Sanyo SAP-KMRV124EH, SAP-KMRV76EH, SAP-KMRV126EH, SAP-KRV96EHDS, SAP-KRV126EHDS Installation Instructions Manual

...

Contents

Page

IMPORTANT!

Please Read Before Starting .................................. 2

1. GENERAL .......................................................... 3

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Optional Copper Tubing Kit

1-4. Type of Copper Tube and Insulation Material

1-5. Additional Materials Required for Installation

2. INSTALLATION SITE SELECTION ................... 4

2-1. Indoor Unit

2-2. Connecting Indoor Units

2-3. Outdoor Unit

2-4. Outer Dimensions of Outdoor Unit

2-5. Diagram of Outdoor Unit Installation

3. INSTALLATION PROCESS .............................. 13

3-1. Embedding the Tubing and Wiring

3-2. Drain Cap and Drain Elbow

3-3. Use of the Flaring Method

3-4. Flaring Procedure with a Flare Tool

3-5. Caution Before Connecting Tubes Tightly

3-6. Tubing Connections

3-7. Insulation of Refrigerant Tubing

3-8. Taping the Tubes

3-9. Finishing the Installation

4. AIR PURGING................................................... 16

! Air Purging with a Vacuum Pump (for Test Run)

! Pump Down

5. WIRING INSTRUCTIONS ................................. 19

5-1. General Precautions on Wiring

5-2. Recommended Wire Length and Diameter

5-3. Wiring System Diagram

5-4. How to Connect Wiring to the Terminal

5-5. Wiring Instructions for the Outdoor Unit

6. TEST RUN......................................................... 23

7. CONNECTING A HOME AUTOMATION

DEVICE ............................................................. 24

8. INSTALLATION CHECK SHEET ...................... 24

9. ELECTRIC WIRING DIAGRAM......................... 24

INSTALLATION INSTRUCTIONS

Model Combinations

Combine indoor and outdoor units only as listed below.

Indoor Unit Outdoor Unit

Combine indoor and outdoor units only as listed in

the combination tables for 2-room, 3-room or

4-room outdoor unit as shown in its respective

manual.

Powe r Source:

50 Hz, single-phase, 220 – 240 VAC

– Inverter Multi Split System Air Conditioner –

COOL/ DRY/ HEAT Model

This air conditioner uses the new refrigerant R410A.

Be sure to read the yellow instruction sheet

attached to the outdoor unit for models using the

new refrigerant R410A.

The illustrations are based on the typical appearance of

a standard model. Consequently, the shape may differ

from that of the air conditioner that you are installing.

Combination example

For Outdoor Unit

85264190442002 © SANYO 2008 SANYO Electric Co., Ltd.

Osaka, Japan

Español

Français

Deutsch Italiano

Português

EEÏÏÏÏËËÓÓÈÈÎο¿

English

SAP-KMRV74EH

SAP-KMRV94EH

SAP-KMRV124EH

SAP-KMRV76EH

SAP-KMRV96EH

SAP-KMRV126EH

SAP-KRV96EHDS

SAP-KRV126EHDS

SAP-KRV184EH

SAP-KRV244EH

SAP-KRV186EH

SAP-KRV246EH

SAP-CMRV1926EH

SAP-CMRV1936EH

SAP-CMRV2446EH

SAP-CMRV3146EH

Indoor unit A

Indoor unit B

Indoor unit C

Outdoor unit

Indoor unit D

NOTE

2

English

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system

so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

!

Carefully read this instruction booklet before beginning.

!

Follow each installation or repair step exactly as

shown.

!

Observe all local, state, and national electrical codes.

!

Pay close attention to all war ning and caution notices

given in this manual.

This symbol refers to a hazard or unsafe practice which

can result in severe personal

injury or death.

This symbol refers to a hazard or unsafe practice which

can result in personal injury

or product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for

a special problem, contact our sales/service outlet or

your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED ELECTRICIAN SHOULD ATTEMPT TO WIRE

THIS SYSTEM.

•Do not supply power to the unit until all wiring and tub-

ing are completed or reconnected and checked.

•Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or

death.

•Ground the unitfollowing local electrical codes.

•Connect all wiring tightly.Loose wiring may cause over-

heating at connection points and a possible fire hazard.

•Install a protective leakage breaker depending on the

installation location (especially a damp or humid location). If a leakage breaker is not installed, electric

shock can occur.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or

thin aluminum fins on the air conditioner can cut your fingers.

When Installing…

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

•

Position the outdoor unit in a protected location

where snow will not blow into it.

• Install the outdoor unit on a raised platform that is

higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

•Use the flare method for connecting tubing.

•Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free connection.

•Check carefully for leaks before starting the test run.

When Servicing

•Turn the power OFFat the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

•Keep your fingers and clothing away from any moving

parts.

•Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit being serviced.

Others

•Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously toxic

gas.

•Confirm upon completing installation that no refrigerant

gas is leaking. If escaped gas comes in contact with a

stove, gas water heater, electric room heater or other

heat source, it can produce dangerously toxic gas.

•Do not install only a single indoor unit.

WARNING

WARNING

CAUTION

CAUTION

3

English

1. General

This booklet briefly outlines where and how to install

the air conditioning system. Please read over the entire

set of instructions for the indoor and outdoor units and

make sure all accessory parts listed are with the system before beginning. If the electric wiring diagram

does not appear in this manual, please check for the

diagram on the indoor unit.

1-1. Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Carpenter’s level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

16. Vacuum pump (For R410A)

17. Manifold valve

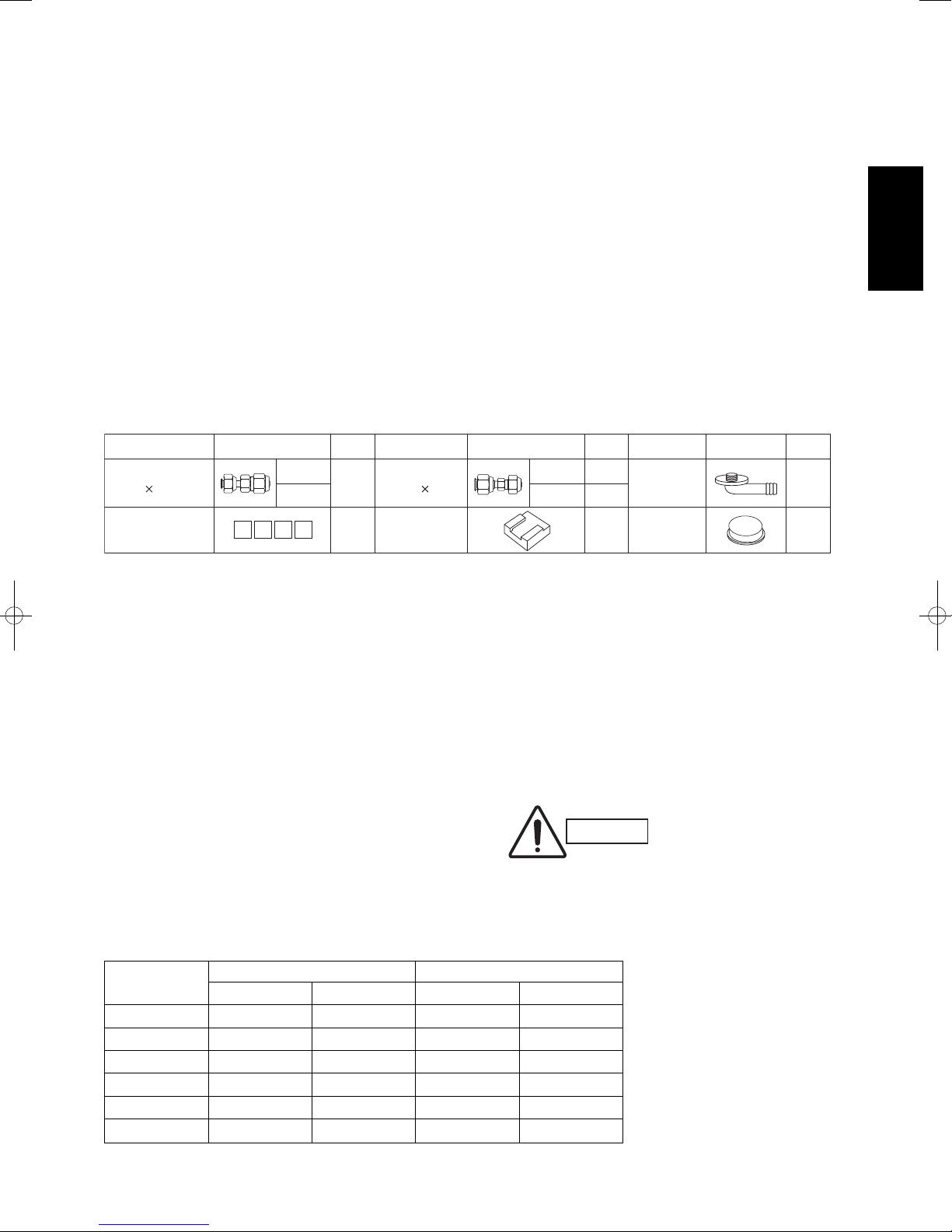

1-2. Accessories Supplied with Unit

Tabl e 1

1-3. Optional Copper Tubing Kit

Copper tubing for connecting the outdoor unit to the

indoor unit is available in kits which contain the narrow

and wide tubing, fittings and insulation. Consult your

nearest sales outlet or air conditioning workshop.

1-4. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately

from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant

tubing as detailed in Table 2.

Cut each tube to the appropriate lengths +30 cm

to 40 cm to dampen vibration between units.

Tabl e 2

2. Foamed polyethylene insulation for the specified

copper tubes as required to precise length of tubing. Wall thickness of the insulation should be not

less than 8 mm.

3. Use insulated copper wire for field wiring.

Wire size varies with the total length of wiring.

Refer to 5. Wiring Instructions for details.

CAUTION

Check local electrical codes

and regulations before

obtaining wire. Also, check

any specified instructions or

limitations.

Model

Narrow Tube Wide Tube

Outer Dia. Thickness Outer Dia. Thickness

KMRV74/76 6.35 mm 0.8 mm 9.52 mm 0.8 mm

KMRV94/96 6.35 mm 0.8 mm 9.52 mm 0.8 mm

KMRV124/126 6.35 mm 0.8 mm 9.52 mm 0.8 mm

KRV184/186 6.35 mm 0.8 mm 12.70 mm 0.8 mm

KRV244/246 6.35 mm 0.8 mm 15.88 mm 1.0 mm

KRV96/126 6.35 mm 0.8 mm 9.52 mm 0.8 mm

Parts Figure Q’ty Parts Figure Q’ty Parts Figure Q’ty

Reducer

(ø9.52 ø12.70)

Labels for inter-unit

cable and tube

CMRV1926

CMRV1936

ABCD

Reducer

1

(ø12.70 ø9.52)

4 each

Cushion rubber 4 Drain cap

CMRV2446

CMRV3146

1

Drain elbow 1

2

5

Packed in the outdoor unit.

4

English

1-5. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See local codes)

3. Putty

4. Refrigeration lubricant

5. Clamps or saddles to secure refrigerant tubing

2. Installation Site Selection

2-1. Indoor Unit

AVOID:

! direct sunlight.

! nearby heat sources that may affect performance of the

unit.

! areas where leakage of flammable gas may be expected.

! placing or allowing any obstructions near the Air

Conditioner inlet or outlet.

! installing in rooms that contain instant-on (rapid-start)

fluorescent lamps. (These may prevent the Air Conditioner

from receiving signals.)

! places where large amounts of oil mist exist.

! installing in locations where there are devices that

generate high-frequency emissions.

DO:

! select an appropriate position from which every corner of

the room can be uniformly cooled. (High on a wall is best.)

! select a location that will hold the weight of the unit.

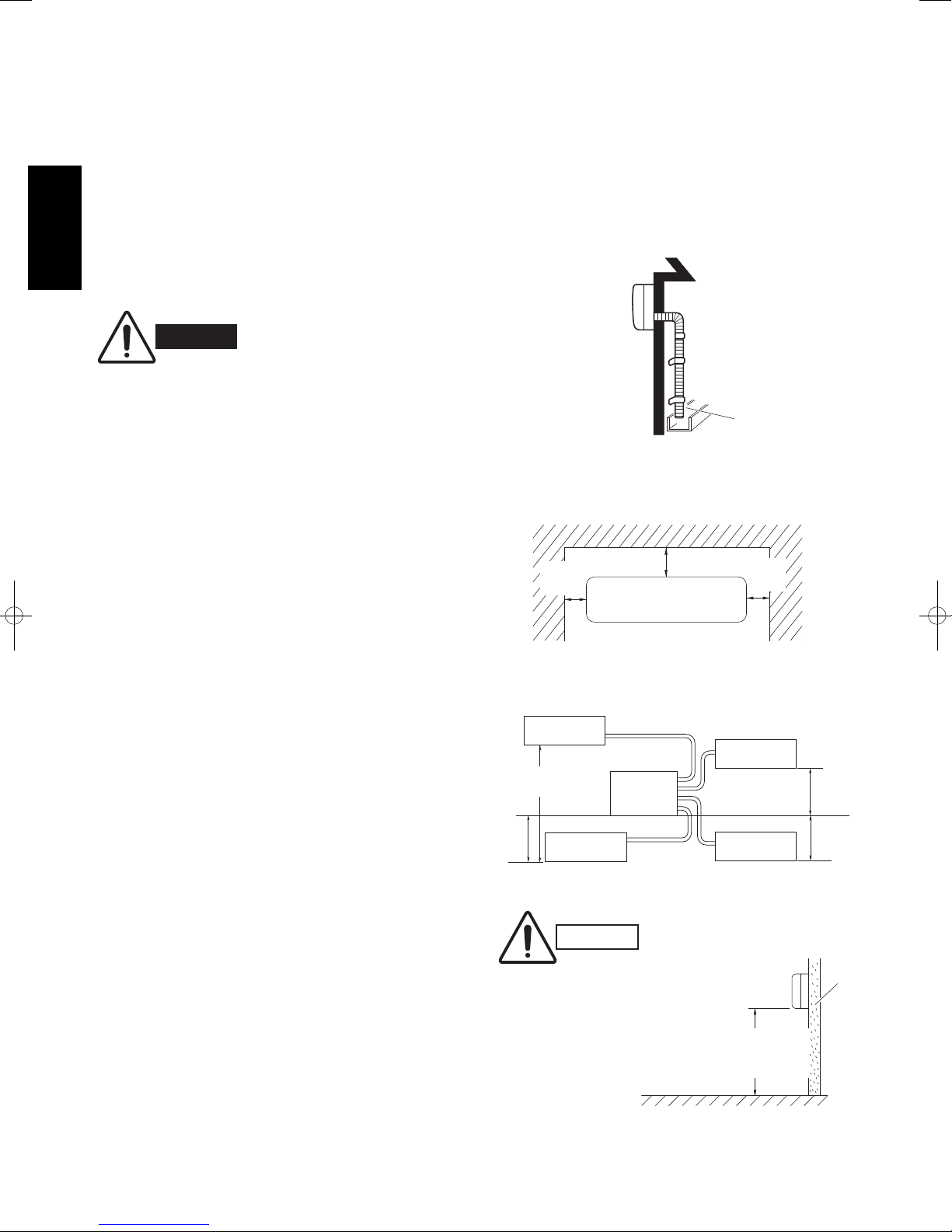

! select a location where tubing and drain hose have the

shortest run to the outside. (Fig. 1)

! allow room for operation and maintenance as well as

unrestricted air flow around the unit. (Fig. 2)

! install the unit within the maximum elevation difference

(H1, H2, H3, H4) above or below the outdoor unit and

within a total tubing length (L1+L2, L1+L2+L3,

L1+L2+L3+L4) from the outdoor unit as detailed in

Ta b le 3 a n d F i g . 3 a .

Fig. 1

Fig. 2

INDOOR

UNIT (1)

INDOOR

UNIT (4)

INDOOR

UNIT (3)

INDOOR

UNIT (2)

Tubing length (L1)

L2

L3

L4

H2

H3

H4

OUTDOOR

UNIT

Elevation

difference (H1)

Fig. 3a

WARNING

To prev ent abnormal heat generation

and the possibility of fire, do not

place obstacles, enclosures and

grilles in front of or surrounding the

air conditioner in a way that may

block air flow.

Fig. 3b

For stable operation of the air

conditioner, do not install

wall-mounted type indoor

units less than 1.5 m from

floor level.

CAUTION

5 cm

min.

Indoor unit

Outside drainage

Front View

15 cm min.

Drain hose

5 cm

min.

Indoor unit

Minimum height

from floor level

1.5 m

Floor level

Wall

5

English

! install the indoor unit more than 1 meter away from any

antenna or power lines or connecting wires used for television, radio, telephone, security system, or intercom.

Electrical noise from any of these sources may affect

operation.

! install in a sturdy manner to avoid increased operating

noise.

Tabl e 3

unit: mm

* If total tubing length becomes 45 to 60 m (max.) or 45 to 70 m (max.), charge additional refrigerant (R410A) by 20 g/m.

No additional charge of compressor oil is necessary.

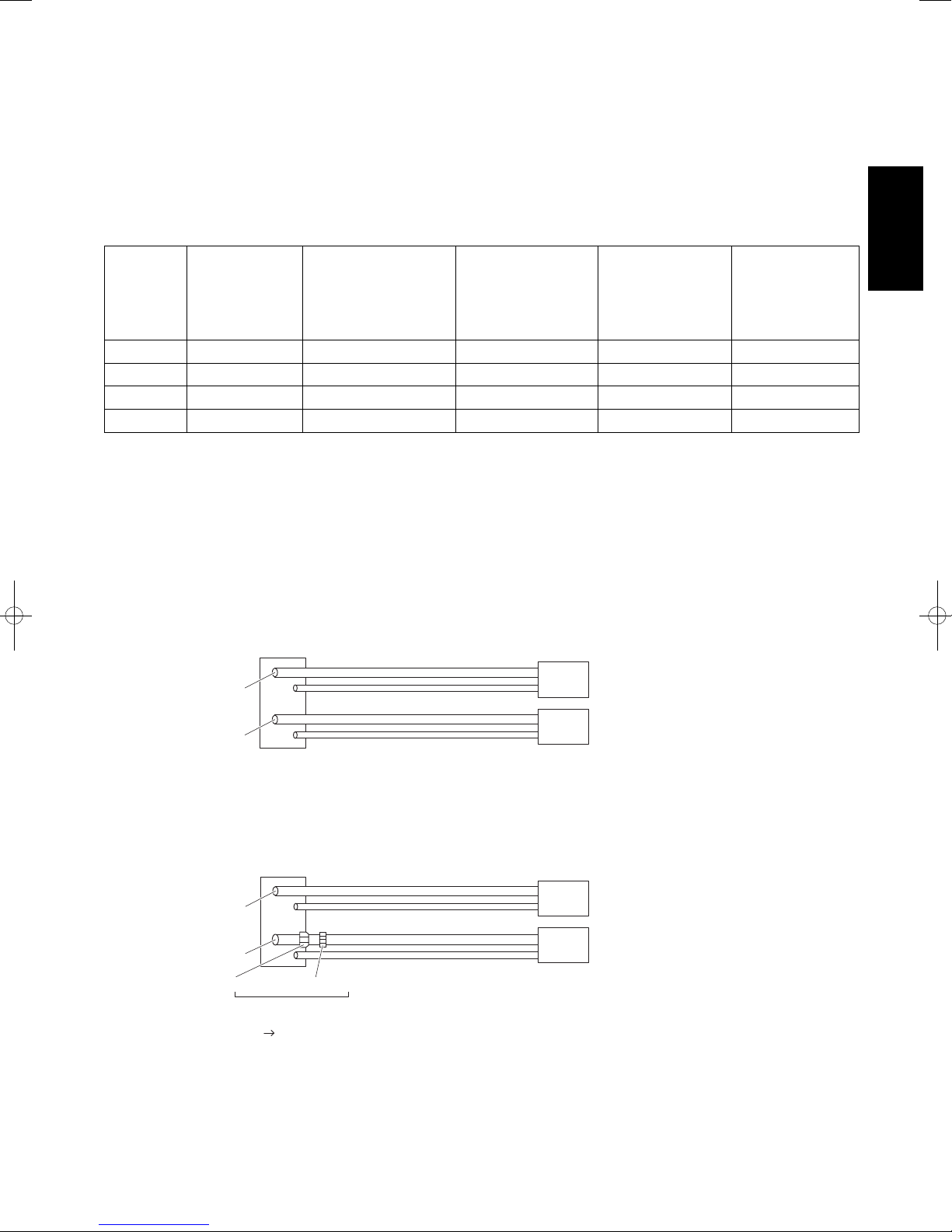

2-2. Connecting Indoor Units

(1) Connecting indoor unit for SAP-CMRV1926

Fig. 4a

ø12.70Unionø9.52Flare

A joint for connecting tubes of

different sizes

(ø9.52 ø12.70) Supplied Reducer

ø9.52

ø6.35

ø12.70

ø6.35

ø9.52

B

ø9.52

A

Outdoor unit Indoor unit

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

ø9.52

ø6.35

ø9.52

ø6.35

ø9.52

B

ø9.52

A

Outdoor unit Indoor unit

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(A)

(B)

Max. Allowable Max. Allowable Total Limit of Limit of Elevation Required Amount

Tubi ng L en gt h Tub in g Length Total Tubing Length Difference of Additional

Model per unit at shipment (L1+L2) or (L1+L2+L3) (H1, H2, H3, H4) Refrigerant

(m) (L1+L2) or (L1+L2+L3) or (L1+L2+L3+L4) (m) (g/m)*

or (L1+L2+L3+L4) (m)

(m)

CMRV1926 25 45 (L1+L2) 45 (L1+L2) 15 –

CMRV1936 25 45 (L1+L2+L3) 45 (L1+L2+L3) 15 –

CMRV2446 25 45 (L1+L2+L3+L4) 60 (L1+L2+L3+L4) 15 20

CMRV3146 30 45 (L1+L2+L3+L4) 70 (L1+L2+L3+L4) 15 20

Fig. 4

6

English

(A)

Fig. 4d

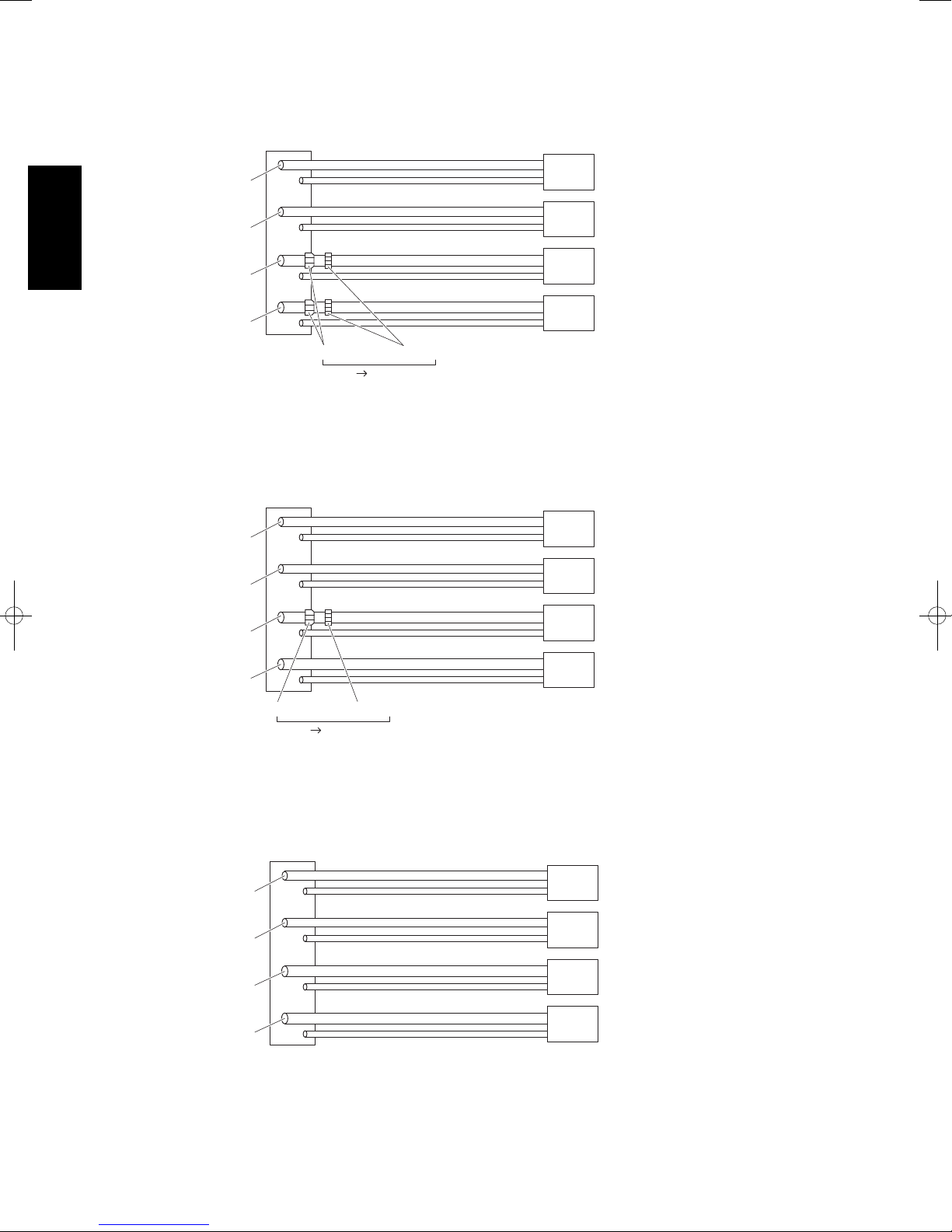

(3) Connecting indoor unit for SAP-CMRV2446

unit: mm

(A)

(B)

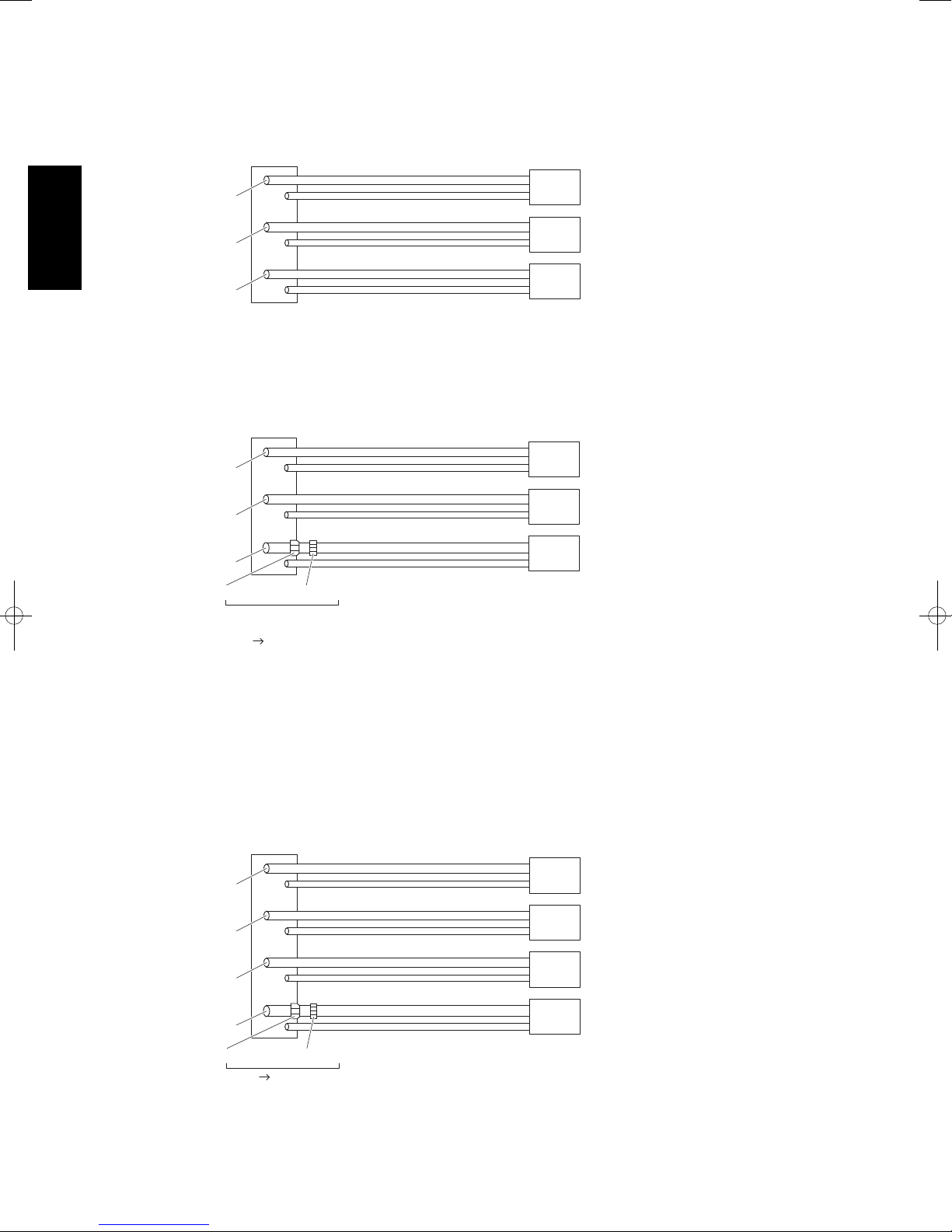

Fig. 4c

(2) Connecting indoor unit for SAP-CMRV1936

Fig. 4b

Outdoor unit Indoor unit

C

ø9.52

B

ø9.52

A

ø9.52

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø9.52

Outdoor unit Indoor unit

C

ø9.52

B

ø9.52

A

ø9.52

A joint for connecting tubes of

different sizes

(ø9.52 ø12.70) Supplied Reducer

ø6.35

ø6.35

ø6.35

ø12.70Unionø9.52Flare

ø9.52

ø9.52

ø12.70

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø9.52

A

ø12.70

ø9.52Unionø12.70Flare

(ø12.70 ø9.52) Supplied Reducer

ø6.35

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø9.52

ø9.52

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

7

English

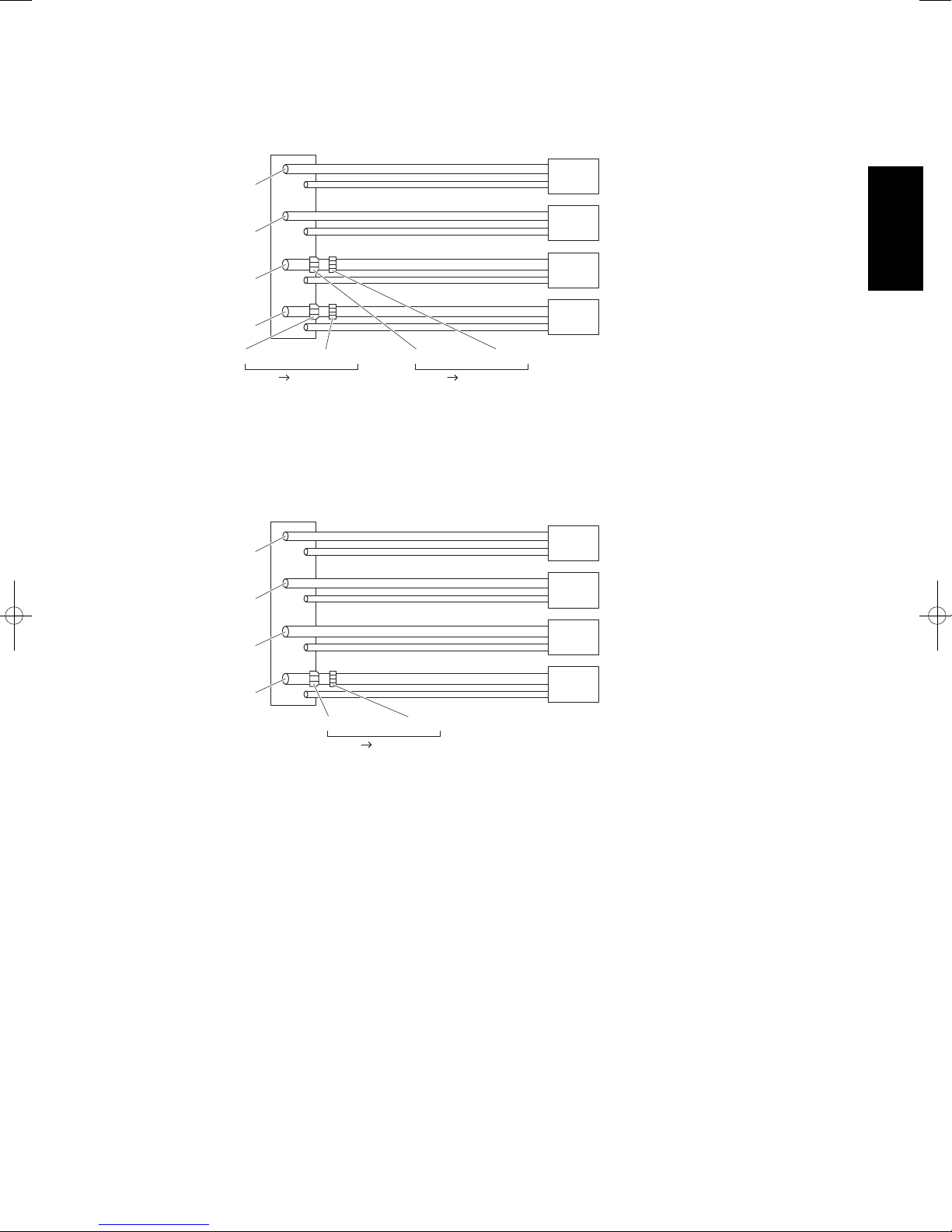

(B)

Fig. 4e

(D)

Fig. 4g

(C)

Fig. 4f

unit: mm

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø9.52

A

ø12.70

ø6.35

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø9.52

ø12.70

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø9.52

A

ø12.70

(ø12.70 ø15.88) Locally purchased

ø6.35

ø6.35

ø6.35

ø6.35

ø15.88Unionø12.70Flare

ø9.52

ø9.52

ø9.52

ø15.88

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV244EH)

(SAP-KRV246EH)

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø9.52

A

ø12.70

(ø12.70 ø15.88)

Locally purchased

ø6.35

ø6.35

ø6.35

ø6.35

ø15.88Unionø12.70Flare

(ø9.52 ø12.70)

Locally purchased

ø9.52

ø9.52

ø12.70

ø15.88

ø12.70Unionø9.52Flare

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

(SAP-KRV244EH)

(SAP-KRV246EH)

8

English

(A)

Fig. 4h

(4) Connecting indoor unit for SAP-CMRV3146

(B)

Fig. 4i

(C)

Fig. 4j

unit: mm

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø12.70

A

ø12.70

(ø12.70 ø9.52) Supplied Reducer

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø9.52

ø9.52

ø6.35

ø9.52Unionø12.70Flare

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø12.70

A

ø12.70

(ø12.70 ø9.52) Supplied Reducer

ø6.35

ø6.35

ø6.35

ø6.35

ø9.52Unionø12.70Flare

ø9.52

ø9.52

ø9.52

ø12.70

(SAP-KMRV74EH, KMRV94EH,KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø12.70

A

ø12.70

ø6.35

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø12.70

ø12.70

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

(SAP-KRV184EH)

(SAP-KRV186EH)

9

English

(D)

Fig. 4k

(E)

Fig. 4l

unit: mm

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø12.70

A

ø12.70

(ø12.70 ø15.88)

Locally purchased

ø6.35

ø6.35

ø6.35

ø6.35

ø15.88Unionø12.70Flare

(ø12.70 ø9.52)

Supplied Reducer

ø9.52

ø9.52

ø9.52

ø15.88

Outdoor unit Indoor unit

D

ø9.52

C

ø9.52

B

ø12.70

A

ø12.70

(ø12.70 ø15.88) Locally purchased

ø6.35

ø6.35

ø6.35

ø9.52

ø9.52

ø12.70

ø15.88

ø6.35

ø15.88Unionø12.70Flare

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV244EH)

(SAP-KRV246EH)

ø9.52Unionø12.70Flare

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KMRV74EH, KMRV94EH, KMRV124EH)

(SAP-KMRV76EH, KMRV96EH, KMRV126EH)

(SAP-KRV96EHDS, KRV126EHDS)

(SAP-KRV184EH)

(SAP-KRV186EH)

(SAP-KRV244EH)

(SAP-KRV246EH)

Loading...

Loading...