Sanyo EMP415WS Schematic

File No :File No :

File No :

File No :File No :

SER SER

SER

SER SER

VICE MANUALVICE MANUAL

VICE MANUAL

VICE MANUALVICE MANUAL

Micr Micr

Micr

Micr Micr

owave Ovenowave Oven

owave Oven

owave Ovenowave Oven

Pr Pr

oduct Code No.oduct Code No.

Pr

oduct Code No.

Pr Pr

oduct Code No.oduct Code No.

EM-P415WS EM-P415WS

EM-P415WS

EM-P415WS EM-P415WS

437 499 00437 499 00

437 499 00

437 499 00437 499 00

(U.S.A.)(U.S.A.)

(U.S.A.)

(U.S.A.)(U.S.A.)

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

WW

ARNING TO SERARNING TO SER

W

ARNING TO SER

WW

ARNING TO SERARNING TO SER

VICE TECHNICIANSVICE TECHNICIANS

VICE TECHNICIANS

VICE TECHNICIANSVICE TECHNICIANS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary :

(1) Interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage),

(4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse.

(c) Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity,

and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and

transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before

the oven is released to the owner.

(e) A microwave leakage check to verify compliance with the Federal per formance standard should be performed

on each oven prior to release to the owner.

REFERENCE NO. SM-860251

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

For micrFor micr

For micr

For micrFor micr

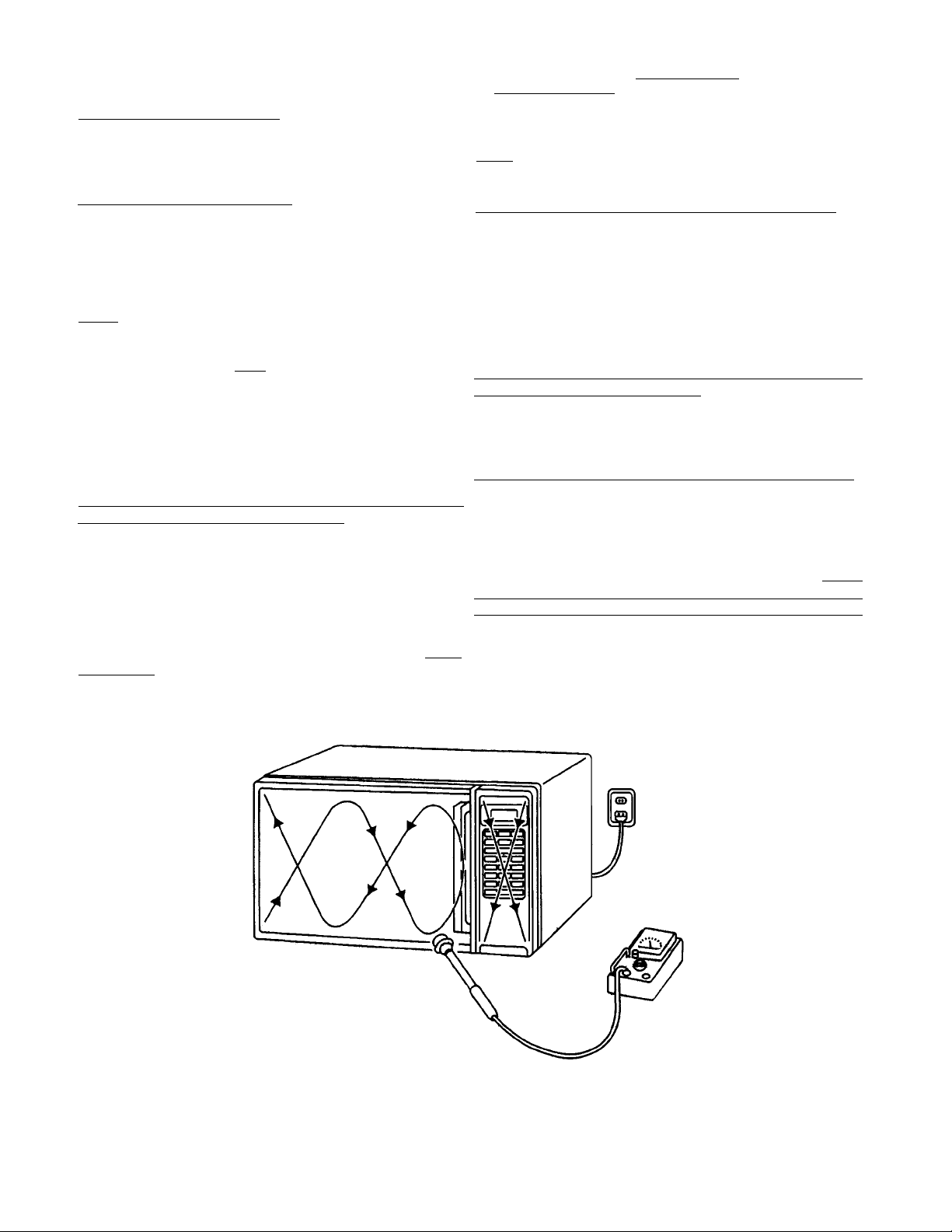

On every service calls, check for microwave energy

emission, must be made according to the following manner.

MeasurMeasur

Measur

MeasurMeasur

Measurement must be made with the microwave oven

operating at its maximum output and containing a load of

275±15 milliliters of tap water initially at 20

±9oF) placed within the cavity at the center.

NOTENOTE

NOTE : The water container must be a 600 milliliter beaker

NOTENOTE

A properly operating door and seal assembly will normally

register emission on greater than 4mW/cm

measurement uncertainty with the cooking shelf or tray in

place.

All repairs must be performed in such a manner All repairs must be performed in such a manner

All repairs must be performed in such a manner

All repairs must be performed in such a manner All repairs must be performed in such a manner

micrmicr

micr

micrmicr

Follow the instructions supplied with a detector being used

and performed an R.F. emission test around the door front

and edges and all edges and vent of the outer case. The

cabinet (wrapper) must be in place and the oven fully

assembled.

When performing emission survey, with the meter on FAST

RESPONSE the movement of a detector probe shall not

exceed one (1) inch per second.

owave enerowave ener

owave ener

owave enerowave ener

ement of enerement of ener

ement of ener

ement of enerement of ener

and made of an electrically none conductive

material such as glass or plastic.

The cook tray must be in place when measuring

emission.

owave enerowave ener

owave ener

owave enerowave ener

gy emissiongy emission

gy emission

gy emissiongy emission

gy emissiongy emission

gy emission

gy emissiongy emission

gy emission argy emission ar

gy emission ar

gy emission argy emission ar

e minimal.e minimal.

e minimal.

e minimal.e minimal.

o±5o

2

celsius (68

to allow for

thatthat

that

thatthat

In the area emitting the highest reading, switch the meter

to SLOW RESPONSE, and take a reading for minimum of

three (3) seconds. We recommended the pattern outline

shown below when the door surface is surveyed.

NOTENOTE

NOTE : Periodically check to be sure that the probe tip is

NOTENOTE

not worn or dirty.

The following U.S. standard applies to microwave ovens :

21 CFR 1030.10, Performance Standard for Microwave

Ovens.

It requires that the power density of the microwave

radiation emitted by a microwave oven shall not exceed

five (5) milliwatts per square centimeter at any point 5

centimeter (about 2 inches) or more from the external

surface of the oven.

All microwave ovens exceeding the emission level of

4mW/cm

microwave ovens and the manufacturer immediately and

the owner should be told not to use the microwave oven

until it has been repaired completely.

If a microwave oven is found to operate with the door open,

report to Dept. of Service, the manufacturer and CDRH*

immediately. Also tell the owner not to use the oven.

*CDRH : Center for Device and Radiological Health.

The interlock monitor switch acts as the final safety switch

protecting the customer from microwave radiation. If the

interlock monitor switch operates to blow the fuse with

interlocks failed, you must replace all interlock switches

primary and secondary interlock switches and the monitor

switch with new ones because the contacts of those

interlock switches may be melted and welded together.

2

must be reported to Dept. of Service for

- i -

- TABLE OF CONTENTS -

Adjustment Procedures ................................................... 1

Specifications .................................................................. 2

Power Output Measurement ........................................... 2

Precautions and Repair Service Tips .............................. 2

Circuit Diagram ............................................................... 3

1.1.

ADJUSTMENT PROCEDURESADJUSTMENT PROCEDURES

1.

ADJUSTMENT PROCEDURES

1.1.

ADJUSTMENT PROCEDURESADJUSTMENT PROCEDURES

TT

O AO A

VOID POSSIBLE EXPOSURE TO MICROWVOID POSSIBLE EXPOSURE TO MICROW

T

O A

VOID POSSIBLE EXPOSURE TO MICROW

TT

O AO A

VOID POSSIBLE EXPOSURE TO MICROWVOID POSSIBLE EXPOSURE TO MICROW

ENERGY LEAKAGE, THE FOLLOWINGENERGY LEAKAGE, THE FOLLOWING

ENERGY LEAKAGE, THE FOLLOWING

ENERGY LEAKAGE, THE FOLLOWINGENERGY LEAKAGE, THE FOLLOWING

ADJUSTMENT OF THE INTERLOCK SWITCHESADJUSTMENT OF THE INTERLOCK SWITCHES

ADJUSTMENT OF THE INTERLOCK SWITCHES

ADJUSTMENT OF THE INTERLOCK SWITCHESADJUSTMENT OF THE INTERLOCK SWITCHES

SHOULD BE MADE ONLSHOULD BE MADE ONL

SHOULD BE MADE ONL

SHOULD BE MADE ONLSHOULD BE MADE ONL

SERSER

VICE PERSONNEL.VICE PERSONNEL.

SER

VICE PERSONNEL.

SERSER

VICE PERSONNEL.VICE PERSONNEL.

The SANYO service center should have the designated

detector to measure the microwave energy leakage

after the repair or adjustment.

NOTENOTE

NOTE : Detector to be used at the service center is

NOTENOTE

NARDA 8100, 8200 or the equivalent.

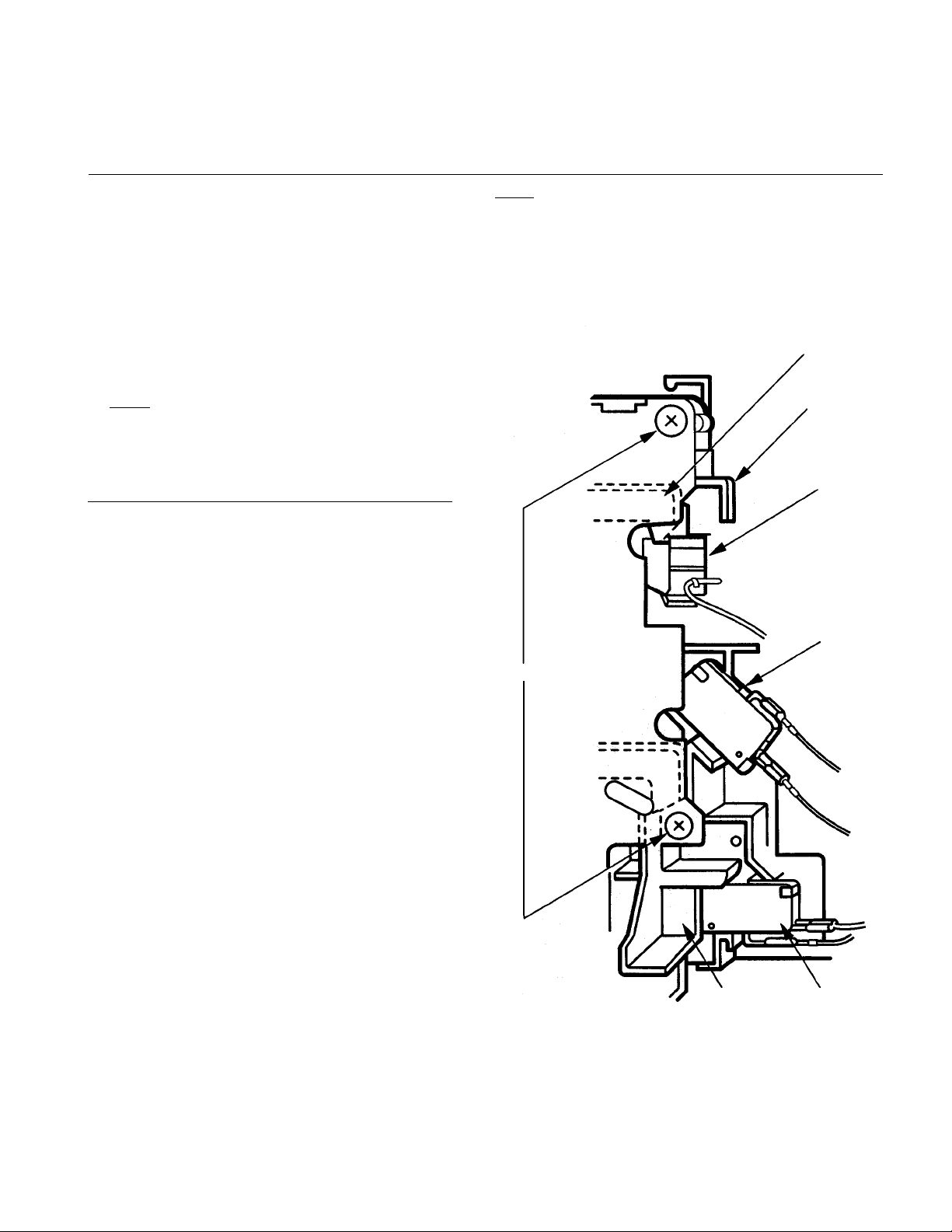

PRIMARPRIMAR

PRIMAR

PRIMARPRIMAR

MONITOR SWITCH AND DOOR SENSING SWITCHMONITOR SWITCH AND DOOR SENSING SWITCH

MONITOR SWITCH AND DOOR SENSING SWITCH

MONITOR SWITCH AND DOOR SENSING SWITCHMONITOR SWITCH AND DOOR SENSING SWITCH

ADJUSTMENTADJUSTMENT

ADJUSTMENT

ADJUSTMENTADJUSTMENT

(Figure 1)(Figure 1)

(Figure 1)

(Figure 1)(Figure 1)

Y INTERLOCK SWITCH, INTERLOCKY INTERLOCK SWITCH, INTERLOCK

Y INTERLOCK SWITCH, INTERLOCK

Y INTERLOCK SWITCH, INTERLOCKY INTERLOCK SWITCH, INTERLOCK

Y BY AUTHORIZEDY BY AUTHORIZED

Y BY AUTHORIZED

Y BY AUTHORIZEDY BY AUTHORIZED

AA

A

AA

Test Procedures and Troubleshooting .................... 4 ~ 10

Disassembly Instructions ....................................... 11 ~ 14

Exploded View and Parts List ................................ 15 ~ 20

Overall Circuit Diagram .......................................... 21

NOTENOTE

NOTE : If the Interlock Monitor Circuit operates and at the

NOTENOTE

same time the Fuse blows with the Door opened,

VEVE

VE

VEVE

be sure to replace the Control Circuit Board because

Relay 2 on the Control Circuit Board, the Door Sensing

Switch and the electric circuit related on the

Door Sensing Switch, which act as Secondary

Interlock Switch.

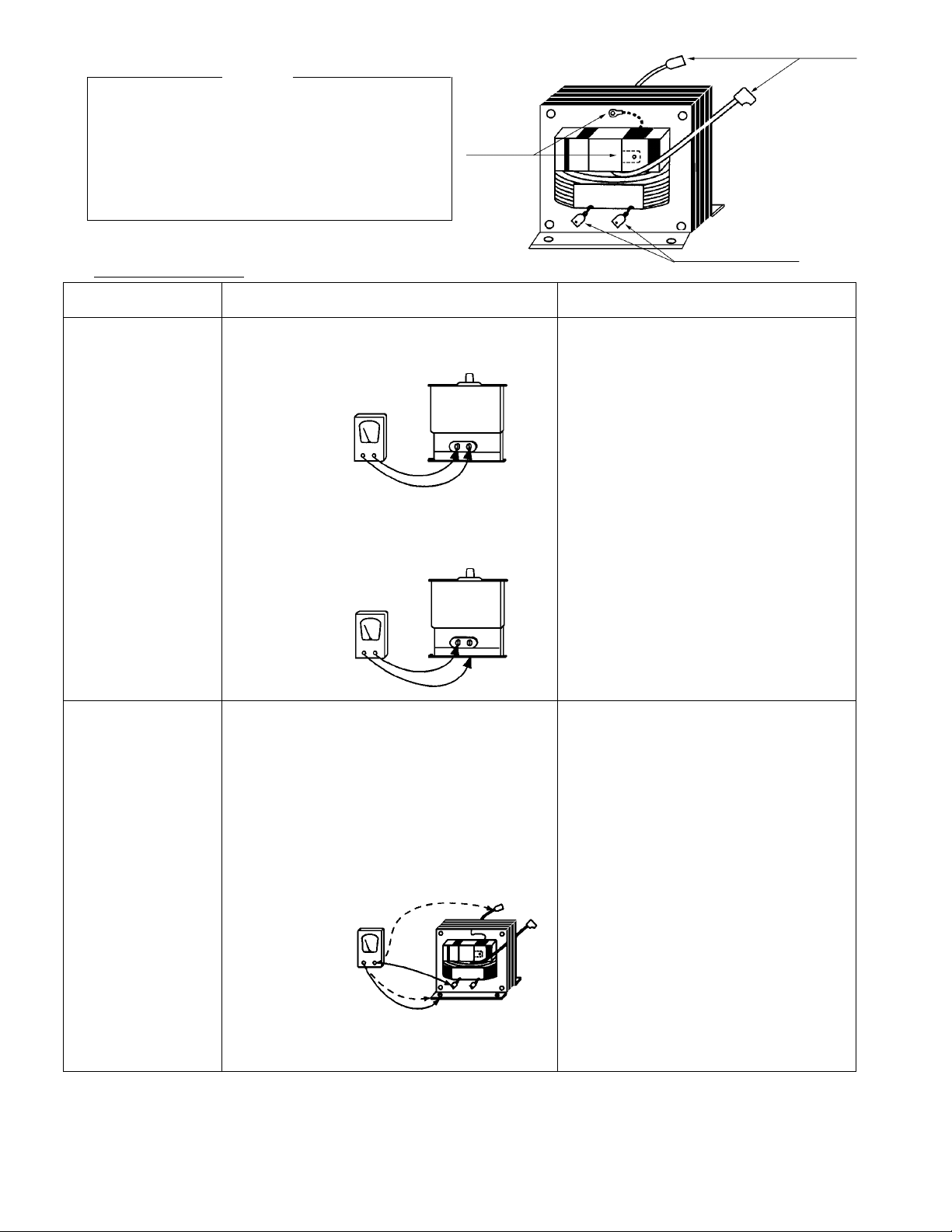

Door

Latch

Lever Stopper

Door

Sensing

Switch

(1) Loosen 2 screws securing the Lever Stopper.

(2) Adjust the Lever Stopper position so that it is pushed

forward and pull backward until there is about zero

gap between the Latch Lever and the switch body on

the Primary Interlock Switch and at the same time

there is about zero gap between the Door Latch and

the switch body on the Door Sensing Switch when

the Door Latch is securely locked.

(3) Tighten the Lever Stopper screws securely.

(4) Make sure the Interlock Monitor Switch closes after

the Primary Interlock Switch opens when the Door

is opened very slowly, according to “CHECKOUT

PROCEDURE FOR SWITCHES” on page 6.

(5) Make sure the Interlock Monitor Switch opens before

the Primary Interlock Switch closes when the Door is

closed very slowly, according to “CHECKOUT

PROCEDURE FOR SWITCHES” on page 6.

(6) Make sure the microwave energy leakage should be

no greater than 4mW/cm2 to allow for measurement

uncertainty when measured with a detector.

(All service adjustments must be made for

minimum microwave energy leakage readings.)

Interlock

Monitor

Switch

Screws

- 1 -

Figure 1Figure 1

Figure 1

Figure 1Figure 1

Latch

Lever

Primary

Interlock

Switch

2.2.

SPECIFICASPECIFICA

2.

SPECIFICA

2.2.

SPECIFICASPECIFICA

Rated Power Consumption .. 1650W.

Microwave Output ................ 1100W.

Frequency ............................. 2,450MHz±50MHz.

Power Supply ........................120V±12V, 60Hz.

Rated Current ....................... 14 Amp.

Safety Devices ..................... Thermal Fuse open at

Timer .....................................Electronic Digital, up to

Overall Dimensions ................ 205/8”(W) x 161/2”(D) x 113/8”(H)

Oven Cavity Size .................. 133/4”(W) x 145/8”(D) x 81/4”(H)

Turn Table Diameter ..............107/8”

Effective Capacity of

Oven Cavity .......................... 1.1 Cubic Feet.

Net Weight ........................... Approx. 34.1 Lbs.

3.3.

POWER OUTPUT MEASUREMENTPOWER OUTPUT MEASUREMENT

3.

POWER OUTPUT MEASUREMENT

3.3.

POWER OUTPUT MEASUREMENTPOWER OUTPUT MEASUREMENT

NOTENOTE

NOTE

NOTENOTE

The power output specification, 1100W. on this model is

measured with IEC measurement. The power output is

measured with two (2) liters water is equivalent to 1100W.

in measurement with IEC, when measured with the following

power output.

(1) Fill two beakers (glass or plastic) with each one liter of

tap water (about 20°C) and measure the water temperature.

(Use a thermometer with a 1/10 degree gauge).

(2) Place the beakers side by side in the center of the glass tray.

(3) Close the door, set the “TIME” for two minutes. (“200” in

the display window). Touch the “START” key and heat

the water exactly for two minutes.

(4) Take the beakers out, immediately stir the water and

measure the water temperature respectively.

(5) Calculate the temperature rise of water in each beaker.

Then calculate the average value of two temperature rises.

Output power can be calculated by the equation :

Power Output (W) = 70 x ∆t

Where ∆t is an average temperature rise in degrees

Centigrade.

(6) Power Output shall be in the following range :

Minimum 22.9°F (12.7°C) 889W

Maximum 29.3°F (16.3°C) 1141W

(7) Power Output is affected by the line voltage under load.

For correct Power Output measurement, the line voltage

under load must be 120±1 volts.

TIONSTIONS

TIONS

TIONSTIONS

332°F (167°C) for Cavity.

Thermal Protector open at

275°F (135°C) for Magnetron.

Fuse (Cartridge Type 20A)

Primary Interlock Switch,

Door Sensing Switch and

Relay 2.

Interlock Monitor Switch.

99 min. 99 sec.

Average Temperature Rise Power Output

4.4.

PRECAUTIONS AND REPPRECAUTIONS AND REP

4.

PRECAUTIONS AND REP

4.4.

PRECAUTIONS AND REPPRECAUTIONS AND REP

PRELIMINARPRELIMINAR

PRELIMINAR

PRELIMINARPRELIMINAR

A.A.

SINCE NEARLSINCE NEARL

A.

SINCE NEARL

A.A.

SINCE NEARLSINCE NEARL

CUITS OF THIS MICROWCUITS OF THIS MICROW

CUITS OF THIS MICROW

CUITS OF THIS MICROWCUITS OF THIS MICROW

BE CARRIED OUT WITH GREABE CARRIED OUT WITH GREA

BE CARRIED OUT WITH GREA

BE CARRIED OUT WITH GREABE CARRIED OUT WITH GREA

B.B.

TO ATO A

B.

TO A

B.B.

TO ATO A

ENERGY LEAKAGE, THE FOLLOWING PRECAUTIONSENERGY LEAKAGE, THE FOLLOWING PRECAUTIONS

ENERGY LEAKAGE, THE FOLLOWING PRECAUTIONS

ENERGY LEAKAGE, THE FOLLOWING PRECAUTIONSENERGY LEAKAGE, THE FOLLOWING PRECAUTIONS

MUST BE TMUST BE T

MUST BE T

MUST BE TMUST BE T

(1) Before the power is applied :

(a) Open and close door several times to make sure the

(b) Make sure the perforated screen and the choke die-

(2) After the power is applied :

(a) Open and close the door to see if the interlock mech-

(b) Check microwave energy leakage with a leakage

(3) Do not operate the unit until it is completely repaired,

if any of the following conditions exists :

(a) Door does not close firmly against the cavity front.

(b) The hinge is broken.

(c) The choke dielectric or the door seal is damaged.

(d) The door is bent or warped, or there is any other

NOTE :

(e) Make sure that there are no defective parts in the

(f) Make sure there are no defective parts in the

(4) The following items should be checked after the unit

is repaired :

(a) The interlock monitor switch is connected correctly

(b) The magnetron gasket on the magnetron is properly

(c) Waveguide and oven cavity are intact (no leakage of

(d) The door can be properly closed and the safety

(e) The oven must be stopped when the door is opened

The oven must not be operated with any of the aboveThe oven must not be operated with any of the above

The oven must not be operated with any of the above

The oven must not be operated with any of the aboveThe oven must not be operated with any of the above

components rcomponents r

components r

components rcomponents r

YY

Y

YY

Y 2,000 VOLY 2,000 VOL

Y 2,000 VOL

Y 2,000 VOLY 2,000 VOL

VOID POSSIBLE EXPOSURE TO MICROWVOID POSSIBLE EXPOSURE TO MICROW

VOID POSSIBLE EXPOSURE TO MICROW

VOID POSSIBLE EXPOSURE TO MICROWVOID POSSIBLE EXPOSURE TO MICROW

AKEN BEFORE SERAKEN BEFORE SER

AKEN BEFORE SER

AKEN BEFORE SERAKEN BEFORE SER

primary interlock switch, the interlock monitor switch

and the door sensing switch operate properly.

(Listen for the clicking sound from the switches).

Make sure the interlock monitor switch closes after

the primary interlock switch is opens when the door

is opened. (See pages 1 and 6).

lectric of the door are correctly mounted.

anism operates properly.

detector and confirm the energy leakage should be

no greater than 4mW/cm

uncertainty.

visible damage to the oven that may cause microwave

energy leakage.

Always keep the seal clean.Always keep the seal clean.

Always keep the seal clean.

Always keep the seal clean.Always keep the seal clean.

interlock mechanism.

microwave generating and transmission assembly.

(especially waveguide).

and firmly.

positioned.

microwave energy).

switches work properly.

or the time is up.

emoved or bypassed.emoved or bypassed.

emoved or bypassed.

emoved or bypassed.emoved or bypassed.

AIR SERAIR SER

AIR SER

AIR SERAIR SER

TS EXISTS IN SOME CIR-TS EXISTS IN SOME CIR-

TS EXISTS IN SOME CIR-

TS EXISTS IN SOME CIR-TS EXISTS IN SOME CIR-

AA

VE OVEN, REPVE OVEN, REP

A

VE OVEN, REP

AA

VE OVEN, REPVE OVEN, REP

T CARE.T CARE.

T CARE.

T CARE.T CARE.

VICING.VICING.

VICING.

VICING.VICING.

2

to allow for measurement

VICE TIPSVICE TIPS

VICE TIPS

VICE TIPSVICE TIPS

AIRS SHOULDAIRS SHOULD

AIRS SHOULD

AIRS SHOULDAIRS SHOULD

AA

VEVE

A

VE

AA

VEVE

- 2 -

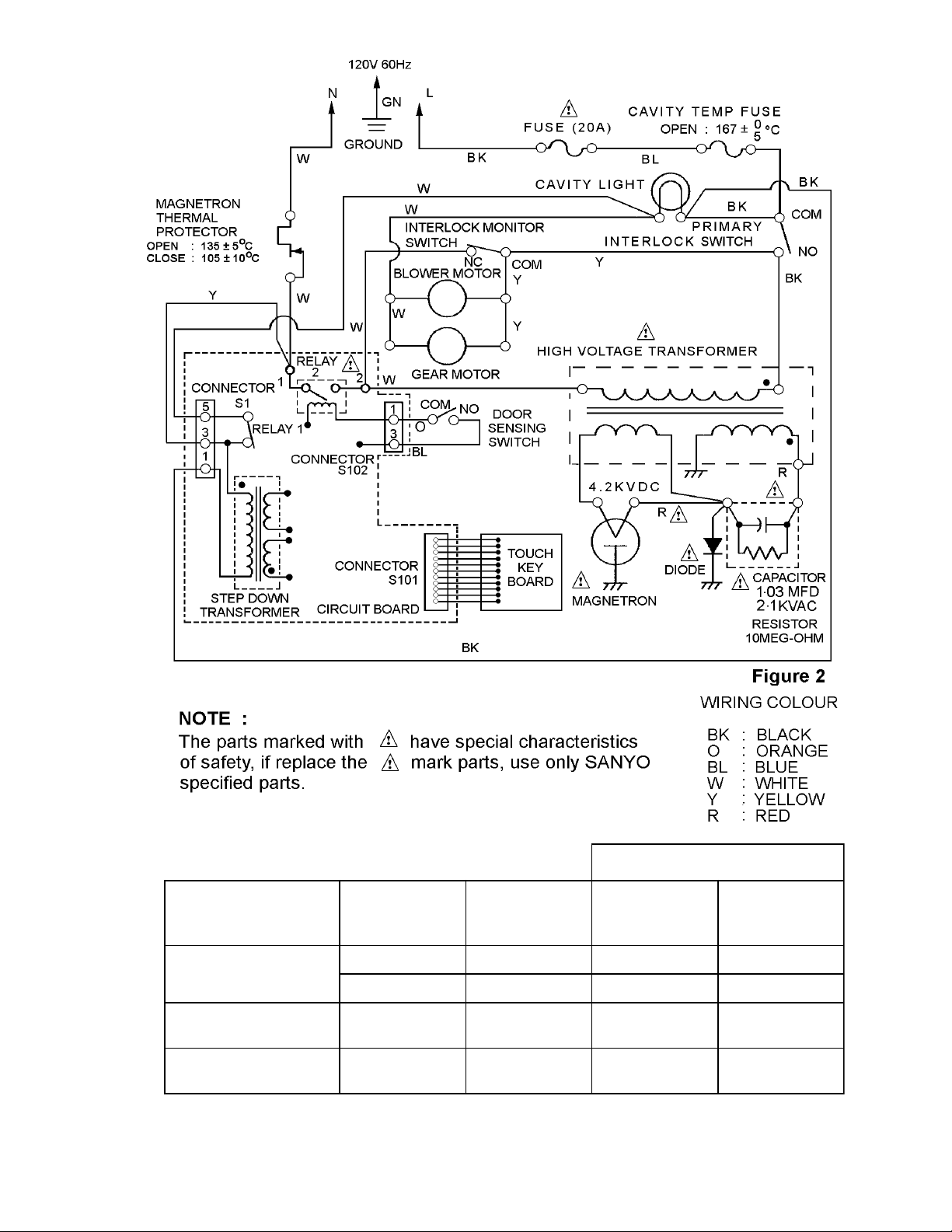

5. CIRCUIT DIAGRAM

DNOCTINOI

KCOLRETNIYRADNOCES

YRAMIRP

EDAMHCTIWS

•

NEPOROOD

ESOLCROOD

•••

KCOLRETNI

HCTIWS

MOCMOCMOCMOC

ONCNONON

•

- 3 -

KCOLRETNI

ROTINOM

HCTIWS

ROOD

GNISNES

HCTIWS

2YALER

6. TEST PROCEDURES AND TROUBLESHOOTING6. TEST PROCEDURES AND TROUBLESHOOTING

6. TEST PROCEDURES AND TROUBLESHOOTING

6. TEST PROCEDURES AND TROUBLESHOOTING6. TEST PROCEDURES AND TROUBLESHOOTING

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

- DISCONNECT THE POWER SUPPL- DISCONNECT THE POWER SUPPL

- DISCONNECT THE POWER SUPPL

- DISCONNECT THE POWER SUPPL- DISCONNECT THE POWER SUPPL

THE WTHE W

ALL OUTLET WHENEVER REMOVING THEALL OUTLET WHENEVER REMOVING THE

THE W

ALL OUTLET WHENEVER REMOVING THE

THE WTHE W

ALL OUTLET WHENEVER REMOVING THEALL OUTLET WHENEVER REMOVING THE

CABINET FROM THE UNITCABINET FROM THE UNIT

CABINET FROM THE UNIT

CABINET FROM THE UNITCABINET FROM THE UNIT

TESTS ONLTESTS ONL

TESTS ONL

TESTS ONLTESTS ONL

VOLVOL

TT

VOL

T

VOLVOL

TT

WIRES FROM THE PRIMARWIRES FROM THE PRIMAR

WIRES FROM THE PRIMAR

WIRES FROM THE PRIMARWIRES FROM THE PRIMAR

HIGH VOLHIGH VOL

HIGH VOL

HIGH VOLHIGH VOL

A.A.

TEST PROCEDURESTEST PROCEDURES

A.

TEST PROCEDURES

A.A.

TEST PROCEDURESTEST PROCEDURES

Y AFTER DISCHARGING THE HIGHY AFTER DISCHARGING THE HIGH

Y AFTER DISCHARGING THE HIGH

Y AFTER DISCHARGING THE HIGHY AFTER DISCHARGING THE HIGH

AGE CAPAGE CAP

AGE CAP

AGE CAPAGE CAP

ACITOR AND REMOVING THE LEADACITOR AND REMOVING THE LEAD

ACITOR AND REMOVING THE LEAD

ACITOR AND REMOVING THE LEADACITOR AND REMOVING THE LEAD

TT

AGE TRANSFORMER. (SEE FIGURE 3)AGE TRANSFORMER. (SEE FIGURE 3)

T

AGE TRANSFORMER. (SEE FIGURE 3)

TT

AGE TRANSFORMER. (SEE FIGURE 3)AGE TRANSFORMER. (SEE FIGURE 3)

Y CORD FROMY CORD FROM

Y CORD FROM

Y CORD FROMY CORD FROM

, PROCEED WITH THE, PROCEED WITH THE

, PROCEED WITH THE

, PROCEED WITH THE, PROCEED WITH THE

Y WINDING OF THEY WINDING OF THE

Y WINDING OF THE

Y WINDING OF THEY WINDING OF THE

Secondary

Windings

Filament Windings

Primary

Windings

Figure 3Figure 3

Figure 3

Figure 3Figure 3

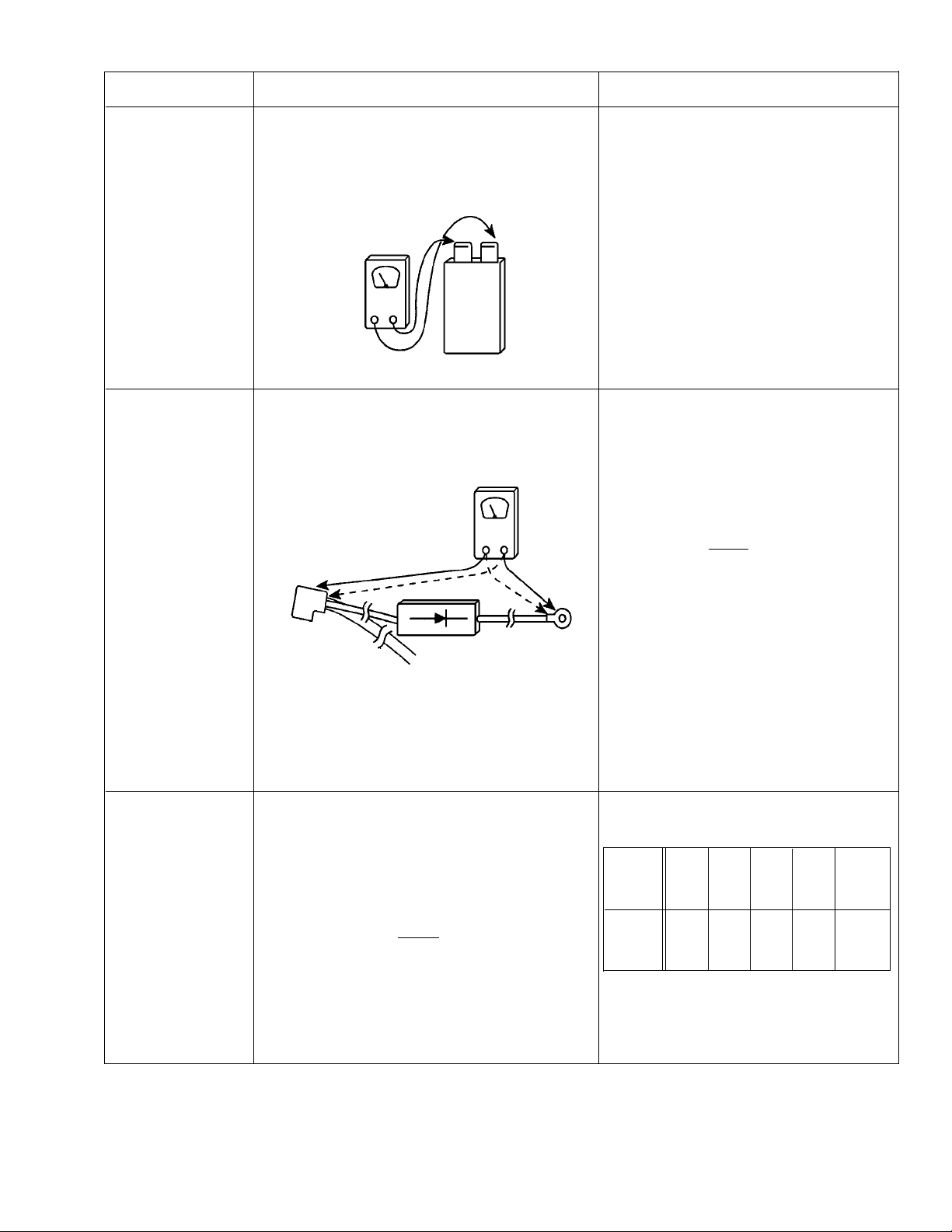

COMPONENT COMPONENT

COMPONENT

COMPONENT COMPONENT

MAGNETRON

CHECKOUT PROCEDURE CHECKOUT PROCEDURE

CHECKOUT PROCEDURE

CHECKOUT PROCEDURE CHECKOUT PROCEDURE

1) Check for resistance : Across the filament Normal reading :

terminals of the Magnetron with an Ohm-Meter Less than 1 Ohm.

on R x 1 scale.

Ohm-MeterOhm-Meter

Ohm-Meter

Ohm-MeterOhm-Meter

Figure 4Figure 4

Figure 4

Figure 4Figure 4

2) Check for resistance : Between each filament Normal reading :

terminal of the Magnetron and the chassis Infinite Ohms.

ground with an Ohm-Meter on highest scale.

Ohm-MeterOhm-Meter

Ohm-Meter

Ohm-MeterOhm-Meter

Figure 5Figure 5

Figure 5

Figure 5Figure 5

1) Measure the resistance : Normal readings :

With an Ohm-Meter on R x 1 scale.

a. Primary winding : Approximately 0.31 Ohms.

b. Filament winding : Less than 1 Ohm.

c. Secondary winding : Approximately 67.5 Ohms.

RESUL RESUL

RESUL

RESUL RESUL

TT

T

TT

HIGH-VOLTAGE

TRANSFORMER

2) Measure the resistance : Normal readings :

With an Ohm-Meter on highest scale.

a. Primary winding to ground. Infinite Ohms.

b Filament winding to ground. Infinite Ohms.

Ohm-meterOhm-meter

Ohm-meter

Ohm-meterOhm-meter

Figure 6Figure 6

Figure 6

Figure 6Figure 6

Note Note

Note : Remove varnish of

Note Note

measured point.

- 4 -

COMPONENT COMPONENT

COMPONENT

COMPONENT COMPONENT

CHECKOUT PROCEDURE CHECKOUT PROCEDURE

CHECKOUT PROCEDURE

CHECKOUT PROCEDURE CHECKOUT PROCEDURE

Measure the resistance : Across two terminals Normal reading :

with an Ohm-Meter on highest scale. Momentarily indicates several ohms,

RESUL RESUL

RESUL

RESUL RESUL

and gradually returns to 10 Meg-Ohms.

TT

T

TT

HIGH-VOLTAGE

CAPACITOR

including

BLEEDER

RESISTOR

HIGH-VOLTAGE

DIODE

Abnormal reading :

Indicates continuity or 10 Meg-Ohms

from the beginning.

Ohm-MeterOhm-Meter

Ohm-Meter

Ohm-MeterOhm-Meter

Figure 7Figure 7

Figure 7

Figure 7Figure 7

Measure the resistance : Across two terminals Normal reading :

with an Ohm-Meter on R x 10,000 scale. Indicates about the middle position in

one direction (forward direction) and

infinite Ohms in the reverse direction,

using meter which is provided with a

Ohm-MeterOhm-Meter

Ohm-Meter

Ohm-MeterOhm-Meter

9 volt battery.

NOTENOTE

NOTE

NOTENOTE

- Some digital meter may show over

even in a forward direction because

low measuring voltage of meter does

not allow the meter current to pass

through the High Voltage Diode.

CONTROL

CIRCUIT

BOARD

Figure 8Figure 8

Figure 8

Figure 8Figure 8

Measure the voltage : Between test point TP-1,

TP-2 , TP-3 or TP-4 and Ground between TP-5

and TP-6 (See Control Circuit Board on page 19).

- Proceed with the check of the Step-Down

Transformer, to see if any one of the measured

values is different from the specified values.

NOTENOTE

NOTE

NOTENOTE

Abnormal reading :

Indicates continuity or infinite Ohms

in both directions.

Test TP-5 /

Point

Voltage

TP-1 TP-2 TP-3 TP-4

-5V -15V -25V -36V 2.0V

DC DC DC DC AC

TP-6

- 5 -

Loading...

Loading...