Page 1

SERVICE MANUAL

FILE NO.

COLOUR CCD Camera

SPECIFICATIONS

TV system : PAL standard (625 TV lines, 25 frames/sec.)

Scanning system : 625 TV lines, 50 field/sec., 2:1 interlace

Image device : Interline transfer method, 1/3 inch solid state CCD

Picture elements : 795 (Horizontal) x 596 (Vertical)

Effective picture elements : 752 (Horizontal) x 582 (Vertical)

Synchronization system : Internal sync.

Resolution : 480 TV lines horizontally, 400 TV lines vertically

Video output signal level : 1.0 Vp-p/75 Ω (screw-on terminal)

S/N ratio : More than 48 dB

Minimum required illumination : 1.8 lux (F 1.6 lens)

White balance : A (Automatic: TTL system)/M (Manual) manual switching

Backlight compensation : 1 (On)/0 (Off) manual switching,

Active-zone light measuring system

Backlight compensation iris level adjustment : Manual LEVEL volume control

Aperture : 1 (High)/0 (Normal) manual switching

Gain control : Automatic

MONITOR output pin : 1.0 Vp-p/75 Ω, test point pin

Lens : F1.6 ~ 2.3, f=2.6 ~ 6.0 mm, varifocal lens, manual zoom and focus adjustment

Iris system : Mechanical auto iris

Operational environmental conditions : Temperature: -10 °C ~ + 50 °C

Humidity: less than 90 %

Storage environmental conditions : Temperature: -20 °C ~ + 60 °C

Humidity: less than 70 %

Power supply : 12-15 V DC/ 24 V AC, 50 Hz

Power consumption : 3.5 W

Weight : Approx. 420 g

VCC-9615P

(Product Code : 117 047 15)

(Europe)

CONTENTS

1. DISASSEMBLY, VR AND TP LOCATION

AND BOARD LOCATION .................... 2

2. ADJUSTMENT .....................................3

3. PARTS LIST .........................................5

CIRCUIT DIAGRAM &

PRINTED WIRING BOARDS ................. C1

PRODUCT SAFETY NOTICE

The components designated by a symbol ( ! ) in this schematic diagram designates components whose value are of

special significance to product safety. Should any component designated by a symbol need to be replaced, use only the

part designated in the Parts List. Do not deviate from the resistance, wattage, and voltage ratings shown.

NOTE : 1. Parts order must contain model number, part number, and description.

2. Substitute parts may be supplied as the service parts.

3. N. S. P. : Not available as service parts.

Design and specification are subject to change without notice.

L5AR2/XE

REFERENCE No. SM5310516

Page 2

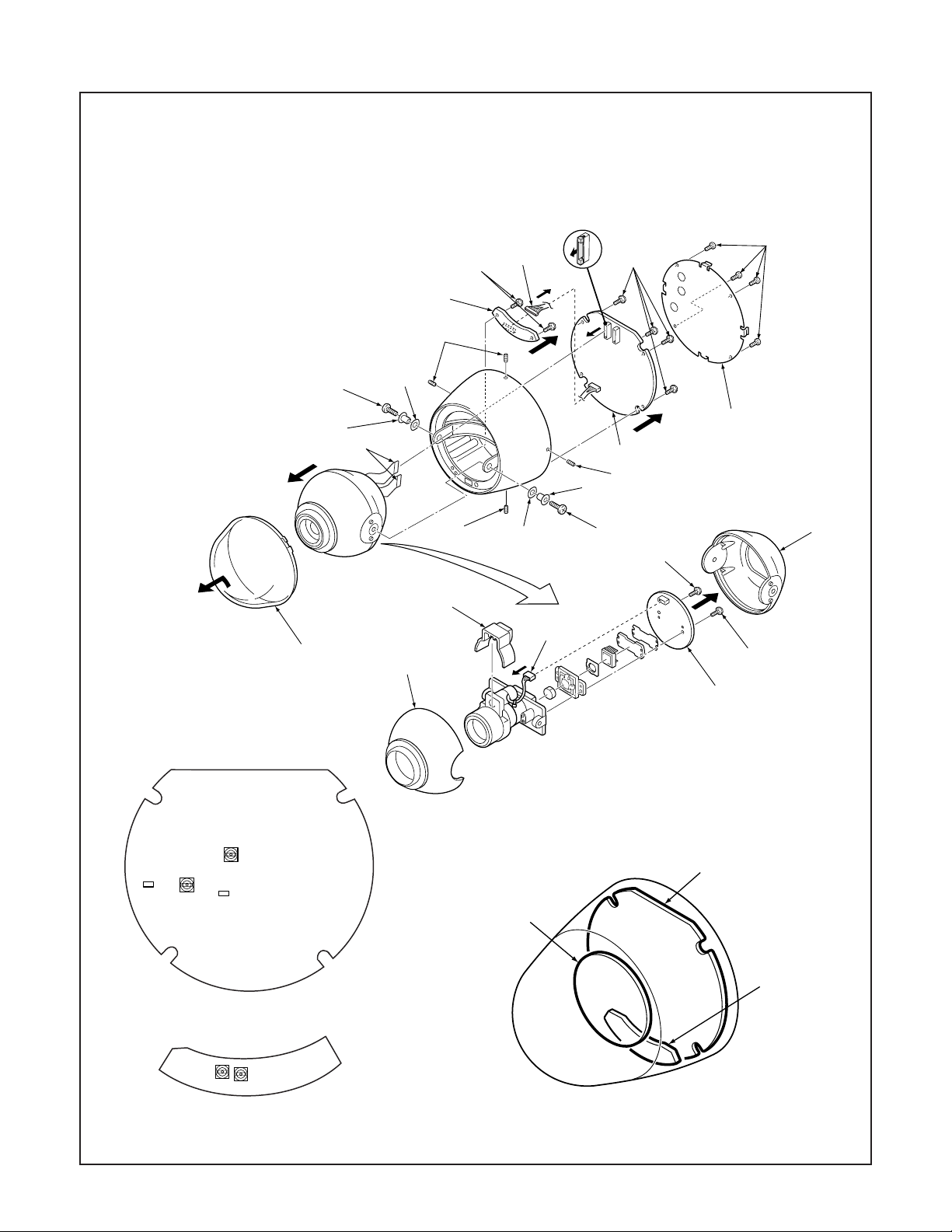

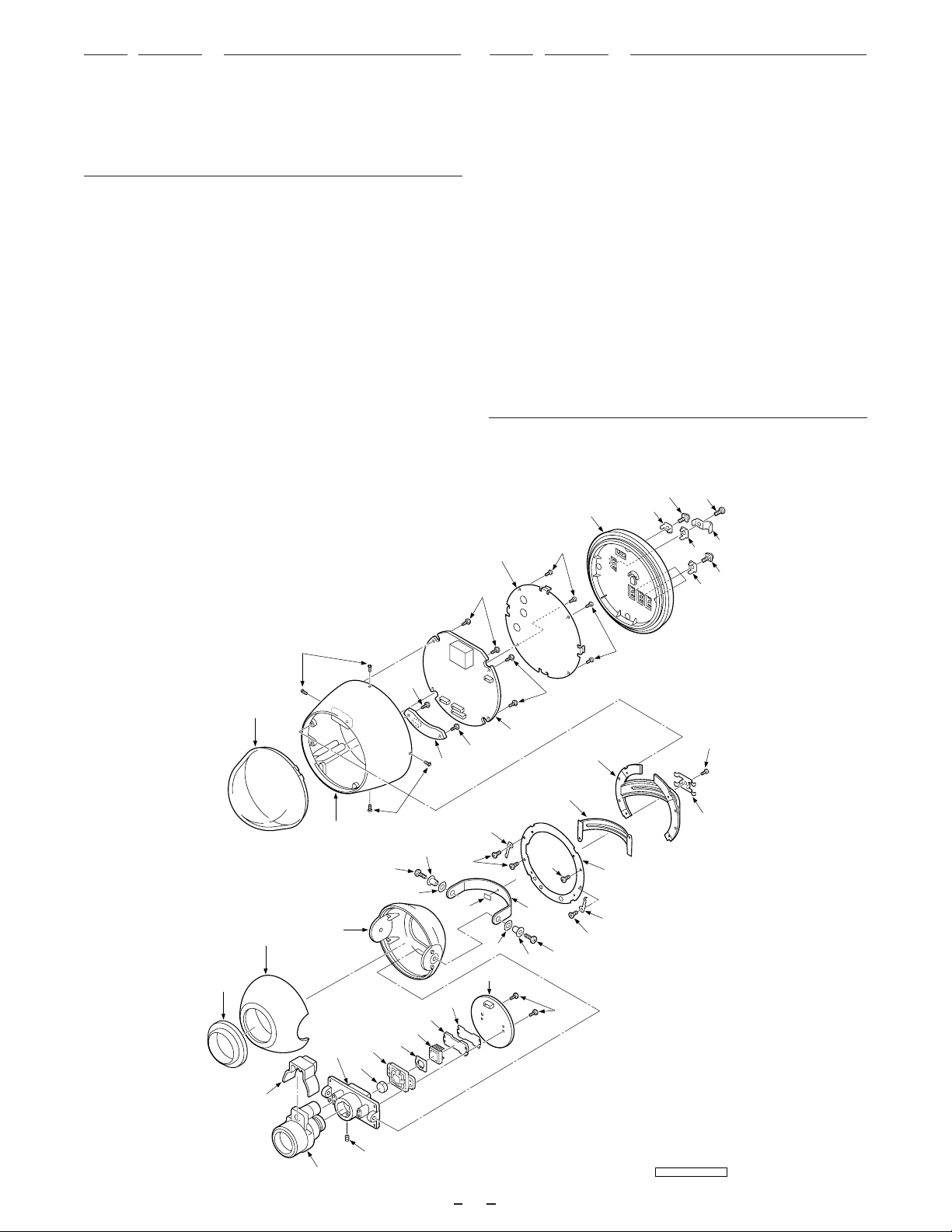

1. DISASSEMBLY, VR AND TP LOCATION AND BOARD LOCATION

1. Dec window

2. Four screws 2 x 5

3. Four screws 2.6 x 4

4. Lid

5. Four screws 2 x 5

6. Two FPCs

7. Connector

8. CA2 board

9. Two screws 2 x 5

10. CA3 board

11. Two screws 3 x 8

12. Two Pipes

13. Two special washers

14. Cover front

15. Cover back

16. Food iris

17. Two screws 2 x 6

18. Connector

19. CA1 board

11

12

10

2

13

6

2

7

9

5

8

2

12

13

11

3

4

15

17

TP200

CT232

VR244

TP200

CA-2 board (Side B)

16

18

1

14

17

19

CA2 board

CA1 board

CA3 board

VR303

CA-3 board (Side A)

VR302

– 2 –

Page 3

2. ADJUSTMENT

ADJUSTMENT (VHJ_0159) Ver.1.00

x

START

CLOSE

SCHEDULE

STATUS

Rom Clear(Others Adj Value)

Adj.WhiteClip

Awb.Off(Manual White Balance)

Agc Off(AutoIrisLens Adj)

Adj.Agc

Adj.Chroma

Wait Inkey

Adj.CCD White Defect Detection

NEXT

STOP

+

–

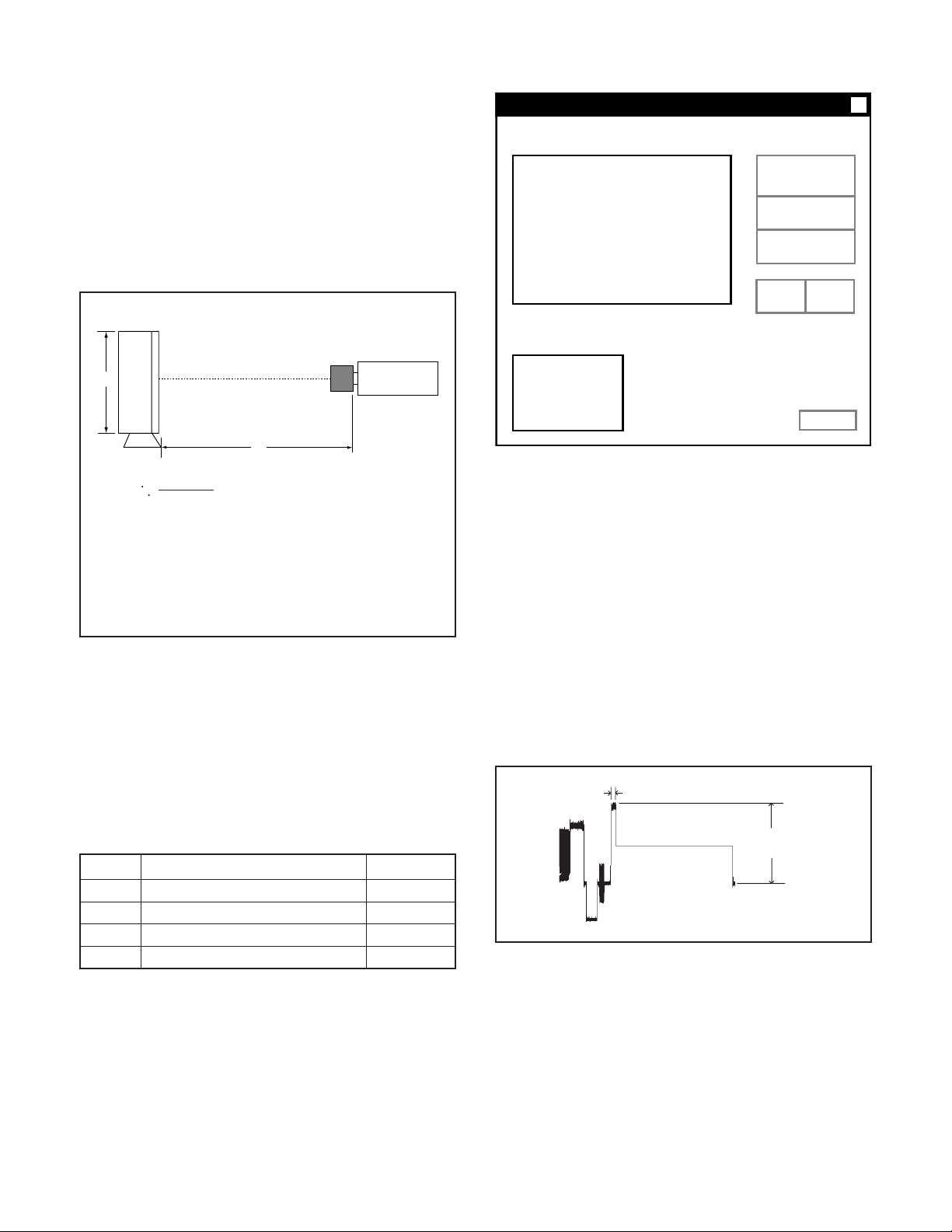

2-1. ADJUSTMENT CONDITION

1. Use the 5,100K viewer for the subject.

2. Set the trigger signal of oscilloscope to VIDEO OUT, and

apply H sync unless specified.

3. Set S3001 (CA-3) to the all OFF position.

4. In adjustments without direction to display charts, shield light

with a lens cap to provide dark condition.

5. Connect the video output to a video monitor with an input

impedance of 75 Ω.

6. Ground test point is TP200 (CA-2).

5,100 K viewer

CCD camera

H

2-3-1. Computer screen during adjustment

2

(H + h)

L = x f – 12.5 mm

H x h

L: Distance from CS mount to pattern (mm)

H: Pattern height (mm)

f : Lens focal length (standard 12 mm)

h: Height (4.8 mm) of CCD imaging surface

Note : The video monitor should be an under-scan TV.

2-2. PREPARATION

1. Install the adjustment software (VHJ-0157) in a computer

running the Windows operating system.

2. Use the adjustment tool (VHJ-0127) to connect the camera

to be adjusted to the serial port of the computer with RS232C cross cable, and then turn on the power for the computer and the camera.

3. Use COM1 serial port on the computer.

2-3. TABLE FOR SERVICING TOOLS

Ref. No.

J-1 VJ8-0007

J-2

J-3

J-4

Color viewer

Adjustment jig

Calibration software

Chart for color adjustment

L

Name

CS mount surface

Part code

VHJ-0127

VHJ-0159

VJ8-0155

From 2-4. to 2-9. adjustments are continuous adjustment by adjustment software.

2-4. White Clip Adjustment

Adjustment location:

Measuring location: VIDEO OUT

Measuring equipment: Oscilloscope

Subject: No designation

Adjusting method:

1. Click the adjustment software installed from the personal

computer, and the adjustment window will be displayed.

2. Click the start button. Rom clear to be white clip adjustment.

3. Display the viewer 2-10 µsec at the edge of the screen.

4. Adjust (+) and (-) button so that the adjustment value is 830

± 10 mVp-p.

2~10 µsec

830 ± 10 mVp-p

VIDEO OUT

2-5. White Balance Adjustment

Adjustment location: VR302, VR303 (CA-3)

Measuring location: VIDEO OUT

Measuring equipment: Oscilloscope, Vectorscope

Subject: Color bar chart

Adjusting method:

1. Display the color bar chart at designated picture angle.

2. Click the “NEXT” button to be white balance adjustment.

3. Adjust VR302 and VR303 so that the luminescent spot representing white is overlapping with the crosshair mark in

the center of the vectorscope.

– 3 –

Page 4

30 µsec

30 µsec

VIDEO OUT

cy

g

R

v

75%

YL

yl

100%

G

MG

b

U

B

Cy

mg

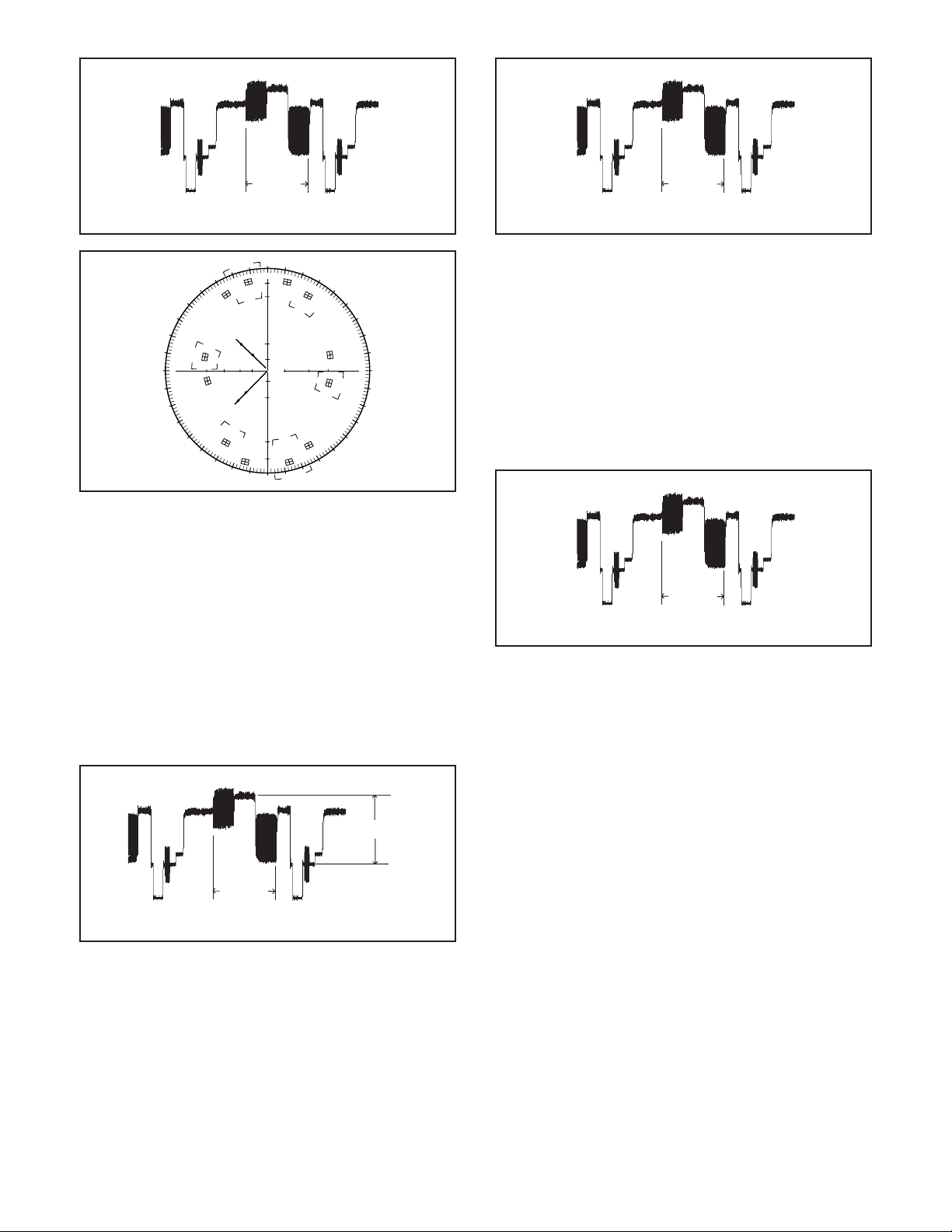

2-6. Iris Level Adjustment

Adjustment location: VR244 (CA-1)

Measuring location: VIDEO OUT

Measuring equipment: Oscilloscope, color bar chart

Subject: Gray scale chart

Adjusting method:

1. Display the color bar chart at designated picture angle.

2. Click the “NEXT” to be “Agc Off(AutoIrisLens Adj)” in the

adjustment window.

3. Turn the VR244 to the right so that the white level is maximum.

4. Turn the VR244 to the left so that the output level is 550 ±

20 mVp-p.

550 ± 20 mVp-p

30 µsec

VIDEO OUT

2-7. AGC Level ADJUSTMENT

Adjustment location: Computer screen

Measuring location: VIDEO OUT

Measuring equipment: Oscilloscope, color bar chart

Subject: Gray scale chart

Adjusting method:

1. Display the color bar chart at designated picture angle.

2. Click the “NEXT” to be “Adj.Agc” in the adjustment window.

VIDEO OUT

After finishing AGC level adjustment, start Hue and

chroma adjustment automatically.

2-8. Hue and Chroma Adjustment

Adjustment location: Computer screen

Measuring location: VIDEO OUT

Measuring equipment: Oscilloscope, vectorscope,

color bar chart

Subject: Color bar chart (Display the color bar chart at desig-

nated picture angle.)

1. Adjust “Adj.Chroma” in the adjustment window.

30 µsec

VIDEO OUT

2-9. CCD White Point Defect Detect Adjustment

Measuring location: VIDEO OUT

Measuring equipment: Monitor display

Adjustment method:

1. After finishing Hue and Chroma adjustment, shield light with

a lens cap to provide dark condition.

2. Click the “NEXT” button to be CCD White Point Defect De-

tect Adjustment.

3. After completing this adjustment, it comfirms that white point

can not be seen on the monitor display.

4. “OK” will display in the “STATUS”.

5. Click the “CLOSE” in the adjustment window, and complete

the adjustment window.

2-10. 28 MHz VCO Voltage ADJUSTMENT

Adjustment location: CT232 (CA-2)

Measuring location: TP232 (CA-2)

Measuring equipment: Digital voltmeter

Subject: No designation

Adjusting method:

1. Adjust with CT232 to 6.0 ± 0.2 V.

– 4 –

Page 5

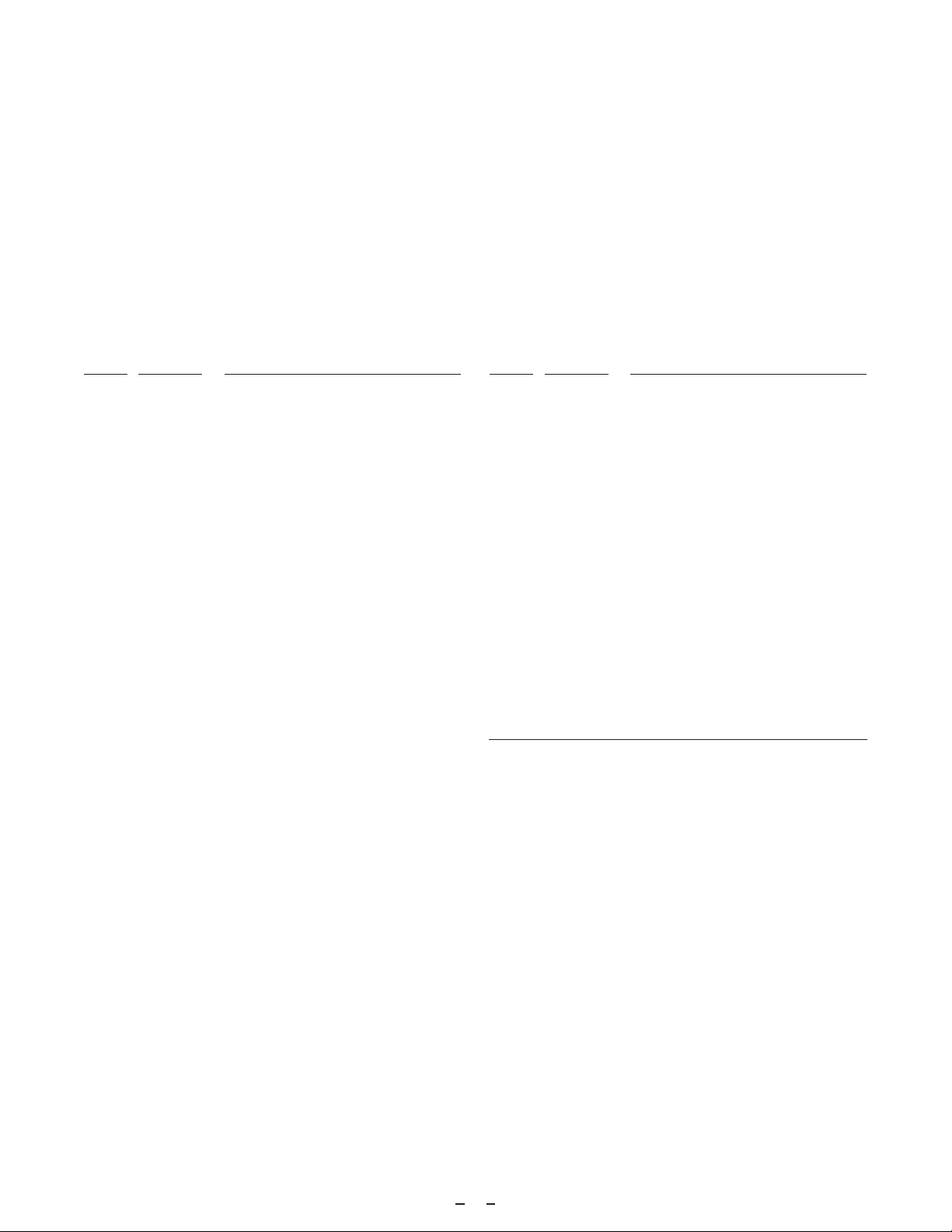

3. PARTS LIST

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

ACCESSORIES & PACKING MATERIALS

9102 613 200 9003 INSTRUCTION MANUAL, English, French

9103 613 201 6414 INSTRUCTION MANUAL,German, Chinese

9201 411 073 6705 SCR TPG PAN 4X35

7001 613 200 8983 CARTON CASE INNER

7002 613 182 2375 CUSHION

7010 613 139 4896 P.E COVER

CABINET & CHASSIS PARTS

5005 636 044 4706 CABINET

5010 636 044 4980 DEC WINDOW

5015 636 052 2138 TERMINAL BASE

5016 636 029 7876 TERMINAL

5017 636 045 0059 EARTH

6005 613 179 1848 COVER FRONT

6006 613 179 1855 COVER BACK

6007 613 180 9376 HOOD LENS

6010 613 179 1862 OPTICAL BASE

6011 613 163 5258 SPACER

6012 613 194 2813 HOLDER CCD

6013 613 194 1199 SPACER INSULATOR

6014 613 179 6027 HOLDER CCD

6015 613 180 9383 HOOD IRIS

6020 636 051 6236 ARM

6021 636 044 9213 ARMREST

6022 636 044 8278 SPRING PLATE

6023 613 179 3958 PIPE

6027 613 183 0349 EARTH

6028 613 201 3048 DEC PLATE

6030 636 045 5641 SPRING PLATE

6035 636 051 6243 LID

6050 636 070 7788 SHIELD TAPE EMC-SX591

8000 645 045 7654 ASSY,LENS

8001 645 002 7079 OPTICAL FILTER

8002 409 495 7400 IC ICX409AK-A ,IC101

CA1 613 200 9324 COMPL PWB,CA-1

CA2 613 200 9331 COMPL PWB,CA-2

CA3 613 200 9348 COMPL PWB,CA-3

NJ506 411 163 1504 SCR SET 2X5

NJ510 411 122 1309 SCR BIN 3X6

NJ515 412 046 4704 SPECIAL SCREW-3.0X8.0

NJ600 411 129 5102 SCR PAN+SW+W 2X5

NJ615 411 158 9409 SCR PAN PCS 2.6X6

NJ620 411 002 5908 SCR PAN 2.6X4

NJ625 411 063 1307 SCR SET HEX-SCT 2.6X4

NJ630 411 001 9006 SCR BIN 3X8

NJ635 412 057 3802 SPECIAL WASHER 43X0.2

NJ640 411 030 7202 SCR BIN 2X6

6007

5010

6005

NJ506

5005

6006

6010

6014

8001

NJ630

NJ600

NJ506

NJ635

8002

6011

6023

6012

CA3

NJ615

6050

6013

NJ600

NJ600

6030

6035

NJ635

CA1

CA2

6020

6023

NJ620

NJ600

NJ615

6027

NJ630

NJ640

5015

6021

NJ615

6028

6030

5016

NJ620

NJ515

NJ510

5016

5016

6022

5017

NJ515

NJ620

6015

8000

NJ625

CH-L5AR2/XE(MS)

5

Page 6

ELECTRICAL PARTS

Note:

1. Materials of Capacitors and Resistors are abbreviated as follows ;

Resistors Capacitors

MT-FILM Metallized Film Resistor MT-POLYEST Metallized Polyester Capacitor

MT-GLAZE Metallized Glaze Resistor MT-COMPO Metallized Composite Capacitor

OXIDE-MT Oxide Metallized Film Resistor TA-SOLID Tantalum Solid Capacitor

AL-SOLID Aluminum Solid Capacitor

NP-ELECT Non-Polarized Electrolytic Capacitor

OS-SOLID Aluminum Solid Capacitors with Organic

2. Tolerance of Capacitor (10pF over) and Resistor are noted with follow symboles.

DL-ELECT Double Layered Electrolytic Capacitor

F ............1% G ............2% J ............5% K ............10%

M ..........20% N ..........30% Z ..........+80% ~ -20%

3. Capacitors

µ

FP : pF

U :

4. Inductors

µ

H MH : mH

UH :

5. N.S.P. : Not available as service parts.

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

COMPL PWB,CA-1

613 200 9324

(SEMICONDUCTORS)

Q1011 405 045 8200 TR 2SK443-6-TB

Q1012 405 079 6302 TR 2SC4399-5

(INTEGRATED CIRCUITS)

IC102 409 446 8708 IC CXD3400N

IC103 409 525 5901 IC AD9848AKST

IC104 409 427 7805 IC TC74ACT32FT

(DIODES)

D1001 407 113 5609 DIODE DSH015

D1011 407 113 5609 DIODE DSH015

(INDUCTORS)

L1011 645 043 5881 INDUCTOR,10U J

L1101 645 043 5881 INDUCTOR,10U J

L1102 645 043 5881 INDUCTOR,10U J

L1103 645 043 5881 INDUCTOR,10U J

L1201 645 018 9326 INDUCTOR,1000 OHM

(CAPACITORS)

C1001 403 346 2309 CERAMIC 0.1U K 10V

C1002 403 285 6406 TA-SOLID 1U M 35V

C1003 403 381 4702 ELECT 22U M 16V

C1004 403 164 0204 CERAMIC 0.1U Z 25V

C1005 403 164 0204 CERAMIC 0.1U Z 25V

C1011 403 155 1807 CERAMIC 0.01U K 25V

C1012 403 311 7605 CERAMIC 2200P K 50V

C1013 403 155 1807 CERAMIC 0.01U K 25V

C1014 403 376 6902 TA-SOLID 3.3U M 25V

C1015 403 164 0204 CERAMIC 0.1U Z 25V

C1016 403 346 2309 CERAMIC 0.1U K 10V

C1101 403 285 6802 TA-SOLID 10U M 6.3V

C1102 403 346 2309 CERAMIC 0.1U K 10V

C1103 403 285 6802 TA-SOLID 10U M 6.3V

C1104 403 346 2309 CERAMIC 0.1U K 10V

C1105 403 346 2309 CERAMIC 0.1U K 10V

C1106 403 346 2309 CERAMIC 0.1U K 10V

C1107 403 346 2309 CERAMIC 0.1U K 10V

C1108 403 164 0204 CERAMIC 0.1U Z 25V

C1111 403 285 6802 TA-SOLID 10U M 6.3V

C1112 403 346 2309 CERAMIC 0.1U K 10V

C1113 403 346 2309 CERAMIC 0.1U K 10V

C1114 403 346 2309 CERAMIC 0.1U K 10V

C1115 403 346 2309 CERAMIC 0.1U K 10V

C1116 403 346 2309 CERAMIC 0.1U K 10V

C1117 403 346 2309 CERAMIC 0.1U K 10V

C1118 403 283 6309 CERAMIC 1U Z 10V

C1119 403 283 6309 CERAMIC 1U Z 10V

C1120 403 346 2309 CERAMIC 0.1U K 10V

(RESISTORS)

R1001 401 224 8900 MT-GLAZE 100K JA 1/16W

R1002 401 225 0903 MT-GLAZE 82K JA 1/16W

R1011 401 225 1504 MT-GLAZE 3.9K JA 1/16W

R1012 401 224 9600 MT-GLAZE 2.7K JA 1/16W

R1013 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R1014 401 224 8900 MT-GLAZE 100K JA 1/16W

R1015 401 225 8107 MT-GLAZE 10 JA 1/16W

R1016 401 225 8107 MT-GLAZE 10 JA 1/16W

R1017 401 224 8801 MT-GLAZE 100 JA 1/16W

R1031 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1032 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1033 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1034 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1035 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1101 401 225 8107 MT-GLAZE 10 JA 1/16W

R1102 401 224 8801 MT-GLAZE 100 JA 1/16W

R1103 401 224 8801 MT-GLAZE 100 JA 1/16W

R1104 401 224 8801 MT-GLAZE 100 JA 1/16W

R1105 401 224 8801 MT-GLAZE 100 JA 1/16W

R1106 401 224 8801 MT-GLAZE 100 JA 1/16W

R1107 401 224 8801 MT-GLAZE 100 JA 1/16W

R1108 401 224 8801 MT-GLAZE 100 JA 1/16W

R1109 401 224 8801 MT-GLAZE 100 JA 1/16W

R1110 401 224 8801 MT-GLAZE 100 JA 1/16W

R1111 401 224 8801 MT-GLAZE 100 JA 1/16W

CN101 645 060 3129 SOCKET,FFC 30P (N.S.P)

CN102 645 060 3112 SOCKET,FFC 24P (N.S.P)

CN121 645 023 0578 PLUG,4P (N.S.P)

COMPL PWB,CA-2

613 200 9331

Q2121 405 014 4509 TR 2SC2412K-R

Q2152 405 137 2000 TR 2SA1576A-R

Q2154 405 092 4101 TR 2SC4081-R

Q2161 405 092 4101 TR 2SC4081-R

Q2165 405 137 2000 TR 2SA1576A-R

Q2227 405 137 2000 TR 2SA1576A-R

Q2231 405 137 2000 TR 2SA1576A-R

Q2232 405 092 4101 TR 2SC4081-R

Q2233 405 137 2000 TR 2SA1576A-R

Q2234 405 092 4101 TR 2SC4081-R

Q2236 405 092 4101 TR 2SC4081-R

Q2237 405 092 4101 TR 2SC4081-R

Q2401 405 129 7808 TR UMG2N

Q2501 405 131 4505 TR 2SD1767Q

Q2511 405 133 8907 TR DTC114EUA

Q2512 405 133 8907 TR DTC114EUA

Q2521 405 169 1101 TR 2SK3617

Q2541 405 128 9605 TR 2SC2411K-Q

OR 405 035 5905 TR 2SC2411K-R

Q2561 405 141 0603 TR 2SA1037AK-R

IC201 410 388 5106 IC SCC0020

IC213 409 246 9707 IC LA6358NM

Semiconductive Electrolytic Capacitor

(CONNECTORS)

(SEMICONDUCTORS)

(INTEGRATED CIRCUITS)

6

Page 7

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

IC227 409 475 2005 IC BA7664FV

IC235 409 246 9707 IC LA6358NM

IC238 409 320 9104 IC TC7SU04FU

IC239 409 323 9002 IC TC7S04FU

IC241 410 494 0606 IC MB90F654APFV-G

IC242 409 541 4803 IC BD4829G

IC243 409 479 2803 IC BR24C04F-W

IC251 409 506 8907 IC FA7700V

IC253 409 528 1405 IC TLV431ASNT1

IC254 409 528 1405 IC TLV431ASNT1

IC255 409 531 8507 IC MC78L12ABD

IC256 409 521 3703 IC BA00BC0WF

(DIODES)

D2223 407 206 5400 ZENER DIODE UDZS8.2B

D2224 407 206 5400 ZENER DIODE UDZS8.2B

D2304 407 151 0406 VARACTOR DI HVU200A

D2401 407 113 5609 DIODE DSH015

D2501 407 103 0409 DIODE DBB08C

D2503 407 218 7409 ZENER DIODE UDZS15B

D2511 407 208 9703 ZENER DIODE UDZS5.6B

D2512 407 173 1108 PHOTO COUPLE TLP181-GB

D2521 407 231 0005 DIODE 1SR159-200

D2531 407 231 0005 DIODE 1SR159-200

D2533 407 207 7700 ZENER DIODE PTZ3.9B

D2541 407 226 3905 DIODE RSD376

OR 407 199 4909 DIODE 1SS376

D2551 407 167 3101 DIODE D1FS6

D2561 407 226 3905 DIODE RSD376

OR 407 199 4909 DIODE 1SS376

D2562 407 218 7706 ZENER DIODE UDZS20B-TE17

(OSCILLATORS)

X2001 645 036 9872 OSC,CRYSTAL 17.73447MHZ

X2301 645 007 6947 OSC,CRYSTAL 28.375KHZ

X2401 645 046 1415 OSC,CERAMIC 4.00MHZ

(VARIABLE RESISTORS)

VR244 645 000 0232 VR,SEMI,10K S

OR 645 017 2922 VR,SEMI,10K S

(TRIMMER)

CT232 645 051 7655 TRIMMER,30PF

(INDUCTORS)

L2001 645 043 5881 INDUCTOR,10U J

L2002 645 043 5881 INDUCTOR,10U J

L2003 645 043 5881 INDUCTOR,10U J

L2011 645 018 9326 INDUCTOR,1000 OHM

L2012 645 018 9326 INDUCTOR,1000 OHM

L2013 645 018 9326 INDUCTOR,1000 OHM

L2121 645 043 5881 INDUCTOR,10U J

L2221 645 043 5881 INDUCTOR,10U J

L2236 645 043 7380 INDUCTOR,33U J

L2241 645 055 3134 INDUCTOR,68U J

L2301 645 043 5881 INDUCTOR,10U J

L2302 645 043 5898 INDUCTOR,47U J

L2401 645 043 5881 INDUCTOR,10U J

L2531 645 052 4264 INDUCTOR,100U N

L2541 645 050 7489 INDUCTOR,100U K

L2551 645 052 4264 INDUCTOR,100U N

L2561 645 050 7489 INDUCTOR,100U K

(TRANSFORMER)

T2521 645 053 8223 TRANS,POWER,PULSE

(CAPACITORS)

C2001 403 285 6802 TA-SOLID 10U M 6.3V

C2002 403 346 2309 CERAMIC 0.1U K 10V

C2003 403 346 2309 CERAMIC 0.1U K 10V

C2004 403 346 2309 CERAMIC 0.1U K 10V

C2005 403 346 2309 CERAMIC 0.1U K 10V

C2006 403 346 2309 CERAMIC 0.1U K 10V

C2007 403 285 6802 TA-SOLID 10U M 6.3V

C2008 403 346 2309 CERAMIC 0.1U K 10V

C2009 403 285 6802 TA-SOLID 10U M 6.3V

C2010 403 346 2309 CERAMIC 0.1U K 10V

C2011 403 346 2309 CERAMIC 0.1U K 10V

C2012 403 346 2309 CERAMIC 0.1U K 10V

C2013 403 285 6802 TA-SOLID 10U M 6.3V

C2014 403 346 2309 CERAMIC 0.1U K 10V

C2015 403 346 2309 CERAMIC 0.1U K 10V

C2016 403 346 2309 CERAMIC 0.1U K 10V

C2120 403 382 1908 ELECT 47U M 16V

C2121 403 164 0204 CERAMIC 0.1U Z 25V

C2122 403 381 4702 ELECT 22U M 16V

C2123 403 164 0204 CERAMIC 0.1U Z 25V

C2124 403 164 0204 CERAMIC 0.1U Z 25V

C2126 403 383 7602 NP-ELECT 0.47U M 50V

C2133 403 346 2309 CERAMIC 0.1U K 10V

C2134 403 285 6802 TA-SOLID 10U M 6.3V

C2161 403 285 3504 TA-SOLID 3.3U M 6.3V

C2162 403 285 7809 TA-SOLID 0.47U M 35V

C2224 403 285 7700 TA-SOLID 10U M 16V

C2225 403 382 5807 ELECT 100U M 10V

C2227 403 382 5807 ELECT 100U M 10V

C2231 403 346 2309 CERAMIC 0.1U K 10V

C2245 403 311 7506 CERAMIC 22P J 50V

C2246 403 317 2307 CERAMIC 20P J 50V

C2247 403 311 3409 CERAMIC 0.01U K 16V

C2253 403 311 7506 CERAMIC 22P J 50V

C2254 403 311 7506 CERAMIC 22P J 50V

C2255 403 305 0001 TA-SOLID 10U M 10V

C2256 403 384 8905 ELECT 220U M 25V

C2257 403 382 5807 ELECT 100U M 10V

C2258 403 382 1809 ELECT 47U M 6.3V

C2259 403 285 4006 TA-SOLID 4.7U M 10V

C2263 403 285 5003 TA-SOLID 1U M 25V

C2268 403 346 2309 CERAMIC 0.1U K 10V

C2283 403 311 3409 CERAMIC 0.01U K 16V

C2308 403 311 3409 CERAMIC 0.01U K 16V

C2309 403 311 3409 CERAMIC 0.01U K 16V

C2310 403 346 2309 CERAMIC 0.1U K 10V

C2311 403 285 5003 TA-SOLID 1U M 25V

C2313 403 384 5201 NP-ELECT 4.7U M 16V

C2315 403 346 2309 CERAMIC 0.1U K 10V

C2316 403 346 2309 CERAMIC 0.1U K 10V

C2317 403 285 3603 TA-SOLID 4.7U M 6.3V

C2327 403 285 3603 TA-SOLID 4.7U M 6.3V

C2331 403 346 2309 CERAMIC 0.1U K 10V

C2332 403 311 4505 CERAMIC 1000P K 50V

C2333 403 311 4505 CERAMIC 1000P K 50V

C2402 403 285 6802 TA-SOLID 10U M 6.3V

C2403 403 346 2309 CERAMIC 0.1U K 10V

C2404 403 346 2309 CERAMIC 0.1U K 10V

C2405 403 346 2309 CERAMIC 0.1U K 10V

C2406 403 285 6802 TA-SOLID 10U M 6.3V

C2500 403 379 7104 CERAMIC 1000P K 630V

C2501 403 377 2804 ELECT 470U M 50V

C2504 403 070 0909 CERAMIC 0.1U K 50V

C2505 403 381 4603 ELECT 22U M 35V

C2506 403 298 9609 CERAMIC 0.1U K 16V

C2509 403 379 7104 CERAMIC 1000P K 630V

C2510 403 379 7104 CERAMIC 1000P K 630V

C2511 403 372 4506 CERAMIC 2.2U K 25V

C2512 403 189 0807 CERAMIC 0.1U K 25V

C2514 403 325 6304 CERAMIC 0.22U K 10V

C2521 403 376 9309 CERAMIC 0.047U K 250V

C2522 403 379 2703 CERAMIC 470P J 200V

C2525 403 357 3302 CERAMIC 0.01U K 630V

C2532 403 333 3609 POS-SOLID 33U M 10V

C2534 403 333 3609 POS-SOLID 33U M 10V

C2535 403 189 0807 CERAMIC 0.1U K 25V

C2536 403 298 9609 CERAMIC 0.1U K 16V

C2542 403 372 4506 CERAMIC 2.2U K 25V

C2543 403 372 4506 CERAMIC 2.2U K 25V

C2544 403 298 9609 CERAMIC 0.1U K 16V

C2545 403 189 0807 CERAMIC 0.1U K 25V

C2546 403 372 4506 CERAMIC 2.2U K 25V

C2547 403 189 0807 CERAMIC 0.1U K 25V

C2552 403 333 3609 POS-SOLID 33U M 10V

C2553 403 333 3609 POS-SOLID 33U M 10V

C2554 403 298 9609 CERAMIC 0.1U K 16V

C2555 403 333 3609 POS-SOLID 33U M 10V

C2562 403 372 4506 CERAMIC 2.2U K 25V

C2563 403 372 4506 CERAMIC 2.2U K 25V

C2564 403 372 4506 CERAMIC 2.2U K 25V

C2565 403 298 9609 CERAMIC 0.1U K 16V

(RESISTORS)

R2001 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2002 401 224 8801 MT-GLAZE 100 JA 1/16W

R2011 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2012 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

7

Page 8

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

R2013 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2014 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2015 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2016 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2017 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2018 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2019 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2121 401 038 6307 MT-GLAZE 470 JA 1/10W

R2122 401 038 6307 MT-GLAZE 470 JA 1/10W

R2123 401 038 6307 MT-GLAZE 470 JA 1/10W

R2124 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R2125 401 225 0507 MT-GLAZE 33K JA 1/16W

R2126 401 225 0705 MT-GLAZE 56K JA 1/16W

R2131 401 225 0606 MT-GLAZE 5.6K JA 1/16W

R2132 401 225 0101 MT-GLAZE 27K JA 1/16W

R2136 401 225 8107 MT-GLAZE 10 JA 1/16W

R2150 401 224 8900 MT-GLAZE 100K JA 1/16W

R2151 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2153 401 224 9303 MT-GLAZE 1K JA 1/16W

R2155 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2156 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2161 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2162 401 224 9303 MT-GLAZE 1K JA 1/16W

R2164 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2165 401 224 9303 MT-GLAZE 1K JA 1/16W

R2168 401 224 8900 MT-GLAZE 100K JA 1/16W

R2170 401 224 8900 MT-GLAZE 100K JA 1/16W

R2224 401 261 9601 MT-FILM 68 DD 1/16W

R2226 401 261 9601 MT-FILM 68 DD 1/16W

R2227 401 225 1603 MT-GLAZE 390 JA 1/16W

R2228 401 225 1603 MT-GLAZE 390 JA 1/16W

R2232 401 224 9303 MT-GLAZE 1K JA 1/16W

R2233 401 224 9303 MT-GLAZE 1K JA 1/16W

R2234 401 224 9907 MT-GLAZE 22K JA 1/16W

R2235 401 225 0507 MT-GLAZE 33K JA 1/16W

R2237 401 224 9303 MT-GLAZE 1K JA 1/16W

R2239 401 224 9303 MT-GLAZE 1K JA 1/16W

R2240 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R2242 401 225 3805 MT-GLAZE 1.5K JA 1/16W

R2243 401 225 1405 MT-GLAZE 47K JA 1/16W

R2244 401 225 1405 MT-GLAZE 47K JA 1/16W

R2246 401 224 9303 MT-GLAZE 1K JA 1/16W

R2248 401 224 9105 MT-GLAZE 150 JA 1/16W

R2249 401 224 9105 MT-GLAZE 150 JA 1/16W

R2250 401 225 0507 MT-GLAZE 33K JA 1/16W

R2251 401 224 9907 MT-GLAZE 22K JA 1/16W

R2252 401 224 9303 MT-GLAZE 1K JA 1/16W

R2253 401 225 2006 MT-GLAZE 680 JA 1/16W

R2256 401 225 3805 MT-GLAZE 1.5K JA 1/16W

R2284 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R2286 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2311 401 224 9006 MT-GLAZE 10K JA 1/16W

R2312 401 224 8900 MT-GLAZE 100K JA 1/16W

R2313 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2314 401 229 3900 MT-GLAZE 180 JA 1/16W

R2315 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2316 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2317 401 224 9808 MT-GLAZE 220K JA 1/16W

R2336 401 234 4800 MT-GLAZE 3.3 JA 1/16W

R2339 401 224 9006 MT-GLAZE 10K JA 1/16W

R2340 401 224 8900 MT-GLAZE 100K JA 1/16W

R2341 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R2401 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2402 401 224 9006 MT-GLAZE 10K JA 1/16W

R2403 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R2404 401 224 9006 MT-GLAZE 10K JA 1/16W

R2405 401 224 9006 MT-GLAZE 10K JA 1/16W

R2406 401 224 9006 MT-GLAZE 10K JA 1/16W

R2407 401 224 9006 MT-GLAZE 10K JA 1/16W

R2412 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2414 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2416 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2417 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2418 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2423 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2424 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2426 401 037 5004 MT-GLAZE 0.000 ZA 1/10W

R2431 401 224 9006 MT-GLAZE 10K JA 1/16W

R2432 401 224 9006 MT-GLAZE 10K JA 1/16W

R2433 401 224 9006 MT-GLAZE 10K JA 1/16W

R2435 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2436 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2437 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2438 401 224 9006 MT-GLAZE 10K JA 1/16W

R2439 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2443 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2445 401 224 8900 MT-GLAZE 100K JA 1/16W

R2446 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2501 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R2502 401 240 9707 MT-GLAZE 820K JA 1/16W

R2511 401 224 9907 MT-GLAZE 22K JA 1/16W

R2512 401 261 8109 MT-FILM 33K DD 1/16W

R2513 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R2514 401 224 9501 MT-GLAZE 2.2K JA 1/16W

R2516 401 224 8801 MT-GLAZE 100 JA 1/16W

R2521 401 302 7207 MT-FILM 330 JE 1W

R2522 401 225 0309 MT-GLAZE 33 JA 1/16W

R2523 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R2531 401 225 1801 MT-GLAZE 47 JA 1/16W

R2533 401 226 5501 MT-GLAZE 120 JA 1/16W

R2534 401 261 5306 MT-FILM 470 DU 1/16W

R2535 401 261 4309 MT-FILM 1.2K DU 1/16W

R2536 401 225 8107 MT-GLAZE 10 JA 1/16W

R2537 401 261 5108 MT-FILM 1.0K DU 1/16W

R2541 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R2542 401 226 2401 MT-GLAZE 560 JA 1/16W

R2543 401 261 5108 MT-FILM 1.0K DU 1/16W

R2544 401 261 2602 MT-FILM 10K DU 1/16W

R2545 401 261 5108 MT-FILM 1.0K DU 1/16W

R2551 401 261 5108 MT-FILM 1.0K DU 1/16W

R2552 401 261 4101 MT-FILM 2.7K DU 1/16W

R2553 401 261 5900 MT-FILM 330 DU 1/16W

R2561 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R2562 401 224 9303 MT-GLAZE 1K JA 1/16W

R2752 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

(FILTER)

F2301 645 006 3404 FILTER,EMI 470PF

(FUSE)

F2501 423 030 0800 FUSE 125V 2A

(CONNECTORS)

CN201 645 060 3129 SOCKET,FFC 30P (N.S.P)

CN202 645 060 3112 SOCKET,FFC 24P (N.S.P)

CN211 645 003 2387 PLUG,2P (N.S.P)

CN241 645 002 3057 PLUG,7P (N.S.P)

CN251 645 026 6911 PLUG,3P (N.S.P)

COMPL PWB,CA-3

613 200 9348

(DIODES)

D3001 407 206 5400 ZENER DIODE UDZS8.2B

D3002 407 206 5400 ZENER DIODE UDZS8.2B

(VARIABLE RESISTORS)

VR301 645 005 5805 VR,SEMI,10K S

VR302 645 005 5805 VR,SEMI,10K S

VR303 645 005 5805 VR,SEMI,10K S

(SWITCH)

S3001 645 004 1532 SWITCH,DIP 1P-1TX3, MODE

(CONNECTORS)

CN302 645 002 3071 PLUG,9P (N.S.P)

FLEXIBLE FLAT CABLES

W0001 645 060 2177 FLEXIBLE FLAT CABLE,CN101-CN201

W0002 645 063 4291 FLEXIBLE FLAT CABLE,CN102-CN202

8

Page 9

CIRCUIT DIAGRAMS & PRINTED WIRING BOARDS

TABLE OF CONTENTS

OVERALL WIRING, BLOCK DIAGRAM & CIRCUIT DIAGRAMS

OVERALL WIRING C3

OVERALL CIRCUIT BLOCK DIAGRAM C4

IC101 & IC102 BLOCK DIAGRAMS

CA-1 CIRCUIT C5

CA-1 CIRCUIT WAVEFORMS C6

IC103 & IC104 BLOCK DIAGRAMS

CA-2 CIRCUIT WAVEFORMS

CA-2 CIRCUIT C7

CA-3 CIRCUIT C12

PRINTED WIRING BOARDS (P.W.B.)

CA-1 BOARD (SIDE A & B) C12

CA-3 BOARD (SIDE A & B)

CA-2 BOARD (SIDE A) C13

CA-2 BOARD (SIDE B) C14

C1

Page 10

NOTES:

1. All resistance values in "OHMS" unless otherwise noted.

(K=1,000 ; M=1,000,000)

2. All capacitance values in "

p=pico farad ;

3. All inductance values in "

µ ,u or U=micro farad

µF" unless otherwise noted.

µH" unless otherwise noted.

µ ,u or U=micro henry ; m=milli henry

PRODUCT SAFETY NOTICE

THE COMPONENTS DESIGNATED BY A SYMBOL ( ) IN THIS

SCHEMATIC DIAGRAM DESIGNATES COMPONENTS WHOSE

VALUE ARE OF SPECIAL SIGNIFICANCE TO PRODUCT SAFETY.

SHOULD ANY COMPONENT DESIGNATED BY A SYMBOL NEED TO

BE REPLACED, USE ONLY THE PART DESIGNATED IN THE PARTS

LIST.

DO NOT DEVIATE FROM THE RESISTANCE, WATTAGE AND VOLTAGE RATINGS SHOWN.

EXPLANATORY NOTES (EXAMPLES)

Resistor 10K:1/16J means 10kilo ohm

1M:1/10K means 1mega ohm

Capacitor 0.047:F means 0.047micro farad, Ftype.

Electrolytic capacitor

10:16 means 10micro farad, 16volt max.

Inductor 330:J means 330micro henry ±5%

470:K means 470micro henry

No description J or K means

±5%, 1/16watt max.

±10%, 1/10watt max.

±10%

±5%

C2

PAL-C-EX

Page 11

OVERALL WIRING, BLOCK DIAGRAM & CIRCUIT DIAGRAMS

K

J

CA-1

OVERALL WIRING

CA-2

CA-3

K

J

CN101 CN201

CCD & IRIS

GND

GND

5V

5V

I

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

H

CCD8

CCD9

GND

GND

GND

AGC_CS

AGC_CLK

G

AGC_DATA

VD

ADCK

CLP

3.3V

3.3V

3.3V

F

CN121

1

BLAKE+

2

BLAKE-

3

DRIVE-

4

DRIVE+

E

TO LENS

3.3V

GND

GND

GND

CN102

GND

GND

15V

15V

15V

V1

V2

D

V3

V4

VSUB

GND

GND

GND

GND

C

XSG1

XSG2

-7V

-7V

-7V

IRIS BLAKEIRIS DRIVE+

IRIS BLAKE+

B

GND

GND

1

FFC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

FFC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 7

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

GND

5V

5V

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

GND

GND

GND

AGC_CS

AGC_CLK

AGC_DATA

VD

ADCK

CLP

3.3V

3.3V

3.3V

3.3V

GND

GND

GND

CN202

GND

GND

15V

15V

15V

V1

V2

V3

V4

VSUB

GND

GND

GND

GND

XSG1

XSG2

-7V

-7V

-7V

IRIS BLAKEIRIS DRIVE+

IRIS BLAKE+

GND

GND

MAIN PROCESS,

MICON & POWER

AWB/MWB

BLC OFF

BLC LEVEL

MANUAL R

MANUAL B

3.3V

GND

MONITOR

AP

CN211

VIDEO OUT

GND

CN251

AC24V/DC+

FG

AC24V/DC-

CN241

3.3V

GND

RS232IN

MD0

RS232OUT

RESET

MD2

SW & VR

CN302W2003

1

WIRE

2

3

4

5

6

7

8

99

1

2

1

2

3

1

2

3

4

5

6

1

2

3

4

5

6

7

8

AWB/MWB

BLC OFF

BLC LEVEL

MANUAL R

MANUAL B

3.3V

GND

MONITOR

AP

I

H

G

F

W1-04715/L5AR2-XE

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

C3

A

Page 12

K

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

(NOTE)

(NOTE : PHOTO SENSOR)

V

OUT

V

SS

V

GG

GND

V

1

V

2

V

3

V

4

V

DD

GND

SUB

V

L

RG

LH

1

H

1

H

2

H REGISTER

Cy

Ye

Cy Ye

Mg

G

Mg G

Cy

Ye

Cy Ye

GMgGMg

Cy Ye Cy Ye

MgGMgG

V REGISTER

V REGISTER

V REGISTER

V REGISTER

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10 GND

V2

V4

V1A

V

H

V1B

V3A

V

L

V3B

SHT

XV2

XV4

XSG1A

XSG1B

XV1

XSG3A

XSG3B

XV3

XSHT

V

DD

Input Buffer

K

OVERALL CIRCUIT BLOCK DIAGRAM

J

I

H

G

F

J

I

H

G

F

IC102 BLOCK DIAGRAM (CXD3400N)

IC101 BLOCK DIAGRAM (ICX409AK)

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

E

D

C

B

CXD3400N

A

C4

Page 13

CA-1 CIRCUIT

K

K

CN102

GND

GND

J

15V

15V

15V

V1

V2

V3

V4

VSUB

I

GND

GND

GND

GND

XSG1

XSG2

-7V

H

-7V

-7V

IRIS BLAKEIRIS DRIVE+

IRIS BLAKE+

GND

GND

TO CA-2

G

CN202

CN121

BLAKE+

BLAKEDRIVEDRIVE+

F

TO LENS

CN101

GND

GND

5V

E

D

C

B

5V

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

GND

GND

GND

AGC CS

AGC CLK

AGC DATA

VD

ADCK

CLP

3.3V

3.3V

3.3V

3.3V

GND

GND

GND

TO CA-2

CN201

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

L1201

A102S

V1

V2

V3

V4

VSUB

XSG1

XSG2

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

AGCCS

AGCCLK

AGCDATA

VD

ADCK

CLP

AGCCS

AGCDATA

AGCCLK

VD

CLP

C1120

0.1;B

10;J

L1101

C1101

10;6.3-T

CT-A

1608

1608

1;F

1;F

0.1;B

C1118

C1119

C1117

36 35 34 33 32 31 30 29 28 272625

SL

REFT

37

38

39

40

41

42

43

44

45

46

47

48

SDI

SCK

CLPOB

CLPDM

HBLK

PBLK

VD

HD

DVSS3

DVDD3

NC

NC

REFB

D0D1D2D3D4

1 2 3 4 5 6 7 8 9 10 11 12

100

100

100

100

R1102

R1103

R1104

R1105

CCD2

CCD1

CCD0

R1031

0

VSUB

V3

XSG2

V1

XSG1

V4

V2

C1001

C1116

C1115

C1114

0.1;B

0.1;B

1.5

BYP3

AVDD2

CCDIN

BYP2

AVSS2

CMLEVEL

IC103

AD9848A

CDS,AGC,A/D

DVSS2

DVDD2D6D5

100

100

100

0.1;B

C1102

R1106

R1107

R1108

CCD6

CCD5

CCD4

CCD3

3.3

1.5

3.0

0.0

0.1

3.2

3.0

0.1

0.1;B

C1113

0.1;B

0.1;B

BYP1

D7D8D9

100

R1109

CCD7

1

2

3

4

5

6

7

8

9

10

C1112

0.1;B

3.24

AVDD1

100

R1110

CCD8

100

R1111

IC102

CXD3400N

VDD

XSHT

XV3

XSG3B

XSG3A

XV1

XSG1B

XSG1A

XV4

XV2

V,SUB DRIVER

L1102

CT-A

C1111

10;6.3-T

AVSS1

24

AVDD0

CL1

23

AVSS0

22

DVDD1

21

RG

20

DVSS1

19

H4

18

H3

17

DVDD0

16

DVSS0

15

H2

14

H1

13

CCD9

10;J

C1107

0.1;B

C1103

10;6.3-T

SHT

V3B

VL

V3A

V1B

VH

V1A

V4

V2

GND

L1103

CT-A

20

19

18

17

16

15

14

13

12

11

10;J

C1104

0.1;B

C1105

0.1;B

C1002

1;35-T

CT-B2

C1106R1101

0.1;B10

1608

C1108

0.1;F

1608

C1005

0.1;F

D1001

DSH015

R1001

100K

C1003

22;16

CE-C

R1033

ICX409AK-A

ADCK

0

R1002

IC101

CCD

82K

R1034

0

0

R1032

1608

C1004

0.1;F

-0.2

-6.7

-0.2

-6.7

12345678

V3V2V1

NC

H2 V4

RG

H1

16 15 14 13 12 11 10 9

4.3

4.0

13.2

-7.0

1M

R1013

10

R1015

R1035

10

R1016

0

0.1;B

C1016

C1012

4.3

2.6

4.0

2.4

5.0

2SK443AJ6

NC

NC

GND

VOUT

VDD

GND

VSUB

VL

14.5 9.9

1608

C1013

0.01;B

2200P

8

3Y

3A

3B

4Y

4A

4B

VCC

GND

2Y

2B

2A

1Y

1B

1A

9

10

11

12

13

14

IC104

TC74ACT32FT

H DRIVER

Q1011

3.9K

R1011

C1014

3.3;25-T

7

6

5

4

3

2

1

CA-1

C1-04715/L5AR2-XE

CT-B2

D1011

DSH015

2.7K

R1012

100K100

R1014R1017

C1015

0.1;F

C1011

0.01;B

Q1012

2SC4399

1608

L1011

1608

J

10;J

I

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

C5

A

Page 14

K

TEST POINT

LOCATION

WAVEFORM

IC201-42

200mV/div

10µs/div

CA OUT

IC201-55

200mV/div

10µs/div

YA OUT

WF-CA2-L5AR2XE

TEST POINT

LOCATION

WAVEFORM

IC201-79

1V/div

50ns/div

ADCK

IC201-47

1V/div

5ms/div

VD

CDS

PxGA

VGA

ADC

CLAMP

CLAMP

VREF

HORIZONTAL

DRIVERS

PRECISION

TIMING

CORE

TM

INTERNAL

CLOCKS

10 or 12

REFT

REFB

DOUT

CCD0-9

CCDIN

CL1

RG

H1-H4

SYNC

GENERATOR

INTERNAL

REGISTERS

SL

SCK

SDATA

HD

VD

PBLK

CLPDM

CLPOB

4–6 dB

2 to 36 dB

AD9848

35

34

1-5

8-12

39

40

42

23

37

38

36

43

44

13

14

17

18

20

29

K

CA-1 CIRCUIT WAVEFORMS

J

I

H

G

TEST POINT

LOCATION

IC101-1

2V/div

20µs/div

V4

IC101-2

5V/div

20µs/div

V3

IC101-3

WAVEFORM

TEST POINT

LOCATION

IC101-15

2V/div

50ns/div

H1

IC101-16

2V/div

50ns/div

H2

IC103-29

WAVEFORM

IC103 BLOCK DIAGRAM (AD9848A) IC104 BLOCK DIAGRAM

(TC74ACT32FT)

J

I

H

G

F

5V/div

20µs/div

V2

0.5V/div

10µs/div

CCD IN

CA-2 CIRCUIT WAVEFORMS

E

IC101-4

5V/div

D

20µs/div

V1

IC103-43

2V/div

20µs/div

VD

C

B

A

IC101-13

2V/div

50ns/div

RG

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

IC103-44

2V/div

10ms/div

HD

WF-CA1-L5AR2XE

C6

F

E

D

C

B

A

Page 15

CA-2 CIRCUIT

K

D2531

+3.3V

1SR159-200

6

T2521

CEE156

C2510

1000P

UDZS5.6B

D2501

DBB08C

C2501

+~

1

C2500

1000P

24

**

22K

R2511

Q2512Q2511

DTC114EUKDTC114EUK

470;50

3

*

~-

R2501

3.3K

Q2501

2SD1767

C2506

820K

R2502

8765

CS VCC OUT GND

IC251

FA7700V

2.2

33K

0.1

R2512

C2512

(0.5%)

C2511

0.1

C2504

D2503

UDZS15B

C2505

22;35

0.1

FBIN-REFRT

4321

2.2K

R2514

0

3

R2513

4

*

D2512

TLP181(GB)

R2522

33

Q2521

2SK3617

SWITCHING

CONTROL

3301SR159-200

0.047

R2521D2521

C2521

470P

C2522

2

*

3

1

*

R2523

3.3K

0.22

C2514

100

R2516

F2501

2A DC60V/AC125V

CN251

1

AC24V/DC+

2

J

FG

AC24V/DC-

3

C2509

1000P

I

D2511

H

*

4

5

8

*

*

D2541

+15V

+6.5V

GND

-7V

7

*

9

*

3

*

10

*

1SS376

C2542

D2551 L2551

D1FS6 100U

C2552

C2562

D2561

1SS376

VIN2

1

*

2

*

VIN1

C2525

0.01

2.2

33;10-U

2.2

L2531

100U

47

R2531

1

C2532

33;10-U

L2541

100U

2.2

3.3K3.3K

C2543

R2541R2561

0.1

C2554

C2553

33;10-U

2.2

C2563

L2561

100U

*

C2534

33;10-U

2

*

REG.

3

*

IC253

TLV431

5

*

Q2541

2SC2411

560

R2542

C2544

0.1

3

*

REG.

IC254

4

TLV431

5

*

4321

VCC NC NCOUT

C GND GND CTL

8765

IC256

BA00BC0WF

R2551

1K

REG.

(0.5%)

470

R2534

D2512

C2535

0.1

4

R2544

(0.5%)(0.5%)

1.2K

R2535

R2533

120

1K

R2537

1K

R2543

10K

2.2

0.1

(0.5%)

C2546

C2545

1K

R2545

(0.5%) (0.5%)

2.7K

R2552

(0.5%)

C2555

33;10-U

330

R2553

(0.5%)

10 0.1

R2536 C2536

D2533

PTZ3.9B

(0.5%)

IC255

MC78L12AB

REG.

1234

GND NCGNDVOUT

VINGNDGNDNC

5678

2.2

C2564

D2562

UDZS20B

1K

R2562

Q2561

2SA1037K

3.3V

12V

15V

1K

R2233

R2237

1K

1K

R2232

2.0

Q2231

2SA1576A(R)

0.1

C2547

0.1

C2565

1.4

5V

-7V

3.3K

R2240

1.7

L2236

33;J

C2245

22P;CH

C2253

22P;CH

C2246

20P;CH 0.01;B

2.3

Q2233

2SA1576A(R)

22K33K

C2255

R2234R2235

10;10-T

CT-A

2.8

Q2232

2SC4081(R)

R2248

150

2.2

1K

C2254

22P;CH

L2241

68;J

R2239

5.0

Q2234

C2247

47K

R2243

2SC4081(R)

R2286 C2283

2.3

0 0.01;B

1.7

1.5K

R2242

1K

47K

R2244

R2246

33K

CT-A

C2259

R2250

4.7;10-T

R2249

Q2236

2SC4081(R)

CE-E

C2256

220;25

150

C2258

47;6.3

CE-C

2.0

2.0

Q2237

3.1

2SC4081(R)

C2263

1.9

1;25-T

CT-A

1.3

1M

22K

680 1K

1.5K

R2256

R2253 R2252

Vcc

MUTEA

OUT1

YIN

OUT2

GND

CIN

MUTEB

IC227

BA7664FV

YC-MIX,75DRIVER

R2284

C2257

100;10

CE-D

C2268

0.1

1.0

7

0.9

6

5

R2251

18

2

3

4

C2224

10;16-T

CT-B2

C2225

100;10

CE-D

2SA1576A(R)

L2221

10;J

5V

TP221

VIDEO OUT

R2224

68

(0.5%)

D2223

UDZS8.2B

D2224

390

390

R2227

R2228

Q2227

C2227

100;10

CE-D

UDZS8.2B

R2226

68

(0.5%)

1

2

CN211

VIDEO OUT

GND

VIDEO OUT

K

J

I

H

CN201

30

GND

29

GND

28

G

F

E

D

C

5V

5V

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

GND

GND

GND

AGC_CS

AGC_CLK

AGC_DATA

VD

ADCK

CLP

3.3V

3.3V

3.3V

3.3V

GND

GND

GND

TO CA-1

CN101

CN202

GND

GND

15V

15V

15V

V1

V2

V3

V4

VSUB

GND

GND

GND

GND

XSG1

XSG2

-7V

-7V

-7V

IRIS BLAKEIRIS DRIVE+

IRIS BLAKE+

GND

GND

TO CA-1

CN102

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

B

5V

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

AGCCS

AGCCLK

AGCDATA

3.3V

15V

V1

V2

V3

V4

VSUB

XSG1

XSG2

-7V

L2011

L2012

L2013

CA-2

C2-04715/L5AR2-XE

CCD9

CCD8

CCD7

CCD6

CCD5

CCD4

CCD3

CCD2

CCD1

CCD0

CT-A

C2012

0.1;B

C2013

10;6.3-T

75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

VCC

CCDI6

CCDI9

CCDI7

CCDI5

CCDI4

CCDI3

CCDI2

HRST

PCOHD

SCK

VRST

GND

CCDI1

CAMERA ASIC

GND

PCOVD

IC235

LA6358NM

1

2

3

GND

45

28MHZ VCO LPF

76

GND

C2014

77

GND

0.1;B

78

R2011

0

R2012

0

R2013

0

V1

R2014

0

V2

R2015

0

V3

R2016

0

V4

R2017

0

XSG1

R2018

0

XSG2

R2019

0

VSUB

L2001 R2001

10;J 0

3.3V

A102S

A102S

A102S

VCC1

79

ADCK

80

SHD

81

SHP

82

GND

83

CLP

84

CLPOB

C2015

85

PBLK

0.1;B

86

VCC1

87

V1

88

V2

89

V3

90

V4

XSG1

91

XSG2

92

93

VSUB

94

GND

95

H1

96

H2

97

RG

98

VCC1

99

GND

C2016

0.1;B

100

GND

CKI2 CCDI8

VCC

CKI1

CT-A

C2001

C2002

0.1;B

10;6.3-T

ZRST

TMC1

CCDI0

IC201

SCC0020

ALE

ZRD

ZWR

ZRD

ZWR

ALE

VCC

8

7

6

AMC

TEB

GND

TMC2

BUNRI

ZCS

SMC

DB2

DB1

DB0

DB2

DB0

DB1

CT-A

C2310

C2311

0.1;B

1;25-T

220K

R2317

C2313

GND

CPUCK

C2011

0.1;B

C2010

0.1;B

GND

GND

VCC

AGND

AVDD

YAOUT

DB4

DB3

DB4

DB3

L2301

10;J

NP-B

4.7/16

R2315

DB5

DB6

DB7

DB5

DB6

DB7

12V

R2314

180

4.7K

50

GND

49

CSYNC

48

TEST

47

VD

46

FLD

45

GND

44

GND

43

AVDD

42

CAOUT

41

AGND

40

GND

39

GND2

38

VCC2

37

PCOSC

36

EXTSCI

35

ADJSCI

34

SCI

33

SCO

32

GND2

31

CKSCO

30

CKSCI

29

VCC2

28

GND2

27

GND

26

GND

VCC

25242322212019181716151413121110987654321

C2003

0.1;B

4.7K

R2313

R2312R2316

100K4.7K

TP232

28MHZ PLL

R2339 R2340

10K 100K

C2332

1000P;B

VD

L2003

10;J

3.3V

CT-A

VD

FLD

C2008 C2009C2006

0.1;B 10;6.3-T0.1;B

CT-A

C2007

10;6.3-T

R2002

100

L2002

10;J

C2004

0.1;B

C2005

0.1;B

34

VCC

OUT

INH

GND

12

X2001

17.734475MHZ

F2301

L2302

470P

47;J

CT-A

C2317

4.7;6.3-T

R2311

10K

C2309 C2308

0.01;B 0.01;B

R2336

IC238

3.3

TC7SU04FU

1

28MHZ OSC

2

GND

R2341

C2333

1M

1000P;B

X2301

28.63636MHZ

D2304

HVU200A

3.3V

C2316

C2315

0.1;B

0.1;B

IC213

CT-A

C2327

C2331

0.1;B

VCC

4.7;6.3-T

VCC

1

453

2

GND

354

IC239

TC7S04FU

BUFFER

30P

28MHZ

CT232

LA6358NM

1

2

3

GND

45

IRIS DRIVE

R2121

R2122

R2123

VCC

Q2121

2SC2412(R)

470

470

470

Q2401

UMG2N

1

B

2

E

B

8

7

6

0

R2401

C

C

3.3V

C2121

C2124

0.47/50

10K

R2402

453

16081608

0.1;F

0.1;F

R2124

C2126

54

GNDVCCOUT

123

4.7K

R2403

C2403

0.1;B

DB1

DB0

L2401

10;J

L2121

10;J

CE-D

C2122

22;16

C2123

0.1;F

1608

1M

NP-B

IC242

BD4829G

RESET

D2401

DSH015

X2401

123

C2162

0.47;35-T

1K

R2162

2SC4081(R)

0.1

C2231

C2402

4MHz

X1

Q2161

C2161

CT-A

10;6.3-T

GND

12V

3.3;6.3-T

AP

0

R2426

0

V SW

R2424

0

R2435

SHUTTER2

AGC ON/OFF

R2153

1K

Q2152

2SA1576A

10K

R2433

SHUTTER1

ALE

ALE

10K

R2432

SHUTTER0

ZRD

ZRD

10K

R2431

R2151

0

R2423

MOTOR+

MOTOR-

C/BW LEVEL

IC241

MICON

VSS

ZWR

ZWR

IC243

BR24C04F-W

4.7K

100K

R2150

56K

R2126

RESERVE

VIDEO(D/A)

APERTURENOR/SHP

*

AI/EI

INT/LL(ES/FL)

1

2

3

4

R2125

33K

WB

ATW/MTW

RS232C IN

RS232C OUT

232O

232I

A0

A1

A2

GND

EEPROM

BLC MODE0

VCC

TEST

SCL

SDA

0

0

10K

R2439

R2438

R2436

R2437

0

EXT-C

EXT-BW

RESETIN

76

77

X2

78

79

80

81

82

83

84

85

DB2

86

DB3

87

DB4

88

DB5

89

DB6

90

DB7

91

92

93

94

95

96

97

98

99

100

R2132

27K

GAMMA CTL

LSI RESET

VSS

VSS

X IN

X OUT

VDD

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

PLLCTL1

PLLCTL2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Q2154

2SC4081

R2156

4.7K

4.7K

5.6K

R2155

R2131

BLC1

BLC MODE1

VSS

AGC DATA

AGCDATA

8

7

6

5

C2133

0.1;B

0

0

0

0

0

R2412

R2414

R2416

R2418

R2417

51525354555657585960616263646566676869707172737475

VARIOP

SIMOP2

SIMOP1

SIMOP0

NTSC/PAL

50

TEST

49

MD2

48

MD1

47

MD0

46

FLD

FLD

45

VD

VDO

44

43

42

41

BLCLEVEL

40

VSS

39

LLPHASE

38

IRIS REF IN

37

E2PROM

WBB

36

WBR

35

34

33

32

31

30

29

VSS

28

VDD

27

26

CLK

10K

R2405

MANU WB B

MANU WB R

IRIS VCA

IRIS REF OUT

AGC CLK

AGC CS

VCC

E2PROM DATA

AGCCS

AGCCLK

10K

R2404

C2404

0.1;B

R2406

10K

R2407

10K

R2443

0

REFI

R2446

0

10K

VR244

100K

R2445

CT-A

C2406

C2405

0.1;B

10;6.3-T

0

R2752

3.3V

232I

232O

WB

BLC1

REFI

WBR

WBB

3.3V

AP

CN241

1

2

3

RS232IN

4

5

RS232OUT

6

7

ADJUSTMENT

W2003

1

AWB/MWB

2

BLC OFF

3

BLC LEVEL

4

MANUAL R

5

MANUAL B

6

7

8

MONITOR

9

TO CA-3

3.3V

GND

MD0

RESET

MD2

3.3V

GND

AP

CN302

G

F

E

D

C

R2136

10

3.3V

CT-A

C2134

10;6.3-T

TP201

GND

B

4.7K

R2164

R2165

1K

4.7K

R2161

Q2165

2SA1576A

R2168

100K

100K

R2170

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

C7

A

Page 16

CA-2 CIRCUIT [UPPER-LEFT]

3

4

K

K

6

*

8

*

7

*

9

*

3

*

10

*

D2531

1SR159-200

C2532

33;10-U

D2541

1SS376

2.2

C2542

D2551 L2551

D1FS6 100U

C2552

33;10-U

2.2

C2562

D2561

1SS376

L2541

100U

L2561

100U

2.2

C2543

C2553

33;10-U

2.2

C2563

L2531

100U

3.3K3.3K

R2541R2561

0.1

C2554

C2534

33;10-U

560

R2542

R2551

1K

(0.5%)

REG.

IC254

TLV431

VCC NC NCOUT

C GND GND CTL

REG.

IC253

TLV431

C2544

3

*

4

5

*

47

R2531

D2512

1

*

2

*

3

*

C2535

0.1

4

5

*

Q2541

2SC2411

R2544

0.1

4321

8765

IC256

BA00BC0WF

REG.

10K

R2533

120

1K

R2543

(0.5%)

C2545

1K

R2545

2.7K

R2552

330

R2553

0.1

(0.5%) (0.5%)

(0.5%)

(0.5%)

470

R2534

1.2K

R2535

2.2

C2546

C2555

33;10-U

(0.5%)(0.5%)

10 0.1

R2536 C2536

1K

R2537

(0.5%)

IC255

MC78L12AB

REG.

1234

GND NCGNDVOUT

5678

2.2

C2564

D2562

1K

R2562

Q2561

2SA1037K

D2533

PTZ3.9B

VINGNDGNDNC

C2547

UDZS20B

C2565

3.3V

J

12V

15V

1K

L2236

33;J

C2253

22P;CH

C2254

L2241

68;J

R2233

C2255

10;10-T

22P;CH

CT-A

C2247

R2242

Q2236

2SC4081(R)

CE-E

C2256

220;25

C2258

47;6.3

CE-C

2.0

33K

R2250

1.9

22K

680 1K

R2251

R2253 R2252

MUTEA

18

2.0

2

YIN

3

GND

4

CIN

IC227

BA7664FV

YC-MIX,75DRIVER

3.1

1.3

Vcc

OUT1

OUT2

MUTEB

1.5K

R2256

Q2237

2SC4081(R)

C2263

1;25-T

CT-A

1.0

7

0.9

6

5

1M

R2284

C2257

100;10

CE-D

C2268

0.1

CT-A

22K33K

R2234R2235

2.8

2.2

47K

R2243

2.3

1.7

1.5K

47K

R2244

C2259

4.7;10-T

Q2232

2SC4081(R)

R2248

150

1K

R2239

5.0

Q2234

2SC4081(R)

R2286 C2283

0 0.01;B

1K

R2246

R2249

150

R2237

1K

1K

R2232

Q2231

0.1

0.1

2SA1576A(R)

5V

-7V

2.0

1.4

C2245

22P;CH

C2246

3.3K

R2240

20P;CH 0.01;B

2.3

1.7

Q2233

2SA1576A(R)

I

H

G

F

+3.3V

T2521

CEE156

J

CN251

AC24V/DC+

FG

AC24V/DC-

I

F2501

2A DC60V/AC125V

1

2

3

C2509

1000P

C2510

1000P

C2500

1000P

H

D2511

R2511

G

UDZS5.6B

F

22K

DTC114EUKDTC114EUK

D2501

DBB08C

+~

1

3

*

24

**

~-

Q2512Q2511

C2501

470;50

0.1

C2504

R2501

3.3K

C2506

0.1

IC251

FA7700V

C2505

22;35

0

R2513

D2503

UDZS15B

FBIN-REFRT

4321

2.2K

R2514

3

4

*

D2512

TLP181(GB)

R2522

Q2501

2SD1767

820K

R2502

8765

CS VCC OUT GND

2.2

33K

0.1

R2512

C2512

(0.5%)

C2511

Q2521

2SK3617

33

SWITCHING

CONTROL

0.047

C2521

470P

C2522

R2523

3.3K

0.22

C2514

100

R2516

3

*

3301SR159-200

R2521D2521

2

*

1

4

5

*

+15V

VIN2

1

*

2

*

GND

VIN1

+6.5V

-7V

C2525

0.01

E

VD

CN201

GND

D

GND

5V

5V

CCD0

CCD1

CCD2

CCD3

CCD4

C

CCD5

CCD6

CCD7

CCD8

CCD9

GND

GND

GND

B

AGC_CS

AGC_CLK

AGC_DATA

VD

ADCK

CLP

3.3V

3.3V

A

3.3V

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

5V

CCD0

CCD1

CCD2

CCD3

CCD4

CCD5

CCD6

CCD7

CCD8

CCD9

AGCCS

AGCCLK

AGCDATA

3.3V

L2003

C2008 C2009C2006

0.1;B 10;6.3-T0.1;B

CT-A

FLD

C2007

10;J

VD

10;6.3-T

3.3V

Q2401

1

2

3

CT-A

CCD9

CCD8

CCD7

CCD6

CCD5

CCD4

CCD3

CCD2

CCD1

CCD0

CT-A

C2012

C2013

0.1;B

10;6.3-T

C2014

0.1;B

R2011

0

R2012

0

C2015

0.1;B

R2013

R2014

R2015

R2016

0

0

0

0

V1

V2

V3

V4

75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

VCC

CCDI9

CCDI7

CCDI5

CCDI4

CCDI3

CCDI2

CCDI1

CCDI8

CCDI6

GND

76

GND

77

VCC1

78

ADCK

79

SHD

80

SHP

81

GND

82

CLP

83

CLPOB

84

PBLK

85

VCC1

86

V1

87

V2

88

V3

89

V4

90

CCDI0

IC201

SCC0020

CAMERA ASIC

ZRST

TMC1

TMC2

TEB

BUNRI

AMC

GND

GND

AGND

YAOUT

AVDD

GND

GND

C2011

0.1;B

VCC

GND

CSYNC

TEST

VD

FLD

GND

GND

AVDD

CAOUT

AGND

GND

GND2

VCC2

PCOSC

EXTSCI

0.1;B

C2010

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

0

R2401

UMG2N

C

B

E

C

B

54

123

10K

R2402

C2403

5

4

DB0

0.1;B

DB1

GNDVCCOUT

R2403

4.7K

IC242

BD4829G

RESET

D2401

DSH015

CT-A

C2402

10;6.3-T

X2401

4MHz

X1

GND

X2

123

DB2

DB3

DB4

DB5

DB6

DB7

E

D

C

7

7

7

7

8

8

B

8

8

8

8

8

8

8

8

A

9

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

C8

Page 17

CA-2 CIRCUIT [UPPER-RIGHT]

R2537

(0

5%)(0

5%)

K

3.3V

.

K

J

I

H

G

F

10 0.1

.

R2536 C2536

1K

(0.5%)

IC255

MC78L12AB

REG.

1234

GND NCGNDVOUT

5678

2.2

C2564

D2562

1K

R2562

2SA1037K

D2533

PTZ3.9B

VINGNDGNDNC

C2547

UDZS20B

C2565

Q2561

J

12V

15V

L2221

10;J

1K

L2236

33;J

C2253

22P;CH

C2254

L2241

68;J

R2233

C2255

10;10-T

CT-A

22P;CH

R2242

C2247

Q2236

2SC4081(R)

CE-E

C2256

220;25

C2258

47;6.3

CE-C

2.0

33K

R2250

1.9

22K

680 1K

R2251

R2253 R2252

18

MUTEA

2.0

2

YIN

3

GND

CIN

4

3.1

1.3

Vcc

OUT1

OUT2

MUTEB

1.5K

R2256

Q2237

2SC4081(R)

C2263

1;25-T

CT-A

1.0

7

0.9

6

5

1M

R2284

C2257

100;10

CE-D

C2268

0.1

C2224

10;16-T

CT-B2

C2225

100;10

CE-D

Q2227

2SA1576A(R)

390

R2227

390

R2228

C2227

100;10

CE-D

R2224

68

(0.5%)

CT-A

22K33K

R2234R2235

2.8

2.2

47K

R2243

2.3

1.7

1.5K

47K

R2244

C2259

4.7;10-T

Q2232

2SC4081(R)

R2248

150

1K

R2239

5.0

Q2234

2SC4081(R)

R2286 C2283

0 0.01;B

1K

R2246

R2249

150

R2237

1K

1K

R2232

Q2231

0.1

0.1

2SA1576A(R)

5V

-7V

2.0

1.4

C2245

22P;CH

C2246

3.3K

R2240

20P;CH 0.01;B

2.3

1.7

Q2233

2SA1576A(R)

D2223

R2226

68

(0.5%)

5V

TP221

VIDEO OUT

UDZS8.2B

D2224

UDZS8.2B

CN211

1

VIDEO OUT

2

VIDEO OUT

GND

I

H

G

F

IC227

BA7664FV

YC-MIX,75DRIVER

E

VD

54

0

R2401

D

L2003

10;J

3.3V

CT-A

123

10K

R2402

C

VD

FLD

B

A

C2008 C2009C2006

0.1;B 10;6.3-T0.1;B

C2007

10;6.3-T

CT-A

Q2401

UMG2N

C

B

1

E

2

C

B

3

5

4

DB0

C2403

0.1;B

DB1

GNDVCCOUT

R2403

IC242

BD4829G

4.7K

D2401

RESET

C2402

DSH015

X2401

4MHz

X1

123

CT-A

10;6.3-T

GND

DB2

DB3

DB4

DB5

DB6

R2426

V SW

0

0

0

10K

R2439

R2438

0

76

LSI RESET

77

X2

VSS

78

VSS

79

X IN

80

X OUT

81

VDD

82

DB0

83

DB1

84

DB2

85

DB3

86

DB4

87

DB5

88

DB6

89

R2437

EXT-BW

RESETIN

EXT-C

R2436

R2435

GAMMA CTL

AGC ON/OFF

10K

R2433

SHUTTER1

SHUTTER2

10K

10K

R2432

R2431

SHUTTER0

C/BW LEVEL

0

R2423

MOTOR+

MOTOR-

IC241

MICON

RESERVE

*

0

0

R2424

VIDEO(D/A)

INT/LL(ES/FL)

APERTURENOR/SHP

AP

AI/EI

WB

ATW/MTW

BLC MODE0

BLC1

0

R2418

VARIOP

BLC MODE1

0

R2417

SIMOP2

0

R2416

SIMOP1

0

R2414

SIMOP0

0

R2412

51525354555657585960616263646566676869707172737475

NTSC/PAL

TEST

BLCLEVEL

LLPHASE

IRIS REF IN

MANU WB B

MD2

MD1

MD0

FLD

VDO

VSS

CN241

50

49

48

47

46

45

44

43

42

41

40

39

38

37

FLD

VD

WBB

R2406

10K

R2443

0

R2407

10K

REFI

3.3V

232I

232O

1

3.3V

2

GND

3

RS232IN

4

MD0

5

RS232OUT

6

RESET

7

MD2

ADJUSTMENT

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

C9

Page 18

6

7

8

9

0

2

3

4

5

6

7

8

9

0

2

3

4

5

6

7

8

9

0

CCD5

CA-2 CIRCUIT [LOWER-LEFT]

K

CCD6

CCD7

CCD8

CCD9

GND

GND

GND

J

AGC_CS

AGC_CLK

AGC_DATA

VD

ADCK

CLP

3.3V

3.3V

I

3.3V

3.3V

GND

GND

GND

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TO CA-1

CN101

H

G

F

E

CN202

GND

GND

15V

15V

15V

V1

V2

V3

V4

VSUB

GND

GND

GND

GND

XSG1

XSG2

-7V

-7V

-7V

IRIS BLAKEIRIS DRIVE+

IRIS BLAKE+

GND

GND

TO CA-1

CN102

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

D

C

B

CCD6

CCD7

CCD8

CCD9

AGCCS

AGCCLK

AGCDATA

3.3V

15V

V1

V2

V3

V4

VSUB

XSG1

XSG2

-7V

L2011

L2012

L2013

CA-2

C2-04715/L5AR2-XE

A102S

A102S

A102S

V1

V2

V3

V4

XSG1

XSG2

VSUB

VCC

CCDI9

CCDI7

CCDI5

CCDI4

CCDI3

CCDI2

CCDI1

CCDI6

76

CT-A

100

GND

77

GND

78

VCC1

79

ADCK

80

SHD

81

SHP

82

GND

83

CLP

84

CLPOB

85

PBLK

86

VCC1

87

V1

88

V2

89

V3

90

V4

91

XSG1

92

XSG2

93

VSUB

94

GND

95

H1

96

H2

97

RG

98

VCC1

99

GND

GND

HRST

CKI2 CCDI8

C2002

0.1;B

VCC

CKI1

GND

VRST

SCK

C2014

0.1;B

R2011

0

R2012

0

C2015

0.1;B

R2013

0

R2014

0

R2015

0

R2016

0

R2017

0

R2018

0

R2019

0

C2016

0.1;B

L2001 R2001

10;J 0

3.3V

C2001

10;6.3-T

CCDI0

IC201

SCC0020

CAMERA ASIC

ZRD

GND

PCOVD

PCOHD

ZRD

IC235

LA6358NM

1

2

3

GND

45

28MHZ VCO LPF

VCC

ZRST

ZWR

ZWR

TMC1

ALE

ALE

8

7

6

TMC2

DB0

DB0

TEB

DB1

DB1

C2311

BUNRI

DB2

DB2

1;25-T

220K

R2317

AMC

SMC

CT-A

GND

ZCS

C2310

0.1;B

GND

CPUCK

C2313

4.7/16

AGND

DB3

DB3

L2301

NP-B

10;J

YAOUT

DB4

DB4

R2315

AVDD

DB5

DB5

GND

VCC

GND

GND

CSYNC

TEST

VD

FLD

GND

GND

AVDD

CAOUT

AGND

GND

GND2

VCC2

PCOSC

EXTSCI

ADJSCI

SCI

SCO

GND2

CKSCO

CKSCI

VCC2

GND2

GND

GND

DB6

VCC

DB7

25242322212019181716151413121110987654321

C2003

0.1;B

DB6

DB7

12V

4.7K

R2313

R2314

180

4.7K

R2339 R2340

10K 100K

R2312R2316

100K4.7K

C2332

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

TP232

28MHZ PLL

1000P;B

C2008C2006

0.1;B0.1;B

C2004

0.1;B

C2309 C2308

0.01;B 0.01;B

C2007

L2002

10;J

R2311

R2336

3.3

VD

FLD

10K

CT-A

10;6.3-T

C2005

0.1;B

TC7SU04FU

1000P;B

D2304

HVU200A

R2002

100

34

VCC

OUT

INH

GND

12

X2001

17.734475MHZ

C2317

4.7;6.3-T

IC238

28MHZ OSC

C2333

F2301

470P

CT-A

VCC

1

2

GND

3

R2341

1M

X2301

28.63636MHZ

C2316

0.1;B

5

4

30P

CT232

L2302

47;J

C2315

28MHZ

3.3V

0.1;B

C2327