Schlage VIP 5100 series Installation Manual

Form 57032 Rev. A

01-05-2004

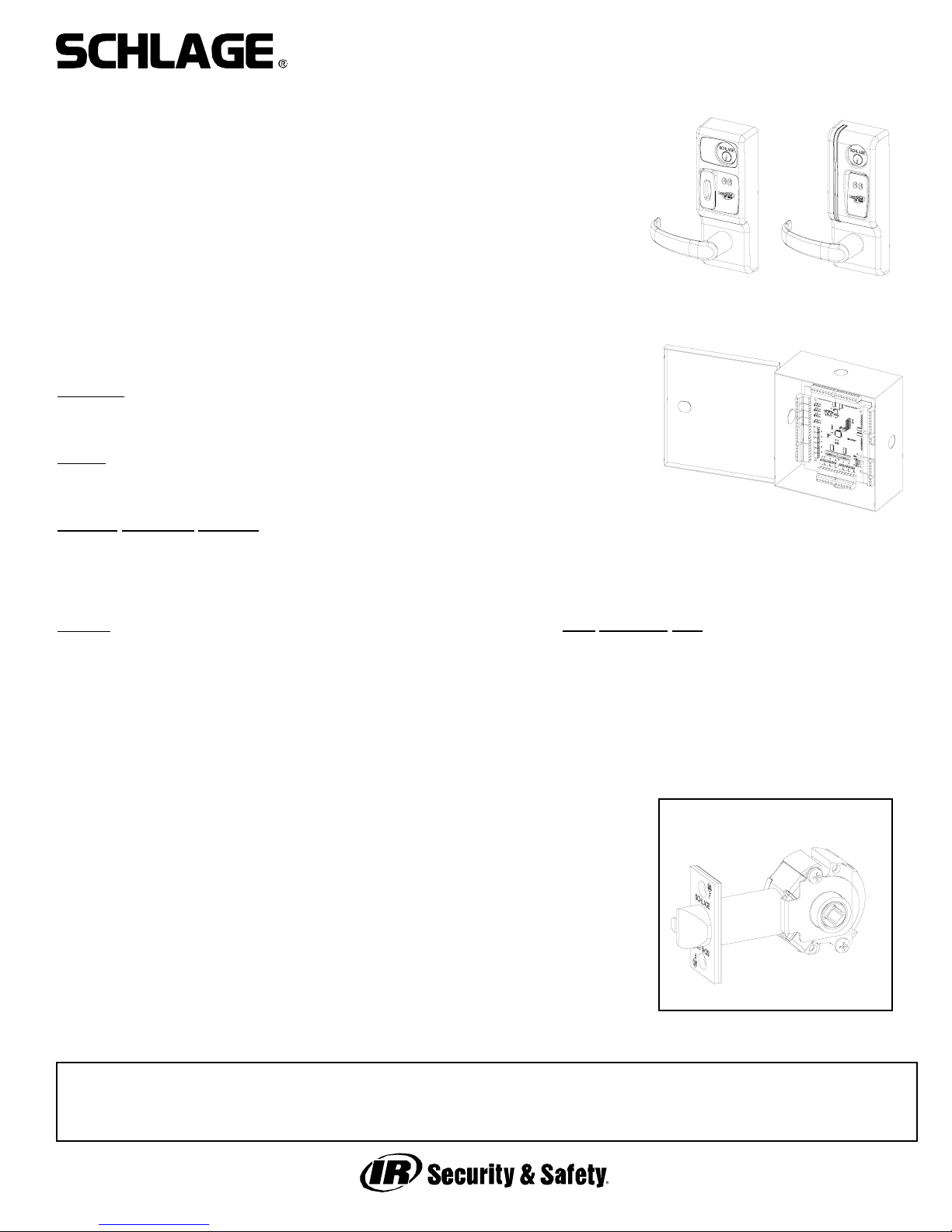

VIP 5100 OPEN ARCHITECTURE CYLINDRICAL LOCK

INSTALLATION MANUAL

5100 CYLINDRICAL

LOCKSET - STANDARD

The VIP 5100 series lock is a microprocessor controlled, electromechanical locking system.

It is an open architecture product designed to interface with 3rd party panels ecompassing

all the features of the lock, reader, door status* and egress (rex/request to exit) indication in

one fire-rated piece of hardware. The 5100 employs a heavy-duty mechanical design tested

and complying with ANSI/BHMA grade 1 standards for performance and reliability. It is powered by 12 or 24 volts DC with only four wires required - two for power and two for communications. The lock communicates with a PIB (panel interface board) which communicates

with the panel as if it were separate components of an access control system.

Operationally, the outside lever is normally locked and the inside lever always retracts the

bolt to allow egress. Electronic access control is achieved by entering an”Access Credential”

(magnetic stripe card or Prox fob or card). The panel controls the lock through the PIB.

*Cylindrical model requires separate door status switch (included) to be installed in the door

and frame and connected to the VIP lock.

Please refer to all instruction manuals involved in the installation before you begin.

Functions

:

VIP 5196-FSA: Cylindrical, Fail Safe (unlocked)

VIP 5196-FSE: Cylindrical, Fail Secure (locked)

Models

:

MG: Magnetic stripe card reader

PX: HID Prox card reader

S

tandard Monitoring Switches:

DSM: Provides door status via data link to panel interface

KSM: Provides mechanical key use events via data link to panel interface

REX: Provides indication of inside lever use for request to exit input via data link

to panel interface

Options

:

T3: Track 3 card reader (data must be ABA track 2 format) - MG only

EXT: exterior use option - MG only (PX model has this standard)

KD: Keyed Different, includes Schlage Everest cylinder

KA: Keyed Alike, includes Schlage Everest cylinder

LC: Less Cylinder

SLB: 2-3/4” backset, 1/2” latch bolt

OLB: 2-3/8” backset, 1/2” latch bolt

ELB: 2-3/4” backset, 3/4” latch bolt

BEFORE YOU BEGIN:

Standard units are shipped from the factory to fit 1-3/4” doors. Verify the

door thickness. If the door is not 1-3/4” thick, verify that the door thickness

option was ordered or consult factory.

PRE-INSTALLATION CHECK:

AN OPEN ARCHITECTURE SYSTEM REQUIRES AT LEAST THREE COMPONENTS - A PANEL INTERFACE BOARD (PIB), AN ACCESS CONTROL PANEL

(BY OTHERS) TO WHICH THE PIB IS CONNECTED AND THE VIP LOCK. SEE

DOCUMENTATION FOR THE ACCESS CONTROL PANEL/SOFTWARE THIS

LOCK WILL BE USED WITH FOR ANY PRE-INSTALLATION TESTING REQUIREMENTS AND REMEDIES. REFER TO THE WIRING INFORMATION INCLUDED

WITH THE PIB FOR MORE INFORMATION.

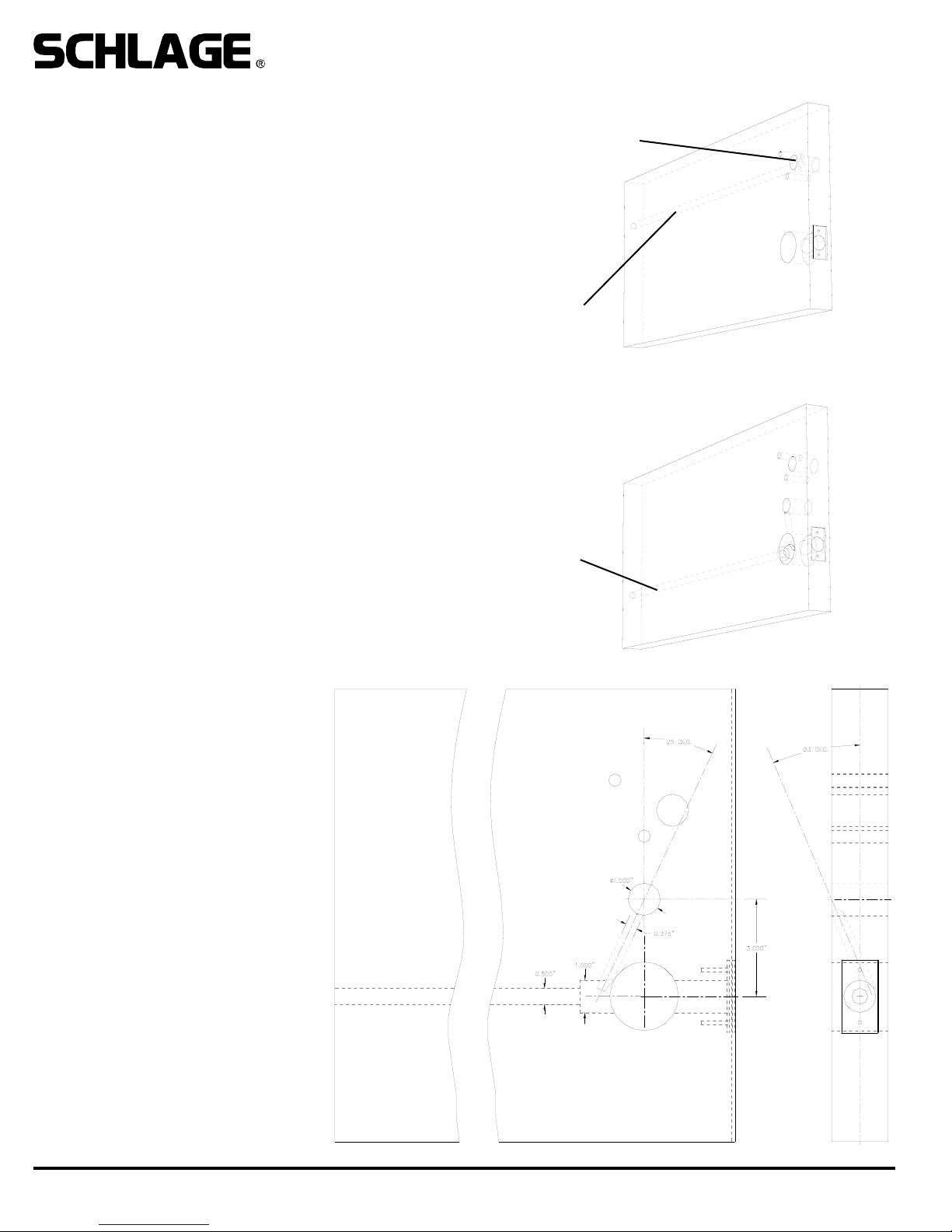

PIB

PX MG

Door Thickness Kits:

Available in 1/8” increments from 1-3/8” to 2-1/2”

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including any interference that may

cause undesired operation. Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Form 57032 Rev. A

01-05-20042

VIP 5100 OPEN ARCHITECTURE CYLINDRICAL LOCK

INSTALLATION MANUAL

WIRE RACEWAY REQUIRED:

It is best to have the wire race way prepared at the door and

frame manufacturer. If this has not been done there are two

suggested preparation methods for making wire paths for the

FSE and FSA models in the field. Select method A or B;

depending on the door and frame circumstances, one may be

better than the other. Consult door manufacturer with any ques-

tions regarding agency listings with respect to fire integrity.

METHOD A:

1. Prep door and frame according to standard template.

2. Determine location of standard 1 inch wire harness through

hole and mark centerline of hole on hinge side of door.

3. Using appropriate drilling jig and drill bits, drill 3/8” or 1/2”

wire race from edge of hinge side into standard wire harness

through hole.

4. Install electric hinge or door cord and run wires.

METHOD B:

1. Prep door and frame according to standard template.

2. Using a 1” drill bit, continue the 1” latch hole through retractor

hole to a depth of 5”. This will allow room for the wiring to pass

around the retractor.

3. Using appropriate drilling jig and drill bits, drill 3/8” or 1/2”

wire race from the latch hole through the door toward the hinge

side. It is not necessary to continue drilling the hole through the

hinge side.

4. Measure up 3 inches from the center of the 2 1/8” retractor

hole and drill a 1 inch through hole on center as shown below.

5. Using a 3/8 inch drill bit, place the tip of the drill into the 1”

wire hole drilled in step 3 and aim at the angles shown. Drill

down and toward the hinge side to intersect the 1” latch hole

(where it was continued in step 2.

4. Install electric hinge or door cord and

run wires.

Note: this method offers the advantage of

not having holes exiting the door edges.

If a door cord is used the door cord wire

hole can be cross drilled into the long

wire race.

WIRE RACE

WIRE RACE

STANDARD WIRE

HARNESS THROUGH

HOLE

METHOD B:

METHOD A:

FSE & FSA HARD WIRED MODELS

REQUIRE WIRING TO BE RUN TO

THE LOCK PREP FROM THE HINGE

SIDE. BELOW IS A SUGGESTED

METHOD TO DO THIS. A DOOR CORD

OR ELECTRIC HINGE OR POWER

TRANSFER DEVICE IS USED TO

ROUTE WIRING FROM FRAME TO

DOOR. NOTE THAT WHEN USING AN

ELECTRIC HINGE IT IS RECOMMENDED THAT THE POWER WIRES

BE DOUBLED OR TRIPLED UP (ON

BOTH THE POSITIVE AND GROUND

LEGS) TO AVOID SIGNIFICANT VOLTAGE DROP THROUGH THE THIN

WIRES IN THE HINGE.

Form 57032 Rev. A

01-05-20043

VIP 5100 OPEN ARCHITECTURE CYLINDRICAL LOCK

INSTALLATION MANUAL

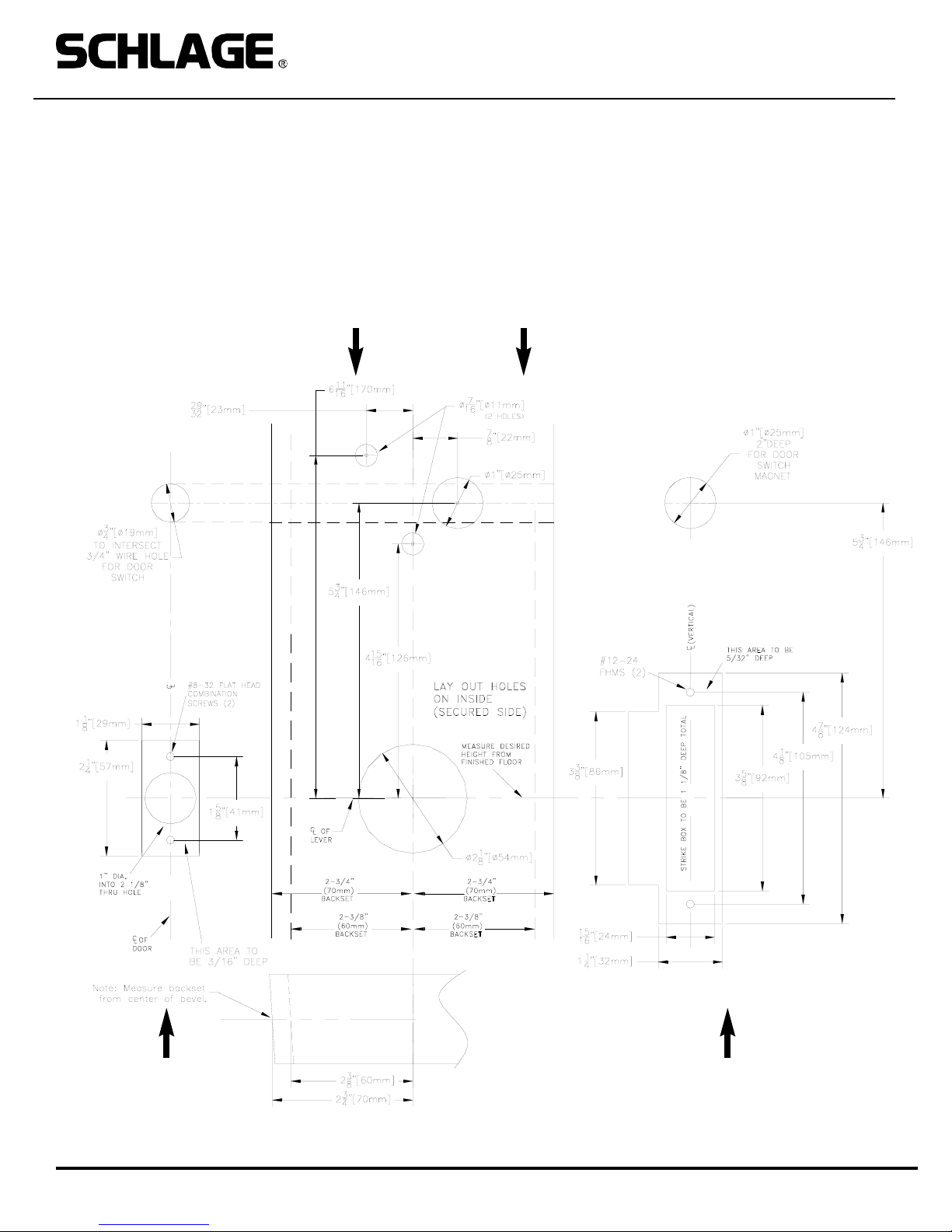

1. PREP DOOR AND FRAME:

A. Determine door hand and correct backset.

B. Mark the horizontal and vertical centerlines for the lockset, latch and strike.

C. Place template on inside of door (opposite the side that the keypad/reader will be on). Line up the correct reference lines

on the template with the edge of the door. The centerline on the door should line up with the vertical centerline of the template.

D. Drill holes as described by template.

DOOR EDGE (LATCH)

FRAME (STRIKE)

DOOR FACE (LAY OUT ON INSIDE)

Loading...

Loading...