XPSUAB

EIO0000003454 11/2020

XPSUAB

Safety Module

Original instructions

11/2020

EIO0000003454.01

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000003454 11/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Device Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front View and Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Functional Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Engineering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety-Related Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization of Safety-Related Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Interlock Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Prerequisites and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Application Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Configuration and Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Diagnostics via LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics via Status Output Z1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Accessories, Service, Maintenance, and Disposal. . . . . . . . . . . . . . . . . . . 67

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transportation, Storage, and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

13

14

15

18

20

21

23

24

28

29

32

34

35

36

38

39

40

46

53

58

59

62

64

68

69

70

71

73

EIO0000003454 11/2020 3

4 EIO0000003454 11/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

QUALIFICATION OF PERSONNEL

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation as well as all documentation of all components and equipment

of the machine/process are authorized to work on and with this product.

The qualified person must be a certified expert in safety engineering.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying configurations, settings, and wiring, and generally from mechanical, electrical, or electronic

equipment. The qualified person must be able to understand the effects that modifications to

configurations, settings, and wiring may have on the safety of the machine/process.

EIO0000003454 11/2020 5

INTENDED USE

The qualified person must be familiar with and understand the contents of the risk assessment as per ISO

12100-1 and/or any other equivalent assessment as well as all documents related to such risk assessment

or equivalent assessments for the machine/process.

The qualified person must be familiar with the standards, provisions, and regulations for the prevention of

industrial accidents, which they must observe when designing, implementing, and maintaining the

machine/process.

The qualified person must be thoroughly familiar with the safety-related applications and the non-safetyrelated applications used to operate the machine/process.

This product described in the present document is a safety module intended to perform safety-related

functions in a machine/process according to the present document, to the specified related documents,

and to all other documentation of the components and equipment of the machine/process.

The product may only be used in compliance with all applicable safety regulations and directives, the

specified requirements and the technical data.

Prior to using the product, you must perform a risk assessment as per ISO 12100-1 in view of the planned

application. Based on the results of the risk assessment, the appropriate safety-related measures must be

implemented.

Since the product is used as a component in an overall machine or process, you must ensure the safety

of persons by means of the design of this overall machine or process.

Operate the product only with the specified cables and accessories. Use only genuine accessories.

Any use other than the use explicitly permitted is prohibited and can result in hazards.

6 EIO0000003454 11/2020

At a Glance

Document Scope

Validity Note

Related Documents

About the Book

This manual describes technical characteristics, installation, commissioning, operation and maintenance

of the safety module XPSUAB.

The present document is valid for the products listed in the type code

(see page 15)

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

.

The technical characteristics of the devices described in the present document also appear online. To

access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

.

The characteristics that are described in the present document should be the same as those characteristics that appear online. In line with our policy of constant improvement, we may revise content over time

to improve clarity and accuracy. If you see a difference between the document and online information, use

the online information as your reference.

.

Title of documentation Reference number

XPSUAB User Guide EIO0000003454 (ENG)

XPSUAB Instruction Sheet PHA71839 (ENG, FRE, GER,

XPSUAB Instruction Sheet PHA71840 (ENG, JAP, KOR,

PreventaSupport Library Guide EIO0000003835 (ENG)

You can download these technical publications and other technical information from our website at

www.schneider-electric.com/en/download

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any covers or

doors, or installing or removing any accessories, hardware, cables, or wires except under the specific

conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Where 24 Vdc or Vac is indicated, use PELV power supplies conforming to IEC 60204-1.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper

ground connection exists before applying power to this equipment.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

EIO0000003455 (FRE)

EIO0000003456 (GER)

EIO0000003457 (ITA)

EIO0000003458 (SPA)

EIO0000003461 (CHS)

ITA, SPA, CHS)

POR, RUS, TUR)

.

DANGER

This equipment has been designed to operate outside of any hazardous location. Only install this

equipment in zones known to be free of a hazardous atmosphere.

EIO0000003454 11/2020 7

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for certain critical control functions, provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop and overtravel stop, power outage

and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest edition), "Safety

Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive

Systems" or their equivalent governing your particular location.

1

INSUFFICIENT AND/OR INEFFECTIVE SAFETY-RELATED FUNCTIONS

Verify that a risk assessment as per ISO 12100 and/or other equivalent assessment has been

performed before this product is used.

Before performing any type of work on or with this product, fully read and understand all pertinent

manuals.

Verify that modifications do not compromise or reduce the Safety Integrity Level (SIL), Performance

Level (PL) and/or any other safety-related requirements and capabilities defined for your

machine/process.

After modifications of any type whatsoever, restart the machine/process and verify the correct

operation and effectiveness of all functions by performing comprehensive tests for all operating states,

the defined safe state, and all potential error situations.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or that

appear in or on the products themselves, are generally derived from the terms or definitions of international

standards.

In the area of functional safety systems, drives and general automation, this may include, but is not limited

to, terms such as

,

message

dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

WARNING

safety, safety function, safe state, fault, fault reset, malfunction, failure, error, error

, etc.

General principles for design.

Part 1: General requirements and tests.

8 EIO0000003454 11/2020

Standard Description

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

In addition, terms used in the present document may tangentially be used as they are derived from other

standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

is defined as it is for a

ISO 12100:2010

zone of operation

hazard zone

.

may be used in conjunction with the description of specific hazards, and

or

danger zone

in the

Machinery Directive (2006/42/EC

) and

EIO0000003454 11/2020 9

10 EIO0000003454 11/2020

XPSUAB

Introduction

EIO0000003454 11/2020

Introduc tion

Chapter 1

Introduction

What Is in This Chapter?

This chapter contains the following topics:

Device Overview 12

Front View and Side View 13

Nameplate 14

Type Code 15

Topic Page

EIO0000003454 11/2020 11

Introduction

Device Overview

Outline

The device is a safety module for interruption of safety-related electrical circuits.

The device provides application functions used to monitor signals from different types of sensors/devices.

Equipment with the following types of outputs can be connected to the safety-related inputs of the device:

NO, NC, C/O, for example, Emergency Stop push-buttons, guard door switches, coded magnetic

switches, two-hand control devices

PNP transistors, for example, magnetic switches, proximity switches

OSSD, for example, light curtains

The device is available in four different types: either spring terminals or screw terminals and either

24 Vac/Vdc supply voltage or 48 … 240 Vac/Vdc supply voltage.

Feature summary:

6 application functions

Configurable start function

1 safety-related input

2 safety-related relay outputs

1 non-safety-related status/diagnostics output

1 non-safety-related start input with 8 selectable start functions

12

EIO0000003454 11/2020

Front View and Side View

Front View and Side View

Introduction

1 Removable terminal blocks, top

2 Removable terminal blocks, bottom

3 LED indicators

4 Start function selector

5 Application function selector

6 Sealable transparent cover

EIO0000003454 11/2020 13

Introduction

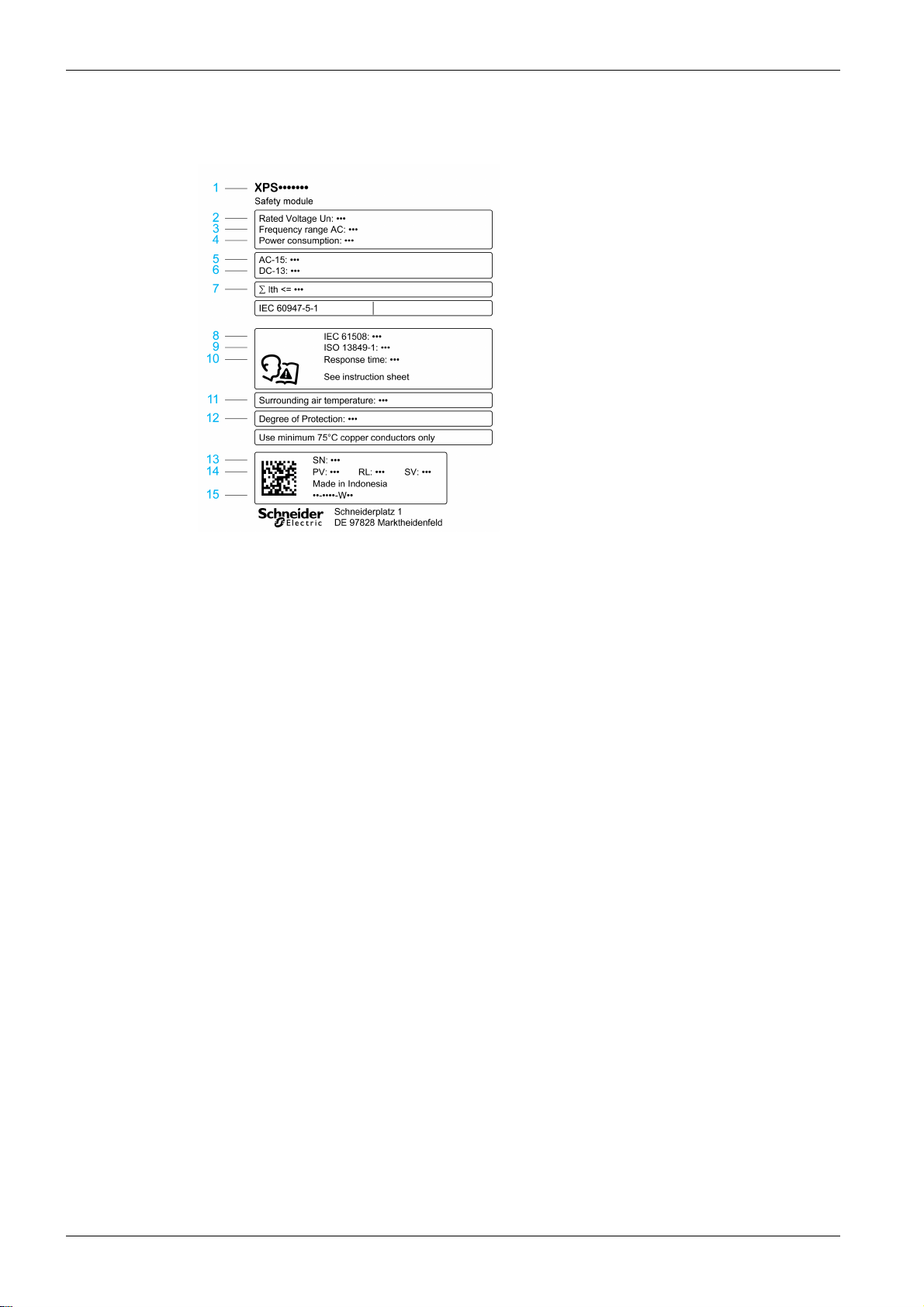

Nameplate

Nameplate

The nameplate contains the following data:

1 Device type (refer to chapter Type Code

(seepage15)

)

2 Nominal voltage

3 Frequency range Vac supply

4 Input power

5 Maximum current of safety-related outputs with utilization category AC15 (250 Vac)

6 Maximum current of safety-related outputs with utilization category DC13 (24 Vdc)

7 Maximum total thermal current

8 Maximum Safety Integrity Level (SIL) as per IEC 61508-1:2010

9 Maximum Performance Level and Category as per ISO 13849-1:2015

10 Maximum response time to request at safety-related input

11 Permissible ambient temperature range during operation

12 IP degree of protection

13 Serial number

14 Product version (PV), release (RL), software version (SV)

15 Plant code and date of manufacture (example: PP-2019-W10 means plant code PP, year of

manufacture 2019, week of manufacture 10)

14

EIO0000003454 11/2020

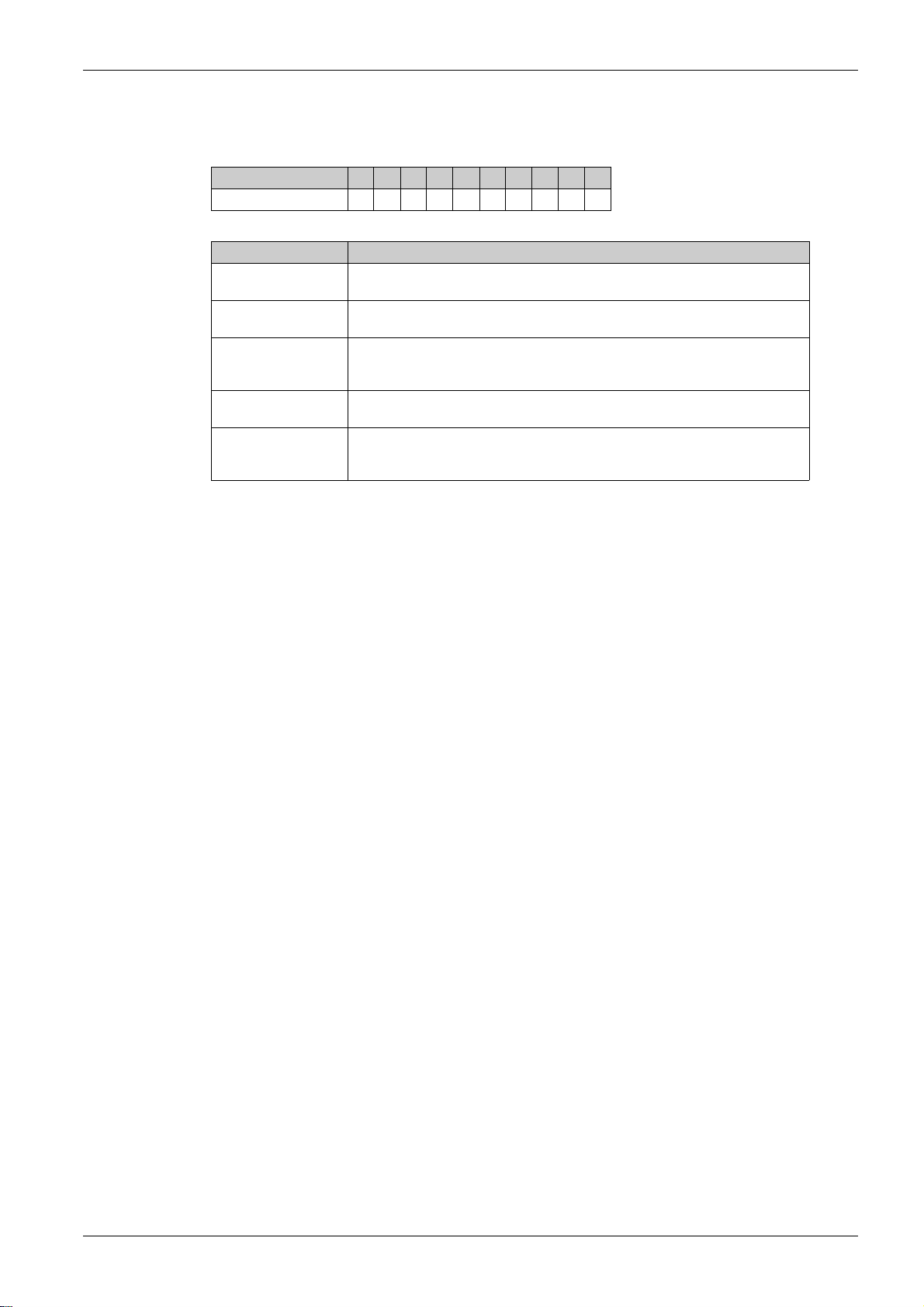

Type Code

Type Code

Introduction

Item 1 2 3 4 5 6 7 8 9 10

Type code (example) X P S U A B 1 1 C C

Item Meaning

1 ... 4 Product range

XPSU = Universal

5 ... 6 Product version

AB

7 Supply voltage

1 = 24 Vac/Vdc

3 = 48 … 240 Vac/Vdc

8 ... 9 Number of safety-related outputs

1C = 1 changeover relay

10 Terminal type

C = Spring terminals, removable

P = Screw terminals, removable

If you have questions concerning the type code, contact your Schneider Electric service representative.

EIO0000003454 11/2020 15

Introduction

16

EIO0000003454 11/2020

XPSUAB

Technical Data

EIO0000003454 11/2020

Technical Data

Chapter 2

Technical Data

What Is in This Chapter?

This chapter contains the following topics:

Environmental Conditions 18

Mechanical Characteristics 20

Electrical Characteristics 21

Timing Data 23

Data Functional Safety 24

Topic Page

EIO0000003454 11/2020 17

Technical Data

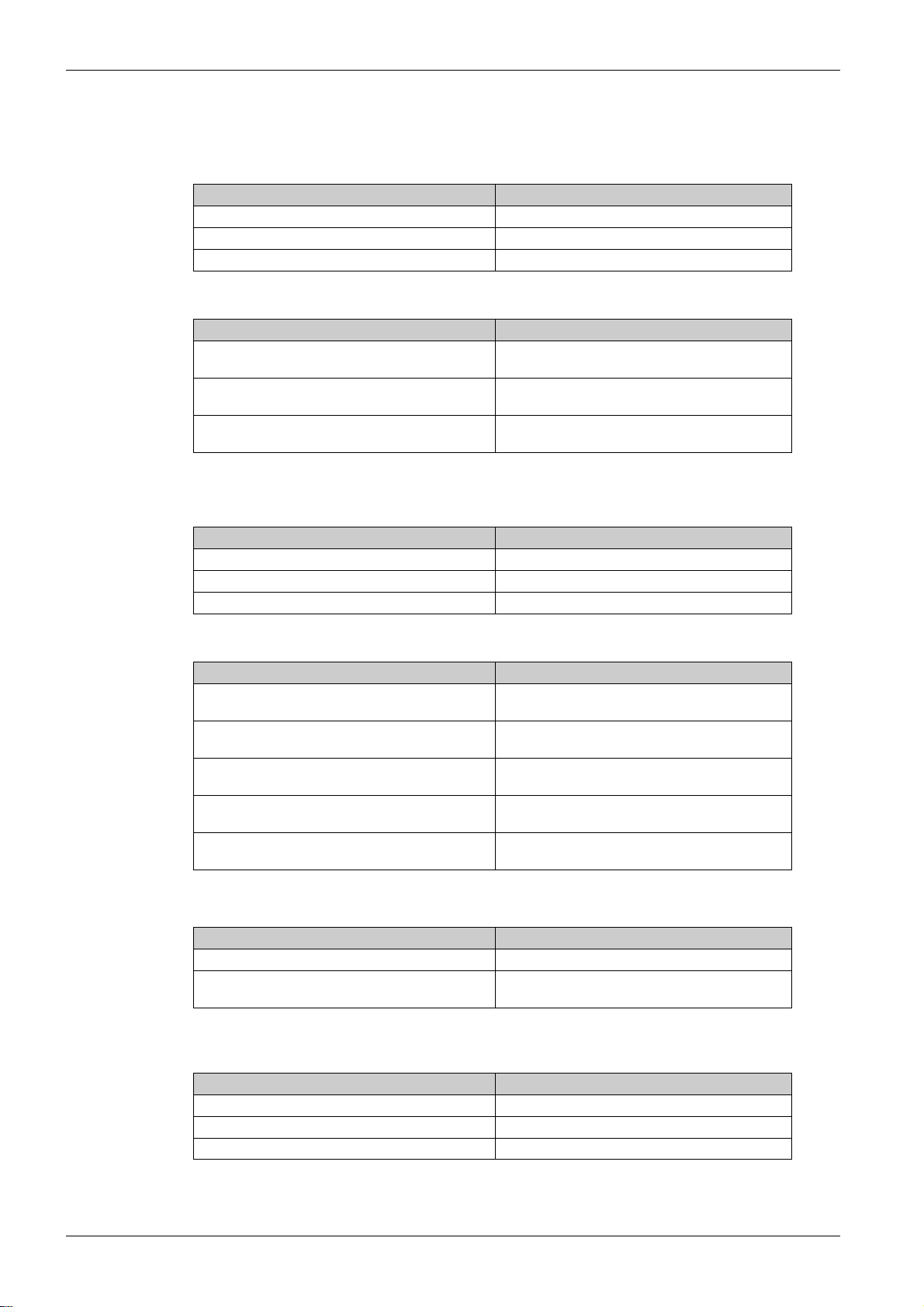

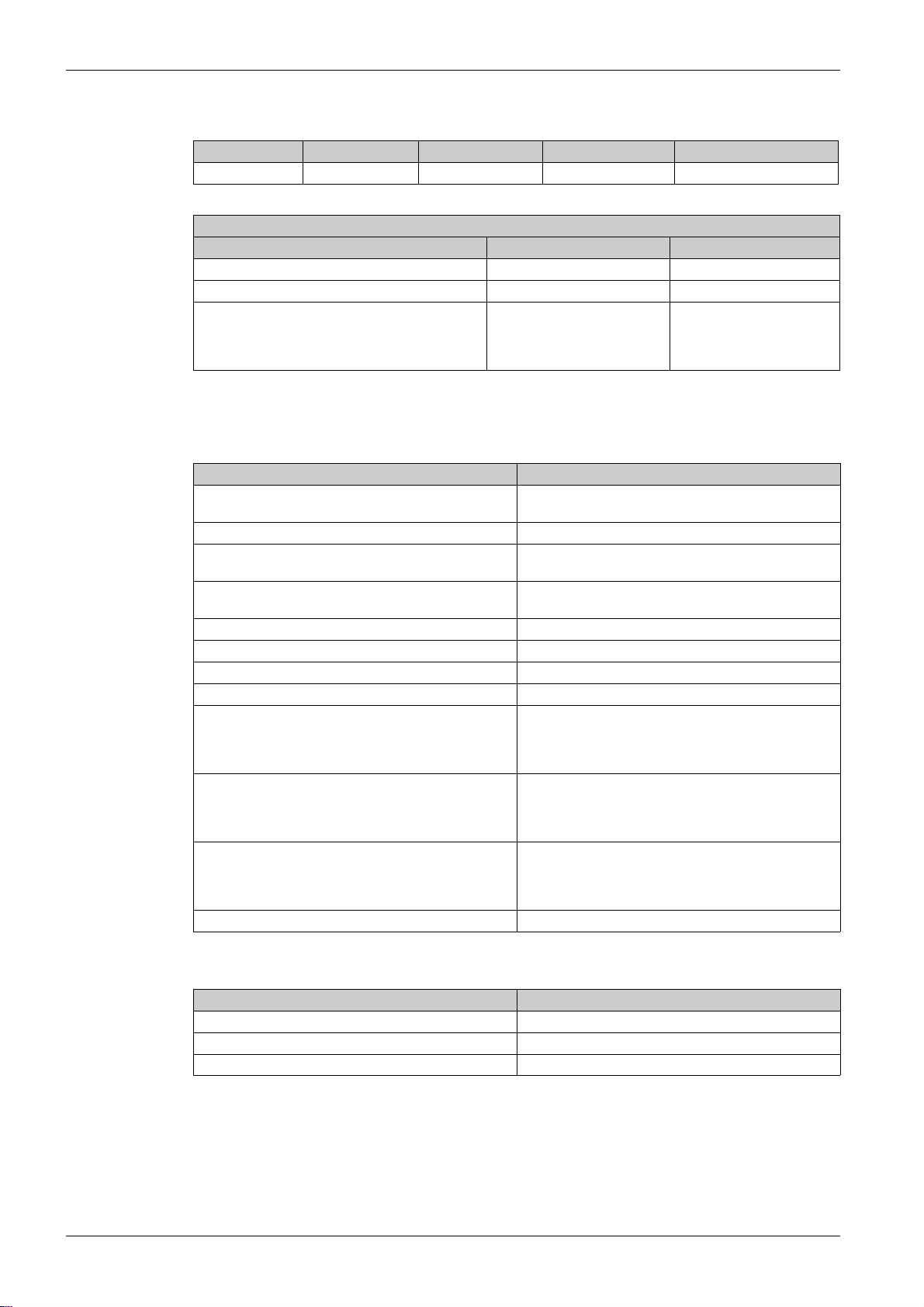

Environmental Conditions

Environmental Conditions For Storage

The device complies with class 1K5 as per IEC 60721-3-1:1997 (climatic conditions):

Characteristic Value

Ambient temperature -40 ... 70 °C (-40 ... 158 °F)

Rate of change of temperature 1 °C/min (1.8 °F/min)

Ambient humidity 10 ... 100 % relative humidity

The device complies with class 1M2 as per IEC 60721-3-1:1997 (mechanical conditions):

Characteristic Value

Vibration, sinusoidal, displacement amplitude

2...9Hz

Vibration, sinusoidal, acceleration amplitude

9 ... 200 Hz

Shock, shock response spectrum type L, peak

acceleration

Environmental Conditions For Transportation

The device complies with class 2K5H as per IEC 60721-3-2:1997 (climatic conditions):

1.5 mm

5m/s

40 m/s

2

2

Characteristic Value

Ambient temperature -25 ... 85 °C (-13 ... 185 °F)

Change of temperature, air/air -25 ... 30 °C (-13 ... 86 °F)

Ambient humidity 5 ... 95 % relative humidity, no condensation

The device complies with class 2M2 as per IEC 60721-3-2:1997 (mechanical conditions):

Characteristic Value

Vibration, sinusoidal, displacement amplitude

2...9Hz

Vibration, sinusoidal, acceleration amplitude

9 ... 200 Hz

Vibration, sinusoidal, acceleration amplitude

200 ... 500 Hz

Shock, shock response spectrum type I, peak

acceleration

Shock, shock response spectrum type II, peak

acceleration

Environmental Conditions For Operation

Characteristic Value

Maximum installation altitude above mean sea level 2000 m (6562 ft)

Installation required in control cabinet/enclosure with

degree of protection

3.5 mm

10 m/s

15 m/s

100 m/s

300 m/s

IP54

2

2

2

2

18

The device complies with class 3K5 and special class 3Z11 as per IEC 60721-3-3:2008 (climatic

conditions):

Characteristic Value

Ambient temperature -25 ... 55 °C (-13 ... 131 °F), no icing

Rate of change of temperature 0.5 °C/min (0.9 °F/min)

Ambient humidity 5 ... 95 % relative humidity, no condensation

EIO0000003454 11/2020

The device complies with class 3M4 as per IEC 60721-3-3:2008 (mechanical conditions):

Characteristic Value

Vibration, sinusoidal, displacement amplitude

3mm

2...9Hz

Vibration, sinusoidal, acceleration amplitude

10 m/s

2

9 ... 200 Hz

Shock, shock pulse shape: half-sine, peak

100 m/s

2

acceleration

The devices complies with the following vibration and shock values as per IEC 60947-1:

Characteristic Value

Vibration, sinusoidal, displacement amplitude

2...13Hz

Vibration, sinusoidal, acceleration amplitude

13.2 ... 100 Hz

Shock, shock pulse shape: half-sine, peak

acceleration

1mm

2

7m/s

150 m/s

2

Technical Data

EIO0000003454 11/2020 19

Technical Data

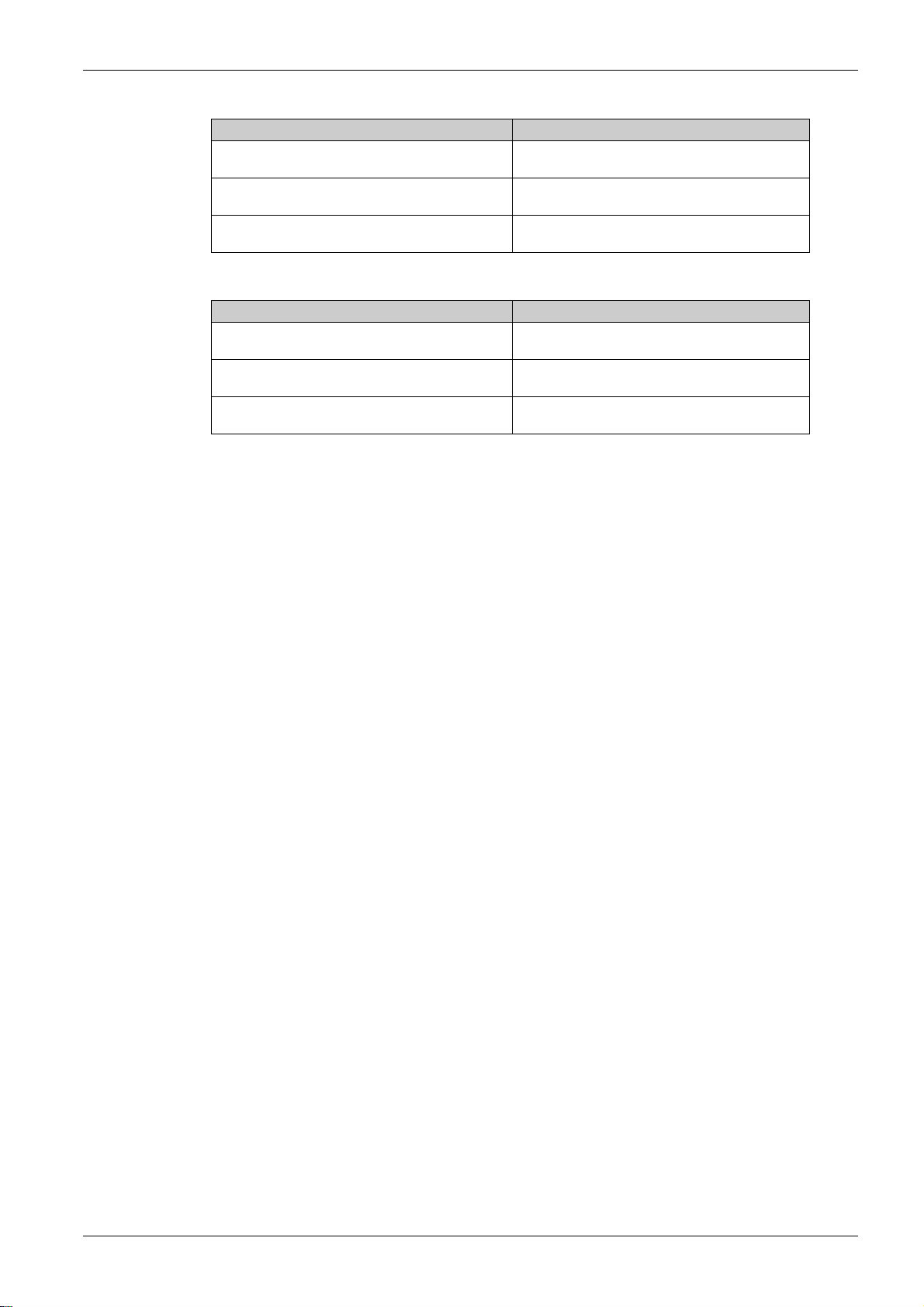

Mechanical Characteristics

Dimensions

Characteristic Value

Width 22.5 mm (0.89 in)

Height without terminals 99 mm (3.90 in)

Height with terminals 119 mm (4.70 in) 109 mm (4.30 in)

Depth 117 mm (4.61 in)

XPSUAB•••C XPSUAB•••P

Weight

Characteristic Value

Weight 0.2 kg (0.44 lbs)

Degree Of Protection

Characteristic Value

Housing IP40

Terminals IP20

Wire Cross Sections, Stripping Lengths, and Tightening Torques

Characteristic Value

Stripping length for spring terminals 12 mm (0.47 in)

Stripping length for screw terminals 7 ... 8 mm (0.28 ... 0.31 in)

Wire cross section, single wire without wire ferrule

Wire cross section, single wire with wire ferrule

Wire cross section, two wires without wire ferrule

Wire cross section, two wires with uninsulated wire

ferrule

Wire cross section, two wires with insulated wire

ferrule

Tightening torque for screw terminals 0.5 ... 0.6 N m (4.4 ... 5.3 lb in)

(1) Stranded or solid

(1)

0.2 ... 2.5 mm2 (AWG 24 ... 12)

0.25 ... 2.5 mm2 (AWG 24 ... 12)

(1)

0.2 ... 1.5 mm2 (AWG 24 ... 16)

0.25 ... 1 mm

0.5 ... 1.5 mm

2

(AWG 24 ... 18)

2

(AWG 20 ... 16)

20

EIO0000003454 11/2020

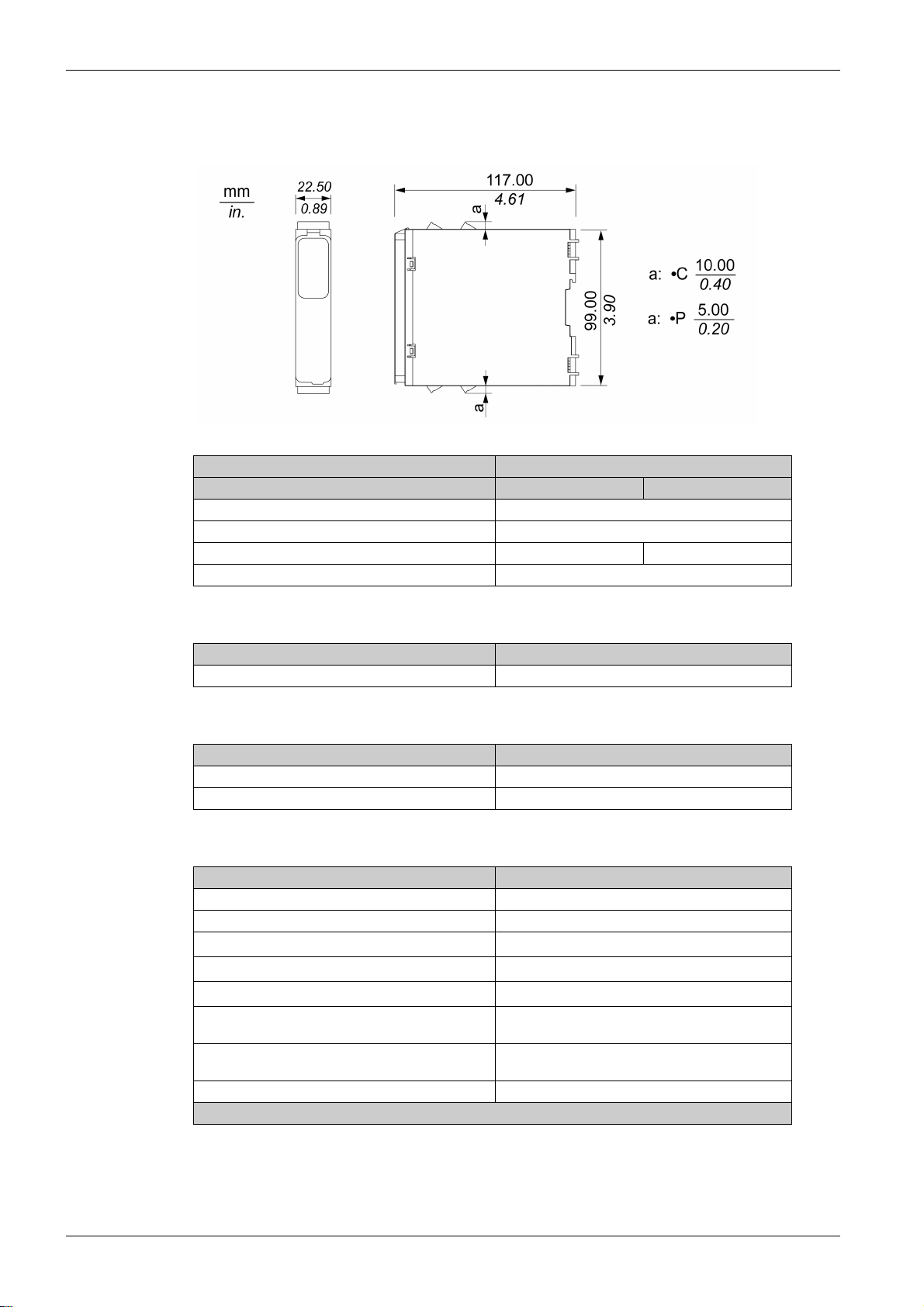

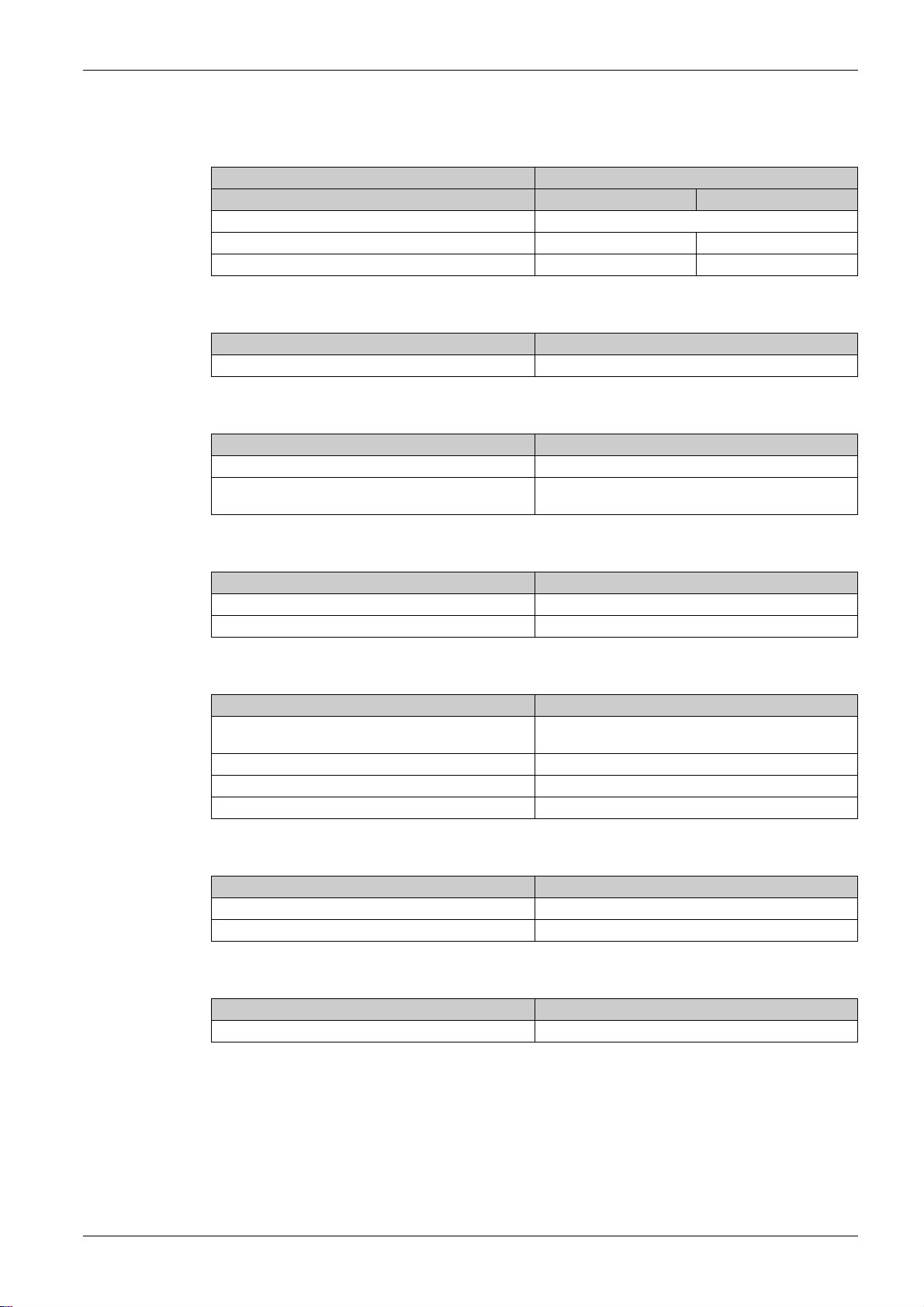

Electrical Characteristics

Supply

Characteristic Value

Supply voltage AC 24 Vac (-15 ... 10 %) 48 ... 240 Vac (-10 ... 10 %)

Supply voltage DC 24 Vdc (-20 ... 20 %) 48 ... 240 Vdc (-10 ... 10 %)

Nominal input power AC 3.5 VA (24 Vac) 6.5 VA (240 Vac)

Nominal input power DC 1.5 W (24 Vdc) 2 W (48 Vdc)

Frequency range AC 50 ... 60 Hz

Overvoltage category II

Pollution degree 2

Insulation voltage 300 V

Impulse withstand voltage 4 kV

Electromagnetic Compatibility (EMC)

Characteristic Value

Conducted and radiated emissions as per IEC CISPR 11 Group 1/class B Group 1/class A

Usage in environment as per IEC/UL 60947-1 Environment B Environment A

Technical Data

XPSUAB1••• XPSUAB3•••

XPSUAB1••• XPSUAB3•••

Common Reference Potential

Terminal B2 is provided to obtain a common reference potential for 24 Vdc signals.

Safety-Related Inputs

Characteristic Value

Number of inputs, positive supplied (1 control output DC+

(S11) and 2 inputs CH+ (S12–S13)), single-channel. The

input can be also be used as single-channel input with

only one CH+ terminal connected (S11–S12). In this case,

S13 must remain unconnected.

Output voltage at DC+ >15 Vdc

Input voltage at CH+ 0 ... 24 Vdc (+20 %)

Switching voltage for activation of CH+ >15 Vdc

Switching voltage for deactivation of CH+ <5 Vdc

Input current 5 mA

Maximum wire resistance 500 Ω

Start Input

Characteristic Value

Output voltage at DC+ >15 Vdc

Input voltage at CH+ 0 ... 24 Vdc (+20 %)

Switching voltage activate CH+ >15 Vdc

Switching voltage deactivate CH+ <5 Vdc

Input current 5 mA

Maximum wire resistance 500 Ω

1

EIO0000003454 11/2020 21

Technical Data

Classification of Safety-Related Inputs and Start Input as per ZVEI CB24I

Representation and values as per identifying key, ZVEI CB24I:

Source/sink Interface type Additional measure Source/sink Interface type

Sink: A M Source: C0

Interface type A: Sink

Parameter Minimum value Maximum value

Input current Ii (in the ON state) 3 mA 5 mA

Output voltage Ui 15 V 24 V (+20 %)

Additional measure M The inputs are not types as per

IEC 61131-2.

TG is S•1 for S•2 and S•3

TG is Y1 for Y2

>15 Vdc

Refer to Dynamization of Safety-Related Inputs and Start Input

Safety-Related Outputs

Characteristic Value

Number of relay contacts, changeover (Normally Closed

to Normally Open), instantaneous

Maximum short circuit current IK 1 kA

Maximum continuous current, Normally Open relay

contacts

Maximum continuous current, Normally Closed relay

contacts

Maximum total thermal current ΣIth 3 A

Minimum current 10 mA

Minimum voltage 12 V

Utilization category as per UL 60947-5-1 D300 and R300

Utilization category as per IEC 60947-4-1 and IEC 609475-1)

Maximum current, normally open relay contacts AC1: 5 A

Maximum current, normally closed relay contacts AC1: 3 A

External fusing 6 A, category gG

1

3A

3A

AC1: 250 V

AC15: 250 V

DC1: 24 V

DC13: 24 V

AC15: 3 A

DC1: 5 A

DC13: 2 A

AC15: 1 A

DC1: 3 A

DC13: 1 A

(see page 23)

for test pulse times.

Additional Non-Safety-Related Outputs

Characteristic Value

Number of semiconductor pulsed outputs 1

Output voltage 24 Vdc

Maximum current 20 mA

22

EIO0000003454 11/2020

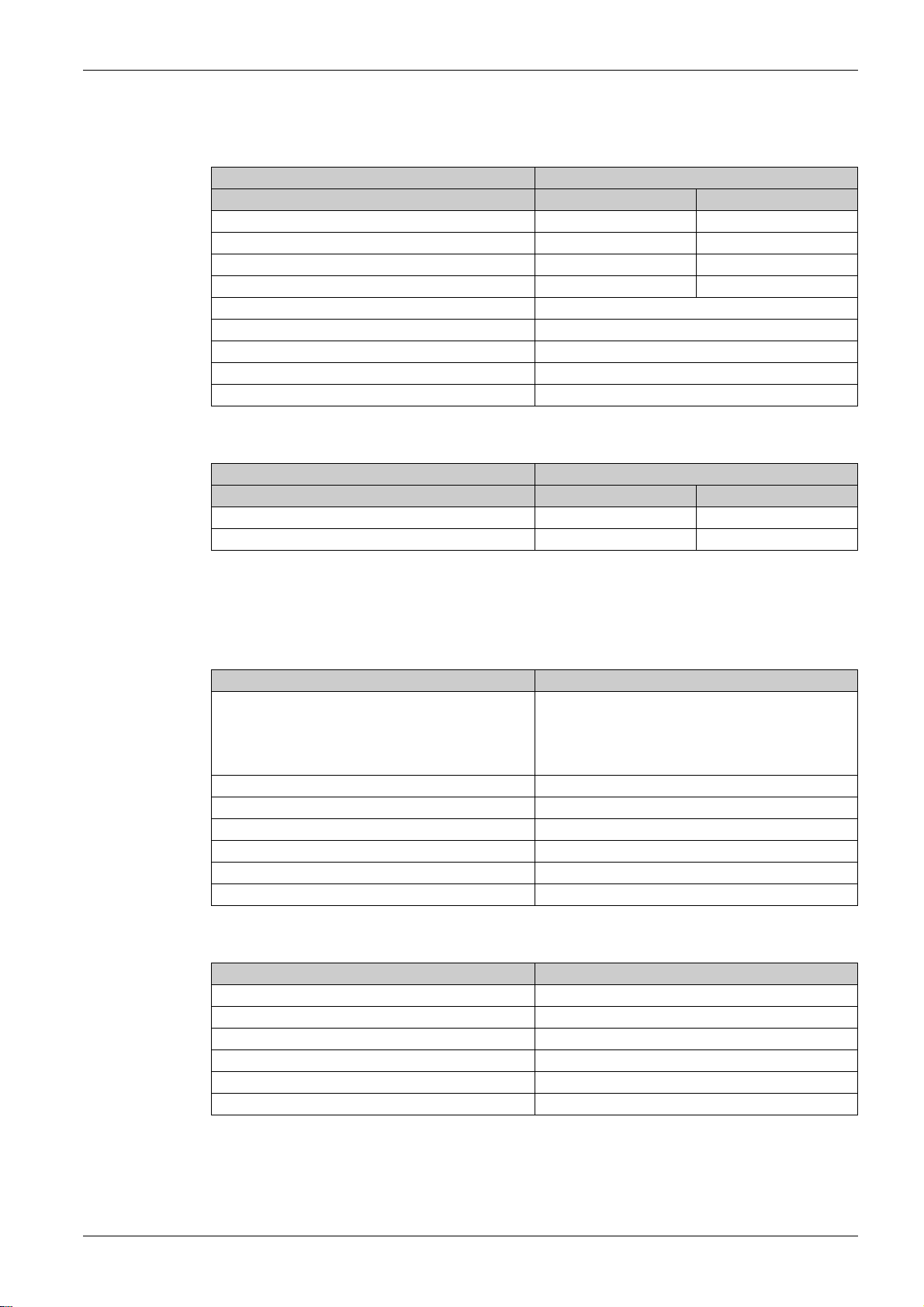

Timing Data

Maximum Response Times

Characteristic Value

Maximum response time to request at safety-related input 20 ms

Maximum response time after power outage AC 200 ms 80 ms

Maximum response time after power outage DC 120 ms 80 ms

Recovery Time

Characteristic Value

Recovery time after request at safety-related input 200 ms

Switch-On and Activation Delays

Characteristic Value

Switch on delay after power on and automatic start 2500 ms

Delay after activation of safety-related input or valid start

condition

Technical Data

XPSUAB1••• XPSUAB3•••

100 ms

Monitored Start

Characteristic Value

Waiting time 2500 ms

Minimum duration of start pulse for monitored start 80 ms

Dynamization of Safety-Related Inputs and Start Input

Characteristic Value

Test pulse duration (safety-related input must be activated

for longer than duration of test pulse)

Test pulse interval 500 ms

Maximum delay of test pulse 40 ms

Test pulse phase shift At least 70 ms

Debounce Time of Safety-Related Inputs

Characteristic Value

Debounce time, standard 2.5 ms

Debounce time, with OSSD 4 ms

Signal Interlock Monitoring Time

2ms

Characteristic Value

Signal interlock monitoring time 200 ms

Synchronization Times

The synchronization times for the synchronization of safety-related inputs depend on the application

function

EIO0000003454 11/2020 23

(see page 46)

.

Technical Data

Data Functional Safety

Data Functional Safety

Characteristic Value

Defined safe state Safety-related outputs are de-energized

Maximum Performance Level (PL), Category

(as per ISO 13849-1:2015)

Maximum Safety Integrity Level (SIL)

(as per IEC 61508-1:2010)

Safety Integrity Level Claim Limit (SILCL)

(as per IEC 62061:2005+AMD1:2012+AMD2:2015)

Type

(as per IEC 61508-2)

Hardware Fault Tolerance (HFT)

(as per IEC 61508 and IEC 62061)

Stop Category for Emergency Stops

(as per ISO 13850 and IEC 60204-1)

Lifetime in years at an ambient temperature of 55 °C

(131 °F)

Safe Failure Fraction (SFF)

(as per IEC 61508 and IEC 62061)

Probability of Dangerous Failure per hour (PFHD) in 1/h

(as per IEC 61508 and ISO 13849-1)

Mean Time To Dangerous Failure (MTTFd) in years

(high as per ISO 13849-1)

Average Diagnostic Coverage (DC

(none as per ISO 13849-1)

Maximum number of cycles over lifetime DC13, 24 Vdc 2 A: 50000

avg

XPSUAB1••• XPSUAB3•••

Normally Open: open

Normally Closed: closed

PL c, Category 1

Actual PL and category depend on wiring and

configuration.

1

Actual SIL depends on wiring and configuration.

1

Actual SILCL depends on wiring and configuration.

B

0

0

20

>60 %

1175.6 x 10

-9

1176.1 x 10

-9

>30

)

≥60 %

AC15, 250 Vac 3 A: 50000

24

EIO0000003454 11/2020

B

values as per ISO 13849

10d

Technical Data

1 B

10d

value

2 Nominal current in A

Refer to chapter Timing Data

(see page 23)

for additional technical data that may affect your functional

safety calculations.

EIO0000003454 11/2020 25

Technical Data

26

EIO0000003454 11/2020

XPSUAB

Engineering

EIO0000003454 11/2020

Engineering

Chapter 3

Engineering

What Is in This Chapter?

This chapter contains the following topics:

Electromagnetic Compatibility (EMC) 28

Basic Principles of Operation 29

Safety-Related Inputs 32

Synchronization of Safety-Related Inputs 34

Dynamization 35

Signal Interlock Monitoring 36

Topic Page

EIO0000003454 11/2020 27

Engineering

Electromagnetic Compatibility (EMC)

Conducted and Radiated Electromagnetic Emissions

Equipment of class A as per IEC CISPR 11 is not intended for use in residential environments and may not

provide adequate protection to radio reception in such environments.

INSUFFICIENT ELECTROMAGNETIC COMPATIBILITY

Verify compliance with all EMC regulations and requirements applicable in the country in which the

device is to be operated and with all EMC regulations and requirements applicable at the installation

site.

Do not install and operate devices of class A as per IEC CISPR 11 in residential environments.

Implement all required radio interference suppression measures and verify their effectiveness.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

According to IEC CISPR 11, device type XPSUAB1••• is a group 1, class B device. Class B as per

IEC CISPR 11 corresponds to environment B as per IEC 60947-1.

According to IEC CISPR 11, device type XPSUAB3••• is a group 1, class A device. Class A as per

IEC CISPR 11 corresponds to environment A as per IEC 60947-1.

WARNING

28

EIO0000003454 11/2020

Basic Principles of Operation

Introduction

The following sections provide basic information on the principles of operation of the device to assist you

in engineering your application function.

Operating States

The following graphic illustrates the operating states and state transitions of the device:

Engineering

State Transitions

Operating state Description In defined

safe state

Off / Configuration Configuration only possible in this operating state Yes

Initialization Self-tests Yes

Run: Outputs Deenergized Regular operation with safety-related function active Yes

Run: Outputs Energized Regular operation with safety-related function not active No

Error Error detected Yes

NOTE: See the chapter Data Functional Safety

State transition Condition

T1

T2

T3

T4

T5

Power on

Initialization successful

Switch on delay has passed

Start condition fulfilled (for example, automatic start or manual start with start

button pressed)

Safety-related inputs activated

For application functions with signal interlock monitoring: no signal interlock

condition

For application functions with synchronization: synchronization time

requirements met

Safety-related inputs deactivated (corresponds to triggering of the safety-

related function)

Error detected on

(see page 24)

for the defined safe state of the device.

EIO0000003454 11/2020 29

Engineering

State transition Condition

T6 Power off

NOTE: Refer to the Activation and Deactivation

and “deactivated” in the present document.

Example with Emergency Stop

The following example uses a machine with an Emergency Stop pushbutton, a start pushbutton for manual

start, and a motor to demonstrate the individual operating states and state transitions. The selected

application function is Monitoring of Emergency Stop Circuits. The selected start function is Manual Start.

The example assumes that the equipment is properly wired and configured.

After the device is powered on, it enters the operating state Initialization (T1).

If the initialization is successful, the device enters the operating state Run: Outputs Deenergized (T2).

If an error is detected, the device transitions to the operating state Error (T5).

On entering the operating state Run: Outputs Deenergized, the device verifies the state of the safety-

related input and of the start input. The motor is at a standstill.

If the start pushbutton is not pressed, the start input stays deactivated and the device remains in the

operating state Run: Outputs Deenergized. The motor is at a standstill.

Detailed information on the start functions and the timing can be found in the chapter Start Functions

(see page 53)

If the start pushbutton is pressed, the start input is activated, i.e. the start condition is fulfilled.

The state of the safety-related input determines whether the device transitions to the operating state

Run: Outputs Energized.

If the safety-related input is not activated (actuator of Emergency Stop pushbutton pushed down), the

device remains in the operating state Run: Outputs Deenergized. The motor remains at a standstill.

If the safety-related input is activated (actuator of Emergency Stop pushbutton pulled out), the device

transitions to the operating state Run: Outputs Energized (T3). The motor runs. This operating

corresponds to regular operation of the machine.

If an application function with synchronization

transition only occurs if the input channels of the safety-related input are activated within the synchronization time.

In the operating state Run: Outputs Energized, the device monitors the state of the safety-related input.

If the actuator of the Emergency Stop pushbutton is pushed down (safety-related input deactivated), the

safety-related output is deactivated within the response time (transition T4 to operating state Run:

Outputs Deenergized). The device is again in the defined safe state. The motor is stopped.

This corresponds to the Emergency Stop condition of the machine.

To return to the operating state Run: Outputs Energized (T3), the start input and the safety-related

inputs need to be activated again (start button pressed and actuator of the Emergency Stop pushbutton

pulled out).

If an application function with synchronization

transition only occurs if the input channels of the safety-related input are activated within the synchronization time.

(see page 32)

for details on the use of the terms “activated”

.

(see page 34)

(see page 34)

of the safety-related input is used, this

of the safety-related input is used, this

Timing Diagram for Example with Emergency Stop

The following timing diagram provides an overview of the example with Emergency Stop.

30

EIO0000003454 11/2020

Legend

Item Description

1

2

3

4

The safety-related input is activated (actuator of Emergency Stop button pulled out).

The device remains in the defined safe state.

The start button is pressed.

The start condition is fulfilled. See the chapter Start Functions

information on the start functions.

The safety-related output is activated within the activation delay time

If an application function with synchronization

the safety-related output is only activated if the two channels of the safety-related input have

been activated within the synchronization time.

The motor runs. The device is not in the defined safe state.

The start button is released.

The safety-related input is deactivated (actuator of Emergency Stop button pushed).

The safety-related output is deactivated within the response time

The Emergency Stop is triggered. The device is in the defined safe state.

(see page 34)

Engineering

(see page 53)

for detailed

(see page 23)

.

of two input channels is used,

(see page 23)

.

EIO0000003454 11/2020 31

Engineering

Safety-Related Inputs

Overview

WARNING

INSUFFICIENT AND/OR INEFFECTIVE SAFETY-RELATED FUNCTIONS

Only connect a sensor/device to a safety-related input that meets all requirements as per your risk

assessment and that complies with all regulations, standards, and process definitions applicable to your

machine/process.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The following sections provide basic information on the safety-related inputs such as principle of activation

and deactivation as well as antivalent behavior. Refer to the chapters Electrical Characteristics

(see page 21)

General Information on Activation and Deactivation of Safety-Related Inputs

In the present document, “activation” of a safety-related input means that a safety-related input changes

its state so that the device can enter the operating state Run: Outputs Energized.

The term “deactivation” of a safety-related input means that a safety-related input changes its state so that

the device enters the operating state Run: Outputs Deenergized.

See Operating States

and Electrical Installation

(see page 29)

(see page 41)

for details on the state machine of the device.

for more details on the safety-related inputs.

Activation and Deactivation with Antivalent Behavior Between Two Input Channels of One Safety-Related Input

Depending on the selected application function, the input channels of the safety-related input are

configured for antivalent behavior. Antivalent is defined here as a normally open and a normally closed

contacts working in synchronization.

For example, for application function 3

normally open contact, whereas the signal for input channel S13 is provided by a normally closed contact.

One safety-related input with two input channels with antivalent behavior (magnetic switch with NO at S12

and NC at S13):

If the level at terminal S12 is logically 0 and the level at terminal S13 is logically 1, the safety-related input

is activated.

Timing diagram for one safety-related input with two input channels with antivalent behavior:

(see page 49)

, the signal for input channel S12 is provided by a

32

1 = Activation, transition to operating state Run: Outputs Energized

2 = Deactivation, transition to operating state Run: Outputs Deenergized (defined safe state)

EIO0000003454 11/2020

Truth table for one safety-related input with two input channels with antivalent behavior:

Engineering

Signal State

at S12

0 1 Safety-related input channel activated, operating state Run: Outputs

1 0 Safety-related input channel deactivated, operating state Run: Outputs

Identical signal states are only permissible within the synchronization time

Signal State

at S13

Activation State and Operating State

Energized

Deenergized

(see page 29)

(see page 34)

. Otherwise,

identical signal states trigger an alert.

The truth table applies to the wiring diagrams presented for the application functions.

If the magnetic switch in the wiring example above is used for guard monitoring, this means that the

magnetic switch is presented in the activated state and the guard is closed.

Consult the manual of the sensor/device you want to use for your application function for details on signal

state required for activation and deactivation as defined in the present document.

EIO0000003454 11/2020 33

Engineering

Synchronization of Safety-Related Inputs

Overview

The device can monitor synchronized behavior of the two input channels of the safety-related input using

various synchronization mechanisms with different synchronization times. If the two synchronized

channels of the safety-related input are not activated within the synchronization time, the safety-related

output is not deactivated.

The synchronized terminals of the safety-related input and the corresponding synchronization times are

listed for each individual application function

the sequences in which the synchronized input channels are activated, if applicable.

Refer to the chapter Safety-Related Inputs

“activation” in the present document.

(see page 46)

(see page 32)

using synchronization, including information on

for additional information on the use of the term

34

EIO0000003454 11/2020

Dynamization

Dynamization of Inputs

Dynamization is used for cross circuit detection between the control output and an input channel of the

safety-related input or between the safety-related input and the Start input or a cross-circuit to an external

power supply unit or to ground. Dynamization is implemented by means of periodically generated test

pulses at the control outputs of the safety-related inputs S•1 and of the start input Y1.

Whether dynamization of the safety-related inputs is used depends on the selected application function

(see page 45)

The following diagram illustrates the dynamization principle and timing:

Engineering

.

The same logic applies to Y1 and Y2.

Designation Value Explanation

T

DDUR

T

DINT

T

DDEL

2 ms Duration of the test pulse. The duration of the test pulse is the

time between the start of the test pulse and the end of the test

pulse.

500 ms Interval between test pulses. This interval is the time between the

start of a test pulse and the start of the next test pulse at the same

control output.

40 ms Maximum delay of test pulse. This delay is the maximum time

between the start of the test pulse at the control output and the

associated input channel, that is, the maximum time during which

the input expects to “see” dynamization.

EIO0000003454 11/2020 35

Engineering

Signal Interlock Monitoring

Overview

Signal interlock is a monitoring function used to detect conditions in which one of the sensors/devices

cannot provide the expected input signal for the device, for example, as a result of contact welding.

The device expects “simultaneous” deactivation of the two input channels of the safety-related input within

the signal interlock monitoring time of 200 ms.

If the two monitored input channels of the safety-related input are not deactivated within 200 ms, this is a

signal interlock condition and the device triggers a signal interlock alert. The device remains in the defined

safe state, i.e., there is no transition from operating state Run: Outputs Deenergized to operating state Run:

Outputs Energized (T3).

To exit the signal interlock condition, the two affected input channels of the safety-related input must be

deactivated for at least one second. After that, the input channels of the safety-related input can be

activated again which activates the safety-related output as well.

Signal interlock is available for certain of the application functions

Examples

The following figure illustrates a condition without signal interlock:

(seepage46)

the device provides.

Both input channels of the safety-related input are deactivated within the signal interlock monitoring time

of 200 ms. When they are activated again, the safety-related output is also activated.

The following figure illustrates a condition with signal interlock:

The first input channel of the safety-related input is deactivated which starts the signal interlock monitoring

time of 200 ms. It is then activated again before the second input channel of the safety-related input is

deactivated. This immediately triggers a signal interlock alert even though the 200 ms have not yet

elapsed.

The following figure illustrates a condition with signal interlock:

36

The first input channel of the safety-related input is deactivated which starts the signal interlock monitoring

time of 200 ms. The second input channel of the safety-related remains activated longer than 200 ms. This

triggers a signal interlock alert 200 ms after interlock monitoring has started.

EIO0000003454 11/2020

XPSUAB

Installation

EIO0000003454 11/2020

Installat ion

Chapter 4

Installation

What Is in This Chapter?

This chapter contains the following topics:

Prerequisites and Requirements 38

Mechanical Installation 39

Electrical Installation 40

Topic Page

EIO0000003454 11/2020 37

Installation

Prerequisites and Requirements

Inspecting the Device

Damaged products may cause electric shock or unintended equipment operation.

ELECTRIC SHOCK OR UNINTENDED EQUIPMENT OPERATION

Do not use damaged products.

Keep foreign objects (such as chips, screws or wire clippings) from getting into the product.

Failure to follow these instructions will result in death or serious injury.

DANGER

Verify the product type by means of the type code

Control Cabinet/Enclosure

Install the device in a control cabinet or enclosure with degree of protection IP54 that is secured by a keyed

or tooled locking mechanism.

The ventilation of the control cabinet/enclosure must be sufficient to comply with the specified ambient

conditions for the device and the other components operated in the control cabinet/enclosure.

(see page 15)

and the data printed on the device.

38

EIO0000003454 11/2020

Mechanical Installation

Mounting to DIN Rail

The device can be mounted to the following DIN rails as per IEC 60715:

35 x 15 mm (1.38 x 0.59 in)

35 x 7.5 mm (1.38 x 0.29 in)

Mounting procedure (left illustration)

Step Action

1 Slightly tilt the device and hook it onto the DIN rail.

2 Push the lower part of the device towards the DIN rail.

3 Snap in the DIN rail clip.

Installation

Screw-Mounting

Dismounting procedure (center illustration)

Step Action

1 Unlock the DIN rail clip using a screwdriver.

2 Pull the lower part of the device away from the DIN rail and lift the device towards the top to

remove it from the DIN rail.

Mounting procedure:

Step Action

1 Push the additional fastener into the grooves at the device.

2 Prepare the holes.

3 Screw the device to the mounting surface using the specified screws and a washer M4 as per

ISO 7093 for each screw.

EIO0000003454 11/2020 39

Installation

Electrical Installation

General Information

FIRE, ELECTRIC SHOCK OR ARC FLASH

Disconnect all power from all equipment of your machine/process prior to electrical installation of the

Confirm the absence of power using a properly rated voltage sensing device.

Place a "Do Not Turn On" or equivalent hazard label on all power switches and lock them in the non-

Failure to follow these instructions will result in death or serious injury.

Wiring of the device depends on the safety-related function to be implemented. Before wiring the device,

engineer the safety-related function, perform a risk assessment with regard to your machine/process, and

determine the suitability of the device as well as the connected equipment.

Refer to the Schneider Electric Safety Chain Solutions at

examples of wiring the device, including the safety-related outputs with feedback and the start input with

external start condition.

You can wire the device with the terminal blocks in the device or you can remove the terminal blocks. For

the latter, pull the terminal blocks out of the device, connect the individual terminals and push the terminal

blocks back into the device.

Use 75 °C (167 °F) copper conductors to wire the device.

device.

energized position.

DANGER

https://www.se.com

for application-specific

Wire Cross Sections, Stripping Lengths, and Tightening Torques

Characteristic Value

Stripping length for spring terminals 12 mm (0.47 in)

Stripping length for screw terminals 7 ... 8 mm (0.28 ... 0.31 in)

Wire cross section, single wire without wire ferrule

Wire cross section, single wire with wire ferrule

Wire cross section, two wires without wire ferrule

Wire cross section, two wires with uninsulated wire

ferrule

Wire cross section, two wires with insulated wire

ferrule

Tightening torque for screw terminals 0.5 ... 0.6 N m (4.4 ... 5.3 lb in)

(1) Stranded or solid

Block Diagram and Terminals

The following drawings present the block diagram and the terminals with their designations in the

removable terminal blocks.

(1)

0.2 ... 2.5 mm2 (AWG 24 ... 12)

0.25 ... 2.5 mm2 (AWG 24 ... 12)

(1)

0.2 ... 1.5 mm2 (AWG 24 ... 16)

0.25 ... 1 mm

0.5 ... 1.5 mm

2

(AWG 24 ... 18)

2

(AWG 20 ... 16)

40

EIO0000003454 11/2020

Terminal Designation Explanation

A1, A2 Power supply

Y1 Control output (DC+) of start input

Y2 Input channel (CH+) of start input

S11 Control output (DC+) of safety-related input. Two

terminals S11 are provided to facilitate wiring.

Connect only one of the S11 terminals.

S12, S13 Input channels (CH+) of safety-related input

B2 Terminal for common reference potential for 24 Vdc

11, 12, 14 Terminals of the safety-related outputs

Z1 Pulsed output for diagnostics

Depending on the selected application function, the

safety-related input is used with terminals S11-S12

only or with terminals S11-S12-S13. Refer to the

chapter Application Functions

signals. The power supplies of the connected

equipment must have a common reference potential

to be connected to this terminal.

safety-related

(see page 46)

(see page 64)

.

, not

Installation

Safety-Related Inputs

WARNING

INSUFFICIENT AND/OR INEFFECTIVE SAFETY-RELATED FUNCTIONS

Only connect a sensor/device to a safety-related input that meets all requirements as per your risk

assessment and that complies with all regulations, standards, and process definitions applicable to your

machine/process.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The device provides one safety-related input.The safety-related input consists of one control output DC+

(terminal S11) and two input channels CH+ (terminals S12, S13).

Even though the safety-related input has two input channels for increased diagnostics, it is still a single

input for single-channel operation as per ISO 13849.

The input channels receive the input signal from the connected sensor/device.

Depending on the application function

(see page 46)

to a device/sensor (for example, terminals S11–S12–S13 or terminals S11–S12 or terminals S12-S13 or

terminal S12). If only one CH+ terminal is connected, terminal S13 must remain unconnected.

The control output DC+ provides a nominal voltage of 24 Vdc to the connected sensor/device. It is also

used for dynamization

(see page 35)

.

, both or only one of the CH+ terminals are connected

EIO0000003454 11/2020 41

Installation

Respect the maximum wire resistance of 500 Ω when determining the cable length. The maximum wire

length between the safety-related input and a sensor/device is 30 m (98.43 ft) if the supply via the control

output (terminals S11) of the safety-related input is not used.

Wire the terminals of the safety-related input according to the wiring diagram for the application function

(see page 46)

Safety-Related Outputs

INCORRECT USE/WIRING OF SAFETY-RELATED OUTPUT

Connect all terminals of the safety-related changeover relay output if the output is to be used for

Verify that the changeover output is not used for safety-related purposes if only terminals 11 and 12

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The wiring of the safety-related output depends on the safety-related function to be implemented.

Install fuses with the rating specified in the chapter Electrical Characteristics

Start Input

to be implemented.

safety-related purposes.

are connected.

WARNING

(see page 22)

.

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not use the Start function for safety-related purposes.

Use Monitored Start or Startup Test if unintended restart is a hazard according to your risk

assessment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The start input consists of one control output DC+ (terminal Y1) and one input channel CH+ (terminal Y2).

The control output provides a nominal voltage of 24 Vdc to the connected sensor/device. It is also used for

dynamization

The wiring of the start input depends on the start function

For automatic start, bridge terminals Y1 and Y2 or connect terminal Y2 to an external 24 Vdc power supply.

For manual start or monitored start and if the control output Y1 (DC+) is to be used:

Connect terminals Y1 and Y2 to the device providing the start signal, such as a push-button.

For manual start or monitored start and if the device providing the start signal is supplied externally:

Connect terminal Y2 to the device providing the start signal, such as a push-button or a logic controller.

Leave terminal Y1 unconnected.

The common reference potential is established via terminal B2.

Respect the maximum wire resistance of 500 Ω when determining the cable length. The maximum wire

length between the start input and a sensor/device is 30 m (98.43 ft) if the supply via the control output

(terminal Y1) of the start input is not used.

(see page 35)

.

(see page 53)

to be implemented.

Additional, Non-Safety-Related Output Z1

INCORRECT USE OF OUTPUT

Do not use the additional output Z1 for safety-related purposes.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Connect the semiconductor pulsed output Z1 to a suitable input of the logic controller if you want to use

the diagnostics pattern the output provides.

The maximum wire length between the additional output Z1 and connected equipment is 30 m (98.43 ft)

42

WARNING

EIO0000003454 11/2020

The common reference potential is established via terminal B2.

Power Supply

Connect the terminals A1 and A2 to a power supply providing the supply voltage specified for the device

in the chapter Electrical Characteristics

Common Reference Potential

Terminal B2 is provided to obtain a common reference potential for 24 Vdc signals.

The power supplies of the connected equipment must have a common reference potential.

(see page 21)

Installation

.

EIO0000003454 11/2020 43

Installation

44

EIO0000003454 11/2020

XPSUAB

Functions

EIO0000003454 11/2020

Functions

Chapter 5

Functions

What Is in This Chapter?

This chapter contains the following topics:

Application Functions 46

Start Functions 53

Topic Page

EIO0000003454 11/2020 45

Functions

Application Functions

Introduction

The following sections provide an overview of the available application functions and a detailed listing of

requirements and values of each of the application functions. The chapter Configuration

describes the configuration procedure by means of the selectors of the device.

Overview of Application Functions

(see page 58)

Typical applications Type of outputs of sensor/device providing

the input signal for application function

Monitoring of Emergency Stop circuits

as per ISO 13850 and IEC 60204-1,

stop category 0

Monitoring of guards as per

ISO 14119/14120 with electrical

switches

Monitoring of two-hand control devices,

type III A as per ISO 13851

Monitoring of guards as per

ISO 14119/14120 with electrical

switches

Monitoring of guards as per

ISO 14119/14120 with coded magnetic

switches

Monitoring of proximity switches

Monitoring of proximity switches One PNP output No No Position 5

Monitoring of electro-sensitive

protective equipment such as type 4

light curtains as per IEC 61496-1

Monitoring of RFID sensors

Normally open, normally closed and/or

changeover outputs

OSSD (Output Signal Switching Device)

outputs

Synchroni

zation

No Yes Position 1

Dynamizat

ion

Application

function

selector

(seepage47)

Yes Yes Position 2

(seepage48)

Yes Yes Position 3

(seepage49)

Yes Yes Position 4

(seepage50)

(seepage51)

Yes No Position 6

(seepage52)

46

EIO0000003454 11/2020

Application Function 1

Functions

Characteristic Value/Description

Typical applications Monitoring of Emergency Stop circuits as per

ISO 13850 and IEC 60204-1, stop category 0

Monitoring of guards as per ISO 14119/14120

with electrical switches

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S11-S12

Dynamization Yes

Signal interlock monitoring No

Synchronization of safety-related inputs No

Normally open, normally closed and/or changeover

outputs

Signals at terminal S13 are not evaluated. Do not connect

this terminal.

Wiring of the inputs for Emergency Stop

Wiring of the inputs for guards

EIO0000003454 11/2020 47

Functions

Application Function 2

Characteristic Value/Description

Typical applications Monitoring of two-hand control devices,

type III A as per ISO 13851

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S11-S12 and S11-S13

Dynamization Yes

Signal interlock monitoring No

Normally open, normally closed and/or changeover

outputs

This application function requires the start function selector to be set to positions 1 or 5, automatic start

without startup test. Refer to Start Functions

(see page 53)

for details.

Synchronization:

Synchronized terminals Synchronization time

S12 synchronized with S13 S12 and S13 have to be activated within 0.5 s.

Wiring of the inputs for two-hand control devices

48

EIO0000003454 11/2020

Application Function 3

Functions

Characteristic Value/Description

Typical applications Monitoring of guards as per ISO 14119/14120

with electrical switches

Monitoring of guards as per ISO 14119/14120

with coded magnetic switches

Monitoring of proximity switches

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S11-S12 and S11-S13

Dynamization Yes

Signal interlock monitoring No

Normally open, normally closed and/or changeover

outputs

Synchronization:

Synchronized terminals Synchronization time

S12 synchronized with S13 S12 and S13 have to be activated within 0.5 s.

Wiring of the inputs for coded magnetic switches

EIO0000003454 11/2020 49

Functions

Application Function 4

Characteristic Value/Description

Typical applications Monitoring of guards as per ISO 14119/14120

with electrical switches

Monitoring of guards as per ISO 14119/14120

with coded magnetic switches

Monitoring of proximity switches

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S11-S12 and S11-S13

Dynamization Yes

Signal interlock monitoring No

Normally open, normally closed and/or changeover

outputs

Synchronization:

Synchronized terminals Synchronization time

S12 synchronized with S13 S12 and S13 have to be activated within 2.2 s.

Wiring of the inputs for coded magnetic switches

50

EIO0000003454 11/2020

Application Function 5

Functions

Characteristic Value/Description

Typical applications Monitoring of proximity switches

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S12

Dynamization No

Signal interlock monitoring No

Synchronization of safety-related inputs No

One PNP output

Signals at terminal S13 are not evaluated. Do not connect

this terminal.

Wiring of the inputs for sensors/devices with PNP output

EIO0000003454 11/2020 51

Functions

Application Function 6

Characteristic Value/Description

Typical applications Monitoring of electro-sensitive protective

equipment such as type 4 light curtains as per

IEC 61496-1

Monitoring of RFID sensors

Type of outputs of sensor/device providing the input signal

for application function

S•• terminals to be connected S12 and S13

Dynamization No

Signal interlock monitoring Between terminals S12 and S13

OSSD (Output Signal Switching Device) outputs

Synchronization:

Synchronized terminals Synchronization time

S12 synchronized with S13 S12 and S13 have to be activated within 0.5 s.

Wiring of the inputs for sensors/devices with OSSD outputs

52

EIO0000003454 11/2020

Start Functions

Overview

Functions

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not use the Start function for safety-related purposes.

Use Monitored Start or Startup Test if unintended restart is a hazard according to your risk

assessment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The devi ce p rov ide s se ver al s tar t functions which are selected by means of the start function selector. The

start function determines the start behavior of the device after power-on and for a transition from the

operating state Run: Outputs Deenergized (defined safe state) to the operating state Run: Outputs

Energized.

The start behavior is configured using the following characteristics:

Type of start (automatic/manual start and monitored start)

With or without startup test

With or without dynamization

Refer to the chapter Electrical Installation

(see page 35)

(see page 42)

for additional information on wiring the start input.

Automatic Start

Manual Start

With automatic start, the start input is permanently active. This can be achieved by bridging the start input

or providing an external power supply. When the safety-related input is activated, the safety-related output

is activated within a maximum of 100 ms (activation delay).

The following timing diagram illustrates the automatic start:

1 Activation delay (100 ms): maximum time between activation of safety-related input and activation of safety-related

output

2 Response time (20 ms): maximum time between deactivation of safety-related input and deactivation of safety-

related output

3 Recovery time (200 ms): time that must pass before the safety-related input can be activated again

A manual start requires the start input to be activated. The safety-related output is activated after both the

start input and the safety-related input have been activated.

EIO0000003454 11/2020 53

Functions

The following timing diagram illustrates the manual start:

1 Activation delay (100 ms): maximum time between activation of start input and activation of safety-related output

2 Response time (20 ms): maximum time between deactivation of safety-related input and deactivation of safety-

related output

3 Recovery time (200 ms): time that must pass before the safety-related input can be activated again

The signal required for activation of the Start input can be provided, for example, via a push-button, or a

logic controller.

Monitored Start with Falling Edge

In the case of a monitored start with falling edge, the start input must be activated and remain active for a

duration of 80 ms. The safety-related outputs are activated with a falling edge of the start input if the safetyrelated inputs have been activated in the meantime.

Startup Test

54

1 Activation delay (100 ms): maximum time between deactivation of start input and activation of safety-related output

2 Response time (20 ms): maximum time between deactivation of safety-related input and deactivation of safety-

related output

3 Waiting time after power-on (2500 ms): time that must pass between power-on and activation of the start input

4 Minimum duration of start pulse (80 ms): time for which the start input must be activated before the falling edge at

the start input

The signal required for activation of the Start input can be provided, for example, via a push-button or a

logic controller.

The startup test is performed after the device is powered on. The startup test is typically used for

applications involving guard monitoring. The start input is permanently activated by, for example, bridging.

After power-on, the safety-related input must be deactivated and activated before the safety-related output

is activated. This is achieved by, for example, opening and closing the guard.

EIO0000003454 11/2020

Functions

1 Activation delay (100 ms): time between activation of safety-related input and activation of safety-related output

2 Response time (20 ms): time between deactivation of safety-related input and deactivation of safety-related output

3 Recovery time (200 ms): time that must pass before the safety-related input can be activated again

After power up, the safety-related outputs are not activated before each of the safety-related inputs has

been deactivated and activated again, either concurrently or one after the other, regardless of sequence.

If the safety-related inputs are already inactive at startup (power cycle), the startup test is considered to

have been completed and the safety-related outputs are activated once the safety-related inputs have

been activated and the activation delay has passed. If the safety-related inputs are active at power up, they

must be deactivated and activated again for the startup test to complete.

Configuring the Start Function

The start function is configured by means of the start function selector.

Position of start function selector Configured start function

1

2

3

4

5

6

7

8

Manual/automatic start (depends on

sensor/device connected to start input)

Without startup test

With dynamization

Manual/automatic start (depends on

sensor/device connected to start input)

With startup test

With dynamization

Monitored start

Without startup test

With dynamization

Monitored start

With startup test

With dynamization

Manual/automatic start (depends on

sensor/device connected to start input)

Without startup test

Without dynamization

Manual/automatic start (depends on

sensor/device connected to start input)

With startup test

Without dynamization

Monitored start

Without startup test

Without dynamization

Monitored start

With startup test

Without dynamization

A start function with dynamization is typically if the start input is connected to a start push-button. A start

function without dynamization is typically used if the start input is connected to a logic controller. Refer to

the chapter Dynamization

EIO0000003454 11/2020 55

(see page 35)

for details.

Functions

56

EIO0000003454 11/2020

XPSUAB

Configuration and Commiss ioning

EIO0000003454 11/2020

Configuration and Commissioni ng

Chapter 6

Configuration and Commissioning

What Is in This Chapter?

This chapter contains the following topics:

Configuration 58

Commissioning 59

Topic Page

EIO0000003454 11/2020 57

Configuration and Commissioning

Configuration

Overview

The device detects certain technically incorrect configurations (for example, a configured start function

cannot be used with a configured application function). The device cannot detect unwanted configurations

(for example, automatic start has been configured, but a monitored start is required for your application as

a result of your risk assessment).

INEFFECTIVE SAFETY-RELATED FUNCTION AND/OR UNINTENDED EQUIPMENT OPERATION

Only modify the settings of the selectors of the device if you are fully aware of all effects of such

modifications.

Verify that the settings of the selectors match the intended safety-related function and the

corresponding wiring of the device.

Verify that modifications do not compromise or reduce the Safety Integrity Level (SIL), Performance

Level (PL), and/or any other safety-related requirements and capabilities defined for your

machine/process.

Commission the device before it is used for the first time and after each configuration according to the

instructions in the present manual and in compliance with all regulations, standards, and process

definitions applicable to your machine/process

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

The device is configured by means of the application function selector and the start function selector.

The device must be installed and wired according to the requirements of the safety-related function to be

implemented before you can configure it.

Modifications to the positions of the selectors only become effective after power-up. Remove power from

the device before modifying the position of the selectors. If the positions of the selectors are modified while

power is applied to the device, the device detects a configuration error.

Go through the full commissioning procedure

selectors.

Configuration Procedure