

Frequency: 60 Hz

Rated load: 2.5 kW

Circuit

breaker: 15 A

per phase

Height: 850 mm / 33.5”

Width: 598 mm / 23.54”

Depth: 600 mm / 23.75”

Depth with

door open: 1200 mm / 47”

Weight: 80 kg / 176 lbs

Max. Running Noise: 78 dBA

Utility Hook-ups

Installation:

Installation should be undertaken by a

SciCan approved technician. The use of

an unapproved installer may invalidate

the warranty.

If the HYDRIM is installed in a Sterilization

Center, the manufacturer of the Sterilization

Center should allow a 10mm / 1/2” space

at the top, back and both sides of the HYDRIM.

This will facilitate installation, and service

access to the HYDRIM.

Do not move the HYDRIM into place by

maneuvering the open wash chamber door.

This may cause to door to become misaligned

and leak.

During installation, all consumables should

have been added to the machine as appropriate.

It is important that this be done before starting

the machine.

For safety reasons, do not install

the HYDRIM without the top cover.

Hose / Length / Max. Distance Water Shut-off

Cord Diameter Distance from Pressure valve

inlet / drain

Hot Inlet 1.9 m / 6 ft. 1.5 m / 5 ft. 1-10 bar / Yes

3/4” 14.5-145 psi

Cold Inlet 1.9 m / 6 ft. 1.5 m / 5 ft. 1-10 bar / Yes

3/4” 14.5-145 psi

R/O Inlet 1.9 m / 6 ft. 1.5 m / 5 ft. 1-10 bar / Yes

3/4” 14.5-145 psi

Drain 1.5 m / 5 ft. — — —

3/4”

Electrical 1.8 m — — —

AWG 14-3

Levelling the HYDRIM:

The unit is standing on three supports: rollers (wheels) at the

back and two legs at the front.

1. Remove the front kickplate. Push the HYDRIM

into place while lifting the strap at the front to allow the unit

to roll on the rollers.

2. Adjust the front legs as required until the

HYDRIM is level.

3. The rear two legs are used only if the oor is uneven or

cannot provide support to the rollers.

4. Tuck the strap under the machine before

replacing the kickplate, so as not to interfere

with the exhaust air vents.

Rear of Unit

power

connector

cold water

inlet hose

RO water

inlet hose

ethernet

connector

printer

connector

fuse holder

drain hose

hot water

inlet hose

4

Page 7

4. Installation Instructions

Connecting the water inlet hoses:

Connect the hot and cold water inlet hoses to the hot and cold water supply.

Drain requirements:

Connect the drain hose to the drain outlet. The drain hose can be attached to existing drain

lines using a 3.5 cm / 1.5” or larger standpipe / P-trap combination. If the hose is connected

directly to the drain line, ttings and adapters should not reduce water ow. The drain hose

should be attached to the main drain at a point no more than 1 metre /3 ft. above the base of

the HYDRIM. A oor drain is acceptable (check local codes).

Electrical requirements:

Connect the electrical cord to the power supply. The HYDRIM must have a dedicated circuit

equipped with a 15A fuse. The outlet must be grounded.

Additional Information:

• The HYDRIM unit is heavy. Use a forklift or dolly and exercise caution when moving it.

• The HYDRIM should be serviced on site.

• The HYDRIM is equipped with an air gap / anti-suction device to prevent backow of dirty

water into the water supply. No other air gap device is necessary.

• If you need to extend the water inlet and drain hoses, ensure that you use commercial grade

plumbing hose.

• The maximum length of the drain hose is 3.3 m / 13 ft.

Installing the water softener salt:

Unscrew the salt container lid and pour 1 litre / 1 quart of water into

the water softener. Add 1 kg / 2.2 lbs of water softening salt in the

same manner. Screw the salt container cap on tightly.

Handling and installing the HIP™ cleaning solution

The HIP™ cleaning solution is used in dilute form as a detergent for the cleaning

of surgical instruments in the HYDRIM range of washers and washer disinfectors. It is a

colourless and almost odourless liquid which is completely soluble in water.

The pH range of the concentrated solution is between 9.3 to 9.8 and the solution is

therefore alkaline. It is therefore advised that certain precautionary measures are observed

when handling and during the loading of the solution into the machine, and when removing

and disposing of the empty box.

5

Page 8

4. Installation Instructions

Recommended precautionary measures with regard to safe handling of HIP™ cleaning solution.

• Always wear undamaged gloves made of natural or butyl rubber, nitrile, or neoprene

(Surgical gloves are ideal).

• Always wear eye protection.

• Protect exposed skin on arms.

• If solution is spilled on clothing, remove the item of clothing and wash affected skin

with plenty of water, in accordance with the Material Safety Data Sheet requirements.

• Use good industrial hygiene practices in handling this material. When handling,

do not eat or drink.

• After handling the product, remove and dispose of gloves and wash hands prior to

removing eye protection.

• Do not use the personal protective equipment you use for clinical activities to handle

HIP™ products.

• Always ensure that personal protective equipment, if contaminated with HIP™

cleaning solution, is cleaned, or disposed of as appropriate.

For comprehensive data on HIP™ cleaning solution, please visit SciCan.com to

view or download a PDF of the Material Safety Data Sheet.

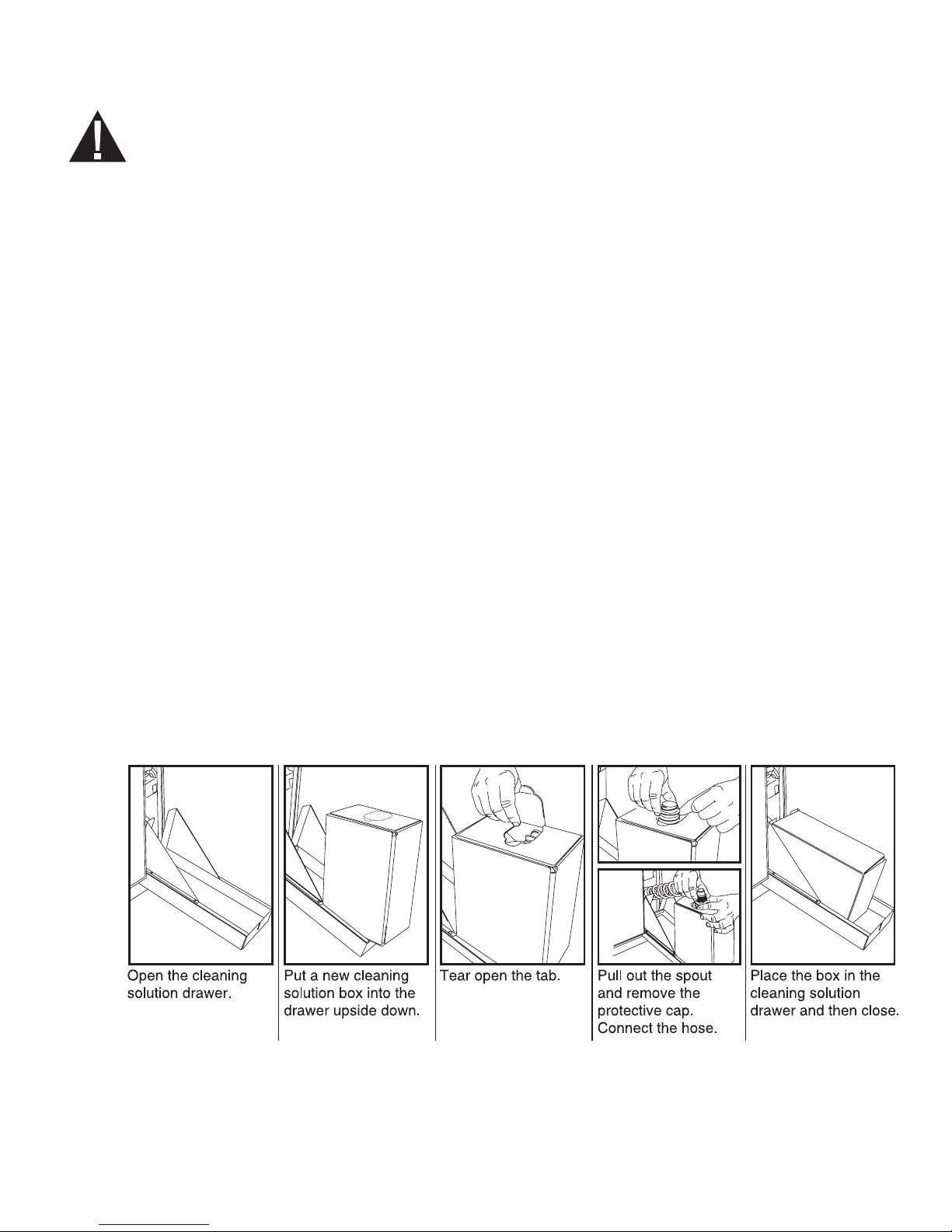

To install the HIP™ cleaning solution box, follow these steps:

salt container

Installing Cleaning Solution:

Install HIP™ Cleaning Solution as follows:

Technician Installation Test: Turn on the shut-off valves. Run a cycle, checking for leaks in

the plumbing connections.

6

Page 9

4. Installation Instructions

Water quality

The quality of the water being used in the HYDRIM to clean the instruments is very critical

to achieving satisfactory cleaning results and to protecting the instruments and the internal

parts of the unit from deterioration.

Drinking water typically contains many dissolved solids. The amount of dissolved solids

greatly depends on the local natural geological conditions and they can cause stains, spots

and corrosion on instruments and on the internal parts of the HYDRIM. Among others, Iron,

Manganese, Chloride, and Calcium Carbonate (CaCO

that affect the cleaning results when using a washer.

Iron and Manganese can cause orange and brown or black stains on the instruments and

on the internal parts of the HYDRIM. Chloride is usually responsible for causing stains,

spotting, pitting and scaling. If the instruments or the inner parts of the HYDRIM L110w G4,

such as the chamber, show any of these spots or stains, a water test may be required to

determine the cause. The installation of a water treatment system may be required to

reduce the amount of dissolved solids in the water and to improve the cleaning

performance of the HYDRIM.

) are the dominant dissolved solids

3

Calcium Carbonate is the principle cause of water hardness and leaves white spots or

scales. The HYDRIM is equipped with a built-in water softening system that must be

adjusted according to the local water hardness. Please see the next section of this manual

for recommended regeneration settings.

Before using the HYDRIM, SciCan recommends testing the water and recording

the results for water hardness, pH value, and water conductivity for future reference.

IMPORTANT: The HYDRIM's water softening system reduces the water hardness by

taking out Calcium Carbonate. If your water testing results show that your water hardness

is outside the unit's range of adjustment, or if other dissolved solids in the water cause

stains or deposits on the instruments or chamber, an external water treatment system may

be required.

7

Page 10

4. Installation Instructions

Testing water quality

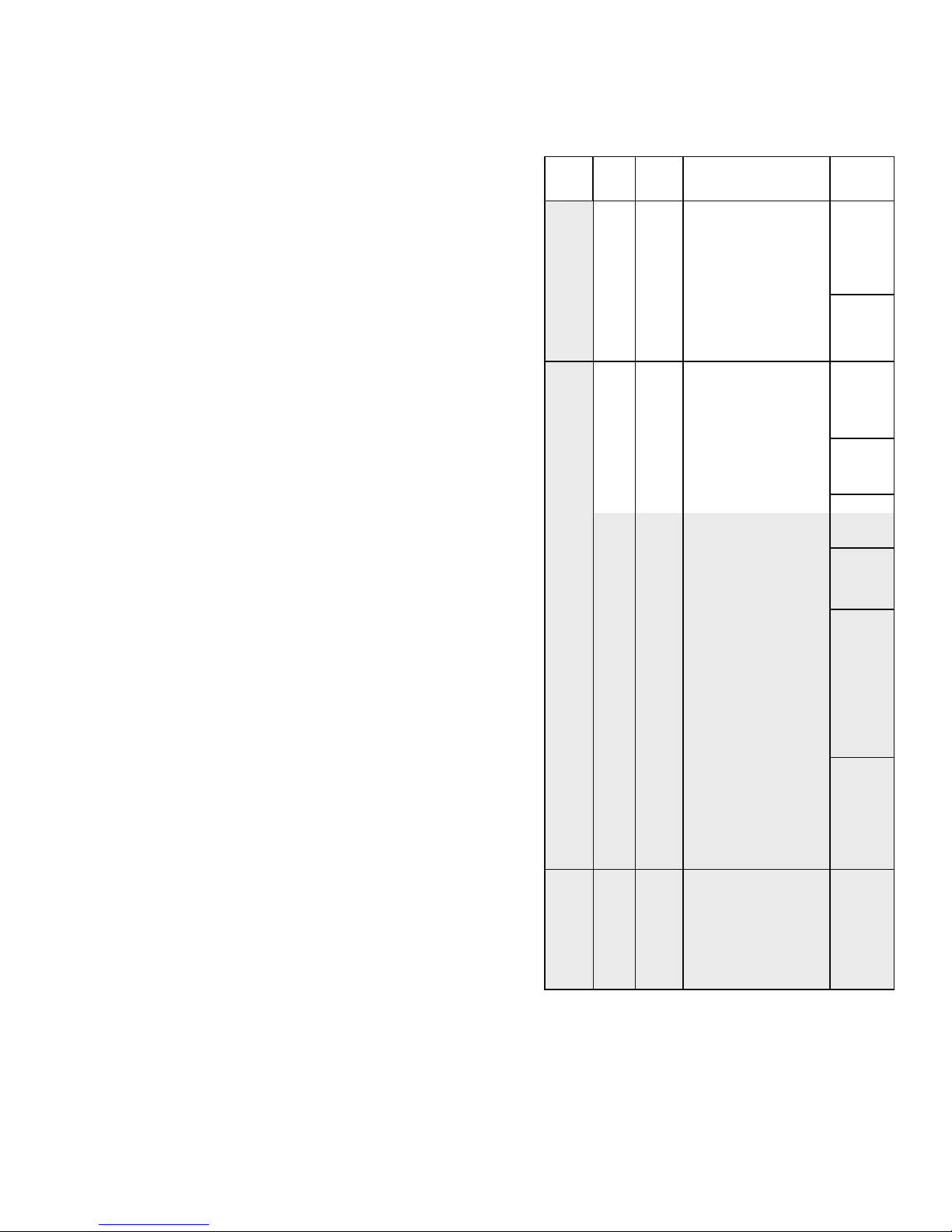

Water Hardness Conversion and salt regeneration levels

The HYDRIM L110w G4 is equipped with

a built-in water softening system that must

be adjusted according to the local water

hardness. To read local water hardness,

proceed as follows:

1. The water test kit included with your

HYDRIM contains three water

hardness test strips in bags. Take a

water sample from the location where

the machine will be installed.

2. Open one of the bags, remove the

test strip and dip it into the water.

3. Compare the color of the strip with

the chart on the back of the bag

Determine the water hardness according

to the chart on the water test kit envelope.

4. Power the unit on and select the

Settings key from the main menu.

5. Go to the Setup Menu and select

“Set Regeneration”.

6. Using the up and down arrows, set the

water softener regeneration level

according to the water hardness table

in this section. If your water hardness

falls between two settings, select the

higher setting.

7. Unscrew the water softener container

lid from the bottom right of the chamber

and pour at least 1.0 litres (0.26 gal) of water

into the water softener container. Then fill the

salt container to the top (maximum 1 kg/

2.2 lbs.) with salt. Close by screwing the lid

°dH

1 1.0 18

2 2.1 36

3 3.1 54

Very Soft

4 4.2 71

Necessary

5 5.2 89

5.6 5.8 100

Typically

External Treatment

6 6.3 107

6.2 6.4 110

(values from 18-143)

7 7.3 125

No Treatment

8 8.3 143

8.4 8.8 150

9 9.4 161

10 10.4 178

10.1 10.5 180

11 11.5 196

11.2 11.7 200

11.8 12.3 210

12 12.5 214

13 13.6 232

14 14.6 250*

15 15.6 268

16 16.7 286

16.8 17.5 300

17 17.7 303

18 18.8 321

19 19.8 339

19.6 20.5 350

20 20.9 357

20.2 21.0 360

(values from 150-535)

21 21.9 375

May Require External Treatment

22 22.9 393

22.4 23.4 400

23 24.0 411

24 25.0 428

25 26.1 446

25.2 26.3 450

26 27.1 464

27 28.2 482

28 29.2 500

28.6 29.8 510

29 30.2 518

30 31. 3 535

≥30.3 ≥31.6

Required

(values >535)

tightly back into place and run a complete

cycle with no instruments. An improper seal can lead to corrosion.

US

GPG

PPM

(mg CaCO3 / Litre)

≥540

Regen.

1

2

3

4

5

6

7

8

Additional

Water

Treatment

Required

*Please note: The water test strip is only accurate up to 250 ppm. If the reading on the test strip exceeds

250 ppm and/or if the location in which the HYDRIM is installed has known water quality problems, having

a more detailed and accurate water test done by a test lab is strongly recommended.

8

Page 11

5. Instructions for Use

5.1 Instrument Reprocessing Recommendations

The HYDRIM L110w G4 is designed to clean general dental and medical instruments.

Terminal sterilization MUST follow processing in the HYDRIM L110w G4.

Prior to placing instruments in the HYDRIM, consult the instrument manufacturer’s reprocessing

instructions.

Examples of medical and dental instruments suitable for cleaning in the HYDRIM L110w G4

include:

• Stainless steel scalers, spatulas and hemostats.

• Stainless steel retractors, needle holders, skin hooks, tissue forceps, scissors, curettes, and

other stainless steel instruments free of deep cavities.

For best results, instruments processed in the HYDRIM L110w G4 should

have the following properties:

• Heat resistance to a temperature of up to 70°C / 158°F

• Corrosion resistance in the presence of heat and alkalinity.

Burs, microkeratomes, phaco tubing, beroptics and electrical equipment should not be processed

in the HYDRIM.

Nickel-plated instruments, or instruments containing aluminum or colour anodized aluminum

as well as single use instruments are not suited for processing in the HYDRIM.

HIP™ (HYDRIM Cleaning Solution with Instrument Protection) has been carefully formulated to

provide outstanding material compatibility with a wide range of metals and coatings. However,

some manufacturers’ instruments or instrument coatings may not be compatible.

Please consult the instrument manufacturer for their recommended cleaning procedures.

In general, it is not recommended to process carbon steel and chrome plated instruments

in the HYDRIM.

All hinged instruments should be placed in open position in open baskets or in the hinged

instrument rack (SciCan part number 01-110409S) in P3 Heavy-Duty cycle.

When processing small or light objects in the HYDRIM use the basket with lid (SciCan part number

01-109966S).

Only the outer surfaces of dental handpieces can be cleaned in the HYDRIM L110w G4 with

the handpiece holder (9 handpieces, PN 01-113113S or 21 Handpieces, PN 01-113112S).

Set-able materials, such as cements, amalgam, and composites need to be removed from the

instruments after use at chairside. The HYDRIM will not be able to clean them off the instruments.

.

9

Page 12

5. Instructions for Use

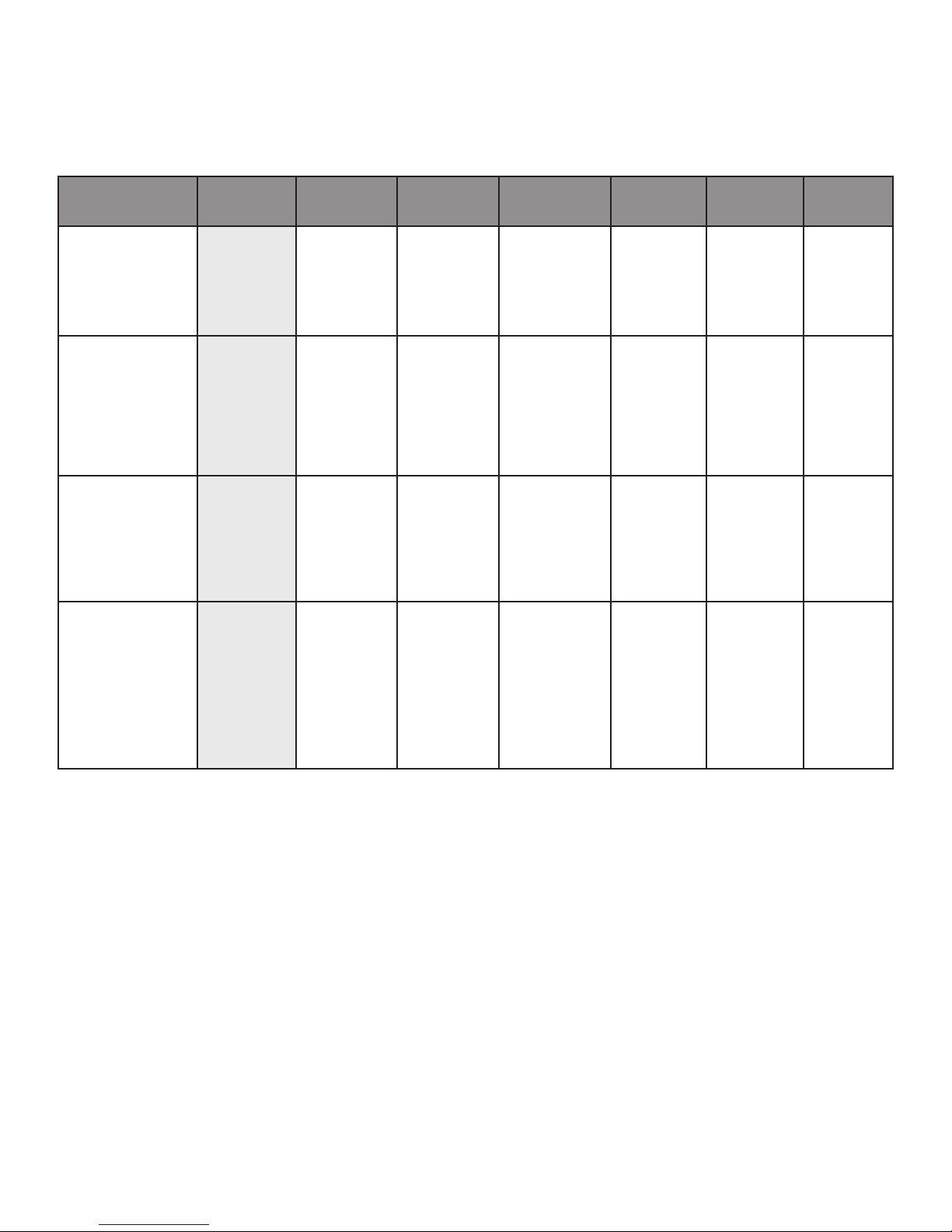

5.2 Cycle Description Chart

Cycle Prewash Wash

P0 – Machine

Cleaning Cycle

No initial draining.

<30ºC/86°F

(cold)

3 minutes

P1 – Rinse and

Hold Cycle*

Use to prevent

soil from drying on

instruments when they

will not be washed

within one hour.

<30ºC/86°F

(cold)

3 minutes

P2 – Regular

Cycle

Use for moderately

soiled loose

instruments.

N/A

N/A N/A

N/A N/A

50ºC/122°F

5-15 minutes

(default 5

minutes)

Intermediate

Rinse

<60ºC/140°F

1 minute

Rinse Dry

<30ºC (cold)

2 minutes

60ºC/140°F

1 minute

60ºC/140°F***

1-10 minutes

(default 1 minute)

N/A

N/A

1-20

minutes

(default 10

minutes)

Total Time**

w/o Drying

7

minutes

17

minutes

25

minutes

Water

Consumption

16 L

4.23 Gal

16 L

4.23 Gal

24L

6.34 Gal

P3 – Heavy Duty

Cycle

Use for heavily soiled

instruments and

cassettes.

* This is not a wash cycle. Always run a wash cycle following the rinse & hold cycle.

** Cycle times depend on the temperature and pressure of incoming water.

*** Rinse times are adjustable up to 10 minutes by an authorized technician.

<30ºC/86°F

(cold)

3 minutes

50ºC/122°F

5-15 minutes

(default 9

minutes)

<60ºC/140°F

1 minute

60ºC/140°F

1 minute

1-20 minutes

(default 10

minutes)

34

minutes

32L

8.45 Gal

10

Page 13

5. Instructions for Use

5.3 Hints and tips for best cleaning results

Remove all cement, composite material and amalgam from instruments at chairside prior to

processing in the Hydrim.

• Use only accessories, such as baskets, cassettes, trolleys and racks to hold instruments

that are designed for the HYDRIM L110w G4.

• Use accessories for their intended purpose only. For example, do not place hinged

instruments in cassettes. Use the hinged instrument rack instead.

• Disassemble instruments if possible.

• Do not overlap instruments. Each instrument must be kept separate.

• All instruments must be placed in the instrument washer in such a way as to allow good

rinsing of all surfaces. Any surface that is shielded from water and detergent cannot

be cleaned.

• Open hinged instruments widely when placed in baskets or hinged instrument rack

(PN 01-110409S). Closed hinged instruments cannot be cleaned.

• Place suction tubes in the rack for vertical instruments and ensure that water can flow

unrestricted in and out of the tubes. Do not place suction tubes horizontally in a basket

or in a cassette. For instruments containing lumens, such as dental handpieces, only the

external surfaces are cleaned.

• Place trays and other concave shaped items at an angle to ensure water can run off

surfaces easily.

• Do not overload the HYDRIM.

• Verify the Hydrim setup:

– Ensure that the washer spray arms are free of any blockage and can rotate freely.

– Ensure that the mesh filters in the chamber drain are free from debris.

• To achieve best cleaning results, instruments should be processed in the HYDRIM as

soon as possible. If immediate cleaning is not possible, it is recommended to process

the instruments using the P1 Rinse and Hold program immediately after use on

the patient.

• Visually inspect instruments for cleanliness and integrity (corrosion, material changes)

after cleaning and repair or replace instruments if necessary.

• If process enforced is activated, the operator must confirm that the instruments are

visually clean after a complete cycle is finished.

11

Page 14

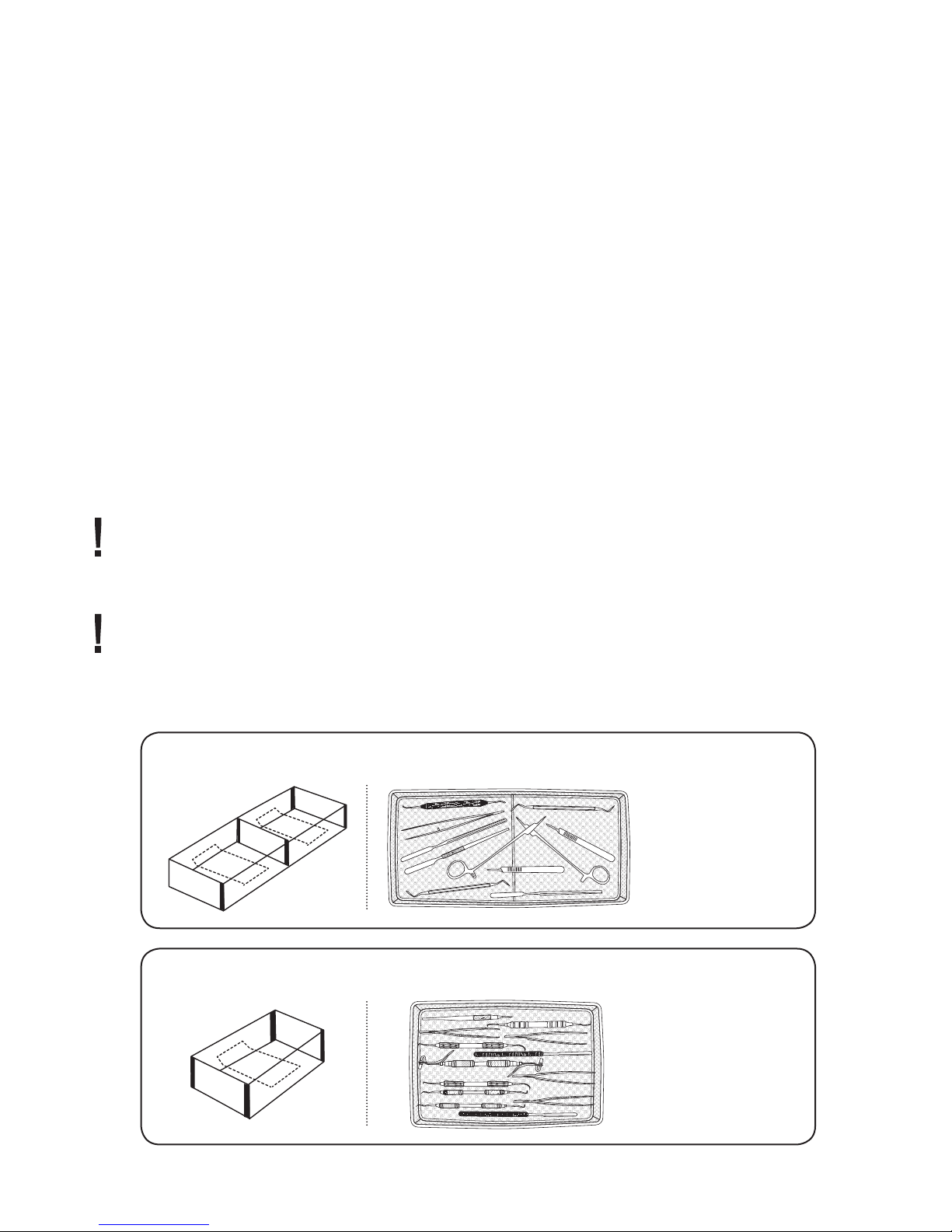

5. Instructions for Use

5.4 Recommended load congurations

The intended purpose of the L110w G4 washer is a clinical general instrument washer,

predominantly aimed at the general dental and medical markets. There will be many

combinations of instruments that can be processed in the L110w G4 unit depending on:

• Size of practice

• Types of procedures undertaken at any one time

• Specialization of practice

• Instrument management protocols

It is difcult to illustrate all the possible combinations av ailable, so below we have given

examples of the most common typical basket loadings, the recommended loading

of general instruments, and the worst case loading, for which the unit has been type

tested and validated.

Handle all instruments with care to prevent personal injuries through punctures for

example. Follow local health and safety regulations for preventing accidents, bodily

harm and personal injuries.

Observe the instrument manufacturer’s recommendations for cleaning and care.

When loading the unit, arrange loose instruments so that they do not touch one

another. Instruments with concave surfaces or cavities should be placed so that water

can drain freely.

Sample loading:

Example 1 – solid straight & hinged instruments

Example 2 – solid straight instruments

12

Page 15

5. Instructions for Use

Example 3 – hinged instruments, solid instruments and open hollow instruments

For example:

Scalers, curettes,

dental elevators,

single part mirrors,

suction tubes etc.

Example 4 – small & disassembled instruments

For example: Two piece mirrors, scalpel knife handles, etc.

Example 5 – instrument sets in cassettes – full load

For example:

Rongeurs, forceps,

scissors etc.

For example: Bone fi les, pluggers, curettes, excavators, etc.

Example 6 – instrument sets in cassettes – half load

For example: Bone fi les, pluggers, curettes, excavators, etc.

Example 7 – instrument trays

13

Page 16

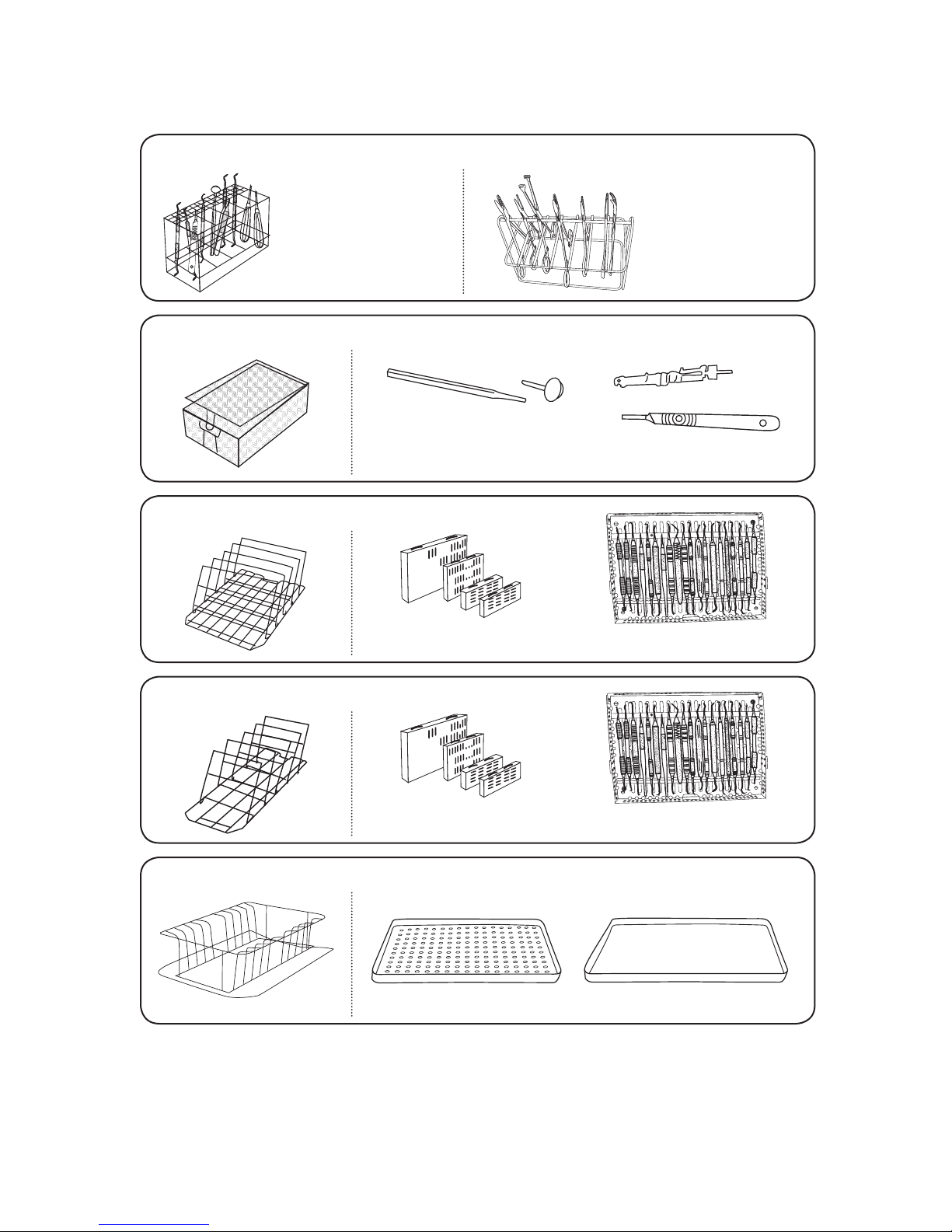

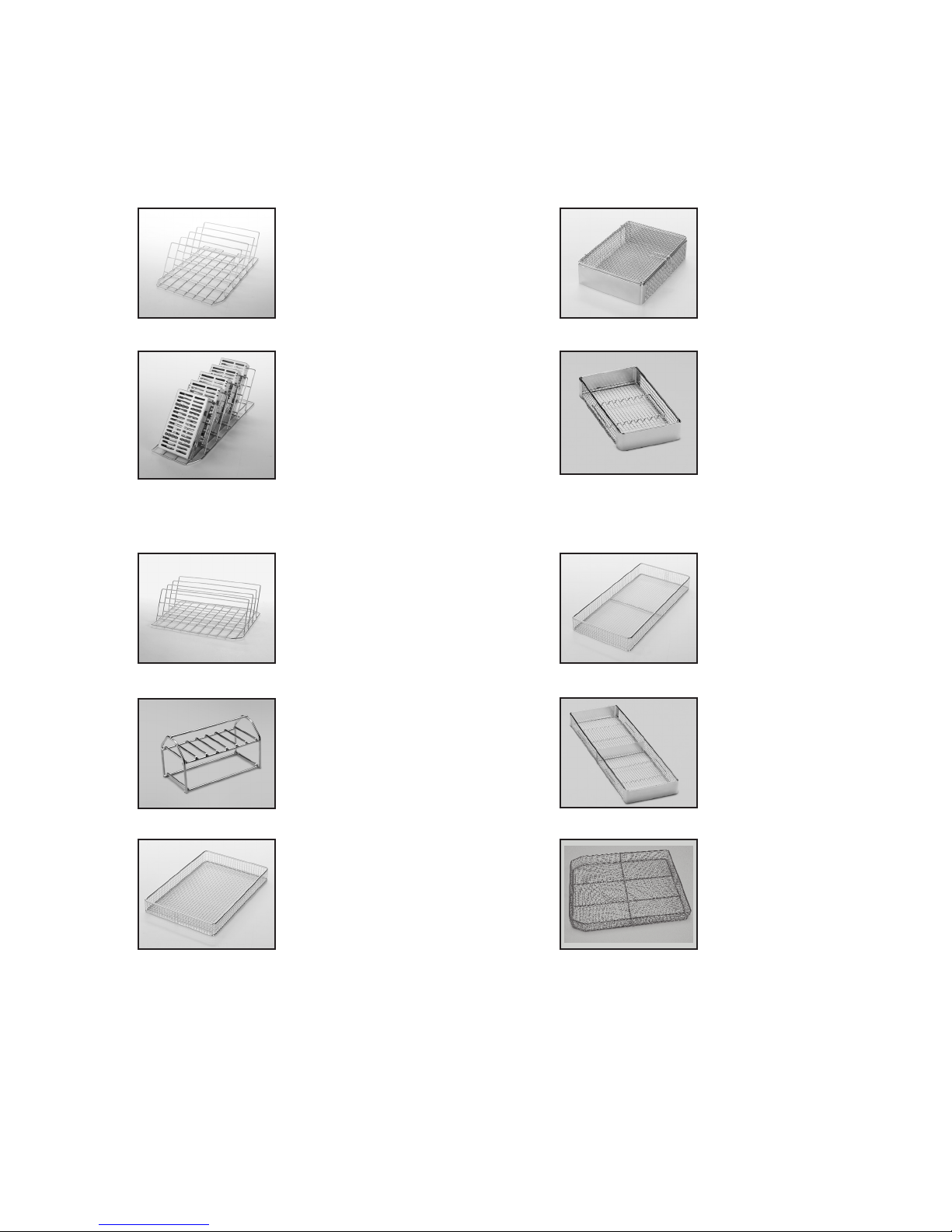

5. Instructions for Use

5.5 Baskets and Accessories

The following are included with the HYDRIM:

Rack for ve 8” x11”

cassettes, for upper

or lower trolley. Full size (1/1).

Part-number

01-109963S

Rack for ve medium

size cassettes, for upper

or lower trolley. Half-size (1/2).

Part-number

01-109964S

The following are optional:

Rack for four 11” x 14”

cassettes, for upper

or lower trolley. Full size (1/1).

Part-number

01-109965S

Basket with lid.

Quarter size (1/4).

Part-number

01-109966S

Hygiene basket for

loose instruments.

Quarter size (1/4).

Part-number

01-109967S

STATIM 5000 basket.

Part-number

01-107241

Hinged instrument rack.

Part-number

01-110409S

STATIM 2000 basket.

Part-number

01-107240

Long Basket.

Part-number

01-108232

Full Size Basket.

Part-number

01-111598

14

Page 17

5. Instructions for Use

5.6 Touchscreen overview

Programs

Network connectivity

(green when active)

USB status

(green when active)

Unlock door

Settings

Water softener,

detergent level,

and door status

15

Page 18

5. Instructions for Use

5.7 Set up menu overview

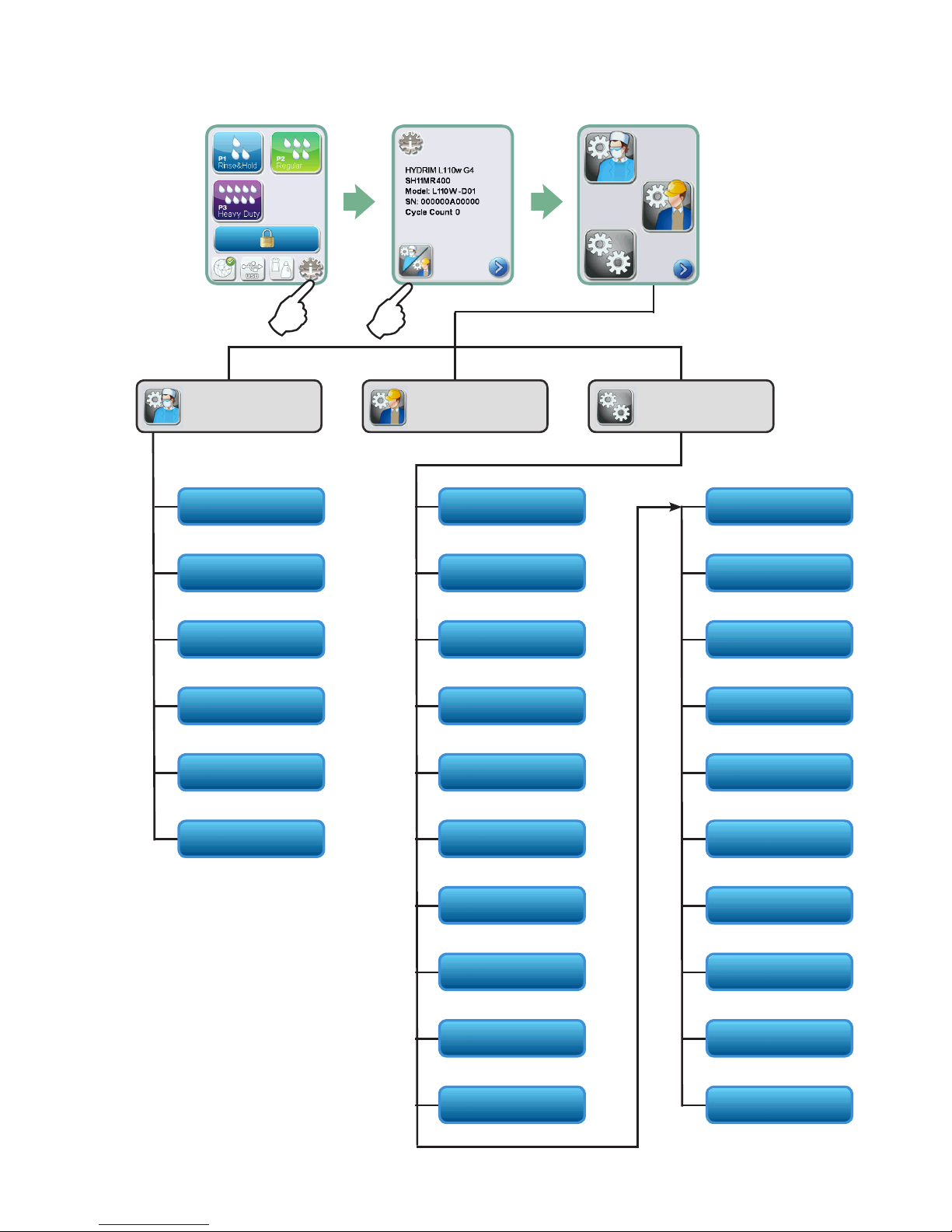

User Technician Setup

Cleaning

Set Drying Time

Set Wash Time

Cycle Count

Process Enforced

User

Country

Date/Time

Unit No.

Network Setup

Screen Saver

Temperature C/F

Baud RateLanguage

Set EOL CR/LF

Set Regeneration

LCD Contrast

Theme

Remote Screen

Instructions

Set Button Beep

Beep Volume

Set Printer

16

Instructions Delay

Remote Access

Prepare for Shipping

Page 19

5. Instructions for Use

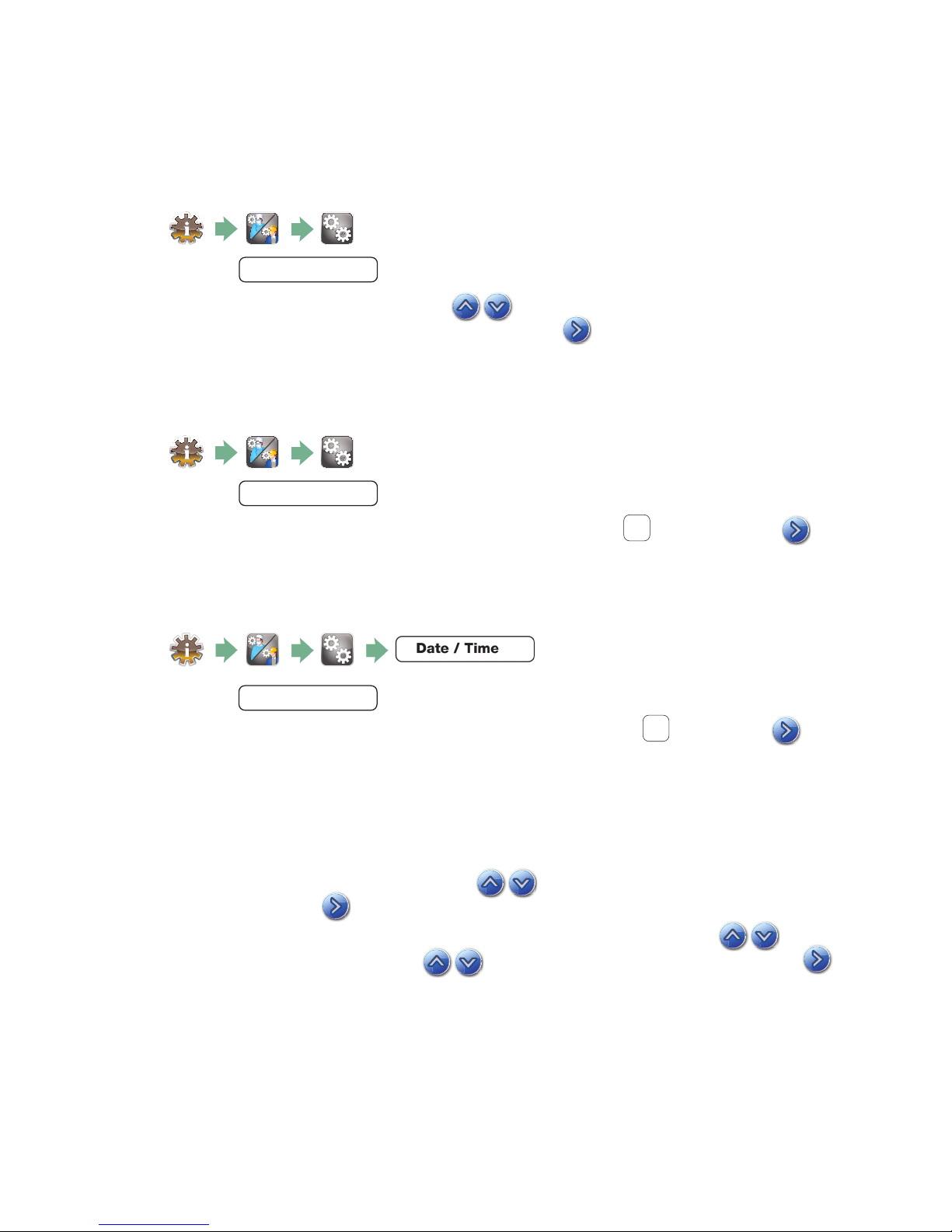

5.8 Setting the language

The messages displayed by your HYDRIM can be presented in a number of different

languages. To change the current language, follow these steps:

1.

2. Scroll to

Language

and select.

3. From the LANGUAGE screen, press to scroll through the list of languages.

When you have found the desired language, press

to the Setup menu.

to save your selection and return

5.9 Setting the country

1.

2. Scroll to

3. Using the keypad, type the name of the country and press

to save and return to the Setup menu.

Country

and select.

EN

to select. Press

5.10 Setting the time

1.

2. Scroll to

Date / Time

and select TIME.

3. From the TIME screen, use the keypad to set the time. Press

to return to the Setup menu.

NOTE: If the HYDRIM is connected to a network, it is important to also enter the correct

Time Zone. Enter the Time submenu, select Time Zone and scroll and select your local

time zone.

EN

to save and

4. To change your unit to display 12-hour time format (24-hour time format is the default

setting), go to the Setup menu and use

toggle to 12. Press

to save and return to the Setup menu.

5. To activate daylight savings time (DST), go to the Setup menu and use

to DST ON/OFF and select. Use

to save and return to the Setup menu. If connected to the network, the time will

automatically adjust to DST.

to toggle DST ON or OFF and press the

to scroll to TIME 12/24, select it and

to scroll

17

Page 20

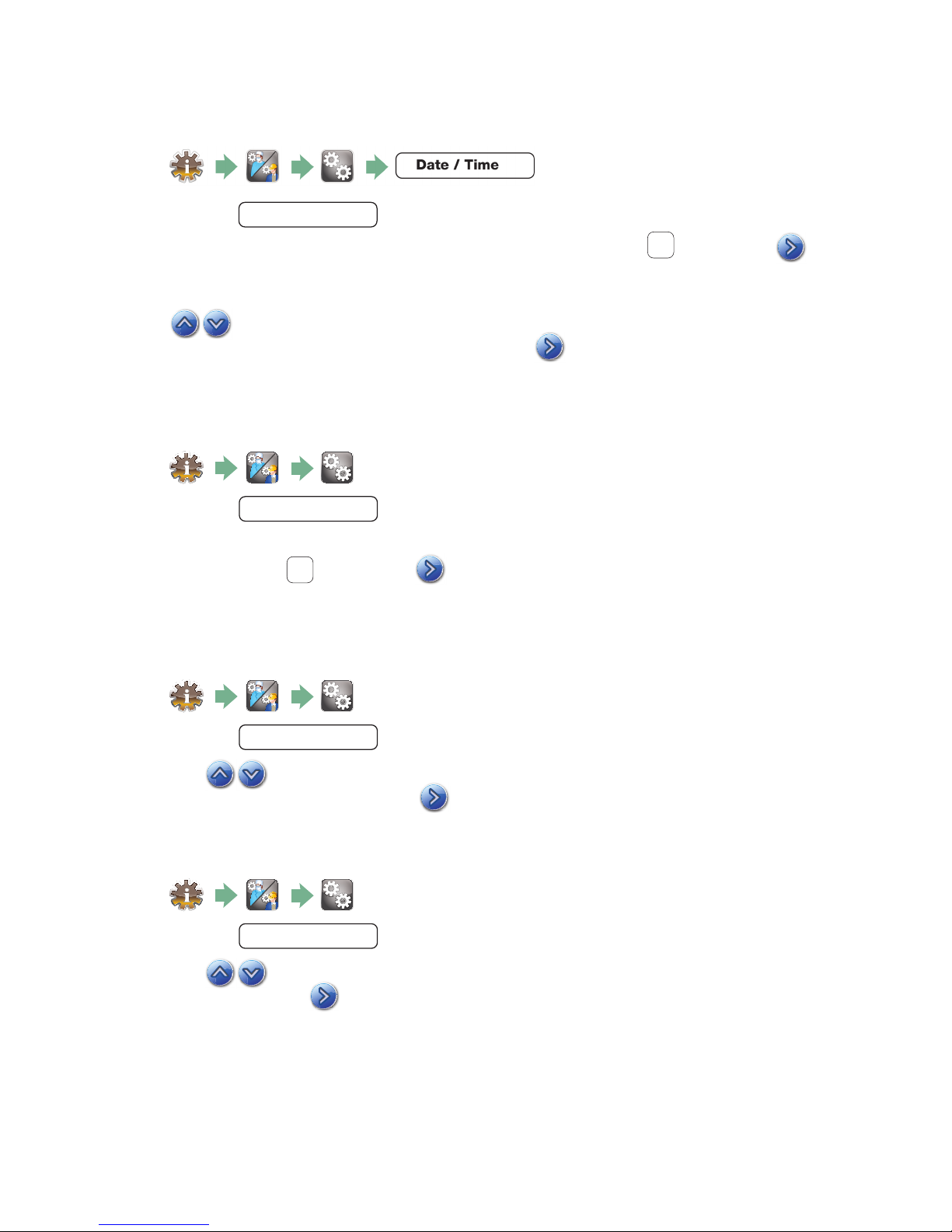

5. Instructions for Use

5.11 Setting the date

1.

2. Scroll to

Date / Time

3. From the DATE screen, use the keypad to set the date. Press

to return to the Setup menu.

and select DATE.

EN

to save and

4. To change the format in which the date appears, return to the Setup menu and use

to scroll to DATE FORMAT. Select it, and follow the prompts to have

the date displayed in the desired format. Press

the Setup menu.

to save and return to

5.12 Assigning unit identi er number

1.

2. Scroll to

Unit No

and select.

3. Using the keypad, select a maximum of 3 digits to be used as the unit’s identifi er

number. Press

to save and to return to the Setup menu.

EN

5.13 Adjusting the screensaver delay

To change the length of time before the screensaver is activated, follow these steps:

1.

2. Scroll to

Screensaver

and select.

3. Use to scroll through your time options. When you have found the amount of

time you require, press it. Press

to save and return to the Setup menu.

5.14 Adjusting the temperature display

1.

2. Scroll to

3. Use to choose between having information displayed in degrees Celsius or

Fahrenheit. Press

Temperature C/F

to save and return to the Setup menu.

and select.

18

Page 21

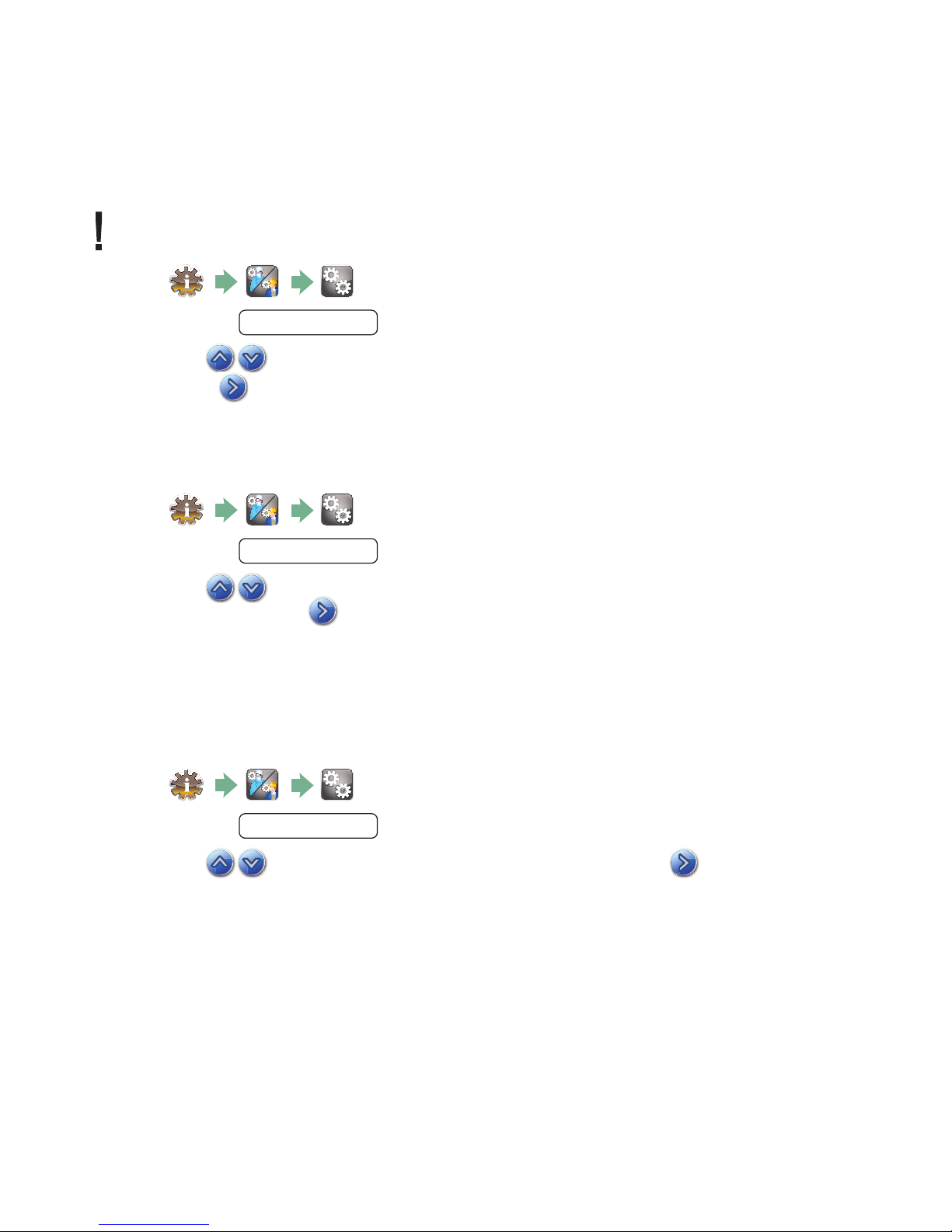

5. Instructions for Use

5.15 Turning the button sound ON or OFF

The HYDRIM is preset to beep when a button is pressed. If you would like to turn the button

sound off, follow these steps:

NOTE: Turning OFF the button sound does NOT turn off other alarms and cycle notifi cation

beeps.

1.

2. Scroll to

Beep ON/OFF

and select.

3. Use to scroll through your ON or OFF options and select it by pressing it.

Press

to save and move back to the Setup menu.

5.16 Adjusting the button beep volume

If you would like to adjust the beep volume, follow these steps:

1.

2. Scroll to

Beep Volume

and select.

3. Use to scroll through the volume settings. Select the one you want by

pressing it. Press

to save and move back to the Setup menu.

5.17 Adjusting the salt regeneration

Salt regeneration should be set according to the local water hardness. See section 4

Testing Water Quality for instructions on determining correct settings. To set salt

regeneration, follow these steps:

1.

2. Scroll to

Set Regeneration

3. Use to change the value. The default setting is 1. Press to save and return

to the Setup menu.

and select.

19

Page 22

5. Instructions for Use

5.18 Adjusting the screen contrast

The touchscreen is calibrated for the lighting condition of most sterilization centers. Should

you need to adjust the contrast for your offi ce, follow these steps:

1.

2. Scroll to

LCD Contrast

and select.

3. Use to scroll through your contrast options. When you have found the contrast

you require, press it. Press

to save and return to the Setup menu.

5.19 Changing the touchscreen display themes

The touchscreen themes (i.e. icons and background colours) can be changed to one of the

preset options. To change themes follow these steps:

1.

2. Scroll to

3. In the

As you scroll, each theme will display on the touchscreen. Press

theme and return to the Setup menu.

Theme

Change Theme

and select.

screen, use to scroll through your available options.

to select your

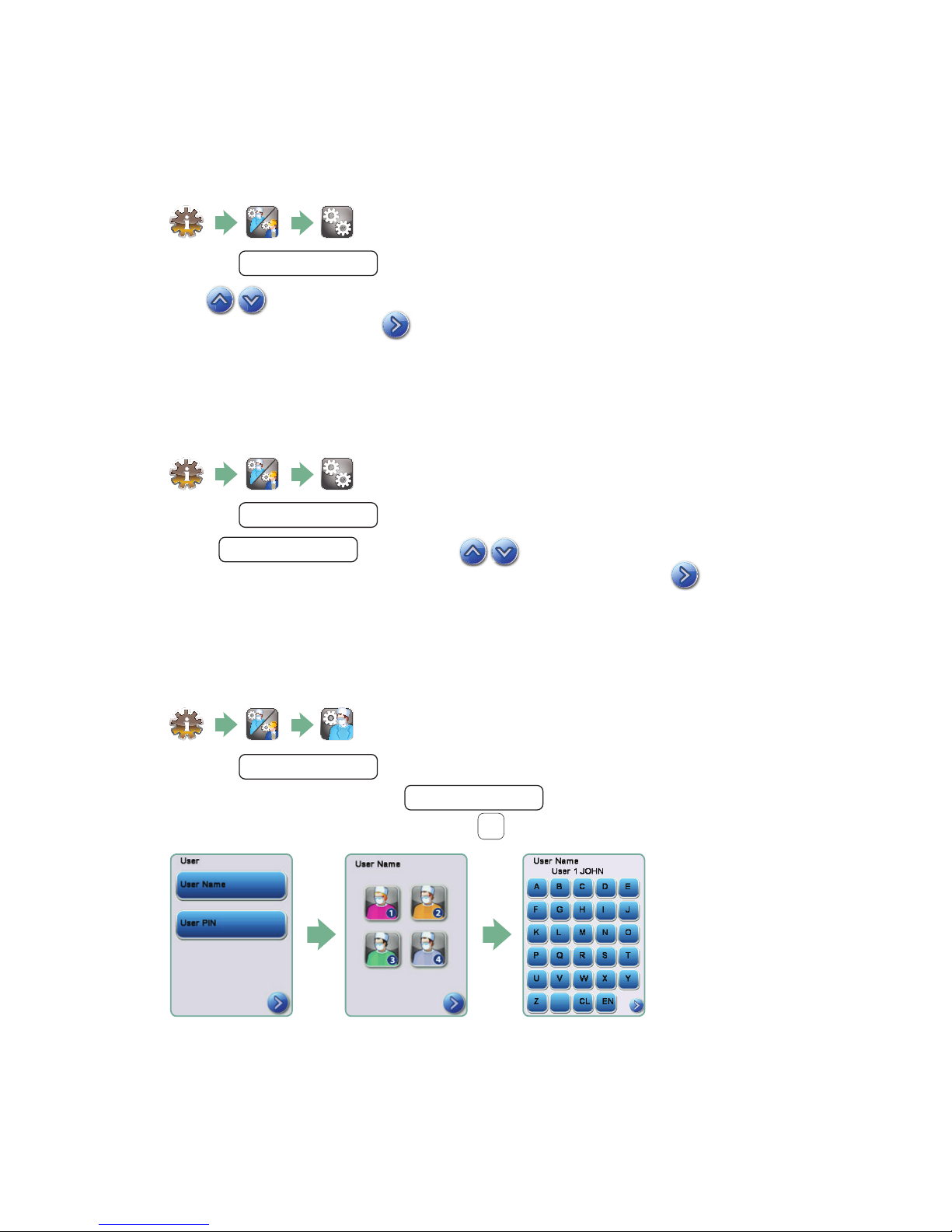

5.20 Creating a User Name

Up to four unique User Names can be created. To assign a User Name follow these steps:

1.

2. Scroll to

3. To assign a user name, select

a name (up to 12 characters) and press

User

and select.

User Name

to save.

EN

and use the alphabetic keypad to enter

20

Page 23

5. Instructions for Use

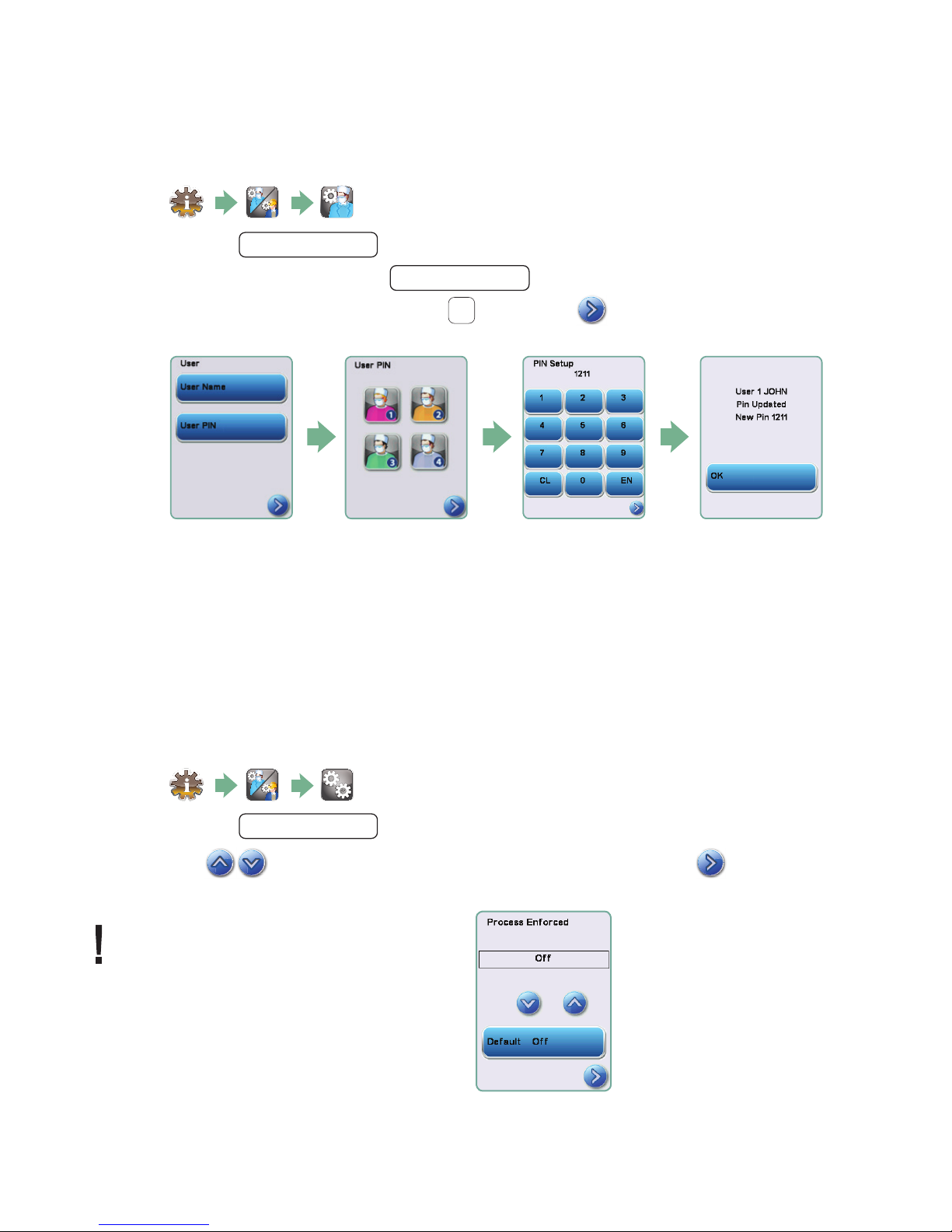

5.21 Creating a User PIN

From the User PIN screen, you can assign up to four PINs. To assign a PIN, follow these

steps:

1.

2. Scroll to

3. To assign a user PIN, select

a number (up to 4 digits) and select

screen.

User

and select.

User PIN

and use the numeric keypad to enter

to save and to move to the confi rmation

EN

5. If all of the information presented in the confi rmation screen is correct, press OK

to be returned to the User PIN screen. To make a correction, select the User PIN you

want to change and repeat the process described above.

5.22 Setting up process enforced usage

When process enforced usage is activated, users are required to enter a PIN at the end of

a cycle. For process enforced usage to function, User IDs and PINs must fi rst be assigned.

To set up User ID and PINs, refer to sections 5.19 and 5.20 on creating a user name and

PIN. To activate process enforced usage, follow these steps:

1.

2. Scroll to

Process Enforced

3. Use to toggle process enforced function ON or OFF. Press

to save your selection and return to the Setup menu.

NOTE: Any user can stop a cycle even

with process enforced usage ON.

However, the cycle data will record

that an unauthorized user has stopped

the cycle.

and select.

21

Page 24

5. Instructions for Use

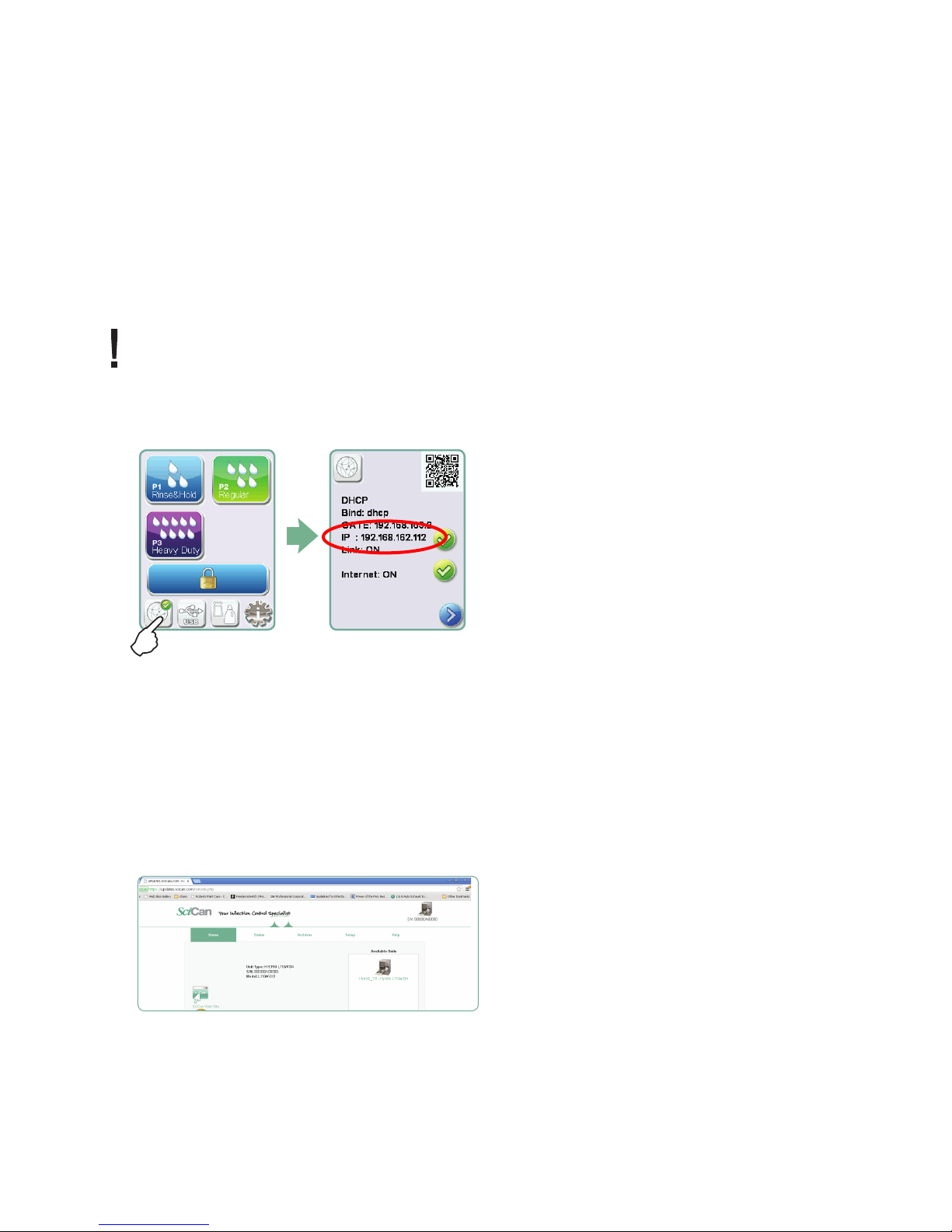

5.23 Connecting to a network

The HYDRIM L110w G4 has a 10/100Base-T Ethernet port located at the back of the unit.

To connect your HYDRIM to a network using a router, follow these steps:

1. Connect your network cable to the Ethernet port at the back of the unit. If your offi ce

uses a router, the router should automatically assign the unit an IP address. A red X on the

network icon means the unit is not connected. A yellow check mark means the unit has

an IP address but is not connected to the Internet and cannot send emails. A green check

mark means the Internet connection is set up properly and the unit can send out emails.

NOTE: In some circumstances, where you do not have a router, for example when using

Windows Network Sharing, you may have to assign a dedicated or ‘static’ IP address.

To assign a static IP address, contact your local network administrator.

2. From the main screen, press the Network icon. The Network screen displays information

about your HYDRIM’s connectivity, including its IP address.

3. Type the IP address displayed on the touchscreen into the browser of any web enabled

device to access your unit’s web portal. When the Network icon is active (for example when

sending email) it will turn green.

NOTE: Use QR code if connecting to a mobile device.

NOTE: Connection time will vary depending on your network speed, and making an initial

connection can take longer.

In Canada and USA you can call our network support line at 1-800-635-5179 for additonal networking support.

5.24 Connecting to a wireless network

The HYDRIM can be confi gured for wireless use by connecting the Ethernet port to an

external wireless bridge / access point. SciCan currently recommends the use of the

®

D-Link

to learn more about setting up a wireless bridge.

DAP-1522 Xtreme N® Duo Wireless Bridge. Contact your network administrator

22

Page 25

5. Instructions for Use

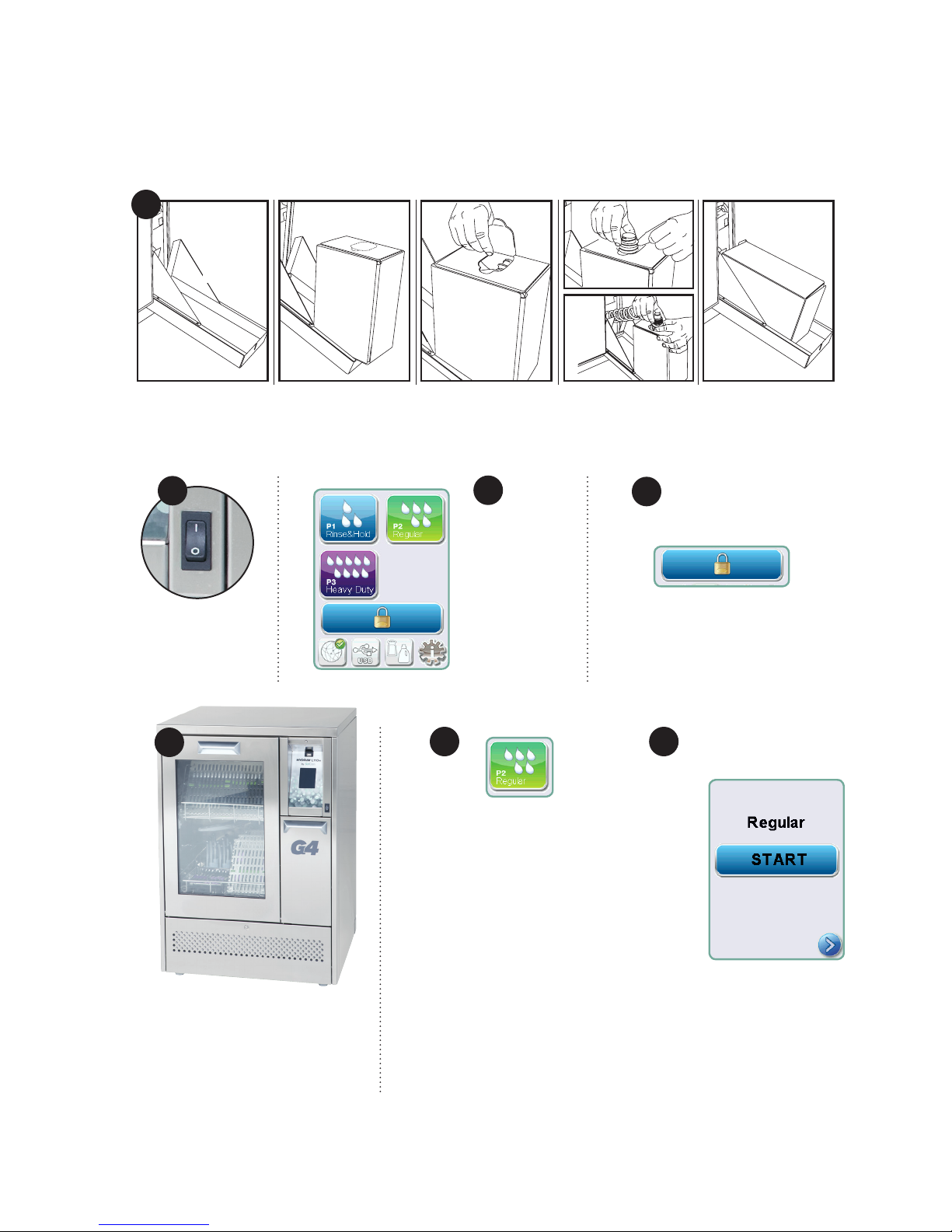

5.25 Activating the HYDRIM L110w G4

Prior to activating the washer, check that the water supply is on and follow these steps:

1

Open the chemical door and ensure that a box of HIP™ Cleaning Solution has

been installed.

2

Turn the

unit on.

5

3

Touch

the screen

to begin.

4

Press to unlock door.

6 7

Select the

desired cycle.

(

Use a heavy duty

cycle for cassettes,

hinged instruments

or heavily soiled

instruments.)

Press START.

Load instruments into

the baskets or cassettes,

place them in the machine

and close the door.

23

Page 26

5. Instructions for Use

7. The cycle will begin.

8

The cycle will start by draining the unit. The bar on the screen

indicates the progression of the cycle. The stage within the cycle

is shown beneath the bar (e.g. Filling, Rinsing). The estimated time

remaining (in minutes) is always displayed. Please note that the

time will increase or decrease depending on the projected cycle

completion.

8. The cycle is complete.

9

When the cycle is complete, the program name and “Cycle

Complete” is displayed, and the unit beeps three times. Press “OK”

to open the door. Use gloves to unload the instruments. After all

cycles, exercise caution as the instruments, trolley, baskets and

cassettes may be hot. Inspect the instruments for debris prior to

packaging / sterilizing.

5.26 Interrupting / aborting a cycle

The door of the HYDRIM is locked during the cycle. If the STOP

button is pressed, the cycle is aborted and cannot be re-started.

The message “Draining. Please wait” will appear. The unit will drain.

Then the message “Instruments not processed” will appear. Press

OK. Open the door by pressing

instruments. Exercise caution as instruments, trolley, baskets and

cassettes may be hot. The cycle must be repeated to ensure that

instruments are properly processed.

NOTE: If the drying phase of the cycle is interrupted, the critical parts of the cycle are

complete and the message displaying the program name and “Cycle Complete. Drying

interrupted” will appear.

. Use gloves if handling the

24

Page 27

5. Instructions for Use

5.27 Additional user and setup menu functions

To access the user or setup menus, follow these steps:

This cycle is used to periodically remove hardwater deposits from

the chamber walls and racks. Pour 1.0 litres (0.26 gal) of vinegar into

the chamber before starting the cycle. Touch “cleaning.” A cleaning

cycle, similar to a normal wash cycle, will run. Failure to clean

chamber can promote corrosion.

The drying times for P2 and P3 can be set independently. Touch

the cycle for which you want to set the drying time. Use the up and

down arrows to select the desired drying time. Touch “default” if you

wish to return to the factory default. Use the back arrow to return to

the previous screen.

OR

Chamber cleaning

Set drying time

Set wash time

The wash time for P2 and P3 can be set independently. P2 and P3

cycles can be adjusted from 5 to 15 minutes. Touch the cycle for

which you want to set the wash time. Use the up and down arrows

to select the desired wash time. Touch “default” if you wish to return

to the factory default. Use the back arrow to return to the previous

screen.

Cycle count

This allows the user to see how many cycles have been run on

the HYDRIM. Touch cycle count and the number of cycles

(completed and aborted) will be displayed. This cannot be reset.

Touch the back arrow to return to the previous menu.

Instructions

Users can access a database of pictorial instructions on how to

perform routine maintenance such as installing the cleaning solution.

25

Page 28

5. Instructions for Use

5.28 Opening the Door in Case of Power Failure

If there is a power failure, remove the kickplate of the HYDRIM. Remove the screw

with a screwdriver and lift the kickplate up and toward you. Locate the ring and pull

it to open the door. Exercise caution! There may be uid remaining in the unit and

the instruments may be hot. Instruments that have not completed the cycle should

not be used and should be reprocessed. When replacing the kickplate, ensure that

the grounding wire is attached.

Ring

Kickplate

Grounding wire

Screw

26

Page 29

5. Instructions for Use –

5.29 Storing and Retrieving Cycle Information

The HYDRIM L110w G4 has an internal Data Logger capable of storing all the data

on every cycle, whether successful or incomplete, for the lifetime of the unit. You can

access this information through the touchscreen, through the web portal or by using a

USB storage device.

Retrieving cycle information using the touchscreen

1. From the main menu, press the USB icon.

2. The unit will record up to the last ve successful cycles and the last ve incomplete

cycles.

If you select a cycle from the list, it will display cycle information in a format similar

to how it would be printed.

3. Use the arrow keys to scroll through and read.

NOTE: Regardless of whether you have a USB storage device attached to the

unit or not, you can always see the last ve successful cycles and the last ve

incomplete cycles.

Use the HYDRIM L110w G4 web portal to access all the cycle information stored

on your Hydrim from your computer. To connect your HYDRIM see section 5.23

Connecting to a Network.

27

Page 30

5. Instructions for Use –

Retrieving cycle information using the USB data back up

The USB storage device can be used to transfer cycle information stored in the unit to

a computer. Best practice suggests this should be done once a week. To transfer data

using the USB port, follow these steps:

1. Plug the USB storage device into the USB port.

2. The HYDRIM keeps track of what data has already been transferred to the USB

storage device and will automatically load only new data. Data stored in the internal

memory of the HYDRIM can be copied once only. Access to previously transferred

information can be made from the web portal.

3. When the activity light on your USB storage device stops blinking or the USB icon

on the LCD turns from a ashing green to a solid grey, remove the USB storage

device and transfer the information to your computer.

NOTE: If you select the USB storage device icon from the main menu, you will only be

able to view the last ve complete cycles and the last ve incomplete cycles. To view all

the cycles stored on the USB storage device, you must use your computer.

NOTE: If you lose your USB storage device and would like to transfer your unit’s cycle

history to a new device, follow these steps:

1. Plug the new USB storage device into the USB port.

2. Select the USB icon.

3. From the cycle information screen, select the USB icon again.

4. Select Copy and the unit will copy all cycle information to the USB storage device.

28

Page 31

5. Instructions for Use –

5.30 Printer / Data Logger Setup

The HYDRIM L110w G4 has an RS-232 port at the back, and can be used with

an external printer or the SciCan Data Logger. The printers in the chart below

have been tested with the HYDRIM. To add or change a printer or SciCan Data

Logger, follow these steps:

Turn off the HYDRIM and the printer or Data Logger before connecting these

devices to the unit.

1. With the printer or Data

Logger connected, turn on

the HYDRIM and press the i

to move to the Menu screen.

2. In the Setup Menu, select

Printer Selection.

3. Select Serial Printer if

connecting a printer, or USB

Flash/MSD if connecting the

SciCan Data Logger. Press

the back arrow to return to

the Setup Menu.

4. In the Setup Menu, select

Baud rate.

5. Select the rate required

(refer to chart below for

recommended Baud rates).

Use the back arrow to return

to the Start screen.

Printer Model

Epson

TM-U220D (C31C515603)

Citizen

IDP-3110-40 RF 230B

Star Micro

SP212FD42-230

Star Micro

SP216FD42-230

Star Micro

SP512MD42-R

SciCan Data Logger

For Mass Storage Device 9600

Serial Port

Baud Rate

9600

9600

9600

9600

9600

Serial Port

Baud Rate

6. Ensure that the date and time have been set (see Setup Menu – Date / Time)

7. Now the HYDRIM will write its cycle information to the device chosen.

29

Page 32

6. Care and Maintenance

6.1 Replacing the HIP™ Cleaning Solution

The HYDRIM L110w G4 uses a 3.8L / 1 gallon container of HIP™ Cleaning Solution

(Part number CS-HIPL). Use only the recommended cleaning solution and read the

MSDS before inserting into the unit.

HIP™ cleaning solution is used in dilute form as a detergent for the cleaning of surgical

instruments in the HYDRIM washer. It is a colourless and almost odourless liquid that is

completely soluble in water. Some precautions must be taken to safely handle this

chemical. For more information, see Chapter 4 Handling and Installing the HIP™

cleaning solution.

NOTE: To avoid spillage, replace the solution container only when the message appears

and be sure to wear gloves.

When a red X appears on the water softener/detergent icon. Press on the icon to

determine if the problem is with the water softener or cleaning solution level. If the

cleaning solution must be replaced, a red X will appear next to it.

To order additional HIP™ Cleaning Solution, contact your local dealer. When the message

“no detergent” appears on the screen, the cleaning solution container is empty and is in

need of changing. To avoid spillage, replace the solution container only when the message

appears and be sure to wear gloves.

NOTE: Each cleaning solution container will last approximately 30 cycles,

depending on which cycles are used.

To replace the cleaning solution container, follow these steps:

1. Turn the power switch OFF.

2. Open the cleaning solution door.

3. Disconnect the cleaning solution connector. Remove any dried chemical by

immersing the connector in a cup of water.

4. Remove the empty cleaning solution container and discard or recycle.

30

Page 33

6. Care and Maintenance

5. Connect new container and insert into the cleaning solution compartment.

Follow the instructions printed on each cleaning solution container.

6. Close the door.

7. Turn the power switch ON

To prime the cleaning solution dosing pump, press the water softener/detergent icon

on the main screen. In the water softener/detergent screen, press the red X next to

“Detergent”. The unit will prime the dosing system and a green check mark will appear in

place of the red X when it is ready for use.

NOTE: The system can also be primed by simply starting a cycle and selecting “Detergent

Replaced”, when prompted.

31

Page 34

6. Care and Maintenance

6.2 Relling the Water Softening Salt Reservoir

When a red X appears on the detergent and water

softener level indicator, press on the icon to determine if the problem lies with the water softener or

cleaning solution level. If the water softener must be

relled, follow these steps:

To ll the salt reservoir, follow these steps:

1. Unscrew the salt container lid.

2. Fill the salt container to the top

(maximum 1 kg / 2.2 lbs.)

3. Screw the salt container lid on tightly.

4. Run a complete cycle, with no instruments.

salt container

6.3 Cleaning the HYDRIM L110w G4

To clean outer surfaces and the decal covering the touchscreen, use a soft cloth

moistened with soap and water or a surface disinfectant. Do not use harsh cleaning

chemicals.

32

Page 35

6. Care and Maintenance

6.4 Filter and Wash Arm Maintenance

Filter Maintenance:

Inspect the lter in the bottom of the

chamber daily for debris and clean if

necessary. To clean, remove the lter,

rinse under a tap and replace. Ensure

that the lter is rmly locked into position

when replaced.

Wash arms

Wash Arm Maintenance:

If the wash arms are not turning

easily, remove them, rinse under a tap

and reassemble. To remove the upper

or middle arm, unscrew the collar

counterclockwise. To remove the lower

arm unscrew the collar clockwise.

Filter

6.5 Preparing the unit for shipping

If preparing the unit for transport or storage, waste water should be removed from the

sump. Waste water in the unit may contain biological contaminants. From the Setup menu,

select the Prepare for Shipping function.

Use a mechanical means or absorbent material to siphon the contents from the sump.

Wear disposable rubber gloves. Dispose of absorbent material according to biological

waste disposal regulations.

33

Page 36

6. Care and Maintenance

6.6 Annual maintenance

If the message “Preventative Maintenance Required. Call for Service” appears, the annual

maintenance is required. To continue using the HYDRIM, press OK. Call for service as

soon as possible. The annual maintenance should be done after 365 days have elapsed

since the initial installation or since the last service call was performed.

When Who What Tests

Daily tests and checks

By the user

• door lock check

• wash arm rotation check

• door seal check

• load carrier check

• check and clean chamber filters

• visual examination of each load for residual soil.

Annually

Bi-Annually

By a

SciCan-approved

technician

By a

SciCan-approved

technician

• Annual maintenance schedule

as outlined in the service manual

• Re-validation if required by local regulations.

To ensure that the ongoing efcacy of the machine is assured, SciCan recommends that

the following periodic testing protocols are observed.

IMPORTANT NOTES:

• This document outlines the minimum requirements to ensure that the equipment

performs to specication. In some regions, local/national guidance documents may

require additional testing. Please contact your dealer or local medical authorities

for details.

• Installation, commissioning, annual servicing MUST be undertaken by SciCan

approved technicians. Failure to maintain this equipment may invalidate the results of

the following testing regime.

34

Page 37

6. Care and Maintenance

Tests to be performed by the user:

Door lock check

This test is to ensure that the door cannot be opened while a cycle is running or a cycle

will not start with the door open. To check that these features are working correctly,

attempt to open the door using the handle immediately after a cycle has started. Caution

– DO NOT attempt this when the wash arms are rotating and/or the water is above

ambient temperature. The door should not open. When you attempt to start a cycle with

the door open, the cycle should not start. If the unit fails this test, stop using it immediately

and call your dealer for technical service.

Wash arm rotation check

Run a P1 cycle and check that wash arms are rotating. If wash arms are not rotating,

remove, visually check and clean as described in Section 6.4.

Door seal check

Visually check the door seal for debris or wear. If the seal is worn or damaged, call your

dealer for technical service.

Load carrier check

Visually check load carriers (trolleys) for wear and tear, damage and that the runners

move freely over their full range.

Chamber lter check

Remove, visually check and clean as described in section 6.4.

Load check

Visually inspect each load for residual soil. Washers are designed to ensure that the

surfaces of instruments are free from debris that may compromise the sterilization process.

A visual check of the instruments processed in each load should be undertaken prior to

sterilization to ensure that no residual debris is present on the instrument.

If debris is still apparent, the instrument should not be considered clean and should be

reprocessed through the HYDRIM again prior to sterilization.

Note: Some set-able materials such as cements, amalgam, and composites, if set on

the instrument will not be removed in a HYDRIM. If these materials are noticed on the

instrument then abrasive removal may be required.

35

Page 38

7. Troubleshooting

Possible Causes and SolutionsProblem

Instruments are

not clean

Touchscreen /

Unit does not come on

The wash arms

do not rotate

The door cannot be

opened

Operating cycles appear

to be taking too long

to complete

• Do not overload cassettes or instrument baskets.

• Do not load too many cassettes into the HYDRIM.

• Use the Heavy Duty cycle for cassettes and hinged

instruments.

• Check lters and wash arms for debris.

• Ensure that the power button is turned ON.

• Ensure that the plug is properly inserted into the wall

socket.

• Check if a fuse or circuit is blown – call service

for assistance.

• Remove the wash arms, clean and reinstall them.

• The cycle is not complete.

• The cycle was aborted and the unit has not

completed draining yet.

• The water is not hot enough. Check that the incoming

hot water temperature is in the recommended range.

• Check that the hot and cold hoses are not reversed.

“No detergent” message

• Check for a kink in chemical tubing.

comes on when there is still

chemical left in the container

Drying Performance is

• Increase the drying time (user menu).

inadequate

NOTE: Fuses should NOT be replaced by the operator. Call an authorized service technician for assistance.

36

Page 39

7. Troubleshooting

Error Messages

CF1 Water Heating

failure

CF2 Chamber

Filling Failure

CF3 Chamber

temper ature

reading failure

CF4 Draining

failure

CF9 Software or

PCB Failure

Cause

The water does not reach the

required temperature in the

specied time

The water does not ll the

chamber within the specied time.

Faulty sensor.

Water cannot drain

from the unit.

Cycle length is more than

3hr 30 min.

SolutionError

Call for service.

Check that the water hoses

are not kinked. Open the

water shut-off valves.

Call for service.

Check that the drain hose

is not kinked. Check that the

lter in the bottom of the

chamber is not obstructed.

Call for service.

CF14 Water

Temperature too high

CF19 Pressure

Sensor

CF21 No detergent

CF28 No water

pressure

Water in prewash stage too hot.

Pressure sensor is stuck.

Flow switch did not detect detergent

during wash phase.

Not enough water during cycle.

Check water connections

at back of unit.

Call for service.

Replace detergent box

if empty.

If the problem persists,

call for service.

Check water hoses are not

kinked. Open water shut-off

valves.

Check for leaks.

Call for service.

37

Page 40

8. Specications

Height, freestanding: 850 mm / 33.5”

Width: 598 mm / 23.54”

Depth: 600 mm / 23.75”

Depth with door open: 1200 mm / 47”

Weight: 80 kg / 176 lbs.

Maximum Running Noise: 78 dB(A)

Hot and cold water connections: 3/4”

Inlet water pressure: 1-10 bar

Incoming hot water temperature: 50-70°C / 122-158°F

Drain: 3/4”

Water softener: 1 kg / 2.2 lbs salt capacity

Filling System: 5.5L / 1.5 gallon safety maximum

Drying System: Heater 1 kW

Electrical Connection: 208-240 V 60 Hz 15 A

Equipment pollution degree: Pollution Degree 2

Equipment installation category: Installation category II

Maximum relative humidity: 80% for temp up to 31°C / 88°F

Operating temperature range: +5°C to 40°C / 41-104°F

Max. altitude: 2000m / 6561.7 ft.

Mains supply: + / -10% of nominal

9. Serial Number Plate

When ordering supplies, spare parts or requesting service, please ensure that

the information contained on the serial number plate is available (Model number,

serial number etc.).

50% for temp up to 40°C / 104°F

The serial number plate is located at the bottom left on the rear panel of

the HYDRIM L110w G4 unit. A small label is located on the left hand side of

the chemical door.

38

Page 41

10. Warranty

Limited Warranty

For a period of one year, SciCan guarantees that the HYDRIM L110w G 4,

when manufactured in new and unused condition, will not fail during normal

service due to defects in material and workmanship that are not due to apparent

abuse, misuse, or accident. In the event of failure due to such defects during

this period of time, the exclusive remedies shall be repair or replacement, at

SciCan’s option and without charge, of any defective part(s), provided SciCan

is notified in writing within thirty(30) days of the date of such a failure and further

provided that the defective part(s) are returned to SciCan prepaid.

This warranty shall be considered to be validated, if the product is accompanied

by the original purchase invoice from the authorized SciCan dealer, and

such invoice identifies the item by serial number and clearly states the date

of purchase. No other validation is acceptable. After one year, all SciCan’s

warranties and other duties with respect to the quality of the product shall

be conclusively presumed to have been satisfied, all liability therefore shall

terminate, and no action or breach for any such warranty or duty may thereafter

be commenced against SciCan.

Any express warranty not provided hereon and any implied warranty or

representation as to performance, and any remedy for breach of contract which,

but for this provision, might arise by implication, operation of law, custom of

trade or course of dealing, including any implied warranty of merchantability or of

fitness for particular purpose with respect to all and any products manufactured

by SciCan is excluded and disclaimed by SciCan.

To register your product warranty with SciCan, go to Scican.com, click on

the appropriate country, and then click on the Register Your Warranty tab.

39

Page 42

Table des matières

1. Introduction ......................1

2. Informations importantes ...........2

3. Avertissements ...................3

4. Instructions d’installation ............4

5. Mode d’emploi ....................9

5.1 Recommandations pour le retraitement

des instruments ....................9

5.2 Tableau descriptif des cycles ........10

5.3 Conseils pour de meilleurs résultats

de nettoyage .....................11

5.4 Configurations recommandées pour

le chargement ....................12

5.5 Paniers et accessoires..............14

5.6 Aperçu de l’écran tactile ............15

5.7 Aperçu du menu Configuration .......16

5.8 - 5.22 Options du menu Configuration ..17

5.23 Connexion à un réseau .............22

5.24 Connexion à un réseau sans fil .......22

5.25 Mise en marche

du HYDRIM L110w G4 .............23

5.26 Interrompre/annuler un cycle.........24

5.27 Fonctions supplémentaires des menus

Utilisateur et Configuration ..........25

5.28 Ouvrir la porte lors d’une panne

de courant .......................26

5.29 Enregistrer et récupérer

les informations de cycles ...........27

5.30 Configuration de l’imprimante et

de l’enregistreur de données.........29

6. Entretien et maintenance .........30

6.1 Remplacer le contenant de solution

nettoyante HIP

6.2 Remplissage du réservoir de sel

adoucisseur d’eau ..................32

6.3 Nettoyage du HYDRIM L110w G4 ....32

6.4 Entretien du filtre et du bras

de lavage........................33

6.5 Préparation de l’appareil

pour l’expédier ...................33

6.6 Entretien annuel ..................34

MC

.................30

7. Dépannage .....................36

8. Spécifications ..................38

9. Plaque du numéro de série .......38

10. Garantie ......................39

HYDRIM et STATIM sont des marques déposées de SciCan ltée.

BRAVO, HIP, et Sys

Toute autre marque dont il est fait mention dans le présent manuel appartient

à son propriétaire respectif..

Pour toute demande de renseignements relatifs

à l’entretien et à la réparation, composer :

Au Canada : 1-800-870-7777

Aux États-Unis : 1-800-572-1211

En Allemagne:

International : (416) 446-4500

Courriel : techservice.ca@scican.com

Fabriqué par :

TM

sont des marques de commerce de SciCan ltée.

+49 (0)7561 98343 - 0

SciCan

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Tél. : (416) 445-1600

Téléc. : (416) 445-2727

Sans frais : 1-800-667-7733

Représentant UE

SciCan GmbH

Wangener Strasse 78

88299 Leutkirch ALLEMAGNE

Tél.: +49 (0)7561 98343 - 0

Téléc. : +49 (0)7561 98343 - 699

SciCan Inc.

701 Technology Drive

Canonsburg, PA 15317 USA

Tél. : +1 724 820 1600

Téléc. : +1 724 820 1479

Sans frais : 1-800-572-1211

SciCan Medtech

Alpenstrasse 16

CH-6300 ZOUG SUISSE

Tél. : +41 (0) 41 727 7027

Téléc. : +41 (0) 41 727 7029

Page 43

1. Introduction

Merci d’avoir choisi le lave-instruments HYDRIM L110w G4. Le HYDRIM est un appareil

complémentaire aux autoclaves STATIMMD et BRAVOMC; il permet de préparer de façon

salubre les instruments souillés pour la stérilisation. . Afin d’assurer un fonctionnement

sécuritaire et sans problème de l’appareil à long terme, veuillez lire attentivement le

présent manuel de l’utilisateur avant de mettre l’appareil en marche. Le HYDRIM L110w

G4 ne doit être utilisé qu’aux fins mentionnées dans ce manuel. L’utilisation du HYDRIM

à toute autre fin peut être dangereuse. Le fabricant ne peut être tenu responsable des

dommages causés par une utilisation inappropriée.

Les instructions d’utilisation, d’entretien et de remplacement doivent être suivies

scrupuleusement pour que ce produit exécute les fonctions pour lesquelles il a été conçu.

Toute marque dont il est fait mention dans le présent manuel appartient à son propriétaire

respectif. Le contenu du présent manuel peut être modifié sans préavis afin de refléter les

modifications et améliorations apportées au produit HYDRIM.

Le HYDRIM L110w G4 devrait être installé et entretenu uniquement par un sous-traitant

qualifié, puisqu’il s’agit d’un dispositif de catégorie d’installation 2. Avant de brancher

l’appareil, l’installateur doit s’assurer que la tension et la fréquence de l’alimentation

électrique correspondent bien aux spécifications mentionnées dans les instructions

d’installation. L’appareil ne doit être branché que dans une prise mise à la terre. Veuillez

noter que cet appareil n’est complètement isolé de l’alimentation électrique que lorsqu’il

est débranché ou que le disjoncteur est fermé. Vous devez l’isoler complètement avant

d’effectuer toute réparation.

Le HYDRIM L110w G4 utilise exclusivement la solution de nettoyage HIPMC. L’appareil

ne donnera pas les résultats escomptés si vous utilisez d’autres détergents ou produits

nettoyants. L’utilisation de détergents ou de produits nettoyants autres que la solution

HIPMC pourrait endommager l’appareil ou les instruments, causer une mousse excessive et annuler la garantie. N’utilisez aucun solvant dans cet appareil. Ne permettez pas

l’accès à cet appareil ou à ses commandes à des enfants ou à du personnel non autorisé.

1

Page 44

2. Informations importantes

Les symboles suivants sont utilisés dans ce manuel.

Attention, danger potentiel pour l’utilisateur.

Cette situation pourrait entraîner une défaillance mécanique.

Information importante.

2

Page 45

3. Avertissements

Permettre exclusivement à du personnel autorisé de fournir les pièces, d’entretenir ou de réparer

le HYDRIM. SciCan n’est pas responsable des dommages accessoires, spéciaux ou indirects

causés par des travaux de maintenance ou de réparation effectués sur le HYDRIM par du personnel non autorisé ou par l’utilisation d’équipements ou de pièces fabriqués par une tierce partie, y

compris le manque à gagner, le préjudice commercial, la perte économique ou toute perte causée

par des blessures.

Ne jamais enlever les panneaux de l’appareil et ne jamais insérer d’objets dans les trous ou les

ouvertures du boîtier.

Cela pourrait endommager l’appareil et présenter un risque pour l’utilisateur.

Une utilisation autre que celle spécifiée dans le présent manuel pourrait entraîner une diminution

du niveau de protection offert par l’équipement.

Les solutions nettoyantes peuvent être irritantes. Éviter tout contact avec les yeux, la peau et la

bouche.

Ne jamais s’asseoir, se tenir ou s’appuyer sur la porte lorsque celle-ci est ouverte. L’appareil

pourrait basculer vers l’avant et pourrait causer des blessures.

Toujours éteindre l’appareil avant d’ajouter du sel adoucisseur, des solutions ou d’effectuer

l’entretien régulier de l’appareil.

Le propriétaire de l’appareil doit interdire l’utilisation de l’appareil à toute personne non autorisée

ni formée.

SciCan recommande de laisser l’appareil allumé en tout temps, particulièrement lorsqu’aucune

personne n’est présente dans le cabinet ou qu’aucun mécanisme d’arrêt d’alimentation en eau

n’est installé. En laissant l’appareil allumé, la pompe de vidange s’activera s’il y a fuite d’eau dans

la chambre à la suite d’une quelconque défaillance.

Pour de plus amples renseignements ou en cas de questions à propos du HYDRIM L110w G4,

communiquez avec votre détaillant autorisé.

3

Page 46

4. Instructions d’installation

Pour ouvrir la porte de la chambre de lavage,

brancher l’appareil, le mettre en marche et

appuyer sur le symbole de déverrouillage.

En cas de panne de courant, retirer la vis

de la plaque de protection et tirer sur l’anneau.

Consulter la section 5.28.

Outils et accessoires requis pour l’installation :

• Tournevis à lame plate

• Pinces multiprises

Spécifications :

Tension : 208 à 240 V

Fréquence : 60 Hz

Charge nominale : 2.5 kW

Disjoncteur 15 A

phase: par phase

Hauteur : 850 mm (33,5 po)

Largeur: 598 mm (23,54 po)”

Profondeur: 600 mm (23,75 po)

Profondeur avec la porte

ouverte : 1200 mm (47 po)

Poids: 80 kg (176 lb)

Bruit maximal de fonctionnement : 78 dBA

Utility Hook-ups

Installation :

L’installation devrait être effectuée par un technicien approuvé par SciCan. L’installation faite par

un installeur non approuvé peut annuler la garantie

de l’appareil.

Si le HYDRIM est installé dans un Stéri-Centre, le

fabricant de ce dernier doit prévoir un espace de

10 mm (½ po) au-dessus, à l’arrière et de chaque

côté de l’appareil. Ceci afin de faciliter l’installation

et l’entretien du HYDRIM.

Ne pas empoigner la porte de la chambre de

lavage pour déplacer le HYDRIM. Cela pourrait

désaligner la porte et causer des fuites.

Lors de l’installation, il est essentiel d’ajouter tous

les consommables requis dans l’appareil. Il est

important que cette étape soit effectuée avant

de mettre l’appareil en marche.

Pour des raisons de sécurité, ne pas

installer le HYDRIM sans son panneau

supérieur

Tuyau/ Longueur /

Cordon Diamètre

Entrée d’eau

chaude 3/4 po (14,5-145 psi)

Entrée d’eau

froide 3/4 po (14,5-145 psi)

Entrée OI 1,9 m (6 pi) 1,5 m (5 pi) 1-10 bars Oui

3/4 po (14,5-145 psi)

Vidange 1,5 m (5 pi) — — —

3/4 po

Électrique 1,8 m — — —

AWG 14-3

1,9 m (6 pi) 1,5 m (5 pi) 1-10 bars Oui

1,9 m (6 pi) 1,5 m (5 pi) 1-10 bars Oui

Distance maximale

Distance à partir

de l’entrée/du drain

Pression Valve

d’eau d’arrêt

Mise au niveau du HYDRIM :

L’appareil est en appui sur trois supports : roulettes (roues) à

l’arrière et deux pattes à l’avant.

1. Retirer la plaque de protection à l’avant. Placer le

HYDRIM à l’endroit convenu en soulevant la courroie à

l’avant pour permettre de déplacer l’appareil à l’aide de

ses roulettes.

2. Ajuster les pattes avant au besoin afin de mettre

le HYDRIM au niveau.

3. Utiliser les deux pattes arrière uniquement si le plancher est

inégal ou ne peut fournir suffisamment de soutien aux roulettes.

4. Placer la courroie sous la machine avant de remettre en

place la plaque de protection, de sorte à ne pas interférer avec les conduits d’évacuation d’air.

4

Arrière de l’appareil

Prise

d’alimentation

Tuyau

de vidange

Tuyau d’eau OI

Tuyau d’eau chaude

Port

Ethernet

Connecteur

d’imprimante

Porte-fusible

Tuyau d’eau froide

Page 47

4. Instructions d’installation

Raccordement des tuyaux d’alimentation en eau :

Raccorder les tuyaux d’alimentation en eau chaude et froide à l’alimentation d’eau chaude

et d’eau froide.

Exigences concernant la vidange :

Raccorder le tuyau de vidange à la sortie du drain. Le tuyau de vidange peut être fixé aux

conduites de drain existantes à l’aide d’une combinaison colonne d’alimentation/siphon P

de 3,5 cm (1,5 po) ou plus. Si le tuyau est directement relié à la conduite de drain, les raccords et adaptateurs ne devraient pas réduire le débit d’eau. Le tuyau de vidange doit être

fixé au drain principal à un point ne dépassant pas 1 mètre (3 pi) au-dessus de la base du

HYDRIM. Un drain de plancher est acceptable (vérifier les codes locaux).

Spécifications électriques :

Brancher le cordon électrique à l’alimentation électrique. Le HYDRIM doit posséder

un circuit dédié doté d’un fusible 15A. La prise doit être mise à la terre.

Informations supplémentaires :

• L’appareil HYDRIM est lourd. Utiliser une fourche d’élévation ou un chariot et faire preuve

de prudence en le déplaçant.

• L’entretien et la réparation du HYDRIM devraient se faire sur place.

• Le HYDRIM est doté d’un dispositif de coupure anti-retour et anti-aspiration afin de prévenir

le retour d’eaux usées dans l’alimentation d’eau. Aucun autre dispositif de coupure

anti-retour n’est nécessaire.

• S’il est nécessaire d’allonger les tuyaux d’alimentation en eau et

de vidange, s’assurer d’utiliser des tuyaux de plomberie

de catégorie commerciale.

• La longueur maximale du tuyau de vidange est de 3,3 m (13 pi).

Mise en place du sel adoucisseur d’eau :

Dévisser le couvercle du réservoir de sel et verser 1 litre (1 pinte)

d’eau dans le réservoir. Ajouter 1 kg (2,2 lb) de sel adoucisseur d’eau de la même façon.

Revisser solidement le couvercle du réservoir de sel.

Manipulation et mise en place de la solution nettoyante HIP

La solution nettoyante HIPMC est utilisée, dans une forme diluée, comme détergent pour le

nettoyage des instruments chirurgicaux pour la gamme de lave-instruments et de laveursdésinfecteurs d’instruments HYDRIM. Il s’agit d’un liquide incolore et presque inodore

complètement soluble dans l’eau.

Le pH de la solution concentrée varie entre 9,3 et 9,8, ce qui en fait une solution alcaline.

Par conséquent, certaines mesures de sécurité devraient être observées au cours de la

manipulation et de la mise en place de la solution dans l’appareil, ainsi que lors du retrait et

de l’élimination du contenant vide.

MC

5

Page 48

4. Instructions d’installation

Mesures de sécurité recommandées pour manipuler la solution nettoyante HIPMC.

1. Toujours porter des gants, non endommagés, en caoutchouc naturel ou en butylcaou-

tchouc, en nitrile, ou en néoprène (les gants chirurgicaux sont idéals).

2. Toujours porter un dispositif de protection oculaire.

3. Protéger la peau exposée des bras.

4. Si la solution est renversée sur les vêtements, enlever le ou les vêtements souillés

et rincer abondamment la peau touchée avec de l’eau.

5. Utiliser les bonnes pratiques d’hygiène industrielle lors de la manipulation de cette

substance.

6. Ne pas boire ni manger tout en manipulant cette substance.

7. Après avoir terminé de manipuler la substance, enlever et jeter les gants et se laver

les mains avant de retirer la protection oculaire.

8. Ne pas utiliser l’équipement de protection individuelle qui sert habituellement pour vos

MC

activités cliniques pour manipuler les produits HIP

.

9. Toujours s’assurer que l’équipement de protection individuelle, si contaminé avec

MC

la solution nettoyante HIP

Pour obtenir toutes les données sur la solution nettoyante HIP

de visualiser ou de télécharger la fiche signalétique en format PDF.

Pour installer le contenant de solution nettoyante HIP

, a été nettoyé correctement ou jeté selon le cas.

MC

, visiter SciCan.com afin

salt container

MC

, suivre ces étapes:

Mise en place de la solution nettoyante :

Mettre la solution nettoyante HIPMC en place comme suit :

Ouvrir le tiroir destiné

à la solution nettoyante.

Insérer un nouveau

contenant de solution

nettoyante dans le tiroir

en le mettant à l’envers.

Test d’installation effectué par un technicien : Ouvrir les valves d’arrêt. Mettre un cycle

en marche et vérifier s’il y a des fuites au niveau des raccords de plomberie.

Retirer la partie

détachable.

6

Tirer sur la buse et

enlever le bouchon