Important information

XXXXXX

Altivar 61/71/LIFT

Variable speed drives

for synchronous and asynchronous motors

Safety integrated function manual

02/2014

S1A91443

www.schneider-electric.com

Important information

The information provided in this documentation contains general descriptions and/or technical characteristics

of the performance of the products contained herein. This documentation is not intended as a substitute for

and is not to be used for determining suitability or reliability of these products for specific user applications. It

is the duty of any such user or integrator to perform the appropriate and complete risk analysis, evaluation and

testing of the products with respect to the relevant specific application or use thereof. Neither Schneider

Electric nor any of its affiliates or subsidiaries shall be responsible or liable for misuse of the information

contained herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be

followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2013 Schneider Electric. All rights reserved.

2

S1A91443 02/2014

Table of contents

Table of contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 1 Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Qualification of personnel and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Standards and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

(STO) Safe Torque Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4 Incompatibility with safety functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Prerequisites for using safety functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 5 Safety monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

STO Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 6 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety function capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Certified architectures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Process system SF - Case 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Process system SF - Case 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Process system SF - Case 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connection diagram conforming to IEC 61508 and IEC 60204-1 . . . . . . . . . . . . . . . . . 37

Chapter 7 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ATV61 Product sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ATV71 Product sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

S1A91443 02/2014 3

Table of contents

4

S1A91443 02/2014

§

Safety Information

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages may appear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists, which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result in death, serious

injury or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or

equipment damage.

NOTICE

NOTICE, used without the safety alert symbol, indicates a potentially hazardous situation which, if not

avoided, can result in equipment damage.

PLEASE NOTE

The word "drive" as used in this manual refers to the controller portion of the adjustable speed drive as defined

by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No

responsibility is assumed by Schneider Electric for any consequences arising out of the use of this product.

© 2013 Schneider Electric. All Rights Reserved.

S1A91443 02/2014 5

Safety Information

6

S1A91443 02/2014

About the book

At a Glance

Document Scope

Validity Note

Related Documents

About the book

The purpose of this document is to provide information about safety functions incorporated in Altivar 61/71/

LIFT. These functions allow you to develop applications oriented in the protection of man and machine.

Please, read before the installation and programming manual.

This documentation is valid for the Altivar 61, Altivar 71, Altivar LIFT, Altivar 61Q, Altivar 71Q, Altivar 61 Plus

and Altivar 71 Plus drives.

Title of Documentation Reference Number

ATV61E installation manual

55 kW (75 HP) ... 90 kW (125 HP) / 200 - 240 V

90 kW (125 HP) ... 630 kW (900 HP) / 380 - 480 V

90 kW (125 HP) ... 800 kW (800 HP) / 500 - 690 V

ATV71E Installation manual

55 kW (75 Hp) ... 75 kW (100 Hp) / 200 - 240 V

90 kW (125 Hp) ... 500 kW (700 Hp) / 380 - 480 V

90 kW (125 Hp) ... 630 kW (700 Hp) / 500 - 690 V

ATV61S Installation manual

0.37 kW (0.5 HP) ... 45 kW (60 HP) / 200 - 240 V

0.75 kW (1 HP) ... 75 kW (100 HP) / 380 - 480 V

2.2 kW (3 HP) ... 7.5 kW (10 HP) / 500 - 600 V

2.2 kW (3 HP) ... 90 kW (100 HP) / 500 - 690 V

ATV71S Installation manual

0.37 (0.5 HP) ... 45 kW (60 HP) / 200 - 240 V

0.75 (1 HP) ... 75 kW (100 HP) / 380 - 480 V

1.5 (2 HP) ... 7.5 kW (10 HP) / 500 - 600 V

1.5 (2 HP) ... 90 kW (100 HP) / 500 - 690 V

ATV61Q Mounting instructions

110 kW (150HP) ... 630 kW (800HP) / 380 - 480 V

110 kW (150HP) ... 800 kW (800HP) / 500 - 690 V

ATV71Q Mounting instructions

90 kW (125HP) ... 500 kW (700HP) / 380 - 480 V

90 kW (125HP) ... 630 kW (700HP) / 500 - 690 V

ATV61 Plus Configuration Guide

90 kW ... 1400 kW / 380 - 415 V

90 kW ... 1800 kW / 500 - 525 V

110 kW ... 2400 kW / 690 V

ATV71 Plus Configuration Guide

90 kW ... 1300 kW / 380 - 415 V

90 kW ... 1500 kW / 500 - 525 V

110 kW ... 2000 kW / 690 V

ATV61 Plus-Marine

630 kW ... 1400 kW / 380 - 415 V

800 kW ... 2400 kW / 690 V

760655

755849

760643

755843

8P02534

8P02535

8P02503

8P02504

8P02526

S1A91443 02/2014 7

Title of Documentation Reference Number

ATV71 Plus-Marine

500 kW ... 1300 kW / 380 - 415 V

630 kW ... 2000 kW / 690 V

ATV61_71 Atex manual AAV49434

ATV61 Programming manual 760649

ATV71 Programming_manual 755855

ATV_LIFT programming manual BBV19478

ATV61_71 Canopen manual 755865

ATV61_71 Cc-link manual AAV49429

ATV61_71 Ethernet manual 755879

ATV61_71 Ethernet TCP Daisy Chain manual AAV69931

ATV61_71 EthernetIP manual AAV68822

ATV61_71 FIPIO manual 755883

ATV61_71 Interbus manual 755871

ATV61_71 PROFIBUS DPv1 manual AAV52935

ATV61 Apogee FLN P1 manual BBV10543

ATV61 Bacnet manual 765274

ATV61 LonWorks_manual 765273

ATV61 metasys N2 manual AAV33578

ATV61 multi pump manual 765272

ATV61 communication parameters 760661

ATV71 communication parameters 755861

ATV71 Controller inside manual 757062

ATV71 Devicenet manual 755877

ATV71 Modbus integrated manual 755863

ATV71 Modbus jbus manual 755875

ATV71 Modbus plus manual 755869

ATV71 profibus manual 755873

ATV71 regen units manual 757361

ATV71 Uni-Telway manual 755867

ATV61 and 71 other option manuals: see www.schneider-electric.com.

8P02527

About the book

You can download the latest versions of the technical publications related to the Altivar 61 and 71 on

www.schneider-electric.com.

8

S1A91443 02/2014

Before you begin

Before you begin

What's in this Chapter?

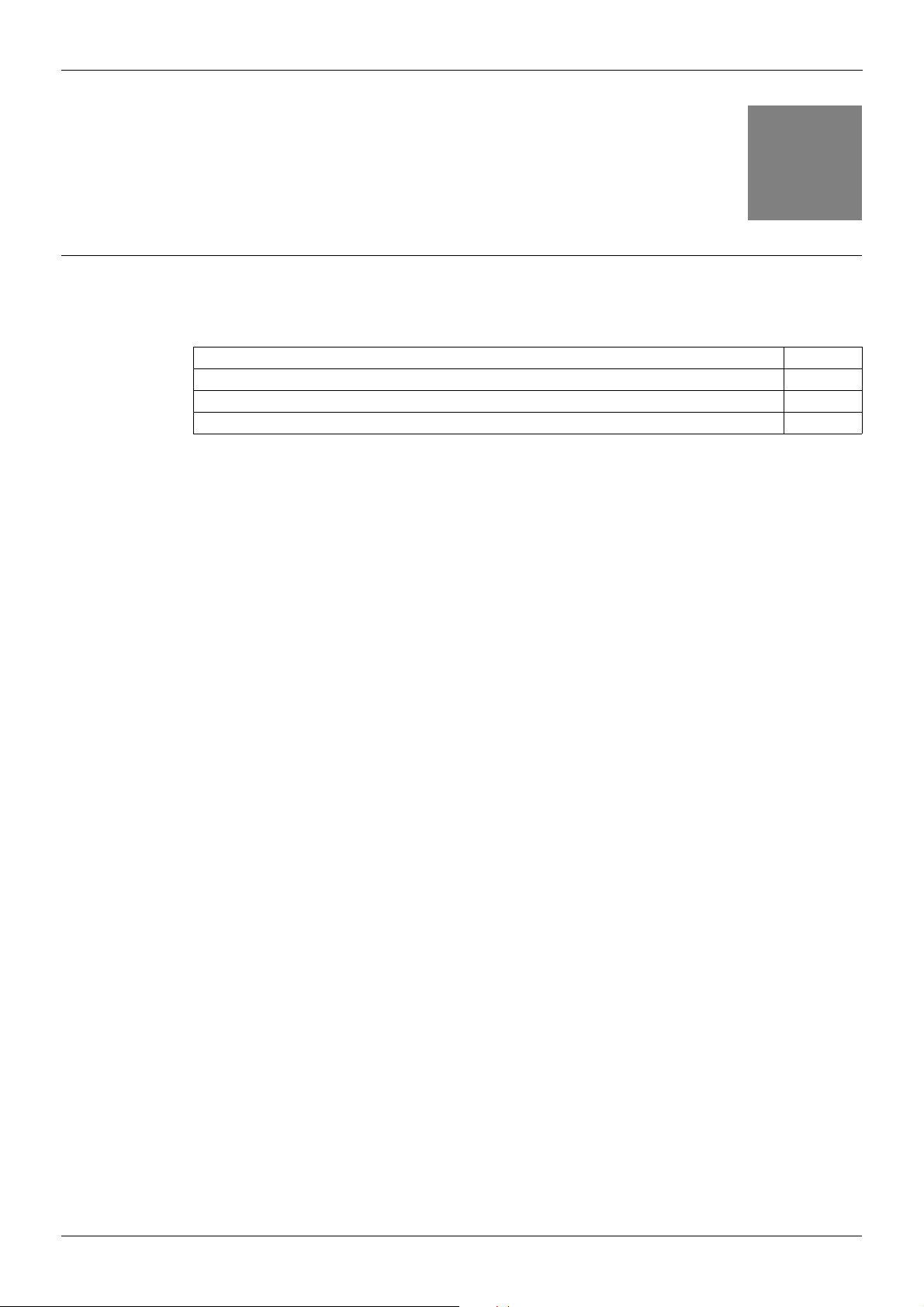

This chapter contains the following topics:

Topic Page

Safety instructions 10

Qualification of personnel and use 12

1

S1A91443 02/2014 9

Safety instructions

The information provided in this manual supplements the product ma nuals.

Carefully read the product manuals before using the product.

Read and understand these instructions before performing any procedure with this drive.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

z Only appropriately trained persons who are familiar with and understand the contents of this manual and

z The system integrator is responsible for compliance with all local and national electrical code

z Many components of the product, including the printed circuit boards, operate with mains voltage. Do not

z Do not touch unshielded components or terminals with voltage present.

z Motors can generate voltage when the shaft is rotated. Prior to performing any type of work on the drive

z AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused

z Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

z Before performing work on the drive system:

z Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

Before you begin

DANGER

all other pertinent product documentation and who have received safety training to recognize and avoid

hazards involved are authorized to work on and with this drive system. Installation, adjustment, repair and

maintenance must be performed by qualified personnel.

requirements as well as all other applicable regulations with respect to grounding of all equipment.

touch. Use only electrically insulated tools.

system, block the motor shaft to prevent rotation.

conductors of the motor cable.

- Disconnect all power, including external control power that may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 15 minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator of the

absence of DC bus voltage that can exceed 800 Vdc.

- Measure the voltage on the DC bus between the DC bus terminals using a properly rated voltmeter to

verify that the voltage is < 42 Vdc.

- If the DC bus capacitors do not discharge properly, contact your local Schneider Electric representative.

DANGER

UNINTENDED EQUIPMENT OPERATION

z Read and understand this manual before installing or operating the drive.

z Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10

S1A91443 02/2014

Before you begin

WARNING

LOSS OF CONTROL

z The designer of any control scheme must consider the potential failure modes of control paths and, for

critical control functions, provide a means to achieve a safe state during and after a path failure. Examples

of critical control functions are emergency stop, overtravel stop, power outage, and restart.

z Separate or redundant control paths must be provided for critical control functions.

z System control paths may include communication links. Consideration must be given to the implications

of unanticipated transmission delays or failures of the link.

z Observe all accident prevention regulations and local safety guidelines.

z Each implementation of the product must be individually and thoroughly tested for proper operation before

1

being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1. For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection,

Installation and Operation of Adjustable Speed Drive Systems.

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the line voltage is compatible with the supply voltage

range shown on the drive nameplate. The drive may be damaged if the line voltage is not compatible.

Failure to follow these instructions can result in injury or equipment damage.

NOTICE

RISK OF DERATED PERFORMANCE DUE TO CAPACITOR AGING

The product capacitor performances after a long time storage above 2 years can be degraded.

In that case, before using the product , apply the following procedure:

z Use a variable AC supply connected between L1 and L2 (even for ATV61/71pppN4 references).

z Increase AC supply voltage to have:

- 80% of rated voltage during 30 min

- 100% of rated voltage during 30 min

Failure to follow these instructions can result in equipment damage.

S1A91443 02/2014 11

Qualification of personnel and use

Qualification of personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and all

other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical

and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with all applicable standards, directives, and

accident prevention regulations when performing such work.

Intended use

The functions described in this manual are only intended for use with the basic product; you must read and

understand the appropriate product manual.

The product may only be used in compliance with all applicable safety regulations and directives, the specified

requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application. Based on

the results, the appropriate safety measures must be implemented.

Since the product is used as a component in an entire system, you must ensure the safety of persons by

means of the design of this entire system (for example, machine design).

Before you begin

Operate the product only with the specified cables and accessories. Use only genuine accessories and spare

parts.

Any use other than the use explicitly permitted is prohibited and can result in hazards.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

The product must NEVER be operated in explosive atmospheres (hazardous locations, Ex areas).

12

S1A91443 02/2014

Overview

Overview

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Introduction 14

Standards and Terminology 15

Basics 16

2

S1A91443 02/2014 13

Introduction

The safety function incorporated in Altivar 61/71/LIFT, allows you to develop applications oriented in the

protection of man and machine.

Safety integrated function provides the following benefits:

z Replacement of external safety equipment

z Reduced wiring efforts and space requirements

z Reduced costs

The Altivar 61/71/LIFT drives are compliant with normative requirements to implement the safety function

Safety function as per IEC 61800-5-2

(STO) Safe Torque Off

The function purpose is to bring the motor into a no torque condition so it is relevant in terms of safety since

no torque is available at the motor level. Power modules are inhibited and the motor coasts dow or prohibits

the motor from starting.

Notation

The graphic display terminal (reference VW3A1101) menus are shown in square brackets.

Example: [COMMUNICATION]

The integrated 7-segment display terminal menus are shown in round brackets.

Example: (COM-)

Parameter names are displayed on the graphic display terminal in square brackets.

Example: [Fallback speed]

Parameter codes are displayed on the integrated 7-segment display terminal in round brackets.

Example: (LFF)

Overview

14

S1A91443 02/2014

Overview

Standards and Terminology

Technical terms, terminology and the corresponding descriptions in this manual are intended to use the terms

or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms such as "safety function", "safe state",

"fault", "fault reset", "failure", "error", "error message", "warning", "warning message", etc.

Among others, these standards include:

z IEC 61800 series: "Adjustable speed electrical power drive systems"

z IEC 61508 series Ed.2: "Functional safety of electrical/electronic/programmable electronic safetyrelated

systems"

z EN 954-1 Safety of machinery - Safety related parts of control systems

z EN ISO 13849-1 & 2 Safety of machinery - Safety related parts of control systems

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be obtained on www.schneider-electric.com

ATEX certification

The ATEX certificate can be obtained on www.schneider-electric.com

Certification for functional safety

The integrated safety function is compatible and certified following IEC 61800-5-2 Ed.1 Adjustable speed

electrical power drive systems – Part 5-2 : Safety requirements – Functional

IEC 61800-5-2 as a product standard, sets out safety-related considerations of Power Drive Systems Safety

Related “PDS (SR) s” in terms of the framework of IEC 61508 series Ed.2 of standards.

Compliance with IEC 61800-5-2 standard, for the following described safety function, will facilitate the

incorporation of a PDS(SR) (Power Drive System with safety-related functions) into a safety-related control

system using the principles of IEC 61508, or the ISO 13849-1, as well as the IEC 62061 for process-systems

and machinery.

The defined safety function is:

z SIL 2 capability in compliance with IEC 61800-5-2 and IEC 61508 series Ed.2.

z Performance Level “d” in compliance with ISO 13849-1.

z Compliant with the Category 3 and 4 of European standard ISO 13849-1 (EN 954-1).

Also refer to Safety function capability, page 29

The safety demand mode of operation is considered in high demand or continuous mode of operation

according to the IEC 61800-5-2 standard.

The certificate for functional safety is accessible on www.schneider-electric.com.

.

S1A91443 02/2014 15

Loading...

Loading...