Page 1

TECHNICAL & SERVICE MANUAL

STK-RCS-7TWSUA

WIRED REMOTE CONTROLLER

Model No.

STK-RCS-7TWSUA

Product Code No.

1 852 353 85

FILE NO.

Destination: North America

REFERENCE NO. SM700799

Page 2

Important!

Please Read Before Starting

This air conditioning system meets strict safety and operating

standards. As the installer or service person, it is an

important part of your job to install or service the system so it

operates safely and efficiently.

For safe installation and trouble-free operation, you must:

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all warning and caution notices given

in this manual.

This symbol refers to a hazard or

WARNING

CAUTION

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for

a special problem, contact our sales/service outlet or

your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard

or unsafe practice which can

result in personal injury or

product or property damage.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or thin

aluminum fins on the air conditioner can cut your fingers.

When Installing

In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the unit’s

weight. It may be necessary to construct a strong wood or

metal frame to provide added support.

In a Room

Properly insulate any tubing run inside a room to prevent

"sweating" that can cause dripping and water damage to walls

and floors.

In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a metal

frame. Provide a suitable air baffle.

In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher than

drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

•

Use the flare method for connecting tubing.

•

Apply refrigerant lubricant to the matching surfaces of the

flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

•

Check carefully for leaks before starting the test run.

When Servicing

WARNING

•

Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

•

Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or death.

•

Ground the unit following local electrical codes.

•

Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

•

Turn the power off at the main power box (mains) before

opening the unit to check or repair electrical parts and

wiring.

•

Keep your fingers and clothing away from any moving parts.

•

Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left inside

the unit being serviced.

Others

CAUTION

Ventilate any enclosed areas when installing or testing the

•

refrigeration system. Escaped refrigerant gas, on contact

with fire or heat, can produce dangerously toxic gas.

Confirm upon completing installation that no refrigerant gas

•

is leaking. If escaped gas comes in contact with a stove,

gas water heater, electric room heater or other heat source,

it can produce dangerously toxic gas.

2

Page 3

Table of Contents

Page

1. SPECIFICATIONS

2. APPLICABLE INDOOR UNITS

3. FUNCTIONS

4. SELF-DIAGNOSTICS

4-1. Self-Diagnostics Procedure

4-2. Self-Diagnostics Table (Ceiling Cassette Type)

4-3. Self-Diagnostics Table (Wall Mounted Type)

APPENDIX A INSTRUCTION MANUAL

APPENDIX B INSTALLATION INSTRUCTIONS

(STK-RCS-7TWSUA)

APPENDIX C INSTALLATION INSTRUCTIONS

(Installing the Connection Kit for Wall-Mounted Models)

.........................................................................................................................

.....................................................................................................

.................................................................................................................................

...................................................................................................................

...................................................................................................

.....................................................................

.........................................................................

.......................................................................................

...........................................................................

...........................................................................

4

5

5

6

6

7

8

A-1

A-2

A-3

3

Page 4

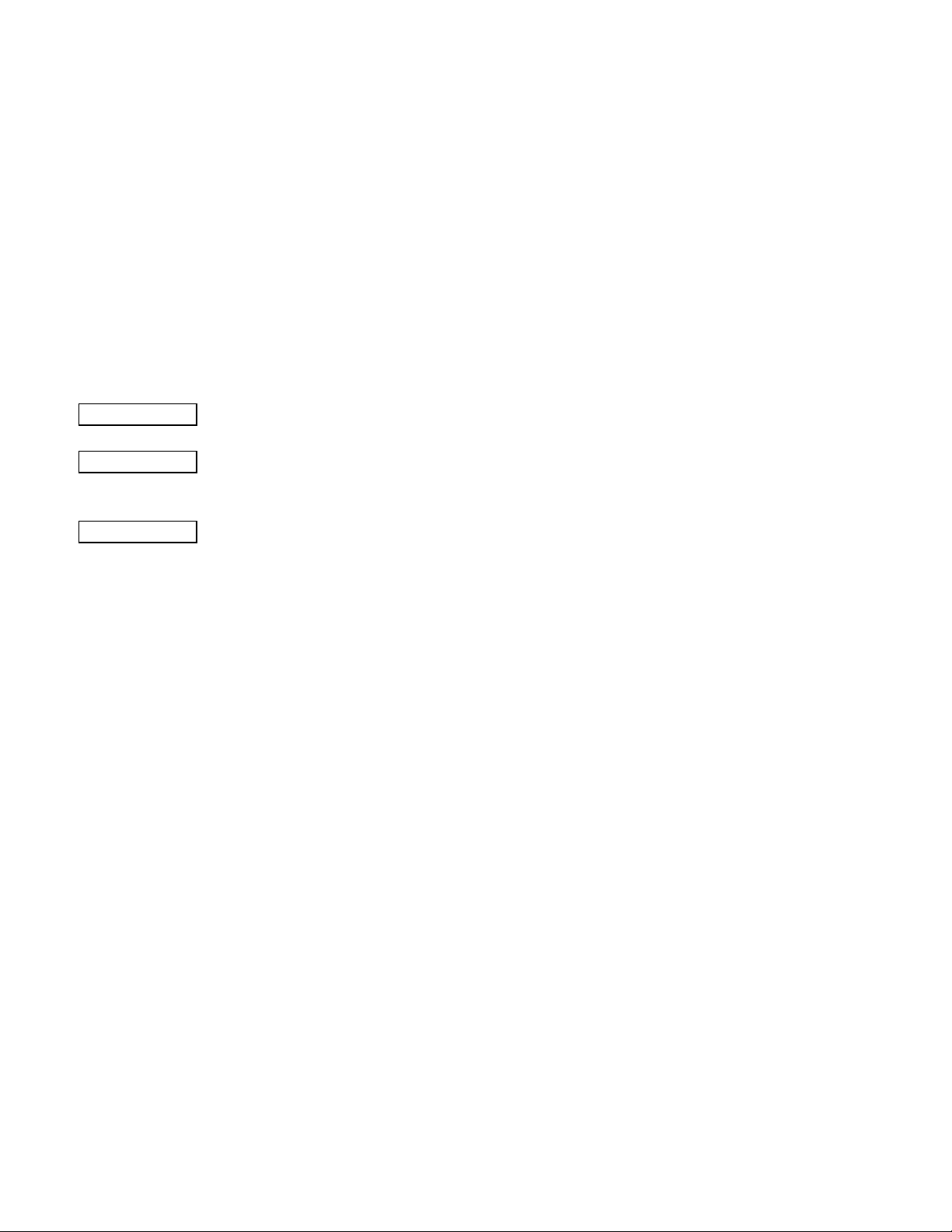

1. SPECIFICATIONS

Item

Description

Signal Transmission Method Dedicated Remote Controller Cable

Power Source

Display Panel Type

Temperature

Display Items

Airflow Direction

Time

Temperature Sensor

Functions

Operation Section

DC5V supplied from Indoor Unit

Liquid Crystal

Set Temperature Indication (68 ºF to 86 ºF)

Six Directions Indication

AM and PM 12-Hour Indication (Minute Indication Unit: 1 minute)

Displayed when indoor unit sensor is in use

AUTO, HEAT, DRY and FAN Operation

Push Switch

Detection using the Sensor in the Remote Controller or

Room Temperature Detection

Indoor Unit Temperature Sensor

(The detection result is transmitted to the indoor unit every 5 minutes)

NOTE

1. When the indoor unit is modified from one for wireless remote controller to that for

wired remote controller, some of the functions becomes unavailable.

Therefore, before such modification, make sure to receive an approval of the client.

Also, the self-diagnostics procedure is changed.

• Unavailable Functions : Refer to "3. FUNCTIONS".

• Self-Diagnostics Procedure : Refer to "4. SELF-DIAGNOSTICS".

2. The mode change or SINGLE/MULTI change-over operation is performed using the slide switch

located inside the rear of the remote controller.

Refer to "APPENDIX B : INSTALLATION INSTRUCTIONS" for details.

NOTE

NOTE

2

2

70.0 16.5

120.0

4

Page 5

2. APPLICABLE INDOOR UNITS

Type Indoor Unit Model No.

Ceiling Cassette Type

Wall Mounted Type

XHS1271, XHS1872, XS1271, XS1872

KHS0971, KHS1271, KHS1872, KHS2472

KS0971, KS1271, KS1872, KS2472

KMHS0772, KMHS0972, KMHS1272, KMHS1872, KMHS2472

KMS0772, KMS0972, KMS1272, KMS1872, KMS2472

3. FUNCTIONS

When the unit is modified from one for wireless remote controller to that for wired remote controller,

the following functions become unavailable.

(1) Ceiling Cassette Type

• Wireless Remote Controller

• High Power Operation

(2) Wall Mounted Type

• Wireless Remote Controller

• High Power Operation

• Quiet Operation

• ION Operation

5

Page 6

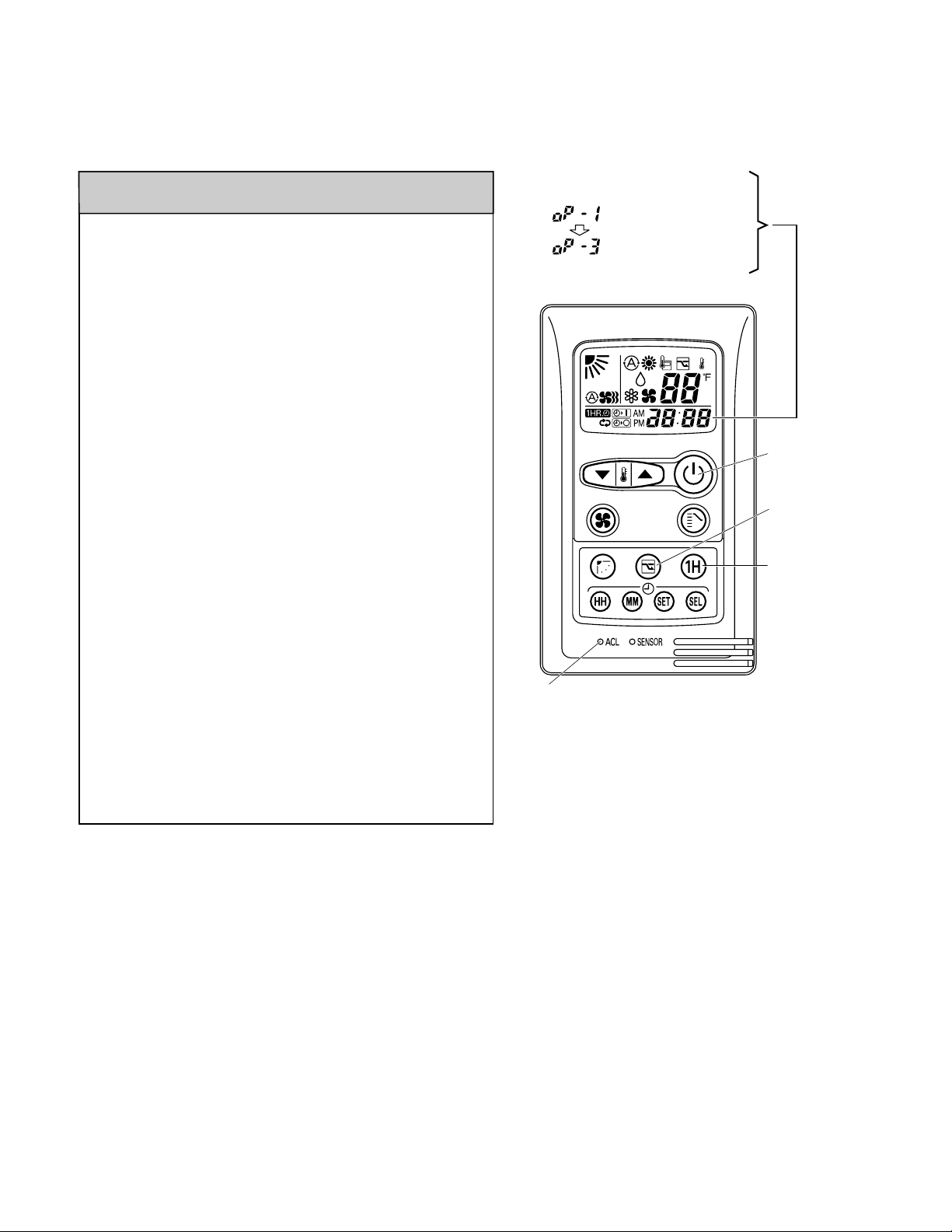

4. SELF-DIAGNOSTICS

PROCEDURE

After turning on power to the air conditioner, use the remote

controller and follow the steps below to execute selfdiagnostics.

Step 1: Press and hold the remote controller NIGHT SET

BACK (NSB) button and 1 HR TIMER button. Then,

press and hold the ACL (reset) button with a pointed

object such as the tip of a pen. After 5 seconds,

release ACL button first, then release NIGHT SET

BACK (NSB) and 1 HR TIMER buttons, "oP-1" (test

run) appears, blinking in the remote controller clock

display area.

Step 2: Next, press the 1 HR TIMER button once to change

the display from "oP-1" to "oP-3" (self-diagnostics).

(The display continues to blink.)

Step 3: Finally press the ON/OFF button to engage self-

diagnostics mode.

• The self-diagnostics function utilizes the 3 indicator lamps

on the main unit, in combinations of ON lamps, blinking

lamps, and OFF lamps, to report the existence of sensor

trouble or a protective operation. (The lamps blink or

remain ON for 5 seconds, then turn OFF for 2 seconds.)

Self-diagnostics is completed when the buzzer sounds 3

short beeps.

• A maximum of 3 self-diagnostics reports are displayed, for

5 seconds each, beginning with the most recent report.

Following this display the lamps turn OFF. In order to view

the self-diagnostics results again, press the ON/OFF button

again.

• The 3 lamps remain OFF if no trouble has occurred.

<IMPORTANT> After self-diagnostics is completed, be sure

to press the ACL (reset) button to return to

normal mode. The air conditioner will not

operate if this is not done.

ON/OFF

operation button

1 HR.TIMER

button

NIGHT SETBACK

button

ACL (Reset)

button

< Clock display >

Test run mode

Self-diagnostics mode

4-1. Self-Diagnostics Procedure

6

Page 7

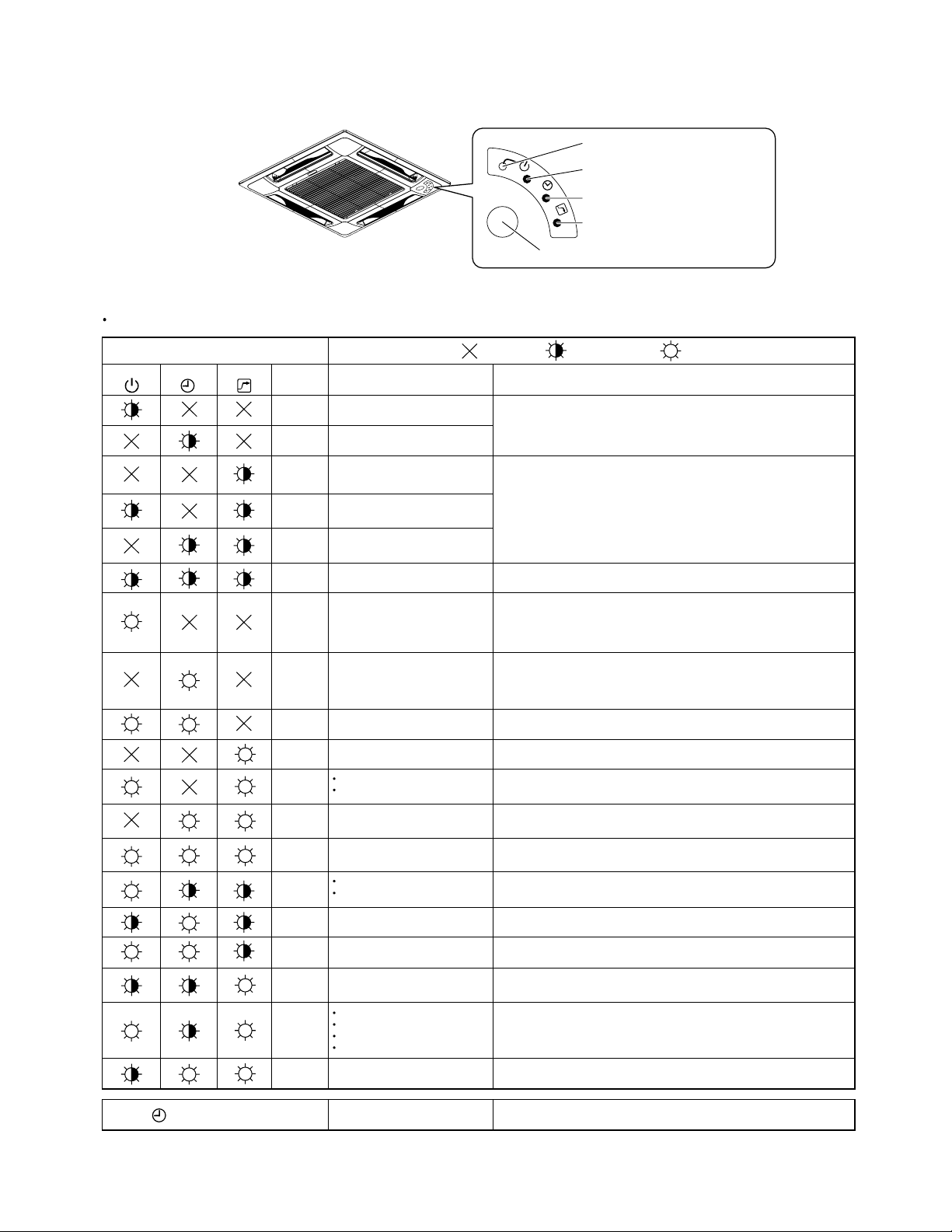

4-2. Self-Diagnostics Table (Ceiling Cassette Type)

Since the indications cover various units, the corresponding parts listed below may not be present in some models.

Indication on indoor unit

....

OFF

Timer HIGH POWER

Code Diagnostics itemsDiagnostics contents

S01

Room temperature sensor failure

Indoor heat exchanger sensor failure

Compressor temperature sensor failure

Outdoor heat exchanger sensor failure

Outdoor air temperature sensor failure

Indoor/outdoor communications failure

(serial communications)

Outdoor unit external ROM (OTP data)

failure

Peak current cut-off

• HIC circuit failure

• Power Tr (transistor) circuit failure

PAM circuit failure

Active circuit failure

Outdoor system communications failure

OLR operation

Outdoor power supply open phase

Outdoor coil freezing

Compressor discharge overheat

prevention activated.

Indoor fan operating failure

No-refrigerant protection

DC compressor drive circuit failure

Outdoor fan operating failure

Freeze-prevention operation activated.

4-way valve switching failure

Indoor zero-cross failure

Outdoor electrical current detection

failure

S02

S04

S05

S06

S07

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

....

Blinking

....

ON (Illuminated)

OPERATION

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(3) Indoor/outdoor PCboard failure

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(3) Outdoor PCboard failure

Outdoor PCboard failure

(1) Mis-wiring (2) AC power failure (3) Blown fuse (4) Power Relay failure

(5) Indoor or outdoor PCboard failure (6) Outdoor Fan Motor failure (7) Reactor failure

(8) High-Pressure Switch failure (9) Overload Relay failure (10) Magnetic Coil failure

* See detailed flowchart in this section.

(1) HIC or power Tr failure (2) Outdoor fan does not turn. (3) Instantaneous power outage

(4) Service valve not opened. (5) Outdoor fan blocked. (6) Continuous overload operation

(7) Compressor failure (8) Outdoor PCboard failure

(1) External ROM data failure (2) Outdoor PCboard failure

(1) Instantaneous power outage (2) HIC or power transistor failure

(3) Outdoor PCboard failure

(1) Outdoor PCboard failure (2) Outdoor power supply voltage failure

(1) Electric expansion valve failure (2) Capillaries choked (3) Shortage of refrigerant

(4) Continuous overload operation (5) Outdoor fan does not rotate (6) Outdoor

PCboard

failure

(1) Fan motor failure (2) Contact failure at connector (3) Indoor PCboard failure

(1) 4-way valve failure (heat pump model only)

(2) Outdoor PCboard failure

(1) Service valve not opened. (2) Shortage of refrigerant

(1) Open phase (2) Outdoor PCboard failure

(1) Fan motor failure (2) Contact failure at connector (3) Outdoor PCboard failure

(1) Mis-wiring (2) Blown fuse (3) Power Relay failure (4) Outdoor PCboard failure

(5) Compressor failure

* See detailed flowchart in this section.

(1) DRAIN PUMP FAILURE (2) FS FAILURE (3) CHOKED DRAIN HOSE

(1) Indoor fan system failure (2) Shortage of refrigerant (3) Low-temperature operation

REMOTE CONTROL receiver

OPERATION lamp

TIMER lamp

OPERATION button

HIGH POWER lamp

INDOOR UNIT

TIMER

LAMP

BLINKING (3 SEC. INTERVAL)

FLOAT SWICTH (FS) IS ACTIVED.

7

Page 8

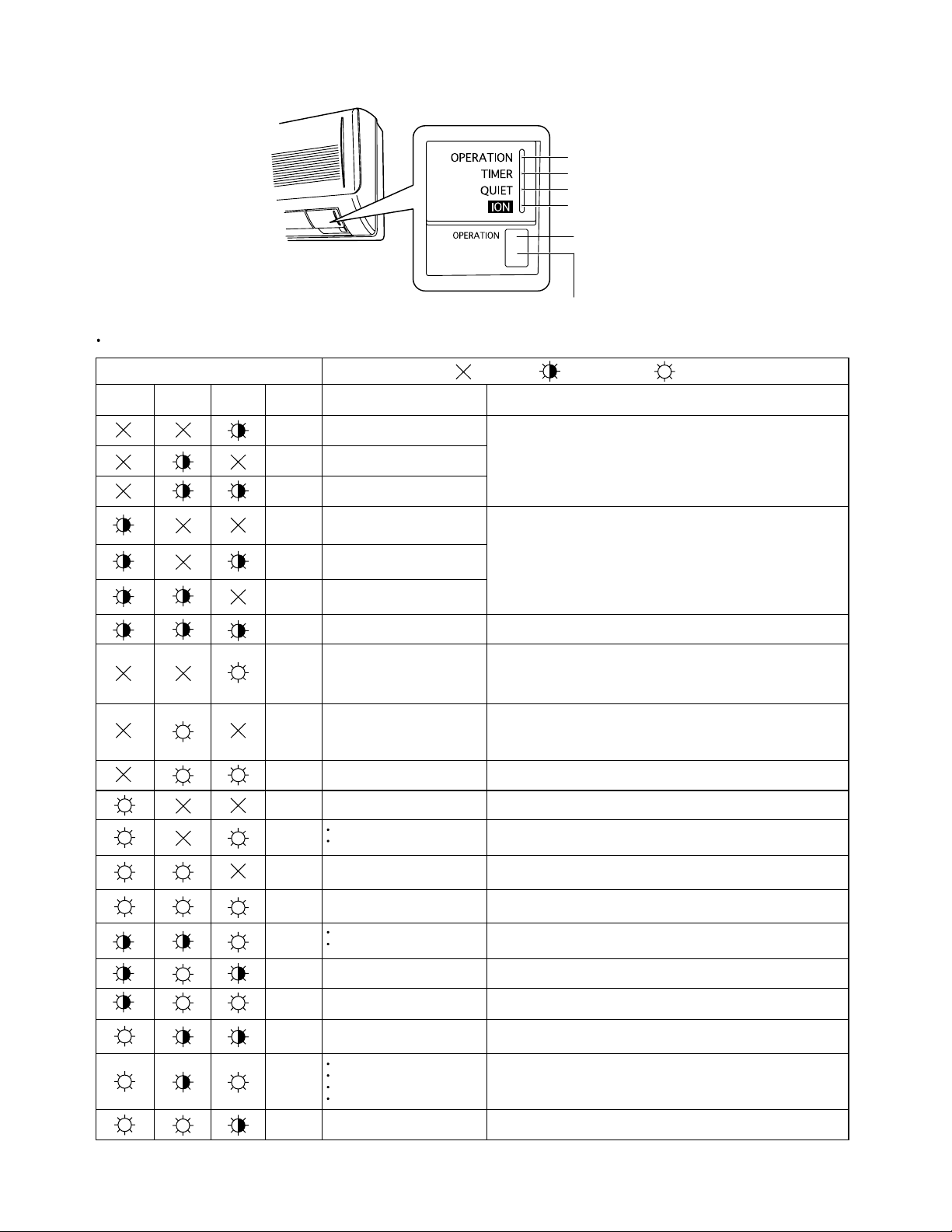

4-3. Self-Diagnostics Table (Wall Mounted Type)

Since the indications cover various units, the corresponding parts listed below may not be present in some models.

REMOTE CONTROL receiver

(1) OPERATION lamp

(2) TIMER lamp

(3) QUIET lamp

ION lamp

OPERATION button

INDOOR UNIT

Indication on indoor unit

....

OFF

Timer Operation

Code Diagnostics items Diagnostics contents

S01

Room temperature sensor failure

Indoor heat exchanger sensor failure

Humidity sensor failure

Compressor temperature sensor failure

Outdoor heat exchanger sensor failure

Outdoor air temperature sensor failure

Indoor/outdoor communications failure

(serial communications)

Outdoor unit external ROM (OTP data)

failure

Peak current cut-off

• HIC circuit failure

• Power Tr (transistor) circuit failure

PAM circuit failure

Active circuit failure

Outdoor system communications failure

OLR operation

Outdoor power supply open phase

Outdoor coil freezing

Compressor discharge overheat

prevention activated.

Indoor fan operating failure

No-refrigerant protection

DC compressor drive circuit failure

Outdoor fan operating failure

Freeze-prevention operation activated.

4-way valve switching failure

Indoor zero-cross failure

Outdoor electrical current detection

failure

S02

S03

S04

S05

S06

S07

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

....

Blinking

....

ON (Illuminated)

Quiet

(3)(2) (1)

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(short-circuit detection only for the humidity sensor)

(3) Indoor/outdoor PCboard failure

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(3) Outdoor PCboard failure

Outdoor PCboard failure

(1) Mis-wiring (2) AC power failure (3) Blown fuse (4) Power Relay failure

(5) Indoor or outdoor PCboard failure (6) Outdoor Fan Motor failure (7) Reactor failure

(8) High-Pressure Switch failure (9) Overload Relay failure (10) Magnetic Coil failure

* See detailed flowchart in this section.

(1) HIC or power Tr failure (2) Outdoor fan does not turn. (3) Instantaneous power outage

(4) Service valve not opened. (5) Outdoor fan blocked. (6) Continuous overload operation

(7) Compressor failure (8) Outdoor PCboard failure

(1) External ROM data failure (2) Outdoor PCboard failure

(1) Instantaneous power outage (2) HIC or power transistor failure

(3) Outdoor PCboard failure

(1) Outdoor PCboard failure (2) Outdoor power supply voltage failure

(1) Electric expansion valve failure (2) Capillaries choked (3) Shortage of refrigerant

(4) Continuous overload operation (5) Outdoor fan does not rotate (6) Outdoor

PCboard

failure

(1) Fan motor failure (2) Contact failure at connector (3) Indoor PCboard failure

(1) 4-way valve failure (heat pump model only)

(2) Outdoor PCboard failure

(1) Service valve not opened. (2) Shortage of refrigerant

(1) Open phase (2) Outdoor PCboard failure

(1) Fan motor failure (2) Contact failure at connector (3) Outdoor PCboard failure

(1) Mis-wiring (2) Blown fuse (3) Power Relay failure (4) Outdoor PCboard failure

(5) Compressor failure

* See detailed flowchart in this section.

(1) Indoor fan system failure (2) Shortage of refrigerant (3) Low-temperature operation

8

Page 9

APPENDIX A

STK-RCS-7TWSUA

INSTRUCTION MANUAL

(OI-852-6-4181-139-00-0)

A-1

Page 10

STK-RCS-7TWSUA

This wired remote controller is designed for

both the “COOL/DRY/HEAT Model” and

“COOL/DRY Model” indoor unit.

Before using the remote controller, be sure

to confirm the “model type” specified on the

front cover of the INSTRUCTION MANUAL

INSTRUCTION MANUAL

Wired Remote Controller

MODE D’EMPLOI

Télécommande Filaire

supplied with the indoor unit.

Once the wired remote controller is

connected, the wireless remote controller

cannot be used.

Save These Instructions!

Conserver ce mode d’emploi

Pub. OI-85264181139000

© SANYO 2009

Page 11

CONTENTS

PRODUCT INFORMATION ................................................................................................................ 2

ALERT SYMBOLS..............................................................................................................................2

INSTALLATION LOCATION ................................................................................................................2

ELECTRICAL REQUIREMENTS........................................................................................................2

SAFETY INSTRUCTIONS..................................................................................................................2

FEATURES ......................................................................................................................................... 3

REMOTE CONTROL UNIT.................................................................................................................4

OPERATION WITH THE REMOTE CONTROL UNIT ........................................................................6

1. Automatic Operation (only for COOL/DRY/HEAT Model).................................................... 6

2. Manual Operation................................................................................................................6

3. Adjusting the Fan Speed .....................................................................................................7

4. Fan Only..............................................................................................................................7

5. Night Setback Mode............................................................................................................ 7

SPECIAL REMARKS..........................................................................................................................7

SETTING THE TIMER........................................................................................................................8

USING THE 1-HOUR OFF TIMER..................................................................................................... 9

ADJUSTING THE AIRFLOW DIRECTION .........................................................................................9

Page

PRODUCT INFORMATION

If you have problems or questions concerning your wired

remote controller, you will need the following information.

Model No. __________________________________

Date of purchase _____________________________

Dealer’s address _____________________________

Phone number________________

ALERT SYMBOLS

The following symbols used in this manual, alert you

to potentially dangerous conditions to users, service

personnel or the appliance:

This symbol refers to a hazard or unsafe

practice which can result in severe

personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe

practice which can result in personal

injury or product or property damage.

INSTALLATION LOCATION

We recommend that this wired remote controller be

installed properly by qualified installation technicians

in accordance with the Installation Instructions

provided with the unit.

• Do not install this wired remote

controller where there are fumes or

flammable gases, or in an extremely

humid space such as a greenhouse.

• Do not install the wired remote

controller where excessively high

heat-generating objects are placed.

Avoid:

To protect the air conditioner from heavy corrosion, avoid installing

the outdoor unit where salty sea water can splash directly onto it or

in sulphurous air near a spa.

ELECTRICAL

REQUIREMENTS

1. All wiring must conform to the local electrical codes.

Consult your dealer or a qualified electrician for details.

2. Each unit must be properly grounded with a ground (or

earth) wire or through the supply wiring.

3. Wiring must be done by a qualified electrician.

SAFETY INSTRUCTIONS

• Read this Instruction Manual carefully before using

this air conditioner. If you still have any difficulties

or problems, consult your dealer for help.

• This air conditioner is designed to give you

comfortable room conditions. Use this only for its

intended purpose as described in this Instruction

Manual.

• Never use or store gasoline or other

flammable vapor or liquid near the air

conditioner — it is very dangerous.

• This air conditioner has no ventilator

for intaking fresh air from outdoors.

You must open doors or windows

frequently when you use gas or oil

heating appliances in the same room,

which consume a lot of oxygen from

the air. Otherwise there is a risk of

suffocation in an extreme case.

CAUTION

• Do not turn the air conditioner on and

off from the power mains switch. Use

the ON/OFF operation button.

• Do not stick anything into the air outlet

of the outdoor unit. This is dangerous

because the fan is rotating at high

speed.

• Do not let children play with the air

conditioner.

• Do not cool or heat the room too much

if babies or invalids are present.

2

OI-139-2-EG

Page 12

FEATURES

• Microprocessor Controlled Operation

• 24-Hour ON or OFF Timer

• 1-Hour OFF Timer

•Night Setback

• Automatic and 3-step Fan Speed

• Air Sweep Control

NOTE

• Since the wired remote controller is designed to be commonly used for various air conditioners, some of the functions of the wireless

remote controller supplied with the indoor unit cannot be used.

• “Single use” means that only one indoor unit is connected with one outdoor unit in a one-unit-to-one-unit configuration.

• “Multiple use” (i.e. Flexi-Multi system) means that two or more indoor units are connected with one outdoor unit in a multiple-unit-to-one-unit

configuration.

• Automatic Restart Function for Power Failure

• Automatic Switching between Cooling and Heating

(This function is available only for “Single use” of COOL/DRY/

HEAT Model.)

• Hot Start Heating System

(This function is available only for COOL/DRY/HEAT Model.)

REMOTE CONTROL UNIT (DISPLAY)

Displayed when indoor unit sensor

is in use

Displayed when setting timer

(1) Operation mode

AUTO .....................................

(only for COOL/DRY/HEAT

Model)

HEAT ......................................

(only for COOL/DRY/HEAT

Model)

MILD DRY..............................

Displayed when operating NIGHT

SETBACK mode

Displayed when setting

temperature

Displayed when temperature is

shown

Symbols

(3) Temperature setting

60 – 86 °F ..............................

When set to 80 °F

temperature indication...........

(4) Timer

24-hour clock with ON/OFF

program Timer .......................

COOL.....................................

FAN ........................................

(2) Fan speed

Automatic operation ...............

HIGH .....................................

MEDIUM.................................

LOW.......................................

OI-139-3-EG

ON Timer. ..............................

OFF Timer. ............................

1-hour OFF Timer..................

(5) NIGHT SETBACK..................

(6) Flap angle indication..............

Sweep indication....................

3

Page 13

REMOTE CONTROL UNIT

NOTE

The descriptions on the AUTO ( ) or HEAT ( ) operation mode are only for the “COOL/DRY/HEAT Model,” and not for the

“COOL/DRY Model.”

Display

Information on the operating conditions is displayed while the remote control

unit is switched on. If the unit is turned off, only the mode that was set

previously is still displayed.

Temperature setting buttons (TEMP.)

Press the button to increase the set temperature.

Press the button to reduce the set temperature.

The temperature setting changes by 2 °F each time one of the TEMP. buttons

is pressed.

FAN SPEED selector button

: The air conditioner automatically decides the fan speeds.

: High fan speed

: Medium fan speed

: Low fan speed

NIGHT SETBACK button

For details, see “5. Night Setback Mode”. When you press this button in the

HEAT, DRY or COOL mode, the mark appears in the display, and the

remote control unit will automatically adjust the set temperature to save

energy.

FLAP button

Press this button either to select the setting of the airflow direction to one of

the six possible positions manually or to select the sweep function which

moves the flap up and down automatically.

: The airflow direction can be set manually. (six positions)

: The flap moves up and down automatically.

NOTE

When you press the FLAP button, the air flow direction will be changed one by

one as follows.

SWEEP

Timer and Present Time setting buttons

First, press the SET button to select the mode (ON, OFF and Present Time

settings) you want.

Each time you press the ‘‘HH’’ button, the hours advance by one.

(PM0, PM1.....PM11, AM0, AM1.....AM11)

Each time you press the ‘‘MM’’ button, the minutes advance by one when

setting Present Time and by ten when setting ON and OFF Time.

SET button

For details, see ‘‘Setting the Timer’’.

Press this button to select the mode you want to program.

ACL button (ALL CLEAR)

When you press the ACL button while the

operation button is ON, all settings are cleared.

Press the ACL button if the air conditioner is not

operating correctly.

4

OI-139-4-EG

Page 14

ON/OFF operation button

This button is for turning the air conditioner on and off.

MODE selector button

Use this button to select AUTO, HEAT, DRY, COOL or FAN mode.

(AUTO) : When this setting is selected, the air conditioner calculates the difference between the

thermostat setting and the room temperature and automatically switches to the ‘‘COOL’’ or

‘‘HEAT’’ mode as appropriate. (This function is available only for “Single use” of COOL/DRY/

HEAT Model.)

(HEAT) : The air conditioner makes the room warmer.

(DRY) : The air conditioner reduces the humidity in the room.

(COOL) : The air conditioner makes the room cooler.

(FAN) : The air conditioner works only as a circulation fan except for “Multiple use” of COOL/DRY/

HEAT Model.

1 HR. TIMER button (1-HOUR OFF TIMER)

: When you press this button, regardless of whether the unit is operating or stopping, the unit operates for

one hour and then shuts down.

TIMER SELECT button

No display :The timer does not operate.

: The air conditioner starts at the set time.

: The air conditioner stops at the set time.

: The air conditioner stops and starts, or starts and stops, at the set times every day.

Sensor

A temperature sensor inside the remote control unit senses the room temperature.

SENSOR button

When you press this button (use a small-tipped object such as a ballpoint pen), the mark will disappear at the

display. And the room temperature is detected by the sensor which is built into the remote control unit and the air

conditioner is controlled accordingly.

NOTE

If the remote control unit is located near a heat source, such as a space heater or in direct sunlight, press the

SENSOR button to switch to the sensor on the indoor unit.

NOTE

The indoor fan runs continuously when the system is in normal operation. It does not turn off when the desired room temperature is

reached. If Night Set Back mode is selected, the fan will turn off intermittently during cooling operation in order to control air flow.

OI-139-5-EG

5

Page 15

OPERATION WITH THE REMOTE CONTROL UNIT

1. Automatic Operation

(only for COOL/DRY/HEAT Model)

• Single use

This unit automatically switches between cooling operation and

heating operation according to the difference between the room

temperature and the temperature setting.

• Multiple use

The air conditioner calculates the difference between the

thermostat setting and room temperature, and automatically

determines the mode to operate under cooling or heating. Then,

the air conditioner continuously operates under the mode selected

at initial operation.

STEP 2

STEP 1

NOTE

NOTE

Check that the circuit breaker on the power panel is

turned on.

Once mode is selected and the unit is preset by

following the steps below, you can have the air

conditioner automatically bring the room to the desired

temperature simply by pressing the ON/OFF operation

button.

STEP 1 Press the MODE selector button to .

STEP 2 Press the ON/OFF operation button.

To stop the air conditioner, press the ON/OFF operation

button again.

To change the temperature setting; press the

temperature setting buttons and change the setting to

the desired temperature.

2. Manual Operation

STEP 4

STEP 5

NOTE

Check that the circuit breaker on the power panel is

turned on.

If the automatic operation settings of the unit do not

meet your needs, press the setting buttons as

described below and change the settings as desired.

STEP 1 Press the MODE selector button

and select the desired mode.

For heating operation

For dehumidifying operation

For cooling operation

For fan only operation

(No Fan mode in “Multiple use” of

COOL/DRY/HEAT Model)

STEP 2 To start the air conditioner, press the ON/

OFF operation button.

STEP 3 Press the TEMP. setting buttons to change

the temperature setting to the desired

temperature.

Adjustable temperature range:

86 °F max.

60 °F min.

STEP 4 Set the FAN SPEED selector button to the

setting you want.

STEP 5 Press the FLAP button and set the airflow

direction as desired.

(Refer to “ADJUSTING THE AIRFLOW

DIRECTION” on page 9.)

To stop the air conditioner, press the ON/OFF

operation button again.

STEP 2

STEP 3

STEP 1

→

→

→

→

NOTE

6

• Choose the best position in the room for the remote

control unit, which also acts as the sensor for room

comfort and transmits the operating instructions.

Once you’ve found this best position, always keep the

remote control unit there.

• This appliance has a built-in 5-minute time delay

circuit to ensure reliable operation. When the

operation button is pressed, the compressor will start

running within three minutes. In the event of power

failure, the unit will stop.

• The display on the remote control unit shows the

setting temperature and not the room temperature.

• When multiple indoor units are used and units in other

rooms are already operating, they will be operating

with the same mode as the operating indoor units.

(only for “Multiple use” of COOL/DRY/HEAT Model)

OI-139-6-EG

Page 16

3. Adjusting the Fan Speed

A. Automatic fan speed

Simply set the FAN SPEED selector button to the

position.

This automatically sets the best fan speed for the room

temperature.

B. Manual fan speed

If you want to adjust fan speed manually during operation,

just set the FAN SPEED selector button as desired. [ ,

, or ]

4. Fan Only

A. In Cooling and DRY Mode: ( and )

When the night setback mode is selected, the air conditioner

automatically raises the temperature setting 2 °F when 30 minutes

have passed after the selection was made, and then another 2 °F

after another 30 minutes have passed, regardless of the indoor

temperature when night setback was selected. This enables you

to save energy without sacrificing comfort. This function is

convenient when gentle cooling is needed.

Setting

temperature

2°F

2°F

STEP 3

If you want to circulate air without any temperature

control, follow these steps:

NOTE

STEP 1 Press the MODE selector button to switch to

STEP 2 Press the ON/OFF operation button.

STEP 3 Press the FAN SPEED selector button to

There is no FAN only function in “Multiple use” of

COOL/DRY/HEAT Model.

the fan mode .

select the fan speed of your choice ( ,

or ).

5. Night Setback Mode

STEP 2

STEP 1

Press the NIGHT

SETBACK button

30 min.

30 min.

Time

B. In Heating Mode: ( )

(only for COOL/DRY/HEAT Model)

When the night setback mode is selected, the air conditioner

automatically lowers the temperature setting 4 °F when 30

minutes have passed after the selection was made, and then

another 4 °F after another 30 minutes have passed, regardless of

the indoor temperature when night setback was selected. This

enables you to save energy without sacrificing comfort. This

function is convenient when gentle heating is needed.

30 min.

4°F

30 min.

4°F

Time

Setting

temperature

Press the NIGHT

SETBACK button

SPECIAL REMARKS

Night Setback Mode is used for saving energy.

Press the NIGHT SETBACK button while operation.

The mark appears in the display.

To release the night setback function, press the NIGHT SETBACK

button again.

OI-139-7-EG

Power failure during operation

In the event of power failure, the unit will stop. When the power is

resumed within 8 hours, the unit will restart automatically in

approximately five minutes, or 15 minutes in “Multiple use” of COOL/

DRY/HEAT Model on AUTO mode by the remote control unit.

Remote Control Unit

The remote control unit sends the setting condition to the air

conditioner regularly at five minute intervals.

Remote Control Unit Display

If the display malfunctions, press the ACL button.

This resets the remote control unit back to the initial settings.

Make the settings again.

7

Page 17

SETTING THE TIMER

1. How to set the present time

(Example) To set to 9:10 pm.

3. How to set the ON time

(Example) To start operation at 7:10 am.

ON TIME Present time

Operation Indication

1. Press the SET button once. The timer indication alone

2. • Press the HH button until

AM 7 is displayed.

• Press the MM button until

10 is displayed.

3. Press the TIMER SELECT

button once to set ON time.

flashes and the previous settime is only displayed.

The display will change

automatically back to show the

present time after about 10 sec.

The present time and are

displayed.

Operation Indication

1. Press the SET button three

times.

2. • Press the HH button until

PM 9 is displayed.

• Press the MM button until

10 is displayed.

The time indication alone

flashes.

The display will flash for 10 sec.

and automatically stop flashing

except for the “ : ” symbol.

2. How to set the OFF time

(Example) To stop the air conditioner at 11:30 pm.

OFF TIME Present time

Operation Indication

1. Press the SET button twice. The timer indication alone

2. • Press the HH button until

PM 11 is displayed.

• Press the MM button until

30 is displayed.

3. Press the TIMER SELECT

button twice to set OFF time.

To cancel the setting, press the TIMER SELECT button twice.

flashes and the previous settime is only displayed.

The display will change

automatically back to show the

present time after about 10 sec.

The present time and are

displayed.

To cancel the setting, press the TIMER SELECT button three times.

4. How to set daily ON/OFF repeat timer

(Example) To start operation at 7:10 am. and stop the air conditioner

at 11:30 pm.

Present time OFF TIME

ON TIME

9:10 pm.

Present time

7:10 am.

ON

Operation Indication

Set the timer ON/OFF times as

shown in 2 and 3.

To cancel the setting, press the TIMER SELECT button once.

The present time PM 9:10 and

are displayed.

NOTE

You can check the timer ON/OFF times after you have set them by

pressing the SET button.

Programmed

daily ON / OFF

11:30 pm.

OFF

5. Backup function

Even if the main power supply to the unit is turned off, the remote

controller will store the previous settings in its internal memory for up

to 8 hours. If the power is not turned back on within 8 hours, the

previous settings will be lost. In this case, the mode settings must be

reset by the user.

8

OI-139-8-EG

Page 18

USING THE 1-HOUR OFF

ADJUSTING THE AIRFLOW

TIMER

1. 1-Hour OFF Timer

This function causes the unit to operate for one hour and then

stop, regardless of whether the unit is on or off when this

button is pressed.

The indicator in the display indicates that this function is

operating.

Setting procedure:

Regardless of whether the unit is operating or stopped, press the 1

HR. TIMER button.

appears in the display.

Cancellation procedure:

Press the ON/OFF operation button to turn the unit off, wait for the

unit to stop operating, and then press the ON/OFF operation button

again.

The 1-Hour Timer function is now cancelled and the unit operates

normally.

NOTE

DIRECTION

The vertical airflow can be adjusted by moving the flap with the

remote control unit. Do not move the flap with your hands. Confirm

that the remote control unit has been turned on. Use the FLAP

button to set either the sweep function or one of the six airflow

direction settings.

A. Sweep function

The flap starts moving

up and down to deliver

air over the sweep

range.

B. Setting the airflow manually

Referring to the above

illustration, use the

FLAP button to set the

airflow direction within

the range used during

the heating, cooling, or

dehumidifying

operation.

COOL

DRY

SWEEP

SWEEP

HEAT

FAN

• If, while the 1-Hour Timer function is operating, the 1HR. TIMER

button is pressed once to cancel the function and then again, the

unit continues to operate for one hour from that point in time and

then stops.

• It is not possible to use the OFF Timer and 1-Hour OFF Timer

together. Whichever function is set last takes precedence. If the 1

HR. TIMER button is pressed while the TIMER OFF function

operates, the OFF Timer is cancelled and the unit will stop

operating one hour later.

2. Operation together with the daily ON/OFF

repeat timer

The 1-Hour OFF Timer setting is given priority over the DAILY ON/

OFF REPEAT setting.

NOTE

• The flap automatically closes when the unit is off.

• During the heating operation, the fan speed will be very low and the

flap will be in the horizontal position (position ) until the air being

blown out of the unit begins to warm. Once the air warms up, the

flap position and fan speed change to the settings specified with

the remote control unit.

CAUTION

• Use the FLAP button on the remote control unit to adjust the

position of the flap. If you move the flap by hand, the flap

position according to the remote control unit and the actual

flap position may no longer match. If this should happen,

shut off the unit, wait for the flap to close, and then turn on

the unit again; the flap position will now be normal again.

• Do not have the flap pointed down during cooling operation.

Condensation may begin to form around the air vent and drip

down.

OI-139-9-EG

9

Page 19

APPENDIX B

INSTALLATION INSTRUCTIONS

(STK-RCS-7TWSUA)

STK-RCS-7TWSUA

(II-852-6-4190-481-00-1)

A-2

Page 20

IMPORTANT

Q'ty Q'ty

1

Parts

Wired

remote

controller

Machine

screws

Tapping

screws

2

2

2

Spacers

1

Parts

1

1

Instruction

manual

Figure Figure

Installation

Instructions

Wire

harness

5/32

15/16"

5/32

15/16"

(4

25mm)

(4

25mm)

26.2 ft. (8m)

INSTALLATION INSTRUCTIONS

W

IMPORTANT

• In order to install this wired remote controller onto a wall-mounted model, the connection kit

(STK-KCW1), which must be purchased separately, is required.

• Once the wired remote controller is connected, the wireless remote controller cannot be used.

I Parts supplied with the remote controller

See Table 1.

I Remote controller installation guidelines

Installation location

• Mount the remote controller 3.3 to 4.9 ft. (1 to 1.5

meters) off the floor where it can sense the average

temperature of the room.

• Do not mount the remote controller in a place

exposed to direct sunlight or where it is exposed to

outside air such as near a window.

• Do not mount the remote controller behind a curtain or

other object so that it is separated from the air circulation of the room.

• Mount the remote controller inside the room being air

conditioned.

Switching the room temperature sensor

Table 1

Room temperature sensors are separately incorporated in both the indoor unit and the remote controller. Either sensor can

be used to sense the room temperature. The indoor unit sensor is usually used.

If you wish the remote controller to sense the room temperature, press the SENSOR button with a ballpoint pen or tool with

a small tip. (Refer to Fig. 9 on page 4 to locate the SENSOR button.)

I How to install the remote controller

• The remote controller is set to “Cool/Dry/Heat model” at

the time of shipment from the factory. If the purchased air

conditioner is a COOL/DRY model, follow the instructions

on the label and change the switch on the reverse side of

the remote controller unit to “Cool/Dry model”. (Fig. 1)

• The remote controller is also set to “Single” at the time of

shipment from the factory. For multiple use, set the

switch on the reverse side of the remote controller unit to

“Multi”. (Fig. 1)

• After all work is completed, if any switches have been

changed, then be sure to press the ACL (Reset) button.

(Refer to Fig. 9 on page 4 to locate the ACL (Reset) button.)

85264190481001 © SANYO 2009

Fig. 1

SANYO Commercial Solutions In Canada

A Division of SANYO North America Corporation SANYO Canada Inc.

1300 Michael Drive, Suite A 1-300 Applewood Crescent, Concord

Wood Dale, IL 60191, U.S.A. Ontario, L4K 5C7, Canada

Page 21

A. Installing with in-wall junction box

Remote

controller

Machine

Opening

In-wall junction box

from the indoor unit

Wire harness

Spacers

Wall

screws

Back plate

Wall

Remote

controller

Wire harness

Tapping

screws

Back plate

WallWall

Cut out

Connector

Hook

PCB

Slot

Ta b

Back

plate

2-3/8"

(60mm)

In-wall junction box (locally purchased)

4-3/16"

(106mm)

3-9/32"

(83.5mm)

(1) Install the junction box (locally purchased) into the wall.

(Figs. 2-a and 3)

(2) Pass the wire harness through the junction box and

conduit. (Fig. 3)

(3) Insert a flathead screwdriver into the 5 tab locations

and disconnect the back plate of the remote controller by

lifting up slightly. (Fig. 2-b)

The tabs are thin; take care not to chip them.

(4) Pass the wire harness connector through the cord open-

ing on the back plate of the remote controller.

Use nippers or a similar tool to cut out the slots for the

remote controller back plate screws. Insert the spacers

and use the machine screws to install the remote controller back plate. (Fig. 3)

(5) Insert the connector into the PCB of the remote controller

unit, and wrap the wire harness around the hook. (Fig. 4)

(6) Store the excess wire harness inside the junction box,

then hook the remote controller unit onto the top of the

back plate and install the remote controller unit.

(7) To remove the remote controller unit after it has been

installed, insert a flathead screwdriver into the slot on the

bottom of the case and turn it. (Fig. 5)

Fig. 2-a

Fig. 2-b

B. Installing directly onto the wall

(1) Insert a flathead screwdriver into the 5 tab locations and

disconnect the back plate of the remote controller by lifting up slightly. (Fig. 2-b)

The tabs are thin; take care not to chip them.

(2) Use tapping screws to directly fasten the remote con-

troller back plate onto the wall. (Fig. 6)

(3) Insert the connector into the PCB of the remote controller

unit, and wrap the wire harness around the hook. (Fig. 4)

(4) Use nippers or a similar tool to cut out the slot on the top

of the remote controller unit. Pass the wire harness

through the slot, then hook the remote controller unit

onto the top of the back plate and install the remote controller unit.

(5) In order to conceal the exposed wiring, use a wire cover

(locally purchased) or similar means.

NOTE

• When installing the remote controller back plate, be sure

that it is flat and straight. Do not over-tighten the installation screws.

• Install the remote controller away from all sources of elec-

• Install a noise filter or take other appropriate action if elec-

trical noise.

trical noise affects the power supply circuit of the unit.

Fig. 3

Fig. 4

Fig. 5

Fig. 6

2

Page 22

I How to wire the remote controller

Ceiling

panel

5P FLAP

wiring connector

7P IND and 4P RC

wiring connector

Control

box

cover

Power box cover

Indicator

(1) Turn OFF the power and remove the ceiling panel

air-intake grille. (Refer to 3-6-1 Before Installing the

Ceiling Panel in the Installation Instructions supplied

with the indoor unit.)

(2) Remove the 3 power box cover screws and 2 control

box cover screws, then remove both covers. At this

time, take care not to drop the covers. (Fig. 7)

(3) Disconnect the 7P (IND) terminal and 4P (RC) termi-

nal of the 7P IND and 4P RC wiring connectors and

the 5P terminal of the 5P FLAP wiring connector

from the control box PCB connectors (IND, RC,

FLAP). Disconnect each wiring connector from the

clamp that fastens it. (Fig. 7)

(4) Remove the ceiling panel. (To remove the ceiling

panel, follow the steps for 3-6 How to Install the

Ceiling Panel in the reverse order. Refer to the

Installation Instructions supplied with the indoor unit.)

Indicator

Fig. 7

Fig. 8-a

7P IND and 4P RC

wiring connector

7P IND and 4P RC

wiring connector

Terminal cover

Fig. 8

Clamps

Remote

controller

5P FLAP

wiring

connector

Wire harness

4P

RCIND

FLAP

7P

Control PCB

Putty

Wire harness

Clamping strap

Fig. 8-b

Indicator

Ceiling

panel

Wire harness

5P FLAP

wiring connector

(5) Remove the terminal cover screws, then remove the cover. At this time, take care not to drop the cover. (Fig. 8)

(6) Pull in the wire harness from the remote controller as shown in Fig. 8-b.

• Remove the putty before wiring. After wiring, make sure to restore the putty.

(7) Insert the wire harness 4P terminal into the control box PCB connector (RC). (Fig. 8-a)

(8) Install the terminal cover. Then install the ceiling panel. (Refer to 3-6 How to Install the Ceiling Panel in the

Installation Instructions supplied with the indoor unit.)

(9) Insert only the 7P (IND) terminal of the 7P IND and 4P RC wiring connector into the connector (IND) on the control

box PCB. Store the 4P terminal inside the control box. (Fig. 8-a)

(10) Next, insert the 5P terminal of the 5P FLAP wiring connector into the connector (FLAP) on the control box PCB.

(Fig. 8-a)

(11) When the connections are completed, fasten the wire harness and each wiring connector with the clamps.

(12) Install the power box cover and control box cover.

(13) Install the air-intake grille. (Refer to 3-6 How to Install the Ceiling Panel in the Installation Instructions supplied

with the indoor unit.)

3

Page 23

ON/OFF

operation button

1 HR.TIMER

button

NIGHT SETBACK

button

ACL (Reset)

button

SENSOR button

OPERATION lamp

TIMER lamp

HIGH POWER lamp

REMOTE CONTROL receiver

OPERATION button

I How to Test Run the Air Conditioner

IMPORTANT

After turning on the power of the air conditioner, use the

remote controller and follow the steps below to conduct

the test run.

(1) Set the remote controller in Test Run mode. (Fig. 9)

a)Press and hold the NIGHT SETBACK button and

the 1HR. TIMER button.

b)Then press and hold the ACL (Reset) button with

a pointed object such as the tip of a pen. After 5

seconds, release the ACL button first.

c) Then release the NIGHT SETBACK and 1HR.

TIMER buttons.

d) appears and “oP-1” blinking in the remote

controller clock display area. (Fig. 10)

(2) Start Cooling mode test run by pressing the ON/OFF

operation button of the remote controller. (Fig. 9)

• This starts the fan producing uncooled forced air

with the 3 indicator lamps (OPERATION lamp,

TIMER lamp, and HIGH POWER lamp) on the

main unit blinking. (Fig. 11)

• After 3 minutes, the system shifts into cooling

operation, and cool air will start to be felt. Cooling

mode test run is unaffected by the room temperature.

(3) Press the ON/OFF operation button of the remote

controller again to stop the test run. (Fig. 9)

(4) Finally press the ACL (Reset) button of the remote

controller to release it from Test Run mode to return

to normal mode. (Fig. 9)

• “ ” and “oP-1” will disappear from the remote

controller clock display area.

Fig. 9

Fig. 10

Troubleshooting:

In the event that the green OPERATION lamp is blinking upon powering up the system, an error condition

exists. In this case, refer to the self-diagnostics procedure which can be seen by opening the air-intake grille.

After the test run is completed, be sure to press the

ACL (Reset) button to return to normal mode. The air

conditioner will not operate correctly if this is not done.

NOTE

Fig. 11

4

Page 24

STK-KCW1

(II-852-6-4190-491-00-0)

APPENDIX C INSTALLATION INSTRUCTIONS

Installing the Connection Kit

for Wall-Mounted Models

()

A-3

Page 25

INSTALLATION INSTRUCTIONS

W

P.C. board

Connector (10P)

I Parts included in the package

See Table 1.

Table 1

Parts Figure Q'ty Parts Figure Q'ty Parts Figure Q'ty

Truss-head Phillips

5/32 13/32"

(4 10mm)

1

2

Clamping

strap

7-3/32"(180mm)

Wire tube

Wire

(with a

noise filter)

Tapping

screw

1

Clamp

1

1

Installation

instructions

Label

1

1

I Installing the connection kit

A. 7000 BTU, 9000 BTU, and 12000 BTU inverter models

(1) Remove the air intake grille.

(2) Remove the terminal cover. Pull out the thermistor, then remove the grille.

• For details on steps (1) and (2), refer to the Installation Instructions

included in the outdoor unit package.

(3) Disengage the top cover from the tabs on the sides of the component

box, then pull the cover toward you to remove it. (Fig. 1)

(To disengage the tabs, pull the sides of the top cover sideways and outward from the component box.)

(4) Remove the 4 component box

installation screws. (Fig. 1)

(5) Disconnect the indicator-side connec-

tor (10P) of the wires that connect the

indicator and component box (Fig. 2a).

Then disconnect the connector on the

component box side (10P) and remove

the wires. (Lifting the P.C. board up

slightly will make this work easier.)

(Fig. 2b)

(6) After removing the wires, insert

Connector 1 of the wires (Fig. 3a) that

were included in the kit package into

the indicator (Fig. 2a), then insert

Connector 2 into the component box.

(Fig. 2b)

At this time, pass the wires through so

that they are held inside the 2 holders

on the sides of the component box.

(Fig. 3b)

Indicator

Connector 3

Noise filter

Connector 1

Fig. 2a

(4P)

(10P)

Fig. 3a

Connector (10P)

Connector 2

(10P)

Ta b

Screw

Top cover

Screw

Component box

Fig. 1

Fig. 2b

Holder

Fig. 3b

85264190491000 © SANYO 2009

SANYO Commercial Solutions In Canada

A Division of SANYO North America Corporation SANYO Canada Inc.

1300 Michael Drive, Suite A 1-300 Applewood Crescent, Concord

Wood Dale, IL 60191, U.S.A. Ontario, L4K 5C7, Canada

Page 26

(7) Feed the wire harness that was included in the wired remote controller package

Component box

>

Cut-out

Wire harness

Label

Air intake grille

Self-diagnostic label

into the right lower rear of the unit and route it to the component box. (Fig. 4a)

• When feeding the wire harness through the opening, be careful of the motor

cable and be sure to feed the wire harness and motor cable together through

the opening. (Fig. 4b)

• Be careful not to damage the wire harness when installing the conduit during

unit installation work.

Motor cable

Opening

Component box

Wire harness

(8) Cut the wire tube that was included in the kit package to a length

(9) Take the wires (Fig. 3a) and use a wire clamp to bind together the

(10) Pass the wire tube through the clamping strap, and temporarily fasten in place with the screw.

(11) Tighten the 4 screws to install the component box, taking care not to pinch any of the wires,

(12) Route the wire harness out through the small cut-out located at the bottom right side of the

Wire harness

Fig. 4b

Connector 3

(4P)

of approximately 4 inches (100 mm), then feed the wire harness

through it. Then connect Connector 3 (Fig. 3a) to the wire harness

connector (4P). (Fig. 4c)

wire for the noise filter and the wire for the thermistor (Fig. 5a). Then

Connector (4P)

position them so that the noise filter is contained within the space of

the component box. (Fig. 5b)

Noise filter

Clamp

Thermistor

Fig. 5a

Fig. 5b

Next, use a clamp and bind the wires together immediately above the clamping strap, and

fasten in place with the screw in order to prevent pulling on the wire harness. (Fig. 6a)

• Install the wire tube so that the wires cannot be damaged by the edge of the metal plate.

(Fig. 6a)

• When re-installing the grille, confirm that there is no slack in the wire harness wires.

then install the top cover. (Fig. 6b)

indoor unit frame. (Fig. 7a)

(13) Apply the label that was included in

the package at a location close to

the self-diagnostic label applied to

the air intake grille. (Fig. 7b)

(14) Refer to the Installation Instructions

that were included in the outdoor

unit package and re-install the

grille, thermistor, terminal cover,

and air intake grille.

Fig. 7a

Fig. 7b

Fig. 4c

Fig. 6a

Fig. 4a

Connector 3

Connector (4P)

Wire harness

Wire tube

Wire tube

Clamp

Clamping strap

Screw

Wire harness

<

Completion drawing

Fig. 6b

(4P)

2

Page 27

B. 18000 BTU and 24000 BTU inverter models

< Completion drawing >

(1) Remove the air intake grille.

(2) Remove the terminal cover. Pull out the thermistor, then remove the grille.

• For details on steps (1) and (2), refer to the Installation Instructions included in

the outdoor unit package.

(3) Disengage the top cover from the tabs on the sides of the component box, then

pull the cover toward you to remove it. (Fig. 1)

(To disengage the tabs, pull the sides of the top cover sideways and outward

from the component box.)

(4) Disconnect the indicator-side connector (10P) of the wires that connect the indi-

cator and component box (Fig. 2a). Then disconnect the connector on the component box side (10P) and remove the wires. (Lifting the P.C. board up slightly

will make this work easier.) (Fig. 2b)

(5) After removing the wires, insert Connector 1 of the wires (Fig. 3a) that were

included in the kit package into the indicator (Fig. 2a), then insert Connector 2

into the component box. (Fig. 2b)

At this time, pass the wires through so that they are held inside the 2 holders on

the sides of the component box. (Fig. 3b)

(6) Feed the wire harness that was included in the wired remote controller package

into the right lower rear of the unit. (Fig. 4a)

• Be careful not to damage the wire harness when installing the conduit during

unit installation work.

(7) Pass the wire harness through the wire tube that was included in the kit package.

Then connect Connector 3 (Fig. 3a) to the wire harness connector (4P). (Fig. 4c)

(8) Take the wires (Fig. 3a) and use a wire clamp to bind together the wire for the

noise filter and the wire for the thermistor (Fig. 5a). Then position them so that

the noise filter is contained within the space of the component box. (Fig. 5b)

(9) Pass the wire tube through the clamping strap, and temporarily fasten in place

with the screw. Next, use a clamp and bind the wires together immediately above

the clamping strap, and fasten in place with the screw in order to prevent pulling

on the wire harness. (Fig. 6a)

• Install the wire tube so that the wires cannot be damaged by the edge of the

metal plate. (Fig. 6a)

• When re-installing the grille, confirm that there is no slack in the wire harness

wires.

(10) Install the top cover on the component box. (Fig. 8)

(11) Route the wire harness out through the small cut-out located at the bottom right

side of the indoor unit frame. (Fig. 7a)

(12) Apply the label that was included in the package at a location close to the self-

diagnostic label applied to the air intake grille. (Fig. 7b)

(13) Refer to the Installation Instructions that were included in the outdoor unit pack-

age and re-install the grille, thermistor, terminal cover, and air intake grille.

Fig. 8

3

Page 28

ON/OFF

operation button

1 HR.TIMER

button

NIGHT SETBACK

button

ACL (Reset)

button

SENSOR button

OPERATION lamp

TIMER lamp

QUIET lamp

ION lamp

I How to Test Run the Air Conditioner

IMPORTANT

After turning on the power of the air conditioner, use the

remote controller and follow the steps below to conduct

the test run.

(1) Set the remote controller in Test Run mode. (Fig. 9)

a) Press and hold the NIGHT SETBACK button and

the 1HR. TIMER button.

b) Then press and hold the ACL (Reset) button with

a pointed object such as the tip of a pen. After 5

seconds, release the ACL button first.

c) Then release the NIGHT SETBACK and 1HR.

TIMER buttons.

d) appears with “oP-1” blinking in the remote

controller clock display area. (Fig. 10)

(2) Start Cooling mode test run by pressing the

ON/OFF operation button of the remote controller.

(Fig. 9)

• This starts the fan producing uncooled forced air

with the 4 indicator lamps (OPERATION lamp,

TIMER lamp, QUIET lamp, and ION lamp) on the

main unit blinking. (Fig. 11)

• After 3 minutes, the system shifts into cooling

operation, and cool air will start to be felt. Cooling

mode test run is unaffected by the room temperature.

(3) Press the ON/OFF operation button of the remote

controller again to stop the test run. (Fig. 9)

(4) Finally press the ACL (Reset) button of the remote

controller to release it from Test Run mode to return

to normal mode. (Fig. 9)

• “ ” and “oP-1” will disappear from the remote

controller clock display area.

Fig. 9

Fig. 10

Troubleshooting:

In the event that the green OPERATION lamp is blinking upon powering up the system, an error condition

exists. In this case, refer to the self-diagnostics procedure on the inside of the air-intake grille.

After the test run is completed, be sure to press the

ACL (Reset) button to return to normal mode. The air

conditioner will not operate correctly if this is not done.

NOTE

Fig. 11

4

Page 29

SANYO Commercial Solutions

A Division of SANYO North America Corporation

1300 Michael Drive, Suite A

Wood Dale, IL 60191, U.S.A.

Sanyo Canada Inc.

1-300 Applewood Crescent, Concord, Ontario L4K 5C7, CANADA

Apr. / 2009 (T)

Loading...

Loading...