Page 1

Installation Instructions

INPUT

:

CLASS 2 POWER ONLY

24VAC , 0.42A, 10 VA, 50/60HZ

USE COPPER CONDUCTORS ONLY

MORE THAN ONE DISCONNECT SWITCH

MAY BE REQUIRED TO DE-ENERGIZE THIS

EQUIPMENT BEFORE SERVICING.

CAUTION

This equipment complies with part 15 of the FCC rules.

Operation is subject to the following two conditions.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

24 VAC

RET

RET

RET

IN 5

IN 4

IN 3

IN 2

IN 11

21

20

19

18

17

16

15

14

13

OUT4

OUT5

TRIAC REF

AO6

RET

A07

SHIELD

12

OUT3

2

3

4

5

6

7

8

9

10

11

(HIGH)

(LOW)

AIR FLOW

INPUT

UNIVERSAL

INPUTS

RS-485

PORT

ANALOG

OUTPUTS

0-10 VDC

DIGITAL

OUTPUTS

24V AC ,

0.5A

SMART

SENSOR

COM

COM

866-V

P1

(LO)

P2

(HI)

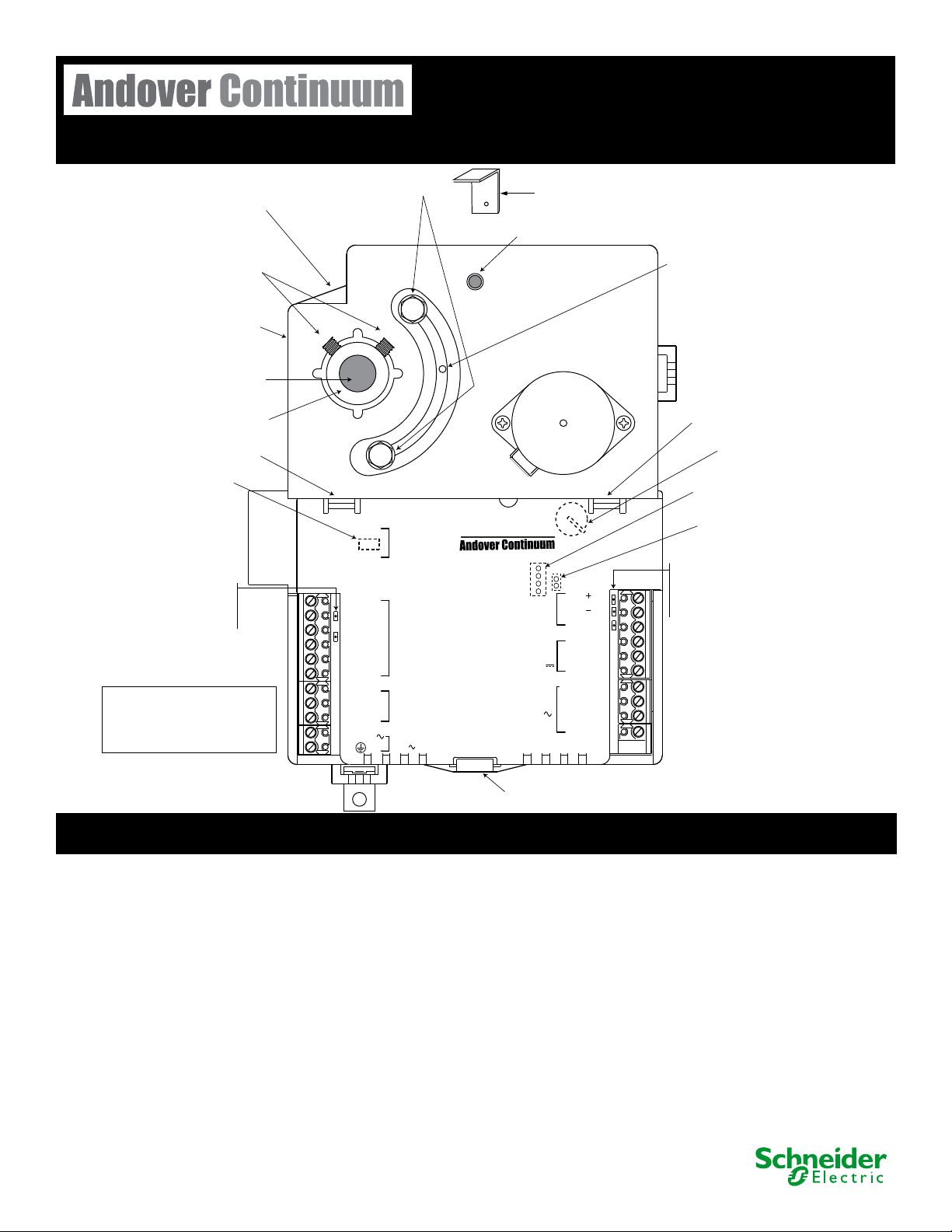

Mounting Clip

Alternative Damper Shaft

Mounting Screw Position

Adjustable Stops

Actuator Clutch Release

Damper Shaft

Hex Mounting Screws

Alternative Damper Shaft

Mounting Screw Position

Damper Shaft

Damper Shaft Collar

Cover Release

Velocity Sensor

Inputs

(Barbed fittings)

Cover Release

Damper Position Indicator

Alternate

Mounting Bracket

Mounting Bracket

Cover Release

Two CPU LEDs

Green = b3 controller

Yellow = i2 controller

TD LED = Yellow

RD LED = Green

Wireless LED = Red

Note: Input, Output, and

Smart Sensor connections will

vary per controller model.

Service Port Location

(Remove cover)

SPWR

4-Position Dipswitch

Battery Location

(Remove cover)

Jumper for Actuator

Direction

Wiring Requirements:

300V

8A

22 - 12AWG

6 inch-lb screw tourque

30-3001-985

i2/b3 865/866/885-V Controller

Rev G.4

i2/b3 865/866/885-V Controller Installation

To install the controller, follow these steps:

1. Check the mounting location for the Andover Continuum i2 or b3

865/866/885-V controller. The unit is typically mounted with the

controller extending down or to the right from the damper shaft.

However, the controller can be operated in any position within

the vertical plane.

Note: Installing the controller to the right (with the barbed

ttings pointing down) helps prevent condensate from

migrating into the on-board velocity sensor.

With a downward extension, the available area around the damp-

er shaft must measure 6” (160 mm) down from the lower edge

of the shaft, 4.5” (120 mm) to the right, 1.5” (40 mm) to the left

and 1.75” (45 mm) above the shaft. Ensure the location allows

enough clearance for servicing.

2. The actuator is designed to mount over a

3. If the exposed damper shaft is less than 2” (51 mm) but at least 1”

4. Select the mounting bracket location that provides the most stability

1

/2” (12.7 mm) diameter

shaft with a minimum of 2.5” (63.5 mm) of exposed shaft. If the

damper shaft diameter is less than 1/2” (12.7 mm) an adapter is

required. An adapter (p/n AM-135) is available from Schneider

Electric to allow mounting on 3/8” (9.5 mm) damper shaft. The

865/866/885-V controller will not work with larger damper shaft

diameters.

(25.4 mm) long, move the two damper shaft mounting screws to the

alternate lower damper shaft positions.

for the operation of the actuator. Position the mounting clip in the

desired mounting bracket. Do not insert the clip more than half-way

into the bracket. This allows the clip and the back of the actuator to

properly align with the VAV box.

© 2018 Schneider Electric, all rights reserved.

Page 2

i2/b3 865/866/885-V Controller Installation (continued)

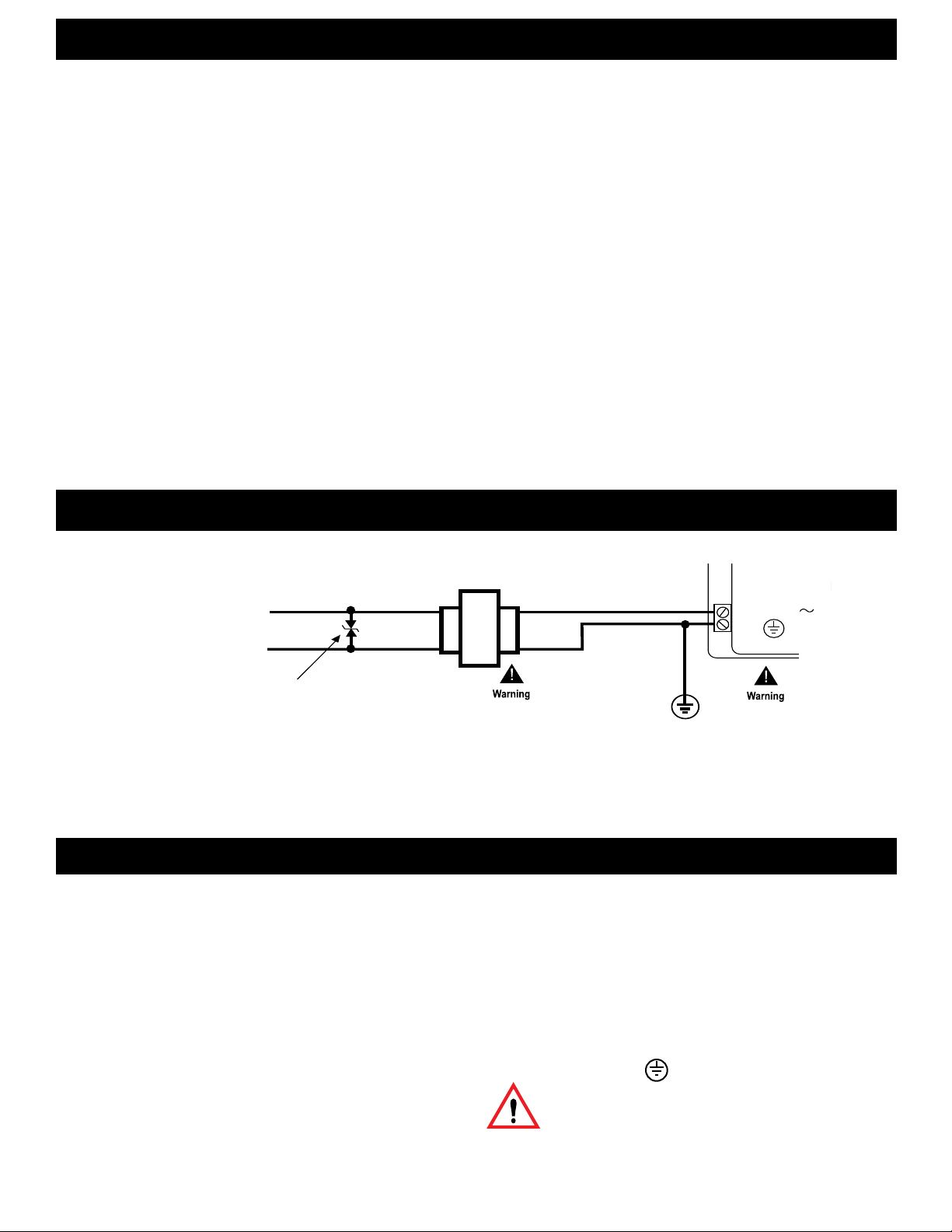

AC Line

Power

Optional Varistor

(Choose a voltage rating appropriate

to the input voltage applied.

For example, 130V or 250V)

24 VAC Step-Down

or Isolation Transformer

X1

X2

11

10 24VAC

Each controller on the network must have its own

24V Step-Down or Isolation Transformer. Be sure to

wire the secondary of the 24V Step-Down Transformer

exactly as shown. Pin 11 must be connected to the grounded

side of the secondary on all transformers used in the system.

Otherwise, damage to one or more controllers may result.

Class 2 power only!

5. Press and hold the green actuator clutch release and rotate the

VAV damper shaft by hand to the fully closed position. Note

whether the damper is rotated clockwise (CW) or counter-clockwise (CCW) to close.

6. Slip the controller over the damper shaft. Position the actuator

and, using a self tapping sheet metal screw, secure the mounting clip to the VAV box.

7. Next, press the actuator toward the box until the actuator comes

into contact with the VAV box, the mounting clip snaps into the

bracket, or the back of the actuator comes into contact with the

VAV box.

8. Press and hold the green actuator clutch release (see Figure on

cover page) and rotate the actuator collar to a nearly closed

position, the 5° index mark, if the damper shaft was rotated

counter-clockwise to close (Step 5). Rotate the actuator collar to

the 85° index mark if the damper shaft was rotated clockwise to

close (Step 5).

1

9. Tighten the two damper hex mounting screws using a

/8” hex

Allen wrench. The minimum torque required to secure the controller to the damper shaft depends on the shaft material. The

maximum torque for the socket screws is 30 inch-pounds (3.4

Nm).

AC Power Connection

Note: The damper should rotate freely when the clutch is released.

If it does not, the actuator may not be properly aligned with

the damper shaft – it may be necessary to repeat Steps 4

through 9 using a new orientation.

10. If the damper does not provide a mechanical stop in the open direction,

or it is not desirable to use the damper’s open stop, set the adjustable

stops on the 865/866/885-V controller to the desired position. Use a

1

/4” hex driver to adjust the screw stop on the controller.

Note: For the 866-V model only, you must calibrate the damper

position feedback reporting option before using. You

calibrate damper position feedback reporting by changing

the damper’s output attribute, LCDState, from DISABLED

to ENABLED. The attribute, OverrideValue, indicates the

damper position as a fractional value from 0 (at the closed

stop) to 1 (at the open stop).

Whenever the Actuator Clutch Release button is pressed and

the Actuator is moved manually, you need to recalibrate

damper position feedback reporting. During damper

calibration, the damper output will rotate from one end- stop

to the other and then return to its original position. It is also

recommended that you periodically recalibrate damper position

feedback reporting using a Plain English (PE) program.

Note: Use care when attaching power wiring to these connectors. They are not to be used as a strain relief.

The connectors cannot withstand excessive bending or exing.

Failing to install this transformer on remote controllers can damage it and other controllers on the network.

Wiring Rules

These modules are intended for installation

within the enclosure of another product.

Do not remotely ground any part of the input sensor wiring.

Remote grounds connected to the return terminal could make

the system operate incorrectly or damage the equipment.

The signal return is not true earth ground. It is an electronic

reference point necessary to interpret the sensor properly.

For reliable input operation, follow these input wiring guidelines:

• Never lay wires across the surface of a printed circuit board.

• Wires should never be within 1” or 25 mm of any component

on a printed circuit board.

• Use shielded input wire.

• Terminate the shield of the input wires at one end of the run

only — preferably at the end where your I/O module is located.

• When stripping wire, be careful not to drop small pieces of wire

inside the cabinet.

• Don’t run your input wiring in the same conduit with AC power.

• Don’t run your input wiring in the same conduit with your

output wiring.

Grounding the Controller

To insure proper operation of the controller, it must be connected to a

good earth ground. The connection must be made as close to the module

as possible.

Caution: Earth ground ( ) must be connected to avoid

module damage.

Removing the Plastic Battery Tab

Before operating the controller, open the cover and remove the

protective plastic battery tab. The battery location is shown in the

illlustration on the cover page.

Page 3

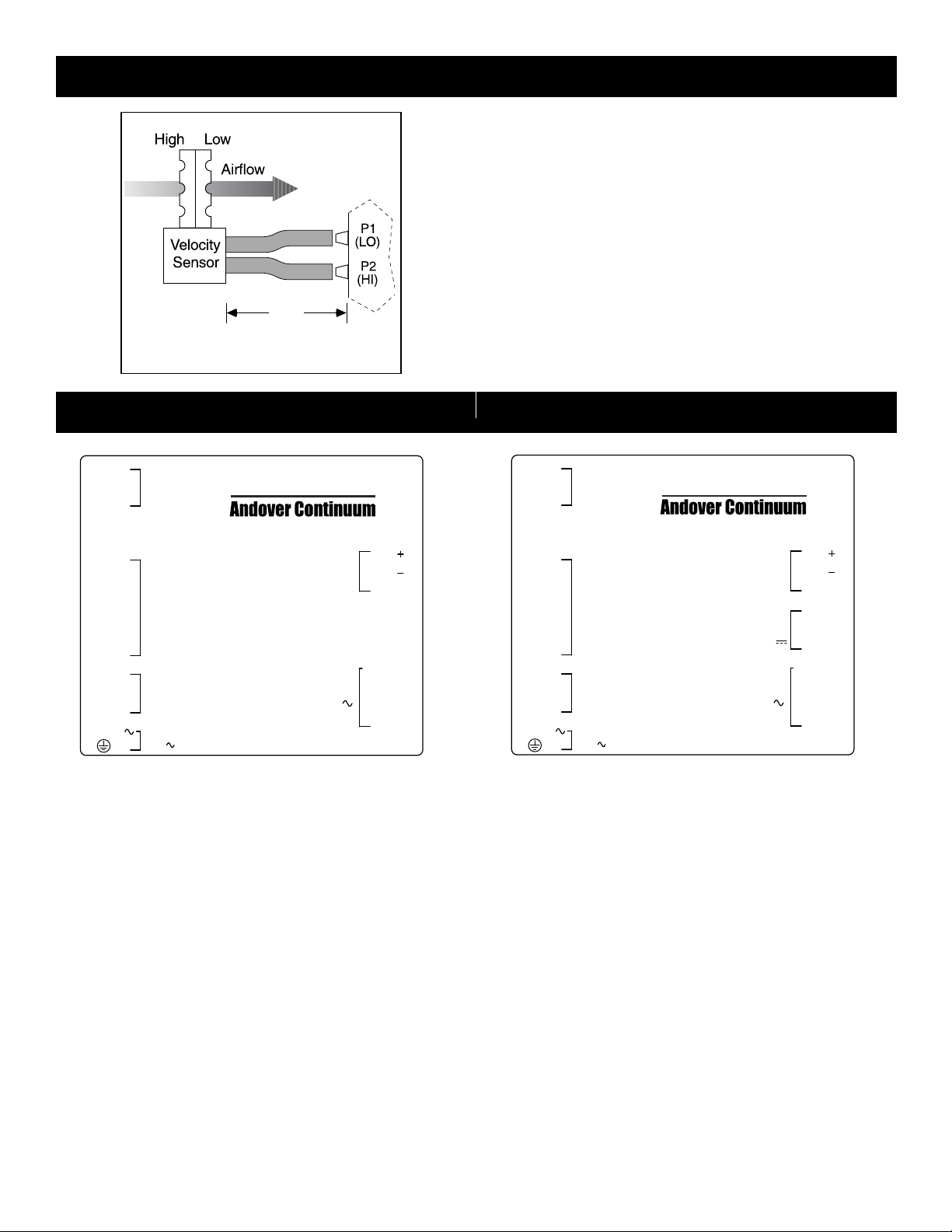

Connecting the Air Velocity Sensor

4’

(1.2 m)

Tubing (Max.)

1. Connect the low pressure side of the velocity sensor to the barbed

tting labeled P1 (LO) on the controller.

2. Connect the high pressure side of the velocity sensor to the tting

labeled P2 (HI) on the controller.

Notes: Use a recommended maximum length of 4’ (1.2 m) FRPE

plyetheylene tubing or 0.25” (6.34 mm) O.D. and 0.125”

(3.175 mm) I.D. Tygon tubing.

Do not expose the velocity sensor to moisture. If moisture

condensation is a potential problem, orient the tubing and

controller so that the barbed ttings are above the lowest

part of the tubing to create a moisture trap.

Connections for i2/b3 865-V Controller Connections for i2/b3 866-V Controller

(LOW)

(HIGH)

2

3

4

5

6

7

8

9

10

11

AIR FLOW

INPUT

CAUTION

IN 1 1

IN 2

RET

IN 3

IN 4

RET

SPWR

RET

IN 5

24 VAC

MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED

TO DE-ENERGIZE THIS EQUIPMENT

BEFORE SERVICING.

UNIVERSAL

INPUTS

This equipment complies with part 15

of the FCC rules. Operation is subject

to the following two conditions.

(1) This device may not cause harmful

interference.

(2) This device must accept any

interference received, including

interference that may cause

undesired operation.

SMART

SENSOR

USE COPPER CONDUCTORS ONLY

INPUT: CLASS 2 POWER ONLY

24VAC , 0.42 A, 10VA, 50/6 0HZ

865-V

PORT

0.5A

COM

COM

SHIELD

TRIAC REF

OUT5

OUT4

OUT3

RS-485

DIGITAL

OUTPUTS

24 VAC ,

Airow Input

One Low and one High connection

Universal Inputs

Four input and two return connections — terminals 1-6

Smart Sensor Bus Interface

One Smart Sensor connection — terminals 7-9

(LOW)

(HIGH)

18

17

16

15

14

13

12

2

3

4

5

6

7

8

9

10

11

AIR FLOW

INPUT

CAUTION

IN 1 1

IN 2

RET

IN 3

IN 4

RET

SPWR

RET

IN 5

24 VAC

MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED

TO DE-ENERGIZE THIS EQUIPMENT

BEFORE SERVICING.

UNIVERSAL

INPUTS

This equipment complies with part 15

of the FCC rules. Operation is subject

to the following two conditions.

(1) This device may not cause harmful

interference.

(2) This device must accept any

interference received, including

interference that may cause

undesired operation.

SMART

SENSOR

USE COPPER CONDUCTORS ONLY

INPUT: CLASS 2 POWER ONLY

24VAC , 0.42 A, 10VA, 50/6 0HZ

866-V

COM

RS-485

PORT

ANALOG

OUTPUTS

0-10 VDC

TRIAC REF

DIGITAL

OUTPUTS

24 VAC ,

0.5A

COM

SHIELD

A07

RET

AO6

OUT5

OUT4

OUT3

21

20

19

18

17

16

15

14

13

12

Airow Input

One Low and one High connection

Universal Inputs

Four input and two return connections — terminals 1-6

Smart Sensor Bus Interface

One Smart Sensor connection — terminals 7-9

Power Connection

One 24 VAC connection and ground — terminals 10-11

Digital Outputs

Three output connections and one triac reference — terminals 12-15

RS-485 Port

One port for a BACnet MS/TP or Innet connection — terminals 16-18

Power Connection

One 24 VAC connection and ground — terminals 10-11

Digital Outputs

Three output connections and one triac reference — terminals 12-15

Analog Outputs

Two analog outputs and one return connection — terminals 16-18

RS-485 Port

One port for a BACnet MS/TP or Innet connection — terminals 19-21

Page 4

Connections for i2/b3 885-V Controller

(LOW)

(HIGH)

2

3

4

5

AIR FLOW

INPUT

IN 1 1

UNIVERSAL

IN 2

INPUTS

RET

USE COPPER CONDUCTORS ONLY

24 VAC

INPUT: CLASS 2 POWER ONLY

24VAC , 0.42 A, 10VA, 50/6 0HZ

CAUTION

MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED

TO DE-ENERGIZE THIS EQUIPMENT

BEFORE SERVICING.

This equipment complies with part 15

of the FCC rules. Operation is subject

to the following two conditions.

(1) This device may not cause harmful

interference.

(2) This device must accept any

interference received, including

interference that may cause

undesired operation.

Physical Dimensions

885-V

OUTPUTS

24 VAC ,

RS-485

PORT

DIGITAL

0.5A

COM

COM

SHIELD

TRIAC REF

NOT USED

OUT4

OUT3

Airow Input

One Low and one High connection

Universal Inputs

Two input and one return connection — terminals 1-3

12

11

10

Power Connection

One 24 VAC connection and ground — terminals 4-5

Digital Outputs

Two output connections and one triac reference — terminals 6-9

9

8

7

6

RS-485 Port

One port for a BACnet MS/TP or Innet connection — terminals 10-12

Page 5

Wiring Digital Outputs

Switching Option - Triac “Form A” Ground Connection

Switching Option - Triac “Form A” Hot Connection

Switching Option - Triac “Form K” Ground Connection

Form A Triac Outputs

The new i2/b3 865/866-V controllers use three Form A triac output

terminals with a single triac reference. This conguration gives you

the exibility to wire the single triac reference as either a hot or

ground connection. On these new controllers, all three outputs must

be wired the same, as either hot or ground switch applications.

To make a hot switch connection, connect one of the output terminals

(OUTX, where X = 3, 4, or 5) to a load, and connect the Triac Reference to the incoming 24 VAC power.

i2/b3 865/866-V Controller

24 VAC Step-Down

AC Line

Power

Transformer

X1

X2

24 VAC

GND

Note: i2/b3 885-V Controller only has two digital outputs

DIGITAL

OUTPUTS

24VA C ,

TRIAC REF

15

OUT5

14

OUT4

13

0.5A

OUT3

12

Form K Triac Outputs

To create a Form K triac connection on the new i2/b3 865/866-V

controllers, make the individual connections from terminals 12

and 13 (OUT3 and OUT4), or use terminals 13 and 14 (OUT4 and

OUT5), with a common ground reference to terminal 15 (TRIAC

REF).*

i2/b3 865/866-V Controller

OUT4

Load

24 VAC Step-Down

Transformer

AC Line

Power

X1

X2

24 VAC

GND

Note: i2/b3 885-V Controller only has two digital outputs

To maintain Form K triac connections on the new i2/b3 885-V

controller, make the individual connections from terminals 6 and 7

(OUT3 and OUT4) with a common ground reference to terminal 9

(TRIAC REF).**

DIGITAL

OUTPUTS

24VA C ,

TRIAC REF

15

OUT5

14

OUT4

13

0.5A

OUT3

12

OUT3

Load

To make a ground switch connection, connect one of the output

terminals (OUTX, where X = 3, 4, or 5) to a load in series with the 24

VAC incoming power, and connect the Triac Reference to ground.

i2/b3 865/866-V Controller

24 VAC Step-Down

AC Line

Power

Transformer

X1

X2

24 VAC

GND

Note: i2/b3 885-V Controller only has two digital outputs

DIGITAL

OUTPUTS

24VA C ,

TRIAC REF

15

OUT5

14

OUT4

13

0.5A

OUT3

12

The new i2/b3 885-V controller, which only has two output terminal

connections, works the same, allowing for either two hot or ground

switch applications

Notes: * Use Andover Continuum CyberStation is set the lower

numbered digital output terminal to “tristate”.

** Terminal 8 is not used on the 885-V controller.

Wireless Network Operation

Cable Access Cut-Out on Cover

Service Port

To connect the controller to a Wireless Adapter, remove the cover and

connect the Andover Continuum Wireless Adapter cable to the Service Port and run the cable through the cable access opening (cut-out)

on the cover.

You must set two Continuum CyberStation software attributes for

wireless operation:

• The comm port must have the Default Mode set to “Wireless”.

• The software must “Learn” (discover) all the controllers on the

Continuum network.

These attributes are set using the CommPort Editor in CyberStation.

You need conguration privileges to congure a controller or comm

port.

Page 6

Specications

Dimensions

7.75” W x 6.25” L x 2.5” H (197 x 159 x 63.5 mm)

Operating Environment

Temperature: 32o to 122o F (0o to 50o C)

Humidity: 10 to 90% RH, non-condensing

Power Requirement

Power: 24 VAC, +10% -15%, 50/60 Hz, Class 2 Limited Power

Power Consumption: Less than 10VA

Overload Protection: Fused, MOV protected

Airow Input

Range: 0 to 1” W.C. (0-250 Pa)

Resolution: 0.0013” W.C. (0.33 Pa) @ 73o F (23o C)

Accuracy: +/- 0.05” W.C. (12.50 Pa) @ 73o F (23o C)

Communications

RS-485 port for implementing BACnet MS/TP or Innet connections, including:

• Three-position removable screw terminal

• Standard service port, four-position shrouded connector

• Support for wireless adapter

• LEDs:

TD = Transmit Enable

RD = Received Data

Wired/Wireless Field Bus

Universal Inputs

Connections:

• Model 865 — Four inputs and two returns

• Model 866 — Four inputs and two returns

• Model 885 — Two inputs and one return

Input Voltage Range: 0-5.115 VDC

Input Impedance: 10K to 5.120 V

Input Voltage Resolution: 5.0 mV

Digital Resolution: 10 bits

Input Voltage Accuracy: +/- 15 mV

Temperature Range: -30

Temperature Accuracy: +/- 1o F from -10o to +150o F

(+/- 0.56

o

to 230o F (-34o to 110o C)

o

C from -23o to +66o C)

Counter Frequency: 4 Hz @ 50% duty cycle

Input Protection: +/- 1000V transients

Input Filter: 16 Hz with a one pole RC lter

Connector: Removable, 5 mm screw terminal

4-Position Dipswitch (Model 865 and Model 866):

• One switch per input

• Four universal inputs

• Enables/Disables input pullup resistors

Smart Sensor Interface

Connections:

• Model 865 — One input, SPWR, and return

• Model 866 — One input, SPWR, and return

• Model 885 — Not Available

CPU LEDs

• Green = b3 software model (BACnet)

• Yellow = i2 software model (Innet)

Damper Shaft Mounting Screws

Torque Minimum: Varies according to shaft material

Torque Maximum: 30 inch-pounds (3.4 Nm)

Hex screws: 10-32 (with supplied hex wrench)

Damper Actuator (Motor)

Shaft Diameter: 1/2” (3/8” with AM-135 adapter)

Shaft Torque: 53 inch-pounds

Damper Speed: 180 sec.@ 60 Hz and 216 sec. @ 50 Hz; for 90

Adjustable end limits with two set screws

Motor:

• Type = 24 VAC synchronous

• Motor Protection: Mechanical clutch

• Manual clutch override with a push-button release

• Hardware position feedback (model 866-V only)

Actuator Jumper Settings (Tri-State for directional control)

Jumper Connected

• + (On) = Clockwise (CW)

• - (-On) = Counter Clockwise (CCW)

• O

Jumper Disconnected

• + (On) = Counter Clockwise (CCW)

• - (-On) = Clockwise (CW)

• O

Digital Outputs

Connections:

• Model 865 — Three triac output and one reference

• Model 866 — Three triac output and one reference

• Model 885 — Two triac output and one reference

SPST Accuracy: 0.1 second for pulse width modulation

Contact Ratings: 0.5A Maximum, 24VAC

Connector: Removable, 5 mm screw terminal

Analog Outputs

Connections:

o

• Model 865 — Not Available

• Model 866 — Two analog output and one return

• Model 885 — Not Available

Analog Output Channels Required: Two, Voltage only

Voltage Output Range: 0-10V

Output Source Current: 5 mA Maximum

Voltage Output Load: 2K Minimum Impedance

Voltage Output Resolution: 50 mV

Digital Resolution: 8 bits

Output Voltage Accuracy: 100 mV

Connector: Removable, 5 mm screw terminal

Terminal Contact Ratings

• 300V

• 8A

• 22 - 12AWG

• 6 inch-lb screw torque

Page 7

Regulatory Notices

Federal Communications Commission

FCC Rules and Regulations CFR 47, Part 15, Class A

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

Caution: The user that changes or makes modications not expressly approved by Schneider Electric for compliance could void the user’s authority to operate the equipment.

Industry Canada

ICES-003

This is a Class A digital device that meets all requirements of the Canadian Interference Causing Equipment Regulations.

CE - Compliance to European Union (EU)

2004/108/EC - EMC Directive

This equipment complies with the rules of the Ocial Journal of the European Communities specied in the EMC directive

89/336/EEC governing the Self Declaration of the CE Marking for the European Union.

C-Tick (Australian Communications Authority (ACA))

This equipment carries the C-Tick label and complies with EMC and radio communications regulations of the Australian Communications Authority (ACA), governing the Australian and New Zealand (AS/NZS) communities.

WEEE - Directive of the European Union (EU)

This equipment and its packaging carry the waste of electrical and electronic equipment (WEEE) label, in compliance with European Union (EU)

Directive 2002/96/EC, governing the disposal and recycling of electrical and electronic equipment in the European community.

and UL listed product for the United States and Canada, Open Energy Management

Related Documentation

Document Document Number

i2/b3 865/866/885-V Controller Retrot Guide 30-3001-988

i2 Controller Technical Reference 30-3001-861

b3 and b4920 Controller Technical Reference 30-3001-862

b3xxx PICS statements — contact Schneider Electric Technical Support

Page 8

Loading...

Loading...