SciCan HYDRIM L110wd,HYDRIM L110w Service Manual

Rin

se

and h

old

Reg

ular was

h

Hea

vy dut

y was

h

Reg

ular was

h and dr

y

Hea

vy dut

y was

h and dry

P2

P3

P4

P1

P0

&

®

®

• Service Guide

• Manuel maintenance

• Wartungsanleitung

• Manuale di manutenzione

www.scican.com

HYDRIM L

w

0

1

1

w Service Guide 96-108019 Rev 3.0

0

1

1

IM L

HYDR

/

d

Copyright 2005 SciCan. All rights reserved.

1. Introduction . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.3 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.4 Hardware Specifications . . . . . . . . . . . . . . . . . .11

1.5 Shipping Instructions . . . . . . . . . . . . . . . . . . . . . .11

1.6 Contact Information . . . . . . . . . . . . . . . . . . . . . . . .11

2. Installation . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Suggested Installation Configurations . . . . . .12

2.2 Water Connections . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3 Water Softener . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 Drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.5 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6 Set up and Installation Tips . . . . . . . . . . . . . . . . .15

2.7 Optional Installation Configurations . . . . . . . . .16

2.8 Controller Software Functions . . . . . . . . . . .17

3. Routine Maintenance . . . . . . . . . . . . . .19

3.1 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Leveling the unit . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.3 Wash Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4 Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4. Schematics . . . . . . . . . . . . . . . . . . . . . .21

4.1 Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . .21

4.2 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5. Troubleshooting . . . . . . . . . . . . . . . . . .24

5.1 Primary Assessment . . . . . . . . . . . . . . . . . . . . . . .24

5.2 Power On Problems . . . . . . . . . . . . . . . . . . . . . . .24

5.3 Controller Problems . . . . . . . . . . . . . . . . . . . . . . .24

5.4 Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.5 Hydraulic Overview . . . . . . . . . . . . . . . . . . . . . . . .26

6. Taking Apart and

Reassembling the Unit . . . . . . . . . . . . .27

6.1 Removing the Cleaning Solution . . . . . . . . . . . .27

6.2 Removing the Back Cover . . . . . . . . . . . . . . . . . .27

6.3 Removing the Top Cover . . . . . . . . . . . . . . . . . . .27

6.4 Removing the Kick Plate . . . . . . . . . . . . . . . . . . .28

6.5 Removing the Left Side Panel . . . . . . . . . . . . . .28

6.6 Removing the Right Side Panel . . . . . . . . . . . . .28

6.7 Removing Door Panel . . . . . . . . . . . . . . . . . . . . .28

6.8 Removing the Dosing Pump . . . . . . . . . . . . . . . .28

6.9 Removing the Dryer . . . . . . . . . . . . . . . . . . . . . . .29

6.9.1 Removing Air Filter . . . . . . . . . . . . . . . . . . .29

6.9.2 Removing Dryer Blower Brushes . . . . . .29

6.10 Removing the Control Panel Fascia . . . . . . . .29

6.10.1 Removing the On / Off Switch . . . . . . . .30

6.10.2 Removing the Door Lock . . . . . . . . . . . .30

6.10.3 Removing the Master Controller . . . . .30

6.11 Removing the Slave Controller . . . . . . . . . . . . .30

6.12 Removing Wash Tank . . . . . . . . . . . . . . . . . . . . . .31

6.13 Removing Drain Pump . . . . . . . . . . . . . . . . . . . . .33

6.14 Removing Circulation Pump . . . . . . . . . . . . . . . .33

6.15 Removing the Heater . . . . . . . . . . . . . . . . . .33

6.16 Removing the Hot and Cold Inlet Valve . . . . . .34

6.17 Removing the Temperature Sensor . . . . . . .34

6.18 Removing the Condenser . . . . . . . . . . . . . .34

7. Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Page 1

HYDRIM L110w/wd Service Guide

Copyright 2005 SciCan. All rights reserved.

HYDRIM is a registered trademark of SciCan, Division of Lux and

Zwingenberger.

Contents

Manufactured by / EU Representative

BHT Hygienetechnik GmbH

Messerschmittstr. 11,

D-86368 Gersthofen

GERMANY

Phone: 49-0821-278-930

Fax: 49-0821-78-40-99

Hydrim L110wd

Distributed by:

SciCan, Division of Lux and Zwingenberger

Toronto, Ontario, Canada

Phone: (416) 445-1600

Fax : (416) 446-2727

SciCan Medtech

Alpenstrasse 16, 2300 Zug, Switzerland

Phone: (41-41) 727-70-27

Fax: (41-41) 727-70-29

Hydrim L110w

Manufactured by:

SciCan

1440 Don Mills Road,Toronto,

ON M3B 3P9 CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

SciCan Inc.

500 Business Center Drive,Pittsburgh, PA 15205 USA

Phone: (412) 494-0181

Fax: (412) 494-4794

Toll free: 1-800-572-1211

Email (Service and Repair): techservice.ca@scican.com

Email: customer_servicecanada@scican.com

For all service and repair inquiries:

In Canada: 1-800-870-7777

In The United States: 1-800-572-1211

Page 2

HYDRIM L110w/wd Service Guide

Sommaire

1. Introduction . . . . . . . . . . . . . . . . . . . . . 38

1.1 Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

1.2 Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

1.3 Informations de sécurité . . . . . . . . . . . . . . . . . . .42

1.4 Eléments de fixation . . . . . . . . . . . . . . . . . . . . . .44

1.5 Instructions d’expédition . . . . . . . . . . . . . . . . . . .44

1.6 Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2. Installation . . . . . . . . . . . . . . . . . . . . . . 45

2.1 Suggestions de configurations

d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

2.2 Prise d’eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

2.3 Adoucisseur d’eau . . . . . . . . . . . . . . . . . . . . . . . . .46

2.4 Vidange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.5 Imprimante . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.6 Conseils pour le montage et l’installation . . . .48

2.7 Autres configurations d’installation . . . . . . . . .49

2.8 Fonctions du logiciel de commande . . . . . . .50

3. Entretien de routine . . . . . . . . . . . . . . .53

3.1 Filtres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

3.2 Mise de niveau de l’appareil . . . . . . . . . . . . . . . .53

3.3 Bras de lavage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

3.4 Flexibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4. Schémas . . . . . . . . . . . . . . . . . . . . . . . .55

4.1 Système hydraulique . . . . . . . . . . . . . . . . . . . . . .55

4.2 Système électrique . . . . . . . . . . . . . . . . . . . . . . . .57

5. Dépannage . . . . . . . . . . . . . . . . . . . . . .58

5.1 Premières mesures . . . . . . . . . . . . . . . . . . . . . . . .58

5.2 Problèmes de mise en marche . . . . . . . . . . . . .58

5.3 Problèmes de commande . . . . . . . . . . . . . . . . . .58

5.4 Codes de défaut . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5.5 Système hydraulique . . . . . . . . . . . . . . . . . . . . . .60

6. Démontage et remontage

de l’appareil . . . . . . . . . . . . . . . . . . . . .61

6.1 Démonter le réservoir de

solution de lavage . . . . . . . . . . . . . . . . . . . . . . . . .61

6.2 Démonter le panneau arrière . . . . . . . . . . . . . . .61

6.3 Démonter le panneau supérieur . . . . . . . . . . . .61

6.4 Démonter la plinthe . . . . . . . . . . . . . . . . . . . . . . . .62

6.5 Démonter le panneau latéral gauche . . . . . . .62

6.6 Démonter le panneau latéral droite . . . . . . . . .62

6.7 Démonter le panneau de la porte . . . . . . . . . . .62

6.8 Démonter la pompe de dosage . . . . . . . . . . . . .62

6.9 Démonter le sécheur . . . . . . . . . . . . . . . . . . . . . . .63

6.9.1 Démonter le filtre à air . . . . . . . . . . . . . . . . .63

6.9.2 Démonter les brosses de

la soufflante du sécheur . . . . . . . . . . . . . . .63

6.10 Démonter le revêtement du panneau

de commande . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.10.1 Démonter l’interrupteur principal . . . . .63

6.10.2 Démonter le verrouillage de

la porte . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

6.10.3 Démonter la commande principale . . .64

6.11 Démonter la commande secondaire . . . . . . . .64

6.12 Démonter la chambre de lavage . . . . . . . . . . . .65

6.13 Démonter la pompe de vidange . . . . . . . . . . . .67

6.14 Démonter la pompe de circulation . . . . . . . . . .67

6.15 Démonter le chauffage . . . . . . . . . . . . . . . .67

6.16 Démonter les valves d’entrée d’eau

froide et d’eau chaude . . . . . . . . . . . . . . . . .68

6.17 Démonter le capteur de température . . . . . .68

6.18 Démonter le condenseur . . . . . . . . . . . . . . .68

7. Pièces . . . . . . . . . . . . . . . . . . . . . . . . . .69

Copyright 2005 SciCan. Tous droits réservés.

HYDRIM est une marque déposée de SciCan, Division of Lux and

Zwingenberger.

Manufactured by / EU Representative

BHT Hygienetechnik GmbH

Messerschmittstr. 11,

D-86368 Gersthofen

GERMANY

Phone: 49-0821-278-930

Fax: 49-0821-78-40-99

Hydrim L110wd

Distributed by:

SciCan, Division of Lux and Zwingenberger

Toronto, Ontario, M3B 3P9 Canada

Phone: (416) 445-1600

Fax : (416) 446-2727

SciCan Medtech

Alpenstrasse 16, 2300 Zug, Switzerland

Phone: (41-41) 727-70-27

Fax: (41-41) 727-70-29

Hydrim L110w

Manufactured by:

SciCan

1440 Don Mills Road,Toronto,

ON M3B 3P9 CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

SciCan Inc.

500 Business Center Drive,Pittsburgh, PA 15205 USA

Phone: (412) 494-0181

Fax: (412) 494-4794

Toll free: 1-800-572-1211

Email (Service and Repair): techservice.ca@scican.com

Email: customer_servicecanada@scican.com

For all service and repair inquiries:

In Canada: 1-800-870-7777

In The United States: 1-800-572-1211

Copyright 2005 SciCan. Alle Rechte vorbehalten.

HYDRIM ist ein eingetragenes Warenzeichen von SciCan, Division of

Lux and Zwingenberger.

Page 3

HYDRIM L110w/wd Service Guide

Inhaltsverzeichnis

1. Einleitung . . . . . . . . . . . . . . . . . . . . . . . . .72

1.1 Überblick . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

1.2 Technische Daten . . . . . . . . . . . . . . . . . . . . .75

1.3 Sicherheitsmaßnahmen . . . . . . . . . . . . . . . . .76

1.4 Angaben zu Verbindungselementen . . . . . . .78

1.5 Transporthinweise . . . . . . . . . . . . . . . . . . . . .78

1.6 Ansprechpartner . . . . . . . . . . . . . . . . . . . . . .78

2. Installation . . . . . . . . . . . . . . . . . . . . . . . .79

2.1 Vorschläge für die Einbaukonfiguration . . . . .79

2.2 Wasseranschluss . . . . . . . . . . . . . . . . . . . . . .79

2.3 Wasserenthärter . . . . . . . . . . . . . . . . . . . . . .80

2.4 Wasserablauf . . . . . . . . . . . . . . . . . . . . . . . . .81

2.5 Drucker . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

2.6 Aufstell- und Installationshinweise . . . . . . . . .82

2.7 Aufstellungsmöglichkeiten . . . . . . . . . . . . . . .83

2.8 Funktionen der Steuerungs-Software . . . . . .84

3. Routinewartung . . . . . . . . . . . . . . . . . . .87

3.1 Siebe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

3.2 Justieren des Geräts . . . . . . . . . . . . . . . . . . .87

3.3 Sprüharme . . . . . . . . . . . . . . . . . . . . . . . . . . .87

3.4 Schläuche . . . . . . . . . . . . . . . . . . . . . . . . . . .88

4. Schematische Darstellungen . . . . . . . . .89

4.1 Schematische Darstellung Wasserkreislauf . .89

4.2 Schaltbild . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5. Fehlersuche . . . . . . . . . . . . . . . . . . . . . . .92

5.1 Als Erstes durchzuführende Prüfungen . . . . .92

5.2 Probleme beim Einschalten . . . . . . . . . . . . . .92

5.3 Probleme mit der Steuerung . . . . . . . . . . . . .92

5.4 Fehlercodes . . . . . . . . . . . . . . . . . . . . . . . . . .93

5.5 Übersicht Wasserkreislauf . . . . . . . . . . . . . . .94

6. Demontage und Wiederzusammenbau

des Geräts . . . . . . . . . . . . . . . . . . . . . . . .95

6.1 Reinigungslösung herausnehmen . . . . . . . . .95

6.2 Rückwand abnehmen . . . . . . . . . . . . . . . . . .95

6.3 Obere Abdeckung abnehmen . . . . . . . . . . . .95

6.4 Fußleiste abnehmen . . . . . . . . . . . . . . . . . . .96

6.5 Linke Seitenwand abnehmen . . . . . . . . . . . . .96

6.6 Rechte Seitenwand abnehmen . . . . . . . . . . .96

6.7 Türverkleidung abnehmen . . . . . . . . . . . . . . .96

6.8 Dosierpumpe ausbauen . . . . . . . . . . . . . . . . .96

6.9 Trockner ausbauen . . . . . . . . . . . . . . . . . . . .97

6.9.1 Luftfilter ausbauen . . . . . . . . . . . . . . .97

6.9.2 Bürsten des Trocknergebläses

herausnehmen . . . . . . . . . . . . . . . . . .97

6.10 Verkleidung des Bedienfeldes entfernen . . .97

6.10.1 Ein- / Aus-Schalter ausbauen . . . . . .98

6.10.2 Türverriegelung ausbauen . . . . . . . .98

6.10.3 Hauptsteuergerät ausbauen . . . . . . .98

6.11 Nebensteuergerät ausbauen . . . . . . . . . . . .98

6.12 Spülkammer ausbauen . . . . . . . . . . . . . . . .99

6.13 Entwässerungspumpe ausbauen . . . . . . .101

6.14 Umwälzpumpe ausbauen . . . . . . . . . . . . .101

6.15 Heizung ausbauen . . . . . . . . . . . . . . . . . . .101

6.16 Einlassventile für Kaltwasser

und Warmwasser ausbauen . . . . . . . . . . .102

6.17 Temperaturfühler ausbauen . . . . . . . . . . . .102

6.18 Kondensator ausbauen (Hydrim L110wd) .102

7. Teile . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Manufactured by / EU Representative

BHT Hygienetechnik GmbH

Messerschmittstr. 11,

D-86368 Gersthofen

GERMANY

Phone: 49-0821-278-930

Fax: 49-0821-78-40-99

Hydrim L110wd

Distributed by:

SciCan, Division of Lux and Zwingenberger

Toronto, Ontario, Canada

Phone: (416) 445-1600

Fax : (416) 446-2727

SciCan Medtech

Alpenstrasse 16, 2300 Zug, Switzerland

Phone: (41-41) 727-70-27

Fax: (41-41) 727-70-29

Page 4

HYDRIM L110w/wd Service Guide

Indice

1. Introduzione . . . . . . . . . . . . . . . . . . . . .106

1.1 Sommario . . . . . . . . . . . . . . . . . . . . . . . . . .106

1.2 Caratteristiche tecniche . . . . . . . . . . . . . . . .109

1.3 Misure di sicurezza . . . . . . . . . . . . . . . . . . . .110

1.4 Specifica degli elementi di collegamento . . .112

1.5 Istruzioni sulla spedizione . . . . . . . . . . . . . .112

1.6 Interlocutori . . . . . . . . . . . . . . . . . . . . . . . . .112

2. Installazione . . . . . . . . . . . . . . . . . . . . .113

2.1 Configurazioni d’installazione consigliate . . .113

2.2 Allacciamento dell’acqua . . . . . . . . . . . . . . .113

2.3 Addolcitore d’acqua . . . . . . . . . . . . . . . . . . .114

2.4 Scarico dell’acqua . . . . . . . . . . . . . . . . . . . .115

2.5 Stampante . . . . . . . . . . . . . . . . . . . . . . . . . .115

2.6 Indicazioni per l’installazione . . . . . . . . . . . .116

2.7 Possibilità di installazione . . . . . . . . . . . . . . .117

2.8 Funzioni del software di controllo . . . . . . . . .118

3. Manutenzione ordinaria . . . . . . . . . . . .121

3.1 Filtri . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

3.2 Livellamento della lavastrumenti . . . . . . . . .121

3.3 Bracci di lavaggio . . . . . . . . . . . . . . . . . . . . .121

3.4 Tubi flessibili . . . . . . . . . . . . . . . . . . . . . . . .122

4. Schemi . . . . . . . . . . . . . . . . . . . . . . . . . .123

4.1 Schema della circolazione d’acqua –

Hydrim L110wd . . . . . . . . . . . . . . . . . . . . . .124

4.2 Schema elettrico . . . . . . . . . . . . . . . . . . . . .125

5. Eliminazione dei guasti . . . . . . . . . . . . .126

5.1 Primi controlli da eseguire . . . . . . . . . . . . . .126

5.2 Problemi all’accensione . . . . . . . . . . . . . . . .126

5.3 Problemi del dispositivo di controllo . . . . . . .126

5.4 Codici di guasto . . . . . . . . . . . . . . . . . . . . . .127

5.5 Panoramica della circolazione d’acqua . . . .128

6. Smontaggio e riassemblaggio

della lavastrumenti . . . . . . . . . . . . . . . .129

6.1 Estrarre la soluzione detergente . . . . . . . . .129

6.2 Rimuovere la copertura posteriore . . . . . . . .129

6.3 Rimuovere la copertura superiore . . . . . . . .129

6.4 Rimuovere lo zoccolo . . . . . . . . . . . . . . . . . .130

6.5 Rimuovere il pannello laterale sinistro . . . . .130

6.6 Rimuovere il pannello laterale destro . . . . . .130

6.7 Rimuovere il pannello dello sportello . . . . . .130

6.8 Smontare la pompa di dosaggio . . . . . . . . . .130

6.9 Smontare l’asciugatrice . . . . . . . . . . . . . . . .131

6.9.1 Smontare il filtro dell’aria . . . . . . . . . .131

6.9.2 Rimuovere le spazzole del soffiante

dell’asciugatrice . . . . . . . . . . . . . . . .131

6.10 Rimuovere la copertura del pannello

di comando . . . . . . . . . . . . . . . . . . . . . . . .131

6.10.1 Smontare l’interruttore On / Off . . . .132

6.10.2 Smontare il dispositivo di chiusura

dello sportello . . . . . . . . . . . . . . . . .132

6.10.3 Smontare il dispositivo di controllo

principale (Master) . . . . . . . . . . . . .132

6.11 Smontare il dispositivo di controllo

ausiliario (Slave) . . . . . . . . . . . . . . . . . . . .132

6.12 Smontare la camera di lavaggio . . . . . . . . .133

6.13 Smontare la pompa di scarico . . . . . . . . . . .133

6.14 Smontare la pompa di circolazione . . . . . . .133

6.15 Smontare il riscaldamento . . . . . . . . . . . . .133

6.16 Smontare le valvole di aspirazione

per l’acqua fredda e calda . . . . . . . . . . . . .136

6.17 Smontare la sonda termica . . . . . . . . . . . .136

6.18 Smontare il condensatore

(Hydrim L110wd) . . . . . . . . . . . . . . . . . . . .136

7. Componenti . . . . . . . . . . . . . . . . . . . . . .137

Manufactured by / EU Representative

BHT Hygienetechnik GmbH

Messerschmittstr. 11,

D-86368 Gersthofen

GERMANY

Phone: 49-0821-278-930

Fax: 49-0821-78-40-99

Hydrim L110wd

Distributed by:

SciCan, Division of Lux and Zwingenberger

Toronto, Ontario, Canada

Phone: (416) 445-1600

Fax : (416) 446-2727

SciCan Medtech

Alpenstrasse 16, 2300 Zug, Switzerland

Phone: (41-41) 727-70-27

Fax: (41-41) 727-70-29

Page 5

HYDRIM L110w/wd Service Guide

Rin

se and h

old

Reg

ular wash

Hea

vy duty wash

Reg

ular w

ash and dr

y

Hea

vy dut

y wash and dry

P2

P3

P4

P1

P0

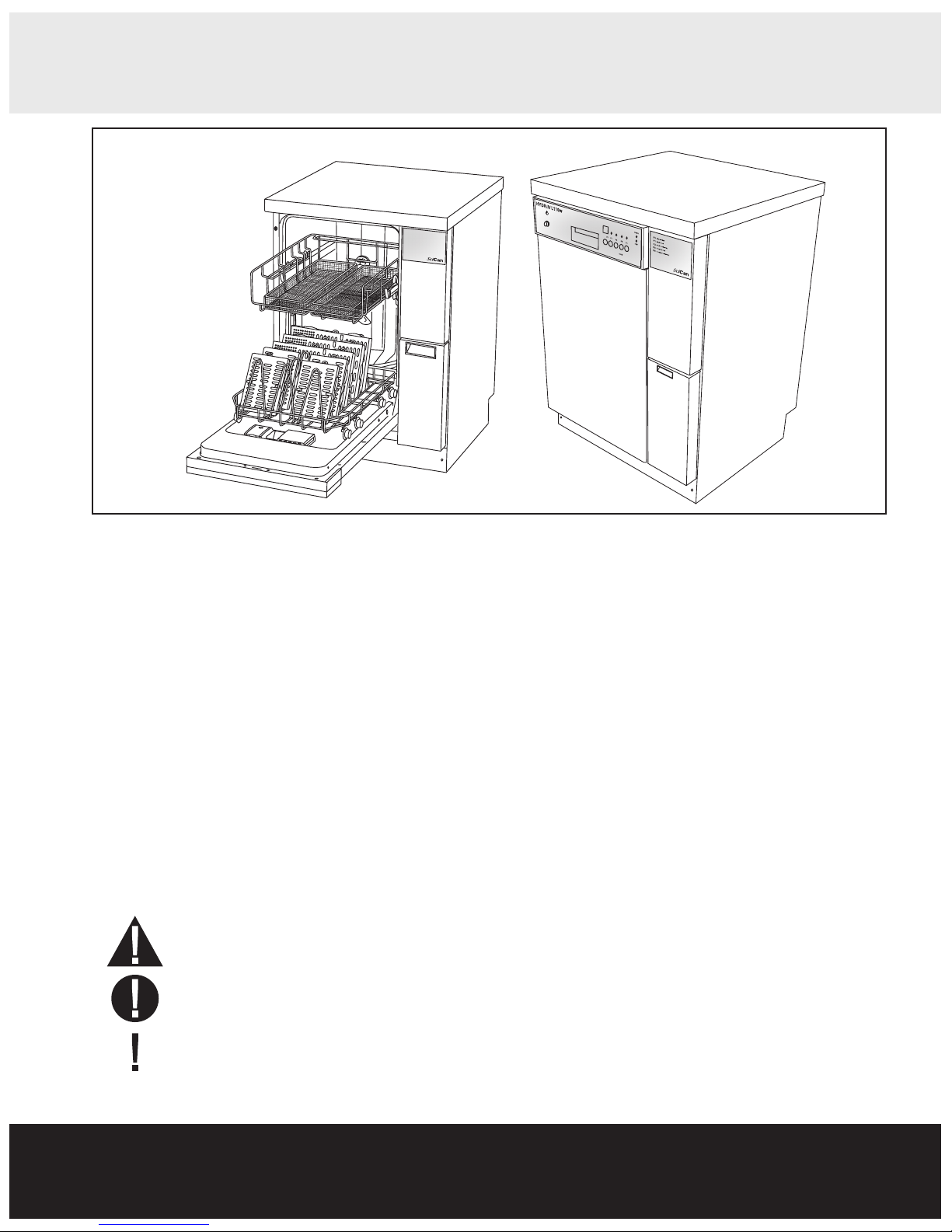

1.1 Overview

This guide provides instructions for the servicing and repair of the HYDRIM®L110wd

washer disinfector and the HYDRIM®L110w instrument washer. Every attempt has been

made to provide accurate, detailed instructions.

All servicing of the Hydrim L110wd and Hydrim L110w should be done by certified

personnel only. All local, provincial, state, and national regulations regarding the servicing

of the class of device and safety requirements must be observed.

Do not permit any person other than certified personnel to supply parts for, service,

or maintain a Hydrim L110wd or Hydrim L110w. SciCan shall not be liable for incidental,

special, or consequential damages caused by any maintenance or services performed on

the Hydrim L110wd or Hydrim L110w by a third party, including lost profits, any

commercial loss, economic loss, or loss arising from personal injury.

Pay close attention to the symbols that appear in the margins.

The following symbols indicate:

a potential hazard to the operator.

a situation or circumstance which may lead to a mechanical failure.

important information.

Figure 1

1. Introduction

Page 6

HYDRIM L110w/wd Service Guide

The Hydrim L110wd and Hydrim L110w are designed to complement the STATIM family of

autoclaves by quickly and hygienically preparing soiled instruments for sterilization.

The Hydrim L110wd and Hydrim L110w work like most domestic dishwashers. The

operator loads the instruments, closes the door, and selects the wash cycle. Both the

Hydrim L110wd and Hydrim L110w automatically dispense cleaning solution via a dosing

mechanism. The operator is responsible for adding water softening salt, adding rinse aid

(if necessary), cleaning the filters, and replacing the cleaning solution container

when necessary.

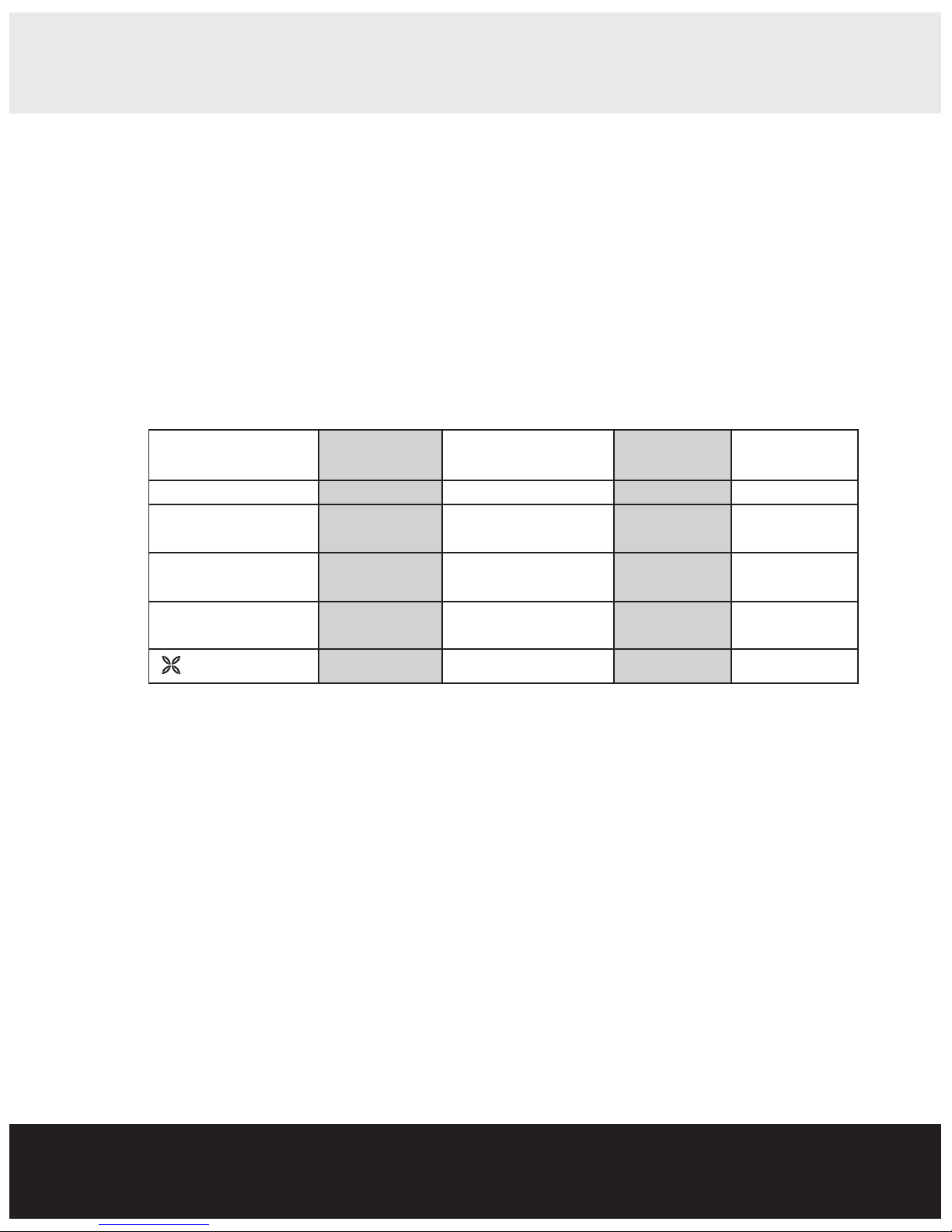

Hydrim L110wd washer disinfector:

The program duration and consumption details are shown in the chart below:

NOTE: For ophthalmology use, an additional rinse is required which lengthens P2, P3,

and P4 by 11 minutes, and increases water consumption by 8 litres. See section 2.8 for

instructions how to program the additional rinse.

Program Wash Rinse / Disinfection Total Time* Water Usage

Temperature Temperature

P1 Pre-wash 30˚C / 5 min. – 8 minutes 4 L

P2 Wash with 65˚C

rinse 50˚C / 5 min. 65˚C / 3 min 38 minutes 19 L

P3 Wash with 80˚C

rinse 50˚C / 5 min. 80˚C / 10 min. 64 minutes 19 L

P4 Wash with 93˚C

disinfection 50˚C / 5 min. 93˚C / 10 min 69 minutes 19 L

Air Drying – –

10 minutes

–

* Actual cycle time will vary depending on incoming water temperature and pressure

1. Introduction

Page 7

HYDRIM L110w/wd Service Guide

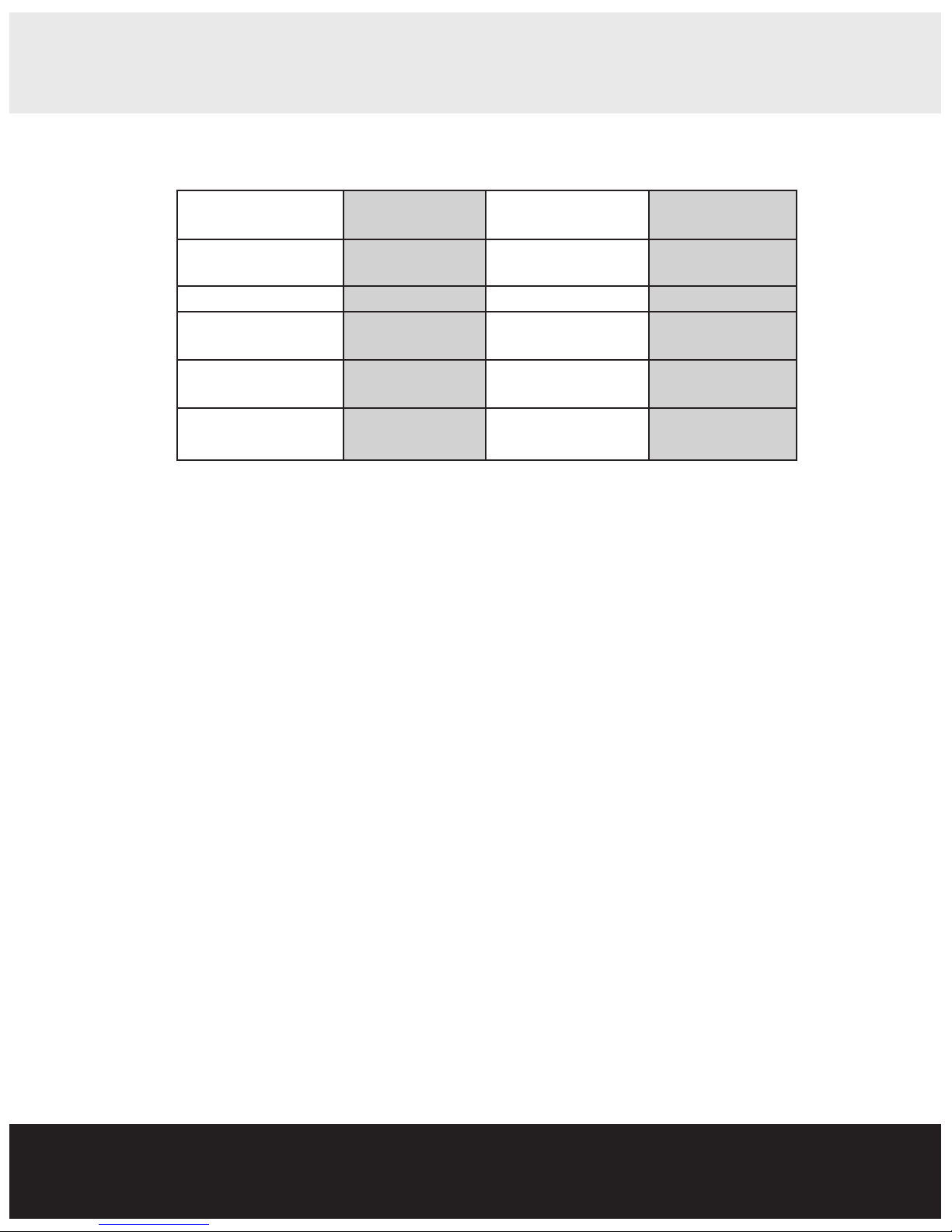

The Hydrim L110w instrument washer:

The program duration and consumption details are shown in the chart below:

* Actual cycle time will vary depending on incoming water temperature and pressure

Program Wash Time* Water Usage

Temperature

P0 - Rinse and 30˚C / 86˚F 8 minutes 4 L / 1 gallon

Hold

P1 - Regular wash 50˚C / 122˚F 20 minutes 16L / 4 gallons

P2 - Regular wash 50˚C / 122˚F 30 minutes 16L / 4 gallons

with dry

P3 - Heavy duty 50˚C / 122˚F 30 minutes 19L / 5 gallons

wash

P4 - Heavy duty 50˚C / 122˚F 40 minutes 19L / 5 gallons

wash with dry

1. Introduction

Page 8

HYDRIM L110w/wd Service Guide

1. Introduction

1.2 Specifications

Hydrim L110wd washer disinfector:

Dimensions:

Height (free-standing) 850 mm

Height (built-in) 810 mm

Width 600 mm

Depth 600 mm

Depth with Door Open 1143 mm

Weight 85 kg

Running Noise 58 dB wash 78 dB dry

Cold Water Connection

3

/4" - 14 NPSM

Pressure 0.3 - 10 bar (gauge)

Waste Water connection direct connection to drain according

to local code requirements

Wash Temperature 50 - 60˚C

Cold Rinse < 30˚C

Thermal Disinfection 93˚C

Electrical Consumption:

Europe 220 - 240 V 50 Hz 10-16 A

North America 220 - 240 V 60 Hz 15A

Rated Load 2.5 kW

Other:

Equipment Pollution Degree 2

Equipment Installation Category II

Maximum relative humidity 20 - 80 %

Maximum altitude 1600 m

Maximum ambient temperature 30˚C

IP XO

Page 9

HYDRIM L110w/wd Service Guide

Dimensions:

Height (free-standing) 850 mm / 33.5"

Height (built-in) 810 mm / 32"

Width 600 mm / 23.75"

Depth 600 mm / 23.75"

Depth with Door Open 1143 mm / 45"

Weight 85 kg / 187 lbs

Running Noise 58 dB wash

78 dB dry

Hot Water Connection 60˚C max / 158˚F

Rinse aid dispenser 120 ml / 4.3 U.S. fl. oz. capacity

Water softener 1.0 kg / 2.2 lbs salt capacity

Filling system 4.5 L / 135 U.S. fl. oz. capacity

Wash Temperature 50˚C / 122˚F

Rinse and hold 30˚C / 86˚F

Electrical Consumption:

North America 208 - 240 V 60 Hz 15 A

Rated Load 2.5 kW

Other:

Equipment Pollution Degree 2

Equipment Installation Category II

Maximum relative humidity 80 % for temp. up to 31˚C / 88˚F

50 % for temp. up to 40˚C / 104˚F

Mains supply + / - 10 % of nominal

Operating mode Free-standing or Built in

1.3 Safety Information

Safe operation

The following applies to both operators and service technicians:

• If you open the door prior to completion of a cycle, hot steam may be released.

• Exercise caution and seek assistance when lifting or carrying the unit.

• Cleaning solutions may irritate. Avoid contact with eyes and mouth.

• Never lean on the open door. The unit may tip forward causing injury.

1.2 Specifications

Hydrim L110w instrument washer:

1. Introduction

Page 10

HYDRIM L110w/wd Service Guide

• Always turn the unit OFF before adding softener salt or solutions. Before

performing routine maintenance or servicing the unit, turn the unit OFF, and unplug

the power cord from the power source.

• The operator should never remove the cover of the unit, or insert objects through

holes or openings in the cabinetry. Doing so may damage the unit and/or create a

hazard for the operator.

Safe servicing

• The Hydrim L110wd and Hydrim L110w units should only be installed and serviced

by a qualified contractor, as these are Installation Category II devices. SciCan will

not be liable for incidental, special, or consequential damages including lost profits,

any commercial loss, economic loss, or loss arising from personal injury caused by

any maintenance or services performed on the Hydrim L110wd or Hydrim L110w

by a third party, nor will it be liable for damage arising from the use of equipment or

parts manufactured by a third party.

• All local, regional, state and national regulations regarding the servicing of this

class of device and safety requirements must be observed.

Exercise caution when the cover is removed:

• Hazardous voltages are accessible. Disconnect the power cord before removing

the cover.

• Sharp metal edges are exposed. Be careful, and wear long sleeves and gloves.

Power main

A dielectric strength test (hi-pot) must be performed on the unit if parts associated with the

power main are serviced or replaced.

Ground

A protective bonding impedance test (ground continuity) must be performed on the unit if

components of the protective earthing system are changed or if connections are broken

and remade.

Reporting

It is vital for SciCan to learn of any problem in the field. This information will help SciCan

solve the problem quickly and improve product reliability in new units. Section 9 of this

service manual contains a service report form that should be completed and returned to

SciCan’s Toronto office.

Biological waste

Waste water in the unit may contain biological contaminants. Use a mechanical means to

siphon the contents. Wear disposable rubber gloves. Dispose of absorbent material

according to biological waste disposal regulations.

1. Introduction

Page 11

HYDRIM L110w/wd Service Guide

1.4 Hardware Specifications

This unit contains the following types of hardware:

• Phillips pan head self-tapping metal screws

• Phillips flat head stainless steel machine screws

• Torx pan head machine screws

• Torx pan head plastite screws

As you remove a screw or nut, be sure to remember where it goes. When you reinsert a

plastite screw, tighten the screw until it is snug.

1.5 Shipping Instructions

The unit should be serviced on site. If it is necessary to send the unit back to SciCan,

follow these instructions. Before shipping the unit, run the Rinse and Hold cycle to remove

most of the water from the system. If there is standing water in the chamber, siphon or

ladle as much water as possible and use an absorbent cloth to remove the rest.

Disconnect and remove the cleaning solution container and then drain the

dosing reservoir. Screw in completely the leveling legs found underneath the unit.

Specify upright, heated, and insured shipping.

1.6 Contact Information

For further information or questions about the Hydrim L110wd and Hydrim L110w, contact

your authorized dealer or:

www.scican.com

SciCan

1440 Don Mills Road

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

SciCan Medtech

Alpenstrasse 16, 6300 Zug

SWITZERLAND

SciCan Inc.

500 Business Center Drive

Pittsburgh PA15205

Phone: (412) 494-0181

Fax: (412) 494-4794

Toll Free: 1-800-572-1211

EU Representative:

BHT Hygienetechnik GmbH

Messerschmittstr. 11

D-86368 Gersthofen

GERMANY

For all Service and Repair inquiries:

Canada: 1-800-870-7777

United States: 1-800-572-1211

International: (416) 446-4500

Email: techservice.ca@scican.com

1. Introduction

Loading...

Loading...