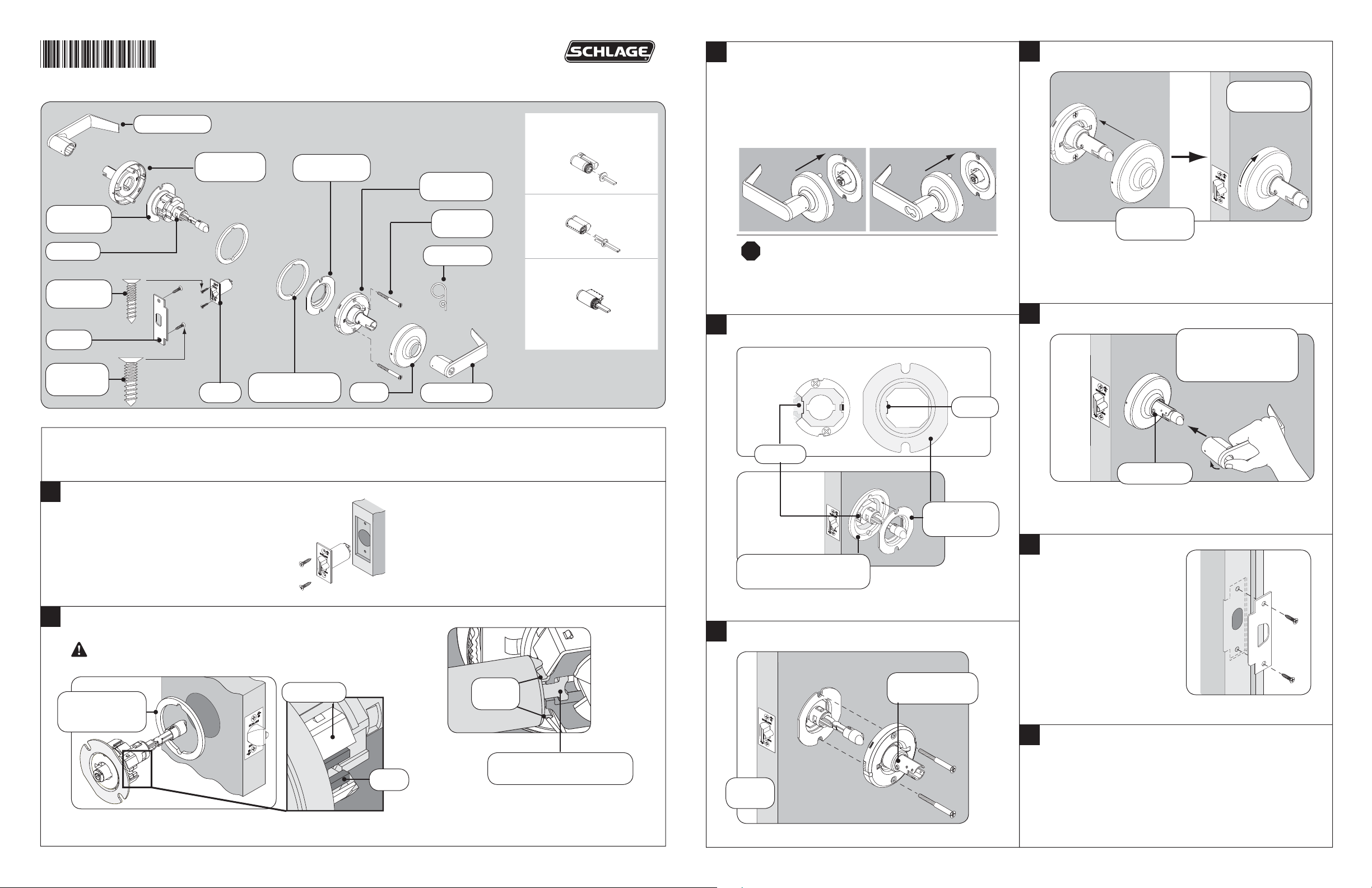

Schlage ND Series,ND70,ND73,ND66,ND60,ND72,ND75,ND93,ND95,ND94,ND97 Standard Installation Instructions

P515-167

Outside Lever

ND-Series

Standard Installation Instructions

ND53 Function Shown

Cylinder Options

Full Size IC (FSIC)

3

Non-Keyed Outside Levers ONLY:

Install Outside Lever and Springcage

Keyed IC Outside Levers ONLY:

Install Outside Lever and Springcage - DO NOT

install IC cylinder

Non Keyed Keyed IC

6

Install Inside Rose

Rotate rose

until it stops.

Adjustment

Plate

Chassis

Latch

Screws (2)

Strike

Strike

Screws (2)

Outside

Spring Cage

Latch

Optional Spacer

for 1³⁄₈” Door (2)

Anti-Rotation

Plate

Rose

Inside Spring

Cage

Small Format (SFIC)

Mounting

Screws (2)

Pin Wrench

Standard Cylinder

See Keyed Levers/Timing

for installation instructions

Inside Lever

Door Preparation

For door preparation use the template included in the package with the lock. For additional information, refer to the Schlage website:

securitytechnologies.ingersollrand.com

Align dimple

and groove.

IMPORTANT! ALL Keyed Outside Levers:

!

Follow steps at Keyed Levers/Timing

Non-Keyed Levers ONLY, go to step 4

7

4

Install Anti-Rotation Plate

Align the tab with the indent

on the hub.

Ta b

Install Inside Lever

Rotate lever slightly

toward lever catch and

fi rmly push on until lever

catch engages.

Indent

Lever catch

1

Install Latch

The bevel must face toward the door stop.

2

Install Chassis

IF DOOR THICKNESS IS NOT 1³⁄₄”,

SEE “DOOR THICKNESS ADJUSTMENT”.

Optional Spacer

1³⁄₈” (35 mm) thick

door ONLY

Latch prongs fi t between slide and slide clip.

Slide Clip

Slide

Latch

Prongs

IMPORTANT!

Push latch to center of slide

Optional Spacer

³⁄₈” (35 mm) door ONLY.

1

5

Install Inside Spring Cage Assembly

Door

edge

Anti-Rotation

Plate

Lever catch

faces door edge.

8

Install Strike

9

Check Lock Function

If a keyed function does not work properly, see

KEYED LEVERS/TIMING.

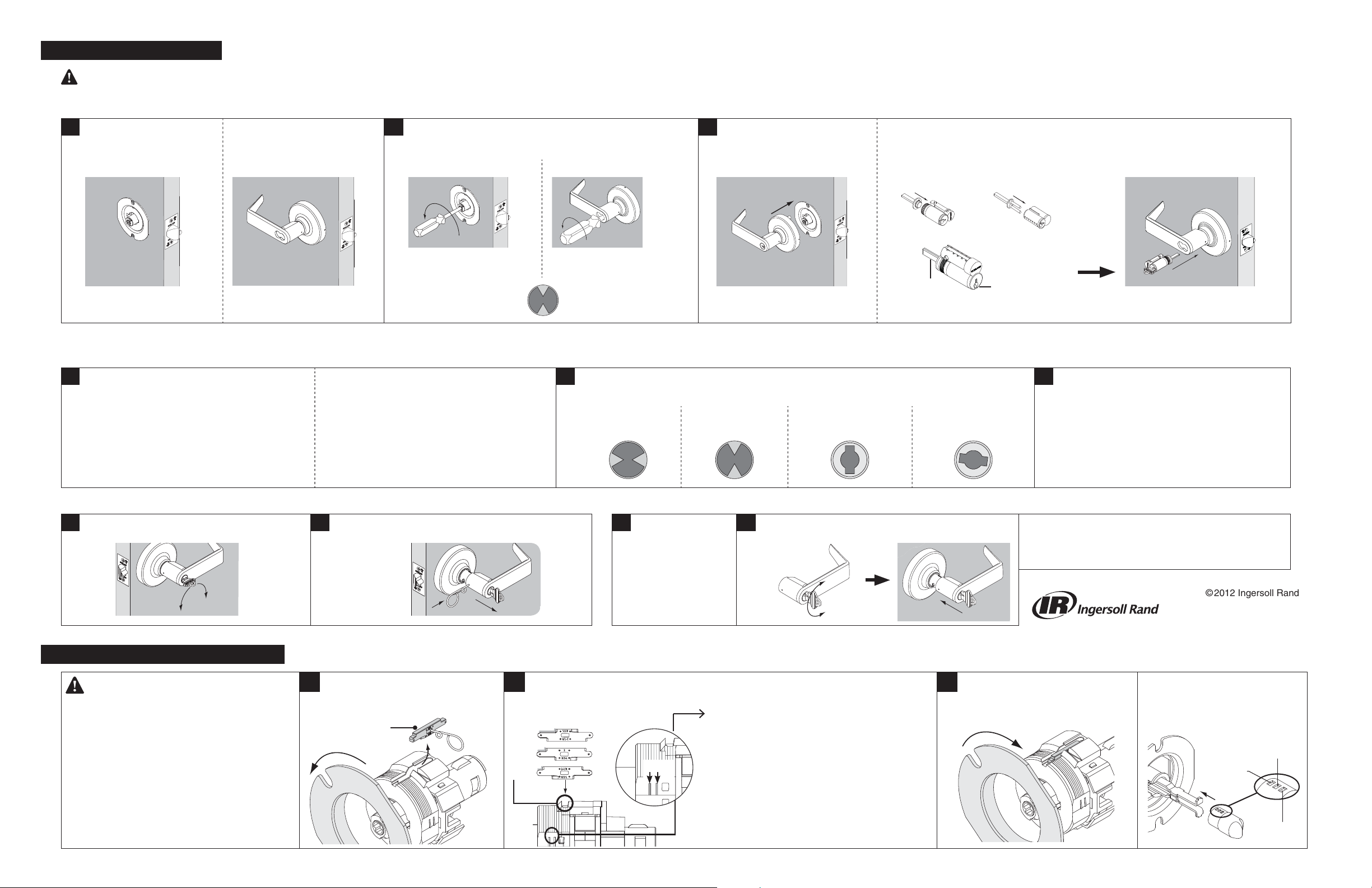

KEYED LEVERS/ TIMING

90°

IMPORTANT: DO NOT insert key in outside cylinder (if applicable) before or during these steps. FAILURE TO PROPERLY TIME THE LOCK WILL RESULT IN IMPROPER FUNCTION, AND CAN CAUSE DAMAGE TO THE LOCK.

ND70 and ND73 ONLY

STANDARD CYLINDER:

a

Install chassis only.

IC CYLINDER:

Install lock except for outside

IC and driver.

b

ND60, ND66, ND72, ND75, ND93, ND94, ND95 and ND97 ONLY

STANDARD CYLINDER:

a

Install lock except for inside lever*

*ND72 ONLY: Install chassis only. Both inside

and outside cams require timing.

IC CYLINDER:

Install lock except for inside IC and driver*

*ND72 ONLY: Install lock except for inside and

outside IC and driver. Both inside and outside

cams require timing.

Rotate key cam counterclockwise until it stops. Then rotate

clockwise to the position as shown below.

STANDARD CYLINDER IC CYLINDER

Rotate key cam clockwise to the correct position as shown below.*

b

*ND72 ONLY: Rquired on inside and outside cams.

Standard Cylinder

STANDARD CYLINDER:

c

Install the outside lever.

Then, continue with Step 4.

IC Cylinder ND66 Standard Cylinder ND66 IC Cylinder

IC CYLINDER:

Insert driver.

Align cylinder tailpiece blade and keyway.

FSIC SFIC

Tailpiece

blade

FSIC shown

Keyway

Turn the key 15° and hold.

Install the cylinder.

Then, continue with Step 4

Follow step C as shown above.

c

Then, continue with Step 4.

Remove a Keyed Lever TROUBLESHOOTING–If levers do not function properly, follow these steps:

To remove a keyed lever, rotate key 90°.

a

Insert pin wrench and push against lever catch.

b

Pull off the lever.

Remove lever as

a

shown at left.

Rotate key 180° and reinstall lever.

b

180°

DOOR THICKNESS ADJUSTMENT

For 1³⁄₄” thick doors, NO ADJUSTMENT

IS REQUIRED.

For 1³⁄₈” thick doors, install the Optional

Spacers (see steps 2 and 4). No further

adjustment is required.

For 1⁵⁄₈”, 2” or 2¹⁄₈” doors, complete the

following steps.

Remove adjustment plate and door

a

thickness insert.

Door thickness

insert

Reinsert door thickness insert with

b

correct dimension visible.

1⁵⁄₈”

2”

2¹⁄₈”

2” 1³⁄₄”

If door thickness insert is missing, use marks

on chassis:

1³⁄₈” Align adjustment plate with 1³⁄₄” mark.

Use optional spacers. (For ND85 rotate additional half

turn CCW.)

1⁵⁄₈” Tighten adjustment plate to bottom, then rotate a

half turn CCW.

1³⁄₄” Align adjustment plate with 1³⁄₄” mark. (For ND85

rotate an additional half turn CCW.)

2” Align adjustment plate with 2” mark.

2¹⁄₈” Align adjustment plate with 2” mark, then rotate an

additional full turn CCW.

CCW = counterclockwise

Reinstall adjustment plate.

c

Tighten until plate contacts door

thickness insert fl at.

For more information call

Technical Support at 877-671-7011.

© 2012 Ingersoll Rand

Printed in U.S.A.

P515-167 Rev. 06/12-e

If applicable, adjust turn button

position.

1³⁄₄" (44 mm)

1³⁄₈" (35 mm)

2" (51 mm)

2¹⁄₈" (54 mm)

1⁵⁄₈" (41 mm)

Loading...

Loading...