SANYO DS 35520 Diagram

AS

FILE NO.

SERVICE MANUAL Remote Control Color

Television

DS35520 (U.S.A.)

(CANADA)

ORIGINAL VERSION

Chassis No. 35520-00

NOTE: Match the Chassis No. on

the unit’s back cover with

the Chassis No. in the

Service Manual.

If the Original Version

Service Manual Chassis

No. does not match the

unit’s, additional Service

Literature is required. You

must refer to “Notices” to the

Original Service Manual

prior to servicing the unit.

Contents

Safety Instructions . . . . . . . . . . . . . . . . . . 2

Service Adjustments. . . . . . . . . . . . . 3 - 10

Service Hints. . . . . . . . . . . . . . . . . . . . . . 10

Mechanical Disassemblies. . . . . . . . . . . 11

Chassis Electrical Parts List . . . . . . 12 - 23

Cabinet Parts List . . . . . . . . . . . . . . . . . . 24

Component and Test Point

Locations . . . . . . . . . . . . . . . . . . . 25 - 28

Schematic Insert . . . . . . . . . . . . . . . 29 - 36

Schematic Notes . . . . . . . . . . . . . . . . . 29

Pin Layouts . . . . . . . . . . . . . . . . . . . . . 29

Capacitor and Resistor Codes . . . . . . 29

Block Diagram . . . . . . . . . . . . . . . 30 - 31

Voltage Charts . . . . . . . . . . . . . . . 30 - 32

Waveforms. . . . . . . . . . . . . . . . . . . . . . 32

Main PC Board . . . . . . . . . . . . . . . 33 - 36

Audio/Video Board. . . . . . . . . . . . 35 - 36

CRT Socket Board . . . . . . . . . . . . . . . . 33

Specifications

Power Rating . . . . . . . . . . . . . . . . . . . . . 120V, 60Hz

107W (Avg), 2.5A (Max)

Antenna Input Impedance. . . . . . . . . . . . . . . . . 75Ω

UHF/VHF/CATV

Receiving Channel . . . . . . . . . . . . . . . . 2 - 13 (VHF),

14 - 69 (UHF),

01, 14-94, 95-125 (CATV)

Remote Ready . . . . . . . . . . 39 Key Remote Control

Sound Output . . . . . . . . . . . . . . . . . . . . . . 3.0 W/CH

Intermediate Frequency

Picture IF Carrier. . . . . . . . . . . . . . . . . . 45.75MHz

Sound IF Carrier . . . . . . . . . . . . . . . . . . 41.25MHz

Color Sub Carrier . . . . . . . . . . . . . . . . . 42.17MHz

Picture Tube . . . . . . . . . . . . . . . . . . . A89AEJ15X01

Semiconductors

Integrated Circuits. . . . . . . . . . . . . . . . . . . . . . . 15

Transistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Except within Tuner and RC Pre-Amp.

Cabinet Dimensions

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 848 mm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . 751 mm

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 619 mm

REFERENCE No. SM780084

DS35520, G7RPM, PRODUCT CODE 111355692

A

S

MENU

CH

VOL

P

OW

E

R

M

T

S

S

T

E

R

E

O

/

S

A

P

/d

b

x

— 2 —

SAFETY PRECAUTIONS

WARNING: The chassis of this receiver has a floating

ground with the potential of one half the AC line voltage in

respect to earth ground. Service should not be attempted by

anyone not familiar with the precautions necessary when

working on this type of equipment.

The following precautions must be observed:

1. An isolation transformer must be connected in the power

line between the receiver and the AC line before any service is performed on the receiver.

2. Comply with all caution and safety-related notes provided on the side of the cabinet, inside the cabinet, on the

chassis, and the picture tube.

3. When replacing a chassis in the cabinet, always be certain

that all the protective devices are installed properly, such

as control knobs, adjustment covers, shields and barriers.

DO NOT OPERATE THIS TELEVISION RECEIVER

WITHOUT THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4. Before replacing the back cover of the set, thoroughly

inspect the inside of the cabinet to see that no stray parts

or tools have been left inside.

Before returning any television to the customer, the

service technician must perform the following safety

checks to be sure that the unit is completely safe to

operate without danger of electrical shock.

ANTENNA COLD CHECK

Remove AC plug from the 120 VAC outlet and place a

jumper across the two blades. Connect one lead of an ohmmeter to the jumpered AC plug, and touch the other lead to

each exposed antenna terminal (UHF and VHF antenna terminals). The resistance must measure between 1M ohm and

5.2M ohm. Any resistance value below or above this range

indicates an abnormality which requires corrective action.

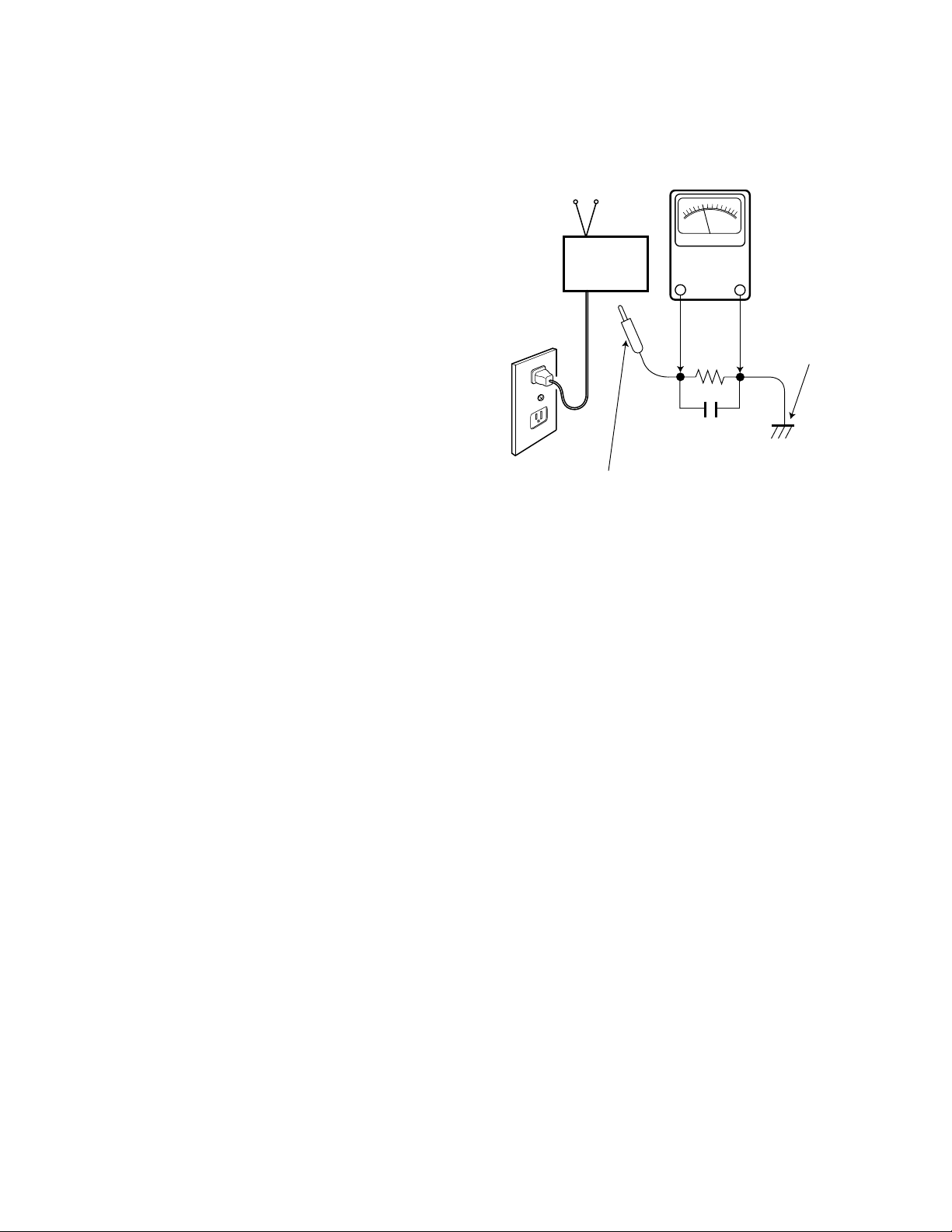

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120 VAC outlet. (Do not

use an isolation transformer for this check.) Use an AC voltmeter, that has 5000 ohms per volt or more sensitivity.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF

150 VAC capacitor, between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of the

cabinet (antennas, handle bracket, metal cabinet, screw

heads, metal overlays, control shafts, etc.). Measure the AC

voltage across the 1500 ohm resistor. The AC voltage

should not exceed 750 mV. A reading exceeding 750 mV

indicates that a dangerous potential exists. The fault must

be located and corrected. Repeat the above test with the

receiver power plug reversed.

NEVER RETURN A RECEIVER TO THE CUSTOMER

WITHOUT TAKING THE NECESSARY CORRECTIVE ACTION.

X-RADIATION PRECAUTION

The primary source of X-RADIATION in solid-state receivers is

the picture tube. The picture tube is specially constructed to

limit X-Ray emission. For continued X-RADIATION protection,

the replacement tube must be the same type as the original

(including the suffix letter in the part numbers). Excessive high

voltage may produce potentially hazardous X-RADIATION. To

avoid such hazards, the high voltage must be maintained within

specific limits. Refer to the X-RADIATION WARNING NOTE on

the CHASSIS SCHEMATIC in this service manual for specific

high voltage limits. If the high voltage exceeds specified limits,

check the components specified on the chassis schematic

diagram and take the necessary corrective action. Carefully

follow the instructions for the +B Voltage Check and the High

Voltage Check to maintain the high voltage within the specified

limits.

HIGH VOL T AGE HOLD-DOWN TEST

To prevent X-RADIATION from the picture tube due to

excessive high voltage, a HOLD-DOWN circuit is provided in

the high voltage circuit. Every time the receiver is serviced,

the high voltage HOLD-DOWN circuit must be tested for

proper operation. Refer to the HIGH VOLTAGE HOLDDOWN TEST in service adjustments.

PRODUCT SAFETY NOTICE

When replacing components in a receiver, always keep in

mind the necessary product safety precautions. Pay special

attention to the replacement of components marked with a

star (★) in the parts list and in the schematic diagrams. To

ensure safe product operation, it is necessary to replace

those components with the exact same PARTS.

SAFETY INSTRUCTIONS

READING SHOULD NOT EXCEED 750 mV.

AC VOLTMETER

(5000 ohms per volt or more sensitivity)

TELEVISION

RECEIVER

Good earth ground

such as a water pipe,

conduit, etc.

AC OUTLET

1500 ohm

10 watt

0.15 µF 150V AC

To be touched to all of exposed metal parts.

Voltmeter Hook-up for Leakage Current Check.

GENERAL

This set has an On-screen Service Menu system included in the CPU that allows remote operation for most of the service adjustments.

ON-SCREEN SERVICE MENU SYSTEM

1. Enter the Service Menu:

• While pressing the MENU key, reconnect the AC power cord. The Service Menu Display will now appear. (See Figure 1.)

2. Service Adjustments:

• Press the ▲or ▼ key to select the desired service menu you want to adjust. (See page 5 for On-screen Service Menu.)

• Use the + or – key to adjust the data.

3. Exit from the Service Menu:

• Press the MENU key to turn off the Service Menu display.

SERVICE AD JUSTMENTS

— 3 —

IC802 (EEPROM) REPLACEMENT

When IC802 (EEPROM) is replaced, IC801 (CPU) will automatically write the initial reference data into IC802 for basic TV operation.

However, the bus data should be checked and some bus data should be set up before attempting the service adjustments.

(See pages 5 – 7 for detailed bus data information.)

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, change the following initial reference data for proper TV operation before

attempting service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

3. Select NO. 4 VS (V Size) with ▲ or ▼ key. Adjust the data with + or – key for 18.

4. Select NO. 5 VLN (V Linearity) with ▲ or ▼ key. Adjust the data with + or – key for 13.

5. Select NO. 6 VSC (V S Correction) with ▲ or ▼ key. Adjust the data with + or – key for 3.

6. Select NO. 7 HP (H Position) with ▲ or ▼ key. Adjust the data with + or – key for 24.

7. Select NO. 8 EWD (H Width) with ▲ or ▼ key. Adjust the data with + or – key for 33.

8. Select NO. 9 EWA (Pincushion Amp) with ▲ or ▼ key. Adjust the data with + or – key for 32.

9. Select NO. 10 EWP (Upper Corner Pincushion) with ▲ or ▼ key. Adjust the data with + or – key for 31.

10. Select NO. 11 EWB(Bottom Corner Pincushion) with ▲ or ▼ key. Adjust the data with + or – key for 38.

11. Select NO. 12 BOW (AFC Bow) with ▲ or ▼ key. Adjust the data with + or – key for 8.

12. Select NO. 13 ANG (AFC Angle) with ▲ or ▼ key. Adjust the data with + or – key for 7.

13. Select NO. 14 UVL (Upper V Lin) with ▲ or ▼ key. Adjust the data with + or – key for 0.

14. Select NO. 15 LVL (Lower V Lin) with ▲ or ▼ key. Adjust the data with + or – key for 0.

15. Select NO. 16 EWT (Pincushion Phase) with ▲ or ▼ key. Adjust the data with + or – key for 4.

16. Select NO. 17 VC (V Compression) with ▲ or ▼ key. Adjust the data with + or – key for 5.

17. Select NO. 21 RB (Red Cutoff) with ▲ or ▼ key. Adjust the data with + or – key for 12.

18. Select NO. 22 GB (Green Cutoff) with ▲ or ▼ key. Adjust the data with + or – key for 3.

19. Select NO. 23 BB (Blue Cutoff) with ▲ or ▼ key. Adjust the data with + or – key for 0.

20. Select NO. 26 STI (Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for 15.

21. Select NO. 27 SCO (Sub Color) with ▲ or ▼ key. Adjust the data with + or – key for 9.

22. Select NO. 28 SB (Sub Bright) with ▲ or ▼ key. Adjust the data with + or – key for 12.

23. Select NO. 29 SSH (Sub Sharpness) with ▲ or ▼ key. Adjust the data with + or – key for 2.

NO. DATA

XX OPT XXX XXXXXXXX

Figure 1. Service Menu Display

ITEM NO.

TITLE

BINARY DATA

(8 bit)

DECIMAL DATA

— 4 —

INITIAL BUS DATA SETUP (Cont.)

24. Select NO. 33 DCO (Dynamic Color Switch) with ▲ or ▼ key. Adjust the data with + or – key for 0.

25. Select NO. 39 DCR (DC Reset) with ▲ or ▼ key. Adjust the data with + or – key for 3.

26. Select NO. 40 YGM (Y Gamma Correction) with ▲ or ▼ key. Adjust the data with + or – key for 2.

27. Select NO. 51 HBR (H Blanking Right) with ▲ or ▼ key. Adjust the data with + or – key for 0.

28. Select NO. 60 OPT (SA Option 1) with ▲ or ▼ key. Adjust the data with + or – key for 44.

29. Select NO. 61 OP2 (SA Option 2) with ▲ or ▼ key. Adjust the data with + or – key for 14.

30. Select NO. 62 HR (OSD Position) with ▲ or ▼ key. Adjust data with + or – key for 36.

31. Select NO. 63 SCA (Sub Color) with ▲ or ▼ key. Adjust data with + or – key for 2.

32. Select NO. 64 STA (Sub Tint Offset) with ▲ or ▼ key. Adjust the data with + or – key for 254.

33. Select NO. 67 SBT (Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for 6.

34. Select NO. 68 SBL (Sub Color) with ▲ or ▼ key. Adjust the data with + or – key for 14.

35. Select NO. 70 RTN (Tint Offset for RF) with ▲ or ▼ key. Adjust the data with + or – key for 0.

36. Select NO. 71 RCL (Color Offset for RF) with ▲ or ▼ key. Adjust the data with + or – key for 0.

37. Select NO. 74 PPR (Preshoot/Overshoot Ratio for RF) with ▲ or ▼ key. Adjust the data with + or – key for 1.

38. Select NO. 79 DTN (Tint Offset for YUV) with ▲ or ▼ key. Adjust the data with + or – key for 4.

39. Select NO. 80 DCL (Color Offset for YUV) with ▲ or ▼ key. Adjust the data with + or – key for 13.

40. Select NO. 92 EVB (Vertical Blanking Width Top for 16:9) with ▲ or ▼ key. Adjust the data with + or – key for 2.

41. Select NO. 95 EVA (Vertical Size Offset for 16:9) with ▲ or ▼ key. Adjust the data with + or – key for 22.

42. Select NO. 97 SED (H Width Offset for 16:9) with ▲ or ▼ key. Adjust the data with + or – key for 255.

43. Select NO. 98 SEA (Pin Offset for 16:9) with ▲ or ▼ key. Adjust the data with + or – key for 255.

44. Select NO. 103 VAP (Vertical Aspect) with ▲ or ▼ key. Adjust the data with + or – key for 15.

45. Select NO. 104 VSR (Vertical Scroll) with ▲ or ▼ key. Adjust the data with + or – key for 31.

46. Select NO. 105 ATT (MTS Input Level) with ▲ or ▼ key. Adjust the data with + or – key for 6.

47. Select NO. 106 WDB (MTS Low Separation) with ▲ or ▼ key. Adjust the data with + or – key for 31.

48. Select NO. 107 SPC (MTS Hi Separation) with ▲ or ▼ key. Adjust the data with + or – key for 21.

49. Press the MENU key to turn off the Service Menu display.

SERVICE AD JUSTMENTS (Cont.)

— 5 —

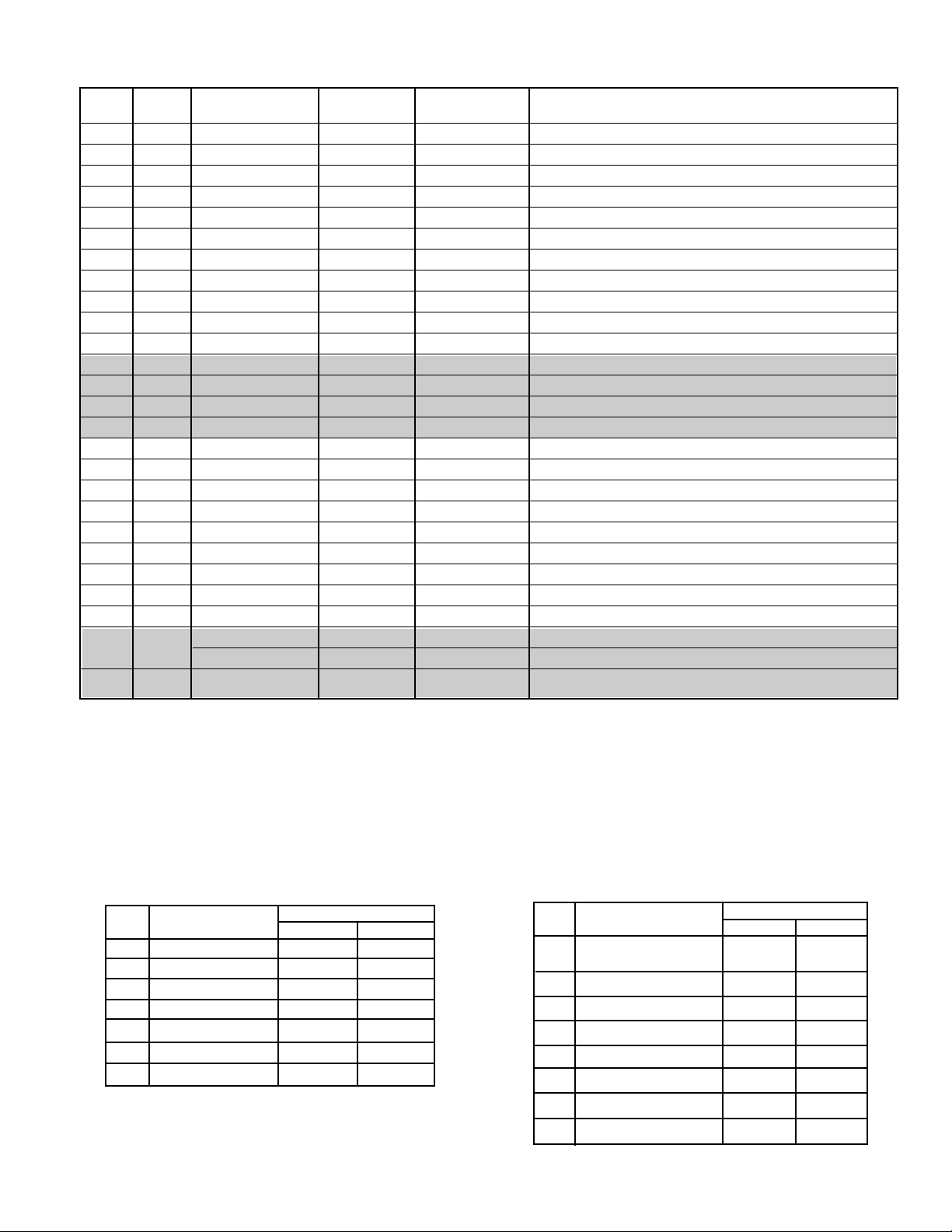

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be

checked and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked

with an * should be changed from Initial Reference Data. (See pages 3 and 4 for Initial Bus Data Setup.)

NO. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

01 HFR 7 7 0~63 Horizontal Frequency

02 C16 244 244 0~255 16:9 Mode Contrast Offset

03 VPO 0 0 0~63 Vertical Position

04 VS 29 18* 0~63 Vertical Size

05 VLN 6 13* 0~15 Vertical Linearity

06 VSC 0 3* 0~15 Vertical S Correction

07 HP 20 24* 0~63 Horizontal Position

08 EWD 29 33* 0~63 Horizontal Width

09 EWA 43 32* 0~63 Pin Amp

10 EWP 29 31* 0~63 Up Corner Pin

11 EWB 37 38* 0~63 Bottom Corner Pin

12 BOW 10 8* 0~15 AFC Bow

13 ANG 9 7* 0~15 AFC Angle

14 UVL 2 0* 0~15 Upper Vertical Linearity

15 LVL 1 0* 0~15 Lower Vertical Linearity

16 EWT 8 4* 0~15 Pin Phase

17 VC 6 5* 0~15 Vertical Compression

18 RD 31 31 0~63 Red Drive

19 GD 31 31 0~63 Green Drive

20 BD 31 31 0~63 Blue Drive

21 RB 13 12* 0~15 Red Cutoff

22 GB 2 3* 0~15 Green Cutoff

23 BB 8 0* 0~15 Blue Cutoff

24 FLS 3 3 0~3 Filter System

25 SCN 11 11 0~15 Sub Contrast

26 STI 7 15* 0~15 Sub Tint

27 SCO 7 9* 0~15 Sub Color

28 SB 7 12* 0~31 Sub Bright

29 SSH 0 2* 0~255 Sub Sharpness

30 AFC 0 0 0~3 AFC Gain (Except TV Mode)

31 REF 0 0 0, 1 Reference Pulse Position

32 CDM 3 3 0~3 CD Mode Select

33 DCO 1 0* 0, 1 Dynamic Color Switch

34 ABL 1 1 0, 1 ABL Mode Switch

35 BAT 1 1 0, 1 ABL Level Switch 4:3 Mode

36 B16 1 1 0, 1 ABL Level Switch 16:9 Mode

37 CTP 1 1 0, 1 Chroma Trap Off Switch

38 CBP 0 0 0, 7 Chroma Bandpass Filter Switch

39 DCR 2 3* 0~3 DC Transmission select Switch

40 YGM 1 2* 0~3 Gamma Correction Select

41 POS 1 1 0, 1 Preshoot/Overshoot Switch

42 WP 0 0 0~3 RGB Limit Level

43 VM 3 3 0~3 Velocity Modulation

44 GYA 0 0 0, 1 G-Y Angle

45 CRS 0 0 0, 1 Aging Mode

46 HMA 1 1 0, 1 H Mask On/Off

47 HBS 1 1 0, 1 Horizontal Blanking Switch

Table 1. ON-SCREEN SERVICE MENU (Continued)

— 6 —

NO. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

48 VBL 0 0 0~3 Vertical Blanking

49 WVB 0 0 0, 1 WV Blanking Select

50 HBL 15 15 0~15 Horizontal Blanking Left

51 HBR 5 0* 0~15 Horizontal Blanking Right

52 AFR 0 0 0~3 AFC Gain (TV Mode)

53 RHS 0 0 0, 1 Horizontal Sync Slice Level for RF

54 RVS 0 0 0, 1 Vertical Sync Slice Level for RF

55 EHS 0 0 0, 1 Horizontal Sync Slice Level for AV

56 EVV 1 1 0, 1 Vertical Sync Slice Level for AV

57 CDR 3 3 0~3 CD Mode (TV)

58 BGP 1 1 0, 1 BGP Switch

59 FSC 1 1 0, 1 FSC Switch

60 OPT 0 32* 0~255 Option 1 (See Note 1 page 6)

61 OP2 2 82* 0~255 Option 2 (See Note 2 page 6)

62 HR 23 34* 0~63 OSD Horizontal Position

63 SCA 0 2* 0~255 Color Offset (‘00’ In Adjust)

64 STA 0 254* 0~255 Tint Offset (‘00’ In Adjust)

65 SUB –- – – Not Used

66 SBC 11 11 0~15 Sub Contrast

67 SBT 15 5* 0~15 Sub Tint for Adjustment

68 SBL 15 10* 0~31 Sub Color for Adjustment

69 RCN 0 0 0~255 Contrast Offset for RF

70 RTN 253 0* 0~255 Tint Offset for RF

71 RCL 2 0* 0~255 Color Offset for RF

72 RBR 0 0 0~255 Bright Offset for RF

73 RSP 0 0 0~255 Sharpness Offset for RF

74 PPR 0 1* 0, 1 Pre/Overshoot Ratio for RF

75 SSF 3 3 0~3 Sharpness FO for S Input

76 AKB 48 48 0~255 AKB Timer

77 VMT 72 72 0~255 Video Mute Timer

78 DCN 249 249 0~255 Contrast Offset for YUV

79 DTN 254 4* 0~255 Tint Offset for YUV

80 DCL 10 13* 0~255 Color Offset for YUV

81 DBR 0 0 0~255 Bright Offset for YUV

82 DSP 0 0 0~255 Sharpness Offset for YUV

83 DVM 0 0 0~255 Velocity Offset for YUV

84 CBO 7 7 0~15 Cb Offset for YUV

85 CRO 7 7 0~15 Cr Offset for YUV

86 DRD 0 0 0~255 Red Drive Offset for YUV

87 DGD 0 0 0~255 Green Drive Offset for YUV

88 DBD 0 0 0~255 Blue Drive Offset for YUV

89 DRC 0 0 0~255 Red Cutoff Offset for YUV

90 DGC 0 0 0~255 Green Cutoff Offset for YUV

91 DBC 0 0 0~2557 Blue Cutoff Offset for YUV

92 EVB 3 2* 0~3 Vertical Blanking Width Top for 16:9

93 EWV 0 0 0, 1 Vertical Blanking Width Bottom for 16:9

SERVICE AD JUSTMENTS (Cont.)

— 7 —

PROGRAM CODES

The microprossesor used in this model is a multi-purpose type and is used in several different models. To ensure proper

operation and the correct features for your particular model, the program codes must be correct.

Note 1. Option Data 1 (NO. 60 OPT) should be decimal 44

(00101100 binary). See page 4 INITIAL DATA SETUP, step

28, for set up procedure. If this program code is wrong the

TV will not operate properly.

Note 2. Option Data 2 (NO. 61 OP2) should be decimal 14

(00001110 binary). See page 4 INITIAL DATA SETUP,

step 29, for set up procedure. If this program code is

wrong the TV will not operate properly.

BIT FUNCTION

DATA

01

0 ~1 NOT USED — —

2 SCAN VELOCITY NONE YES

3 CLOCK NONE YES

4 NOT USED — —

5 WIDE MODE NONE YES

6 SURROUND NONE YES

7 NOT USED — —

BIT FUNCTION

DATA

01

0

SHIPPING CONDITION

NORMAL COOL

OF COLOR ENHANCER

1 COLOR ENHANCER NONE YES

2 INITIAL CH & XDS NONE YES

3 FIXED/VARIABLE FIXED FIX/VAR

4 PIP NONE YES

5 AV INPUTS AV1/2 AV1/2/3

6 BASS & TREBLE / TONE BASS & TR TONE

7 V-GUIDE NONE

YES

NO. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

94 EVS 0 0 0~255 Vertical Position Offset for 16:9

95 EVA 14 22* 0~255 Vertical Size Offset for 16:9

96 ERE 0 0 0, 1 Reference Pulse Position for 16:9

97 SED 254 255* 0~255 Horizontal Width Offset for 16:9

98 SEA 254 255* 0~255 Pin Offset for 16:9

99 SET 255 255 0~255 Pin Phase Offset for 16:9

100 DHS 0 0 0~255 Horizontal Width Offset for YUV

101 DHC 0 0 0~255 Horizontal Center Offset for YUV

102 EDC 0 0 0, 1 EW DC On/Off

103 VAP 32 15* 0~63 V Aspect

104 VSR 17 31* 0~63 V Scroll

105 ATT 10 6* 0~15 MTS Input Level

106 WDB 32 31* 0~63 MTS Low Separation

107 SPC 32 21* 0~63 MTS Hi Separation

108 SBO 0 0 0~255 Sub Bright Detector Voltage Offset

109 PCO 90 90 0~127 PIP Chroma Gain

110 PTI 42 42 0~63 PIP Tint

111 PUV 24 24 0~255 PIP Top Location

112 PDV 147 147 0~255 PIP Bottom Location

113 PLH 15 15 0~255 PIP Left Location

114 PRH 101 101 0~255 PIP Right Location

115 PCN 67 67 0~127 PIP Y Signal Gain

116 PBS 15 15 0~63 PIP BGP Phase for VCXO

117 – – – – Not Used

118 DRV

31 31 0~63 Red Drive Adjustment (See Grayscale Adjustment)

31 31 0~63 Blue Drive Adjustment (See Grayscale Adjustment)

119 – – – – Screen Adjust (See Grayscale Adjustment)

— 8 —

SERVICE AD JUSTMENTS (Continued)

ANTENNA CONNECTIONS

This receiver is designed for UHF/VHF reception. A 75 ohm

terminal is provided for UHF and VHF receptions. When

connecting a CATV antenna system, connect the 75 ohm

coaxial cable directly to the 75 ohm terminal. For 300 ohm

VHF antenna, use an adapter (not included with the TV set).

CIRCUIT PROTECTION

Fuse F601 (4A) is included in the AC line. This fuse must be

replaced with the proper fuse (see Parts List).

+B VOL T AGE CHECK

Connect Voltmeter + lead to TJ1 130V and – lead to ground

(TE7). Connect receiver to AC 120V line. Tune receiver to an

active channel. Reset the picture controls to the FACTORY

PRESET levels (press remote control RESET key twice).

Voltage must measure between +128.0V and +132.0V. If the

voltage is out of this range, the power circuit must be

checked. No +B adjustment is provided on this chassis.

HORIZONT AL WIDTH ADJUSTMENT

1. Tune receiver to an active channel.

2. Check the picture for p roper width. If width is not correct,

perform steps 3 ~ 6.

3. Turn off the receiver and disconnect the AC power cord

(120V AC line).

4. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

5. Select NO. 08 EWD (Horizontal Width) with ▲ or ▼ key.

6. Adjust the data with + or – key for proper width. To turn

off the Service Menu display, press the MENU key.

HORIZONTAL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Check that picture is in the horizontal center of TV screen.

If picture is not centered horizontally, perform steps 3 ~ 6.

3. Turn off the receiver and disconnect the AC power cord.

4. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

5. Select NO. 07 HP (Horizontal Position) with ▲ or ▼ key.

6. Adjust the data with + or – key for horizontal center. To

turn off the Service Menu display, press the MENU key.

VERTICAL SIZE ADJUSTMENT

1. Tune receiver to an active channel.

2. Check the vertical size of the picture. If the vertical size is

too large or small, perform steps 3 ~ 6.

3. Turn off the receiver and disconnect the AC power cord.

4. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

5. Select NO. 04 VS (Vertical Size) with ▲ or ▼ key.

6. Adjust the data with + or – key for full scan. To turn off

the Service Menu display, press the MENU key.

VERTICAL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Che ck that picture is in the center of TV screen. If picture

center is too low, add resistor R513 (1K ohm 1W). If picture

center is too high, add resistor R512 (1K ohm 1W). .

GRA Y SCALE ADJUS TMENT

1. Connect a color-bar generator to the antenna terminals.

2. Switch the generator to the white pattern.

3. Set the picture controls to the Sports level or Reset (use

MENU key and ▲ or ▼ key or RESET key).

4. Turn off the receiver and disconnect the AC power cord

(120V AC line).

5. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

6. Select NO. 18 RD (Red Drive), NO. 19 GD (Green Drive), and

NO. 20 BD (Blue Drive) with ▲or ▼key and set each data to

31 with + or – key.

7. Select NO. 21 RB (Red Cutoff) with ▲ or ▼ key and set

data to 12 with + or – key.

8. Set NO. 22 GB (Green Cutoff) data to 3, and NO. 23 BB (Blue

Cutoff) data to 0 with + or – key.

9. Set NO. 28 SB (Sub Brightness) data to 12, NO. 29 SSH

(Sub Sharpness) data to 2, NO. 33 DCO (Dynamic Color

Switch) data to 0, and NO. 108 SBO (Sub Bright Offset)

data to 0 with ▲ or ▼, and + or – keys.

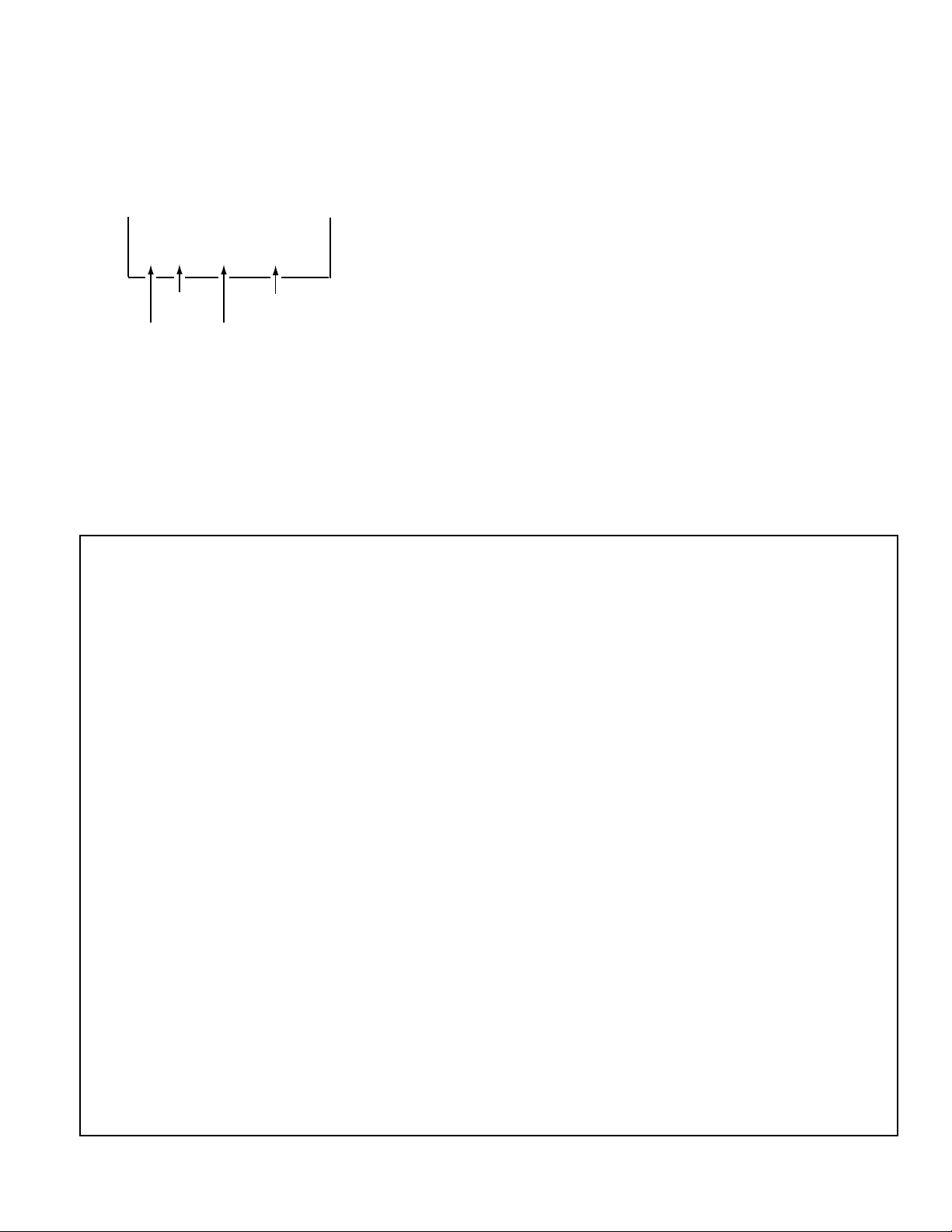

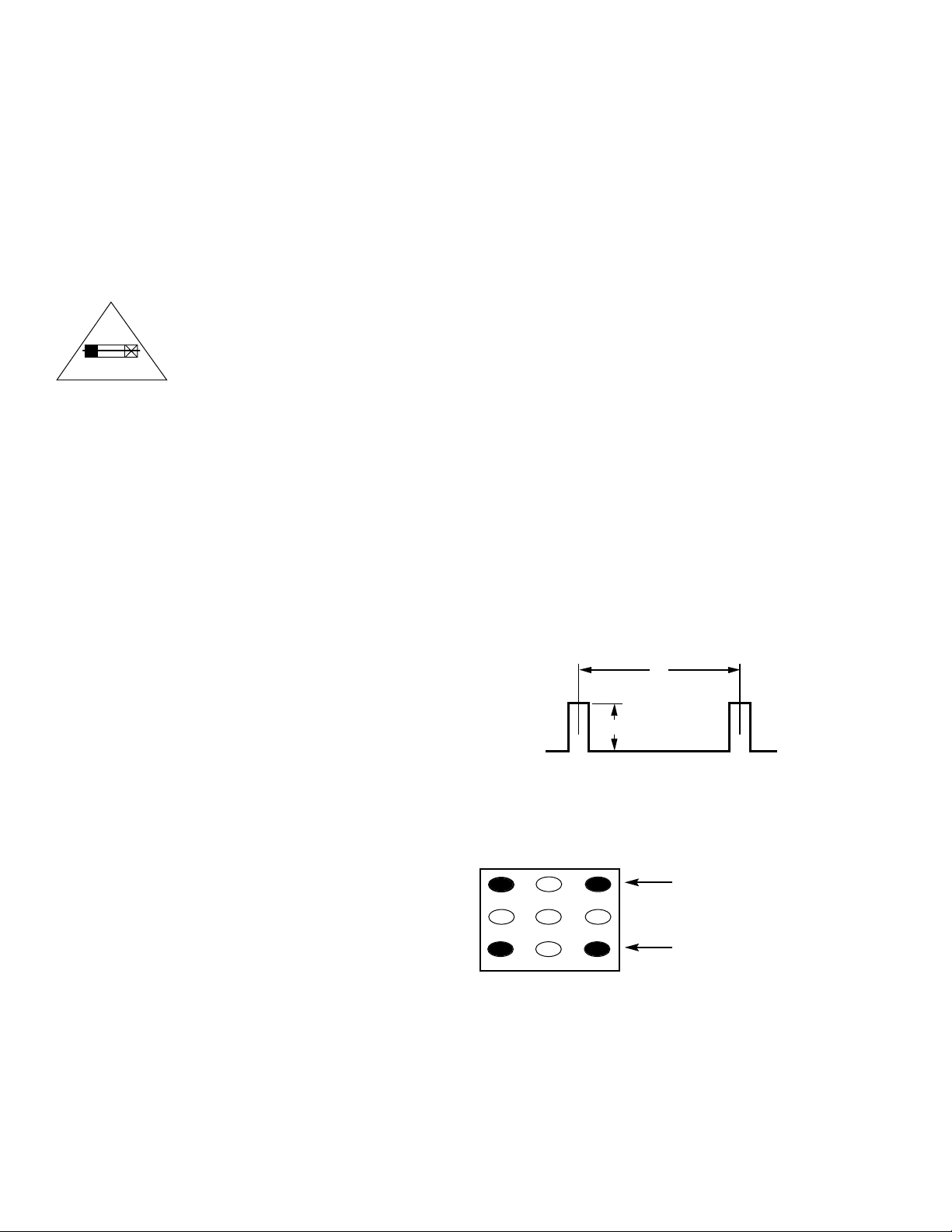

10. Connect oscilloscope probe (at least 50:1) to TP47G and

ground lead to TE47 on the CRT Socket PWB.

11. Select Service Menu NO. 119 with ▲ or ▼ key.

12. Adjust Screen Control (T402) to obtain 20 VP-P from

black to white level. (See Figure 2.)

13. Select the Service Menu NO. 118 DRV (Drive Adjustments)

with ▲ or ▼ key.

14. Adjust Red and Blue Drive Levels alternately with 1, 3, 7, or 9

key to produce normal black and white picture in highlight

areas. The Drive Level adjustment data will be written in the

Service Menu No. 18 and 20 automatically. (See Figure 3.)

17. Check for proper grayscale at all brightness levels.

Note: If Grayscale Adjustment is made after picture tube

replacement, check Brightness Level Adjustment.

CAUTION

FOR CONTINUED PROTECTION AGAINST

A RISK OF FIRE, REPLACE ONLY WITH THE

SAME TYPE 4A, 125V FUSE.

ATTENTION : POUR MAINTENIR LA PROTECTION CONTRE LES RISQUES

D’ INCENDIE UTILISER UN FUSIBLE DE

RECHANGE DE MEME TYPE 4A, 125V.

1

2

3

4 5 6

7 98

RD(–)

RD(+)

BD(–)

BD(+)

(N/A)

(N/A)

(N/A)

(N/A)

(N/A)

Figure 3. Remote Control Number keys’ functions in

Service Menu NO. 118 DRV

FOR RED DRIVE ADJUSTMENT

FOR BLUE DRIVE ADJUSTMENT

Figure 2.

4A 125V

1H

20 Vp-p

— 9 —

BRIGHTNESS LEVEL ADJUSTMENT

Note: Grayscale Adjustment and High Voltage Check must be

completed before attempting Brightness Level

Adjustment.

1. Connect a color-bar generator to the antenna terminals.

2. Switch the generator to the crosshatch pattern.

3. Reset the picture controls to the Sports level.

4. Connect voltmeter (high impedance) + lead to terminal

TP51 and – lead to terminal TP50 on main board. Set

voltmeter for 1.5V ~ 3V range.

5. Turn off the receiver and disconnect the AC power cord.

6. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

7. Select NO. 28 SB (Sub Brightness) with ▲ or ▼ key.

8. Adjust the data with + or – key for 890 mVDC.

9. Press the MENU key to turn off the Service Menu display.

10. Check brightness level on every active channel, readjust

(repeat steps 5 ~ 9), if necessary.

Note: Do not set to excessive brightness level, otherwise

the contrast level will be suppressed.

HIGH VOL T AGE HOLD-DOWN TEST

Every time the receiver is serviced, the HIGH VOLTAGE

HOLD-DOWN circuit must be tested for proper operation by

following these steps:

1. Connect receiver to 120V AC line. Tune receiver to active

channel. Reset the picture controls to the Sports level.

2. Check that the voltage measured between TP7 and TE7

(ground side) is within 16.5 VDC to 21 VDC. If the voltage

is out of this range, the Hold-Down Circuit must be checked.

3. Connect a DC Voltage supply to TP7 and TE7 through a

100 ohm 1/4W resistor. Adjust the DC voltage to 23 VDC.

The receiver should shutdown, losing raster and sound.

Then the receiver should turn off automatically. This

reaction indicates that the Hold-Down circuit is functioning properly. If the receiver does not shutdown, a

malfunction is indicated and its cause must be found and

corrected.

4. To obtain picture again, remove the DC Supply and wait

a few minutes. Now turn on the receiver.

HIGH VOL T AGE CHECK

Note: +B (+130V) Voltage Check and Grayscale Adjustment

must be completed before attempting High Voltage

Check.

1. Connect high voltage voltmeter – lead to ground, and

connect + lead to anode of picture tube.

2. Tune receiver to an active channel and confirm TV is

operating properly.

3. Eliminate the beam current by adjusting the contrast and

brightness controls to minimum.

4. Confirm high voltage is within 29.9 KV and 34.6 KV. If

reading is not within range, check horizontal circuit.

No high-voltage adjustment is provided on this chassis.

FOCUS ADJUSTMENT

Adjust focus control (T402) for well defined scanning lines.

MULTI-SOUND SECTION ADJUSTMENTS

Note: Multi-Sound Section must be adjusted after

A101 (U/V Tuner), IC3401 (MTS Decoder), or IC802

(EEPROM) is replaced.

INPUT LEVEL ADJUSTMENT

1. Connect a signal to the antenna terminals with audio of

1 KHZ 100% modulation.

2. Turn off the receiver and disconnect the AC power cord

(AC 120V line).

3. Connect voltmeter (RMS) to TP317 and ground.

4. While pressing the Menu key, reconnect the AC power

cord. The Service Menu will now appear.

5. Select NO. 105 ATT (MTS Input Level) with the ▲ or ▼

key.

6. Adjust the + or – key for a voltmeter reading of 400 ± 20

mVrms at TP317.

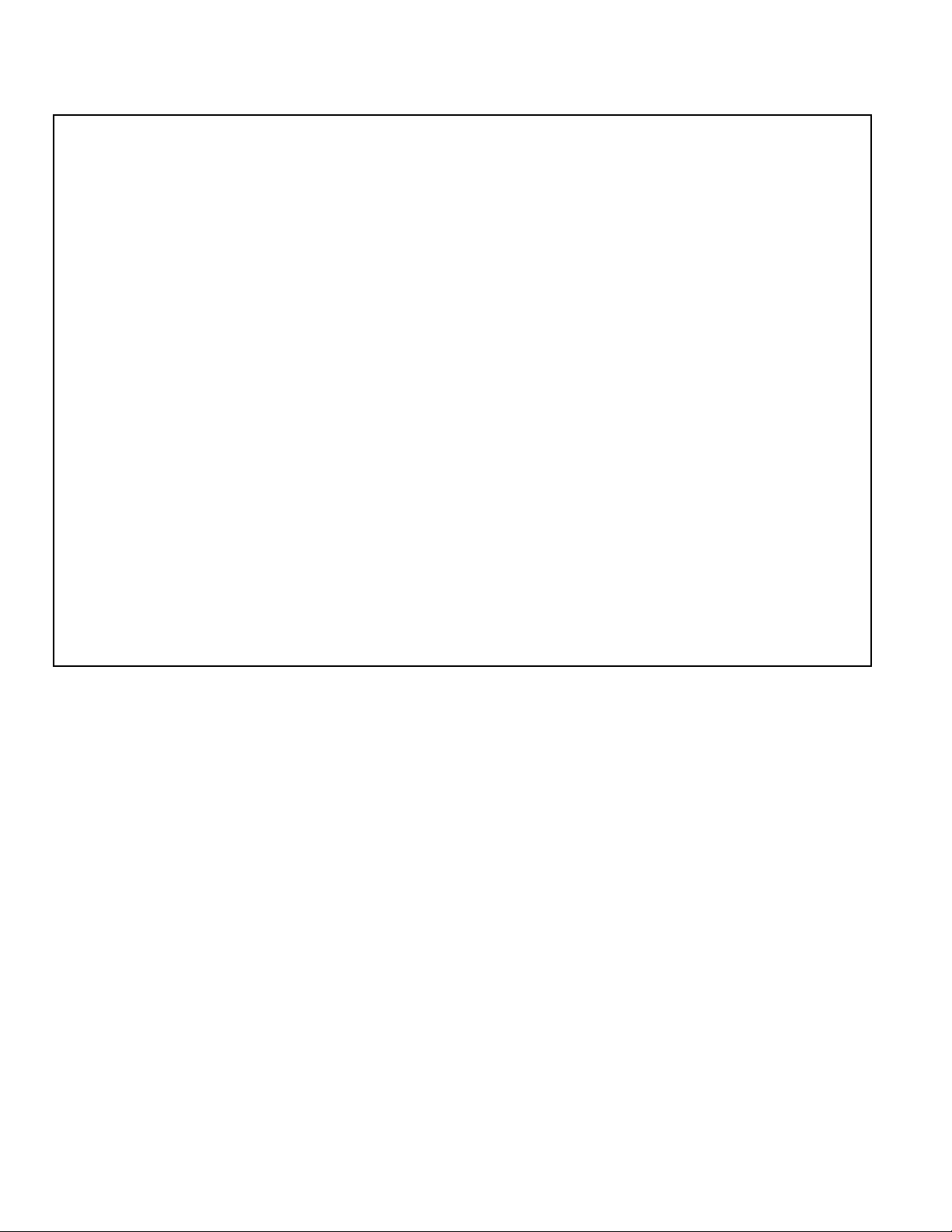

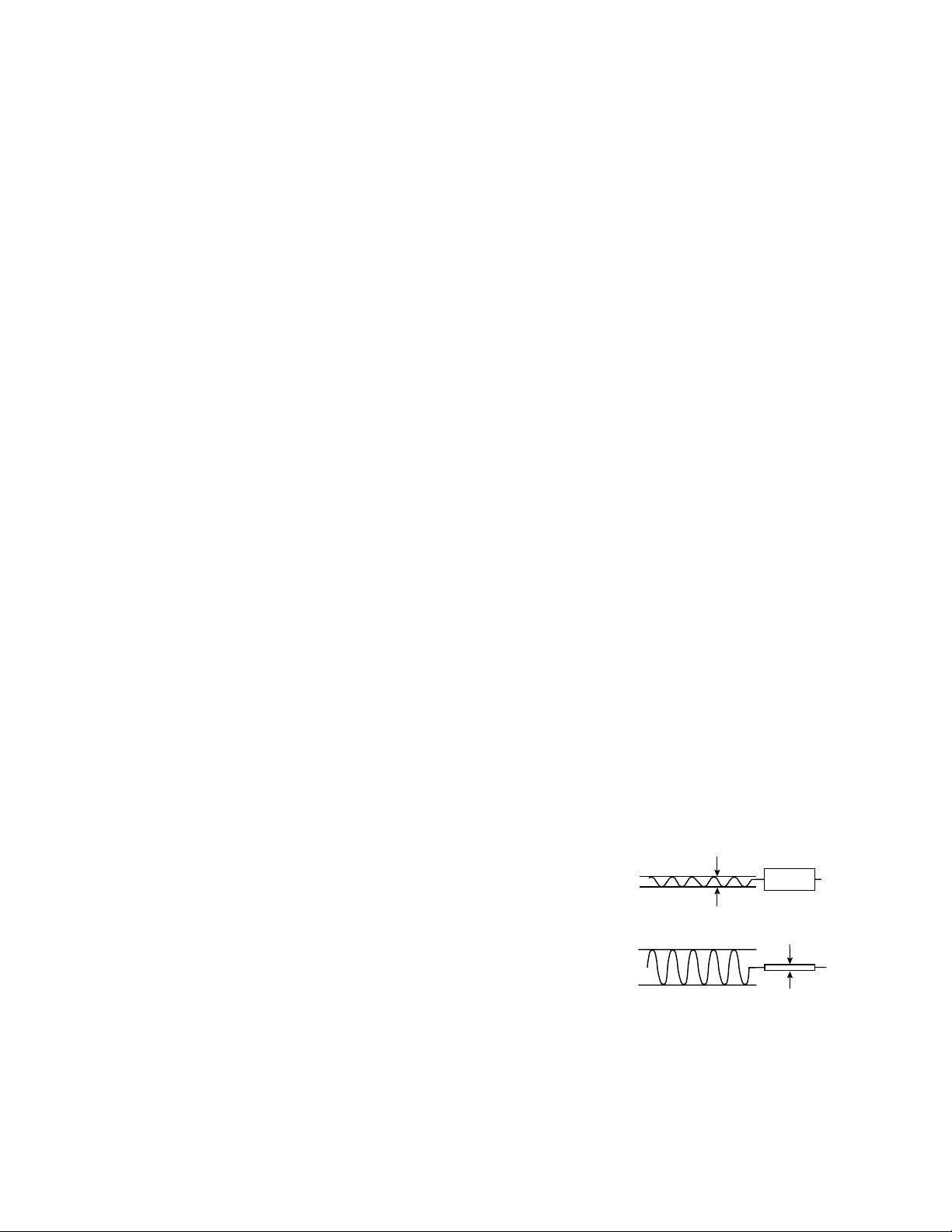

SEP ARA TION AD JUSTMENT

7. Turn off the receiver and disconnect the AC power cord

(AC 120V line).

8. Connect oscilloscope CH1 to TP317 and CH2 to TP318

and ground.

9. Connect an MTS TV/Stereo generator to antenna terminal.

10. While pressing the Menu key, reconnect the AC power

cord. The Service Menu will now appear.

11. Select pilot, 300Hz audio frequency and Left modulating

signal.

12. Select NO. 106 WDB (Wideband) with the ▲ or ▼ key.

13. Adjust the + or – key for minimum low frequencies at

TP317. (See Figure 4.)

14. Select 4 KHz audio frequency and Right modulating signal.

15. Select NO. 107 SPC (Spectral) with the ▲ or ▼ key.

16. Adjust the + or – key for minimum high frequencies at

TP318. (See Figure 4.)

Repeat adjustments (steps 11–16) until no further decreases

in amplitude can be obtained. Press the MENU key to turn

off the Service Menu display.

PURITY AND CONVERGENCE ADJUSTMENTS

Purity and Convergence have been aligned at the factory.

No re-alignment is necessary.

Figure 4. Separation Adjustments

Minimize L leakage

TP317 (R)

300Hz

Minimize R leakage

TP318 (L)

4KHz

Loading...

Loading...