Page 1

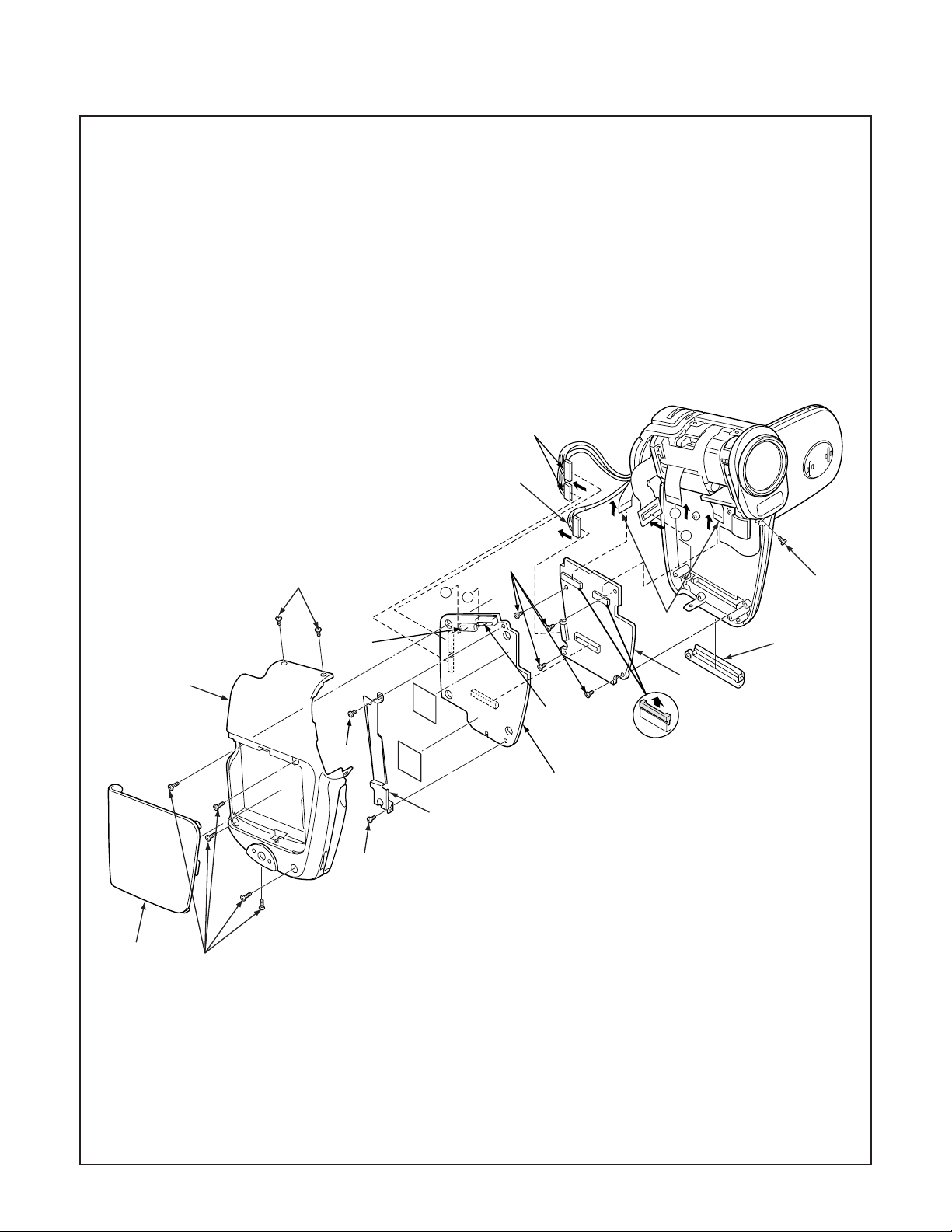

2. DISASSEMBLY

2-1. REMOVAL OF CABINET LEFT, CP1 BOARD AND SY1 BOARD

1. Cover battery

2. Five screws 1.7 x 5

3. Three screws 1.7 x 3

4. Cabinet left

5. Cover card

6. Connector

7. FPC

8. Screw 1.7 x 4

4

9. Screw 1.7 x 3

10. Shield CP1

11. CP1 board

12. Two connectors

13. Two FPCs

14. Four screws 1.7 x 4

15. Connector

16. SY1 board

3

6

9

12

15

B

A

14

A

B

3

13

5

16

7

11

10

8

1

2

– 11 –

Page 2

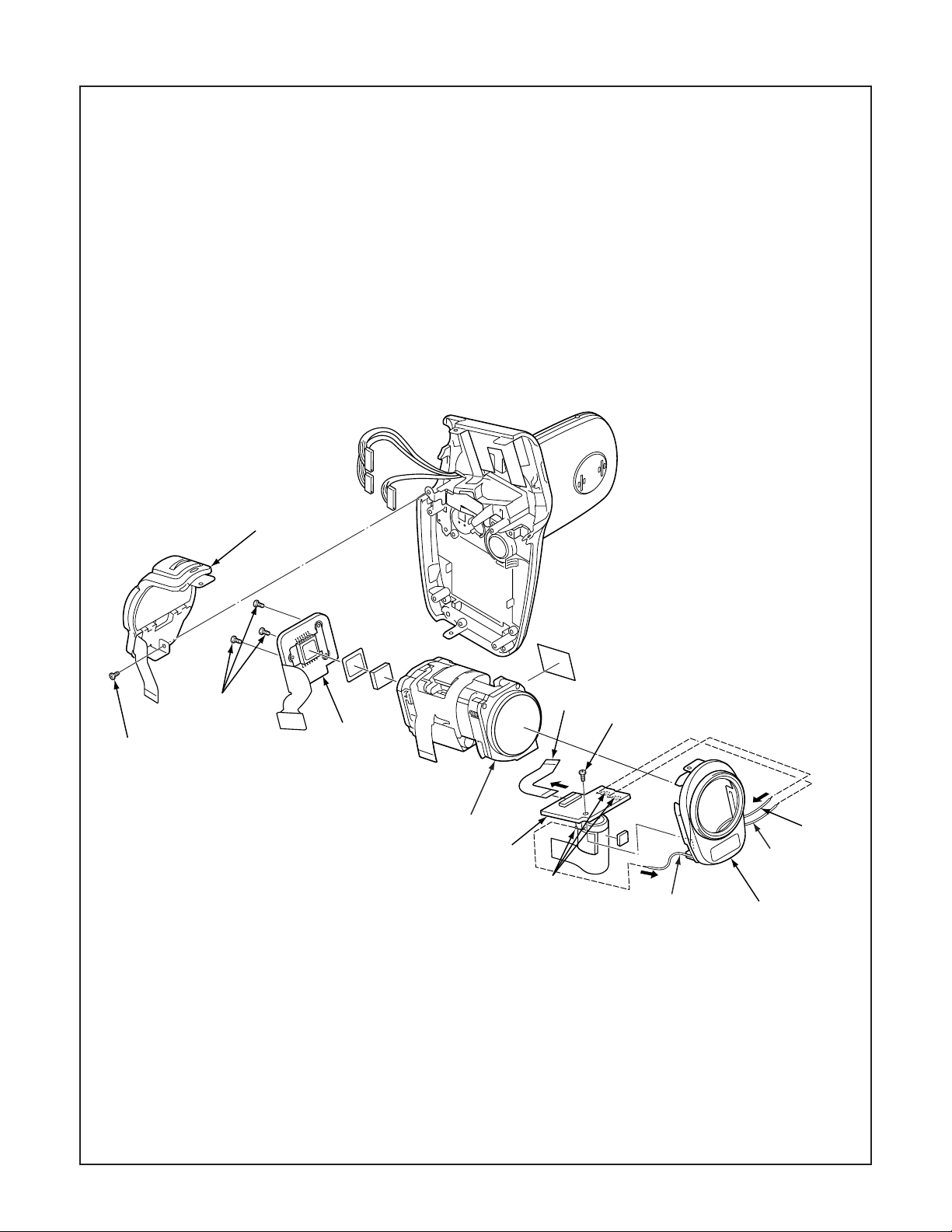

2-2. REMOVAL OF CABINET FRONT, ST1 BOARD AND CA1 BOARD

1. Assy lens

2. Cabinet front

3. Screw 1.7 x 4

4. Flexible PWB

5. Remove the solder.

6. ST1 board

7. Three screws 1.4 x 3.5

8. CA1 board

9. Screw 1.7 x 3

10. Unit control

10

c

b

a

7

9

When assembling,

tighten the screws order.

a → b → c

NOTE: Discharge a strobe capacitor

with the discharge jig (VJ8-0188) for

electric shock prevention.

4

3

8

1

6

black

pink

5

gray

2

– 12 –

Page 3

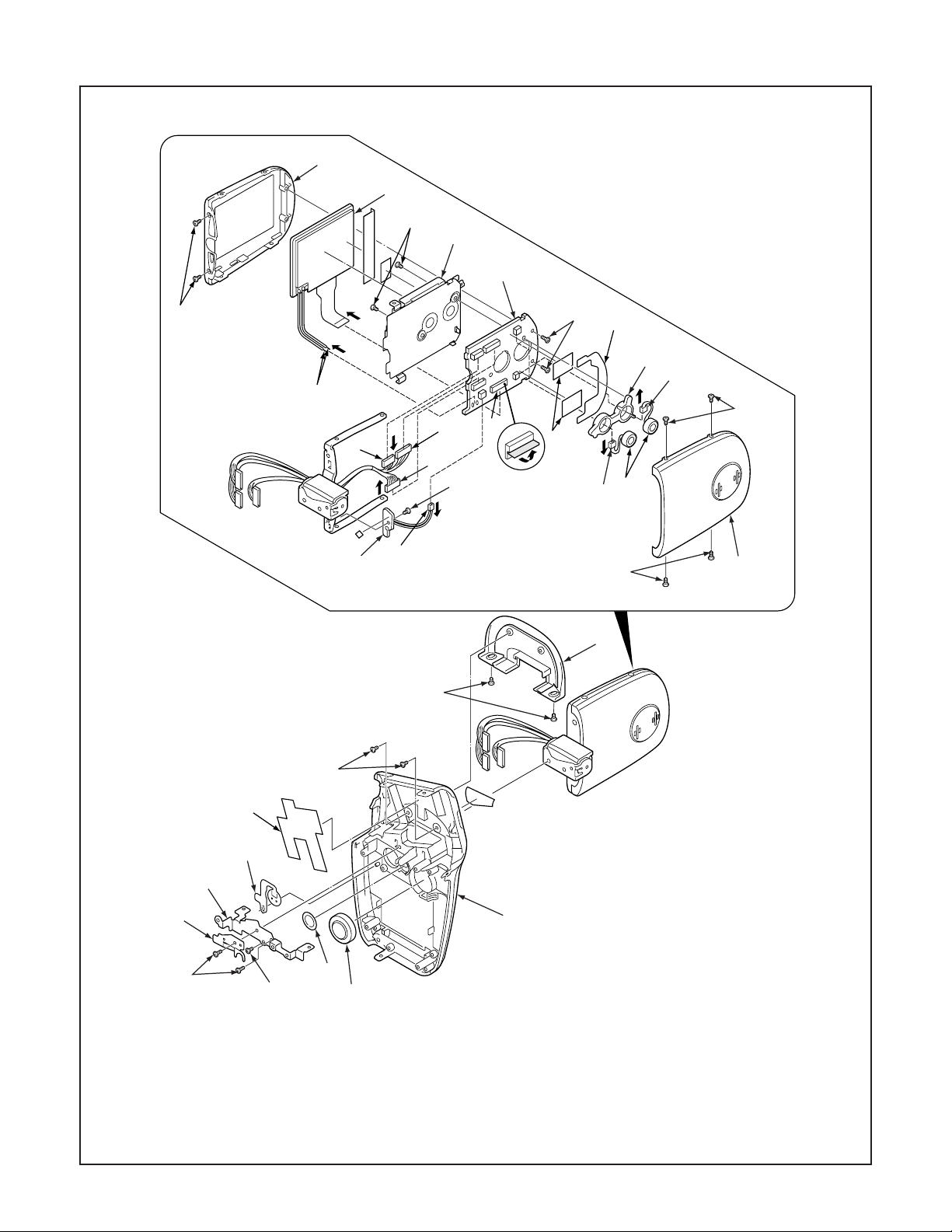

2-3. REMOVAL OF CABINET RIGHT, LCD, VF1 BOARD AND TB1 BOARD

32

25

26

27

28

31

1. Two screws 1.7 x 4

2. Spring button

3. Button LCD

4. Shield tape right

5. Two screws 1.7 x 2.5

6. Two screws 1.7 x 2

7. Assy cover joint base

8. Screw 1.7 x 2.5

24

22

15

29

21

13

23

17

18

16

19

34

33

20

21

13

30

14

7

6

5

4

10

9

2

1

9. Holder joint

10. Assy button power

11. Speaker, 8

12. Cabinet right

13. Four screws 1.4 x 3

19. Assy wire VF1 & SY1

20. Connector

21. Two connectors

22. Two screws 1.7 x 4

23. FPC

12

3

8

11

14. Cover LCD back

15. Shield tape LCD

16. Spacer LCD

17. Assy wire VF1 & CP1-2

18. Assy wire VF1 & CP1-1

– 13 –

24. Remove the solder.

25. LCD

26. Two screws 1.7 x 2.5

27. Holder monitor

28. VF1 board

29. Holder mic

30. Microphone

31. Two screws 1.4 x 3

32. Cover LCD front

33. Screw 1.4 x 2

34. TB1 board

Page 4

2-4. BOARD LOCATION

CA1 board

VF1 board

CP1 board

TB1 board

ST1 board

SY1 board

– 14 –

Page 5

3. ELECTRICAL ADJUSTMENT

Firmware

Data

AWB

Focus

UV Matrix

R Bright

RGB Offset

Tint

B Bright

Gain

Phase

LCD

Calibration

Upload

PAF Cal.

LCD Type

H AFC Test

VCOMDC

VCOMPP

Cal Data

Cal Mode

OK

OK

EVF

USB storage

Get

Set

VID

Set

PID

Set

Serial

Set

Rev.

Set

Setting

Language

Video Mode

VCO

Factory Code

Hall Cal.

Backrush pulse :

Set

Get

3-1. Table for Servicing Tools

Ref. No.

J-1

J-2

J-3

J-4

J-5

J-6

Name

Pattern box (color viewer)

Calibration software

Chroma meter

Spare lump

Discharge jig

Collimator

Number

1

1

1

1

1

1

Part code

VJ8-0190

VJ8-0263

VJ8-0192

VJ8-0191

VJ8-0188

VJ8-0260

3-4. Setup

1. System requirements

Windows 98 or Me or 2000 or XP

IBM R -compatible PC with pentium processor

CD-ROM drive

3.5-inch high-density diskette drive

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

Note: J-1 Pattern box (color viewer) is 100 - 110 VAC only.

J-1 J-2

J-3

J-4

J-5

2. Installing calibration software

1. Insert the calibration software installation diskette into your

diskette drive.

2. Open the explorer.

3. Copy the DscCalDI_150 folder on the floppy disk in the FD

drive to a folder on the hard disk.

3. Installing USB driver

Install the USB driver with camera or connection kit for PC.

4. Pattern box (color viewer)

Turn on the switch and wait for 30 minutes for aging to take

place before using Color Pure. It is used after adjusting the

chroma meter (VJ8-0192) adjust color temperature to 3100 ±

20 K and luminosity to 900 ± 20 cd/m

2

. Be careful of handling

the lump and its circumference are high temperature during

use and after power off for a while.

5. Computer screen during adjustment

3-2. Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. PC (IBM R -compatible PC, Pentium processor, Window

98 or Me or 2000 or XP)

3-3. Adjustment Items and Order

1. IC501 Oscillation Frequency Adjustment

2. Lens Adjustment

3. AWB Adjustment

4. CCD White Point Defect Detect Adjustment

5. CCD Black Point And White Point Defect Detect Adjust-

ment In Lighted

Note: Item 2-5 adjustments should be carried out in sequence.

– 15 –

Page 6

3-5. Connecting the camera to the computer

1. Line up the arrow on the cable connector with the notch on the camera's USB port. Insert the connector.

2. Locate a USB port on your computer.

3. Insert the AC adaptor’s cable to DC jack.

4. Choose the “CARD READER”, and press the SET button.

AC adaptor

To USB port

USB cable

NOTE: Discharge a strobe capacitor

with the discharge jig (VJ8-0188) for

electric shock prevention.

– 16 –

Page 7

3-6. The adjustment item which in necessary in part exchange

CCD Black

Point And White

Point Defect

Detect

Adjustment In

Lighted

Factory

Cord

Setting

Language

Setting

COMPL PWB CP-1

(636 091 3738)

COMPL PWB SY-1

(636 091 3769)

COMPL PWB CA-1

(636 091 3806)

COMPL PWB ST-1

(636 091 3745)

COMPL PWB VF-1

(636 091 3752)

COMPL PWB TB-1

(636 091 4025)

LENS ASSY

(645 082 0519)

IC501

Oscillation

Frequency

Adjustment

Lens

Adjustment

AWB

Adjustment

CCD White

Point Defect

Detect

Adjustment

: Be sure to carry out the necessary adjustments after replacing the unit.

: Adjustment is possible from the menu setting screen of the camera and by using the calibration software.

3-7. Adjust Specifications

[CP1 board (Side B)]

Adjustment method:

1. Adjust with VR501 to 496.5 ± 1 kHz.

USB storage

information

registration

Reset

Setting

VR501

CL501

Note:

1. Frequency adjustment is necessary to repair in the CP1

board and replace the parts.

Preparation:

1. Remove the cabinet left. You can see VR501 and CL501

in the CP1 board.

2. Insert the SD card.

3. Set the main switch to the REC.

4. Press the power button, and comfirm that the through im-

age from CCD can be seen in the LCD.

1. IC501 Oscillation Frequency Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

CL501

Frequency counter

VR501

496.5 ± 1 kHz

2. Lens Adjustment

Camera

Collimator

Preparation:

POWER switch: ON

If using a ready-made collimator, set to infinity.

Note:

Do not vibrate during the adjustment.

Adjustment method:

1. Set the camera 0 cm from the collimator. (Do not enter any

light.)

2. Set the camera so that it becomes center of the screen in

the collimator.

3. Double-click on the DscCalDi.exe.

4. Click the Focus, and click the Yes.

5. Lens adjustment value will appear on the screen.

6. Click the OK.

– 17 –

Page 8

DscCalDi

x

Dsc Calibration x

Focus Result

!

STD_AFPOS=1168

FOCUS=-5,-14,-15,-4,-71

ADJ_PZPOS=15

OK

Adjustment value determination is effectuated using the "STD

AFPOS" and "FOCUS" values.

If FOCUS=focus1, focus2, focus3, focus4, focus5 and the ad-

justment values fulfill the conditions below, they are determined

as within specifications.

Adjustment value determination

1050<=STD_AFPOS<1240

-40<=focus1<=+40, -50<focus2<+50,

-60<=focus3<=+60, -60<=focus4<=+60,

-150<=focus5<=+150

3. AWB Adjustment

Camera

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Adjusting method:

1. When setting the camera in place, set it to an angle so that

nothing appears in any part of the color viewer except the

white section. (Do not enter any light.)

2. Double-click on the DscCalDi.exe.

3. Click the AWB, and click the Yes.

4. AWB adjustment value will appear on the screen.

5. Click the OK.

AWB Result:

1:

AGC=187,356,525,694,863

3F_AGC=1,2

WB=276,516,678

CHECK=128,128,141

WB_ND=275, 515, 691

CHECK_ND=128, 128, 142

IRIS_GAIN: 52

IRIS_OFFSET: 153

MS=1705,2101,2378,2934

IRIS=171,156,137,116,109

0

IRIS=0

Adjustment value determination is effectuated using the "AGC",

“CHECK", “CHECK_ND”, "MS", “IRIS”, “IRIS_GAIN” and

“IRIS_OFFSET” values.

If AGC= a1, a2, a3, a4, a5, CHECK= wc0, wc1, wc2,

CHECK_ND= wnc0, wnc1, wnc2, MS= ms1, ms2, ms3, ms4,

IRIS= s1, s2, s3, s4, s5, IRIS_GAIN= g and IRIS_OFFSET=

o the adjustment values fulfill the conditions below, they are

determined as within specifications.

Adjustment value determination

100<a1<250, 250<a2<450, 450<a3<600,

550<a4<800, 750<a5<1024

wc0=128 ± 2, wc1=128 ± 2, wc2=130 ± 40

wnc0=128 ± 2, wnc1=128 ± 2, wnc2=130 ± 40

1400<ms1<=2500, 1700<ms2<=2900, 1800<ms3<=3100,

2300<ms4<=3600

100<=s1<=220, 100<=s2<=220, 100<=s3<=220,

100<=s4<=220, 100<=s5<=220

s1>s2>s3>s4>s5

0<=g<=255

0<=o<=255

Adjustment values other than the above are irrelevant.

OK

Copy

4. CCD White Point Defect Detect Adjustment

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalDi.exe.

2. Select “CCD Defect” on the LCD “Test”, and click the “Ye s ”.

3. After the adjustment is completed, OK will display.

4. Click the OK.

– 18 –

Page 9

5. CCD Black Point And White Point Defect Detect

Firmware

Data

AWB

Focus

UV Matrix

R Bright

RGB Offset

Tint

B Bright

Gain

Phase

LCD

Calibration

Upload

PAF Cal.

LCD Type

H AFC Test

VCOMDC

VCOMPP

Cal Data

Cal Mode

OK

OK

EVF

USB storage

Get

Set

VID

Set

PID

Set

Serial

Set

Rev.

Set

Setting

Language

Video Mode

VCO

Factory Code

Hall Cal.

Backrush pulse :

Set

Get

Adjustment In Lighted

Camera

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

Adjusting method:

1. Set the camera 0 cm from the pattern box. (Do not enter

any light.)

2. Double-click on the DscCalDi.exe.

3. Select “CCD Black” on the LCD “Test”, and click the “Ye s ”.

4. After the adjustment is completed, the number of defect

will appear.

2

)

3-8. Factory Code Setting

1. Check the "Factory Code" display within the Setting group.

2. For U.S.A., Canada and NTSC general area

If "FC_SANYO_U" does not appear, click on the " " mark

located on the right of the "Factory Code" display BOX and

select "FC_SANYO_U".

3. For Europe and PAL general area

If "FC_SANYO_EX" does not appear, click on the " " mark

located on the right of the "Factory Code" display BOX and

select "FC_SANYO_EX".

3-9. Language Setting

1. Click on the " " mark located on the right of the

"Language" display BOX.

2. Select language. (Default is English.)

3. End "DscCal" and remove the camera before turning the

camera power OFF.

3-10. Reset Setting

Carry out reset settings after replacing CP1 board.

1. Turn on the camera.

2. Press the MENU button.

3. Choose the OPTION.

4. Choose the RESET SETTINGS, and press the SET

button.

5. Select Yes, and press the SET button.

3-11. The Compulsive boot starting method

1. Keep MENU button, SET button, and SHUTTER button depressed while switching on the power.

2. Connect the camera and the computer with USB cable.

– 19 –

Page 10

3-12. Firmware uploading procedure

1. Uploading the firmware should be carried out if the version

number (COMPL PWB XX-X) on the replacement circuit

board is lower than the version of the distributed firmware.

For XX-X, enter the name of the circuit board containing the

firmware.

2. The firmware is distributed by e-mail in self-extracting archive

format. Change the extension of the distributed file to .EXE

and save it in your preferred folder.

3. When you double-click the saved file, the firmware (binary

file) will be saved in the same folder.

4. The firmware must not be distributed without permission.

1. Overwriting firmware from the SD card

Preparation:

SD card: SD card with firmware rewritten into the root directory

Data: S814Nxxx.BIN (xxx: version)

Overwriting method:

1. Insert the above SD card.

2. Turn on the camera.

3. Set the main switch to the PLAY.

4. Press the MENU button. The playback setting screen appears.

5. Choose the OPTION icon.

6. Choose the FORMAT.

7. Toggle the SET button to the left for 2 seconds. FIRMWARE

UPDATE will display.

8. Choose YES.

9. Press the SET button. Update is starting.

Note:

Do not turn off the camera’s power or remove the SD card

while the firmware is being updated.

The power will turn on automatically after the update is complete.

2. Overwriting firmware from the calibration software

Preparation:

PC with overwriting firmware copied to the preferred folder in

the HD.

Data: S814Nxxx.BIN (xxx: version)

Overwriting method:

1. Connect the camera’s USB/AV terminal to the computer’

USB connector.

2. The USB Connection screen appears on the camera’s LCD

monitor. Choose the “CARD READER”, and press the SET

button.

3. Double-click on the DscCalDi.exe.

4. Click the Firmware.

5. Choose the fimware file to use for overwriting, and click

the Yes.

6. Update is starting. The message will appear, and choose

OK.

7. After the update is complete, disconnect the USB cable

and turn the camera’s power off.

Note:

Do not turn off the camera’s power while the firmware is being updated.

– 20 –

Loading...

Loading...