Page 1

Multimedia Plasma Monitor

SERVICE MANUAL

FILE NO.

Model No. PDP-42H1EV

(EUROPE)

PDP42H1A

(U.S.A., ASIA)

ORIGINAL VERSION

PRODUCT CODE

1 114 019 00

PDP-42H1EV, J3BL

1 114 034 00 PDP-42H1A, J3BJB

REFERENCE NO. SM5110311-00

Chassis No. PDP-42H1E-00

(PDP-42H1EV)

NOTE: Match the Chassis No. on the

unit’s back cover with the Chassis

No. in the Service Manual.

If the Original Version Service

Manual Chassis No. does not

match the unit’s, additional

Service Literature is required. You

must refer to “Notices” to the

Original Service Manual prior to

servicing the unit.

CONTENTS

Pages

SAFETY INSTRUCTIONS --------------------------------------------------------------------- 2

TECHNICAL SPECIFICATIONS ------------------------------------------------------------- 3

DIMENSIONS AND OPTIONS---------------------------------------------------------------- 4

TERMINALS FOR PC----------------------------------------------------------------------- 5 - 6

MECHANICAL DISASSEMBLIES------------------------------------------------------ 7 - 14

ADJUSTMENT ---------------------------------------------------------------------------- 17 - 19

CIRCUIT BLOCK DIAGRAM----------------------------------------------------------- 20 - 21

POWER SUPPLY LINES --------------------------------------------------------------------- 22

POWER FAIL CIRCUIT ----------------------------------------------------------------- 23 - 24

TROUBLESHOOTING ------------------------------------------------------------------ 25 - 26

CONTROL PORT FUNCTIONS ------------------------------------------------------ 27 - 28

IC BLOCK DIAGRAMS------------------------------------------------------------------ 29 - 36

PIN DESCRIPTION OF DIODE, TRANSISTOR AND IC----------------------------- 37

PARTS LIST ------------------------------------------------------------------------------- 38 - 60

PARTS DESCRIPTION AND READING IN SCHEMATIC DIAGRAM ------------ 61

SCHEMATIC DIAGRAMS---------------------------------------------------------- A-1 - A-12

PRINTED WIRING BOARD DIAGRAMS ------------------------------------- A-13 - A-18

Chassis No. J3B-42H1A00

(PDP-42H1A)

Page 2

-2-

■ Safety Instructions

Product safety should be considered when a component replacement is made in any area of the monitor.

Components indicated by mark in the parts list and the schematic diagram designate components in

which safety can be of special significance. It is, therefore, particularly recommended that the replacement of

there parts must be made by exactly the same parts.

PRODUCT SAFETY NOTICE

SAFETY PRECAUTIONS

WARNING : TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO

RAIN OR MOISTURE.

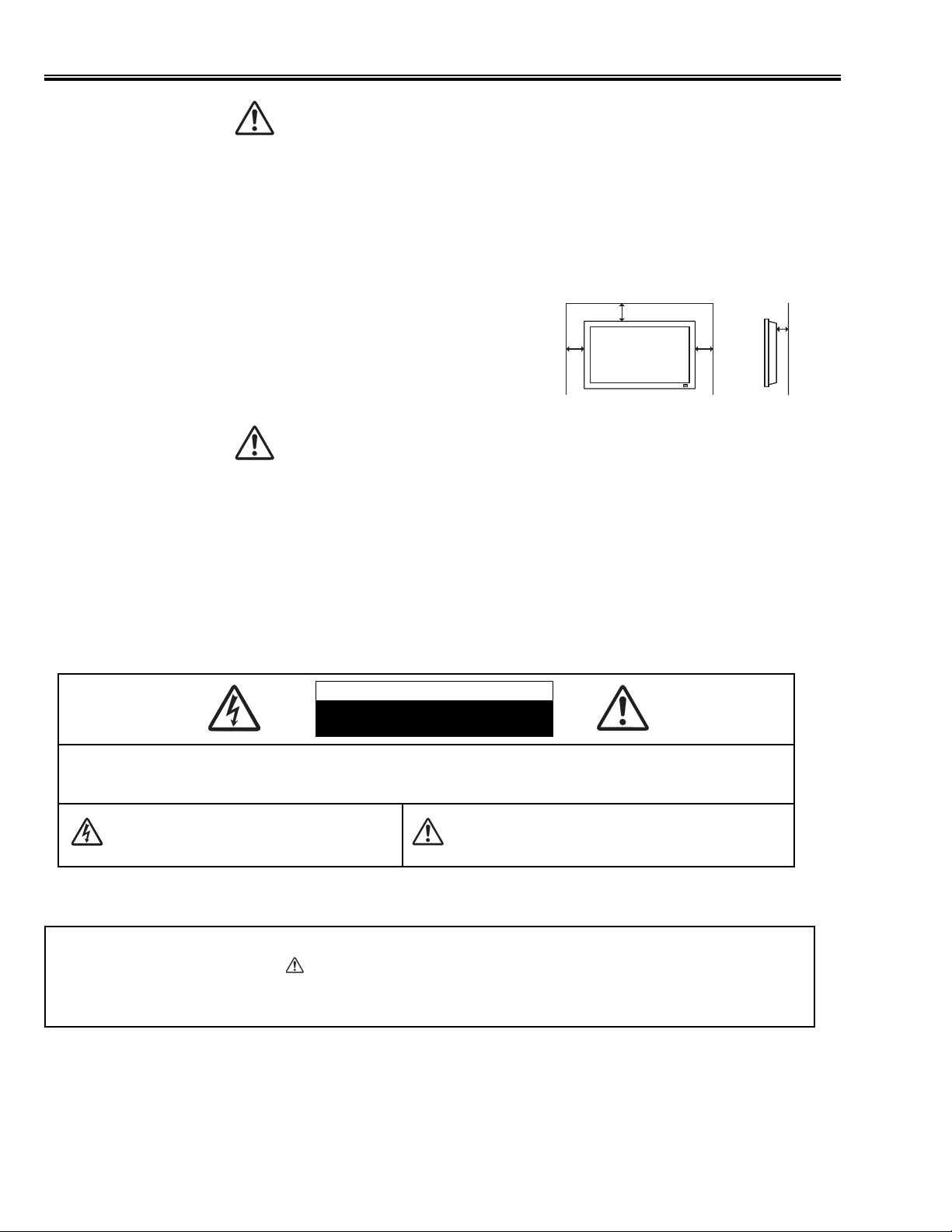

● This Plasma Monitor should be set in the way indicated. If not, it may result in a fire hazard.

● Take appropriate space on the top, sides and rear of the Plasma Monitor cabinet for allowing air circulation and

cooling the Plasma Monitor. Minimum distance should be taken. If the Plasma Monitor is to be built into a

compartment or similarly enclosed, the minimum distances must

be maintained. Do not cover the ventilation slot on the Plasma

Monitor. Heat build-up can reduce the life of your Plasma

Monitor, and can also be dangerous.

● If the Plasma Monitor is not to be used for an extended time,

unplug the Plasma Monitor from the power outlet.

READ AND KEEP THIS OWNER'S MANUAL FOR LATER USE.

CAUTION IN INSTALLING

SIDE and TOP

10 cm

10 cm

REAR

6 cm

10 cm

Handle the

●

Locate set away from heat, excessive dust, and direct sunlight.

●

For correct installation and mounting it is strongly recommended to use a trained, authorized dealer. Failure to

●

follow correct mounting procedures could result in damage to the equipment or injury to the installer.

Plasma

Monitor carefully when installing it and do not drop.

NOTE :

When Plasma Monitor is not used for a long period of time, unlighting dots may be observed. This is caused by

characteristic of the Plasma Monitor. If this occurs, turn the Plasma Monitor on and leave it on about 1 hour. These

dots will gradually disappear.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK). NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

THIS SYMBOL INDICATES THAT DANGEROUS

VOLTAGE CONSTITUTING A RISK OF ELECTRIC

SHOCK IS PRESENT WITHIN THIS UNIT.

THIS SYMBOL INDICATES THAT THERE ARE IMPORTANT

OPERATING AND MAINTENANCE INSTRUCTIONS IN THE

OWNER'S MANUAL WITH THIS UNIT.

Page 3

-3-

■ Technical Specifications

Screen Diagonal

42V

Product name

Multimedia Plasma Monitor

Panel type

Plasma Display Panel (16 x 9)

Display area

922 mm (W) x 522 mm (H)

Resolution / Color

1024 x 1024 pixels / 16,770,000 colors

Viewing Angle

160˚ (Vertical / Horizontal)

Color System

PAL / SECAM / NTSC / NTSC4.43 / PAL-M / PAL-N

PC Interface

D-SUB, RGB

Capability

Up to XGA

Plug & Play

VESA DDC2B

Power Management

VESA DPMS

Audio Amp

10W + 10W (8 Ω)

Terminals

VIDEO1-3 IN

✽

VIDEO (RCA type / BNC type), S-VIDEO (Mini DIN 4pin type)

AUDIO R and L (MONO) (RCA type)

COMPONENT/RGB IN

✽

Y, Pb/Cb, Pr/Cr / R, G, B, VD, HD (BNC type)

AUDIO R and L (RCA type)

THROUGH OUT

✽

Y, Pb/Cb, Pr/Cr / R, G, B, VD, HD (BNC type)

(

COMPONENT/RGB)

AUDIO R and L (RCA type)

MONITOR OUT

✽

VIDEO (RCA type / BNC type)

AUDIO R and L (RCA type)

PC IN

RGB (D-SUB 15pin)

AUDIO R / L (Stereo Mini jack)

RS232C IN

RS232C (D-SUB 9pin)

WIRED RC IN

Mini Jack

HEADPHONE OUT

Stereo Mini Jack

EXT. SP OUT

R and L, 10W (8 Ω), Push type

AC IN

3PIN

POWER SUPPLY

AC 220 - 240V 50 Hz (PDP-42H1EV)

AC 100 - 120V 50/60 Hz, AC 200 - 240V 50/60 Hz (PDP-42H1A)

DIMENSION (W x H x D)

1036 x 641 x 100 mm

(

41.4" x 25.2" x 4" )

(Plasma Monitor only)

WEIGHT (NET)

36 kg

(

79.3 lbs )

(Plasma Monitor only)

Regulations

FCC CLASS-B, UL (PDP-42H1A), CE (PDP-42H1EV, PDP-42H1E)

Environmental Considerations

Operating Temperature

0˚C ~ 40˚C (32˚F ~ 104˚F )

Humidity

20 ~ 80%

Altitude

0 ~ 2,000 m (0 ~ 6,560 ft)

Storage Temperature

-10˚C ~ 50˚C (14˚F ~ 122˚F)

Humidity

20 ~ 80 %

Altitude

0 ~ 3,000 m (0 ~ 9,840 ft)

Accessories

Owner’s Manual

AC Power Cord

Wired/Wireless Remote Control Transmitter and Batteries

Remote Control Cable

BNC / RCA Adapter ( x3)

Ferrite cores

✽ Those terminals are not provided on model PDP-42H1E.

● Specifications are subject to change without notice.

Page 4

-4-

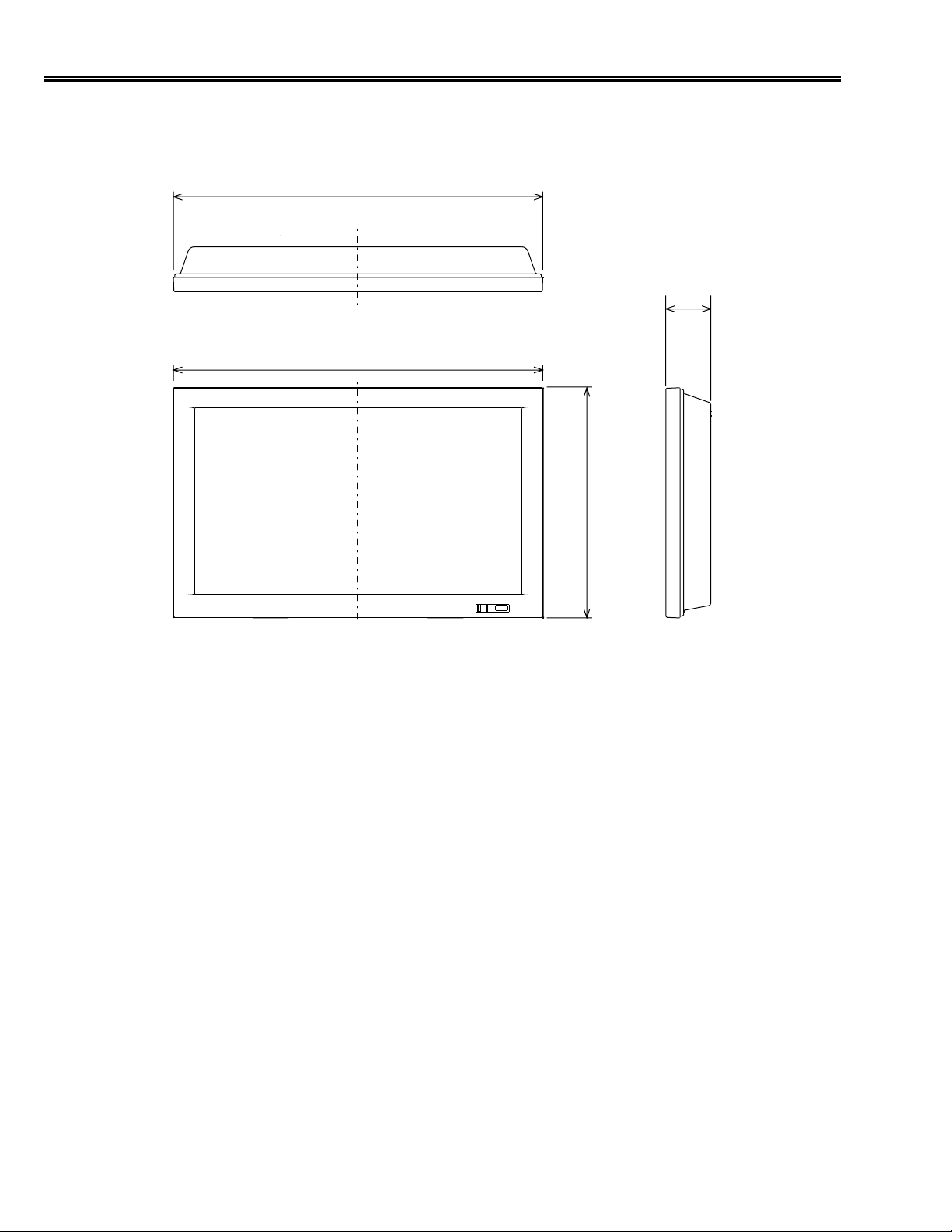

■ Dimensions and Options

MEASUREMENT

OPTIONS

Size in mm (inch)

The products listed below are optionally supplied.

When ordering these products, give name and Type No. to sales dealer.

Speaker unit KA-SX-42H (R and L)

Table top stand KA-TD-H10S

Side rack KA-TD-R100

Tilt mount unit KA-TI-H10

Wall mount unit KA-WA-H10WV

Ceiling mount unit KA-CH-H10

Floor Stand KA-TD-42HW

1036

(41.4)

1036

(41.1)

100

(4.0)

641

(25.2)

Page 5

-5-

■ Ter minals for PC

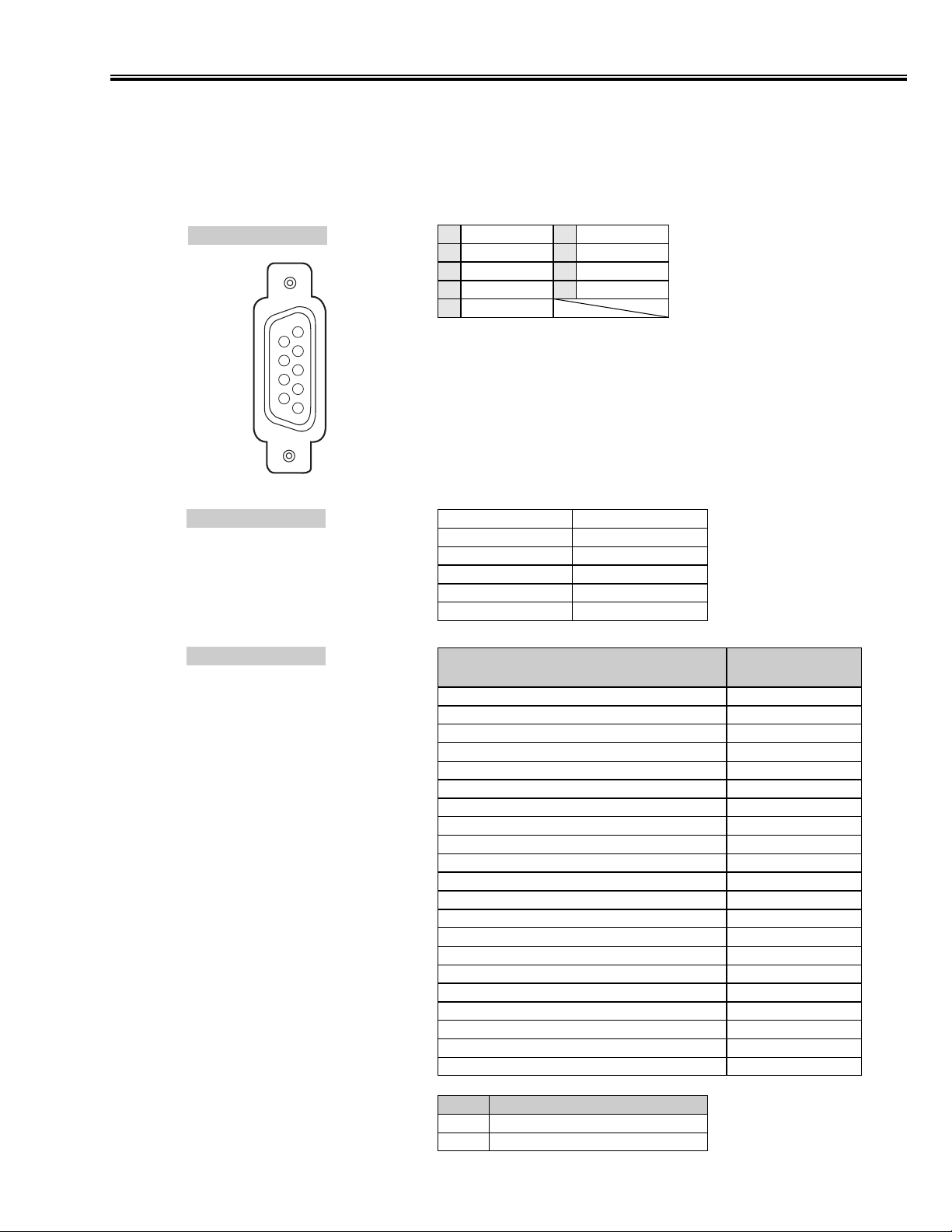

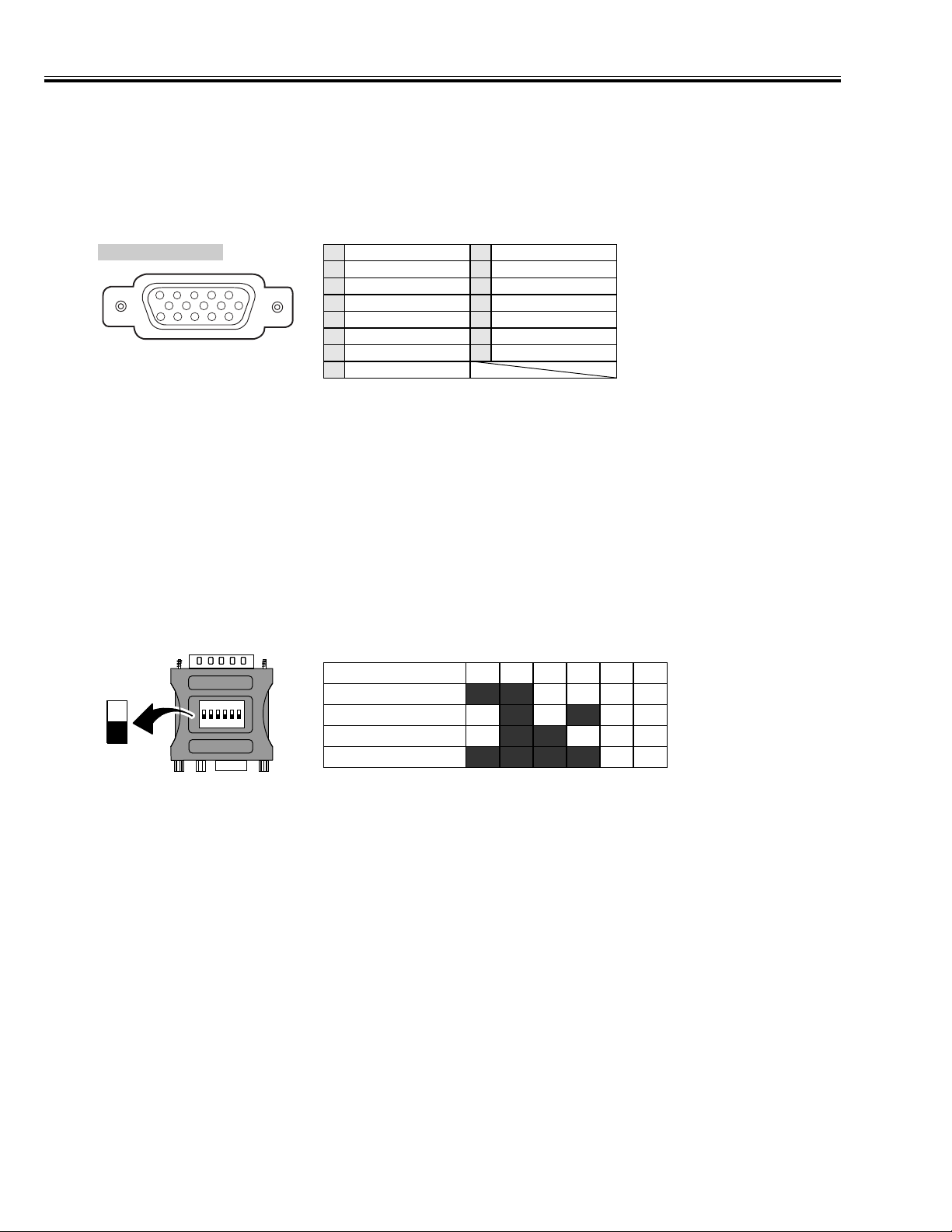

CONFIGURATIONS OF RS232C TERMINALS

RS232C TERMINAL

Terminal : HDB9-PIN

Connect the serial port of computer to this terminal with Serial Cross Cable (not supplied).

No Connect

Pin Configuration

5

9

4

8

3

7

2

6

1

1

2

3

4

5

R x D

T x D

DTR (5V)

Ground

DSR

6

No Connect

7

No Connect

8

No Connect

9

INTERFACE

COMMAND

Protocol

Boadrate

Data length

Parity

Stop bit

Flow control

OPERATION

POWER ON-OFF

POWER ON

POWER OFF

VOLUME UP

VOLUME DOWN

MUTE

INPUT (Input signal select)

INPUT "VIDEO" (VIDEO1 / VIDEO2)

INPUT "COMPONENT" (COMPONENT)

INPUT "PC / RGB" (PC / RGB)

WIDE (Wide mode select)

Wide mode "Normal"

Wide mode "Natural wide"

Wide mode "Zoom"

Wide mode "Zoom (Caption-IN)"

Wide mode "Full"

PICTURE

Screen Saver "Rotation-On"

Screen Saver "Rotation-Off"

Screen Saver "White pattern-On"

Screen Saver "White pattern-Off"

RS-232C

9600 bps

8 bits

2 bits

-

RS232C COMMAND

(ASCII)

C03

C00

C01

C09

C0A

C0B

C22

C23

C24

C25

C10

C0F

C26

C27

C28

C29

C30

C46

C47

C5F

C60

EXAMPLE : POWER ON (C00)

HEX

ASCII

FUNCTION CODE / END CODE

43h 30h 30h 0Dh 0Ah

'C' '0' '0' [CR] [LF]

Page 6

-6-

Terminals for PC

CONFIGURATIONS OF PC TERMINALS

PC IN (D-SUB) TERMINAL

Terminal : HDB15-PIN

Connect the display output terminal of computer to this terminal with VGA Cable (supplied). When connecting the Macintosh

computer, the MAC Adapter (not supplied) is required.

Red Input

Pin Configuration

5

34

10

9 678

15

14

13

1

Green Input

2

Blue Input

2

1

12

11

3

Sense 2

4

Ground (Horiz.sync.)

5

Ground (Red)

6

Ground (Green)

7

Ground (Blue)

8

No Connect

9

Ground (Vert.sync.)

10

Sense 0

11

Sense 1

12

Horiz. sync.

13

Vert. sync.

14

15

Reserved

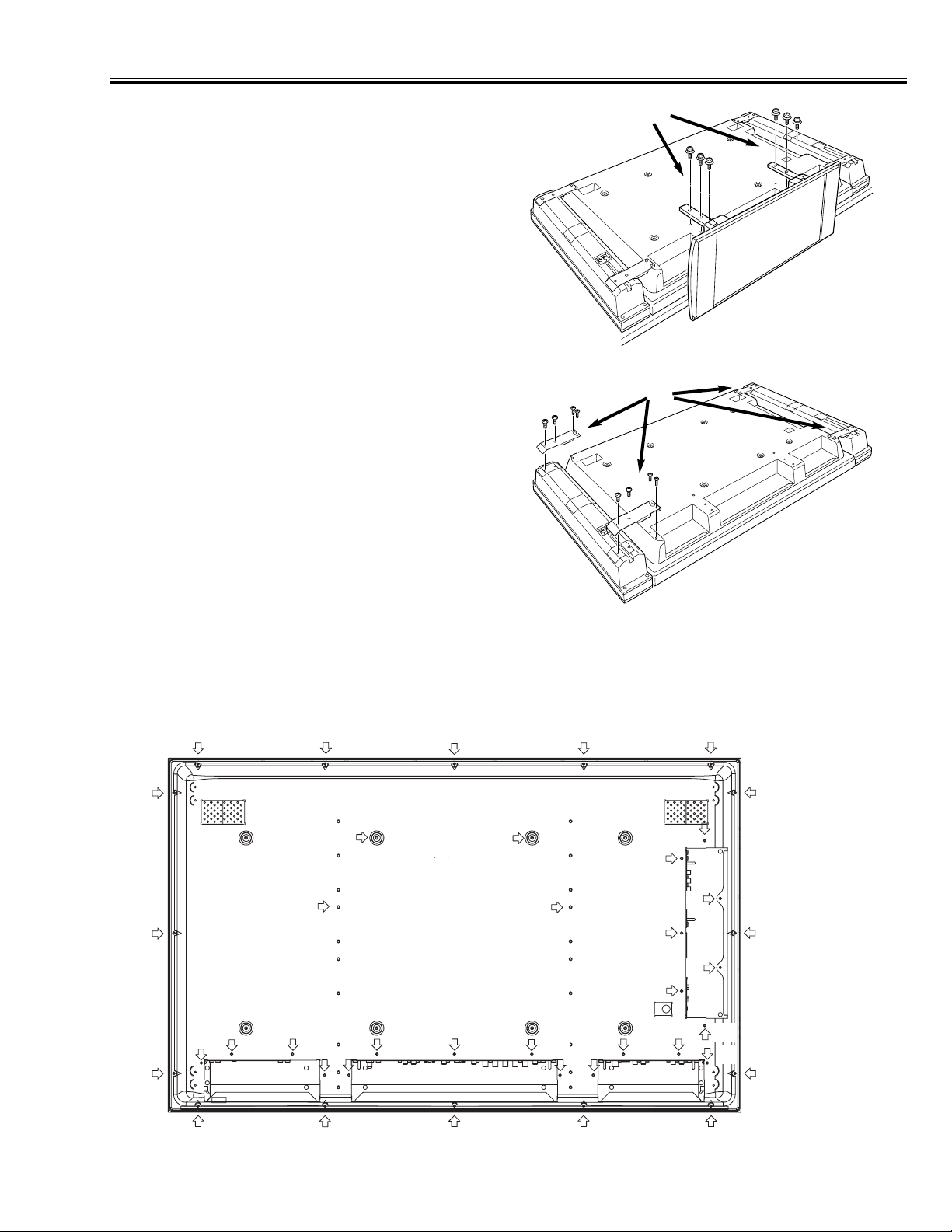

MAC ADAPTER (NOT SUPPLIED)

Set Slide Switches as shown in the table below depending on RESOLUTION MODE that you want to use before

you turn-on Plasma Monitor and computer.

Slide Switches (1 ~ 6)

ON

OFF

ON

2 3 4 5 6

1

DIP

13” MODE (640 x 480)

16” MODE (832 x 624)

19” MODE (1024 x 768)

21” MODE (1152 x 870)

1 2 3 4 5 6

ON

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

Page 7

A

B

A

B

B

B

A

A

A

A

A

A

A A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

-7-

■ Mechanical Disassemblies

■ Optional Stand Removal

1.Put the PDP Monitor Display with the screen face down

on the flat desk.

CAUTION : When placing the display with the face down,

lay the soft cloth under the screen to protect

the screen surface. And make sure there is

nothing to damage the screen surface like a

screw or small part near by before placing the

display.

2.Remove 6 Screws (A). (Fig. 1)

■ Optional Speaker Removal

Fig. 2

Fig. 1

A

1.Remove speaker lead wires (R & L).

2.Remove 16 Screws (B) and 4 plates. (Fig. 2)

B

1. Cabinet Back Removal (Fig. 3)

Remove screws (A,B) and remove Cabinet Back as Fig. 3.

A (36pcs: 4X8), B (4pcs: 5X16)

Fig. 3

Page 8

-8-

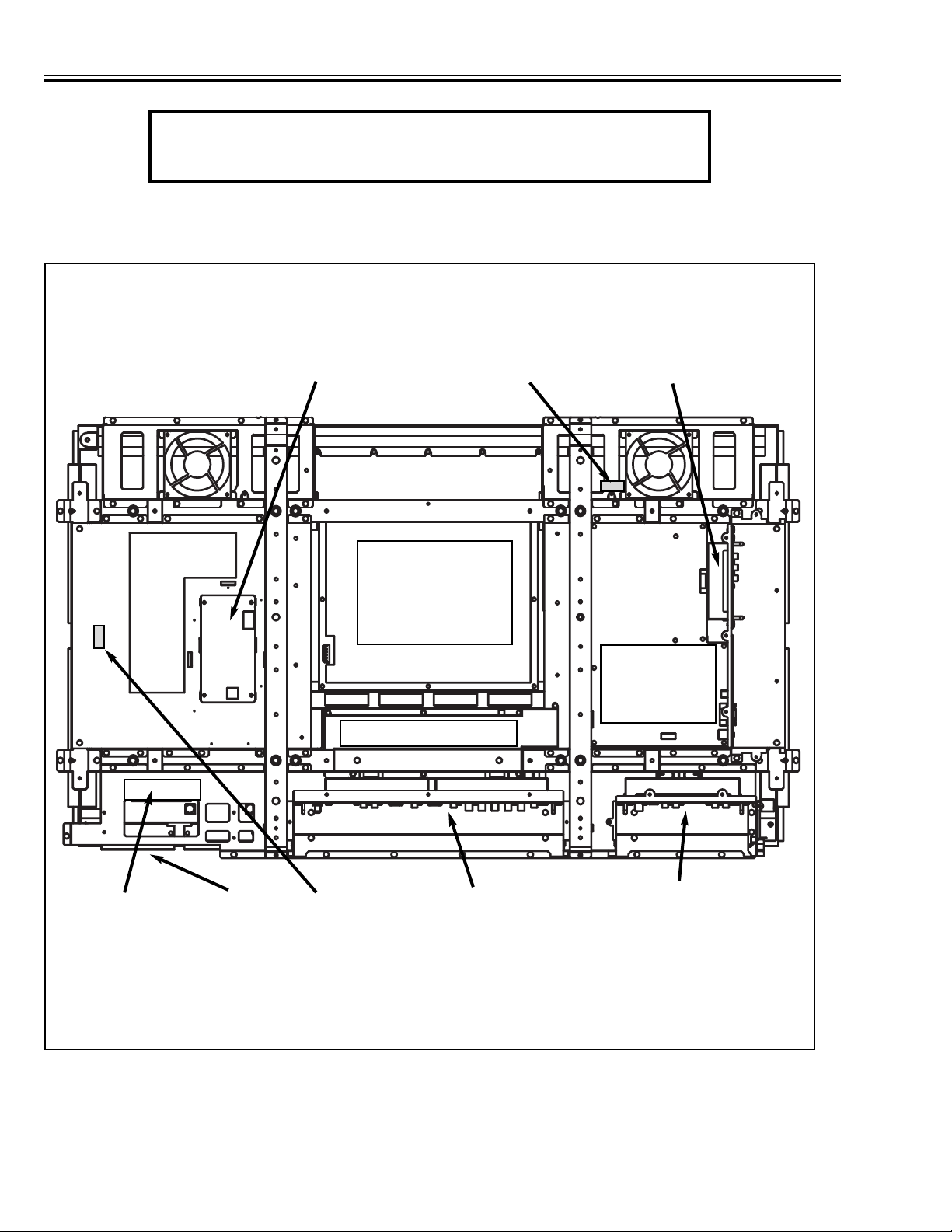

Location of Circuit Board

Mechanical Disassemblies

Sensor

Unit (A)

Jack

Unit (D)

Main

Unit

(PANEL)

Power

Unit

Sub CPU Unit

Sub Power Unit

+

Shield Plate

RC/RS2324

Unit

Front

Unit

Jack

Unit (C)

Contact Unit

+

Jack Unit (A)

Fig. 4

Sensor

Unit (B)

Page 9

-9-

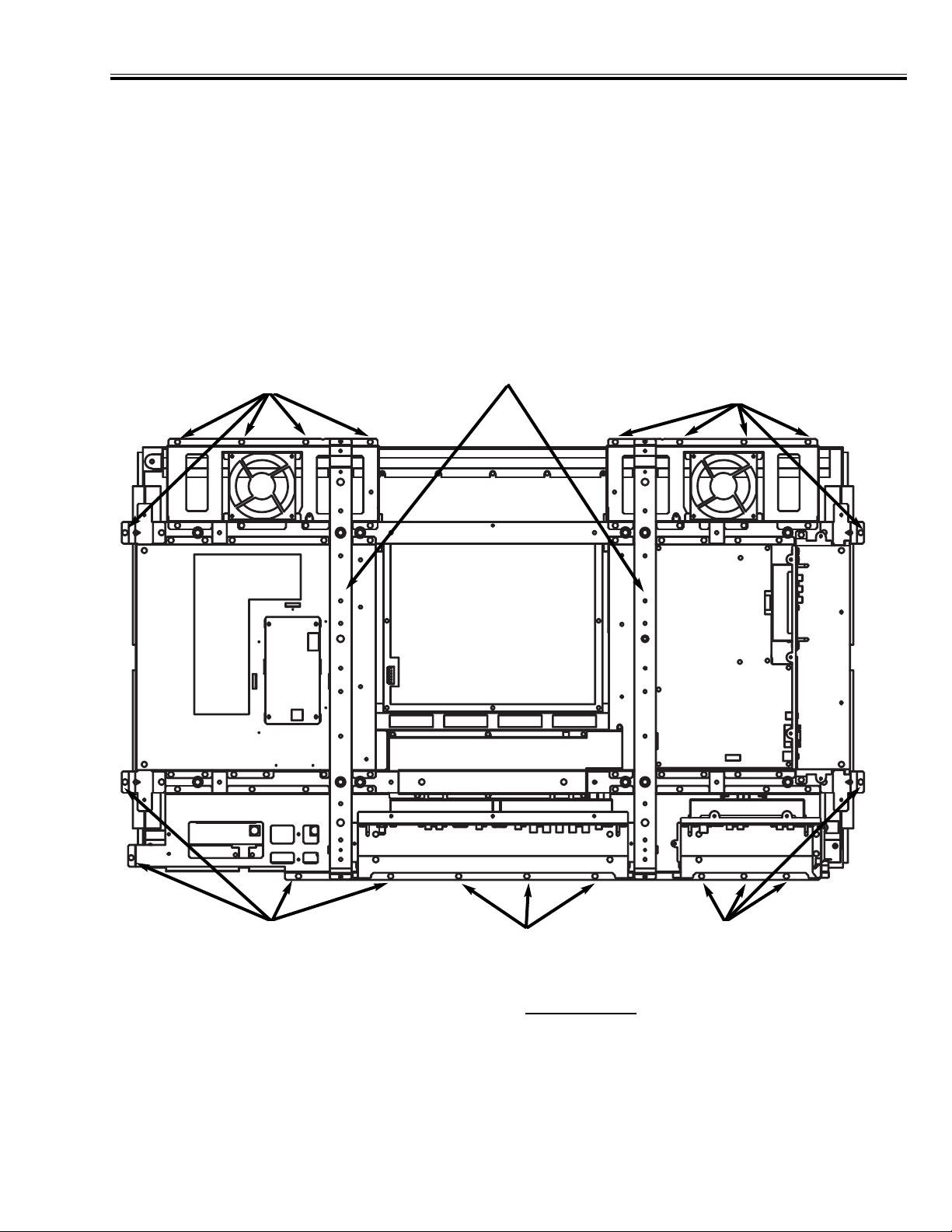

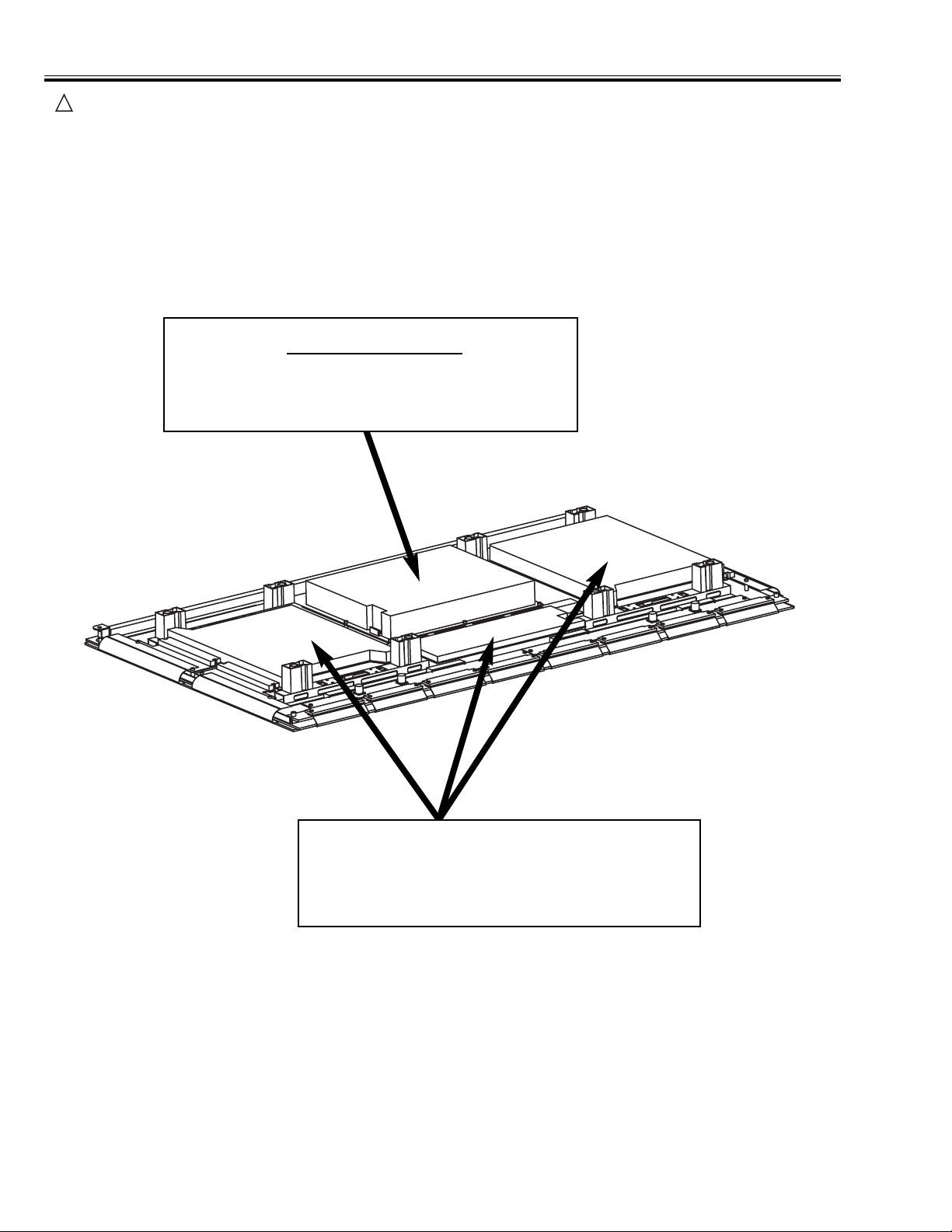

2. Panel Module and Chassis Removal (Fig. 5)

1) Remove 21 screws (C: 4X8). (Fig. 5)

2) Remove Flat Cable from Front Unit (R/C AMP. or Power SW ...etc.) to Sub CPU Unit (K8H).

Note: This cable is fixed with another cables by ferrite core. After servicing, it is necessary to be fixed to previous

position.

3) Remove chassis with Panel Module to have Panel Holders and lift up.

4) Place chassis with the face down to the desk with soft cloth.

[ATTENTION]

This PDP monitor is used the different kind of screw. Using correct screw is needed to avoid the damage.

Mechanical Disassemblies

C

C

C

C

C

Fig. 5

Panel

Holder

Page 10

-10-

3. Chassis Removal (Fig. 6)

To remove chassis from Panel Module.

1) Remove screws D (8pcs: 5X40).

2) Lift up the chassis to have Panel Holders and remove one side of the wire between Main Unit (K7S) and Panel

Module. (Recommended to remove the connector of Panel Module Side.)

3) Remove the connector of 2 black wires between screw (AA) and Panel Module. (Recommended to remove the

terminal of Panel Module Side.)

4) Remove the screw (A) and Yellow - Green wire.

5) Loose the screw (B) and remove the grounding terminal of type “U”.

6) Remove the connectors of (C), (D), (E) and (F) of Panel Power Unit.

7) Lift up Panel Holders and remove the chassis from Panel Module with Panel Power Unit.

8) Remove screws and wires of Panel Power Unit and remove Panel Power Unit from Panel Module.

Note: If the cable is fixed by ferrite core or CV band (fixer), remove it as the need arises. After servicing, it is neces-

sary to be fixed again to previous position.

Mechanical Disassemblies

D

D

D

D

Panel Power Unit

Main

Unit

K7S

(C), (D), (E), (F)

(A)

(B)

(AA)

Fig. 6

[NOTE]

Can not clean Panel surface or Optical Filter after assembling Panel Module, if caught the dust to them.

Page 11

-11-

4. Optical Filter Removal

Cabinet Front includes Optical Filter to protect the damage of Panel, improve picture quality, or prevent exposure of

interference. For removal of Optical Filter, remove screws of Fig.7-1 and Fig.7-2.

[NOTE]

The Optical Filter is easy to be damaged. Do not touch directly by hand. If there is the dust, remove it by watery

neutral detergent.

5. Servicing of Unit

Remove screws which fixed PWB for servicing unit.

For Sub Power Unit, remove the shield plate at first.

For Jack Unit, remove terminal plate together.

Note: If the cable is fixed by ferrite core or CV band (fixer), remove it as the need arises. After servicing, it is neces-

sary to be fixed again to previous position.

6. Servicing of Panel Power Unit

Panel Power Unit is not included in Panel Module. Can be ordered. (Refer to parts list.)

The inside parts of Panel Power Unit are not supplied for servicing.

Fig. 7-2

■ PDP Panel Replacement

For change of PDP Panel (Module), proceed 1 to 3.

Mechanical Disassemblies

Fig. 7-1

Page 12

-12-

■ Flat Cable Removal

This set is used 3 kinds of connector for flat cable. For removal of cable, refer as below not to damage.

■ For Gasket

The gasket is provided to prevent exposure of interference for other radio and television receptions.

The gasket should be

replaced on previous positions after servicing.

For removal of flat cable, slide hook of

both sides.

For insert and fixing, slide hook to pre-

vious position after inserting the flat

cable.

Type A Type B Type C

For removal of flat cable, lift up hook of

both sides.

For insert and fixing, hold down hook

after inserting the flat cable.

For removal of flat cable, pull off only.

For fixing , insert into socket.

Cable

Cable

Cable

Mechanical Disassemblies

Page 13

-13-

■ Notice for service of Unit

In below Unit, can be repaired inside parts or unit itself. Order service parts for repair.

Mechanical Disassemblies

Sensor

Unit (A)

Jack

Unit (D)

Main

Unit

(PANEL)

Power

Unit

Sub CPU Unit

Sub Power Unit

+

Shield Plate

RC/RS2324

Unit

Front

Unit

Jack

Unit (C)

Contact Unit

+

Jack Unit (A)

Sensor

Unit (B)

Page 14

-14-

Mechanical Disassemblies

Do not remove these units.

For changing Panel, it is necessary to change

these all units too.

Refer to parts list.

Attention

Below 3 Units are included with Panel for PDP Module. Do not remove from Panel.

For changing Panel, it is necessary to change these all units together.

!

P

anel Power Unit

This is not included in Panel Module.

For changing Panel Module, remove and use it.

Page 15

-15-

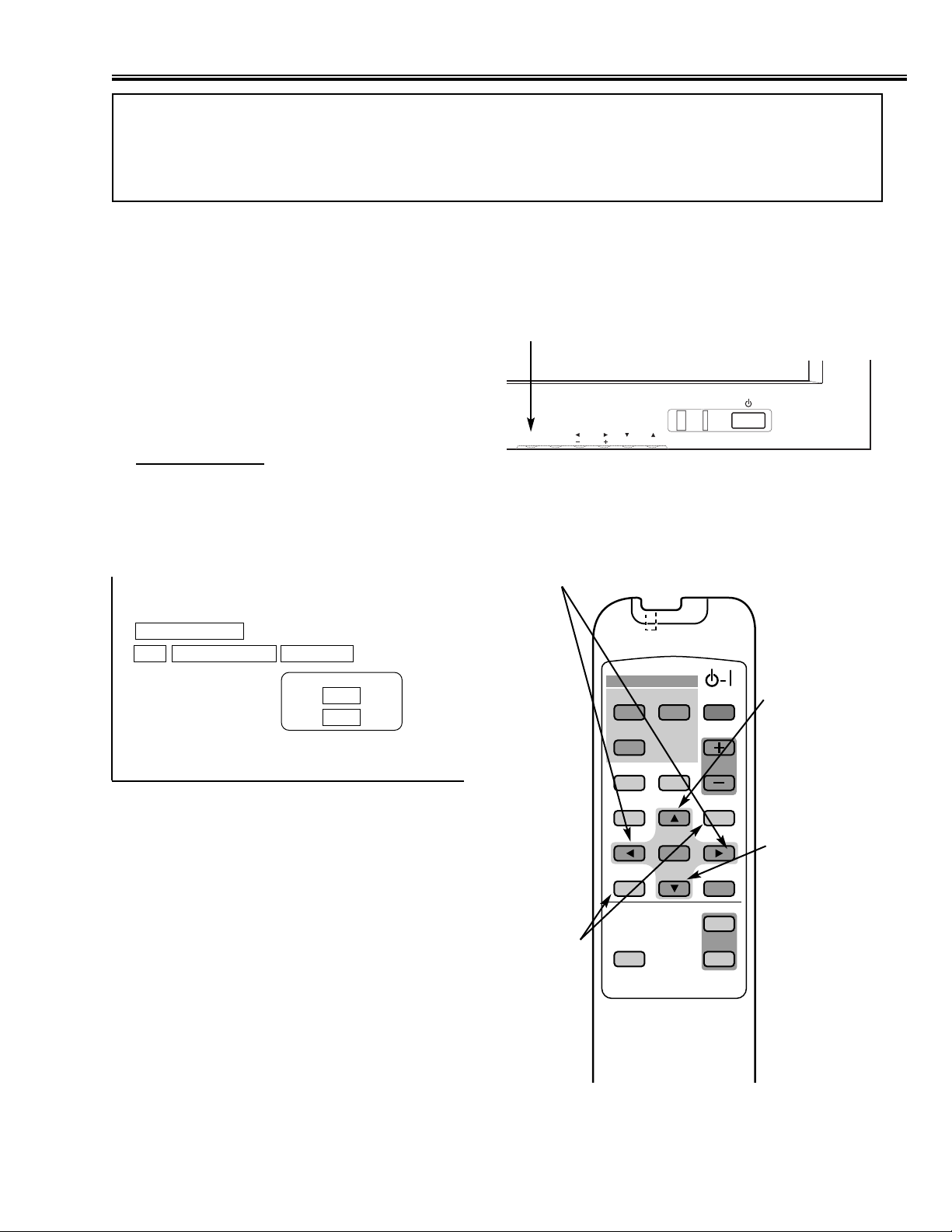

■ Adjustment

Before Adjustment

This adjustment is done to enter Service Mode by Remote

Control Unit.

■ To enter Service Mode

Quick operation is needed to enter Service Mode.

(1) Turn the monitor on.

(2) Press and hold the MENU button on the monitor.

(3) Keep item (2) and press the STATUS button and

release the both buttons.

(4) Within 2 seconds after item (3), press the MUTE

button to appear the Service Mode Display.

■ Service Mode Display

■ To return to the Normal Mode

Once turn the Monitor off by pressing “POWER” button on the monitor or remote control unit and turn it on again.

MENU Button

(←) / (→)

To select :

Adjustment Item

or Data Setting

To enter

Service Mode

STATUS

MUTE

(↑)

● Adjustment :

UP

● Data Setting

(

+)

(↓)

● Adjustment :

DOWN

● Data Setting

(

–)

Av-Dynamic

Cont0 63 (3F)

Main

Sub

42H1

103

040

CAUTION

The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust

the following adjustments except requiring the readjustments in servicing otherwise it may

cause loss of performance and product safety.

OK

INPUT

MENU

VOLUME

VIDEO

PC/RGB

WIDE

INPUT

COMPONENT

OFF TIMER

ON-OFF

VOLUME

PICTURE

MOVE UP

MUTE

STATUS

F

OK

M

OVE DOW

N

MENU

POWER

ON

OFF

Page 16

-16-

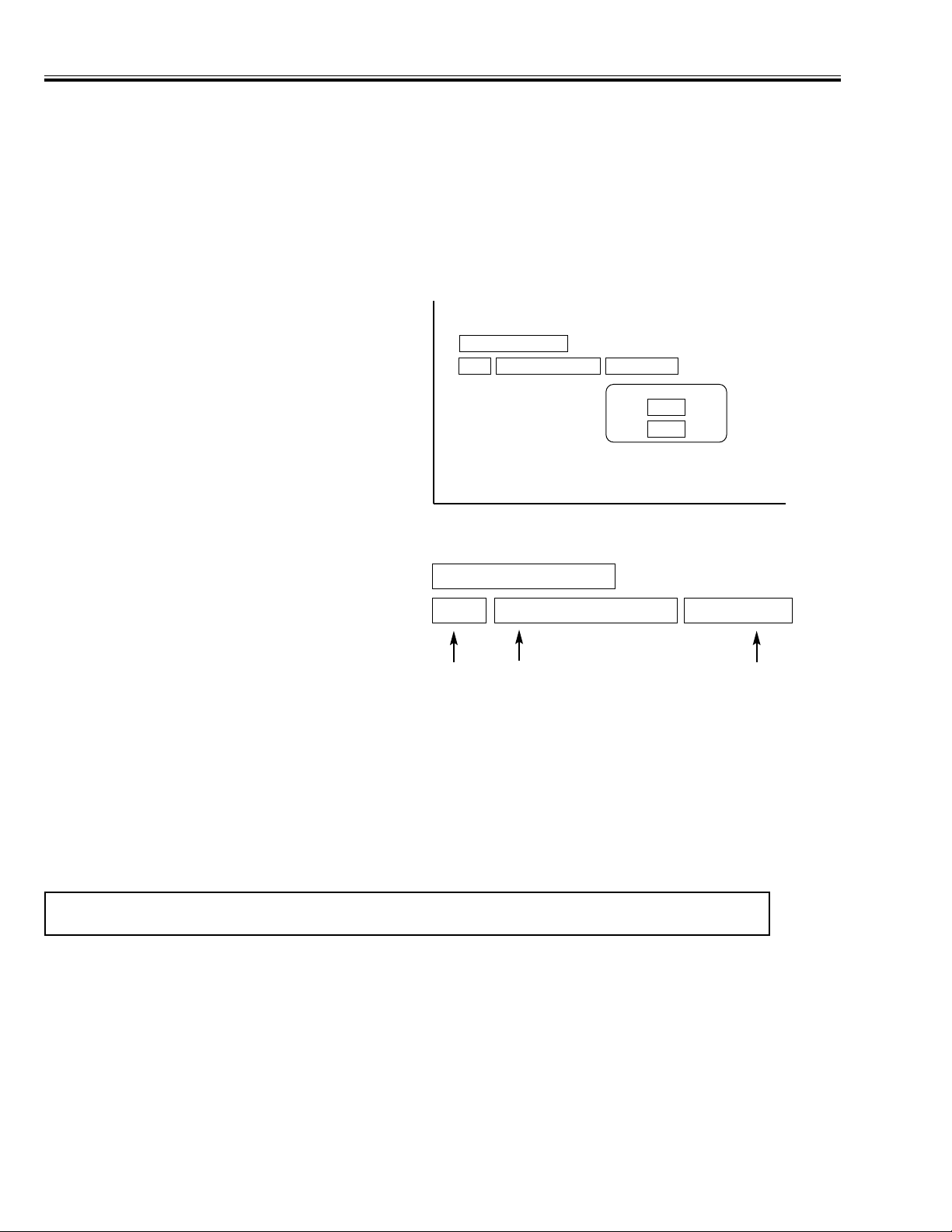

■ To adjust

The next 2 pages show Data for adjustment.

To select adjustment item, press (↑) button on the remote control unit.

To adjust data, press (→) button ( The characters of data become yellow.) and press (↑) or (↓) button to change

data.

The all data adjusted in service mode memorizes into non-volatile memory IC.

Note: In the explanation all buttons are indicated for remote control unit without any notice.

Service Mode Display

Av-Dynamic

1) Select adjustment item by (↑) but-

ton.

Adjustment item displays in order. To reverse

adjustment item, press

(↓) button.

3) Adjust the data by (↑) (↓) button.

To adjust another item, press (←) button to

change color of characters of adjustment item

and repeat 1) to 3).

Select by (↑) Button

and

Press

(→)

Button

( )

Hex decimal data

Adjust by (↑) or

(↓) Button.

4) To exit the Service Mode.

To exit the service mode, press POWER ON-

OFF button on the monitor or remote control

unit.

2) Press (→) button to change color

of characters (of data).

The character of data become yellow by pressing

(→)

button.

0 Cont 63 (3F)

Adjustment Item

Data

Number

Av-Dynamic

Cont0 63 (3F)

Main

Sub

42H1

103

040

Adjustment

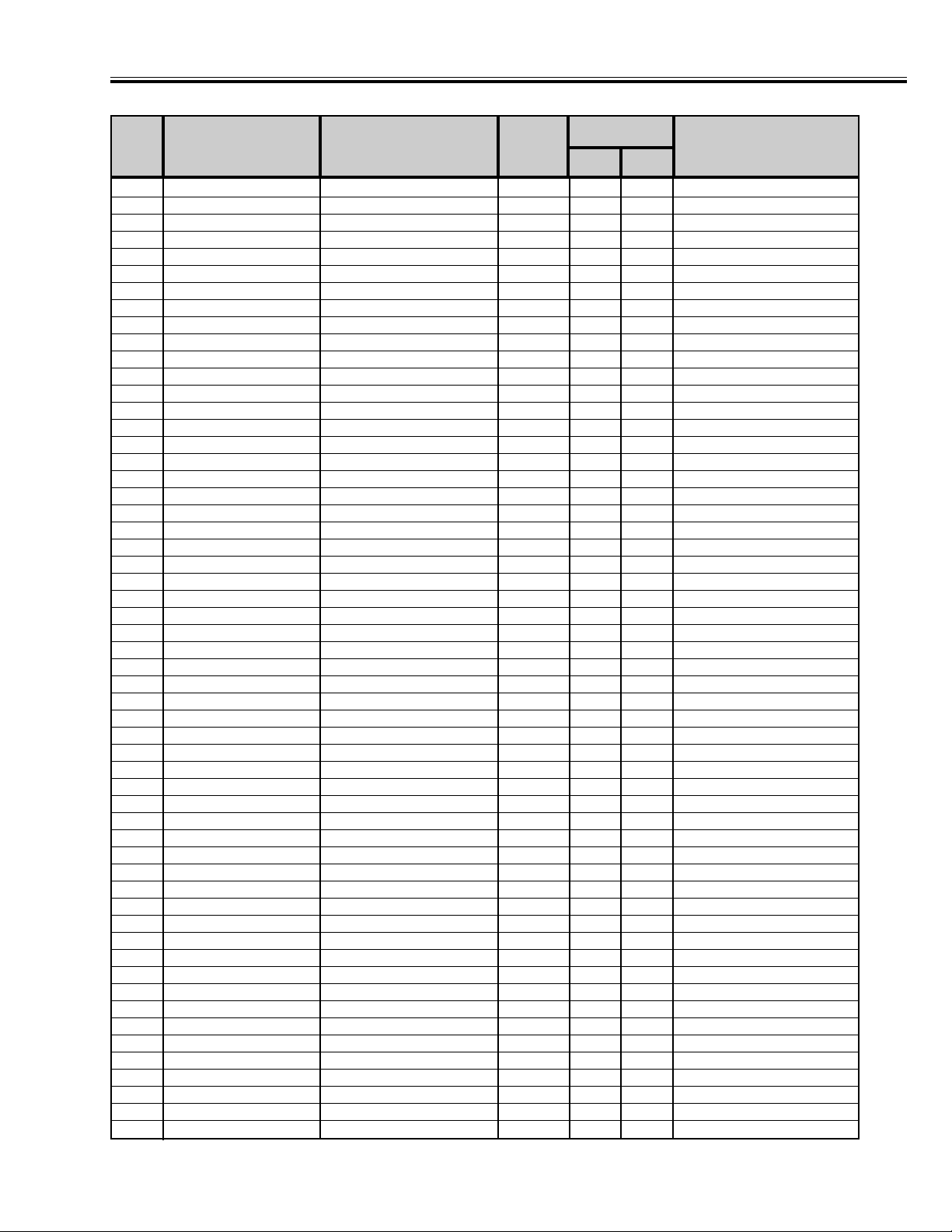

Page 17

-17-

0 AV-Dynamic Contrast 63 0 63 Picture Menu (Dynamic)

1 Brightness 31 0 63

2 Color 42 0 63

3 Tint 0 -31 32

4 Sharpness 15 0 30

5 AV Standard Contrast 50 0 63 Picture Menu (Natural)

6 Brightness 31 0 63

7 Color 31 0 63

8 Tint 0 -31 32

9 Sharpness 15 0 30

10 AV Cinema Contrast 37 0 63 Picture Menu (Cinema)

11 Brightness 32 0 63

12 Color 22 0 63

13 Tint 0 -31 32

14 Sharpness 13 0 30

15 PC Graphic Contrast 63 0 63 Picture Menu (Graphic)

16 Brightness 31 0 63

17 Color 45 0 63

18 Tint 0 -31 32

19 --------------- -- -- -20 PC Standard Contrast 40 0 63 Picture Menu (Standard)

21 Brightness 31 0 63

22 Color 31 0 63

23 Tint 0 -31 32

24 --------------- -- -- -25 PC-Text Contrast 31 0 63 Picture Menu (Text)

26 Brightness 31 0 63

27 Color 26 0 63

28 Tint 0 -31 32

29 --------------- -- -- -30 Sub Menu AV Contrast 6Bh 00h FFh Composite, S-Video

31 Brightness 33h 00h FFh

32 Color-S 78h 00h FFh S-Video

33 --------------- -- -- -34 Tint FFh 80h 7Fh

35 Sharpness 0Fh 00h 1Fh 0Fh=9415add.5Dh:78h

36 Sub Menu PC Contrast 61h 00h FFh

37 Brightness 32h 00h FFh

38 Color 80h 00h FFh

39 Tint 00h 80h 7Fh

40 Sharpness 40h 00h FFh

41 Sub Menu AV-D2-D4 Contrast 5Bh 00h FFh D2–4 Input

42 Brightness 32h 00h FFh

43 Color 80h 00h FFh

44 Tint FAh 80h 7Fh

45 Sharpness 40h 00h FFh

46 Sub Menu AV-D1 Contrast 6Dh 00h FFh D1 Input (480i)

47 Brightness 33h 00h FFh

48 Color C0h 00h FFh

49 Tint 00h 80h 7Fh

50 Sharpness 0Ch 00h 1Fh 0Fh=9415add.5Dh:78h

51 Color Temp H-AV Red DCh 00h FFh AV Color Temperature (High)

52 Green F0h 00h FFh

53 Blue FFh 00h FFh

54 Color Temp M-AV Red FFh 00h FFh AV Color Temperature (STD)

55 Green FFh 00h FFh

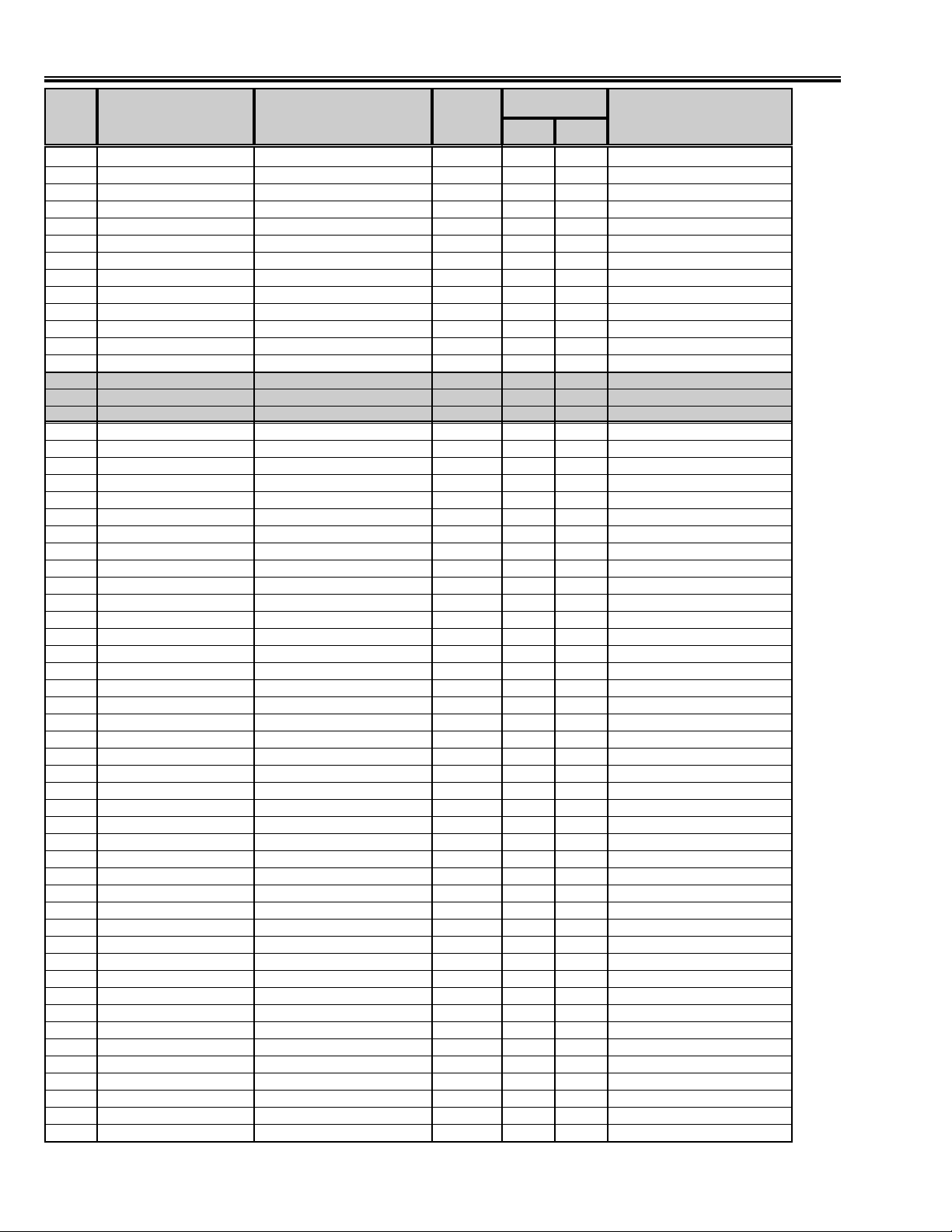

■ Service Adjustment Data Table

Adjustment

• All data except in gray box area is fixed. Do not change for correct operating.

• Data in gray box area is initial. Can be set according to adjustment information.

No.

NoteAdjustment Name

Data Area

Adjustment Item

Initial

Data

Min Max

Page 18

-18-

Adjustment

No.

NoteAdjustment Name

Data Area

Adjustment Item

Initial

Data

Min Max

56 Blue FFh 00h FFh

57 Color Temp L-AV Red FFh 00h FFh AV Color Temperature (Low)

58 Green EBh 00h FFh

59 Blue CDh 00h FFh

60 Color Temp H-PC Red DCh 00h FFh

PC Color Temperature (High)

61 Green F0h 00h FFh

62 Blue FFh 00h FFh

63 Color Temp M-PC Red FFh 00h FFh

PC Color Temperature (STD)

64 Green FFh 00h FFh

65 Blue FFh 00h FFh

66 Color Temp L-PC Red FFh 00h FFh

PC Color Temperature (Low)

67 Green EBh 00h FFh

68 Blue CDh 00h FFh

69 Cont AV Red FFh 00h FFh White Balance Adjustment

70 Green FFh 00h FFh

71 Blue FFh 00h FFh

72 Bright AV Red 80h 00h FFh Black Balance Adjustment

73 Green 80h 00h FFh

74 Blue 80h 00h FFh

75 Cont PC Red 00h 00h FFh W/B (Differential Data to AV)

76 Green 00h 00h FFh

77 Blue 00h 00h FFh

78 Bright PC Red 00h 00h FFh B/B

(Differential Data to AV)

79 Green 00h 00h FFh

80 Blue 00h 00h FFh

81 Cont PC Red 00h 00h FFh W/B

(Differential Data to AV)

82 Green 00h 00h FFh

83 Blue 00h 00h FFh

84 Bright PC Red 00h 00h FFh B/B

(Differential Data to AV)

85 Green 00h 00h FFh

86 Blue 00h 00h FFh

87 Cont-AV-D1 Red FEh 00h FFh W/B

(Differential Data to AV)

88 Green 00h 00h FFh

89 Blue 00h 00h FFh

90 Bright-AV-D1 Red 00h 00h FFh B/B

(Differential Data to AV)

91 Green 00h 00h FFh

92 Blue 00h 00h FFh

93 Sharpness-AV50 Sharpness 10 0 – Filter

94 Sharpness-AV60 Sharpness 6 0 – Filter

95 Sharpness-PC Sharpness 0 0 – Filter

96 Sharpness-HD Sharpness 10 0 – Filter

97 Snd-Sep Snd Sep 3Fh 0 3Fh Sound Separation

98 AFC Tuning-TV ABh 21Ch 000h FFFh

99 ACh 218h 000h FFFh

100 AFC Tuning-Video50 ABh 21Ch 000h FFFh

101 ACh 21Ch 000h FFFh

102 AFC Tuning-Video60 ABh 21Ch 000h FFFh

103 ACh 21Ch 000h FFFh

104 AFC Tuning-Video BEh 06h 00h FFh

105 AFC Tuning-D1 ABh 298h 000h FFFh

106 ACh 5D1h 000h FFFh

107 AFC Tuning-525i ABh 298h 000h FFFh

108 ACh 5D1h 000h FFFh

109 Color System Auto Auto/NTSC only

110 Wide Squeeze Off Off/On

111 Display Language English English/Japanese

112 PDP COLOR8 PDP Internal Pattern Display (∆ Key)

113 PDP WHITE PDP Internal Pattern Display (∆ Key)

Page 19

-19-

■ Setting the fixed data

(1) Receive the good quality signal.

(2) Enter the Service Mode

(3) Confirm fixed data to be same as data table. If it is different, change to

correct data.

(4) Return to the Normal Mode

This adjustment is controlled by the CPU (IC801) thorough the IIC Data Bus Line in the chassis, and those

adjustment data are memorized into the memory IC (IC808). Therefore, SUB CPU Board or the memory

IC (IC808) is replaced, data of those will be disappeared. Readjustment should be made. Initial data is

provided in the CPU ROM ,when memory IC (IC808) is replaced with new one, CPU ROM data is loaded

into the memory. (Data list will be shown in previous 2 pages.) Initial data is provided to operating the

monitor basically. For operating the monitor quality performance, further adjustment required following

chassis electrical adjustment.

Adjustment

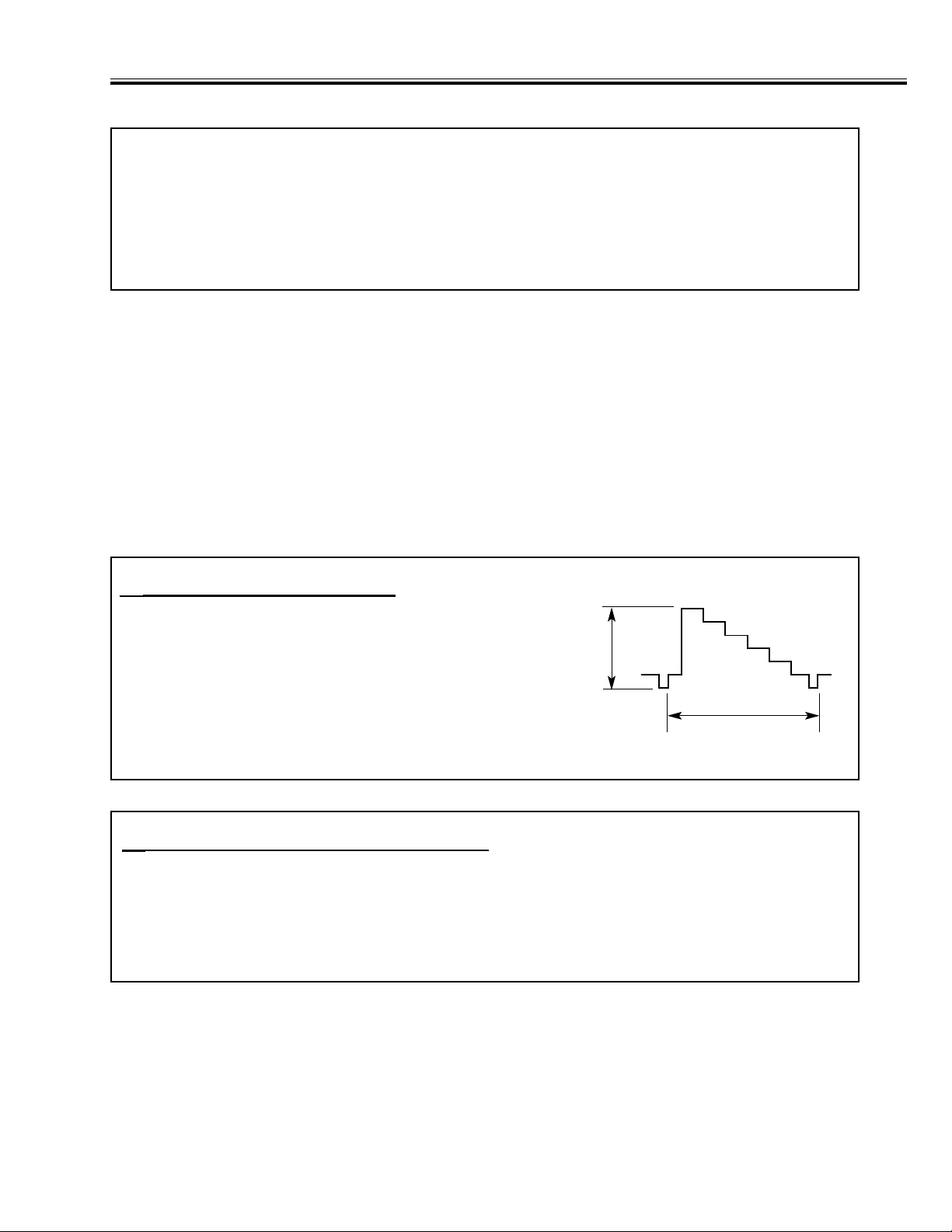

■ Y-Le

vel Adjustment

Pattern : Color Bar Pattern

Equipment : Oscilloscope

Connection: S-Terminal(K1912) of Monitor Out

Y– Signal – Ground

Note: 75Ω Terminated

Adjustment: To be 1±0.1Vp-p by VR7001 in Main

Unit.

1±0.1Vp–p

White100%

(H)

■ Circuit Adjustment

■ White Balance Adjustment

Pattern : White Pattern

Condition : Screen Size : FULL, Picture Image Level : NATURAL

Adjustment : Enter the service mode, select item No. 69 [ Red ], 70 [ Green ] or 71 [ Blue ] (Cont AV), and

adjust a proper white balance.

Note : After adjustment, confirm white balance again by normal picture.

● Input Signal : 1.0Vp-p / 75Ω terminated

Page 20

-20-

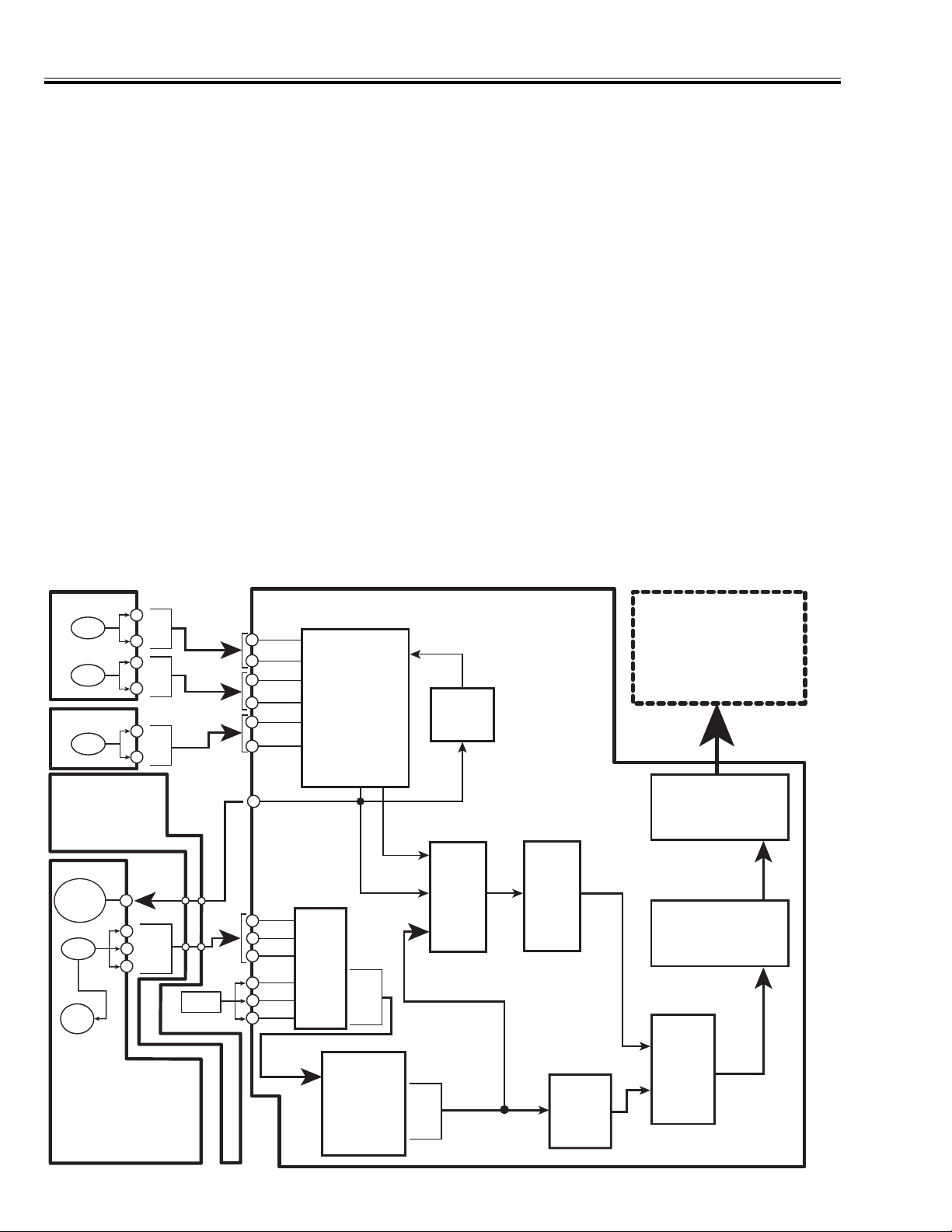

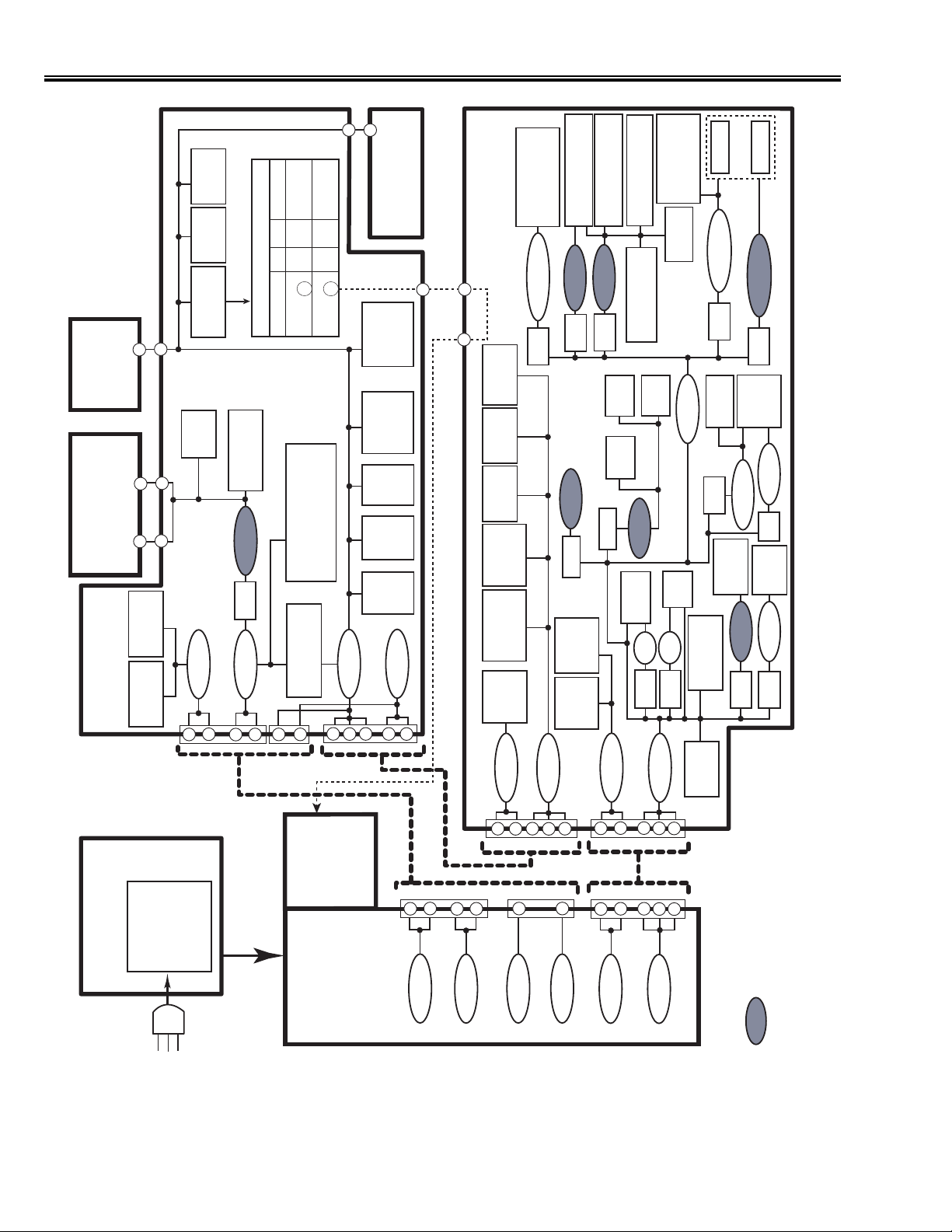

■ Circuit Block Diagram

■ Video

Signal Flow

(1) CVBS, Y/C

CVBS (Composite Video) or Y/C signal from AV1, AV2 or AV3 terminal is input to AV SW IC (IC1001) and

selected signal.

CVBS signal selected by IC1001 is input to 3 Dimension Y/C Separation IC (IC7101) and input to IC1001 again.

(In case of NTSC Signal) On the other hand it is input to Digital Decoder IC (IC401) and output for Monitor Out

signal (CVBS only).

(2) RGB, Component

RGB or Component signal from AV4 terminal is output for “Through Out” terminal and input to RGB /

Component SW IC (IC1123) and selected to D-SUB RGB signal. Selected signal by IC1123 is input to IC1124.

(3) Decoder, I/P Conversion

CVBS or Y/C signal from IC1001 or Component signal (480i) from IC1124 is input to Digital Decoder IC

(IC401). Component signal from IC401 is input to I/P (interlace / Progressive) Conversion IC (IC501).

(4) A/D Conversion

RGB ( or Progressive Component) signal from IC1124 is input A/D Conversion IC (IC207) and converted.

(5) Panel Drive

Signal from IC501 or IC207 is input to RGB Matrix IC (IC601) and proceeded for picture control.

Signal from IC601 is input to Main Scaler IC (IC301) and LVDS Interface IC (IC751) and input to PDP Panel

Module.

Jack A

AV1

AV2

Jack D

AV3

Sub CPU

Jack C

Monitor

Out

AV4

Through

Out

CVBS1

Y/C1

CVBS2

CVBS3

M/O

CVBS

R/Pr/Cr4

G/Y4

B/P

Y/C2

Y/C3

b/Cb4

PC Analog Input

D-SUB

CVBS1

Y/C1

CVBS2

Y/C2

CVBS3

Y/C3

M/O CVBS

IC1123

RGB,

Component

SW

7

R/Pr/Cr4

9

G/Y4

11

b/Cb4

B/P

1

R

3

G

5

B

RGB

Y/P

b/Pr

Y/Cb/Cr

IC1001

AV S w itch

1

3(Y)

5(C)

7

9(Y)

11(C)

13

15(Y)

17(C)

21

19

15

1(R/Pr/Cr)

3(G/Y)

5(B/P

53

R/Pr/Cr

G/Y4

B/P

b/Cb

b/Cb)

49(Y)

51(C)

56(Y)

58(C)

RGB

Y/C

CVBS

b/Cr

Y/C

CVBS

Y/C

IC1124

RGB,

Component

SW

R/Pr/Cr

21

G/Y4

19

15

b/Cb

B/P

84(Y),83(C)

88

73(Y)

71(C)

75

6(R/Cr)

5(G/Y)

b)

4(B/C

IC401

Digital

Decoder

Main

IC7101

3D Y/C Sep.

For NTSC

RGB

Y/C

b/Cr

IC501

Interlace/

Progressive

Converter

RGB

b/Pr

Y/P

RGB

Y/P

b/Pr

IC207

A/D Converter

7(R/Pr)

15(G/Y)

22(B/Pb)

PDP

Panel

Module

RGB

IC751

LVDS

Interface

IC301

Main Scaler

RGB

IC601

RGB Matrix

Page 21

-21-

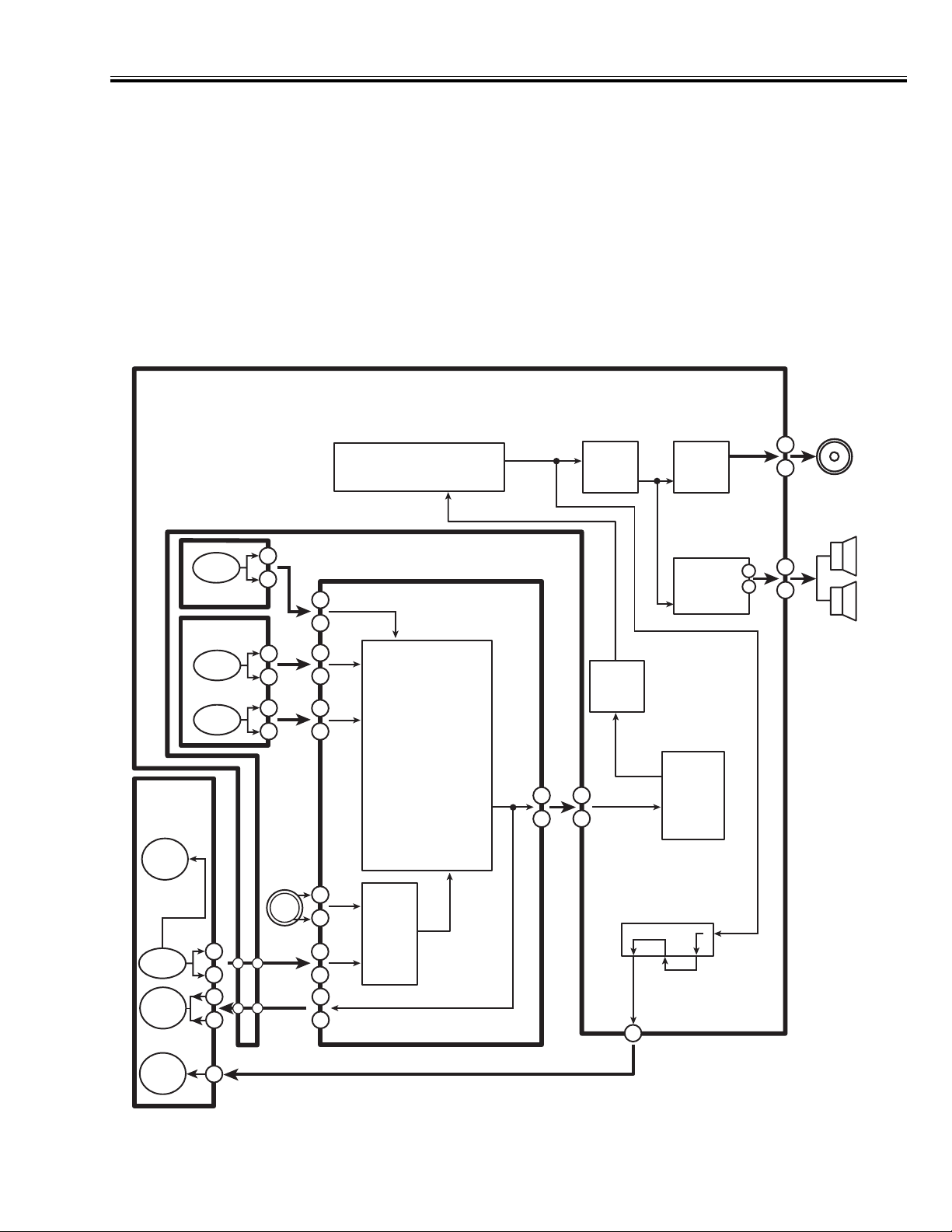

Circuit Block Diagram

■ Audio

Signal Flow

Sound signals (L & R) from AV1, AV2 or AV3 are input to AV SW IC (IC1001) and selected.

Sound signals from AV4 terminal are output for “Through Out” terminal.

Sound signals from D-SUB or AV4 are input to IC1001 after selected by SW IC (IC1002) .

The selected signals by IC1001 are output to Monitor Out and also input to below ICs.

Q-Sound IC (IC002) ➔ AMP IC (IC003) ➔ Audio Control IC (IC001) ➔ BBE IC (IC121)

Finally signals from IC121 are input to Digital AMP IC (IC071) for speakers and AMP IC (IC031) for Head Phone.

Note: Sound signals from IC001 is input Woofer AMP IC (IC004) too.

Sub CPU

Jack C

Through

Out

AV4

Monitor

Out

AV3

Jack D

Jack A

AV1

AV2

L

R

L

R

IC031

IC001

Audio Control

22(L),21(R)

16(L),15(R)

SURROUND

EFFECTED

IC121

BBE

1(L),24(R)

6(L),19(R)

Head Phone

AMP

BBE

6(L),2(R)

IC071

7(L),1(R)

Digital

IC003

AMP

1

W

Sound AMP

25(L),20(R)

23(L),22(R)

10(L),13(R)

13(L),11(R)

23(L),2(R)

IC002

Q Suond

(Suurround)

6

2

7

IC004

Woofer

AMP

+

-

L

R

L

R

AV3

14(L),16(R)

2(L),4(R)

AV1

8(L),10(R)

AV2

5(L),14(R)

PC

3(L),13(R)

1(L),12(R)

AV4

Monitor Out

PC

L

R

L

R

L

R

L

R

L

R

L

R

L

R

Main

52(L),54(R)

59(L),61(R)

PC

IC1002

PC Sound

Switch

IC1001

AV Switch

L

R

7(L),1(R)

6(L),2(R)

SURROUND

L

R

SELECTED

Head Phone

(Main Unit)

L

R

Speaker X2

L

R

Woofer

Out

W

Page 22

-22-

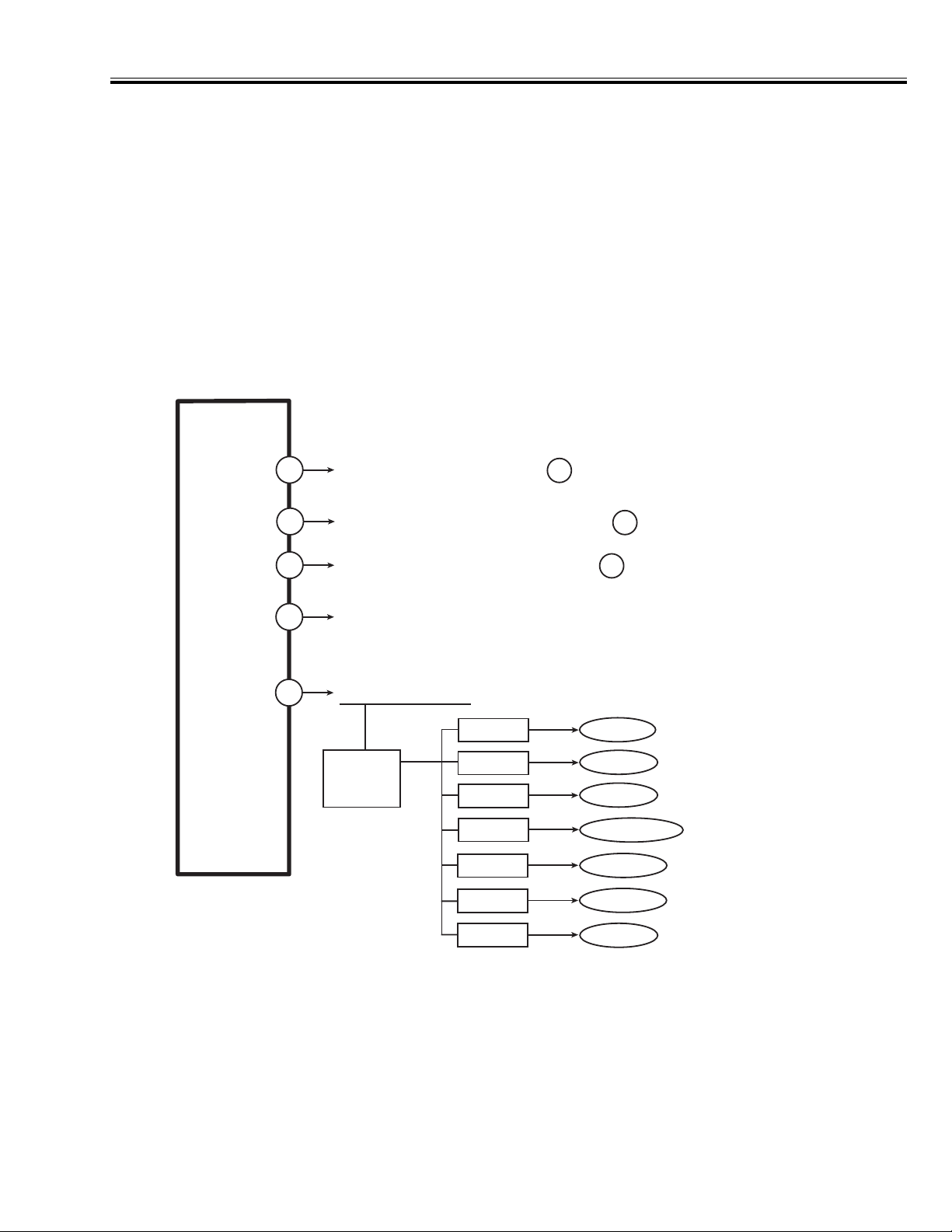

[NOTE]

Refer to next page for Power Fail Circuit

■ Power Supply Lines

Memory

3

3

K8H

K19H

FRONT

A1901

K8N

K19N

5

5

K19M

5

5

Sensor A, B

IC1981,IC1991

K8M

IC808

Reset

IC802

(SUB) CPU

IC801

Reset

IC1822

Fan / Sensor

Control IC1821

5VANA

IC101

H

L

H

Power ON/OFF Table

Line On Off Stand-by

CPUGO

(IC801 48 )

Audio Control, Surround,

4

4

K8J

K20J

L

RC/232C

IC2009

L

H

K8B

PDPGO

(IC801 49 )

Sync.

AMP

IC811/812

DD

Converter

IC821

Mute

AMP

IC807

Line

Switch

IC816

AMP, Woofer AMP, BBE

IC001, 002, 003, 004, 121

Reset

Switch

IC344

K6B

K7S

Sync. Sep.

IC1201

AMP

IC981 / 2

DD Conv.

IC1951

Video

Switch

LVDS

Interface

IC753

3.3VLVDS

IC755

IC1123 / 4

Main Scaler

IC301

Signal Processor

IC303/4/5/6/7/8,IC331

3.3VPIX

2.5VPIX

IC620

IC302

3D Y/C

Reset

2.5VGR

IC7080

IC7081

DD Conv. (Factory)

IC1851

Sync. Processor

IC1251/2/4/6/7

D-RAM

IC7100

IC7101

IC8902

3.3VYC

AMP

IC201 / 3

RGB Matrix

IC601

IC602 (Reset)

DD Conv.

IC823

5VDIG

AMP

IC202

IC1401

IC1402

3.3VFPGA

2.5VFPGA

IC610

IC606

Video

Decoder

Reset

IC404

IC415

3.3VDEC

A/D Conv.

IC207

Timing Control

IC401

5VDEC

L402

I/P Conv.

IC501

Fan Drive

IC1823

SUB CPU

Audio AMP

IC071

Fuse

F001

(SUB) POWER

AC IN

12VAUD

K6Q

3

2

Line Filter

6

LF1601/2

9VANA

7

AC IN

Headphone AMP

IC031

K6P

1

1

3

5VSTB

3

4

PANEL

MODULE

(Panel)

3.3VSTB

7

1

5

POWER

K8B

8

2

CN09

Data

Switch

IC803 / 4 / 6

PC Audio

Switch

IC1002

IC309

5

1

AV

Switch

5VSTB

3

4

3

IC1001

9VANA

2

2

CN10

3

3

Reset

Switch

MAIN

3.3VSTB

K6B

8

7

7

3

6

CN07

-5V

IC204

6

6

-5V

IC208

5VDIG

7

8

7

8

Sync. Sep.

DD Conv.

K6A

IC8971

IC822

3.3VAD

IC206

3.3VIP

IC506

: Protected by Power Fail Line 1

9VANA

For Audio

12VAUD

5VSTB

For Analog

For Stand-by

3.3VSTB

9VANA

For Stand-by

5VDIG

For Analog

For Digital

Note

Page 23

-23-

■ Power Fail Circuit

CPU (IC801) is programmed that the set goes to standby mode when there is circuit fail as

below.

1. AUDIO AMP FAIL(2) : Detected the fail of Audio AMP IC (IC071)

2. POWER FAIL (3) : Detected the voltage fail in SUB CPU Unit

( Not used in this model.)

3. POWER FAIL (1) : Detected the voltage fail in SUB CPU Unit (1 point) and Main Unit (6 points).

4. OTHERS

TEMPERATURE FAIL : Detected the temperature fail ( about 80 degree) by thermal sensor IC (IC1981). CPU

communicates to FAN & Sensor Control IC (IC1821) for detection.

FAN FAIL : Detected the fan fail by the communication to FAN & Sensor Control IC (IC1821).

(The set does not go to standby mode in this fail. Display Only.)

IC801

FAN FAIL

TEM. FAIL

P FAIL 2

P FAIL 3

P FAIL 1

52

78

55

56

54

Fan Fail Detect ( To IC1821 37 )

Temperature Fail Detect ( To IC1821 38 )

Sound AMP Fail Detect ( To IC071 17 )

Power Fail Detect (SUB CPU)

Not used in this model.

Power Fail Detect (Main)

5VANA

3.3VYC

2.5VGR

2.5VFPGA

3.3VPIX

2.5VPIX

Q831/2

(SUB CPU)

D102

D7080/1

D7082/3

D601/2

D603/4

D301/2

(SUB CPU)

D201/2

3.3VAD

Page 24

-24-

Power Fail Circuit

When operating the Power Fail Circuit, On-Screen-Display message or LED flashing time is

shown as below.

On-Screen-Display Message

1. FAN FAIL

When the cooling fan is trouble, below message is displayed. This message is displayed for 10 seconds in

every 10 minutes.

2. TEMPERATURE FAIL

When the internal temperature exceeds normal ( approximately more than 80 degrees ), below message is

displayed for 10 seconds and the Plasma monitor will be turned off automatically.

LED Flashing

1. TEMPERATURE FAIL : The color of LED is ‘RED’.

2. POWER FAIL : The color of LED is ‘GREEN’.

3. SOUND AMP FAIL : The color of LED is ‘YELLOW’.

Warning!

Internal fan is trouble, not working properly.

Warning!

Internal temperature is too high.

Time of flashing Fail Name

2Temperature

Time of flashing Fail Number

1P FAIL 1

2P FAIL 3

3P FAIL 1 & 3

Time of flashing Fail Number

1P FAIL 2

Note:

1. In case of overlapped fail, 1 to 3 is repeated in turn.

2. If power fail is detected 3 times in 15 minutes, the monitor will stop operating.

3. If pull the AC cord, the information of these fails will be disappeared.

Page 25

-25-

■ Troubleshooting

No Power

Refer to Schematic Diagram or Power Supply Line, find out the part of trouble.

In advance check the AC cord and power SW to be on.

No Picture

Refer to Schematic Diagram or Chassis Block Diagram, find out the part of trouble.

In advance check the setting mode according to Instruction Manual.

Is LED flashed?

Ye s

Is

the voltage of

all lines in Power Unit

supplied?

No

(All 0V)

Is fuse (F001)

in Sub Power Unit

broken?

No

Ye s

Ye s

No

(or the voltage of some

lines is not supplied.)

After few seconds,

the set is switched off.

Check 'Fail' Circuit to refer

service manual.

Panel Power Unit

is broken.

Check '5VSTB' line in SUB

CPU or Main Unit.

Also check Panel Power

Unit is broken.

Panel Power Unit

is broken.

Ye s

All Mode ?

No

AV1, AV2, AV3

D-SUB, AV4

Is there

signal from IC1123

(15,19,21) in Main

Unit ?

No

Check arround IC1123 in Main Unit.

Also check the line from IC1123 to

AV4, or D-SUB terminal.

Ye s

Check arround IC601, IC301, IC751, or

PDP panel module is broken.

Is there

video signal of

monitor out

Is there

signal from IC1124

(15,19,21) in Main

Unit ?

No

No

Ye s

Ye s

Check arround IC1124 in Main Unit.

Check arround IC1001 or IC7101 in Main Unit.

Also check the line from IC1001 to AV1, AV2,

or AV3 terminal.

Check arround IC401 or IC501 in Main Unit.

Check arround IC207 in Main Unit.

No

480i ?

Ye s

Page 26

-26-

Troubleshooting

No Sound

Refer to Schematic Diagram or Chassis Block Diagram, find out the part of trouble.

In advance check the setting mode according to Instruction Manual.

Ye s

All mode?

No

D-SUB, AV4

AV1 , AV 2, AV3

Check the line from

IC1001 in Main Unit

to AV1, AV2 or AV3.

Is there

sound signal from

monitor out

Ye s

No Sound from Headphone

No Sound from Speaker

No Sound from Woofer

No Sound from Headphone,

Woofer & Speaker

No

Check the line from IC1001

(Pin 52 or 54) in Main Unit to

IC121 via IC002, IC003, IC001

in SUB CPU Unit.

Check around IC1001

in Main Unit.

Check around IC031

in SUB CPU Unit.

Check around IC071

in SUB CPU Unit.

Check around IC004

in SUB CPU Unit.

Check around IC1002 in Main Unit. Also check

the line from IC1001 to D-SUB or AV4 via IC1002.

Page 27

-27-

● System Control (CPU : IC801)

■ Control Port Functions

Pin Name Function I/O Description Note

pin 1 PA3/WR F-CLK I CLOCK for Flash Writing

pin 2 PA4/RD F-DATA I DATA for Flash Writing

pin 3 PA5/RS F-ENABLE I ENABLE for Flash Writing Pull-Up

pin 4 P70/INT0 CHIP SEL I CHIP SELECT (Communication to PIXEL) Pull-Up

pin 5 P71/INT1 V-SYNC I V-SYNC Input (PC/NTSC) NTSC: Positive PC:Depending on input

pin 6 P72/INT2 H-SYNC I H-SYNC Input (PC/NTSC) NTSC: Positive PC:Depending on input

pin 7 P73/INT3 RC I Remote Control Input

pin 8 RES RESET I RESET Input Normal : H Reset : L

pin 9 XT1 XT1 I XT1

pin10 XT2 XT2 I XT2

pin11 VSS1 VSS1 GND

pin12 CF1 CF1 I CF1

pin13 CF2 CF2 I CF2

pin14 VDD1 VDD1 +5V

pin15 P80/AN0 KEY-IN I Key Input

pin16 P81/AN1

LINE1/AV1S2 I DTV Mode : LINE1 / AV1 Aspect Ratio

pin17 P82/AN2

LINE2/AV2S2 I DTV Mode : LINE2 / AV2 Aspect Ratio

pin18 P83/AN3

LINE3/AV3S2 I DTV Mode : LINE3 / AV3 Aspect Ratio

pin19 P84/AN4 N.C.

pin20 P85/AN5 N.C.

pin21 P86/AN6 N.C.

pin22 P87/AN7 SENSOR I SENSOR Input :0 – 5V AD Input Pull-Up (Not Used)

pin23 P30 BUS/OPEN I Open IIC, Write to EEPROM, Open=L Pull-Up

pin24 P31 Q SOUND O Q–Sound ON/OFF Pull-Up

pin25 P32 GIJI ST O Pseudo Stereo ON/OFF Pull-Up

pin26 P33 BBE O

BBEMachBASS IC CTL BBE ON/OFF Pull-Up

pin27 P34 MachBASS O

BBEMachBASS IC CTL Mach3Bass ON/OFF Pull-Up

pin28 P10/SO0 DATA OUT O DATA OUT (Communication to PIXEL) Pull-Up

pin29 P11/SI0 DATA IN I DATA IN (Communication to PIXEL) Pull-Up

pin30 P12/SCK0 CLK I CLOCK (Communication to PIXEL) Pull-Up

pin31 P13/SO1 RX SUB O RS-232C

pin32 P14/SI1 TX SUB I RS-232C

pin33 P15/SCK1 N.C. (Not Used)

pin34 P16/

T1PWML DPMS O DPMS

pin35 P17/

T1PWMH AMP MUTE O AMP Mute = H

pin36 SI2P0/SO2 PHONE I Head Phone Control

pin37 SI2P1/SI2 N.C. (Not Used)

pin38 SI2P2/SCK2 N.C. (Not Used)

pin39 SI2P3/SCK2 N.C. (Not Used)

pin40 PWM1 O N.C. (Not Used)

pin41 PWM0 O N.C. (Not Used)

pin42 VDD2 VDD2 +5V

pin43 VSS2 VSS2 GND

pin44 P00 YELLOW O LED (Yellow) Output ON = H, OFF = L (Not Used)

pin45 P01 GREEN O LED (Green) Output ON = H, OFF = L

Page 28

-28-

Pin Name Function I/O Description Note

pin46 P02 RED O LED (Red) Output ON = H, OFF = L

pin47 P03 N.C. (Not Used)

pin48 P04 POWER-1 O Power Control CPU-GO

pin49 P05 POWER-2 O Power Control PDP-GO

pin50 P06 SWA O PC1/PC2(BNC)Audio SW PC1=H, PC2=L

pin51 P07 SWB O PC1/PC2(BNC)Audio SW PC1=L, PC2=L

pin52 P20/INT4 FANFAIL I FUN / Panel Temperature Det. Normal = L Pull-Up

pin53 P21/INT4 IRQ I Panel Condition Normal = L

pin54 P22/INT4 P-FAIL1 I Power Fail 1 Normal = H Pull-Up (Inside)

pin55 P23/INT4 P-FAIL2 I Power Fail 2 Normal = L Pull-Up (Inside)

pin56 P24/INT5 P-FAIL3 I Power Fail 3 Normal = H Pull-Up (Inside)

pin57 P25/INT5 P-FAIL4 I (Not Used)

pin58 P26/INT5 PWRSW I Main SW ON/OFF

pin59 P27/INT5 AV4/5 O AV Switching CTL Line Signal AV4/AV5 SW

pin60 PB7/D7 S2/D4 O AV Switching CTL For Aspect Ratio AV1/AV2/AV3 SW

pin61 PB6/D6 N.C. (Not Used)

pin62 PB5/D5 PCSW1 O PC Switching1 CTL

pin63 PB4/D4 PCSW2 O PC Switching2 CTL

pin64 PB3/D3 PCSW3 O PC Switching3 CTL

pin65 PB2/D2 PCSW4 O PC Switching4 CTL

pin66 PB1/D1 M MUTE O Monitor MUTE Pull-Up

pin67 PB0/D0 O N.C. (Not Used)

pin68 VSS3 VSS3 GND

pin69 VDD3 VDD3 +5V

pin70 PC7/A7 BOARD1 I Port for Board

pin71 PC6/A6 BOARD2 I Port for Board

pin72 PC5/A5 PW RET O PIXEL Reset (Low Reset) Pull-Up

pin73 PC4/A4 PDWN O Power Down of LVDS Tx PD=L Pull-Up

pin74 PC3/A3 IIC SCL O AV Switch CTL

pin75 PC2/A2 IIC SDA I/O AV Switch CTL

pin76 PC1/A1 N.C. (Not Used)

pin77 PC0/A0 N.C. (Not Used)

pin78 PA0/CS2 FANLOCK I FAN Stop Normal = H

pin79 PA1/CS1 FAN CTL1 O Forced FAN Control 1

pin80 PA2/CS0 FAN CTL2 O Forced FAN Control 2

Control Port Functions

Page 29

-29-

● Digital Decoder (IC401: VPC3230D)

■ IC Block Diagrams

● 3D Y/C Separation / Noise Reduction (IC7101: UPD64082GF)

CIN

VIN1

VIN2

VIN3

VIN4

VOUT

RGB/

YCrCb

FB

RGB/

YCrCb

Analog

Front-end

AGC

2XADC

Analog

Component

Front-End

4XADC

Y/G

U/B

U/R

FB

Adaptive

Comb

Filter

NTSC

PA L

Processing

Matrix

Contrast

Saturation

Brightness

Tint

Colour

Decoder

NTSC

PA L

SECAM

Saturation

Tint

Y

Cr

Cb

FB

Y

Cr

Cb

Mixer

Y

2D Scaler

Cr

Contrast

Cb

Brightness

Peaking

Clock

Gen.

20.25MHz

RIP

2

CBus

I

2

I

CBus

Output

Formatter

ITU-R 656

ITU-R 601

Memory

Control

Sync

+

Clock

Generation

YOUT

Cr,Cb

OUT

YCOE

FIFO

CNTL

CL Clock

H Sync

V Sync

AVO

Page 30

-30-

● I / P Converter (IC501: SDA9415)

● RGB Matrix (IC601: MN82860)

IC Block Diagrams

RESET

TEST

HINM

VINM

SYNCENM

CLKM

clock

doubling

PLLM

ISCM

Input sync controller Master

LM

Line memory

LBD

Letter

box

detection

VM

Vector

Memory

ME

motion

estimation

X2

clock

doubling

PLLD

X1CLKD

OSCM/S

Output sync

controller

Master

CLKOUT

INTERLACED

HOUT

VOUT

BLNK

YINM

UVINM

YINS

UVINS

CLKM

HINS

VINS

SYNCENS

IFCM

Input

format

conversion

IFCM

Input

format

conversion

clock

doubling

PLLS

ISCS

Input sync controller Slave

VHCOMM

Ver tical and

Horizontal

compression

expansion

VHCOMM

Ver tical and

Horizontal

compression

expansion

LM

Line memory

TSNR

Temporal,

spetial

noise

reduction

controller

Memory

Controller

AnalogG/Y

AnalogB/U

AD

AD

ED

DRAM

+

Buffer

+

Vol tage

control

+

Test-

MC

Black/White

Expander

White

Character

Collection

LM

Line

Memory

SRAM

Scan rate

conversion

Master

Ver tical

expansion

SRCS

OFC

DLTI

DCTI

4:4:4

3:3:3

Framiong

Delay

SDA

PC

SCL

M

U

Peaking

X

OSD Data Input

DAC

DAC

DAC

YO

UO

VO

YOUT

UVOUT

R

G

AnalogR/V

DiditalG/Y

DiditalB/U

DiditalR/V

AD

YUV MATRIX

Color

Adjustment

De-Modulation

Axis

RGB MATRIX

OSD Data Insert

White Balance Adjust

B

γ Collection

Adjustment

De-Modulation

Gain

DIGITAL YUV INTERFACE

Adjustment

I2C Bus

I/F

2

C Bus

I

Clock Input

Page 31

-31-

● Main Scaler (IC301: PW365)

IC Block Diagrams

● Sync. Separation (IC8971: LA7217-T-TRM)

Page 32

-32-

● Sync. Separation (IC1201: BA7078AF)

IC Block Diagrams

● RGB / Component Switch (IC1123/24: BA7657F)

Page 33

-33-

● Audio / Video Switch (IC1001: CXA1845Q)

IC Block Diagrams

Page 34

-34-

● Audio Control (IC001: CXA2013N)

● Q–Sound (IC002: MM1369BD)

IC Block Diagrams

Page 35

-35-

● BBE (IC121: NJM2155M)

IC Block Diagrams

● Digital AMP (IC071: TA1101B)

Page 36

-36-

● Clock Generator (IC303: AV9155C)

IC Block Diagrams

SCLK20-22

14.318MHz

crystal

14.318MHz

14.318MHz

11

19

20

2

3

13

14

3

REFERENCE

CLOCK

CPU

CLOCK

PERIPHERAL

CLOCK

OUTPUT

BUFFERS

OUTPUT

BUFFERS

17

2XCPU

18

CPU

10

OE

8

KBCLK

6

BUSCLK

7

FDCLK

1

COMMCLK

16

VDD

GND

15

POWER-DOWN

12

9

AGND

Page 37

-37-

■ Pin Description of Diode, Transistor and IC

● Diode

K

A

● Transistor/FET

E

C

B

C

E

C

B

E

B

C

● IC

K

A

K

A

K

K

K: Cathode

A: Anode

AA

C

E

E

B

C

B

B1

C1

CBE

C2

B2

E

C

BE

B1

C1

E

C2

Vdd

2

KK

C1

C2

B1 B2

E

B2

C2

E2 C1

B1

B2

A

B1

E1

B2

(GND)

2

Index

E1

C1

C2

E2

A

C: Collector

B: Base

E: Emitter

D: Drain

G: Gate

S: Source

S

G

D

S

D

G

3

1

3

2

Index

Index

N

1

Index

1

3

2

Index

Index

1

3

RESET

1

2

N

1

GND

N

Index

(IN)

N

3

1

(OUT)

4

5

6

21

5

4

3

2

1

Index

1

2

1

2

1

3

1

N

N

Index

Index

N

1

N

1

Page 38

-38-

■ Parts List

MECHANICAL PARTS

9 610 295 4869 ASSY,CABINET BACK-J3BA

2 610 291 7987 BUTTON POWER-J3DA

1 610 297 1125 CABINET FRONT-J3BL

5 610 291 8021 DEC IND-J3DA

(A) 610 297 1132 DEC SHEET L J3BL

(B) 610 295 8775 DEC SHEET MID J3BL

(C) 610 295 8768 DEC SHEET R J3BK

(D) 610 298 4484 DEC SHEET SIDE UP J3BL

(E) 610 298 4477 DEC SHEET SIDE BTM J3BK

3 610 295 8553 SPRING-J3DA

7 645 049 9203 BADGE,SANYO*53.5X12L53.5

4 411 076 3404 SCR TPG BRZ+FLG 3X6

ACCESSORY

645 049 5359 ASSY,REMOCON SXTG

610 296 3243 RC-BATTERY LID-SXTG

645 046 9206 ADAPTOR,BNC/RCA

or 645 036 5447 ADAPTOR,BNC/RCA

or 645 030 7324 ADAPTOR,BNC/RCA

645 051 2322 RC CABLE,FXAF

645 020 3640 CORE,FERRITE

645 044 3367 CORE,CLAMP

645 003 4022 CORD,POWER-3.0MK (UL)

645 011 6131 CORD,POWER-3.0MK (EU)

645 011 6148 CORD,POWER-3.0MK (UK)

INSTRUCTIONS MANUAL

610 297 1217 MANUAL-J3BL (English)

610 299 0294 MANUAL-J3BL-D (Germany)

610 299 0300 MANUAL-J3BL-F (French)

610 299 0317 MANUAL-J3BL-I (Italian)

610 299 0324 MANUAL-J3BL-E (Spanish)

!

!

!

Fig. No. Part No. Description Part No. Description

Center

Tape (Double Face)

Button

See Electric Parts.

➈

(B) (A)

(C)

(D)

(E)

dC i@{^32 [J3DA

Page 39

-39-

Electrical Parts List

Product safety should be considered when a component replacement is made in any area of a PDP monior.

Components indicated by a mark in this parts list and the circuit diagram show components whose value have

special significance to product safety. It is particularly recommended that only parts specified on the following parts

list be used for components replacement pointed out by the mark.

!

● Read Description in the parts list

Read description in the Capacitor and Resistor as follows:

CAPACITOR

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

Less than 10pF

A : Not specified B : ±0.1pF C : ±0.25pF

D : ±0.5pF E : +0 -1pF F : ±1PF

G : ±2pF H : +0.1 -0pF L : +0 -0.1pF

R : ±0.25 -0pF S : +0-0.25pF

More than 10pF

A : Not specified B : ±0.1% C : ±0.25%

D : ±0.5% F : ±1% G : ±2%

H : ±3% J : ±5% K : ±10%

L : ±15% M : ±20% N : ±30%

P : +100-0% Q : +30-10% T : +50-10%

U : +75-10% V : +20-10% W : +100-10%

X : +40-20% Y : +150-10% Z : +80-20%

Rated value: P=pico farad, U=micro farad

Material:

CERAMIC........... Ceramic

MT-PAPER......... Metallized Paper

POLYESTER...... Polyester

MT-POLYEST.....Metallized Polyester

POLYPRO.......... Polypropylene

MT-POLYPRO....Metallized Polypropylene

COMPO FILM.....Composite film

MT-COMPO........Metallized Composite

STYRENE...........Styrene

TA-SOLID........... Tantalum Oxide Solid Electrolytic

AL-SOLID........... Aluminium Solid Electrolytic

ELECT................ Aluminum Foil Electrolytic

NP-ELECT..........Non-polarised Electrolytic

OS-SOLID.......... Aluminium Solid with Organic Semiconductive Electrolytic

POS-SOLID........ Polymerized Organic Semiconductive

DL-ELECT.......... Double Layered Electrolytic

PPS-FILM...........Polyphenylene Sulfide Film

MT-PPS-FILM.....Metalized Polyphenylene Sulfide Film

MT-PEN-FILM.....Metalized Polyethylenenaphthalate Film

CAPACITOR.......Other

RESISTOR

CARBON 4.7K J A 1/4W

Performance Symbols:

A: General B: Non flammable Z: Low noise

Other: Temperature coefficient

T: ±10ppm/°C U: ±25ppm/°C C: ±50ppm/°C

D: ±100ppm/°C E: ±200ppm/°C F: ±250ppm/°C

G: ±350ppm/°C H: ±1000ppm/°C±10% W: ±1200ppm/°C±10%

Y: ±1400ppm/°C±10% J: ±2000ppm/°C±10% K: ±2400ppm/°C±10%

L: ±2700ppm/°C±10% M: ±3000ppm/°C±10% N: ±3300ppm/°C±10%

P: ±3600ppm/°C±10% Q: ±3900ppm/°C±10% R: ±4200ppm/°C±10%

S: ±4300ppm/°C±10% V: ±4500ppm/°C±10% X: ±8000ppm/°C±10%

Tolerance Symbols:

A: ±0.05% B: ±0.1% C: ±0.25% D: ±0.5%

F: ±1% G: ±2% J: ±5% K: ±10%

M: ±20% P: +5-15% Z: 0 ohm

Rated value, ohms:

Material:

CARBON........... Carbon

MT-FILM............ Metal Film

OXIDE-MT......... Oxide Metal Film

SOLID................ Composition

MT-GLAZE......... Metal Glaze

WIRE WOUND...Wire Wound

CERAMIC RES.. Ceramic

FUSIBLE RES....Fusible

RESISTOR ........Other

K: 1,000, M: 1,000,000

Rated Wattage

Page 40

Electrical Parts List

-40-

OUT OF CIRCUIT BOARD

LF901 645 030 4200 UNIT,NOISE FILTER

MISCELLANEOUS

EL901 645 048 4766 PDP MODULE

EL902 645 048 4940 OPTICAL FILTER

FN901 645 049 8671 MOTOR,FAN DC 1.32W

FN902 645 049 8671 MOTOR,FAN DC 1.32W

KSP901 610 225 5317 SPEAKER TERMINAL

KSP902 610 225 5317 SPEAKER TERMINAL

K7S-CN1 610 299 2687 CORD 20P 1.25MM (LVDS CABLE)

M901 610 291 7437 BUTTON-32-J3DA ( Fig. No.8 )

U901 645 053 4225 UNIT,POWER

610 296 9993 ASSY,PWB,MAIN J3BL 1AA0B10N020B0

TRANSISTOR

Q1001 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1002 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1003 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1004 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1007 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1008 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1009 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1012 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1013 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1014 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q1851 405 045 8705 TR 2SK536-TB

Q1852 405 045 8705 TR 2SK536-TB

Q201 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q202 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q203 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q403 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q406 405 134 5905 TR 2SA1037AK-T146-R

!!!!!

Key No. Part No. Description Key No. Part No. Description

Page 41

-41-

Electrical Parts List

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q409 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7007 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7008 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q7009 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7010 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7011 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7012 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q7013 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7014 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7051 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q7052 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q7053 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q7100 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q8973 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

Key No. Part No. Description Key No. Part No. Description

Page 42

Electrical Parts List

-42-

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q947 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q948 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

Q971 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q972 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

Q973 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

INTEGRATED CIRCUIT

IC1001 409 318 0007 IC CXA1845Q

IC1002 409 051 2702 IC TC4052BF(EL)

IC1123 409 501 0906 IC BA7657F

IC1124 409 501 0906 IC BA7657F

IC1201 409 484 2003 IC BA7078AF-E2

IC1251 410 348 7409 IC TC74LCX125FT(EL)

IC1252 410 348 7409 IC TC74LCX125FT(EL)

IC1254 409 400 7105 IC TC7W53FU-(TE12L)

IC1256 410 348 7409 IC TC74LCX125FT(EL)

IC1257 409 155 8006 IC TC7S04F-TE85L

IC1401 410 406 8508 IC EP1K30TC144-3

IC1402 410 407 9207 IC EPC1LC20-B878

IC1851 409 339 3605 IC 24LC16BT/SN-T

IC1951 409 462 0304 IC 24LC21AT/SN

IC201 409 461 7304 IC AD8057ART

IC202 409 461 7304 IC AD8057ART

IC203 409 461 7304 IC AD8057ART

IC204 409 448 5903 IC BD6111FV-E2

IC206 409 416 6406 IC BA033FP-E2

IC207 410 388 7001 IC AD9884AKS-100

IC208 409 448 5903 IC BD6111FV-E2

IC301 409 501 8308 IC PW365-10U

IC302 409 499 1701 IC PQ025EZ01ZP

409 461 7700 IC PQ2TZ15

IC303 409 428 7101 IC AV9155C

IC304 410 325 4605 IC TC74LCX244FT

IC305 409 480 1307 IC PST573IM

IC306 409 429 2808 IC TC74LCX04FT-(EL)

IC307 410 443 3009 IC MBM29LV800TA90C009AS

410 443 3108 IC MBM29LV800TA90C009A

IC307A 410 354 3808 IC MBM29LV800TA-90PFTN

IC308 410 397 0406 IC IS61LV6416-15T

IC309 409 458 2305 IC TC7SZ32FU-TE85L

IC331 409 501 9107 IC ICS512MT

IC401 410 401 4604 IC VPC3230D-QA-B3

IC404 409 496 9601 IC PST600IM

IC415 409 416 6406 IC BA033FP-E2

IC501 409 496 9700 IC SDA9415

IC506 409 416 6406 IC BA033FP-E2

IC601 409 500 8903 IC MN82860

IC602 409 496 9601 IC PST600IM

IC606 409 499 1701 IC PQ025EZ01ZP

409 461 7700 IC PQ2TZ15

IC610 409 416 6406 IC BA033FP-E2

IC620 409 416 6406 IC BA033FP-E2

IC7080 409 437 4801 IC L88M33TL-TL

IC7081 409 475 8403 IC SI-3025LS-TL

IC7100 410 342 8808 IC MSM54V16258BSL-40TS-K

IC7101 409 453 9309 IC UPD64082GF-3BA

IC753 410 423 7201 IC THC63LVDM83R

IC755 409 416 6406 IC BA033FP-E2

IC803 409 434 8109 IC TC4053BFT-(EL)

IC804 409 434 8109 IC TC4053BFT-(EL)

IC806 409 434 8109 IC TC4053BFT-(EL)

IC822 409 438 5609 IC TC74ACT08FT

IC823 409 399 4000 IC 74LVX32SJX

IC8902 409 074 9603 IC M51957BFP

IC8971 409 441 8406 IC LA7217M-T-TRM

IC981 409 428 8405 IC TC7WT125FU-TE12L

IC982 409 428 8405 IC TC7WT125FU-TE12L

CAPACITOR

C1000 403 149 9208 CERAMIC 0.01U Z 50V

C1001 403 330 7709 ELECT 47U M 25V

C1002 403 345 6605 CERAMIC 1U M 10V

C1003 403 345 6605 CERAMIC 1U M 10V

C1005 403 149 9208 CERAMIC 0.01U Z 50V

Key No. Part No. Description Key No. Part No. Description

Page 43

-43-

Electrical Parts List

C1008 403 149 9208 CERAMIC 0.01U Z 50V

C1009 403 149 9208 CERAMIC 0.01U Z 50V

C1010 403 343 3408 ELECT 10U M 25V

C1011 403 149 9208 CERAMIC 0.01U Z 50V

C1012 403 149 9208 CERAMIC 0.01U Z 50V

C1013 403 149 9208 CERAMIC 0.01U Z 50V

C1014 403 343 3408 ELECT 10U M 25V

C1015 403 149 9208 CERAMIC 0.01U Z 50V

C1016 403 149 9208 CERAMIC 0.01U Z 50V

C1017 403 149 9208 CERAMIC 0.01U Z 50V

C1018 403 343 3408 ELECT 10U M 25V

C1019 403 343 3408 ELECT 10U M 25V

C1020 403 345 6605 CERAMIC 1U M 10V

C1021 403 345 6605 CERAMIC 1U M 10V

C1022 403 343 3408 ELECT 10U M 25V

C1023 403 345 6605 CERAMIC 1U M 10V

C1024 403 345 6605 CERAMIC 1U M 10V

C1025 403 343 3408 ELECT 10U M 25V

C1026 403 345 6605 CERAMIC 1U M 10V

C1027 403 345 6605 CERAMIC 1U M 10V

C1032 403 149 9208 CERAMIC 0.01U Z 50V

C1033 403 321 7503 ELECT 220U M 16V

C1034 403 353 2705 ELECT 22U M 25V

C1039 403 343 4900 ELECT 470U M 25V

C1040 403 353 2705 ELECT 22U M 25V

C1041 403 353 2705 ELECT 22U M 25V

C1043 403 149 9208 CERAMIC 0.01U Z 50V

C1122 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C1125 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C1127 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C1129 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C1151 403 330 7709 ELECT 47U M 25V

C1152 403 149 9208 CERAMIC 0.01U Z 50V

C1154 403 330 7709 ELECT 47U M 25V

C1155 403 149 9208 CERAMIC 0.01U Z 50V

C1156 403 330 7709 ELECT 47U M 25V

C1157 403 149 9208 CERAMIC 0.01U Z 50V

C1158 403 330 7709 ELECT 47U M 25V

C1159 403 149 9208 CERAMIC 0.01U Z 50V

C1160 403 330 7709 ELECT 47U M 25V

C1161 403 149 9208 CERAMIC 0.01U Z 50V

C1162 403 330 7709 ELECT 47U M 25V

C1163 403 149 9208 CERAMIC 0.01U Z 50V

C1164 403 149 9208 CERAMIC 0.01U Z 50V

C1165 403 343 4900 ELECT 470U M 25V

C1166 403 282 1206 NP-ELECT 22U M 16V

C1167 403 149 9208 CERAMIC 0.01U Z 50V

C1169 403 282 1206 NP-ELECT 22U M 16V

C1170 403 149 9208 CERAMIC 0.01U Z 50V

C1171 403 282 1206 NP-ELECT 22U M 16V

C1172 403 149 9208 CERAMIC 0.01U Z 50V

C1180 403 149 9208 CERAMIC 0.01U Z 50V

C1181 403 343 4900 ELECT 470U M 25V

C1204 403 267 0606 NP-ELECT 4.7U M 16V

C1205 403 314 5905 CERAMIC 0.47U K 16V

C1206 403 345 6605 CERAMIC 1U M 10V

C1207 403 314 5905 CERAMIC 0.47U K 16V

C1208 403 358 8603 ELECT 2.2U M 50V

C1209 403 345 6605 CERAMIC 1U M 10V

C1210 403 157 3601 CERAMIC 100P J 50V

C1211 403 164 0204 CERAMIC 0.1U Z 25V

C1212 403 321 7404 ELECT 100U M 16V

C1213 403 283 6309 CERAMIC 1U Z 10V

C1214 403 330 7709 ELECT 47U M 25V

C1250 403 164 0204 CERAMIC 0.1U Z 25V

C1251 403 343 3408 ELECT 10U M 25V

C1252 403 164 0204 CERAMIC 0.1U Z 25V

C1253 403 164 0204 CERAMIC 0.1U Z 25V

C1254 403 164 0204 CERAMIC 0.1U Z 25V

C1391 403 345 6605 CERAMIC 1U M 10V

C1392 403 345 6605 CERAMIC 1U M 10V

C1400 403 113 3805 CERAMIC 1000P K 50V

C1401 403 164 0204 CERAMIC 0.1U Z 25V

C1402 403 334 8603 ELECT 220U M 6.3V

C1403 403 164 0204 CERAMIC 0.1U Z 25V

C1404 403 164 0204 CERAMIC 0.1U Z 25V

C1405 403 164 0204 CERAMIC 0.1U Z 25V

C1406 403 164 0204 CERAMIC 0.1U Z 25V

C1407 403 164 0204 CERAMIC 0.1U Z 25V

C1408 403 164 0204 CERAMIC 0.1U Z 25V

C1409 403 164 0204 CERAMIC 0.1U Z 25V

C1410 403 164 0204 CERAMIC 0.1U Z 25V

C1411 403 164 0204 CERAMIC 0.1U Z 25V

C1412 403 334 8603 ELECT 220U M 6.3V

C1413 403 164 0204 CERAMIC 0.1U Z 25V

C1421 403 164 0204 CERAMIC 0.1U Z 25V

C1811 403 353 2705 ELECT 22U M 25V

C1851 403 343 3408 ELECT 10U M 25V

C1852 403 164 0204 CERAMIC 0.1U Z 25V

C1951 403 343 3408 ELECT 10U M 25V

C1952 403 164 0204 CERAMIC 0.1U Z 25V

C201 403 164 0204 CERAMIC 0.1U Z 25V

C202 403 164 0204 CERAMIC 0.1U Z 25V

C203 403 164 0204 CERAMIC 0.1U Z 25V

C205 403 334 8603 ELECT 220U M 6.3V

C208 403 334 8603 ELECT 220U M 6.3V

C209 403 164 0204 CERAMIC 0.1U Z 25V

C210 403 164 0204 CERAMIC 0.1U Z 25V

C211 403 157 3106 CERAMIC 56P J 50V

C212 403 157 3106 CERAMIC 56P J 50V

C213 403 157 3106 CERAMIC 56P J 50V

C214 403 334 8603 ELECT 220U M 6.3V

C215 403 334 8603 ELECT 220U M 6.3V

C216 403 164 0204 CERAMIC 0.1U Z 25V

Key No. Part No. Description Key No. Part No. Description

Page 44

Electrical Parts List

-44-

C217 403 164 0204 CERAMIC 0.1U Z 25V

C218 403 283 6309 CERAMIC 1U Z 10V

C219 403 283 6309 CERAMIC 1U Z 10V

C220 403 283 6309 CERAMIC 1U Z 10V

C221 403 283 6309 CERAMIC 1U Z 10V

C222 403 283 6309 CERAMIC 1U Z 10V

C223 403 283 6309 CERAMIC 1U Z 10V

C224 403 283 6309 CERAMIC 1U Z 10V

C225 403 283 6309 CERAMIC 1U Z 10V

C230 403 334 8603 ELECT 220U M 6.3V

C231 403 334 8603 ELECT 220U M 6.3V

C235 403 334 8603 ELECT 220U M 6.3V

C236 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C237 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C238 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C239 403 345 6605 CERAMIC 1U M 10V

C240 403 345 6605 CERAMIC 1U M 10V

C241 403 345 6605 CERAMIC 1U M 10V

C243 403 157 2505 CERAMIC 27P J 50V

C244 403 157 2505 CERAMIC 27P J 50V

C246 403 157 2505 CERAMIC 27P J 50V

C253 403 164 0204 CERAMIC 0.1U Z 25V

C254 403 334 8603 ELECT 220U M 6.3V

C256 403 164 0204 CERAMIC 0.1U Z 25V

C257 403 298 9609 CERAMIC 0.1U K 16V

C260 403 164 0204 CERAMIC 0.1U Z 25V

C261 403 343 3408 ELECT 10U M 25V

C262 403 298 9609 CERAMIC 0.1U K 16V

C263 403 298 9609 CERAMIC 0.1U K 16V

C264 403 215 2201 CERAMIC 0.01U K 50V

C265 403 343 3408 ELECT 10U M 25V

C266 403 164 0204 CERAMIC 0.1U Z 25V

C301 403 283 6309 CERAMIC 1U Z 10V

C302 403 164 0204 CERAMIC 0.1U Z 25V

C303 403 164 0204 CERAMIC 0.1U Z 25V

C304 403 164 0204 CERAMIC 0.1U Z 25V

C305 403 334 8603 ELECT 220U M 6.3V

C306 403 164 0204 CERAMIC 0.1U Z 25V

C308 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C309 403 164 0204 CERAMIC 0.1U Z 25V

C310 403 334 8603 ELECT 220U M 6.3V

C311 403 334 8603 ELECT 220U M 6.3V

C312 403 164 0204 CERAMIC 0.1U Z 25V

C313 403 334 8603 ELECT 220U M 6.3V

C314 403 164 0204 CERAMIC 0.1U Z 25V

C321 403 164 0204 CERAMIC 0.1U Z 25V

C322 403 334 8603 ELECT 220U M 6.3V

C323 403 164 0204 CERAMIC 0.1U Z 25V

C324 403 164 0204 CERAMIC 0.1U Z 25V

C325 403 164 0204 CERAMIC 0.1U Z 25V

C326 403 155 4204 CERAMIC 15P J 50V

C330 403 164 0204 CERAMIC 0.1U Z 25V

C334 403 164 0204 CERAMIC 0.1U Z 25V

C341 403 164 0204 CERAMIC 0.1U Z 25V

C342 403 334 8603 ELECT 220U M 6.3V

C343 403 330 7709 ELECT 47U M 25V

C344 403 164 0204 CERAMIC 0.1U Z 25V

C401 403 334 8603 ELECT 220U M 6.3V

C402 403 351 1601 ELECT 27U M 6.3V

C403 403 351 1601 ELECT 27U M 6.3V

C404 403 164 0204 CERAMIC 0.1U Z 25V

C405 403 164 0204 CERAMIC 0.1U Z 25V

C406 403 164 0204 CERAMIC 0.1U Z 25V

C407 403 281 5205 CERAMIC 0.22U Z 16V

C408 403 155 2101 CERAMIC 1500P K 50V

C409 403 164 0204 CERAMIC 0.1U Z 25V

C410 403 215 0900 CERAMIC 390P J 50V

C411 403 113 3805 CERAMIC 1000P K 50V

C412 403 330 7709 ELECT 47U M 25V

C413 403 164 0204 CERAMIC 0.1U Z 25V

C414 403 155 2101 CERAMIC 1500P K 50V

C415 403 205 2808 CERAMIC 0.047U K 25V

C416 403 307 7008 CERAMIC 0.068U K 16V

C417 403 307 7008 CERAMIC 0.068U K 16V

C418 403 307 7008 CERAMIC 0.068U K 16V

C419 403 155 2101 CERAMIC 1500P K 50V

C420 403 205 2808 CERAMIC 0.047U K 25V

C421 403 164 0204 CERAMIC 0.1U Z 25V

C422 403 343 3408 ELECT 10U M 25V

C424 403 281 5205 CERAMIC 0.22U Z 16V

C425 403 157 1508 CERAMIC 3P C 50V

C426 403 281 5205 CERAMIC 0.22U Z 16V

C427 403 155 2101 CERAMIC 1500P K 50V

C428 403 215 0900 CERAMIC 390P J 50V

C429 403 343 3408 ELECT 10U M 25V

C430 403 205 2808 CERAMIC 0.047U K 25V

C431 403 164 0204 CERAMIC 0.1U Z 25V

C432 403 164 0204 CERAMIC 0.1U Z 25V

C433 403 215 0900 CERAMIC 390P J 50V

C434 403 281 5205 CERAMIC 0.22U Z 16V

C435 403 343 3408 ELECT 10U M 25V

C436 403 205 2808 CERAMIC 0.047U K 25V

C437 403 155 2101 CERAMIC 1500P K 50V

C438 403 157 1508 CERAMIC 3P C 50V

C446 403 281 5205 CERAMIC 0.22U Z 16V

C448 403 281 5205 CERAMIC 0.22U Z 16V

C451 403 281 5205 CERAMIC 0.22U Z 16V

C454 403 281 5205 CERAMIC 0.22U Z 16V

C480 403 281 5205 CERAMIC 0.22U Z 16V

C481 403 153 9300 CERAMIC 82P J 50V

C500 403 164 0204 CERAMIC 0.1U Z 25V

C501 403 164 0204 CERAMIC 0.1U Z 25V

C502 403 164 0204 CERAMIC 0.1U Z 25V

C503 403 164 0204 CERAMIC 0.1U Z 25V

Key No. Part No. Description Key No. Part No. Description

Page 45

-45-

Electrical Parts List

C504 403 164 0204 CERAMIC 0.1U Z 25V

C505 403 164 0204 CERAMIC 0.1U Z 25V

C506 403 155 4204 CERAMIC 15P J 50V