Important information

XXXXXX

Altivar 61/71/LIFT

Variable speed drives

for synchronous and asynchronous motors

Safety integrated function manual

02/2014

S1A91443

www.schneider-electric.com

Important information

The information provided in this documentation contains general descriptions and/or technical characteristics

of the performance of the products contained herein. This documentation is not intended as a substitute for

and is not to be used for determining suitability or reliability of these products for specific user applications. It

is the duty of any such user or integrator to perform the appropriate and complete risk analysis, evaluation and

testing of the products with respect to the relevant specific application or use thereof. Neither Schneider

Electric nor any of its affiliates or subsidiaries shall be responsible or liable for misuse of the information

contained herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be

followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2013 Schneider Electric. All rights reserved.

2

S1A91443 02/2014

Table of contents

Table of contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 1 Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Qualification of personnel and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Standards and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

(STO) Safe Torque Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4 Incompatibility with safety functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Prerequisites for using safety functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 5 Safety monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

STO Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 6 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety function capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Certified architectures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Process system SF - Case 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Process system SF - Case 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Process system SF - Case 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connection diagram conforming to IEC 61508 and IEC 60204-1 . . . . . . . . . . . . . . . . . 37

Chapter 7 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ATV61 Product sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ATV71 Product sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

S1A91443 02/2014 3

Table of contents

4

S1A91443 02/2014

§

Safety Information

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages may appear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists, which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result in death, serious

injury or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or

equipment damage.

NOTICE

NOTICE, used without the safety alert symbol, indicates a potentially hazardous situation which, if not

avoided, can result in equipment damage.

PLEASE NOTE

The word "drive" as used in this manual refers to the controller portion of the adjustable speed drive as defined

by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No

responsibility is assumed by Schneider Electric for any consequences arising out of the use of this product.

© 2013 Schneider Electric. All Rights Reserved.

S1A91443 02/2014 5

Safety Information

6

S1A91443 02/2014

About the book

At a Glance

Document Scope

Validity Note

Related Documents

About the book

The purpose of this document is to provide information about safety functions incorporated in Altivar 61/71/

LIFT. These functions allow you to develop applications oriented in the protection of man and machine.

Please, read before the installation and programming manual.

This documentation is valid for the Altivar 61, Altivar 71, Altivar LIFT, Altivar 61Q, Altivar 71Q, Altivar 61 Plus

and Altivar 71 Plus drives.

Title of Documentation Reference Number

ATV61E installation manual

55 kW (75 HP) ... 90 kW (125 HP) / 200 - 240 V

90 kW (125 HP) ... 630 kW (900 HP) / 380 - 480 V

90 kW (125 HP) ... 800 kW (800 HP) / 500 - 690 V

ATV71E Installation manual

55 kW (75 Hp) ... 75 kW (100 Hp) / 200 - 240 V

90 kW (125 Hp) ... 500 kW (700 Hp) / 380 - 480 V

90 kW (125 Hp) ... 630 kW (700 Hp) / 500 - 690 V

ATV61S Installation manual

0.37 kW (0.5 HP) ... 45 kW (60 HP) / 200 - 240 V

0.75 kW (1 HP) ... 75 kW (100 HP) / 380 - 480 V

2.2 kW (3 HP) ... 7.5 kW (10 HP) / 500 - 600 V

2.2 kW (3 HP) ... 90 kW (100 HP) / 500 - 690 V

ATV71S Installation manual

0.37 (0.5 HP) ... 45 kW (60 HP) / 200 - 240 V

0.75 (1 HP) ... 75 kW (100 HP) / 380 - 480 V

1.5 (2 HP) ... 7.5 kW (10 HP) / 500 - 600 V

1.5 (2 HP) ... 90 kW (100 HP) / 500 - 690 V

ATV61Q Mounting instructions

110 kW (150HP) ... 630 kW (800HP) / 380 - 480 V

110 kW (150HP) ... 800 kW (800HP) / 500 - 690 V

ATV71Q Mounting instructions

90 kW (125HP) ... 500 kW (700HP) / 380 - 480 V

90 kW (125HP) ... 630 kW (700HP) / 500 - 690 V

ATV61 Plus Configuration Guide

90 kW ... 1400 kW / 380 - 415 V

90 kW ... 1800 kW / 500 - 525 V

110 kW ... 2400 kW / 690 V

ATV71 Plus Configuration Guide

90 kW ... 1300 kW / 380 - 415 V

90 kW ... 1500 kW / 500 - 525 V

110 kW ... 2000 kW / 690 V

ATV61 Plus-Marine

630 kW ... 1400 kW / 380 - 415 V

800 kW ... 2400 kW / 690 V

760655

755849

760643

755843

8P02534

8P02535

8P02503

8P02504

8P02526

S1A91443 02/2014 7

Title of Documentation Reference Number

ATV71 Plus-Marine

500 kW ... 1300 kW / 380 - 415 V

630 kW ... 2000 kW / 690 V

ATV61_71 Atex manual AAV49434

ATV61 Programming manual 760649

ATV71 Programming_manual 755855

ATV_LIFT programming manual BBV19478

ATV61_71 Canopen manual 755865

ATV61_71 Cc-link manual AAV49429

ATV61_71 Ethernet manual 755879

ATV61_71 Ethernet TCP Daisy Chain manual AAV69931

ATV61_71 EthernetIP manual AAV68822

ATV61_71 FIPIO manual 755883

ATV61_71 Interbus manual 755871

ATV61_71 PROFIBUS DPv1 manual AAV52935

ATV61 Apogee FLN P1 manual BBV10543

ATV61 Bacnet manual 765274

ATV61 LonWorks_manual 765273

ATV61 metasys N2 manual AAV33578

ATV61 multi pump manual 765272

ATV61 communication parameters 760661

ATV71 communication parameters 755861

ATV71 Controller inside manual 757062

ATV71 Devicenet manual 755877

ATV71 Modbus integrated manual 755863

ATV71 Modbus jbus manual 755875

ATV71 Modbus plus manual 755869

ATV71 profibus manual 755873

ATV71 regen units manual 757361

ATV71 Uni-Telway manual 755867

ATV61 and 71 other option manuals: see www.schneider-electric.com.

8P02527

About the book

You can download the latest versions of the technical publications related to the Altivar 61 and 71 on

www.schneider-electric.com.

8

S1A91443 02/2014

Before you begin

Before you begin

What's in this Chapter?

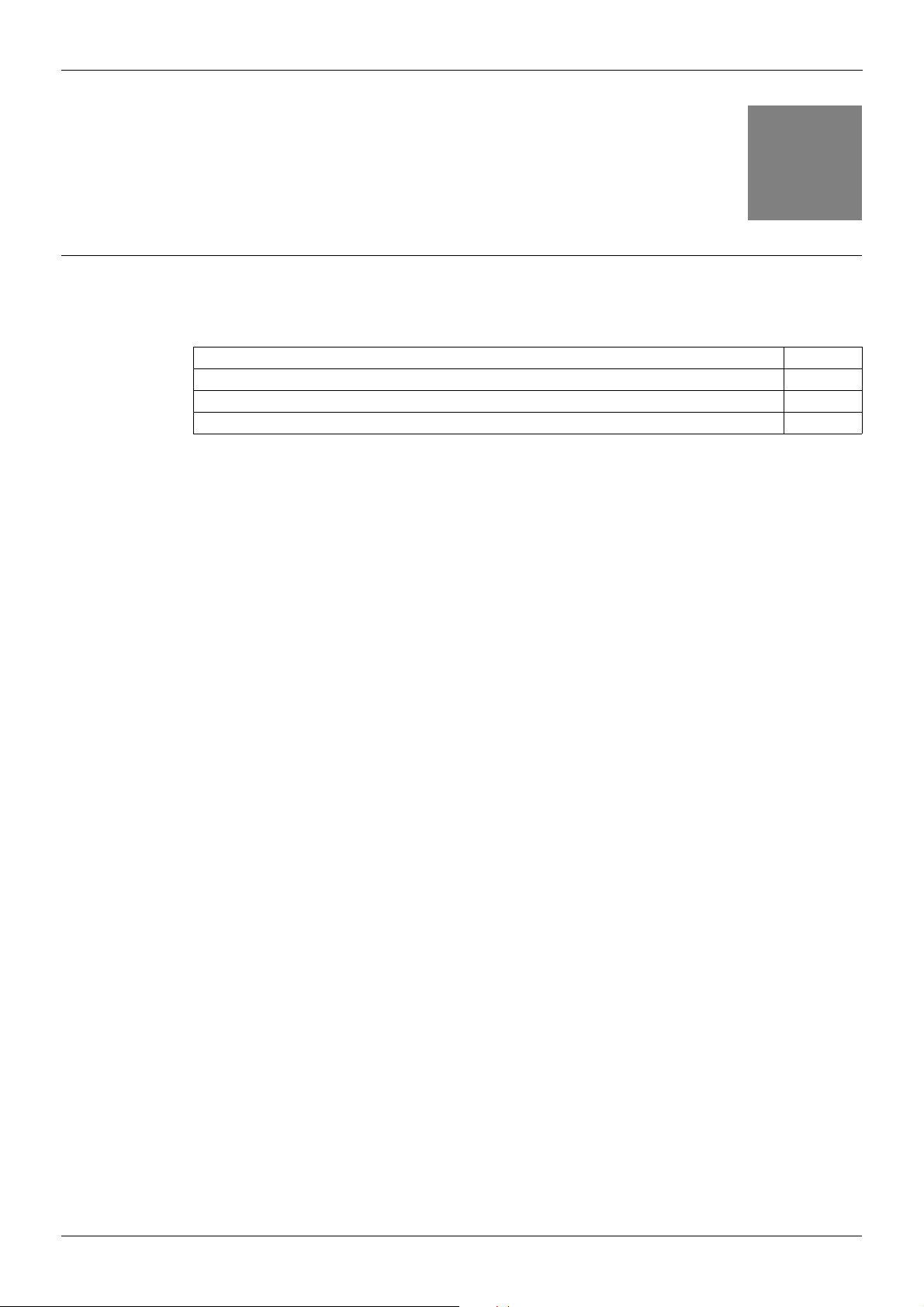

This chapter contains the following topics:

Topic Page

Safety instructions 10

Qualification of personnel and use 12

1

S1A91443 02/2014 9

Safety instructions

The information provided in this manual supplements the product ma nuals.

Carefully read the product manuals before using the product.

Read and understand these instructions before performing any procedure with this drive.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

z Only appropriately trained persons who are familiar with and understand the contents of this manual and

z The system integrator is responsible for compliance with all local and national electrical code

z Many components of the product, including the printed circuit boards, operate with mains voltage. Do not

z Do not touch unshielded components or terminals with voltage present.

z Motors can generate voltage when the shaft is rotated. Prior to performing any type of work on the drive

z AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused

z Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

z Before performing work on the drive system:

z Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

Before you begin

DANGER

all other pertinent product documentation and who have received safety training to recognize and avoid

hazards involved are authorized to work on and with this drive system. Installation, adjustment, repair and

maintenance must be performed by qualified personnel.

requirements as well as all other applicable regulations with respect to grounding of all equipment.

touch. Use only electrically insulated tools.

system, block the motor shaft to prevent rotation.

conductors of the motor cable.

- Disconnect all power, including external control power that may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 15 minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator of the

absence of DC bus voltage that can exceed 800 Vdc.

- Measure the voltage on the DC bus between the DC bus terminals using a properly rated voltmeter to

verify that the voltage is < 42 Vdc.

- If the DC bus capacitors do not discharge properly, contact your local Schneider Electric representative.

DANGER

UNINTENDED EQUIPMENT OPERATION

z Read and understand this manual before installing or operating the drive.

z Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10

S1A91443 02/2014

Before you begin

WARNING

LOSS OF CONTROL

z The designer of any control scheme must consider the potential failure modes of control paths and, for

critical control functions, provide a means to achieve a safe state during and after a path failure. Examples

of critical control functions are emergency stop, overtravel stop, power outage, and restart.

z Separate or redundant control paths must be provided for critical control functions.

z System control paths may include communication links. Consideration must be given to the implications

of unanticipated transmission delays or failures of the link.

z Observe all accident prevention regulations and local safety guidelines.

z Each implementation of the product must be individually and thoroughly tested for proper operation before

1

being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1. For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection,

Installation and Operation of Adjustable Speed Drive Systems.

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the line voltage is compatible with the supply voltage

range shown on the drive nameplate. The drive may be damaged if the line voltage is not compatible.

Failure to follow these instructions can result in injury or equipment damage.

NOTICE

RISK OF DERATED PERFORMANCE DUE TO CAPACITOR AGING

The product capacitor performances after a long time storage above 2 years can be degraded.

In that case, before using the product , apply the following procedure:

z Use a variable AC supply connected between L1 and L2 (even for ATV61/71pppN4 references).

z Increase AC supply voltage to have:

- 80% of rated voltage during 30 min

- 100% of rated voltage during 30 min

Failure to follow these instructions can result in equipment damage.

S1A91443 02/2014 11

Qualification of personnel and use

Qualification of personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and all

other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical

and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with all applicable standards, directives, and

accident prevention regulations when performing such work.

Intended use

The functions described in this manual are only intended for use with the basic product; you must read and

understand the appropriate product manual.

The product may only be used in compliance with all applicable safety regulations and directives, the specified

requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application. Based on

the results, the appropriate safety measures must be implemented.

Since the product is used as a component in an entire system, you must ensure the safety of persons by

means of the design of this entire system (for example, machine design).

Before you begin

Operate the product only with the specified cables and accessories. Use only genuine accessories and spare

parts.

Any use other than the use explicitly permitted is prohibited and can result in hazards.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

The product must NEVER be operated in explosive atmospheres (hazardous locations, Ex areas).

12

S1A91443 02/2014

Overview

Overview

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Introduction 14

Standards and Terminology 15

Basics 16

2

S1A91443 02/2014 13

Introduction

The safety function incorporated in Altivar 61/71/LIFT, allows you to develop applications oriented in the

protection of man and machine.

Safety integrated function provides the following benefits:

z Replacement of external safety equipment

z Reduced wiring efforts and space requirements

z Reduced costs

The Altivar 61/71/LIFT drives are compliant with normative requirements to implement the safety function

Safety function as per IEC 61800-5-2

(STO) Safe Torque Off

The function purpose is to bring the motor into a no torque condition so it is relevant in terms of safety since

no torque is available at the motor level. Power modules are inhibited and the motor coasts dow or prohibits

the motor from starting.

Notation

The graphic display terminal (reference VW3A1101) menus are shown in square brackets.

Example: [COMMUNICATION]

The integrated 7-segment display terminal menus are shown in round brackets.

Example: (COM-)

Parameter names are displayed on the graphic display terminal in square brackets.

Example: [Fallback speed]

Parameter codes are displayed on the integrated 7-segment display terminal in round brackets.

Example: (LFF)

Overview

14

S1A91443 02/2014

Overview

Standards and Terminology

Technical terms, terminology and the corresponding descriptions in this manual are intended to use the terms

or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms such as "safety function", "safe state",

"fault", "fault reset", "failure", "error", "error message", "warning", "warning message", etc.

Among others, these standards include:

z IEC 61800 series: "Adjustable speed electrical power drive systems"

z IEC 61508 series Ed.2: "Functional safety of electrical/electronic/programmable electronic safetyrelated

systems"

z EN 954-1 Safety of machinery - Safety related parts of control systems

z EN ISO 13849-1 & 2 Safety of machinery - Safety related parts of control systems

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be obtained on www.schneider-electric.com

ATEX certification

The ATEX certificate can be obtained on www.schneider-electric.com

Certification for functional safety

The integrated safety function is compatible and certified following IEC 61800-5-2 Ed.1 Adjustable speed

electrical power drive systems – Part 5-2 : Safety requirements – Functional

IEC 61800-5-2 as a product standard, sets out safety-related considerations of Power Drive Systems Safety

Related “PDS (SR) s” in terms of the framework of IEC 61508 series Ed.2 of standards.

Compliance with IEC 61800-5-2 standard, for the following described safety function, will facilitate the

incorporation of a PDS(SR) (Power Drive System with safety-related functions) into a safety-related control

system using the principles of IEC 61508, or the ISO 13849-1, as well as the IEC 62061 for process-systems

and machinery.

The defined safety function is:

z SIL 2 capability in compliance with IEC 61800-5-2 and IEC 61508 series Ed.2.

z Performance Level “d” in compliance with ISO 13849-1.

z Compliant with the Category 3 and 4 of European standard ISO 13849-1 (EN 954-1).

Also refer to Safety function capability, page 29

The safety demand mode of operation is considered in high demand or continuous mode of operation

according to the IEC 61800-5-2 standard.

The certificate for functional safety is accessible on www.schneider-electric.com.

.

S1A91443 02/2014 15

Basics

Functional Safety

Automation and safety engineering are two areas that were completely separated in the past but recently have

become more and more integrated.

Engineering and installation of complex automation solutions are greatly simplified by integrated safety

functions.

Usually, the safety engineering requirements depend on the application.

The level of the requirements results from the risk and the hazard potential arising from the specific application.

IEC 61508 standard

The standard IEC 61508 "Functional safety of electrical/electronic /programmable electronic safety-related

systems" covers the safety-related function. Instead of a single component, an entire function chain (for

example, from a sensor through the logical processing units to the actuator) is considered as a unit. This

function chain must meet the requirements of the specific safety integrity level as a whole. Systems and

components that can be used in various applications for safety tasks with comparable risk levels can be

developed on this basis.

SIL - Safety Integrity Level

The standard IEC 61508 defines 4 safety integrity levels (SIL) for safety functions. SIL1 is the lowest level and

SIL4 is the highest level. A hazard and risk analysis serves as a basis for determining the required safety

integrity level. This is used to decide whether the relevant function chain is to be considered as a safety

function and which hazard potential it must cover.

Overview

PFH - Probability of a dangerous Hardware Failure per Hour

To maintain the safety function, the IEC 61508 standard requires various levels of measures for avoiding and

controlling detected faults, depending on the required SIL. All components of a safety function must be

subjected to a probability assessment to evaluate the effectiveness of the measures implemented for

controlling detected faults. This assessment determines the PFH (probability of a dangerous failure per hour)

for a safety system. This is the probability per hour that a safety system fails in a hazardous manner and the

safety function cannot be correctly executed. Depending on the SIL, the PFH must not exceed certain values

for the entire safety system. The individual PFH values of a function chain are added. The result must not

exceed the maximum value specified in the standard.

SIL Safety Integrity

Level

4

3

2

1

Probability of a dangerous Failure per Hour

(PFH) at high demand or continuous demand

≥10

≥10

≥10

≥10

-9

… <10

-8

… <10

-7

… <10

-6

… <10

-8

-7

-6

-5

PL - Performance level

The standard IEC 13849-1 defines 5 Performance levels (PL) for safety functions. “a” is the lowest level and

“e” is the highest level. Five level (a, b, c, d, e) correspond to different values of average probability of

dangerous failure per hour.

Performance

level

e

d

c

b

a

Probability of a dangerous

Hardware Failure per Hour

≥10

≥10

≥10

≥3*10

≥10

-8

… <10

-7

… <10

-6

… <3*10

-5

… <10-4

-6

… <10

-7

-6

-6

-5

16

S1A91443 02/2014

Overview

HFT - hardware detected fault tolerance and SFF - Safe Failure Fraction

Depending on the SIL for the safety system, the IEC 61508 standard and SFF, Safe Failure Fraction requires

a specific hardware detected fault tolerance HFT in connection with a specific proportion of safe failures SFF

(safe failure fraction).

The hardware detected fault tolerance is the ability of a system to execute the required safety function in spite

of the presence of one or more hardware detected faults.

The SFF of a system is defined as the ratio of the rate of safe failures to the total failure rate of the system.

According to IEC 61508, the maximum achievable SIL of a system is partly determined by the hardware

detected fault tolerance HFT and the safe failure fraction SFF of the system.

IEC 61508 distinguishes two types of subsystems (type A subsystem, type B subsystem). These types are

specified on the basis of criteria which the standard defines for the safety-relevant components.

SFF HFT type A subsystem HFT type B subsystem

012 012

< 60% SIL1 SIL2 SIL3 --- SIL1 SIL2

60% … < 90% SIL2 SIL3 SIL4 SIL1 SIL2 SIL3

60% … < 99% SIL3 SIL4 SIL4 SIL2 SIL3 SIL4

u 99%

SIL3 SIL4 SIL4 SIL3 SIL4 SIL4

Detected fault avoidance measures

Systematic errors in the specifications, in the hardware and the software, usage detected faults and

maintenance detected faults of the safety system must be avoided to the maximum degree possible. To meet

these requirements, IEC 61508 specifies a number of measures for detected fault avoidance that must be

implemented depending on the required SIL. These measures for detected fault avoidance must cover the

entire life cycle of the safety system, i.e. from design to decommissioning of the system.

S1A91443 02/2014 17

Overview

18

S1A91443 02/2014

Description

Description

What's in this Chapter?

This chapter contains the following topics:

Topic Page

(STO) Safe Torque Off 20

3

S1A91443 02/2014 19

(STO) Safe Torque Off

Frequency

Actual

frequency

Time

(STO)

activation

The purpose of this function is to bring the motor into a no torque condition with motor coasts down or prohibits

the motor from starting. So it is relevant in terms of safety since no torque is available at the motor level.

The logic input “PWR” is always assigned to this function.

The (STO) status is accessible with the drive.

(STO) Normative reference

The normative definition of (STO) function is in §4.2.2.2 of the IEC 61800-5-2 (on the 07/2007 version):

"Power, that can cause rotation (or motion in the case of a linear motor), is not applied to the motor. The

PDS(SR)(Power Drive System with safety-related functi ons) will not provide energy to the motor which can

generate torque (or force in the case of a linear motor).

NOTE 1 This safety function corresponds to an uncontrolled stop in accordance with stop category 0 of IEC

60204-1.

NOTE 2 This safety function may be used where safe torque off (STO) is required to help prevent an

unexpected start-up.

NOTE 3 In circumstances where external influences (for example, falling of suspended loads) are present,

additional measures (for example, mechanical brakes) ma y be necessary to help prevent any hazard.

NOTE 4 Electronic means and contactors are not adequate for protection against electric shock, and additional

measures for isolation may be necessary."

Description

Safety function (SF) level required for (STO) function

Configuration SIL

(STO) with Preventa module SIL 2 PL "d"

The Preventa module is required for the machine environment because:

z For the machine environment (IEC60204-1 & Machine Directive), reset shall not initiate a restart in any

cases. One of the most constringent case is when PWR (STO) is activated, then the power supply is switch

off. In this case, if (STO) is deactivated during the loss of supply, the motor do not have to restart

automatically. The Preventa module can help prevent a spurious restart in the previous condition. So the

Preventa module is mandatory for machine applications.

z E_stop of several BDM in a PDS: the Preventa module has some safety outputs for application which

requires one or several safety outputs.

For other environments, the Preventa module is not required, except if the application requires it: System

fallback position.

(Safety Integrity Level)

according to IEC 61-508

PL

(Performance Level)

according to ISO-13849

20

S1A91443 02/2014

Incompatibility with safety functions

Incompatibility with safety functions

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Prerequisites for using safety functions 22

4

S1A91443 02/2014 21

Prerequisites for using safety functions

Some parameters have to be fulfilled for a proper operation:

z Motor size is adequate to the application and is not in the limit of its capacity

z Speed drive size has been properly chosen for the electrical mains, sequence, motor and application and

it is not in the limit of their catalogued capacities.

z If required, the adequate options are used. Example: like dynamic brake resistor or motor inductor.

z The drive is properly setting up for the right speed loop and torque characteristics for the application; the

speed profile of the reference is mastered by the drive control loop.

Incompatibility with safety functions

22

S1A91443 02/2014

Incompatibility with safety functions

Fault Inhibition

For some kind of detected fault, [Fault inhibit assign.] (InH) can be requested to avoid the drive to stop

when the fault occurred. The fault inhibition goal is not compatible with the safe function behavior.

When a safe function is activated, detected fault generated by the safe function PrA can’t be inhibited.

Factory settings

If the drive is in safe mode and you active the factory settings only non safety parameters will be downloaded

in the drive. Safe parameters are not impacted by factory settings.

S1A91443 02/2014 23

Incompatibility with safety functions

24

S1A91443 02/2014

Safety monitoring

Safety monitoring

What's in this Chapter?

This chapter contains the following topics:

Topic Page

STO Function 26

5

S1A91443 02/2014 25

STO Function

Description

Safety monitoring

When the dedicated PWR logical input is activated, the output power bridge of the drive is locked by the

Hardware in order to avoid any torque in the motor. The output power bridge of the drive is also locked by a

redundant software and hardware channel.

When the STO Function is active, the drive locks its output power bridge in order to avoid any torque in the

motor.

When a fault is detected into the hardware of the STO Function, the drive trips and locks its output power

bridge by the redundant hardware and software channel, even if the PWR Input is not activated.

If STO is Active, then Power Bridge is locked by Software and STO status (PrA) is activated and displayed.

If STO is Active and an error is detected, the drive trips in PrF detected fault.

26

S1A91443 02/2014

Technical data

Technical data

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Electrical Data 28

Safety function capability 29

Certified architectures 31

Process system SF - Case 1 32

Process system SF - Case 2 33

Process system SF - Case 3 35

Connection diagram conforming to IEC 61508 and IEC 60204-1 37

6

S1A91443 02/2014 27

Electrical Data

LI1

LI5

+24

0V

A1

ATV71Hppppp

PWR

+10

AI1+

AI2

AI1-

COM

COM

AO1

LI3

LI2

LI6

LI4

Reference

potentiometer

0 ± 10 V

or

X-Y mA

0 ± 10 V

or

X-Y mA

A1

ATVp1Hppppp

SW1

Ext

Source

Sink

Int

LI1

LI5

+24

0V

LI3

LI2

LI6

LI4

A1

ATVp1Hppppp

SW1

Ext

Source

Sink

Int

LI1

LI5

+24

0V

LI3

LI2

LI6

LI4

+24 V

0 V

24 V c supply

The Logic inputs and Logic outputs of the drive can be wired for logic type 1 or logic type 2.

Logic Type Active state

1 Output draws current (Sink)

2 Output supplies flows from the input Current

Safe function only used in source mode, sink is not compatible with safe functions.

Signal inputs are protected against reverse polarity, outputs are short-circuit protected. The inputs and outputs

are galvanically isolated.

Control connection diagrams

Technical data

Current flows to the input

Current (Source)

Logic input switch (SW1)

The logic input switch (SW1) is used to adapt the operation of the logic inputs to the technology of the

programmable controller outputs.

• Set the switch to Source (factory setting) if using PLC outputs with PNP transistors.

• Set the switch to Sink Int or Sink Ext if using PLC outputs with NPN transistors.

• Switch SW1 set to “Source” position

UNINTENDED EQUIPMENT OPERATION

Prevent accidental grounding of logic inputs wired in "sink logic". Accidental grounding can result in

unintended activation of drive functions.

Protect the signal conductors against damage that could result in unintentional conductor grounding.

Failure to follow these instructions will result in death or serious injury.

• Switch SW1 set to “Source” position and use of an external power supply for the LIs

DANGER

28

S1A91443 02/2014

Technical data

Safety function capability

Safety functions of PDS (SR) are part of a global system

If qualitative and quantitative objectives of safety set by the final application requires to make some

adjustments to use the safety functions in a safe way, then the integrator of the BDM is responsible of these

complementary evolutions (for example management of the mecanichal brake on the motor).

Also, the output information generated by the utilization of safety functions (default relay activation, relay of

brake logic command, errors codes or information on the display, …) aren't considering safety

informations.Machine application

Function (STO)

Configuration

Standard

IEC 61800-5-2 /

IEC 61508 /

IEC 62061 (1) SIL2 CL

EN 954-1 (2) Category 3

(STO)

with Preventa

XPS AF or

equivalent

SIL2

Process application

ISO 13849-1 (3)

IEC 60204-1 Category stop 0

(1) Because the standard IEC 62061 is an integration standard, this standard distinguishes the global safety function (which

is classify SIL2 for ATV61/71/LIFT according to diagrams Process system SF - Case 1, page 32

Case 2, page 33

(2) According to table 6 of IEC 62061 (2005)

(3) According to table 4 of EN13849-1 (2008)

Function (STO)

Configuration

Standard

IEC 61800-5-2 /

IEC 61508 /

IEC 62061 (1) SIL2 CL

(1) Because the standard IEC 62061 is an integration standard, this standard distinguishes the global safety function (which

is classify SIL2 for ATV61/71/LIFT according to diagrams Process system SF - Case 1, page 32

Case 2, page 33

Category 3

PL "d"

and Process system SF -

) from components which constitute the safety function (which is classify SIL2 CL for ATV61/71/LIFT)

(STO)

SIL2

and Process system SF -

) from components which constitute the safety function (which is classify SIL2 CL for ATV61/71/LIFT)

Input signals safety functions

Input signals

safety functions

Logic 0 (Ulow) Vdc < 2

Logic 1 (Uhigh) Vdc > 17

Impedance (24V) kΩ 1.5

Debounce time ms < 1

Response time of safety function ms < 10

S1A91443 02/2014 29

Units Value for

(STO)

Synthesis of the dependability study

Standard Input size 2 - 5 size 6 - 8 size 9 - 10 size 11 -15 size 23 -24

IEC61508 Ed.2

IEC 62061 (1)

EN 954-1 (2)

ISO 13849-1 (3)

(1) Because the standard IEC 62061 is an integration standard, this standard distinguishes the global safety

function (which is classify SIL2 for ATV61/71/LIFT according to diagrams Process system SF - Case 1,

page 32

and Process system SF - Case 2, page 33 ) from components which constitute the safety function

(which is classify SIL2 CL for ATV61/71/LIFT)

(2) According to table 6 of IEC 62061 (2005)

(3) According to table 4 of EN13849-1 (2008)

Preventive annual activation of the safety function is recommended. However the safety levels are reached

with lower margins without annual activation.

Note: The table above is not sufficient to evaluate the PL of a PDS. The PL evaluation has to be done at the

system level. The fitter or the integrator of the BDM has to do the system PL evaluation by including sensors

data with numbers from the table above.

Technical data

SFF 92% 91% 91% 91% 92 %

PFH

Type BBBBB

HFT 11111

DC avg 70,40% 68,30% 71,20% 69,70% 69,70%

SIL capability 22222

SIL CL capability 22222

Category 33333

PL ddddd

Category 33333

MTTFd in years 1800 1900 1750 1850 1850

1 E-8 h

-1

1 E-8 h

-1

1 E-8 h

-1

1 E-8 h

-1

1 E-8 h

-1

Drive sizes table

Please refer to the tables, page 39

EN ISO 13849 standard

This European Standard specifies the validation process, including both analysis and testing, for the safety

functions and categories for the safety-related parts of control systems. Descriptions of the safety functions

and the requirements for the categories are given in EN 954-1 (ISO 13849-1) which deals the general

principles for design. Some requirements for validation are general and some are specific to the technology

used. EN ISO 13849-2 also specifies the conditions under which the validation by testing of the safety-related

parts of control systems should be carried out.

Isolation distances and interval are sized at least according to IEC 60264-1. See the following table

Printed circuits boards/assemblies

Fault considered Fault exclusion Remarks

Short-circuit between two

adjacent tracks/pads

Open-circuit of any track None -

for correspondence between product sizes and references.

Short-circuits between

adjacent conductors in

accordance with

remarks 1) to 3).

The base material used is according to IEC 60249 and the creepage distances and clearances are dimensioned at least to

IEC 60664-1: 1992 with at least pollution/installation category III.

The printed side(s) of the assembled board is covered with an agoing-resistant varnish or a protective layer covering all conductor

paths in accordance with IEC 60664-3

All enclosures of the safety-related parts of the control system, including those mounted remotely, should provide a degree of protection of at least IP54 [see EN 60529 (IEC 60529)], when

mounted as specified.

30

S1A91443 02/2014

Technical data

Certified architectures

NOTE: For the certification relative to functional aspects, only the PDS(SR) (Power Drive System with safety-

related functions) will be in consideration, and not the complete system in which fits into to help to ensure the

functional safety of a machine or a system/process.

These are the two architectures certified:

z Process system SF - Case 1, page 32

z Process system SF - Case 2, page 33

z Process system SF - Case 3, page 35

z Safety according to IEC 61508 and IEC 60204-1, page 37

Safety functions of PDS (SR) (Power Drive System with safety-related functions) are part of a global system.

If qualitative and quantitative objectives of safety set by the final application require to make some adjustments

to use the safety functions in a safe way, then the integrator of the BDM (background debug module) is

responsible of these complementary evolutions (for example management of the mechanical brake on the

motor).

Also, the output information generated by the utilization of safety functions (default relay activation, relay of

brake logic command, errors codes or information on the display, …) are not considering safety informations.

S1A91443 02/2014 31

Technical data

S2

A1 23 33Y2 13

A2

PE

14 24 34

Y43

Y44

Y1

K2K1

48 V, 115 V, 230 V

K1

K2

T

ESC

XPS AC

S1

F1

L1

N

U / T1

V / T2

W / T3

R / L1

U1

W1

V1

M

3 a

S / L2

T / L3

A1

(1)

(4)

ATVp1Hppppp

+24

PWR

R1A

R1C

R1B

LI1

LI6

LI2

P0

PA / +

PB

PC / -

(2)

(3) (3)

Logic

Process system SF - Case 1

Connection diagrams conforming to standards EN 954-1 category 3, ISO 13849-1 and IEC/EN 61508 capacity SIL2, stopping category 0 in accordance with standard IEC/EN 60204-1

This connection diagram is suitable for use with machines with a short freewheel stop time (machines with low

inertia or high resistive torque).

When the stop request is activated, the motor power supply is cut immediately and it stops in accordance

with category 0 of standard IEC/EN 60204-1.

Note: This diagram must be used for hoisting applications if a mechanical brake is controlled by an ATV71.

A contact on the Preventa XPS AC module must be inserted in the brake control circuit to engage it safely

when the (STO) Safe Torque Off function is activated.

32

(1)Line choke (if used)

(2)Standardized coaxial cable, type RG174/U according to MIL-C17 or KX3B according to NF C 93-550,

external diameter 2.54 mm /0.09 in., maximum length 15 m / 49.21 ft. The cable shielding must be earthed

(3)Use cable ends DZ5CE020 (yellow) on wires connected to PWR and +24 inputs

(4)Braking resistor (if used)

- Standard EN 954-1 category 3 and ISO 13849-1 require the use of a dual-contact stop button (S1).

- S1 is used to activate the Power Removal safety function.

- S2 is used to initialize the Preventa module when powering up or after an emergency stop. ESC enables

the use of other initialization conditions for the module.

- One Preventa module can be used for the STO function on several ATV61/71/LIFT drives.

- A logic output on the Preventa module can be used to indicate reliably that the drive is operating in safe

conditions.

Note:

For preventive maintenance, the STO function must be activated at least once a year.

The drive power supply must be turned off and then on again before carrying out this preventive maintenance.

The drive logic output signals cannot be considered as safety-type signals.

Install interference suppressors on all inductive circuits near the drive or coupled to the same circuit (relays,

contactors, solenoid valves, etc).

Choice of associated components:

Please refer to the catalog.

S1A91443 02/2014

Technical data

Process system SF - Case 2

Connection diagram conforming to standards EN 954-1 category 3, ISO 13849-1 and IEC/EN 61508 capacity SIL2, stopping category 1 in accordance with standard IEC/EN 60204-1

This connection diagram is suitable for use with machines with a long freewheel stop time (machines with high

inertia or low resistive torque).

WARNING

LOSS OF CONTROL

This diagram must not be used for hoisting applications. Use process system SF - Case 1.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

When the stop request is activated, deceleration of the motor, controlled by the drive, is requested first. Then,

after a time delay corresponding to the deceleration time, the STO function is activated.

Example:

- 2-wire control

- LI1 assigned to forward

- LI2 assigned to reverse

L1

F1

(max. 4 A)

N

S1

A1 13 57 67

XPS-ATE

T

(1)

S11S21

B1

S12

K1 K2

S22

Time (s)

Timer 2

Timer 1

LOGIC

K1

23

K3

K1

A2

PE

(1)

S2

S33

K3

K2

K2 K4K1

K3

K4

Y1 Y2 Y3 Y4 Y5 14 24 6858

ESC

K2

K4

77

78 Y88 Y89 Y90 Y91

(A1/A2)

(S12)

+24V

Y+

(S22)

to PLC

c

(Stop1)

A1

ATVp1Hppppp

U1

R / L1

U / T1

3 a

V1

M

S / L2

V / T2

W1

(2)

T / L3

W / T3

(1)

LI1

P0

LI2

PA / +

(3)

PC / -

PWR

(4)(4)

+24

R1A

R1B

R1C

LI6

PB

(5)

(1)In this example, the logic inputs LIp are wired as “Source” but can be wired as “Sink Int” or “Sink Ext”.

(2)Line choke (if used)

(3)Standardized coaxial cable, type RG174/U according to MIL-C17 or KX3B according to NF C 93-550, external

diameter 2.54 mm /0.09 in., maximum length 15 m / 49.21 ft. The cable shielding must be earthed.

(4)Use cable ends DZ5CE020 (yellow) on wires connected to PWR and +24 inputs

(5)Braking resistor (if used)

S1A91443 02/2014 33

Technical data

- Standard EN 954-1 category 3 and ISO 13849-1 require the use of a dual-contact stop button (S1).

- S1 is used to activate the STO function.

- S2 is used to initialize the Preventa module when powering up or after an emergency stop. ESC enables

the use of other initialization conditions for the module.

- One Preventa module can be used for the STO function on several ATV61/71/LIFT drives. In this case the

time delay must be set to the longest stopping time.

- A logic output on the Preventa module can be used to indicate reliably that the drive is operating in safe

conditions.

Note:

For preventive maintenance, the STO function must be activated at least once a year.

The drive power supply must be turned off and then on again before carrying out this preventive maintenance.

The drive logic output signals cannot be considered as safety-type signals.

Install interference suppressors on all inductive circuits near the drive or coupled to the same circuit (relays,

contactors, solenoid valves, etc).

Choice of associated components:

Please refer to the catalog.

34

S1A91443 02/2014

Technical data

Process system SF - Case 3

Multi-drive conforming to standards EN 954-1 category 3, ISO 13849-1 and IEC/EN 61508 capacity SIL2, stopping category 1 in accordance with standard IEC/EN 60204-1

This connection diagram is suitable for use with machines with a long freewheel stop time (machines with high

inertia or low resistive torque).

.

WARNING

LOSS OF CONTROL

This diagram must not be used for hoisting applications. Use process system SF - Case 1.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

L1

F1

(max. 4 A)

A1 13 57 67

XPS-ATE

T

(1)

A2

PE

(1)

N

S2

S11S21

S33

B1

S1

S12

K1 K2

K3

S22

Time (s)

LOGIC

Timer 2

Timer 1

K1

K2

K2 K4K1

K3

K4

Y1 Y2 Y3 Y4 Y5 14 24 6858

ESC

23

K1

K2

77

K3

K4

78 Y88 Y89 Y90 Y91

(A1/A2)

(S12)

+24V

Y+

(S22)

to PLC

c

(Stop1)

A1

ATVp1Hppppp

A1

ATVp1Hppppp

U1

U1

R / L1

U / T1

3 a

R / L1

U / T1

3 a

V1

V1

M

M

S / L2

V / T2

S / L2

V / T2

W1

W1

(3)

T / L3

W / T3

(3)

T / L3

W / T3

LI2

PA / +

LI2

PA / +

(4)

(5) (5)

LI6

PB

PC / -

(6)

(4)

LI6

PB

PC / -

(6)

PWR

(5) (5)

PWR

+24

R1A

R1B

R1C

+24

R1A

R1B

R1C

(2)

LI1

P0

(2)

LI1

P0

(1) 115/230 V ~ only.

(2) In this example, the logic inputs LIo are wired as "Source" but can be wired as "Sink Int" or "Sink Ext".

(3) Line choke (if used)

(4) Standardized coaxial cable, type RG174/U according to MIL-C17 or KX3B according to NF C 93-550, external diameter

2.54 mm /0.09 in., maximum length 15 m / 49.21 ft. The cable shielding must be earthed.

S1A91443 02/2014 35

Technical data

(5) Use cable ends DZ5CE020 (yellow) on wires connected to PWR and +24 inputs.

(6) Braking resistor (if used)

When the stop request is activated, deceleration of the motor, controlled by the drive, is requested first. Then,

after a time delay corresponding to the deceleration time, the STO function is activated.

Example:

- 2-wire control

- LI1 assigned to forward.

- LI2 assigned to reverse.

- Standard EN 954-1category 3 and ISO 13849-1 require the use of a dual-contact stop button (S1).

- S1 is used to activate the STO function.

- S2 is used to initialize the Preventa module when powering up or after an emergency stop. ESC enables the

use of other initialization conditions for the module.

- One Preventa module can be used for the STO safety function on several ATV61/71/LIFT drives. In this case

the time delay must be set to the longest stopping time.

A Logic output on the Preventa module can be used to indicate reliably that the drive is operating in safe

conditions.

Note: For preventive maintenance, the STO function must be activated at least once a year. The drive power

supply must be turned off and then on again before carrying out this preventive maintenance. The drive logic

output signals cannot be considered as safety-type signals.

Install interference suppressors on all inductive circuits near the drive or coupled to the same circuit (relays,

contactors, solenoid, valves, etc).

Choice of associated components:

Please refer to the catalog.

36

S1A91443 02/2014

Technical data

S1

U / T1

V / T2

W / T3

R / L1

U1

W1

V1

M

3 a

S / L2

T / L3

A1

(1)

(4)

ATVp1Hppppp

+24

PWR

R1A

R1C

R1B

LI1

LI6

LI2

P0

PA / +

PB

PC / -

(3) (3)

(2)

Connection diagram conforming to IEC 61508 and IEC 60204-1

Connection diagram conforming to the standard IEC/EN61508 Capacity SIL2, Stopping category 0 in accordance with the standard IEC/EN 60204-1, without protection against supply interruption or voltage reduction an d subsequent rotation.

S1: Emergency Stop

(1)Line choke (if used)

(2)Standardized coaxial cable, type RG174/U according to MIL-C17 or KX3B according to NF C 93-550,

external diameter 2.54 mm /0.09 in., maximum length 15 m / 49.21 ft. The cable shielding must be earthed

(3)Use cable ends DZ5CE020 (yellow) on wires connected to PWR and +24 inputs

(4)Braking resistor (if used)

S1A91443 02/2014 37

Technical data

38

S1A91443 02/2014

Appendix

Appendix

What's in this Chapter?

This chapter contains the following topics:

Topic Page

ATV61 Product sizes 40

ATV71 Product sizes 44

7

S1A91443 02/2014 39

ATV61 Product sizes

Correspondence table

This table allows making the correspondence between the size and the reference of the drive.

Supply

Voltage

200 – 240 V

Power

Reference

ATV61H075M3

ATV61HU15M3

ATV61HU22M3

ATV61HU30M3

ATV61HU40M3

ATV61HU55M3

ATV61HU75M3

ATV61HD11M3X

ATV61HD15M3X

ATV61HD18M3X

ATV61HD22M3X

ATV61HD30M3X

ATV61HD37M3X

ATV61HD45M3X

ATV61HD55M3X

ATV61HD75M3X

ATV61HD90M3X

Appendix

Size 2

Size 3

Size 4

Size 5

Size 6

Size 7

Size 8

(5A – 5B)

p

p

p

p

p

p

p

p

p

p

p

(7A – 7B)

p

p

p

Size 9

p

p

Size 11

Size 10

p

Size 12

Size 13

Size 14

Size 15

40

S1A91443 02/2014

Appendix

Power

Supply

Voltage

380 – 480 V

Reference

ATV61H075N4

ATV61HU15N4

ATV61HU22N4

ATV61HU30N4

ATV61HU40N4

ATV61HU55N4

ATV61HU75N4

ATV61HD11N4

ATV61HD15N4

ATV61HD18N4

ATV61HD22N4

ATV61HD30N4

ATV61HD37N4

ATV61HD45N4

ATV61HD55N4

ATV61HD75N4

ATV61HD90N4

ATV61HC11N4

ATV61HC13N4

ATV61HC16N4

ATV61QC11N4

ATV61QC13N4

ATV61QC16N4

ATV61HC20N4

ATV61HC22N4

ATV61HC25N4

ATV61HC28N4

ATV61HC31N4

ATV61QC20N4

ATV61QC25N4

ATV61QC31N4

ATV61HC40N4

ATV61HC50N4

ATV61HC63N4

ATV61QC40N4

ATV61QC50N4

ATV61QC63N4

Size 2

p

p

p

Size 3

p

p

Size 4

p

p

Size 5

(5A – 5B)

p

p

p

Size 6

p

Size 7

(7A – 7B)

p

p

Size 8

p

p

p

Size 9

p

p

Size 10

p

Size 11

Size 12

Size 13

Size 14

Size 15

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

S1A91443 02/2014 41

Power

Supply

Voltage

500 – 690 V

Reference

ATV61HU30Y

ATV61HU40Y

ATV61HU55Y

ATV61HU75Y

ATV61HD11Y

ATV61HD15Y

ATV61HD18Y

ATV61HD22Y

ATV61HD30Y

ATV61HD37Y

ATV61HD45Y

ATV61HD55Y

ATV61HD75Y

ATV61HD90Y

ATV61HC11Y

ATV61HC13Y

ATV61HC16Y

ATV61HC20Y

ATV61QC13Y

ATV61QC16Y

ATV61QC20Y

ATV61HC25Y

ATV61HC31Y

ATV61HC40Y

ATV61QC25Y

ATV61QC31Y

ATV61QC40Y

ATV61HC50Y

ATV61HC63Y

ATV61HC80Y

ATV61QC50Y

ATV61QC63Y

ATV61QC80Y

Size 2

Size 3

Size 4

Size 5

(5A – 5B)

Size 6

p

p

p

p

p

p

p

p

p

Size 7

(7A – 7B)

Size 8

p

p

p

p

p

Size 9

Size 10

p

p

p

p

p

p

p

Appendix

Size 11

Size 12

Size 13

Size 14

Size 15

p

p

p

p

p

p

p

p

p

p

p

p

42

S1A91443 02/2014

Appendix

Power

Supply

Voltage

380 – 415 V

500 V

690 V

Reference

Size 23

ATV61EXppC63N4

ATV61EXppC71N4

p

p

ATV61EMppC63N4 p

ATV61EMppC71N4 p

ATV61EMppC90N4 p

ATV61EMppM11N4 p

ATV61EMppM13N4 p

ATV61EMppM14N4 p

ATV61EXppC90N4

ATV61EXppM11N4

ATV61EXppM13N4

ATV61EXppM14N4

ATV61EXppC63N

ATV61EXppC71N

ATV61EXppC90N

p

p

p

ATV61EXppM11N

ATV61EXppM13N

ATV61EXppM15N

ATV61EXppM18N

ATV61EXppC80Y p

ATV61EXppM10Y p

ATV61EXppM12Y p

ATV61EMppC80Y p

ATV61EMppM10Y p

ATV61EMpp

M12Y p

ATV61EXppM15Y p

ATV61EXppM18Y p

ATV61EXppM21Y p

ATV61EXppM24Y p

ATV61EMppM15Y p

ATV61EMppM18Y p

ATV61EMppM21Y p

ATV61EMppM24Y p

Size 24

p

p

p

p

p

p

p

p

S1A91443 02/2014 43

ATV71 Product sizes

Correspondence table

This table allows making the correspondence between the size and the reference of the drive.

Supply

Voltage

200 – 240 V

380 – 480 V

Power

Appendix

Reference

ATV71H037M3 p

ATV71H075M3 p

ATV71HU15M3 p

ATV71HU22M3 p

ATV71HU30M3 p

ATV71HU40M3 p

ATV71HU55M3 p

ATV71HU75M3 p

ATV71HD11M3X p

ATV71HD15M3X p

ATV71HD18M3X p

ATV71HD22M3X p

ATV71HD30M3X p

ATV71HD37M3X p

ATV71HD45M3X p

ATV71HD55M3X p

ATV71HD75M3X p

ATV71H075N4 p

ATV71HU15N4 p

ATV71HU22N4 p

ATV71HU30N4 p

ATV71HU40N4 p

ATV71HU55N4 p

ATV71HU75N4 p

ATV71HD11N4 p

ATV71HD15N4 p

ATV71HD18N4 p

ATV71HD22N4 p

ATV71HD30N4 p

ATV71HD37N4 p

ATV71HD45N4 p

ATV71HD55N4 p

ATV71HD75N4 p

ATV71HD90N4 p

ATV71HC11N4 p

ATV71HC13N4 p

ATV71QD90N4 p

ATV71QC11N4 p

ATV71QC13N4 p

ATV71HC16N4 p

ATV71HC20N4 p

ATV71HC25N4 p

ATV71HC28N4 p

ATV71QC16N4 p

ATV71QC20N4 p

ATV71QC25N4 p

ATV71HC31N4 p

ATV71HC40N4 p

ATV71HC50N4 p

ATV71QC31N4

ATV71QC40N4 p

ATV71QC50N4 p

Size 2

Size 3

Size 4

Size 5

Size 6

Size 7

Size 8

(5A – 5B)

(7A – 7B)

Size 9

Size 11

Size 10

Size 12

Size 13

Size 14

Size 15

p

44

S1A91443 02/2014

Appendix

Power

Supply

Voltage

500 – 690 V

Reference

Size 2

Size 3

Size 4

Size 5

Size 6

Size 7

Size 8

(5A – 5B)

(7A – 7B)

Size 9

Size 10

Size 11

Size 12

Size 13

Size 14

ATV71HU22Y p

ATV71HU30Y p

ATV71HU40Y p

ATV71HU55Y p

ATV71HU75Y p

ATV71HD11Y p

ATV71HD15Y p

ATV71HD18Y p

ATV71HD22Y p

ATV71HD30Y p

ATV71HD37Y p

ATV71HD45Y p

ATV71HD55Y p

ATV71HD75Y p

ATV71HD90Y p

ATV71HC11Y p

ATV71HC13Y p

ATV71HC16Y p

ATV71QC11Y p

ATV71QC13Y p

ATV71QC16Y p

ATV71HC20Y p

ATV71HC25Y p

ATV71HC31Y p

ATV71QC20Y p

ATV71QC25Y p

ATV71QC31Y p

ATV71HC40Y p

ATV71HC50Y p

ATV71HC63Y p

ATV71QC40Y p

ATV71QC50Y p

ATV71QC63Y p

Size 15

S1A91443 02/2014 45

Power

Supply

Voltage

380 – 415 V

500 V

690 V

Reference

Size 23

ATV71EXppC50N4

ATV71EXppC63N4

ATV71EMppC63N4

p

p

p

ATV71EXppC71N4

ATV71EXppC90N4

ATV71EXppM11N4

ATV71EXppM13N4

ATV71EMppC71N4

ATV71EMppC90N4

ATV71EMppM11N4

ATV71EMppM13N4

ATV71EXppC50N

ATV71EXppC63N

ATV71EXppC80N

p

p

p

ATV71EXppC90N

ATV71EXppM11N

ATV71EXppM13N

ATV71EXppM15N

ATV71EXppC63Y p

ATV71EXppC80Y p

ATV71EXppM10Y p

ATV71EMppC63Y p

ATV71EMppC80Y p

ATV71EMppM10Y p

ATV71EXpp

M12Y p

ATV71EXppM15Y p

ATV71EXppM18Y p

ATV71EXppM20Y p

ATV71EMppM12Y p

ATV71EMppM15Y p

ATV71EMppM18Y p

ATV71EMppM20Y p

Appendix

Size 24

p

p

p

p

p

p

p

p

p

p

p

p

46

S1A91443 02/2014

ATV61_71_LIFT_Safety_function_manual_EN_S1A91443_03

S1A91443 02/2014

Loading...

Loading...