Page 1

APPLICATION

For proportional temperature control of pneumatic valves and

actuators to maintain air or liquid temperatures in duct,

plenum chambers, liquid lines, tanks, etc. May also be used

as a low limit thermostat.

SPECIFICATIONS

Thermostat: Proportional two pipe type. Thermostats are

ambient compensated.

Sensing Element: Remote liquid-filled copper.

Control Dial Range: -20 to 240°F (

as -20 to 120°F, reverse side of dial 100 to 240°F.

Throttling Range: Adjustable 3 to 35°F/10

kPa) change in output, factory set at 5°F (3°C).

Output Air Signal: 0.5 psig (3.4 kPa) to supply air pressure

-0.5 (-3.4 kPa).

Action: See Table 1.

Ambient Limits:

Shipping, -40 to 150°F (-40 to 65°C). 0 to 98% R.H.,

non-condensing.

Case Operating, 40 to 150°F (4 to 65°C). 10 to 98%

R.H., non-condensing.

Bulb, 310°F (1

54°C) maximum.

Supply Air Pressure: Clean, oil free, dry air required

(reference EN-123).

Nominal, 20 psig (138 kPa).

Minimum, 15 psig (103 kPa).

Maximum, 30 psig (207 kPa).

Air Connections: 1/8" FNPT for main, branches and

gauges (not included).

AL-362

Air Consumption for Sizing Air compressor: 0.008 scfm

l/s).

(3.8 m

Air Capacity for Sizing Air Mains: 16 scim (4.4 ml/s).

Mounting: Upright position on a wall or vertical flat surface.

Bulb Dimensions: See Table 1.

Capillary Length: 6’ (1.8 m).

Case Dimensions: 5-13/16" high x 6-3/16" wid e x 4" deep

mm x 157 mm x 102 mm).

(148

ACCESSORIES

AL-362 Stem mounted back connected 0-30 psi gauge

AT-201 3/8" x 9-1/2" with 3/4" MNPT copper bulb well

AT -203 3/8" x 9-1/2" with 3/4" MNPT stainless steel bulb

AT-206 3/8" x 4-1/2" with 1/2" MNPT copper bulb well

AT-208 Duct mounting kit

AT-209 Liquid line or tank mounting kit

AT-211 Bulb shield

AT-539 Pilot pressure kit

TOOL-95 Pneumatic calibration tool kit (required for use

ires AT-209

requ

equires AT-209

well r

as low limit thermostat)

-29 to 115°C). Shipped

psi (2 to 19°C/69

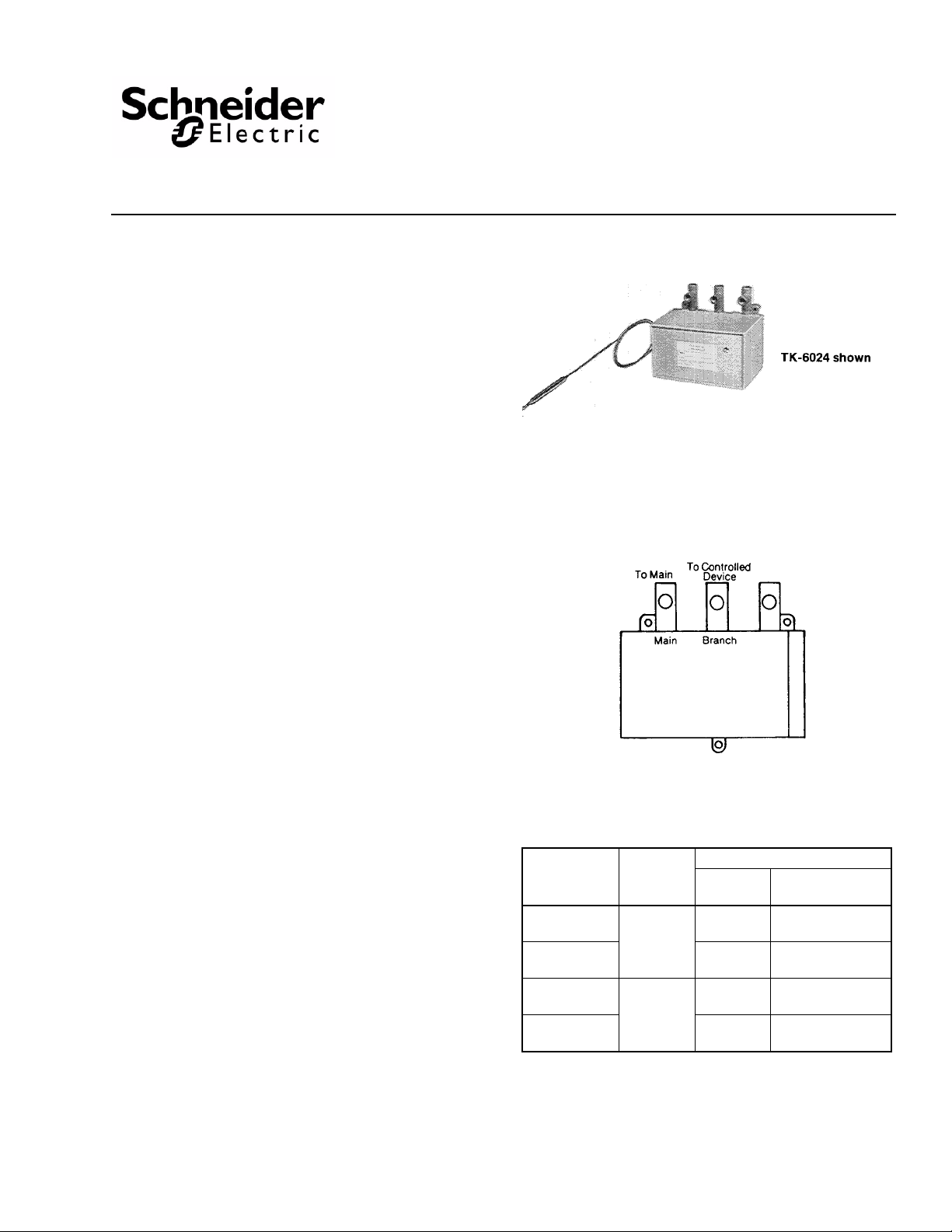

TK-6024, TK-6124, TK-8024,

TK-8124

Pneumatic Bulb Thermostats

General Instructions

MAINTENANCE PARTS

AT-520-011 Relay repair kit

AT-528 Pilot restrictor kit

DYDK-77-031 Thermal element for TK-8X24

DYDK-99-011 Thermal element for TK-6X24

Figure-1 Piping Connections.

Table-1 Specifications.

Bulb

Part Number Action

TK-6024

TK-8024 Averaging

TK-6124

TK-8124 Averaging

a

Direct Acting (DA) - increase output pressure on temperature rise.

Reverse Acting (RA) - Decrease output pressure on temperature rise.

DA

RA

a

a

Style

Straight

Straight

Dimensions

in (mm)

3/8 x 4-5/8

(9.5 x 117)

3/32 x 8’

(2.4 x 2.4 m)

3/8 x 4-5/8

(9.5 x 117)

3/32 x 8’

(2.4 x 2.4 m)

Printed in U.S.A. 12/09 © Copyright 2009 Schneider Electric All Rights Reserved. F-14684-5

Page 2

PRE-INSTALLATION

Inspection

Visually inspect the carton for damage. If damaged, notify the

appropriate carrier immediately. Visually inspect the device for

obvious defects. Return damaged or defective products.

Required Installation Items

• Tools (not provided):

Appropriate drill, drill bits and screwdriver for mounting

screws

Needle nose pliers or 3/16" open-ended wrench to hold

dial shaft

• Appropriate Accessories

• Mounting screws and appropriate fittings (not provided)

INSTALLATION

Caution: Installer must be a qualified, experienced

technician.

Make all connections in accordance with the job piping

diagrams, local and national codes.

Avoid locations near steam or hot water coils or pipes, or

wherever radiant heat will affect the bulb or capillary tube.

THERMOSTAT MOUNTING

Mount the thermostat in an upright position on a wall or vertical

flat surface that does not vibrate.

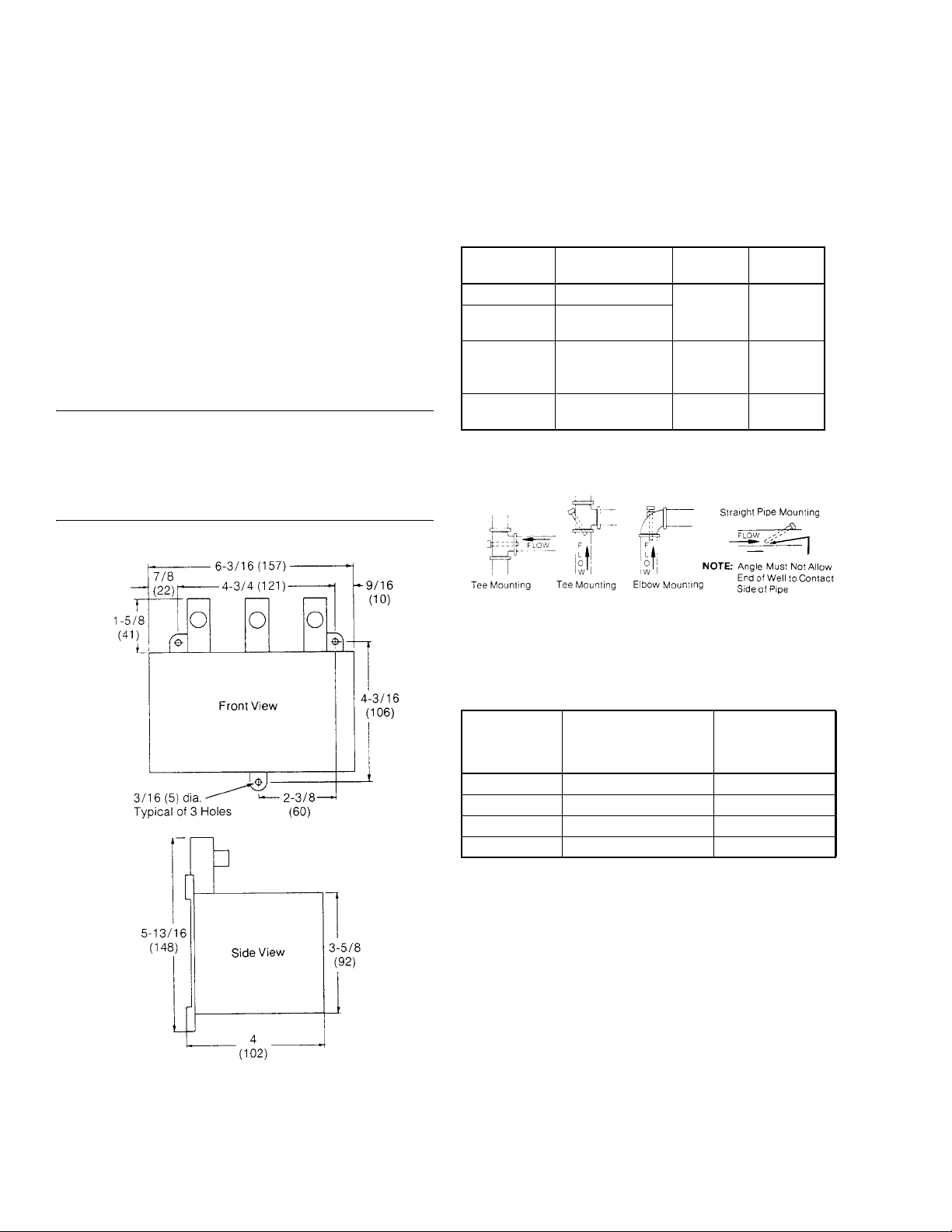

Three (3) mounting holes 3/16" (5 mm) provided on case.

BULB MOUNTING

Table-2 Liquid Line and Tank for TK-6X24.

Part Number Description Mt. Fitting

a

AT-201

AT-203

AT-206 Copper bulb well 1/2" MNPT

AT-209

a

Requires AT-208.

b

Recommended installation is with a bulb well.

Copper bulb well

Stainless steel bulb

a

b

well

Bulb mounting kit 3/4" MNPT

3/4" MNPT

Insertion

Size

1/2" dia.

OD (9-1/2”

long

1/2" dia.

OD 4-1/2"

long

Length of

bulb

Figure-2 Mounting Dimensions.

Figure-3 Bulb Well Installation.

Table-3 Application Limitations at 250°F Fluid Temp.

(Max. 350°F)

Part Number

AT-201 11 250

AT-203 20 500

AT-206 11 250

AT-209 4 150

Max. Recommended

Velocity (FPS)

Max.

Recommended

Static Pressure

(psig)

Installation of TK-6X24 Bulb into AT-206 Bulb Well

1. Install AT-206 bulb well into 1/2" FNPT opening.

2. Place packing (included with AT-206) over bulb support section and insert bulb into well.

3. Push packing into nut on well using a screwdriver.

2 © Copyright 2009 Schneider Electric All Rights Reserved. F-14684-5

Page 3

Figure-4 Installation of TK-6X24 into AT-206 Bulb Well.

Installation of TK-6X24 Bulb into AT - 201 or AT-203 Bulb Well (Requires AT-209 Kit)

1. Install bulb well or adaptor from AT-209 into 3/4" FNPT opening.

2. Place packing nut, washers and packing from AT-209 over bulb support section and insert bulb into well or AT-209 adaptor.

3. Push interlocking washers and packing into well or adaptor and tighten packing nut until firmly sealed.

Outdoor Installation of TK-6X24

Install with AT-211 kit as shown below.

1. Mount bulb to outside wall or surface with bulb clip.

2. Place shield over bulb and fasten to mounting surface.

Figure-7 Installation of TK-6X24 Using AT-211 Outside Bulb

Shield.

Duct Installation of TK-6X24

Install bulb with AT-208 kit as shown below.

Figure-5 Installation of TK-6X24 Bulb into AT-201 or AT-203

Bulb Well with Required AT-209 Kit.

Duct Installation of TK-8X24

Install averaging bulb mounting with two AT -208 kits as shown

below.

Figure-6 Installation of TK-8X24 Using AT-208 Duct

Mounting Kit.

Note: Access panel may be required to allow for tying bulb to

copper after it is installed in the duct.

Figure-8 Installation of TK-6X24 Using AT-208 Duct

Mounting Kit.

ADJUSTMENTS

Thermostats are shipped from the factory calibrated to provide

an 8 psig control line pressure when the control point is equal

to the setpoint.

To make all adjustments, remove the cover by first loosening

the cover screws. Squeeze slightly on the top and bottom and

pull forward and down, unhooking the top first.

Setpoint Dial

The thermostat has a total dial range of -20° to +240°F. One

side of the dial is marked -20 to 120 and the other 100 to 240.

If a setpoint higher than 120° is required, proceed as follows:

1. Rotate setpoint dial to 110°.

2. using a 3/16" open end wrench, hold hex shaft below setpoint dial.

3. Loosen screw that holds dial in place and remove.

4. Remove dial and turn over to the 100 to 240 side.

5. Start screw into dial post, before tightening line up dial at 110°, and tighten. Be sure to hold dial post with wrench when tightening screw tight.

6. Proceed with standard throttling range and calibration procedures.

F-14684-5 © Copyright 2009 Schneider Electric All Rights Reserved. 3

Page 4

Throttling Range

The throttling range should be set at the lowes t va lue

which will allow the thermostat to control the system

without cycling under normal load condi tions. The most

satisfactory setting will vary with he type of control system.

The throttling range is changed by sliding the throttling range

adjustment slider to its proper position. See Figure 9.

Calibration of the thermostat should be checked after the

throttling range has been changed. When making the

throttling range adjustment, care should be taken to prevent

excessive side forces on the feedback lever. In no case should

the pivot point be raised when the adjustment is made.

Throttling Range Adjustment

If the throttling range of the thermostat as shipped is not

satisfactory, proceed as follows:

1. Move slider to approximate position desired (see Figure 9).

2. With instrument measuring a stable temperature, rotate setpoint dial CCW to low end of scale, then CW to that temperature “setpoint”.

3. Adjust setpoint calibration screw until 3 psig (RA) or 13 psig (DA) is read on branch gauge.

4. Rotate setpoint dial CW toward upper end of scale until 13 psig (RA) or 3 psig (DA) is read on branch gauge.

5. Difference between setpoint dial readings in step 2 and 4 is the approximate mechanical throttling range of the thermostat. The thermal throttling range will be equal to or less than the mechanical throttling range.

6. If the throttling range in step 5 does not provide the

control desired, move throttling range slider in

appropriate direction and repeat steps 2 through 5 until

desired control is obtained. If unable to obtain satisfactory

control, check system for proper sizing of components

being controlled and sensing element location.

Figure-9 Thermostat Adjustments.

4 © Copyright 2009 Schneider Electric All Rights Reserved. F-14684-5

Page 5

CALIBRATION

After the installation has been completed, the thermostat

should be checked for calibration. As a nominal calibration,

the controlled branch pressure should be 8 psig when the

setpoint is equal to the bulb temperature, indicated by a

thermometer located near the bulb. In some applications, a

value other than 8 psig will be required to get the desired

control results. Change the 8 psig will be required to get the

desired control results. Change the 8 psig designation as used

in the calibration procedure, should this be the case.

1. Using the branch gauges, or a separate test gauge

connected to the branch test port (see Note), rotate the dial

[direct acting (DA) - lower , reverse acting (RA) - rai se] in

the appropriate direction. The branch pressure should

raise to be the same as the supply pressure ±1 psi.

Note: As shown in Figure 9, each thermostat is furnished

with a branch test connection. If a test gauge is to be used at

this connection, use a 5/64" Alle n w r en ch to un scre w

(counterclockwise) the test point screw one full turn before

attaching test gauge.

2. Measure the temperature at the bulb. This must be a stable temperature.

3. Rotate the dial to this temperature.

4. Turn the setpoint calibration screw (see Figure 9) until a branch pressure of 8 psig ±1 psi is read on the branch gauge.

1. Remove restriction cover plate, restriction and two gaskets (see Figure 9 for location).

2. Using the parts from the AT-539 place in order one gasket, restrictor plate, the other gasket and cover plate with the tubing attached on the restrictor mounting pad. Then install the two (2) screws.

3. Route 5/32" plastic tubing through hole in base and connect to constant 15 or 20 psig main.

Calibration When Used As Low Limit

1. Determine throttling range required. This normally is approximately 10°F.

2. Adjust branch pressure from first thermostat to maximum branch pressure.

3. Adjust throttling range as described in Throttling Range Adjustment on page 3.

4. After throttling range is adjusted, proceed with calibration of control point as described in Calibration.

FIELD SERVICE

Relay repair kit, pilot restrictor and thermal elements are

available. See Maintenance Parts on page 1 for specific

part numbers.

Note: The hex nut on the adjusting screw is used to provide

tension only and should not be loosened when making

adjustments.

5. Turn the dial to the desired setpoint.

6. If separate test gauge is used, remove gauge, tighten test point screw and replace cover.

7. Observe operation of system for satisfactory control. If necessary, recalibrate after system has come in control and stabilized.

USE AS A LOW LIMIT THERMOSTAT

These thermostats may be used as low limit thermostats.

Normally in this application, they are used in series with the

branch pressure of another proportional thermostat. When

using two proportional thermostats in series, the second unit

must have an external main air source for the pilot chamber of

the thermostat. This is required to insure the operation of the

second thermostat at low branch pressure from the first

thermostat. An external pilot pressure kit is required for this.

The part number of this kit is AT-539.

Attachment of AT-539

To attach the AT -539 external pilot pressure kit, u se the

following procedure.

MAINTENANCE

Regular maintenance of the total system is

recommended to assure sustained optimum

performance.

F-14684-5 © Copyright 2009 Schneider Electric All Rights Reserved. 5

Page 6

On Oc tober 1st, 2009, TA C became the Buildings business of its pa rent company Schneider Electri c. This document reflect s the visual identit y of Schneider Electric,

ho wever t her e rema ins referenc es to TAC as a corpora te brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

Copyright 2009, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-14684-5

Loading...

Loading...