Page 1

28/10/08

Main Table

Fence

Sliding Table

HF0000

W872

Hafco

Setup Procedure

FORSA-9

SCHEPPACH PANEL SAW

to be used in conjunction with

factory manuals supplied

Table Length

Cross Cut

Rail

Extension

Table Width

Extension

Adjustable

Support

Outrigger

Table

Table Stroke

Max wide rip capacity 1320

Saw blade

Blade bore

Max depth of cut @ 90° 107mm

Max depth of cut @ 45° 75mm

Cutting speed

Tilt

Scribe blade

Bore

Max height

3200mm

315mm

30mm

66m/sec

90° - 45°

120

20

4mm

Telescopic

Arm

Page 1 of

6

Page 2

There are five boxes containing the parts for the saw, the serial number should be on each box and they

should all have the

into boxes

1.

Place the main

using the four jacking bolts

HF0000

same number, because the machine is set in the factory and then dismantled and packed

table

in position and level

2. M

ount the sliding table to the main table by

lowering it over th

nuts should be factory set to the correct height

Adjust the height of the sliding table so that it is

0.3mm above the main table, this is to stop the

material dragging on the main table as it passes

through the blade

3. D

o not

tighten the main bolts at this stage, nip

them up until the sliding table is squared up

e six mounting studs, the nyloc

,

Page 2 of

6

Page 3

4.

Before tightening the main bolts pull the table

towards the main table tight against the two

adjusting blots

5.

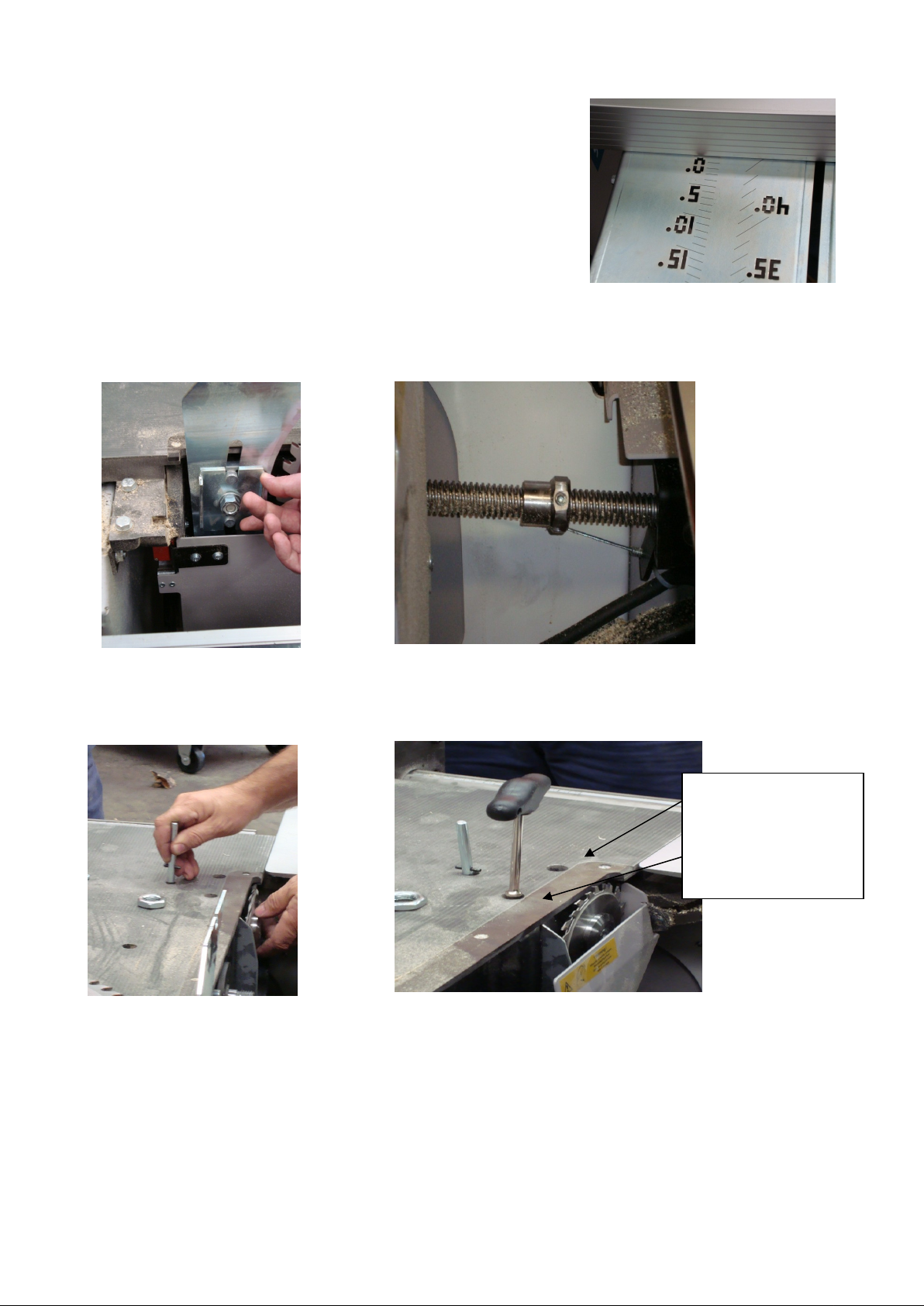

Mount a dial indicator as shown

traverse it along the blade then

the

sliding table

adjusting screws

6.

The sliding table should be square to

the blade to a tolerance of +/- 0.1mm

and

adjust

if necessary by using

.

HF0000

7.

Tightened main bolts

8.

Fix the mounting brackets to the table

w

idth

extension, then fit the extension

to the main table, adjust so that the

side extension table is flush with the

main table

Page 3 of

6

Page 4

9.

Outer end of the

can be levelled using the two adjusting bolts

table width

extension table

HF0000

10. Fit

11. Fit the fence to the rail and slide up to the

12. Adjust the rail until the fence is square to

13. With the fence against the blade adjust

the fence rail to the table and nip the

bolts up

blade and lock in position

the blade and tighten bolts

the indicator

plastic indicator holding screws and

repositioning the indicator

to zero by loosening the

14. Fit the

15. This can be adjusted by the mounting

16. The outer end is adjusted by the

table length

so that it sits just below the surface of the

main table

bolts for th

stabilising leg

e hinge pins

extension and adjust

Page 4 of

6

Page 5

17. Place fence across the sliding table and measure from

the fence to the top of the

measurement at the further most forward point of the

telescopic

point of travel

arm travel and t

telescopic

hen again at the rear most

arm, do this

HF0000

18. Adjust the pivot pin until both readings are the same

19. Fit the

surfaces are flush

20. Fit

21. the

22. Adjust the whole

23. Place a set square against the blade and square the

to the blade with t

outrigger

crosscut rail

crosscut rail

a.

from the blade

table to the sliding table so that both

to the sliding table and fit t

and lock it in position at the 100mm mark

crosscut rail

he adjusting screw

until the face of the stop is 100mm

he adjustable stop to

crosscut rail

Page 5 of

6

Page 6

blades

Rear bolt adjusts blade

HF0000

24. The

MAIN SPINDLE

The blade cover has a micro switch so the cover must be shut for

crosscut rail

loosening the whole plate and sliding until the zero mark lines

up with the fence

scale can also be adjusted to zero by

the saw to operate

The riving knife can be

adjusted to suit different

blades

Fit pin into spindle to

loosen blade nut

MAINTENANCE

At the end of each day wipe off sawdust and wipe down sliding surfaces with a rag wet with WD40

, both

The maximum blade ang

be set by this nut

To adjust scribe blade

position

le can

Front bolt adjusts

blade up or down

from side to side

Page 6 of

6

Loading...

Loading...