1

FILE No.

SERVICE MANUAL

MICROWAVE OVEN

WITH GRILL

EM-G200(UK)

EM-G200(Spain)

EM-G200(Portugal)EM-G400(Portugal)

Product

EM-G200(UK)

EM-G200(Spain)

EM-G200(Portugal

EM-G400(UK)

EM-G400(Spain)

EM-G400(Portugal

Code No.

EM-G400(UK)

EM-G400(Spain)

FOREWORD

Rea

d this manual carefully, especially precaution

stri

tly. Careless servicing and testing may expose y

PRECAUTIONS TO BE OBSERVED

POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety

other microwave source, and make repairs if necessary:

(1) Interlock operation, (2) proper door closing, (3)

otherdamage), (4) damage to or loosening of

abuse.

(c)

Before

(d) Any defective or misadjusted components

generation and transmission systems

described

turning on microwave power for any

microwave generating compartments, check the magnetron, wave-guide or transmission line,

and cavity for proper alignment, integrity, and connections.

in

this manual

checks on all ovens

before

BEFORE

shall

the oven is

in

be repaired, replaced, or adjusted by procedures

microwave energy, and follow the procedu

on

,ourself

AND DURING SERVICING TO AVOID

to be serviced

hinges

service

the interlock, monitor, door

released

to the microwave energy leakage.

before

seal

and sealing surfaces (arcing, wear, and

and

latches,

test or inspection within the

to the owner.

activating the magnetron or

(5)

evidence

seal,

of dropping or

and microwave

re

ENG 30

.

REFERENCE No.

SM-850023

Adjustment Procedures

Specifications

Power Output

Precautions andRepair Service Tips..

PERSONNEL SHOULD NOT BE EXPOSED TO

THE

MICROWAVE ENERGY WHICH MAY RADIATE FROM THE MAGNETRON OR OTHER

MICROWAVE GENERATING DEVICE IF IT

IMPROPERLY

INPUT AND

TIONS, WAVE GUIDES,

KETS MUST BE

THE DEVICE WITHOUT A MICROWAVE

GY ABSORBING LOAD ATTACHED. NEVER

LOOK INTO

ANTENNA WHILE THE DEVICE

.......................................................

Measurement

MICROWAVE ENERGY

USED OR CONNECTED.

OUTPUT

AN

OPEN WAVE GUIDE OR

........................................

................................

CAUTION

MICROWAVE

FLANGES,

SECURE.

NEVER

IS

................

IS

ALL

CONNEC-

AND GAS-

OPERATE

ENER-

ENERGISED

TABLE OF CONTENTS

1

Circuit Diagram

Test Procedures and Troubleshooting..

2

2

Disassembly Instructions

Exploded View and Parts list

2

....................................................

...............

.....................................

...............................

3-4

5-8

9-10

11-15

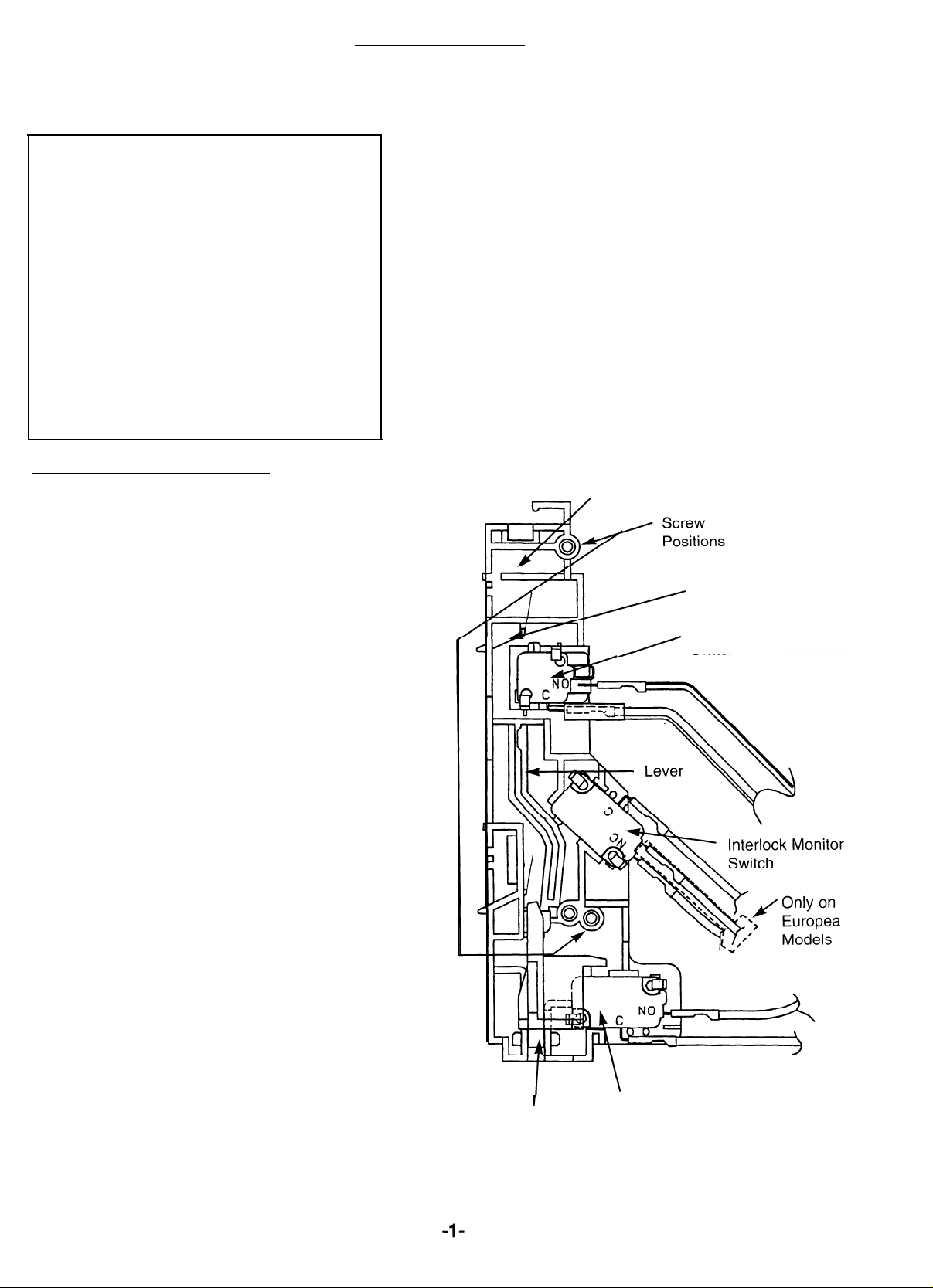

1. ADJUSTMENT PROCEDURES

TO AVOID POSSIBLE EXPOSURE TO MICRO-WAVE

ENERGY LEAKAGE, THE FOLLOWING

MENT OF THE INTERLOCK SWITCHES SHOULD

BE MADE ONLY BY AUTHORISED SERVICE

PERSONNEL

PRIMARY INTERLOCK SWITCH, DOOR SENSING

SWITCH AND INTERLOCK MONITOR SWITCH

ADJUSTMENT

(Figure 1)

(1)

Loosen

(2) Adjust the

up and

2-l. Between the Iever and the switch body

2-2. Between the Iever and the switch body

2-3. Between the

(3) Tighten the

(4) Make

the primary interlock switch opens when the door

opened very slowly, according to “CHECKOUT

PROCEDURE FOR SWITCHES”

(5) Make

the primary interlock and secondary interlock

switches

according to “CHECKOUT PROCEDURE FOR

SWITCHES”

(6) Make

the

measured with a detector. (

adjustments must be made for minimum energy

leakage readings.)

2 screws securing the

lever

stopper position so that it is pushed

pull

forward until there is about zero gap.

the door sensing switch.

on

the interlock monitor switch.

latch lever

on

the primary interlock switch.

when the door

sure

sure

sure

limit

of the regulation

latch is

lever

stopper screws securely.

the interlock monitor is

the interlock monitor is open

close

when the door is

on

page 7.

the

microwave

lever

and the switch body

securely locked.

energy leakage is below

(5mW/cm2)

All Service

stopper.

closed

on

page 7.

closed

when

ADJUST-

after

before

very slowly,

on

Lever Stopper

/

Door

Latch

rl

/

is

I

Latch Lever

Primary Interlock

Switch

Door Sensing

Switch

n

Figure 1

2. SPECIFICATIONS - EM-G200

Rated Power Consumption........ Micro1250W

Grill1000W

Dual 2250W

Microwave Output . . . . . . . . . . . . . . . . . . . . . .

Frequency.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rated Current

.,...........................Micro

8OOW(

Adjustable 80W

through 800W

2,450MHz ±

50MHz

230V,50Hz

5.6±15%

Grill

4.4±15%

Dual

10.4±15% Amps

)

Amps

Amps

(After 15mins.)

Safety Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Protector for

Magnetron,Open at

135ºC

,

Thermal Protector for

Cavity, Open at

150°C

Thermal Protector for

Cavity, Open at

Fuse

(Cartridge Type 8A)

122ºC

Primary Interlock Switch

Door Sensing Switch

Interlock Monitor Switch

Timer

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overalll

Oven

Turntable

Net Weight

Dimensions . . . . . . . . . . . . . 470(W)x373(D)x284(H)mm

Cavity Size.. . . . . . . . . . . . . . . .288(W)x304(

Diameter . . . . . . . . . . . . . . . . . . . . . 262mm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60min

Approx.

D)x195(

17.0Kg.

H)mm

2. SPECIFICATIONS - EM-G400

Rated Power Consumption........ Micro1 650W Grill 1300W

Dual 2950W

Microwave Output . . . . . . . . . . . . . . . . . . . . . . 1 OOOW( Adjustable

through IOOOW

Frequency

Power Supply

Rated Current

Safety Devices

Timer

Overalll

Oven

Turntable

Net Weight

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2,450MHz ±

230V,50Hz

Micro

Grill

7.6±15%

5.5±15%

Dual 13.1

(After 1

Same

as G200

60min

50MHz

±15%

5mins.)

Dimensions . . . . . . . . . . . . . 47O(W)x373(D)x284(H)mm

Cavity Size . . . . . . . . . . . . . . . . . 288(W)x304(D)x195(H)mm

Diameter . . . . . . . . . . . . . . . . . . . . . 262mm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approx.

1 OOW

)

Amps

Amps

Amps

above.

17.5Kg.

3. POWER OUTPUT MEASUREMENT

(1) Prepare

(2) Adjust water temperature to

1000±5g

tap water.

10°C+2ºC.

(3) Pour water into a container made of

borosilicate glass,

190mm

outer diameter

cylinder, maximum 3mm thickness.

(4) Place the container

cavi

ty.

in

the centre of the oven

(5) Set the timer at any position more than one

minute, set the power controller to the“ High”

position, and

close

the door.

(6) Heat the water correctly for 52 and 42 seconds

for 800W and IOOOW respectively.

(7) Take the container out immediately when

heating time

(8) Stir water for making

in

the container.

(9)

Measure

Water temperature rise should be between 8º C to

for

correct

power output.

is

up.

even

water temperature

water temperature.

12ºC

4.PRECAUTIONS AND REPAIR SERVICE TIPS

PRELIMINARY

A.SINCE NEARLY 4,000

VOLTS

EXIST IN

SOME CIRCUITS OF THIS MICROWAVE

OVEN, REPAIRS SHOULD BE CARRIED

OUT WITH GREAT CARE

B.TO AVOID POSSIBLE EXPOSURE TO

MICROWAVE ENERGY LEAKAGE, THE

FOLLOWING PRECAUTIONS MUST BE

TAKEN

Before

(1)

Open and

a

(

>

BEFORE

SERVICING.

the power is applied.

close

door

several

times to make

sure

the primary interlock switch, the door sensing switch,

and the interlock monitor switch

operate

properly.

(Listen for the clicking sound from switches). Make

sure

the interlock monitor switch is

primary interlock switch

opened.

Make

( w

choke

(2)After the

(a)Open

(See

pages 1 and 7).

sure

the perforated

of the door are correctly mounted.

power is applied.

and

close

the door to

is

opened, when the door

screen

see

closed

after the

and the dielectric

if the interlock

mechanism operates properly.

(b)Check

detector and

microwave

confirm

energy leakage with a leakage

the energy leakage is below

5mW/cm2

(3)Do

not

operate

repaired,

(a)Door

(b)The

(c)The

does

hinge is

choke

(d)The door

visible

damage

microwave

NOTE: Always keep the

(e)Make

sure

microwave

the unit until it is completely

if anv of the

not

close

following

conditions exists.

firmly against the cavity front.

broken.

dielectric or the door

is

bent or warped, or there is

seal is

damaged.

any

other

to the oven that may cause

energy leakage.

seal clean

there are no defective parts in the

generating and transmission assembly.

(especially waveguide).

(4)Following

items should be checked after the unit

repaired.

(a)The interlock monitor switch is connected

correctly and firmly.

(b)The magnetron gasket on the magnetron

is

properly positioned.

(c)Wave guide and oven cavity are intact ( no leakage

of

microwave

(d)The door can be properly

energy).

closed

and the safety

switches work properly.

(e)The oven must be stopped when the door

is

opened or the time is up.

The oven must not be operated with any of the above

components

I m

2

removed or bypassed.

is

is

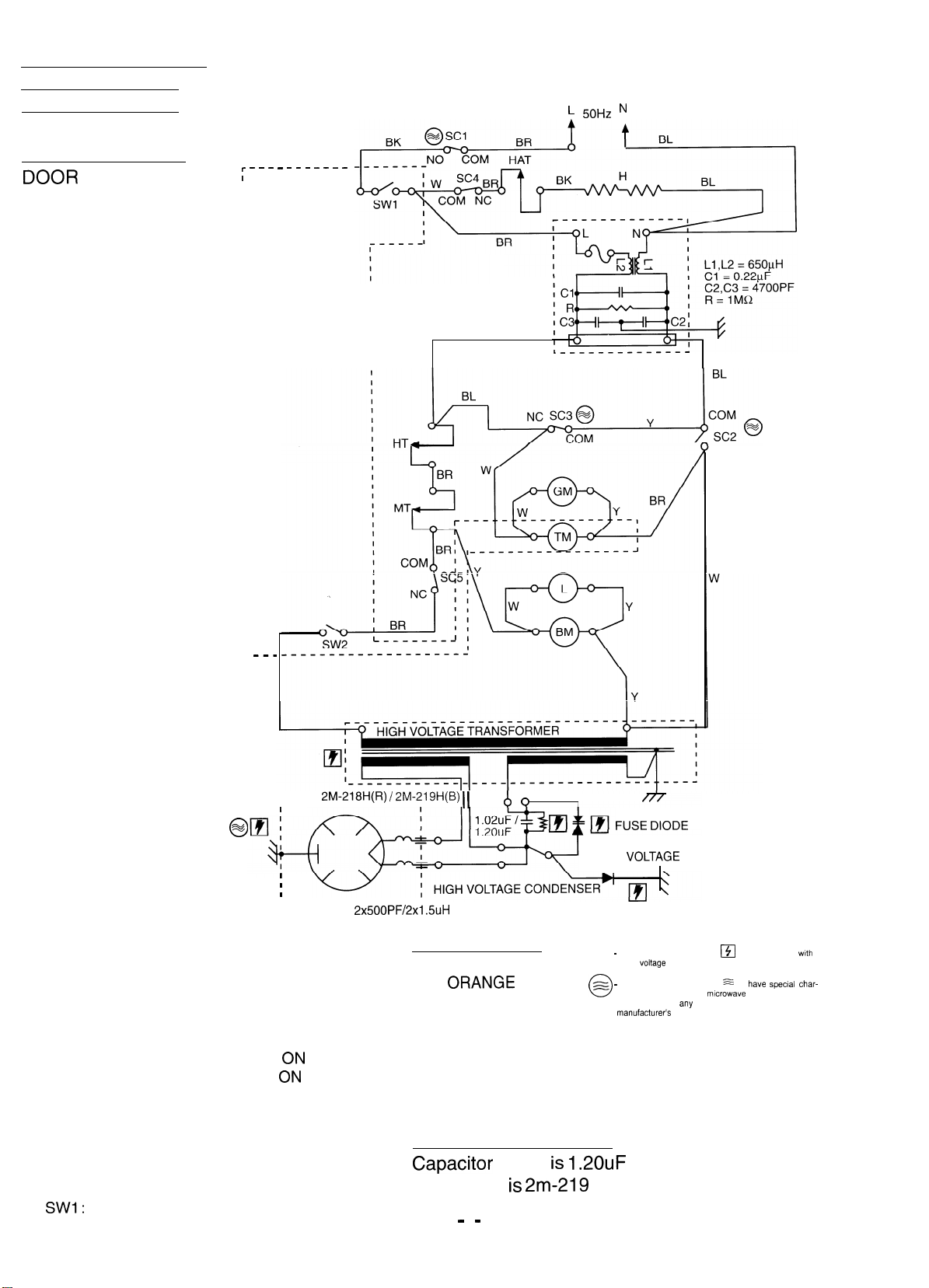

SCIRCUIT

U.K

EM-G2OOEUK

U.K

EM-G4OOEUK

DIAGRAM

230V

L 50Hz N

OVEN CONDITION

DOOR

: OPEN

r - - - - - - - - - - I

BR

NO

SC1

SC2 :

SC3 :

SC4 :

SC5 :

HT :

MT

HAT

TM

BM

GM

L

H

SWI:

PRIMARY INTERLOCK SWITCH

:

DOOR SENSING SWITCH

INTERLOCK MONITOR SWITCH

HEATER ON/OFF SWITCH (IN CONTROL) LB : LIGHT BLUE

MICRO ON/OFF SWITCH (IN COTROL)

THERMAL PROTECTOR FOR CAVITY P : PINK

.

THERMAL PROTECTOR

:

THERMAL PROTECTOR ON DUCT

.

.

TIMER MOTOR

.

.

BLOWER MOTOR

: GEAR MOTOR

: CAVITY LAMP

: QUARTZ HEATER

TIME SWITCH

SW2: POWER SWITCH

1

B-B

BL

MAGNETRON

---------------

I

es

0

I

I

I

---------------

ON

2M-218H(R) / 2M-2~9H(B) 1 1

2~5OOPF/2x15uH

WIRING COLOUR

W : WHITE

ORANGE

0 :

BK : BLACK

WAVEGUIDE BR : BROWN

: YELLOW

Y

BL : BLUE

Please Note for G400.

Capacitar value is

Magnetron is 2m-219 type.

I m

3

6 o

,

FUSE DIODE

HIGH

VOLTAGE

-

The parts marked with

a high voltage which exceeds 250V.

El

@ -

The parts marked with

z

acteristics important for microwave leakage.

When replacing any of these parts use only

manufacturer’s specified parts.

1.2OuF

RE

CTIFIER

El

h,

0

are supplied wlth

have special char-

Figure 2

5.CIRCUIT DIAGRAM

Continental EM-G2OOEES and EM-G2OOESP

Continental E

OVEN CONDITION

DOOR

:

OPEN

,

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I -

mm

I

-------t

L

------------mm

230V

50Hz N

Y

BL

Y

SC1 :

SC2 :

SC3 :

SC4 :

SC5

:

HT :

MT :

HAT :

RL

TM

BM

GM

I

n

;1 I

IR :

SWI:

sw2 :

L------------,,,,,,

COM

R%

0

N”T

BL rg

___________

MAGNETRON 2M-218H(R) / 2

---------------

I I

I

I

I

---------------

~x~OOPF/~XI.~UH

PRIMARY INTERLOCK SWITCH

DOOR SENSING SWITCH

INTERLOCK MONITOR SWITCH

HEATER ON/OFF SWITCH

MICRO ON/OFF SWITCH

THERMAL PROTECTOR FOR CAVITY

THERMAL PROTECTOR

THERMAL CUTOUT ON DUCT

.

.

INRUSH

.

.

TIMER MOTOR

.

BLOWER MOTOR

.

.

TURNTABLE MOTOR

’

CURRENT

ON

WAVEGUIDE

REDUCING

CAVITY LAMP

QUARTZ HEATER

INRUSH RESISTOR 25iJ / 20W

TIME SWITCH

POWER SWITCH

BL

W

HIGH

RELAY

VOLTAGE

I

---------------A-‘------!

I

W

TRANSFORMER

FUSE

DIOD

HIGH

VOLTAGE

WIRING

COLOUR

W : WHITE

0 :

ORANGE

0 -

c

LB : LIGHT BLUE

BK : BLACK

P

: PINK

BR : BROWN

Y

: YELLOW

BL : BLUE

Please Note for

Capacitor value

G400.

is 1.20uF

Magnetron is 2m-219 type.

I I

4

BR

E

RECTIFIER

-

The parts marked with

a high voltage whlch exceeds

The parts marked with

acteristics important for microwave leakage.

When replacing any of these parts use only

manufacturer’s specified parts.

141

25OV.

5~

0

are supplled

have speclal

Figure 2

wlth

char-

Loading...

Loading...