Page 1

-86°C Ultra-Low Freezers

MDF-U500VXC

MDF-U700VXC

GREEN

product

Twin Guard Series

The Industry’s Safest

Ultra-Low Storage

Solution

™

Features:

• SANYO -86 Dual°Cool ultra-low freezer is designed

for -86°C storage of high-value biologicals

• Includes integrated LCD performance monitor

and digital controller for comprehensive system

management

www.sanyobiomedical.com

My Life. My Work. My Choice.

Page 2

ICD Digital

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Battery

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

VIP Vacuum

Insulation Panel

VIP

VIP Plus Vacuum

Insulation Panel

VIP+

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Rechargeable

Battery

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Service

Automatic

Alarm System

Automatic

Alarm System

Rechargeable

Battery

Rechargeable

Battery

Energy

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

VIP

VIP Vacuum

VIP

CPU and

Touch Pad

VIP Vacuum

VIP

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

VIP Vacuum

Insulation Panel

VIP

VIP+

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Service

Battery

Energy

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

ICD Digital

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

MDF-U500VXC

MDF-U700VXC

VIP+

SAVE

Twin Guard Series™-86°C Ultra-Low

Freezers Featuring SANYO -86 Dual°Cool

Independent Refrigeration Systems

The industry’s safest ultra-low storage solution

for high value biologicals.

The 18.3 cu.ft. / 519 L MDF-U500VXC

and the 25.7 cu.ft. / 728 L MDF-U700VXC

V.I.P. PLUS

ed LCD performance monitor and digital

controller for comprehensive system

management, data logging, remote communications, alarms, predictive performance and validation. Maintenance-free,

filterless design.

• The innovative design utilizing two

independent systems allows the unit

to continue to run continuously at

-65°C in the unlikely event of one

compressor failure.

• The combination of additional refrigeration intelligently managed by intuitive

microprocessor controls and integrated

into SANYO’s patented V.I.P. PLUS

vacuum panel cabinet make the most

efficient use of available floor space.

• Twin Guard Series™ freezers significantly increase ultra-low protection

while minimizing energy costs

through a unique EcoMode™ function.

EcoMode™ optimizes power consumption by orchestrating run times

for each refrigeration system in response to cooling demands.

Twin Guard Series™ -86ºC Ultra-Low Upright Freezer Selection

Model Number

MDF-U5 00VXC

MDF-U700V XC

2 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

™

insulated, includes integrat-

Temperature

Range

-50ºC to -86 ºC

-50ºC to -86 ºC

™

Interior

Volume

18.3 cu.ft.

519 L

25.7 cu.ft.

728 L

The SANYO Twin Guard Series™ -86°C ultra-low freezer with dual,

independent refrigeration systems increases reliability.

Pictured: MDF-U700VXC

Area Footprint

(nominal)

8.37 sq.ft.

2

0.78 m

9.51 sq.ft.

2

0.88m

Storage

(2"/ 51 mm boxes)

(3"/76 mm boxes)

352 224 35,200

576 384 57, 6 0 0

Storage

GREEN

product

(2ml vials in boxes)

Storage

Electrical,

60Hz

208/230V

NEMA 6 -15

208/230V

NEMA 6 -15

Page 3

The SANYO MDF-500VXC and MDF-U700VXC Twin Guard Series™ ultra-low freezers are designed for -86°C storage of high-value biologicals.

Ideal for critical material storage in repositories, highly secure BSL3/4 labs, hospitals, clinics and medical research facilities. The Twin Guard

Series™ introduces the concept of dual, independent, auto cascade refrigeration systems contained within a single cabinet.

Ultra-Critical Installations and Applications Overview

Application Justification Benefit

Stem Cells, Cord Blood, T-Cells, Engineered Tissue,

Organ/ Tissue, Vaccines, Bone Marrow, Hybridomas,

Lymphocytes, Cancer Cells, Clinical Specimens,

Fibroblasts, Ova, Sperm

BSL-3/4 or Highly Secured Labs

Highly sensitive to temperature fluctuations or

uneven storage temperatures at different positions

within the interior chamber.

Restricted access to the contained laboratory

limits serviceability.

Enhanced temperature uniformit y, top-to-bottom,

front-to -back, assures sample stability at all

inventory locations.

™

Twin Guard Series

to react in the event of mechanical failure.

extends critical time necessary

The Safest Ultra-Low Freezers

for Long-Term Storage of UltraCritical Biologicals

The SANYO Twin Guard Series™ satisfies

the industry demand for safe, longterm storage for the most high-valued

materials. Two independent refrigeration

systems, combined with optional liquid

nitrogen or liquid CO

offer a circle of protection unmatched in

the marketplace. Developed for use with

conventional inventory racks and boxes,

the Twin Guard Series

age of sensitive stem cells, embryos,

cell lines, and other rare specimens.

back-up systems,

2

™

is ideal for stor-

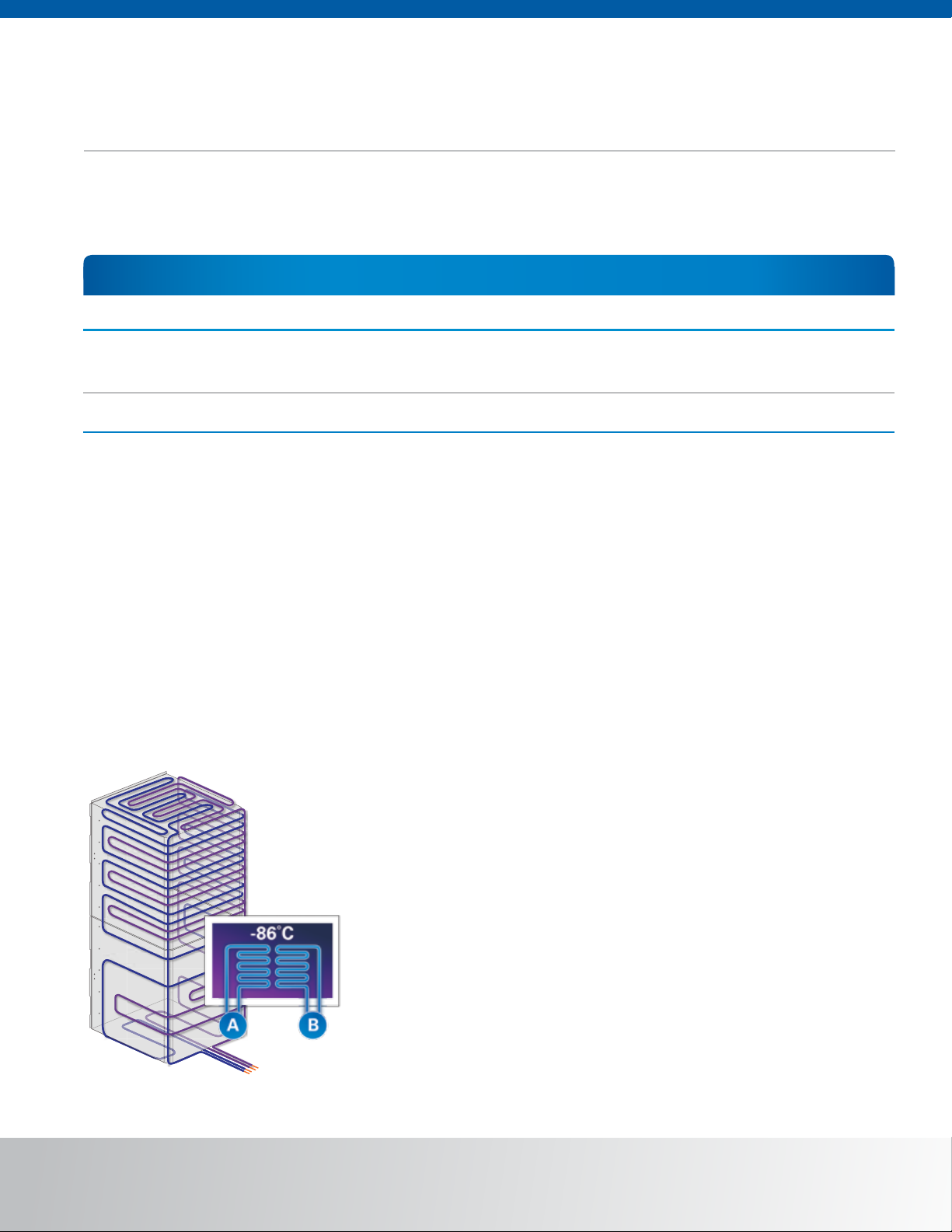

Twin Guard Series™ -86 Dual°Cool

Refrigeration System

The Twin Guard Series™ Ultra-Low Freezer avoids conventional cascade refrigeration technology by using two completely

independent one-compressor, autocascade cooling systems, each capable of

maintaining ultra-low temperatures.

• Each refrigeration circuit includes a

closed-loop cold-wall evaporator configured in parallel to the other.

• Independent evaporators and cooling

fans assure back up status at all times,

eliminating system failure due to

sub-component failure in conventional

cascade systems configured of mutually dependent high- and low-stage

systems.

• In the unlikely event of a compressor

failure in one system, the remaining

system will automatically maintain a

minimum of -65°C for an indefinite

period.

• In the event of a facility power failure

with optional CO

or LN2 backup sys-

2

tem installed, the freezer will maintain

-65°C storage temperature for up to

eight hours (CO

backup system) and

2

-65°C storage temperature for up to

15 hours (LN

• A unique EcoMode

backup system).

2

™

deploys both sys-

tems in overlapping cycles to maintain

-86°C and to reduce energy consumption by as much as 15%.

• Evaporator coils embedded in the patented, high-tech, SANYO V.I.P. PLUS

™

vacuum-insulated thin-wall cabinet are

strategically oriented to deliver the

best temperature uniformity at all shelf

levels, top-to-bottom and front-to-back.

• New SANYO-designed Cool Safe

™

refrigeration compressors feature innovative refrigerant feedback processes

to reduce compressor temperature,

thereby extending compressor life and

minimizing heat output.

Independent systems efficient ultra-low cooling is

achieved through two independent evaporator circuits

surrounding the interior chamber.

3

Page 4

™

Twin Guard Series

-86ºC Ultra-Low Freezers Features

SANYO Twin Guard Series™ -86°C Ultra-Low Freezers

Designed for long-term storage of stem cells, cord blood, T-cells, engineered tissue, organ/tissue,

bone marrow, hybridomas, lymphocytes, cancer cells, clinical specimens, broblasts and other life

science samples.

Twin Guard Series™ Features, Benefits and Performance Advantages

What It Is What It Does Why It Is Important

Energy-Efcient Refrigeration Microprocessor control over all cooling functions

™

SANYO Cool Safe

Environmentally Friendly

Refrigerants

Integrated Control Center Combines all control, alarm, monitoring and data

Compressors Designed specically for ultra-low applications to reduce

delivers cooling on demand.

compressor temperature & improve longevity

Eliminates potential for ozone depletion while

maintaining cooling capacit y.

management functions into a single system.

Optimizes run time to minimize energy consumption.

Increases compressor longevit y and reliability. Reduces

heat output to room and lowers HVAC loads in room.

Complies with the Montreal Protocol and IEC

for safety and ef ciency.

High visibility LCD alphanumeric display provides a convenient user inter face to setpoints, alarm parameters, internal

diagnostics, communications and securit y.

Cabinet Design Integrates inventory management, access

Compliant to International

Standards

Green Design Attributes Integrates design, construction, refrigeration and operation

Ergonomic Design One- handed outer and inner door latches and quiet-running

Improved cell viability through SANYO Ultra-Low Refrigeration Technology

and site installation.

Assures quality standards, safety and performance

criteria are met or exceeded.

functions into an energy efcient friendly system.

compressors improve convenience, minimize sound.

Cabinet design attributes include high- strength, lockable

door latches and doors, latchable inner doors, adjustable

shelves, locking casters and seismic restraints to simplify

operation, installation and to satisfy local codes.

Essential for compliance with LEEDs, RoHS, OS HA

other third -par ty standards and recommended practices.

Minimizes carbon footprint, assists building owners

in LEED Cer tication best practices.

Easy access to controls, displays, inventory racks,

while low noise operation permits a wider choice of

installation locations.

SANYO Refrigeration Delivers

Uniform Temperature

The SANYO cascade refrigeration

system uses SANYO designed compressors for high-performance, reliability and

peace

of mind. Refrigeration components

are carefully selected and matched for

optimum operation under demanding

laboratory environments.

• Increased reserve cooling capacity

improves temperature recovery after

door openings.

• Quieter operation is achieved through

condenser fan blade design, noise

abatement insulation and anti-vibration

mounts.

• Voltage boost and surge protection

devices permit dependable operation

over wider power ranges and environmental conditions.

4 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

Page 5

Twin Guard Series™ Green Features

Because modern laboratories are energy-intensive, SANYO has developed a corporate-wide energy savings and

GREEN

product

environmental impact approach to new product development. The Twin Guard Series™ freezers offer significant benefits

through a balance of refrigeration power, cabinet construction and intelligent control over all functions.

Eco Friendly Technology

• SANYO freezers are designed to

support LEED certication associated

with the U.S. Green Building Council

recommendations.

• Components are compliant with

RoHS directives on the use of hazardous materials in electrical and electronic equipment.

• Noise reduction and operating cost

SANYO is conscious of the need to

protect our environment and conserve

energy. As a corporate pioneer in life

science laboratory equipment and

appliances, and as a global source of

solutions ranging from energy management to solar power and alternative

energies, SANYO remains committed

to providing the best possible laboratory equipment for research and

clinical needs.

efciencies are integrated into the

refrigeration system.

• Heat output is limited to minimize the

impact on facility HVAC demands.

• A microprocessor controller oversees

the refrigeration system to regulate

cooling cycles, reducing energy

consumption.

• SANYO Cool Safe

™

compressor

technology for lower compressor

Uniformity Performance

The placement of evaporator surfaces

within the cabinet walls achieve exceptional documented ultra-low temperature

uniformity, thereby permitting investigators more freedom in placing valuable

cell lines and biologicals within the

interior cabinet, and assuring uniform

cell viability when harvesting products

from the ultra-low archive.

heat internally and externally lower

HVAC loads.

Twin Guard Series™ Comparative Energy Performance

CFC Free Refrigerants

SANYO was the rst ultra-low freezer

manufacturer to employ non-HCFC R508

low-stage refrigerant, now recognized

as today’s industry standard and widely

available. This non-proprietary refrigerant is available to refrigeration service

professionals on the open market.

The high stage refrigerant is available to

refrigeration professionals

on the open market as well.

SANYO Twin Guard Series™ Green

Initiative Program

With a capacity of up to 57,600

two-inch vials in berboard boxes,

the energy-saving advantages of this

efcient SANYO system extend to

lower per-unit storage costs regardless

of the preferred inventory conguration.

Power Consumption by Capacity

(KW/day/box Ef ficiency)

3.0

2.5

2.0

1.5

1.42

1.0

0.5

Watts

0.0

1.74

2.47

SAN YO

MDF-U 700VXC

Brand A

Brand B

SANYO freezers provide reduced operational

cost for highly efficient sample storage*.

Total Annual Electrical Cost

per Box Capacity

12

10

8

6

4

2

Dollars / Cubic Foot

0

8.42

10.31

9.1 5

SAN YO

MDF-U 700VXC

Brand A

Brand B

SANYO freezers emit less heat into the

laboratory, minimizing air conditioning costs*.

*Based on internal performance data. Tested in 25°C ambient environment. Freezer cycling at -80°C. Cabinet

volume, 25.7 cu. ft. Average cabinet temperature based on temperature mapping (15 thermocouples).

Annual CO2 Emissions

by Box Capacit y

1.0

0.9

0.8

0.7

0.75

0.6

0.5

0.4

0.3

0.2

0.1

Dollars ($)

0

0.77

0.82

SANYO freezers help the environment

by reducing carbon footprint*.

SAN YO

MDF-U 700VXC

Brand A

Brand B

5

Page 6

Twin Guard ™ Dual°Cool Refrigeration System

2 compressors are turned ON/OFF at same time

2 compressors and fan motor for each are independently controlled by SV and read AT.

Chamber

Comp A

Comp B

temp

T12 on T12 off

Normal

Normal

Chamber

Comp A

Comp B

temp

T12 on

T12 off

T2 on

T2 off

Chamber

Comp A

Comp B

temp

T on T1 off T12 on T2 offT1 2 on

ECO mode

ECO mode

ECO mode operation image

Pull down

Temp.

Comp A

Comp B

Stable temperature

NORMAL mode operation image

Pull down

Temp.

Comp A

Comp B

Stable temperature

Dual, independent refrigeration systems operate in Normal or energy-saving EcoMode™ which is selected by the user and engaged through the

LCD controller. Normal Mode is used for the strictest of GMP applications. EcoMode™ is applicable to 90-95% of applications.

Twin Guard ™ Dual°Cool Refrigeration System

Status Function Performance

System A and B ON Maximum Pull- Down and Recovery Capcity

System A and B ON, Cycling On/ Off Ec oMode™

System A and B ON, Cycling On/ Off Normal Mode

System A ON Back-Up for System B

System B ON Back-Up for System A

Establishes highly uniform -8 6°C storage

temperature; maximizes recovery following

door openings and heat load additions

Maintains better energ y management at

high or low ambient temperatures as well as

excellent top -to-bottom uniformit y.

Maintains excellent top-to- bottom uniformity.

Maintains most repeatable, cycling wave form

for the strictest of GMP applications.

Maintains minimum -65°C reserve

temperature

Maintains minimum -65°C reserve

temperature

A

A

A

A

A

-86˚C

B

-86˚C

B

-86˚C

B

-65˚C

B

-65˚C

B

EcoMode™ vs. Normal Mode

This chart shows the repeatable cycling wave form of normal mode vs. eco mode.

Normal mode is for strict GMP applications.

6 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

The SANYO Twin Guard Series™ Freezer can be set for Normal or

EcoMode™ operation. EcoMode™ establishes an overlapping cycle to

significantly reduce energy consumption.

Page 7

Failure Mode Comparison

Twin Guard Series™ vs. Conventional Cascade Freezer

Event Conventional Freezer No Back-Up

Conventional Freezer,

with Back-Up System SANYO Twin Guard Series

™

Fan Failure Freezer Fails

High Stage Compressor Failure Freezer Fails

Low Stage Compressor Failure Freezer Fails

20

0

Pull-up while a power failure

-20

-40

Single compressor operation

-60

Chamber temp. (°C)

-80

-100

0 1 2 3 4 5 6 7 8 9 10 11 12

Normal cycle operation (-80°C setting)

(kept at approx. -65°C)

(hour)

Performance Chart, power-failure situation Normal operation and Twin Guard Series™ backup.

Freezer fails, CO

system offers short term protection

until contents can be removed and

or LN2 back-up

2

repairs initiated

40

20

0

-20

-40

-60

Chamber temp. (°C)

-80

-100

0 1 2 3 4 5 6 7 8 9 10 11 12

Pull-up characteristics during power failure

Pull-down charateristics

If one fan fails the second fan

automatically maintains energy

exchange

No high or low stage used. Two refrigeration systems, each with a separate

compressor, operate independently in

overlapping cycles during normal operation. If one compressor fails internal

temperature is maintained indenitely

at -6 5°C with backup compressor.

Optional LN

offers additional protection

or CO2 back-up system

2

Central air temp. in cabinet

Ambient temp. 30°C, No-Load

(hour)

Reduced Power Consumption

The SANYO Twin Guard Series™ Freezer

can be set for Normal or EcoMode

operation, depending on ambient temperature and load. EcoMode

mended for 90-95% of applications.

Although both refrigeration systems are

completely independent, EcoMode

establishes an overlapping cycle to

significantly reduce energy consumption while optimizing interior uniformity

from top-to-bottom and front-to-back for

protection of high value materials.

™

™

is recom-

™

Power Consumption Benefits

Model Number MDF-U500VXC MDF-U700VXC

Ambient Temperature 15°C 23°C 15°C 23°C

Normal Savings -9.7% -7. 8 % -16.7% -17. 5 %

™

EcoMode

Savings -16.8% - 14 .1% -18.5% -18.3 %

7

Page 8

Control, Alarm and Monitoring

• Digital LCD display with alphanumeric information

• Pop-up menu

• Message display

• Visual alarm indicator

• Audible alarm

• Display contrast adjustment

• Positive feedback tactile input buttons

• Positive feedback tactile entry

and function keys

• Buzzer silence temporarily

mutes audible alarm.

• Menu call button

Integrated LCD Control with

Graphical Display

The Twin Guard Series™ is managed by

an integrated microprocessor controller

with LCD information center to simplify

all freezer functions. Uniform ultra-low

temperature is achieved through a

combination of performance systems

supervised by the controller complete

with alarm, programming and diagnostic

protocols.

• The control panel is center mounted

in the outer door for easy, eye-level

access.

• Control and information center

includes an intuitive pop-up menu,

high resolution LCD for inputs, out-

• Multi-point data logging offers a

graphical display for temperature

verification at-a-glance.

• Precise logic systems control and

adjust to temperature setpoints and

alarm parameters.

• Setpoint, alarm and programmable

inputs are established through popup menus and function keys.

• Logged parameters can be exported

to remote databases, off-site alarm

or data capture systems through

optional communications board

module for compliance monitoring.

An optional PC interface permits

remote transmission; see

Accessories.

puts and performance at-a-glance.

8 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

• Standard parameters are factory-set

for quick start-up, and all parameters

can be changed as required.

• A remote alarm terminal mounted at

the side of the cabinet can be connected to an external alarm system.

• Tactile feedback, touch pad data

shift and entry keys simplify operation. All setpoint and alarm functions

are entered through an intuitive

keypad with visual prompts.

• Both refrigeration systems, including compressors and fan motors are

background monitored for performance.

• Out-of-compliance notifications and

warnings are automatically displayed with audible warnings when

necessary.

Page 9

Control, Alarm and Monitoring

Twin Guard Series™ -86°C Ultra-Low Freezers

Alarm & Safety Features Events Visual Audible Signal to Alarm Contact

Abnormal ambient (too high or

Status Alert

High Temperature (+40° C)*

Low Temperature (-40°C)*

Power Failure Loss of power Intermittent Tone N/A

Control Temperature

Sensor Failure

Auto Return

Door Alarm Door open

*New extended range is important for GxP applications to reduce potential incident event reporting.

The integrated microprocessor control aggregates information from the entire system and compares to normal or setpoint values. Out-of-compliance events are

announced by visual and audible warnings, and remote alarm when connected to an external system.

too low), or abnormal freezer

loading (too much warm

product at one time).

Interior chamber warms

beyond high temp setpoint

Interior chamber warms

beyond low temp setpoint

Sensor probe disconnect

short circuit or failure

Touch key is not pressed

for 90 minutes

Notic ation of error on

graphical display

Reverts to chamber

temperature display

Notic ation of error on

graphical display

None None

Intermittent tone. Time delay

of 15 minutes after reaching

alarm setpoint avoids false

alarms. Intermittent tone.

Solid Tone No

None No

Solid tone sounds after

2 minutes

Yes

Yes

Yes

All performance attributes are displayed on a large, visually intuitive alphanumeric display.

Internal temperature log files are expressed in graphical form over time.

Out-of-compliance events are announced by visual and audible warnings.

Error codes quickly identify problem sources and permit fast diagnosis

and remediation.

9

Page 10

Twin Guard Series™ Features

Product Features

1. SANYO patented V.I.P. PLUS™ vacuum

insulation panel cabinet construction

for high insulating value and increased

interior volume in the same footprint.

The V.I.P. PLUS™ minimizes energy

transfer to and from the ultra-low

temperature interior. The composite

construction, complete with reflective

barrier film and structural closed-cell

foam, is used on all walls and the

outer door.

This advanced insulation technology

offers structural stability to eliminate

distortion, and inhibits moisture accumulation that can lead to icing. Aggregate insulation efficiency minimizes

compressor cycle run-time to lower

energy costs.

2. Easy-In/Easy-Out™ door latch for

3. Universal keyed door lock offers

4. Integrated, microprocessor-based con-

5. Circular-chart temperature recorder

6. Insulated and gasketed inner doors

smooth, one-handed operation,

positive seal against gasket. Key

lock provision standard.

added security.

trol system and LCD display information center includes comprehensive

setpoint, alarm, monitoring, diagnostic

and communications functions.

(optional) mounts easily in pre-engineered mounting space.

seal inside to offer additional protection, improve uniformity. Inner door

latches are standard.

13. CFC-refrigerants are highly efficient, environmentally safe, non-ozone depleting.

14. Internal voltage and power management

systems assure component protection

over wide voltage ranges.

15. A vacuum relief valve is mounted in the

left wall.

16. Remote alarm contacts and optional

communication port available; see Accessories.

17. Vacuum relief valve

7. New, air-cooled Super Condenser

energy transfer technology maintains

optimum condenser air flow and

eliminates the need for an air filter or

periodic cleaning and maintenance

required by other manufacturers.

8. High impact, recessed casters and

leveling feet simplify installation.

9. Seismic restraints secure cabinet

to building superstructure to meet

local codes.

10. New generation SANYO designed

Cool Safe™ compressors are specifically designed for one-compressor,

autocascade applications.

11. Twin Guard Series™ redundant refrig-

eration -86 Dual°Cool™ circuits offer

two systems in one, each providing

back-up for the other, or working

together in EcoMode™ operation for

additional energy savings.

12. Multiple access ports permit inser-

tion of independent probes, instrumentation or liquid nitrogen or liquid

CO

back-up injectors.

2

SANYO V.I.P. PLUS™ Series freezers offer high-density

storage that effectively reduces the volumetric unit

costs of ultra-low storage.

Patented SANYO refrigerants are non-ozone depleting,

non-flammable and environmentally safe in compliance

with the Montreal Protocol.

10 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

Page 11

Twin Guard Series™ Features

9

Barrier Film

™

VIP Plus

Interior

Rigid foamed

polyurethane

A vacuum relief valve is

mounted in the left wall.

12

4

1

6

15

17

3

16

10

7

5

13

2

14

11

8

The SANYO ergonomic design features

a high-security Easy-In/Easy-Out door

latch designed for simplicity and safety.

Also allows for one handed operation.

11

Page 12

Twin Guard Series™ Features

Cabinet Construction

The Twin Guard Series™ cabinet features

a patented SANYO V.I.P. PLUS

insulated panel design which optimizes

interior volume in the smallest footprint

possible. The high-tech, composite

thin-wall cellular construction combines

the vacuum panel insulation with

polyurethane foam for structural stability

and high insulation values to minimize

energy use.

• An Easy-In/Easy-Out outer door latch

permits one-handed operation. A

locking provision is designed for use

with a conventional padlock.

• A universal keyed door lock prevents

the outer door from opening.

• The outer door closes uniformly

against a multi-point gasket to form

a tight seal and prevent moisture

migration leading to frost or ice buildup.

• The interior inventory system is based

on a center shelf and two latching

insulated inner doors designed for

one-handed operation. Inner doors

minimize exposure during routine

door openings.

• The two primary compartments can

be sub-divided by adjustable shelves

to accommodate standard stainless

steel inventory racks for 2” or 3”

boxes (see Accessories).

• Rounded interior corners enhance

temperature uniformity and simply

cleaning and decontamination when

required.

™

vacuum

RoHS Compliance

In 2006, RoHS (Restriction of Hazardous Substances) legislation (EU

Directive 2003/95/EU)

became effective. RoHS relates to the

restriction of hazardous substances and

reductions in environmental pollution.

Through RoHS legislation the EU and

other participating countries are banning

toxic substances in electrical equipment

such as lead, cadmium, mercury, chromium 6+, PBB and PBDE.

While compliance with this legislation

has posed a signicant challenge for

SANYO, all SANYO ultra-low freezers and

components are now 100% compliant

to RoHS standards.

Electrical Standards

All SANYO products including ultra-low

temperature freezers are tested and certified by an NRTL (National Recognized

Testing Laboratory) to assure compliance

with US and International standards for

electrical safety prescribed in

29 CFR 1910.7( c ).

MDF-U5 00V XC MDF-U70 0VXC

Noise Reduction

Ultra-low freezers are often located

within research and hospital laboratories

or production facilities. Users prefer

close proximity for easy access to valuable stored products.

If operating noise from refrigeration

compressors is excessive, and/or

compounded by installation of multiple

freezers in adjacent locations, the

working environment is severely

compromised.

SANYO has included advanced noise

abatement in all contemporary ultra-low

freezers and noise reduction levels are

well below those of competitive freezers. Data is available upon request.

12 Twin Guard Series™ -86°C Ultra-Low Freezers

Page 13

Options & Accessories

Twin Guard Series™ Accessories

Accessory Description Catalog Number

Digital Temperature Recorder Auxiliary Data Logger HAMSTERDT2

Liquid CO

Liquid N

Chart Recorder Circular Chart Temperature Recorder, 7 Day MTR-C954

Chart Paper 6" Diameter, 7 Day Chart C710 03 86 RE V

Inner Door Congurations See icons and key to catalog numbers MDF-5ID, MDF-7ID

Replacement Pen, Red Felt tip pens, 6 per pack R252

Replacement Pen, Blue Felt tip pens, 6 per pack R253

Back-Up System Auxiliary tank back in event of power failure CVK- UB2(I)

2

Back-Up System Auxiliary tank back in event of power failure CVK-UBN2

2

Rack Systems

SANYO freezers are available with

a variety of inventory racks to meet

specic applications. Freezers can be

ordered with full-load inventory systems

by selecting one catalog number. For

individual racks, boxes and dividers see

the Storage Capacity Chart.

SANYO's sliding drawer rack with fiberboard boxes,

catalog Number SDR-624, shown here.

The Digital Temperature

Recorder (optional)

The recorder mounts on the cabinet door

and is programmable to capture and store

non-corruptible data points for downloading to an independent data management

system to meet criteria outlined in U.S.

FDA21CFR Part II directives. An independent probe is placed in the interior

chamber.

Inventory

Manufactured by Elpro, Switzerland.

LCO2

Backup System

(CVK-UB2 [I])

LN

2

Backup System

(CVK-UBN2)

Circular

Recorder

(MTR-C954)

Strip Chart

Recorder

(MTR-85H)

Recorder

Mounting

Bracket

(MDF-S3085)

(for MTR-85H)

13

Page 14

MDF-U500VXC

MDF-U700VXC

Twin Guard Series™ -86°C Ultra-Low Freezers

Description

Model Number MDF-U500V XC MDF- U700VXC

Temperature Setpoint Range -50°C to -86° C

Design Cooling Performance

-8 6 Dual°C ool (both compressors)

Single System Cooling Performance (Indenite) -8 6°C (ambient temperature 30° C)

Cabinet Design and Construction

Cabinet Insulation Patented V.I.P. PLUS

Exterior Dimensions (w x f-b x h)

Interior Dimensions (w x f- b x h)

Volume

Shelves 3, adjustable, stainless steel (4 compartments)

Access Port Diameter = 0.5”/17mm; 3 locations

Vacuum Release Port Standard, Manual

35.3” x 34.1” x 78.3”

770 x 870 x 199 0 mm

25.6” x 23.6” x 54. 3”

630 x 6 00 x 1380 mm

18.3 cu.ft.

519 liters

-8 6°C (ambient temperature 30° C)

™

composite wall, energy savings

39.8” x 34.3” x 79.1”

1010 x 870 x 2010 mm

34.3” x 23.6” x 55.1”

870 x 60 0 x 1400 mm

25.7 cu.ft.

728 liters

Refrigeration System

Refrigeration Technique

Compressors

Refrigerant Environmentally safe HFC refrigerant

Air Exchange Dual condenser fans with particulate trap; no lters are required

Cycle Options Standard or energy- saving EcoMode

Controls, Alarm, Monitoring

Controller

Data Management Internal data log with log le memory

Communications Data can be transmitted via RS4 85

Alarms

Remote Alarm Contacts Standard; normally open and normally closed, dry contacts

Electrical

High/ Low temperature, door ajar, power failure, remote alarm contact,

part replacement notication, fan motor lock , individual cooling circuit check

SANYO -86 Dual°Cool independent, redundant

cooling systems with automatic switchover

Per system: Single, hermetic ally- sealed 1100W

SANYO Cool Safe compressor, air-cooled

™

operation

SANYO microprocessor-based, door-mounted

control with graphical LCD information center

208V-203V, AC, 60Hz, 1 phase, NEMA 6-15, 15 amp

separate breaker recommended

14 Twin Guard Series™ -86°C Ultra-Low Freezers www.twinguardseries.com

Page 15

Dimensional Drawings

MDF-U500VXC

MDF-U700VXC

21.0” (533)

34.3” (870)

15

Page 16

Service and Technical Support

Unique SANYO Services

• On-site consultation

• Specialized documentation for each

individual unit

• Customized testing procedures

based on personalized customer

requirements

SANYO Connect

SANYO’s customer-driven biomedical service program guarantees local

attention from qualied SANYO service

representatives, whenever and wherever you need it.

• New Unit Installation and Training

• Preventative Maintenance

• Warranty and Non-Warranty Repairs

• Calibration/Validation Services

• Refurbishment and Reconditioning

• Customized Service and Warranty

Programs

• In-Stock Parts for Immediate Delivery

Predelivery and On-Site Services

Predelivery services include factory

acceptance testing, calibration, and

temperature mapping. On-site services

include installation qualication,

operational qualication, performance

qualication, calibration and temperature

mapping.

Distributed by:

Product conforms to RoHS

(European Restriction of Hazardous

Substance directives)

SANYO Electric Co.,Ltd., Biomedical Division, Gumma is certied for quality management

system:ISO9001/medical devices quality management system:ISO13485/environmental

management system:ISO14001

SANYO North America Corporation

Biomedical Solutions Division

1300 Michael Drive, Suite A, Wood Dale, IL 60191

Toll Free USA (800) 858-8442, Fax (630) 238-0074

www.sanyobiomedical.com

© SANYO Printed in USA 2011.04 AU

AU201104V1

Loading...

Loading...