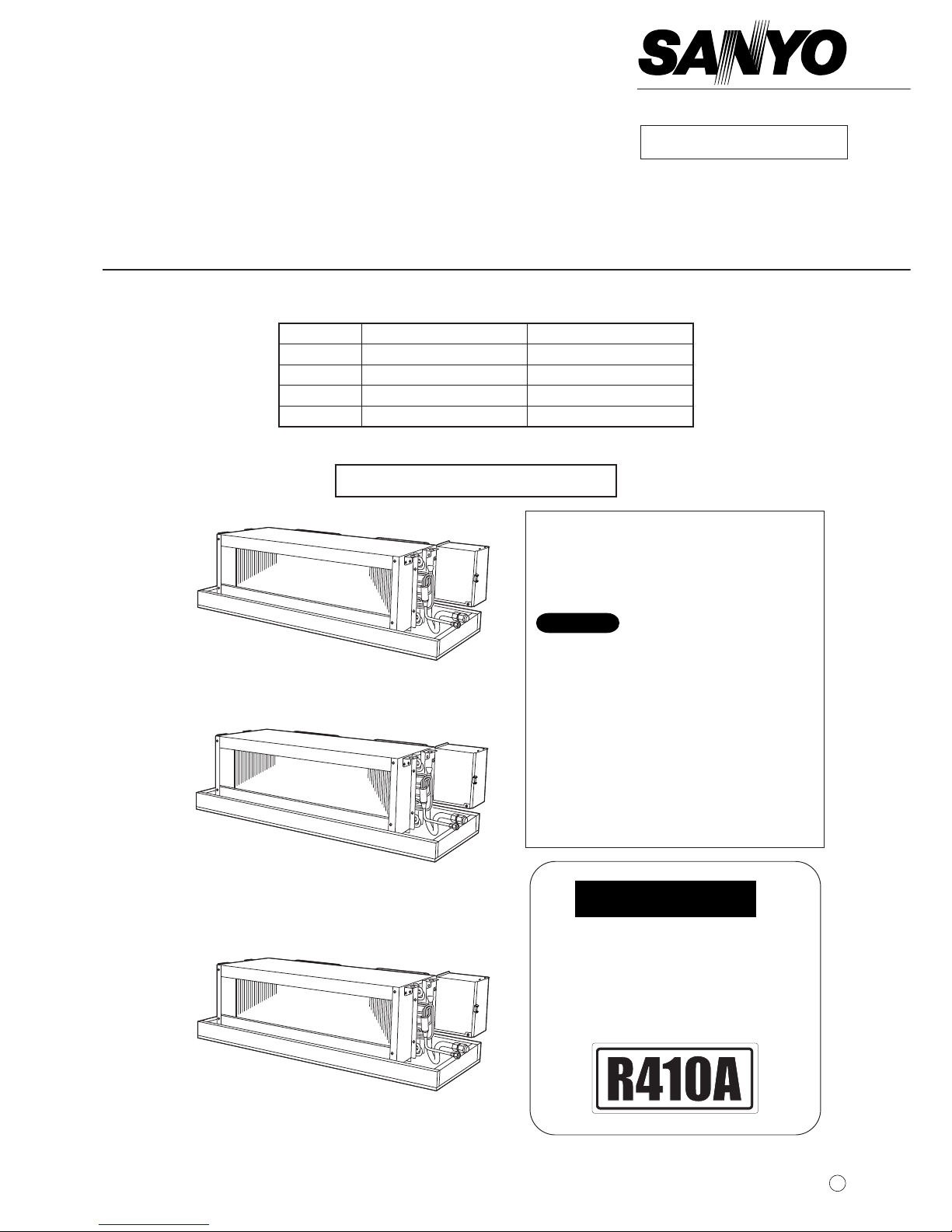

Sanyo SAP-DMRV93GJ,SAP-DMRV123GJ,SAP-DMRV183GJ,SAP-DMRV243GJ Technical & Service Manual

TECHNICAL & SERVICE MANUAL

INDOOR UNIT: SAP-DMRV93GJ

SAP-DMRV123GJ

SAP-DMRV183GJ

SAP-DMRV243GJ

DC INVERTER MULTI-SYSTEM AIR CONDITIONER

SAP-DMRV93GJ

SAP–DMRV123GJ

SAP–DMRV183GJ

Destination: General area (50Hz)

Europe (50Hz)

Australia (50Hz)

General area (60Hz)

Indoor Model No. Product Code No.

SAP-DMRV93GJ-S 1 852 084 90

SAP-DMRV243GJ

REVISION NO. SM700542-01

SAP-DMRV123GJ-S 1 852 084 91

SAP-DMRV183GJ-S 1 852 084 92

SAP-DMRV243GJ-S 1 852 084 93

IMPORTANT

These air conditioners employ

new refrigerant R410A.

Pay special attention when

servicing the unit.

Concealed Duct Type Indoor Unit

< Combined Outdoor unit >

SAP-CMRV1923GJ (2-room multi unit)

SAP-CMRV2433GJ (3-room multi unit)

SAP-CMRV3143GJ (4-room multi unit)

1. The indoor unit SAP-DMRV243 can only be

combined with a 4-room multi unit. Therefore,

do not combine it with a 2-room multi unit or

3-room multi unit.

2. The indoor unit SAP-DMRV243 can operate

only in areas with 50Hz power source.

Therefore, do not use it in regions where the

source is 60Hz.

3. For details about the combinations, refer to

“Unit Combination Table” in the

T. Service

Manual

for the Multi Outdoor Units.

NOTE

Capacity

2.8 kW

3.6 kW

5.0 kW

7.0 kW

W

Revised Edition

NOV.2003

i

Important!

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person,

it is an important part of your job to install or service the

system so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

● Carefully read this instruction booklet before

beginning.

● Follow each installation or repair step exactly as

shown.

● Observe all local, state, and national electrical codes.

● Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or

death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help

for a special problem, contact our sales/service outlet

or your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

Special Precautions

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR

DEATH. ONLY A QUALIFIED,

EXPERIENCED ELECTRICIAN SHOULD

ATTEMPT TO WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and

tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections

and inadequate grounding can cause accidental

injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

WARNING

CAUTION

WARNING

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your

knees when lifting to reduce strain on your back. Sharp

edges or thin aluminum fins on the air conditioner can

cut your fingers.

When Installing…

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to

prevent “sweating” that can cause dripping and water

damage to walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to

provide a solid, level foundation for the outdoor unit.

This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is

higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces

of the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leakfree connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power off at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any

moving parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

Others

• Ventilate any enclosed areas when installing or

testing the refrigeration system. Escaped refrigerant

gas, on contact with fire or heat, can produce

dangerously toxic gas.

• Confirm upon completing installation that no

refrigerant gas is leaking. If escaped gas comes in

contact with a stove, gas water heater, electric room

heater or other heat source, it can produce

dangerously toxic gas.

• Do not install only a single indoor unit.

CAUTION

Table of Contents

Page

1. OPERATING RANGE ............................................................................................................................... 1

2. SPECIFICATIONS

2-1. Unit Specifications.......................................................................................................................... 2

2-2. Major Component Specifications.................................................................................................... 6

2-3. Other Component Specifications.................................................................................................... 10

3. DIMENSIONAL DATA............................................................................................................................... 11

4. REFRIGERANT FLOW DIAGRAM .......................................................................................................... 12

5. DISASSEMBLY PROCEDURE FOR INDOOR UNIT

5-1. Removing Electrical Box................................................................................................................. 13

5-2. Removing Evaporator..................................................................................................................... 13

5-3. Removing Fan and Fan Motor........................................................................................................ 14

6. ELECTRICAL DATA

6-1. Electric Wiring Diagram.................................................................................................................. 17

7. INSTALLATION INSTRUCTIONS

7-1. Indoor Unit...................................................................................................................................... 18

7-2. Embedding the Tubing and Wiring................................................................................................. 21

7-3. Increasing the Fan Speed .............................................................................................................. 22

7-4. Mounting the Receiver.................................................................................................................... 24

7-5. Test Run......................................................................................................................................... 24

8. FUNCTIONS

8-1. Operation Functions....................................................................................................................... 25

8-2. Protective Functions....................................................................................................................... 27

9. TROUBLESHOOTING ............................................................................................................................. 28

.................................................................................................................................................. 32

APPENDIX

ii

1

1. OPERATING RANGE

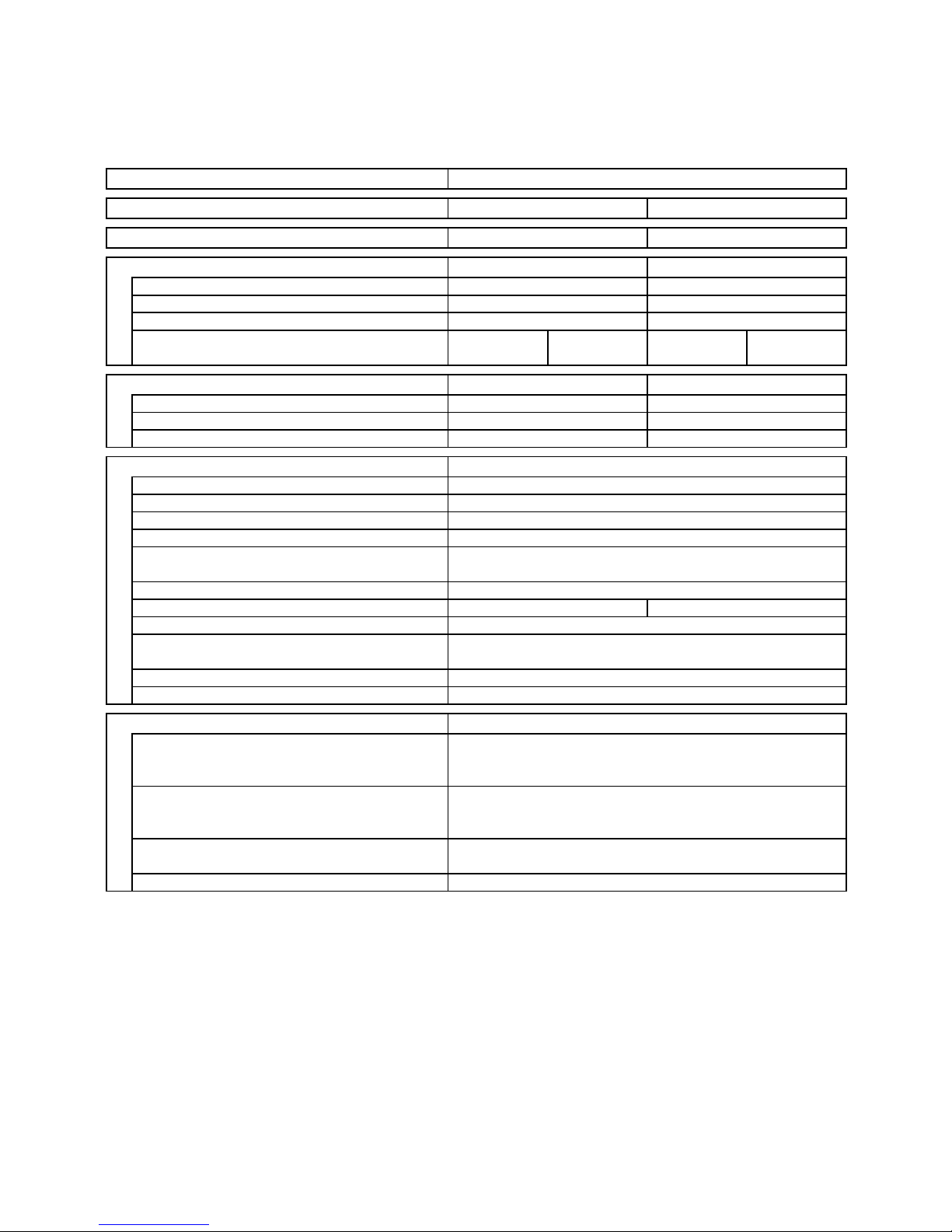

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Maximum 32°C DB / 23°C W.B. 43°C D.B.

Minimum 19°C DB / 14°C W.B. 19°C D.B.

2

2. SPECIFICATIONS

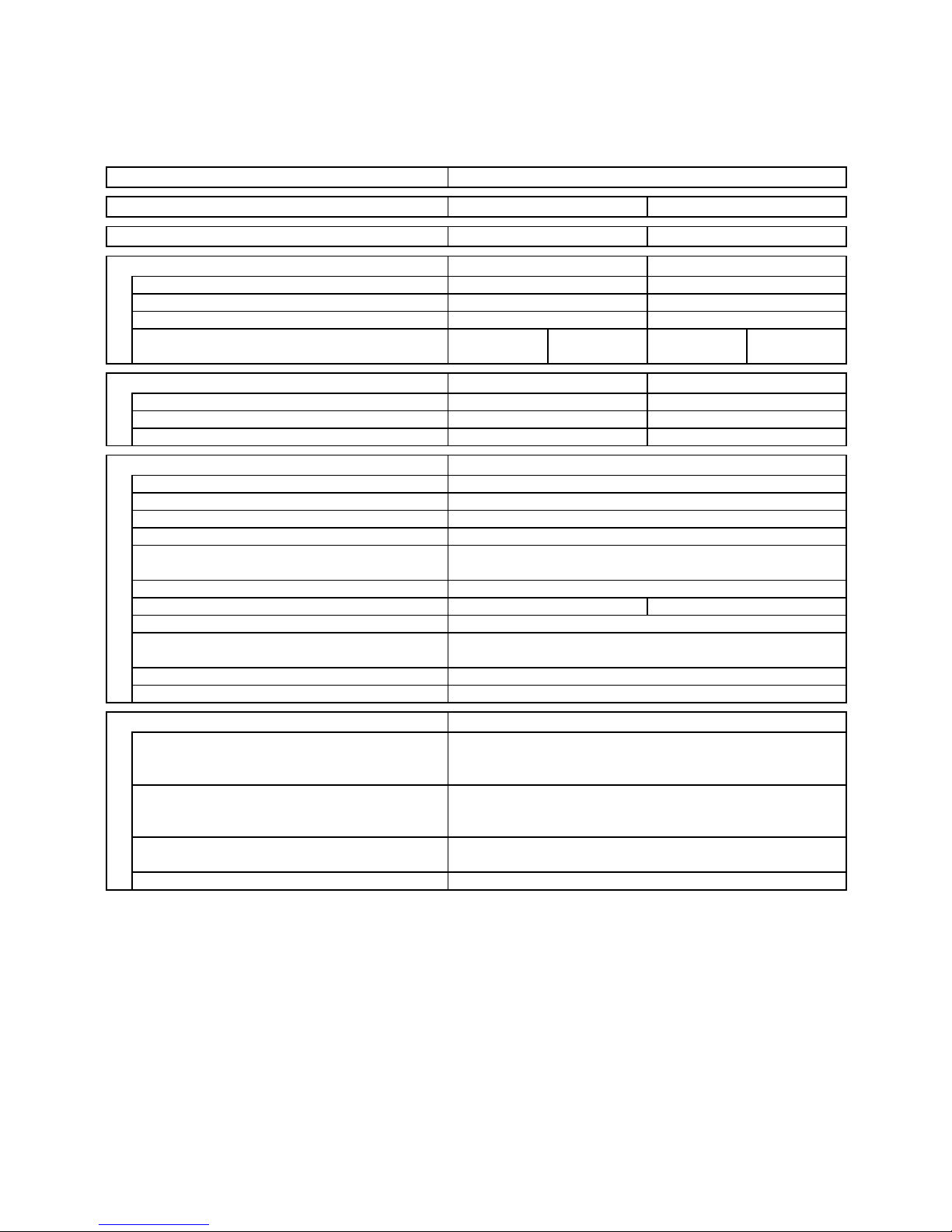

2-1. Unit Specifications

Indoor Unit SAP–DMRV93GJ

Type Concealed duct type indoor unit

Power Source 220–240V ~ 50Hz 220V ~ 60Hz

Voltage rating 230 V 220 V

Performance Cooling Cooling

Capacity kW 2.8 ( 0.7 - 3.2 ) 2.8 ( 0.7 - 3.2 )

Air circulation (Hi / Me / Lo)

m3/h

850 / 760 / 700 850 / 760 / 700

Moisture removal (High) Liters/h 1.6 1.6

External

(Low) Pa 0 to 19.6 0 to 19.6 0 to 19.6 0 to 19.6

static pressure

(High) Pa 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5

Electrical Rating Cooling Cooling

Available voltage range V 198 ~ 264 198 ~ 242

Running amperes A 0.41 0.40

Power input W 95 90

Features

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer ON/OFF 24 hours & Daily program,1-hour OFF

Fan speeds 3 and Auto

Airflow direction (Indoor) Horizontal —

Vertical —

Air filter Field supply

Operation sound Hi / Me / Lo dB-A 41 / 39 / 37 41 / 39 / 37

Refrigerant tubing connections Flare type

Refrigerant Narrow tube mm (in.) 6.35(1/4)

tube diameter Wide tube mm (in.) 9.52(3/8)

Refrigerant g R410A

Refrigerant tube kit Optional

Dimensions & Weight

Unit dimensions Height mm 260

Width mm 958

Depth mm 479

Package dimensions Height mm 374

Width mm 1,039

Depth mm 586

Weight Net kg 19

Shipping kg 25

Shipping volume

m

3

0.23

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

3

Indoor Unit SAP–DMRV123GJ

Type Concealed duct type indoor unit

Power Source 220–240V ~ 50Hz 220V ~ 60Hz

Voltage rating 230 V 220 V

Performance Cooling Cooling

Capacity kW 3.6 ( 0.8 - 3.6 ) 3.6 ( 0.8 - 3.6 )

Air circulation (Hi / Me / Lo)

m3/h

850 / 760 / 700 850 / 760 / 700

Moisture removal (High) Liters/h 2.0 2.0

External

(Low) Pa 0 to 19.6 0 to 19.6 0 to 19.6 0 to 19.6

static pressure

(High) Pa 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5

Electrical Rating Cooling Cooling

Available voltage range V 198 ~ 264 198 ~ 242

Running amperes A 0.41 0.40

Power input W 95 90

Features

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer ON/OFF 24 hours & Daily program,1-hour OFF

Fan speeds 3 and Auto

Airflow direction (Indoor) Horizontal —

Vertical —

Air filter Field supply

Operation sound Hi / Me / Lo dB-A 41 / 39 / 37 41 / 39 / 37

Refrigerant tubing connections Flare type

Refrigerant Narrow tube mm (in.) 6.35(1/4)

tube diameter Wide tube mm (in.) 9.52(3/8)

Refrigerant g R410A

Refrigerant tube kit Optional

Dimensions & Weight

Unit dimensions Height mm 260

Width mm 958

Depth mm 479

Package dimensions Height mm 374

Width mm 1,039

Depth mm 586

Weight Net kg 19

Shipping kg 25

Shipping volume

m

3

0.23

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

4

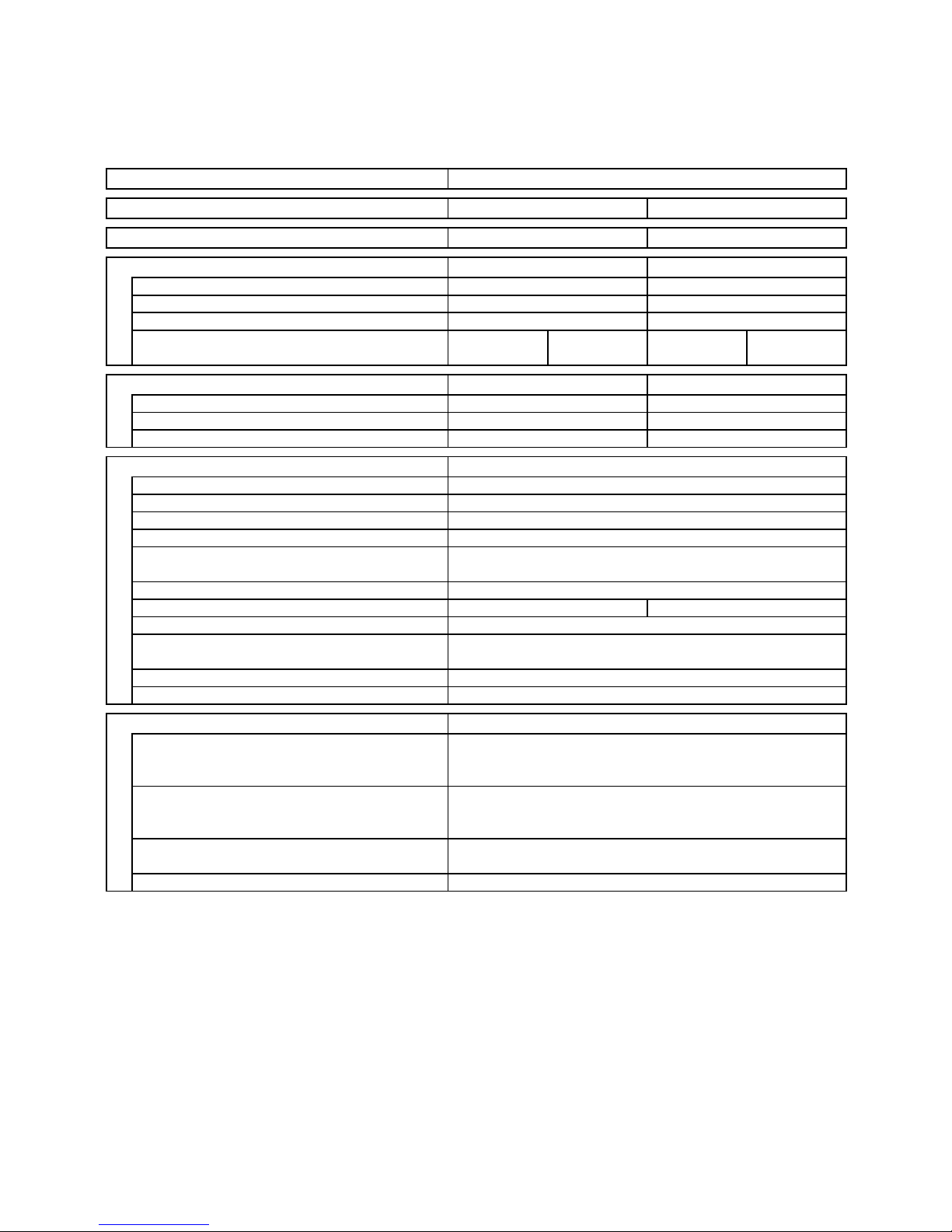

Indoor Unit SAP–DMRV183GJ

Type Concealed duct type indoor unit

Power Source 220–240V ~ 50Hz 220V ~ 60Hz

Voltage rating 230 V 220 V

Performance Cooling Cooling

Capacity kW 5.0 ( 1.1 - 5.8 ) 5.0 ( 1.1 - 5.8 )

Air circulation (Hi / Me / Lo)

m3/h

850 / 760 / 700 850 / 760 / 700

Moisture removal (High) Liters/h 2.8 2.8

External

(Low) Pa 0 to 19.6 0 to 19.6 0 to 19.6 0 to 19.6

static pressure

(High) Pa 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5 19.6 to 73.5

Electrical Rating Cooling Cooling

Available voltage range V 198 ~ 264 198 ~ 242

Running amperes A 0.41 0.40

Power input W 95 90

Features

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer ON/OFF 24 hours & Daily program,1-hour OFF

Fan speeds 3 and Auto

Airflow direction (Indoor) Horizontal —

Vertical —

Air filter Field supply

Operation sound Hi / Me / Lo dB-A 41 / 39 / 37 41 / 39 / 37

Refrigerant tubing connections Flare type

Refrigerant Narrow tube mm (in.) 6.35(1/4)

tube diameter Wide tube mm (in.) 9.52(3/8)

Refrigerant g R410A

Refrigerant tube kit Optional

Dimensions & Weight

Unit dimensions Height mm 260

Width mm 958

Depth mm 479

Package dimensions Height mm 374

Width mm 1,039

Depth mm 586

Weight Net kg 19

Shipping kg 25

Shipping volume

m

3

0.23

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

5

Indoor Unit SAP–DMRV243GJ

Type Concealed duct type indoor unit

Power Source 220–240V ~ 50Hz 220V ~ 60Hz

Voltage rating 230 V 220 V

Performance Cooling Cooling

Capacity kW 7.0 ( 1.5 - 8.1 ) —

Air circulation (Hi / Me / Lo)

m3/h

1,180 / 760 / 680 —

Moisture removal (High) Liters/h 3.4 —

External

(Low) Pa 0 to 19.6 0 to 19.6 — —

static pressure

(High) Pa 19.6 to 73.5 19.6 to 73.5 — —

Electrical Rating Cooling Cooling

Available voltage range V 198 ~ 264 —

Running amperes A 0.61 —

Power input W 138 —

Features

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer ON/OFF 24 hours & Daily program,1-hour OFF

Fan speeds 3 and Auto

Airflow direction (Indoor) Horizontal —

Vertical —

Air filter Field supply

Operation sound Hi / Me / Lo dB-A 52 / 41 / 39 —

Refrigerant tubing connections Flare type

Refrigerant Narrow tube mm (in.) 6.35(1/4)

tube diameter Wide tube mm (in.) 12.7(1/2)

Refrigerant g R410A

Refrigerant tube kit Optional

Dimensions & Weight

Unit dimensions Height mm 260

Width mm 958

Depth mm 479

Package dimensions Height mm 374

Width mm 1,039

Depth mm 586

Weight Net kg 19

Shipping kg 25

Shipping volume

m

3

0.23

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

6

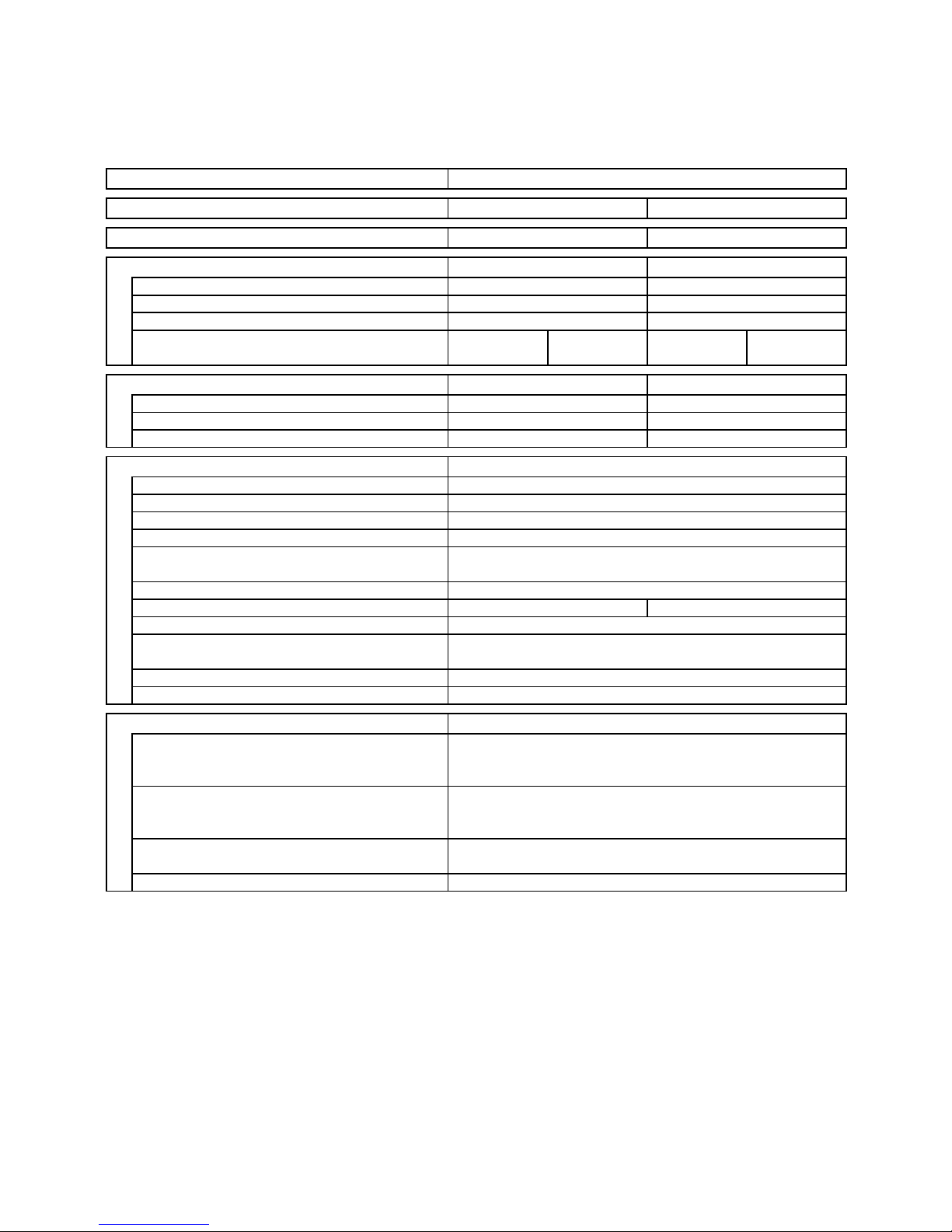

2-2. Major Component Specifications

2-2-1. Indoor Unit

Indoor Unit SAP–DMRV93GJ

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Control PCB

Part No. POW-DMRV243GJ

Controls Microprocessor

Control circuit fuse 2.50V 3.15A

Flap Motor and Louver Motor

Type —

Model —

Rating —

Coil resistance (Ambient temp. 25°C) Ω —

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.6

Face area m

2

0.118

Fan & Fan Motor

Type Centrifugal fan

Q’ty … Dia. and length mm 2 … ø144/L162

Fan motor model … Q’ty KFG4X-51G5P-S

No. of poles … rpm (230V, High) 4 … 1009

Nominal output W 50

Coil resistance (Ambient temp. 20°C) Ω BRN – WHT: 141.0 ORG – YEL: 12.8

WHT – VLT: 37.7 YEL – BLK: 58.2

VLT – ORG: 21.0 BLK – PNK: 33.3

Safety devices Type Thermal protector

Operating temp. Open °C 130 ± 8

Close Automatic reclosing

Run capacitor µF 3.0

VAC 440

Remote Control Unit RCS-3MVPS4E

7

Indoor Unit SAP–DMRV123GJ

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Control PCB

Part No. POW-DMRV243GJ

Controls Microprocessor

Control circuit fuse 2.50V 3.15A

Flap Motor and Louver Motor

Type —

Model —

Rating —

Coil resistance (Ambient temp. 25°C) Ω —

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.6

Face area m

2

0.147

Fan & Fan Motor

Type Centrifugal fan

Q’ty … Dia. and length mm 2 … ø144/L162

Fan motor model … Q’ty KFG4X-51G5P-S

No. of poles … rpm (230V, High) 4 … 1009

Nominal output W 50

Coil resistance (Ambient temp. 20°C) Ω BRN – WHT: 141.0 ORG – YEL: 12.8

WHT – VLT: 37.7 YEL – BLK: 58.2

VLT – ORG: 21.0 BLK – PNK: 33.3

Safety devices Type Thermal protector

Operating temp. Open °C 130 ± 8

Close Automatic reclosing

Run capacitor µF 3.0

VAC 440

Remote Control Unit RCS-3MVPS4E

8

Indoor Unit SAP–DMRV183GJ

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Control PCB

Part No. POW-DMRV243GJ

Controls Microprocessor

Control circuit fuse 2.50V 3.15A

Flap Motor and Louver Motor

Type —

Model —

Rating —

Coil resistance (Ambient temp. 25°C) Ω —

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.3

Face area m

2

0.147

Fan & Fan Motor

Type Centrifugal fan

Q’ty … Dia. and length mm 2 … ø144/L162

Fan motor model … Q’ty KFG4X-51G5P-S

No. of poles … rpm (230V, High) 4 … 1009

Nominal output W 50

Coil resistance (Ambient temp. 20°C) Ω BRN – WHT: 141.0 ORG – YEL: 12.8

WHT – VLT: 37.7 YEL – BLK: 58.2

VLT – ORG: 21.0 BLK – PNK: 33.3

Safety devices Type Thermal protector

Operating temp. Open °C 130 ± 8

Close Automatic reclosing

Run capacitor µF 3.0

VAC 440

Remote Control Unit RCS-3MVPS4E

9

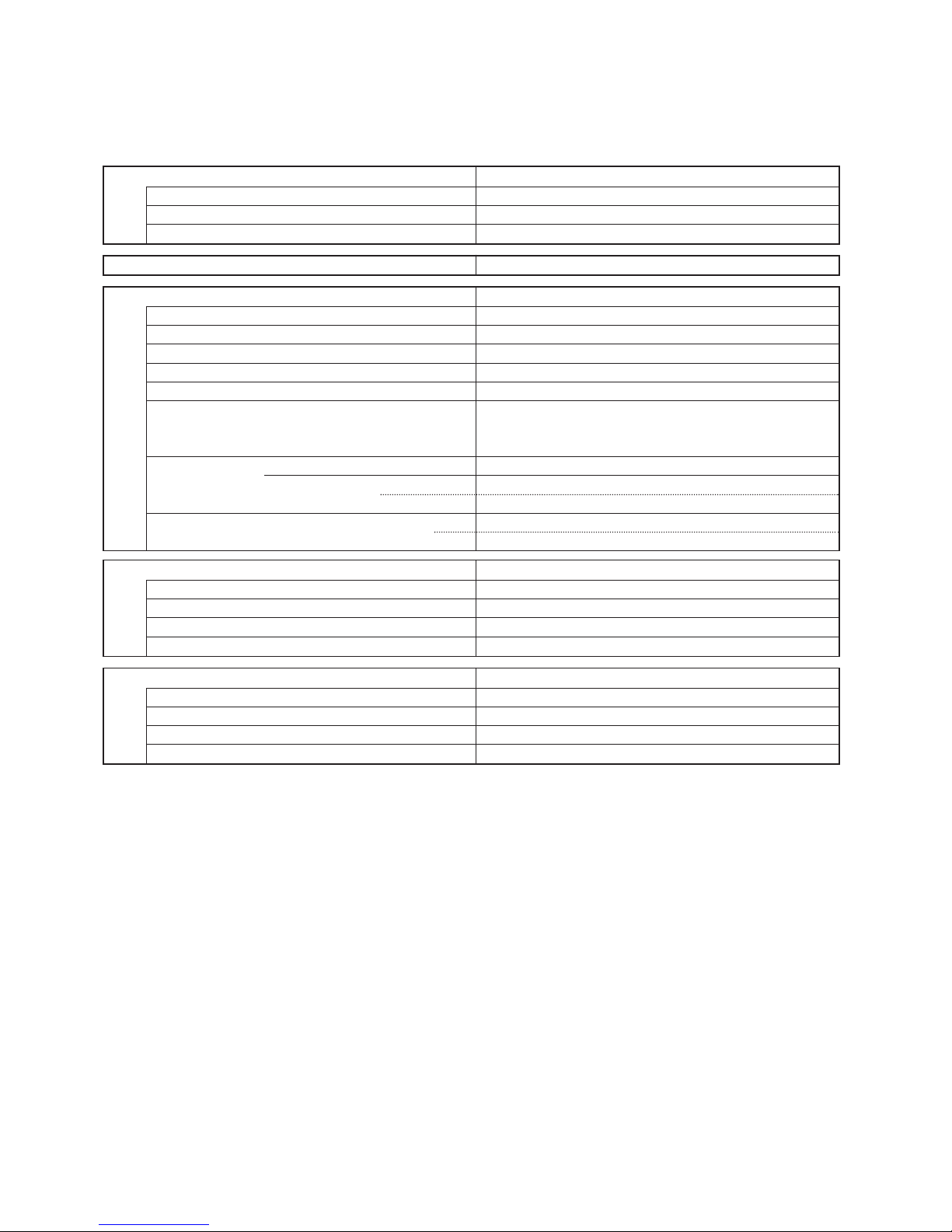

Indoor Unit SAP–DMRV243GJ

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Control PCB

Part No. POW-DMRV243GJ

Controls Microprocessor

Control circuit fuse 2.50V 3.15A

Flap Motor and Louver Motor

Type —

Model —

Rating —

Coil resistance (Ambient temp. 25°C) Ω —

Heat Exchanger Coil

Coil Aluminum plate fin / Copper tube

Rows 3

Fin pitch mm 1.3

Face area m

2

0.147

Fan & Fan Motor

Type Centrifugal fan

Q’ty … Dia. and length mm 2 … ø144/L162

Fan motor model … Q’ty KFG4X-91A5P-S

No. of poles … rpm (230V, High) 4 … 1330

Nominal output W 90

Coil resistance (Ambient temp. 20°C) Ω BRN – WHT: 87.1 ORG – YEL: 32.3

WHT – VLT: 15.1 YEL – BLK: 143.8

VLT – ORG: 111.8 BLK – PNK: 103.6

Safety devices Type Thermal protector

Operating temp. Open °C 130 ± 8

Close Automatic reclosing

Run capacitor µF 3.5

VAC 440

Remote Control Unit RCS-3MVPS4E

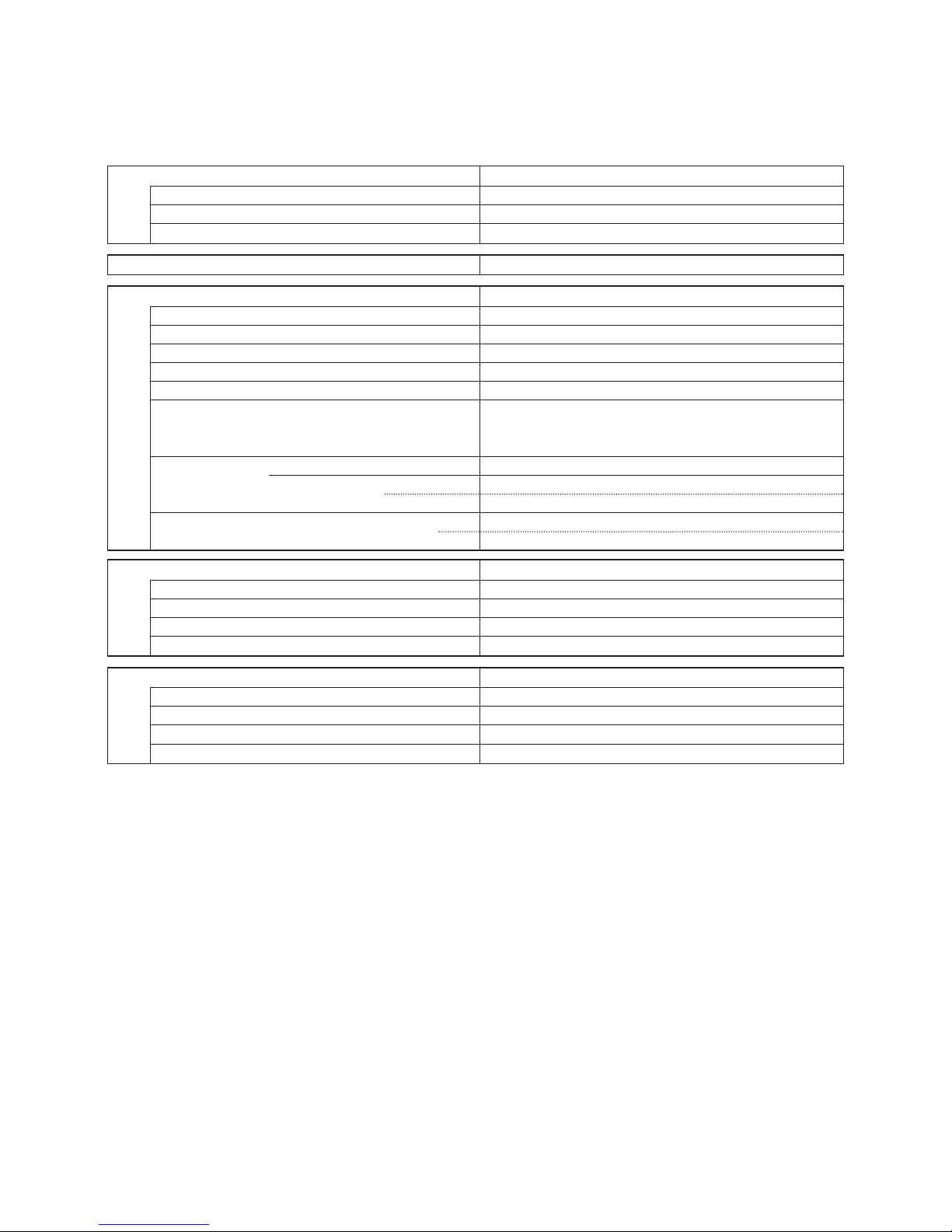

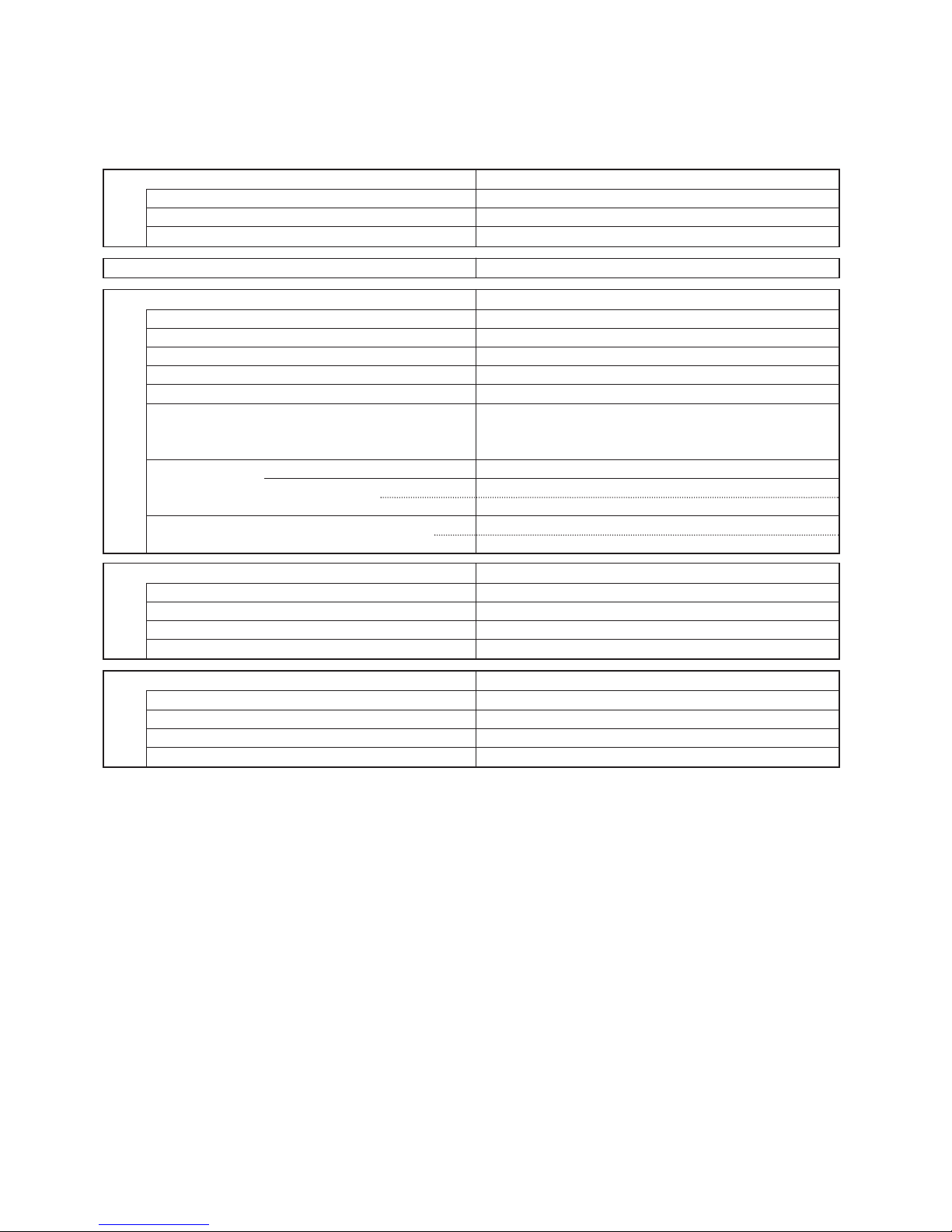

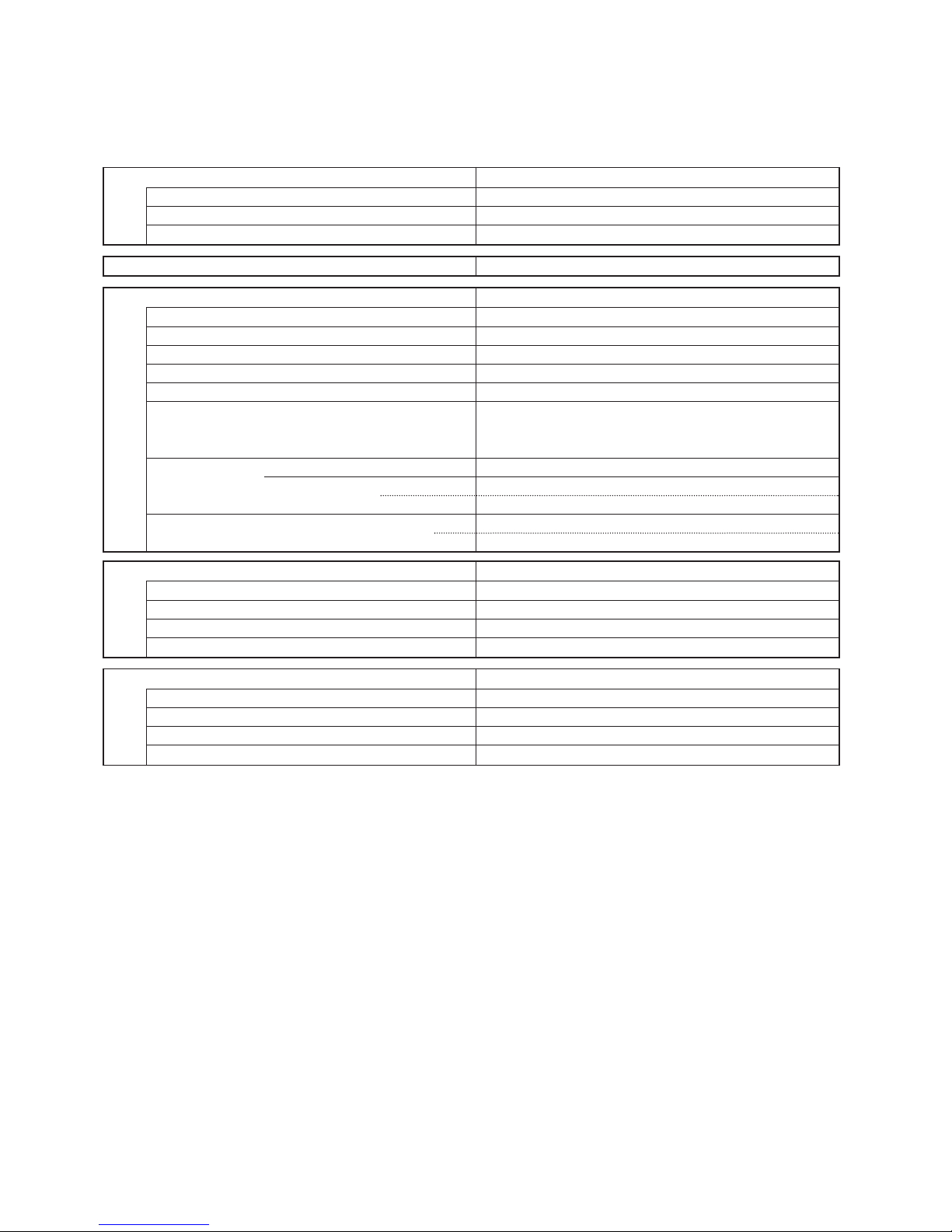

2-3. Other Component Specifications

10

Indoor Unit SAP–DMRV93GJ

SAP–DMRV123GJ

SAP–DMRV183GJ

SAP–DMRV243GJ

0

0 102030405060708090

40

60

80

100

120

140

160

180

200

20

10

1

2

3

4

5

6

7

8

9

10

15 20 25 30 35 40

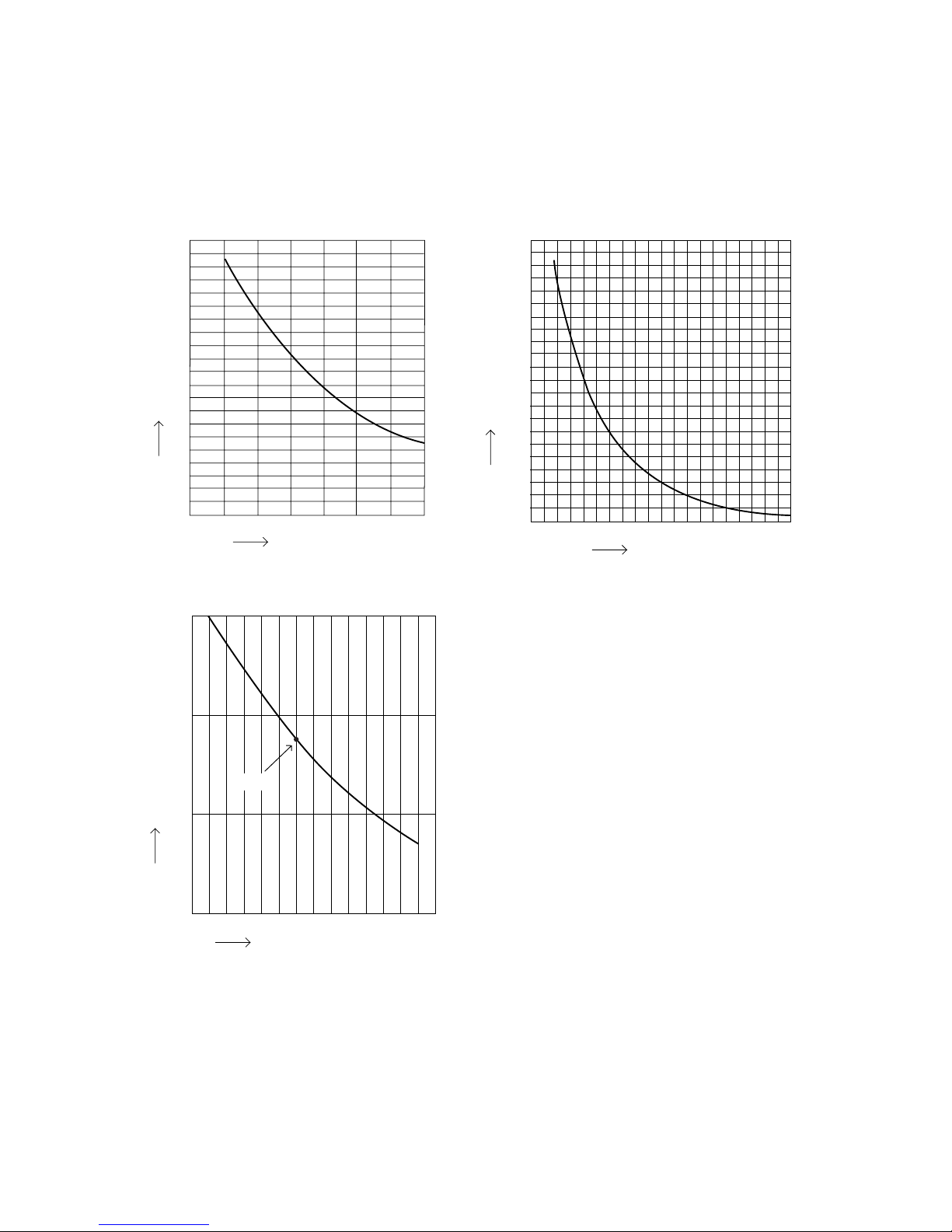

• Indoor air temp sensor

• Indoor heat exchanger sensor

• Humidity sensor

30 35 40 45 50 55 60 65 70 75 80 85 90

1

10

100

1000

25°C

Resistance (Ω)

Resistance (Ω)

Resistance (Ω)

Temperature (°C)

Temperature (°C)

Relative humidity (%)

11

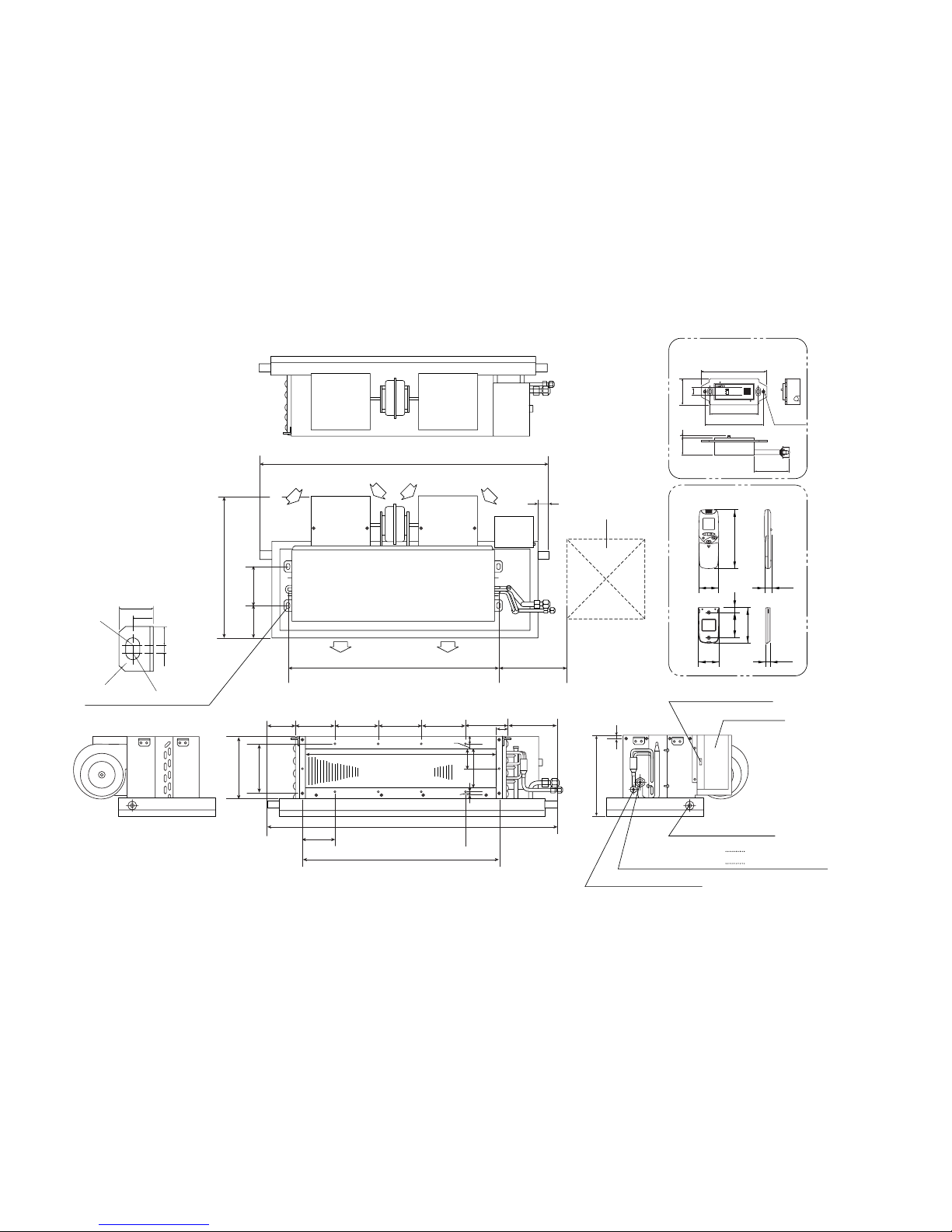

3. DIMENSIONAL DATA

Indoor Unit SAP–DMRV93GJ

SAP–DMRV123GJ

SAP–DMRV243GJ

SAP–DMRV183GJ

738

(Suspension bolt pitch)

(Suspension bolt pitch)

71

139 150 150 150 149 149

662

22

15

6.5

135

68

38

958

960

134

85

480

165

205

450 x 450

30

111

121

682

200

Inspection access

(Field work)

unit: mm

AIR DISCHARGE AIR DISCHARGE

AIR INTAKE

Narrow tube ø6.35 (1/4")

Drain pipe O.D. ø26.9

Wide tube ø9.52 (3/8")

DMRV93, 123, 183

Wide tube ø12.7 (1/2")

DMRV243

3.0

260

Connector for Reciever

Electrical box

16.5

7.0

30.0

18.0

R 6.5

C 5.0

R 6.5

4 – Hole for suspension bolt

AIR INTAKE

AIR INTAKE

Remote control unit

182

61 23

65

110

15

78

14.3

Remote control receiver

ON

OPERATION

TIMER

OFF

TEST

112

101

83.5

3700

2–

ø

3.5

4530.2 3

13

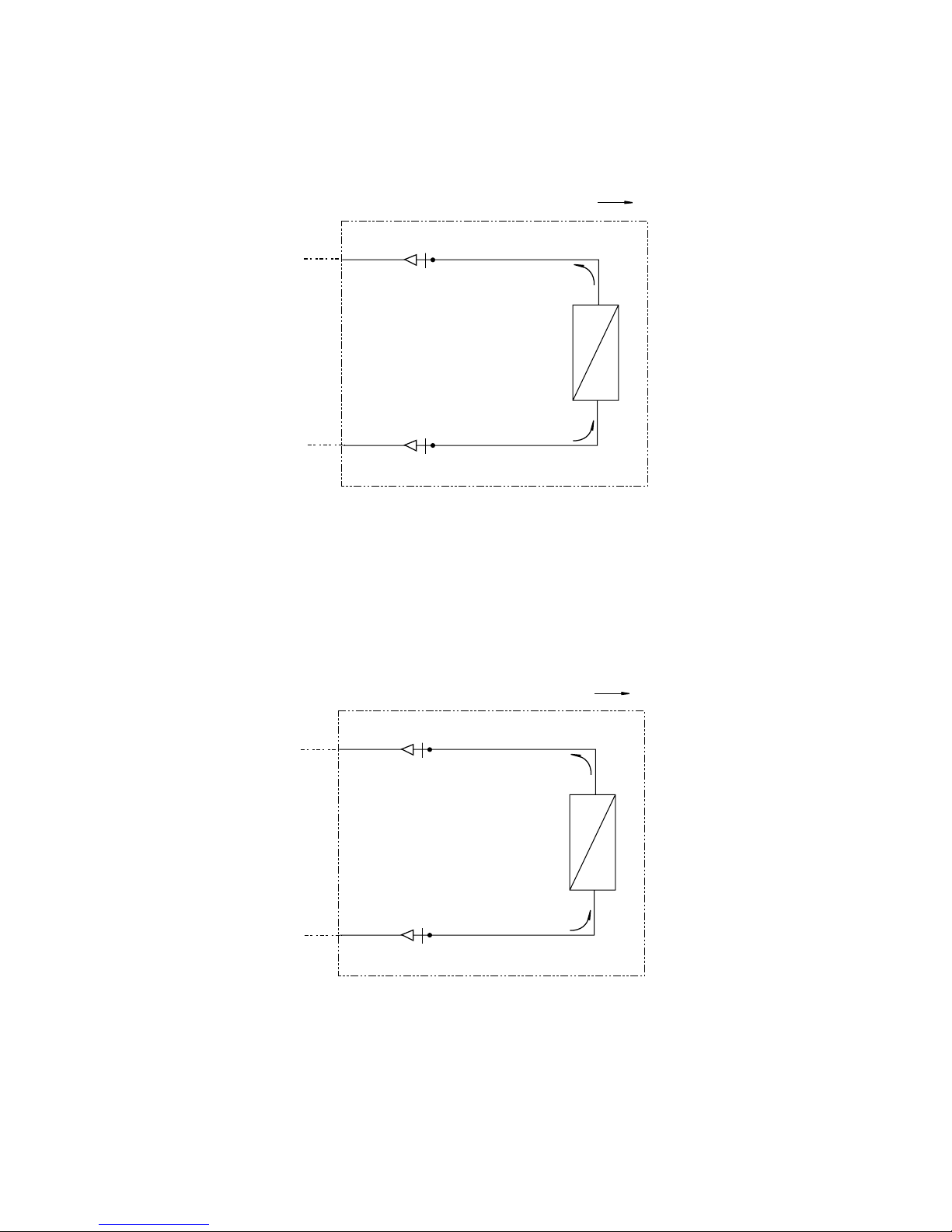

4. REFRIGERANT FLOW DIAGRAM

12

Indoor Unit SAP–DMRV93GJ

SAP–DMRV123GJ

SAP–DMRV183GJ

9.52

EC

P

6.35

Indoor unit

Cooling

Indoor heat

exchanger

12.7

EC

P

6.35

Indoor unit

Cooling

Indoor heat

exchanger

Indoor Unit SAP–DMRV243GJ

13

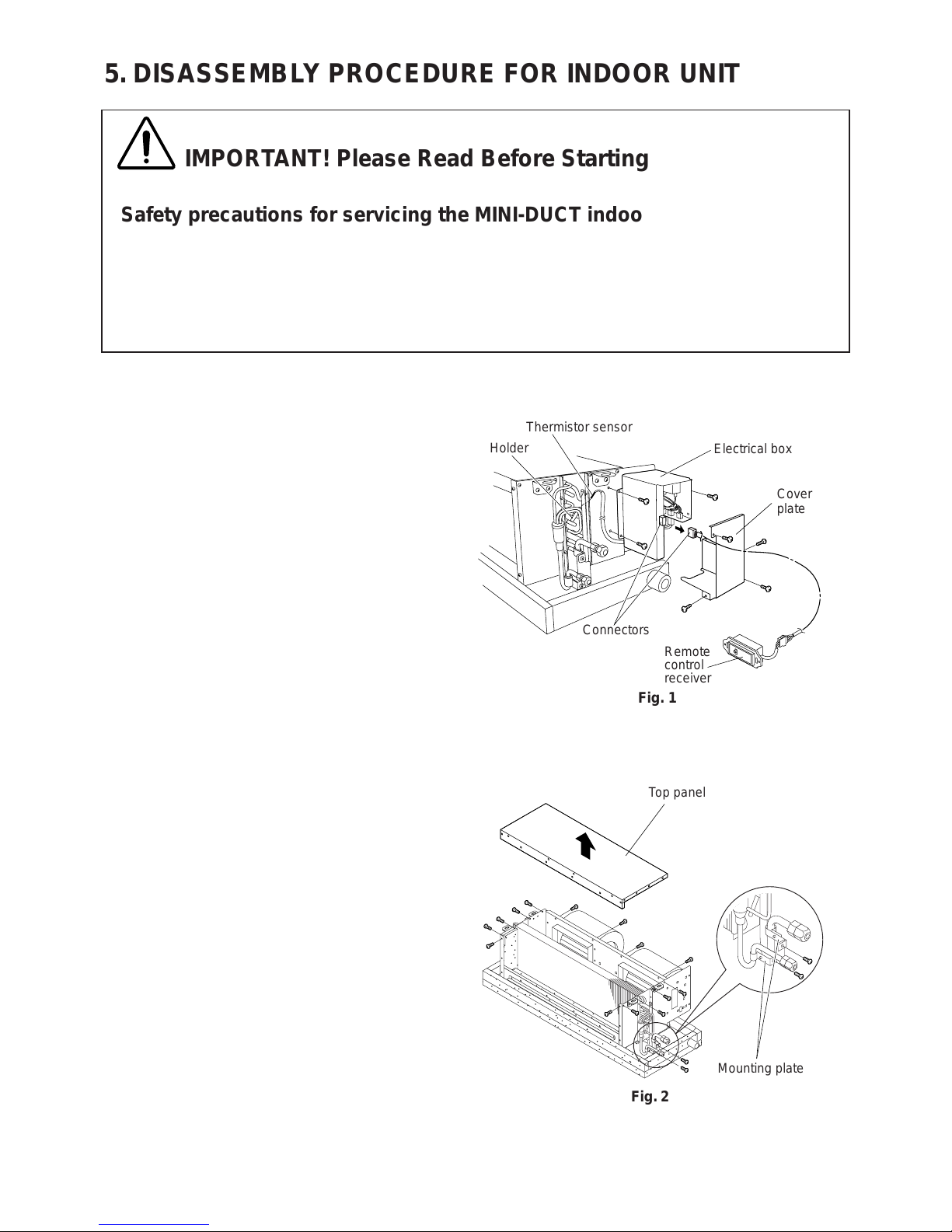

5-1. Removing Electrical Box

(1) Remove 4 screws used to attach the cover plate

of the electrical box. Then pull the plate toward

you. (Fig. 1)

(2) Pull the thermistor sensor from its holder. (Fig. 1)

(3) Remove 3 screws securing the electrical box

to the unit. (Fig. 1)

(4) Disconnect the connectors to disengage the

remote control receiver. (Fig. 1)

5-2. Removing Evaporator

(1) Remove 14 screws securing the top panel. (Fig. 2)

(2) Remove 2 screws holding the evaporator tubing

at the mounting plate. (Fig. 2)

,,

QQ

SS

,,

QQ

Top panel

Mounting plate

Fig. 2

Holder

Thermistor sensor

Electrical box

Cover

plate

Remote

control

receiver

Connectors

Fig. 1

5. DISASSEMBLY PROCEDURE FOR INDOOR UNIT

IMPORTANT! Please Read Before Starting

Safety precautions for servicing the MINI-DUCT indoor unit

●

Before attempting to replace heavy and bulky parts such as the evaporator and fan motor, disconnect the

indoor unit from the system and place it on the floor. Refer to the steps given below.

●

When checking or servicing the unit or electrical component box, first check that power is completely

disconnected. Pay utmost care that your working platform is stable enough. Also, do not drop any replaced

parts and tools on the floor.

14

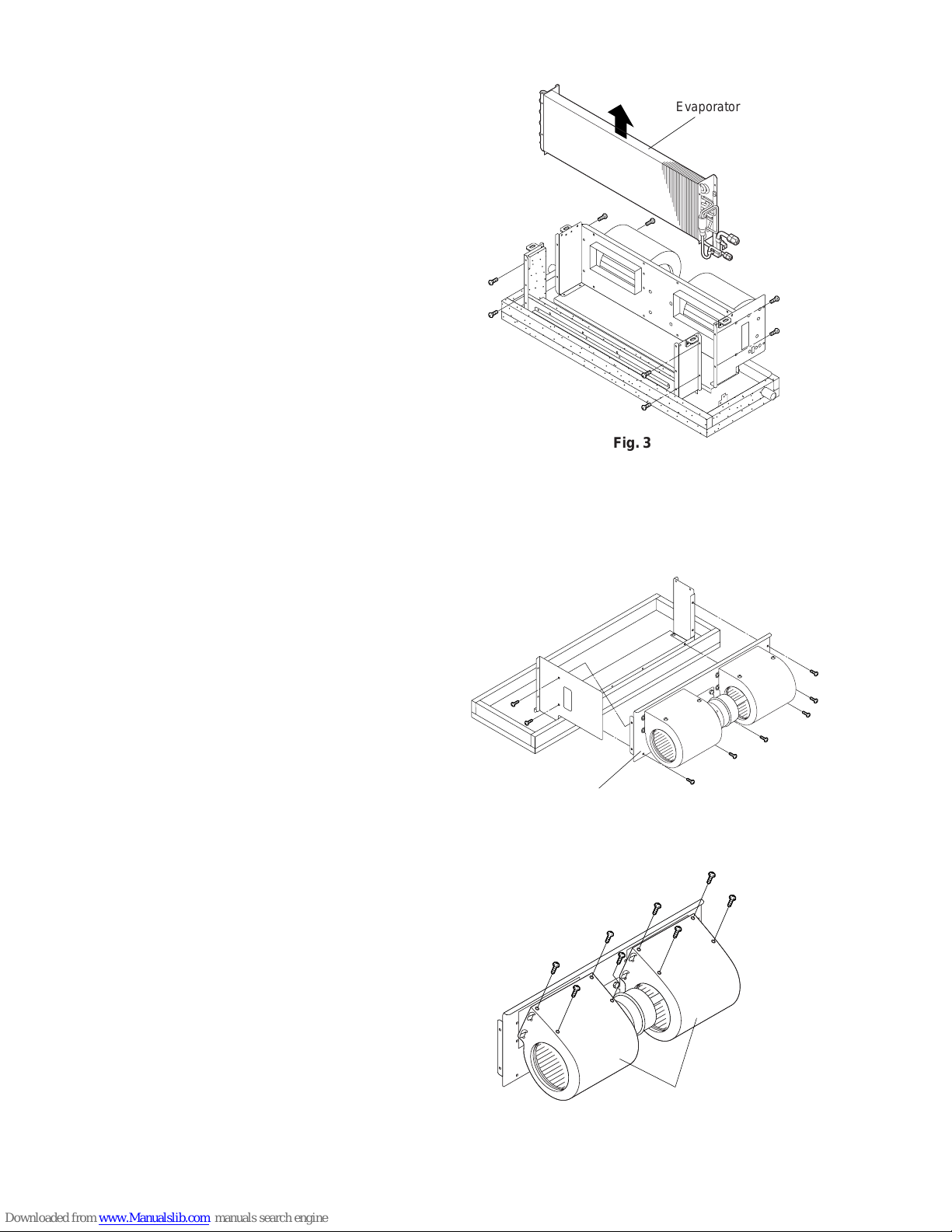

(3) Remove 8 screws holding the evaporator. (Fig. 3)

(4) Lift the evaporator up out of the unit. (Fig. 3)

5-3. Removing Fan and Fan Motor

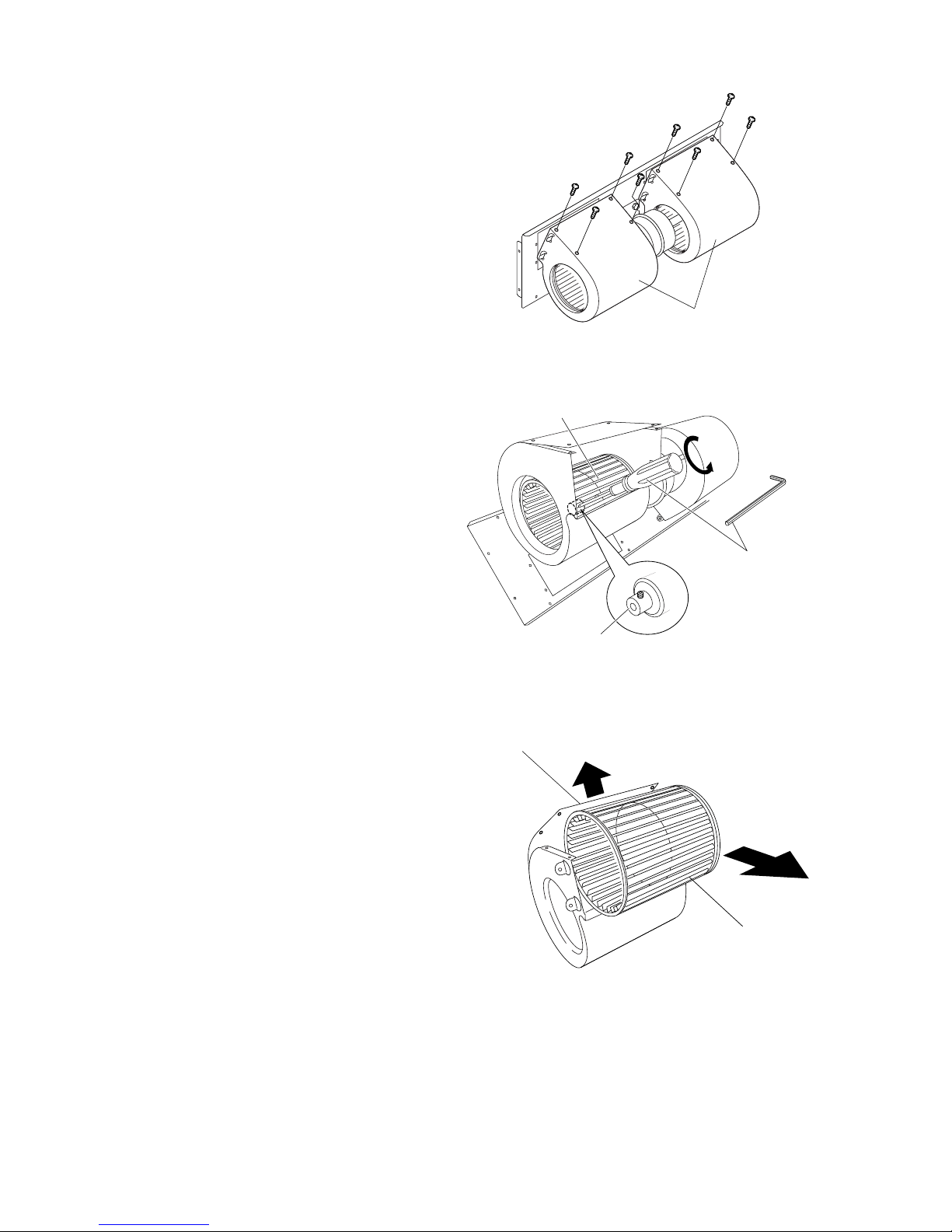

(1) Remove 8 screws holding the base plate for the fan

and fan motor. (Fig. 4)

(2) Remove 8 screws holding the fan casing.

Then pull the casing toward you. (Fig. 5)

Fan casing

Fig. 6

Base plate

Fig. 4

,,

SS

Evaporator

Fig. 3

15

(3) Remove 8 screws holding the fan casing. (Fig. 6)

(4) Insert a hex wrench in the fan boss and turn

it counterclockwise to loosen the fan.

(Fig. 7)

(5) Gently lift the opening of the fan motor casing

to access the fan.

(Fig. 8)

Fan casing

Fan

Fig. 8

Fan

Hex head screwdriver

or hex wrench (3.0 mm)

Fan boss

Fig. 7

Fan casing

Fig. 6

Loading...

Loading...