Page 1

FILE NO.

SERVICE MANUAL

Multimedia Projector

Model No. PLC-XP100L

U.S.A, Canada,

Europe, U.K, Asia

Original Version

* Projection lens is optional.

PRODUCT CODE

1 122 380 20 (KC3AL)

1 122 381 20 (LC3AL)

1 122 381 22 (LC3CL)

Chassis No. KC3-XP100L00

Match the Chassis No. on the unit's back cover with the

Chassis No. in the Service Manual.

If the Original Version Service Manual Chassis No. does

not match the unit’s, additional Service Literature is required. You must refer to “Notices” to the Original Service

Manual prior to servicing the unit.

REFERENCE NO. SM5110873-00

Page 2

Contents

SERVICE MANUAL ....................................................... 1

Contents ........................................................................ 2

Safety Instructions ......................................................... 3

Safety Precautions ..................................................... 3

Product Safety Notice ................................................. 3

Service Personnel Warning ........................................ 3

Specifications ................................................................ 4

Circuit Protections .........................................................5

Fuse ............................................................................ 5

Thermostat (SW905) .................................................. 5

Mechanical sensor switches (SW1891,SW1861) ........6

Temperature sensors, wind sensors .......................... 7

Power failure and fan lock detection .......................... 8

Maintenance .................................................................. 9

Replacing the Filter Cartridge .................................... 9

Resetting the Filter Counter ..................................... 10

Resetting the Scroll Counter .................................... 10

Lamp Replacement .................................................. 11

Resetting the Lamp Counter .................................... 12

How to check Lamp Used Time ............................... 12

Cleaning ................................................................... 13

Quick maintenance ................................................... 14

Security Function Notice ............................................. 15

Mechanical Disassembly............................................. 16

Mechanical disassembly flow chart .......................... 16

Mechanical disassembly .......................................... 17

Optical Parts Disassembly .......................................... 28

Adjustments ................................................................. 38

Adjustments after Parts Replacement ...................... 38

Optical Adjustments .................................................... 39

Contrast adjustment ................................................. 39

Electrical Adjustments ................................................. 40

Service Adjustment Menu Operation ....................... 40

Memory IC (IC301, IC802) Replacement .................

Circuit Adjustments .................................................. 41

Test Points and Locations ........................................ 44

Service Adjustment Data Table ................................ 45

Chassis Description ....................................................64

Chassis over view ..................................................... 64

Input & signal processing stage ...............................65

LCD drive stage ........................................................ 66

40

Lamp control stage ................................................... 67

Fan control stage ...................................................... 68

Motor control stage ................................................... 69

Bus control stage ...................................................... 70

LED drive & RC control stage ................................... 71

Power supply & power failure circuit ......................... 72

Indicators and Projector Condition ........................... 73

Power failure detection system ................................ 75

Error information table .............................................. 75

Power failure detection tree ...................................... 76

Error History Log ...................................................... 77

Diagnosis of Power Failure with RS-232C port ........

Diagnosis procedure ................................................78

Serial Control Interface ............................................. 79

Control Port Functions................................................. 81

System Control I/O Port Functions (SH7727) ..........

Parallel I/O Expander (TIC81592GP) .......................

IIC Bus 8Bits 8ch 5V D/A Converter (M62393FP No.1

Fan Control) .............................................................. 83

Parallel Output Expander (74LCX574) ..................... 83

Waveform ....................................................................84

IC Block Diagrams....................................................... 85

Electrical Parts List ...................................................... 96

Electrical Parts Location ........................................... 97

Electrical Parts List ................................................... 99

Mechanical Parts List ................................................ 131

Cabinet Parts Location ........................................... 131

Mechanical Parts List ............................................. 136

Diagrams & Drawings .................................................. A1

Parts description and reading in schematic diagram ..A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams ................................. A13

Pin description of diode, transistor and IC ................ A17

Note on Soldering ...................................................... A18

78

81

81

-2-

Page 3

Safety Instructions

Safety Precautions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side

of the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is

identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel injury, servicing should be made with qualified personnel.

The following precautions must be observed.

ment covers or shields, barriers, etc.

1: An isolation transformer should be connected in

the power line between the projector and the AC

line before any service is performed on the projector.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND PR

OPERLY SECURED.

2: Comply with all caution and safety-related notes

provided on the cabinet back, cabinet bottom, inside

the cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always

be certain that all the protective devices are

installed properly, such as, control knobs, adjust-

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe

to operate without danger of electric shock.

Product Safety Notice

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark ! in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there

parts must be made by exactly the same parts.

Service Personnel Warning

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always

turn off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages (15kV - 25kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

-3-

Page 4

Specifications

Mechanical Information

Projector Type Multi-media Projector

Dimensions (W x H x D) 14.56” x 7.36” x 17.32” (370 mm x 187 mm x 440 mm) (Not including raised portions)

Net Weight 25.8 lbs (11.7 kg)

Feet Adjustment 0˚ to 6.5˚

Panel Resolution

LCD Panel System 1.3” TFT Active Matrix type, 3 panels

Panel Resolution 1,024 x 768 dots

Number of Pixels 2,359,296 (1,024 x 768 x 3 panels)

Signal Compatibility

Color System

High Definition TV Signal 480i, 480p, 575i, 575p, 720p, 1035i, and 1080i

Scanning Frequency H-sync. 15 kHz–100 kHz, V-sync. 50 Hz–100 Hz

Optical Information

Projection Lamp 330 W NSH lamp

Interface

Input 1 Digital (DVI-D) x 1, Analog (Mini D-sub 15 pin) x 1

Monitor Out

Input 2 BNC Type x 5 (G or Video/Y, B or Cb-Pb, R or Cr-Pr, HV and V)

Input 3 RCA Type x 1, Mini DIN 4 pin x 1

R/C Jack Mini Type (Wired Remote) x 1

Control Port Mini DIN 9 pin x 1

USB Connector USB Series B x 1

Option Network Terminal x 1

Analog RGB (Mini D-sub 15 pin) Terminal x 1

Power

Voltage and Power Consumption AC 100–120 V (4.6A Max. Ampere), 50/60 Hz (The U.S.A and Canada)

AC 200–240 V (2.3A Max. Ampere), 50/60 Hz (Continental Europe and The U.K.)

Operating Environment

Operating Temperature 41˚F–104˚F (5˚C–40˚C)

Storage Temperature 14˚F–140˚F (-10˚C–60˚C)

Remote Control

Battery AAA or LR03 Type x 2

Operating Range 16.4’ (5 m/±30˚)

Dimensions 1.8” (W) x 1.0” (H) x 5.7” (D) (45 mm x 25 mm x 145 mm)

Net Weight 3.5 oz (99 g) (including batteries)

PAL, SECAM, NTSC, NTSC4.43, PAL-M, and PAL-N

● The specifications are subject to change without notice.

● LCD panels are manufactured to the highest possible standards. Even though 99.99% of the pixels are effective, a tiny

fraction of the pixels (0.01% or less) may be ineffective by the characteristics of the LCD panels.

This symbol on the nameplate means the product is Listed by Underwriters

Laboratories Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of fire, casualty and electrical hazards.

-4-

Page 5

Circuit Protections

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

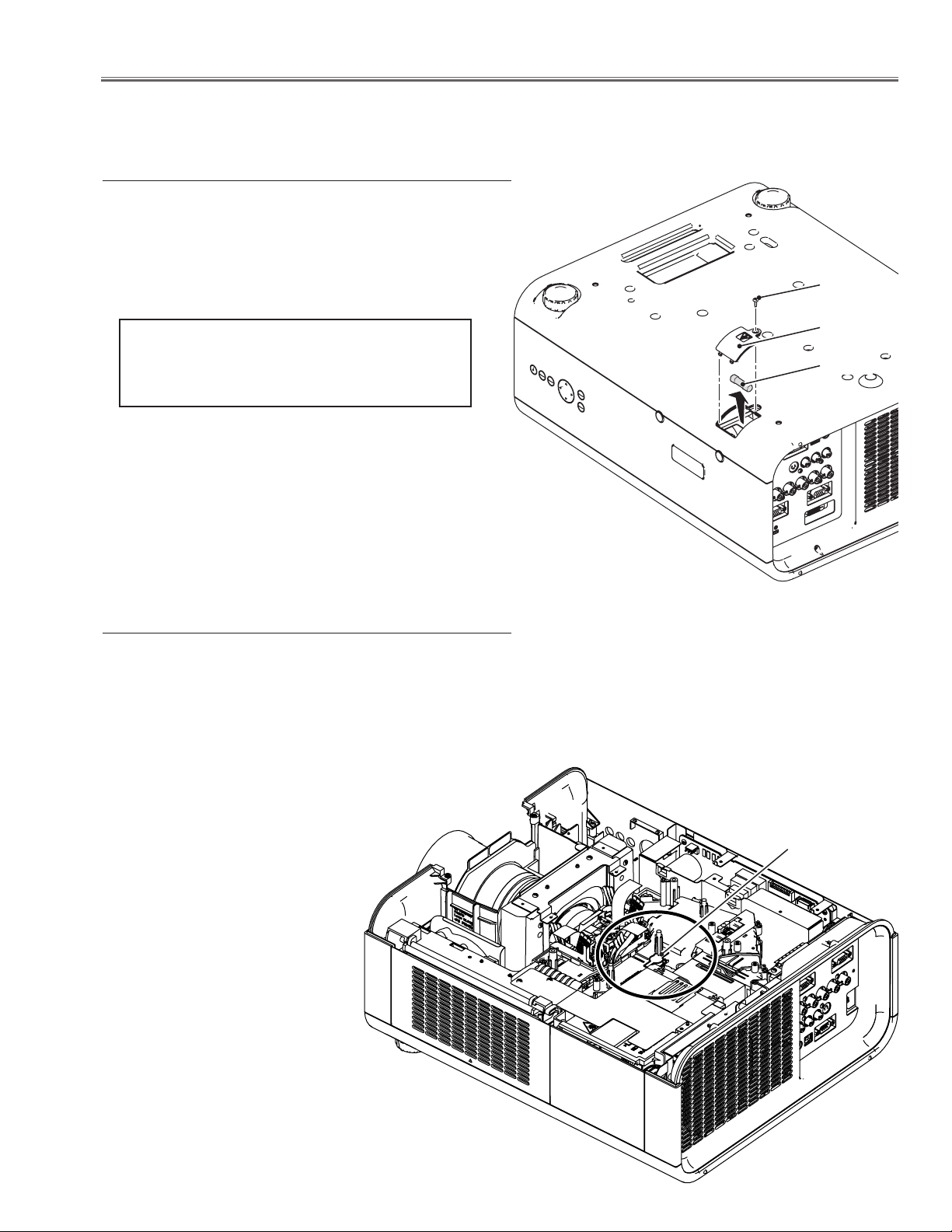

Fuse

A fuse is located inside of the projector. When the POWER

indicator is not lightning, the fuse may be opened. Check

the fuse as following steps.

The fuse should be used with the following type;

Screw

Fuse Part No. : 323 027 2605

TYPE T10AH 250V

LITTEL FUSE INC. TYPE 215010

How to replace the fuse

1. Turn the projector up and down.

2. Remove 1 screw and take the fuse cover off.

3. Remove the fuse from fuse holder on the power board.

To install the fuse, take reversed step in the above.

Thermostat (SW905)

There is the thermostat switch (SW905) inside of the projector to detect the internal temperature rising abnormally. When

the internal temperature reaches near 90˚C, the thermostat

opens to stop the operation of the power supply circuit.

The thermostat will automatically return to normal condition when the internal temperature becomes normal (about

50

˚C)

.

Fuse cover

Fuse

-5-

Thermostat

(SW905)

Page 6

Circuit Protections

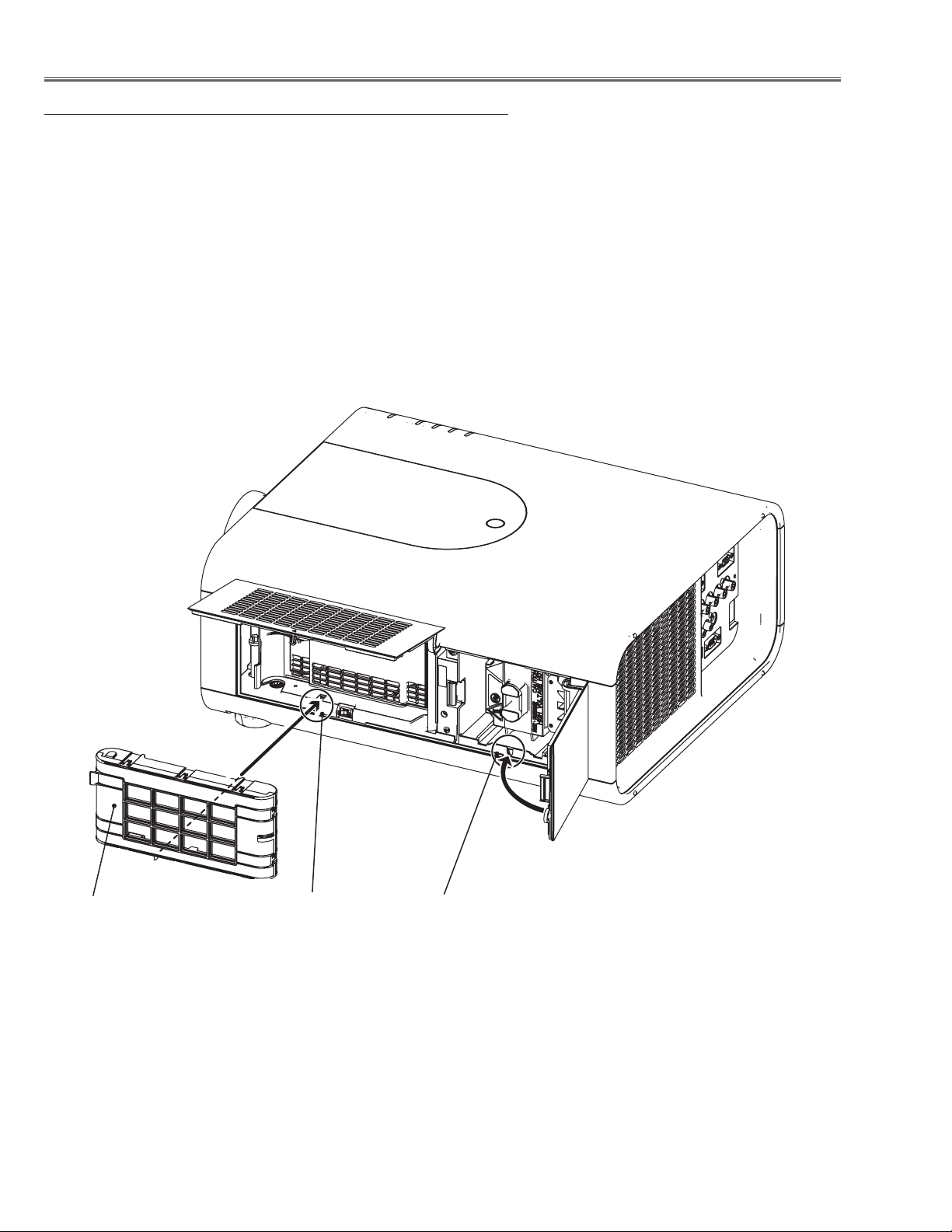

Mechanical sensor switches (SW1891,SW1861)

This projector provides 2 mechanical sensor switches, the one is for

filter cartridge sensor switch (SW1891) and the other one is for lamp

cover sensor switch (SW1861). The filter cartridge sensor switch

detects whether the filter cartridge is installed correctly. If the filter

cartridge is not installed correctly, the projector cannot turn on.

The lamp cover sensor switch detects whether the lamp cover is

closed securely. If lamp cover is opened or not closed completely,

the drive signal to the lamp circuit is cut off. After opening the lamp

cover for replacing the lamp ass’y, place the lamp cover correctly

otherwise the projector cannot turn on.

Filter cartridge

Filter cartridge sensor

switch (SW1891)

Lamp cover sensor

switch (SW1861)

-6-

Page 7

Circuit Protections

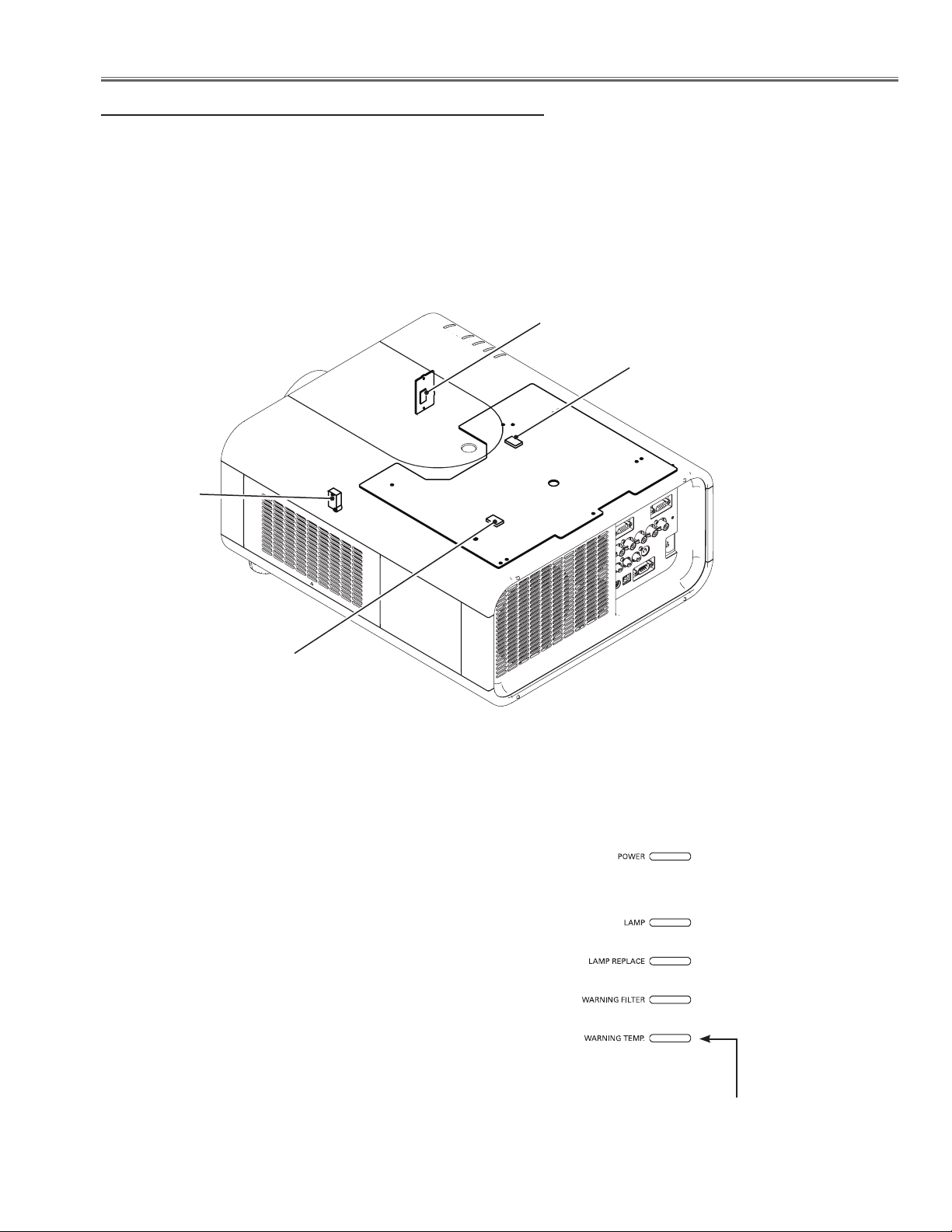

Temperature sensors, wind sensors

The projector provides 3 temperature sensor ICs, 2 sensors on the Main board and 1 sensor on the RC front board,

and 1 wind sensor on the intake duct. The sensor ICs monitor surrounding temperature of the lamp house and panels/prism, and room temperature, and the wind sensor monitors airflow passed through the air filter in the intake

duct.

- Internal temperature sensor A (IC1816) (around the lamp house)

- Internal temperature sensor B (IC1814) (around the panels/prism)

- Room temperature sensor C (IC1692) (around the front cabinet)

- Wind sensor D (S901) (intake duct)

IC1692

IC1814

(Behind)

S901

IC1816

(Behind)

The projector is shut down and the WARNING TEMP. indicator is blinking red.

When the temperature inside the projector reaches a certain

level, the projector will be automatically shut down to protect

the inside of the projector. The POWER indicator is blinking

while the projector is being cooled down. When the projector

has cooled down enough (to its normal operating temperature), it can be turned on again by pressing the ON/STANDBY button.

✔Note:

• The WARNING TEMP. indicator continues to blink even after

the temperature inside the projector returns to normal. When

the projector is turned on again, the WARNING TEMP. indicator stops blinking.

LED indicators

WARNING TEMP.

blinking red

-7-

Page 8

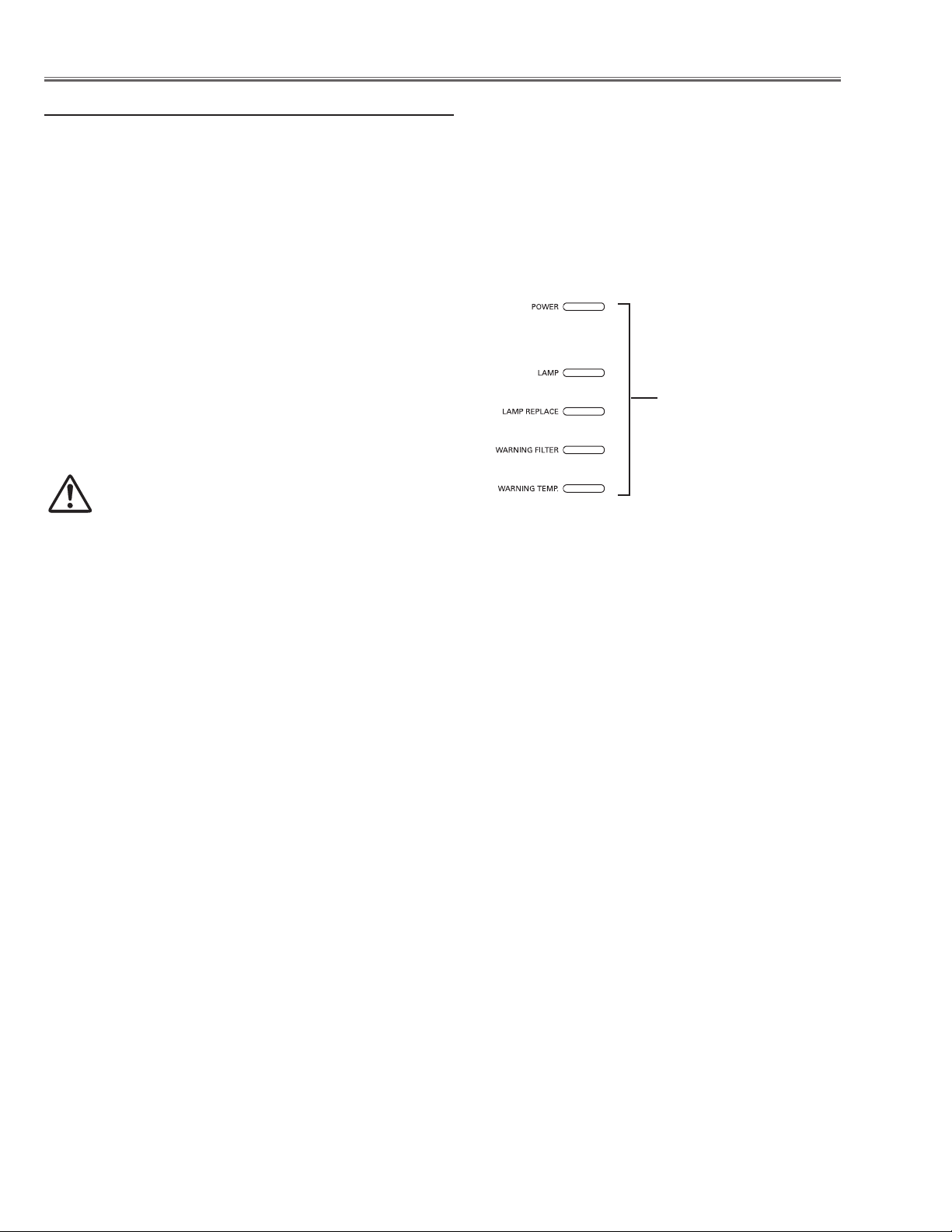

Circuit Protections

Power failure and fan lock detection

The projector provides the detection circuits of the power failure and the fan lock. When the detection circuit detects

an error at the power supply line or at the fan operation circuit, the projector will turn into the standby mode to protect

the other circuits defective.

The projector is shut down; and the LAMP indicator is

lighting and other four indicators are blinking.

When the projector detects an abnormal condition, it will be

automatically shut down to protect the inside of the projector

and all five indicators on the top panel blink. In this case, unplug the AC power cord and plug it, and then turn on the projector once again to verify operation. If the projector cannot

be turned on and these indicators are still blinking, unplug

the AC power cord.

CAUTION

DO NOT LEAVE THE PROJECTOR WITH THE

AC POWER CORD CONNECTED UNDER AN ABNORMAL CONDITION. IT MAY RESULT IN FIRE

OR ELECTRIC SHOCK.

LED indicators

LAMP indicator lights on

and other four indicators

blink

-8-

Page 9

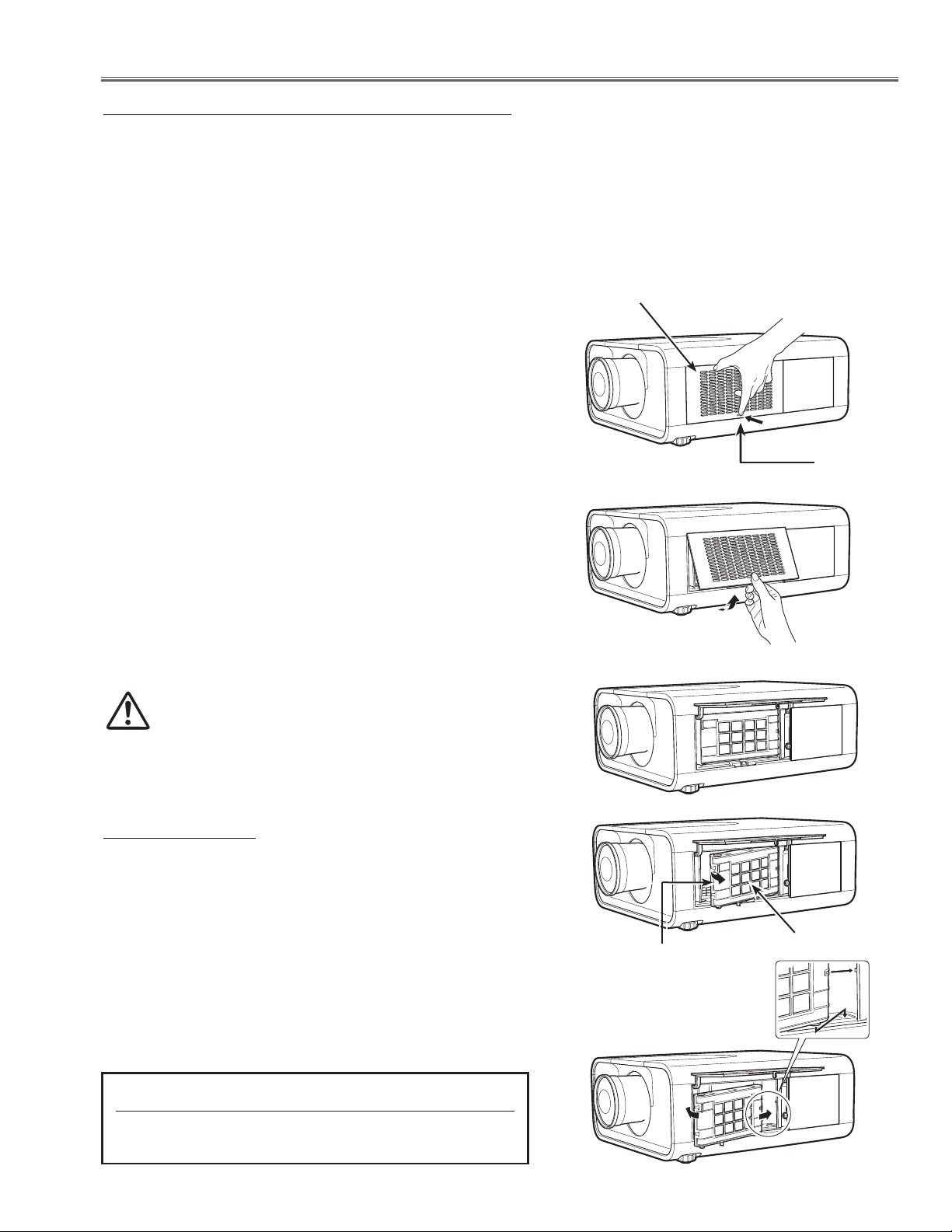

Maintenance

Replacing the Filter Cartridge

Filter prevents dust from accumulating on the optical elements inside the projector. Should the filter becomes clogged

with dust particles, it will reduce cooling fans’ effectiveness and may result in internal heat buildup and adversely

affect the life of the projector. This projector has an electrically operated filter which helps you to replace the filter

easily. The projector monitors the condition of the filter at all time and replaces a filter with a new one automatically

when it detects the clogging.

If the projector detects that the filter is clogged and no scroll is left in the filter cartridge, a Filter cartridge replacement

icon appears on the screen and the WARNING FILTER indicator on the top panel lights up. When you see this icon,

replace the filter cartridge and reset the Filter counter and the Scroll counter.

Filter cover

Turn off the projector, and unplug the AC power cord

1

from the AC outlet.

First, clean up the dust on the projector and around the

2

air vents.

Press d on the filter cover to release the latch and open

3

the filter cover.

Pull out the filter cartridge. When taking out the filter

4

cartridge, put your finger on the filter cartridge’s tab and

then pull.

Put the new one back into the position and close the

5

filter cover. Make sure that the filter cartridge is properly

and fully inserted.

Connect the AC power cord to the projector and turn

6

on the projector.

Reset the filter counter and the scroll counter.

7

CAUTION

Do not operate the projector with the filter removed.

Dust may accumulate on the optical elements degrading the picture quality.

Do not put anything into the air vents. Doing so may

result in malfunction of the projector.

RECOMMENDATION

We recommend avoiding dusty/smoky environments

when operating the projector. Usage in these environments may cause a poor image quality.

Latch

When using the projector under dusty or smoky conditions,

dust may accumulate on a lens, liquid crystal panels, or optical elements inside the projector. Such condition may degrade the quality of the projected image.

When the symptoms above are noticed, contact your authorized dealer or service station for proper cleaning.

ORDER REPLACEMENT FILTER CARTRIDGE

Service Parts No.: 610 334 3747

-9-

Tab

Filter cartridge

Page 10

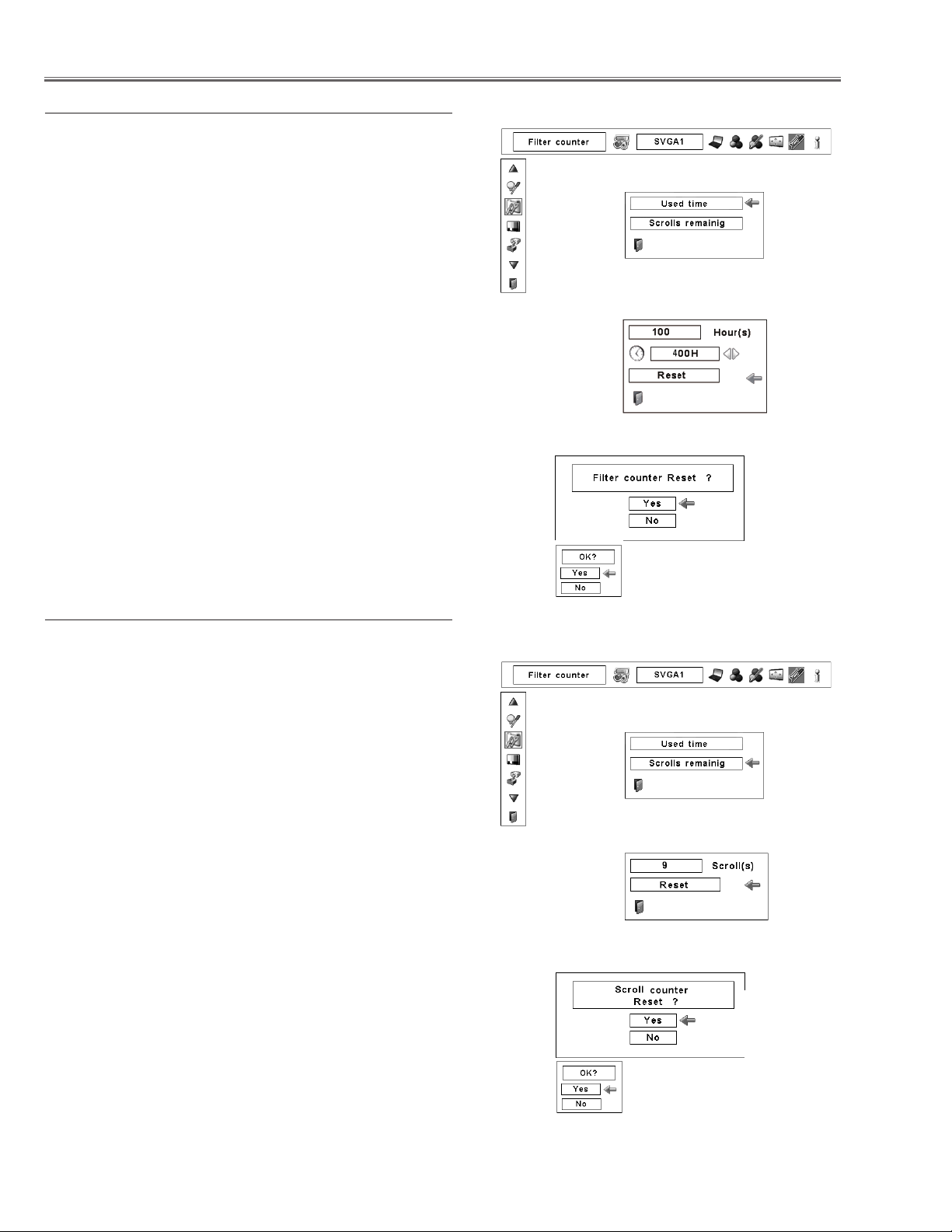

Resetting the Filter Counter

Be sure to reset the Filter counter after replacing the filter and

the filter cartridge.

Press the MENU button to display the On-Screen Menu.

1

Use the Point 7 8 buttons to move the red frame point-

er to the Setting Menu icon.

Use the Point ed buttons to move the red frame point-

2

er to Filter counter and then press the SELECT button.

A dialog box appears showing the Used time option and

the Scrolls remaining option. Use the Point ed buttons

to select Used time.

Used time shows the total accumulated time of the filter

3

use, a timer setting option, and the Reset option. Select

Reset and the “Filter counter Reset?” appears. Select

[Yes] to continue.

Another confirmation dialog box appears, select [Yes]

4

to reset the Filter counter.

Filter counter

Select “Used time” and the dialogue box below appears.

Select Reset and the “Filter

counter Reset?” appears.

Select [Yes],

then another

confirmation

box appears.

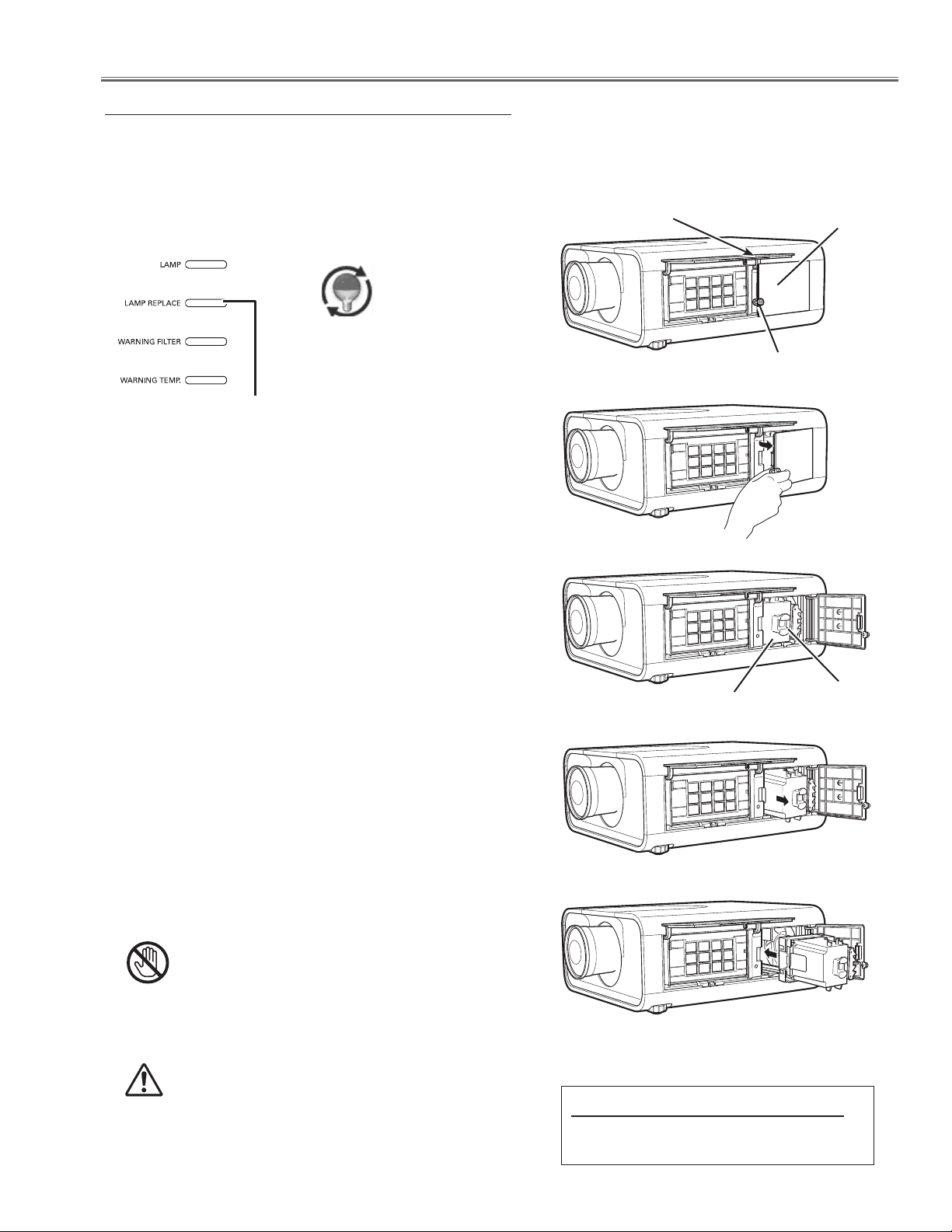

Resetting the Scroll Counter

Be sure to reset the Scroll counter after replacing the filter

cartridge.

Press the MENU button to display the On-Screen Menu.

1

Use the Point 7 8 buttons to move the red frame pointer to the Setting Menu icon.

Use the Point ed buttons to move the red frame point-

2

er to Filter counter and then press the SELECT button.

A dialog box appears showing the Used time option and

the Scrolls remaining option. Use the Point ed buttons

to select Scroll(s) remaining.

Scroll(s) remaining shows the number of the remain-

3

ing scrolls and the Reset option. Select Reset and the

“Scroll counter Reset?” appears. Select [Yes] to continue.

Another confirmation dialog box appears, select [Yes]

4

to reset the Scroll counter.

Select [Yes] again to reset

the Filter counter.

Scroll counter

Select “Scrolls remaining” and

the dialogue box below appears.

Select Reset and the “Scroll

counter Reset?” appears.

Select [Yes],

then another

confirmation

box appears.

-10-

Select [Yes] again to reset

the Scroll counter.

Page 11

Maintenance

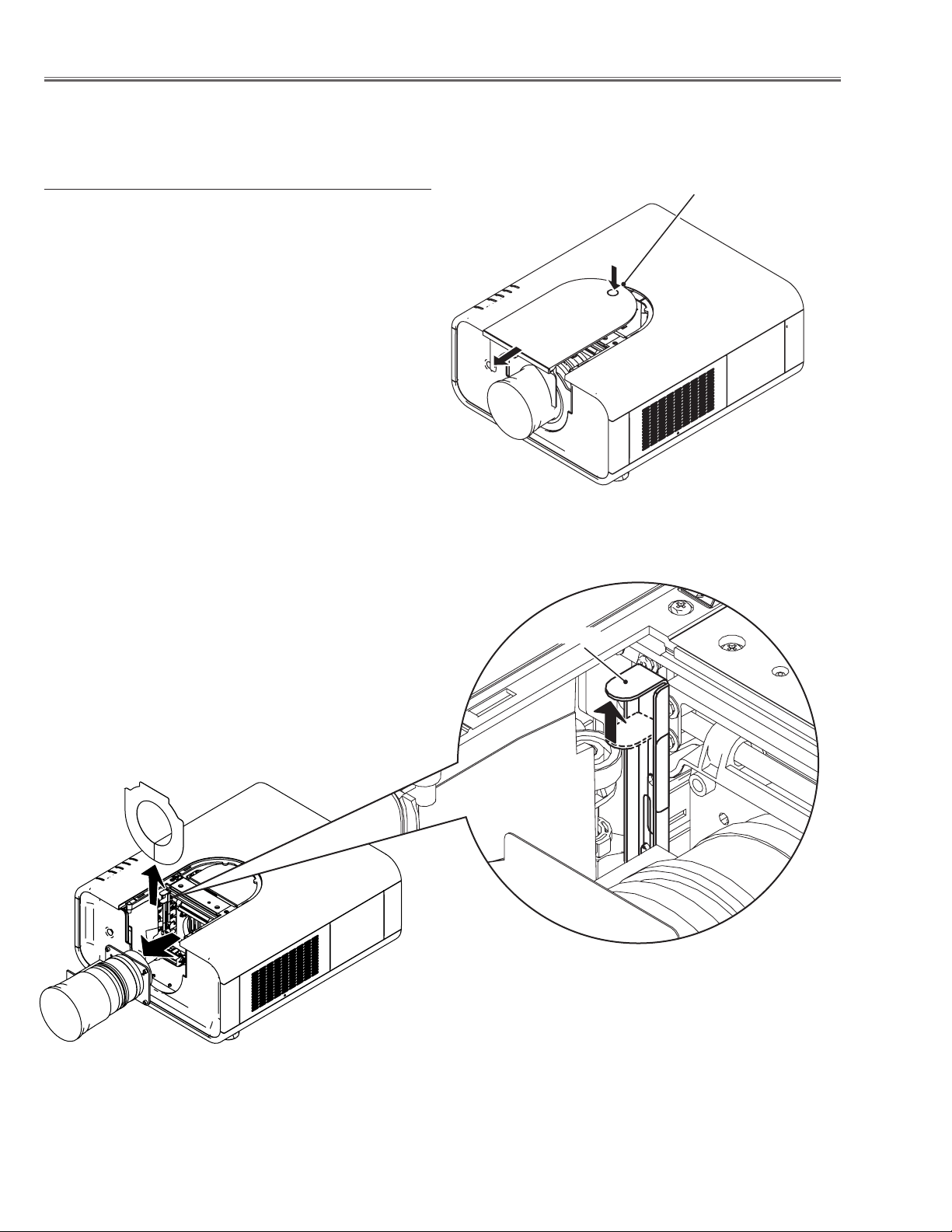

Lamp Replacement

When the projection lamp of the projector reaches its end of life, the Lamp replacement icon appears on the screen

and LAMP REPLACE indicator lights orange. Replace the lamp with a new one promptly. The timing when the LAMP

REPLACE indicator should light is depending on the lamp mode.

Top Panel

Lamp replacement icon

LAMP REPLACE indicator

Follow these steps to replace the lamp.

Turn off the projector and unplug the AC power cord.

1

Let the projector to cool for at least 45 minutes.

Open the filter cover.

2

Filter cover

Lamp cover

Screw

Loosen the screw and open the lamp cover and pull

3

out the lamp by using the built in handle.

Replace the lamp with a new one. Make sure that

4

the lamp is properly and fully inserted.

Close the lamp cover and secure the screw, and

5

close the filter cover.

Connect the AC power cord to the projector and turn on

6

the projector.

Reset the Lamp replacement counter

7

Note:

• Be sure to insert the lamp in the correct direction.

• Do not reset the Lamp replacement counter when the pro

jection lamp is not replaced.

CAUTION

Allow a projector to cool for at least 45 minutes

before you open the lamp cover. The inside of the

projector can become very hot.

Lamp

-

Handle

CAUTION

For continued safety, replace with a lamp of the

same type. Do not drop the lamp or touch the glass

bulb! The glass can shatter and may cause injury.

ORDER REPLACEMENT LAMP

Type No. POA-LMP108

Service Parts No. 610 334 2788

-11-

Page 12

Counter

Projector 500 H

Lamp

Normal 200 H

Eco 300 H

Corresponding value 600 H

Maintenance

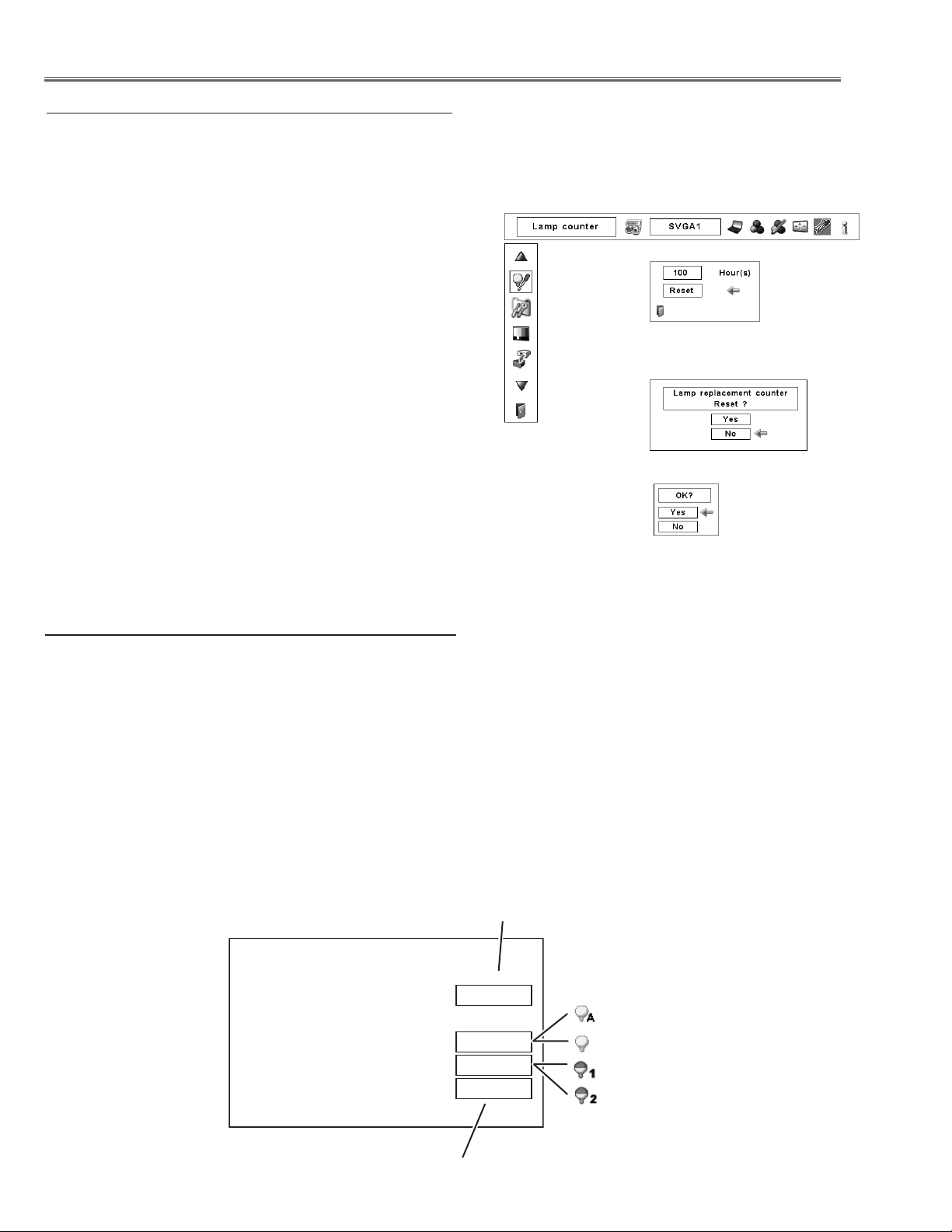

Resetting the Lamp Counter

Be sure to reset the Lamp counter after the lamp is replaced. When the Lamp counter is reset, the LAMP REPLACE indicator stops lighting and the Lamp replacement icon disappears.

Press the MENU button to display the On-Screen Menu.

1

Use the Point 7 8 buttons to move the red frame pointer

to the Setting Menu icon

Use the Point ed buttons to move the red frame pointer

2

to Lamp counter and then press the SELECT button. A

dialog box appears showing the total accumulated time

of the lamp usage and the reset option. Select Reset

and the “Lamp replacement counter Reset?” appears.

Select [Yes] to continue.

Another confirmation dialog box appears and select

3

[Yes] to reset the Lamp replacement counter.

Note:

• Do not reset the Lamp counter without replacing the lamp. Be

sure to reset the Lamp replacement counter only after replacing

the lamp.

How to check Lamp Used Time

Lamp counter

Select Reset and the “Lamp

replacement counter Reset?”

appears.

Select [Yes], then another

confirmation box appears.

Select [Yes] again

to reset the lamp

counter.

The LAMP REPLACE indicator will light yellow when the total lamp used time (Corresponding value) reaches 3,000

hours. This is to indicate that lamp replacement is required.

The total lamp used time is calculated by using the below expression,

Total lamp used time (Corresponding value) = Teco + (Tnormal x 1.5)

Teco: used time in the Eco mode

Tnormal : used time in the Normal mode

You can check the lamp used time following to the below procedure.

1 Press and hold the ON/STAND-BY button on the projector for more than 20 seconds.

2 The projector used time and lamp used time will be displayed on the screen briefly as follows.

Projector used time

Lamp mode

Total lamp used time

-12-

Page 13

Maintenance

Cleaning

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized glass,

lens, etc., causing the picture to darken or color to blur. If this occurs, clean the inside of optical unit.

Remove dust and other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean the

optical unit.

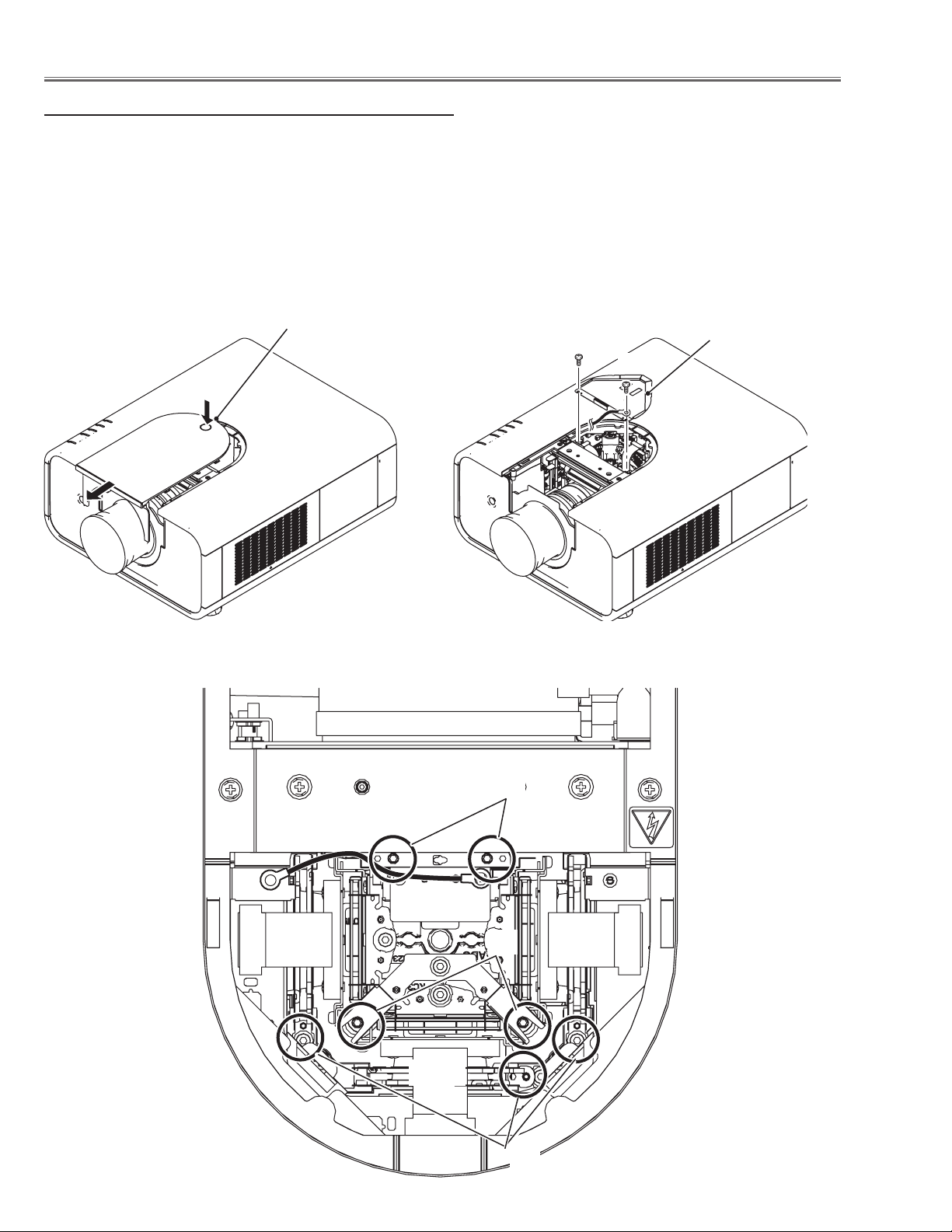

Cleaning with air spray

1. Remove the cabinet top following to “Mechanical Disassembly”.

2. Clean up the LCD panel and polarizing plate by using

the air spray from the cabinet top opening.

Caution:

Use a commercial (inert gas) air spray designed for

cleaning camera and computer equipment. Use a resinbased nozzle only. Be vary careful not to damage optical

parts with the nozzle tip. Never use any kind of cleanser

on the unit. Also, never use abrasive materials on the

unit as this may cause irreparable damage.

Disassembly Cleaning

Disassembly cleaning method should only be performed

when the unit is considerable dirty and cannot be sufficiently cleaned by air spraying alone.

Be sure to readjust the optical system after performing disassembly cleaning.

1. Remove the cabinet top and main units following to

“Mechanical Disassembly”.

2. Remove the optical base top following to “Optical

Unit Disassembly”. If the LCD panel needs cleaning,

remove the LCD panel unit following to “LCD panel

replacement”.

3. Clean the optical parts with a soft cloth. Clean extremely dirty areas using a cloth moistened with alcohol.

Caution:

The surface of the optical components consists of multiple dielectric layers with varying degrees of refraction.

Never use organic solvents (thinner, etc.) or any kind of

cleanser on these components.

Since the LCD panel is equipped with an electronic circuit, never use any liquids (water, etc.) to clean the unit.

Use of liquid may cause the unit to malfunction.

-13-

Page 14

Maintenance

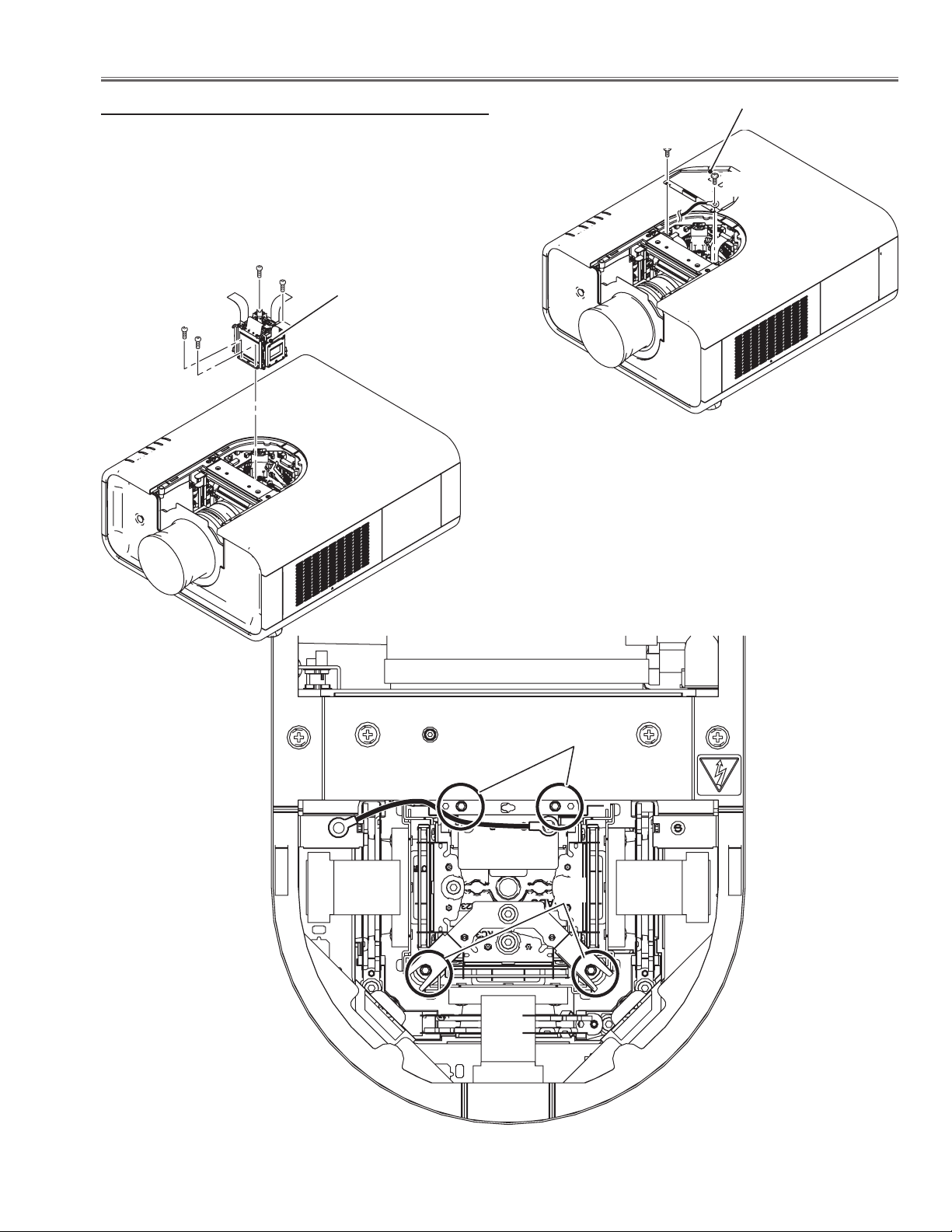

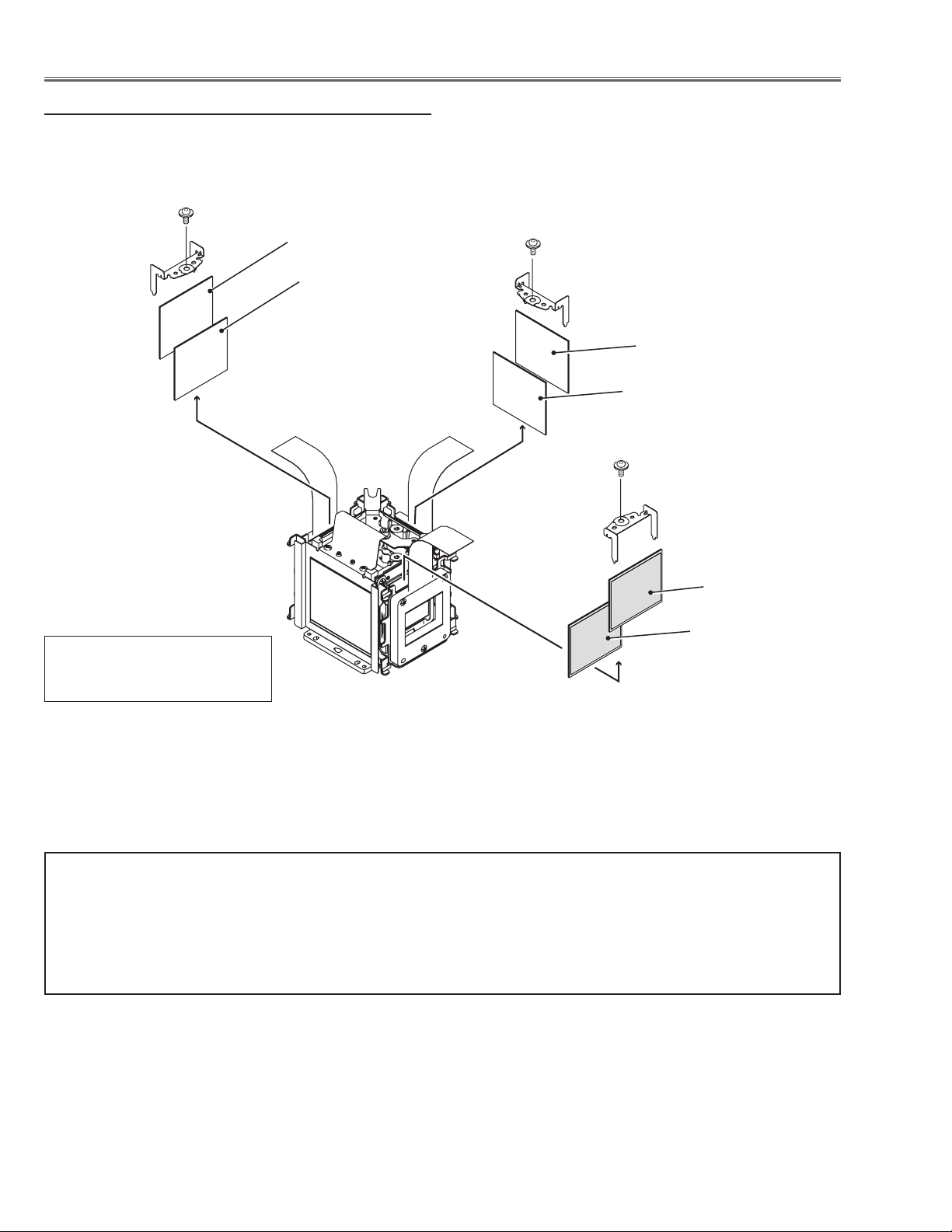

Quick maintenance

This projector provides a cabinet front cover on the cabinet top to enhance the service maintenance. This enables

service personnel to align the optical adjustment or replace the optical parts without disassembly the cabinet top.

1. Press and hold the release button the cabinet front cover and slide the cover frontward to take it off.

2. Remove 2 screws A on the prism shield cover and take prism shield cover off.

3. Loosen 4 screws B and take the LCD Panel/Prism ass'y upward off.

4. Remove 1 screw C on each stopper of the optical filter ass'y and take the optical filter ass'y upward off.

See chapter "Optical Parts Disassembly" for further information of optical parts disassembly.

Release button

A

Prism shield cover

A

Green

-14-

B

B

C

Page 15

Security Function Notice

This projector provides security functions such as "Key lock", "PIN code lock" and "Logo PIN code lock". When the

projector has set these security function on, you are required to enter correct PIN code to use the projector. If you

do not know the correct PIN code to the projector, the projector can no longer be operated or started. In this case,

you must reset those function first according to the resetting procedure described below and then check up on the

projector.

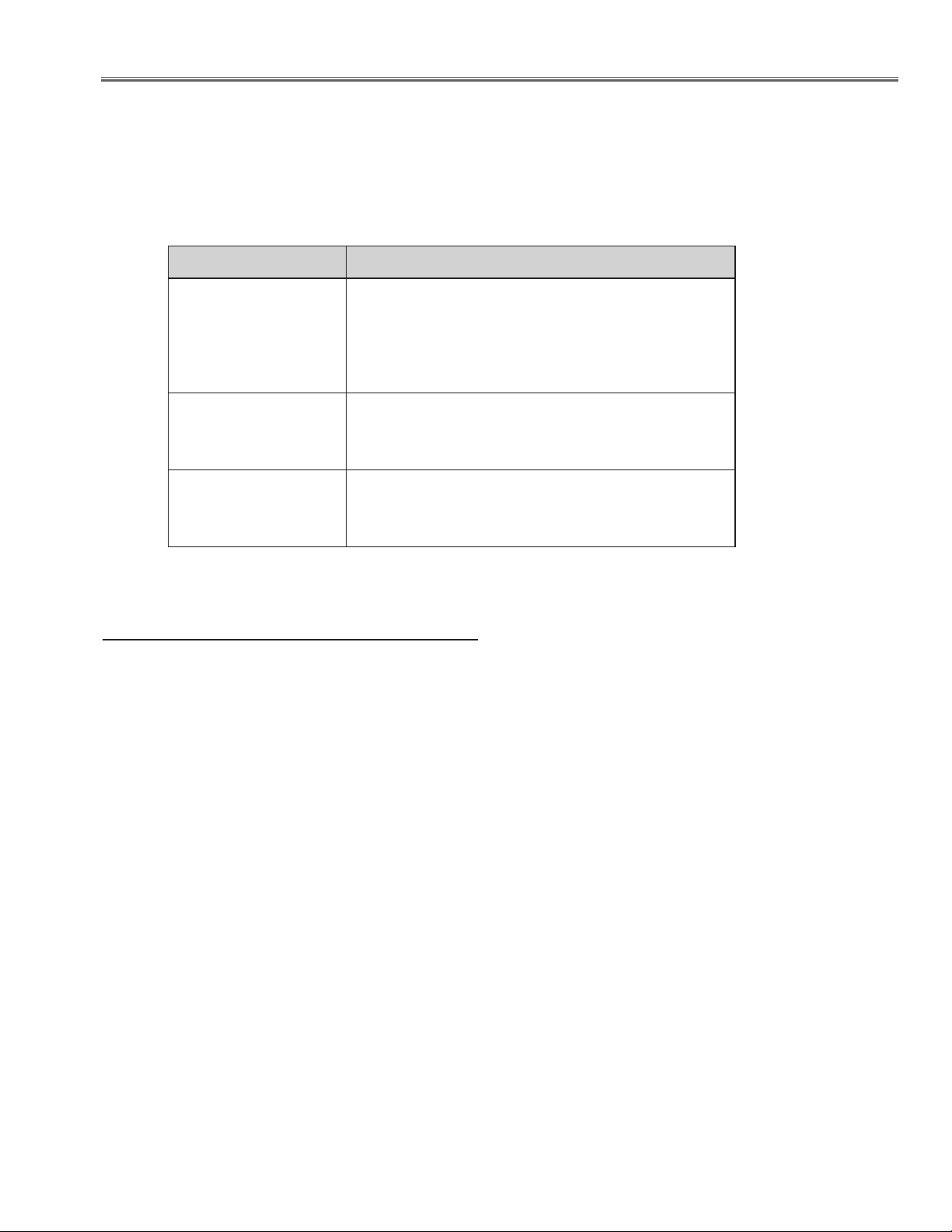

Function Description

Locks operation of the side control or the remote control.

Key lock

PIN code lock

Logo PIN code lock

If the Key lock is enabled with side control lock, the

projector can no longer be started.

Initial setting: Key lock function is disabled

Prevents the projector from being operated by an unauthorized person.

Initial code: “1234”

Prevents an unauthorized person for changing the

start-up logo on the screen.

Initial code: “4321”

Resetting procedure

1 Disconnect the AC power cord from the AC outlet.

2 As pressing the SELECT button on the projector, connect the AC power cord into an AC outlet again. Keep

pressing the SELECT button until the POWER indicator lights continuously.

This is complete the resetting of the security function. The PIN code lock and Logo PIN code lock are reset

as the initial PIN code at the factory and the Key lock function is disabled.

Please refer to the owner's manual for further information of the security functions.

-15-

Page 16

Mechanical Disassembly

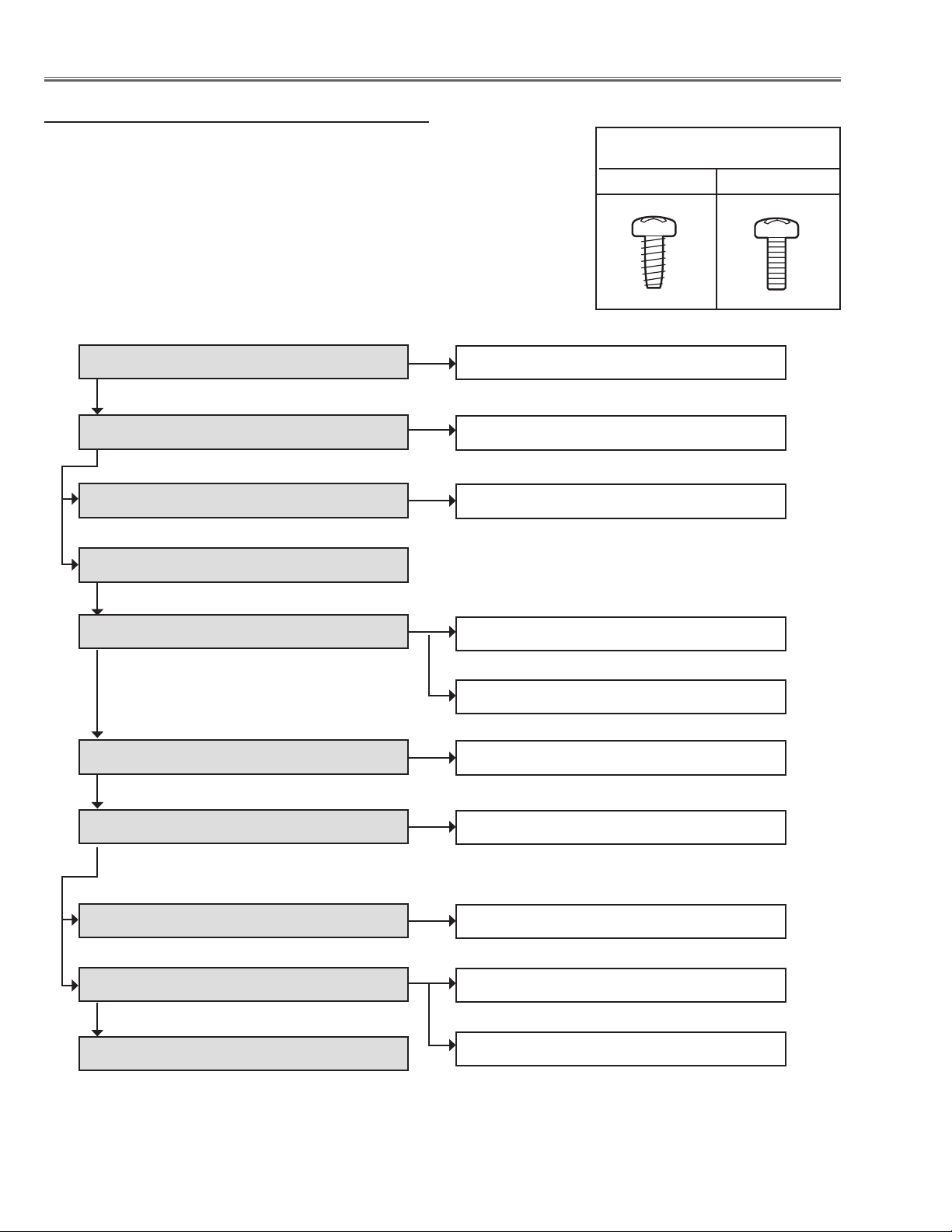

Mechanical disassembly flow chart

Mechanical disassembly should be made by following procedures chart.

Following steps show the basic procedures, therefore unnecessary step may

be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original otherwise it may cause loss of performance and product safety.

The wiring method of the leads and ferrite cores should be returned exactly the

same state as the original, otherwise it may cause lose of performance and

product safety.

Screws Expression

(Type Diameter x Length) mm

T type M Type

1 Cabinet front cover removal

2 Cabinet top removal

3 Control ass'y and filter cover removal

4 Main board removal

5 Cabinet back & lamp cover removal

6 Power box removal

1-1 Cabinet front disassembly

2-1 LED board removal

3-1 Control board fan (FN907) disassembly

5-1 AV board removal

5-2 Fans (FN904, FN905, FN906) removal

6-1 Power box disassembly

7 Optical unit removal

8 Cabinet front & ballast box removal

9 Filter box removal

10 Fan (FN902, FN903) & duct removal

7-1 Lens shift motor ass'y removal

8-1 Ballast box disassembly

9-1 Filter box and fan (FN901) disassembly-

9-2 Filter box disassembly-2

-16-

1

Page 17

Mechanical Disassembly

Mechanical disassembly

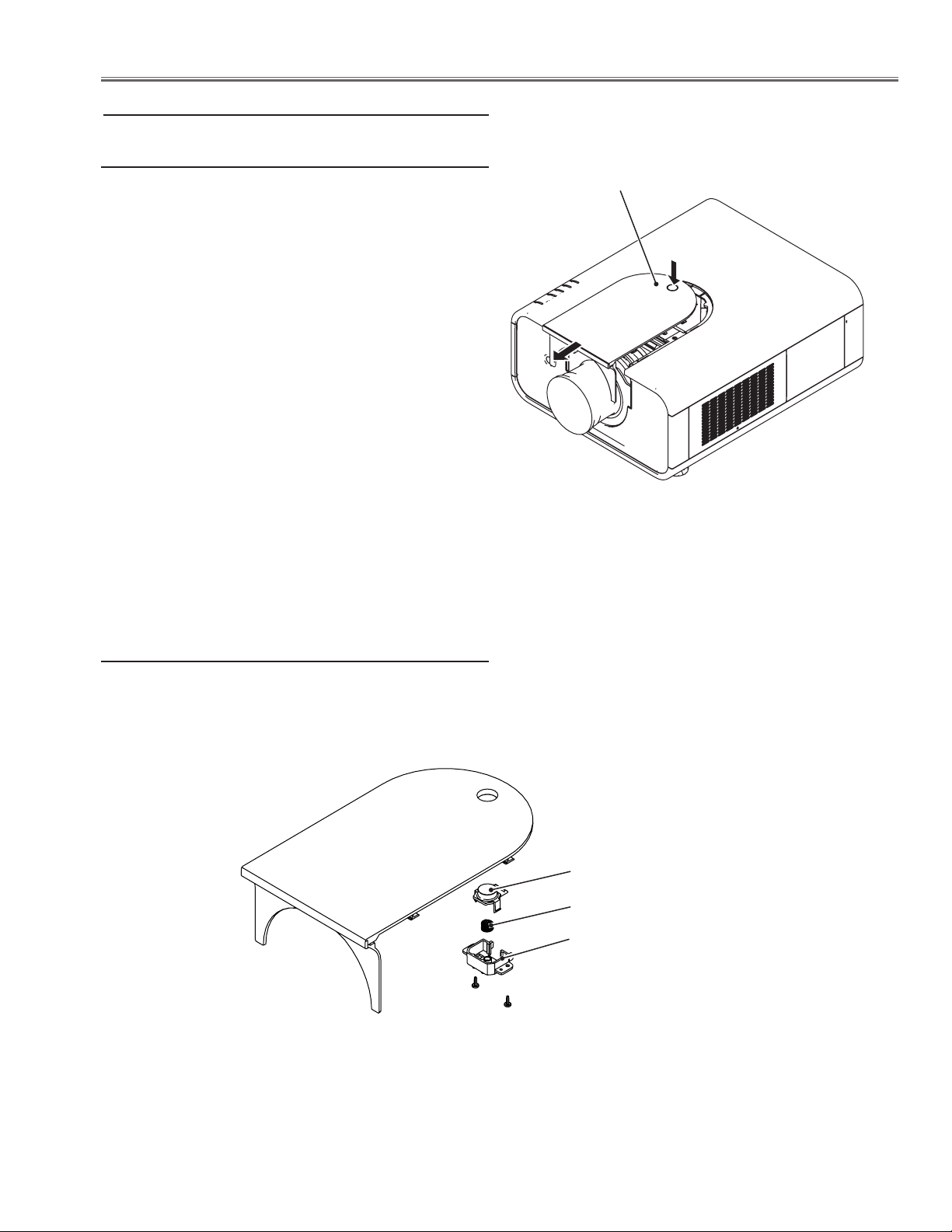

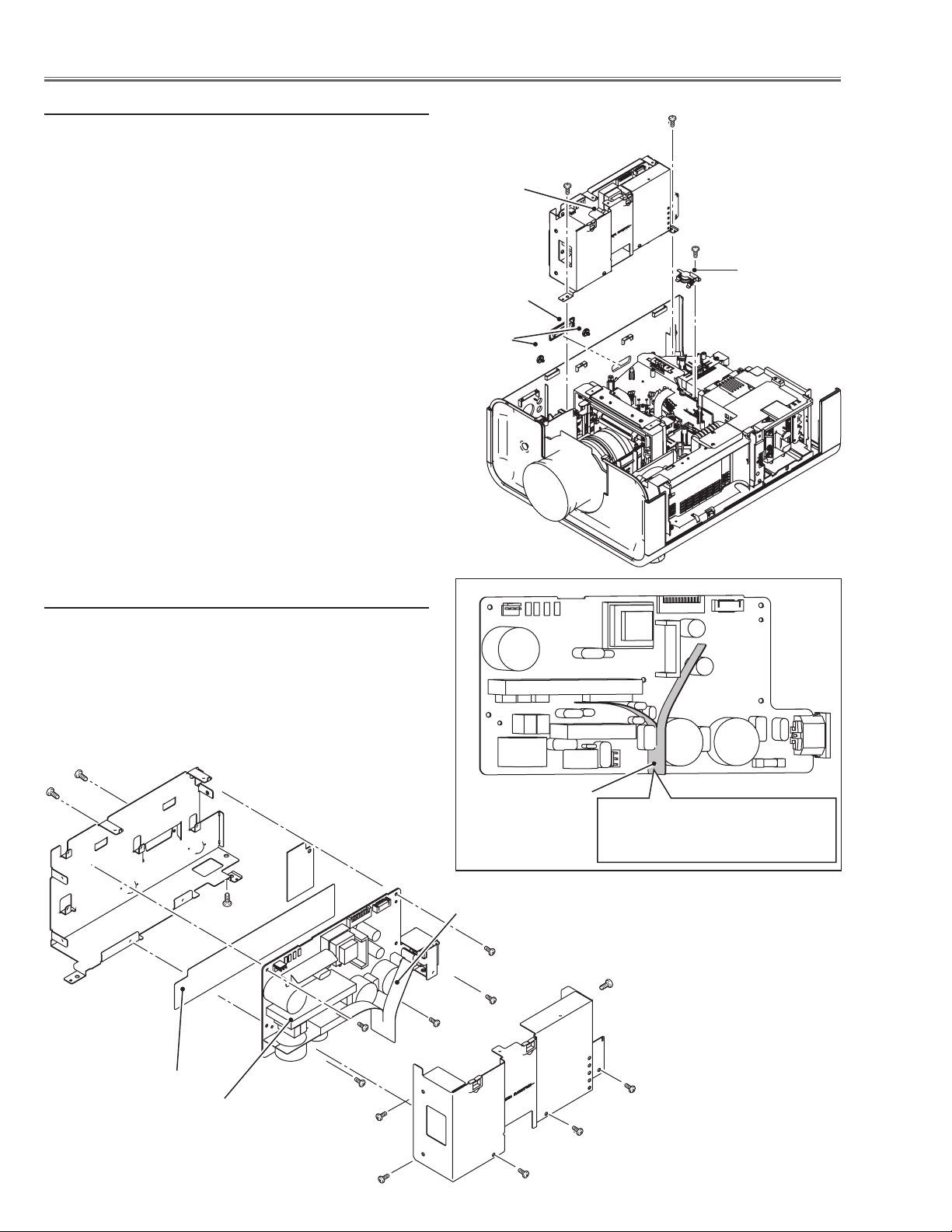

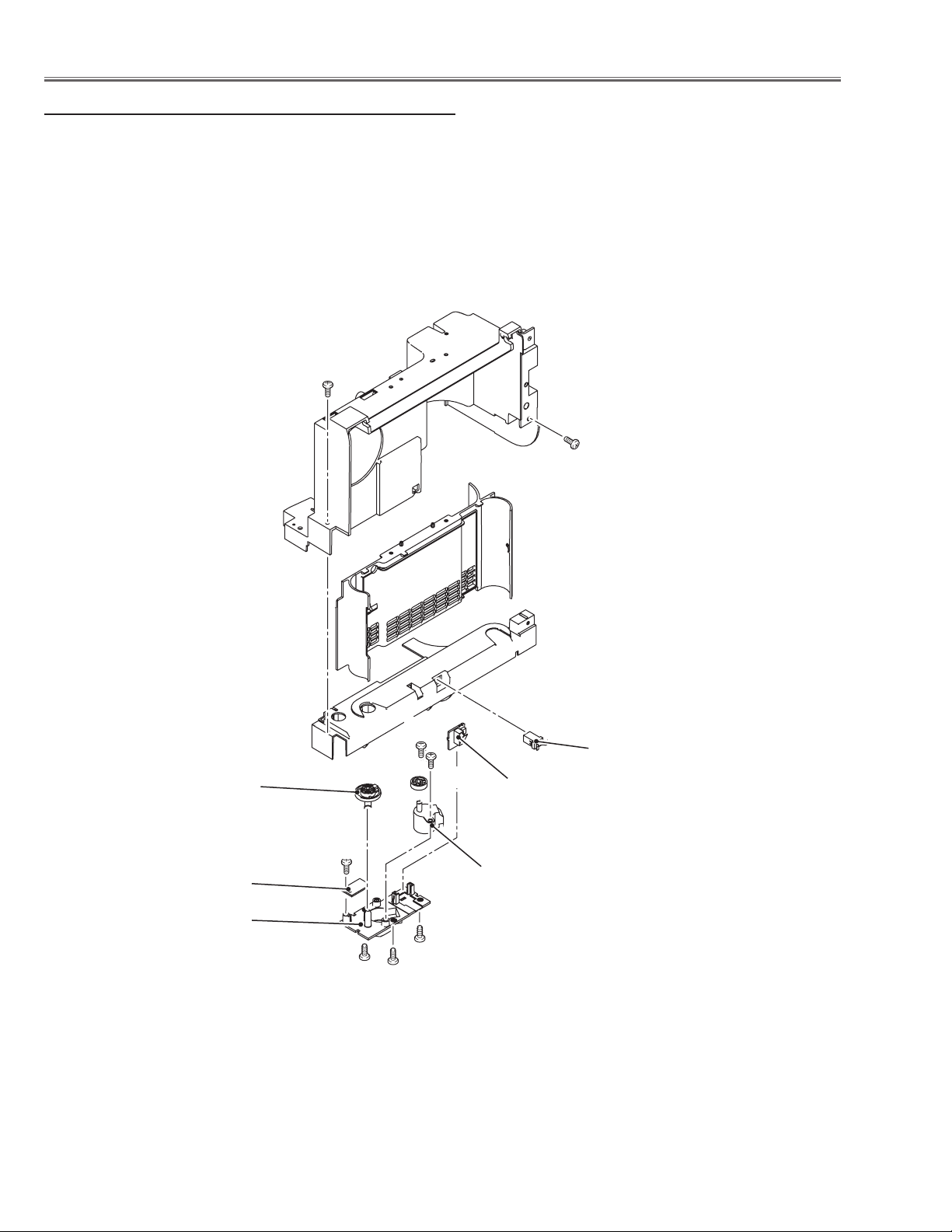

1 Cabinet front cover removal

1 Press the release button and slide the lamp cover to

the arrow direction and remove it.

Release Button

1-1 Cabinet front cover disassembly

1 Remove 2 screws A(T3x8) and take the release button,

button holder and spring off.

A

Fig. 1-1

Release button

Spring

Button holder

A

-17-

Page 18

Mechanical Disassembly

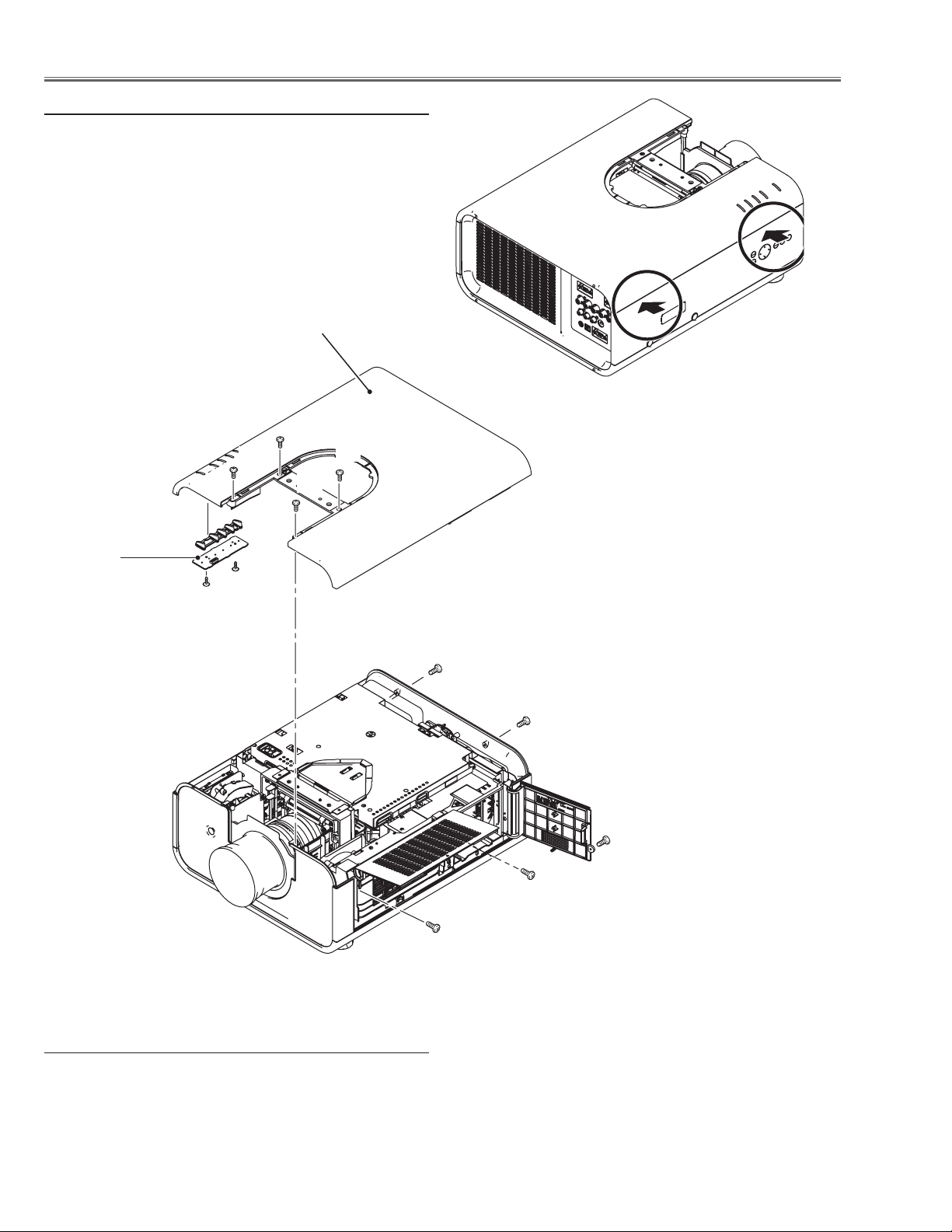

2 Cabinet top removal

1 Open the filter cover and remove 1 screw A (M3x8).

2 Remove 1 screw B (M3x8) and open the lamp cover

and remove 1 screw C (M3x8).

3 Remove 4 screws D (M3x8) on the cabinet top and 2

screws E (M3x8) on the cabinet back.

4 Release the hooks by pressing the side part of cabinet

bottom indicated with the arrows and take the cabinet

top off.

Cabinet top

D

D

D

D

Press here to unhook

LED board

F

F

E

E

B

C

A

2-1 LED board removal

1 Remove 2 screws F (M3x8) and take the LED board

and LED holder off.

Fig. 1-2

-18-

Page 19

Mechanical Disassembly

3 Control board ass’y and covers removal

1 Remove 2 screws A (T3x8) and take the control board &

fan ass’y upward off.

2 Open the filter cover and take the filter cartridge off.

3 Remove the filter cover off by using a flat screw driver as

shown in the figure.

A

A

Control board &

fan(FN907) ass'y

Filter cartridge

Flat screwdriver

Turn the flat screwdriver in the arrow

direction to unhook the filter cover's

hinges.

Note: Be careful not to scratch the filter

cover and holder.

Filter cover

-19-

Page 20

Mechanical Disassembly

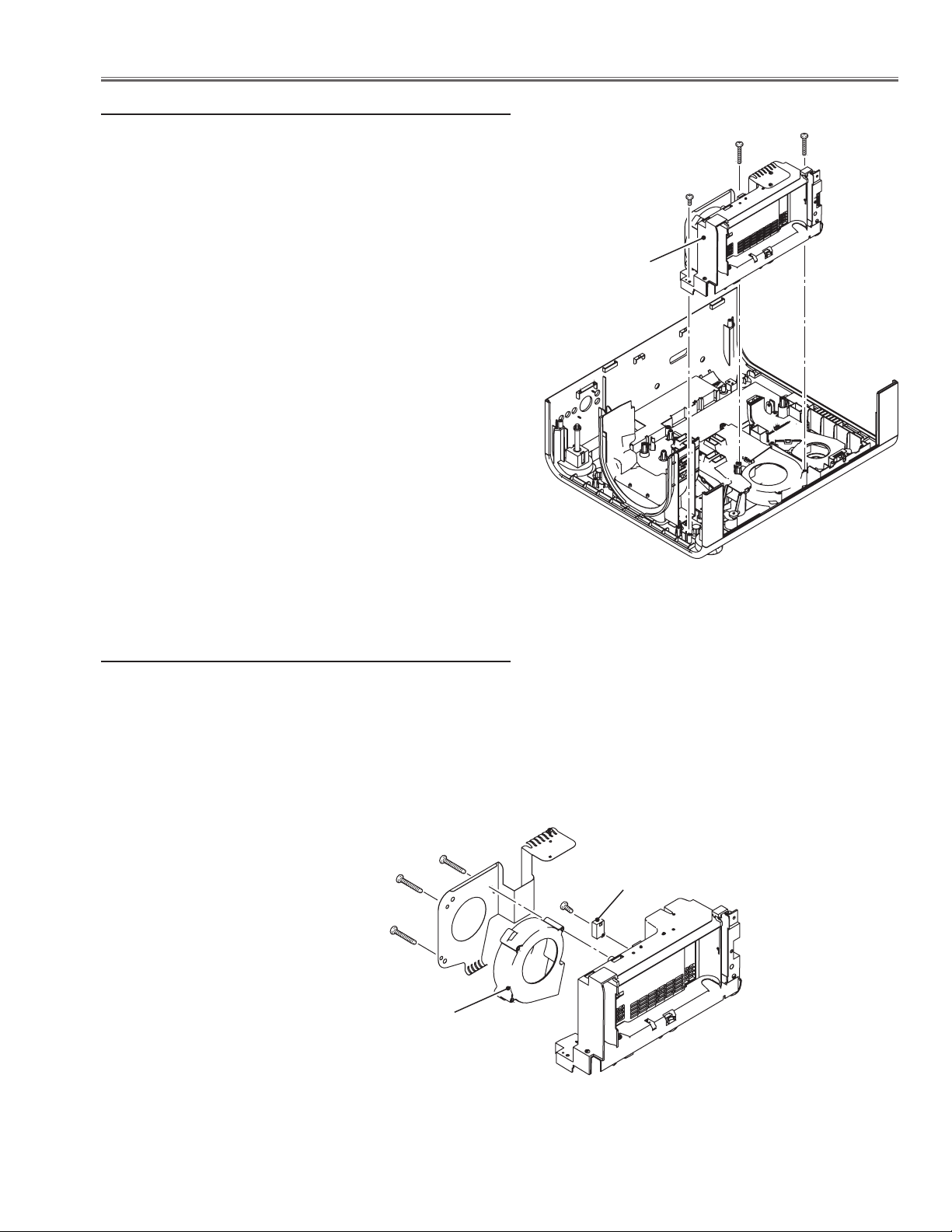

3-1 Control board and fan (FN907) disassembly

1 Remove 2 screws B (M3x6) and take the control board/

button holder off

2 Unhook 4 hooks C on the button holder and take the con-

trol board off.

3 Remove 2 screws D (M3x10) and take fan (FN907) off.

C

Control buttons

C

Control board

4 Main board removal

1 Remove 2 screws A (M3x6) and take the prism shield

cover top off.

2 Remove 6 screws B (M3x6) and take the main shield cover

top off.

3 Remove 1 screw C (M3x6) and take the main board off.

4 Remove 2 screws D (M3x6) and take the main shield cov-

er bottom off.

B

B

FN907

D

B

B

B

B

B

B

A

A

-20-

C

Main

board

D

D

Page 21

Mechanical Disassembly

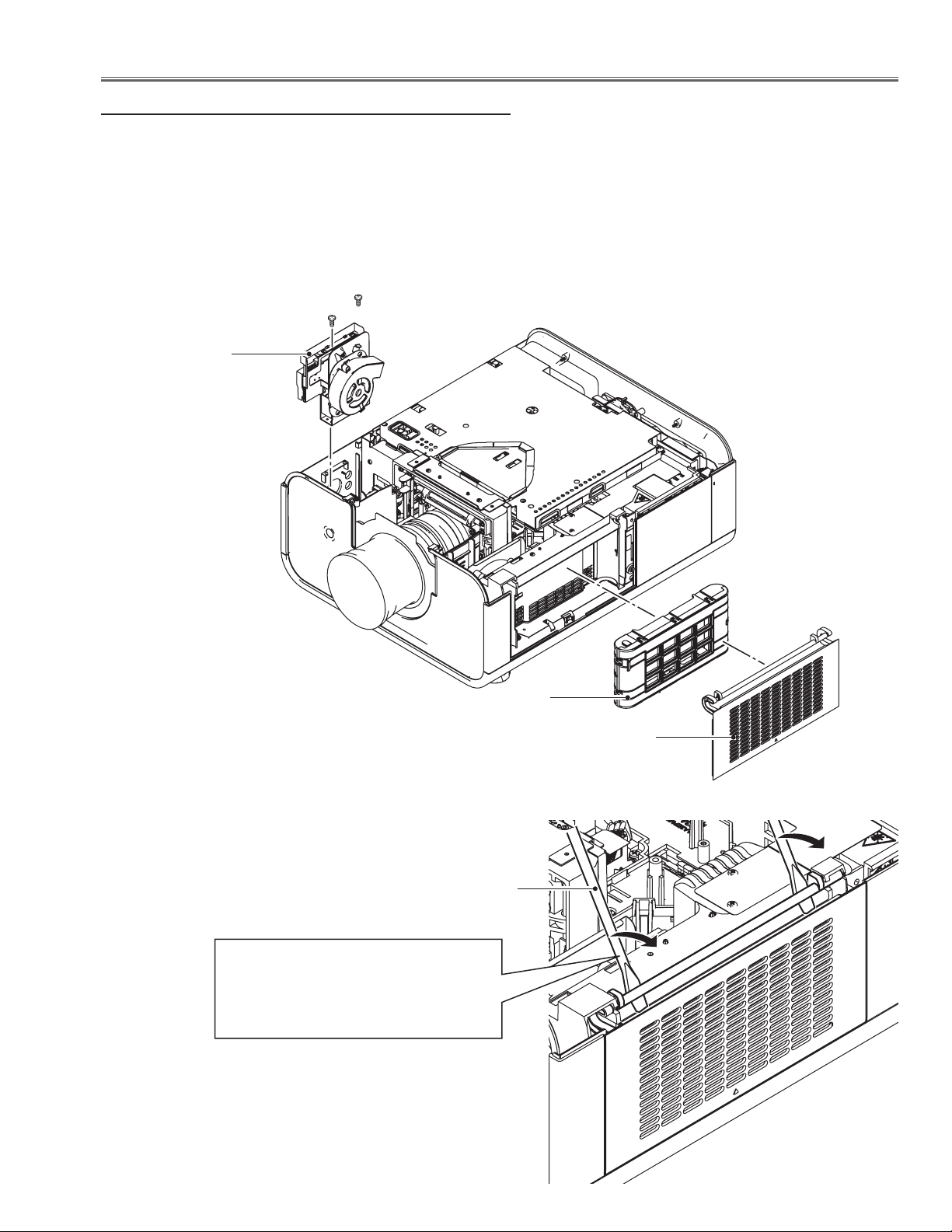

5 Cabinet back ass’y removal

1 Remove 3 screws A (T3x8) and 1 screw B (M3x6) and

take the cabinet back ass’y upward off.

A

A

B

A

Lamp cover

5-1 AV board removal

1 Remove 5 screws D (T3x8) and 4 screws E (T3x10-

black) and take the AV board off.

E

D

AV board

5-2 Fans (FN904, FN905, FN906) removal

1 Remove 6 screws F (T3x8) and take the fans (FN904,

FN905, FN906) off.

FN905

FN906

FN904

F

-21-

Page 22

Mechanical Disassembly

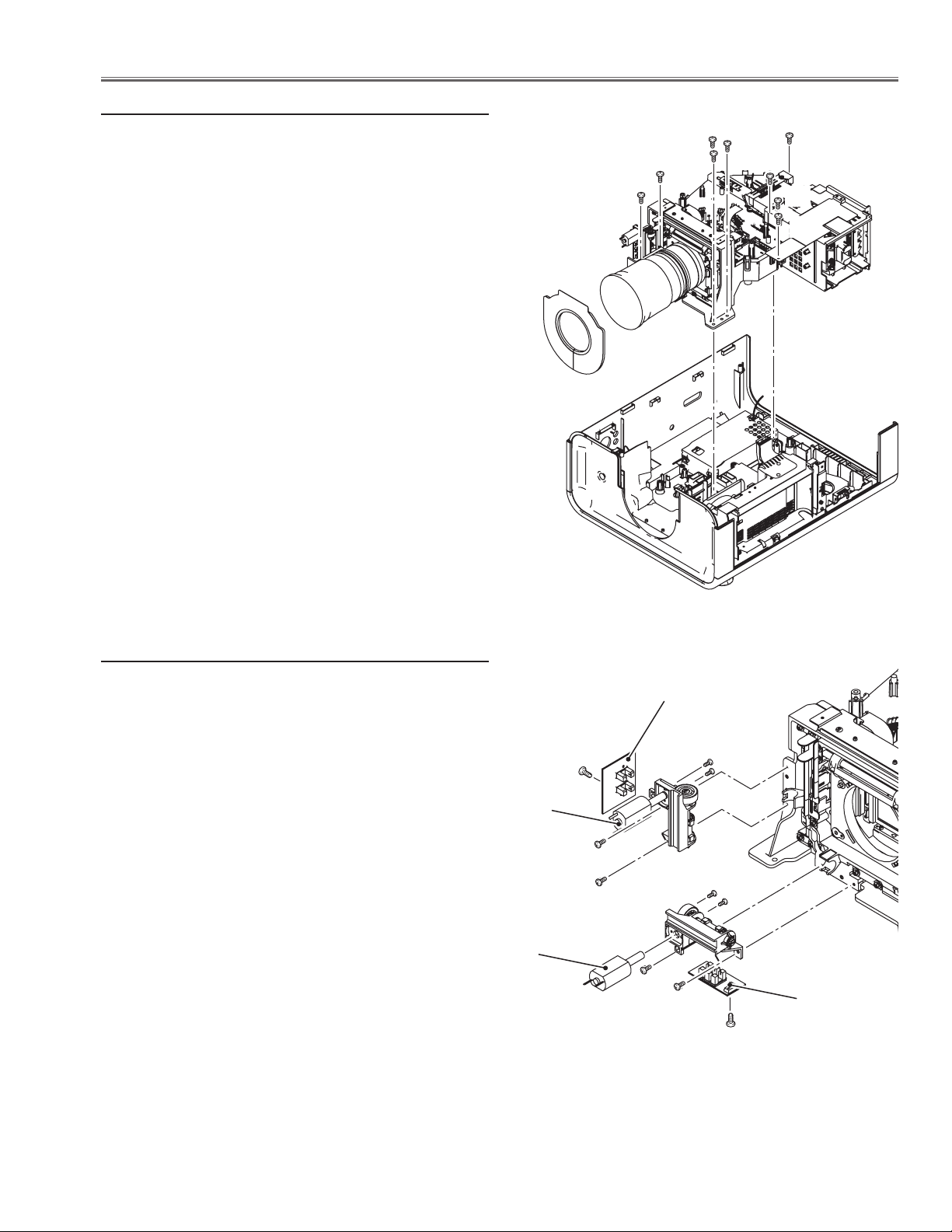

6 Power Box removal

1 Remove the 3 covers A and B on the cabinet.

2 Remove 1 screw C (T3x12) and take thermal switch

(SW905) off

3 Disconnect the socket D (K6B) on the power board.

4 Remove 2 screws E (M4x8) and take the power box

upward off.

E

E

D

C

B

Thermal switch

(SW905)

A

6-1 Power box disassembly

1 Remove 6 screws F (M3x6) and take the power box

cover off.

2 Remove 5 screws G (M3x6), 1 screw H (M4x8), 2

screws J (T3x5) and take the power board off.

J

H

G

Isolation sheet

Power board

G

F

Isolation sheet

Note:

The isolation sheet must be placed

as shown in the figure above.

Isolation sheet

G

F

G

G

F

F

F

-22-

F

Page 23

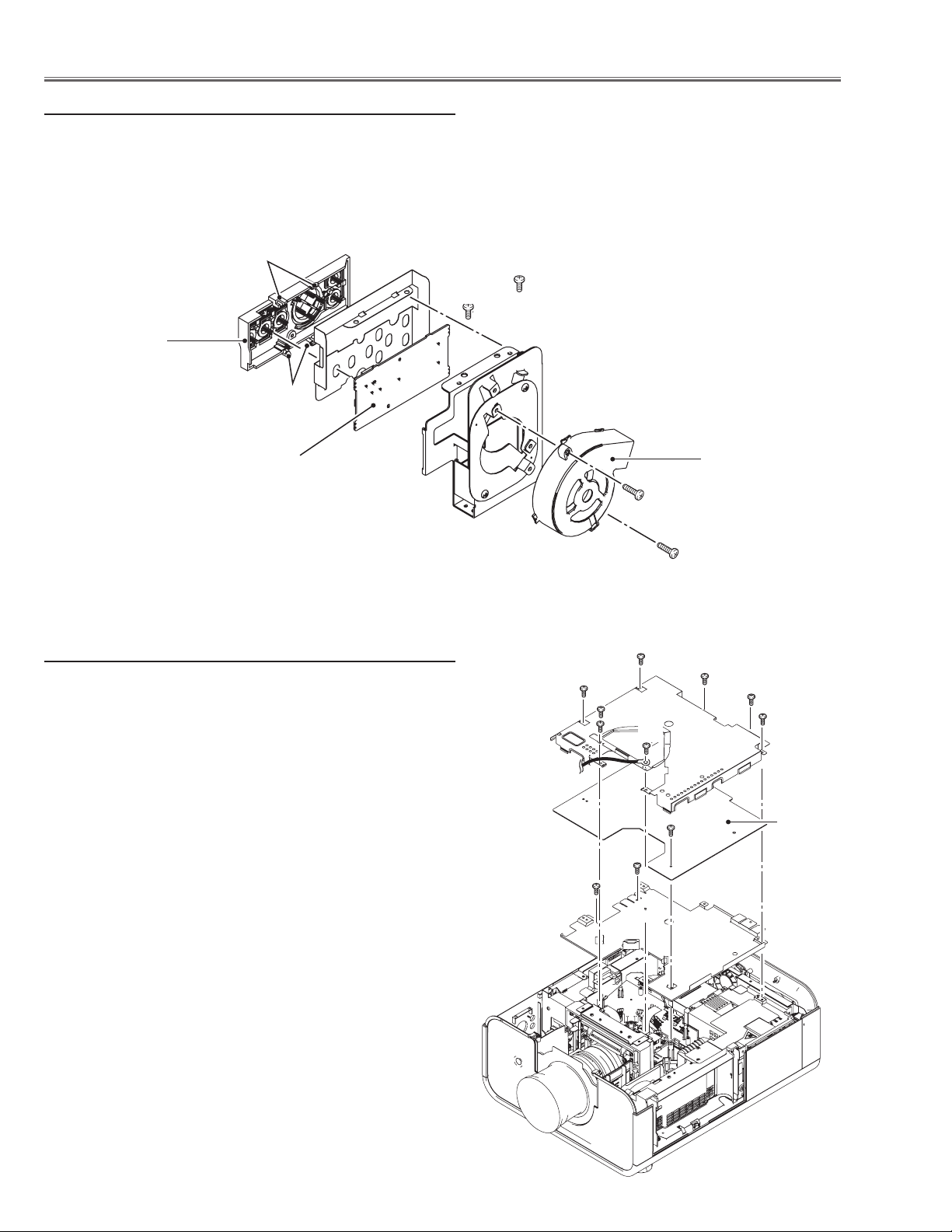

Mechanical Disassembly

7 Optical unit removal

1 Remove 7 screws A (T4x12) and 2 screws B (T3x8),

disconnect ballast socket and take the optical unit upward off.

A

A

A

A

A

A

B

B

7-1 Lens shift motor ass’y removal

1 Remove 2 screws B (M3x6) and take the lens shift mo-

tor ass’y off.

2 Remove 1 screw C (T3x6) and take the lens shift sen-

sor board off.

3 Remove 2 screws D (T2x4) and take the lens shift mo-

tor off

Lens shift motor

Lens shift motor

Sensor board

D

C

B

B

B

B

D

Sensor board

C

-23-

Page 24

Mechanical Disassembly

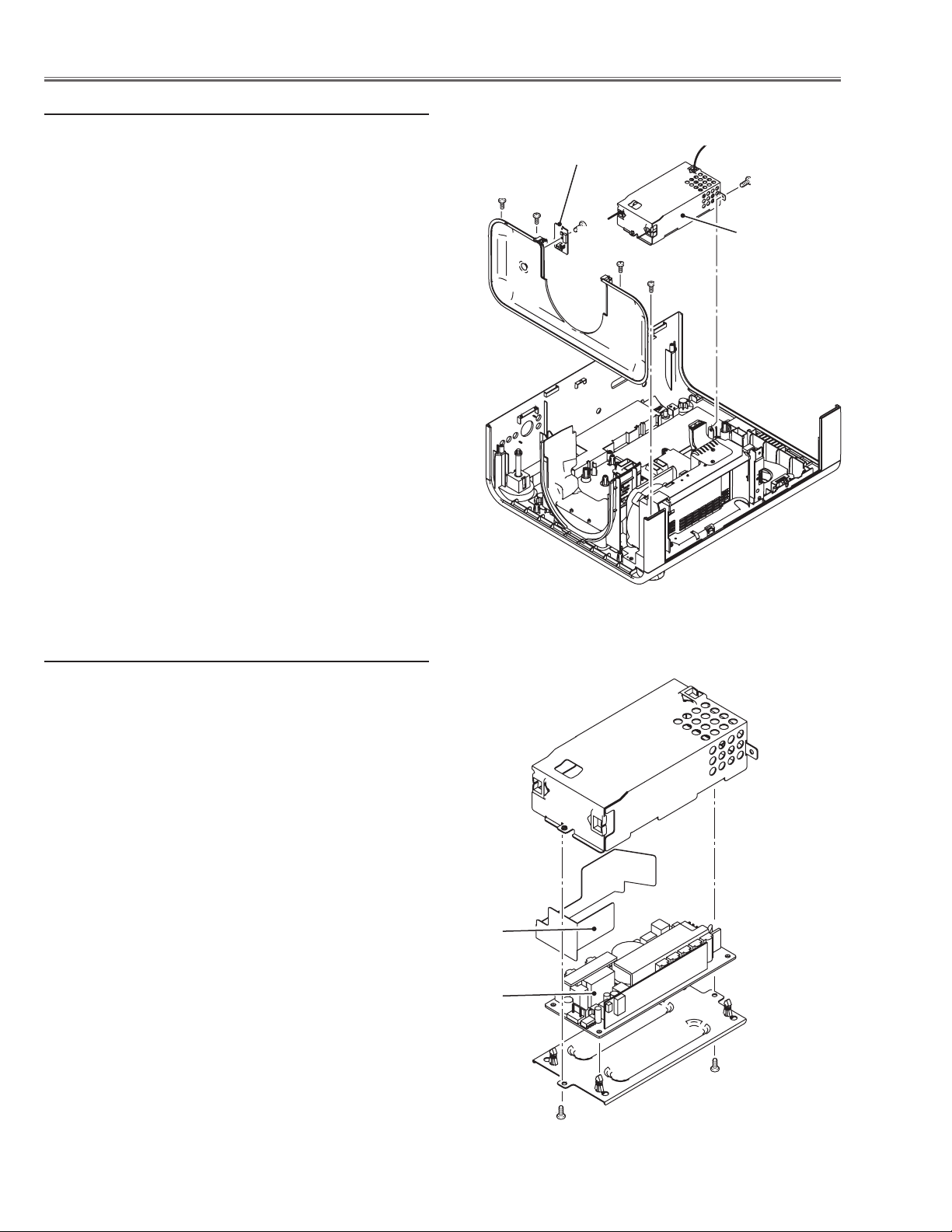

8 Cabinet front and ballast box removal

1 Remove 4 screws A (T3x8) and take the cabinet front

upward off.

2 Remove 1 screw B (T3x8) and take the RC front board

off.

3 Remove 1 screw C (M4x8) and pull the ballast box

backward and remove it off.

RC front board

A

C

A

B

Ballast box

A

A

8-1 Ballast box disassembly

1 Remove 2 screws D (M3x6) and take the shield case

top off

2 Remove ballast board from the shield case bottom.

Isolation sheet

Ballast board

D

-24-

D

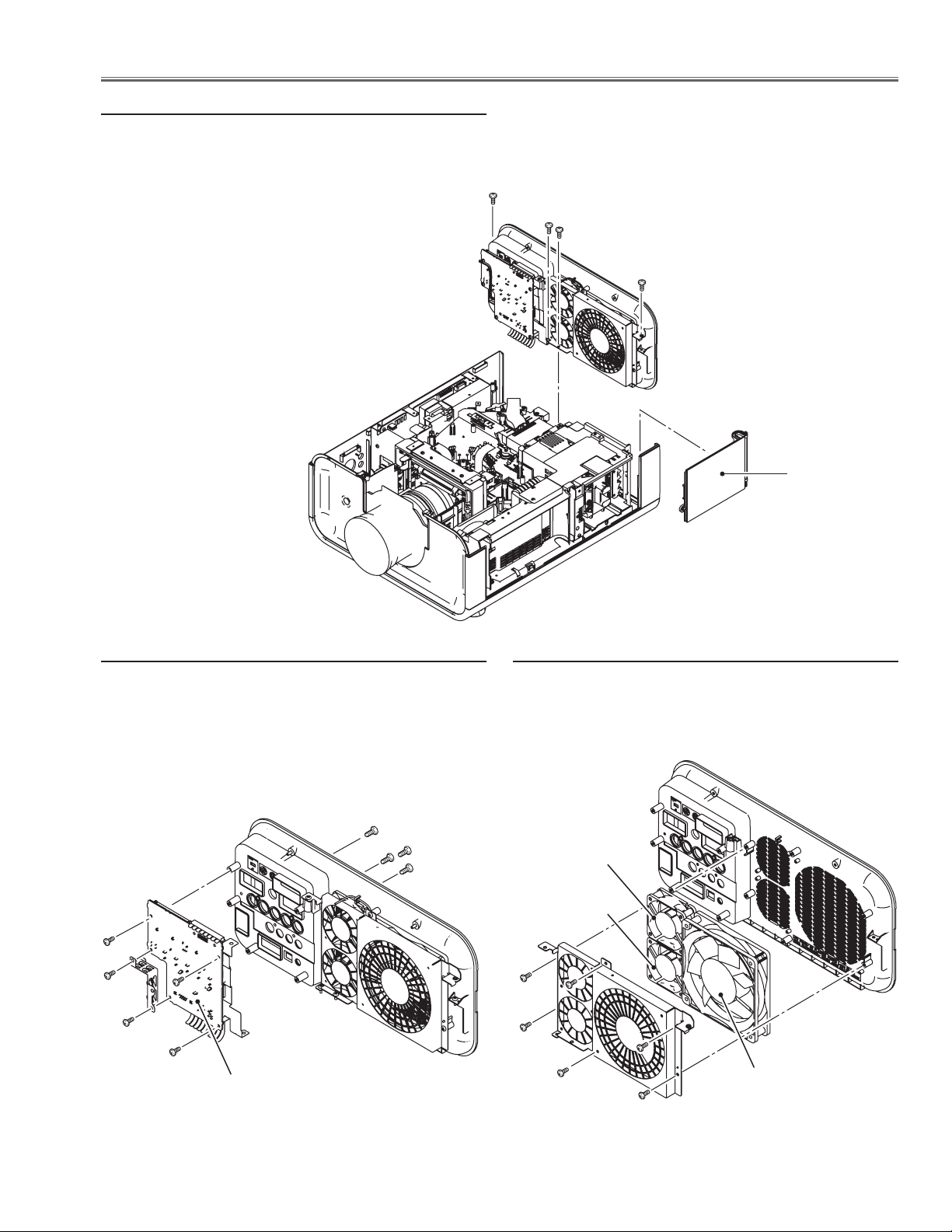

Page 25

Mechanical Disassembly

9 Filter box removal

1 Remove 1 screws A (T3x8), 2 screws B (T4x40) and take

filter box upward off.

Filter box

B

B

A

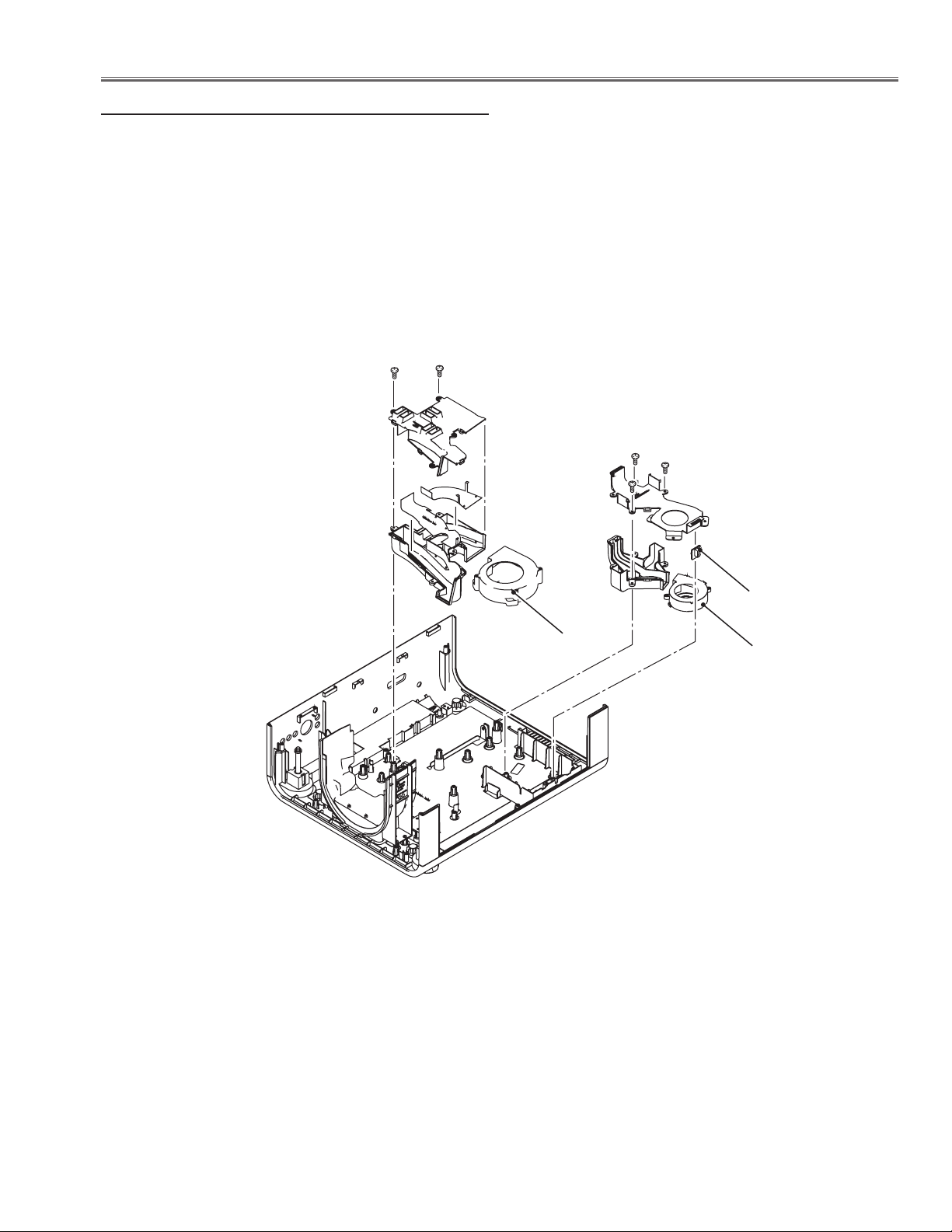

9-1 Filter box and fan (FN901) disassembly-1

1 Remove 3 screws C (T4x35), and take fan (FN901) and

holder off.

2 Remove 1 screw D (T3x14) and take the wind sensor

(S901) off.

C

C

C

FN901

D

S901

-25-

Page 26

Mechanical Disassembly

9-2 Filter box disassembly-2

1 Remove 2 screws E (T3x8) and take the filter cover off.

2 Take the filter cover latch off by pulling it.

3 Remove 3 screws F (T3x8) and take the filter bottom cover

off.

4 Take the filter switch board off, and remove 1 screw G and

take the filter round sensor board off.

5 Remove 2 screws H (T4x8) and filter motor off.

E

E

Filter shaft

holder

Filter round

sensor board

Filter bottom

cover

G

H

Latch

H

Filter switch

board

Filter motor

F

F

F

-26-

Page 27

Mechanical Disassembly

10 Fans (FN902, FN903) and duct removal

1 Remove fan (FN902) upward off.

2 Remove 2 screws A (T3x8) and take duct (prism) up-

ward off.

3 Remove 3 screws B (3x8) and take duct (PBS) upward

off.

4 Remove lamp cover switch board upward off.

5 Remove fan (FN903) upward off.

A

A

B

B

Lamp cover

switch board

FN902

FN903

-27-

Page 28

Optical Parts Disassembly

Disassembly requires a 2.0mm or 2.5mm hex wrench and a slot screwdriver.

1 Projection lens removal

1 Shift the Projection lens to the low end by the lens shift

function.

2. Press and hold the release button on the cabinet front

cover and slide it in the arrow direction as shown in the

figure and open it.

3 Slide the lens lock lever A on the projector to “UN-

LOCK” (UPPER) position and remove the Projection

Lens ass’y off.

Note : When making unlocking, attach your hand to pre-

vent the lens fall.

Release button

Lever A

-28-

Page 29

Optical Parts Disassembly

2-1 LCD panel/Prism ass'y removal

Prism shield cover

1 Remove 2 screws A (M3x6) and take the prism shield

cover off.

2 Remove 4 screws B (M2.5 x6) and take the LCD panel/

prism assembly upward off.

B

B

LCD panel/prism

B

B

assembly

A

A

B

B

-29-

Page 30

Optical Parts Disassembly

2-2 Polarized glasses-out removal

1 Remove 1 screw C (M2.5x6) on each stopper and take

the polarized glasses upward off.

C

Pre-Polarized glass (B)

Polarized glass-out (B)

(Blue)

C

(Green)

Pre-Polarized glass (G)

Polarized glass-out (G)

C

Pre-Polarized glass (R)

Polarized glass-out (R)

* Mount the glasses as the film

attached side comes to the LCD

panel side.

(Red)

Note; Do not replace the LCD panel separately otherwise it cannot obtain

proper picture. Do not touch the prism, the LCD panel and electrode

of flexible cable.

IMPORTANT NOTICE on LCD Panel/Prism Ass'y Replacement

LCD panels used for this model cannot be replaced separately. Do not disassemble the LCD Panel/Prism Ass’y.

These LCD panels are installed with precision at the factory. When replacing the LCD panel, should be replaced

whole of the LCD panels and prism ass’y at once.

When replacing LCD Panel/Prism ass’y, take the optical and electrical adjustments following to the chapter "Adjustment".

-30-

Page 31

Optical Parts Disassembly

LCD Panel Type Check

There are 2 types combination of the LCD panel/prism assembly and the optical unit, named Type-R and Type-L.

Since both have no compatibility, each type should be combined with the same type, and the specific parts should

be used. If not, the poor optical characteristics may degrade the quality of a projected image.

Confirm the "R" label or "L" label on top of the LCD panel/ prism assembly and the optical unit.

NOTE:

LCD panel/prism assembly should be used with the same type of the optical unit.

Confirm that both marking "R" is matched.

R

R

LCD Panel/Prism Ass'y Type-R

Confirm that both marking "L" is matched.

L

L

LCD Panel/Prism Ass'y Type-L

-31-

Page 32

Optical Parts Disassembly

Note on LCD Panel/Prism Ass’y Mounting

After replacing or installing the LCD Panel/Prism ass’y,

please make sure to obtain the best focus in both TELE and

WIDE zoom. If the focus adjustment is required, please adjust the positioning of LCD Panel/Prism Ass’y following to

the procedure below.

Focus adjustment:

1 Loosen 4 screws A on the LCD Panel/Prism ass’y with 2.0

mm hex driver.

2 Turn the projector on and project the image with WIDE

zoom, and adjust the FOCUS control to obtain the best

focus.

3 Turn the ZOOM control to the TELE position.

4 Insert a flat screw driver into the slot B and move the LCD

Panel/Prism Ass’y backward or forward by turning the

screwdriver left or right to obtain the proper focus. Confirm

the focus at TELE and WIDE zoom.

5 Tighten 4 screws A to fix the LCD Panel/Prism ass’y.

A

B

A

-32-

Page 33

Optical Parts Disassembly

3 Polarized glass/Optical filter ass'y removal

1 Remove 1 screw A (M2.5x6) on each stopper and take the

polarized glasses upward off.

Glass holder

Stopper

marker

film

Polarized glass

A

A

Polarized glass/

Optical filter ass'y

Optical filter (HCP)

Red

Glass holder

Blue

Green

-33-

A

Page 34

Optical Parts Disassembly

TYPE-L

TYPE-R

3-1 Polarized glass/Optical filter mounting

There are 2 types combination of the LCD panel/prism assembly named Type-R and Type-L. Mount the polarized

glasses and optical filters according to the type of the LCD panel assembly as shown in the figure below

2 slits

Marker

Marker

(behind)

Polarized glass-in (B)

Optical filter-HCP (B)

* Polarized glasses should be

mounted as the film attached side

comes to the LCD panel side.

2 slits

Marker

Marker

Polarized glass-in (G)

Optical filter-HCP (G)

Marker

Optical filter-HCP (R)

Polarized glass-in (R)

2 slits

(behind)

2 slits

Polarized glass-in (B)

Optical filter-HCP (B)

* Polarized glasses should be

mounted as the film attached side

comes to the LCD panel side.

2 slits

(behind)

Polarized glass-in (G)

Optical filter-HCP (G)

Marker

Optical filter-HCP (R)

Polarized glass-in (R)

2 slits

-34-

Page 35

Optical Parts Disassembly

4 Optical base top removal

Before taking this procedure, remove cabinet top, main

board following to the chapter "Mechanical disassembly".

1 Remove 1 screw A (T3x8) on the thermostat, 1 screw B

(T3x8) on the ballast trigger and 4 screws C (T3x8).

2 Unhook 4 hooks D on the optical base top and take the

optical base top upward off.

Ballast trigger

D

B C

A

C

C

C

D

Thermostat

-35-

Page 36

Optical Parts Disassembly

238

241

240

238

490490

489489

241

240

4-1 Optical parts locations in the Optical Unit

No. Parts Name No. Parts Name

1 LENS,INTEGRATOR(IN) * 9 MIRROR(R)

2 LENS,INTEGRATOR(OUT) * 10 LENS,RELAY(IN)

3 ASSY,PRISM(PBS) 11 LENS,RELAY(OUT) *

4 LENS,CONDENSER(IN) 12 LENS,CONDENSER(R)

5 MIRROR(W-COLD) 13 MIRROR(B)

6 LENS,CONDERSOR(OUT) * 14 POLARIZED GLASS(IN/GB)

7 DICHROIC MIRROR (B) 15 LENS,CONDENSER(G)

8 DICHROIC MIRROR (G) 16 LENS,CONDENSER(B)

12

14

11

10

9

8

16

13

15

7

9

6

2

3

4

1

5

Shield Plate

Note:

The parts indicated with (*) are fixed with the adhesive onto the optical base bottom,

so these parts are not the replaceable parts.

-36-

Page 37

Optical Parts Disassembly

238

241

240

238

490490

489489

241

240

4-2 Optical parts directions in the Optical Unit

When mounting or assembling the optical parts in the optical unit, the parts must be

mounted in the specified location and direction as shown in the figure below.

Mount as the marker

comes this side up.

Mount as the marker

comes this side up.

Mount as the part no.

is facing this side

Mount as the part no.

is facing this side

-37-

Page 38

Adjustments

Adjustments after Parts Replacement

LCD/

Prism Ass’y

Adjustment

Optical

●: Adjustment necessary ❍: Check necessary

Disassembly / Replaced Parts

Polarized

Glass

Optical Filter

Power Board Main Board Fan s

Contrast adjustment

Panel type check and setting

Fan control adjustment

PC-auto calibration

Electrical Adjustments

Video-auto calibration -1

Video-auto calibration -2

Common center adjustment

Gamma shift adjustment

White balance adjustment [PC]

Gamma correction adjustment [PC]

White balance adjustment [AV]

Gamma correction adjustment [AV]

White uniformity adjustment

Wind sensor calibration

● ● ●

❍ ●

● ● ●

●

●

●

● ●

● ●

● ●

● ●

● ●

● ●

❍ ❍ ❍ ❍

● ● ●

Note on the main board replacement

When replacing the main board, take read/write procedure of the gamma adjustment data and color shading correction data.

The “gamma adjustment data” and “color shading correction data” of each panel have been adjusted precisely at

the factory to match the characteristics of each panel.

When you replace the main board, you need to read out the "gamma adjustment data" and "color shading correction data" stored in the memory IC on the previous main board and write down them into the memory IC on the

new main board. By this way, the projector is enabled to reproduce the picture which has the properly adjusted

gamma characteristic and color shading correction.

Use "Projector Service Tool" software for Read/Write of the gamma adjustment data and color shading correction

data. This tool also enable to correct the color shading and gamma characteristics.

PROJECTOR SERVICE TOOL v. 4.10

SERVICE PARTS NO.: 610 337 8787

-38-

Page 39

Optical Adjustments

Contrast adjustment

[Before Adjustment]

- Input a 100% of black raster signal.

1. Loosen a screw A on the polarized glass stopper which you intend to adjust.

2. Turn the lever B of optical filter as shown in figure to obtain the darkest brightness on the screen.

3. Turn the lever C of polarized filter as shown in figure to obtain the darkest brightness on the screen.

4. Tighten the screw A to fix the polarized glass stopper.

Repeat steps 1 to 4 for remaining R, G or B contrast adjustment.

Lever C

(Polarized filter)

Lever B

(Optical filer)

-39-

A

Page 40

Service Mode

Input Video

Group No. Data

0 0 32

Ver. R 1.00

Electrical Adjustments

Service Adjustment Menu Operation

To enter the service mode

To enter the “Service Mode”, press and hold the MENU and SELECT button for more than 3 seconds. The service

menu appears on the screen as follows.

To adjust service data

Select the adjustment group no. by pressing the MENU button (increase) or SELECT button (decrease), and

select the adjustment item no. by pressing the pointer e or d button, and change the data value by pressing the

7 or 8 button. Refer to the “Service Adjustment Data Table” for further description of adjustment group no., item

no. and data value.

To exit the service mode

To exit the service mode, press the ON/STAND-BY button.

Group No.

Item No.

Data value

Memory IC (IC301, IC802) Replacement

Memory ICs on the main board stores the data for the

service adjustments, and should not be replaced except for the case of defective device.

If replaced, the re-adjustments are required following to

the “Electrical Adjustments”.

The data of lamp replacement counter is stored in the

Memory IC.

Please note that the lamp replace counter will be reset

when the memory IC is replaced.

(Lamp replace counter cannot be set to the previous

value.)

●Caution to memory ICs replacement

When memory ICs are replaced with new one, the CPU

writes down the default data of the service adjustments

to the replaced ICs as the mentioned on the service adjustment table. As these data are not the same data as

factory shipped data, it should be required to perform

the re-adjustments following to the “Electrical Adjustments”.

Please note that in this case the lamp replace counter

will be reset.

●Caution of Main Board replacement (in the case

memory ICs are not defective)

When the main board is replaced, memory ICs should

be replaced with the one on previous main board. After

replacement, it should be required to perform the re-adjustments following to the “Electrical Adjustments”.

In this case, the value of lamp replace counter can be

kept as before.

-40-

Page 41

Electrical Adjustment

White 100%

Black 100%

Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the following

adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance

and product safety.

[Adjustment Condition]

16 steps gray scale pattern

● Input signal

Video signal ......................

1.0Vp-p/75W terminated, 16 steps gray scale

(Composite video signal)

Computer signal ................. 0.7Vp-p/75W terminated, 16 steps gray scale

pattern

Component Video signal .... 0.7Vp-p/75W terminated, 16 steps gray scale

(Component video signal with 480p, 575p,

720p or 1080i format)

● Picture control mode ......

“STANDARD” mode unless otherwise noted.

Note:

* Please refer to “Service Adjustment Menu Operation” for entering the service mode and adjusting the service

data.

z Panel Type Check and Setting

* Before setting, you need to check which type of LCD pan-

el is placed on the projector according to the item "LCD

Panel/Prism Ass'y removal" in the chapter "Optical Parts

Disassembly".

1. Enter the service mode.

2. Panel Type Check

Select group no. “290”, item no. “0”. Check the data

value as follows;

Data value: 0 For L-Type of LCD Panel

Data value: 20 For R-Type of LCD panel

3. Panel Type Setting

Select group no. “290”, item no. “1” and change data

value from 10 to 0 or 20 depending on your LCD Panel

type. When the data value reaches 0 or 20, it returns

to 10 quickly. The gamma-characteristics is reset ac-

cording to your selection.

Note:

Be careful to take this adjustment. The value of gamma

adjustment data will be reset and cannot be restored

if you change the mode of LCD panel type.

x Fan Voltages adjustment

1. Enter the service mode.

2. Connect a digital voltmeter to test point

chassis ground (-). (7 test points are provided for this

adjustment, perform all the voltage adjustments in

the table below.)

3. Select group no. “140”. Select item no. B and

change data value to adjust the voltage to be C - 0.1V

+ 0V, and select item no. D and change data value

to adjust the voltage to be E ±0.1V.

4. Repeat step 2 to 3 for the remaining test points in

the table below.

Test Point A Item B Voltage C Item D Voltage E

TPFN5 0 13.8 1 5.0

TPFN3 2 13.8 3 5.0

TPFN4 2 13.8 3 5.0

TPFN2

TPFN1 6 13.8 7 5.0

TPFN7 8 13.8 9 5.0

4 13.8 5 5.0

A (+) and

TPFN6 10 13.8 11 5.0

-41-

Page 42

Electrical Adjustment

c PC-Auto Calibration

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Input 1 [PC analog] mode.

3. To start the auto-calibration for PC adjustment, select

group no. “680”, item no. “0” and then change data

value from “0” to “1”. After the auto-calibration completed, "OK" will appear on the screen.

v Video-Auto Calibration -1

1. Enter the service mode.

2. Receive the 16-step grey scale 480i-component vid-

eo signal with Input 2 [Y,Pb/Cb,Pr/Cr] mode.

3. To start the auto-calibration for Video adjustment, se-

lect group no. “680”, item no. “0” and then change

data value from “0” to “1”. After the auto-calibration

completed, "OK" will appear on the screen.

b Video-Auto Calibration -2

1. Enter the service mode.

2. Receive the 16-step grey scale composite video sig-

nal with Input 3 [Video] mode.

3. To start the auto-calibration for composite video ad-

justment, select group no. “680”, item no. “0” and then

change data value from “0” to “1”. After the auto-calibration completed, "OK" will appear on the screen.

m Gamma Shift adjustment

1. Receive the 100%-whole-white computer signal with

Input 1 [PC analog] mode.

2. Enter the service mode.

3. Measure luminance on the screen with the luminance

meter. It is A for the reading of luminance meter.

4. Change the signal source to the 50%whole-white

computer signal with Input 1 [PC analog] mode.

5. Select group no. “920”, item no. “6” and change the

Data value to make the reading of luminance meter to

be A x 22% .

, White Balance adjustment [PC]

This adjustment is carried out in the both of image mode

"Standard" and "Real".

1. Receive the 50%-whole-white computer signal with

Input 1 [PC analog] mode.

2. Set image mode to "Standard" or "Real" you intend to

adjust.

3. Enter the service mode, select group no. “920” item

no. “5” (Red) or “7” (Blue), and change Data values

respectively to make a proper white balance.

Conform that proper white balance is obtained in the

both of image mode "Standard" and "Real".

n Common Center adjustment

1. Receive the 50%-Whole Gray composite video sig-

nal with Input 3 [Video] mode.

2. Enter the service mode.

3. Select group no. “100”, item no. “92” and change

data value to “2” to reduce the panel frequency.

4. Project only green light component to the screen.

5. Select group no. “200”, item no. “9” and change

data value to obtain the minimum flicker on the

screen.

6. Project only blue light component to the screen.

7. Select item no. “10” and change data value to obtain

the minimum flicker on the screen.

8. Project only red light component to the screen.

9. Select item no. “11 and change data value to obtain

the minimum flicker on the screen.

10. Select group no. “100”, item no. “92” and change

data value to “0” to reset the panel frequency.

. Gamma Correction adjustment [PC]

This adjustment is carried out in the both of image mode

"Standard" and "Real".

1. Receive the 16-step grey scale computer signal with

Input 1 [PC analog] mode.

2. Set image mode to "Standard" or "Real" you intend to

adjust.

3. Enter the service mode, select group no. “920”, item

no. “6” and change the Data value to make a proper

16 steps gradation.

Conform that proper 16 steps gradation is obtained in

the both of image mode "Standard" and "Real".

-42-

Page 43

Electrical Adjustment

⁄0 White Balance adjustment [AV]

This adjustment is carried out in the both of image mode

"Standard" and "Cinema".

1. Receive the 50%-whole-white composite video signal

with Input 3 [Video] mode.

2. Set image mode to "Standard" or "Cinema" you intend to adjust.

3. Enter the service mode, select group no. “920” item

no. “5” (Red) or “7” (Blue), and change Data values

respectively to make a proper white balance.

Conform that proper white balance is obtained in the

both of image mode "Standard" and "Real".

⁄1 Gamma Correction adjustment [AV]

This adjustment is carried out in the both of image mode

"Standard" and "Cinema".

1. Receive the 16-step grey scale composite video signal with Input 3 [Video] mode.

2. Set image mode to "Standard" or "Cinema" you intend to adjust.

3. Enter the service mode, select group no. “920”, item

no. “6” and change the Data value to make a proper

16 steps gradation.

⁄3 Wind Sensor Calibration

1. Enter the service mode, select group no. “170” and

item no. “0” .

2. To start the calibration, change data value from “0”

to “1”. During the calibration, the word "Please wait..."

appears on the screen. After the calibration completed correctly, "OK" will appear on the screen.

IMPORTANT

Before taking this adjustment, you need to replace the

filter cartridge with new one or scrolled up to new filter.

Conform that proper 16 steps gradation is obtained in

the both of image mode "Standard" and "Cinema".

⁄2

White Uniformity Adjustment

If you find the color shading on the screen, please adjust

the white uniformity by using the proper computer and

“Projector Service Toll” software supplied separately.

-43-

Page 44

Electrical Adjustment

K47A

K47B

K1401

IC9201

IC4401

IC4801

K8B

K8C

K8D

K8E

K8J

K8H

K8K

K8L

K8M

K8N

K8X

IC401

IC801

K78BK78H

K78C

K78D

K78E

K78F

K78G

IC1201

IC4701

K25B

K25G

IC101

K25R

IC301

K78A

TPFN2

TPFN7

TP501

TP503TPFN6

TPFN5

TPFN4

TPFN3

TPFN1

TP561

TP563

TP531

TP533

Test Points and Locations

MAIN BOARD

-44-

Page 45

Electrical Adjustment

Service Adjustment Data Table

These initial values are the reference data written from the

CPU ROM to memory IC when replaced new memory IC. The

adjustment items indicated with “✻” are required to readjust following to the “Electrical adjustments”. Other items should be

used with the initial data value.

Grp Item Item Name Function Range Initial

0 Temperatu re Monitor [ Read only ]

0 LM76( Temp) A Monitor Temp. Sensor A ( Room: IC1692) - -

1 LM76( Temp) B Monitor Temp. Sensor B ( Lamp: IC1816) - -

2 LM76( Temp) C Monitor Temp. Sensor C (Pan el:IC1814) - -

1 Pressu re Sensor Mo nitor [R ead only]

0 MPXHZ6115A(Pressure) Monit or Pressure Se nsor - -

1 MPXHZ6115A(Pressure) Monit or Pressure Se nsor [mm Hg] - -

2 MPXHZ6115A(Pressure) Monit or Pressure Se nsor [hpa] - -

3 Angle Sensor Mon itor [Rea d only]

0 MAS1390 (Acc eleratio n) A Monito r Angle Se nsor A -

1 MAS1390 (Acc eleratio n) B Monito r Angle Se nsor B -

4 Wind Se nsor Moni tor [Read o nly]

0 Flow Senso r Monitor Wind Sens or -

5 Fan Voltag e Monitor [ Read only ]

0 FAN A Monitor ( Exhaust : Large ) Fan voltage (x0.01V) [A01] - -

1 FAN B Monitor ( Exhaust : Small ) Fan vol tage (x0.01V) [ A02] - -

2 FAN C Monitor ( PBS) Fan voltag e (x0.01V) [A03 ] - -

3 FAN D Monitor ( Power) Fan voltage (x0.01V) [A0 4] - -

4 FAN E Monitor ( Panel Cool ling) Fan voltag e (x0.01V) [A05 ] - -

5 FAN F Monitor ( Panel Cool ling) Fan vol tage (x0.01V) [A06] - -

-

10 RS232C Se tting

0 Baudrate RS232C Bau d Rate (0 :19200 / 1:9600) 0 / 1 0

1

11 PJ-Net Set ting

0 Reset Dis able PJ-Net Rese t (0: Enable / 1: Disable) 0 / 1 0

20 Logo Proh ibition

0 Logo Prohi bition 0: Menu, 1: Pr ohibiti on 0 / 1 0

30 Color Sh ading /Gamm a Correct ion

0 Color Sha ding Corre ction On /Off 0: Off, 1:O n *Not memor ized 0 / 1 1

1 Gamma Cor rection O n/Off 0: Of f, 1:On *Not memorized 0 / 1 1

40 Dimmer

0

1 Dimmer Leve l 0:Min.W ~ 15: Max.W *Mem orized 0 ~ 15 11

2 DIMMER CTR L LEVEL1 Luminance Level 1 Data f or Dimmer: L ess than val ue 0 ~ 255 7

3 DIMMER CTR L LEVEL2 Luminance Level 2 Data f or Dimmer: L ess than val ue 0 ~ 255 14

4 DIMMER CTR L LEVEL3 Luminance Level 3 Data f or Dimmer: L ess than val ue 0 ~ 255 21

5 DIMMER CTR L LEVEL4 Luminance Level 4 Data f or Dimmer: L ess than val ue 0 ~ 255 28

6 DIMMER CTR L LEVEL5 Luminance Level 5 Data f or Dimmer: L ess than val ue 0 ~ 255 35

7 DIMMER CTR L LEVEL6 Luminance Level 6 Data f or Dimmer: L ess than val ue 0 ~ 255 42

8 DIMMER CTR L LEVEL7 Luminance Level 7 Data f or Dimmer: L ess than val ue 0 ~ 255 49

9 DIMMER CTR L LEVEL8 Luminance Level 8 Data f or Dimmer: L ess than val ue 0 ~ 255 56

10 DIMMER CTRL LEVEL 9 Lumi nance Level 9 D ata for Dimmer: Less tha n value 0 ~ 255 63

11 DIMMER CTRL LEVEL10 Lumina nce Level 10 Data fo r Dimmer: Le ss than valu e 0 ~ 255 70

12 DIMMER CTRL LEVEL11 Lumina nce Level 11 Data for Dim mer: Less t han value 0 ~ 255 77

13 DIMMER CTRL LEVEL12 Lumina nce Level 12 Data for D immer: Le ss than value 0 ~ 255 84

14 DIMMER CTRL LEVEL13 Lumina nce Level 13 Data for D immer: Le ss than value 0 ~ 255 91

15 DIMMER CTRL LEVEL14 Lumina nce Level 14 Data for D immer: Les s than value 0 ~ 255 98

16 DIMMER CTRL LEVEL15 Lumina nce Level 15 Data for D immer: Le ss than value 0 ~ 255 105

17 DIMMER AVE POINT Dimmer Avar age Points 1~16 4

50 Auto Pict ure Contro l

0 Auto Pictu re Control Fo rced OFF 0: Me nu 1: Forced O ff *Memorized 0 / 1 Ini tial =1, Ship= 0

70 COOLIN G

-45-

Page 46

Electrical Adjustment

Grp Item Item Name Function Range Initial

0 COOLING _TIME Coolin g time at Power O ff 10 ~ 120 90

1 Not used Not us ed -1

80 Projec tor used tim e Reset

0 PJ Time Reset Time is re set when the va lue is set to 10. 0 ~ 10 0

90 Operat ion histor y

0 OPERATION_ HISTORY_1 Last Operation hi story 0 ~ 32767 0

~ : : : :

49 OPERATION_HISTO RY_50 50t h Operati on histor y 0 ~ 32767 0

50 OPERATION_HISTO RY Reset History is r eset when th e value is set to 10. 0 ~ 10 0

91 Error Log * Refer to Error Log tab le

0 Warning _Log_1 L ast Error Lo g 0 ~ 32767 0

~ : : : :

49 Warning_Lo g_50 5 0th Error Log 0 ~ 32 767 0

50 Warning_Lo g Reset Log is reset whe n the value is s et to 10. 0 ~ 10 0

112 Lamp Co nfig

0 Lamp Con fig Change L amp Life Sel ect 1000 ~ 80 00 2500

113 Lamp Res et Counter [ Read only ]

0 Lamp Rese t times Lamp rese t times 0 ~ 127 0

115 Lamp Go O ut

0 Lamp Go Ou t 0 :Disa ble / 1:Ena ble - 0

116 Lamp Rep lace Dips play

0 Lamp tim e display 0:D isable / 1: Enable 0/1 1

117 Lamp Life Test

0 Lamp life test enable 0:Disa ble 1:Ena ble for Safet y check - 0

1 Lmap On tim e(for l ife test) Minutes for Safety ch eck - 1

2 Lamp Of f time( for life test) M inutes for Safety chec k - 3

3 Lamp tota l time( for life test) Hours for Safety che ck - 0

120 RC KEY Dis able

0

1 RC KEY Front /Rear Disab le 0: Enable / 1: Front RC Disa ble / 2:R ear RC Disab le / 3:RC KEY All Disable 0 / 1 / 2 / 3 0

2

130 75 ohm terminated

0 TERM_1 In put1(D_ SUB)75 ohm terminated ON/ OFF (0 :OFF 1: ON) 0 / 1 0

1 TERM_ 2 Input2( BNC)75 ohm term inated ON /OFF (0: OFF 1:ON ) 0 / 1 0

140 Fan Adjust ment

0 Fan A Max (DAC ) Fan DAC Output adjust ment 0 ~ 255 2 24

1 Fan A Min (DAC ) * Lamp Mode : Forced Eco 0 ~ 255 3 8

2 Fan B Max (DAC ) 0 ~ 255 22 5

3 Fan B Min (DAC ) Volmin =5V 0 ~ 255 3 6

4 Fan C Max (DAC ) Volm ax=13.8V 0 ~ 255 22 9

5 Fan C Min (DAC ) ( DACmax - DACmin ) / (Volmax - Volmin) * (Volnow - Volmin) + DACmin 0 ~ 25 5 35

6 Fan D Max (DAC ) 0 ~ 255 227

7 Fan D Min (DAC ) 0 ~ 255 38

8 Fan E Max (DAC ) 0 ~ 255 22 2

9 Fan E Min (DAC ) 0 ~ 255 3 6

10 Fan F Max (DAC) 0 ~ 255 22 2

11 Fan F Min (DAC) 0 ~ 255 3 8

141 Fan Optio n

142 Fan Temp Error Set ting [Re ad only} Read only

0 Temp A Warning Temp. A (Room ) to judge fo r abnormal t emp (x0.1°C) 0 ~ 1000 470

1 Temp B Warning Temp. A (Lamp) to judge for abnorma l temp (x0.1°C) 0 ~ 1000 750

2 Temp C Warning Temp. A (Panel) to judge for abn ormal temp ( x0.1°C) 30 0 ~ 1000 6 50

3 Temp B-A Warning Temp. B-A ( Filter Clogge d) to judge f or abnorma l temp (x0.1°C) 0 ~ 1000 500

4 Temp C-A Warning Temp. C-A (F ilter Clog ged) to judge for abno rmal temp (x 0.1°C) 0 ~ 1000 310

-46-

Page 47

Electrical Adjustment

Grp Item Item Name Function Range Initial

143 Fan Manual C ontrol

0 Fan Fix SW

1 Fan Manual SW FanManual Control SW 0 :Auto / 1:Manual * Not memorize d 0 / 1 0

2 Fan A Manual O ut

3 Fan B Manual O ut 0 ~ 2000 1350

4 Fan C Manual O ut 0 ~ 2000 1350

5 Fan D Manual O ut 0 ~ 2000 1350

6 Fan E Manual O ut 0 ~ 2000 1350

7 Fan F Manual O ut 0 ~ 200 0 1350

144 Fan Table Setting

0 Fan Control Max Temp Fan control rang e of Temp Sensor A (x0 .01V) 300 ~ 100 0 380

1 Fan Control Min Temp 0 ~ 1000 310

2 Fan A Normal M ax (Volt) Fan contr ol range at L amp Normal ( x0.01V) 0 ~ 2000 1350

3 Fan A Normal M in (Volt) * It does not c hange wit h real time 0 ~ 2000 900

4 Fan B Normal M ax (Volt) 0 ~ 2000 1350

5 Fan B Normal M in (Volt) 0 ~ 2000 700

6 Fan C Normal M ax (Volt) 0 ~ 2000 1380

7 Fan C Normal M in (Volt) 0 ~ 2000 1380

8 Fan D Normal M ax (Volt) 0 ~ 2000 1350

9 Fan D Normal M in (Volt) 0 ~ 2000 1200

10 Fan E Normal Max ( Volt) 0 ~ 2000 1350

11 Fan E Normal Min (Vol t) 0 ~ 2000 700

12 Fan F Normal Max ( Volt) 0 ~ 2000 1350

13 Fan F Normal Min (Vol t) 0 ~ 2000 700

14 Fan A Eco Max (Volt) Fan control range at Eco N ormal (x0 .01V) 0 ~ 2000 1350

15 Fan A Eco Min (Volt) * It does n ot change in real time 0 ~ 200 0 500

16 Fan B Eco Max (Volt) 0 ~ 2000 1350

17 Fan B Eco Min (Volt) 0 ~ 2000 500

18 Fan C Eco Max (Volt) 0 ~ 2000 70 0

19 Fan C Eco Min (Volt) 0 ~ 2000 70 0

20 Fan D Eco Max (Volt) 0 ~ 2000 1350

21 Fan D Eco Min (Volt) 0 ~ 2000 1100

22 Fan E Eco Max (Volt) 0 ~ 2000 1350

23 Fan E Eco Min (Volt) 0 ~ 2000 500

24 Fan F Eco Max (Volt) 0 ~ 200 0 1350

25 Fan F Eco Min (Volt) 0 ~ 200 0 500

0:n ormal / 1: Normal Mi n / 2:Normal Max / 3 :Eco Mi n / 4 :Eco Ma x

* Not memorized , Abnor mal temp =100°C

Fan Voltage at M anual Mod e * Not memorized (x0.01V)

* Effect ive only Fan Manual SW is 1

0 ~ 4 0

0 ~ 2000 1350

145 Fan Temp. Offse t Setting

0 Temp A Warning Of fset (Temp) Temp. warning of fset value a t Power On (x0.1℃ ) 0 ~ 200 170

1 Temp B Warning Of fset (Temp) 0 ~ 200 170

2 Temp C Warning Of fset (Temp) 0 ~ 200 170

3 Temp B-A Warning O ffset (Temp) 0 ~ 200 170

4 Temp C-A Warning O ffset (Temp ) 0 ~ 200 170

5 Temp A Warning Of fset (Tim e) Temp. warning o ffset tim e at Power On (se c.) 0 ~ 30 0 180

146 Fan Star t Setting

0 Fan Start S tep (Volt /Sec ) Voltage deviation/1 sec at Fan start (Volt/ Sec) 0 ~ 200 0 20

1 Fan A Start Vol t Fa n start vol tage (x0.01V) 0 ~ 2000 700

2 Fan B Start Vol t 0 ~ 2000 700

3 Fan C Start Vol t 0 ~ 2000 70 0

4 Fan D Start Vol t 0 ~ 2000 70 0

5 Fan E Start Vol t 0 ~ 2000 700

6 Fan F Start Vol t 0 ~ 200 0 700

147 Fan Pressur e Setting

0 Press Sour ce Range Low Press se nsor contr ol range (mmHG) 0~1024 525

1 Press Sour ce Range Hi gh 0~1024 700

2 Press Fan Add Range High 0 ~ 2000 0

3 Press Fan Add Range Low 0 ~ 2000 650

148 Fan Ceilin g Setting

0 FAN A Ceiling O ffset Offset volt age at Ceili ng (x0.01V) 0 ~ 2000 0

1 FAN B Ceiling O ffset 0 ~ 2000 0

2 FAN C Ceiling O ffset 0 ~ 2000 0

3 FAN D Ceiling O ffset 0 ~ 2000 0

4 FAN E Ceiling O ffset 0 ~ 200 0 0

4 FAN F Ceiling O ffset 0 ~ 2 000 0

-47-

Page 48

Electrical Adjustment

Grp Item Item Name Function Range Initial

149 Fan Clogg ed Setting

0 Temp C-A Upward High Fan voltage add ition by Se nsor A - C temp Upw ard High 0 ~ 1000 3 00

1 Temp C-A Upward Lo w Fan voltage addit ion by Senso r A - C temp Upward L ow 0 ~ 1000 2 80

2 Temp C-A Downwar d High Fan voltage addition by Se nsor A - C temp Dow nward High 0 ~ 1000 150

3 Temp C-A Downwar d Low Fan voltage addit ion by Senso r A - C temp Downward Low 0 ~ 1000 110

150 Shipping Setting

0 Shipping Setting S hipping S et when the value is set to 10. 0 ~ 10 0

170 Wind Sen sor

0 Flow Senso r Calibrat ion

1 Flow Senso r Offset M in

2 Flow Senso r Offset M ax

3 Flow Senso r Calibrat ion Error Log

4 Clog Chec k Enable Clogged D etectio n (0: Di sable / 1: Enable) 0 ~ 1 Initial =0, Sh ip=1

171 Wind Sen sor

0 Ideal Flo w Data Air flow data th eory for c urrent fan vol tage (Re ad only) - -

1 Flow Dif ference Dat a Dif ferentia l value betw een actual a nd theor y (Read onl y - -

2 Clog Dete ct Flow Dif ference Dat a “Dif ferential value to judg e “Clogg ed”( Read only) - -

3 Warn Detect Flow Diffe rence Data

4 Press Add Data Additional value o f press sens or - -

5 Filter Scr oll Timer

175 Filter

0 Compuls ion Filter Taking Up

1 Take Up Bend

2 Take Up Times Filter scr oll remaining times ( Read only ) - 9

3 Take Up Time Reset

4 Scroll Counter Reset T ime S croll Cou nter reset ti mes (Read o nly) 0 ~ 25 5 0

Wind Sen sor Offset Auto-Ca libration

Calibra tion star ts when the val ue is set to 1. After cal ibration, OK is displaye d.

Wind Sen sor Mini Of fset value

* After ca libration, the value i s set automat ically.

(Of fset Range : 350 - 550 )

Wind Sen sor Max Of fset value

* After ca libration, the value i s set automat ically.

(Of fset Range : 550 - 800 )

Error Log fo r Auto-Ca libratio n

0: No Err or

10: Min no t stabilize d

11: Min out of offs et range

20: Ma x not stabi lized

21: Max out of offset ran ge

“Dif ferential value to judg e “Clogg ed warning" (Read onl y)

Judge w hen the rema ining scro ll times is 0.

Filter sc roll timer (hours)(Read o nly)

* Execut e at 2000 hou rs

Filter sc roll force dly

*Execu te when the val ue is set to 1

Remove flexu re of filter

*Execu te when the val ue is set to 1

Reset of sc roll up tim es

*Reset wh en the value is set to 10.

0 ~ 1 0

0 ~ 1023 0

0 ~ 1023 0

- -

- -

0 ~ 1 0

0 ~ 1 0

0 ~ 10 0

176 Filter Di spplay

0 Filter Icon Display Di splay 0: D isable / 1: Enable 0 /1 1

177 Filter Ti mer

0 Filter Tim er Reset Tim es Filter time reset times with us er menu 0 ~ 255 0

1 Force Power Off Time Forced Po wer Off Tim e (hours ) 0 ~ 1000 10

180 DDC Setting

0 HDCP EDID Dat a Settin g 0:DVI EDID Dat a / 1:HDCP EDID Da ta 0 / 1 1

190 Panel Life Test

0 Panel Life en able 0: Test M ode ON, Test Mod e OFF 0 / 1 1

200 CXA7007

0 G SIG Center 0 ~ 63 32

1 B SIG Center 0 ~ 6 3 32

2 R SIG Center 0 ~ 63 32

3 G Gain Cont rol 0 ~ 255 194

4 B Gain Cont rol 0 ~ 2 55 194

5 R Gain Cont rol 0 ~ 255 194

6 G Bright Co ntrol 0 ~ 255 0

7 B Bright Co ntrol 0 ~ 2 55 0

8 R Bright Co ntrol 0 ~ 255 0

9 G VCOM Contr ol 0 ~ 255 104

10 B VCOM Control 0 ~ 255 104

11 R VCOM Control 0 ~ 255 104

-48-

Page 49

Electrical Adjustment

Grp Item Item Name Function Range Initial

12 G SID Control A 0 ~ 25 5 16

13 B SID Control A 0 ~ 255 16

14 R SID Control A 0 ~ 255 16

15 G SID Control B 0 ~ 25 5 130

16 B SID Control B 0 ~ 255 130

17 R SID Control B 0 ~ 255 130

18 G FRINV 0 ~ 1 0

19 B FRINV 0 ~ 1 0

20 R FRINV 0 ~ 1 0

290 Panel

0 PANEL_LR

1 PANEL_CHG

300 Built-i n Device : CXD3815

0 Compon ent Y Level

1 Compon ent C Level

2 CVBS Y Level

3 CVBS C Level

4 Sub Hue CVBS/ S Input (NTSC )Tint Adj. 0 - 63 32

5 HS Slice Level H Sync Slice L evel 0 - 15 4

6 HS Slice O ffset

7 VS Slice Level V Sync Slice Level 0 - 15 6

8 VS Slice Of fset Offse t for V Sync Sli ce Level 0 - 15 6

9 Samplin g Phase A /D Cloc k Phase 0 - 63 0

10 Pre Shoot Level Sub-Sh arpness 0 - 15 8

11 Over Shoot Level Sub-Sharp ness 0 - 15 8

12 Y Filter

13 C Filter

14 NTSC/PAL Dete ct

Panel Type Disp lay (Read o nly)

0: Type-L / 2 0: Type-R

Gamma da ta will be res et when the val ue is set to 0 or 20.

20: Type- R, 0: Type-L

Component Scar t Input Gain A dj.

Group 01 : <YCbCr >1080i-6 0, 1080i-5 0, 1035i

<RGB >1080i- 60, 1080i-50, 103 5i

Group 02 : <YCbCr>720p- 60, 720p -60

<RGB >720p-60, 720p-50

Group 03 : <YCbCr>48 0p, 575p

<RGB >480p, 575p

Group 04 : <YCb Cr>48 0i, 575i

<RGB >480i, 575i

Group 05 < Scart> 480i, 575i

Component SCart I nput Gain Ad j.

Group 01 : <YCbCr >1080i-6 0, 1080i-5 0, 1035i

<RGB >1080i- 60, 1080i-50, 103 5i

Group 02 : <YCbCr>720p- 60, 720p -60

<RGB >720p-60, 720p-50

Group 03 : <YCbCr>48 0p, 575p

<RGB >480p, 575p

Group 04 : <YCb Cr>48 0i, 575i

<RGB >480i, 575i

Group 05 < Scart> 480i, 575i N ote: Link w ith Group 4

CVBS/ Yinput Gain Adj.

Composite / S-VIDEO

C Input Ga in Adj.

Composite / S-VIDEO

Offse t of H Sync Sli ce Level

Group 01 : <YCbCr >480 i, 575i

Group 02 : <YCbCr>48 0p, 575p

Group 03 : <YCbCr>720p

Group 04 : <YCb Cr>1080i

Group 05 : O thers

Y Input Filter band Set ting

Group 01 : Composite, S -Video

Group 02 : 4 80i, 575i, 480p, 575p

Group 03 : 720p-6 0, 720p-5 0, 1035i, 1080 i-60, 108 0i-50

C Input Filter Band Set ting

Group 01 : Composite, S -Video

Group 02 : 4 80i, 575i, 480p, 575p

Group 03 : 720p-6 0, 720p-5 0, 1035i, 1080 i-60, 108 0i-50

NTSC/ PAL Detection Thres hold Sett ing

0 : 64H /1V - PAL Ident Strong

1 : 96H /1V

2 : 128H/1V

3 : 160H/1V - PAL Ident Weak

* Change i s effecti ve at System -Au to Select ion

- 0

0 ~ 20 10

0 - 255

0 - 255

0 - 255 162 /163

0 - 255 124/127

0 - 15

0 - 7

0 - 7

0 - 3 2

118

118

118

118

134

110

110

127

134

150

5

5

4

3

5

5

5

6

5

5

6

302 Built-i n Deveice : FPGA(D EMO_MOD E) SH

0 FPGA_ DEMO_ON_ OFF De mo mode On /Off( 0:O ff,1:On) * Not m emorized 0 ~ 1 0

1 FPGA_ DEMO_MO DE De mo mode Swi tch (0 :Demo0,1:Demo1 ・・・ ) * Not mem orized 0 ~ 3 0

303 Built-i n Device : FPGA(C olor Maneg .) S H

0 YRange Bright ness (Y) R ange 0 ~ 32 8

1 HueRang e Hue Range 0 ~ 2 0 10

2 GainRange Gain Range 0 ~ 50 30

-49-

Page 50

Electrical Adjustment

Grp Item Item Name Function Range Initial

3 GM_M inSlope Gam ma Mini Slo pe (x0.01) 0 ~ 10 3

4 GM_M axSlope Gamma Max S lope (x0.1) 10 ~ 30 18

5 GM_Converge G amma Convarg e Point Numb ers (x0.1) 1 ~ 5 3

6 Not used Not us ed - -

7 Not used Not us ed - -

8 COLM_GET_KIND_Y_ud Point Nu mbers at Col or Acquire d 1 ~ 9 9

9 Not used Not us ed - -

10 Not used Not used - -

11 SameHue H ue Comp sam e angle rang e 1 ~ 10 3

12 Cut_UVNorm Hue Co mp UV Norm Mi ni Value 0 ~ 64 5

13 Cur_MinY H ue Comp Bri ghtness M ini Value 0 ~ 127 0

14 Cur_MaxY Hue Co mp Bright ness Max Valu e 128 ~ 255 2 55

15 CM_IsAcc ess For Deb ag 0 ~ 1 1

310 Built-i n Device : AD9882

0 GREEN_OFFSET 0 - 127 63

1 RED_OFFSET 0 - 127 63

2 BLUE_OFFS ET 0 - 127 63

3 GREEN_GAI N 0 - 255 78

4 RED_GAIN 0 - 255 78

5 BLUE_GAIN 0 - 255 78

6 BANDWIDTH Analog 0 - 1 1

7 Last Cali b Table [Off set]

8 Last Cali b Table [Gain ]

9 OFFSET_THRESH_ 0

10 OFFSET_THRESH_1

11 OFFSET_THRESH_2