Sanyo DS27930 Service Manual

DS27930

Model:

COLOR TELEVISION

AS

FILE NO.

DS27930, G7WPA, PRODUCT CODE 111357085

REFERENCE No. SM780086-13

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 13

Category :

U.S.A. / CANADA

Destination:

February / 15 / 2005

Date:

27930-13

Effective from : Chassis No.

SM780086-08

REF : No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service

Manual. If the Service Manual Chassis No. does not match the unit’s, additional Service

Literature is required. This chassis is similar to Chassis No. 27930-08. Only the

difference Service Information is given in this manual. For detailed Service Information,

refer to the Original Service Manual and Notices for Chassis No. 27930-08 used in Model

DS27930 (SM780086-08).

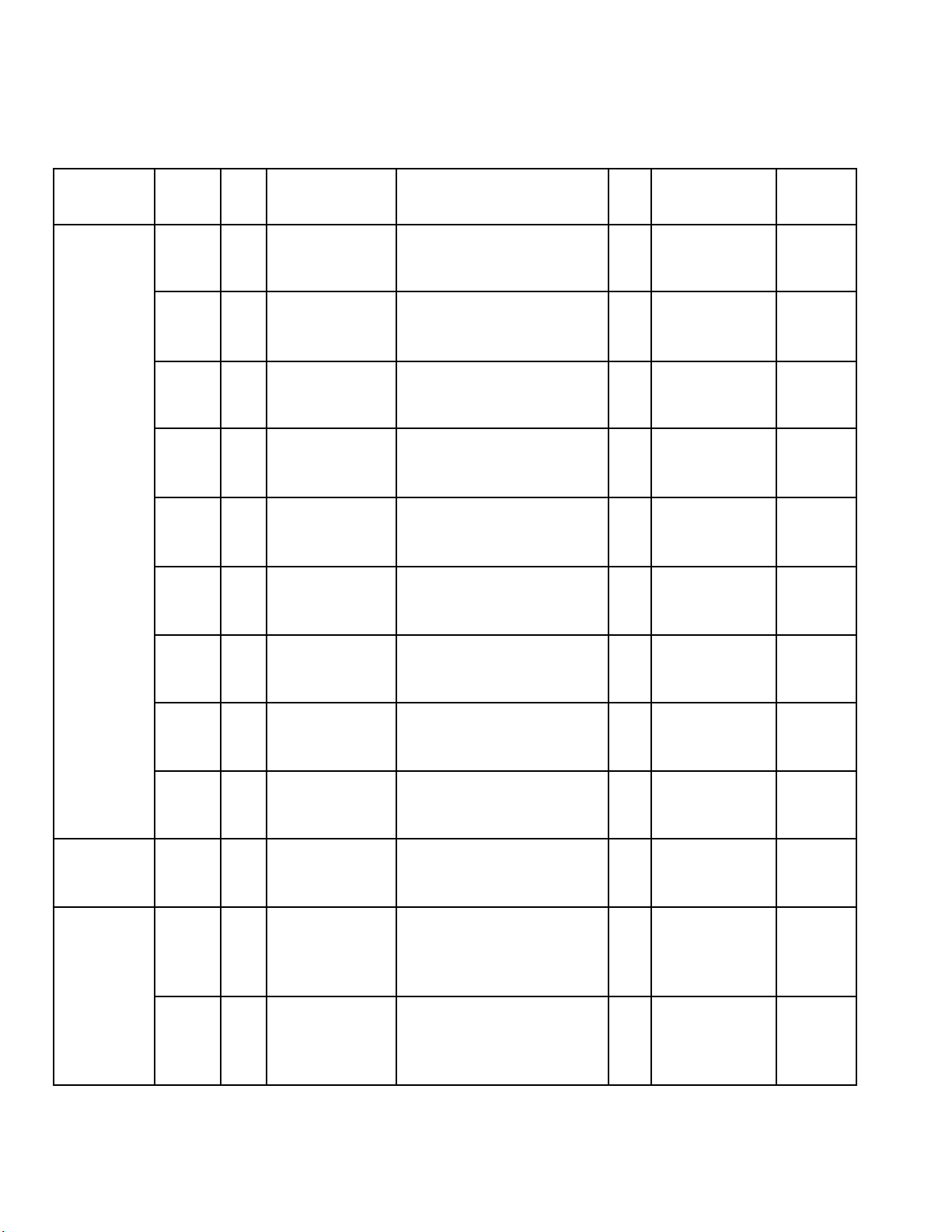

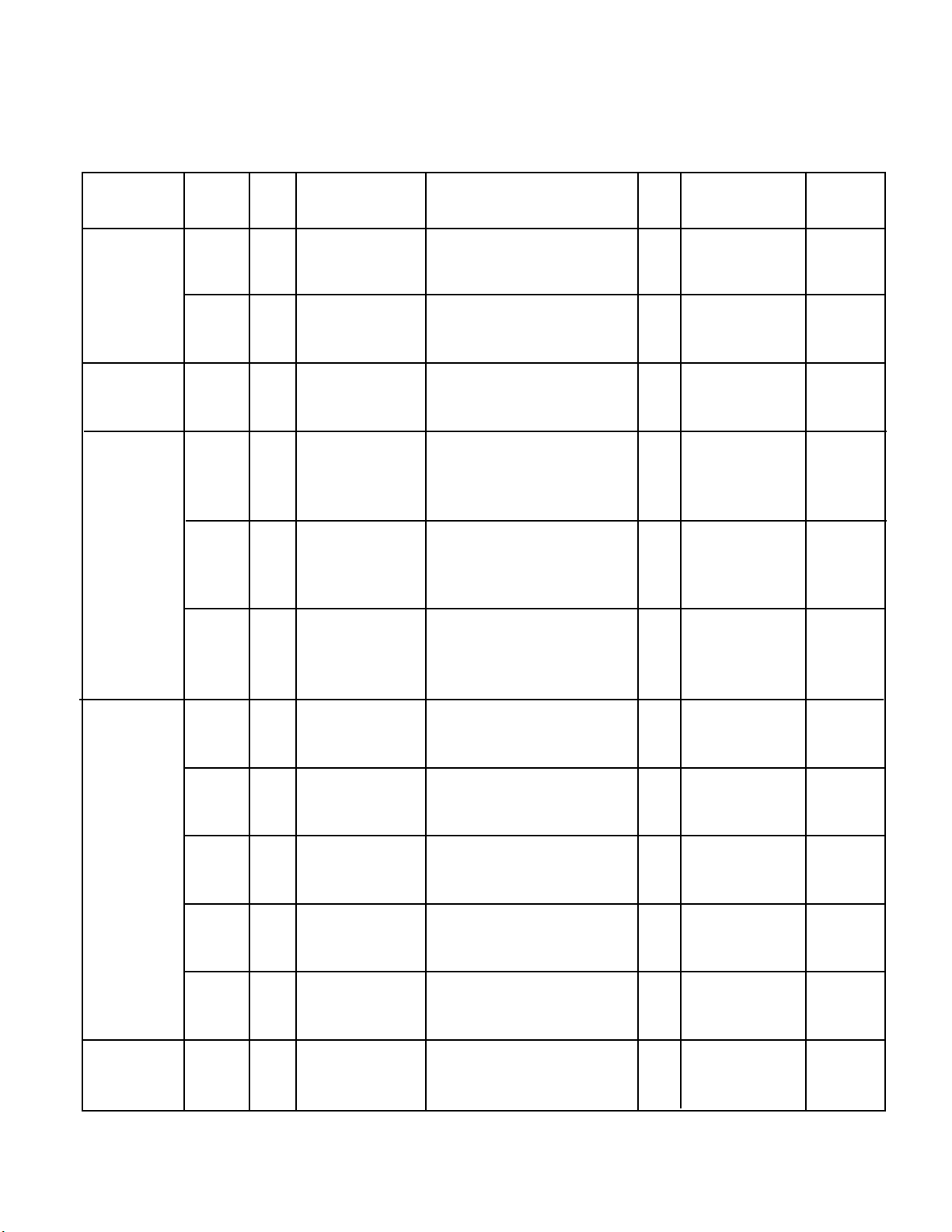

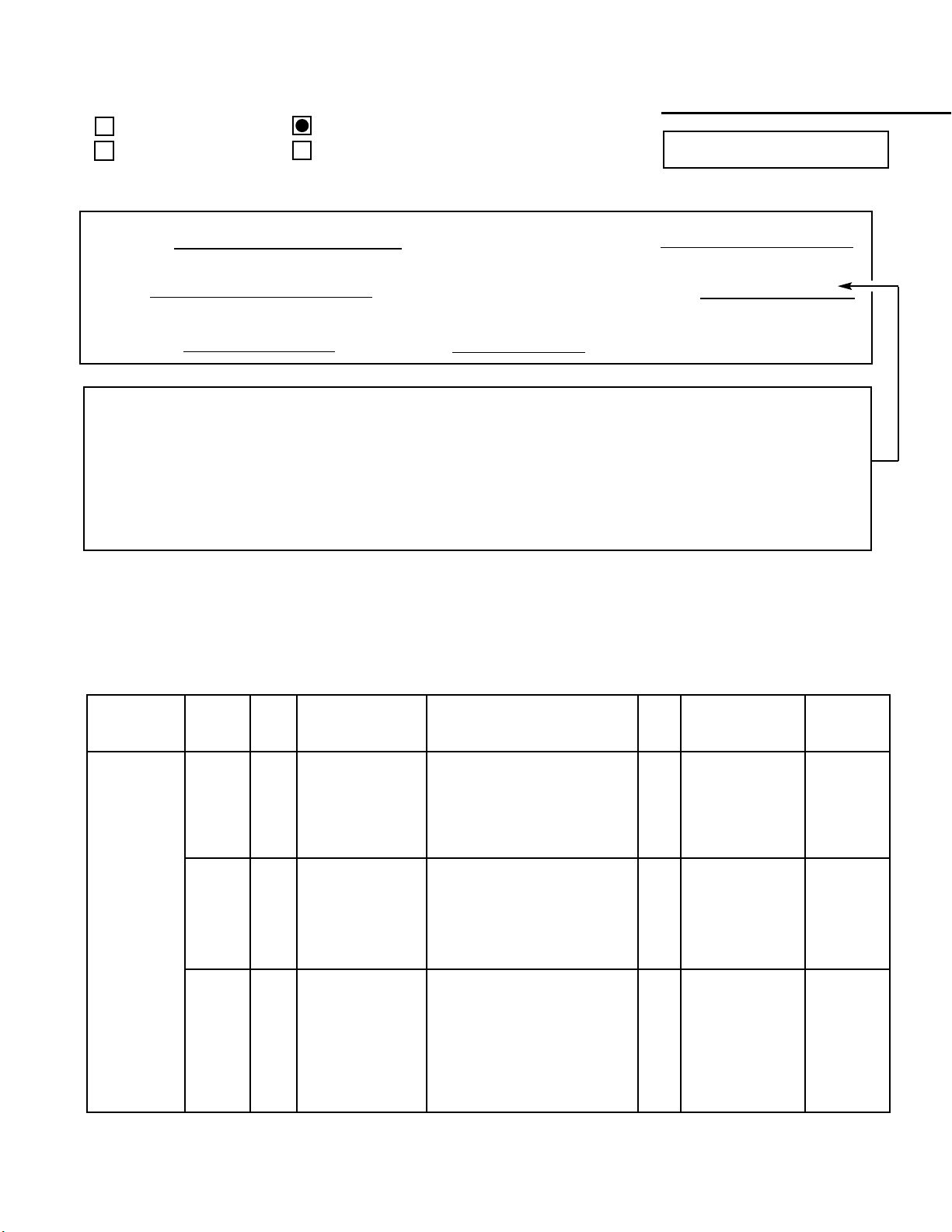

1. IN THE CHASSIS ELECTRICAL PARTS LIST (MAIN PWB ASSY)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Reason

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

#

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

404 076 5509 MT-POLYPRO 6500P H 1.5KV

1NO

403 353 4204 MT-POLYPRO 6500P H 1.5KV

Old N/A NOT USED 0 NO

R343 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 401 059 9608 OXIDE-MT 2.2 JA 1W 1 NO

#

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 064 3806 OXIDE-MT 1.0 JA 2W 1 NO

Old 610 318 5880 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0834 ASSY, PWB, MAIN 1 NO

Old 414 013 1907 CRT A68QCU770X79L 1 NO

#

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 013 2102 CRT A68ELH021X001 1 NO

Page 14

Chassis

Electrical

Parts List

Page 20

Chassis

Electrical

Parts List

Page 23

Chassis

Electrical

Parts List

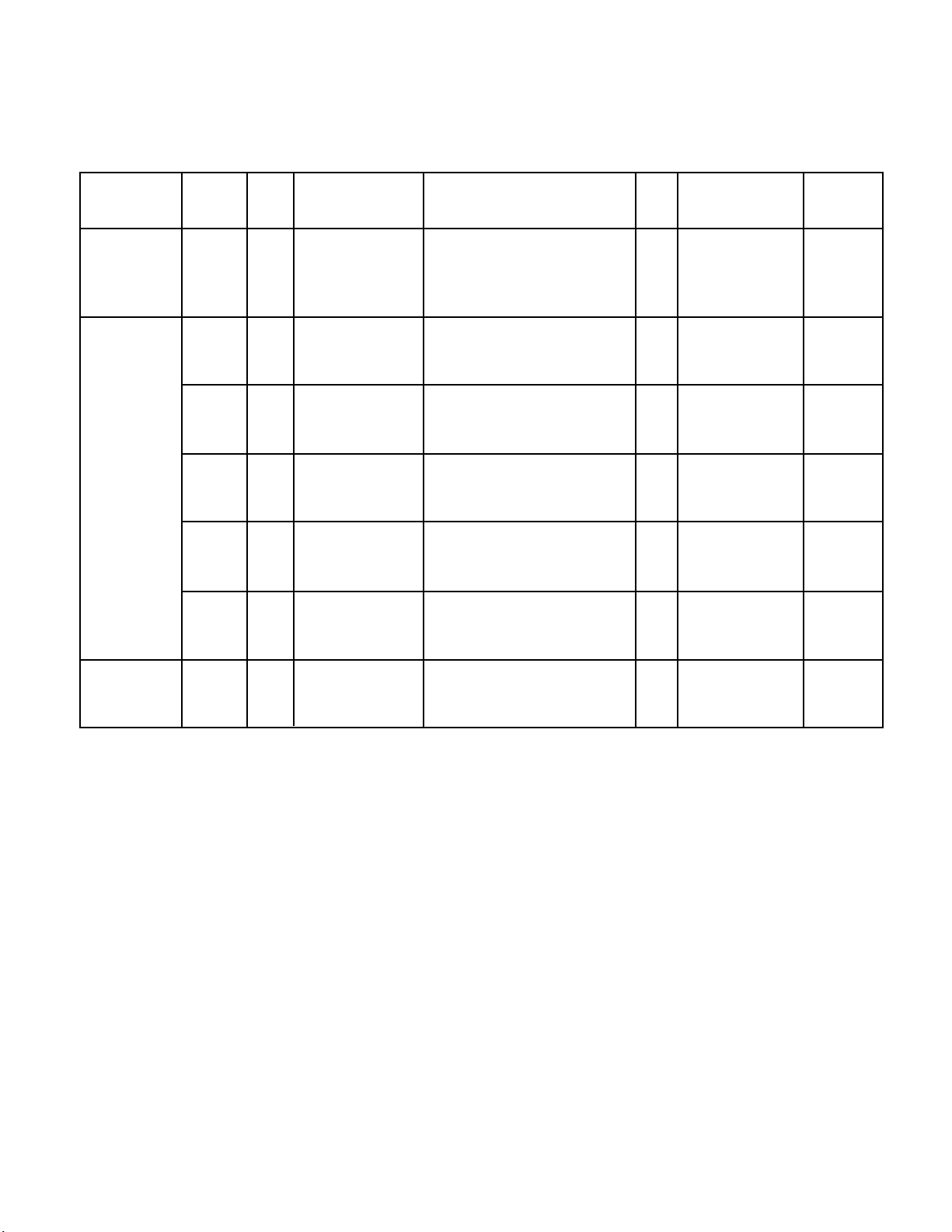

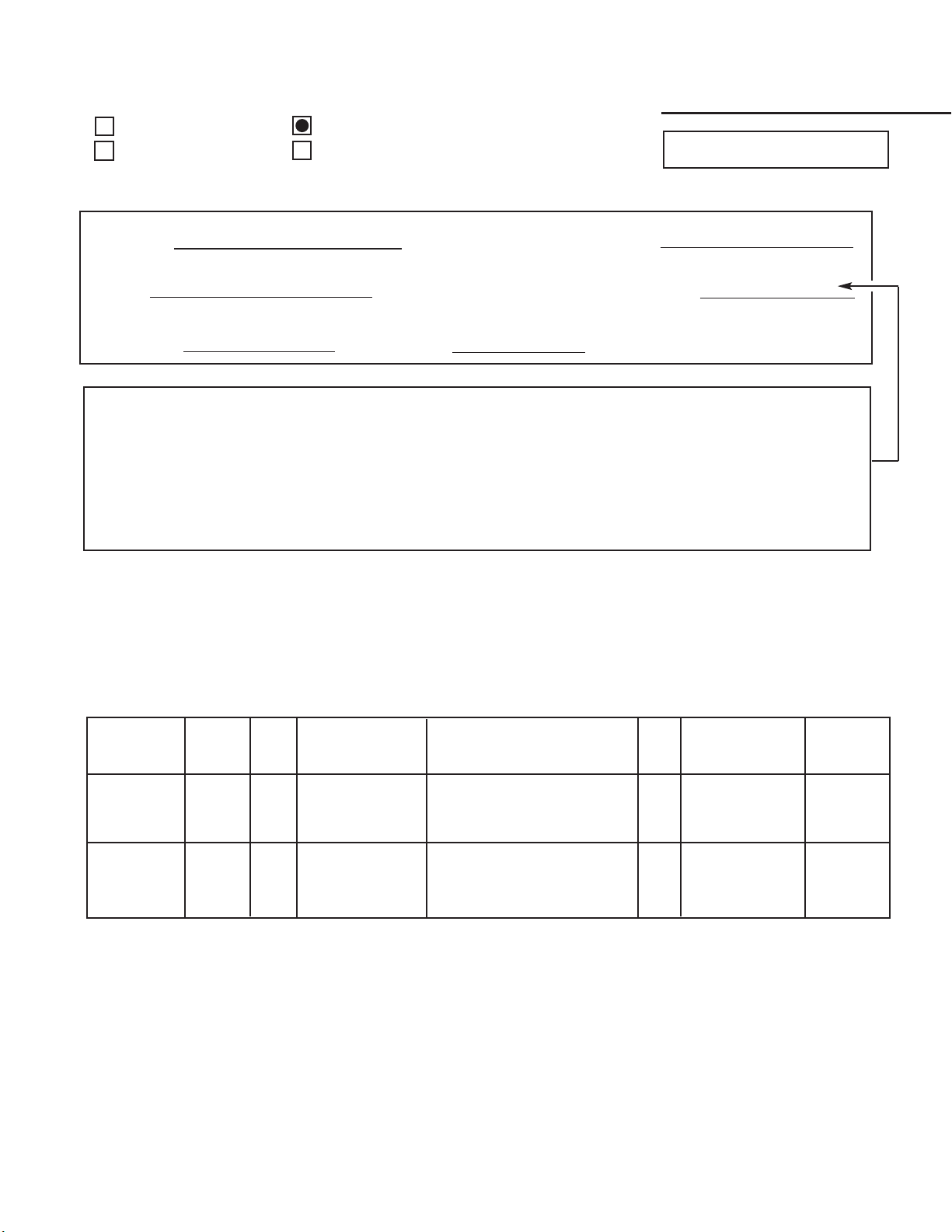

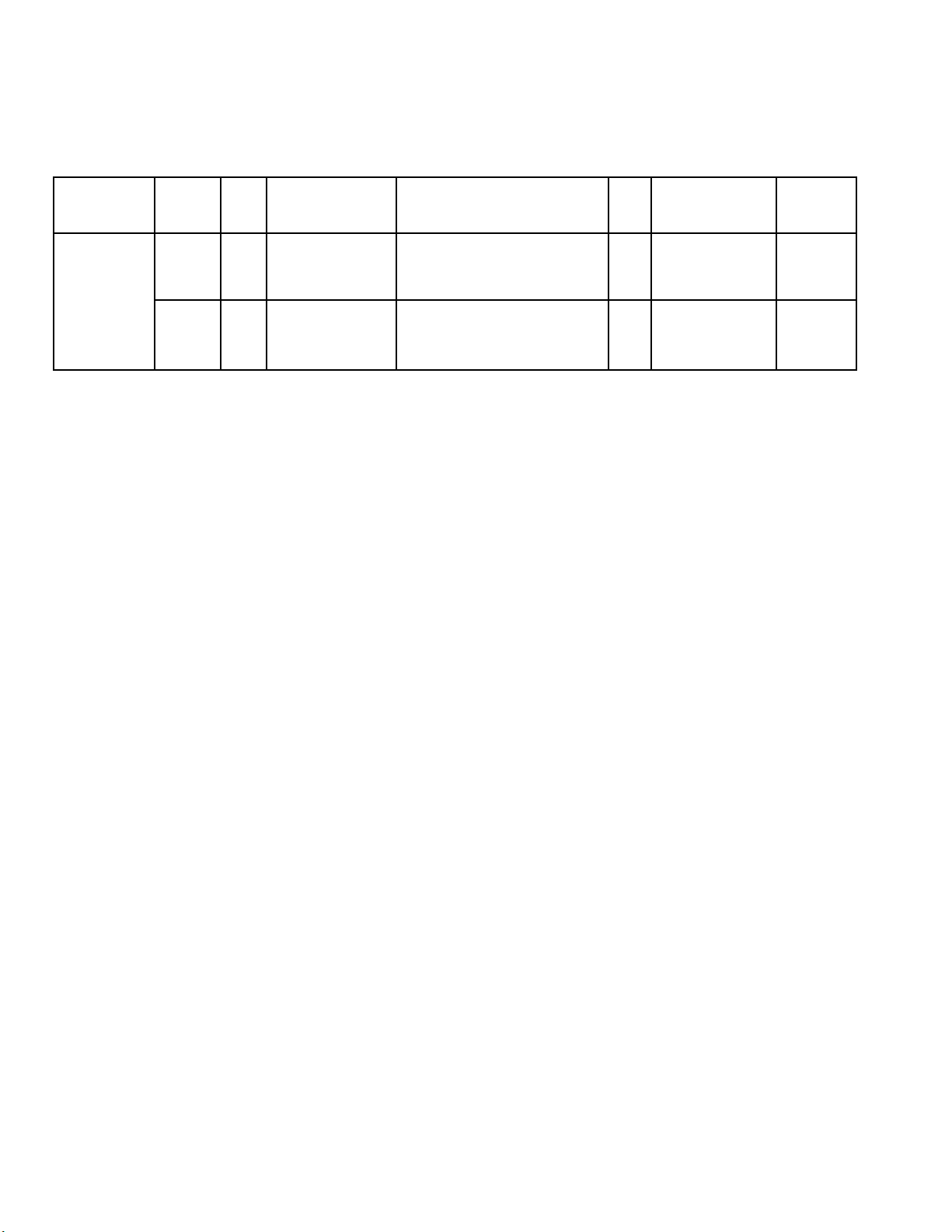

2. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchangeability

Reason

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

C313 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

C315 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C318 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 357 9601 CERAMIC 0.1U Z 50V 1 NO

C319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 319 4804 CERAMIC 0.22U Z 16V 1 NO

C320 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

C323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Old 404 084 3801 ELECT 1U M 50V 1 NO

C324 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

C331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C332 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 409 544 5807 IC LA76604M-TLM-E 1 NO

IC301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 409 491 5608 IC TDA9183T/N1 1 NO

Old

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

L301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old N/A NOT USED 0 NO

L305 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

Page 14,

Chassis

Electrical

Parts List

Page 17,

Chassis

Electrical

Parts List

– 2 –

Page 16,

Chassis

Electrical

Parts List

2. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY CONT.)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchange-

ability

Reason

Old N/A NOT USED 0 NO

L307 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

Old N/A NOT USED 0 NO

R311 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 401 256 0101 MT-GLAZE 8.2K JA 1/10W 1 NO

R319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1 NO

R323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 027 2303 CARBON 560 JA 1/6W 1 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1 NO

R326 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A JUMPER WIRE 1 NO

Old 401 162 2404 MT-GLAZE 1.2K JA 1/10W 1 NO

R331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 150 6001 MT-GLAZE 0.000 ZA 1/10W 1 NO

Old 610 310 4621 ASSY, PWB, AV 1 NO

A1000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0780 ASSY, PWB, AV 1 NO

Page 17,

Chassis

Electrical

Parts List

Page 20,

Chassis

Electrical

Parts List

Page 23,

Chassis

Electrical

Parts List

– 3 –

Printed in U.S.A.

For parts or service contact

21605 Plummer Street

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

SANYO Fisher Service Corporation

February / 2005 / 2000 SMC

– 4 –

DS27930

Model:

COLOR TELEVISION

AS

FILE NO.

DS27930, G7WMA, PRODUCT CODE 111357085

REFERENCE No. SM780086-12

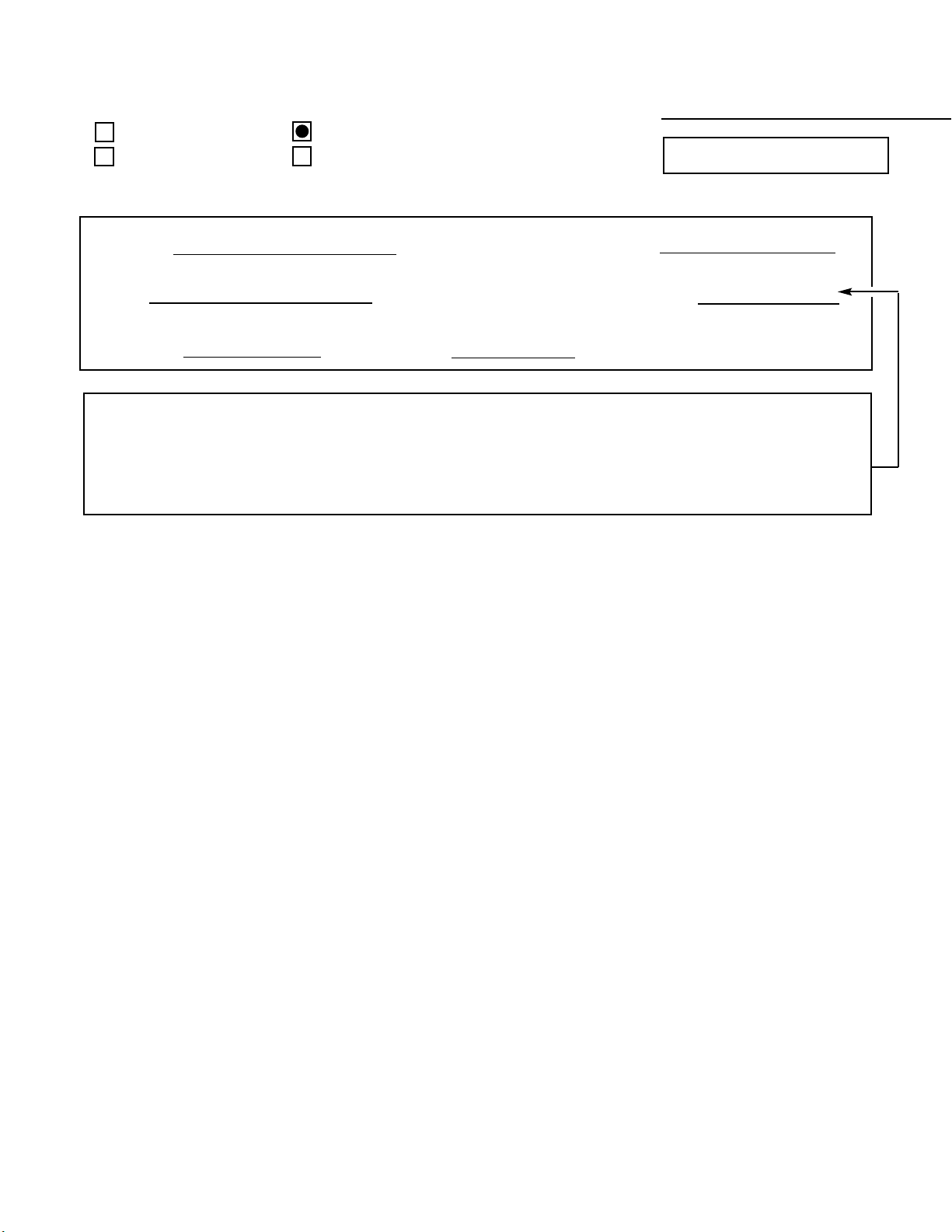

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 12

Category :

U.S.A. / CANADA

Destination:

February / 15 / 2005

Date:

27930-12

Effective from : Chassis No.

SM780086-08

REF : No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service

Manual. If the Service Manual Chassis No. does not match the unit’s, additional Service

Literature is required. This chassis is similar to Chassis No. 27930-08. Only the

difference Service Information is given in this manual. For detailed Service Information,

refer to the Original Service Manual and Notices for Chassis No. 27930-08 used in Model

DS27930 (SM780086-08).

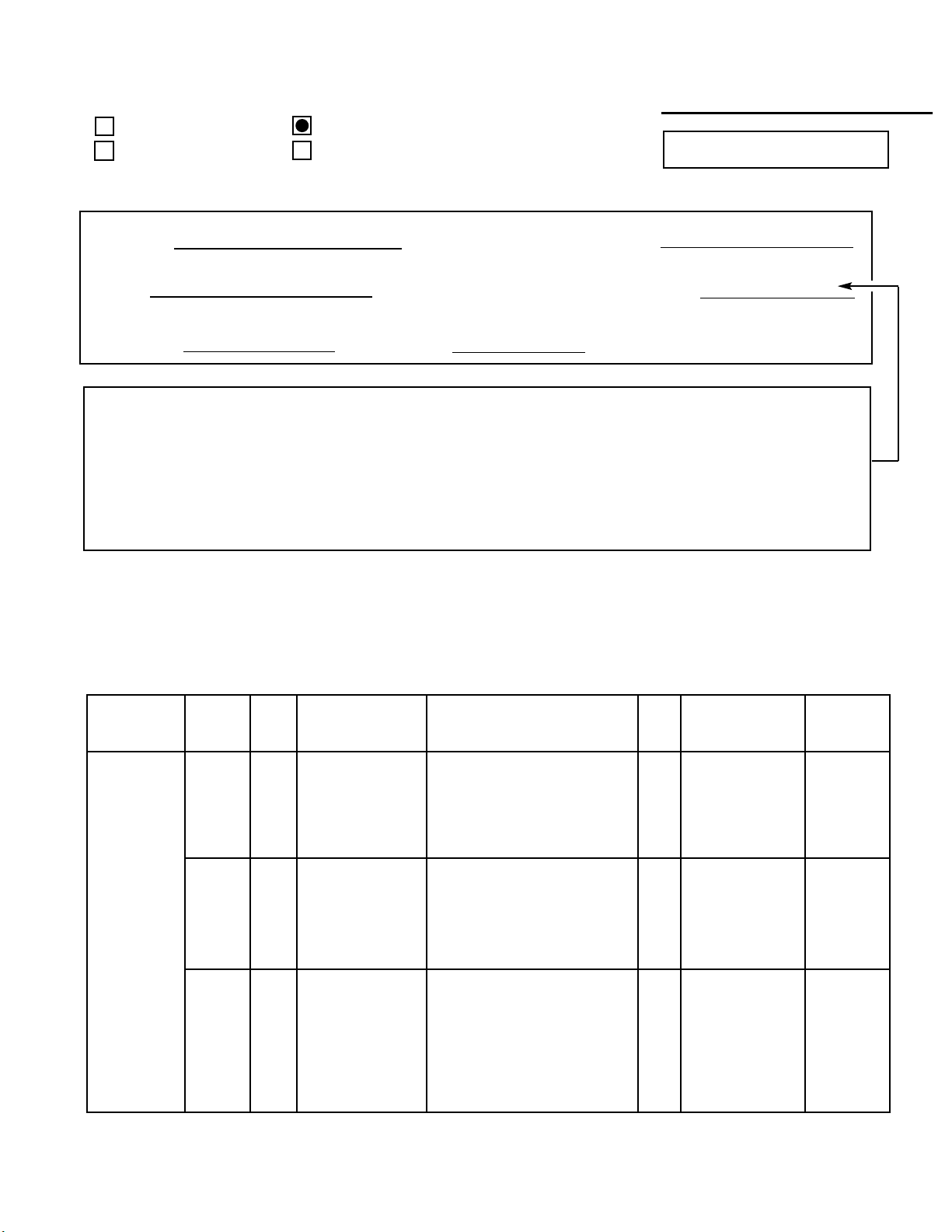

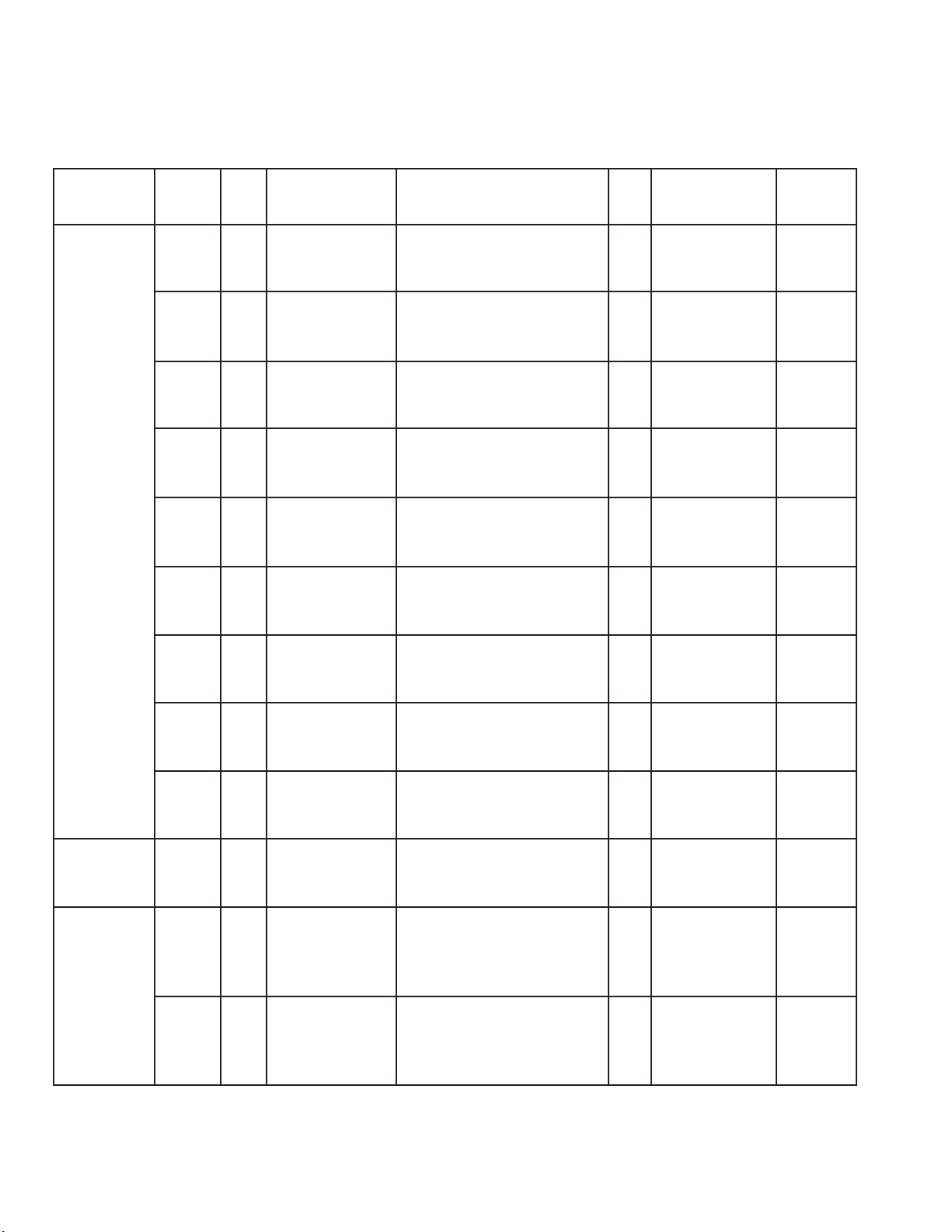

1. IN THE CHASSIS ELECTRICAL PARTS LIST (MAIN PWB ASSY)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Reason

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

#

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

404 076 5509 MT-POLYPRO 6500P H 1.5KV

1NO

403 353 4204 MT-POLYPRO 6500P H 1.5KV

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

#

C412 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 086 0303 MT-POLYPRO 6200P H 1.5KV

1NO

403 369 5103 MT-POLYPRO 6200P H 1.5KV

403 346 6822 MT-POLYPRO 0.2U J 250V

Old 403 392 8201 MT-POLYPRO 0.2U J 250V 1 NO

403 372 6500 MT-POLYPRO 0.2U J 250V

#

C416 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

403 358 7200 MT-POLYPRO 0.15U J 250V

New 403 392 8003 MT-POLYPRO 0.15U J 250V 1 NO

403 372 6302 MT-POLYPRO 0.15U J 250V

Page 14

Chassis

Electrical

Parts List

Parts list continued on back

1. IN THE CHASSIS ELECTRICAL PARTS LIST (MAIN PWB ASSY CONT.)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchangeability

Reason

Old N/A NOT USED 0 NO

R343 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 610 318 5880 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0827 ASSY, PWB, MAIN 1 NO

Old 414 013 1907 CRT A68QCU770X79L 1 NO

#

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 013 2003 CRT A68QCP693X002 1 NO

Page 23,

Chassis

Electrical

Parts List

Page 20,

Chassis

Electrical

Parts List

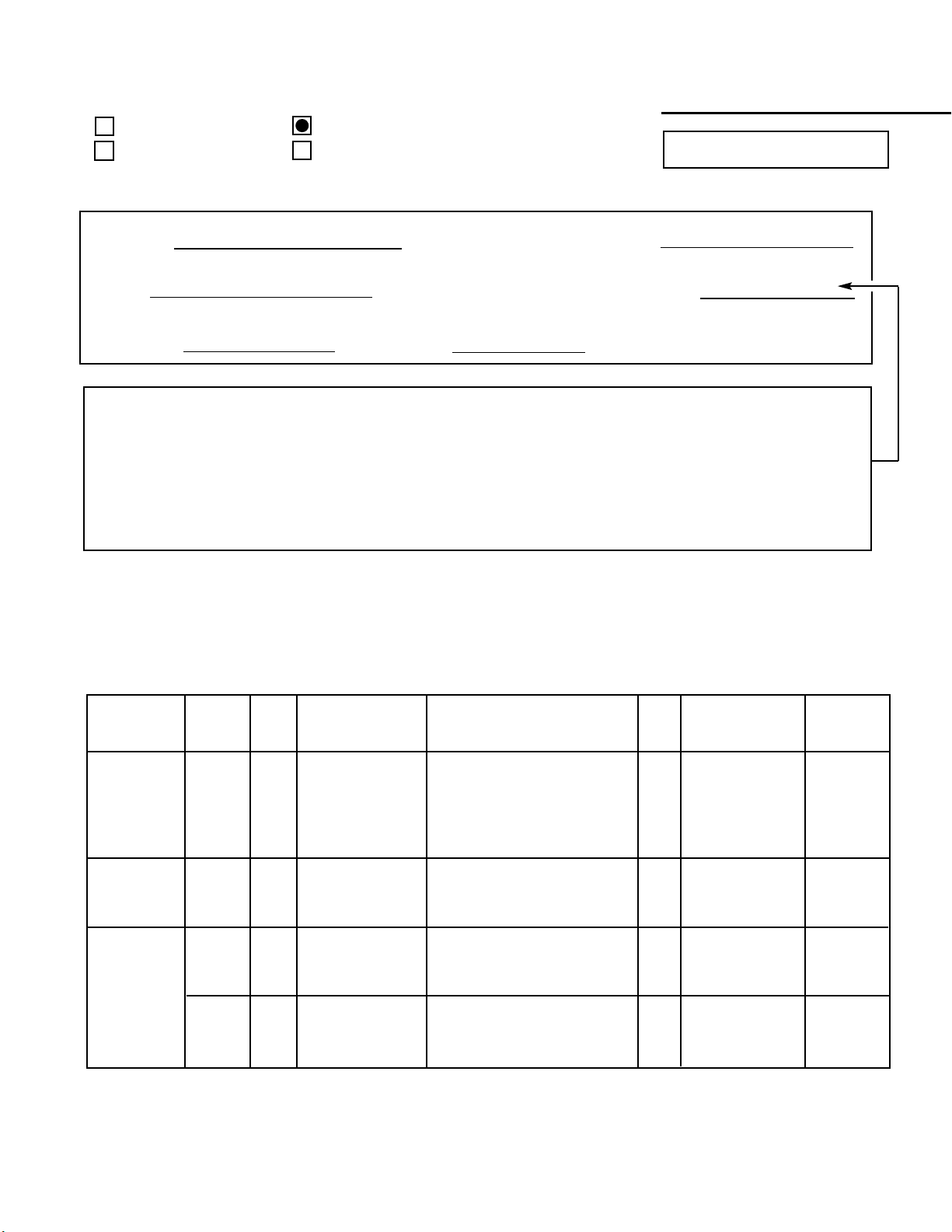

2. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchangeability

Reason

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

C313 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

C315 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C318 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 357 9601 CERAMIC 0.1U Z 50V 1 NO

C319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 319 4804 CERAMIC 0.22U Z 16V 1 NO

C320 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

C323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Old 404 084 3801 ELECT 1U M 50V 1 NO

C324 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Page 14,

Chassis

Electrical

Parts List

– 2 –

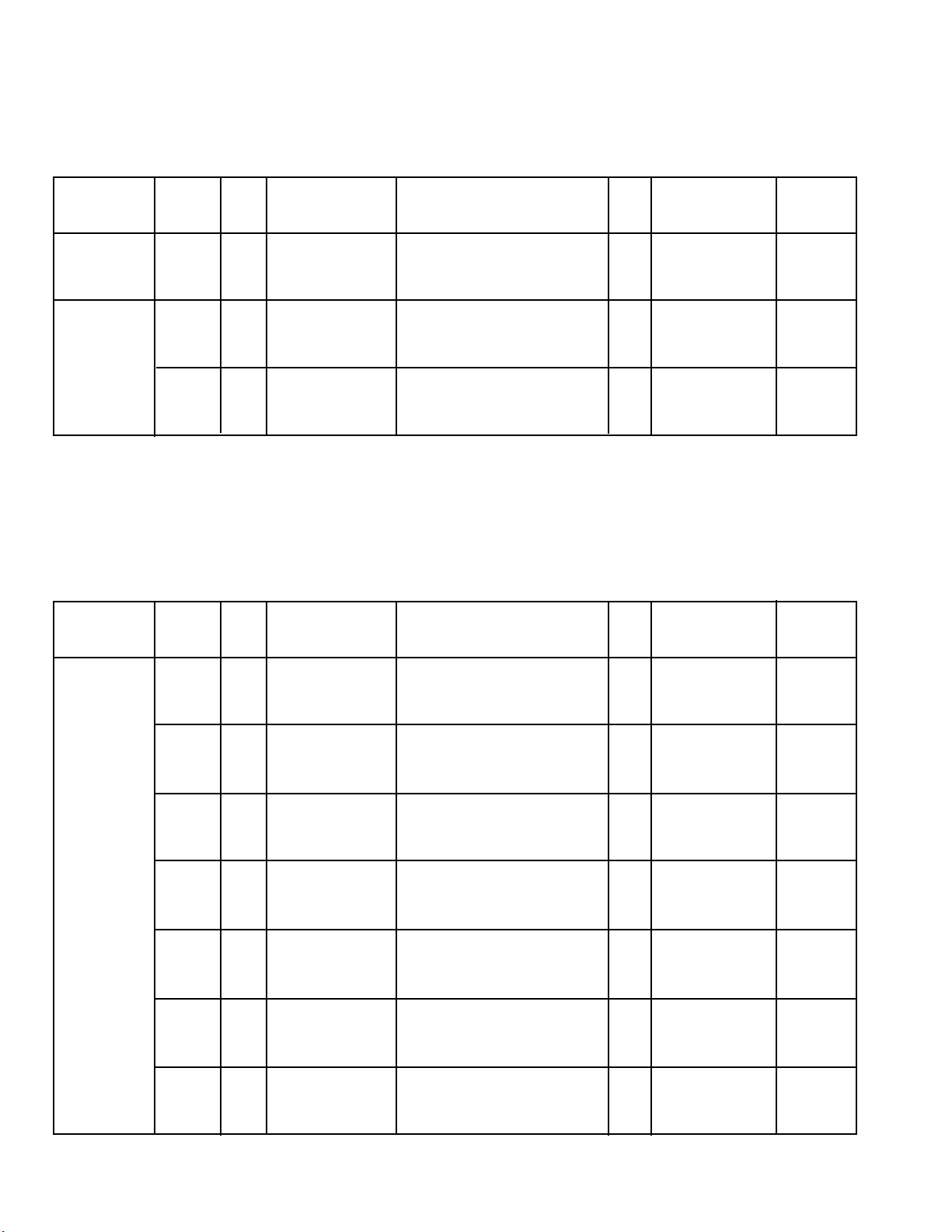

2. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY CONT.)

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchangeability

Reason

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

C331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C332 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 409 544 5807 IC LA76604M-TLM-E 1 NO

IC301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 409 491 5608 IC TDA9183T/N1 1 NO

Old

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

L301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old N/A NOT USED 0 NO

L305 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

Old N/A NOT USED 0 NO

L307 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

645 008 2894 INDUCTOR, 5.6U K

1NO

645 016 3104 INDUCTOR, 5.6U K

Old N/A NOT USED 0 NO

R311 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 401 256 0101 MT-GLAZE 8.2K JA 1/10W 1 NO

R319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1 NO

R323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 027 2303 CARBON 560 JA 1/6W 1 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1 NO

R326 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A JUMPER WIRE 1 NO

Old 401 162 2404 MT-GLAZE 1.2K JA 1/10W 1 NO

R331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 150 6001 MT-GLAZE 0.000 ZA 1/10W 1 NO

Old 610 310 4621 ASSY, PWB, AV 1 NO

A1000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0780 ASSY, PWB, AV 1 NO

Page 14,

Chassis

Electrical

Parts List

Page 17,

Chassis

Electrical

Parts List

Page 23,

Chassis

Electrical

Parts List

Page 20,

Chassis

Electrical

Parts List

Page 16,

Chassis

Electrical

Parts List

– 3 –

For parts or service contact

21605 Plummer Street

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

SANYO Fisher Service Corporation

February / 2005 / 2000 SMC

Printed in U.S.A.

Notice

AS

CORRECTION

SERVICE FLASH

Please add this notice to the Service Manual listed below.

Category :

Model:

Destination:

COLOR TELEVISION

DS27930

U.S.A. / CANADA

PRODUCTION CHANGE

ADD INFORMATION

REF : No.

SM780086-08

FILE NO.

REVISION 11

Date:

Effective from : Chassis No.

February / 15 / 2005

27930-11

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service

Manual.

If the Service Manual Chassis No. does not match the unit’s, additional Service

Literature is required. This chassis is similar to Chassis No. 27930-08. Only the

difference Service Information is given in this manual. For detailed Service Information,

refer to the

Original Service Manual and Notices for Chassis No. 27930-08 used in Model

DS27930 (SM780086-08).

1. IN THE CHASSIS ELECTRICAL PARTS LIST (MAIN PWB ASSY)

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Page 20

Chassis

Electrical

Parts List

Page 23

Chassis

Electrical

Parts List

Schematic

Location

Old

R343 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0810 ASSY, PWB, MAIN 1 NO

Part No.

N/A

610 318 5880 ASSY, PWB, MAIN

NOT USED 0

Description

Q’

ty

1

Interchange-

ability

NO

NO

Reason

Parts list continued on back

DS27930, G7WLA, PRODUCT CODE 111357085

REFERENCE No. SM780086-11

2

. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY)

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Page 14,

Chassis

Electrical

Parts List

Key

umber

N

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

313 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

C

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

315 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

C

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C318 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old

C319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 319 4804 CERAMIC 0.22U Z 16V 1 NO

C320 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 086 2607 NP-ELECT 1U M 50V 1 NO

C323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 403 311 8800 POLYESTER 0.1U J 50V 1 NO

Part No.

403 357 9601 CERAMIC 0.1U Z 50V 1 NO

Description

Q’ty

Interchangeability

Reason

Page 16,

Chassis

Electrical

Parts List

Page 17,

Chassis

Electrical

Parts List

Old 404 084 3801 ELECT 1U M 50V 1 NO

C324 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 235 0102 CERAMIC 39P J 50V 1 NO

C331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 403 234 9304 CERAMIC 8P D 50V 1 NO

C332 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 409 544 5807

IC301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 409 491 5608 IC TDA9183T/N1 1 NO

Old

L301 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old N/A NOT USED 0 NO

L305 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

645 008 2894 INDUCTOR, 5.6U K

645 016 3104 INDUCTOR, 5.6U K

645 008 2894 INDUCTOR, 5.6U K

645 016 3104

IC LA76604M-TLM-E

INDUCTOR, 5.6U K

1

1NO

1NO

NO

– 2 –

2

. IN THE CHASSIS ELECTRICAL PARTS LIST (AV PWB ASSY CONT.)

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Page 17,

Chassis

Electrical

Parts List

Page 20,

Chassis

Electrical

Parts List

ey

K

Number

Old N/A NOT USED 0 NO

L307 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

Old N/A NOT USED 0 NO

R311 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 401 256 0101 MT-GLAZE 8.2K JA 1/10W 1 NO

R319 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A NOT USED 0 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1NO

R323 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 027 2303 CARBON 560 JA 1/6W 1 NO

Old 401 024 9305 CARBON 1.2K JA 1/6W 1 NO

R326 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New N/A JUMPER WIRE 1 NO

Old 401 162 2404 MT-GLAZE 1.2K JA 1/10W 1 NO

R331 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 150 6001 MT-GLAZE 0.000 ZA 1/10W 1 NO

Part No.

45 008 2894 INDUCTOR, 5.6U K

6

645 016 3104 INDUCTOR, 5.6U K

Description

Q’ty

Interchange-

ability

1NO

Reason

Page 23,

Chassis

Electrical

Parts List

Old 610 310 4621 ASSY, PWB, AV 1 NO

A1000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 321 0780 ASSY, PWB, AV 1 NO

– 3 –

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

February / 2005 / 2000 SMC

Printed in U.S.A.

– 4 –

DS27930

Model:

COLOR TELEVISION

AS

FILE NO.

DS27930, G7YWA, PRODUCT CODE 111357085

REFERENCE No. SM780086-10

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 10

Category :

U.S.A. / CANADA

Destination:

January / 15 / 2005

Date:

27930-10

Effective from : Chassis No.

SM780086

REF : No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service

Manual. If the Service Manual Chassis No. does not match the unit’s, additional Service

Literature is required. This chassis is similar to Chassis No. 27930-08. Only the

difference Service Information is given in this manual. For detailed Service Information,

refer to the Original Service Manual and Notices for Chassis No. 27930-08 used in Model

DS27930 (SM780086-08).

1. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Reason

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

404 076 5509 MT-POLYPRO 6500P H 1.5KV

1NO

403 353 4204 MT-POLYPRO 6500P H 1.5KV

Old 401 059 9608 OXIDE-MT 2.2 JA 1W 1 NO

★

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 064 3806 OXIDE-MT 1.0 JA 2W 1 NO

Old 610 318 5880 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 318 5873 ASSY, PWB, MAIN 1 NO

Old 414 013 1907 CRT A68QCU770X79L 1 N0

★

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 013 2102 CRT A68ELH021X001 1 NO

Page 14

Chassis

Electrical

Parts List

Page 20

Chassis

Electrical

Parts List

Page 23

Chassis

Electrical

Parts List

For parts or service contact

21605 Plummer Street

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

SANYO Fisher Service Corporation

January / 2005 / 2000 SMC

Printed in U.S.A.

DS27930

Model:

COLOR TELEVISION

AS

FILE NO.

DS27930, G7YVA, PRODUCT CODE 111357085

REFERENCE No. SM780086-09

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 9

Category :

U.S.A. / CANADA

Destination:

January / 15 / 2005

Date:

27930-09

Effective from : Chassis No.

SM780086

REF : No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service

Manual. If the Service Manual Chassis No. does not match the unit’s, additional Service

Literature is required. This chassis is similar to Chassis No. 27930-08. Only the

difference Service Information is given in this manual. For detailed Service Information,

refer to the Original Service Manual and Notices for Chassis No. 27930-08 used in Model

DS27930 (SM780086-08).

1. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Reason

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

404 076 5509 MT-POLYPRO 6500P H 1.5KV

1NO

403 353 4204 MT-POLYPRO 6500P H 1.5KV

Old

404 077 4303 MT-POLYPRO 7100P H 1.5KV

1NO

403 353 4303 MT-POLYPRO 7100P H 1.5KV

★

C412 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 086 0303 MT-POLYPRO 6200P H 1.5KV

1NO

403 369 5103 MT-POLYPRO 6200P H 1.5KV

403 346 6822 MT-POLYPRO 0.2U J 250V

Old 403 392 8201 MT-POLYPRO 0.2U J 250V 1 NO

403 372 6500 MT-POLYPRO 0.2U J 250V

★

C416 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

403 358 7200 MT-POLYPRO 0.15U J 250V

New 403 392 8003 MT-POLYPRO 0.15U J 250V 1 NO

403 372 6302 MT-POLYPRO 0.15U J 250V

Page 14

Chassis

Electrical

Parts List

Parts list continued on back

For parts or service contact

21605 Plummer Street

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

SANYO Fisher Service Corporation

January / 2005 / 2000 SMC

Printed in U.S.A.

1. IN THE CHASSIS ELECTRICAL PARTS LIST (CONT.)

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Page &

Section

Key

Number

Part No.

Description

Q’ty

Interchangeability

Reason

Old 610 318 5880 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 318 5866 ASSY, PWB, MAIN 1 NO

Old 414 013 1907 CRT A68QCU770X79L 1 N0

★

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 013 2003 CRT A68QCP693X002 1 NO

Page 23,

Chassis

Electrical

Parts List

Contents

Safety Instructions . . . . . . . . . . . . . . . . . . 2

Service Adjustments. . . . . . . . . . . . . 3 - 10

Service Hints. . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Disassemblies. . . . . . . . . . . 12

Chassis Electrical Parts List . . . . . . 13 - 23

Cabinet Parts List . . . . . . . . . . . . . . . . . . 24

Component and Test Point

Locations . . . . . . . . . . . . . . . . . . . 25 - 28

Schematic Insert . . . . . . . . . . . . . . . 29 - 36

Schematic Notes . . . . . . . . . . . . . . . . . 29

Pin Layouts . . . . . . . . . . . . . . . . . . . . . 29

Capacitor and Resistor Codes . . . . . . 29

Block Diagram . . . . . . . . . . . . . . . 30 - 31

Voltage Charts . . . . . . . . . . . . . . . 30 - 32

Waveforms. . . . . . . . . . . . . . . . . . . . . . 32

Schematic Diagrams . . . . . . . . . . 33 - 36

Specifications

Power Rating . . . . . . . . . . . . . . . . . . . . . 120V, 60Hz

95W (Avg), 2.5A (Max)

Antenna Input Impedance. . . . . . . . . . . . . . . . . 75Ω

UHF/VHF/CATV

Receiving Channel . . . . . . . . . . . . . . . . 2 - 13 (VHF),

14 - 69 (UHF),

01, 14-94, 95-125 (CATV)

Remote Ready . . . . . . . . . . 33 Key Remote Control

Sound Output . . . . . . . . . . . . . . . . . . . . . . 3.0 W/CH

Intermediate Frequency

Picture IF Carrier. . . . . . . . . . . . . . . . . . 45.75MHz

Sound IF Carrier . . . . . . . . . . . . . . . . . . 41.25MHz

Color Sub Carrier . . . . . . . . . . . . . . . . . 42.17MHz

Picture Tube . . . . . . . . . . . . . . . . . A68QCU770X79L

Semiconductors

Integrated Circuits. . . . . . . . . . . . . . . . . . . . . . . 12

Transistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Except within Tuner and RC Pre-Amp.

Cabinet Dimensions

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 664mm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . 629mm

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489mm

REFERENCE No. SM780086-08

DS27930, G7YTA, PRODUCT CODE 111357085

DS27930

Model:

COLOR TELEVISION

AS

FILE NO.

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 8

Category :

U.S.A. / CANADA

Destination:

January / 15 / 2005

Date:

27930-08

Effective from : Chassis No.

SM780086

REF : No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service Manual.

If the Service Manual Chassis No. does not match the unit’ s, additional Service Literature is

required. This chassis is similar to Chassis No. 27930-00, however, all Service

Information is given in this Notice for Chassis No. 27930-08 used in Model DS27930.

— 2 —

SAFETY PRECAUTIONS

WARNING: The chassis of this receiver has a floating

ground with the potential of one half the AC line voltage in

respect to earth ground. Service should not be attempted by

anyone not familiar with the precautions necessary when

working on this type of equipment.

The following precautions must be observed:

1. An isolation transformer must be connected in the power

line between the receiver and the AC line before any service is performed on the receiver.

2. Comply with all caution and safety-related notes provided on the side of the cabinet, inside the cabinet, on the

chassis, and the picture tube.

3. When replacing a chassis in the cabinet, always be certain

that all the protective devices are installed properly, such

as control knobs, adjustment covers, shields and barriers.

DO NOT OPERATE THIS TELEVISION RECEIVER

WITHOUT THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4. Before replacing the back cover of the set, thoroughly

inspect the inside of the cabinet to see that no stray parts

or tools have been left inside.

Before returning any television to the customer, the

service technician must perform the following safety

checks to be sure that the unit is completely safe to

operate without danger of electrical shock.

ANTENNA COLD CHECK

Remove AC plug from the 120 VAC outlet and place a

jumper across the two blades. Connect one lead of an ohmmeter to the jumpered AC plug, and touch the other lead to

each exposed antenna terminal (UHF and VHF antenna terminals). The resistance must measure between 1M ohm and

5.2M ohm. Any resistance value below or above this range

indicates an abnormality which requires corrective action.

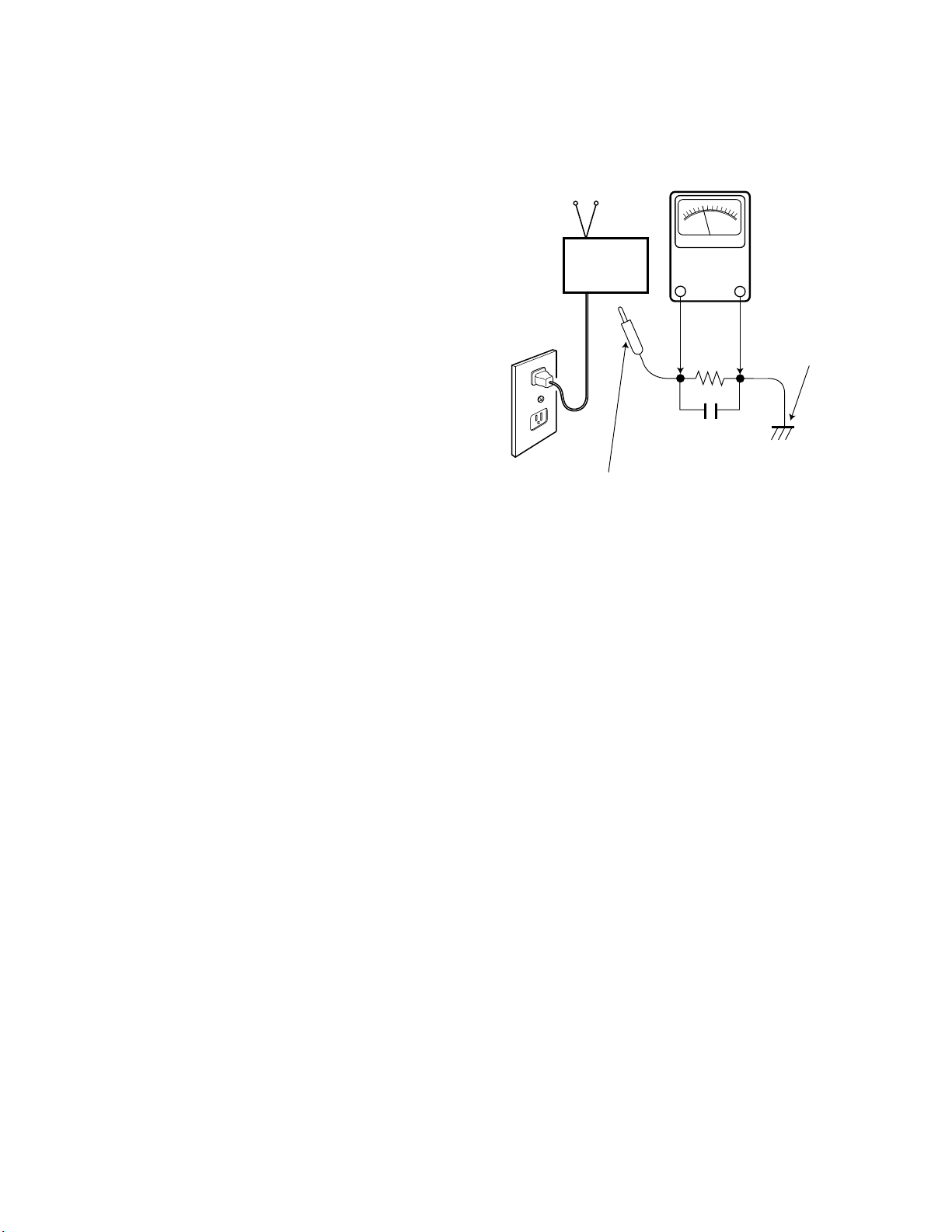

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120 VAC outlet. (Do not

use an isolation transformer for this check.) Use an AC voltmeter, that has 5000 ohms per volt or more sensitivity.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF

150 VAC capacitor, between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of the

cabinet (antennas, handle bracket, metal cabinet, screw

heads, metal overlays, control shafts, etc.). Measure the AC

voltage across the 1500 ohm resistor. The AC voltage

should not exceed 750 mV. A reading exceeding 750 mV

indicates that a dangerous potential exists. The fault must

be located and corrected. Repeat the above test with the

receiver power plug reversed.

NEVER RETURN A RECEIVER TO THE CUSTOMER

WITHOUT TAKING THE NECESSARY CORRECTIVE ACTION.

X-RADIATION PRECAUTION

The primary source of X-RADIATION in solid-state receivers is

the picture tube. The picture tube is specially constructed to

limit X-Ray emission. For continued X-RADIATION protection,

the replacement tube must be the same type as the original

(including the suffix letter in the part numbers). Excessive high

voltage may produce potentially hazardous X-RADIATION. To

avoid such hazards, the high voltage must be maintained within

specific limits. Refer to the X-RADIATION WARNING NOTE on

the CHASSIS SCHEMATIC in this service manual for specific

high voltage limits. If the high voltage exceeds specified limits,

check the components specified on the chassis schematic

diagram and take the necessary corrective action. Carefully

follow the instructions for the +B Voltage Check and the High

Voltage Check to maintain the high voltage within the specified

limits.

HIGH VOLTAGE HOLD-DOWN TEST

To prevent X-RADIATION from the picture tube due to

excessive high voltage, a HOLD-DOWN circuit is provided in

the high voltage circuit. Every time the receiver is serviced,

the high voltage HOLD-DOWN circuit must be tested for

proper operation. Refer to the HIGH VOLTAGE HOLDDOWN TEST in service adjustments.

PRODUCT SAFETY NOTICE

When replacing components in a receiver, always keep in

mind the necessary product safety precautions. Pay special

attention to the replacement of components marked with a

star (★) in the parts list and in the schematic diagrams. To

ensure safe product operation, it is necessary to replace

those components with the exact same PARTS.

SAFETY INSTRUCTIONS

READING SHOULD NOT EXCEED 750 mV.

AC VOLTMETER

(5000 ohms per volt or more sensitivity)

TELEVISION

RECEIVER

Good earth ground

such as a water pipe,

conduit, etc.

AC OUTLET

1500 ohm

10 watt

0.15 F 150V AC

To be touched to all of exposed metal parts.

Voltmeter Hook-up for Leakage Current Check.

GENERAL

This set has an on-screen Service Menu system included in the CPU that allows remote operation for most of the service adjustments.

To enter the Service Menu, first disconnect the AC power cord. Then while pressing the MENU key on the front control panel, reconnect the AC power cord. The adjustments can now be made with the remote control or front control panel keys.

ON-SCREEN SERVICE MENU SYSTEM

1. Enter the Service Menu:

•While pressing the MENU key on the front control panel, reconnect the AC

power cord. The Service Menu Display will now appear. See Figure 1.

2. Service Adjustments:

•Press the ▲ or ▼ key to select the desired service menu item you

want to adjust. (See page 5 for On-screen Service Menu.)

•Use the + or – key or number keys to adjust the data.

The + or – keys will increase or decrease the data sequentially.

The number keys (0 ~ 7) toggle only their respective bits between

1 and 0 and are used to change the Sub-Address. For example to

change bit 5 press the number 5 key. See below.

3. Exit from the Service Menu:

•Press the MENU key to turn off the Service Menu display.

SERVICE ADJUSTMENTS

— 3 —

IC802 (EEPROM) REPLACEMENT

When IC802 (EEPROM) is replaced, IC801 (CPU) will automatically write the initial reference data into IC802 for basic TV operation.

However, the bus data should be checked and some bus data should be set up before attempting the service adjustments.

(See pages 5 – 7, Table 1, for detailed bus data information.)

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, change the following initial reference data for proper TV operation before

attempting service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

3. Select NO. 3C SCO (Sub Color) with ▲ or ▼ key. Adjust the data with + or – key for 1A.

4. Select NO. 3D STI (Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for 0D.

5. Select NO. 3F SSH (Sub Sharpness) with ▲ or ▼ key. Adjust the data with + or – key for 02.

6. Select NO. 40 AFC6HFR (AFC / H Frequency) with ▲ or ▼ key. Adjust the data with number keys for BF.

7. Select NO. 42 VS (V Size) with ▲ or ▼ key. Adjust the data with + or – key for 2B.

8. Select NO. 43 VSP7VPO (V Sync Sep / V Position) with ▲ or ▼ key. Adjust the data with number keys for 20.

9. Select NO. 44 CDM5UVL (V Count Dn Mode / V Lin Top) with ▲ or ▼ key. Adjust the data with number keys for 0F.

10. Select NO. 45 VC5LVL (V Compresion / V Lin Bottom) with ▲ or ▼ key. Adjust the data with number keys for 4D.

11. Select NO. 46 VSC (V S Correction) with ▲ or ▼ key. Adjust the data with + or – key for 10.

12. Select NO. 4A RD (Red Drive) with ▲ or ▼ key. Adjust the data with + or – key for 3A.

13. Select NO. 4C BD (Blue Drive) with ▲ or ▼ key. Adjust the data with + or – key for 3A.

14. Select NO. 4D SBI (Sub Bias) with ▲ or ▼ key. Adjust the data with + or – key for 40.

15. Select NO. 54 FLS (Y/C Filter Mode) with ▲ or ▼ key. Adjust the data with + or – key for 83.

16. Select NO. 57 YGM6DCR4BSS2BSG (Y Gamma / DC Reset / Black Steak Start / Black Streak Gain) with ▲ or ▼ key.

Adjust the data with number keys for A1.

SCO

3C 1A 00011010

Figure 1. Service Menu Display

ITEM NO.

TITLE

BINARY DATA

(8 bit)

HEX DATA

(b7) (b6) (b5) (b4) (b3) (b2) (b1) (b0)

0 1 0 1 0 1 1 0

BINARY DATA

(8 bit)

INITIAL BUS DATA SETUP (Cont.)

17. Select NO. 58 AFC7CBP5 (Auto Flesh / C Band Pass Filter) with ▲ or ▼ key. Adjust the data with number keys for C0.

18. Select NO. 59 DIG6ABL5MSD4BAT (OSD D/A / ABL Defeat / Mid Stop / ABL Threshold) with ▲ or ▼key. Adjust the data

with numbers key for 64.

19. Select NO. 5A RYA (R-Y/B-Y Angle) with ▲ or ▼ key. Adjust the data with + or – key for 00.

20. Select NO. 5F VL5BPF (Video Level / S BPF Sw) with ▲ or ▼ key. Adjust the data with number keys for 80.

21. Select NO. 60 EWD (E/W DC) with ▲ or ▼ key. Adjust the data with + or – key for 26.

22. Select NO. 61 EWA (E/W Amp) with ▲ or ▼ key. Adjust the data with + or – key for 0F.

23. Select NO. 62 EWT (E/W Tilt) with ▲ or ▼ key. Adjust the data with + or – key for 23.

24. Select NO. 63 EWB4EWP (E/W Corner Btm / E/W Corner Top) with ▲ or ▼ key. Adjust the data with number keys for 96.

25. Select NO. 65 BOW4ANG (Bow Correct / Angle Correct) with ▲ or ▼ key. Adjust the data with number keys for 96.

26. Select NO. 66 PRE6OVR4CTT (Pre Shoot Adj / Over Shoot Adj / Chroma Trap Test) with ▲ or ▼ key. Adjust the data

with number keys for 20.

27. Select NO. 67 HBL4HBR (H Blanking L / H Blanking R) with ▲ or ▼ key. Adjust the data with number keys for 2A.

28. Select NO. 68 SSP5VM (Sync Sep Sens / VM Gain) with ▲ or ▼ key. Adjust the data with number keys for 8C.

29. Select NO. 6A YTH2YGA (Y TH / Y Gain) with ▲ or ▼ key. Adjust the data with number keys for 0D.

30. Select NO. 6B RWD6ROF4BWD2BOF (R Width / R Offset / B Width / B Offset) with ▲ or ▼ key. Adjust the data with

number keys for 10.

31. Select NO. 83 OPT (Asp Ratio / Comb F / Clock / Scan Veloc) with ▲ or ▼ key. Adjust the data with number keys for 38.

32. Select NO. 84 OP2 (V Guide / Tone / AV / PIP / F/V / I-Ch / C En / C En Select) with ▲ or ▼ key. Adjust the data with

number keys for 26.

33. Select NO. 8D HR (H Display Position) with ▲ or ▼ key. Adjust the data with + or – key for 18.

34. Select NO. 8E SBO (Sub Bright Offset) with ▲ or ▼ key. Adjust the data with + or – key for 02.

35. Select NO. 92 DTN (YUV Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for FC.

36. Select NO. 96 BDC (YUV Cb Offset) with ▲ or ▼ key. Adjust the data with + or – key for 00.

37. Select NO. 97 RDC (YUV Cr Offset) with ▲ or ▼ key. Adjust the data with + or – key for 00.

38. Select NO. 9A ECN (16:9 Sub Contrast) with ▲ or ▼ key. Adjust the data with + or – key for E9.

39. Select NO. 9B EBR (16:9 Sub Bright) with ▲ or ▼ key. Adjust the data with + or – key for FB.

40. Select NO. A0 EEA(16:9 Sub E/W Amp) with ▲ or ▼ key. Adjust the data with + or – key for F9.

41. Select NO. A1 EET (16:9 Sub E/W Tilt) with ▲ or ▼ key. Adjust the data with + or – key for 00.

42. Select NO. A2 EEP (16:9 Sub E/W Corner Top) with ▲ or ▼ key. Adjust the data with + or – key for FF.

43. Select NO. A3 EEB (16:9 Sub E/W Corner Bottom) with ▲ or ▼ key. Adjust the data with + or – key for FD.

44. Select NO. A4 EUV (16:9 Sub V Lin Top) with ▲ or ▼ key. Adjust the data with + or – key for FE.

45. Select NO. A5 ELV (16:9 Sub V Lin Bottom) with ▲ or ▼ key. Adjust the data with + or – key for 04.

46. Select NO. AB VFL (Filter System AVt) with ▲ or ▼ key. Adjust the data with + or – key for 04.

47. Press the MENU key to turn off the Service Menu display.

— 4 —

SERVICE ADJUSTMENTS (Cont.)

— 5 —

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be

checked and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked

with an * should be changed from Initial Reference Data. See pages 3 and 4 for Initial Bus Data Setup.

No. TITLE

INITIAL REFERENCE INITIAL SETUP INITIAL SETUP

FUNCTION

DATA HEX DATA HEX DATA BINARY

3C SCO 0F 1A* 00011010 Sub Color

3D STI 15 0D* 00001101 Sub Tint

3E SB 20 20 00100000 Sub Bright

3F SSH 08 02* 00000010 Sub Sharpness

40 AFC6HFR A5 BF* 10111111 AFC(6) Horizontal Frequency

41 VTR7HP 0C 0C 00001100 Vertical Trans(7) Horizontal Phase

42 VS 40 2B* 00101011 Vertical Size

43 VSP7VPO 2A 20* 00100000 Vertical Sync Separator(7) Vertical Position

44 CDM5UVL 06 0F* 00001111 Vetical Count Down Mode(5) Vertical Linearity Top

45 VC5LVL 9E 4D* 01001101 Vertical Compression(5) Vertical Linearity Bottom

46 VSC 14 10* 00010000 Vertical S Correction

47 RB 00 00 00000000 Red Bias

48 GB 00 00 00000000 Green Bias

49 BB 00 00 00000000 Blue Bias

4A RD 38 3A* 00111010 Red Drive

4B HT5HTD4GD 37 37 00110111 Half Tone(6~5) Half Tone Defeat(4) Green Drive

4C BD 38 3A* 00111010 Blue Drive

4D SBI 30 40* 01000000 Sub Bias

4E ↓↓↓↓Not Used

4F ↓↓↓↓Not Used

50 OSD 07 07 00000111 On Screen Display Contrast

51 CRG6 80 80 10000000 Coring

52 ↓↓↓↓Not Used

53 ↓↓↓↓Not Used

54 FLS 84 83* 10000011 Y/C Filter Mode

55 GRY7CRS5GYA3CKO 03 03 00000011 Gray(7) Cross B/W(6~5) G-Y Angle(4) Color Killer

56 FBP6YAP4WP 42 42 01000010 FBP Blanking(6) Y APF(4) White Peak

57 YGM8DCR4BSS2BSG A5 A1* 10100001 Y Gamma(7~6) DC Reset(5~4) B Strk Start(3~2)B Strk Gain

58 AFC7CBP5 40 C0* 11000000 Auto Flesh(7) Color Band Pass Filter(5)

59 DIG6ABL5MSD4BAT 44 64* 01100100 OSD D/A(6) ABL Defeat(5) Mid Stop(4) ABL Threshold

5A RYA 0B 00* 00000010 R-Y/B-Y Angle

5B CBO4CRO 88 88 10001000 Cb DC Offset(7~4) Cr DC Offset

5C ↓↓↓↓Not Used

5D STS7RAD 20 20 00100000 S Trap Switch(7) RF AGC Delay

5E FMM7VIF4IAS 00 00 00000000 FM Mute(7) VIF System Switch(4) IF AGC

5F VL5BPF A0 80* 10000000 Video Level(7~5) S BPF Switch

60 EWD 28 26* 00100110 E/W DC

61 EWA 17 0F* 00001111 E/W Amp

62 EWT 1D 23* 00100011 E/W Tilt

63 EWB4EWP 88 96* 10010110 E/W Corner Bottom(7~4) E/W corner Top

64 EWC7HLV6HSC 03 03 00000011 E/W Correction Sw(7) H Lock V Det(6) H Size Comp

65 BOW4ANG 78 96* 10010110 Bow Correction(7~4) Angle Correction

66 PRE6OVR4CTT C0 20* 00100000 Preshoot Adj(7~6) Overshoot Adj(5~4) Chroma Trap Test

67 HBL4HBR 38 2A* 00101010 H Blanking Left(7~4) H Blanking Right

68 SSP5VM 90 8C* 10001100 Sync Sep Sens(7~5) VM Gain

69 VBL4 00 00 00000000 V Size 0.75(7) V Blanking select

6A YTH2YGA 00 0D* 00001101 Y TH(3~2) Y Gain

6B RWD6ROF4BWD2BOF 00 10* 00010000 R Width(7~6) R Offset(5~4) B Width(3~2) B Offset

80 ATT 07 07 00000111 Attenuation (MTS Input Level)

Loading...

Loading...