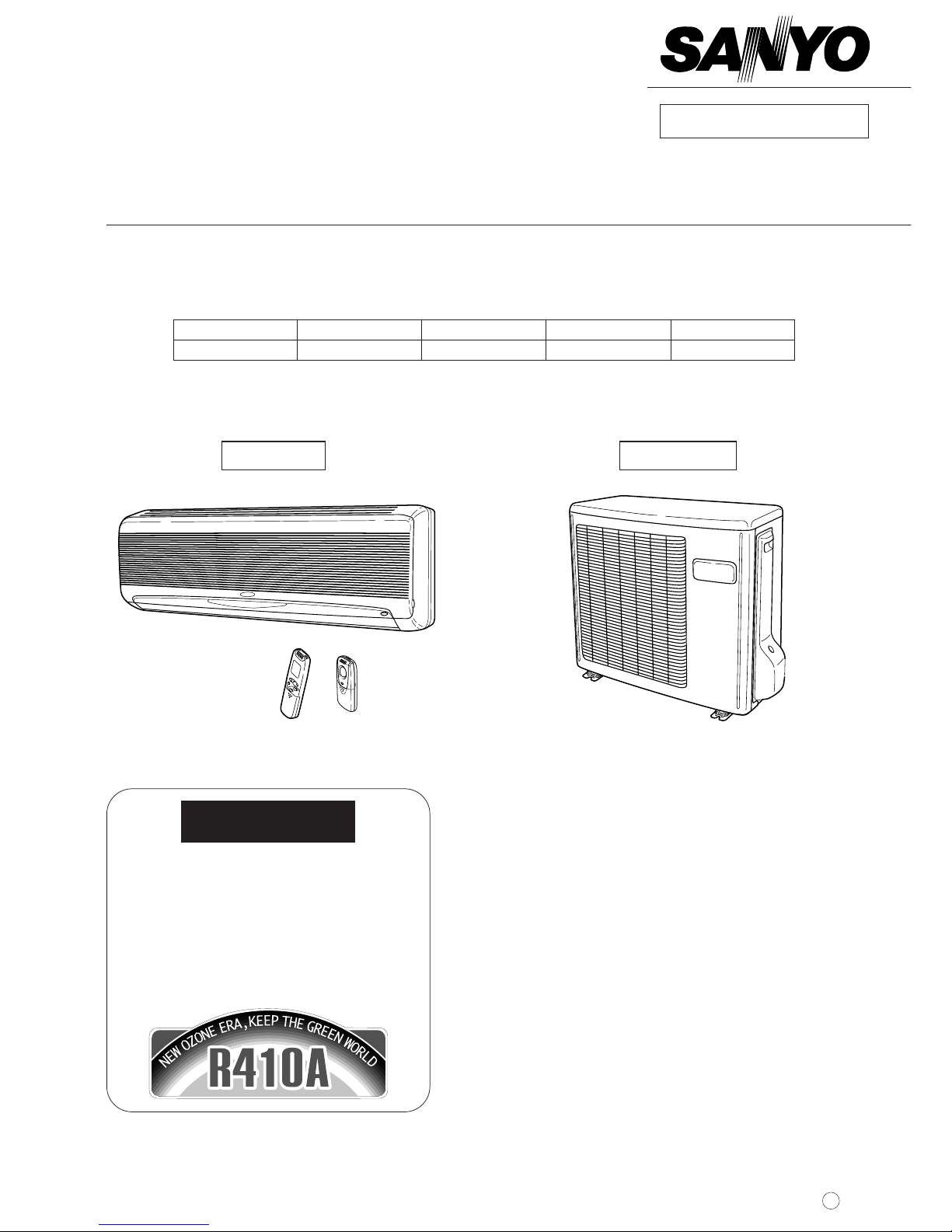

Sanyo SAP-KRV91EH,SAP-CRV91EH Technical & Service Manual

TECHNICAL & SERVICE MANUAL

SAP-KRV91EH + SAP-CRV91EH

INVERTER SPLIT SYSTEM AIR CONDITIONER

SAP-CRV91EHSAP-KRV91EH

FILE NO.

REFERENCE NO. SM700386

W

Indoor Unit Outdoor Unit

IMPORTANT

These air conditioners employ new

refrigerant R410A.

Pay special attention when servicing

the unit.

➞ See “11. REFRIGERANT R410A

SPECIAL PRECAUTIONS WHEN

SERVICING THE UNIT”.

Indoor Model No. Product Code No. Outdoor Model No. Product Code No. Destination

SAP-KRV91EH 1 852 065 78 SAP-CRV91EH 1 852 065 79 Europe

i

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system

so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as

shown.

●

Observe all local, state, and national electrical codes.

●

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or unsafe practice which

can result in severe personal

injury or death.

This symbol refers to a hazard

or unsafe practice which can

result in personal injury or

product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for

a special problem, contact our sales/service outlet or

your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections

and inadequate grounding can cause accidental

injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your

knees when lifting to reduce strain on your back. Sharp

edges or thin aluminum fins on the air conditioner can

cut your fingers.

When Installing…

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leakfree connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit being serviced.

Others

• Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously

toxic gas.

• Confirm upon completing installation that no refrigerant gas is leaking. If escaped gas comes in contact

with a stove, gas water heater, electric room heater or

other heat source, it can produce dangerously toxic

gas.

WARNING

WARNING

CAUTION

CAUTION

ii

Table of Contents

Page

1. OPERATING RANGE................................................................................................................ 1

2. SPECIFICATIONS

2-1. Unit Specifications............................................................................................................ 2

2-2. Major Component Specifications...................................................................................... 3

2-3. Other Component Specifications...................................................................................... 5

3. DIMENSIONAL DATA................................................................................................................ 6

4. REFRIGERANT FLOW DIAGRAM

4-1. Refrigerant Flow Diagram................................................................................................. 8

5. PERFORMANCE DATA

5-1. Temperature Charts..........................................................................................................9

5-2. Air Throw Distance Charts................................................................................................ 10

5-3. Frequency Charts............................................................................................................. 11

6. ELECTRICAL DATA

6-1. Electrical Characteristics ..................................................................................................13

6-2. Electric Wiring Diagrams .................................................................................................. 14

7. INSTALLATION INSTRUCTIONS

7-1. Installation Site Selection .................................................................................................16

7-2. Refrigerant Tubing............................................................................................................ 19

7-3. Remote Control Unit Installation Position......................................................................... 20

8. MAINTENANCE

8-1. Changing Address of Indoor Unit and Remote Control Unit............................................. 21

8-2. Disconnecting and Connecting Positive Connector for Outdoor Unit............................... 21

9. FUNCTION

9-1. Functions for Operation.................................................................................................... 22

9-2. Protective Functions......................................................................................................... 25

10. TROUBLESHOOTING

10-1. Operating State................................................................................................................ 28

10-2. Troubleshooting Using the Self-Diagnostic Monitor......................................................... 29

10-3. Fault Assessment of Indoor/Outdoor Unit........................................................................ 31

10-4. Problems with Noise and Radio Interference................................................................... 32

11. REFRIGERANT R410A: SPECIAL PRECAUTIONS WHEN SERVICING UNIT

11-1. Characteristics of New Refrigerant R410A....................................................................... 33

11-2. Checklist Before Servicing ............................................................................................... 33

11-3. Tools Specifically for R410A............................................................................................. 35

11-4. Tubing Installation Procedures......................................................................................... 35

11-5. In Case of Compressor Malfunction................................................................................. 36

11-6. In Case Refrigerant is Leaking......................................................................................... 38

11-7. Charging Additional Refrigerant....................................................................................... 40

iii

11-8. Retro-Fitting Existing Systems......................................................................................... 40

12. CHECKING ELECTRICAL COMPONENTS

12-1. Measurement of Insulation Resistance............................................................................ 41

12-2. Checking Continuity of Fuse on PCB Ass’y ..................................................................... 42

12-3. Checking Motor Capacitor................................................................................................ 42

INSTRUCTION MANUAL

APPENDIX

1

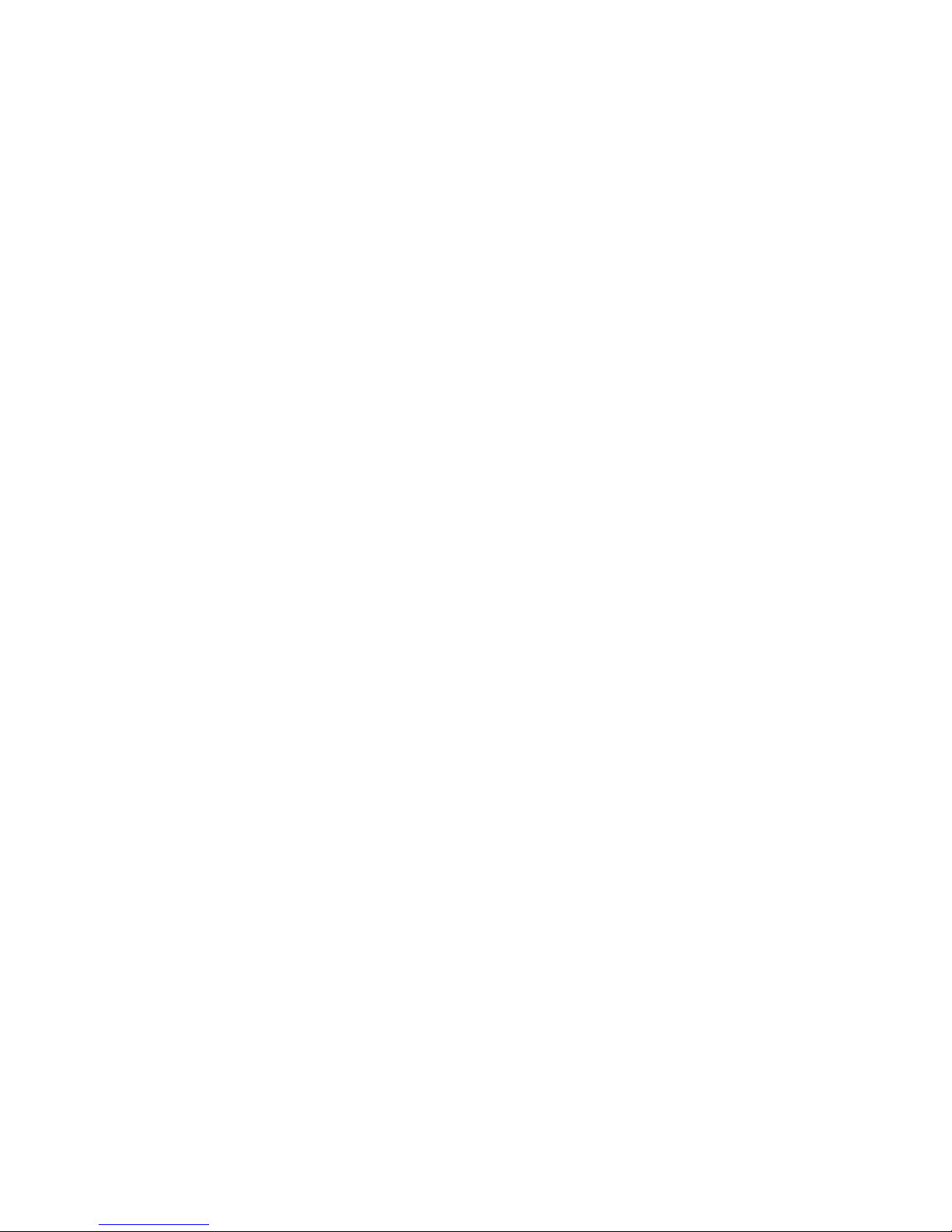

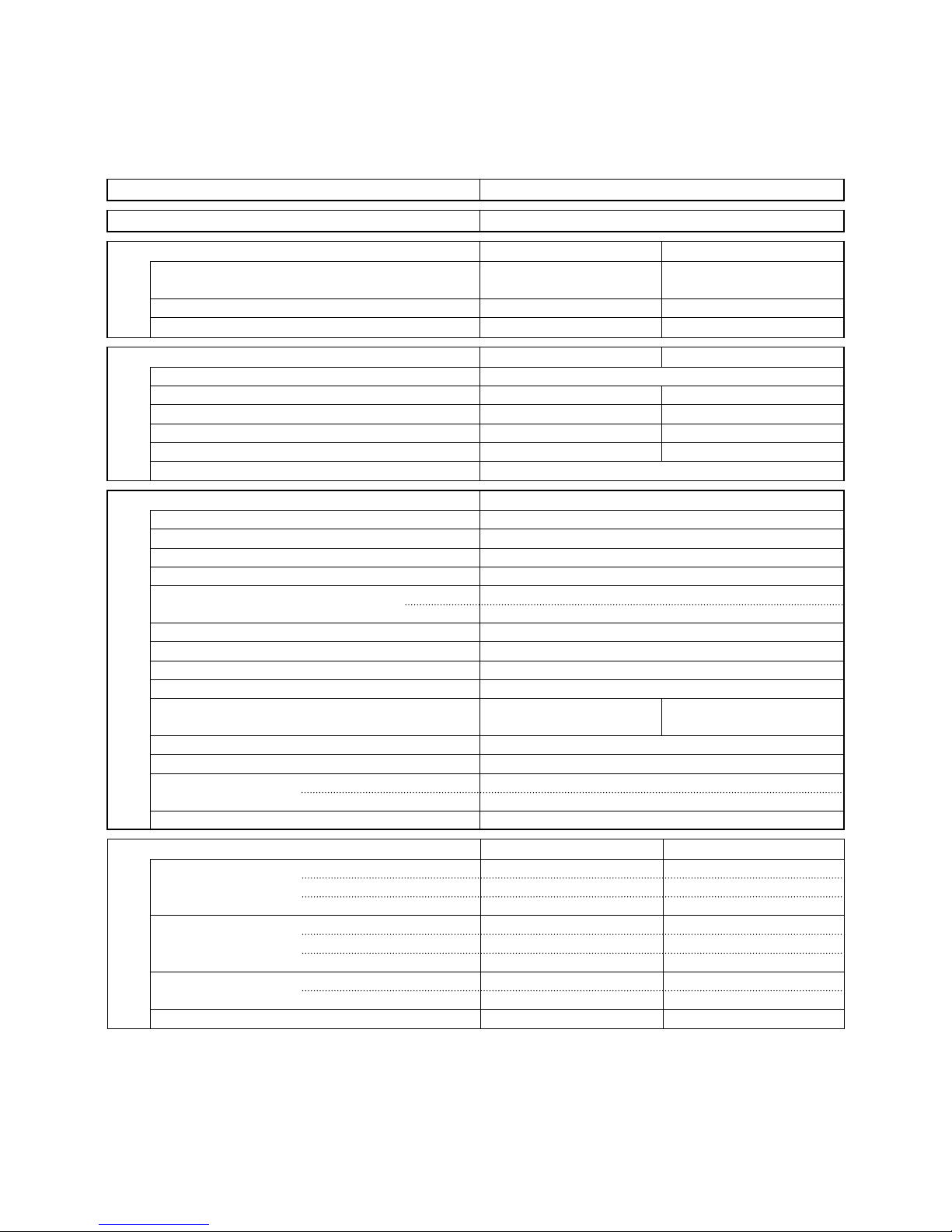

1. OPERATING RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Maximum 32°C D.B. / 23°C W.B. 43°C D.B.

Minimum 19°C D.B. / 14°C W.B. 19°C D.B.

Heating

Maximum 27°C D.B. 24°C D.B. / 18°C W.B.

Minimum 16°C D.B. –8°C D.B. / –9°C W.B.

2

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

Heating: Indoor air temperature 20°C D.B.

Outdoor air temperature 7°C D.B. / 6°C W.B.

2. SPECIFICATIONS

2-1. Unit Specifications

Indoor unit SAP-KRV91EH

Outdoor unit SAP-CRV91EH

Power Source 220 – 230V Single phase 50Hz

Performance Cooling Heating

Capacity kW 2.80 (0.5 – 4.0) 4.20 (0.5 – 6.0)

BTU/h 9,600 (1,700 – 13,600) 14,330 (1,700 – 20,500)

Air circulation (High) m3/h 550 680

Moisture removal (High) Liters/h 1.1 —

Electrical Rating Cooling Heating

Available voltage range V 198 – 253

Running amperes A 3.6 (0.7 – 6.2) 4.6 (0.6 – 7.8)

Power input W 700 (105 – 1,360) 990 (90 – 1,760)

Power factor % 85 94

C.O.P. W/W 4.0 4.2

Compressor locked rotor amperes A 15

Features

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer ON / OFF 24 hours & Daily program, 1-hour OFF

Fan speeds Indoor / Outdoor 3 and Auto / Auto (Variable)

Airflow direction (Indoor) Horizontal Auto

Vertical Auto

Air filter Washable, Anti-Mold

Compressor Rotary (Hermetic)

Refrigerant / Amount charged at shipment g R410A / 1,290

Refrigerant control Electric Expansion Valve

Operation sound Indoor: Hi / Me / Lo dB-A 37 / 35 / 31 42 / 37 / 32

Outdoor: Hi dB-A 43 44

Refrigerant tubing connections Flare type

Max allowable tubing length at shipment m 7.5

Refrigerant Narrow tube mm (in.) 6.35 (1/4)

tube diameter Wide tube mm (in.) 9.52 (3/8)

Refrigerant tube kit / Accessories Optional / Air Clean Filter

Voltage Rating 230V

Dimensions & Weight Indoor Unit Outdoor Unit

Unit dimensions Height mm 285 620

Width mm 805 700

Depth mm 189 260

Package dimensions Height mm 264 681

Width mm 865 835

Depth mm 349 364

Weight Net kg 9.0 36.0

Shipping kg 12.0 38.0

Shipping volume m

3

0.08 0.207

3

2-2. Major Component Specifications

2-2-1. Indoor Unit

Indoor unit SAP-KRV91EH

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

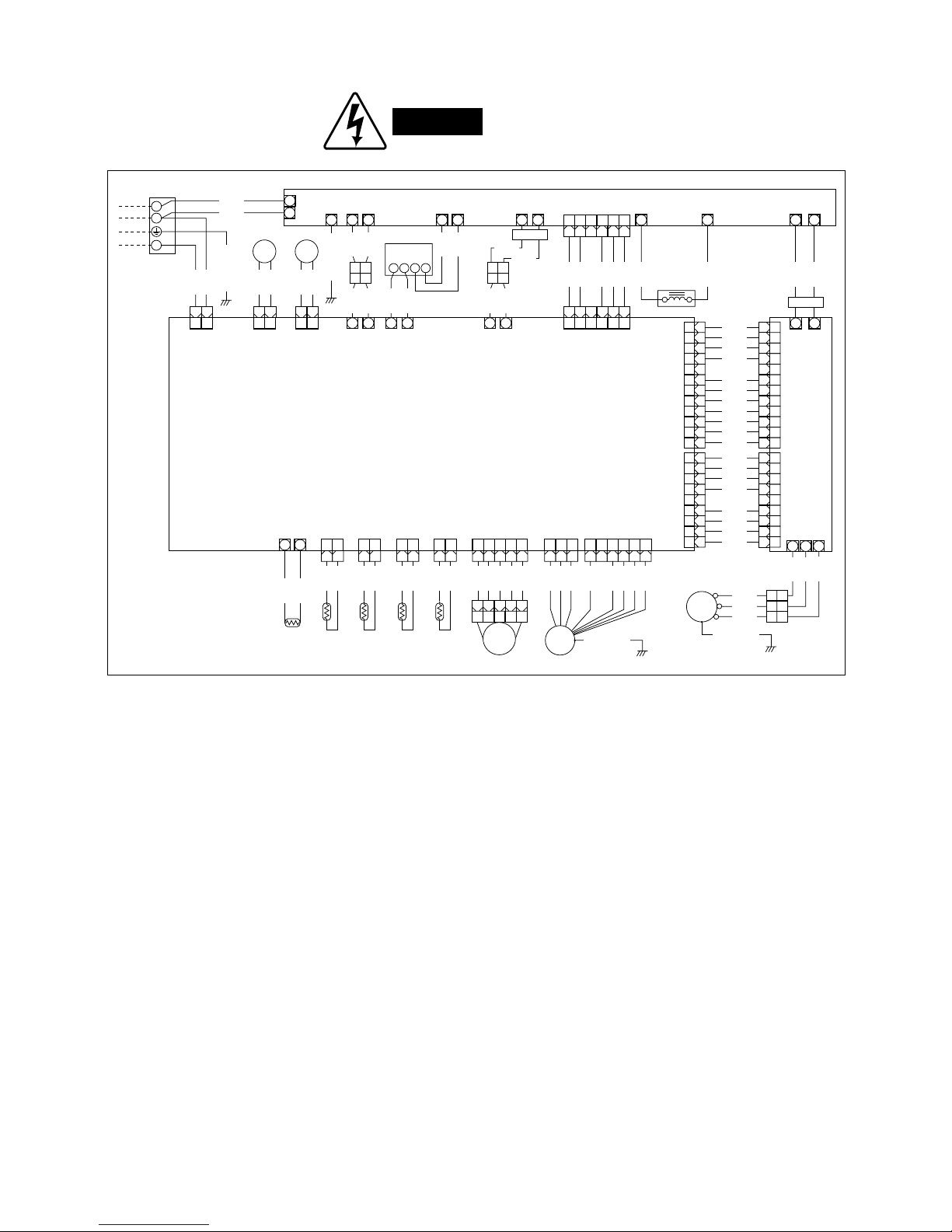

Control PCB

Part No. CB-KRV91EH

Controls Microprocessor

Control circuit fuse 250V 3.15A

Flap Motor and Louver Motor

Type Stepping motor

Model MP24S1-5V MP24S2-5V

Rating DC5V

Coil resistance (Ambient temp. 25°C) Ω WHT – BLU (respectively 4 wires): 70 ± 7%

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.3

Face area m

2

0.130

Fan & Fan Motor

Type Cross-flow

Q’ty … Dia. and length mm 1 … D88

Fan motor model … Q’ty DA4-23P36M … 1

No. of poles … rpm (230V, High) 4 … 1190

Nominal output W 10

Coil resistance (Ambient temp. 20°C) Ω BLU – RED: 5.67

RED – WHT: 5.67

WHT – BLU: 5.67

Safety devices Type —

Operating temp. Open °C —

Close —

Run capacitor µF —

VAC —

Remote Control Unit RCS-IHPS41E / RCS-IHCS4E

4

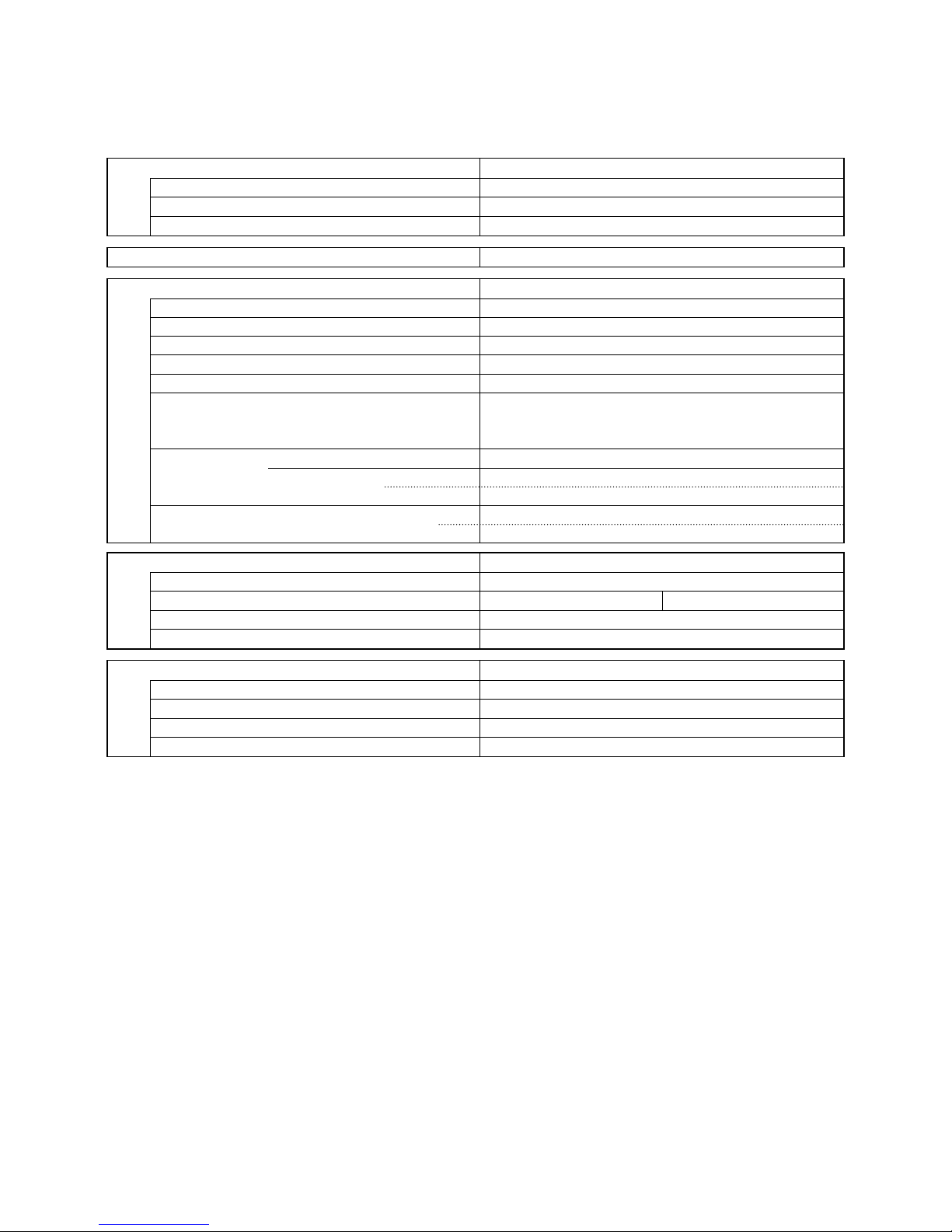

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

2-2-2. Outdoor Unit

Outdoor unit SAP-CRV91EH

Control PCB POW-CV121CH

Compressor

Type Rotary (Hermetic)

Compressor model C-6RVN73HOT 80879680

Compressor oil … Amount cc FV68S … 350

Coil resistance (Ambient temp. 25°C) Ω C – R: 0.781

C – S: 0.781

Safety devices

CT (Peak current cut-off control) YES

Compressor discharge temp. control YES

Operation cut-off control in abnormal ambient temp. YES

Run capacitor µF —

VAC —

Crankcase heater —

Fan & Fan Motor

Type Propeller

Q’ty … Dia. mm 1 … ø400

Fan motor model … Q’ty DB8-33B280H … 1

No. of poles … rpm (230V, High) 8 … 730

Nominal output W 30

Coil resistance (Ambient temp. 20°C) Ω RED – WHT: 150.3

BLU – WHT: 150.3

BLU – RED: 150.3

Safety devices Type —

Operating temp. Open °C —

Close °C —

Run capacitor µF —

VAC —

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.4

Face area m

2

0.366

External Finish Acrylic baked-on enamel finish

5

2-3. Other Component Specifications

2-3-1. Indoor Unit

Indoor unit SAP-KRV91EH

Thermistor (Room sensor) DTN-TKS150Y

Resistance kΩ 25°C 5.0 ± 3%

Thermistor (Coil sensor) DTN-TKS150Y

Resistance kΩ 25°C 58.3

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

4-way Valve (SC) VPV-M0AJ503B (Coil), VHV-0202 (Valve)

Coil rating AC 220 /240V, 50Hz, 6W

Thermostat (Suction sensor) KTM-35D-S1

Resistance kΩ 0°C 15

Thermistor (Coil sensor) DTN-TKS163B

Resistance kΩ 0°C 15

Thermistor (Air sensor) KTEC-35D-S3

Resistance kΩ 0°C 15

Thermistor (Compressor sensor) DTN-TKS164B

Resistance kΩ 25°C 58.3

PTC Thermistor (TH) 912X24E400XR-A

Resistance Ω (at 25°C) 40

2-3-2. Outdoor Unit

Outdoor unit SAP-CRV91EH

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

6

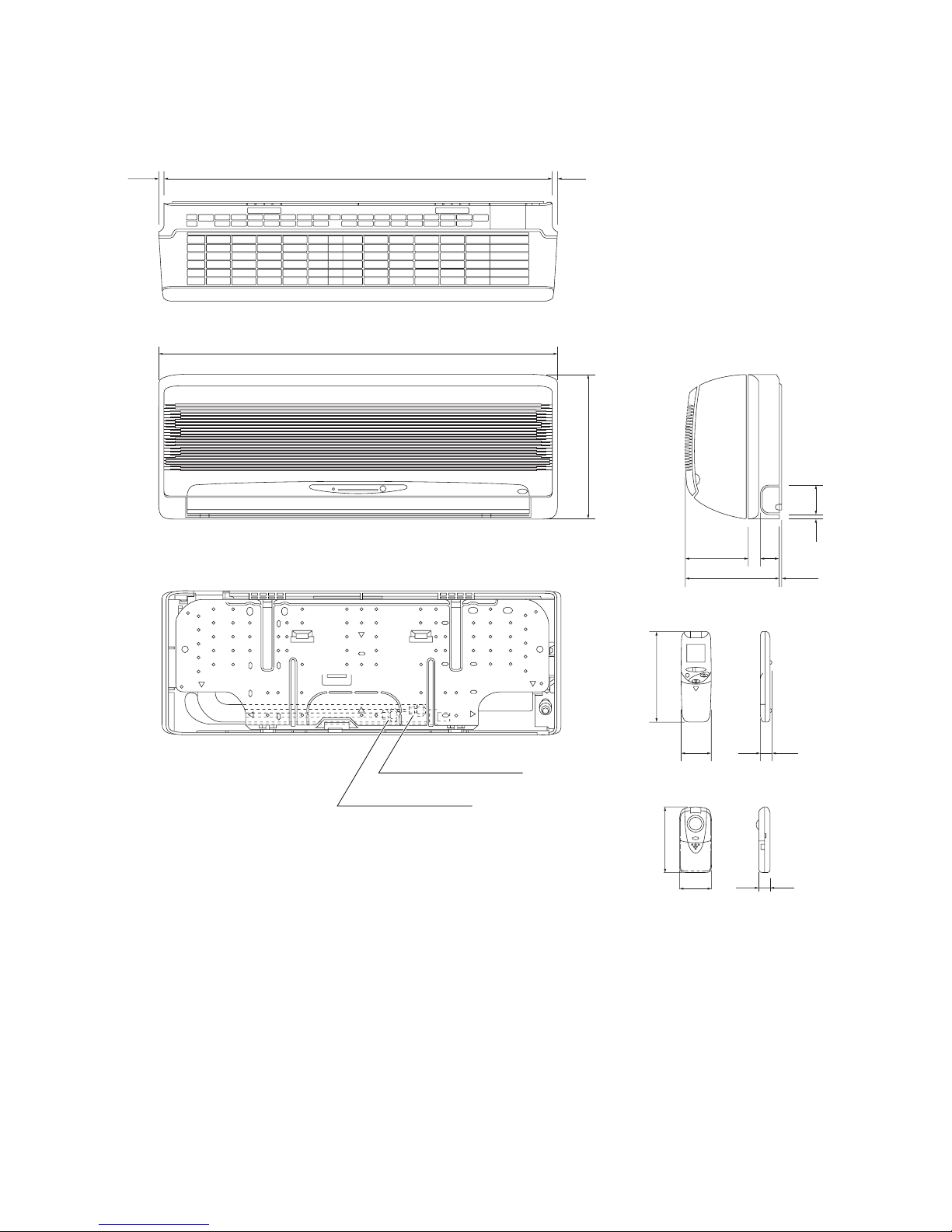

10 10785

805.0

285.0

126.0 40

193.0 (3)

10 56

61

182

23

Remote control unit

People sensor

130

22

Wide tube ø9.52 (3/8")

Narrow tube ø6.35 (1/4")

3. DIMENSIONAL DATA

Indoor unit SAP-KRV91EH

Unit: mm

7

Outdoor unit SAP-CRV91EH

289700

538

538

234

300

300

234

151.5 46

180

81

620

16

70

Narrow tube service valve ø6.35 (1/4")

Wide tube service valve ø9.52 (3/8")

Location of Service Valves

Service valves are located behind the side panel.

See the illustration below.

NOTE

Unit: mm

8

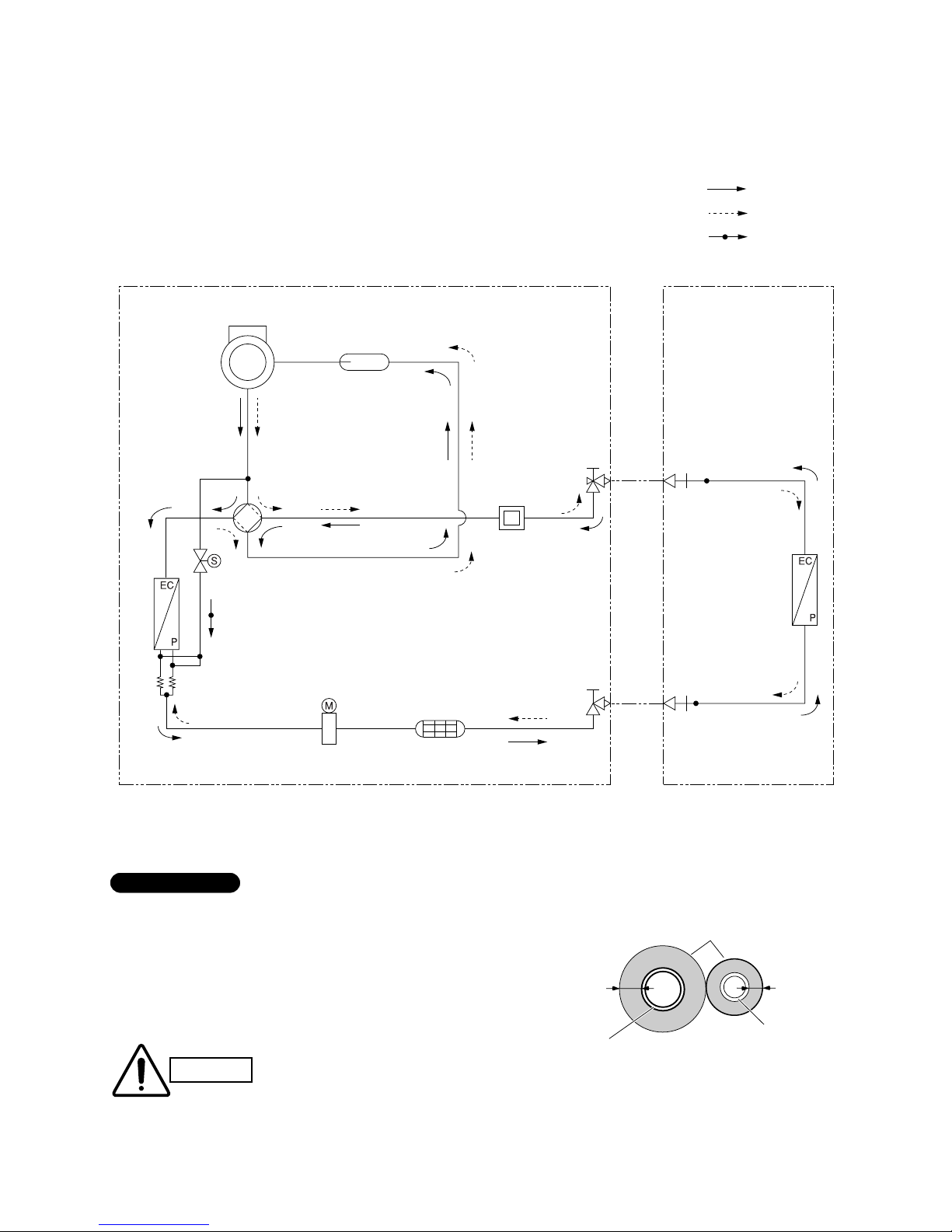

4. REFRIGERANT FLOW DIAGRAM

4-1. Refrigerant Flow Diagram

Indoor unit SAP-KRV91EH

Outdoor unit SAP-CRV91EH

ø9.52

ø6.35

Indoor heat

exchanger

Outdoor

heat exchanger

Outdoor unit Indoor unit

Wide tube

service valve

Narrow tube

service valve

Wide tube

nipple

Narrow tube

nipple

Accumulator

Muffler

Capillary

tube for distribution

EM valve

4-way valve

Cooling cycle

Heating cycle

Defrosting

Compressor

Strainer

Electronic expansion valve

Modulator

Insulation of Refrigerant Tubing

Because capillary tubing is used in the outdoor unit, both the

wide and narrow tubes of this air conditioner become cold. To

prevent heat loss and wet floors due to dripping of condensation, both tubes must be well insulated with a proper insulation material. The thickness of the insulation should be a

minimum 8 mm.

IMPORTANT

CAUTION

After a tube has been insulated,

never try to bend it into a narrow

curve because it can cause the

tube to break or crack.

Wide tube

Thickness:

Min. 8 mm

Insulation

Narrow tube

Thickness:

Min. 8 mm

9

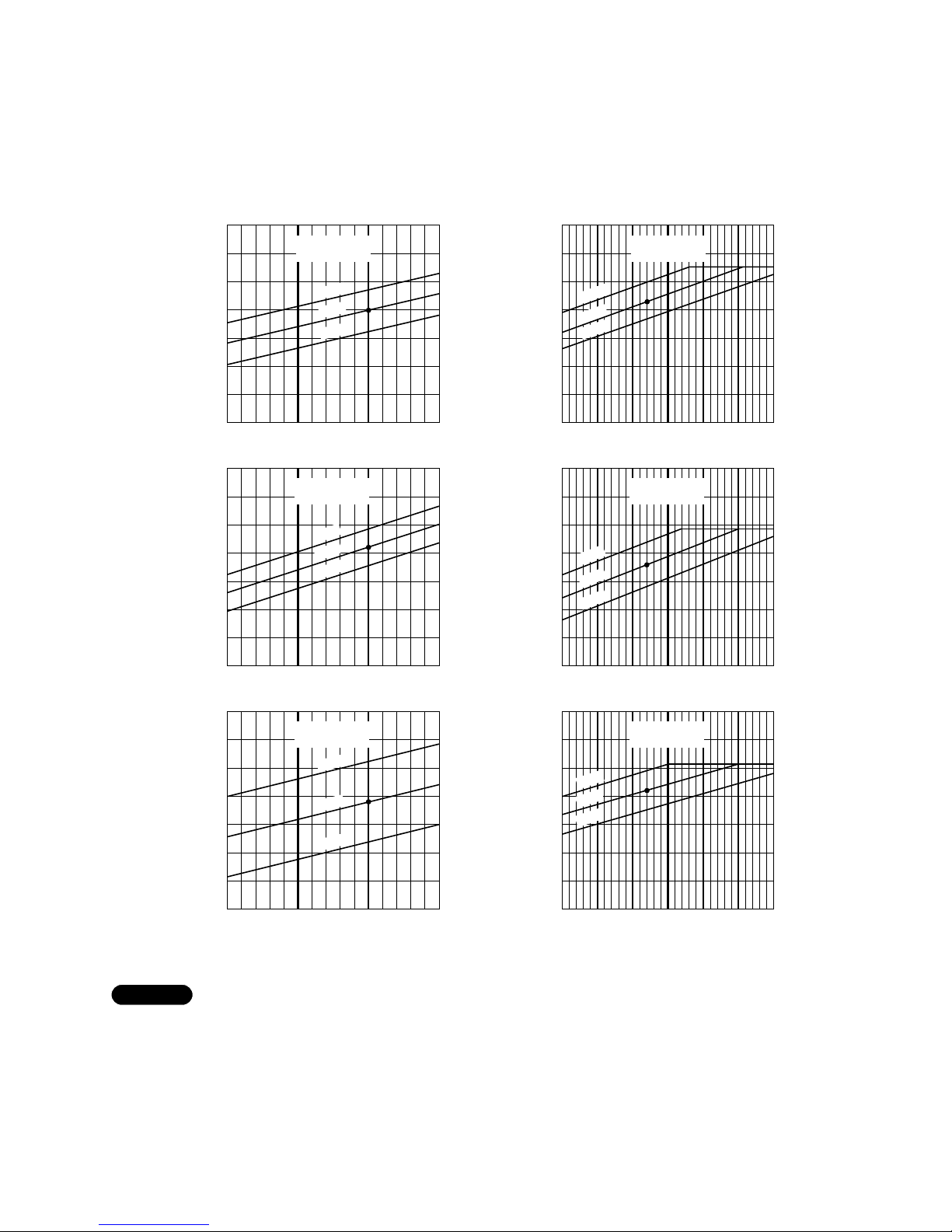

5. PERFORMANCE DATA

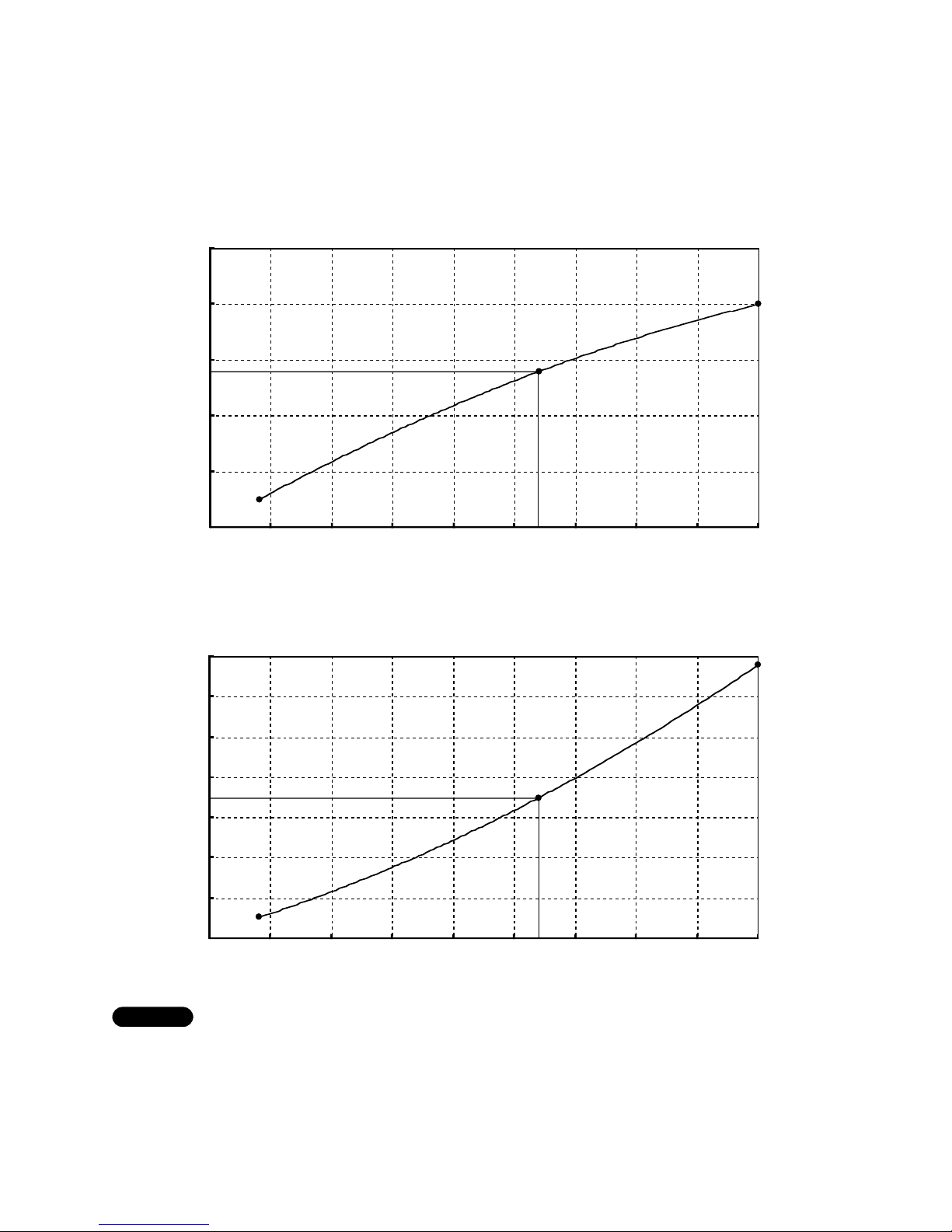

5-1. Temperature Charts

Indoor unit SAP-KRV91EH

Outdoor unit SAP-CRV91EH

■ Cooling Characteristics (50Hz, 230V) ■ Heating Characteristics (50Hz, 230V)

25 30 35 40

0.69

(6)

0.59

(5)

0.49

(4)

25 30 35 40

16

15

14

13

12

11

10

–5 0 5 10 15 20 25

2.45

(24)

2.06

(20)

1.67

(16)

1.28

(12)

–5 0 5 10 15 20 25

8

6

7

4

5

2

3

–5 0 5 10 15 20 25

60

55

50

45

40

35

30

25 30 35 40

Low pressure at wide tube service valve

MPa (kgf/cm

2

G)

High pressure at wide tube service valve

MPa (kgf/cm

2

G)

Outdoor inlet air D.B. temp.(˚C) Outdoor inlet air D.B. temp.(˚C)

Outdoor inlet air D.B. temp.(˚C) Outdoor inlet air D.B. temp.(˚C)

Outdoor inlet air D.B. temp.(˚C) Outdoor inlet air D.B. temp.(˚C)

Indoor inlet air

D.B. temp. (˚C)

Indoor inlet air

D.B. temp. (˚C)

20°C

24°C

27°C

30°C

Operating current (A)

Operating current (A)

Indoor inlet air

D.B. temp. (˚C)

Indoor inlet air

D.B. temp. (˚C)

24°C

27°C

30°C

Indoor discharge air temperature (˚C)

Indoor discharge air temperature (˚C)

Indoor inlet air

D.B. temp. (˚C)

Indoor inlet air

D.B. temp. (˚C)

24°C

27°C

30°C

23°C

17°C

20°C

17°C

23°C

5

4

3

2

20°C

17°C

23°C

Overload prevention operates to protect the air conditioner when outdoor ambient temperature becomes

extremely high in heating mode. (Refer to “9-2-3. Overload Prevention in Heating”.)

● … Points of rating condition

Black dots in above charts indicate the following rating conditions.

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B. Heating: Indoor air temperature 20°C D.B.

Outdoor air temperature 35°C D.B. / 24°C W.B. Outdoor air temperature 7°C D.B. / 6°C W.B.

NOTE

10

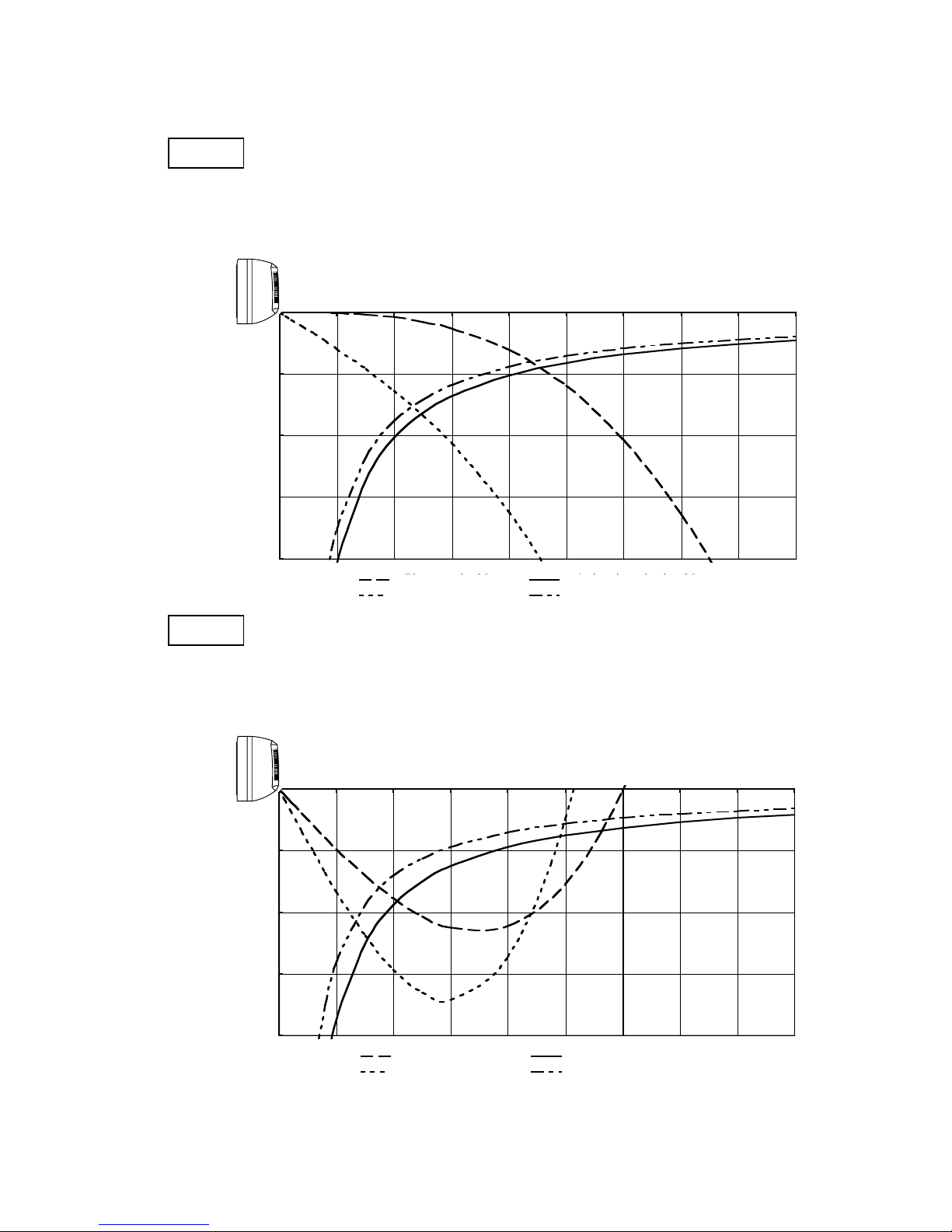

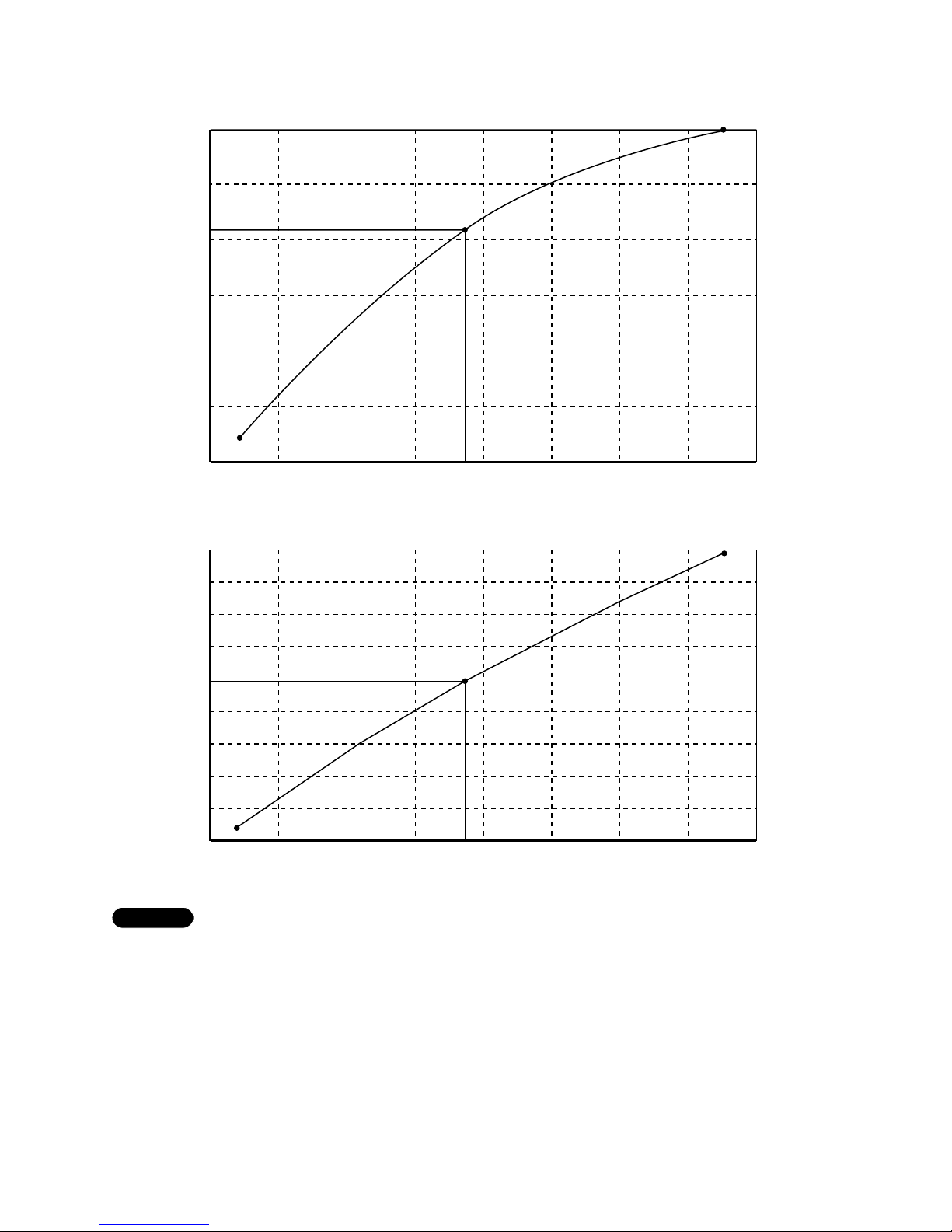

5-2. Air Throw Distance Charts

Indoor unit SAP-KRV91EH

Horizontal distance (m)

Axis air velocity (m/s)

Vertical distance (m)

Room air temp. : 20°C

Fan speed : High

Heating

Horizontal distance (m)

Axis air velocity (m/s)

Vertical distance (m)

Room air temp. : 27°C

Fan speed : High

Cooling

0

1

2

3

4

0123456789

: Flap angle 0° , : Axis air velocity 0°

: Flap angle 30° , : Axis air velocity 30

0

1

2

3

4

0123456789

: Flap angle 45° , : Axis air velocity 45

: Flap angle 60° , : Axis air velocity 60

Flap angle 0°

Flap angle 30°

Axis air velocity 0°

Axis air velocity 30°

Flap angle 45°

Flap angle 60°

Axis air velocity 45°

Axis air velocity 60°

11

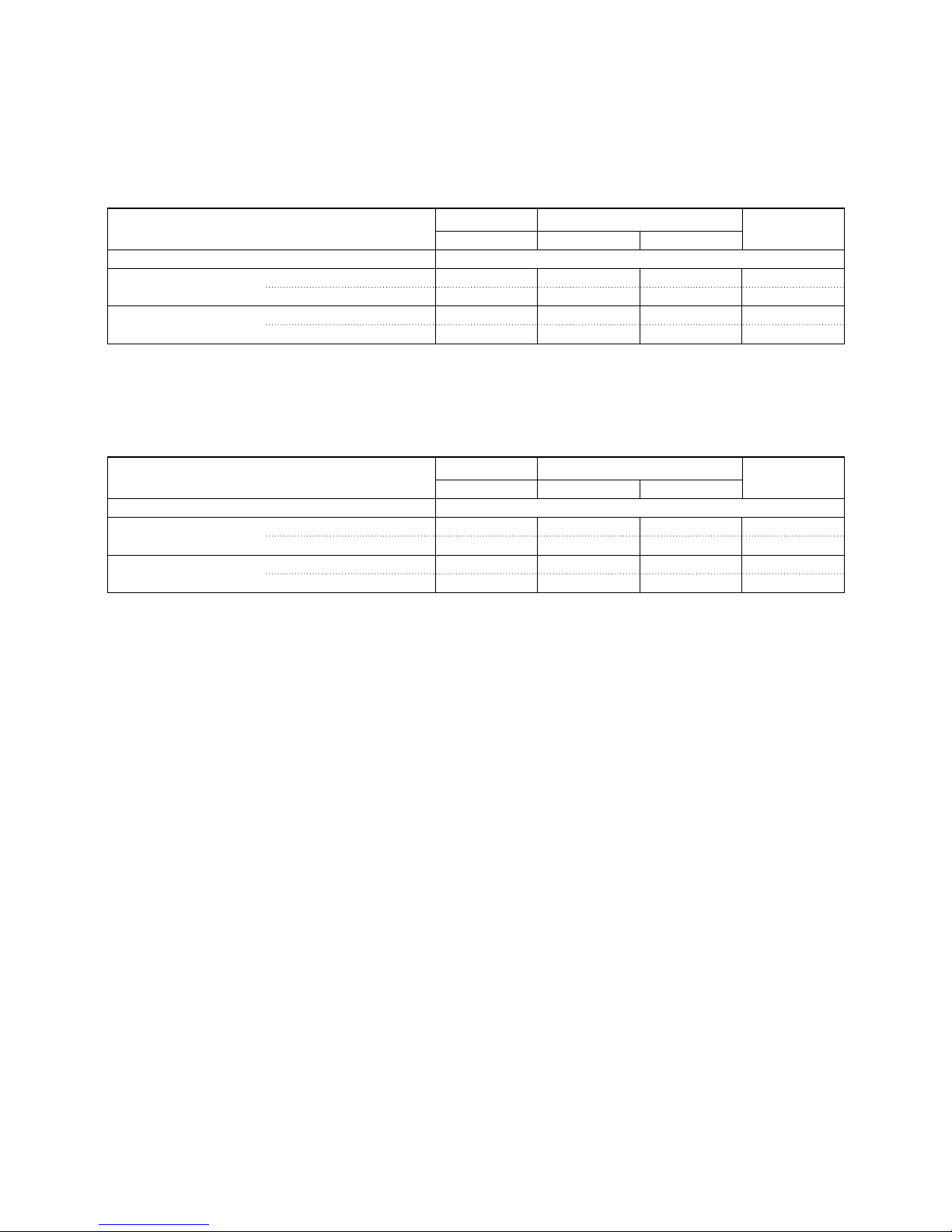

5-3. Frequency Charts

Indoor unit SAP-KRV91EH

Outdoor unit SAP-CRV91EH

1) Rating conditions in cooling mode are:

Indoor: 27°C D.B. / 19°C W.B.

Outdoor: 35°C D.B. / 24°C W.B.

2) Fan speed: High

NOTE

230V Single Phase 50Hz

0

200

400

600

800

1000

1200

1400

0102030405060708090

Operating Freqency (Hz)

Power Input (W)

54

700

■ Cooling

Power input (W)

Operating frequency (Hz)

0

1

2

3

4

5

0102030405060708090

Operating Freqency (Hz)

Cooling Capacity (kW)

54

2.8

Cooling capacity (kW)

Operating frequency (Hz)

12

1) Rating conditions in heating mode are:

Indoor: 20°C D.B.

Outdoor: 7°C D.B. / 6°C W.B.

2) Fan speed: High

NOTE

6

5

4

3

2

1

0

020406076 80 100 120 140 160

4.2

Cooling capacity (kW)

Operating frequency (Hz)

230V Single Phase 50Hz

1800

1600

1200

1000

800

990

600

200

400

0

020406076 80 100 120 140 160

1400

Cooling capacity (kW)

Operating frequency (Hz)

■ Heating

13

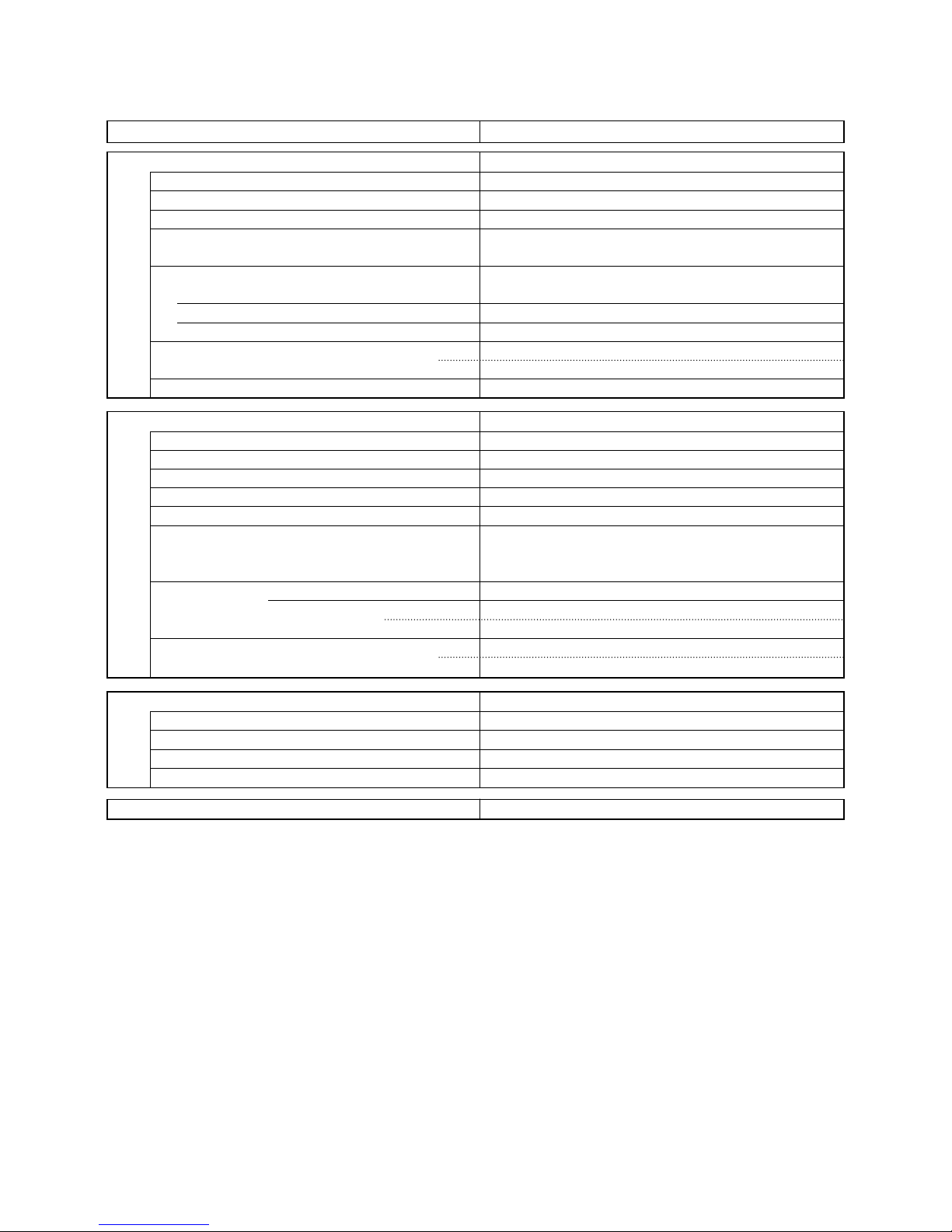

6. ELECTRICAL DATA

6-1. Electrical Characteristics

Indoor unit SAP-KRV91EH

Outdoor unit SAP-CRV91EH

Indoor Unit Outdoor Unit Complete Unit

Fan Motor Fan Motor Compressor

Performance at 230V Single phase 50Hz

Rating conditions Running amp. A 0.23 0.37 3.0 3.6

Power input kW 0.026 0.043 0.631 0.70

Full load Running amp. A 0.23 0.37 5.6 6.2

Power input kW 0.026 0.043 1.291 1.36

Rating conditions: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B.

Rating conditions: Indoor air temperature 20°C D.B.

Outdoor air temperature 7°C D.B. / 6°C W.B.

Indoor Unit Outdoor Unit Complete Unit

Fan Motor Fan Motor Compressor

Performance at 230V Single phase 50Hz

Rating conditions Running amp. A 0.35 0.34 3.91 4.6

Power input kW 0.041 0.037 0.912 0.99

Full load Running amp. A 0.35 0.34 7.11 7.8

Power input kW 0.041 0.037 1.682 1.76

Heating

Cooling

14

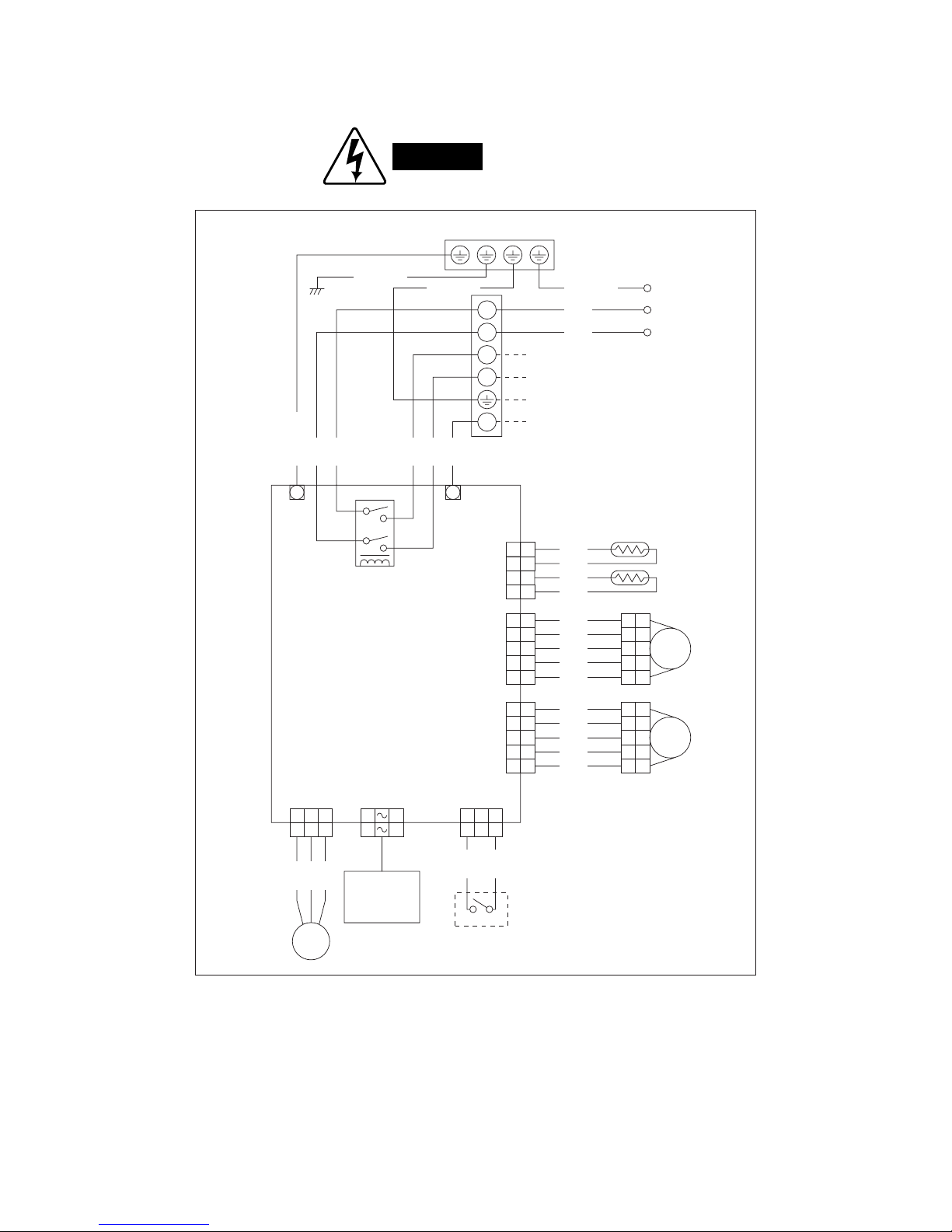

6-2. Electric Wiring Diagrams

Indoor unit SAP-KRV91EH

WARNING

To avoid electrical shock hazard, be sure to

disconnect power before checking, servicing

and/or cleaning any electrical parts.

8512-5253-520xx-2

1

3

5

2

4

6

Earth plate

Power cord

Terminal

plate

Power relay

4P

Room/coil

5P

Flap

(White)

5P

Louver

(Red)

Flap motor

Thermistor (coil)

Thermistor (room)

Louver motor

CONTROLLER

FM

Evaporator

To outdoor unit

L

N

1

2

4

GRN/YELGRN/YEL

BRN

BLU

GRN/YEL

1

2

3

4

5

4

3

2

1

1

321

321

101

101

321

321

2

3

4

5

1

2

3

4

5

4

3

2

1

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

BLK

BLK

ORG

ORG

WHT

GRY

GRY

GRY

GRY

WHT

GRY

GRY

GRY

GRY

WW

GRN/YEL

BRN

BLU

RED

WHT

BLK

3P

Power-SW

Power SW

10P

Lamp

3P

DCM

Fan

motor

IND lamp

assy

WHT

BLU

RED

WHT

WHT

Louver

Flap

15

Outdoor unit SAP-CRV91EH

WARNING

To avoid electrical shock hazard, be sure to

disconnect power before checking, servicing

and/or cleaning any electrical parts.

1

2

4

Terminal

plate

From indoor unit

W

W

W W

W W

+ +

W WW

IN1

E

OUT1

OUT2

DCIN+

DCIN–

DCOUT+

DCOUT–

IN2

BLK

WHT

RED

WHT

GRN/YEL

1 3

13

1 2123344556

11

22

33

44

55

66

77

88

99

10 10

11 11

12 12

6

12 12

11 11

10 10

99

88

77

66

55

44

33

22

11

1 2123344556

6

(BLK)

SI

1 3

13

(WHT)

SV

GRN/YEL

21

21

YEL

ORG

YEL

ORG

W

W W

W W

21

21

RED

BLK

RED

BLK

ACIN2

ACIN1

ACOUT2

(BLK)

A – B

HIC2

(RED)

HIC1

(RED)

(WHT)

A – B

Reactance

L1

W W

L2 DC 0V

–+

DC+DC–

ACOUT1

Ferrite

core

Diode

AC AC

–+

WHT

WHT

BLU

YEL

WHT

WHT

WHT

WHT

WHT

VLT

ORG

CONTROLLER B

+

+

W

DC 280V

+

BLK

WHT

WHT

WHT

WHT

WHT

WHT

WHT

11

22

33

44

55

66

77

88

99

9

22

8

21

7

20

619

518

417

316

215

114

BLK

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

HIC

U

+V+

W

11

22

33

CM

RED

RED

WHT

WHT

BLU

BLU

RED

BLU

Compressor

motor

R

S

T

GRN/YEL

GRN/YEL

CONTROLLER A

12123

3

13135

5

44556

6

(WHT)

SENSE

(WHT)

FM

(WHT)

MV-1

Fan motor

Magnetic

coil

FM

MV

WHT

PNK

BLK

BRN

YEL

VLT

121233445

5

ORG

RED

YEL

GRY

BLK

6 56522114

4

Solenoid valve

BLU

BLU

SV

1 3

13

(RED)

RV

4-way valve

BLU

BLU

RV

PTC

(YEL)

OUT

DOOR

Ooutdoor

thermistor

12

12

BLK

BLK

(WHT)

COMP

Compressor

thermistor

12

12

BLK

BLK

(BLK)

COIL

Coil thermistor

12

12

YEL

YEL

YEL

YEL

(RED)

SUC

SUC thermistor

12

12

W

PTC2

W

PTC1

YEL

YEL

BLK

RED

Ferrite

core

8512-5253-521xx-2

16

7. INSTALLATION INSTRUCTIONS

7-1. Installation Site Selection

7-1-1. Indoor Unit

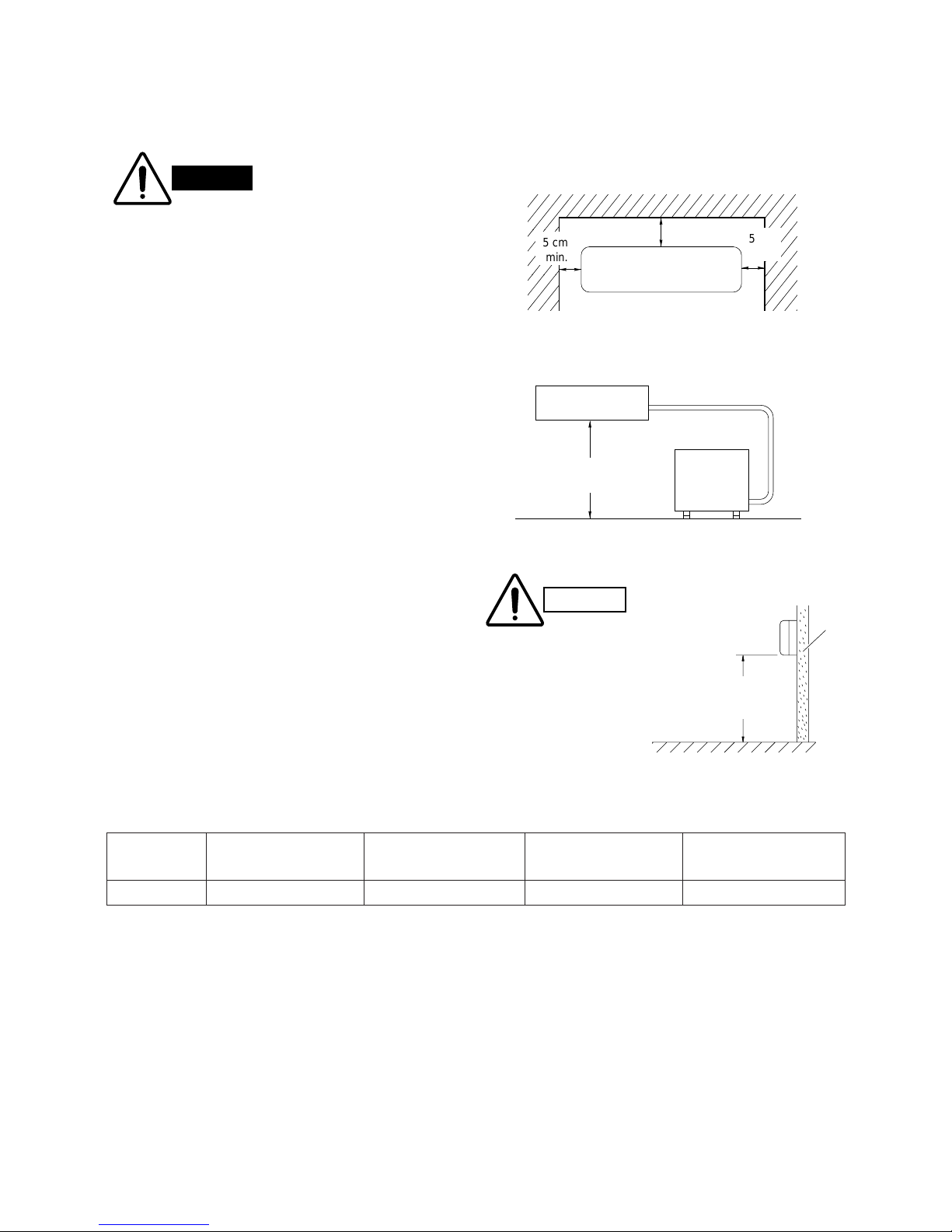

AVOID:

●

direct sunlight.

●

nearby heat sources that may affect performance of

the unit.

●

areas where leakage of flammable gas may be

expected.

●

places where large amounts of oil mist exist.

DO:

●

select an appropriate position from which every corner of the room can be uniformly cooled. (High on a

wall is best.)

●

select a location that will hold the weight of the unit.

●

select a location where tubing and drain hose have

the shortest run to the outside. (Fig. 1)

●

allow room for operation and maintenance as well as

unrestricted air flow around the unit. (Fig. 2)

●

install the unit within the maximum elevation difference (H) above or below the outdoor unit and within

a total tubing length (L) from the outdoor unit as

detailed in Table 1 and Fig. 3.

Table 1

5 cm

min.

5 cm

min.

5 cm min.

Front View

Fig. 1

INDOOR

UNIT

Tubing length (L)

OUTDOOR

UNIT

Elevation

difference (H)

Fig. 2

WARNING

To prevent abnormal heat

generation and the possibility

of fire, do not place obstacles,

enclosures and grilles in front

of or surrounding the air conditioner in a way that may

block air flow.

Indoor unit

Floor level

Wall

Minimum height

from floor level

1.5 m

Fig. 3

For stable operation of

the air conditioner, do not

install wall-mounted type

indoor units under 1.5 m

from floor level.

CAUTION

Max. Allowable Tubing Limit of Tubing Limit of Elevation Required Amount of

Model Length at Shipment Length (L) Difference (H) Additional Refrigerant

(m) (m) (m) (g/m)

*

KRV91 7.5 15 7 15

*

If total tubing length becomes 7.5 to 15 m (max.), charge additional refrigerant (R410A) by 15 g/m.

No additional compressor oil is necessary.

17

7-1-2. Outdoor Unit

AVOID:

●

heat sources, exhaust fans, etc. (Fig. 4)

●

damp, humid or uneven locations.

DO:

●

choose a place as cool as possible.

●

choose a place that is well ventilated.

●

allow enough room around the unit for air intake/

exhaust and possible maintenance. (Fig. 5a)

●

provide a solid base (level concrete pad, concrete

block, 10 ×40 cm beams or equal), a minimum of

10 cm above ground level to reduce humidity and

protect the unit against possible water damage

and decreased service life. (Fig. 5a)

●

Install cushion rubber under unit’s feet to reduce

vibration and noise. (Fig. 5b)

●

use lug bolts or equal to bolt down unit, reducing

vibration and noise.

Outdoor unit

Hot air

Heat source

Exhaust fan

NO

Fig. 4

Air intake

Concrete

or equal

About 10 cm

Min. 10 cm

Anchor bolts

(4 pcs.)

About 40 cm

Fig. 5a

Cushion rubber

Fig. 5b

Air intake Min. 10 cm

Air discharge

Min.

5 cm

Min.

40 cm

Valve

side

Min.

25 cm

Min.

2 m

Min.

2 m

Min. 10 cm

Air intake

Ground

Obstacle

Obstacle above

Air discharge

18

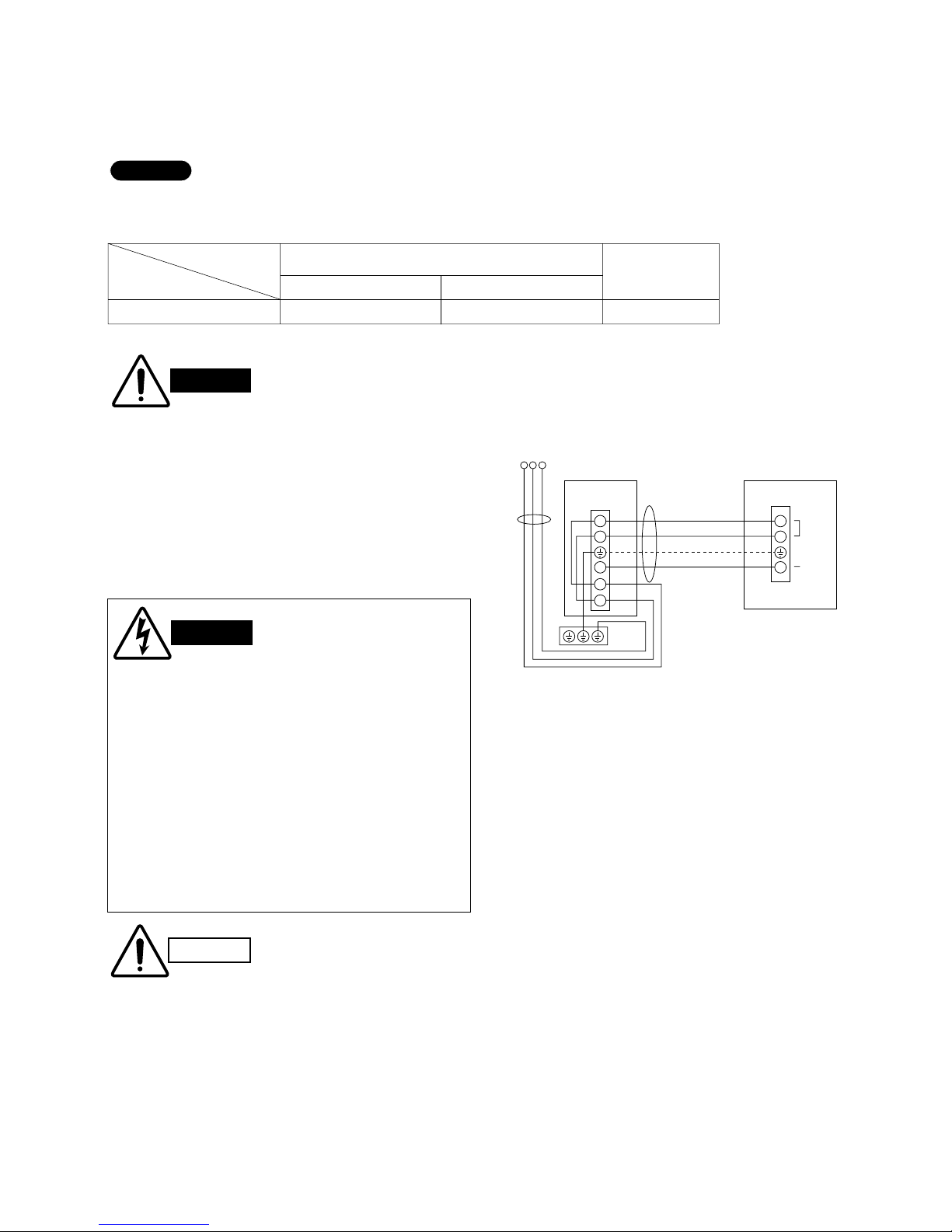

7-1-3. Recommended Wire Length and Diameter

Regulations on wiring diameter differ from locality to locality. For field wiring requirements, please refer to your

local electrical codes. Carefully observe these regulations when carrying out the installation.

Table 2 lists recommended wire lengths and diameters for power supply systems.

Refer to the wiring system diagram (Fig. 6) for the meaning of “A” and “B” in Table 2.

Table 2

NOTE

Cross-Sectional (A)+(B) (A) Power Supply Wiring Length (m)

Fuse or Circuit

Area (mm2) (B) Power Line Length (m)

Model 2 3.5

Capacity

CRV91 33 51 10A

INDOOR UNIT OUTDOOR UNIT

TerminalTerminal

Power

line

Control

line

Ground line

Power supply:

1ø 50 Hz,

220 V – 230 VAC

1

4

2

1

4

2

L

N

(B)

(A)

Fig. 6

CAUTION

Be sure to connect the power

supply line to the indoor unit

as shown in the wiring diagram. The outdoor unit draws

its power from the indoor unit.

WIRING SYSTEM DIAGRAM

WARNING

●

Be sure to comply with local

codes on running the wire

from the indoor unit to the

outdoor unit (size of wire

and wiring method, etc.).

●

Each wire must be firmly

connected.

●

No wire should be allowed

to touch refrigerant tubing,

the compressor, or any

moving part.

●

To avoid the risk of electrical shock, each air

conditioner unit must be grounded.

●

For the installation of a grounding device,

please observe local electrical codes.

●

Grounding is necessary, especially for units

using inverter circuits, in order to release

charged electricity and electrical noise caused

by high tension. Otherwise, electrical shock

may occur.

●

Place a dedicated ground more than 2 meters

away from other grounds and do not have it

shared with other electric appliances.

WARNING

19

Deburring

Before

After

Fig. 7

Reamer

Copper

tubing

Fig. 8

Flare tool

Flare nut

Copper

tubing

Fig. 9

Apply refrigerant

lubricant here and here

0 to

0.5 mm

Fig. 11

Fig. 10

7-2. Refrigerant Tubing

7-2-1. Use of the Flaring Method

Many of the conventional split system air conditioners

employ the flaring method to connect refrigerant tubes

which run between indoor and outdoor units. In this

method, the copper tubes are flared at each end and

connected with flare nuts.

7-2-3. Flaring Procedure with a Flare Tool

a) Cut the copper tube to the required length with a

tube cutter. It is recommended to cut approx. 30 –

50 cm longer than the tubing length you estimate.

b) Remove burrs at the end of the copper tube with a

tube reamer or file. This process is important and

should be done carefully to make a good flare.

(Fig. 7)

When reaming, hold the tube end downward and be

sure that no copper scraps fall into the tube. (Fig. 8)

c) Remove the flare nut from the unit and be sure to

mount it on the copper tube.

d) Make a flare at the end of copper tube with a flare

tool.*(Fig. 9)

(*Use “RIGID” or equivalent.)

e) Use the special flare tool for R410A for making a

flare. If the conventional flare tool for R22 is utilized, use the spacer provided. (Fig. 10)

A good flare should have the following characteristics:

●

inside surface is glossy and smooth.

●

edge is smooth.

●

tapered sides are of uniform length.

7-2-4. Caution before Connecting Tubes

Tightly

a) Be sure to apply a sealing cap or water-proof tape

to prevent dust or water from getting into the tubes

before they are used.

b) Be sure to apply refrigerant lubricant to the match-

ing surfaces of the flare and union before connecting them together. This is effective for reducing gas

leaks. (Fig. 11)

c) For proper connection, align the union tube and

flare tube straight with each other, then screw on

the flare nut lightly at first to obtain a smooth

match. (Fig. 12)

NOTE

NOTE

Where the R410A

flare tool is used

1.2 mm

Spacer

Where the conventional flare tool

is utilized (clutching method)

Flare nut

Union

Fig. 12

By using the spacer, the pipe must be adjusted so that 1.2 mm of the pipe protrudes.

20

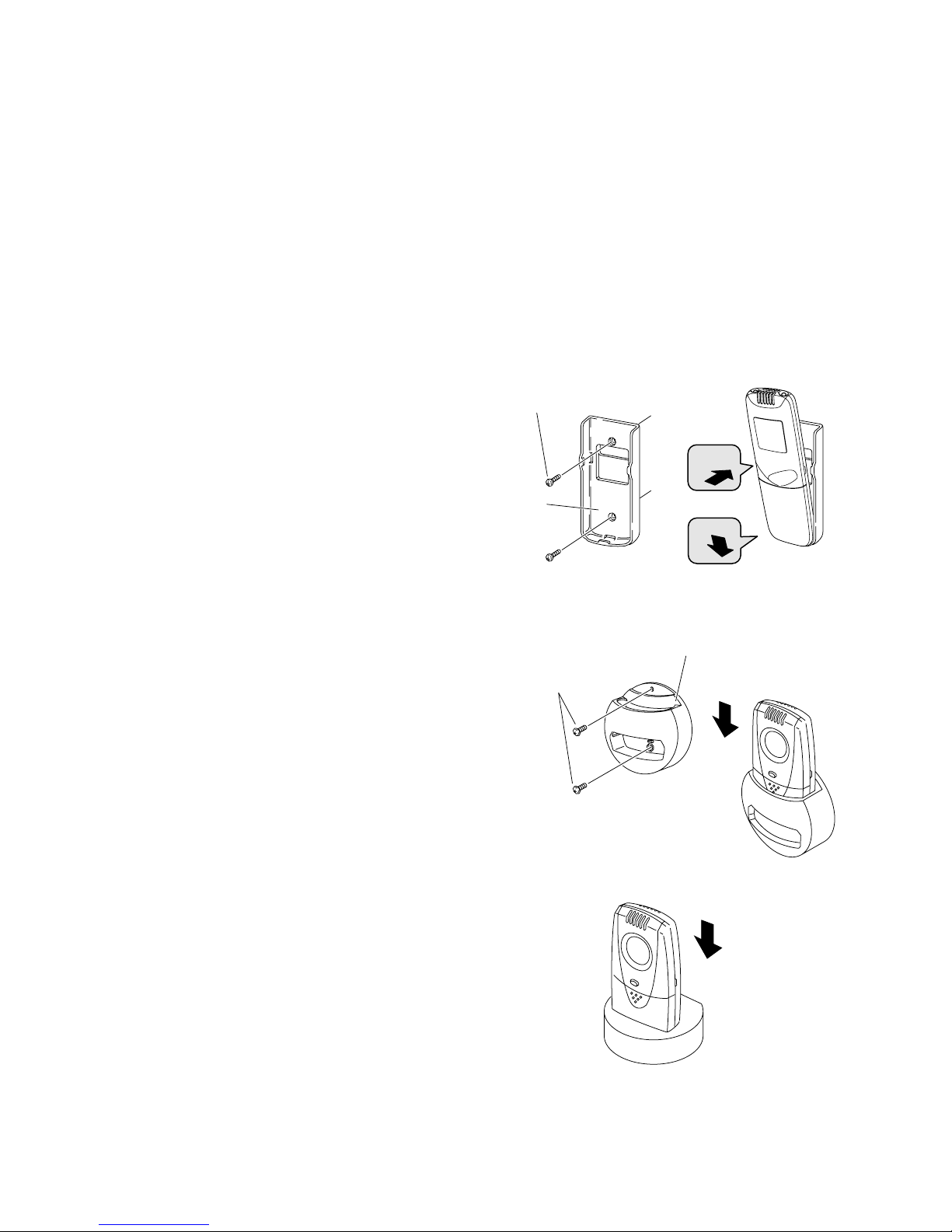

7-3-1. Mounting on a Wall

a) Remote Control Unit

When attaching to wall

(1) Confirm the indoor unit beeps when the ON/OFF

button is pressed at the wall location where the

remote control unit is to be attached, then attach

the holder to the wall. (Fig. 13)

(2) When taking out the remote control unit, pull it

from the holder. (Fig. 14)

When using the remote control unit

●

Point the transmission portion of the remote control

unit at the receiver area of the indoor unit when

operating the remote control unit, and during operation of the air conditioner.

●

Do not place objects which may block the transmitted signals between the receiver and the remote

control unit.

b) People Sensor

How to use the remote control unit holder

Turn the power source switch ON at the spot where

you intend to install the holder, and confirm the

indoor unit beeps. (Figs. 14 and 15)

Truss-head tapping screws

4 × 16 mm (supplied)

Holder for People Sensor-type

remote control unit

Insert

Fig. 14

When attaching to wall

Insert

Fig. 15

When placed on table, etc.

7-3. Remote Control Unit Installation Position

The remote control unit can be operated from either a non-fixed position or a wall-mounted position.

To ensure that the air conditioner operates correctly, do not install the remote control unit in the following places:

●

In direct sunlight

●

Behind a curtain or other place where it is covered

●

More than 8 m away from the air conditioner

●

In the path of the air conditioner’s airstream

●

Where it may become extremely hot or cold

●

Where it may be subject to electrical or magnetic interference

●

Where the temperature changes rapidly (near heater, etc.)

●

Where strong vibration or shock occurs

●

Where there are obstacles which may block or interfere with the infrared signal, such as glass

●

Near telephone, computer or radio

●

Outside the detectable range, such as on top of

refrigerator

1

2

Truss-head

tapping screws

4 × 16 mm (supplied)

Remote

control

unit holder

Press

Hook

Fig. 13

21

8. MAINTENANCE

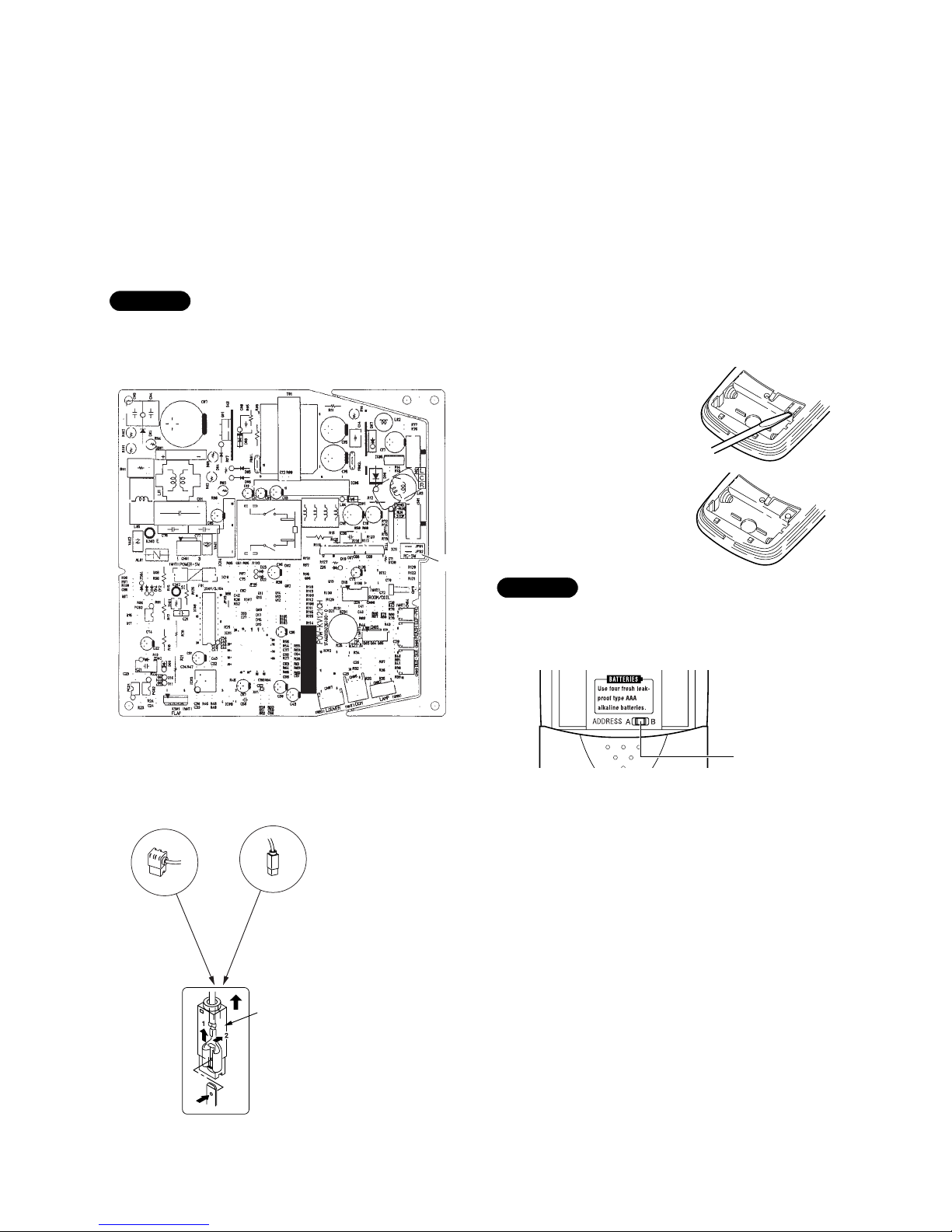

8-1. Changing Address of Indoor Unit and Remote Control Unit

If the operation is disturbed by radio interference of the remote control signals, change the address of the remote

control unit by cutting the jumper wire on the PCB A of the indoor unit.

To Change Address on PCB

(1) Cut jumper wire (JP02) on the indoor unit PCB.

(2) Switch the address switch on the remote control unit to “B” position.

(3) After inserting the batteries, press reset (

リセット

) button.

Once changed, you cannot restore the original address setting of the remote control unit.

NOTE

Pull the cover upward

When the cover is pulled upward, the lock is

released with the sequence of 1 and 2.

Address switch

Control PCB (POW-KV121CH) on Indoor Unit

JP02

(1) Remove tab for changing

the address (

アドレス

) of

the remote control unit.

(2) When it is removed, the

address (

アドレス

) is set

to B.

To Change Address on Remote Control

People Sensor-type remote control unit

(RCS-IHCS4E)

8-2. Disconnecting and Connecting Positive Connector for Outdoor Unit

One of the two types of connectors illustrated at left is used. Their

basic structure is the same for each.

How to Disconnect

Hold the resin connector cover, and pull the connector off.

You cannot disconnect the connector by pulling the wire since

it is locked inside. Always hold the cover to disconnect. (See

illustration at left.) For the connector without the resin cover,

push the lock in the direction of “2” while pulling it off.

How to Connect

In order to connect, hold the resin cover of the connector and

push it in. Confirm the click sound for the inside lock.

Remove the batteries before switching

the address switch.

NOTE

Loading...

Loading...