Page 1

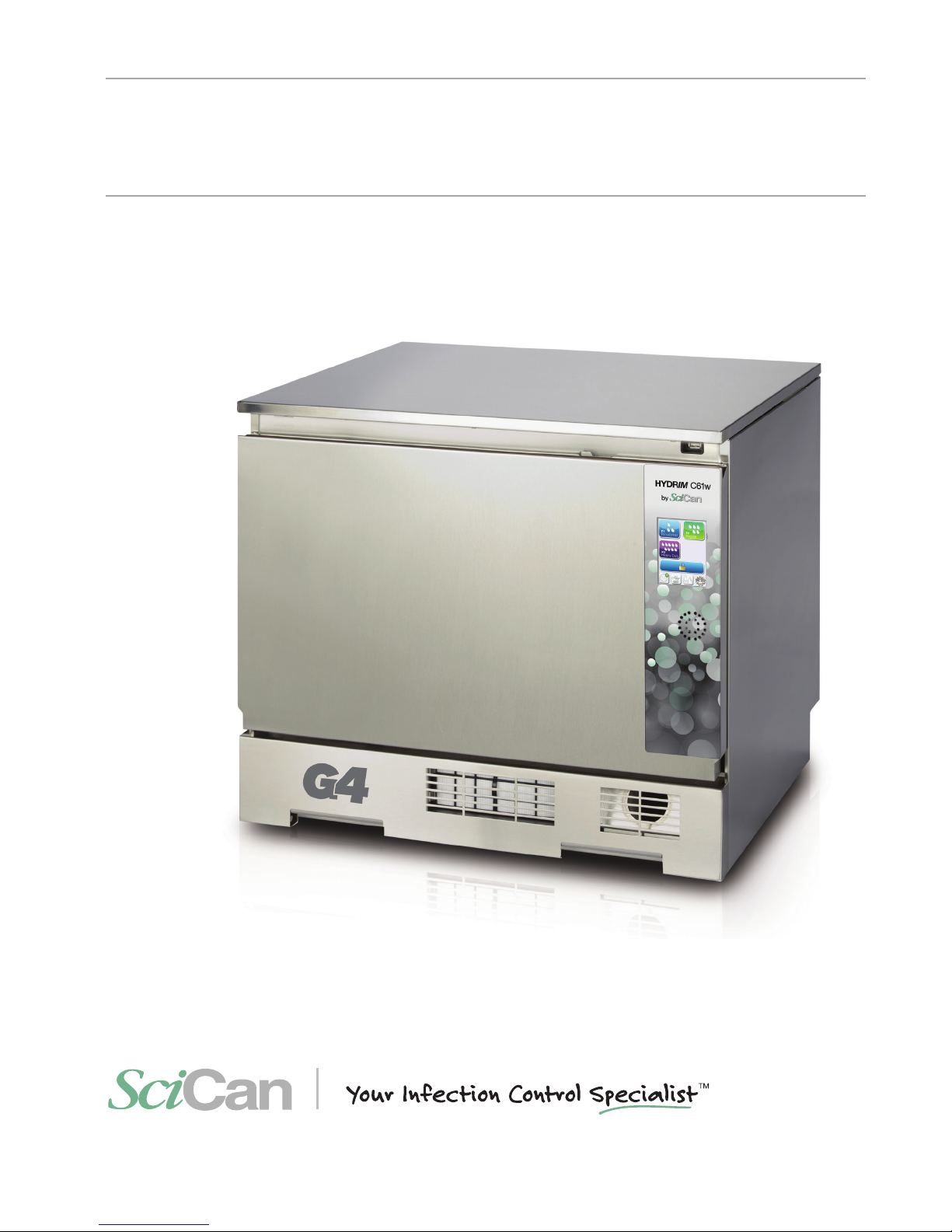

HYDRIM C61w G4

INSTRUMENT WASHER

• Service Manual

• Manuel de l’utilisateur

HYDRIM C61w G4 Service Manual 95-113023 Rev. 1.0 Copyright 2013 SciCan Ltd . All rights reserved.

Page 2

Contents

1. Introduction ................................... 4

1.1 Overview .................................................. 4

1.2 Unit at a glance ....................................... 5

With cover and panels removed top ...... 6

With cover and panels removed bottom 7

1.3 Specifications .......................................... 8

1.4 Safety information ................................... 9

Safe operation......................................... 9

Safe servicing ......................................... 9

1.5 Tools and hardware ............................... 10

1.6 Shipping instructions ............................. 11

1.7 Installation ............................................. 11

1.8 Setting water softener ........................... 12

1.9 Setting the language ............................. 13

1.10 Setting the country .............................. 13

1.11 Setting the time ................................... 13

1.12 Setting the date ................................... 14

1.13 Assigning the unit identifier number.... 14

1.14 Resetting the drying counter ............... 14

1.15 Adjusting the screensaver delay ......... 15

1.16 Adjusting temperature display ............ 15

1.17

Turning the button sound ON or OFF ..

1.18 Adjusting the button beep volume ...... 15

1.19 Adjusting the salt regeneration ........... 16

1.20 Adjusting the screen contrast ............. 16

1.21 Changing the touchscreen

display themes .................................... 16

1.22 Creating a user name .......................... 17

1.23 Creating a user PIN ............................. 17

1.24 Setting up process enforced usage .... 18

1.25 Connecting to a network ..................... 18

1.26 Connecting to a wireless network ....... 19

15

2. Routine Procedures

and Maintenance ......................... 20

2.1

Replacing the HIP™ Ultra cleaning solution

2.2 Changing the HEPA filter ...................... 21

2.3 Filter and wash arm maintenance ......... 21

2.4 Cleaning the chamber ........................... 22

2.5

Draining the unit for service or shipping

2.6 Upgrading the firmware ......................... 22

2.7

Using the HYDRIM remote access function

2.8 Annual Service Requirements ............... 24

20

.. 22

.. 23

3. Diagnostics and Troubleshooting .. 26

3.1 Using the service menu ......................... 26

3.2 Using the setup menu ........................... 27

3.3 Using the user menu ............................. 28

3.4 Using software tools for diagnostics..... 29

Debug Screen ........................................ 29

I/O status screen ................................... 30

3.5 Troubleshooting cycle faults ................. 31

4. Removing and Replacing Panels ... 35

4.1

Removing and reinstalling the top panel

4.2

Removing and reinstalling the left panel

4.3

Removing and reinstalling the right panel

4.4

Removing and reinstalling the back panel

4.5 Removing and reinstalling

the bottom panel ................................... 38

.. 36

.. 36

.. 37

.. 37

5. Front Components ......................... 39

5.1

Removing and reinstalling the kickplate

5.2 Removing and reinstalling

the power switch ................................... 41

6. Door Components .......................... 42

6.1 Removing and reinstalling door fascia .. 43

6.2

Removing and reinstalling door springs

6.3 Removing and reinstalling the door ...... 45

6.4 Removing and reinstalling LCD

and LCD controller ................................ 46

6.5 Removing and reinstalling the LCD fan 46

6.6 Removing and reinstalling the speaker 46

6.7 Removing and reinstalling

the door latch assembly ........................ 47

6.8 Removing and replacing

the door microswitch ............................. 47

6.9 Removing and replacing

the door latch solenoid .......................... 47

6.10

Removing and replacing the door seal

6.11 Removing and replacing

the chamber seal ................................. 49

.. 40

.. 44

.. 48

7. Right Side Components ................. 50

7.1 Removing and reinstalling

the DC power source ............................ 51

7.2 Removing and reinstalling

the reservoir filling pump ....................... 52

7.3 Removing and reinstalling

the dosing/bellows pump ...................... 52

7.4 Removing and reinstalling

the dosing reservoir ............................... 53

7.5 Removing and reinstalling

the I/O board ......................................... 53

7.6 Removing and reinstalling

the chemical bracket ............................. 54

7.7 Removing and reinstalling

the pressure switch ............................... 55

8. Left Side Components ................... 56

8.1 Removing and reinstalling

the air gap ............................................. 57

8.2 Removing and reinstalling

the dryer heater ..................................... 59

8.3 Removing and reinstalling

the dryer assembly ................................ 59

2

Page 3

Contents

9. Rear Components .......................... 60

9.1 Removing and replacing

the power source fan ............................ 61

9.2 Removing and reinstalling

the air gap pump ................................... 62

9.3 Removing and reinstalling

the exhaust duct .................................... 63

10. Top Components ........................... 64

10.1 Removing and reinstalling

the USB port ........................................ 65

10.2 Disconnecting and reconnecting

the upper wash arm inlet ..................... 66

10.3 Removing and reinstalling

the upper wash arm sensor ................. 66

11. Bottom Components ..................... 67

11.1 Removing and reinstalling

the recirculation pump ......................... 68

11.2 Removing and reinstalling

the water heater ................................... 69

11.3 Removing and reinstalling

the drain pump .................................... 70

11.4 Remove and replace

the sump temperature sensor ............. 71

11.5 Removing and reinstalling

the bottom RPM sensor ..................... 72

11.6 Removing and reinstalling

the dryer motor .................................... 73

11.7 Removing and reinstalling

the water softener system ................... 74

11.8 Removing and reinstalling

the water valves ................................... 75

11.9 Removing and reinstalling

the AC power inlet ............................... 75

12. Spare Parts List ............................ 76

13. Appendices ................................... 78

HYDRIM and STATIM are registered trademarks of SciCan Ltd. BRAVO, HIP,

and SysTM are trademarks of SciCan Ltd. All other trademarks referred to

in this manual are the property of their respective owners.

For all service and repair inquiries:

In Canada 1-800-870-7777

United States: 1-800-572-1211

Germany:

International: (416) 446-4500

Email: techservice.ca@scican.com

Manufactured by:

+49 (0)7561 98343 - 0

SciCan

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

Appendix A HYDRIM C61w G4

Electrical Schematic ................................ 78

Appendix B HYDRIM C61w G4

Flow Diagram .......................................... 79

EU Representative

SciCan GmbH

Wangener Strasse 78

88299 Leutkirch GERMANY

Tel.: +49 (0)7561 98343 - 0

Fax: +49 (0)7561 98343 - 699

SciCan Inc.

701 Technology Drive

Canonsburg, PA 15317 USA

Phone: +1 724 820 1600

Fax: +1 724 820 1479

Toll free: 1-800-572-1211

SciCan Medtech

Alpenstrasse 16

CH-6300 ZUG SWITZERLAND

Phone: +41 (0) 41 727 7027

Fax: +41 (0) 41 727 7029

3

Page 4

1 Introduction

1.1 Overview

This guide provides instructions for the servicing and repair of the HYDRIM® C61w G4

Instrument Washer. Every attempt has been made to provide accurate, detailed instructions.

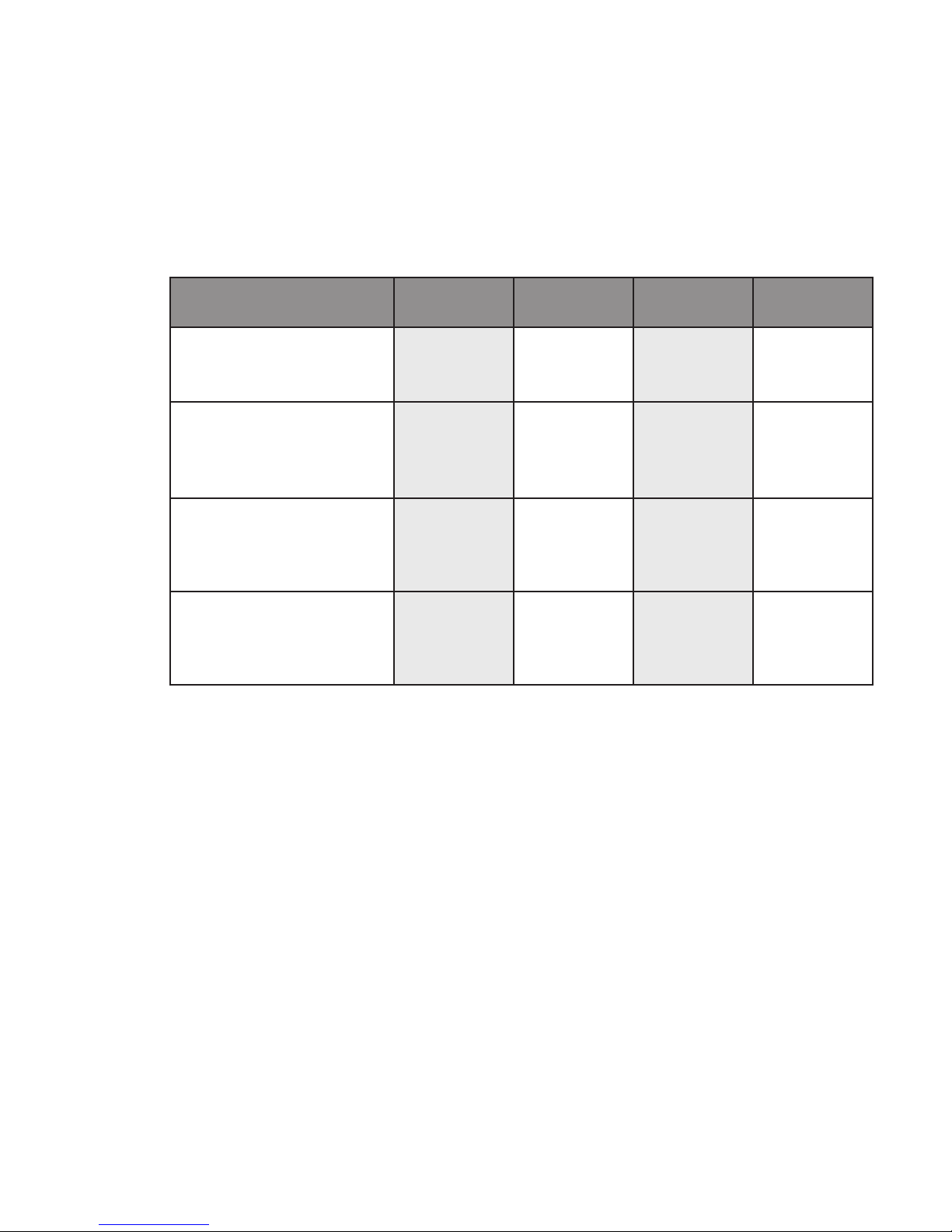

HYDRIM C61w G4 instrument washer cycle description chart

Cycle Prewash Wash Rinse Dry

P0 – Machine Cleaning

Cycle

No initial draining.

P1 – Rinse and Hold

Cycle

Use to prevent soil from drying

on instruments when they will not

be washed within one hour.

P2 – Regular Cycle

Use for moderately soiled loose

instruments.

P3 – Heavy Duty Cycle

Use for heavily soiled instruments

and cassettes.

<30ºC (cold)

2 minutes

<30ºC (cold)

2 minutes

<30ºC (cold)

2 minutes

<30ºC (cold)

2 minutes

N/A

N/A

50ºC

5 minutes

50ºC

9-15 minute s

<30ºC (cold)

2 minutes

<30ºC (cold)

1 minutes

60ºC

1 minute

60ºC

1 minute

N/A

N/A

1-25 minu tes

(default

10 minutes)

1-25 minu tes

(default

10 minutes)

4

Page 5

1 Introduction

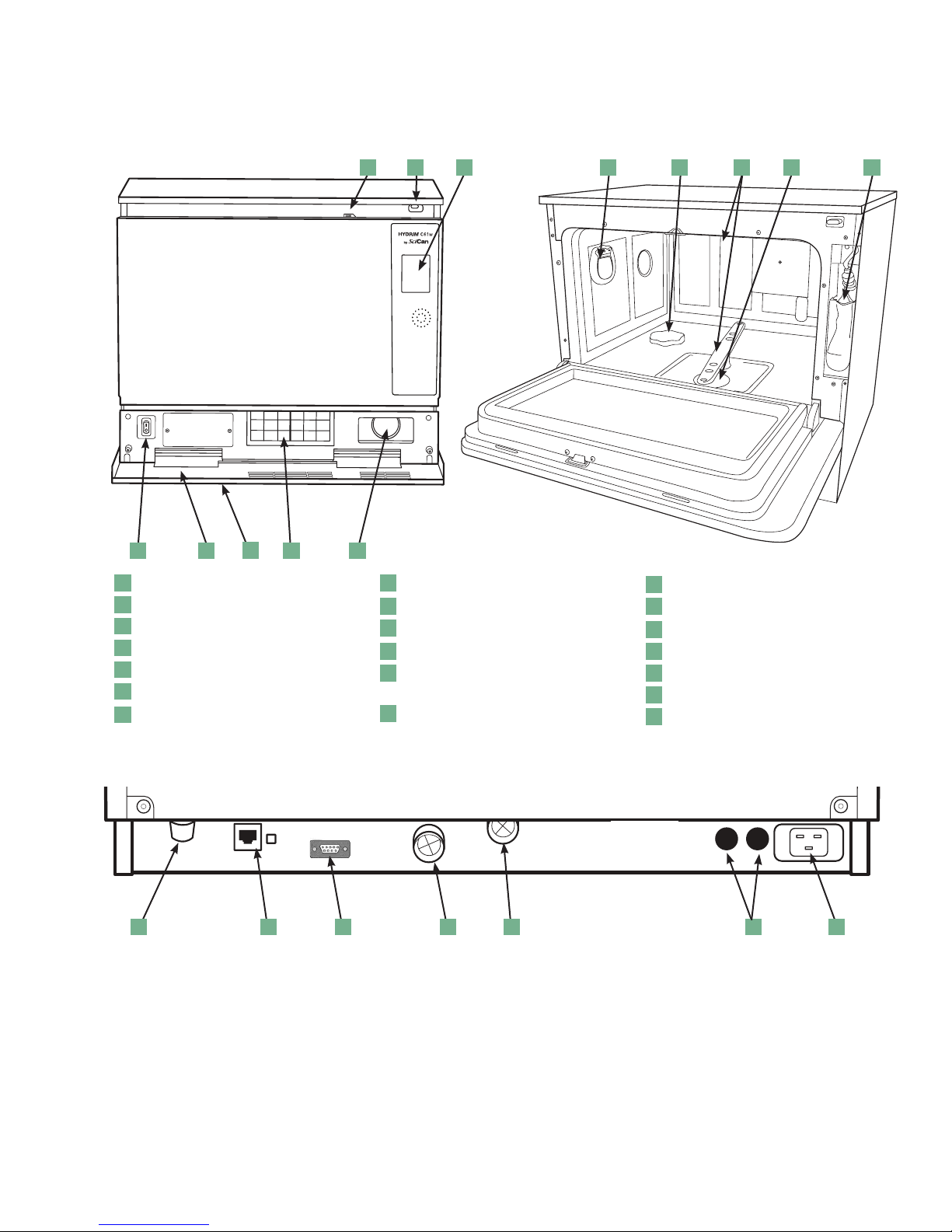

1.2 HYDRIM Unit at a glance

With cover and panels in place

1 2 3 4

20

Figure 1

2

6

2122 825 27

9

10 11

1

n

Power switch

1

1

n

Kickplate

2

1

3

n

HEPA filter

1

4

n

Dryer exhaust

1

5

n

Door latch

1

6

n

USB port

1

n

LCD touchscreen

7

Rear Connections

1

n

Dryer outlet

8

1

n

Water softener

9

1

n

Wash arms (top not shown)

10

1

n

Coarse filter

11

1

n

Cleaning solution

12

1

n

and drawer

1

n

Drain outlet

13

1

n

Ethernet port

14

1

n

RS232 port

15

1

n

Cold water inlet

16

1

n

Hot water inlet

17

1

n

Fuses

18

1

n

Power cable port

19

1

n

Drain tube (behind kickplate)

20

Figure 2

15 19

1714 16 1813

5

Page 6

6

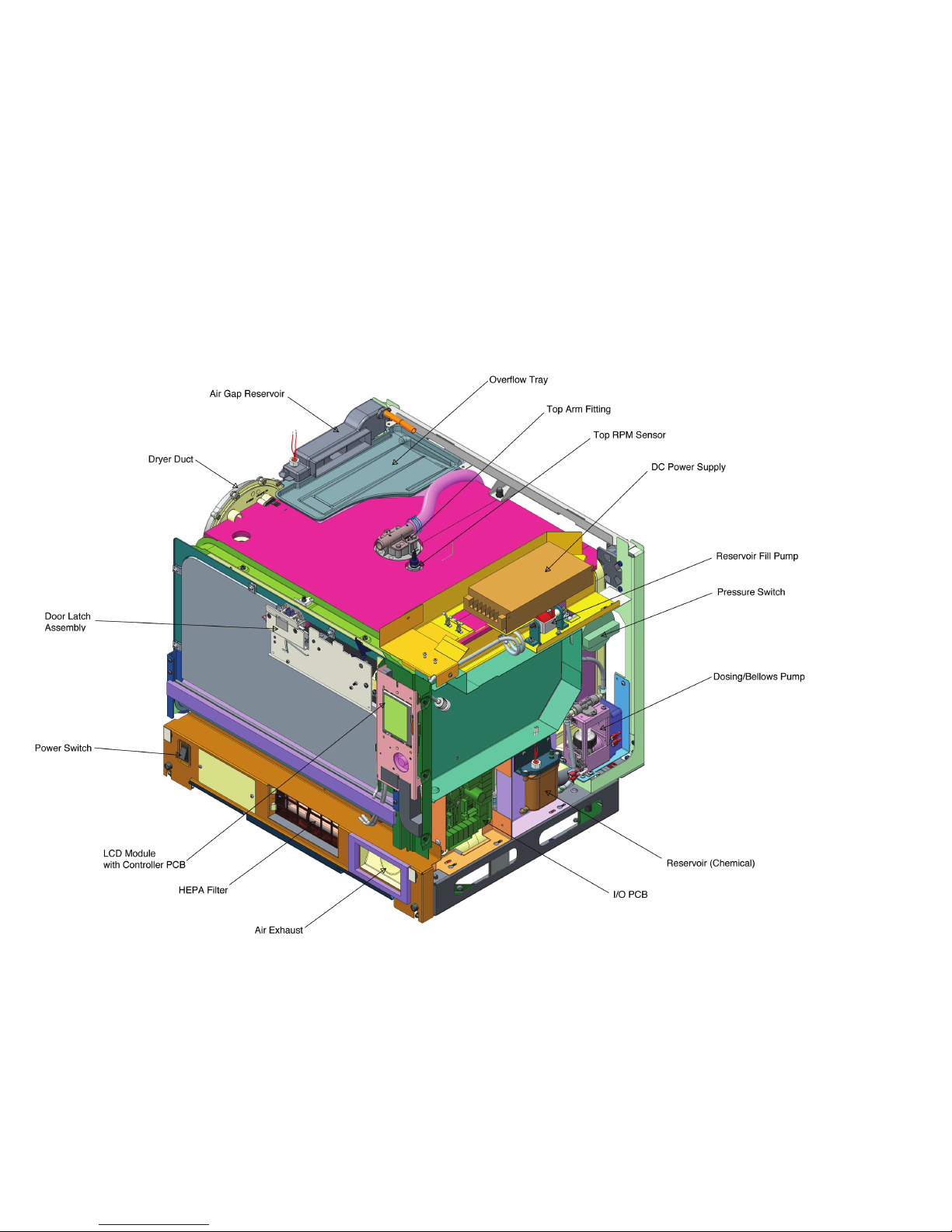

1 Introduction

With cover and panels removed

• Top View (from front right)

Figure 3

Page 7

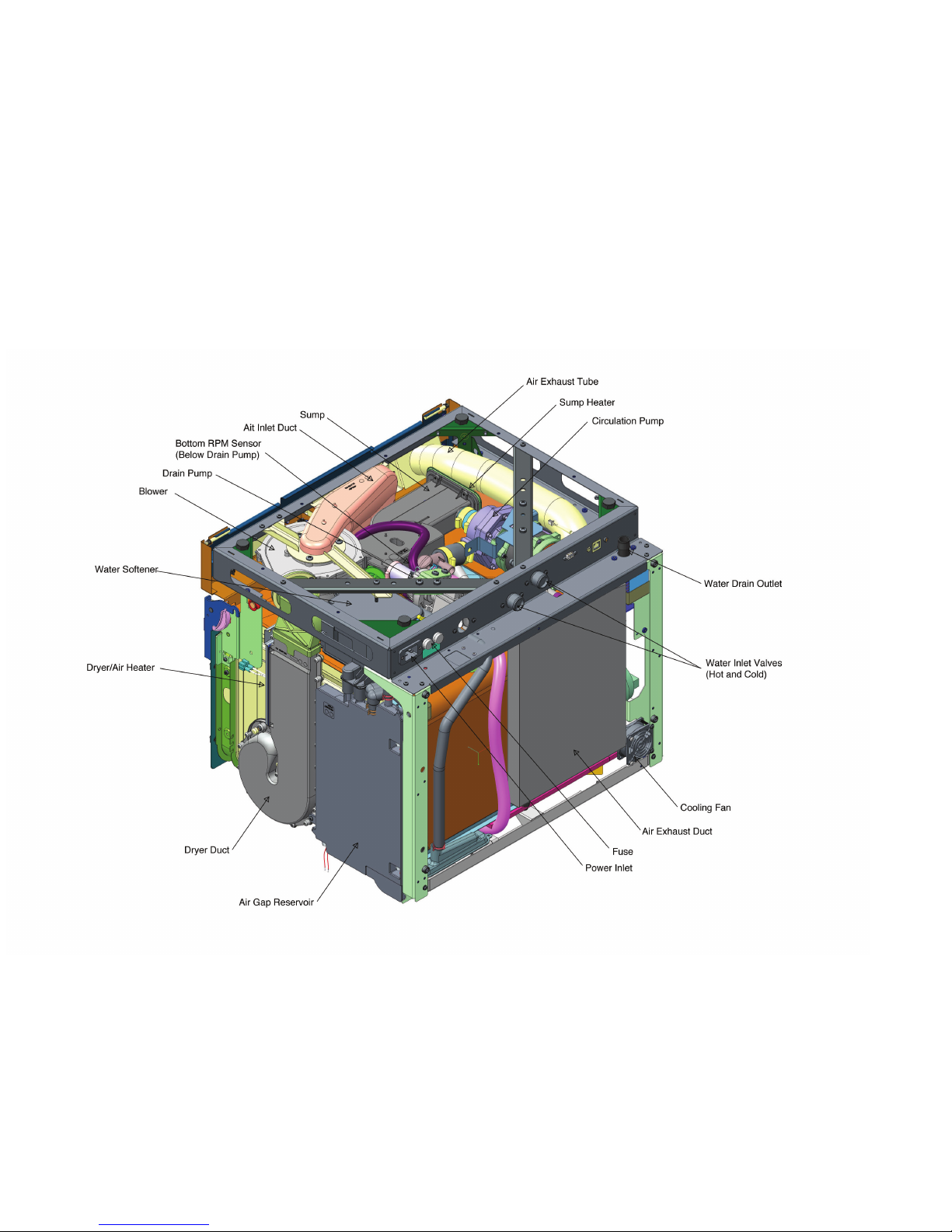

7

1 Introduction

• Bottom View (from back left)

Figure 4

Page 8

1 Introduction

1.3 Specifications

Machine dimensions: Length: 52 cm 20.5"

Width: 59.8 cm 23.5"

Depth: 52.6 cm 20.7"

Depth with door open: 82.9 cm 32.6"

Weight : 44 kg 97 lbs

Running noise: 65 dB

Hot and cold water connections G 3/4"

Inlet water pressure: 1-10 bar

Incoming hot water temperature: 60°C 140°F

Drain: 3/4"

Drying system: Heater 1 kW

Electrical connection: 208-240VAC ±10%, single-phase,

60 Hz, 12A

Protection class: Class I

Equipment pollution degree: Pollution degree 2

Equipment installation category: Installation category II

Maximum relative humidity: 80% for temp up to 31°C/88°F

50% for temp up to 40°C/104°F

Operating temperature range: 5˚C - 40˚C 41°-104°F

Max. altitude: 2000 m 6,562 feet

Mains supply: + / -10% of nominal

Fuses: 15A, 250V, Type F

8

Page 9

1 Introduction

1.4 Safety information

The following symbols

appear in the margins

of this book.

The following symbols appear on the unit:

Caution: Hot Surface

and/or Hot Steam

A potential hazard

to the operator.

Safe operation

The following apply to both operators and service technicians:

• Exercise caution and seek assistance when lifting or carrying the unit.

• Cleaning solutions may irritate. Avoid contact with eyes, skin and mouth.

• Never lean on the open door. The unit may tip forward causing injury.

• Always turn the unit OFF before adding softener salt or solutions. Before performing

routine maintenance or servicing the unit, turn the unit OFF and unplug the power cord

from the power source.

A situation that

may lead to a

mechanical failure.

Caution: Risk of electrical

shock. Disconnect supply

before servicing.

Important

information

Caution: Refer to manual

for details.

• The operator should never remove the cover of the unit or insert objects through holes

or openings in the cabinetry. Doing so may damage the unit and/or pose a hazard to

the operator.

• If the unit is used in a manner other than that specified, the protection provided by

the equipment may be impaired.

Safe servicing

• The HYDRIM C61w G4 Instrument Washer should only be installed and serviced by

a qualified contractor as it is an Installation Category 2 device. The contractor should be

experienced in installing equipment that requires electrical hook-up as well as plumbing.

• SciCan shall not be liable for incidental, special or consequential damages caused by

any maintenance or services performed on the HYDRIM C61w G4 by a third party or for

the use of equipment or parts manufactured by a third party, including lost profits, any

commercial loss, economic loss, or loss arising from personal injury.

• All local, regional, state, and national regulations regarding the servicing of this class

of device and safety requirements must be observed.

9

Page 10

1 Introduction

When the cover and panels are removed:

• Hazardous voltages are accessible. Disconnect the power cord before removing

the cover or any panels.

• Sharp metal edges are exposed. Be careful, and wear long sleeves and gloves.

Power main

• If the cover or panels are removed, a dielectric strength test (hi-pot) must be performed

on the unit once the cover or panels are reinstalled.

Ground

• If the cover or panels are removed, a protective bonding impedance test (ground

continuity) must be performed on the unit once the cover or panels are reinstalled.

Reporting

• It is vital for SciCan to learn of any problem in the field. This information will help

SciCan solve the problem quickly and improve product reliability in new units.

Biological waste

• Waste water in the unit may contain biological contaminants; use a mechanical means

to siphon the contents. Wear disposable rubber gloves. Dispose of absorbent material

according to biological waste disposal regulations.

1.5 Tools and hardware

Tools required for servicing include:

• Needle-nose pliers

• Wrench

• Nut driver

• Hose clamp pliers

• Screwdriver Philips

• Wire stripper

• Screwdriver slot

• Spring clamp pliers

• Silicone applicator with silicone

The unit contains the following types of hardware:

• Phillips pan head self-tapping metal screws

• Phillips pan head stainless steel machine screws

• Spring clamps

• Band / Gear clamps

• Cable ties

10

Page 11

1 Introduction

1.6 Shipping instructions

The unit should be serviced on site. If it is necessary to send the unit back to the dealer,

follow these instructions:

• Run the ‘Prepare for Shipping’ cycle in the setup menu to remove most of the water

from the system before shipping the unit.

• Use the tube clipped under the front of the unit to drain any residual water from the

air gap.

• If there is standing water in the chamber, siphon or ladle as much water as possible and

use an absorbent cloth to remove the rest.

• Disconnect and remove the cleaning solution container and then drain the dosing reservoir.

• Screw in the leveling legs.

• Specify upright, heated, and insured shipping.

• Ensure unit is returned on a pallet with at least two banding straps securing the box

to the pallet. If original packaging is unavailable packaging can be ordered with

part # 01-113317S.

• Shipping outside of these conditions can affect warranty.

1.7 Installation

IMPORTANT INFORMATION

• To open the wash chamber door if the door is locked and the unit is not functional,

release the lever located on the top edge of the door and pull the door open.

• Ensure that HIP™ Ultra cleaning solution (instrument wash chemical) is available.

All other supplies are included with your unit.

• The HYDRIM C61w G4 is heavy (44 kg). Exercise caution when moving it.

• The HYDRIM C61w G4 must be properly grounded.

• The HYDRIM C61w G4 is equipped with an air gap / anti-suction device to prevent

backflow of dirty water into the water supply. No other air gap device is necessary.

Detailed installation instructions are available in a separate document. Installation should

only be undertaken by a manufacturer approved technician. The use of an unapproved

installer may invalidate the warranty. A separate pre-installation checklist should have been

supplied to the user by the dealer. Please review this prior to approving installation.

If the HYDRIM C61w G4 is installed in a sterilization center, the manufacturer of the

sterilization center should allow enough space at the top, back and both sides of

the unit to facilitate installation, leveling, and service access to the unit.

During installation, all consumables should have been added to the machine as appropriate.

It is important to check that this has been undertaken before starting the machine.

11

Page 12

1 Introduction

1.8 Setting the water softener

The HYDRIM C61w G4 is equipped with

a built-in water softening system that must

be adjusted according to the local water

hardness. To read local water hardness,

proceed as follows:

1. The water test kit included with your

HYDRIM contains three water

hardness test strips in bags. Take a

water sample from the location where

the machine will be installed.

2. Open one of the bags, remove the

test strip and dip it into the water.

3. Compare the color of the strip with

the chart on the back of the bag

Determine the water hardness according

to the chart on the water test kit envelope.

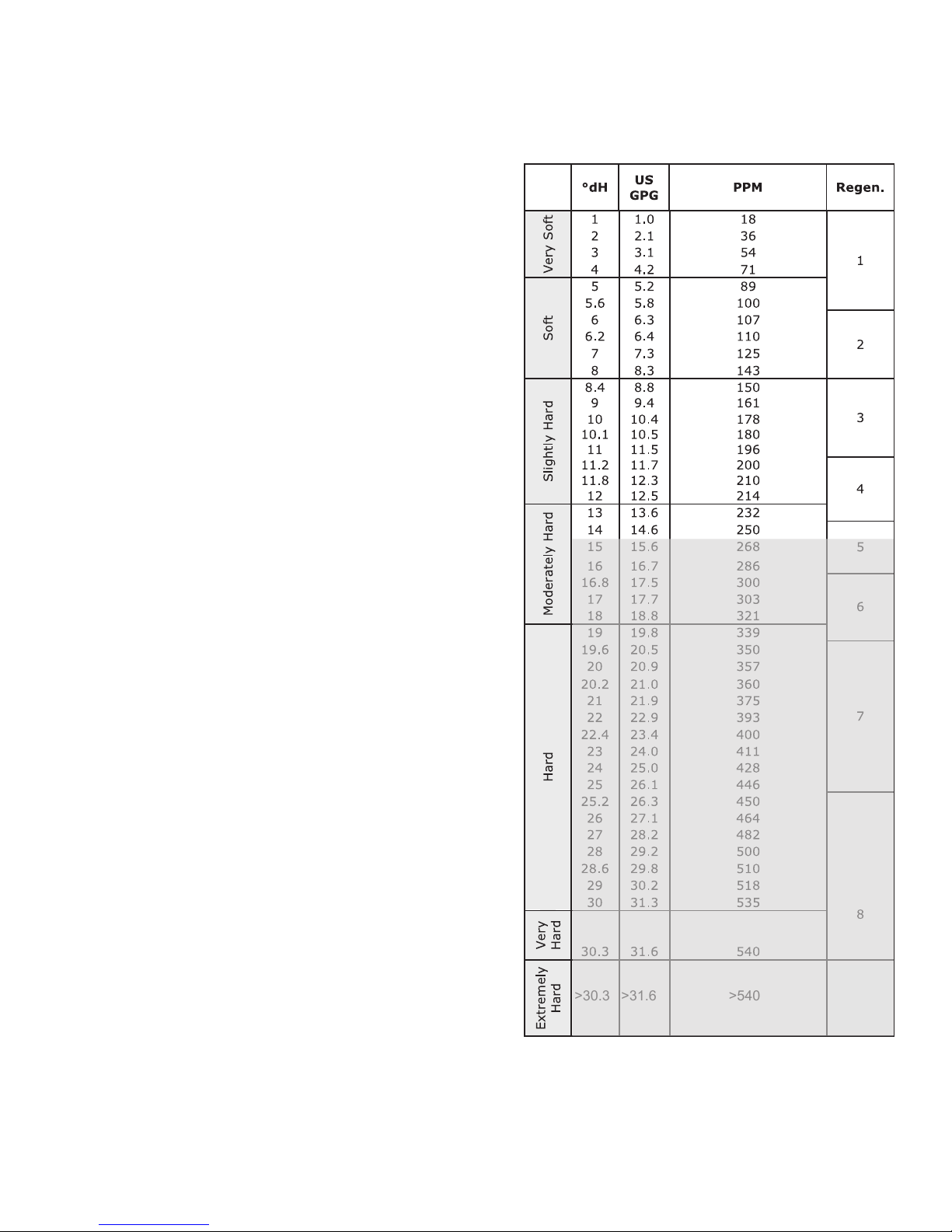

Water hardness and salt regeneration levels

*

4. Power the unit on and select the

Settings key from the main menu.

5. Go to the Setup Menu, Cycle Settings,

and select “Set Regeneration”.

7. Using the up and down arrows, set the

water softener regeneration level

according to the water hardness table

in this section. If your water hardness

falls between two settings, select the

higher setting.

8. Unscrew the water softener container

lid from the bottom left of the chamber

and pour 0.5 litres of water into the

water softener container.

9. Add 0.5 kg of water softening salt to

the water softener container, using

>30.3 >31.6

>540

the supplied funnel to prevent any salt

from spilling into the chamber, and close

by screwing the lid tightly back into place. An improper seal can lead to corrosion.

Additional

Water

Water

treatment

treatment

required

required

*Please note: The water test strip is only accurate up to 250 ppm. If the reading on the test strip exceeds

250 ppm and/or if the location in which the HYDRIM is installed has known water quality problems, having

a more detailed and accurate water test done by a test lab is strongly recommended.

12

Page 13

1 Introduction

IMPORTANT: The HYDRIM’s water softening system reduces the water hardness by

taking out Calcium Carbonate. If the water testing results show that the water hardness

is outside the unit's range of adjustment, or if other dissolved solids in the water cause

stains or deposits on the instruments or chamber, an external water treatment system may

be required.

1.9 Setting the language

The messages displayed by your HYDRIM can be presented in a number of different

languages. To change the current language, follow these steps:

1.

2. Scroll to

Language Selection

and select.

3. From the LANGUAGE screen, press to scroll through the list of languages.

When you have found the desired language, press to save your selection and return

to the Setup menu.

1.10 Setting the country

1.

2. Scroll to

3. Using the keypad, type the name of the country and press

to save and return to the Setup menu.

Country

and select.

EN

to select. Press

1.11 Setting the time

1.

2. Scroll to

Date/Time

and select Time Setup.

3. From the TIME screen, use the keypad to set the time. Press

to return to the Setup menu.

13

EN

to save and

Page 14

1 Introduction

NOTE: If the HYDRIM is connected to a network, it is important to also enter the correct

Time Zone. Enter the Time submenu, select Time Zone and scroll and select your local

time zone.

4. To change your unit to display 12-hour time format (24-hour time format is the default

setting), go to the Setup menu and use to scroll to TIME 12/24, select it and

toggle to 12. Press to save and return to the Setup menu.

5. To activate daylight savings time (DST), go to the Setup menu and use

to DST ON/OFF and select. Use

to save and return to the Setup menu.

to toggle DST ON or OFF and press the

to scroll

1.12 Setting the date

1.

2. Scroll to

3. From the DATE screen, use the keypad to set the date. Press

to return to the Setup menu.

Date/Time

and select Date Setup.

EN

to save and

4. To change the format in which the date appears, return to the Setup menu and use

to scroll to DATE FORMAT. Select it, and follow the prompts to have

the date displayed in the desired format. Press to save and return to

the Setup menu.

1.13 Assigning unit identifier number

1.

2. Scroll to

Unit No

and select.

3. Using the keypad, select a maximum of 3 digits to be used as the unit’s identifier

number. Press EN to save and to return to the Setup menu.

1.14 Resetting the drying counter

The drying counter must be reset when the HEPA filter is changed. User will be prompted

every 750 cycles to do preventative maintenance, which is triggered by the reminder to

change the HEPA filter. To reset the drying counter, follow these steps:

1.

2. Scroll to

3. Select Default 0 to reset. This will stop the reminder to the end user.

Reset Drying Counter

and select.

14

Page 15

1 Introduction

1.15 Adjusting the screensaver delay

To change the length of time before the screensaver is activated, follow these steps:

1.

2. Scroll to

Screensaver

and select.

3. Use to scroll through your time options. When you have found the amount of

time you require, press it. Press to save and return to the Setup menu.

1.16 Adjusting the temperature display

1.

2. Scroll to

Temperature C/F

and select.

3. Use to choose between having information displayed in degrees Celsius or

Fahrenheit. Press to save and return to the Setup menu.

1.17 Turning the button sound ON or OFF

The HYDRIM is preset to beep when a button is pressed. If you would like to turn the button

sound off, follow these steps:

NOTE: Turning OFF the button sound does NOT turn off other alarms and cycle notification

beeps.

1.

2. Scroll to

Beep ON/OFF

and select.

3. Use to scroll through your ON or OFF options and select it by pressing it.

Press to save and move back to the Setup menu.

1.18 Adjusting the button beep volume

If you would like to adjust the beep volume, follow these steps:

1.

2. Scroll to

3. Use to scroll through the volume settings. Select the one you want by

pressing it. Press to save and move back to the Setup menu.

Beep Volume

and select.

15

Page 16

1 Introduction

1.19 Adjusting the salt regeneration

Salt regeneration should be set according to the local water hardness. See section 1.8

Setting the water softener for instructions on determining correct settings. To set salt

regeneration, follow these steps:

1.

2. Scroll to

Set Regeneration

and select.

3. Use to change the value. The default setting is 1. Press to save and return

to the Setup menu.

1.20 Adjusting the screen contrast

The touchscreen is calibrated for the lighting condition of most sterilization centers. Should

you need to adjust the contrast for your office, follow these steps:

1.

2. Scroll to

LCD Contrast

and select.

3. Use to scroll through your contrast options. When you have found the contrast

you require, press it. Press to save and return to the Setup menu.

1.21 Changing the touchscreen display themes

The touchscreen themes (i.e. icons and background colours) can be changed to one of the

preset options. To change themes follow these steps:

1.

2. Scroll to

3. In the

As you scroll, each theme will display on the touchscreen. Press to select your

theme and return to the Setup menu.

Theme

Change Theme

and select.

screen, use to scroll through your available options.

16

Page 17

1 Introduction

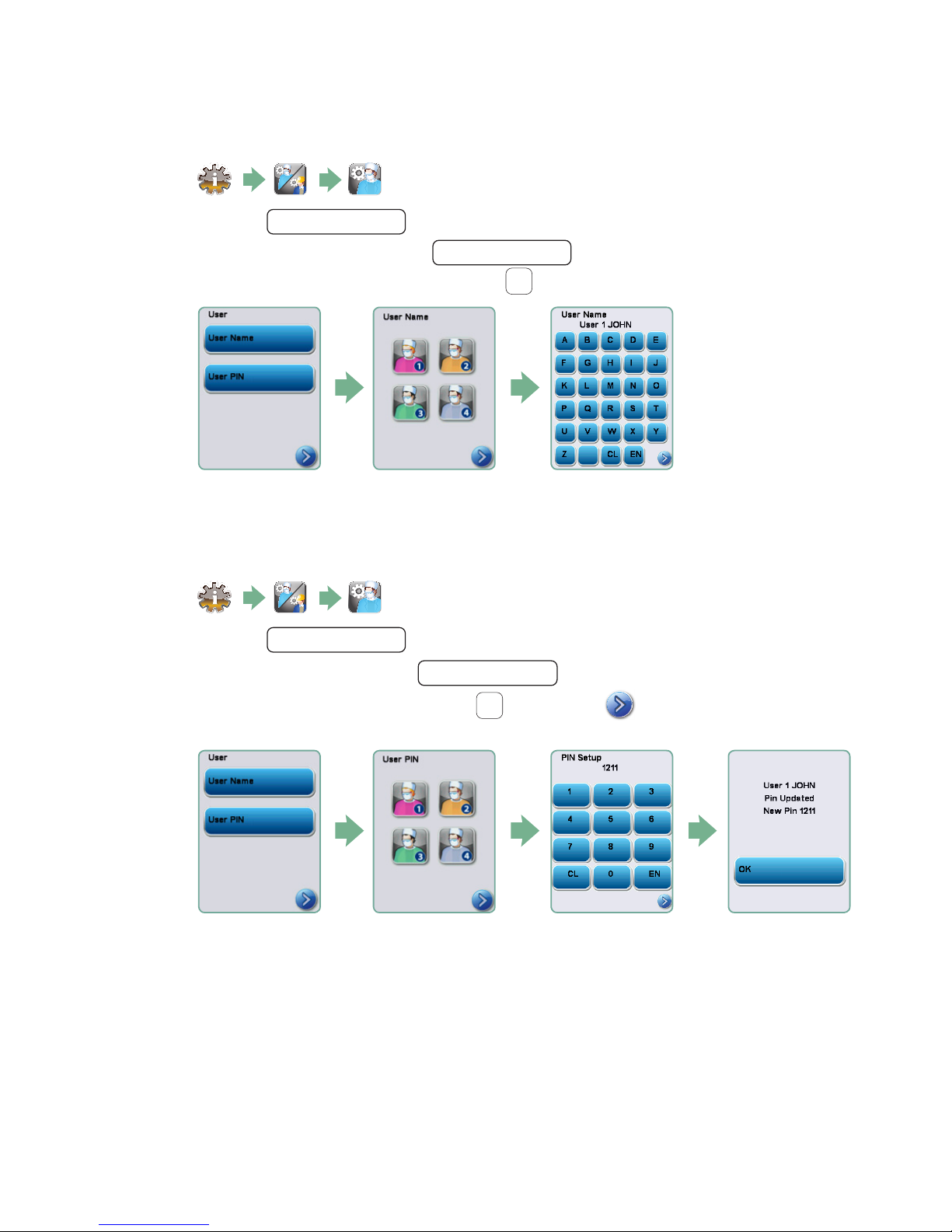

1.22 Creating a User Name

Up to four unique User Names can be created. To assign a User Name follow these steps:

1.

2. Scroll to

3. To assign a user name, select

a name (up to 12 characters) and press EN to save.

User

and select.

User Name

and use the alphabetic keypad to enter

1.23 Creating a User PIN

From the User PIN screen, you can assign up to four PINs. To assign a PIN, follow these

steps:

1.

2. Scroll to

User

and select.

3. To assign a user PIN, select

a number (up to 4 digits) and select EN to save and to move to the confirmation

screen.

User PIN

and use the numeric keypad to enter

5. If all of the information presented in the confirmation screen is correct, press OK

to be returned to the User PIN screen. To make a correction, select the User PIN you

want to change and repeat the process described above.

17

Page 18

1 Introduction

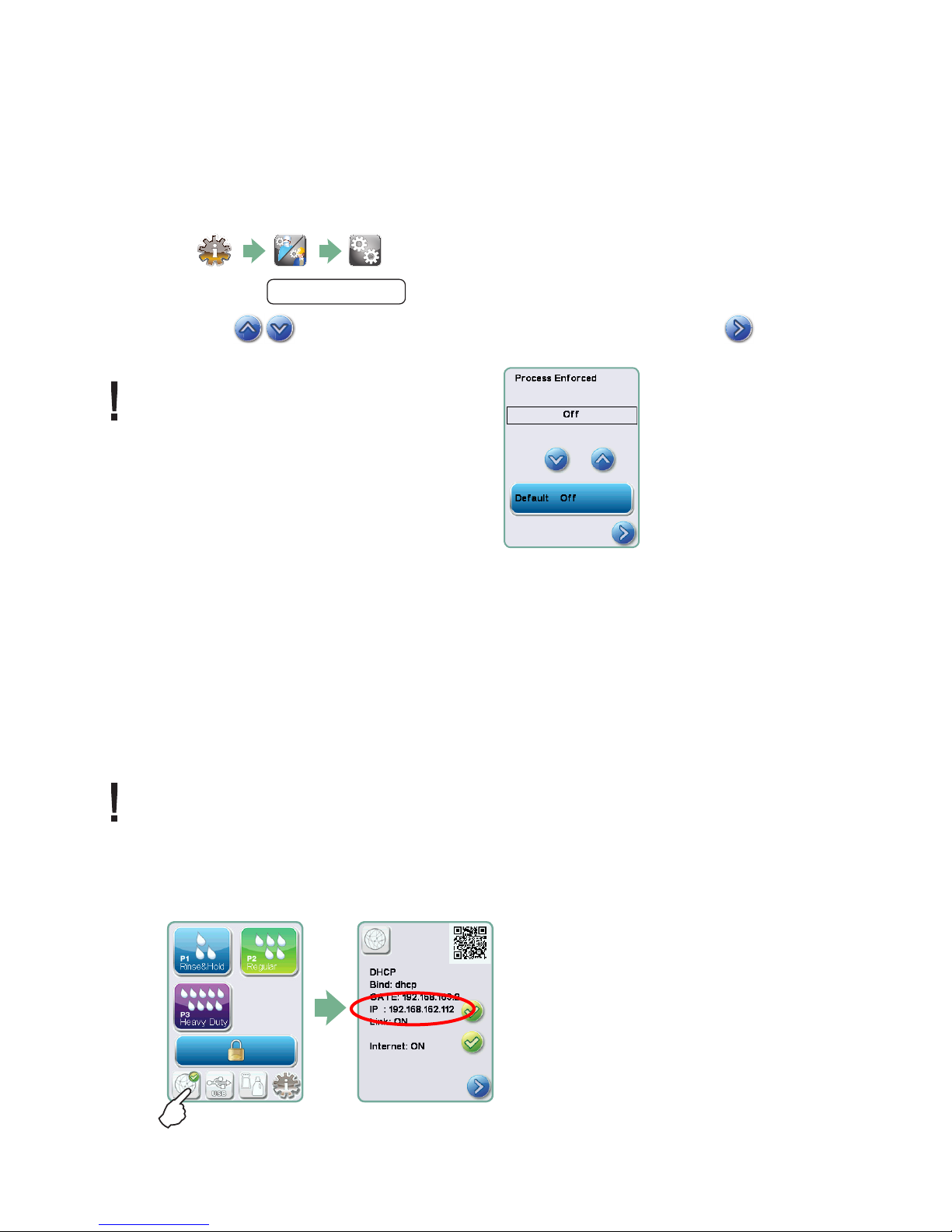

1.24 Setting up process enforced usage

When process enforced usage is activated, users are required to enter a PIN at the end of

a cycle. For process enforced usage to function, User IDs and PINs must first be assigned.

To set up User ID and PINs, refer to sections 1.22 and 1.23 on creating a user name and

PIN. To activate process enforced usage, follow these steps:

1.

2. Scroll to

Process Enforced

and select.

3. Use to toggle process enforced function ON or OFF. Press

to save your selection and return to the Setup menu.

NOTE: Any user can stop a cycle even

with process enforced usage ON.

However, the cycle data will record

that an unauthorized user

has stopped the cycle.

1.25 Connecting to a network

The HYDRIM C61w G4 has a 10/100Base-T Ethernet port located at the back of the unit.

To connect your HYDRIM to a network using a router, follow these steps:

1. Connect your network cable to the Ethernet port at the back of the unit. If your office

uses a router, the router should automatically assign the unit an IP address. A red X on the

network icon means the unit is not connected. A yellow check mark means the unit has

an IP address but is not connected to the Internet and cannot send emails. A green check

mark means the Internet connection is set up properly and the unit can send out emails.

NOTE: In some circumstances, where you do not have a router, for example when using

Windows Network Sharing, you may have to assign a dedicated or ‘static’ IP address.

To assign a static IP address, contact your local network administrator.

2. From the main screen, press the Network icon. The Network screen displays information

about your HYDRIM’s connectivity, including its IP address.

18

Page 19

1 Introduction

3. Type the IP address displayed on the touchscreen into the browser of any web enabled

device to access your unit’s web portal. When the Network icon is active (for example when

sending email) it will turn green.

NOTE: Use QR code if connecting to a mobile device.

NOTE: Connection time will vary depending on your network speed, and making an initial

connection can take longer.

1.26 Connecting to a wireless network

The HYDRIM can be configured for wireless use by connecting the Ethernet port to an

external wireless bridge / access point. SciCan currently recommends the use of the

D-Link® DAP-1522 Xtreme N® Duo Wireless Bridge. Contact your network administrator

to learn more about setting up a wireless bridge.

19

Page 20

2 Routine Procedures and Maintenance

2 3 4 5 6 7

3 4 5 6 7

4 5 6 7

www.scican.com

Lot number:

L0T334.11.2012

Product: CS-HIPC-U

8X 750ML /

25.4 U.S. fl. oz.

7

5 6 7

6 7

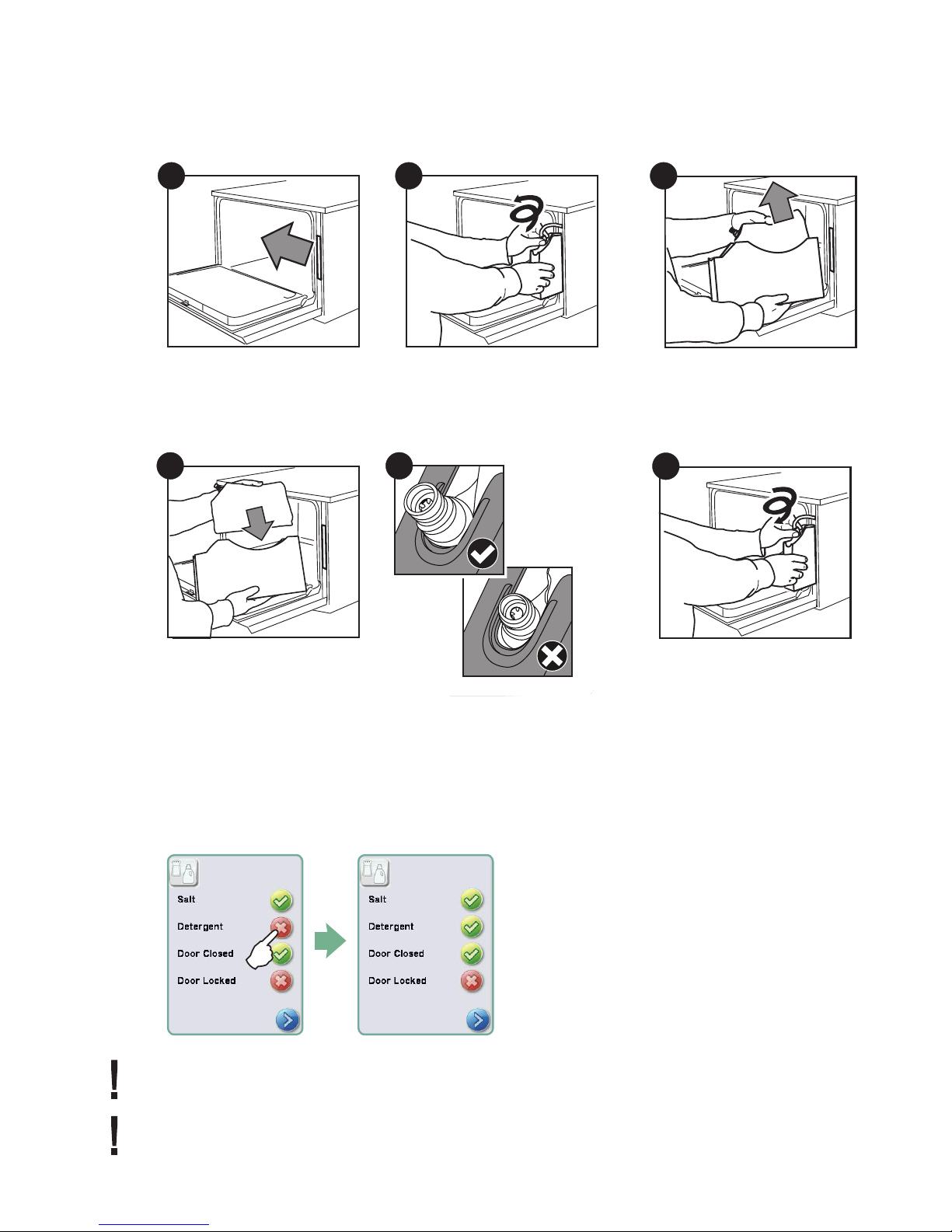

2.1 Replacing the HIP™ Ultra cleaning solution

To replace the cleaning solution, follow these steps:

1

2

3

Turn the power OFF,

open the door and pull out

the chemical drawer.

4

Place a new bag

in the chemical drawer.

To prime the cleaning solution dosing pump, press the water softener/detergent icon on the

main screen. In the water softener/detergent screen, press the red X next to “Detergent”.

The unit will prime the dosing system and a green check mark will appear in place of the

red X when it is ready for use.

Disconnect the cleaning

solution connector.

5

Ensure the nozzle is

in the correct position.

Remove the empty cleaning

solution bag and discard

or recycle it.

6

Connect the new bag,

close the door and

power ON the unit.

NOTE: The system can also be primed by simply starting a cycle and selecting “Detergent

Replaced”, when prompted.

NOTE: A cycle will not start with the red X next to the “Detergent” indicator.

20

Page 21

2 Routine Procedures and Maintenance

2.2 Changing the HEPA filter

When the message “Replace air filter”

appears, the HEPA filter is in need of

changing. To change the filter, proceed as

follows:

1. Open the kickplate below the front door

of the unit and turn the power off.

2. Remove the old filter by pulling it from

the centre.

3. Install the new air filter and close the

Figure 5

HEPA filter

kickplate.

4. After replacing the filter, go to the

“Reset Drying Counter” screen in the

Setup menu and reset the drying counter

to zero.

5. The filter must be replaced every 750

2.3 Filter and wash arm maintenance

Cleaning the chamber’s coarse

and fine filters

Inspect the coarse and fine filters in the

bottom of the chamber daily for debris and

clean if necessary. To clean, remove the

filter (turn the metal nut at the centre front of

the filter to release it), rinse under a tap and

reassemble. Ensure that the filter is firmly

locked into position when replaced.

drying cycles. The unit will continue to

run if the filter is not replaced, but the

drying performance will decrease. (Part

number 01-113277S Filter-Air, C61)

Figure 6

21

Page 22

2 Routine Procedures and Maintenance

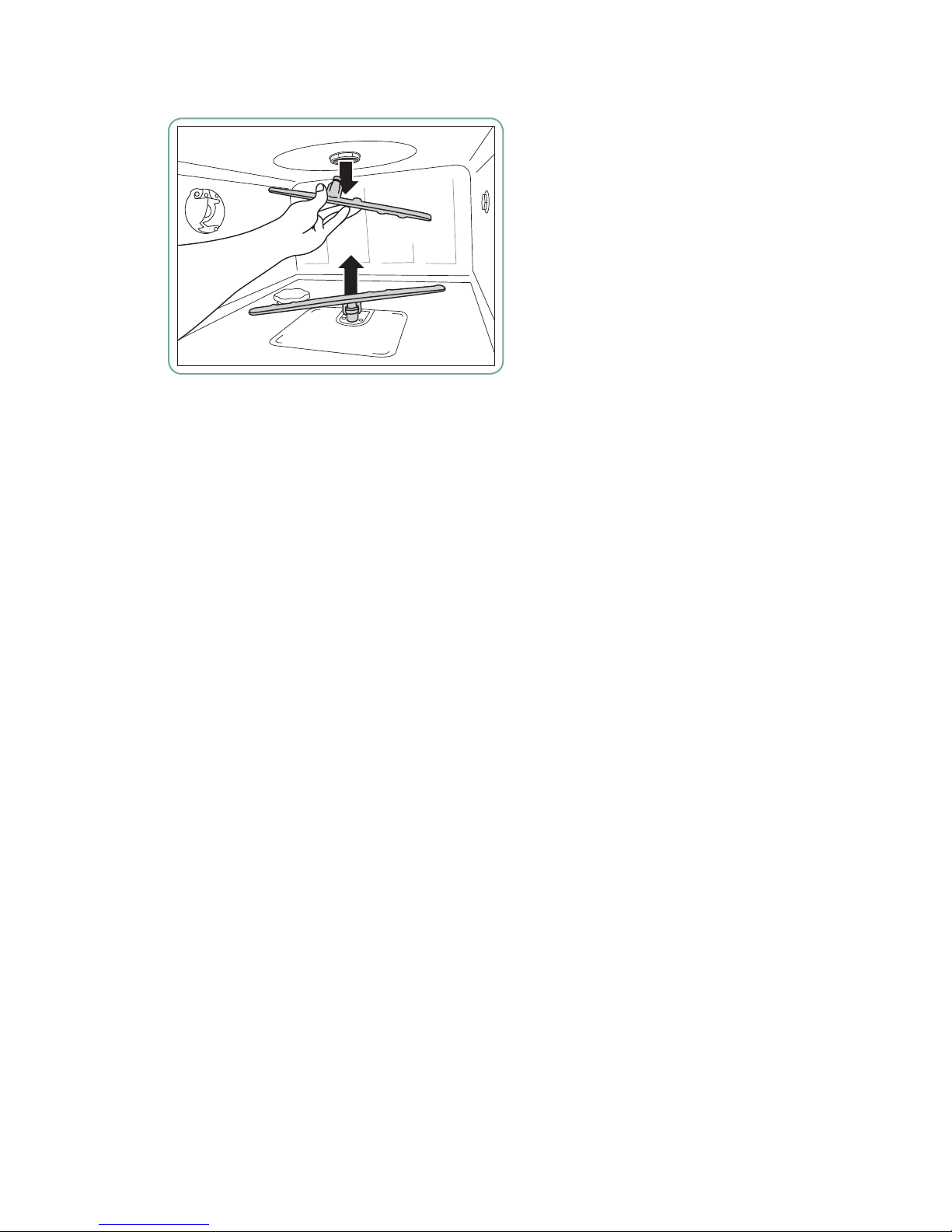

Removing and checking the wash arms

If you see that the wash arms are not

turning easily, remove them. Both the upper

and lower arms are pressure mounted.

To remove the upper arm, pull down and to

remove the lower arm, pull up. Rinse under

a tap, clear obstructions from outlet holes

and reassemble.

Figure 7

2.4 Cleaning the chamber

The HYDRIM C61w G4 chamber can be cleaned using the “Cleaning” program in the User

menu. This cycle is used to periodically remove hardwater deposits from the chamber walls

and racks. Pour 0.5 litres of vinegar into the chamber before starting the cycle. From the

User menu, select “Cleaning” and a cleaning cycle, similar to a normal wash cycle, will run.

The user will be prompted to clean the chamber every 25 cycles. Reminder frequency can

be changed to 25, 50, or 100 cycles. To do this, enter the Technician menu.

2.5 Draining the unit for service or shipping

To drain the unit prior to shipping, or before tipping it onto its back for servicing, run the

“Prepare for Shipping” cycle. Once complete, drain any water remaining in the air gap using

the silicone tube located under the centre of the unit’s kickplate.

2.6 Upgrading the firmware

Instructional videos are availabel on http://updates.scican.com

Upgrading the Interface Software can be done from a USB drive, a MicroSD card or

a web site. The easiest and fastest method is to use a USB drive.

To upgrade the firmware using a USB drive, proceed as follows:

1. Download new firmware. The firmware will be made available on updates.scican.com or

emailed from SciCan upon request. It will be packed into a zip file (e.g. SL00R1XX.zip is

the name of the current revision file, but the number will change with every revision) and

must be extracted to a USB drive.

2. Check that you have the following files on the USB Drive:

• rmware.ini

• Firmware(Folder)

• SL00R100_4_100_CAA29608.sci

• cp.bat

22

Page 23

2 Routine Procedures and Maintenance

3. With the unit powered OFF, insert the USB drive loaded with the firmware update.

4. Power ON the unit. The firmware will be updated automatically using the USB drive.

This should take approximately 6 minutes.

NOTE: The USB icon on the LCD touchscreen will flash green while it is active. Do not

remove the USB key while it is active.

5. When it is complete, the “Firmware.log” file on the USB drive will include the result of

the upgrade (file name, upgrade OK, or upgrade failed, and for what reason).

6. Whether the upgrade is successful or unsuccessful, the “firmware.ini” file on the

USB drive will be automatically deleted.

7. To retry or upgrade another unit, insert the USB drive into the PC’s USB port (NOTE

there is currently no Mac version) and double-click the “cp.bat” file in the Firmware

folder. Then remove the USB drive and repeat Steps 2 to 5.

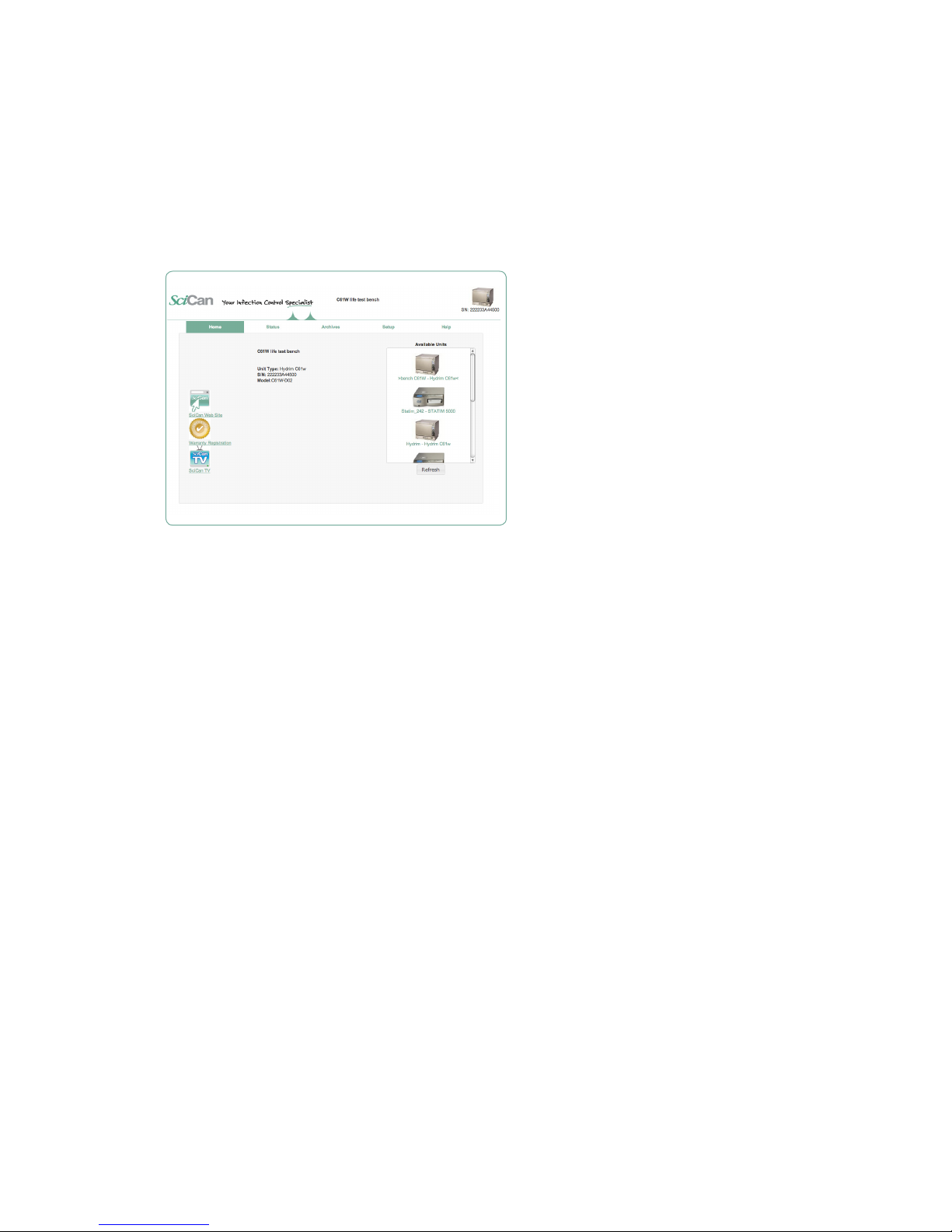

2.7 Using the HYDRIM remote access function

Users can allow offsite technicians to remotely access the LCD touchscreens and web

portals of HYDRIM C61w units connected to a network. This can be done either from within

a network or from outside a network.

From within a network:

For local network remote access, the unit must be connected to a network. See Connecting

to a network in section 1.26 of this manual for more details. From the unit’s web portal,

proceed as follows:

From the TOOLS page, click on the LOCAL CONTROL tab.

Log in using the following credentials:

Username: scican

Password: s23can173

Click on the start button to start a local connection. It will open up a page that mirrors the

HYDRIM unit’s touchscreen so that it can be controlled remotely within a local network.

From outside a local network:

For remote access of a HYDRIM web portal or touchscreen from outside a local network,

proceed as follows:

1. Someone onsite with the unit or from within the network must provide access to an

outside user by generating a ‘token’ (or access code).

23

Page 24

2 Routine Procedures and Maintenance

2. To generate a unique token using the web portal, go to the TOOLS page and click on

the REMOTE ACCESS tab.

3. To generate a unique token using the unit’s LCD touchscreen, go to the SETUP menu

and scroll to REMOTE ACCESS and follow the prompts to enable remote access.

4. The technician attempting to access the unit from outside the network will need to go to

the following URL: http://updates.scican.com and enter their registered email address,

password, token and HYDRIM Serial Number (optional).

5. To create a new account to enable remote access for a HYDRIM , click on the CREATE

NEW ACCOUNT link, complete the form, and click on the SUBMIT FORM link. The

system will send a confirmation email to verify the account. Once confirmed, the

account will be ready to use.

6. Use the valid user name and password to enter Updates.scican.com and enter the

token when prompted. This will bring you to the HYDRIM unit’s web portal page.

7. Click on SETUP. A username and password prompt will appear. Log in using the

following credentials:

• Username:scican

• Password:s23can173

8. Upon authentication, go to TOOLS and click on REMOTE ACCESS. Click on the start

button to start a connection. It will open up a page that mirrors the HYDRIM unit’s

touchscreen so that it can be controlled remotely from outside its local network.

Use your mouse to click and select touchscreen elements.

2.8 Annual Service Requirements

The HYDRIM C61w G4 is designed to be maintenance free; however, it is recommended

that a SciCan-approved service technician perform an annual check.

The following checks are recommended in order to maintain optimum performance of

the unit.

Annual service schedule

• Checkintegrityofincomingandoutgoingservices(power,watersupply,drain)

• Checkwatersupplyinlineltersandcleanasappropriate

• Checkgeneralconditionofmachine

• Replacedryerlterandresetdryercounter(onlyifrequired)

• Inspectandreplacemainchamberseal(onlyifrequired)

• Inspectandreplacelowerdoorseal(onlyifrequired)

• Checksolutioncontainerconnectionforleaks

• Checksaltlevelandreplenishasrequired

• Checkwaterhardness(teststrips)andadjustsaltregenerationsettingsifrequired.

24

Page 25

2 Routine Procedures and Maintenance

• Inspectandcleansumplters(checksumpfordebris)

• Checkwasharmsforblockagesandremovethemforcleaningifrequired.

• Reviewerrorhistory

• Softwareupgrade(ifnecessary)

• Checkindividualcomponentfunctionality.Gotothetechnicianmenu(enteraccess

code 7919) and select ‘Diagnostic Tools’ then select ‘Component Tests’. From here

you can scroll through and check the functionality of the following components:

• Coolingfans

• Airgappump

• ROvalve(iftted)

• Condenservalve(iftted)

• Chamberheater

• Doorlatch

• Saltregenerationvalve

• Dosingpump

• Dryer

• Hotwatervalve

• Coldwatervalve

• Airsolenoidvalve(iftted)

• Wastepump

• Recirculationpump

• Checkprogramselection

• Checkdosingpumpvolume;dosingpumpispre-calibrated.Volumecannot

• be adjusted.

• Checkthermocouplecalibrationandadjustifrequired.

• Resetservicecyclecounter

• Cleanmachine

• Conductelectricalsafetytests

Equipment and parts requirements for annual service

• Dryerlter(HEPA)(Partnumber01-113277S)

• Mainchamberseal(Partnumber01-113300S)

• Lowerdoorseal(Partnumber01-113661S)

• ServiceManual(Partnumber95-113023)

• Electricalsafetytestequipment

• Waterhardnessteststrips(Partnumber01-108305S)

• Calibratedindependenttemperaturemeasuringdevice

• 100mlgraduatedmeasuringcylinder

25

Page 26

3 Diagnostics and Troubleshooting

3.1 Using the service menu

To access the service menu, select the image of the technician and enter

the service code 7919 on the keypad.

User Technician Setup

Wash Test

Diagnostic Tools

Error History

View IO Status

Component Tests

Set Debug Screen

Set Calibration

Cycle Settings

Set Regeneration

Chemical Setup

Cycle Selection

Prewash

Wash

Rinse

Set Drying Time

RO Selection

Set RO water level

Rinse continuous

Factory Default

Repeater Mode

Production Tools

Prod Test Cycle 1

Prod Test Cycle 2

Water Adjustment

SW Upgrade

Network Setup

Subnetmask

Router

DNS

Automatic IP (DHCP)

Renew IP

IP Address

Dealer ID

Preventative Maintenance

Set Cleaning Warning

26

Page 27

3 Diagnostics and Troubleshooting

3.2 Using the setup menu

To access functions and settings on the setup menu, proceed as follows:

User Technician Setup

Language Selection

Country

Date/Time

Unit No.

Network Setup

Reset Drying Counter

Screen Saver

Temperature C/F

Set Printer

Baud Rate

Set EOL CR/LF

Set Regeneration

LCD Contrast

Theme

Remote Screen

Instructions

Prepare for Shipping

Set Button Beep

Beep Volume

Instruction Delay

Remote Access

27

Page 28

3 Diagnostics and Troubleshooting

3.3 Using the user menu

To access functions and settings on the user menu, proceed as follows:

User Technician Setup

Cleaning

Set Drying Time

Set Wash Time

Cycle Count

Process Enforced

User

28

Page 29

3 Diagnostics and Troubleshooting

3.4 Using software tools for diagnostics

Within the service menu, there are two useful tools for troubleshooting: Debug screen

and IO status screen.

Debug Screen

The Debug screen is used when running a cycle to view the I/O status of components.

To access the debug screen, select Diagnostic Tools from the service menu and select

Set Debug Screen, then go to the main menu and select a cycle. The LCD screen will

display the following:

Hot and Cold

Chemical level

Regeneration valve

Validation

Dosing pump

Lower arm rpm

Ambient temperature

Dryer air temperature

3.4 Using software tools for diagnostics

Within the service menu, there are two useful tools for troubleshooting: Debug screen and

IO status screen.

Debug Screen

The Debug screen is used when running a cycle to view the I/O status of components.

To access the debug screen, select Diagnostic Tools from the service menu and select

Set Debug Screen, then go to the main menu and select a cycle. The LCD screen will

display the following:

Figure 8

Upper arm rpm

Air gap

Empty/Full/Over

flowing

Chamber temperature

Air gap valve

and pump

Door status

Dryer / Heater

Salt level

Condenser valve

Evacuation pump

Valves

NOTE: When a cycle is started (P1, P2, P3) the air gap is filled four times before

the circulation pump starts.

Temperature

29

Page 30

3 Diagnostics and Troubleshooting

I/O status screen

The IO status screen is used when testing components and wires for functionality

without the cycle running.

30

Page 31

3 Diagnostics and Troubleshooting

3.5 Troubleshooting cycle faults

Cycle Fault Effect Problem Possible Causes

CF 1 Water Heating

Failure

CF 2 Chamber Filling

Failure

CF 3 Chamber

Temperature Sensor

Reading Failure

CF 4 Water

Evacuation Failure

CF 7 Cycle Aborted or

Interrupted

Improper wash, cycle

aborted

Improper wash, cycle

aborted

Improper wash, cycle

aborted

Cycle interrupted

Cycle interrupted Stop button pressed or

Chamber temperature

less than a set point

after a timeout,

or a temperature

increase rate of 1ºC

per 2 minutes was

not achieved during

“Circulation and

heating” phase

Timeout on filling up

the chamber

Temperature reading

outside acceptable

range for primary or

secondary sensor

Timeout on water

evacuation from

the chamber

power failure

31

This is caused by a water

heater malfunction:

• Check water heater

wire harness for loose

contacts.

• Check for open thermal

cut-off switch due to

high temperature.

• Check that the

heater element is not

interrupted.

• Check I/O PCB water

heater relay output.

• Water supply issue

• Water valves failure

• Air gap water pump

failure

• Air gap valve failure

• Air gap Full/Empty level

switches failure

• Chamber water level

pressure switch

malfunction

• Overflow switch

malfunction triggering

evacuation pump.

This is caused by a

temperature sensor

malfunction:

• Check temperature

sensor wires for loose

contacts.

• Replace sensor with a

good one and verify if

the CF persist.

• Replace I/O PCB.

• Blocked drain tube

• Chamber water level

switch malfunction

• Chamber water

evacuation pump failure

• Drain pump priming

connection hole in the

sump blocked

• Cycle aborted due to

loss of power

Page 32

3 Diagnostics and Troubleshooting

Cycle Fault Effect Problem Possible Causes

CF 8 Cycle Fault

CF 9 Program

Timeout

CF 10 Drying System

Error

CF 13 Temperature

Validation Error

CF 14

CF 15 Chamber

Overflow

Drying aborted Air temperature less

than a set point after

a timeout

Cycle interrupted The unit is running

a cycle for more than

3h ±3 min.

Cycle interrupted Air Dryer RPM not

zero when Dryer motor

should not be activated

Cycle interrupted Water temperature rose

above the maximum

allowed temperature

Cycle interrupted During the Prewash

phase the water

temperature in the

chamber is 5ºC higher

than the target for more

than 1sec

Cycle interrupted Leak in the unit The water reservoir overflow

This is caused by a heater

malfunction:

• Check air heater wire

harness for loose

contacts.

• Check that the

heater element is not

interrupted.

• Check I/O PCB air

heater relay output.

• Defective PCB and/or

software failure

• Replace Color LCD

controller.

Electronics – motor driver

failure (I/O board)

• Check Dryer motor

wiring.

• Verify that motor stops

when in non drying

phase.

• Replace I/O board.

• Replace dryer motor.

The temperature sensor out

of range:

• Check temperature

sensor wires for loose

contacts.

• Run cycle to monitor

that the water

temperature is below

96°C.

• Replace sensor and

verify if the CF persist.

• Replace I/O PCB.

switch was triggered:

• Check the water

reservoir full switch.

32

Page 33

3 Diagnostics and Troubleshooting

Cycle Fault Effect Problem Possible Causes

CF 16 Ambient

Temperature Error

CF 17 Cycle Fault

CF 21 Dosing System

Error

CF 22

Air Temperature error

CF 23 Top RPM error

CF 24 Low RPM error

Cycle interrupted Operating temperature

for one or both logic

boards is too high

Drying Air temperature

above a set point

Dosing System failure

Cycle interrupted

Cycle cannot start or

cycle interrupted

Cycle interrupted Top RPM lower than

Cycle interrupted Low RPM lower than

Dosing system failed

to dispense the preset

amount in a predefined

time (timeout is 3.5s/

pulse). Dosing reservoir

level switch does not

change from Full ON

to OFF by the end of

dosing (no chemical

dispensed)

Ambient temperature

sensor broken

10 while washing or

disinfecting

25 while washing or

disinfecting

The room or enclosure is too

warm and not allowing the

unit to adequately cool:

Check that fans are working.

The air temperature in the air

duct is too high:

• Check dryer motor.

• Verify that the air heater

is not always ON.

• Verify air temperature

sensor.

• Verify I/O PCB.

Dosing pump or switch error:

• Verify bellows dosing

pump

• Verify bellows dosing

pump switch

Temperature sensor

reading error:

• Check air temperature

sensor wires for loose

contacts.

• Replace sensor with

a good one and verify

if the CF persist.

• Replace I/O board.

• Instrument blocking

upper wash arm

• Chamber water level

too low

• Water pump failure

• Instrument blocking

lower wash arm

• Chamber water level

too low

• Water pump failure

33

Page 34

3 Diagnostics and Troubleshooting

Cycle Fault Effect Problem Possible Causes

CF 25 Vref Error

CF 27 Memory Error

Touchscreen is blank/

white

USB storage device

does not contain

the last print out

Unit is not sending

emails

Not receiving emails

from the unit

Cycle cannot start or

cycle interrupted

Hardware failure Color LCD control

Vref and VCC drift, post

CF 25 if VCC and Vref

are more than 3% apart

(power supply error)

board failure

The power supply 5V output

voltage is fluctuating:

• Check power supply 5V

output.

• Replace I/O board.

The internal memory of

the Color LCD Controller

is malfunctioning:

• Replace Color LCD

controller board.

Check power source

Re-insert the USB storage

device and wait for the

data to copy over again. If

problem persists, back up all

the information on the USB

device and reformat it.

NOTE: the web portal allows

access to all of the unit’s

cycle information.

Check email settings by

using the TEST button on

the unit’s web portal.

From the SETUP web page,

select the TOOLS tab.

Click on TEST to check

your router, unit, and Internet

connections. If all settings

appear to be OK. Go to

the unit’s touchscreen

and renew

the IP address by following

these steps:

1. Scroll through the setup

menu to NETWORK

SETUP and select.

2. Select RENEW IP.

Check user’s spam filter.

Be certain the unit has been

identified as an accepted

email source.

34

Page 35

4. Removing and Replacing Panels

WARNINGS AND

PRECAUTIONS

If you have questions about the unit you are repairing, please do not hesitate to

contact your local SciCan representative for information. Also, the HYDRIM is

heavy. Exercise caution and seek assistance when lifting or carrying units.

EXERCISE CAUTION

• Hazardous voltages are accessible when the cover is removed.

• Disconnect the power cord before servicing the power mains portion of the

controller board and associated devices.

• Removing the panels will expose some sharp metal edges. Be careful and wear

long sleeves and gloves.

PERFORM TESTS

• If panels are removed, a dielectric strength test (Hi-Pot) AND a protective

bonding impedance test (ground continuity) must be performed on the HYDRIM

when the work is completed and after the cover has been returned to the unit.

• A dielectric strength test (hi-pot) must be performed on the unit if parts

associated with the power main are serviced or replaced.

• A protective bonding impedance test (ground continuity) must be performed

on the unit if components of the protective earthing system are changed or if

connections are broken and remade.

PROTECT THE UNIT

• The HYDRIM contains electronic circuitry that is static sensitive. Always wear

a static strap when working with or near printed wiring boards. In addition, use

static footstraps, grounding mats and grounded work surfaces when servicing

microprocessor devices. Transport boards and devices in static protected bags.

• In order to ensure adherence to the applicable safety agency approvals,

state, provincial, regional and national laws, replace components with SciCan

approved parts only.

35

Page 36

4. Removing and Replacing Panels

4.1 Removing and reinstalling the top panel

1. Open door to remove 3 screws under the top cover’s

front edge. (Figure 9)

2. Pull top cover to the front and tip up to remove.

To reinstall, place the cover on top of unit and slightly forward.

Push it to the back to engage the tabs. Replace 3 screws at

the front.

Top panel – part # 01-113286S

4.2 Removing and reinstalling the left panel

1. Remove top cover.

2. Open front door to remove 4 screws in the front. (Figure 10)

3. Remove 3 screws on back of unit. (not shown)

4. Tip the panel back and slide it down to disengage

the two tabs that insert into the chassis at bottom.

To reinstall, bring the panel into position slightly lower than

the unit to be able to engage the two bottom tabs and

the one at the top. Slide it up into place and replace 4 screws.

Replace the top cover.

Left side panel – part # 01-113288S

screws

screws

Figure 9

Figure 10

36

Page 37

4. Removing and Replacing Panels

4.3 Removing and reinstalling the right panel

1. Open the door to remove 3 screws in the front. (Figure 11)

2. Remove 3 screws at the back of the unit. (not shown)

3. There are 2 tabs at the bottom of the panel. To disengage these

from the chassis, pull the panel out from the top and slide it down.

To reinstall, bring the panel into position slightly lower than the unit to be

able to engage the two bottom tabs. Slide it up into position and push it

into place at the top. Replace 3 screws at the back and 3 screws

at the front.

Right side panel – part # 01-113290S

screws

4.4 Removing and reinstalling the back panel

1. Remove 8 screws to release the panel.

(Figure 12)

To reinstall, reverse procedure.

Back panel – part # 01-113297S

screws

Figure 11

Figure 12

screws

37

Page 38

4. Removing and Replacing Panels

4.5 Removing and reinstalling the bottom panel

1. With the unit still hooked up, start by disconnecting

the cap from the chemical detergent pouch and

then running a shipping cycle from the set-up menu.

This will drain most of the water and detergent from

the unit.

2. If you cannot run a shipping cycle because the unit is

without power, pull the drainage tube out from under

the middle of the kickplate and allow it to drain into

a waste bottle. (Without power, you may have to

manually unlock the door using the door latch.)

3. Remove the coarse filter and sump filter and use

an absorbent cloth to sop up residual water from

the sump.

4. After draining the unit, turn it off, disconnect the

power and disconnect all water connections.

5. Slide an absorbent cloth under the unit to catch

any remaining water.

6. Using the two handleholds located at the front

under the kickplate, (Figure 13a) pull the unit towards

you and tip it onto its back.

7. On the bottom panel there are 2 small rubber

standoffs connecting the dryer inlet duct to

the bottom panel. Push these through their holes

to detach them from the panel. (Figure 13b)

8. Remove 6 screws and slide the panel up to release

the tabs from the chassis. (Figure 13c)

handleholds

Figure 13a

To reinstall, slide the panel back into position, replace

the screws and pull the rubber standoffs back through

the panel. (NOTE: if the rubber standoffs are not pulled

through the panel, the dryer inlet duct will not

function correctly.)

Bottom panel – part # 01-113296S

rubber standoffs

screws

Figure 13b

Figure 13c

38

Page 39

5. Front Components

WARNINGS AND

PRECAUTIONS

If you have questions about the unit you are repairing, please do not hesitate to

contact your local SciCan representative for information. Also, the HYDRIM is

heavy. Exercise caution and seek assistance when lifting or carrying units.

EXERCISE CAUTION

• Hazardous voltages are accessible when the cover is removed.

• Disconnect the power cord before servicing the power mains portion of the

controller board and associated devices.

• Removing the panels will expose some sharp metal edges. Be careful and wear

long sleeves and gloves.

PERFORM TESTS

• If panels are removed, a dielectric strength test (Hi-Pot) AND a protective

bonding impedance test (ground continuity) must be performed on the HYDRIM

when the work is completed and after the cover has been returned to the unit.

• A dielectric strength test (hi-pot) must be performed on the unit if parts

associated with the power main are serviced or replaced.

• A protective bonding impedance test (ground continuity) must be performed

on the unit if components of the protective earthing system are changed or if

connections are broken and remade.

PROTECT THE UNIT

• The HYDRIM contains electronic circuitry that is static sensitive. Always wear

a static strap when working with or near printed wiring boards. In addition, use

static footstraps, grounding mats and grounded work surfaces when servicing

microprocessor devices. Transport boards and devices in static protected bags.

• In order to ensure adherence to the applicable safety agency approvals,

state, provincial, regional and national laws, replace components with SciCan

approved parts only.

39

Page 40

5. Front Components

5.1 Removing and reinstalling the kickplate

CAUTION: cover sharp edges on the filter cutout with tape

to protect hands.

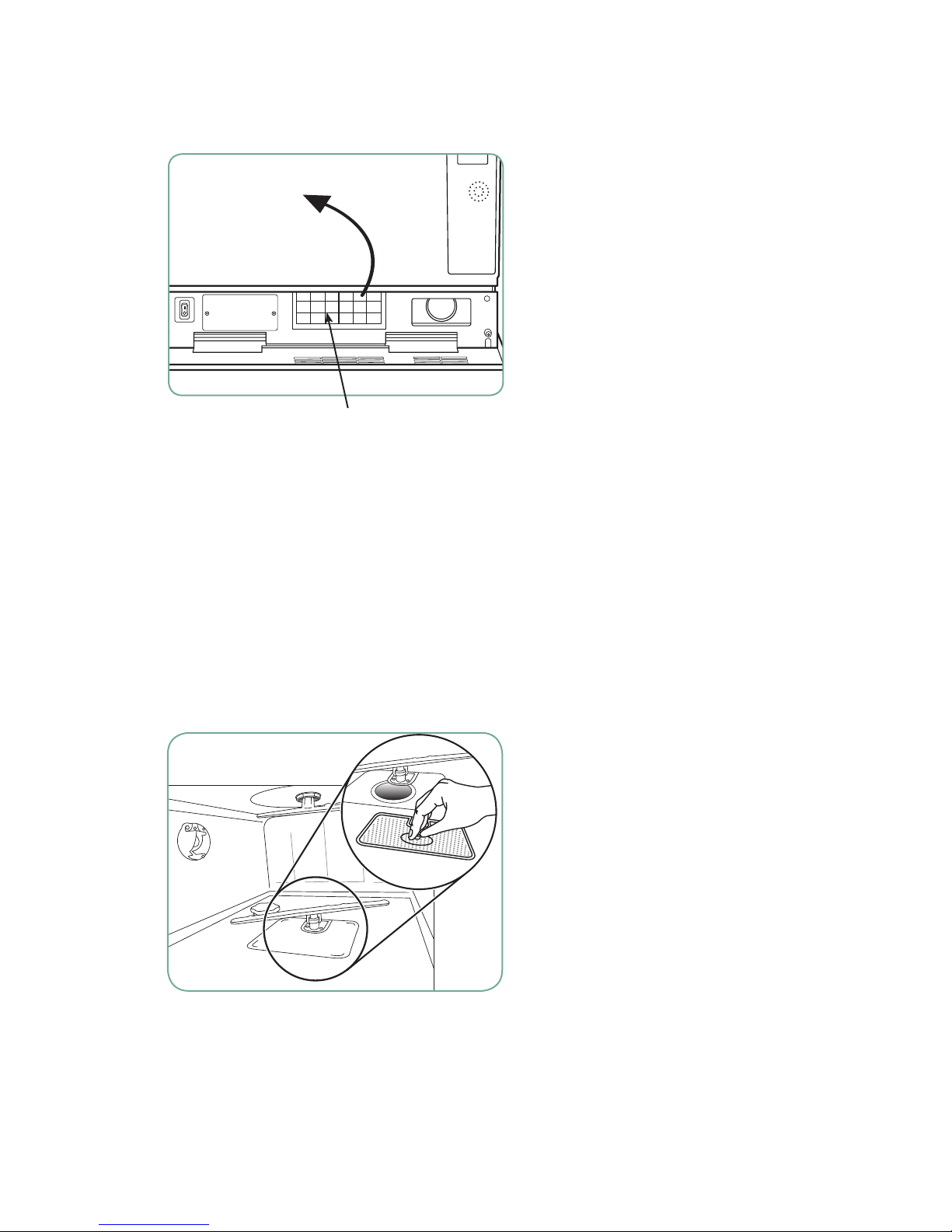

1. Open kickplate and remove HEPA filter. (Figure 14a)

2. Detach the dryer inlet duct by pulling off the HEPA filter

gasket and pulling the dryer inlet duct out of the groove

so that you can push it free of the kickplate. (Figure 14b,

14c)

3. Unscrew the 2 magnets by hand and remove

the 2 screws.

4. Unclip the plastic edge guard at the bottom right of

the door and pull the wire harness free of the kickplate.

5. Remove the metal panel between the power switch and

the HEPA filter to detach the microswitch wires at right.

(Figure 14a)

6. With the condenser exhaust still attached, support

the kickplate door to keep it from falling and pull

the kickplate off.

7. Detach the hose clamp on the exhaust duct hose

and pull the kickplate free.

screws HEPA

metal

panel

filter

screws

Figure 14a

To reinstall:

1. Attach the exhaust duct hose using the hose clamp.

2. Attach the HEPA filter microswitch wires and push

the kickplate into place.

3. Reattach the 2 magnets and the 2 bumpers with screws.

4. To reattach the dryer inlet duct, pull it through

the kickplate and push it back to hook its edges into

the grooves at the top and bottom of the dryer inlet duct

cutout and over the tabs at the left and right of the cutout.

NOTE: Be certain the gasket is properly positioned in the

dryer inlet duct or replace with a new gasket.

Kickplate – part # 01-113292S

Filter gasket – part # 01-113262S

gasketmicroswitch wires

Figure 14b

Figure 14c

40

Page 41

5. Front Components

5.2 Removing and reinstalling the power switch

1. Remove top cover and left panel.

2. Remove two contacts from the back of the

power switch using needle nose pliers.

This will help to pull the power switch

through the cut out in the chassis. (Figure 15)

3. Carefully pry the switch out using a flat

head screwdriver.

4. Remove all the remaining contacts.

NOTE: Switch wire connectors can also be accessed by

removing steel plate in front of kickplate. (Figure 14a)

To reinstall:

1. Reattach contacts to power switch according to

the table below and push into cut out in chassis.

Power switch

terminal position

1 3 BLU

1A 29/30 YEL

2 4 BLU

2A 5 BLU

2. Reinstall left panel and top cover.

Rocker switch – part # 01-112024S

Corresponding

Wire

power switch contacts

Figure 15

41

Page 42

6. Door Components

WARNINGS AND

PRECAUTIONS

If you have questions about the unit you are repairing, please do not hesitate to

contact your local SciCan representative for information. Also, the HYDRIM is

heavy. Exercise caution and seek assistance when lifting or carrying units.

EXERCISE CAUTION

• Hazardous voltages are accessible when the cover is removed.

• Disconnect the power cord before servicing the power mains portion of the

controller board and associated devices.

• Removing the panels will expose some sharp metal edges. Be careful and wear

long sleeves and gloves.

PERFORM TESTS

• If panels are removed, a dielectric strength test (Hi-Pot) AND a protective

bonding impedance test (ground continuity) must be performed on the HYDRIM

when the work is completed and after the cover has been returned to the unit.

• A dielectric strength test (hi-pot) must be performed on the unit if parts

associated with the power main are serviced or replaced.

• A protective bonding impedance test (ground continuity) must be performed

on the unit if components of the protective earthing system are changed or if

connections are broken and remade.

PROTECT THE UNIT

• The HYDRIM contains electronic circuitry that is static sensitive. Always wear

a static strap when working with or near printed wiring boards. In addition, use

static footstraps, grounding mats and grounded work surfaces when servicing

microprocessor devices. Transport boards and devices in static protected bags.

• In order to ensure adherence to the applicable safety agency approvals,

state, provincial, regional and national laws, replace components with SciCan

approved parts only.

42

Page 43

6. Door Components

6.1 Removing and reinstalling the door fascia

1. Open door and remove 3 screws on right side of door,

2 on inside left and 2 on the inside top. (Figure 16a)

2. Slide the door fascia up just enough to disengage it.

CAUTION: the LCD and controller are attached to

the door fascia.

3. Pull it up and out from the top and rest it on the

worksurface in front of the unit to access the

LCD bracket.

4. Unscrew the two nuts fastening the LCD bracket to

the door fascia and lift the bracket out. (Figure 16b)

nuts

5. Hook the LCD bracket into its service position on

the door (hooks into two slots and one spring lock

at right on door). (Figure 16c, 16d)

Figure 16b

Figure 16c

slots

spring lock

screws

Figure 16a

Figure 16d

To reinstall:

1. Remove the LCD bracket from its service position on the door, place it into position in the door fascia

and fasten the two retaining nuts.

2. Bring the fascia into position onto the front of the door and slide it down into place.

3. Replace the 3 screws on the right side of the door, the 2 on the inside left and the 2 on the inside top.

Cover stainless door C61w part – # 01-113294S

43

Page 44

6. Door Components

6.2 Removing and reinstalling the door springs

To remove the left side door spring:

1. Remove top cover

2. Remove left panel.

3. Unhook the door spring to replace. (Figure 17a)

To reinstall, reverse procedure.

Door spring kit – part # 01-113298S

(kit has set of two springs and rope)

spring

To remove the right side door spring:

1. Remove top cover.

2. Remove left and right panel. (Left panel

must be removed to remove chamber

fascia.)

3. Remove 1 screw at rear of reservoir refill

pump bracket. (Figure 17b)

4. Remove 6 screws on chamber fascia and

remove chamber fascia. (Figure 17c)

5. Loosen 3 screws at base of chemical

bracket. (Figure 17b)

6. Slide chemical bracket to rear and tip it

back to access right door spring.

7. Unhook the door spring to replace.

(Figure 17d)

To reinstall, reverse procedure.

Figure 17a

Figure 17b

screws screw

fascia screws

Figure 17c

44

spring

Figure 17d

Page 45

6. Door Components

6.3 Removing and reinstalling the door

1. Remove door fascia. (See 6.1 Removing and

reinstalling door fascia)

2. Unhook LCD bracket from service position. (Figure 18a)

3. Remove door rebar by removing the 2 screws at left

and 3 screws at right. Then sliding left side up and

slide right side up to bring it up and out of position.

(Figure 18b)

4. Remove latch assembly (see 6.7 Removing and

reinstalling door latch assembly) but do not

disconnect wires.

5. Remove 2 screws on the left inside of door and

2 screws on right inside of door. (Figure 18c)

Pull the door out. CAUTION: Door edges are

extremely sharp.

To reinstall, push the door back into position and

fasten screws. Reattach latch assembly, door rebar,

and door fascia.

Inner door panel – part # 01-113299S

door latch assembly LCD bracket

Figure 18a

screws

screws

Figure 18b

door rebarscrews

screws

Figure 18c

45

Page 46

6. Door Components

6.4 Removing and reinstalling LCD and LCD controller

1. Remove the door fascia to access the LCD.

(See 6.1 Removing and reinstalling door fascia)

2. Remove all wire connections from the controller

board and cut cable ties affixing the wiring harness

to the LCD. (Figure 19a)

3. Remove the retaining nuts on each corner of the

board. CAUTION: Lift the board gently – it is

attached to the LCD by a ribbon cable. (Figure 19a)

4. Flip the board over to expose the ribbon cable

latch fastener. Using your fingernail, gently flip up

the latch to release the ribbon cable. (Figure 19b)

5. The LCD is affixed to the bracket and (replacement

LCD will come attached to bracket).

6. Remove the speaker and fan if replacing the LCD

so that these can be used on the replacement

LCD bracket.

retaining

nuts

speaker

To reinstall:

1. Place the controller board on a flat surface next to

the LCD/LCD bracket and connect the ribbon cable.

2. Reattach the LCD controller board using the

4 retaining nuts.

3. Reattach all the wire connections to the LCD controller

board and fasten with cable ties. (Reference Appendix A)

4. Reattach the LCD bracket to the door fascia using

the 2 retaining nuts.

5. Reinstall the door fascia.

LCD Assembly – part # 01-113311S

LCD Controller C61w – part # 01-113391S

6.5 Removing and reinstalling the LCD fan

(Figure 19a, 19b)

1. Remove the LCD bracket.

2. Remove the 2 screws affixing the fan to the bracket.

3. Remove the fan.

To reinstall, reverse procedure.

Blower – part # 01-113284S

ribbon cable

LCD fan

Figure 19a

latch

6.6 Removing and reinstalling the speaker

(Figure 19a, 19b)

1. Remove the LCD bracket.

2. Remove the 2 screws affixing the speaker to the bracket.

3. Remove the speaker.

To reinstall, reverse procedure.

Speaker assembly – part # 01-113682S

46

Figure 19b

Page 47

6. Door Components

6.7 Removing and reinstalling the door latch assembly

1. Remove the door fascia. (See 6.1 Removing and

reinstalling door fascia)

2. Remove the 3 screws on the latch assembly

(2 screws at inside top of door and 1 at right

of assembly). (Figure 20a)

3. Disconnect the wires on the latching microswitch

(wires 69, 70), the filter (wires 67, 68), and

the door latching solenoid (wires 93, 94). (Figure 20a, 20b)

4. Unstick double-sided tape to remove capacitor, if required.

To reinstall:

1. Reattach all the wires.

2. Re-stick capacitor to door

latch assembly.

3. Fasten the 2 screws at the top of

the door latch. (CAUTION: door

has sharp edges)

4. Fasten the 1 screw into bracket

at right.

5. Fasten cable ties.

Door latch – part # 01-113322S

door latching microswitch

screws screwfilter

Figure 20a

6.8 Removing and replacing

the door microswitch

1. Remove the door latch assembly.

2. Unscrew the 2 screws fastening the

door miscroswitch to the door latch

assembly and remove.

To reinstall:

1. Replace the door microswitch

and fasten with the 2 screws.

2. Reinstall the door latch assembly and door fascia.

Door latch microswitch – part # 01-113605S

door latch door latching solenoid manual door latch

6.9 Removing and replacing the door latch solenoid

1. Remove door latch assembly.

2. Remove 2 screws fixing solenoid to assembly.

3. Disconnect wiring. CAUTION: connector terminals are delicate. Hold terminals with pliers while

pulling connections.

Figure 20b

To reinstall, reverse procedure.

Door latch solenoid – part # 01-113319S

47

Page 48

6. Door Components

6.10 Removing and replacing the door seal

1. To remove the door seal, open the door, pull the old seal

out and remove all silicone residues.

(Figure 21a)

Figure 21a

To replace the door seal:

1. Use a silicone sealant to adhere the new door seal

to the chamber. Ensure the inside surface is clean

and dry and run 2 thick beads of silicone, the width

of the new seal apart, from left to right and up the

sides to the edges. (Figure 21b)

2. Put one end of the seal into place pushing it firmly

up under the door edge, then put the other end into

place. Then push the middle section into place

ensuring it does not bulge out.

3. Slowly close the door, holding the middle of the

new door seal to keep it in position. (Figure 21c, 21d)

4. Allow to dry for 12 hours before use.

Door seal – part # 01-113661S

Figure 21b

Figure 21c

48

Figure 21d

Page 49

6. Door Components

6.11 Removing and replacing the chamber seal (Figure 22)

1. Before pulling the chamber seal,

note how the bottom left and right

edges touch the bottom of

the chamber.

2. Pull the seal out from the seal recess.

To replace:

1. Place the bottom left and right ends

of the new seal into position,

ensuring that the ends touch

the chamber bottom.

2. Tuck the corners into the seal

recess and push the rest of

the seal into place.

Chamber seal – part # 01-113300S

Figure 22

49

Page 50

7. Right Side Components

WARNINGS AND

PRECAUTIONS

If you have questions about the unit you are repairing, please do not hesitate to

contact your local SciCan representative for information. Also, the HYDRIM is

heavy. Exercise caution and seek assistance when lifting or carrying units.

EXERCISE CAUTION

• Hazardous voltages are accessible when the cover is removed.

• Disconnect the power cord before servicing the power mains portion of the

controller board and associated devices.

• Removing the panels will expose some sharp metal edges. Be careful and wear

long sleeves and gloves.

PERFORM TESTS

• If panels are removed, a dielectric strength test (Hi-Pot) AND a protective

bonding impedance test (ground continuity) must be performed on the HYDRIM

when the work is completed and after the cover has been returned to the unit.

• A dielectric strength test (hi-pot) must be performed on the unit if parts

associated with the power main are serviced or replaced.

• A protective bonding impedance test (ground continuity) must be performed

on the unit if components of the protective earthing system are changed or if

connections are broken and remade.

PROTECT THE UNIT

• The HYDRIM contains electronic circuitry that is static sensitive. Always wear

a static strap when working with or near printed wiring boards. In addition, use

static footstraps, grounding mats and grounded work surfaces when servicing

microprocessor devices. Transport boards and devices in static protected bags.

• In order to ensure adherence to the applicable safety agency approvals,

state, provincial, regional and national laws, replace components with SciCan

approved parts only.

50

Page 51

7. Right Side Components

DC power

source

reservoir

filling pump

chemical

bracket

I/O board

dosing reservoir

7.1 Removing and reinstalling DC power source

1. Turn off unit and disconnect power cord.

2. Remove 7 wire contacts from

the DC power source.

3. Remove 1 screw at the front right of

the power supply bracket and loosen

1 screw at the back of the bracket.

Slide forward to remove.

To reinstall:

1. Slide the bracket back into position,

tighten rear screw and replace

screw at front right.

2. Reattach contacts according to Figure 24.

Power supply – part # 01-113266S

LN (AC)

7 31/32

COM

88

GRD

41

Figure 23

+V2

87

pressure

dosing/bellows

COM

89

switch

pump

+V1

90

51

Figure 24

Page 52

7. Right Side Components

7.2 Removing and reinstalling the reservoir filling pump (Figure 25)

1. Disconnect chemical bag and run shipping cycle

to drain dosing system.

2. Turn off unit and disconnect power cord.

3. Remove right panel.

4. Remove 2 wire connections at top of pump.

5. Cut cable ties on input and output tubing.

6. Pull pump out from between rubber mounts.

To reinstall:

1. Put pump into position between rubber mounts

and attach tubing to inlet and outlet.

2. Fasten the tubing to the pump with cable ties.

3. Reattach 2 wire connections.

4. Run device test on service menu before replacing panel.

5. Reinstall right panel.

Chemical pump – part # 01-113307S

wire

connections

cable ties

Figure 25

7.3 Removing and reinstalling the dosing/bellows pump (Figure 26a, 26b)

1. Disconnect chemical bag, run shipping cycle

to drain system, power off unit, and disconnect

power cord.

2. Remove right panel.

3. Cut the cable ties on the inlet and outlet tubes.

4. Disconnect wires 53 and 54 from microswitch.

5. Disconnect yellow wire from 22 and