Gas Hob Operating Instructions

Page 1 of 11

English

Contents

AU

Installation, 2-5

!

Positioning

!

Electrical Connection

!

Gas Connection

!

Data Plate

!

Burner & Injector Specification

!

!

Description of the Appliance, 6

!

Overall View

!

!

Start-up and Use, 7-8

!

Practical advise on using the burners

!

TGL 641

Precautions and Tips, 9

TGL 751

General Safety

!

Disposal

!

!

Maintenance and Care, 10

!

Switching the appliance off

!

Cleaning the appliance

!

Gas tap maintenance

!

!

Troubleshooting, 11

!

!

!

!

!

!

!

!

!

Gas Hob Operating Instructions

Page 2 of 11

Installation

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information for safe use, installation and

care of the appliance.

! Please keep these operating instructions for

future reference. Pass them on to possible new

owners of the appliance.

! Keep packaging material out of the reach of

children. It can become a choking or suffocation

hazard (see Precautions and tips)

! This appliance shall be installed only by

authorised personnel and in accordance with the

manufacturer’s installation instructions, local gas

fitting regulations, municipal building codes, water

supply regulations, electrical wiring regulations,

AS 5601/AG 601 - Gas Installations and any other

statutory regulations.

! Ventilation - Ventilation must be in accordance

with AS5601/AG 601 - Gas Installations. In

general, the appliance should have adequate

ventilation for complete combustion of gas, proper

flueing and to maintain temperature of immediate

surrounding within safe limits.

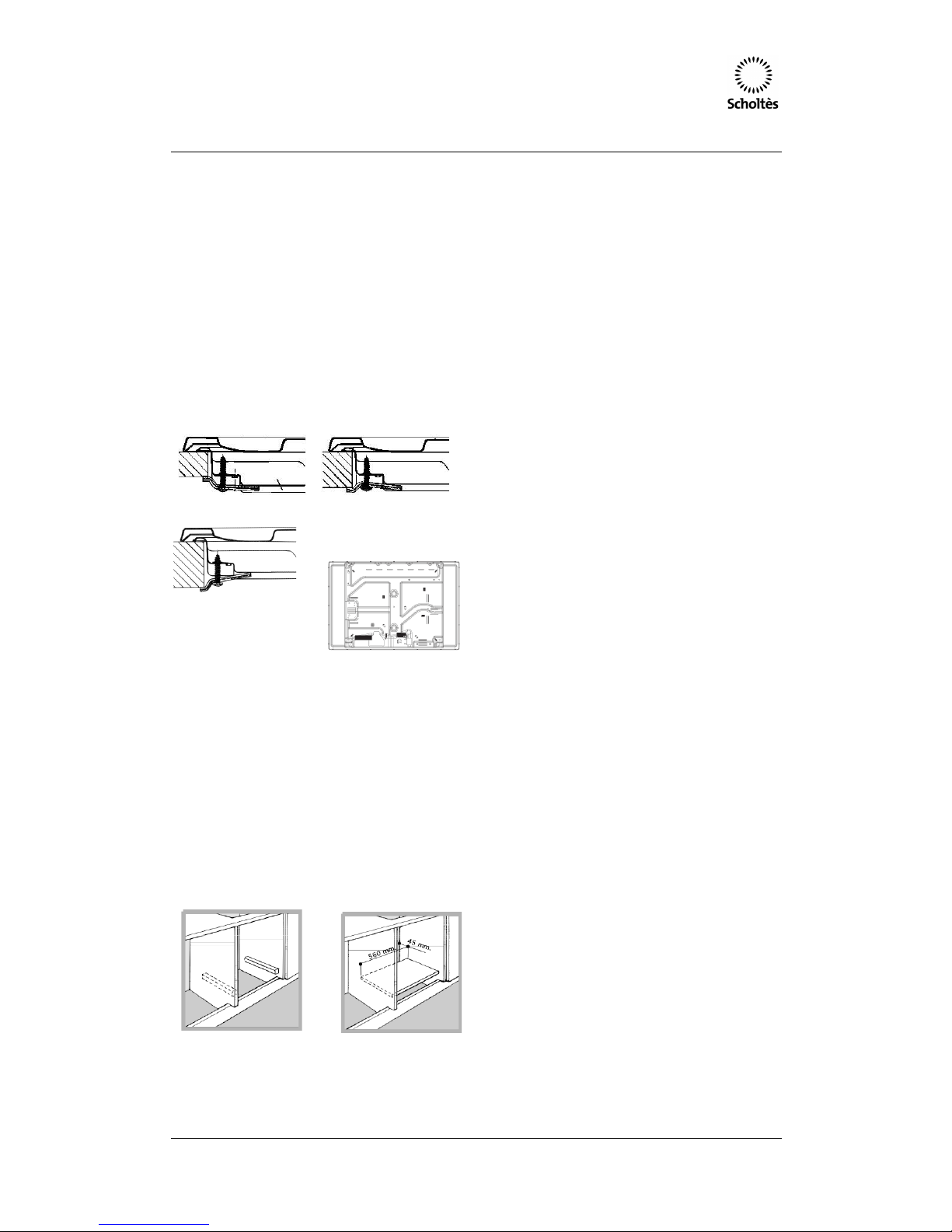

Positioning - The appliance can be fitted into a

working area as illustrated on the corresponding

figure. Apply the seal provided over the whole of

the area perimeter.

Combustible Surfaces - Any adjoining surface

situated within 200mm from the edge of any hob

burner must be a suitable non-combustable

material for a height of 150mm for the entire

length of the hob. Any combustible construction

above the hotplate must be at least 600mm above

the top of the burner and no construction shall be

within 450mm above the top of the burner. A

minimum depth of 60mm from the top of the

worktop surface must be provided for the

appliance.

Access to base - Where the base of the hotplate

can be accidentally touched, such as through a

cupboard or a pot drawer, a panel should be fixed

15mm below the base of the hotplate to prevent

accidental contact. The base of the hotplate is

very hot during operation.

Data Label - The Data Label is located on the

underside of the appliance. A duplicate label is

supplied to adhere in an accessible area adjacent

to the appliance. This appliance is suitable for

Natural and Propane Gas; ensure the available

gas supply matches the data label.

Gas connection - The Gas Connection is male

1/2” BSP and is situated 50mm from the right,

50mm from the rear of the hotplate and 25mm

below the top surface of the bench top.

There are two ways to carry out the connection to

the main gas line:

A. The hotplate can be connected with rigid

pipe as specified in AS5601 table 3.1.

B. The hotplate can be connected with a

Flexible Hose, which complies with

AS/NZS 1869 (AGA Approved), 10mm

ID, class B or D, no more than 1.2m long

and in accordance with AS5601

Ensure that the Hose does not contact the hot

surfaces of the hotplate, oven, dishwasher or

other appliance that may be installed underneath

or next to the hotplate.

The hose should not be subjected to abrasion,

kinking or permanent deformation and should be

able to be inspected along its entire length. Unions

compatible with the hose fittings must be used and

connections tested for gas leaks. The supply

connection point shall be accessible with the

appliance installed.

When the installation has been carried out, check

the perfect sealing of the entire connection

system, by using soapy solution.

Power Connection - Simply plug into a 3 pin

household socket outlet which is properly earthed.

Warning: In order to avoid hazard, any electrical

work performed on this equipment or its

associated wiring, should only be done by persons

authorised by the supplier or similarly qualified

persons.

The socket outlet for this hotplate shall be installed

near the hotplate and shall be easily accessible.

Gas Hob Operating Instructions

Page 3 of 11

MODEL

L (mm)

W (mm)

Electrical Connection

The hobs come equipped with a 3 pin plug and

power cable. The plug and power cable comply

with Australian requirements. Please check the

power rating, voltage and frequency indicated on

the data plate (located on the bottom of the hob as

well as on the front cover of this manual).

If the appliance is to be installed above an electric

built-in electric oven, the electrical connection to

the hob and oven must be carries out separately,

both for electrical safety purposes and to make it

easier to remove the oven.

The supply cable must not come into contact with

surfaces higher than 50°C.

! The installer must ensure the electrical

connection has been made and is compliant with

AS/NZS 3000 wiring rules.

Before connecting to the power supply, make sure

that:

• The appliance is earthed and the plug is

compliant with the law.

• The socket can withstand the maximum

power of the appliance, which is indicated

on the data plate.

• The voltage is in the range between the

values indicated on the data plate.

• The socket is compatible with the plug of

the appliance. If the socket is

incompatible with the plug, ask an

authorised technician to replace it. Do not

use extension cords or multiple sockets.

! Once the appliance has been installed, the power

supply cable and the electrical socket must be

easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and

replaced by authorised technicians only (see

Assistance).

! The manufacturer declines any liability should

these safety measures not be observed.

Adapting to various types of gas

Warning: Servicing should be carried out only by

authorised personnel. Should the appliance be

pre-set for a different type of gas than that

TGL 641

640

520

TGL 751

680

520

Bench cutout for both models is 555mm x 475mm

The installation cavity should have the dimensions

indicated in the figure.

Fastening hooks are provided, allowing you to

fasten the hob to tops that are between 20 and 40

mm thick. To ensure the hob is securely fastened

to the top, we recommend you use all the hooks

provided.

Hook fastening diagram

Hooking position Hooking position

For top H=20 mm for top H=30 mm

Hooking position

For top H=40 mm

Front

Back

! Use the hooks contained in the “accessory pack”

Where the hob is not installed over a built-in oven,

a wooden panel must be installed as insulation.

This must be placed at a minimum distance of 20

mm from the lower part of the hob.

Ventilation

To ensure adequate ventilation, the back panel of

the cabinet must be removed. It is advisable to

install the oven so that it rests on two strips of

wood, or on a completely flat surface with an

opening of at least 45 x 560 mm (see diagrams).

! The Hob can only be installed above built-in

ovens with a cooling ventilation system.

Gas Hob Operating Instructions

Page 4 of 11

available, proceed as follows:

− replace the injectors with the

corresponding type of gas to be used (see

table “Uses characteristics”).

− to adjust to the minimum, use a

screwdriver on the screw placed on the tap

after turning the tap to its minimum

position.

To adapt the hob to a different type of gas other

than default type (indicated on the rating plate at

the base of the hob or on the packaging), the

burner nozzles should be replaced as follows:

1. Remove the hob grids and slide the

burners off their seats.

2. Unscrew the nozzles using a 7 mm

socket spanner, and replace them with

nozzles for the new type of gas (see

table 1 “Burner and nozzle

characteristics”).

3. Reassemble the parts following the

above procedure in the reverse order.

4. Once this procedure is finished, replace

the old rating sticker with one indicating

the new type of gas used. Sticker are

available from any of our Service

Centres.

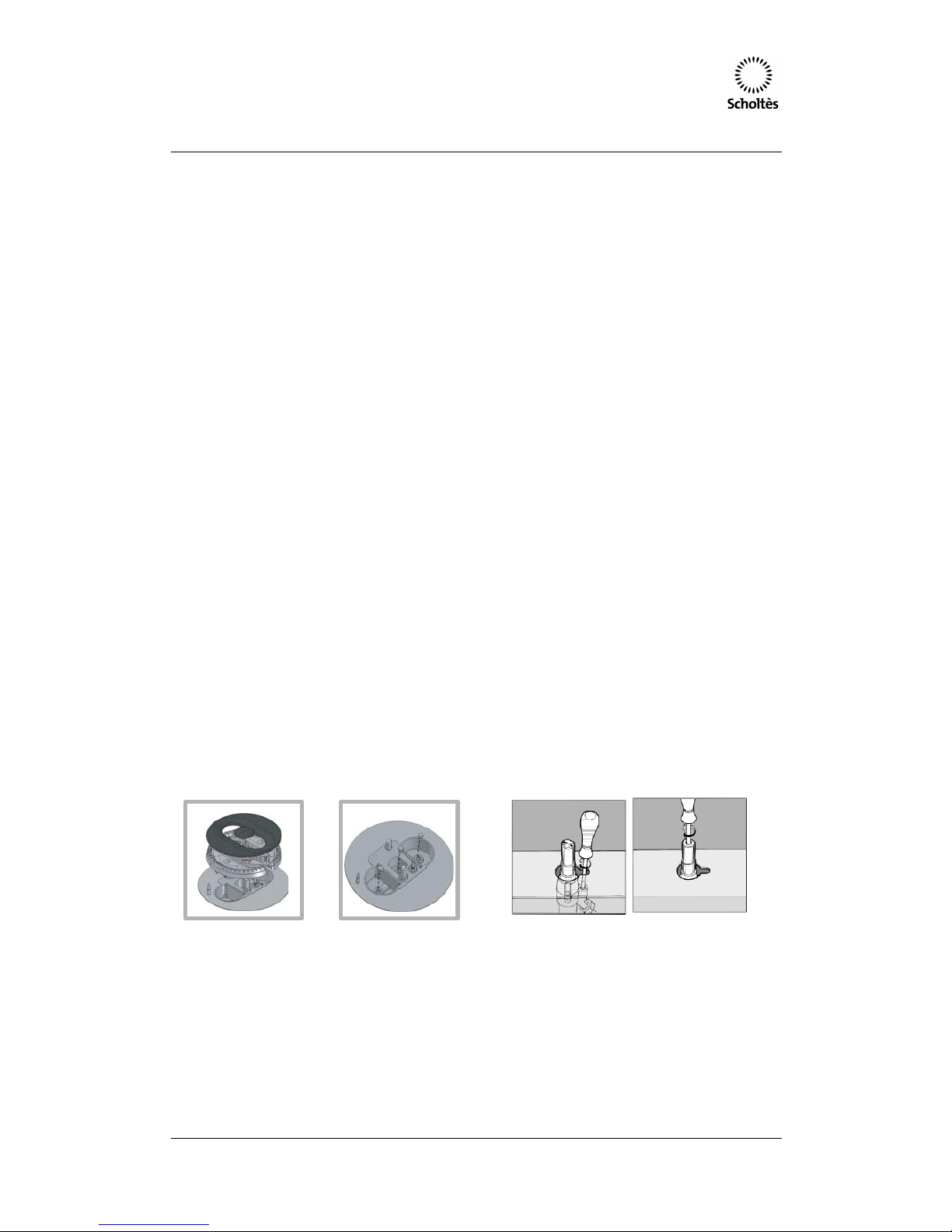

Replacing the nozzles on separate “double flame”

burners:

1. remove the grids and slide the burners

from their housings. The burner consists

of 2 separate parts (see figure);

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the

adjustment screw, which is positioned in

or next to the tap pin, until the flame is

small but steady.

3. Having adjusted the flame to the required

low setting, while the burner is alight,

quickly change the position of the knob

from minimum to maximum and vice

versa several times, checking that the

flame does not go out.

4. Some appliances have a safety device

(thermocouple) fitted. If the device fails to

work when the burners are set to the low

flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made,

replace the seals on the by-passes using

sealing wax or a similar substance.

When converting from Natural Gas to Propane

ensure that the NG regulator is removed and

replaced with the test point assembly. A gas

regulator suitable for a supply pressure of

2.75kPa should be part of the gas tank supply and

should be adjusted with the wok burner operating

at maximum.

The appliance is factory set for Natural Gas. The

test point pressure should be adjusted to 1.00kPa

with the wok burner (or rapid burner if there is no

wok burner) operating at maximum.

6. Unscrew the burners with a 7 mm

wrench spanner. The internal burner has

a nozzle, the external burner has two (of

the same size). Replace the nozzle with

models suited to the new type of gas

(see table page 5).

7. Replace all the components by repeating

the steps in reverse order.

• Adjusting the burners primary air:

Does not require adjusting.

Replace the old data plate with one which is

suitable for the type of gas for which the appliance

has been regulated.

Before Leaving - Check all connections for gas

leaks with soap and water. DO NOT use a naked

flame for detecting leaks. Ignite all burners to

ensure correct operation of gas valves, burners

and ignition.

Loading...

Loading...