Sanyo MDF-U500VXC User Manual

Twin Guard Series™ -86°C Ultra-Low

Freezer Featuring -86 Dual°Cool

™

Independent Refrigeration Systems

MDF-U500VXC

The Industry’s Safest

Ultra-Low Storage Solution

for High Value Biologicals

The 18.3 cu.ft. V.I.P. PLUS™ insulated MDF-U500VXC

holds up to 352 two-inch boxes. Includes integrated

LCD performance monitor and digital controller

for comprehensive system management, data

logging, remote communications, alarms, predictive

performance and validation. Maintenance free,

filterless design.

GREEN

product

For interactive product demo visit: www.twinguardseries.com

2

3

General Features & Benefits

ICD Digital

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Battery

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

VIP Vacuum

Insulation Panel

VIP

VIP Plus Vacuum

Insulation Panel

VIP+

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Rechargeable

Battery

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Service

Automatic

Alarm System

Automatic

Alarm System

Rechargeable

Battery

Rechargeable

Battery

Energy

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

VIP

VIP+

VIP Vacuum

VIP

CPU and

Touch Pad

VIP Vacuum

VIP

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

VIP Vacuum

Insulation Panel

VIP

VIP+

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

Service

Battery

Energy

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

ICD Digital

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

Insulation Panel

VIP

SAVE

VIP Plus Vacuum

Insulation Panel

VIP+

Filterless

Design

Insulated

Inner Doors

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

ICD Digital

Display

Remote Alarm

CPU and

Touch Pad

VIP Vacuum

VIP

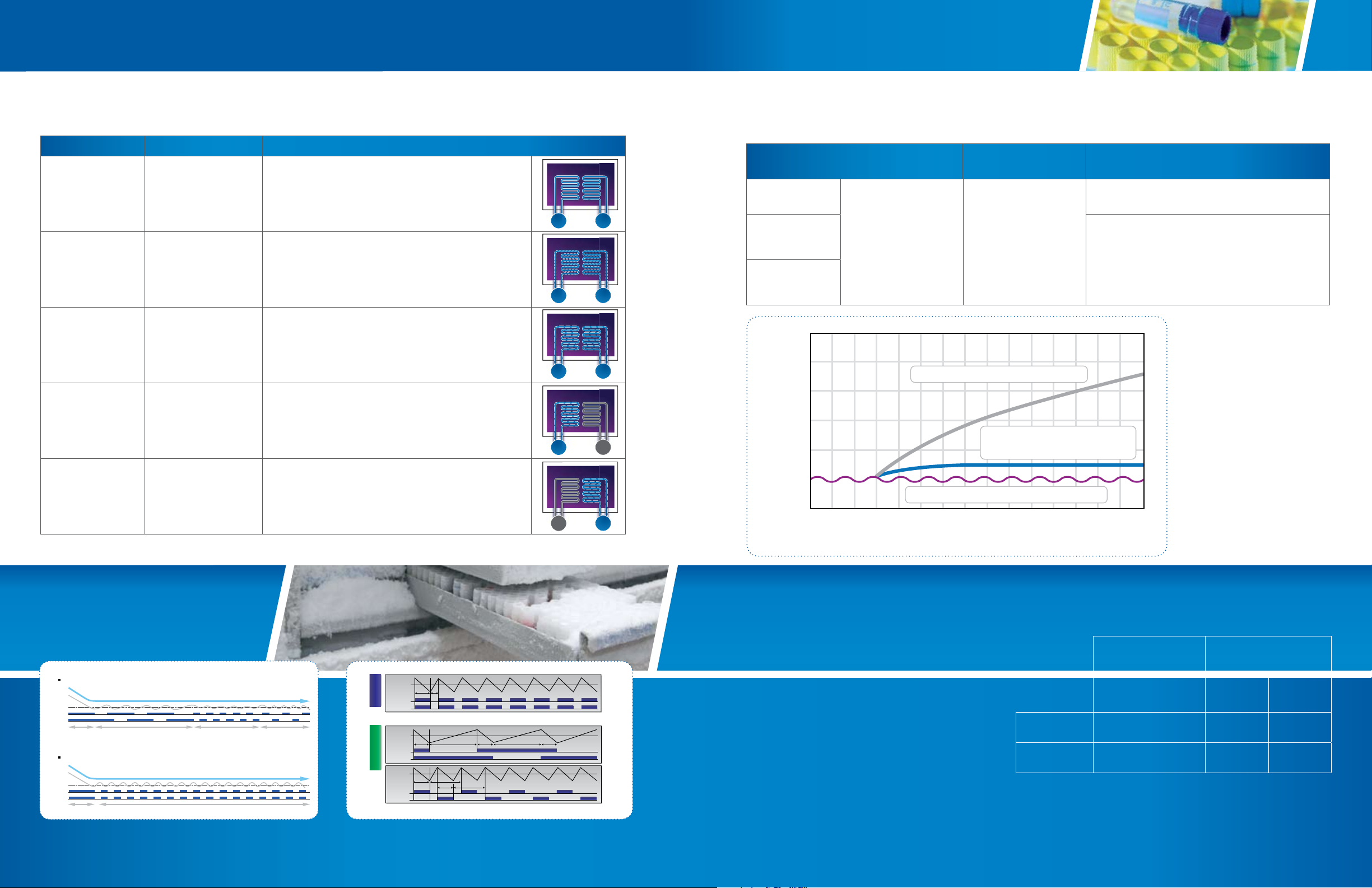

What It Is What It Does Why It Is Important

-86 DualºCool Refrigeration Technology Two independent refrigeration systems operate

together or individually, depending on demand

and performance environment.

™

EcoMode

Environmentally Friendly Refrigerants Eliminates potential for ozone depletion while

Filterless Condenser Design Transfers energy from the refrigeration system

Patented V.I.P. PLUS

Composite Insulation

Integrated Graphical LCD Control Center Combines all control, alarm, monitoring and

Structural Enhancement Integrates inventory management, access

Compliant to International Standards Assures quality standards, safety and

Performance Two independent refrigeration systems running

in overlapping cycles,

maintaining cooling capacity.

with minimal heat output.

™

Vacuum Panel

Combines high-efficiency vacuum-panels with

conventional polyurethane structural foam and

barrier film into a high-tech wall assembly.

data management functions into a single

door-mounted system controller.

and site installation.

performance criteria are met or exceeded.

One refrigeration system is always available

to back-up the other in the event of a component

failure.

EcoMode™ optimizes run time, minimizes energy

costs and maximizes interior temperature

uniformity.

Complies with the Montreal Protocol and IEC

for safety and efficiency.

Eliminates the need for an air filter; optimizes

heat exchange and minimizes compressor heat

built-up over time.

Increases interior volume within conventional

dimensions offering more storage capacity per

sq.ft. of occupied floor space.

High visibility LCD display provides a convenient

user interface to setpoints, current and previous

temperature status, alarm parameters, internal

diagnostics, communications and security.

Cabinet design attributes include high-strength,

lockable door latches and doors, latchable inner

doors, adjustable shelves, vacuum release ports,

locking casters and seismic restraints to simplify

operation, installation and to satisfy local codes.

Essential for compliance with LEEDs, RoHS,

UL and other third-party standards and

recommended practices.

Product Features

Service

Rechargeable Battery CPU and Touch Pad CFC Free

Automatic Alarm System Remote Alarm Energy Savings

Power Failure Alarm LCD Digital Display Quiet, Reliable Compressors

V.I.P. PLUS

Vacuum Insulation Panel

Insulated Inner Doors

™

Filterless Design

The SANYO Twin Guard Series™ Ultra-Low Freezer

for Ultra-Critical Installations and Applications

Application Sensitivity Benefit

Stem Cells, Cord Blood, T-Cells, Engineered

Tissue, Organ/Tissue, Vaccines, Bone Marrow,

Hybridomas, Lymphocytes, Cancer Cells,

Clinical Specimens, Fibroblasts, Ova, Sperm

BSL4 or Highly Secured Labs Restricted access to the contained laboratory

The SANYO MDF-500VXC Twin Guard Series™ ultra-low freezer is designed for -86°C storage of high-value biologicals. Ideal for critical material

storage in repositories, highly secure BSL4 labs, hospitals, clinics and medical research facilities. The Twin Guard Series™ introduces the

concept of dual, independent, auto cascade refrigeration systems contained within a single cabinet.

The innovative design utilizing two independent systems •

allows the unit to continue to run continuously at -65°C

in the unlikely event of one compressor failure.

The combination of additional refrigeration intelligently •

managed by intuitive microprocessor controls and

integrated into SANYO’s patented V.I.P. PLUS™ vacuum

panel cabinet make the most efficient use of available

floor space.

Twin Guard Series•

low protection while minimizing energy costs through

a unique EcoMode

™

freezers significantly increase ultra-

™

function. EcoMode™ optimizes

power consumption by orchestrating run times for each

refrigeration system in response to cooling demands.

The Safest Ultra-Low Freezer for Long-Term

Storage of Ultra-Critical Biologicals

The SANYO Twin Guard Series™ satisfies the industry demand

for safe, long-term storage for the most high-valued materials.

Two, independent refrigeration systems, combined with

optional liquid nitrogen or liquid CO

2

back-up systems, offer a

circle of protection unmatched in the marketplace. Developed

for use with conventional inventory racks and boxes, the Twin

Guard Series

™

is ideal for storage of sensitive stem cells,

embryos, cell lines, and other rare specimens.

Twin Guard Series™ -86 Dual°Cool™

Refrigeration System

The Twin Guard Series™ Ultra-Low Freezer avoids conventional

cascade refrigeration technology by using two completely

independent one-compressor, autocascade cooling systems,

Highly sensitive to temperature fluctuations

or uneven storage temperatures at different

positions within the interior chamber.

limits serviceability.

Either circuit will maintain -65°C. In the unlikely event of a •

compressor failure in one system , the remaining system

will automatically maintain a minimum of -65°C for an

indefinite period.

In the event of a facility power failure with optional CO•

2

or LN

backup system installed, the freezer will maintain

-65°C storage temperature for up to 8 hours (CO

system) and -65°C storage temperature for up to 15 hours

(LN

2

backup system)

A unique EcoMode•

cycles to maintain -86°C and to reduce energy consumption

by as much as 15%.

Evaporator coils embedded in the patented, high-tech, •

SANYO V.I.P. PLUS

are strategically oriented to deliver the best temperature

uniformity at all shelf levels, top-to-bottom and front-to-back.

New SANYO designed Cool Safe•

feature innovative refrigerant feedback processes to reduce

compressor temperature, thereby extending compressor life

and minimizing heat output.

Enhanced temperature uniformity, top-tobottom, front-to-back, assures stability at all

inventory locations.

™

Twin Guard Series

necessary to react in the event of mechanical

failure.

™

deploys both systems in overlapping

™

vacuum-insulated thin-wall cabinet

extends critical time

2

2

backup

™

refrigeration compressors

each capable of maintaining ultra-low temperatures.

2 3

Patented SANYO refrigerants are non-ozone depleting, non-flammable and

environmentally safe in compliance with the Montreal Protocol.

Each refrigeration circuit includes a closed-loop cold-wall •

evaporator configured in parallel to the other.

Independent evaporators and cooling fans assure back-•

up status at all times, eliminating system failure due to

sub-component failure in conventional cascade systems

configured of mutually dependent high- and low-stage

systems.

Independent Systems

Efficient ultra-low cooling

is achieved through two

independent evaporator

circuits surrounding the

interior chamber.

B

A

Chamber temp. (°C)

Pull-up while a power failure

Single compressor operation

(kept at approx. -65°C)

Normal cycle operation (-80°C setting)

20

0

-20

-40

-60

-80

-100

0 1 2 3 4 5 6 7 8 9 10 11 12

(hour)

Twin Guard Series™ DualºCool Refrigeration System

B

-86˚C

A

B

-86˚C

A

B

-86˚C

A

B

-86˚C

A

B

-86˚C

A

2 compressors are turned ON/OFF at same time

2 compressors and fan motor for each are independently controlled by SV and read AT.

Chamber

Comp A

Comp B

temp

T12 on T12 off

Normal

Normal

Chamber

Comp A

Comp B

temp

T12 on

T12 off

T2 on

T2 off

Chamber

Comp A

Comp B

temp

T on T1 off T12 on T2 offT1 2 on

ECO mode

ECO mode

ECO mode operation image

Pull down

Temp.

Comp A

Comp B

Stable temperature

NORMAL mode operation image

Pull down

Temp.

Comp A

Comp B

Stable temperature

Dual, independent refrigeration systems operate in Normal or energy-saving EcoMode™ which is selected by the user and engaged through the

LCD controller. Normal Mode is used for the strictest of GMP applications. EcoMode™ is applicable to 90-95% of applications.

Status Function Performance

System A and B ON Maximum Pull-Down and

Recovery Capacity

System A and B ON,

Cycling On/Off

System A and B ON,

Cycling On/Off

System A ON Back-Up for System B Maintains minimum -65°C reserve temperature

EcoMode

Normal Mode Maintains excellent top-to-bottom uniformity.

™

Establishes highly uniform -86°C storage temperature;

maximizes recovery following door openings and heat load

additions

Maintains better energy management at high or low

ambient temperatures as well as excellent top-to-bottom

uniformity.

Maintains most repeatable, cycling wave form for

the strictest of GMP applications.

Failure Mode Comparison:

Twin Guard Series™ vs. Conventional Cascade Freezer

Event

Fan Failure

High Stage

Compressor Failure

Low Stage

Compressor Failure

Conventional Freezer,

No Back-Up

Freezer fails.

Conventional Freezer,

With Back-Up System

Freezer fails,

back-up system offers

short term protection until

contents can be removed

and repairs initiated.

CO

2

or LN2

SANYO

Twin Guard Series

If one fan fails, the second fan automatically maintains

energy exchange.

No high or low stage used. Two refrigeration systems,

each with a single compressor, operate independently

in overlapping cycles during normal operation. If one

compressor fails internal temperature is maintained

indefinitely at -65°C. Optional LN

offers additional protection.

™

2

or CO2 back-up system

System B ON Back-Up for System A Maintains minimum -65°C reserve temperature

EcoMode™ vs.

Normal Mode

This chart shows the repeatable cycling wave form of normal mode vs. eco mode.

Normal mode is for strict GMP applications.

The SANYO Twin Guard Series™ Freezer can be set for Normal or

EcoMode™ operation. EcoMode™ establishes an overlapping cycle to

significantly reduce energy consumption.

SANYO Twin Guard Series™

Energy Savings vs. Conventional Freezers

Reduced Power Consumption

The SANYO Twin Guard Series™ Freezer can be set for

Normal or EcoMode

temperature and load. EcoMode

90-95% of applications. Although both refrigeration

systems are completely independent, EcoMode

establishes an overlapping cycle to significantly reduce

energy consumption while optimizing interior uniformity

from top-to-bottom and front-to-back for protection

of high value materials.

™

operation, depending on ambient

™

is recommended for

™

Performance Chart, power-failure

situation Normal operation and

Twin Guard Steries™ backup.

Power Consumption Benefits

Conventional

Cascade System

Ambient

Temperature

15°C – – – -9.7%

23°C – – – -7.8%

Twin Guard Series

Normal

Savings

SANYO

EcoMode™

™

Savings

-16.8%

-14.1%

54

Loading...

Loading...