Page 1

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges,or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Thick Film Hybrid IC

2-Channel Convergence Correction Circuit

(I

C

max = 6A)

Ordering number:ENN5169

STK391-020

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Overview

The STK391-020 is a conver gence correction circuit IC for

video projectors. It incorporates two output amplifiers in a

single package, making possible the construction of CRT

horizontal and vertical convergence correction output circuits for each of the RGB colors using ust three hybrid ICs.

Applications

• V ideo projectors

Features

• 2 output amplifier circuits in a single package

• High maximum supply voltage (VCC max = ±44V)

• Low thermal resistance (θj-c=2.7°C/W)

• High temperature stability (good idling current temperature compensation)

• Low correction coil inductance for improved oscillator

stability (up to fH = 64kHz)

• Pin compatible with the STK4274 for easy replacement

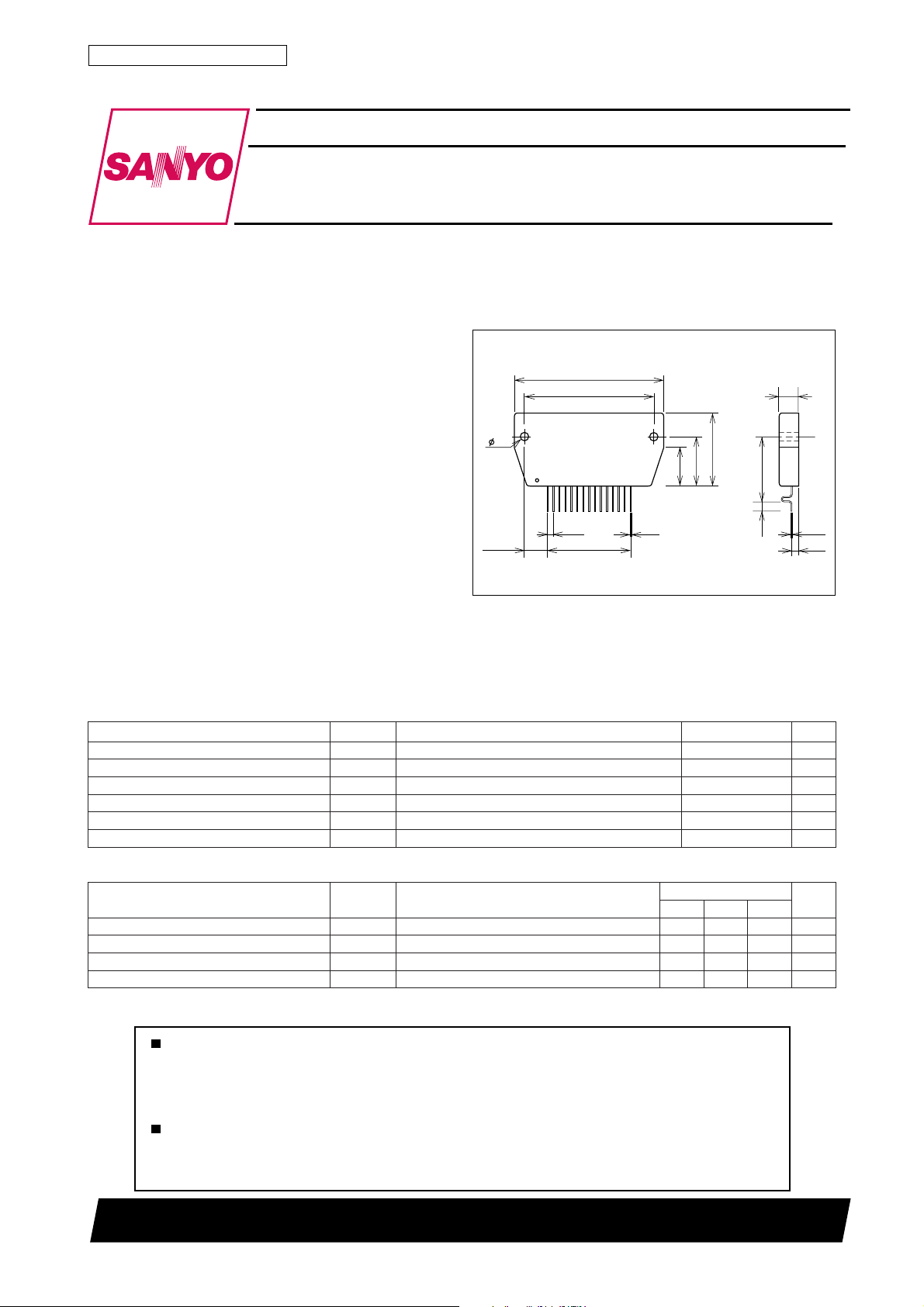

Package Dimensions

unit:mm

4062

3.6

1

(10.02)

64.0

55.6

2.54

14×2.54=35.56

[STK391-020]

16.5

15

0.5

21.0

31.0

8.5

4.0 28.0

SANYO : SIP15

0.4

2.9

Specifications

Maximum Ratings at Ta = 25˚C

retemaraPlobmySsnoitidnoCsgnitaRtinU

egatlovylppusmumixaMV

tnerrucrotcellocmumixaMI

ecnatsiserlamrehT

erutarepmetnoitcnuJjT 051

erutarepmetgnitarepOcT 501

erutarepmetegarotSgtsT 501+ot03–

Operating Characteristics at Ta = 25˚C, Rg=50Ω, VCC=±24V

retemaraPlobmySsnoitidnoC

egatlovesiontuptuOV

tnerructnecseiuQI

egatlovlartueNV

emityaledtuptuOt

xam 44±V

CC

C

θ c-j

ON

OCC

N

D

22,02,11,9rT 0.6A

)rotsisnartrep(22,02,11,9rT 7.2

V,tupnievawralugnairt,zHk57.51=f

p-pV5.1=1sµ

TUO

92099TH (KT)/80995HA (ID) No.5169–1/6

sgnitaR

nimpytxam

2.0smrVm

0204Am

05–005+Vm

˚C/W

˚C

˚C

˚C

tinU

Page 2

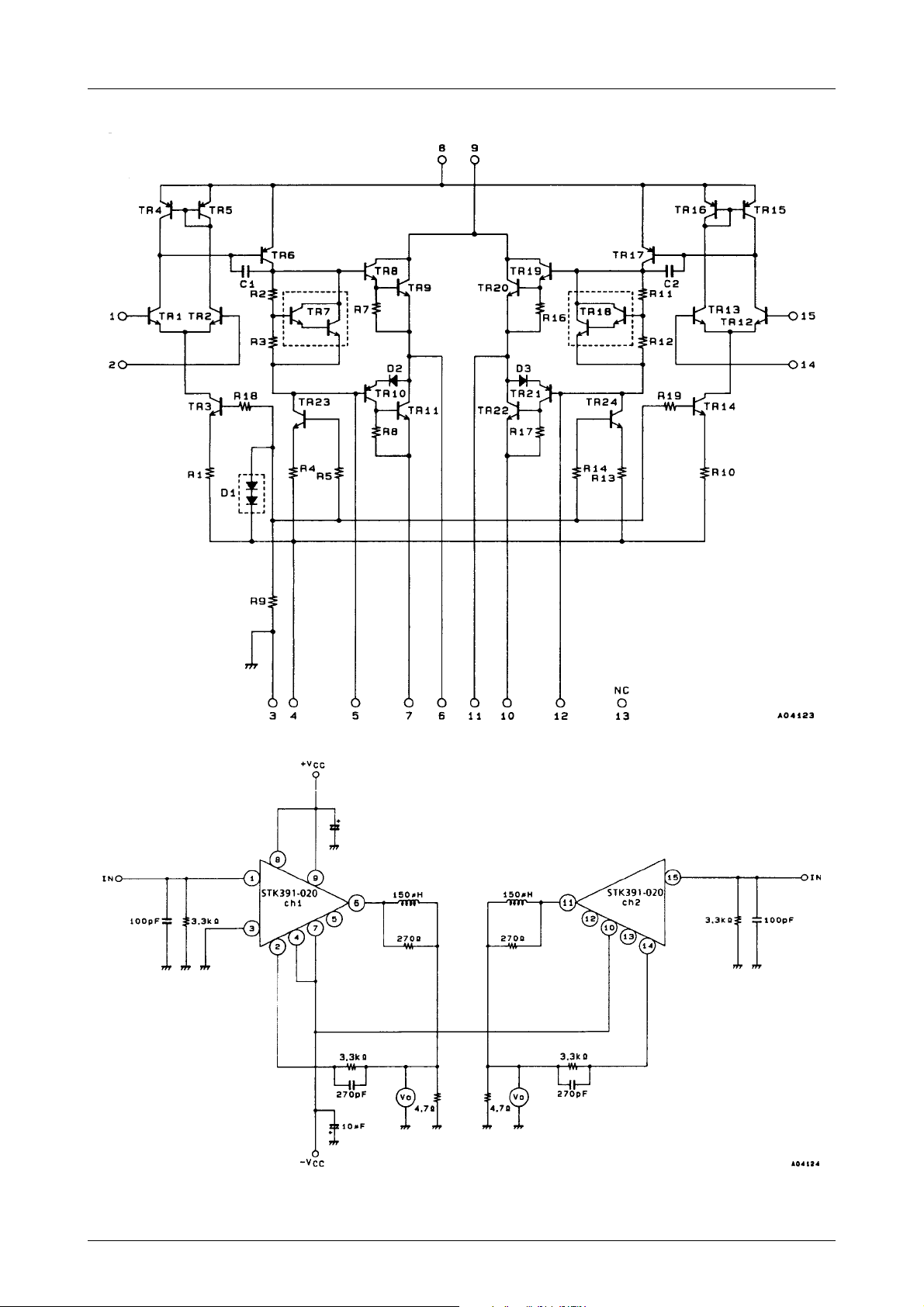

Equivalent Circuit

STK391-020

Test Circuit

Vo : VNO is measured by connecting a VTVM.

VN is measured by connecting a DC voltmeter.

tD is measured by connecting an oscilloscope.

No.5169–2/6

Page 3

STK391-020

No.5169–3/6

Page 4

STK391-020

Maximum Ratings

Tj max, Tc max, θj-c

The heatsink design is determined by the maximum ratings of several key parameters–Tj max, Tc max and θj-c.

• Tj max (junction temperature)

Tj max is dependent on the physical structure of each functional element. A junction temperature exceeding this r ating can lead to device deterioration and breakdown, so

the design must not exceed this rating.

• Tc max (operating substrate temperature)

Tc max is dependent on the materials used within an element and on the circuit design, and should be selected on

the basis of reliability. Operation exceeding this value is

not guaranteed.

• θj-c (thermal resistance)

θj-c is dependent on the heatsink design, which can vary

greatly. the heatsink necessary is determined by calcula-

tion using the maximum rating for Tj.

As Tj and Tc operating conditions are independent, the

heatsink must be designed to satisfy the maximum ratings

for both parameters.

Heatsink Design Considerations

In the expressions below Pd represents the operating IC

substrate internal power dissipation and Pc represents the

power dissipation per transistor. The heatsink thermal resistance, θc-a, required to dissipate the total power dissipation, Pd, is determined as follows :

The power dissipation, Pd, is the sum of channel 1, Pd1,

and channel 2, Pd2, power dissipations.

Pd max=Pd1 max+Pd2 max

Therefore, form equation (1),

θc-a< ................................ (3)

the necessary heatsink resistance is determined (note that

Tc max=105°C)

The power dissipation per power transistor per channel, Pc,

is related to the transistor junction temperature by the following equation.

Tj=Pd max×θc-a+Ta+Pc×θj-c ............................ (4)

where Tj cannot exceed Tj max=105°C. Therfore, in order

to maintain Tj below 150°C, a lower heatsink thermal resistance, θc-a, is necessary to lower Tc.

Heatsink Design Example

This example assumes the following worst-case conditions–

VCCH=±35V, VCCL=±25V, output coil LY=80µH and

RY=0Ω, current detector resistance RNF=4.7Ω, Ip-o

max=0.6Ap-o (Ip-o (Ip-p=1.2A) sawtooth wave input, Io

(DC) max=0.6A DC input, both chanels operating, Ta

max=60°C (guaranteed maximum).

Tc max – Ta max

Pd max

Condition 1: IC substrate temperature not to exceed 105°C

Pd×θc-a+Ta<105°C (Tc max) ............................ (1)

Where Ta is the guaranteed maximum ambient temperature.

Condition 2: Power transistor junction temperature, Tj, not

to exceed 150°C

Pd×θc-a+Pc×θj-c+Ta<150°C (Tj max) .............. (2)

Where θj-c is the power transistor thermal resistance per

transistor. Therefore, the heatsink design m ust satisfy both

these expression.

Design Process

A model circuit for a single channel in the STK319-020 is

shown below.

The channel1 power dissipation, Pd1, is given from Figures 1 and 2.

• Pd1 max=7.0W (AC) with sawtooth wave input

• Pd1 max=13.2W (DC) with DC input

As Pd1 max (AC) < Pd1 max (DC), the power dissipation

is greater with DC input. Also, lokking at the output transistor dissipation, Pc,

• Pc=0.5Pd1 with sawtooth wave input

• Pc=Pd1 with DC input (one side transistor continuously

ON)

the power dissipation is also higher with DC input. Accordingly, the heatsink design example below assumes DC

input. The power dissipation in the predriver stage is ignored.

As Pd1 max=Pd2 max+13.2W, Pd max (both channels) is

given by.

Pd max=Pd1 max+Pd2 max=26.4W

From equation (3) with Ta=60°C,

θc-a= = = ........ 1.70°C/W

For a 2mm aluminum heatsink with no surface coating, the

necessary surface area, S, is given from Figure 3.

Tc max – Ta

Pd max

105–60

26.4

S=780cm2 (28cm×28cm)

No.5169–4/6

Page 5

STK391-020

Also from equation (4), the output stage power transistor

jucntion temperature is given by

Tj =Pd max×θc-a+Ta+Pc max×θj-c

=26.4×1.7+60+13.2×2.7

=140.5°C

which provides a 9.5°C derating below Tj max=150°C.

However, an allowance for the predri v er stage power dissipation (transistors, resistors, etc.) should also be included

in the substrate internal power dissipation, Pd.

No.5169–5/6

Page 6

STK391-020

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of September, 1999. Specifications and information herein are

subject to change without notice.

PS No.5169–6/6

Loading...

Loading...