Schmitz OPX Service manual

Service manual

Operating table OPX mobilis and OPX mobilis RC

This service manual contains instructions how to carry out repairs on the mobile operating tables

–OPX mobilis 200

–OPX mobilis 300 C

–OPX mobilis 300 CL

–OPX mobilis 300 CE

–OPX mobilis 300 CLE

–OPX mobilis RC30

–OPX mobilis RC30L

–OPX mobilis RC40

2 |

Service manual |

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 About this service manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Symbols used in the text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Description of the operating table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Removing and re-attaching the cladding panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Removing and re-attaching the cladding of the mobile base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Replacing or lowering the floor pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Detaching and re-attaching the table-top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Height adjustment column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Filling new hydraulic cylinders with hydraulic fluid and installing them . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 De-aerating the lateral and Trendelenburg adjustment cylinders and the check valves . . . . . . . . . . . . . . . . 18 Replacing the check valve and the hydraulic cylinder for lateral adjustment . . . . . . . . . . . . . . . . . . . . . . . . 19 Replacing check valves and hydraulic cylinder for Trendelenburg adjustment . . . . . . . . . . . . . . . . . . . . . . . 22 Sealing or replacing the hydraulic cylinder for height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Sensors in the mobilis RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Adjusting the guidings at the height adjustment column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table-top. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Folding the back section on top of the seat section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Replacing the latches at the seat and back sections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Replacing the gas springs at the back section and repairing the release mechanism . . . . . . . . . . . . . . . . . . 31 Replacing the hydraulic cylinders for back section adjustment in the RC40 model . . . . . . . . . . . . . . . . . . . . 35 Replacing the piloted check valve for back section adjustment in the RC40 model . . . . . . . . . . . . . . . . . . . 37

Longitudinal displacement function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Detaching one side of the table-top from and re-attaching it to the column . . . . . . . . . . . . . . . . . . . . . . . . 39 Replacing the stop panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Replacing the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Repairing the relay arm for the stop panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Repairing the release mechanism for longitudinal adjustment function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Replacing the bearing bushes and the sliding strips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

3 |

Contents

Table base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 Replacing the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 Replacing the reed board (not in the RC models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Piloted check valve for height adjustment cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Removing and re-installing the control box of mobilis 300 E tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Removing and re-installing the control box of the mobilis RC tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 Adjusting the directional castor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 Adjusting the dead centre of the pedal for the brake and for the directional castor . . . . . . . . . . . . . . . . . . . 55 Replacing the hydraulic switch valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 Replacing double castors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Replacing the electro-hydraulic pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Carrying out the measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Documentation and evaluation of the tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Visual inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Measuring the resistance of the protective conductor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Measuring the equivalent of the leakage current to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Block diagram electric system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Block diagram hydraulic system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 Overview electric system mobilis 300 E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 Overview electric system mobilis RC30/40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 Cabling of the valves mobilis RC30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Cabling of the valves mobilis RC40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Cabling of the sensors mobilis RC30/40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 Hydraulic diagram mobilis 200 to 300E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 Hydraulic diagram mobilis RC30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Hydraulic diagram mobilis RC40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 Hydraulic diagram mobilis kidney bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

After sales service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4 |

Service manual |

Introduction

About this service manual

In this paragraph you will find information about the layout of this service manual and explanations regarding the marks and symbols used in the text.

This service manual contains instructions how to carry out repairs on the operating tables OPX mobilis, also called operating tables in the following.

Our products are constantly being improved, this is why constructional changes carried out after printing of this

service manual could not be taken into consideration. In case of any questions, we therefore kindly ask you to contact Schmitz u. Söhne.

In addition to this service manual and the obligatory regulations for the prevention of accidents effective in the user’s country and on the site of use, the acknowledged rules for safe and professional work are also to be observed.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

5 |

Introduction

Symbols used in the text

In this service manual following designations or signs are used for pieces of information of special importance

gDanger!

This symbol will appear wherever safety hints are designed to protect people from physical harm. The symbol stands for imminent danger of death or serious injury.

vCaution!

This symbol will appear where situations are described which might be dangerous, and which might inflict slight injuries.

aAttention!

This symbol will appear in front of warning hints which shall prevent the table or other equipment from being damaged.

hThis symbol will appear in front of additional helpful pieces of advice.

•A dot in front of the text means: This is what you have got to do.

–A dash in front of the text means: This is part of a listing.

6 |

Service manual |

Safety instructions

The operating table OPX mobilis has been constructed according to the latest state of engineering and according to the acknowledged rules of safety engineering. Nevertheless, its use may inflict danger to life or physical safety of the user or of third parties, or impairment to the operating table or other material assets.

Do not use the operating table unless in perfect condition and only for its intended use, with regard to safety and possible dangers, and observing the operating manual! Any malfunction which may affect the safety has to be eliminated immediately!

Electrically conductive double castors, electrically conductive pads and a potential equalization socket are standard features of the operating table OPX mobilis. An electrically conductive floor provided, the operating table OPX mobilis may be used in area M. If the operating OPX mobilis is equipped with non-electrically conductive (coloured) pads, it must not be used in area M.

Always keep the operating manual at hand at the site of use of the operating table!

Additionally to the operating manual, observe the general rules implied by the law and otherwise obligatory for accident prevention and environmental protection!

Do not carry out any modifications, extensions or reconstructions of the operating table unless approved by the manufacturer.

Spare parts have to meet the requirements stipulated by the manufacturer. This is always guaranteed when using original spare parts.

Observe the intervals prescribed or stated in the operating manual for periodical check-ups!

Take care that running and process materials as well as parts replaced are disposed of safely and with minimum environmental impact!

Intended use

According to the German VDE (i. e. the Association of German Electrical Engineers) 0107 standard, the operating table OPX mobilis may be used inside rooms of the application groups 0, 1 or 2. It is exclusively designed for purposes of human medicine. The operating table serves to position patients during an examination or during surgical interventions. The nursing staff has to take care to position the patients in such a way as to prevent any danger to their respiration, to their nervous system or to their circulation. This is especially important when patients are under anaesthetics. Any use apart or beyond these purposes is not intended. The manufacturer is not

liable for any damage resulting of such non-intended use, which would be entirely at the user’s risk.

The operating table may only be handled by persons who have been briefed in its professional handling and who have familiarized themselves with the product by means of the operating manual.

Intended use also means following the operating manual and observing the conditions for inspection and maintenance.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

7 |

Introduction

8 |

Service manual |

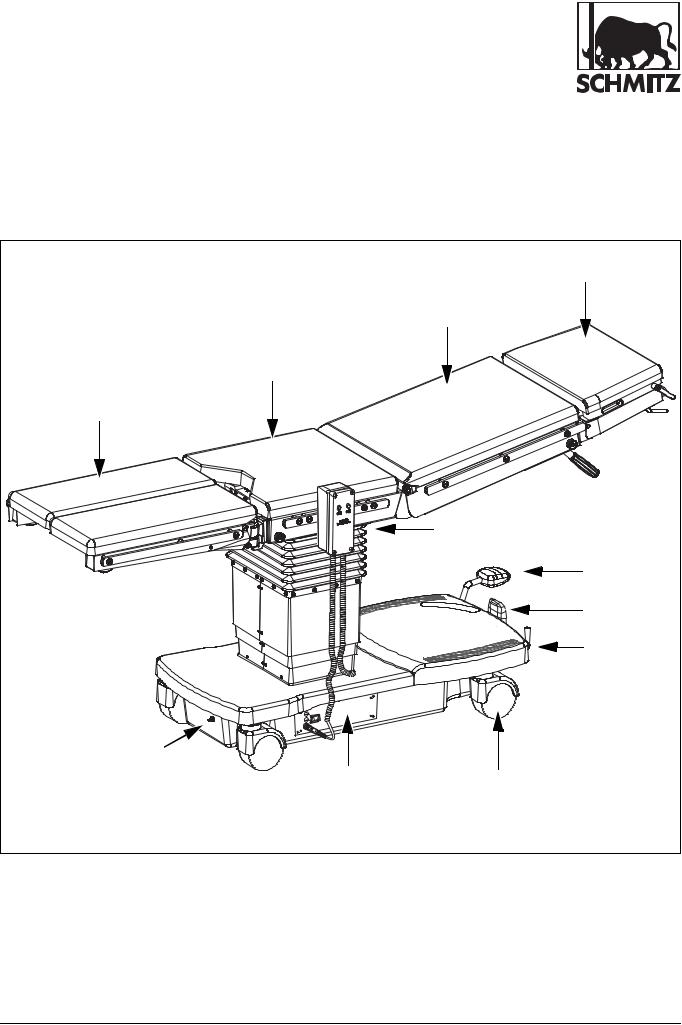

Description of the operating table

|

Head section |

|

|

Back section |

|

Seat section |

|

|

Leg plate |

|

|

|

Battery charger for electric |

|

|

version |

|

|

Foot pump lever |

|

|

Pedal for brake and |

|

|

for directional |

|

|

castor |

|

|

Swivelling lever |

|

Potential equalization socket |

|

|

Control panel for |

Swivel-type castor |

|

electric version |

||

|

In the following service manual the terms left, right, front, and rear are used as seen by a person sitting or lying on the operating table.

The operating tables OPX mobilis can be equipped differently, depending on the model.

All operating table models are mobile. They are equipped with four electrically conductive double castors with central locking device. The operating tables with a “C” in their type designation as well as the RC models have got an additional directional castor.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

9 |

Description of the operating table

All operating table models are equipped with mechanically operated hydraulic pumps. The operating tables of the model series 200 have got two hydraulic adjustment functions: Height adjustment Raise/Lower and Trendelenburg/Reverse Trendelenburg adjustment. The operating tables of the model series 300 and RC have got an additional lateral adjustment function. The tables of the RC40 model series feature a fourth hydraulic adjustment function, which is additional hydraulic adjustment of the back section.

Operating tables with an “E” in their type designation are equipped in addition with an electrically-driven hydraulic pump. These operating tables are also equipped with a hand-held control unit to operate the electro-hydraulic pump.The different table functions to be carried out by the hydraulic system are preselected by means of the selector lever.

The RC operating table models, same as the E-type models, are driven electrically, however, the table functions to be carried out by the hydraulic system are operated directly by means of the hand-held control unit. By means of the hand-held control unit, it is also possible to operate a 0 position function, which makes the table return into horizontal and lowest position. Moreover, the assignation of the functions on the hand-held control unit can be reversed by means the “Reverse” function, in order to enable a correct operation when the patient is positioned in reverse orientation on the operating table.

All operating table models with electric operation are equipped with rechargeable batteries inside the floor pan.

The operating tables with an “L” in their type designation are equipped with a table-top with longitudinal displacement function. By means of this feature, such parts of the patient’s body can be screened which are otherwise inaccessible to the C-arm equipment.

The operating tables with a “G” in their type designation are equipped with an integrated kidney bridge. The integrated kidney bridge is adjusted in height hydraulically by means of the foot pump of the table.

All operating tables can be optimally adapted to various applications by means of accessories. All operating tables can be equipped with X-ray cassettes, which can be inserted below the table-top either from the head end or from the foot end.

According to the regulations of the European Standard 60601-2-46 the operating tables are designed to carry a maximum patient weight of 135kg. In case a higher charge is intended, please observe the instructions given below.

hA patient weight of max. 135 kg allows all surgical interventions to be carried out in either orientation of the patient (patient’s head lying at head or foot end of the table), provided the castors of the operating table are blocked.

hIn the case of normal patient orientation and table-top in mid-position (for operating tables with longitudinal displacement function) the operating table may be charged with a patient weight of max. 185 kg. When transferring a patient, or when letting a patient mount the operating table, make sure that the table is charged principally on the table column. Familiarize yourself with the reactions of the operating table under this kind of charge before starting a surgical intervention.

Pads

The operating tables are normally equipped with black antistatic pads. Coloured pads, which, however, are not electrically conductive, are available upon special request. The antistatic black version fulfils the limits of resistance according to ISO 2882. Coloured pads are not electrically conductive, which means that in this case the operating table is not explosion-proof.

10 |

Service manual |

Preparations

Repairs

Preparations

Removing and re-attaching the cladding panels

The bellows is attached to the upper cladding panel by means of screws and expanding arbours. In order to remove the cladding panels, the bellows has to be detached first from the upper cladding panel.

Detaching the bellows

Detaching the cladding panels

The cladding panels consist of two parts, which are interconnected by means of connecting strips. The upper and lower cladding panels are fixed to the frame. In order to detach the cladding panels, loosen the fastening screws at the connecting strips and detach the upper and lower cladding panels from the frame.

Expanding arbours with fastening screws

•Screw out four screws each at both sides and six screws each at the front and at the rear.

•Pull the expanding arbours out of the holes in the upper cladding panel and lift the bellows.

The four fastening screws at the upper rim of the upper cladding panel are now accessible.

hFor some kinds of repairs it is sufficient to raise the column and loosen only the four upper or lower screws. The cladding sheets can then be pushed up or down.

Fastening screws at the

Fastening screws at the  connecting strip

connecting strip

Fastening screws at the frame

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

11 |

Repairs

•Loosen two fastening screws each at the left and right hand side of one section of the cladding panels.

•Loosen the upper and lower cladding panel from the frame as well and pull the cladding panels apart.

The height adjustment column is now accessible, and repairs can be carried out. When the repairs have been finished, the cladding panels have to be re-attached.

Re-attaching the cladding panels

The cladding panels have to be re-attached in reverse order.

•Place the lower cladding panels onto the mobile base and connect them by means of the screws screwed

into the connecting strips. Fix the cladding panels to the frame by means of the fastening screws.

•First, fix the middle and then the upper cladding panels to the connecting strips. Fix the upper cladding panel to the frame by means of the fastening screws.

Re-attaching the bellows

The bellows is re-attached in reverse order.

•Press the expanding arbours into the holes in the upper cladding panel and then press or screw the screws into the expanding arbours.

The bellows is now re-attached.

12 |

Service manual |

Preparations

Removing and re-attaching the cladding of the mobile base

Removing the cladding of the mobile base

The cladding of the mobile base can be removed. In order to carry out repairs on the table base, the cladding can be fastened to the upper section of the operating table by means of a piece of string.

•Adjust the table-top and the back section into horizontal position.

•Lift the cladding of the mobile base up to the lower side of the table-top. Fix it there using a piece of string tied to the side rails.

Now repairs on the table base can be carried out. When the repairs have been finished, the cladding has to be placed back onto the mobile base.

Placing the cladding back onto the mobile base

•Untie the string fixing the cladding of the mobile base to the side rail.

•Place the cladding back onto the mobile base.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

13 |

Repairs

Replacing or lowering the floor pan

For some kinds of repairs, the floor pan has to be removed. The floor pan is fixed to the mobile base by means of two screws each at the sides and two additional screws at the front. In addition, the floor pan engages on top of a bolt head on each side of the foot pump.

Preparation

•In order to remove the floor pan, detach the cladding panels at the height adjustment column. You will find details under “Removing and re-attaching the cladding panels” on page 11.

•Remove the cladding of the mobile base. You will find details under “Removing and re-attaching the cladding of the mobile base” on page 13.

•Remove the bolt lock from the bolts of the actuating rod and pull the actuating rods off to the outside.

hFor certain kinds of repairs it is sufficient to lower the floor pan. The control box remains inside the floor pan.

•In the case of E type models: Remove the control box. You will find details in the chapter “Removing and installing the control box in mobilis 300 E table models” on page 51 or in the chapter “Removing and installing the control box in mobilis RC table models” on page 53.

•Prepare the necessary tools for jacking the operating table up.

Removing or lowering the floor pan

•Loosen the two fastening screws at the front and the four fastening screws at the sides of the mobile base. At the same time, loosen also the earthing cable of the control box.

•Loosen the connecting cable for the potential equalization socket from the frame of the mobile base.

•Lever the floor pan, e. g. by means of a screwdriver, over the bolt heads at the foot pump and over the shaft of the brake lever.

•Pull the floor pan carefully down and out by slightly moving it.

Now repairs at the underside of the mobile base can be carried out.

Installing the floor pan

The floor pan can be installed in reverse order.

•Put the floor pan back into place and fix the connecting cable for the potential equalization socket to the frame of the mobile base.

•Screw the two fastening screws at the front and the four fastening screws at the sides of the frame in. At the same time, also connect the earthing cable of the control box to the left hand rear fastening screw.

Final tasks

•Re-install the control box

•Put the cladding of the mobile base back into place.

•Re-attach the cladding panels at the height adjustment column.

14 |

Service manual |

Preparations

Detaching and re-attaching the table-top

For some kinds of repairs, the table-top has to be detached. The table-top is fixed to a holding plate on top of the height adjustment column.

Preparation

•Remove the leg plates, the head plate and the pads of the seat and back sections.

•If a universal adapter is at hand, insert it into the seat section. Otherwise, insert the head plate into the seat section in order to stabilize the frame.

Detaching the table-top

hThe position and quantity of the fastening screws are different in the table models with and without longitudinal displacement function of the table-top. However, the work to be carried out is similar.

Mounting in case of tables without longitudinal displacement function

RC table models with longitudinal adjustment function and with integrated kidney bridge

The RC table models with longitudinal adjustment function and with integrated kidney bridge have got a

plastic cladding which is fixed to the cheeks by means of expansion rivets.

•Drive the pins of the expansion rivets out, pull the expansion rivets out and lift the plastic cladding off.

Mounting in case of tables with longitudinal displacement function

Disconnecting the hydraulic system between the upper section and the lower section for the kidney bridge and for the RC 40 model

At the cover plate of the height adjustment column of the RC 40 operating table models you will find the piloted check valve for back section adjustment. The hydraulic hoses leading to the actuating cylinders are accessible from above, and the hydraulic hoses coming from the gate valve are connected to the underside of the check valve. The hydraulic hose for the integrated kidney bridge is also conducted through the block of the piloted check valve. The hydraulic hoses between the upper section and the lower section have to be disconnected at the check valve in order to remove the table-top.

•In order to disconnect the hydraulic hose between the upper section and the lower section, loosen the screw joint of the hydraulic hoses at the check valve, and close the hydraulic hoses immediately.

•If there is a kidney bridge, loosen the corresponding hydraulic hose at the T-piece. Close the hose immediately afterwards.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

15 |

Repairs

•For operating table models RC 30 with kidney bridge: Loosen the screw joint at the T-piece. Close the T-piece immediately afterwards.

•Then loosen the clamping sheet for the T-piece.

The hydraulic systems of the upper section and of the lower section are now separated.

•In order to detach the table-top, remove the covers of the fastening screws.

•Remove the fastening screws fixing the seat section on top of the table column.

•Lift off the table-top.

Re-attaching the table-top

•In order to re-attach the table-top, position the tabletop on top of the table column and adjust it.

•Screw the fastening screws in and tighten them.

Connecting the hydraulic system

•Re-establish the connection between the hydraulic systems of the upper section and of the lower section. If required, top the hoses up with hydraulic fluid.

Final tasks

•Attach the head plate and the leg plates and put the pads back on top of the seat and back sections.

•Check the functions of the receptacles for the accessories and of the back section adjustment, and check if the head plate and the universal adapter can still be inserted easily into the seat section.

16 |

Service manual |

Height adjustment column

Height adjustment column

Filling new hydraulic cylinders with hydraulic fluid and installing them

New hydraulic cylinders together with their check valves as well as the hydraulic hoses have to be filled with hydraulic fluid upon installation.

•In order to fill a new hydraulic cylinder with hydraulic fluid, push the piston rod of the hydraulic cylinder completely in. Connect the hydraulic hoses firmly with the check valve.

•Connect the tubes of the check valves at the hydraulic cylinder, but let them remain loose, pulling the tubes slightly out of their seat.

•Turn the hydraulic cylinder in such a way as to make the piston rod point to the ceiling. Make the piston rod extract by means of the selector lever. Pump hydraulic fluid carefully into the piston end of the cylinder using the foot pump. As soon as hydraulic fluid emerges from the loose screw joint, tighten the screw joint. Make the piston rod extract completely.

•Turn the hydraulic cylinder in such a way as to make the piston rod point to the floor. Make the piston rod retract by means of the selector lever. Loosen the screw joints at the piston end of the hydraulic cylinder, pulling the tube slightly out of its seat. The screw joints at the piston rod end are still loose. Wait 2 to 5 minutes until the residuary air has ascended inside the piston end of the cylinder. Pump hydraulic fluid

carefully into the piston rod end of the cylinder. As soon as hydraulic fluid emerges from the loose screw joint at the piston rod end of the cylinder, tighten the screw joint.

•Go on pumping hydraulic fluid carefully into the cylinder until the residuary air has been discharged from the screw joint at the piston end of the cylinder. Then tighten the screw joint at the piston end of the cylinder. Make the piston rod retract completely.

•Turn the hydraulic cylinder in such a way as to make the piston rod point to the ceiling. Make the piston rod extract by means of the selector lever. Loosen the screw joint at the piston rod end again, pulling the tube slightly out of its seat. Wait 2 to 5 minutes until the residuary air has ascended inside the piston end of the cylinder. Pump hydraulic fluid carefully into the piston end of the cylinder using the foot pump. As soon as the residuary air has been discharged from the loose screw joint at the piston rod end of the cylinder, tighten the screw joint.

•Install the de-aerated hydraulic cylinder.

•If there is still a remainder of air left inside the hydraulic system, which affects the stability of the table-top, de-aerate the system as described in the following paragraph.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

17 |

Repairs

De-aerating the lateral and Trendelenburg adjustment cylinders and the check valves

If the table-top is unstable after replacement of the lateral or Trendelenburg adjustment cylinder, we recommend to proceed as follows in order to attain optimal stability.

•Remove the connected lateral or Trendelenburg adjustment cylinder together with the corresponding check valve from the height adjustment column. You will find details regarding the bolt fastenings in the chapter “Removing the hydraulic cylinder for lateral adjustment” on page 20 or in the chapter “Removing the hydraulic cylinder for Trendelenburg adjustment” on page 23.

•Turn the hydraulic cylinder in such a way as to make the piston rod point to the ceiling. Make the piston rod extract by means of the selector lever. Wait 2 to

5 minutes until the residuary air has ascended inside the piston rod end of the cylinder. Then loosen the screw joints at the piston rod end of the hydraulic cylinder, pulling the tube slightly out of its seat. The screw joints at the piston end are still loose. Pump

hydraulic fluid carefully into the piston end of the cylinder. As soon as hydraulic fluid emerges from the loose screw joint, tighten the screw joint. Then make the piston rod extract completely.

•Turn the hydraulic cylinder in such a way as to make the piston rod point to the floor. Make the piston rod retract by means of the selector lever. Wait 2 to

5 minutes until the residuary air has ascended inside the piston end of the cylinder. Then loosen the screw joints at the piston end of the hydraulic cylinder, pulling the tube slightly out of its seat. Pump hydraulic fluid carefully into the piston rod end of the cylinder using the foot pump. As soon as the residuary air has been discharged from the loose screw joint, tighten the screw joint. Then make the piston rod retract completely.

•Repeat these procedures until there is no more air left in the hydraulic fluid inside the cylinder.

18 |

Service manual |

Height adjustment column

Replacing the check valve and the hydraulic cylinder for lateral adjustment

All operating tables can be adjusted by means of hydraulic cylinders. The hydraulic cylinders are equipped with check valves. Hydraulic cylinders and check valves can be replaced.

Preparation

•In order to replace one of the check valves or one of the hydraulic cylinders, detach the cladding panels of the height adjustment column. You will find details under “Removing and re-attaching the cladding panels” on page 11.

Removing the check valve at the hydraulic cylinder for lateral adjustment

• Make the hydraulic cylinder retract completely.

Installing the check valve at the hydraulic cylinder for lateral adjustment

•Connect the check valve to the hydraulic tubes and retighten all sleeve nuts at the tubes. Mind the tilt position of the check valve.

•Refasten the hydraulic hoses at the check valve.

•De-aerate the system afterwards. You will find details in the chapters “Filling new hydraulic cylinders with hydraulic fluid and installing them” on page 17 and “De-aerating the lateral or Trendelenburg adjustment cylinder and the check valves” on page 18.

Check valve for lateral adjustment cylinder

Hoses |

Observe slight |

longitudinal tilt! |

•Mind the position of the hydraulic hoses at the check valve in order not to confound the directions of motion.

•Loosen the sleeve nuts at the two hydraulic hoses and at the two tubes connected to the valve.

•Loosen also the sleeve nuts at the tubes at the hydraulic cylinder.

•Remove the check valve from the hydraulic cylinder.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

19 |

Repairs

Removing the hydraulic cylinder for lateral adjustment

The rod of the hydraulic cylinder for lateral adjustment is connected to the table-top. A bolt is driven through the fork rest on top of the rod of the hydraulic cylinder and through the bearing eye at the table-top. The bolt is secured by means of circlips.

Bolt with circlip |

•Remove the check valve.

•In order to detach the hydraulic cylinder from the upper bearing, remove the circlip at the bolt of the upper bearing and start the bolt.

•Lift the table-top up, so that the upper bearing is exposed.

•In order to detach the hydraulic cylinder from the lower bearing, loosen the locking screw, screw the lower fastening screw out, remove the washer guarding this screw against twisting, and take out the hydraulic cylinder.

Lower fastening screw |

Locking screw |

|

20 |

Service manual |

Height adjustment column

Installing the hydraulic cylinder for lateral adjustment

aAttention!

Mind the exact guiding of the hydraulic hoses, and especially the position of the laces at the hoses and at the cables. The initial state has to be exactly restored.

hIf an important loss of hydraulic fluid has occurred during assembly or replacement of a hydraulic cylinder, hydraulic fluid has to be topped up as required.

•Top the hydraulic cylinder up with hydraulic fluid. You will find details in the chapter “Filling new hydraulic cylinders with hydraulic fluid and installing them” on page 17.

•Fix the hydraulic cylinder to the lower bearing by means of the fastening screw, together with the washer guarding this screw against twisting, and screw the locking screw in.

•Lower the table-top, so that the bearing eye rests in the fork rest, drive the bolt in and put on the circlip.

hBefore re-attaching the cladding, make sure that there are no kinks in the hydraulic hoses, and that they are able to follow all movements of the cylinder.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

21 |

Repairs

Replacing check valves and hydraulic cylinder for Trendelenburg adjustment

All operating tables can be adjusted by means of hydraulic cylinders. The hydraulic cylinders are equipped with check valves. Hydraulic cylinders and check valves can be replaced.

Preparation

•In order to replace one of the check valves or one of the hydraulic cylinders, detach the cladding panels at the height adjustment column. You will find details under “Removing and re-attaching the cladding panels” on page 11.

Removing the check valves at the hydraulic cylinder for Trendelenburg adjustment

• Make the hydraulic cylinder retract completely.

Installing the check valve at the hydraulic cylinder for Trendelenburg adjustment

hThe inner construction of the check valves of the operating tables with electro-hydraulic adjustment differ from those of the operating tables with manually-hydraulic adjustment.

•Place the check valve onto the hydraulic tubes and tighten all sleeve nuts at the tubes. Mind the tilt position of the check valve.

•Refasten the hydraulic hoses at the check valve.

•De-aerate the system. You will find details in the chapters “Filling new hydraulic cylinders with hydraulic fluid and installing them” on page 17 and “Deaerating the lateral or Trendelenburg adjustment cylinder as well as the check valves” on page 18.

•Mind the position of the hydraulic hoses at the check valve in order not to confound the directions of motion.

•Loosen the sleeve nuts at the two hoses and at the two tubes, which are connected to the valve.

•In addition, loosen the sleeve nuts at the tubes at the cylinder.

•Remove the check valve from the hydraulic cylinder.

22 |

Service manual |

Height adjustment column

Removing the hydraulic cylinder for Trendelenburg adjustment

The piston rod of the hydraulic cylinder is connected to the table-top. A bolt is driven through the fork rest on top of the piston of the hydraulic cylinder and through the bearing eye at the table-top. The bolt is secured by means of a locking screw.

•Remove the check valve.

•In order to detach the hydraulic cylinder from the upper bearing, unscrew the locking screw and start the bolt.

•Lift the table-top, so that the upper bearing is exposed.

•In order to detach the hydraulic cylinder from the lower bearing, unscrew the locking screw. Remove the bearing bolt using an M8 screw and a pair of pliers or a gear puller.

Installing the hydraulic cylinder for Trendelenburg adjustment

•Install the new hydraulic cylinder. You will find details in the chapters “Filling new hydraulic cylinders with hydraulic fluid and installing them” on page 17 and “De-aerating the lateral or hydraulic cylinder as well as the check valves” on page 18.

•Fix the hydraulic cylinder to the lower bearing by means of the bolt and the locking screw.

•Lower the table-top so that the bearing eye rests in the clevis, drive the bolt in and screw the locking screw in.

aAttention!

Mind the exact guiding of the hydraulic hoses and especially the position of the laces at the hoses and at the cables. The initial state has to be exactly restored.

hIn case of an important loss of hydraulic fluid occurred during the assembly or during replacement of a hydraulic cylinder, top up hydraulic fluid as required.

hBefore re-attaching the cladding, make sure there are no kinks in the hydraulic hoses, and that they are able to follow all movements of the hydraulic cylinders.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

23 |

Repairs

Sealing or replacing the hydraulic cylinder for height adjustment

The operating tables can be adjusted in height by means of a hydraulic cylinder. The hydraulic cylinder for height adjustment can be sealed.

Preparation

•Remove the table-top. You will find details under “Detaching and re-mounting the table-top” on page 15.

•Detach the cladding sheets at the height adjustment column. You will find details under “Removing and reattaching the cladding sheets” on page 11.

Sealing the hydraulic cylinder for height adjustment

Circlip |

•Make the hydraulic cylinder for height adjustment retract completely.

•Remove the circlip at the upper mounting.

•Detach the four hydraulic hoses of the lateral cylinder and of the Trendelenburg cylinder at their lower ends.

•Loosen the lateral guidings of the height adjustment column. You will find details under “Adjusting the guidings of the height adjustment column” on page 27.

•In the case of E type models, detach the cable of the hand-held control unit.

•Pull out the internal member of the height adjustment column.

•Now detach the leakage hose from the height adjustment cylinder.

•Unscrew the upper section of the cylinder using two pairs of pliers and replace the seals.

•Reassemble the system in reverse order.

•Refasten the lateral guidings with sufficient initial tension as to prevent the column, without the tabletop, from sinking by its proper weight. You will find details under “Adjusting the guidings of the height adjustment column” on page 27.

24 |

Service manual |

Height adjustment column

Replacing the hydraulic cylinder

•Position the table onto assembly jigs.

•Remove the floor pan. You will find details under “Replacing or lowering the floor pan” on page 14.

•Make the hydraulic cylinder for height adjustment retract completely.

•Remove the circlip at the upper mounting.

•Detach the four hydraulic hoses at the lateral adjustment cylinder and at the Trendelenburg cylinder at their lower ends.

•Loosen the lateral guidings of the height adjustment column. You will find details under “Adjusting the guidings of the height adjustment column” on page 27.

•In the case of E type models, detach the cable for the hand-held control unit.

•Pull out the interior member of the height adjustment column.

•Now detach the leakage hose from the height adjustment cylinder.

•Detach the hydraulic hose from the height adjustment cylinder. Loosen the lower fastening screw of the cylinder.

•Lift the height adjustment cylinder up and out.

Assembly

•Re-assemble the system in reverse order.

•Refasten the lateral guidings with sufficient initial tension as to prevent the column, without the tabletop, from sinking by its proper weight. You will find

details under “Adjusting the guidings of the height adjustment column” on page 27.

aAttention!

Mind the exact guiding of the hoses and especially the position of the laces at the hoses and at the cables. The initial state has to be exactly restored.

Final tasks

•Check the function of the hydraulic cylinder for height adjustment.

•Make the lateral cylinder and the Trendelenburg cylinder carry out their individual movements several times and vent them. You will find details under “Installing the hydraulic cylinder for lateral adjustment” on page 21 or under “Installing the hydraulic cylinder for Trendelenburg adjustment” on page 23.

•Fix the cable for the hand-held control unit, making sure that the cable is still slack enough when the tabletop is in maximum Reverse Trendelenburg and at the same time lateral tilt, right hand side, position.

•Check if the hoses and cables have been correctly installed by making the table carry out the complete up/down movement.

•Re-attach the cladding sheets at the height adjustment column.

Operating table OPX mobilis and OPX mobilis RC – EDITION 05-03-GB ID.-Nr.: 02008857 |

25 |

Repairs

Sensors in the mobilis RC

The sensors for 0 position in the RC table models are positioned next to the cylinders for Trendelenburg and for lateral adjustment. The sensor for height adjustment is positioned below the lateral adjustment cylinder. The sensor for back section adjustment is installed inside the left hand side of the seat section frame.

|

Sensor |

Sensor |

|

|

Terminal box |

Sensor |

for the |

|

sensors |

The sensors are connected to a green terminal box. The terminal box for the sensors is installed below the Trendelenburg cylinder. You will find details concerning the cabling of the terminal box and the colour code for the connections in the chapter “Cabling of the sensors in the mobilis RC30/40 models” on page 78.

Checking the functions of the sensors

The functional state of the sensors or of the terminal box can be checked by means of the LEDs at the sensors themselves and at the terminal box next to the corresponding connections. The LEDs at the sensor and at the terminal box should flash up as soon as a piece of metal, e. g. a screwdriver, is positioned in front of the sensor. The LED of the sensor for back section adjustment inside the seat section frame is covered.

The operating table is adjusted into horizontal and lowest position by pressing the 0 key on the hand-held control unit or on the foot control unit. The components of the operating table will return into initial position one after the other in following order: back section (RC 40 model only), lateral tilt, Trendelenburg adjustment, height adjustment. In case one of the sensors is defective or not adjusted correctly, the table will move into the end position of the relative function, and the following positionings are no longer activated.

Adjusting the sensors

Each of the sensors for lateral adjustment, for Trendelenburg adjustment and for height adjustment are fixed to an angle bracket inside an oblong hole. If 0 position is activated, the sensors for lateral adjustment and for Trendelenburg adjustment will respond to a second angle bracket. The height adjustment sensor is activated by means of the cross-bar of the mobile base. If one of the sensors does not respond while 0 positioning is being carried out, the sensors can be readjusted after loosening of the fixing screws. The distance between the sensor and the second angle bracket or the cross-bar must not exceed 5mm.

26 |

Service manual |

Loading...

Loading...