Page 1

Altivar 61/71

Migration from ATV78 -> ATV61/71

Migration Manual

12/2009

AAV50749

www.schneider-electric.com

Page 2

This manual is intended to guide you through the process of replacing an Altivar 78 drive with an Altivar 61 or Altivar 71

drive.

Scope of application:

Constant torque applications:

- Replacing an Altivar 78 across the range: 525 V 690 V three-phase up to 630 kW

Variable torque applications:

- Replacing an Altivar 78 across the range: 525 V 690 V three-phase up to 800 kW

Using this manual you will be able to select the most appropriate Altivar 61 or Altivar 71 drive for your application, as well

as various options and accessories, based on the existing hardware configuration used on your Altivar 78.

You will notice that Altivar 61 and Altivar 71 drives integrate additional functionalities in terms of number of I/O and

application functions.

This manual also contains practical mounting, installation, and wiring recommendations.

To obtain maximum benefit from your Altivar 61 or Altivar 71 drive, you will need to

refer to the Installation and Programming manuals supplied with each drive.

Page 3

Contents

Determining catalog numbers____________________________________________________________________________________ 5

Choice of Altivar 61 or Altivar 71 ___________________________________________________________________________ 5

Selecting the power circuit options _________________________________________________________________________ 8

Mounting accessories ___________________________________________________________________________________ 8

Control circuit option: Remote display terminal ________________________________________________________________ 9

Choice of I/O extension cards ____________________________________________________________________________ 10

Drive setup _________________________________________________________________________________________________ 11

Mounting: Standard torque applications ____________________________________________________________________ 11

Comparison of dimensions ______________________________________________________________________________ 12

Remote display terminal ________________________________________________________________________________ 18

Power section wiring ___________________________________________________________________________________ 19

AAV50749 12/2009 3

Page 4

Setup procedure

b 1 Identifying the existing ATV 78

v Make an inventory of your Altivar 78 installation

Steps 3 and 4

must be

performed with

the power off

b 2 Selecting the ATV 61 or ATV 71

v Determine the Altivar 61 or Altivar 71 catalog number

v Choose the various options required

b 3 Mounting

v Mount the drive in accordance with the

instructions in this document

v Install any internal and external options

b 4 Wiring

v Connect the motor, ensuring that its

connections correspond to the voltage

v Connect the control section

v Connect the speed reference

v Connect the line supply, after making sure

that the power is off

Migrating from ATV 78 ATV 61/71

b 5 Configuration

v Drive

V

4 AAV50749 11/2009

Page 5

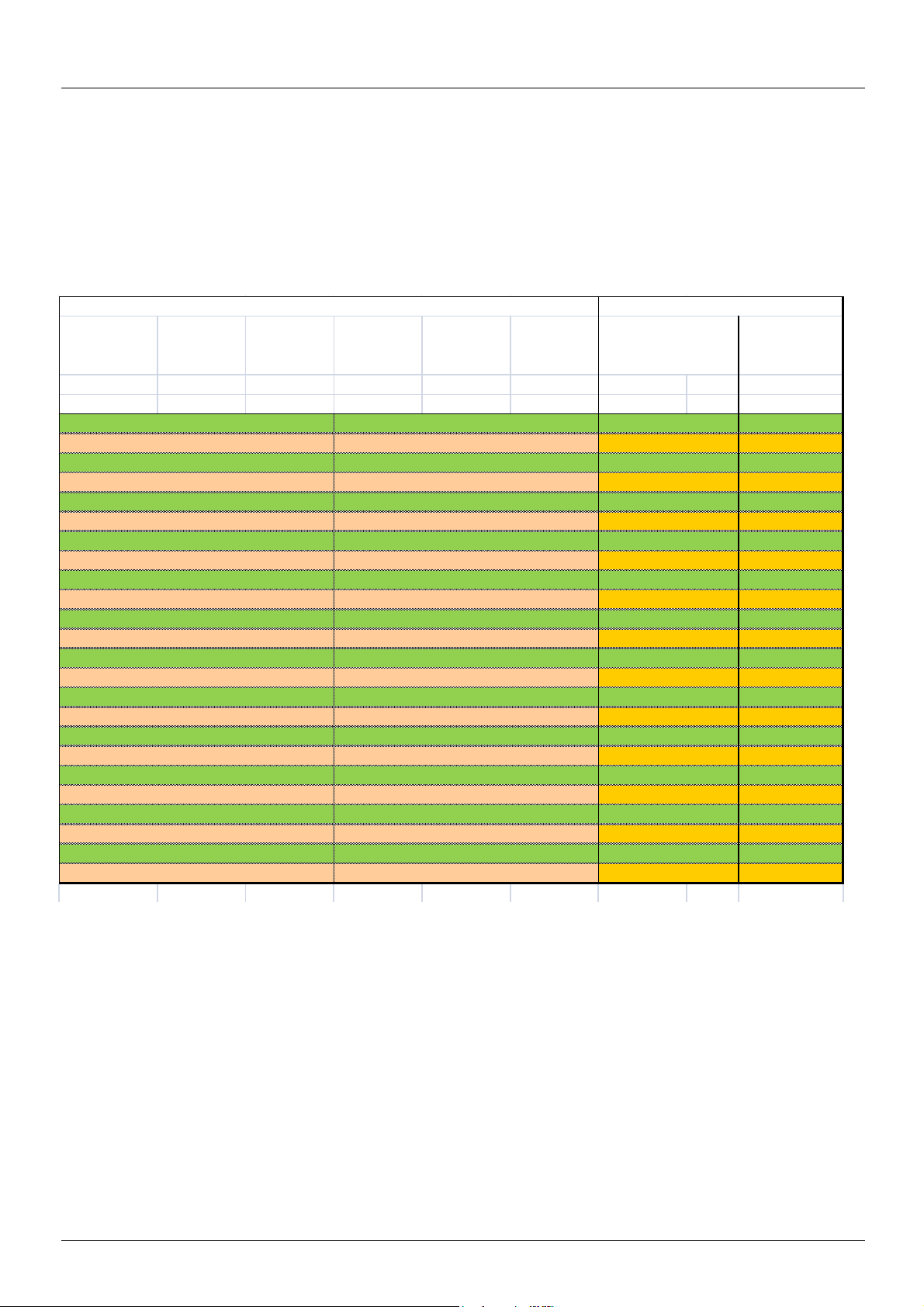

Determining catalog numbers

Motor power

according to

supply voltage

ATV78.(F)

catalog

number

Line choke

(1)

kW Hp kW I nominal I max

525 V 600 V 690 V A A

2.3 3 3 4.5 6.4 U22Y ATV71H U30Y VW3A4551

3 3 4 5.5 9 U30Y ATV71H U40Y VW3A4551

4.2 5 5.5 7.5 11 U40Y ATV71H U55Y VW3A4552

5.7 7.5 7.5 10 15 U55Y ATV71H U75Y VW3A4552

8.4 11 11 13 20 U75Y ATV71H D11Y VW3A4553

11.4 15 15 18 27 D11Y ATV71H D15Y VW3A4553

14.1 20 18.5 22 36 D15Y ATV71H D18Y VW3A4554

16.7 25 22 27 44 D18Y ATV71H D22Y VW3A4554

22.8 30 30 34 54 D22Y ATV71H D30Y VW3A4555

28.5 40 37.5 41 68 D30Y ATV71H D37Y VW3A4555

34 50 45 52 82 D37Y ATV71H D45Y VW3A4555

42 60 55 62 104 D45Y ATV71H D55Y VW3A4556

57 75 75 80 124 D55Y ATV71H D75Y VW3A4556

68 100 90 100 160 D75Y ATV71H D90Y VW3A4556

84 125 110 125 200 D90Y ATV71H C11Y VW 3A4570

100 150 132 144 250 C11Y ATV71H C13Y VW3A4571

122 150 160 170 288 C13Y ATV71H C16Y VW3A4571

152 200 200 208 340 C16Y ATV71H C20Y VW3A4560

190 250 250 261 370 C20Y ATV71H C25Y VW3A4572

240 300 315 325 440 C25Y ATV71H C31Y VW3A4572

270 400 355 385 620 C31Y ATV71H C40Y 2 x VW3A4568

342 450 450 460 770 C35Y ATV71H C50Y 2 x VW3A4572

380 500 500 502 920 C45Y ATV71H C50Y 2 x VW3A4572

426 600 560 590 1004 C50Y ATV71H C63Y 2 x VW3A4572

ATV71

catalog number

Determining the type of use for the ATV 78: Standard or high torque?

• Standard torque corresponds to the ATV 71 drive (constant torque) or to the ATV 61 drive (variable torque) depending on the application.

• High torque corresponds to the ATV 71 drive (constant torque).

The following tables show the possible ATV 78/ATV 61 or ATV 78/ATV 71 combinations according to the torque required.

Choice of Altivar 61 or Altivar 71

Standard constant torque applications

ATV 78

(1)]Line chokes must be ordered separately.

These are optional on ATV71H U30Y to D90Y drives. On ATV71H C11Y to C63Y drives, however, they are compulsory, unless a special

transformer is used (such as a 12-pulse type).

AAV50749 12/2009 5

ATV 71

catalog number

Page 6

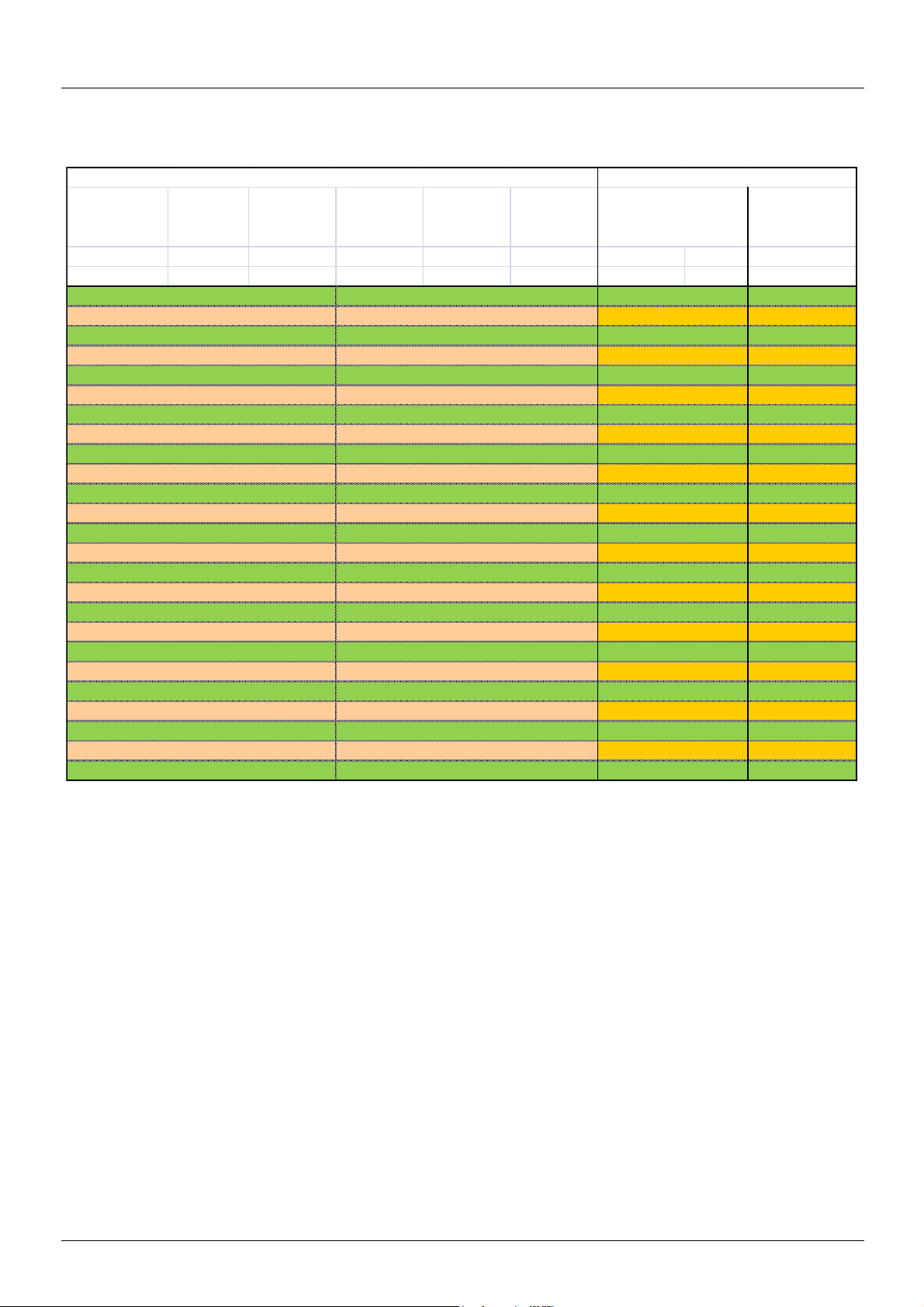

Determining catalog numbers

Motor power

according to

supply voltage

ATV78.(F)

catalog

number

Line choke

catalog number

(1)

kW Hp kW I nominal I max

525 V 600 V 690 V A A

1.7 2 2.2 3.2 6.7 U22Y ATV71H U22Y VW3A4551

2.3 3 3 4.5 9 U30Y ATV71H U30Y VW3A4551

3 3 4 5.5 11 U40Y ATV71H U40Y VW3A4551

4.2 5 5.5 7.5 15 U55Y ATV71H U55Y VW3A4552

5.7 7.5 7.5 10 20 U75Y ATV71H U75Y VW3A4552

8 11 11 13.5 27 D11Y ATV71H D11Y VW3A4553

11 15 15 18 36 D15Y ATV71H D15Y VW3A4553

14 20 18.5 22 44 D18Y ATV71H D18Y VW3A4554

17 25 22 27 54 D22Y ATV71H D22Y VW3A4554

23 30 30 34 68 D30Y ATV71H D30Y VW3A4555

29 40 37 41 82 D37Y ATV71H D37Y VW3A4555

34 50 45 52 104 D45Y ATV71H D45Y VW3A4555

42 60 55 62 124 D55Y ATV71H D55Y VW3A4556

57 75 75 80 160 D75Y ATV71H D75Y VW3A4556

68 100 90 100 200 D90Y ATV71H D90Y VW3A4556

84 125 110 125 250 C11Y ATV71H C11Y VW3A4570

100 150 132 144 288 C13Y ATV71H C13Y VW3A4571

122 150 160 170 340 C16Y ATV71H C16Y VW3A4571

152 200 200 208 370 C20Y ATV71H C20Y VW3A4560

190 250 250 261 440 C25Y ATV71H C25Y VW3A4572

240 300 315 325 620 C31Y ATV71H C31Y VW3A4572

270 400 355 385 770 C35Y ATV71H C40Y 2 x VW3A4568

342 450 450 460 920 C45Y ATV71H C50Y 2 x VW3A4572

380 500 500 502 1004 C50Y ATV71H C50Y 2 x VW3A4572

426 600 560 590 1180 C56Y ATV71H C63Y 2 x VW3A4572

ATV71

catalog number

High constant torque applications

ATV 78

ATV 71

(1)Line chokes must be ordered separately.

These are optional on ATV71H U22Y to D90Y drives. On ATV71H C11Y to C63Y drives, however, they are compulsory, unless a special

transformer is used (such as a 12-pulse type).

6 AAV50749 11/2009

Page 7

Determining catalog numbers

11.4 15 15 18 27 D11Y ATV61H D15Y VW3A4553

14.1 20 18.5 22 36 D15Y ATV61H D18Y VW3A4553

16.7 25 22 27 44 D18Y ATV61H D22Y VW3A4554

22.8 30 30 34 54 D22Y ATV61H D30Y VW3A4554

28.5 40 37.5 41 68 D30Y ATV61H D37Y VW3A4555

34 50 45 52 82 D37Y ATV61H D45Y VW3A4555

42 60 55 62 104 D45Y ATV61H D55Y VW3A4555

57 75 75 80 124 D55Y ATV61H D75Y VW3A4556

68 100 90 100 160 D75Y ATV61H D90Y VW3A4556

84 125 110 125 200 D90Y ATV61H C11Y VW3A4570

100 150 132 144 250 C11Y ATV61H C13Y VW 3A4570

122 150 160 170 288 C13Y ATV61H C16Y VW 3A4571

152 200 200 208 340 C16Y ATV61H C20Y VW 3A4571

190 250 250 261 370 C20Y ATV61H C25Y VW 3A4560

240 300 315 325 440 C25Y ATV61H C31Y VW 3A4572

270 400 355 385 620 C31Y ATV61H C40Y VW 3A4572

342 450 450 460 770 C35Y ATV61H C50Y 2 x VW3A4568

380 500 500 502 920 C45Y ATV61H C50Y 2 x VW3A4568

426 600 560 590 1004 C50Y ATV61H C63Y 2 x VW3A4572

479 650 630 650 1180 C56Y ATV61H C63Y 2 x VW3A4572

540 800 710 650 1300 C63Y ATV61H C80Y 2 x VW3A4572

609 800 800 820 1500 C71Y ATV61H C80Y 2 x VW3A4572

Standard variable torque applications

The Altivar 61 is designed for pumping and ventilation applications where the torque varies with the speed.

(1)Line chokes must be ordered separately.

These are optional on ATV61H U22Y to C11Y drives. On ATV61H C13Y to C80Y drives, however, they are compulsory, unless a special

transformer is used (such as a 12-pulse type).

AAV50749 12/2009 7

Page 8

Determining catalog numbers

Selecting the power circuit options

Line chokes

Altivar 78 drives were supplied with line chokes across all ratings.

On the Altivar 71 or Altivar 61, line chokes are optional up to 90 kW (120 HP). Above this rating, however, they are compulsory, unless a

special transformer, such as a 12-pulse type, is used. Line chokes must be ordered separately (see the equivalence tables on pages 5

to 7).

Mounting accessories

Altivar 78 drives U22Y to C16Y offer IP21 degree of protection and are NEMA type 1. Altivar 61 and Altivar 71 have a different degree of

protection depending on which access panel is used (please refer to the catalog), specifically IP20 or IP00 from below depending on the

rating.

• If IP21 protection is required, add an IP21/IP31 mounting kit.

• If NEMA type 1 is required, add a NEMA type 1 mounting kit.

IP21/IP31 mounting kit

Information required: Altivar 61 or Altivar 71 catalog number

Catalog number selection guide:

ATV 61H drive ATV 71H drive IP21 kit IP31 kit

U30Y, U40Y, U55Y, U75Y, D11Y, D15Y,

D18Y, D22Y, D30Y, D37Y

D45Y, D55Y, D75Y, D90Y D37Y, D45Y, D55Y, D75Y, D90Y VW3 A9 108 C11Y, C13Y, C16Y, C20Y C11Y, C13Y, C16Y - VW3 A9 111

C25Y, C31Y, C40Y C20Y, C25Y, C31Y - VW3 A9 113

C50Y, C63Y, C80Y C40Y, C50Y, C63Y - VW3 A9 116

NEMA type 1 mounting kit

Information required: Altivar 61 or Altivar 71 catalog number

U22Y, U30Y, U40Y, U55Y, U75Y, D11Y,

D15Y, D18Y, D22Y, D30Y

VW3 A9 106 -

Catalog number selection guide:

ATV 61H drive ATV 71H drive NEMA kit

U30Y, U40Y, U55Y, U75Y, D11Y, D15Y,

D18Y, D22Y, D30Y, D37Y

D45Y, D55Y, D75Y, D90Y D37Y, D45Y, D55Y, D75Y, D90Y VW3 A9 208

C11Y, C13Y, C16Y, C20Y C11Y, C13Y, C16Y VW3 A9 211

C25Y, C31Y, C40Y C20Y, C25Y, C31Y VW3 A9 213

U22Y, U30Y, U40Y, U55Y, U75Y, D11Y,

D15Y, D18Y, D22Y, D30Y

VW3 A9 206

8 AAV50749 11/2009

Page 9

Determining catalog numbers

Control circuit option: Remote display terminal

Remote connection of the Altivar 61 or Altivar 71 graphic display terminal on the enclosure door

IP54 version Remote mounting kit : VW3 A1 102

3-meter cable : VW3 A1 104 R30

IP65 version Remote mounting kit : VW3 A1 102

IP65 door : VW3 A1 103

3-meter cable : VW3 A1 104 R30

Female/female RJ45 adapter : VW3 A1 105

This should be used in the above two instances.

Note: Order an Altivar 61 or Altivar 71 with graphic display terminal (without a Z at the end of the catalog number).

Other cable lengths are available:

Cable 1 m VW3 A1 104 R10

5 m VW3 A1 104 R50

10 m VW3 A1 104 R100

Note: The graphic display terminal catalog number is VW3 A1 101.

AAV50749 12/2009 9

Page 10

Determining catalog numbers

Choice of I/O extension cards

Drive or

extension card

catalog number

ATV 7862121

VW3A78203 2 1

VW3A78204 3

VW3A78205 3

VW3A78206 6 2 1 1

VW3A78207 2

VW3A78208 3

VW3A78209 5 1

VW3A78210 1 2

VW3A78211 3

ATV 61/71 6 2 2 1 1

VW3A3201 4 2 1 1

VW3A3202422121

VW3A340

For more information, please refer to the catalog.

Logic inputs Analog inputs Logic outputs Relay outputs Analog outputs Inputs for PTC

p 1

probes

Inputs for

PT100 probes

Encoder inputs

10 AAV50749 11/2009

Page 11

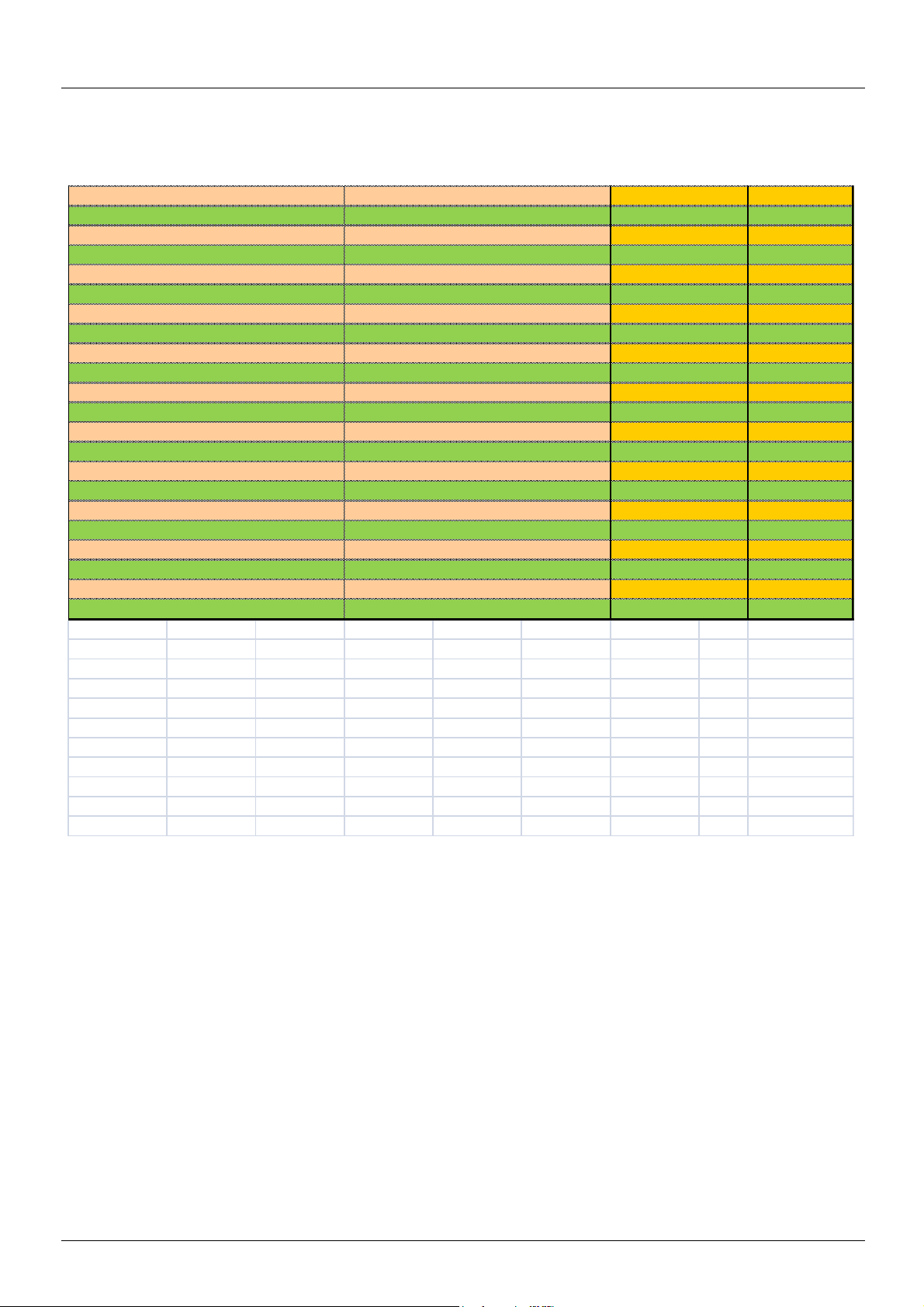

Drive setup

Mounting: Standard torque applications

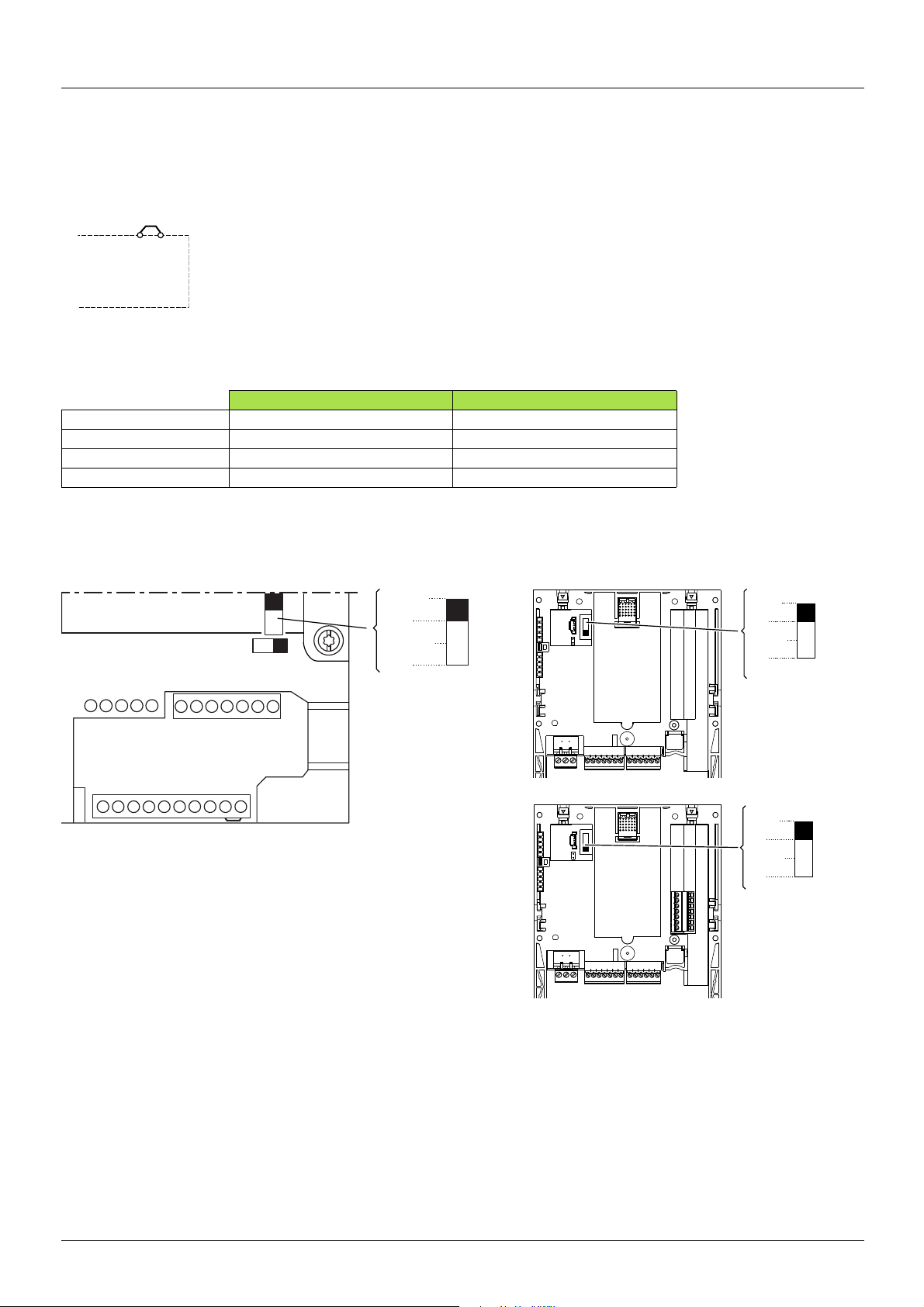

Comparison of dimensions

Width (mm) Height (mm) Depth (mm)

ATV78 HU22Y 195 558 237

ATV71 HU22Y 240 420 236

ATV61 HU30Y 240 420 236

ATV78 HU30Y 195 558 237

ATV71 HU30Y 240 420 236

ATV61 HU40Y 240 420 236

ATV78 HU40Y 195 558 237

ATV61 HU40Y 240 420 236

ATV61 HU55Y 240 420 236

ATV78 HU55Y 195 558 237

ATV71 HU55Y 240 420 236

ATV61 HU75Y 240 420 236

ATV78 HU75Y 195 558 237

ATV71 HU75Y 240 420 236

ATV61 HD11Y 240 420 236

ATV78 HD11Y 195 558 237

ATV71 HD11Y 240 420 236

ATV61 HD15Y 240 420 236

ATV78 HD15Y 195 558 237

ATV71 HD15Y 240 420 236

ATV61 HD18Y 240 420 236

ATV78 HD18Y 195 558 237

ATV71 HD18Y 240 420 236

ATV61 HD22Y 240 420 236

ATV78 HD22Y 195 558 237

ATV71 HD22Y 240 420 236

ATV61 HD30Y 240 420 236

ATV78 HD30Y 237 630 257

ATV71 HD37Y 320 630 290

ATV61 HD37Y 320 630 290

To determine the correspondence between standard and constant torque

AAV50749 12/2009 11

Page 12

Drive setup

H

c

a

4xØ9

G

b

2xØ12

325

500

5040

850

57

879242

17

3030

425

2xØ23

2xØ12

455

1165

506

15

150

275

30

a

120 120

b1

b

G

c

c1

6xØ

8xØ9x14

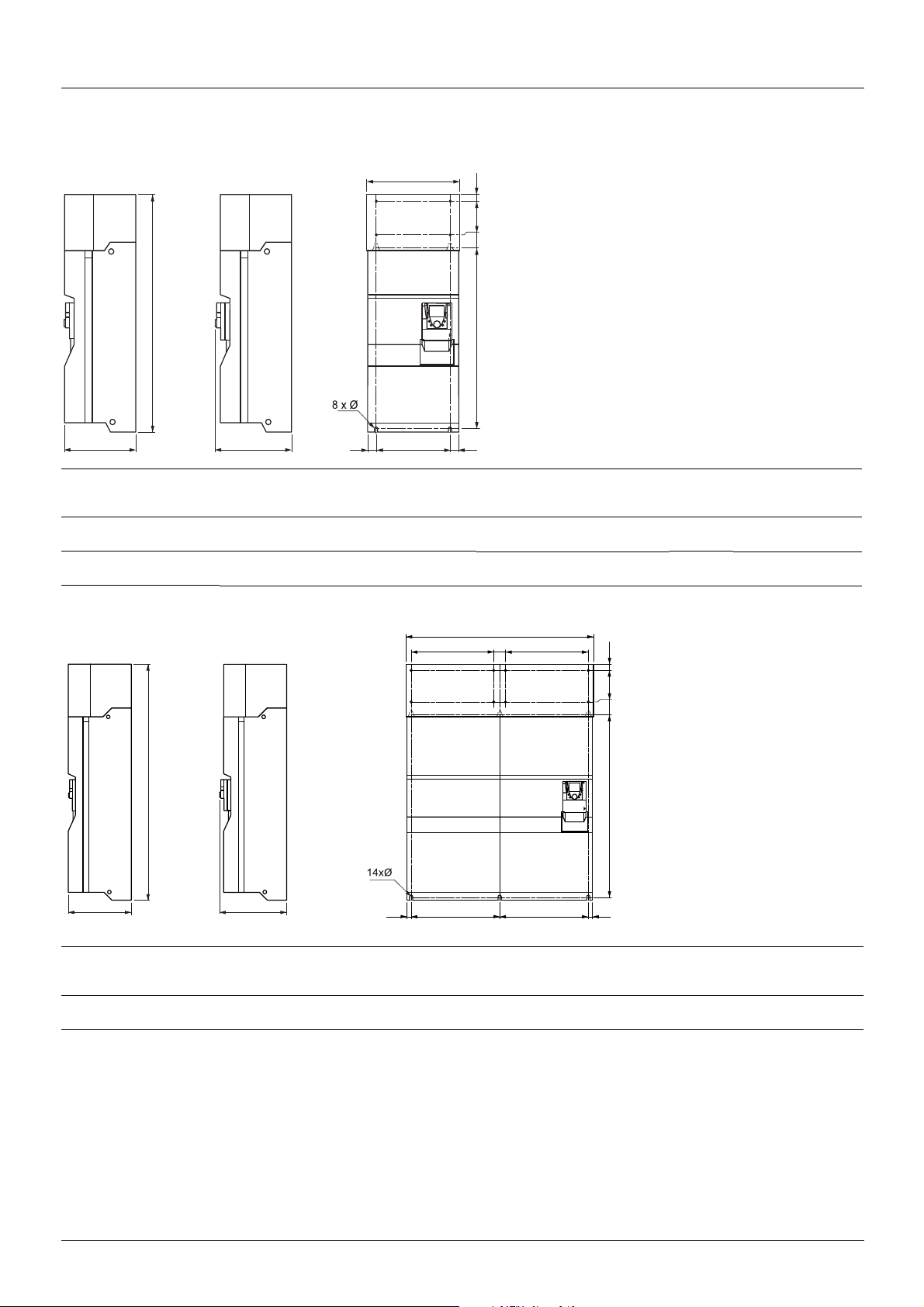

Comparison of dimensions

ATV 78p(F)U22Y to ATV 78p(F)C16Y (line choke supplied pre-installed)

ATV 78p, ATV 78pF a b c G H

U22Y…D22Y 195 558 237 148 541

D30Y…D37Y 237 630 257 190 614

D45Y…D75Y 289 755 344 255 732

D90Y…C16Y 480 1150 362 400 1120

ATV 780(F)C20Y to ATV 780(F)C31Y (line choke supplied with drive but not pre-installed)

Line choke

12 AAV50749 11/2009

For ATV 78 drives a b b1 c c1 G Ø

0C20Y,

0FC20Y

0C25Y…0C31Y

0FC25Y…0FC31Y

354 357 319 230 206 108 9x14

350 421 383 262 238 140 11x15

Page 13

Drive setup

468

709

1206

240

506

850

225 225 67

225 225 67

6xØ12

22 2

200

145

244

204

40

20

399

446

497

165 165

6xØ11x15

4xØ13

6xØ11x15

30

15

150

275

350

120 120

140

262

421

383

238

8xØ9x14

Variable speed drives (continued)

ATV 780(F)C35Y to ATV 780(F)C50Y (line choke supplied with drive but not pre-installed)

Terminal cover removed

Line choke for ATV 780(F)C35Y and ATV 780(F)C45Y drives

Line choke for ATV 780(F)C50Y drives (1)

(1) Two line chokes are supplied with the drive.

AAV50749 12/2009 13

Page 14

Drive setup

455

1165

506

2xØ12

325

500

5040

850

57

879242

17

3030

425

2xØ23

2xØ12

6xØ11x15

30

15

150

275

350

120 120

140

262

421

383

238

8xØ9x14

Variable speed drives (continued)

ATV 780(F)C56Y to ATV 780(F)C71Y (1) (line choke supplied with drive but not pre-installed)

(1) Two power units and one control unit are supplied with the drive.

Line choke (1)

(1) Two line chokes are supplied with the drive.

14 AAV50749 11/2009

Page 15

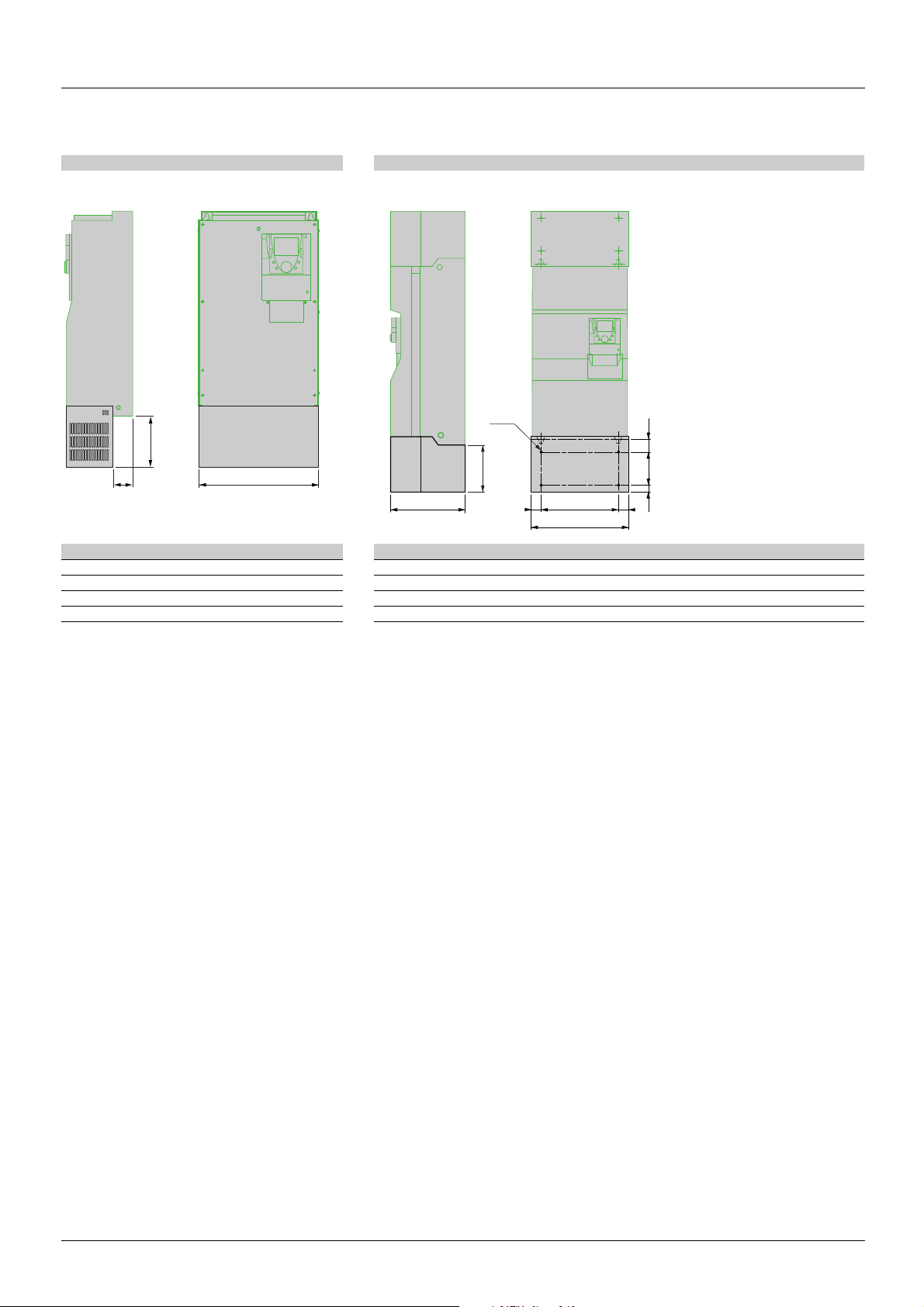

Drive setup

With 2 option cards (1)

With 1 option card (1)

No option card

c

c1

c2

G

a

=

=

H

h

b

4 x

With 2 option cards (1)

With 1 option card (1)

No option card

ATV 61/ATV 71 with graphic display terminal

ATV61H/ATV71H a

mm

(in.)

ATV61H U30Y to D30Y,

ATV71H U22Y to D30Y

ATV61H D37Y to D90Y,

ATV71H D37Y to D90Y

240

(9.45)

320

(12.60)

b

mm

(in.)

420

(16.54)

630

(24.80)

c

mm

(in.)

236

(9.29)

290

(11.42)

c1

mm

(in.)

259

(10.20)

313

(12.32)

c2

mm

(in.)

282

(11.10)

334

(13.15)

G

mm

(in.)

206

(8.11)

280

(11.02)

H

mm

(in.)

h

mm

(in.)

Ø

mm

(in.)

403

(15.87)11(0.45)6(0.24)

604.5

(23.80)15(0.59)9(0.35)

For

screws

M5 30

M8 45

Weight

kg

(lb.)

(66.14)

(99.21)

ATV 61/ATV 71 without graphic display terminal

For a drive without a graphic display terminal, dimensions c, c1 and c2 in the table above are reduced by 26 mm (1.01 in.). The other

dimensions are unchanged.

(1)For the addition of I/O extension cards, communication cards, or the "Controller Inside" programmable card.

AAV50749 12/2009 15

Page 16

Drive setup

With 2 option cards (1)With 0 or 1 option card (1)

ATV61H C11Y to C80Y,

ATV71H C11Y to C63Y

G=G=

J1 J J1

a

b

377 mm

(14.77 in)

392 mm

(15.43 in)

K2KK1H

With 2 option cards (1)With 0 or 1 option card (1)

ATV61H C50Y to C80Y,

ATV71H C40Y to C63Y

ATV 61/ATV 71

b

a

HK1KK2

377 mm

(14.77 in)

392 mm

(15.43 in)

ATV61H/ATV71H a

mm

(in.)

ATV61H C11Y to C20Y,

ATV71H C11Y to C16Y

ATV61H C25Y to C40Y,

ATV71H C20Y to C31Y

340

(13.39)

595

(23.43)

b

mm

(in.)

1190

(46.62)

1190

(46.62)

==G

G

mm

(in.)

285

(11.22)

540

(21.26)

H

mm

(in.)

920

(36.22)

920

(36.22)

K

mm

(in.)

K1

mm

(in.)

K2

mm

(in.)

150

(5.91)75(2.95)30(1.18)

150

(5.91)75(2.95)30(1.18)

Ø

mm

(in.)

11.5

(0.45)

11.5

(0.45)

For

Weight

screws

M10 110

M10 190

kg

(lb.)

(242)

(418)

For

ATV61H/ATV71H a

ATV61H C50Y to C80Y,

ATV71H C40Y to C63Y

mm

(in.)

1120

(44.09)

b

mm

(in.)

1390

(54.72)

G

mm

(in.)

J

mm

(in.)

532.5

(20.96)70(2.76)

J1

mm

(in.)

495

(1949)

H

mm

(in.)

1120

(44.09)

K

mm

(in.)

K1

mm

(in.)

mm

(in.)

150

(5.91)75(2.95)30(1.18)

K2

Ø

mm

(in.)

11.5

(0.45)

screws

Weight

kg

(lb.)

M10 400

(880)

(1)For the addition of I/O extension cards, communication cards, or the "Controller Inside" programmable card.

16 AAV50749 11/2009

Page 17

Drive setup

a

c

b

G

K2

K

K1

4xØ

b

c

a

==

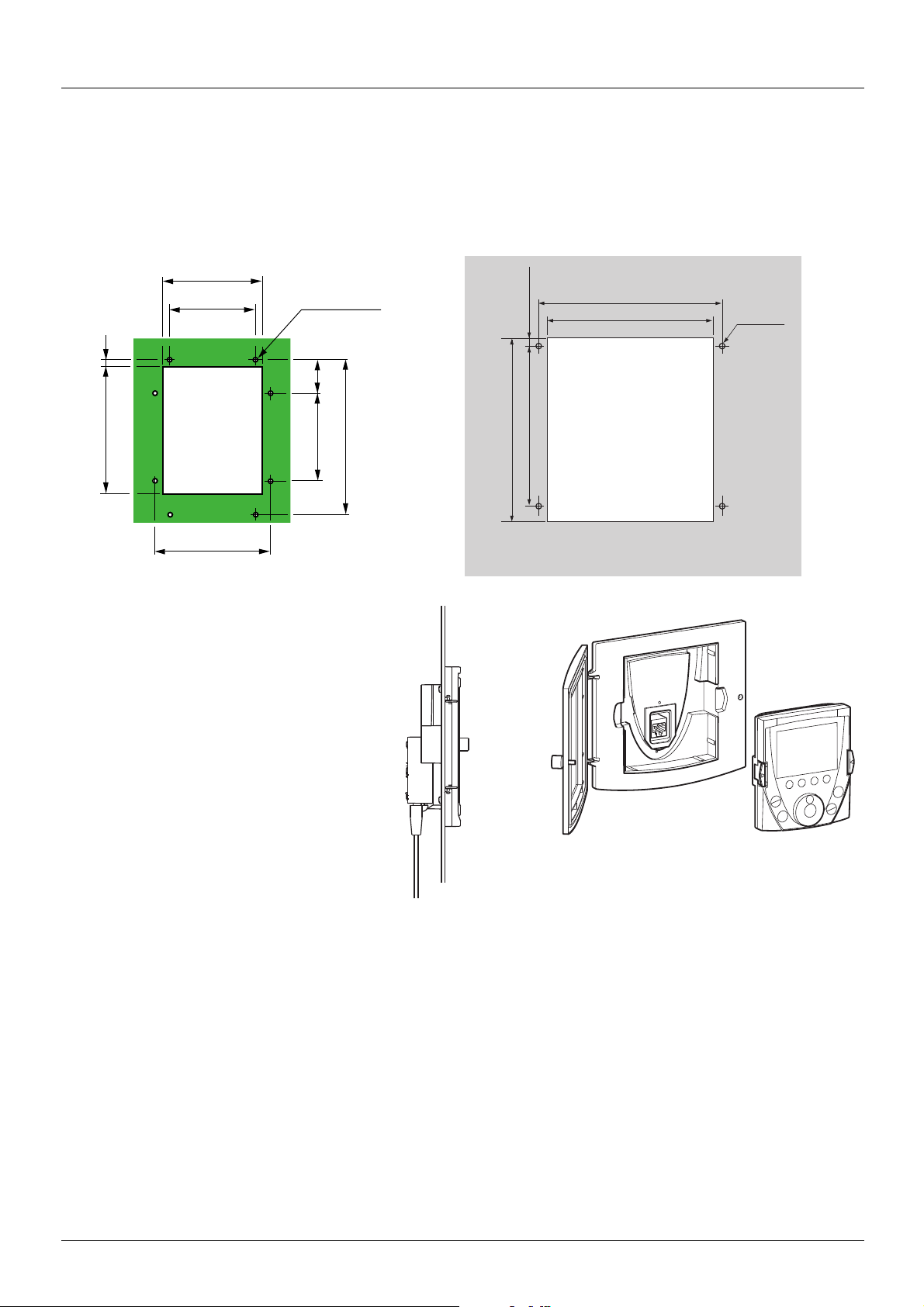

ATV 61/ATV 71 - IP 21 or IP 31 conformity kits (VW3 A9 1pp), UL Type 1 conformity kits (VW3 A9 2pp)

VW3 A9 106, 108, 206, 208 VW3 A9 111, 112, 211, 212

VW3 a b c VW3 a b c G K K1 K2 Ø

A9 106 240 75 102 A9 111 345 315 377 285 250 65 75 11.5

A9 108 320 163 102 A9 112 445 375 377 350 250 65 75 11.5

A9 206 240 59.9 102 A9 211 345 315 377 285 250 65 75 11.5

A9 208 320 136 102 A9 212 445 375 377 350 250 65 75 11.5

AAV50749 12/2009 17

Page 18

Drive setup

115

100

8xØ4,5…5

8144

37,5

100

175

135

115 mm (4.53 in)

104 mm (4.09 in)

115 mm (4.53 in)

100 mm (3.93 in) 5 mm (0.2 in)

4 x ∅ 3 mm

(0.12 in)

R

U

N

STOP

RESET

F

2

F

1

F

3

F

4

E

S

C

FW

D

REV

Remote display terminal

Used to connect the programming terminal remotely on the front of the enclosure.

Mounting:

As the dimensions are not the same, the drill holes must be modified.

ATV 78 ATV 71

18 AAV50749 11/2009

Page 19

Drive setup

U

V

W

L1

U1

W1

V1

M

3 a

L2

L3

A1

RO2

RO2

R-

R+

RO1

RO1

RO1

ATV78pppppp

RO2

(1)

Braking resistor

(if used)

ATVp1HpppY

U / T1

V / T2

W / T3

R / L1

M

3 a

S / L2

T / L3

A1

R1A

R1C

R1B

R2A

R2C

U1

W1

V1

PWR

+24

P0

PA / +

PB

PC / -

(2)

Braking resistor

(if used)

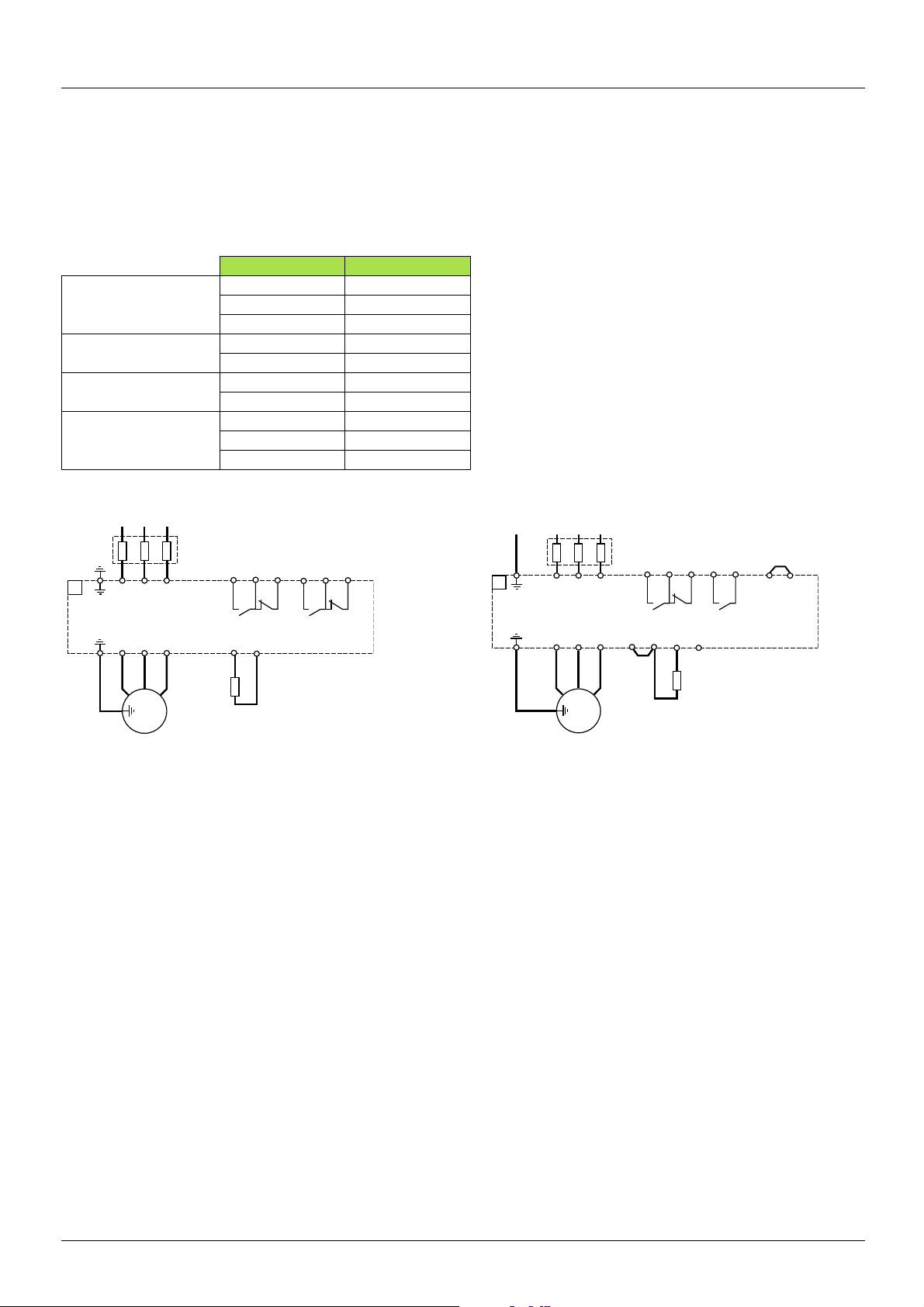

Power section wiring

The layout and type of power terminals have changed.

Ring terminals must be used rather than ferrules for the ground terminals, although for the power terminals the ferrules used previously can

be retained if they are in good condition (a flattened ferrule will not make a good connection).

Table of correspondence for power terminals

ATV 78 ATV 61/ATV 71

Power supply L1 R/L1

L2 S/L2

L3 T/L3

DC bus B+ PO

B- PC/-

Braking resistor R+ PA/+

R- PB

Motor output U U/T1

VV/T2

WW/T3

Connecting the Altivar 78 Connecting the Altivar 61 or Altivar 71

(1)Line choke, installed and wired separately for ATV780C20Y rating and above

(2)Line choke to be mounted and wired separately

Disconnecting the RFI filter if using an IT system

IT system: Isolated or impedance grounded neutral

Use a permanent insulation monitor compatible with non-linear loads, such as a Merlin Gerin type XM200 or equivalent.

Altivar 61 and 71 drives feature built-in RFI filters. When using Altivar 61 and 71 drives on an IT system, the link between these filters and

ground must be removed. Please refer to the Installation Manual on the CD-ROM supplied with the drive.

Corner grounded system: System with one phase connected to ground

ATV61H...Y and ATV71H...Y drives must not be connected to a corner grounded system.

Arrangement and characteristics of ATV 61 and ATV 71 power terminals

Please refer to the Installation Manual on the CD-ROM supplied with the drive.

AAV50749 12/2009 19

Page 20

Drive setup

ATVp1HpppM3

PWR

+24

R1B

R1A

R1C

R2A

R2C

AI1+

+10

AI1-

COM

AI2

COM

AO1

0V

P24

LI1

LI2

LI3

LI4

LI5

LI6

+24

PWR

RJ45

SW1

SW2

Ext

Source

Sink

Int

SW3

Ext

Source

Sink

Int

SW4

Ext

Source

Sink

Int

VW3 A3 201

VW3 A3 202

Control section wiring and I/O characteristics

Caution: Check the I/O assignments.

In order to ensure that the Altivar 61 or 71 functions correctly, the following rules must be adhered to:

• Check that the strap is present between +24 and PWR.

• The PTC probes connected to an ATV 61 or ATV 71 correspond to the market standard. Check that the trip thresholds are suitable for

the temperature levels supported by the motor.

ATV 78 value (kOhms) ATV 61/ATV 71 value (kOhms)

Probe short-circuit - < 0.05

Reset - 1.8

Overheating 4.7 3

Probe break - > 100

• Check that switch SW1 on the Altivar 61 or 71 and switches SW3 and SW4 on the option cards correspond with the position of jumpers

CMA and CMB (group of jumpers (X3) on the base card) on the Altivar 78 and that the connections comply with the recommendations

on the next page.

20 AAV50749 11/2009

Page 21

Drive setup

DI1

GND

DI2

DI3

Position (CMA grounded)

+ 24 V/Internal + 24 V

A1

ATV71Hppppp

SW1

Ext

Source

Sink

Int

LI1

LI5

+24

0V

LI3

LI2

LI6

LI4

DI1

GND

DI2

DI3

Position (CMA isolated)

External

+ 24 V + 24 V/Internal + 24 V

Weight

A1

ATV71Hppppp

SW1

Ext

Source

Sink

Int

LI1

LI5

+24

0V

LI3

LI2

LI6

LI4

+24 V

0 V

24 V c supply

DI1

DI2

DI3

Position (CMA isolated)

External

+ 24 V

+ 24 V/External + 24 V

Weight

A1

ATV71Hppppp

SW1

Ext

Source

Sink

Int

LI1

LI5

+24

0V

LI3

LI2

LI6

LI4

+24 V

0 V

24 V c supply

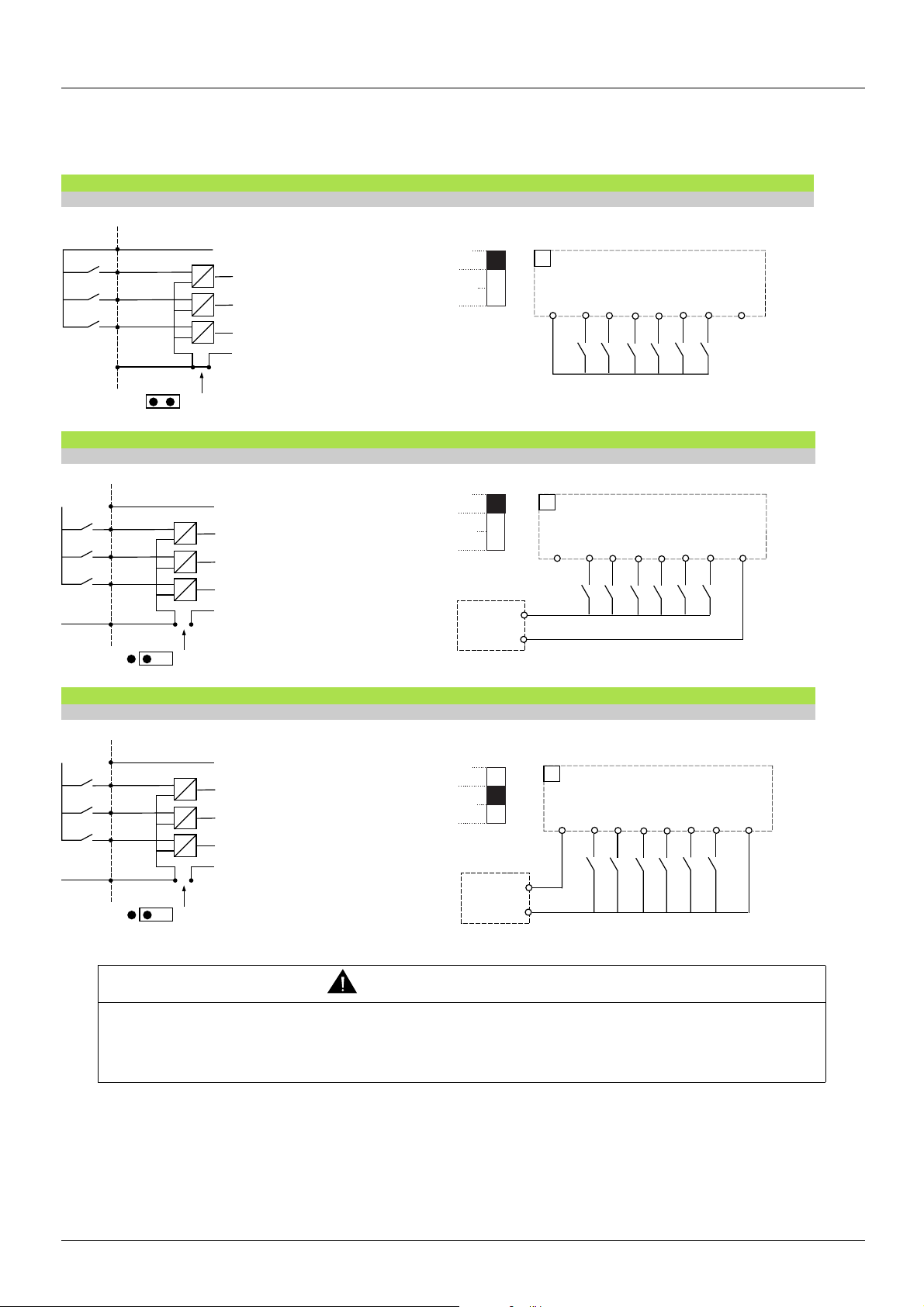

Control section and option card logic input wiring

Examples of correspondence of various jumper positions to ensure equivalent operation:

ATV 78 ATV 61 or ATV 71 correspondence

With + 24 V internal power supply

• Switch SW1 set to "Source" position

ATV 78 ATV 61 or ATV 71 correspondence

With external + 24 V power supply. Positive logic

• Switch SW1 set to "Source" position

ATV 78 ATV 61 or ATV 71 correspondence

With external + 24 V power supply. Negative logic

Unintended equipment operation

When switch SW1 is set to "Sink Int" or "Sink Ext", the common must never be connected to ground or the protective ground, as there is

then a risk of unintended equipment operation on the first insulation fault.

Failure to follow this instruction can result in death or serious injury.

Wiring other I/O

Please refer to the catalog, the Installation Manual and the Programming Manual on the CD-ROM supplied with the drive.

AAV50749 12/2009 21

• Switch SW1 set to "Sink Ext" position

WARNING

Page 22

ATV78-61/71_migration_EN_AAV50749_02

AAV50749 12/2009

Loading...

Loading...