Page 1

24303034

PIM400-485 USER GUIDE

User guide for the panel interface module PIM400-485

Version 2

Version 1

(Manufacturing discontinued)

Para el idioma español, navegue hacia www.schlage.com/support

Pour la portion française, veuillez consulter le site www.schlage.com/support

Page 2

Contents

Overview ........................................................................................................................... 3

Getting started ..................................................................................................................3

Features ............................................................................................................................ 4

Components .....................................................................................................................4

Installation ......................................................................................................................... 6

Determine the location .................................................................................................. 6

Pre-installation test........................................................................................................6

Drill holes for wiring ....................................................................................................... 7

Mount the PIM400-485 ................................................................................................. 8

Wire routing ................................................................................................................... 8

Cable/wire specications .............................................................................................. 8

Retrot...........................................................................................................................9

PIM400-485 to ACP connection ......................................................................................10

Typical PIM400-485 to ACP Wiring Diagrams ............................................................. 11

Optional remote antenna ................................................................................................13

Link mode .......................................................................................................................13

Schlage utility software (SUS) ........................................................................................13

Reset to factory defaults ................................................................................................. 14

DC power ........................................................................................................................ 14

Complete the installation ................................................................................................14

Troubleshooting ..............................................................................................................15

FCC/IC Statements ........................................................................................................ 16

To comply with FCC and Industry Canada RF radiation exposure limits for general

population, the antenna(s) used for this transmitter must be installed such that a minimum

separation distance of 20cm is maintained between the radiator (antenna) and all persons

at all times and must not be co-located or operating in conjunction with any other antenna or

transmitter.

This product is compliant of UL 294 and ULC S319 standard. This product’s compliance

would be invalidated through the use of any add-on, expansion, memory or other module

that has not yet been evaluated for compatibility for use with this UL Listed product, in

accordance with the requirements of the Standards UL 294 and ULC S319. This product has

been evaluated for ULC-S319 Class I.

2 • Schlage • PIM400-485 user guide

Page 3

Overview

This manual describes the installation, operation and interaction of all Schlage PIM400-485

models with Access Control Panels (ACPs) and Wireless Access Point Modules (WAPMs).

The PIM400-485 is a product in the AD-400 Wireless Panel Interface Module (WPIM)

category.

There are two versions of the PIM400-485. Both versions have the same features and

connections, and both have interchangeable congurations and settings.

• The PIM400-485 is wired to a UL or cUL Listed compatible Access Control Panel (ACP).

• The PIM400-485 has been evaluated for UL and cUL compliance in indoor applications

only, within the protected premises.

• Connect the PIM400-485 to external power using a UL294 Listed power limited power

supply for UL installations, and a ULCS318/ULC S319 Listed Power Supply for cUL

installations.

• Installation location is determined by the location of the WAPM. The PIM400-485 is

ideally installed very close to the ACP.

• The PIM400-485 communicates to the WAPM(s) using Radio Frequency (RF).

• The WAPM is installed at the access point where access will be controlled and/or

monitored.

• The PIM400-485 enclosure is NEMA Type 4.

Getting started

The following is an overview of the steps required to set up the PIM400-485:

1. Install the WAPM (AD-400, WPR400, etc). See the installation guide that came with the

WAPM, or visit www.schlage.com/support for more information.

2. Make sure the PIM400-485 is located to allow for optimum RF signal transmission. See

Determine the location on page 6 for more information.

3. Before installing the PIM400-485, check for proper communication function and linking

with WAPM(s). See Pre-installation test on page 6 for more information.

4. Make sure to follow unique installation procedures if installing on an indoor metallic

wall. Refer to Mount the PIM400-485 on page 8 for more information. Consult the

Schlage Utility Software User Manual for information about conguring the PIM400-485

and the WAPM.

5. Familiarize yourself with the information contained in this user guide.

This user guide is for the PIM400-485 only.

Save this user guide for future reference.

3

Page 4

Features

Feature Description

Power status Power status is indicated by the Power/Tamper LED. When the

PIM400-485 is powered and tamper is not detected (cover is on), the

Power/Tamper LED will illuminate steady green.

ACP

communication

status

ACP communication status is indicated by the receive (RX) LED and

the transmit (TX) LED. When the PIM400-485 communicates with an

ACP, the receive (RX) LED and the transmit (TX) LED will continuously

ash randomly.

WAPM

communication

status

WAPM Communication Status is indicated by the link 1 LED and the

link 2 LED. When the PIM400-485 communicates with a WAPM, the

link 1 LED will blink if the WAPM is assigned an odd number, and the

link 2 LED will blink if the WAPM is assigned an even number.

Tamper status Tamper Status is indicated by the power/tamper LED. When the cover

is off, tamper is detected and the power/tamper LED will ash green.

When the cover is on, tamper is not detected and the power/tamper

LED will illuminate steady green.

Reset Reset is performed by the reset button. Press the reset button if the

PIM400-485 does not seem to work properly.

Components

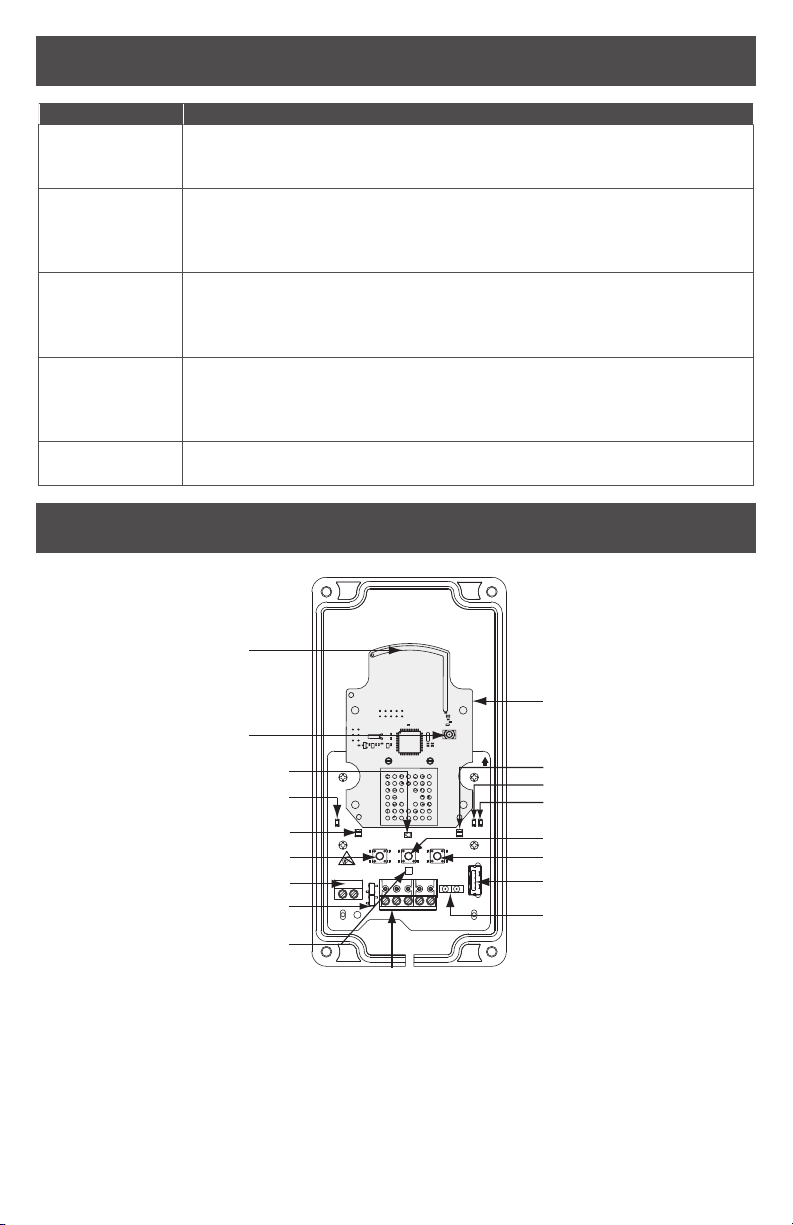

Internal Antenna

External Antenna

Connector

Optical Transmitter (LED6)

Powe r/Tamper LED (LED1)

Link 1 LED (LED4)

Link 1 Button (SW1)

Power Connector (J2)

2|4 Wire Jumpers (P5)

Optical Receiver (U6)

4 • Schlage • PIM400-485 user guide

POWER

TAMPER

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

12-24 VDC

+ POWER -

2

I4

RDA–TDA–RDB+ TDB+GND AUXTAMPER

WIRE

RS485

RX

USB

PIM400-485

RS485

Connector (P4)

PIM400-485 (Version 2)

TX

I

MOUNT THIS SIDE UP

Antenna Module

Link 2 LED (LED5)

Receive LED (LED2)

Transmit LED (LED3)

Reset Button (SW3)

Link 2 Button (S3)

USB Connector (J1)

Aux/Tamper

Connector (P6)

Not used

Page 5

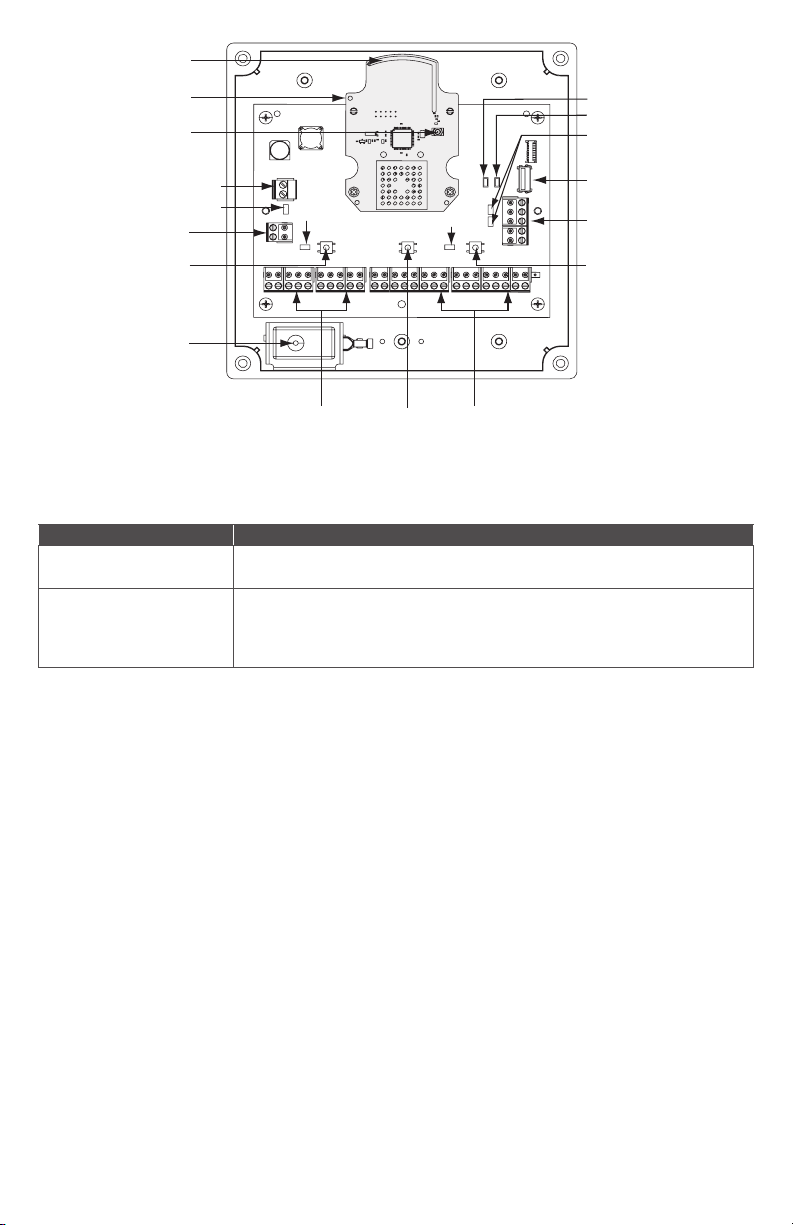

Not used

(J8, J7)

Not used

(J10, J11)

Reset

Button

(S1)

Power/Tamper LED (D3)

Link 2 Button (S3)

Link 1 Button (S2)

Tamper Switch

Connector (J1)

2

|

4 Wire Jumpers

(J19, J20)

Power Connector (J2)

Link 1

LED

USB Connector (J9)

RS485 Connector (J5)

Tamper Switch

Internal Antenna

Receive LED (D4)

Transmit LED (D5)

External Antenna

Connector

Link 2 LED

Antenna Module

PIM400-485 (Version 1)

Component Description

RS485 connector The PIM400-485 connects up to 16 WAPMs to an Access Control

Panel using the RS485 connection.

Power connector The PIM400-485 power input is non-polarized. If power is lost

or cycled, upon restoring power, the PIM400-485 will continue

operation with the same conguration and linking information.

There is no need to re-congure or re-link.

5

Page 6

Installation

Determine the location

The PIM400-485 communicates with WAPMs using radio frequency (RF) signals. RF signals

are diminished by walls, distance, metal objects or barriers. Consider the following when

placing the PIM400-485:

• Mount the PIM400-485 within 200 horizontal feet (61 meters) of each WAPM with typical

building construction. When clear line-of-sight is available, communication may be

possible up to 1000 feet (305 meters).

• Do not mount the WAPM(s) and the PIM400-485 on different oors. The signal may be

degraded and functionality could be severely limited.

• Do not mount the PIM400-485 on a metal surface. A separation of at least one inch

must be maintained in all directions from any metal.

• Signal will not pass through metal walls or metal mesh in the walls (stucco). Use a

remote antenna module located outside the room when necessary.

• Moving vehicles will interrupt the signal. Placement distance should be reduced by half

when vehicles may temporarily block the signal.

• Mount the PIM400-485 or the remote antenna so that the antenna is vertical for

optimal communication.

Locations and wiring methods shall be in accordance with the National Electrical Code,

ANSI/NFPA 70 for U.S. and Canadian Electrical Code for Canada.

Pre-installation test

Once the location for a PIM400-485 is estimated to support the WAPM(s), check

performance prior to installation.

If using a remote antenna module, install the antenna as indicated in the ANT400 user guide.

1. As close as possible to its exact mounting location, temporarily mount the WAPM to the

access control point (i.e. door, gate, elevator). Do not connect power yet.

The WPR400 may be used as a portable range tester to facilitate properly locating the

PIM400-485.

2. Temporarily mount the PIM400-485 in the exact location and orientation it will be

mounted.

3. Power the PIM400-485 with a 12 or 24 VDC supply capable of delivering 250 mA.

4. Put the PIM400-485 into link mode. Refer to Link mode on page 13.

5. Go to the most distant WAPM being tested and apply power.

6. Put the WAPM into link mode. Refer to the WAPM’s User Guide for Link instructions.

7. Verify that linking has occurred, indicated at the WAPM by the green LED ashing and

optionally by an internal sounder beeping. The number of green ashes and audible beeps

will be the same as the channel number to which the PIM400-485 is set.

If linking occurred successfully on the rst WAPM, repeat the pre-installation test on any

additional WAPMs. If all linking is successful, follow steps to wire and mount the PIM400-485

and any additional WAPMs (see Drill holes for wiring on page 7).

• If linking is unsuccessful, move the PIM400-485 six to ten inches (15.2 to 25.4 cm) in

any convenient direction until all WAPMs link successfully. If still not successful, move

the PIM400-485 closer to the WAPMs and repeat the pre-installation test, or add more

PIM400-485s.

• If still not successful, RF interference may be the cause. Refer to the Schlage Utility

Software user guide for information on changing the RF channel.

6 • Schlage • PIM400-485 user guide

Page 7

Drill holes for wiring

Drill hole(s) in the PIM400-485 enclosure to accommodate the size and number of entry/exit

connectors to be used.

Drill a hole in the top of the PIM400-485 for remote antenna installation only.

DO NOT run signal or power wiring through the top of the PIM400-485 enclosure.

Be sure to follow all local electrical code requirements.

Internal

antenna

PIM400-485

MOUNT THIS SIDE UP

RX

TX

I

USB

Z\x”

(25 mm)

hole

POWER

TAMPER

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

12-24 VDC

I4

2

RDA–TDA–RDB+ TDB+GND AUXTAMPER

WIRE

RS485

PIM400-485

MOUNT THIS SIDE UP

TX

RX

I

USB

Z\x”

(25 mm)

hole

(alternate

POWER

TAMPER

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

12-24 VDC

I4

2

RDA–TDA–RDB+ TDB+GND AUXTAMPER

WIRE

RS485

location)

(primary

location)

IMPROPER Wire Routing PROPER Wire Routing

PIM400-485 (Version 2)

Internal

antenna

Z\x” (13 mm) holes

IMPROPER Wire Routing PROPER Wire Routing

PIM400-485 (Version 1)

L A single drill hole may be used for wire routing, however be sure to avoid

routing wires near the internal antenna and the mechanical tamper switch.

L If using a remote antenna module, an additional hole is required. Refer to the

ANT400 user guide for drilling instructions.

7

Page 8

Mount the PIM400-485

1. Remove the cover and place the PIM400-485 against the wall in the location where it

successfully passed the Pre-Installation Test.

2. Mark the four (4) mounting hole locations on the wall with a pencil using the PIM400485 enclosure as a template.

L Be sure to mount the PIM400-485 vertically (refer to diagrams on page 7).

Mounting holes Mounting holes

PIM400-485 (version 2)

PIM400-485 (version 1)

3. Remove the PIM400-485 from the wall and drill the four holes (Z\zn” diameter drill bit

recommended).

L If the wall does not adequately support the PIM400-485, wall anchors should be

used.

4. Place the PIM400-485 against the wall where the four holes are drilled and screw four

screws into the mounting holes (#6 screws recommended).

L If mounted on a metallic surface or where metal is within 1 inch (25 mm) of the

back of the PIM400-485, mount the PIM400-485 at least 1 inch (25 mm) from the

wall.

L If a remote antenna is to be used, refer to the ANT400 user guide.

Wire routing

Avoid routing the wires near the internal antenna and the tamper detection mechanism.

Improper wire routing may reduce RF performance and/or prevent tamper detection. Wire

routing inside the enclosure should be as short as possible. Do not coil any excess wire inside

the enclosure.

Refer to wire routing diagrams on page 7.

Cable/wire specications

Application Part number AWG Description Max distance

DC Power

Input

RS485

Belden 8760 or equivalent 18 2 Conductor

Belden 9841 or 9842 or

equivalent, or as specied

by local electrical codes or

2 or 4 Conductor

24

shielded

1000 Feet

(305 meters)

4000 Feet

(1219 meters)

the ACP provider

8 • Schlage • PIM400-485 user guide

Page 9

Retrot

If desired, to retrot an existing PIM400-485 (version 1) installation with a PIM400-485

(version 2), complete the following steps:

1. Disconnect all electrical connections to the PIM400-485 (version 1) PCBA.

2. Remove the four screws from the PIM400-485 (version 1) PCBA. Set aside two (2) of

the screws for later use.

3. Remove the PIM400-485 (version 1) PCBA from the enclosure.

4. Drill a Z\x” (25 mm) wire routing hole in the bottom of the PIM400-485 (version 2) as

shown below.

5. Place the PIM400-485 (version 2) into the PIM400-485 (version 1) enclosure as shown

below.

6. Secure the PIM400-485 (version 2) enclosure to the PIM400 (version 1) enclosure using

the two screws removed at step 2.

PIM400-485

(version 1)

Enclosure

PIM400-485

(version 2)

POWER

TAMPER

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

2

I

4

12-24 VDC

WIRE

+ POWER -

RDA–TDA–RDB+ TDB+GND AUXTAMPER

RS485

PIM400-485

MOUNT THIS SIDE UP

TX

RX

I

USB

Secure with two

screws

Enclosure covers for both the PIM400-485 (version 2) and PIM400-485 (version 1) are used

when installing the retrot conguration.

If a remote antenna is to be used, refer to the ANT400 user guide.

The retrot installation procedure is not evaluated by UL/cUL.

9

Page 10

PIM400-485 to ACP connection

Review Components on page 4 before connecting the PIM400-485 to an Access

Control Panel.

CAUTION: Disconnect the Access Control Panel power and batteries before wiring the

PIM400-485 to the panel.

WARNING: Because every Access Control Panel is different, always check the panel’s

instruction manual for appropriate interface wiring.

The EIA RS485 specication labels the data wires as “A” and “B”, however, many RS485

products label their wires “+” and “-”. Some products associate the “+” signal with “A”,

some with “B”. Reversing polarity will not damage either RS485 device, it will just not

communicate; if it does not work, switch the connections.

• The wires from the Access Control Panel must be a shielded twisted pair. For maximum

wire lengths and cable specications, refer to Cable/wire specications on page 8.

• For compliance with UL 294 or ULC S319, product must be used with a UL 294 or

ULC S319 Listed Access Control Panel or unit, respectively.

• Must be used with a UL294 or ULC S318/ULC S319 Listed power-limited Power Supply

capable of sourcing at least 250mA @ 12 or 24 VDC.

ACCESS CONTROL PANEL CONNECTIONS

PIM400-485

connector

Power (J2)

RS485 (P5)

PIM400-

485

signal

+ 12 or 24 VDC

– DC Ground

RDA –

TDA –

RDB +

TDB +

GND Signal Ground

Access

control panel

signal

– Receive

Data

– Transmit

Data

+ Receive

Data

+ Transmit

Data

Description

PIM400-485 inputs for 12 or 24 VDC power.

Draws 250mA max.

If the Access Control Panel (ACP) reader

power outputs do not source enough

current for the PIM400-485, use the ACP

main regulated 12 VDC power supply or

a separate UL294 or ULCS318/ULCS319

Listed 12 or 24 VDC power-limited power

supply.

Power input is non polarized.

4-Wire or 2-Wire bi-directional RS485

communication port for interface to Access

Control Panels.

2-Wire installation: Both 2|4 wire jumpers

should be added.

4 -Wire installation: Both 2|4 wire jumpers

should be removed.

Refer to Typical PIM400-485 to ACP wiring

diagrams on page 11 and page 12.

10 • Schlage • PIM400-485 user guide

Page 11

Typical PIM400-485 to ACP wiring diagrams

POWER

TAMPER

2-Wire

Power Supply

UL294 or ULCS318/

ULCS319 Listed power limited

250mA 12 or 24 V DC

18 AWG, 1000 feet

max. run length

Access Control

Panel

4-Wire

AB+

Power Supply

UL294 or ULCS318/

ULCS319 Listed power limited

250mA 12 or 24 V DC

18 AWG, 1000 feet

max. run length

Access Control

Panel

RDATDARDB+

TDB+

Install Jumpers

+

−

Remove Jumpers

+

−

Shield

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

12-24 VDC

POWER

TAMPER

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

12-24 VDC

|4

2

RDA–TDA–RDB+ TDB+GND AUXTAMPER

WIRE

P5

RS485

PIM400-485

|4

2

RDA–TDA–RDB+ TDB+GND AUXTAMPER

WIRE

P5

RS485

PIM400-485

USB

MOUNT THIS SIDE UP

RX

TX

I

USB

Shield

PIM400-485 Version 2

11

Page 12

J5

J2

GND

TDB+

RDB+

TDA-

RDA-

J20

J19

AB+

+

−

J20

J19

J5

J2

GND

TDB+

RDB+

TDA-

RDA-

RDATDARDB+

TDB+

+

−

2-Wire

Power

Supply

UL294 or

ULCS318/

ULCS319

Listed power

limited 250mA

12 or 24 V DC

18 AWG,

1000 feet max.

run length

Access

Control

Panel

4-Wire

Power

Supply

UL294 or

ULCS318/

ULCS319

Listed power

limited 250mA

12 or 24 V DC

Install Jumpers

Shield

Remove Jumpers

18 AWG,

1000 feet max.

run length

Access

Control

Panel

12 • Schlage • PIM400-485 user guide

Shield

PIM400-485 Version 1

Page 13

Optional remote antenna

The PIM400-485 may be used with a remote antenna when:

• the PIM400-485 needs to be located in a remote, more serviceable or secure area,

• the RF range needs to be increased, or

• the PIM400-485 needs to communicate with a WAPM located outdoors.

L When the optional remote antenna is used, the PIM400-485 internal antenna will

be disabled.

Optional remote antenna models are shown below. For more information on remote antenna

use and installation, refer to the ANT400 optional remote antenna user guide.

The optional remote antenna is not evaluated by UL.

OPTIONAL REMOTE ANTENNA MODELS

Model Enclosure Location Description

ANT400-REMCEILING

ANT400-REM-I/O NEMA 4

ANT400-REM-HALL Indoor

ANT400-REM-

I/O+6dB

NEMA 4

Indoor

Indoor/

Outdoor

Indoor/

Outdoor

Optional remote omni-directional

antenna (0 dB gain)

Optional remote omni-directional

antenna (0 dB gain)

Optional remote bi-directional

antenna (3.5 dB gain)

Optional remote directional antenna

(6 dB gain)

Link mode

The PIM400-485 can be placed into link mode using the Schlage utility software (SUS) on the

handheld device (HHD). Refer to the Schlage utility software user guide for information.

The PIM400-485 can also be placed into Link Mode directly through select Access Control

Panels.

Schlage utility software (SUS)

The Schlage utility software is used for programming and setup only.

The SUS is used to congure this device’s links and outputs. For information about the SUS,

refer to the Schlage utility software user guide.

Reset to factory defaults

All conguration information will be deleted and the PIM400-485 will be reset to factory

defaults!

1. Remove the PIM400-485 cover.

2. Press and hold the Link 1 button and Link 2 button for about three (3) seconds. The

Link 1 LED and the Link 2 LED will ash red when factory default reset conguration

begins.

3. Release both the Link 1 button and Link 2 button. The Link 1 LED and the Link 2

LED will ash green when factory default reset conguration is complete.

4. Replace the PIM400-485 cover.

13

Page 14

DC power

This connection is always required regardless of the system application or conguration.

Refer to page 10 for instructions to connect DC power to the PIM400-485.

Complete the installation

After all required connections have been made, connect the power and Access Control

Panel standby batteries (optional) to the panel. Standby batteries are required for ULCS319

applications for Access Control Panels and must be able to provide 30 minutes of standby

for Class I. The system must be tested for operation at least once per year. Refer to Access

Control Panel installation instructions for additional details.

Troubleshooting

Problem Possible cause Solution

The PIM400485 does not

communicate with

the Access Control

Panel.

The RS485 cable between

the PIM400-485 and the

Access Control Panel may

be damaged.

The RS485 signals between

the PIM400-485 and the

Access Control Panel may

be wired incorrectly.

The RS485 address of the

PIM400-485 may not match

the RS485 address assigned

in the Access Control Panel.

The 2 | 4 wire jumpers (P5)

may be improperly installed

for communication with

RS485 4-Wire or improperly

removed for communication

with RS485 2-Wire.

Replace the RS485 cable between

the PIM400-485 and the Access

Control Panel.

Refer to PIM400-485 to ACP

connection on page 10 or ACP

system documentation for proper

wiring instructions.

Change the RS485 address of the

PIM400-485 to match the RS485

address assigned within the Access

Control Panel. Refer to the Schlage

utility software guide for more

information.

Install the 2 | 4 wire jumpers (P5)

when communicating with RS485

2-Wire. Remove the 2 | 4 wire

jumpers when communicating with

RS485 4-Wire. Refer to Typical

PIM400-485 to ACP wiring diagrams

on page 11 and page 12.

14 • Schlage • PIM400-485 user guide

Page 15

Problem Possible cause Solution

The PIM400-485

reports false tamper

detections to the

Access Control

Panel.

An intense light source may

cause interference with the

optical receiver (version

2 model only) when the

enclosure cover is removed.

Improper wiring may cause

interference with the optical

Move the PIM400-485 (version 2

model only) away from the intense

light source and ensure that the

enclosure cover is installed.

Refer to Wire routing on page 8

for proper wire routing instructions.

transmitter and optical

receiver (version 2 model

only).

Improper wiring may cause

false tamper detection at the

ACP (version 1 model).

The PIM400485 does not

The Antenna Module may

not be properly installed.

Ensure that the Antenna Module is

installed and properly seated.

communicate with

Wireless Access

Point Modules

(WAPMs)

Wiring may cause

interference with the internal

antenna on the Antenna

Module.

Check to ensure that wiring is

properly routed in the PIM400-485

enclosure and the area around

the internal antenna is clear of any

wire. See Wire routing on page

8 for more information.

The PIM400-485 may not be

linked to the Wireless Access

Point Module (WAPM).

Link the PIM400-485 to the

Wireless Access Point Module.

See Link mode on page 13 for

more information. Also refer to the

Wireless Access Point Module’s

User Guide for Link instructions.

15

Page 16

FCC/ IC Statements

The communication module is a 900 MHz transceiver for electronic locks and non-lock devices. The communication

module links the access device to the Access Control Management System, with feedback control to the Access

Device via a wireless means. The module contains the embedded rmware implementing the radio physical and

data layers. There are 4 antennas associated with this module:

1. PCB trace inverted-L with a measured gain of 5.7dBi.

2. Omni, wall/post, indoors/outdoors.

3. Omni, ceiling, indoors.

4. Directional, wall/post, indoors/outdoors.

5. Bi-directional, ceiling, indoors.

Specications of the radio module:

Power Output: 19.6 dBm

Operating Frequency: 906 -924 MHz

Modulation: BPSK

NOTE: The intended use of this module is not for the general public. It is generally for industry/commercial use only.

This transceiver is to be professionally installed in the end product by Allegion, and not by a third party. The Schlage

AD400 900 MHz Communication Board Module will not be sold to third parties via retail, general public or mail order.

In the case of a repair, the transceiver will be replaced by a professional Installer.

Federal Communication Commission interference statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communication. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC/IC caution

Any changes or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate this equipment.

To comply with FCC/IC RF exposure limits for general population/uncontrolled exposure, the antenna(s) used for

this transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must not be

co-located or operating in conjunction with any other antenna or transmitter.

Industry Canada statements

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may cause undesired operation of the device.

To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the

equivalent isotropically radiated power (e.i.r.p.) is not more than that permitted for successful communication.

This device has been designed to operate with the antennas listed below, and having a maximum gain of 9.3 dBi.

Antennas not included in this list or having a gain greater than 9.3 dBi are strictly prohibited for use with this device.

The required antenna impedance is 50 ohms.

Approved antenna list

Model Number

23530553 1 Remote antenna, Omni, wall/post, indoors/outdoors

23530561 1 Remote antenna, Omni, ceiling, indoors

23530579 1 Remote antenna, Directional, wall/post, indoors/outdoors

23520587 1 Remote antenna, Bi-directional, ceiling, indoors

To comply with IC RF exposure limits for general population/uncontrolled exposure, the antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must not be

collocated or operating in conjunction with any other antenna or transmitter.

Customer Service

1-877-671-7011 www.allegion.com/us

© 2014 Allegion

24303034 Rev. 03/14-a

Loading...

Loading...