Page 1

SD-438 EU EN R5

1

SciCan Ltd. 1440 Don Mills Road, Toronto, Ontario, Canada. M3B 3P9

HYDRIM G4 Washer-Disinfector

Pre-Installation Instructions

To ensure the optimum performance of SciCan’s washer-disinfector models it is imperative that the

correct services are made available and that the positioning of the unit does not compromise the

function of the unit in any way.

Prior to installation it is important that the site be inspected and all the appropriate conditions are met

to ensure the safe and efficient operation of the washer-disinfector.

Practice details and summary results.

Practice/Office location details

Customer Name:

Address:

Tel:

Signature:

Installer/Pre-installation inspector

Name:

Dealer details:

Tel:

Conditions approved/rejected for installation subject to checklist below (!/" )

Name:

Signature:

Date:

On behalf of (Dealer):

Page 2

SD-438 EU EN R5

2

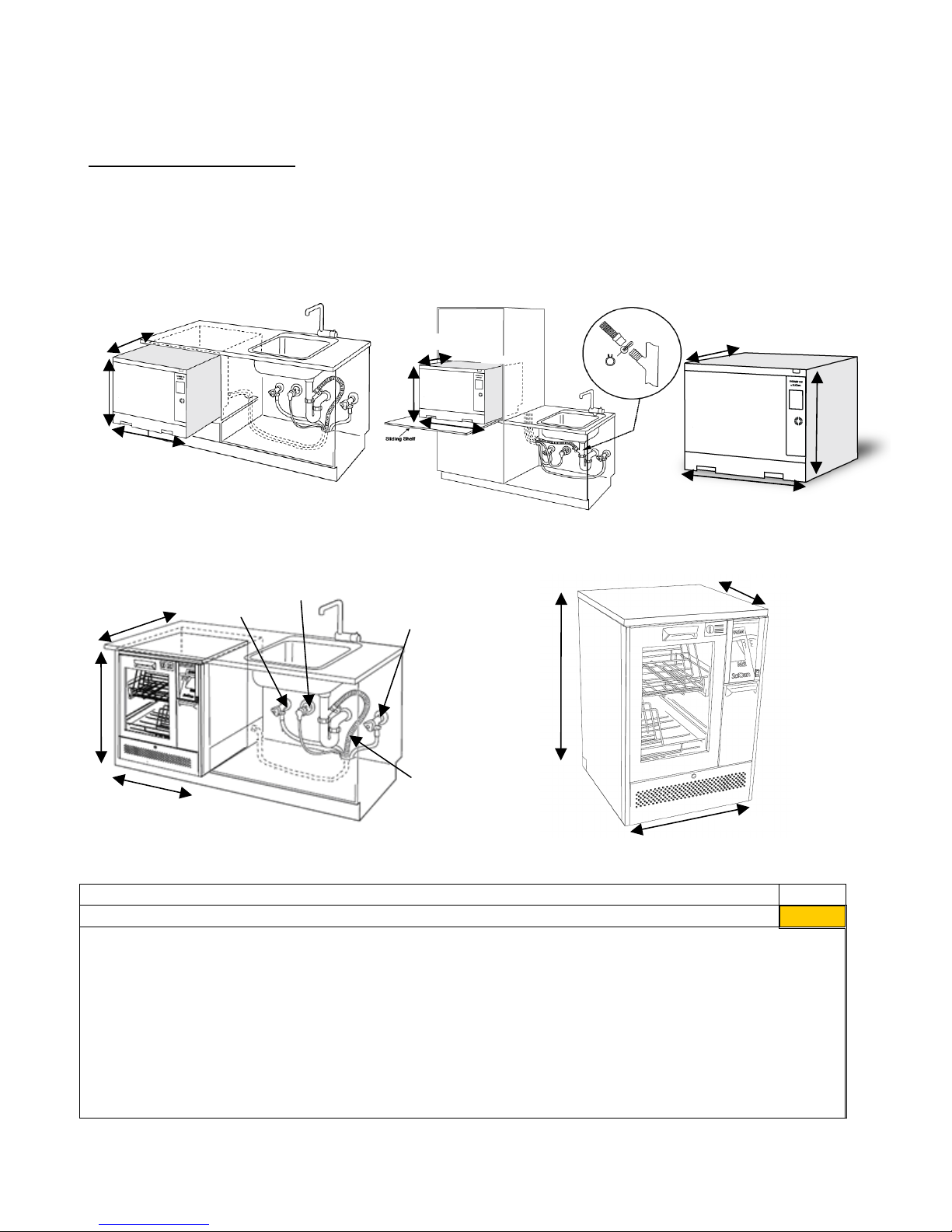

Installation Configuration

The washer-disinfector may be installed under-bench or free standing dependent on space and

service availability. Please select appropriate model number for the installation configuration.

The HYDRIM C61wd G4 configuration options are:

NOTE: LCS Models must also have a compressed air supply within 2 m of installation site

Option 1: Cabinet/ Sterilization Center Option 2: Sliding Shelf Option 3: Counter Top

The HYDRIM M2 G4 configuration options are:

Option 1: Cabinet/ Sterilization Center (M2 G4 Short model) Option 2: Free Standing (M2 G4 Standard model)

Space Requirements

!/"

• Ensure adequate space is available to install the unit

Note 1: Although not required, if the HYDRIM is installed under a counter, it is recommended to allow at least

10 mm space at the top and both sides of the unit. This will facilitate installation levelling, and service access

to the HYDRIM.

Note 2: Avoid installing the HYDRIM in direct sunlight.

Note 3: Important! Ventilation during drying is via the front of the machine. Some increase in humidity may

be apparent during this drying phase and it is imperative that sufficient air circulation is available surrounding

the machine to enable this humidity to be dissipated. Failure to provide adequate ventilation may lead to

equipment or cabinetry damage (depending on installation configuration).

Note 4: The drying system has a filtered air intake at the front of the unit. The free movement of air to this

Power connection

Hot Water

connection

Cold Water

connection

Drain

connection

598 mm + 10mm

820 mm

598 mm + 20mm

850 mm

598mm

598mm

520mm + 10mm

598mm + 20mm

526mm

520mm

+ 10mm

598mm + 20mm

526mm

520mm

598mm

526 mm

Page 3

SD-438 EU EN R5

3

intake is important and failure to provide the required space may cause overheating of the dryer motor

and/or compromise drying efficiency.

Note 5: The unit should be installed as supplied as every part of the unit has a purpose to guarantee trouble

free operation. In particular, the legs of the HYDRIM G4 have been designed to distribute the weight of the

machine to the chassis of the unit and to ensure a leveled installation. If units are installed without legs, the unit

may start to leak from the door. Therefore, the legs of the unit cannot be removed for installation

purposes.

Pre Installation Checklist

The following items are required to be in place before installation begins.

Description

!/"

Hot water/Cold water/Reverse Osmosis (RO) water feed with G ¾” or DN 20 shut off

valve (washing machine fitting)

Distance of water connections

• Maximum distance from installation less than 1.50 m / 5 ft

Water inlet pressure

• HYDRIM C61wd G4: 1 to 10 bar / 14 to 145 psi

• HYDRIM M2 G4: 2 to 5 bar / 29 to 72 psi

Minimum water supply for each inlet

• HYDRIM C61wd G4: 2.5 L/min

• HYDRIM M2 G4: 4.5 L/min

Note 1: If hot water is not available then it must be possible to attach a ‘Y’ fitting to the cold water feed valve

so that both machine pipes can be connected to the cold supply. The machine will not work with only one

supply attached as it requires pressure in both supplies to activate the feed pressure switches. Please note

that cold fill only will increase cycle times.

Note 2: Water feeds should be adjacent to the machine and not behind it so that the shut off valves may be

accessed in case emergency isolation is required and to ensure unit can be inserted fully under the work

surface.

Drain outlet

!/"

• Maximum distance from installation is 1.50 m / 5 ft with supplied drain hose

• The maximum length of an extended drain hose should not exceed 3.30 m / 10.8

ft.

• Drain should be no more than 1 m / 3.2 ft above the base of the HYDRIM unit.

• ‘P’ trap spur connection (preferred method) OR standpipe connection

• Accommodate ¾” drain hose

• Material of drain must withstand 95°C fluid

Note 1: The preferred method of connection of the HYDRIM to the drain is by the use of a ‘spurred’ ‘P’ trap

fitting.

Note 2: The waste connection pipe is clamped on to the spur by the clips provided with the HYDRIM.

Wherever possible, if the HYDRIM is located close to a sink unit, then this method should be used. If the

HYDRIM is not close to a sink unit and a ‘P’ trap cannot be used, then a standpipe with ‘U’ bend fitting can

be used. This must be a dedicated standpipe. Under no circumstances should any other equipment

Page 4

SD-438 EU EN R5

4

share the standpipe.

Note 3: Waste connection should be adjacent to the machine and not behind it.

General Notes

Note 1: Washer-disinfectors, by their very nature, use water and chemicals and also generate heat. It is

important therefore that their surroundings (cabinetry and flooring) are of good quality and in good condition

to minimise the risk of damage, particularly where a ‘built in’ configuration is used.

Note 2: The HYDRIM G4 is also heavy! Consideration should therefore be given to the structural integrity of

the flooring (see “Technical Specifications Summary”)

Note 3: It is also important that the flooring is flat, and does not run out greater than 2mm front to back and

side to side over the footprint of the unit (see “Technical Specifications Summary”)

Note 4: From time to time, access will be required to change the air filter and/or service the machine. It is

important therefore to ensure that adequate space is available in front of the machine to allow easy removal

of the equipment. Ensure that when the machine is pulled out that the integrity of the services is not

compromised.

Optimum features should be as follows:

• Cabinetry/floor

!/"

o Waterproof

o Sealed edges

o Heat resistance

o Sound structural integrity

o Post installation access

o Flatness (See note 3 above)

Water Quality

The quality of the water being used in the HYDRIM to clean the medical instruments is very critical to

achieving satisfying cleaning results and to protecting the instruments and the internal parts of the HYDRIM

from deterioration. Dissolved solids in the water can cause stains, spots, and corrosion on instruments and

the internal parts of the HYDRIM.

Before installing and using the HYDRIM, SciCan recommends testing the water and recording the results for

future references here.

The following table lists the desired levels of the water parameters:

If the water hardness exceeds 250 mg/L, then external water softener may be required as the built-in water

softener may not be as effective at that level of water hardness.

In addition, if the test results of any of the water parameters exceed the stated problem levels, a full water

analysis is recommended and the installation of a water treatment system may be required.

The following table lists the desired levels of additional water parameters:

Water Parameter

Desired Level

Units*

Problem Level

Alkalinity

75

mg/L

< 40 or > 120

Iron

< 0.05

mg/L

> 0.20

Water Parameter

Desired Level

Units*

Problem Level

pH value

7.0 – 7.5

S.U.

< 6.8 or > 8.5

Hardness

< 85

mg/L

> 100

Total Dissolved Solids (TDS)

< 175

mg/L

> 300

Page 5

SD-438 EU EN R5

5

Manganese

< 0.01

mg/L

> 0.04

Chloride

< 20

mg/L

> 30

*For water, milligram per liter (mg/L) equals parts per million (ppm)

If full water analysis results in parameters exceeding problem level, then a water treatment system

is highly recommended. The HYDRIM washer-disinfectors are fitted with an additional water inlet,

specifically for external water treatment systems (such as deionised or RO).

There may be instances where parameters are below the stated problem levels, however staining

still occurs. A water treatment system may be needed to prevent the staining – see SD-447 Water

Quality Document available on mySciCan for additional information.

The HYDRIM is also equipped with an air gap / anti-suction device to prevent backflow of dirty

water into the water supply.

• Water hardness

o Hot water

o Cold water

• Water conductivity

• pH value

o

Action required (if any):

Internet Connection

!/"

Install a Cat 5 or 6 Ethernet port

Note 1: The port should be installed in a cabinet adjacent to the unit.

Note 2: Ensure that the port has access to the office network and the internet.

Note 3: Although the unit can be connected to a bridge for wireless access, it is recommended to use hard

wired connection to minimize risks with network connections.

Note 4: If the office has purchased (or plans to purchase) other internet connectivity (G4) products, install

multiple Ethernet ports to accommodate other G4 products from SciCan.

HIP/HIP Ultra cleaning solution

!/"

Order Cleaning solution

HYDRIM C61wd G4: HIP Ultra cleaning solution (CS-HIPC-U)

HYDRIM M2 G4: HIP cleaning solution (CS-HIPL) or HIP Enzymatic (CS-HIPL-E)

Note 1: HIP, HIP Ultra or HIP Enzymatic cleaning solution is required to run the machine and is not included

with the machine. Please ensure cleaning solution has been provided prior to installation.

Compressed Air (HYDRIM C61wd G4 LCS Model ONLY)

!/"

Availability of a DN 7.2 connection for compressed air

Air pressure must be between 1 bar (15 PSI) - 10 bar (145 PSI)

Distance between unit installation site and compressed air connection must be within 2 m

Page 6

SD-438 EU EN R5

6

Electrical supply

Refer to model number for specific requirements

Model Number

Ending

Current

(see note 1)

Voltage

Frequency

Maximum power supply

location for installation site

Rated

load

!/"

-D01

12A

208-240 V

60 Hz

1.50 m / 5 ft

2.7 kW

-D06

12A

200-230 V

60 Hz

1.50 m / 5 ft

2.7 kW

-D11

12A

200-230 V

60 Hz

1.50 m / 5 ft

2.7 kW

-D02

12A

200-230 V

50 Hz

1.50 m / 5 ft

2.7 kW

-D04

12A

200-230 V

50 Hz

1.50 m / 5 ft

2.7 kW

-D05

12A

200-230 V

50 Hz

1.50 m / 5 ft

2.7 kW

-D12

12A

200-230 V

50 Hz

1.50 m / 5 ft

2.7 kW

HYDRIM C61wd G4

(including LCS models)

-D13

12A

200-230 V

50 Hz

1.50 m / 5 ft

2.7 kW

-D01

12A

230-240 V

60 Hz

1.50 m / 5 ft

2.5 kW

-D03

13A

230-240 V

60 Hz

1.50 m / 5 ft

2.5 kW

-D02

13A

230-240 V

50 Hz

1.50 m / 5 ft

2.5 kW

-D04

13A

230-240 V

50 Hz

1.50 m / 5 ft

2.5 kW

HYDRIM M2 G4

(including short models)

-D10

13A

230-240 V

50 Hz

1.50 m / 5 ft

2.5 kW

Note 1 - The HYDRIM G4 is supplied with a domestic fused plug as standard. A dedicated hard wired supply can also be used.

Note 2 - Due to the power requirements of the HYDRIM, (see rated load) especially during drying, it is advised that no other equipment is

connected to the same supply outlet.

Note 3 - Power supply outlet should be adjacent to the machine and NOT behind it. The cable should be routed away from the back panel and

hot water inlet hose.

Page 7

SD-438 EU EN R5

7

INSTALLATION OVERVIEW

SUMMARY

!/"

Sufficient space for unit installation

Hot and cold water feeds are installed

Drain pipes are prepared

Electrical requirements are met

Cabinetry/floors can withstand operation of the unit

Water quality is acceptable

Internet connection installed

HIP/HIP Ultra cleaning solution ordered

Compressed air connection (HYDRIM C61wd G4 LCS model ONLY)

Follow-up Comments:

Page 8

SD-438 EU EN R5

8

Technical Specifications Summary

HYDRIM C61wd G4

Applicable Standards

ISO 15883-1/2

Height

520 mm

Width

598 mm

Depth (Door closed)

598 mm

Depth (Door open)

829 mm

Weight

44 kg

Floor loading per support when full

152 N

Required clearance on top and sides

>10mm

Running Noise

65 dB(A)

Inlet water connections

G ¾” or DN 20

Inlet water pressure

1-10 bar

Minimum water supply

HYDRIM C61wd G4: 2.5 L/min

Drain

¾”

Maximum water flow to drain

47 L/min

Maximum water discharge temperature to drain

95°C

Maximum water hardness

30.3°dH, 31.6 US GPG, 540 PPM

Maximum water conductivity

844 µS/cm

pH range

>6.8 and < 8.5

Water volume per process stage

3.8 L ± 0.5 L

P3 has additional 18.9 ± 1L for drying

Total water consumption per cycle with drying

P1 & P2: 11.4 L ± 1.5 L

P3: 30.3 L ± 2.5 L

Maximum heat transmitted through fascia

1200 W

Water softener salt capacity

0.5 kg / 1.1 lbs

Equipment installation category

II

Voltage*

208 – 240 VAC, OR

200 – 230 VAC ± 10%

Frequency*

50 Hz or 60 Hz

Rated load

2.7 kW

Current

12A

Operating temperature range

5°C – 40°C

Maximum relative humidity

80% for temp up to 31°C

50% for temp up to 40°C

Maximum operating altitude

2000 m

Equipment pollution degree

2

Maximum deviation from plane horizontal surface.

2mm

Suitable process chemicals for each stage

HIP Ultra

Total amount of process chemical

43.5 mL

Material Safety Data Sheet

Refer to download page of website

Cycle recording options

USB, G4 web portal, external printer

Air pressure range (LCS Model Only)

1 bar (15 PSI) - 10 bar (145 PSI)

Compressed air connection

DN 7.2

*Refer to Electrical Supply table

Page 9

SD-438 EU EN R5

9

Technical Specifications Summary

HYDRIM M2 G4

Applicable Standards

ISO 15883-1/2

Height (Standard height unit)

850 mm

Height (Short height unit)

820 mm

Width

598 mm

Depth (Door closed)

600 mm

Depth (Door open)

1200 mm

Weight

90 kg

Floor loading per support when full

310 N

Required clearance: Top and Sides

Rear

>10mm

>50mm

Running Noise

<78 dB(A)

Inlet water connections

G 3/4” or DN 20

Inlet water pressure

2-5 bar

Minimum water supply

HYDRIM M2 G4: 4.5 L/min

Drain

3/4”

Maximum water flow to drain

47 L/min

Maximum water discharge temperature to drain

95°C

Maximum water hardness

30.3°dH, 31.6 US GPG, 540 PPM

Maximum water conductivity

844 µS/cm

pH range

>6.8 and < 8.5

Water volume per process stage

8 L ± 1 L

P3 has additional 8 ± 1L for drying

Total water consumption per cycle with drying

P1: 16 L ± 2 L

P2: 32 L ± 4 L

P3: 40 L ± 5 L

Maximum heat transmitted through fascia

2388 W

Water softener salt capacity

1.0 kg

Equipment installation category

II

Voltage

230 – 240 VAC ± 10%

Frequency*

50 Hz or 60 Hz

Rated load

2.5 kW

Current*

12A or 13A

Operating temperature range

5°C – 40°C

Maximum relative humidity

80% for temp up to 31°C

50% for temp up to 40°C

Maximum operating altitude

2000 m

Equipment pollution degree

2

Maximum deviation from plane horizontal surface.

2mm

Suitable process chemicals for each stage

HIP or HIP Enzymatic

Total amount of process chemical

108 mL

Material Safety Data Sheet

Refer to download page of website

Cycle recording options

USB, G4 web portal, external printer

*Refer to Electrical Supply table

Loading...

Loading...