Page 1

Microwave Oven

EM-Z2000S

Service Manual

REFERENCE NO. SM-GA0004

Page 2

INTRODUCTION

This Microwave Oven Service Manual is printed in a loose-leaf format. Each part is divided into sections relating

to a general group of components and each section is subdivided into various parts describing a particular

component or service procedure.

The subdividing of the subject matter plus the loose leaf form will facilitate the updating of the manual as new or

revised components and service procedures are introduced.

Each page of this service manual will be identified in the lower right hand corner and, as new or revised pages

are published, it will be easy to keep the manual up to date by following the filing instructions on the cover letter.

This Service Manual is a valuable service tool and care should be taken to keep it up to date by prompt and

proper filling of subsequent pages as they are issued.

CONTENTS

SAFETY PRECAUTIONS..........................................................................................................................................2

EM-Z2000S Microwave Oven Explode Drawing .......................................................................................................3

EM-Z2000S Microwave Oven Parts & Components List...........................................................................................4

THE HEATING PRINCIPLE OF MICROWAVE .........................................................................................................5

THE STRUCTURE AND WORKING PRINCIPLE OF MICROWWAVE OVEN.........................................................6

1.1 HIGH VOLTAGE RECTIFYING CIRCUIT. ..........................................................................................6

1.2 MICROWAVE GENERATER...............................................................................................................7

1.3 COOLING SYSTEM............................................................................................................................7

1.4 ELECTRIC CONTROL SYSTEM........................................................................................................7

TYPICAL CIRCUIT ANALYASIS OF MICROWAVE OVEN .....................................................................................10

HOW TO ASSEMBLE AND DISASSEMBLE MICROWAVE OVEN COMPONENTS .............................................11

1.5 THE CABINET ..................................................................................................................................11

THE DOOR COMBINATION ............................................................................................................................12

1.7 THE CONTROL PANEL AND THE DOOR RELEASE MECHANISM. .............................................13

1.8 THE MAGNETRON. .........................................................................................................................13

1.9 THE TRANSFORMER. .....................................................................................................................14

1.10 THE FAN MOTOR. ...........................................................................................................................14

1.11 THE CAPACITOR. ............................................................................................................................15

1.12 THE DIODE. .....................................................................................................................................15

1.13 THE TURNTABLE COMBINATIOM..................................................................................................16

1.14 THE DOOR SAFTY INTERLOCKS. .................................................................................................16

THE CONTROL PANEL OF A TYPICAL MICROWAVE OVEN .......................................................................17

BREAKDOWN ANALYSIS AND THE MEANS OF OVERHAULING .......................................................................18

1.16 EXAMINING THE BREAKDOWN CAUSES. ....................................................................................18

SPOT EXAMINING STEPS OF THE MICROWAVE OVEN.............................................................................18

1.18 REPAIRING METHOD OF SEVERAL BREAKDOWN .....................................................................21

1.19 THE CHARACTERS REQUIREMENTS OF MICROWAVE AFTER IT HAS BEEN REPAIRED ......22

CRITICAL PARTS SERVICING ...............................................................................................................................23

1.20 IMPORTANT THINGS TO DO PRIOR TO CRITICAL PARTS SERVICING:....................................23

1.21 Interlock Assembly Replacement and Adjustment............................................................................23

COMMON BREAKDOWN OF MICROWAVE OVEN AND MEANS OF REPAIRING..............................................24

SPECIFICATIONS ...................................................................................................................................................25

1

Page 3

SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be operated with the door open.

B. Make the following safety checks on all ovens to be serviced before activating the magnetron or

other microwave source, and make repairs as necessary.

(1). Interlock operation

(2). Proper door closing

(3). Seal and sealing surfaces (arcing, wear, and other damage).

(4). Damage to or loosening of hinges and latches.

(5). Evidence of dropping or abuse.

C. Before turning on microwave power for any service test or inspection within the microwave

generating compartments, check the magnetron, wave guide or transmission line, and cavity for

proper alignment, integrity, and connections.

D. Any defective or misaligned components in the interlock, monitor, door seal and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures

described in this manual before the oven is released to the owner.

E. A microwave leakage check to verify compliance with the Federal performance standard should be

performed on each oven prior to release to the owner.

THIS MANUAL, AS WELL AS THE INFORMATION CONTAINED IN IT, IS TO BE USED ONLY BY AN

AUTHORIZED SERVICE TECHNICIAN FAMILIAR WITH AND KNOWLEDGEABLE OF PROPER

SAFETY AND SERVICING PROCEDURES AND POSSESSING HIGH QUALITY TEST EQUIPMENT

ASSOCIATED WITH MICROWAVE AND ELECTRICAL APPLIANCE REPAIR.

ALL INDIVIDUALS WHO ATTEMPT REPAIRS BY IMPROPER MEANS OR ADJUSTMENT SUBJECT

THEMSELVES AND OTHERS TO THE RISK OF SERIOUS OR FATAL INJURY.

2

Page 4

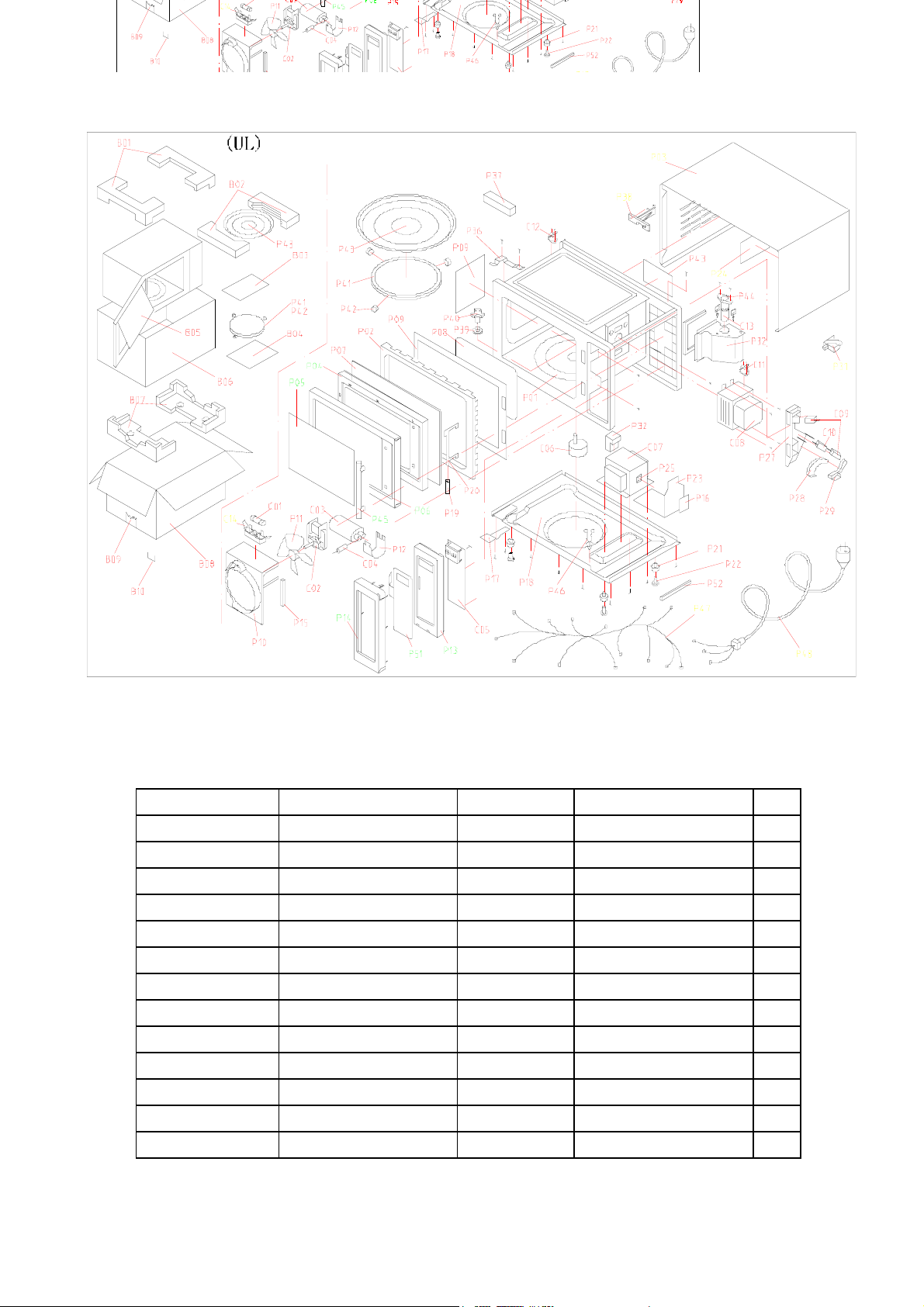

EM-Z2000S Microwave Oven Explode View

EEMM--ZZ22000000SS MMiiccrroowwaavvee OOvveenn CCoommppoonneennttss LLiisstt

COMPONENT No.

COMPONENT CODE Name Model QTY

C01 GA-1000AS23C01 Fuse 65TS 125V 20A 1

C02 GA-1000AS23C02 Fan motor SP-6309-120 1

C03 GA-1000AS23C03 H.V.Capacitor CH85 1.0µF 2200V 1

C04 GA-1000AS23C04 H.V.Diode HVM12(450mA) 1

C05 GA-1000AS23C05 PC board GAL9823 1

C06 GA-1000AS23C06 Turntable motor SM012 or GAL-5-120-TD 1

C07 GA-1000AS23C07 Transformer GAL-1000U-1 1

C08 GA-1000AS23C08 Magnetron 2M248K-N 1

C09 GA-1000AS23C09 Microswitch V-5230Qor VP533B-OFB 2

C10 GA-1000AS23C10 Microswitch V-5220Qor VP532B-OFB 1

C11 GA-1000AS23C11 Thermostat KSD180 1

C12 GA-1000AS23C12 Thermostat KSD105 1

C13 GA-1000AS23C13 Oven lamp KEI T22/120V 20W 1

3

Page 5

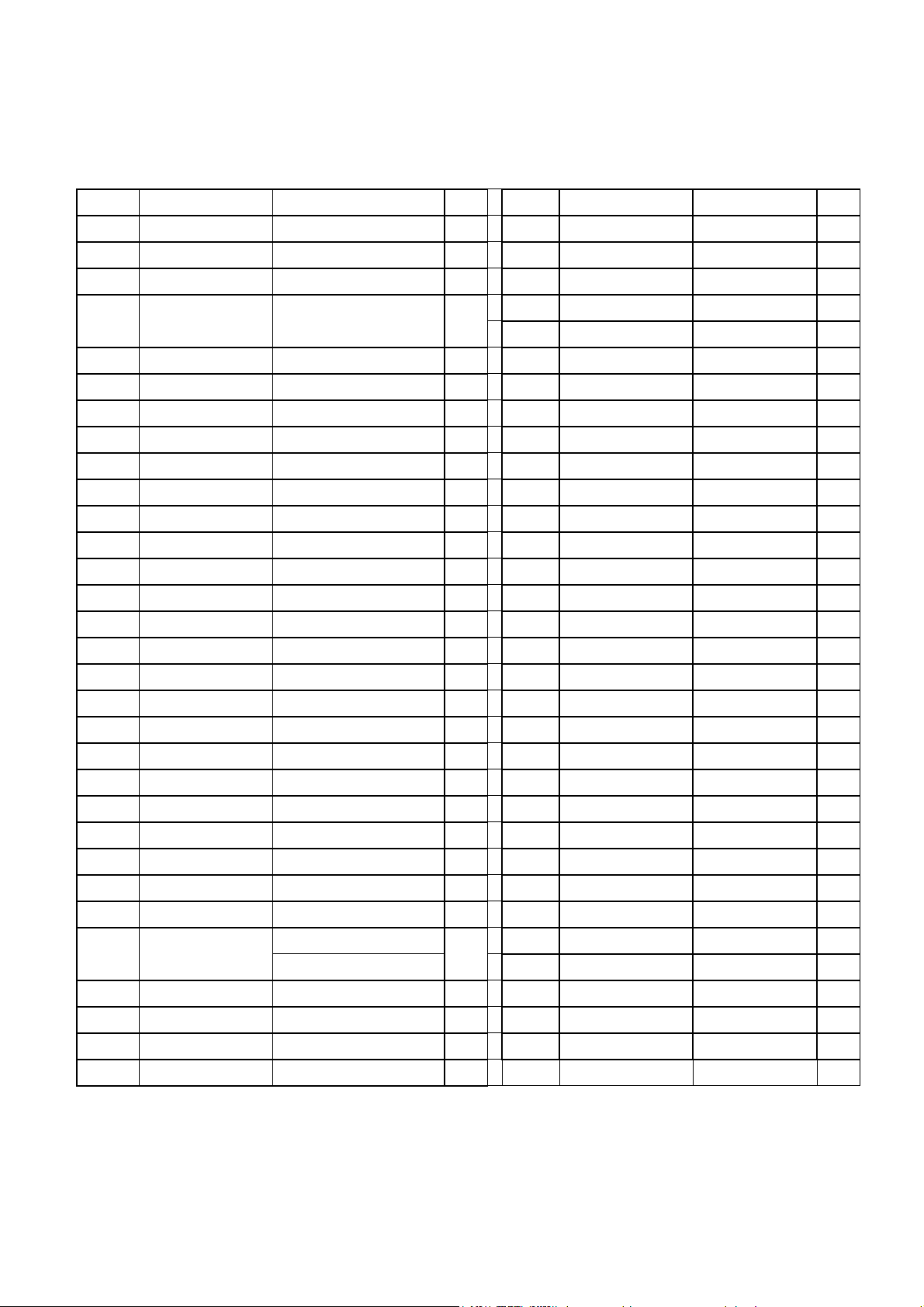

EEMM--ZZ22000000SS MMiiccrroowwaavvee OOvveenn PPaarrttss LLiisstt

PART PART CODE NO NAME QTY PART PART CODE NO NAME QTY

PART PART CODE NO NAME QTY PART PART CODE NO NAME QTY

P01 GA-1000AS23P01 Oven cavity 1 P32 GA-1000AS23P32 Air duct 1

P02 GA-1000AS23P02 Door frame 1 P34 GA-1000AS23P34 Wire fastener 2

P03 GA-1000AS23P03 Outer enclosure 1 P36 GA-1000AS23P36 Upper hinge 1

P04 GA-1000AS23P04 Stainless steel door 1 P37 GA-1000AS23P37 Sponge 1

P38 GA-1000AS23P38 Spacer 1

P05 GA-1000AS23P05 Door window 1 P39 GA-1000AS23P39 Washer 1

P06 GA-1000AS23P06 Door 1 P40 GA-1000AS23P40 Shaft 1

P07 GA-1000AS23P07 Choke cover 1 P41 GA-1000AS23P41 Roller ring 1

P08 GA-1000AS23P08 Inner viewing barrier 1 P42 GA-1000AS23P42 Ring wheel 3

P09 GA-1000AS23P09 Mica sheet 1 P43 GA-1000AS23P43 Glass tray 1

P10 GA-1000AS23P10 Fan shroud 1 P44 GA-1000AS23P44 Lamp holder 1

P11 GA-1000AS23P11 Fan blade 1 P45 GA-1000AS23P45 Door handle 1

P12 GA-1000AS23P12 Capacitor holder 1 P46 GA-1000AS23P46 Wire fastener 1

P13 GA-1000AS23P13 Control panel 1 P47 GA-1000AS23P47 Wire harness 1 set

P14 GA-1000AS23P14 Control panel enclosure 1 P48 GA-1000AS23P48 Power cord 1

P15 GA-1000AS23P15 Sponge 1 P51 GA-1000AS23P51 Touch key board 1

P16 GA-1000AS23P16 Nameplate 1 P52 GA-1000AS23P52 Sponge 1

P18 GA-1000AS23P18 Bottom enclosure 1 B01 GA-1000AS23B01 Foam cushion 2

P19 GA-1000AS23P19 Latch spring 1 B02 GA-1000AS23B02 Foam cushion 2

P20 GA-1000AS23P20 Door latch 1 B03 GA-1000AS23B03 Plastic bag 1

P21 GA-1000AS23P21 Foot 4 B04 GA-1000AS23B04 Owner's manual 1

P22 GA-1000AS23P22 Foot pin 4 B05 GA-1000AS23B05 Foam cushion 1

P23 GA-1000AS23P23 Transformer bracket 1 B06 GA-1000AS23B06 Plastic film 1

P24 GA-1000AS23P24 Insulating film 1 B07 GA-1000AS23B07 Foam cushion 2

P25 GA-1000AS23P25 Shock proof rubber 2 B08 GA-1000AS23B08 Packing belt 1

P26 GA-1000AS23P26 Nameplate 1 B09 GA-1000AS23B09 Carton 1

P27 GA-1000AS23P27 Microswitch mounting 1 B10 GA-1000AS23B10 Wrapping nail 12

Bracket PART PART CODE NO NAME QTY

P28 GA-1000AS23P28 Inner rotary arm 1 P32 GA-1000AS23P32 Air duct 1

P29 GA-1000AS23P29 Outer rotary arm 1 P34 GA-1000AS23P34 Wire fastener 2

P31 GA-1000AS23P31 Power cord holder 1 P36 GA-1000AS23P36 Upper hinge 1

4

Page 6

TTHHEE HHEEAATTIINNGG PPRRIINNCCIIPPLLEE OOFF MMIICCRROOWWAAVVEE

Microwave is one kind of radio wave whose wavelength is very short, frequency is very high. Therefore, it is

called ultrahigh frequency electromagnetic wave. Microwave can heat food mainly result in the mutual affect of

the food in the microwave field and the microwave field itself.

Under the affect of microwave field, the thermal effect mechanism produced from the mutual affect of the

microwave and the food includes two aspects. One is Dielectric loss of polar molecule; the other is conductive

loss of ion.

Usually, food is constituted of organism (plant and animal). The organism is formed by all kinds of polar water

molecule, polar protein molecule, and all sorts of saltion. The center of gravity of the positive and negative charge

in the molecule is not coinciding. In normal condition, the molecule is in irregular order due to its thermal action,

thus the food do not appear polarity. (FIG.1-la). Under the action of outer electric field, the positive end of the

polar molecule trend to the negative electric field, the negative end of polar molecule trend to the positive electric

field, and somewhat arrange in order through the direction of the electric field (FIG.1-1c). This phenomenon

usually is called “TORQUE POLARITY”. When the outer electric field apply for the opposite polarity, the polar

molecule then arrange an opposite direction order accordingly (FIG.1-1b). If the direction of the outer electric field

changed repeatedly, the polar molecule would repeatedly sway accordingly. During the swaying, it is

understanding that the polar molecule would produce heat due to somewhat similar friction among them. When

the electric field is applied for ultrahigh frequent microwave field from the outside, its direction would change tens

billion times per second, so do the molecule. This kind of molecule swaying producing similar frictional heat from

the interference and block of the action strength among the molecule, and changed to microscopic microwave

heating. Microwave heating not only concerned the nature of the matter itself, but also closely connected with the

electric strength and frequency. When the frequency is low, the molecule swaying rate and the acute degree of

the mutual friction among the molecule is low, and would produce much heat. When the frequency is too high, as

the swing of the polar molecule is with rotating inertia, it made the swing do not in line with the changing rhythm

of the electric field because of the friction drag, thus, actually lowed the polar molecule swaying speed. The

friction dragging degree is concerning about the magnelectric wave frequency, polar molecule shape, and the

matter’s sticky degree. To different matter’s molecule, there is different special frequency zone. Those absorbing

microwave energy from this zone are most capable to turn microwave energy to heat energy.

(a) (b) (c)

Fig.1-1

Apart from the above said action, there is another action which is electric ion under the action of microwave field,

act fiercely accompanied with the acceleration of electric field. The positive ion transfer to the negative polarity of

the field while the negative ion does opposite. Accompanying with the changing electric field, the electric ion

hanging accordingly. During the transferring, heat produced with the crash among the ion. This kind of action

takes the main effect to those microwaves heating of high salt molecule.

No matter it is the polar molecule swaying or the ion transferring, they both are turning the microwave energy

which the heating matter got from the microwave field to heat energy. From the analysis of theory, we can draw

such a conclusion that the power which a unit of volume matter absorbed from the microwave field as the

following formula:

Pa=KE fErtgδ

Pa Stands for the power the heated matter adsorbed from the microwave field.

5

Page 7

K Stands for a constant

E Stands for the microwave frequency.

f Stands for the microwave frequency.

tgδ Stands for loss angle tangent of the heated matter.

Er Stands for relative dielectric constant of the heated matter.

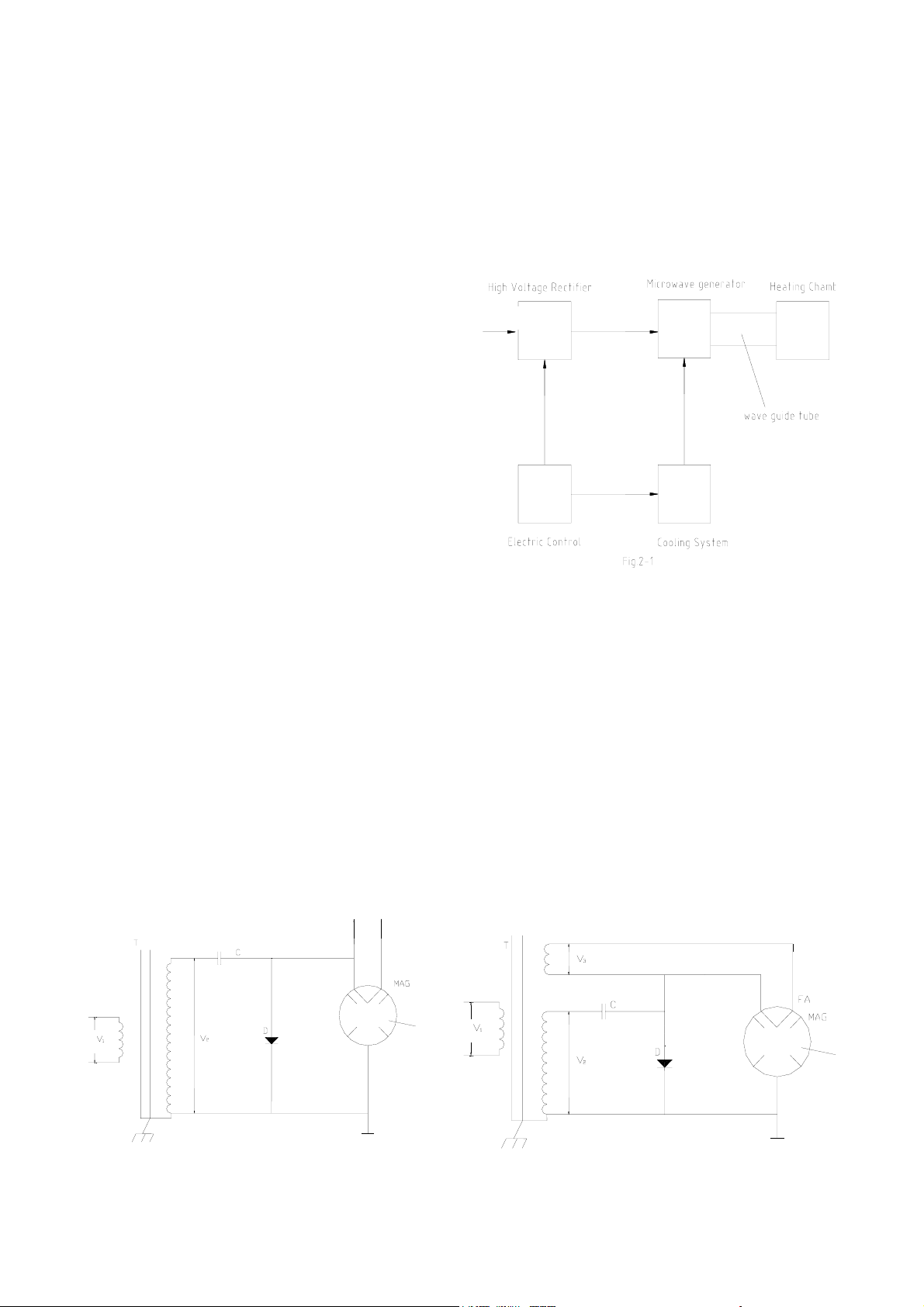

TTHHEE SSTTRRUUCCTTUURREE AANNDD WWOORRKKIINNGG PPRRIINNCCIIPPLLEE OOFF MMIICCRROOWWWWAAVVEE OOVVEENN..

Microwave oven can be classified to many kinds

according to various construction, volume and control

function. But anyhow, the main electric parts are all

composed of high voltage rectification, cooling system.

Microwave generator, electric control system and

heating chamber (FIG.2-1). Its working process are as

follows: 120V power frequency voltage transferred to

the rectifier through electric control system, and then be

changed to 4000V direct volt-age by the rectifier, and be

then transferred to the microwave generator, the

generator stars working to transfer the microwave

energy to the heating chamber for heating food through

wave guide tube. At the same time, the electric control

system set off the cooling system to cool the working

rectifier and the microwave generator to keep the oven

working steadily from a too high temperature. If

something wrong with the cooling system cause the temperature too high, the control system would cut off the

power automatically to prevent microwave generator being damaged form the high temperature. Now, we’d like to

introduce the working principle of each part of the widely used model, mechanical control and touch control

microwave oven.

11..11 HHIIGGHH VVOOLLTTAAGGEE RREECCTTIIFFYYIINNGG CCIIRRCCUUIITT..

At present, home use microwave oven adopt this high voltage rectifying circuit as shown at diagram 2-2.The

circuit is a single phase, semi-wave, double voltage rectifying circuit. The circuit has only a high voltage capacitor,

a high voltage diode, a magnetic leakage transformer besides the magnetron, is very simple.

The working principle of the circuit: 120V power boosted through the transformer, output about 2000V alternating

high voltage current when the high voltage winding is at the positive half-circle, the high voltage winding is at the

negative half-circle, the diode is cut off and the magnetron is conducted. The electricity charged at the positive

half-circle of the capacitor is series connected with the positive phase of the winding voltage, and got a doubled,

about 4000V direct high voltage, then transferred to between the cathode and the anode of the magnetron.

120V

120V

120V

Fig.2-2

6

Fig.2-3

Page 8

11..22 MMIICCRROOWWAAVVEE GGEENNEERRAATTEERR..

Microwave generator is the heart of microwave oven. The quality of a microwave oven mostly depends on the

quality of the microwave generator. A microwave generator is mainly composed of magnetron and its power

supply circuit, FIG.2-3 is the typical circuit diagram of the present used microwave oven’s generator. The power

supply circuit is composed of rectifying circuit and filament circuit.

Usually, we adopt continuous wave magnetron. It can turn the direct energy which is applied to the magnetron

after being high voltage rectified to microwave energy, the power supply circuit supply a direct high voltage

between the cathode and anode of the magnetron, a filament voltage to the cathode filament of the magnetron.

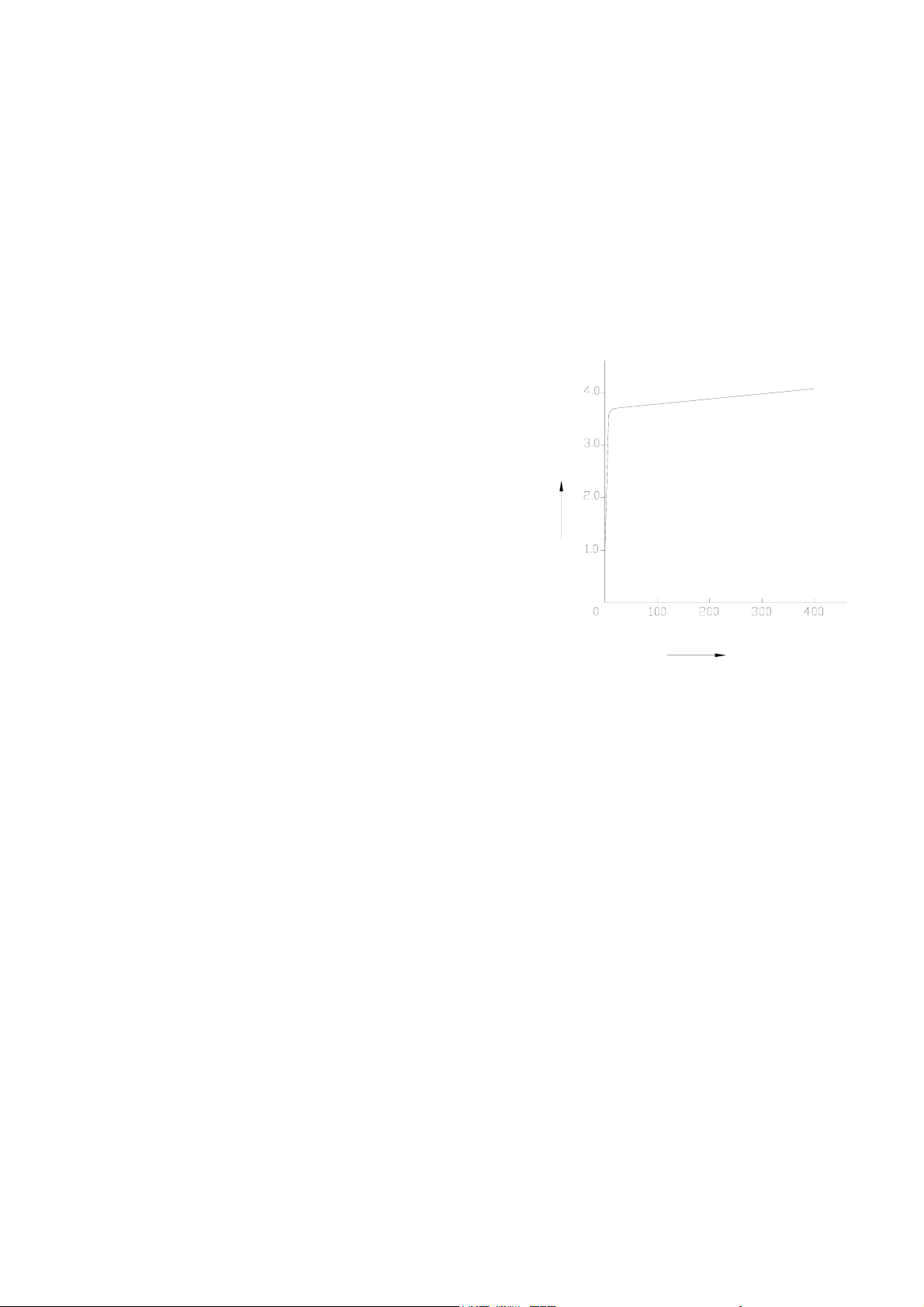

The working process of the magnetron: When the anode volt-age gradually rises from zero, the anode current is

approx.zero, the power is very small as well. When the anode voltage rises to “THRESHOLD” voltage value, the

magnetron starts oscillating, and the anode current would increase obviously, provided the anode voltage rises a

little more, the anode current would increase a lot (FIG.2-4), and would reach the rate value quickly.

If the anode voltage is undulating, it would cause the anode

current swing fiercely, even made the magnetron stop oscillating.

For keeping a steady output, the power supply circuit of the

oven must supply a stead direct current voltage. The filament

voltage of the magnetron must be supplied by an alternating

current voltage. For simplifying the circuit, it would be supplied

by the same leakage magnetic transformer with the anode

power (high voltage power). The filament of the magnetron

which the present used microwave ovens are all treated through

some special technology, and all have the cold start character.

)

V

k

(

m

b

e

e

g

a

t

l

o

v

e

d

o

n

a

But when in cold start, there still is a very strong surge electric

field attached to the surface of the anode, and would be harmful

to the anode. In order to reduce the surge voltage, the filament

of the magnetron must be connected as the FIG.2-3 shown. In

this figure, when the anode current of the magnetron circulates,

anode current

Ib(mA)

the filament current should flow to the FA end from the lower

end.

Fig.2-4

11..33 CCOOOOLLIINNGG SSYYSSTTEEMM

In the working process of the microwave oven, the magnetron often makes the anode temperature rise due to

anode loss

caused by the electronics strike the oven surface and the heat radiate of the cathode. To prevent the anode

temperature rise too high, thus affect the working steady and its life span, it is necessary to cool the magnetron.

According to the different models and rate output of the magnetron, compelling wind cooling and flowing

water-cooling can be adopted. Usually, the home used microwave oven adopts the compelling wind cooling

method, and all are fixed with cooling fin.

Cooling system includes fan motor, air duct, air entrance, air vent etc. The flowing direction of the cooling wind

should. Be parallel to the cooling fin of the magnetron. Generally, we adopt the method of air blast rather than air

absorb. And all the cabinet of the oven is with air entrance and air vent, the hot wind blowing through the

magnetron is guided with air tube to improve the cooling effect. In the technical parameter chart of the magnetron,

it usually will give out the requirement of cooling wind. A shortage of cooling wind would damage the character of

the magnetron, even burn out the magnetron. The amount that the fan blasted should not be less than the

requirement. When fix the fan, attention must be paid to prevent the cool wind from blowing directly to the glass

part of the magnetron to avoid blasting.

11..44 EELLEECCTTRRIICC CCOONNTTRROOLL SSYYSSTTEEMM..

To those mechanical control microwave oven, electric control system mainly composes of interlock switch, timer,

power distributor and thermal cutout, etc. The electric control system of those tough control microwave oven is

mainly composed of interlock switch, computer controller and thermal cutout, etc.

7

Page 9

11..44..11 DDOOOORR IINNTTEERRLLOOCCKK SSWWIITTCCHH

Drawing 2-5(a) is the circuit and construction diagram

of the door interlock switch of a microwave oven. It

mainly consists of interlock switches (S1, S2), and

monitor switch (S3), door hook and starting mechanism

of the door interlock switch.

There fixed hooks on the oven door, and opened two

rectangle hole at the corresponding place at the right of

the oven and the hook. Inside each rectangle hole,

L

E

N

there fixed a micro switch. When the oven door closed,

the two hook on it would insert into the rectangle hole,

and just push down several micro switches. At that time,

S1, S2 are closed, S3 is cut off, and the microwave

oven is under preparation of working.

door closed

To that mechanical control microwave oven, no sooner

you turn the time switch to set the heating time than the

power would be supplied to the back to start the oven. To those touch

control microwave oven, hardly do you set the heating time and power,

and touch the start button when the power would supplied to the back to

start the oven.

When pressing down the door release button or pulling the door handle

to open the door, the safety interlock switches S1, S2 are cut off, and

the monitor switch S3 is closed, and the microwave oven would stop

operating immediately. Provided due to some man - made or the

appliance itself reasons, when the door is open, and the safety interlock

switches S1, S2 are not automatically cut off, due to the existence of the

fuse

ch holder

tch

itch

main latch switch

pilot switch

(a)

Fig.2-5

door hook

S

1

3

S

2

S

assistant latch switch

latch switch holder

latch switch

pilot switch

monitor switch (S3) which is still at conducted condition, the monitor

switch would immediately make the 120V voltage short-circuited and

screw

blow up the fuse, and will never let the microwave oven working when

the door is open.

From this we can understand the function of the interlock switch is

when the door is unclosed, the oven wouldn’t work, when the door is

opened when the oven is working, it would stop the working

door hook

latch switch

pilot switch

immediately (FIG.2-5b).

11..44..22 TTIIMMEE AANNDD PPOOWWEERR DDIISSTTRRIIBBUUTTOORR

door release button

Fig.2-5(b)

screw

Time and power distributor is mainly composed of timer motor and two

sets of gear switch S4 and S5. When the timer is at zero position, the gear switches are cut off, when the heating

time is settled, the gear switch is closed. When started

the oven, the time motor starts working. When it

reaches the settled time, it would cut off the gear

switch (s4) to step the oven working. The gear switch

timer & power motor

transformer

(S5) is designed for controlling the output of the

microwave oven, actually for controlling the output of

the magnetron. It mainly by the method which make

120V

the magnetron working internally at the same working

point to change the output of the magnetron. This

4

S

5

S

method was called “CONDUCTION RATIO CONTROL”.

But there is another method which is called

Fig.2-6

“ELECTRIC LEVEL CONTROL” which is through

changing the working point (such as anode voltage or magnetic field) to change the output of the magnetron.

Because of conduction ratio control method is low cost, high function and high reliability, it is widely used for

8

Page 10

those microwave oven which have the power control function.

FIG.3-1 is the power control circuit diagram of brand microwave oven, WP700. This is a typical instance of

conduction ratio control. This oven adopt time and power controller as a whole. When a 120V, 60Hz alternating

current is inputted, the time and power motor is always at working condition. At the FIG.2-7, S5 is always

conducted. Made the S5 working 30 seconds as a circle, the conduct time can be successively adjusted from 5

seconds to 30 seconds. When power select switch is set at “HIGH”, S5 is always conducted, the output of the

microwave oven is 700W(full power) when the power select switch is set at defrost position, S5 would conduct for

14.4 seconds, and cut off for 15.5 seconds, and the average output of the oven is 336W.

11..44..33 TTHHEERRMMAALL CCUUTTOOUUTT

Thermal cutout actually is a thermal sensor switch, usually, it is fixed on the shell of the magnetron, and series

connected with the primary circuit of the magnetron to control the power input. At normal condition, the thermal

cutout is always conducted (FIG.2-8). When something wrong with the cooling system that cause some abnormal

conditions, such as molding or thermal breakdown, which made the temperature of the magnetron reach the limit

value. Then, the thermal cutout would work to turn off the power to prevent the magnetron from being damaged.

11..44..44 HHEEAATTIINNGG CCHHAAMMBBEERR

Heating chamber is the place where the microwave and the food affect mutually. There are lots kinds of chamber.

Accord-ing to the working characters, it can be classified to carton type, cavity type, radiation type, slow type

(surface wave type), etc. The present adopt chamber for food cooking microwave oven is the typical carton type

heating. (FIG.2-8). The heating chamber is mainly composed of oven door and oven cavity. From the microwave

theory, it is a microwave resonant cavity that can contain many kinds of oscillating models simultaneously.

Microwave enters into the oven cavity through the wave guide and the coupling appliance, and most of its energy

is absorbed by the food after it is reflected in the cavity repeatedly, those which haven’t been absorbed will be

reflect to the magnetron. A good designed oven cavity should have a good impedance matching with the

magnetron, the energy should be less reflect, and distribute evenly in the oven cavity, improve the heating

efficiency. Generally, at the same input power, the larger the cavity, the less the energy density a unit volume

would have in the oven, and the more energy on the inside wall of the cavity would lose, thence, it would certainly

slow down the heating speed, low the heating efficiency. Moreover, too big of the cavity would either waste the

material or appears very heavy. The material for cavity usually use non - magnetic stainless steel or zinc - plating

steel, and have no high requirements for the conducting rate. The inside coating of the cavity requires beautiful in

look, durable when use (should be resistant against damp, heat, acid and alkali), it should also comply with the

food health requirements.

To improve the heating evenness there often fixed a turntable glass tray at the bottom of the cavity (FIG. 2-8). It is

through changing the relative place of the microwave and the heating matter to improve the heating evenness.

The turntable tray is usually made of heat – resistant glass, the glass contains some dielectric loss, it can,

somewhat, protect the magnetron when the cavity loading less.

There often fixed a dust – proof, low – loss and heat – resistant dielectric cover (such as mica sheet). Sometimes,

an impedance matching metal stick was fixed near the coupling or in the wave guide.

The door is designed for inspecting, taking and placing the heating food, it is also one side of the cavity (FIG .2 -

1. Safety interlock switch

2. Door window

3. Air vent

4. Roller Shaft

5. Turntable supporter

6. Glass tray

7. control panel

9

Page 11

8). It is the most liable place where microwave leakage occurs. Especially, after a long time using, the microwave

leakage would enlarge at the hinge and the hook. Anyway, mechanic damage would also cause large amount of

microwave leakage. Therefore, the main methods designed for preventing microwave leakage of the door are as

follows:

1) Assemble a layer of steel filament or a thin metal plate with many holes at the middle of the window to made it

is possible to observe the heating as well as shielding the microwave.

2) The widely used seal measurement at present

is to assemble a current – resistant construct

between the door and the doorframe. FIG.2-9 is

the typical construction fig of the door. It was

current-resistant

constructure

designed according to the theory of

“THETRANSFERING LINE ONE–FOURTHWAVE

LENGTH IMPEDANCE CHANGER”. Although

there is no connecting point from a mechanical

point. It is sealed at the seam from the point of

front door plate

noise filter

electricity, so it is called “CURRENT-RESISTANT”.

Recently, with the installation of noise filter in the

current resistant trough, the effect to restrain the

microwave leakage (include high subharmonic)

Fig.2-9

oven door

have been much improved.

TTYYPPIICCAALL CCIIRRCCUUIITT AANNAALLYYAASSIISS OOFF MMIICCRROOWWAAVVEE OOVVEENN

We have introduced the structure and the working principle of the microwave oven previously. We shall analyze

the complete set circuit of the microwave oven link with the practical circuit at this chapter.

SCHEMATIC DIAGRAM

NOTE: Door is closed

Unit is not operated

MAGNETRON

FA

(MAG.)

FUSE

THERMAL

CUTOUT

MONITOR

SWITCH

(OVEN)

120V

60Hz

L

N

PRIMARY

SWITCH

FAN

OVEN

MOTOR

LAMP

FM

L

MAIN

RELAY

MT

TURNTABLE

MOTOR

POWER

RELAY

C

F

HIGH

VOLTAGE

CAPACITOR

HIGH

VOLTAGE

DIODE

SECONDARY

SWITCH

HIGH

VOLTAGE

TRANSFORMER

LOW VOLTAGE

TRANSFORMER

DIGITAL PROGRAMMER CIRCUIT

10

Page 12

Fig.3–1 is the practical circuit diagram of a microwave oven. Its corresponding working conditions are as follows:

The door closed, SW1 and SW2 turned on, SW3 closed, power control relay has no power, R1, R2 is cut off.

When cooking, touch the starting switch to power the timer and the power relay. RY1, RY2 closed the power

supply to the anode of the magnetron and the filament, changing the power frequency electric energy to

microwave energy, the microwave energy then transferred to the heating chamber for food heating. At the same

time, the lamp turned on, the fan motor begins to cool the magnetron. The turntable motor set off to drive the food

around and making the food heated evenly. The microcomputer begins reckon the time, when it reached the sets

time, power relay are cut off, the power of the lamp, all the motor and the magnetron are cut off, the food –

heating process ended. During the heating, if the door was opened, the interlock S1, S2 will cut off, S3 will close,

all the motors and the magnetron will also be cut off, the lamp will turn on, the oven stop heating immediately. If

heating need go on, just push down the starting button and closed the door, the oven will continue its working.

When something wrong with the fan motor or the air vent was blocked that breakdown the cooling system, the

magnetron temperature would rise high very quickly. When the temperature reached the working point of the

thermal cutout (S6), S6 will be cut off immediately to cut off the power supply to the magnetron and the

magnetron will stops working right away. The PC board is cut off to prevent the magnetron from being damaged

by overheating. When the thermal cutout is cut off, the magnetron, motors and the lamp would stop working

simultaneously. Moreover, the thermal cutout has the self - resuming character, when the temperature lowered, it

will resume to close condition.

Circuit diagram of computer controlled microwave ovens:

Circuit diagram for mechanical controlled microwave ovens:

HHOOWW TTOO AASSSSEEMMBBLLEE AANNDD DDIISSAASSSSEEMMBBLLEE MMIICCRROOWWAAVVEE OOVVEENN CCOOMMPPOONNEENNTTSS

In the following pages, we will introduce the ways in which the various parts of a typical microwave oven can be

disassembled and assembled.

11..55 TTHHEE CCAABBIINNEETT

To disassemble the cabinet

1. Pull out the power plug.

2. Loosen the four screws at the back of the oven with a “+”- screwdriver. (FIG.4-1a)

3. Push the cabinet back 25mm according to the arrow direction shown at FIG.4-1 (b), and the cabinet can be

taken off.

To assemble the cabinet

1. Put the cabinet on the oven, and push it full ahead.

2. Check whether the up, right and left troughs have been inserted with the curved with the curved rim of the

oven (FIG.4-1 (b)). If the cabinet and the oven are not tallied exactly, then it should be reassembled or those

untallied parts should be smoothed.

3. Tighten those four screws, please make sure that one of the screws should have a plum blossom shape

washer to keep a good earth.

11

Page 13

11..66 TTHHEE DDOOOORR CCOOMMBBIINNAATTIIOONN

six-angle screw

To disassemble,

1. Pull out the power plug.

2. Take off the cabinet.

3. Loosen the two six –angle screws of left hinge (up)

hinge(up)

with a socket wrench (FIG.4 - 2).

4. Push the door release button to have the hook out

oven

(FIG.4 -3).

5. Pull the hinge with the door out of the oven

together, and take off the washer of the hinge (low)

shaft (FIG.4 - 2).

6. Pick up the ten inverse hooks which around the

cover with a small screwdriver

carefully(ATTENTION: the cover is made of

Fig.4-2

plastics, and is very liable to be broken), and take

out the cover.

7. Take off the two screws at the door side

with a “+”-screwdriver

8. Take off the hinge (up)(FIG.4- 2).

9. Apart the doorframe from the doorplate

(FIG.4-2).

10. Take off the hook spring with a pointed

plier, then the hook combination.

11. Clamp the window plate with hand, push it

door hook

latch switch holder

latch switch

door hook

pilot switch

latch switch holder

latch switch

pilot switch

down according to the arrow direction,

and take it off.

(a)

(b)

To assemble the door combination(see sketch

4-2 to 4-5)

1. Apply proper silicon grease or lubricating

Fig.4-3

grease on the “★” mark of the hook first, then fix the hook on the oven door, and the spring on its place

(FIG.4 - 5), check whether the hook is operating in normal.

2. Apply proper silicon grease or lubricating grease on the “★” mark of the hinge (UP), install the hinge (UP) in

the hole at right above of the door as FIG.4 - 2, then install the window on the door as FIG.4 - 1, make sure

the hook won’t out. Then tighten each hook on the window to the trough of the door. After assembled, check

whether the door hook is working in normal.

3. Tear off the back protective paper of the window, then the sides of adhesive tape as FIG.4 – 1, and stick it on

the window, Tear three right sides protective paper about 10mm, and fix the window in the doorframe as

12

Page 14

FIG.4 – 1.

4. Tear off the adhesive protective paper of the lining and stick it on the door as FIG.4 – 1, slip the hook on the

doorframe, and fix the doorframe on the door, tighten it with “+” – screws. After assembled, check whether

the hook working in normal and whether the hinge (UP) is its position.

5. According to the FIG. 4 –4 shown, paste the inner lining inside the doorframe, make sure it is pasted

smoothly, and should have no air bubble.

6. Slip the washer in the hinge shaft, then put the hinge shaft in the hinge hole on the bottom of the oven, the

hinge in the rectangle hole on the left above, and hooked it with the door hook.

7. Place a 0.15mm thin paper between the door and the oven, level the door and the oven, then push the door

close to the oven, and tighten the two screws of the hinge (UP) and paint them.

11..77 TTHHEE CCOONNTTRROOLL PPAANNEELL AANNDD TTHHEE DDOOOORR RREELLEEAASSEE MMEECCHHAANNIISSMM..

1. Pull out the power plug.

2. Take off the cabinet.

3. Discharge between one end of the capacitor and the baseboard with a

screwdriver.

To disassemble

1. Pull out the terminal plug of the time and power distributor.

2. Take off the screw which fix the control panel with a “+” – screwdriver

(FIG.4 - 6)

3. Take off the control panel.

To assemble,

(1) Place the two buckles under the control panel into the two rectangle

holes under the oven as FIG.4 – 6, then make close of the control panel and

the oven with being fixed with a screw. Plug in the terminal plug.

11..88 TTHHEE MMAAGGNNEETTRROONN..

Firstly, do as 1,2,3, steps at Ⅲ of this part.

To disassemble,

1. Take off the screw beside the oven lamp (FIG.4 - 8).

2. Take out the four screws which fixed the magnetron, and take the magnetron off (FIG.4 - 7).

screwe

magnetron

lamp shade

Fig.4-7

magnetron

screwe

magnetron holder

thermal cutout

magnetron holder

Fig.4-8

To assemble the magnetron,

1. Check whether the copper filament weaved washer of the magnetron antenna has been placed well. It

should not be fixed if there is no copper filament weaved washer, for it may cause the magnetron and the

oven can’t earth well, and cause large amount of microwave leakage. Attention : When a new oven matches

a magnetron, the meatl lustre at “★” mark should be polished with a sand paper (FIG.4 -7).

2. Aim the head of the magnetron antenna to the hole of the wave guide housing, tighten the four screws of the

13

Page 15

magnetron vertically, and also tighten the screws of the lampshade (FIG.4 - 8).

3. Plug in the two terminals of the magnetron filament and the thermal cutout.

11..99 TTHHEE TTRRAANNSSFFOORRMMEERR..

Firstly, do as the 1,2,3, steps at Ⅲ of this part.

Dismantling steps for the transformer: (as FIG.4 -9).

1. Pull out all the terminal of the transformer.

2. Turn the microwave over.

3. Take off the right baseboard with the transformer after loosened the four screws, which fix the board on the

oven. (4-10).

4. Take off the four screws, a, b, c, d with a “+”- screwdriver.

5. Take off the right baseboard, the seat and the rubber space between the transformer and the oven.

screw

base board

transformer

seat

Fig.4-10

Fig.4-9

to mount the transformer,

1. Place the transformer as the FIG.4 - 9, tear off the protective paper of the rubber lining tape, stick it on the

transformer as shown on the figure. Then put on the seat and the right base board, make sure the screw

hole are tallied, then tighten the four screws for the high voltage winding is earthing here.

2. Fix the transformer on the oven as FIG.4-10.tear off the protect paper of the rubber spacer, set it between the

transformer and the oven, make sure the adhesive side is sticked on the oven.

3. Plug in all the terminals of the transformer precisely.

11..1100 TTHHEE FFAANN MMOOTTOORR..

Firstly, do as the 1, 2, 3, steps of Ⅲ of this part.

To disassemble,

1. Pull out the two terminal of the fan motor (FIG. 4 –11).

2. According to the FIG.4 –12, pull out the lead plug which

marked “A” and “C” from the thermal cutout and the fuse

housing separately, and take off the earthing screw which

marked “B” (FIG.4 -12).

3. Take out the power supply cord from the trough as the

figure shows.

4. Loosen the screws shown on the FIG.4 –13 with a “+” –

screwdriver, and take off the fan holder.

5. Take off the fan from the fan motor shaft as FIG.4 –14, then the fan motor.

to mount the fan motor,

lead

fan motor

Fig.4-11

power supply cord

14

Page 16

1. Assemble the fan motor as FIG.4 – 14. Drip the glue on

the “★” place of the fan motor shaft, and fix the fan on the

motor, make sure it must be fixed to the bottom of the

shaft. Attention: The fan motor shaft should not be curved,

the fan should have no abnormal stick up. After assembled,

check whether the running fan would knock the fan holder.

2. Assemble the fan holder as FIG.4 – 13, Then connect the

power supply cord with the two wires of the fan motor, and

tighten the screws as FIG.4 – 11 and FIG.4 – 12.

earthing screw

fuse housing

power supply cord

Fig.4-12

fan

Fig.4-13

11..1111 TTHHEE CCAAPPAACCIITTOORR..

Firstly, do as the 1, 2, 3, steps of Ⅲ of this part.

To disassemble,

1. Pull the wires of the capacitor out (4-15).

2. Loosen and take out the screw which fix the capacitor clip

with a “+” – screwdriver, and take out the clip and the

capacitor. (4-15).

To assemble,

1. Place the capacitor in the capacitor clip with the end which

have three foot near the diode (4-16).

2. Insert one end of the clip in the fan holder trough (FIG.4-15).

3. Tighten the screw, which fix the capacitor clip.

4. Plug in all the plugs of the capacitor.

fan motor

Fig.4-14

capacitor

diode

back board

screw

fan holder

screw

Fig.4-15

11..1122 TTHHEE DDIIOODDEE..

Firstly, do as the 1, 2, 3, steps of Ⅲ of this part.

To disassemble,

1. Pull out the diode plug, which plugged in the

capacitor.

2. Loosen the screw, which fixed the diode, and

take the diode off.

To assemble,

transformer

15

magnetron

H.V.fuse

Fig.4-16

capacitor

diode

Page 17

1. Insert one end of the diode to one feet of the capacitor’s connect piece.

2. Fix the diode with one screw (pay attention to the polarity of the diode, refer to FIG.4 - 16).

11..1133 TTHHEE TTUURRNNTTAABBLLEE CCOOMMBBIINNAATTIIOOMM..

Firstly, do as the 1, 2, 3, stops of Ⅲ of this part.

To disassemble,

1. Turn the microwave oven over (FIG. 4- 17).

2. Take off the two screws which fix the middle base board with a

“+” – screwdriver and take off the middle cover (FIG.4 - 18).

3. Loosen out the two screws of turntable motor with a “+”-

screwdriver, take out the turntable motor and pull out the two

wires (4 -17).

Assembling steps:

1. Put the motor shaft into its connecting hole, and fix the motor

with two screws (FIG.4 - 17).

2. Plug in the two wires.

3. Assemble and fix the middle base board with two screws

(FIG.4 - 18).

4. Turn the oven back.

5. As the FIG.4 – 19 shown, fix in the turntable shaft supporter,

the place in the roller ring and the glass tray as FIG .4 – 20.

turntable shaft supporter

roller ring

Fig.4-19

Fig.4-17

Fig.4-18

11..1144 TTHHEE DDOOOORR SSAAFFTTYY IINNTTEERRLLOOCCKKSS..

Firstly, do as the same with 1, 2, 3, steps of Ⅲ of this part.

Steps for dismantling:

(1) Pull out the terminal plugs of the interlock switch and the pilot switch.

(2) Loosen out the two screws which fixed the switch holder with a “+”- screwdriver, and take the switch holder

off.

(3) Take off the interlock switch and the pilot switch from the holder.

(4) Take off the switch connecting lever arm and the working lever from the holder.

Assembling steps:

(1) Slip on the connecting lever arm and the working lever into the switch holder.

(2) Assemble the interlock switch and pilot switch to the switch holder, make sure they are assembled correctly.

(3) Tightly fix the holder with two screws.

(4) Check the position of the hook and the switch holder. Close the door, push and pull the low and up part of the

16

Page 18

front door pla

latch switch hold

door to check whether the door is flexible. If it does, back

and front position of the holder should be adjusted.

Provided the up hook is loose, the door should be pushed

more closely to the oven, and pull the holder inside closely

after loosen the screw which fix the holder, then, tighten the

screw and check whether it is still loose. If it is not or the

loose is minor, it would be OK. Open the door, then close it

lightly, check whether the hook is in position, if not,

readjustment is needed. If the loose is at lower part of the

door, the adjust methods is the same with the above said

steps but the screw is the one below (FIG.4 - 21).

screw

Fig.4-21

11..1155 TTHHEE CCOONNTTRROOLL PPAANNEELL OOFF AA TTYYPPIICCAALL

MMIICCRROOWWAAVVEE OOVVEENN

Pull out the power plug.

Take off the cabinet.

Discharge between one end of the capacitor and the

control panel

light tough switch

PC board

baseboard with a screwdriver.

Means of dismantling the PC board and door release

mechanism:

(1) Pull out all the terminal plug of the PC board.

(2) Loosen out the two screws which fix the control panel

with a “+”- screwdriver (FIG.4 -6).

(3) Take off the control panel.

(4) Take off the three “+”- screws which fix the PC board

Fig.4-22

as the FIG.4 – 22.

(5) Take off the range terminal plugs as FIG.4 – 24 shown, that is press the two places according to the arrow

direction at the figure, while pull it up about 2mm, then off

the row plastic board.

(6) Take off the PC frame.

light tough switch

(7) Tear off the undried glue of the light touch switch (FIG.4

- 23).

control panel

to assemble the PC board and door release mechanism,

(1) Tear off the undried glue patch of the light tough switch

(1) and (2) as the Fig.shown, and place them into the

rectangle hole of the surface of the plastic board.

(2) After uprighted the light tough switch, tear off the

protective paper on the back, and stick it on the plastic

board smoothly.

Fig.4-23

(3) Tear off the protective paper of the light touch switch (2), and stick the switch on the back of the plastic board

smoothly.

(4) Assemble in the PC frame and PC board as FIG .4 –22,

and fix them with three “+”- screwes.

(5) Fix the range wires as FIG.4-24, the means are: Insert

the range wires first, make sure that its notch is tallied with

the flange of the row seat, then, press it down to its normal

position.

(6) Fix the control panel on the oven (FIG.4-6).

(7) Plug in the terminal plugs of the PC board.

17

Page 19

BBRREEAAKKDDOOWWNN AANNAALLYYSSIISS AANNDD TTHHEE MMEEAANNSS OOFF OOVVEERRHHAAUULLIINNGG

Before overhauling a microwave oven, you should judge the breakdown and the cause correctly, then you can

repair it with corresponding ways. The overhauling must be proceed in order, any hasty conclusion is not

recommendable, otherwise over-working would be done when repair. The microwave oven may occur compound

breakdown due to all kinds of different reasons, thus, when overhaul, they all should be taken into consideration.

Special attention must be given to the microwave leakage and the electric insulation when examine because they

may do harmful to the repairing staff.

11..1166 EEXXAAMMIINNIINNGG TTHHEE BBRREEAAKKDDOOWWNN CCAAUUSSEESS..

How to examine a microwave oven with breakdown? A better means which demonstrated in practical operating

are through inspecting and listening. On the basis of large amounts of perceptual knowledge, you can judge and

analysie the break down quickly and correctly.

11..1166..11 IINNSSPPEECCTTIIOONN..

Inspect whether the oven shape is disordered and where is the disordered position, If any. It is normal if the

cabinet disordered a little, but abnormal if the oven, the door disordered, the door hook broken, the door crooked,

or there are too much looseness between the door and the oven after the door is closed .

11..1166..22 LLIISSTTEENNIINNGG..

Listening to the sound of the oven operating and the noise of the fan. Minor “wen wen” noise, cycling“kala”noise

and “shishi” noise should be considered as normal. But it is abnormal if the following noises occur:

(1) Sound “wen wen ” noise.

(2) Long time “shishi” noise.

(3) Strike sound like “Pipa pipa”

11..1177 SSPPOOTT EEXXAAMMIINNIINNGG SSTTEEPPSS OOFF TTHHEE MMIICCRROOWWAAVVEE OOVVEENN

11..1177..11 EEXXAAMMIINNEE TTHHEE MMIICCRROOWWAAVVEE IINNSSUULLAATTIINNGG RREESSIISSTTAANNCCEE

Measure the insulating resistance with a avometer or a

megaohmmeter the value should not be less than 2 megaohms.

Otherwise, part examination should be taken at once. Such as

checking whether the motor, the thermal cutout, the transformer or

the capacitor are electricity leaking.

glass tray

11..1177..22 EEXXAAMMIINNAATTIIOONN OOFF TTHHEE RREESSIISSTTAANNCCEE VVAALLUUEE OOFF TTHHEE

MMIICCRROOWWAAVVEE OOVVEENN..

Close the door, set the time (the oven is at operating condition but

the power plug haven’t been plugged in ), measure the two feet (L N) of the power plug with R×1 grade of an avometer, the resistance

value should be about 2.5 ohm. If open circuit occurs, then you must

check whether the 8A fuse is broken、the primary winding of the transformer is open circuit、the thermal cutout is

open circuit or not, you must check whether the interlock device is put through or all the plugs are connected well.

If short circuit occurred or the resistance less than 1.5 ohms, you

should check whether the primary winding of the power transformer

is short – circuited or part short – circuited.

11..1177..33 EEXXAAMMIINNAATTIIOONN OOFF MMIICCRROOWWAAVVEE LLEEAAKKAAGGEE..

Measure the microwave leakage with a microwave leakage measure.

Place a graduate of 275ml water at the middle of the glass tray of the

oven (FIG.5 - 1). Close the door, power set high, time set to 3

minutes, press the starting button to operate the oven. After rectified

the microwave leakage measure, measure around the door crack,

those hole position of the window and the air vent at four sides of the

oven with the probe of the measure. When measure, the moving

18

Fig.5-1

Page 20

speed of the probe should not exceed 25mm per second, and

the measuring direction should be the same with the outing

direction of the probe should not exceed 25mm per second, and

the measuring direction should be the same with the outing

direction of the microwave leakage (FIG.5 - 2)..

When measuring the ultimate value of microwave leakage of all

the measure position should not exceed 1 milliwatt/cm2, of

should be considered as abnormal.

11..1177..44 EEXXAAMMIINNEE WWHHEENN TTHHEE OOVVEENN AATT OOPPEERRAATTIINNGG,, BBUUTT TTHHEE

FFOOOODD CCAANN’’TT BBEE HHEEAATTEEDD..

(1) Examine when the lamp is on, the glass tray is cycling, the

fan operating in normal:

Take off the cabinet, starting the oven, measure the plug of the

transformer with an avometer to see whether it is enough to

120V. If it is enough to 120V, then the secondary high voltage of

the transformer should be examined as FIG.5 – 3.

Measure it with the 2500V-alternating grade of model 500

avometer. One rod of the avometer connects the iron core of the

transformer, the other rod connects the secondary high voltage

plug (FIG.5 - 4). The avometer reading should be about 2100V

(when measure, be careful with the high voltage). If no voltage

at all, it indicates that the transformer has broken, and should be

replaced by a new one. If it is enough to 2100V, then check the

filament voltage of the transformer with alternating 10V grade of

an avometer, the value should be about 3.4V (FIG.5 - 5).

If there is no voltage at all, it indicates the transformer has

broken, and should be replaced by a new one. If it is enough to

3.4V, check the filament resistance of the magnetron, measure

the filament plug with the R×1 grade of a avometer (FIG.5 - 6). If

it is open – circuited, it indicates the magnetron has broken, and

should be replaced by a new one. It is normal if the resistance

very small. Then check whether the magnetron steel has broken,

if broken, replace with a new magnetron.

If there is no problem with the magnetron, check the high

voltage diode then. Measure the diode with R×10K grade of an

avometer, the “+” rod end of the avometer connect the cathode

of the diode, the “-” rod end of the avometer connect the anode

of the diode (FIG.5 - 7).

The avometer reading should be about 150 thousand ohms.

The change the rod to different electrode, the reading should be

“∞” . If the reading is very small, and near to short circuit, it

indicates the high voltage diode has been punctured, and

should be replaced by a new one.

If the high voltage diode is OK, then check the forwarding plug

Fig.5-3

Fig.5-4

Fig.5-5

magnetron

of the transformer to see whether it is enough to 120V. If it is not

enough, check the micro – switch of the time and power

distributor. Connect the two rods of the avometer to the 1,2 place

of the timer with R×1K grade. It is normal if the reading is “0”

when at cut off condition. If the reading is “∞”, it indicates the

micro switch has broken, and the timer should be replaced by a

new one. If all the above examination shows normal ,then check

whether the terminal plug of the magnetron and the capacitor

have loosened, if it is loosened, pinch it tightly with a pliers.

19

Page 21

11..1177..55 EEXXAAMMIINNEE TTHHEE SSTTAARRTTIINNGG AANNDD TTHHEE 88AA FFUUSSEE OOFF TTHHEE

MMIICCRROOWWAAVVEE OOVVEENN..

Pull out the power plug, take off the cabinet, discharge the

capacitor, measure the resistance value of the primary

winding and the secondary winding of the transformer with an

avometer (FIG.5 – 10 and FIG.5 - 9). The resistance value of

the primary winding should be about 2.2 ohms, the secondary

winding should be about 130 ohms. Otherwise, it indicates the

transformer has broken, and should be replaced by a new

one.

If the transformer is normal, then the high voltage capacitor

should be checked. Pull out the connecting plug of the

capacitor, and measure it with R×1 grade of an avometer, the

two rods of the avometer connect the two polarity of the

capacitor. When they just connected, the reading of the

avometer should be zero, then increases to nine megaohm

slowly. Change the rod to different polarity, the reading repeat

from zero to nine megaohm (FIG.5 - 11), it means the

capacitor is normal. If the indicator of the avometer can’t point

out from zero to nine megaohms, it indicates the high voltage

capacitor has broken, and should be replaced by a new one.

If it is normal between the two pole of the capacitor, then the

insulation between the capacitor pole and the cabinet should

be measured with R×10K grade of an avometer. The

resistance value should be “∞” (FIG.5 - 12). If it is short

circuited or have a number reading, it indicates that the

capacitor has been punctured or electricity leaked, and should

be replaced by a same model, same capacity one.

Fig.5-8

Fig.5-9

Fig.5-10

If the resistance value of the capacitor’s two pole are “∞”, the capacitor is normal. Then check the earth of the

magnetron’s two filaments to see whether they are short –

circuited (FIG.5 - 13). If they are short – circuited and the

filament strikes the shell of the magnetron, it indicates the

magnetron has broken, and should be replaced by a new,

same model one.

If the magnetron is also normal, then test the pilot switch.

Pull out the two plugs of the switch. Measure it with the R×1

grade of avometer, the two rod connect the plug of the

switch, the resistance value should be “∞” (FIG.5 - 8).

Then press down the pilot switch with a screwdriver, if the

reading of the avometer pointed to zero, it indicates the pilot

switch has broken, and should replace it with a new, same

model one.

Fig.5-11

20

Fig.5-12

magnetron

Page 22

21

door pushing

part at

screw

right above

micro switch

door pushing

screw

part at

right below

11..1188 RREEPPAAIIRRIINNGG MMEETTHHOODD OOFF SSEEVVEERRAALL BBRREEAAKKDDOOWWNN

1. Repair when there occurred large amounts microwave

leakage. There are many factors which may cause microwave

leaking. Following mentioned may be the main causes of

microwave leakage:

(1) The door deformed, the hinge loosed or damaged that

caused the door can not close tightly.

(2) The door pressing cover or the embed piece damaged or

come off.

(3) Obvious damage or uneven of the oven.

(4) There are filth between the door and the oven.

(5) The door and the oven are serious loosed after the door

closed.

(6) The crack of the door shielding net cover.

Before repairing, check whether the above listed point are

existed, if not, can you start the microwave oven. Place a graduate of about 275ml water at the middle of the

glass tray, close the door, time set at 3 minutes, power at high, make the oven operating in normal. Rectify the

microwave leakage measure, measure the amount of the microwave leakage around the oven with its probe. If

there are places which the leakage exceeds the standard requirement, then repair them accordingly. If the

leakage amount exceeds 1 milliwatt/cm2 at the left door crack,

then pull out the power plug, take down the cabinet, adjust the

screws of the hinge (up and low) as figure5-14 to less the gap

between the door and the oven. Then measure again, the

leakage amount should be less than 1 milliwatt/cm2. Generally,

it should be controlled below 0.75 milliwatt/cm2 with some

allowance.

If the leakage occurred at the right door crack, adjust the

screws which fix the interlock holder and the hook. If the

leakage is the larger side at the right – above of the oven, then

adjust the upper screw as FIG.5 – 15. Loosen out the screw,

push the door close to the oven to hook the door hook with the

plastic parts, then tighten the Screw again. If the leakage is

larger at the right – below, then adjust the lower screw as FIG. 5

– 15. Loosen the screw, push the door close to the oven to hook the door hook with the switch holder tightly, then

tighten the screw again, and open and close the door repeatedly, to check whether the door can operate flexibly,

whether the hook and the switch are in their normal position. If it is not in position, then adjust the door hook and

the switch holder repeatedly to make them to normal position, to put through the interlocks, to cut off the pilot

switch, to less the loose between the door and the oven, then measure the leakage with microwave measure

again.

If the leakage still exceeds standard requirement, then inspect whether the right oven is even or not, if not,

smooth it. Then adjust the door and the oven to eliminate their loose to the ultimate.

If there still exist microwave leakage, measure near the

magnetron with the probe of the microwave leakage mea-sure.

If the leakage is larger, the oven should be turned off and

check whether the four screws which fix the magnetron have

been loosed, if loosed, twist them tightly with socket wrench. If

the four screws are fixed, then the magnetron should be taken

down to check the copper filament weaved washer of the

magnetron has been placed well or whether the wave guide

housing coupling has been oxidized or have lacquer on it. If do

have, scrape the oxidized layer or the lacquer off. When fix the

magnetron, the copper filament weaved washer must be

placed well, the screws must be twist tightly. Then turn on the

oven and measure again until it comply with the requirement. If

Page 23

the microwave leakage is larger at those hole position of the window board. The oven should be turned off to

inspect whether there are crack among them (fig.5 - 16). If several holes formed a crack, it would enlarge the

microwave leakage. If that is the case, it indicates the door has broken, and should be replaced with a new door.

2. Means of repair when the oven can heat, but the turntable glass can’t move

Firstly, check whether the turntable holder is placed correctly. If it is correct, then pull out the power plug and take

down the turntable combination, measure the resistance value of the turntable motor R×1K grade of a avometer.

If it is open – circuited, it indicates the turntable motor has broken, and should be replaced by a new, same model

one. If the resistance value is between 15 –22 K, it indicates the turntable motor is normal. Then check the

connecting shaft weave. If the plastics which the shaft insert in has broken, a new shaft weave should replace it .

3. Repair when the oven can heat, but the lamp is not on.

Pull out the power plug, take down the cabinet an discharge the capacitor.

Pull out the two terminal plugs of the lamp. Measure the two plugs of the lamp with the R×100 grade of a

avometer.

If it is open – circuited, it indicates the lamp has broken, and should be replaced by a same model one.

4.Means of repair when the oven stop working after several minutes operating.

The phenomenon indicates the thermal cutout is playing its protective role, and you should check whether the fan

is working in normal. Turn off the oven, pull out the power plug, take down the cabinet, discharge the capacitor,

then turn the fan with hand to see whether it is moving flexibly. If not, it indicates that the oil bearing of the fan

motor has run off the oil, and should take down the fan combination to repair the motor. Loosen the two screws

which fix the bearing out the shaft and the bearing, and rinse them with kerosene (ATTENTION: The bearing can

only be wiped with a silk which moistened with kerosene rather than be washed in the kerosene because there

are felt on it. If the felt are soaked with kerosene, then the engine oil can not be sucked up. ). After the bearing

being cleaned, the felt should be refueled fully with engine oil (for when the oven is operating, the engine oil

empty into the oil bearing slowly). Fix the bearing cover with two screws, turn the fan around till it can move

flexibly. Then install them to the oven, and plug in the two terminal plugs.

If the fan can move flexibly, then the winding of the fan motor should be examined. Measure the winding with

R×100 grade of a avometer, if it is open – circuited, it indicates the winding of the fan motor has broken, and

should be re-placed by a new, same model one.

11..1199 TTHHEE CCHHAARRAACCTTEERRSS RREEQQUUIIRREEMMEENNTTSS OOFF MMIICCRROOWWAAVVEE AAFFTTEERR IITT HHAASS BBEEEENN RREEPPAAIIRREEDD

After being repaired, the microwave oven should have a 30 minutes trial operation. It can be used only when it

has been demonstrated that it is in good conditions of safety, heating and defrosting. The oven must have the

following identifications when it at trial operating:

11..1199..11 IINNSSUULLAATTIIOONN::

Before conducted, measure the insulation resistance among those electric metal parts and the nonelectric metal

cabinet with a 500V.D.C. Megaohmmeter. The resistance value should not be less then 2 megaohm.

Testing condition: Door closed, power at “high”, time set at 3 minutes. This is the operating condition of the oven,

but the power plug is not connected.

11..1199..22 MMIICCRROOWWAAVVEE LLEEAAKKAAGGEE::

Microwave leakage can not be tell by watching or touching. To be responsible for the user, the amount of

microwave leakage should be measured strictly, and should not exceed 5 milliwatt/cm2, according to the IEC

STANDARD. Some countries stipulate that the maximum microwave leakage should not exceed 1 milliwatt/cm2.

For safety concern, we must control the leakage under 1 milliwatt/cm2 after the oven being repaired, otherwise, it

should be repaired again. Test must be proceeded completely and comply with the following procedures:

Put a graduate of about 275ml water at the middle of the turntable glass tray of the oven, insert the power plug,

close the door, power set high, time set 3 minutes to make the oven in operation. Rectify the microwave leakage

measure first, measure around the door crack the metal net of the door and the air vent with the probe of the

measure when measuring, the moving speed of the probe should not exceed 25mm/sec. The measuring direction

of the probe must be the same with the outgoing direction of the microwave leakage.

11..1199..33 MMIICCRROOWWAAVVEE HHEEAATTIINNGG..

Place a graduate of about 250ml water on the turntable tray. Close the door, power set high, time set 4 minutes

22

Page 24

(To those 700W microwave oven) to make the oven operating in normal. When the bell of the timer rings, open

the oven door, the water should have boiled. If it have not been boiled yet, but is very hot, check whether the

voltage is less than 120V. If the voltage below 120V but the water can be boiled after a little more time beating, it

is normal.

11..1199..44 MMIICCRROOWWAAVVEE DDEEFFRROOSSTT::

Place a graduate of about 200ml water on the turntable glass tray of the oven, power set middle, time set 4

minutes to make the oven operating in normal. When the bell of the time ring, open the door. It would be normal if

the water is lukewarm.

11..2200 IIMMPPOORRTTAANNTT TTHHIINNGGSS TTOO DDOO PPRRIIOORR TTOO CCRRIITTIICCAALL PPAARRTTSS SSEERRVVIICCIINNGG::

The following instructions are CRITICAL to the owner’s safety. Be sure to follow all the instructions. Contact the

manufacturer or distributor if you have any question.

1. If the oven is operative prior to servicing, a Microwave Leakage Test (a. k. a. Microwave Emission Check)

should be performed prior to servicing the oven Refer to Section 7.3, Microwave Leakage Test. For the

detailed check procedures.

2. In the event that any microwave oven found to have microwave emission level in excess of 4 mW/cm2. The

following procedures should be followed:

(1). .Inform the distributor; importer, or manufacturer the finding. Record it in the logbook as well.

(2). .Repair the unit at no cost to the owner.

(3). .Investigate the oven and ascertain the cause of the excessive leakage.

(4). .Hold the oven in your facility and instruct the owner not to use the unil until the oven has.

3. In the event that the oven operates with the door open. The following procedures should be followed:

(1). Tell the user not to operate the oven.

(2). Hold the oven in your facility until it is investigated and repaired.

(3). Contact the manufacturer and CDRH (FDA) immediately.

CCRRIITTIICCAALL PPAARRTTSS SSEERRVVIICCIINNGG

11..2211 IINNTTEERRLLOOCCKK AASSSSEEMMBBLLYY RREEPPLLAACCEEMMEENNTT AANNDD AADDJJUUSSTTMMEENNTT..

1. If you suspect defective primary, secondary or monitor interlock switches, use your ommeter (digital or

analog type) to check the electrical continuity.

2. Make sure the power cord is pulled out and the high-voltage capacitor is discharged before the electrical

continuity check.

3. Set the ohmmeter to “Low Resistance” range and connect both leads (alligator clips) to the switch terminals.

4. Open the door and notice the meter reading the primary or secondary interlock switch should show an

“infinite” resistancc when the door is open. Replace it when it is defective. The monitor interlock should show

a “zero or near zero” resistance when the door is open. When the door is closed, the readings will be

opposite.

5. If the oven has been rendered inoperative due to the failure of the monitored safety (primary and /or

secondary ) interlock(s). You should replace all of the monitored safety interlock switched and the monitor

switch.

6. Refer to Chapter 4, Sections I and X for how to remove and assemble the interlock and monitor switches.

7. Always refer to Section 0.4 for adequate wiring diagram. Monitor interlock must always be installed. Repeat

Step 6.2.4 to check electrical continuity.

8. Perform required checks and tests as described in Chapter 7 before releasing the oven to the owner.

23

Page 25

CCOOMMMMOONN BBRREEAAKKDDOOWWNN OOFF MMIICCRROOWWAAVVEE OOVVEENN AANNDD MMEEAANNSS OOFF RREEPPAAIIRRIINNGG

PHENOMENON CAUSE REPAIRING MEANS

1. When starting the

oven, the lamp is not on,

the turntable tray can’t

rotate and the food can’t

be heated

2.When starting the

oven, the lamp is on, the

turntable rotating, the fan

cycling but the food can’t

be heated.

3. The food can be

heated, but the lamp is

not on

4. The food can be

heated but the turntable

tray is not rotating.

5. The oven can heat

within 2-3 minutes, but

can not heat from the

fourth minutes

6. When starting the

oven, it can’t heat, and

with “wenwen” noise.

7. The oven can heat, but

with sound “shishi” noise

8. Large amount of

microwave leakage

8A fuse broken.

The primary and secondary winding of the

transformer are short – circuited.

The earthing or the polarity of the polarity of

the capacitor is punctured.

The pilot switch can’t cut off.

The interlock switch hasn’t closed.

The power plug and the socket are not in

good connection.

The door hook broken.

The primary and secondary winding, the

filament of the transformer are open –

circuit-ed.

The magnetron filament is open – circuited,

the magnetic steel of the magnetron broken

or the magnetron is air leaking.

Time and power distributor broken.

The plugs of the magnetron or the capacitor

loosed.

The lamp broken.

The plug falls off.

The turntable motor broken

The plug fall off

Connecting shaft weave broken

The winding of the fan motor in

open-circuited.

The fan falls off

The plug of the fan motor falls off

The turnatable shaft is griped with the

mo-tor bearin

The cooling vent blocked

The high voltage diode was punctured Change a new diode

The iron core of the transformer loosed Change a new transformer

The door deformed

The door metal net cracked

The gap of the door crack is too large

The welding point of the oven falls off

The screws which fix the magnetron loosed

The wave guide connection oxidized

The magnetron copper filament washer is

too thin cause the wave guide opening not

in good earth.

Change a new fuse.

Change a new transformer.

Change a new capacitor.

Change a new pilot switch.

Change a new interlock

switch.

Adjust the connection or

replace it by a new one.

Change a new hook.

Change a new transformer.

Change the magnetron.

Change the time power

distributor or the

micro-switch.

Fix them.

Change a new lamp

Insert the plug again

Change the turntable motor

Inset the plug securely

Change the weave

1.Change the fan motor

2.Change the fan

3.Insert the plug

4.Overhauling them

5.Repairing it

Mend the door

Change the door

Adjust the gap

Change the oven

Tighten the screws

Scrape the oxidized and

tighten the screws

Thick the copper filament

washer

24

Page 26

9. The door can’t open

10. The door release

button fall off

11. Electricity leaking

After long time using, the wear and the rust

–eaten enlarged the gap of the door shaft

and the shaft hole, thus cause the door

crooked.

The door hook broken.

Worn out and aged after long time

operating

The earthing insulation resistance of all the

motors or the transformer are less than 2

megaohms.

Adjust the hinge to rectify the

position of the door.

Change the hook.

Overhaul it or renew it

Test where is the leaking

place, then repair it or change

those damaged components.

SSPPEECCIIFFIICCAATTIIOONNSS

Power Consumption: 120V~60Hz, 1450W

Microwave Power Output: 1000W

Operation Frequency: 2450MHz

Outside Dimensions(H×W×D): 12×20×16 9/16 in.

Oven Cavity Dimensions(H×W×D): 8 7/16×13 3/4×13 in.

Oven Capacity: 0.8cu.ft

Cooking Uniformity: Turntable System (Φ12 3/8” )

Net Weight: Approx. 34.4lbs.

25

Loading...

Loading...