Page 1

FILE NO.

Service Manual

DVD & Hi-Fi VCR

Home Theater System

CONTENTS

Important warning ............................................................ 1

Service notice on checking .............................................. 1

How to order parts ........................................................... 1

Disassembly instruction ................................................... 2

Mechanical and adjustment ............................................. 14

Service fixtures and tools ................................................. 18

Preparation for servicing .................................................. 18

Preventive check and service intervals ............................ 19

Service mode list .............................................................. 21

When replacing EEPROM(MEMORY) IC ........................ 22

Re-write for DVD firmware ............................................... 23

Electrical adjustment ........................................................ 24

Trouble shooting guide .................................................... 26

Exploded View (Cabinet & Chassis) ................................ 54

Parts List .......................................................................... 55

Exploded View (DVD Mechanism) and Parts list ............. 60

Exploded View (VCR Mechanism) and Parts list ............. 62

Exploded View (Speaker) and Parts list ........................... 65

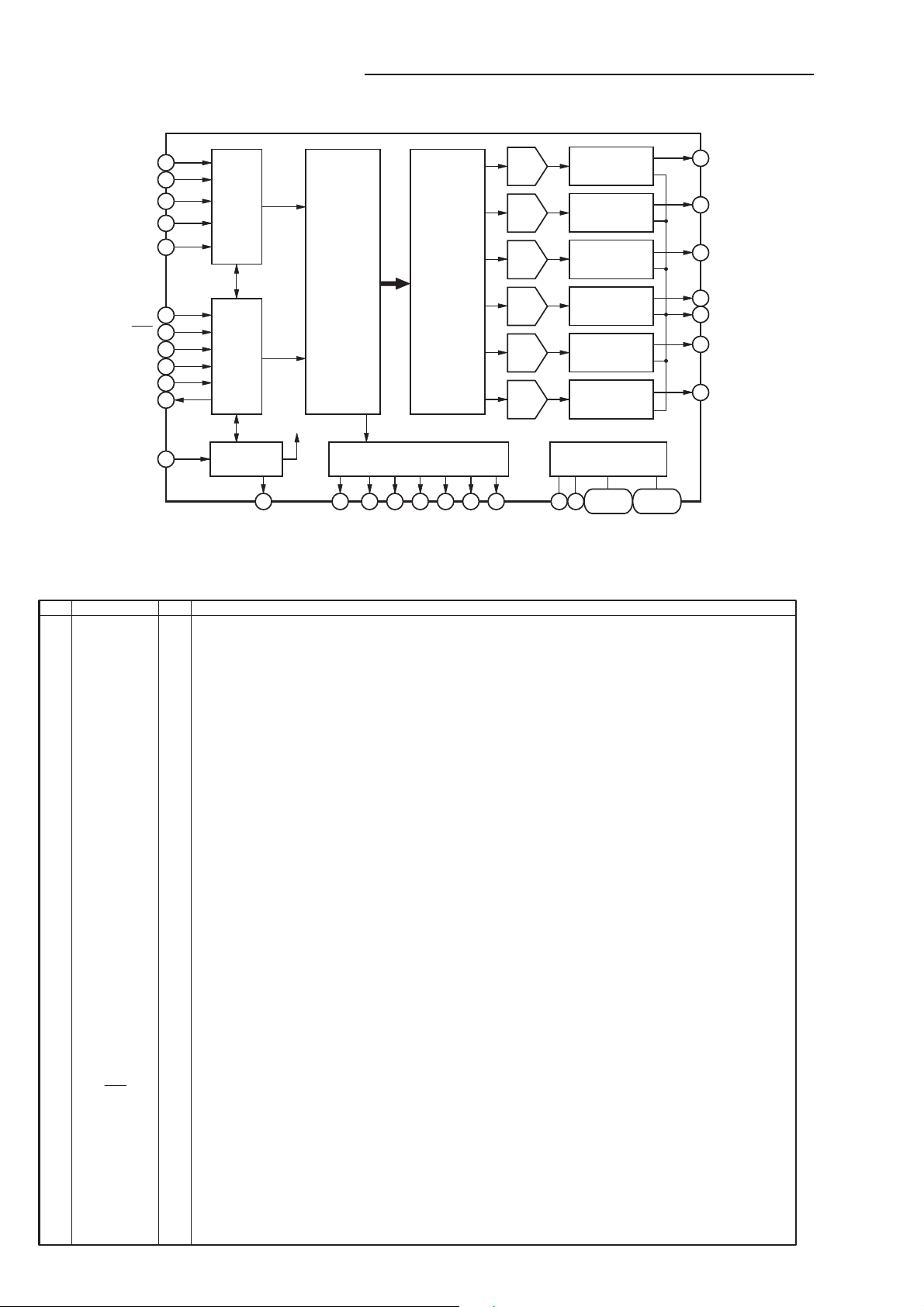

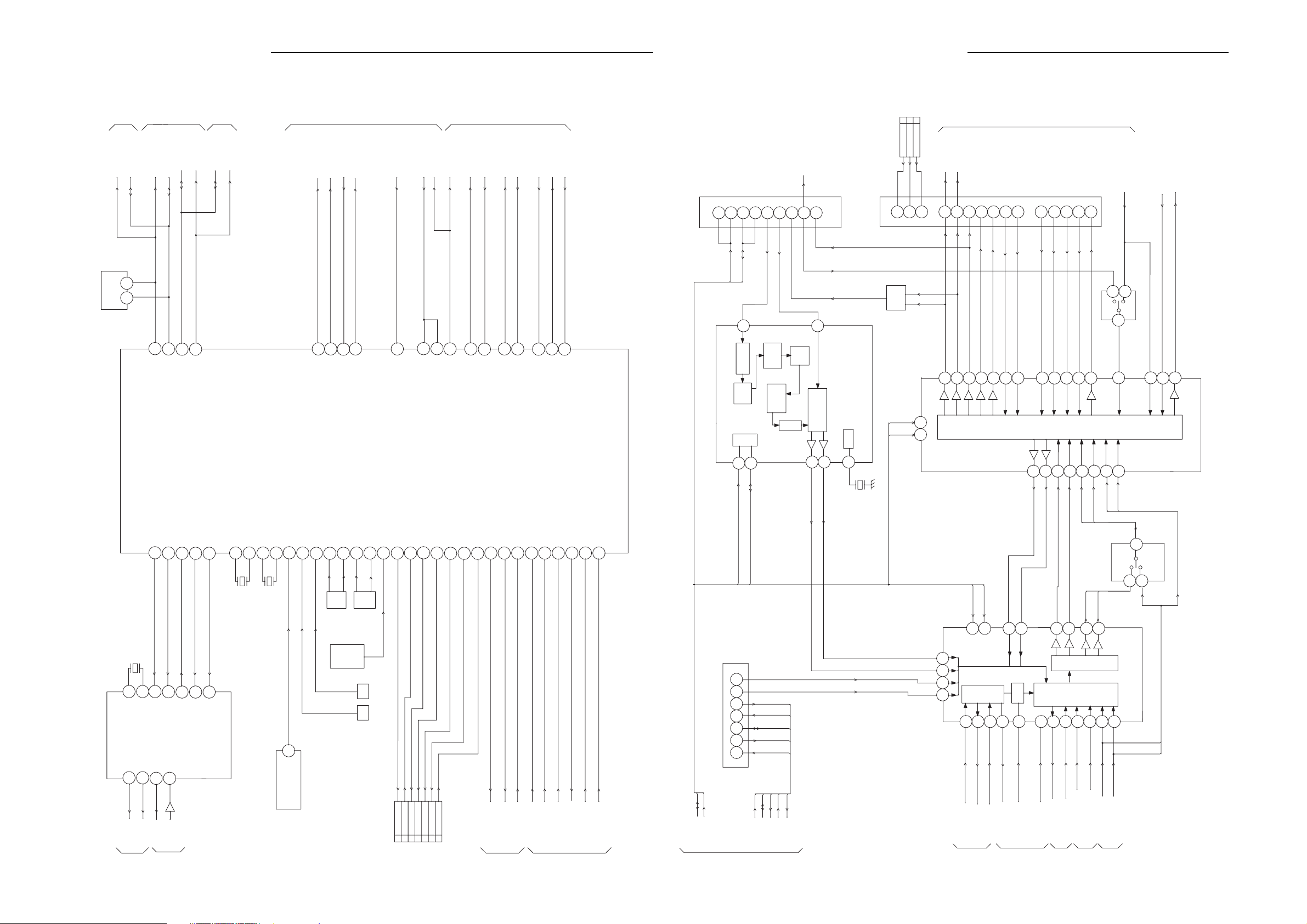

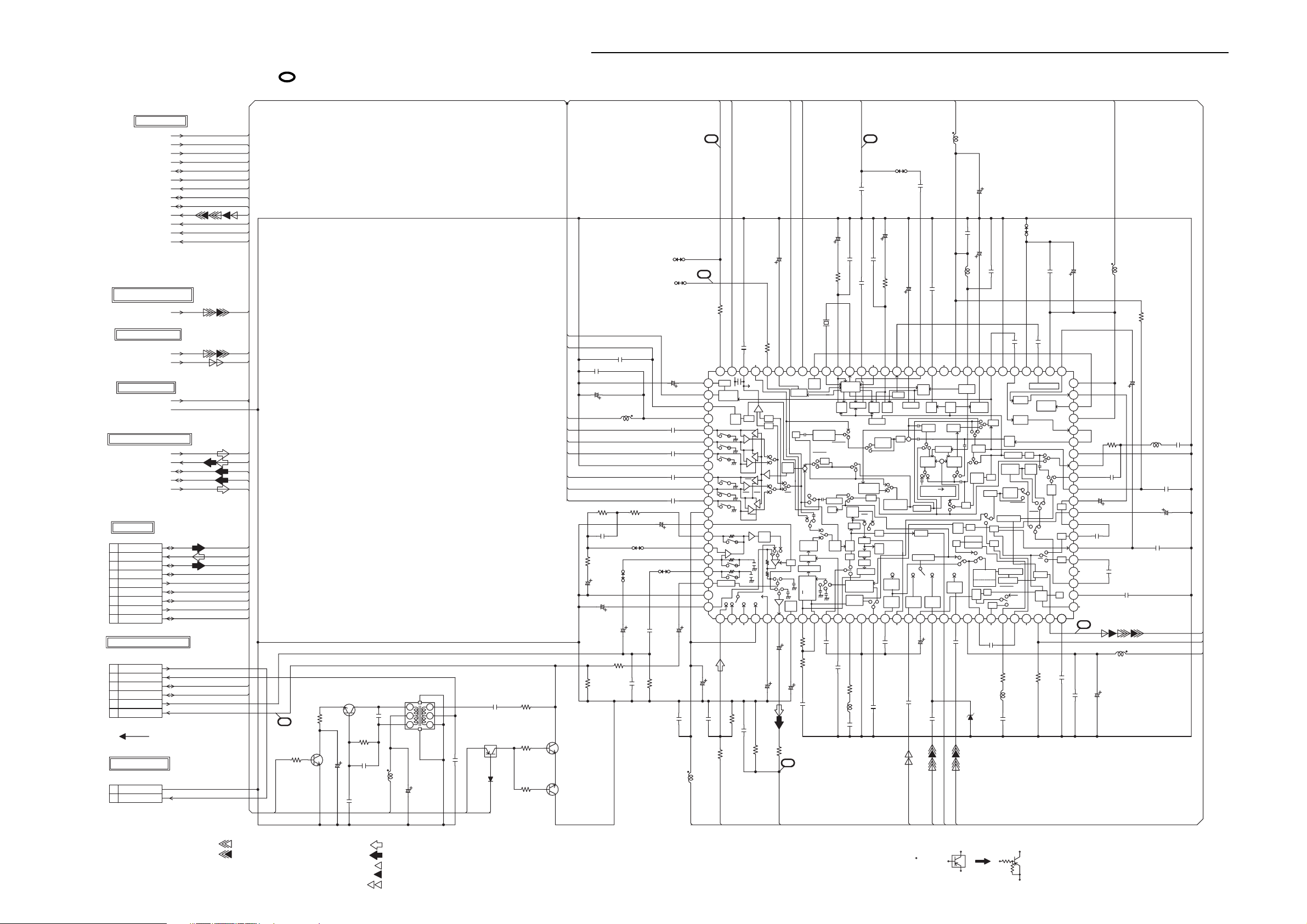

IC Block Diagram & Description ....................................... 68

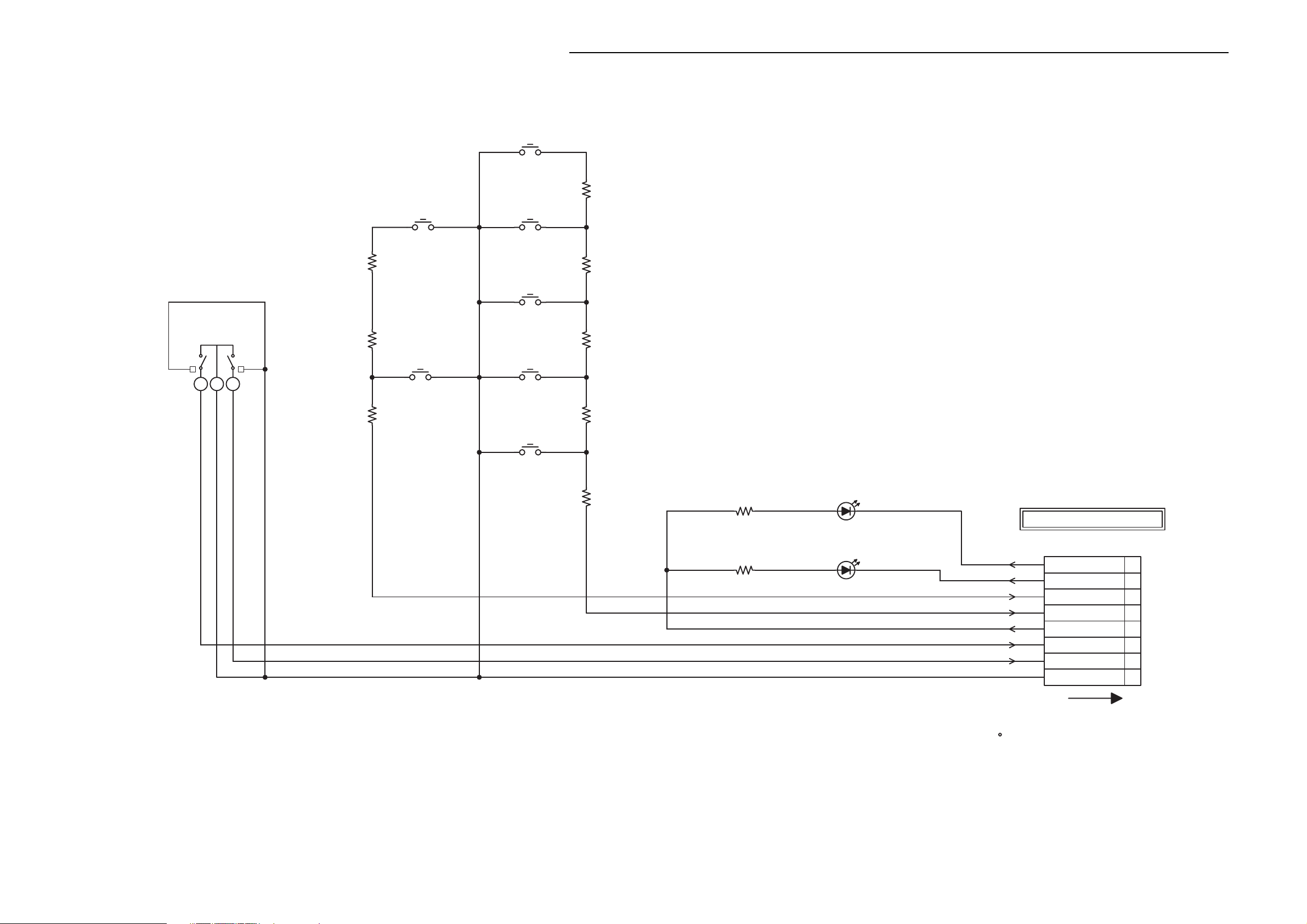

Interconnection Diagram .................................................. 74

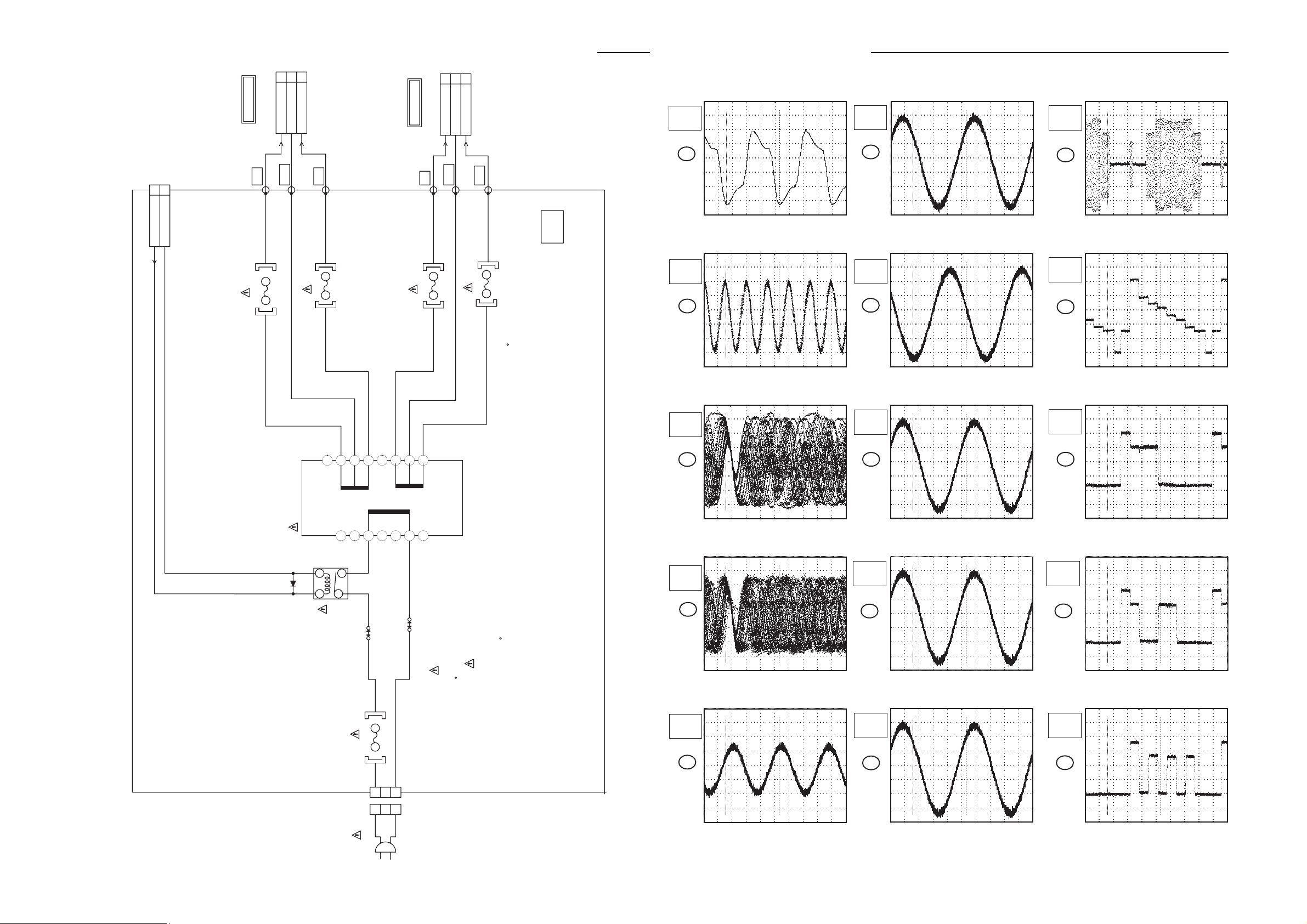

Block Diagram .................................................................. 76

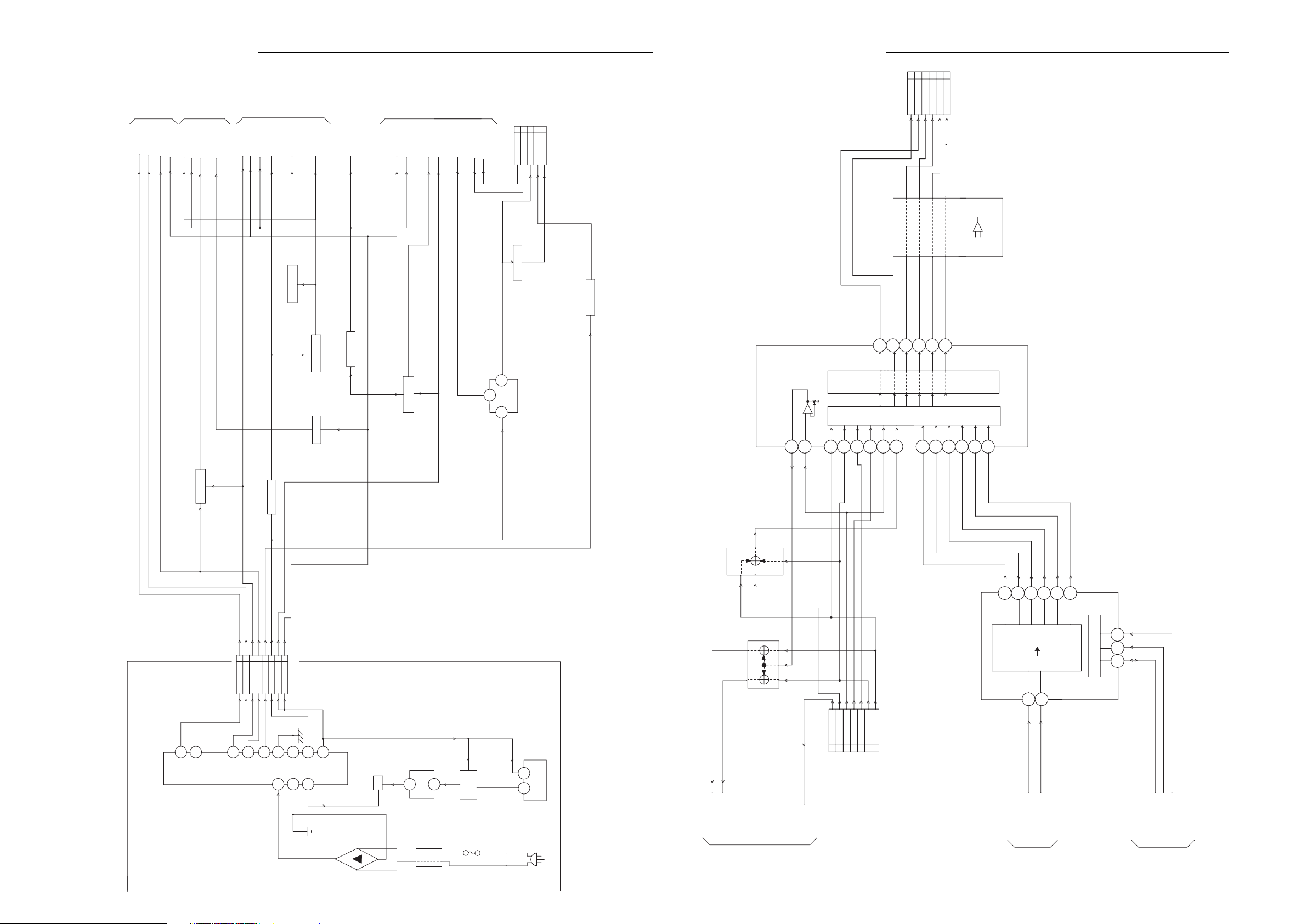

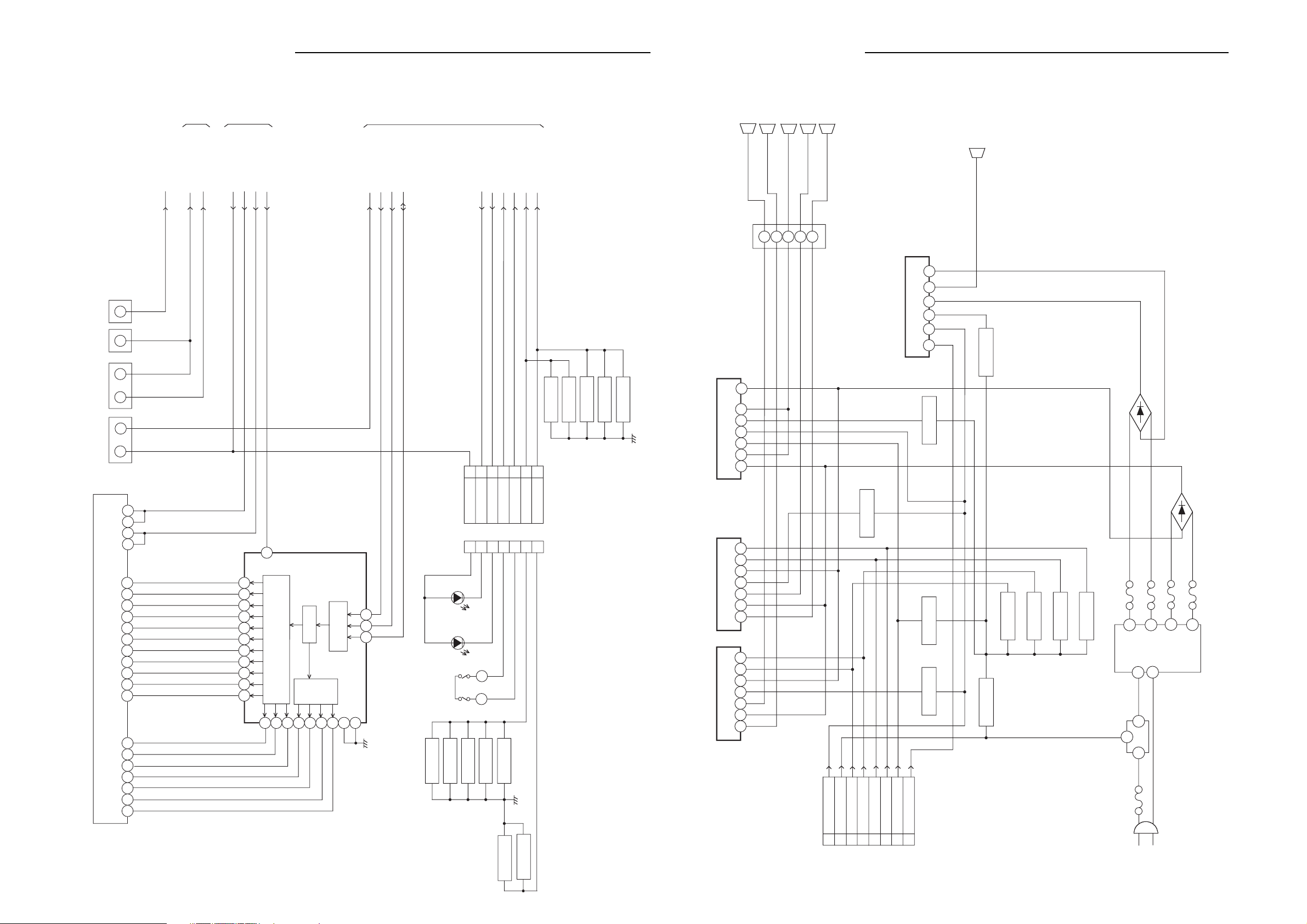

Schematic Diagram and Check for Waveform ................. 84

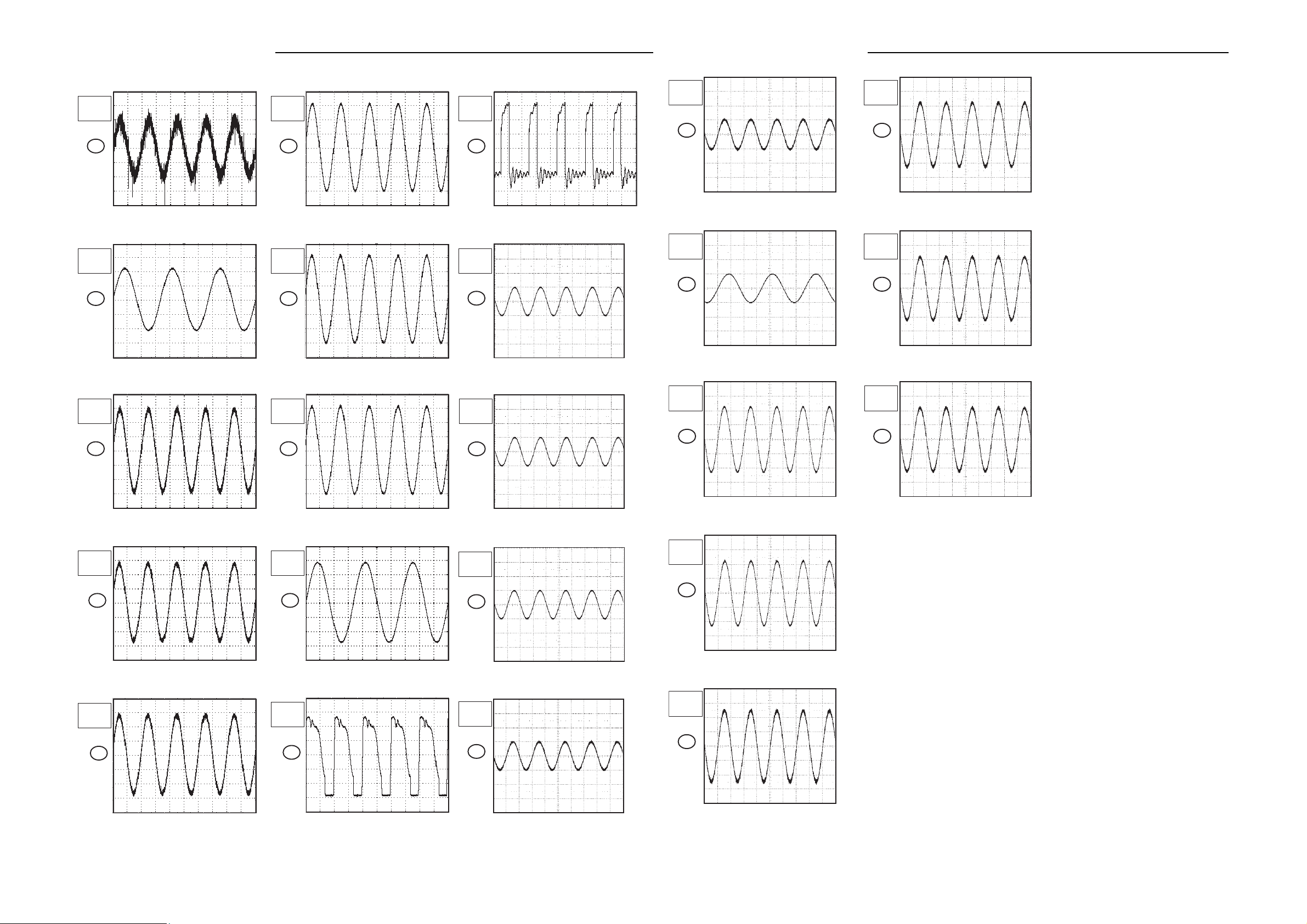

Waveform of Check Point ................................................ 115

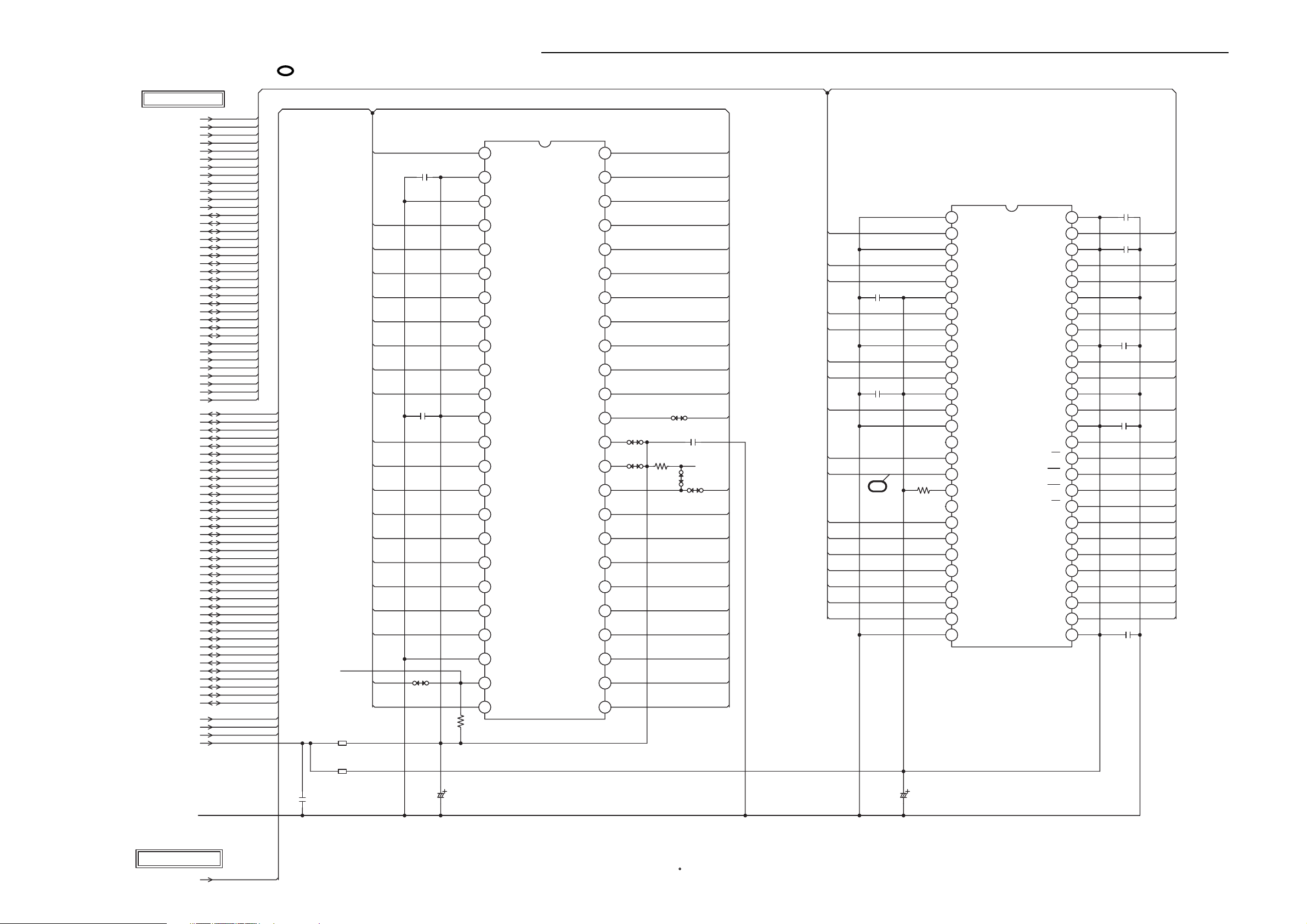

Wiring Diagram ............................................................... 120

DC-TS3000

PRODUCT CODE No.

129 673 04

(XE)

REFERENCE No.

SM5810453

Page 2

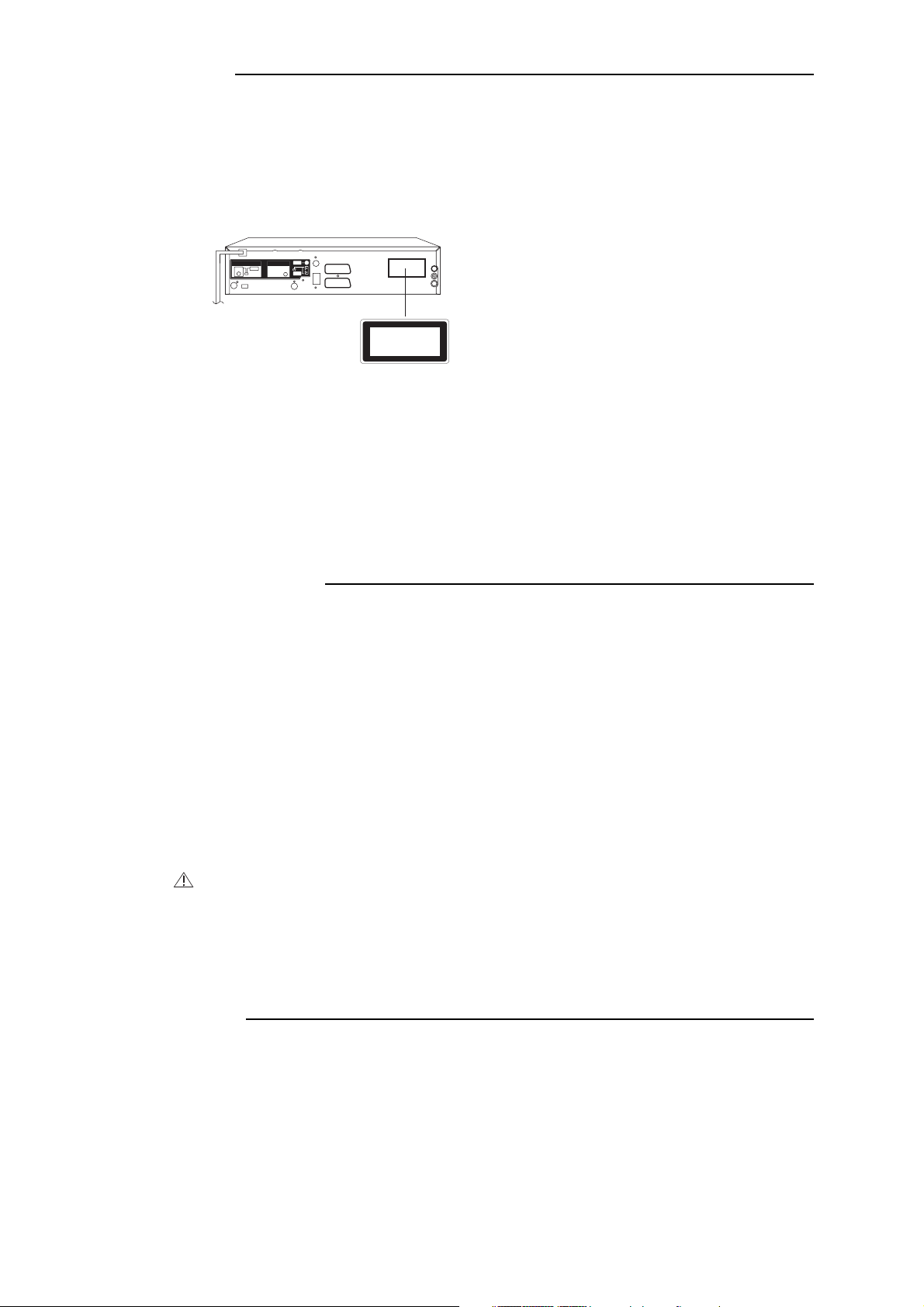

IMPORTANT WARNING

CAUTION:

DVD PLAYER IS A CLASS 1 LASER PRODUCT. HOWEVER THIS PLAYER USES A VISIBLE LASER

BEAM WHICH COULD CAUSE HAZARDOUS RADIATION EXPOSURE IF DIRECTED. BE SURE TO

OPERATE THE PLAYER CORRECTLY AS INSTRUCTED.

THE FOLLOWING CAUTION LABEL IS LOCATED ON THE REAR PANEL OF THE PLAYER.

CLASS 1

LASER PRODUCT

(Printed on the Rear Panel)

WHEN THIS PLAYER IS PLUGGED TO THE WALL OUTLET, DO NOT PLACE YOUR EYES CLOSE

TO THE OPENING OF THE DISC TRAY AND OTHER OPENINGS TO LOOK INTO THE INSIDE OF

THIS PLAYER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

DO NOT OPEN COVERS AND DO NOT REPAIR YOURSELF. REFER SERVICING TO QUALIFIED

PERSONNEL.

SERVICE NOTICE ON CHECKING

1. KEEP THE NOTICES 3. PUT PARTS AND WIRES IN THE

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

PERFORM A SAFETY CHECK AFTER

4.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

- 1 -

Page 3

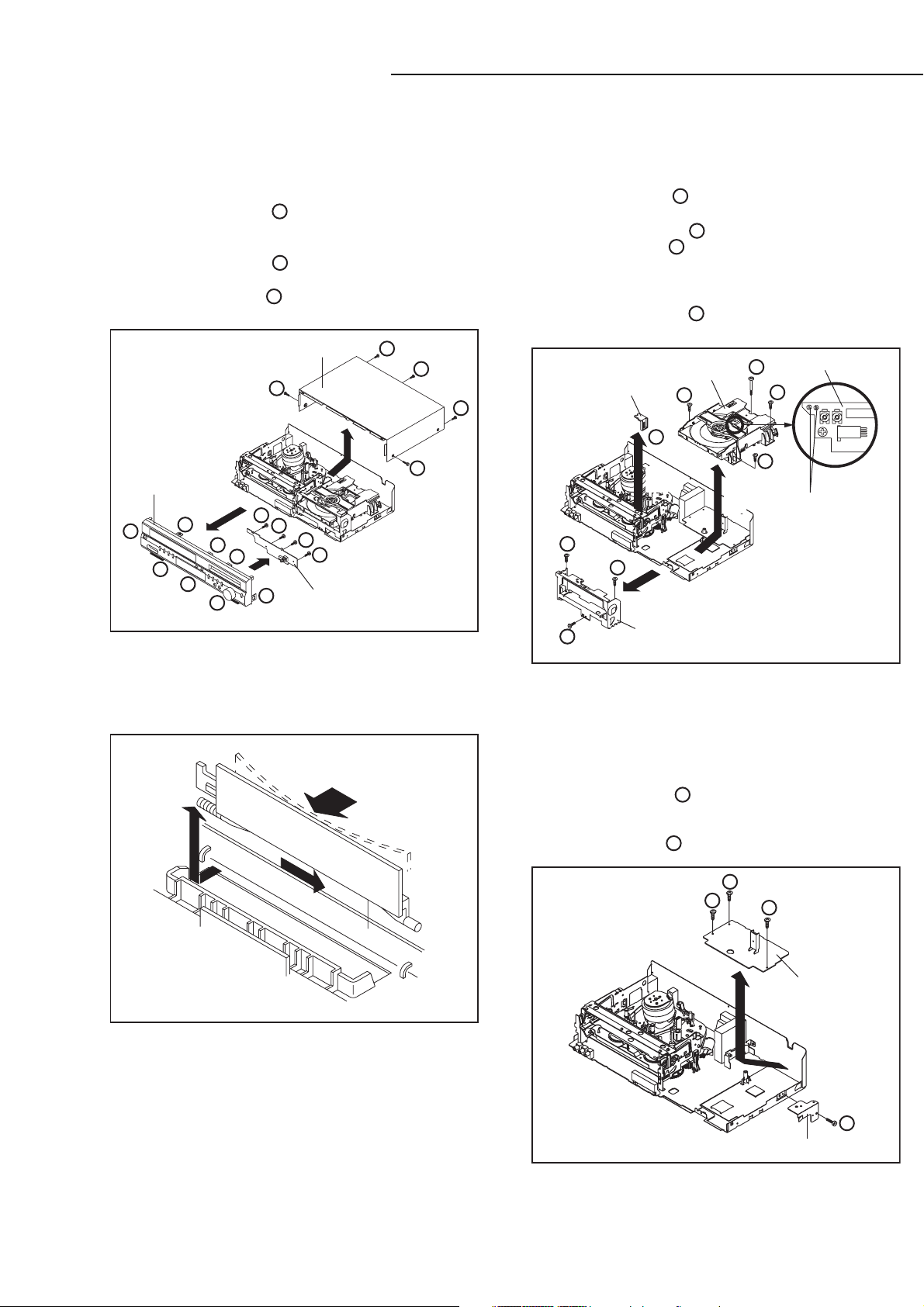

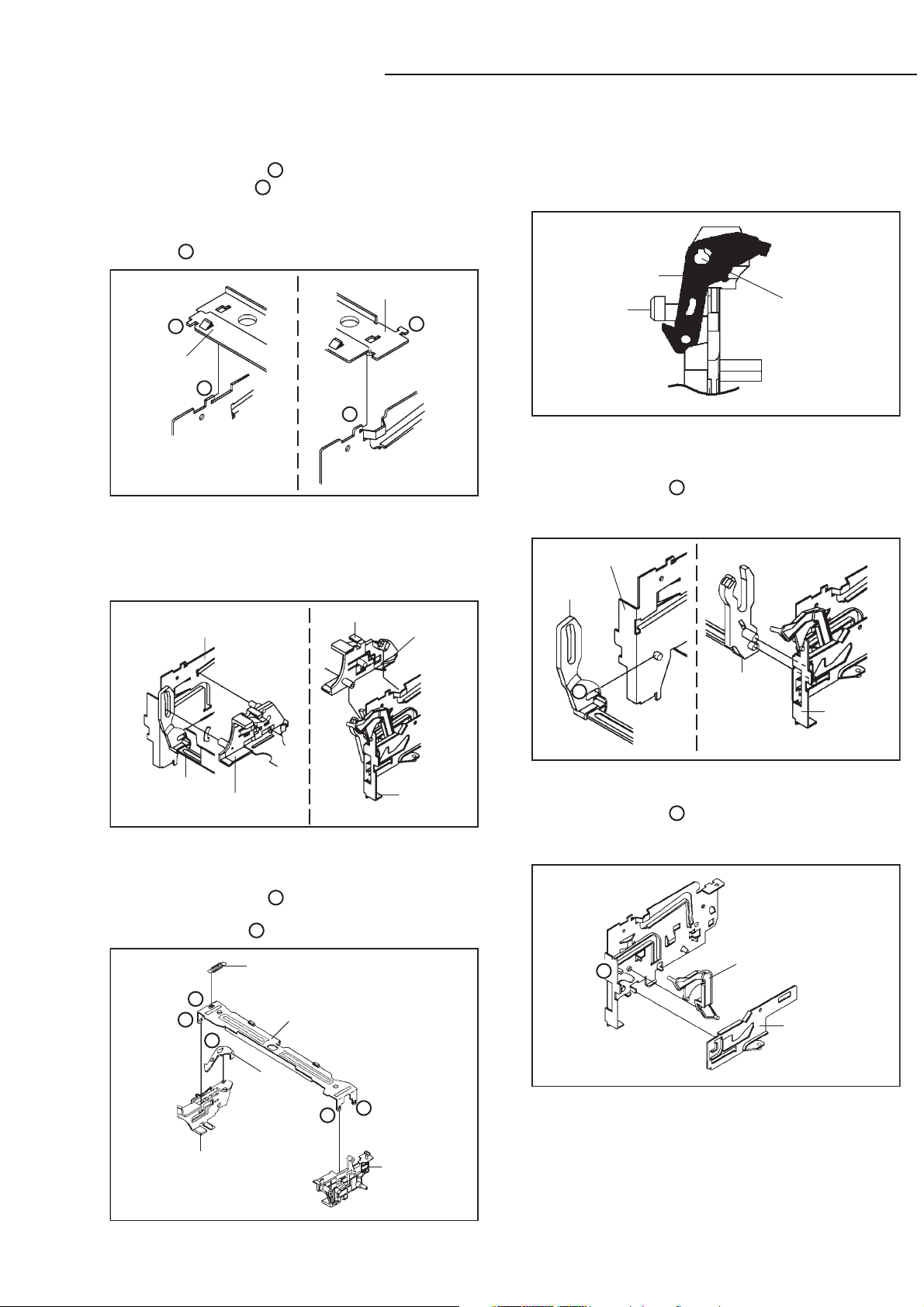

DISASSEMBLY INSTRUCTION

1.

REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

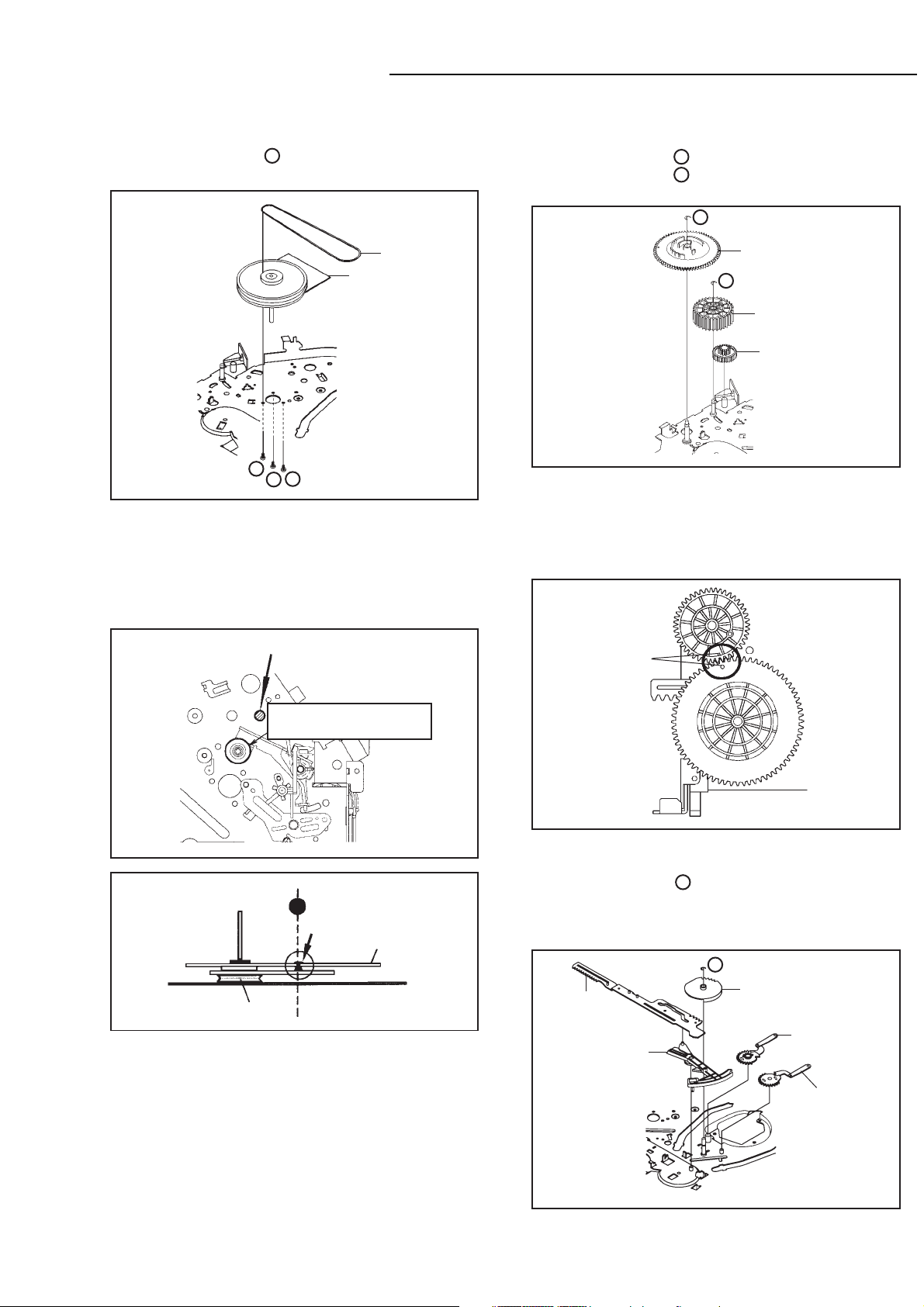

1-1:

TOP CABINET AND FRONT CABINET

(Refer to Fig. 1-1)

1.

Remove the 5 screws .

2.

Remove the Top Cabinet in the direction of arrow (A).

3.

Disconnect the following connector: (CP651).

4.

Unlock the 8 supports .

5.

Remove the Front Cabinet in the direction of arrow (B).

6.

Remove the 4 screws .

7.

Remove the Operation PCB in the direction of arrow (C).

Front Cabinet

(B)

2

2

2

2

2

2

1-2: FLAP (Refer to Fig. 1-2)

1.2.Open Flap to 90˚ and flex in direction of arrow (A), at

the same time slide in direction of arrow (B).

Then lift in direction of arrow (C).

1

2

3

(A)

1

1

1

3

1

3

Top Cabinet

3

2

(C)

2

3

Operation PCB

Fig. 1-1

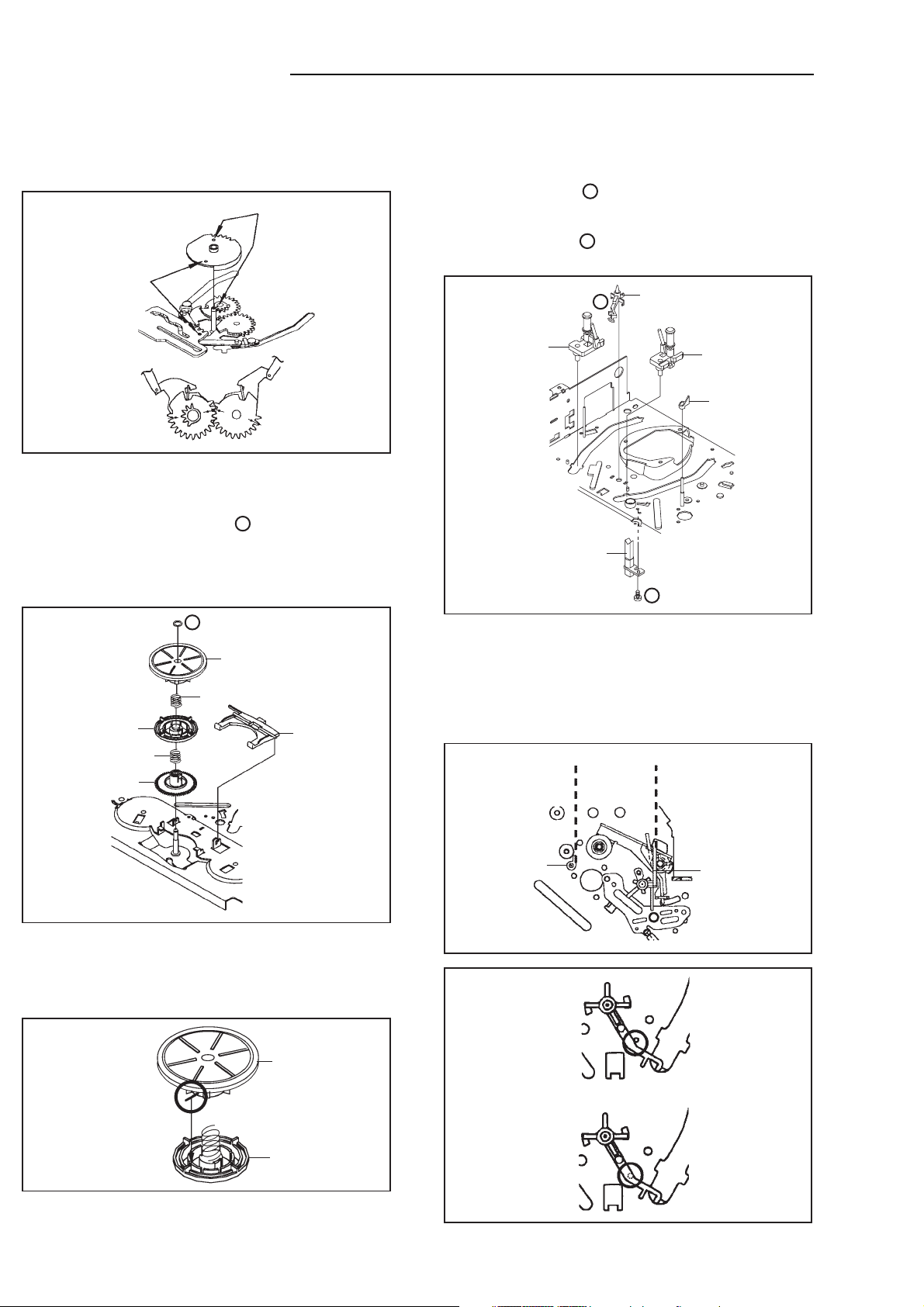

1-3: DVD DECK (Refer to Fig. 1-3)

1.

Make the short circuit on the position as shown Fig. 1-3

using a soldering. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

2.

Unlock the support and remove the Deck Top Holder

1

in the direction of arrow (A).

3.

Remove the 3 screws .

4.

Remove the screw .

5.

Disconnect the following connectors: (CP2601,

2

3

CP2602, CP2603).

Remove the DVD Deck in the direction of arrow (B).

6.

7.

Remove the 3 screws .

8.

Remove the Front

Deck Top Holder

1

4

4

4

Front Angle

4

Angle in the direction of arrow (C).

Pick Up PCB

2

2

Make the sort circuit

using a soldering.

(A)

(C)

DVD Deck

2

3

1

(B)

Fig. 1-3

NOTE

When the installation of the DVD Deck, remove all the

soldering on the short circuit position after the connection

of Pick Up PCB and DVD PCB connector.

(C)

(B)

(A)

Flap

Fig. 1-2

1-4: POWER PCB (Refer to Fig. 1-4)

1. Remove the 3 scres .

1

2. Disconnect the following connector; (CP1701)

3. Remove the Power PCB in the direction of srrow.

4. Remove the svrew and remove the DVD Angle.

2

1

1

1

Power PCB

DVD Angle

2

Fig. 1-4

- 2 -

Page 4

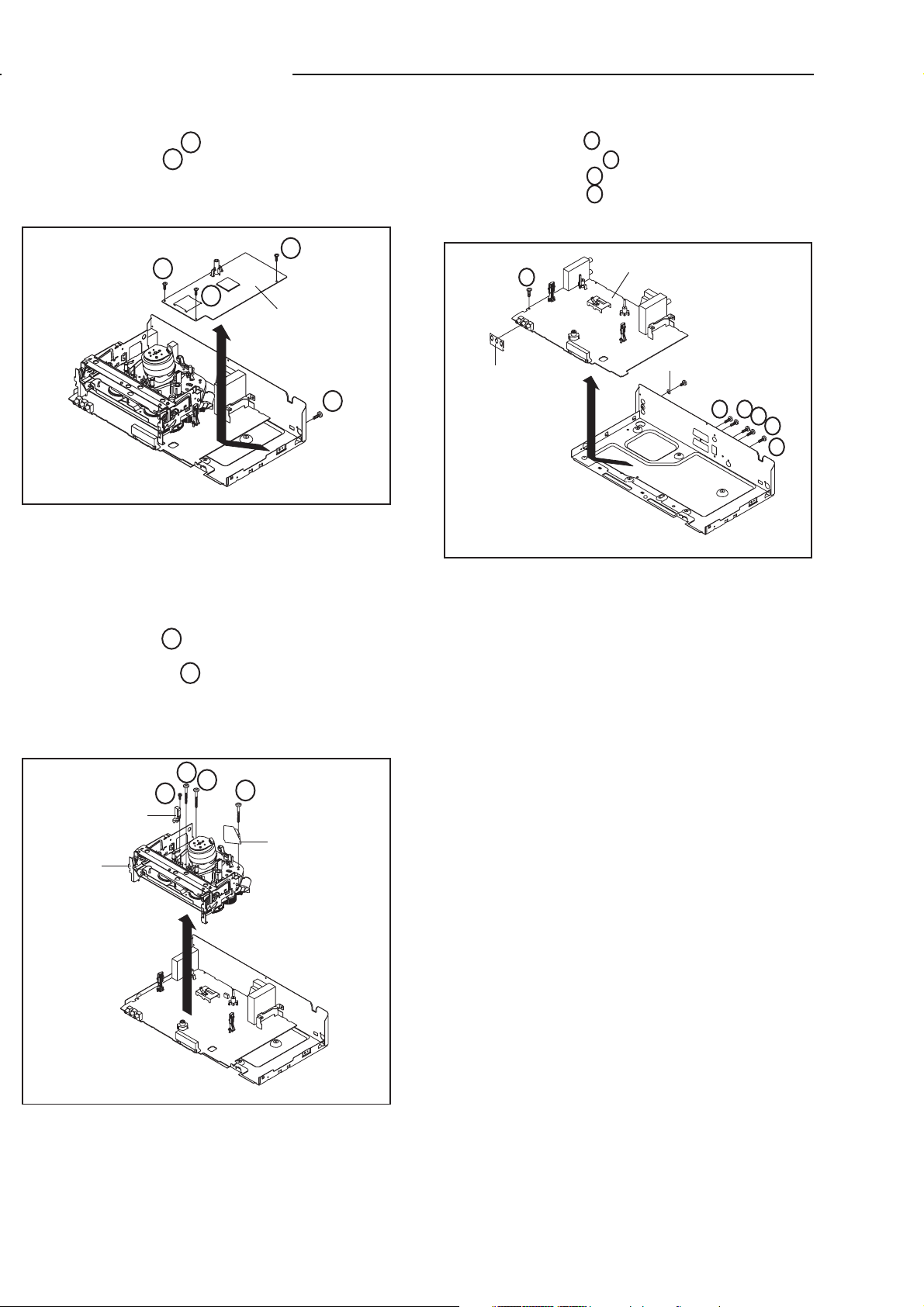

DISASSEMBLY INSTRUCTION

1-5: DVD PCB (Refer to Fig. 1-5)

Remove the 3 screws

1.

Remove the screw

2.

Disconnect the following connectors: (CP4002, CP8101

3.

2

1

.

.

and CP8102).

4.

Remove the DVD PCB in the direction of arrow

1

1

1

DVD PCB

2

.

Fig. 1-5

1-6: VCR DECK (Refer to Fig. 1-6)

NOTE

Do not remove the cable at the FE Head section. The FE

Head may be damaged if you remove the cable by force.

1.

Move the Cassette Holder Ass’y to the back side.

2.

Remove the screw

3.

Remove the FE Head.

Remove the 3 screws

4.

5.

Disconnect the following connectors: (CP101, CP102,

1

.

2

.

and CP3001).

6.

Remove the AC Head Cover and VCR Deck in the

direction of arrow

.

1-7: VCR PCB (Refer to Fig. 1-7)

1.

Remove the screw and remove the Fiber Washer.

2.

Remove the 4 screws

3.

Remove the screw

4.

Remove the screw

5.

Remove the 3 Pin Shield.

6.

Remove the VCR PCB in the direction of arrow

4

3 Pin Shield

1

3

4

2

.

.

VCR PCB

.

asher

Fiber W

2

2

.

2

2

3

Fig. 1-7

VCR Deck

FE Head

1

2

2

2

AC Head Cover

Fig. 1-6

- 3 -

Page 5

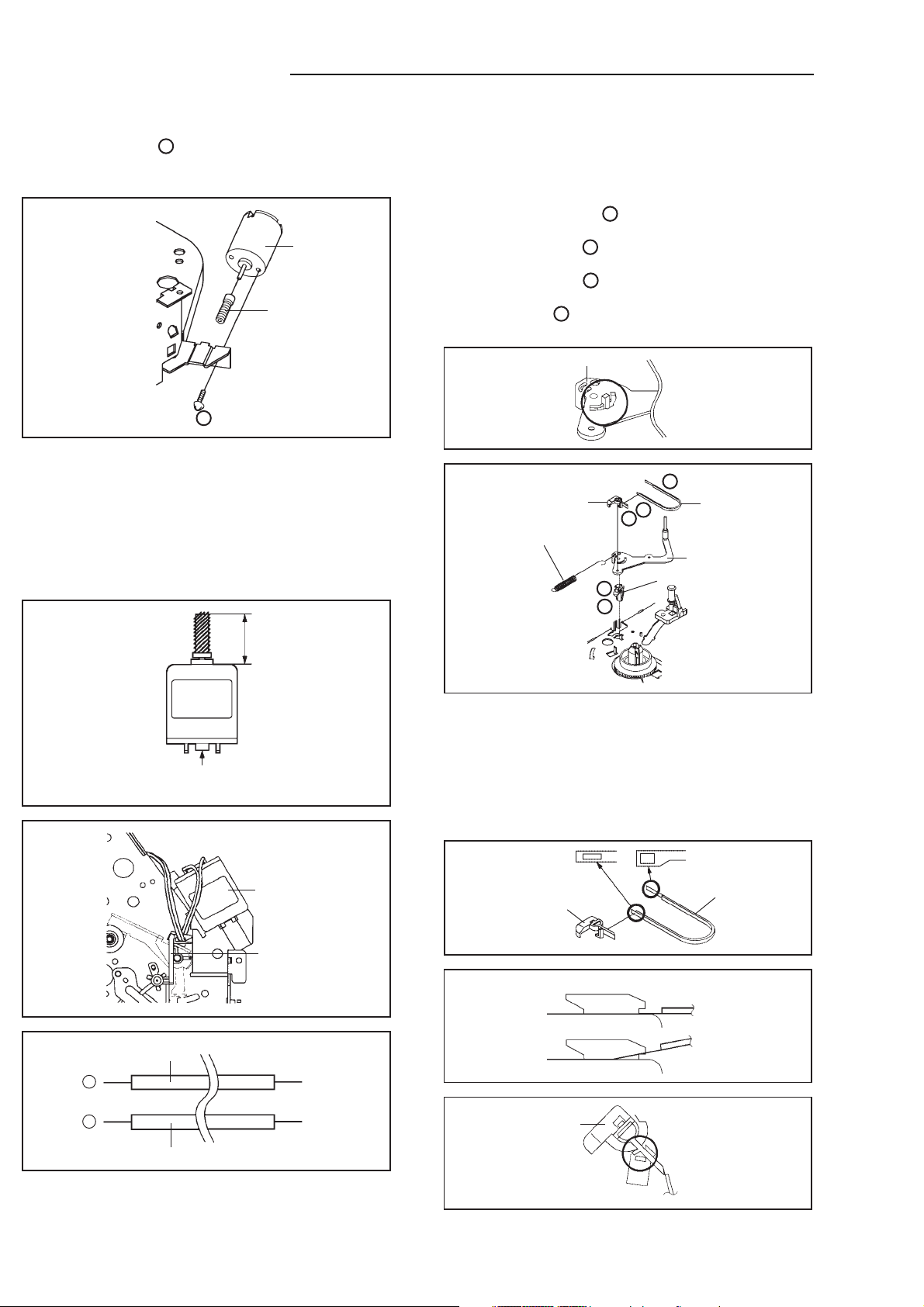

DISASSEMBLY INSTRUCTION

2. REMOVAL OF VCR DECK PARTS

2-1: TOP BRACKET (Refer to Fig. 2-1)

Extend the 2 supports .

1.

Slide the 2 supports and remove the Top Bracket.

2.

NOTE

1. After the installation of the Top Bracket, bend the

support so that the Top Bracket is fixed.

1

1

Top Bracket

Main Chassis

2

2-2: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the front side.

1.

Push the Locker R to remove the Cassette Side R.

2.

Remove the Cassette Side L.

3.

Main Chassis

1

2

Top Bracket

1

2

Main Chassis

Fig. 2-1

Cassette Side R

Locker R

NOTE

1.2.In case of the Locker R installation, check if the one

position of Fig.2-3-B are correctly locked.

When you install the Cassette Side R, be sure to move

the Locker R after installing.

Locker R

Check if this position

Cassette Side R

is locked.

Fig. 2-3-B

2-4: LINK UNIT (Refer to Fig. 2-4)

1.

Set the Link Unit to the Eject position.

Unlock the support .

2.

3.

Remove the (A) side of the Link Unit first, then remove

1

the (B) side.

Main Chassis

Link Unit

Link Unit

Cassette Side L

Main Chassis

Fig. 2-2

2-3: CASSETTE SIDE L/R (Refer to Fig. 2-3-A)

Remove the Locker Spring.

1.

Unlock the 4 supports and then remove the Cassette

2.

1

Side L/R.

2

2

Locker Spring

Cassette Holder

Locker R

1

1

3.

Unlock the support and then remove the Locker R.

1

1

(A)

1

(B)

Link Unit

Main Chassis

2-5: LINK LEVER/FLAP LEVER (Refer to Fig. 2-5)

Extend the support .

1.

Remove the Link Lever.

2.

Remove the Flap Lever.

3.

1

1

Flap Lever

Link Lever

Fig. 2-4

Fig. 2-5

Cassette Side R

Cassette Side L

Fig. 2-3-A

- 4 -

Page 6

DISASSEMBLY INSTRUCTION

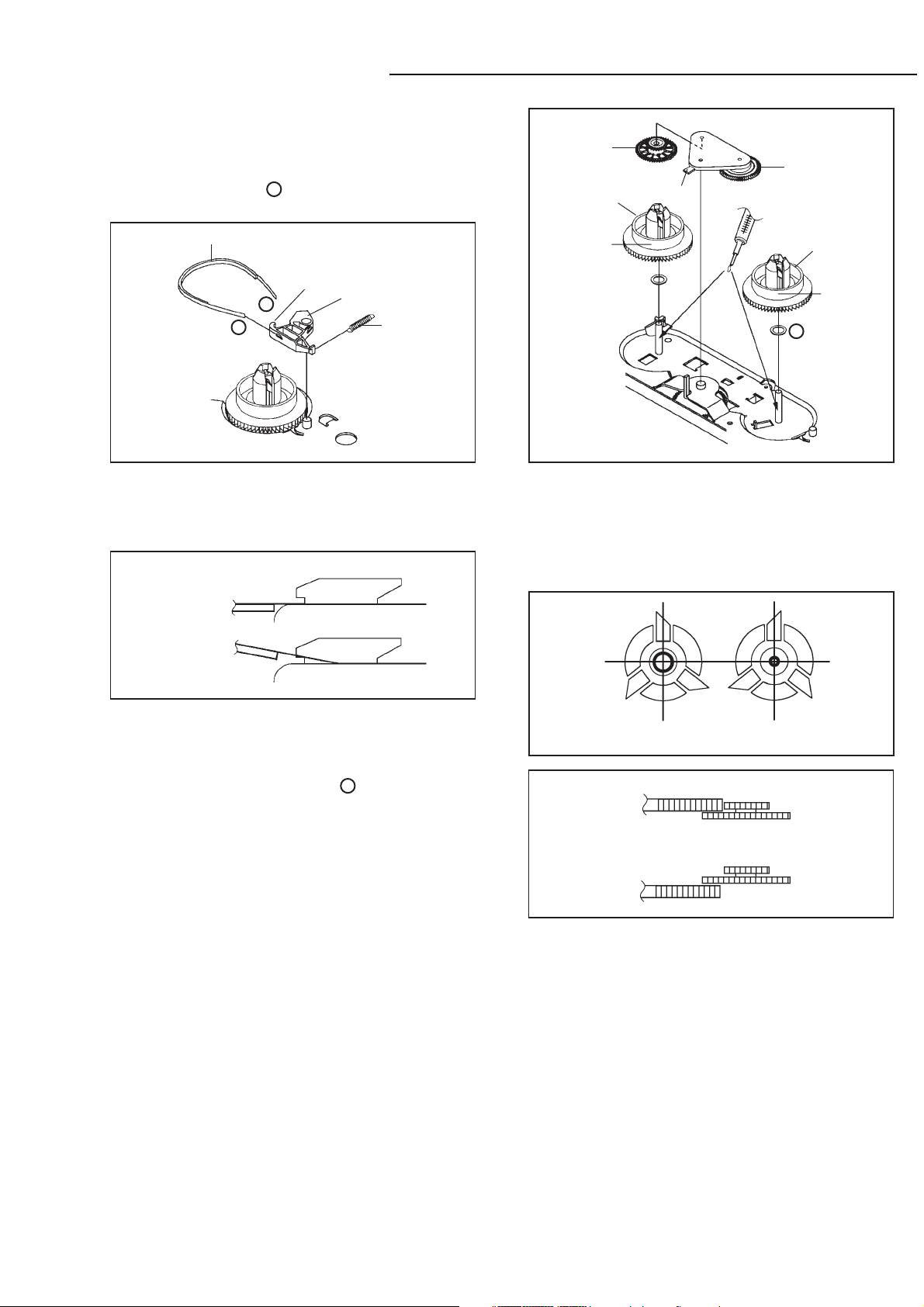

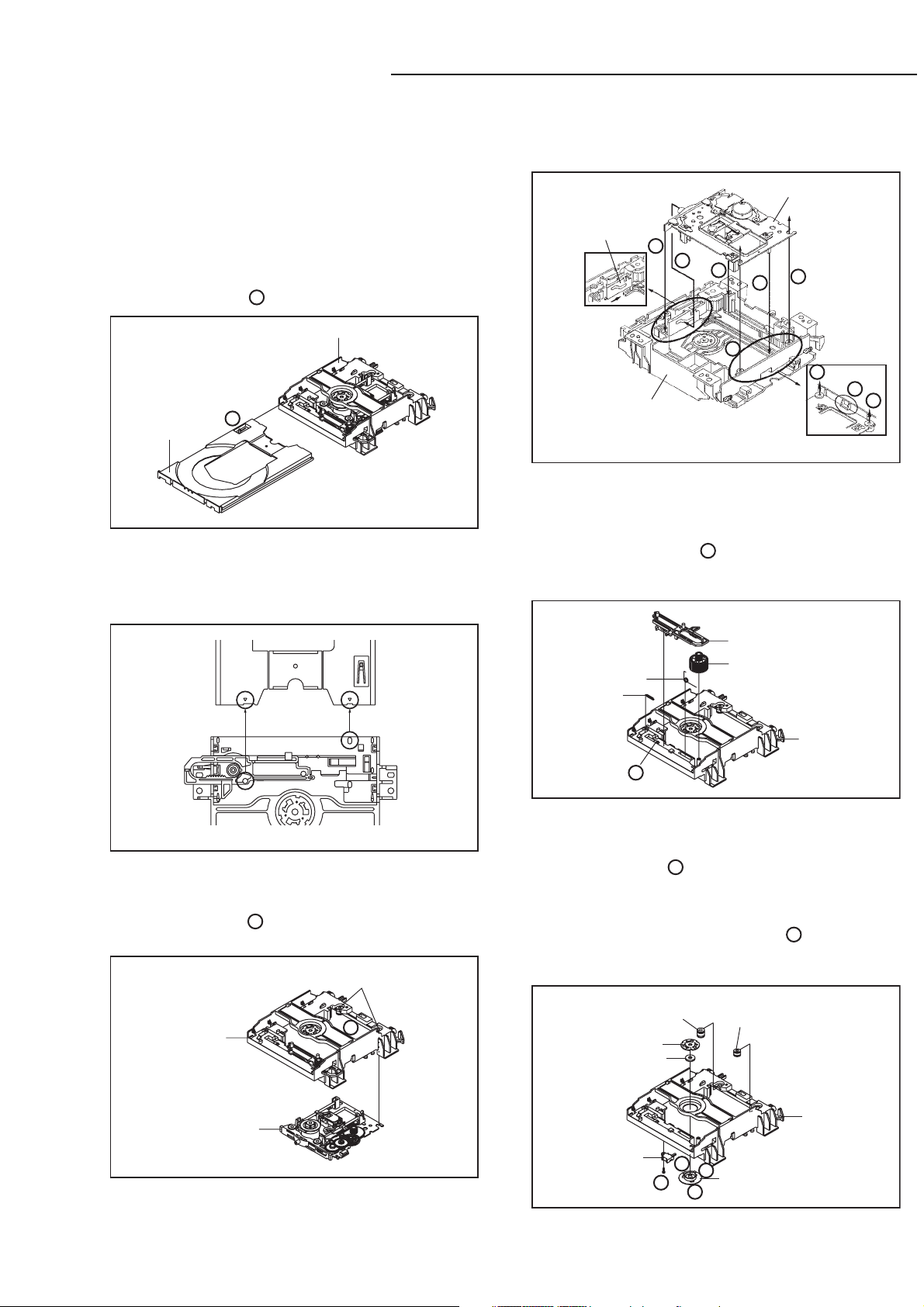

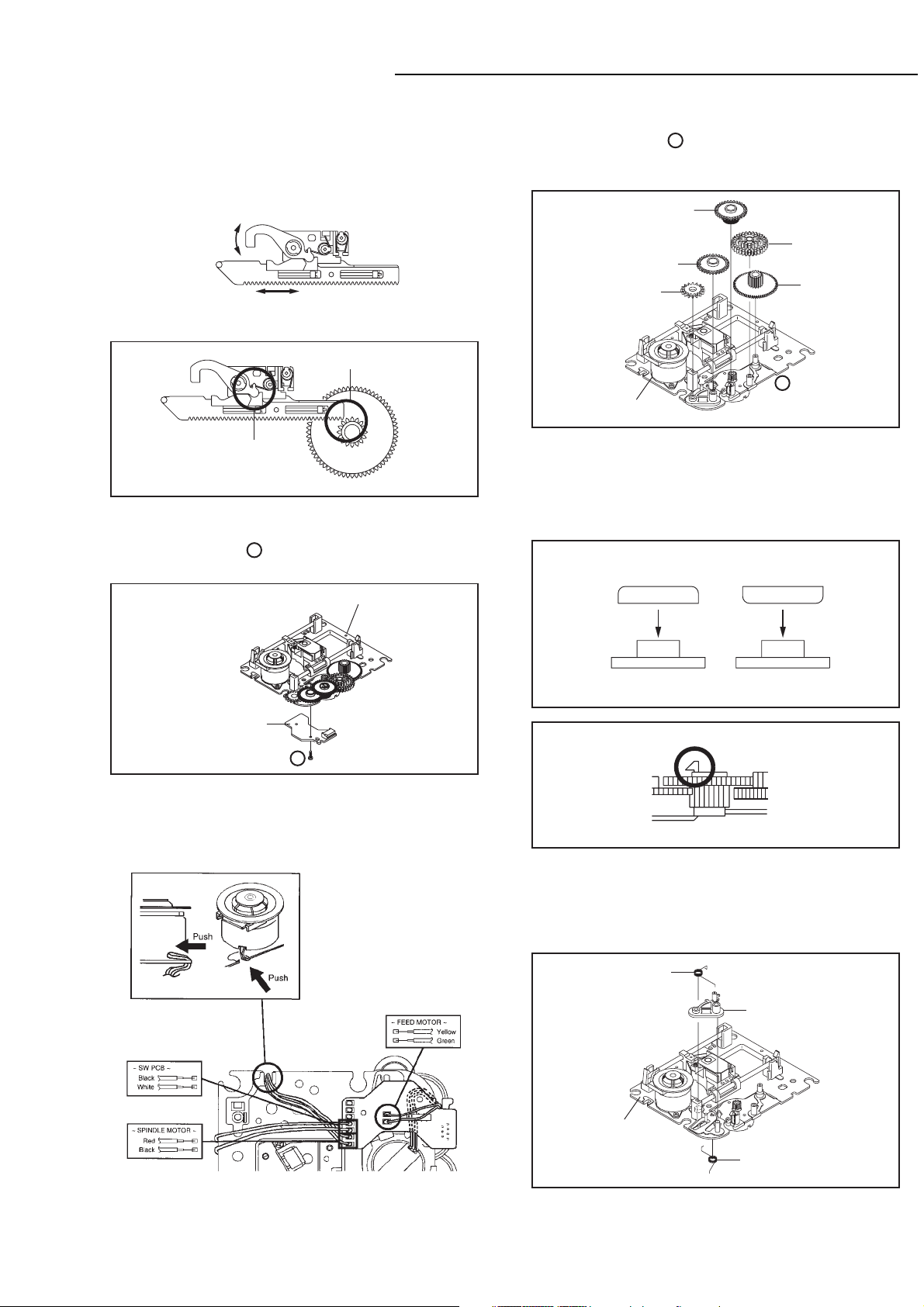

2-6: LOADING MOTOR/WORM (Refer to Fig. 2-6-A)

Remove the screw .

1.

Remove the Loading Motor.

2.

Remove the Worm.

3.

Main Chassis

• Screw Torque: 3± 0.5kgf•cm

1

Loading Motor

Worm

1

Fig. 2-6-A

NOTE

In case of the Worm installation, check if the value of

1.

the Fig. 2-6-B is correct.

2.

In case of the Loading Motor installation, hook the wire

on the Cassette Opener as shown Fig. 2-6-C.

3.

When installing the wires between Capstan DD Unit

and Loading Motor, connect them correctly as shown

Fig. 2-6-D.

2-7: TENSION ASS'Y (Refer to Fig. 2-7-B)

Turn the Pinch Roller Cam clockwise so that the

1.

Tension Holder hook is set to the position of Fig. 2-7-A

to move the Tension Arm Ass'y.

Remove the Tension Spring.

2.

Unlock the 2 supports and remove the Tension

3.

1

Band.

Unlock the support and remove the Tension Arm

4.

2

Ass'y.

Unlock the support and remove the Tension

5.

3

Connect.

6.

Float the hook and turn it clockwise then remove the

4

Tension Holder.

Tension Arm Ass'y

Fig. 2-7-A

1

Tension Connect

Tension Spring

2

4

1

3

Tension Holder

Tension Band

Tension Arm Ass'y

19.2 0.1mm

Safety surface for pressing

of the insert.

Loading Motor

Cassette Opener

Fig. 2-6-B

Fig. 2-6-C

Loading Motor Capstan DD Unit

-

Pink

L2

Fig. 2-7-B

NOTE

1.

In case of the Tension Band installation, note the

direction of the installation. (Refer to Fig. 2-7-C)

2.

In case of the Tension Band installation, install correctly

as Fig. 2-7-D.

In case of the Tension Connect installation, install as

3.

the circled section of Fig. 2-7-E.

Tension Connect

Tension Band

Fig. 2-7-C

[OK]

[NG]

Tension Connect

Tension Connect

Tension Band

Tension Band

Fig. 2-7-D

+

White

L1

Fig. 2-6-D

- 5 -

Tension Connect

Main Chassis

Fig. 2-7-E

Page 7

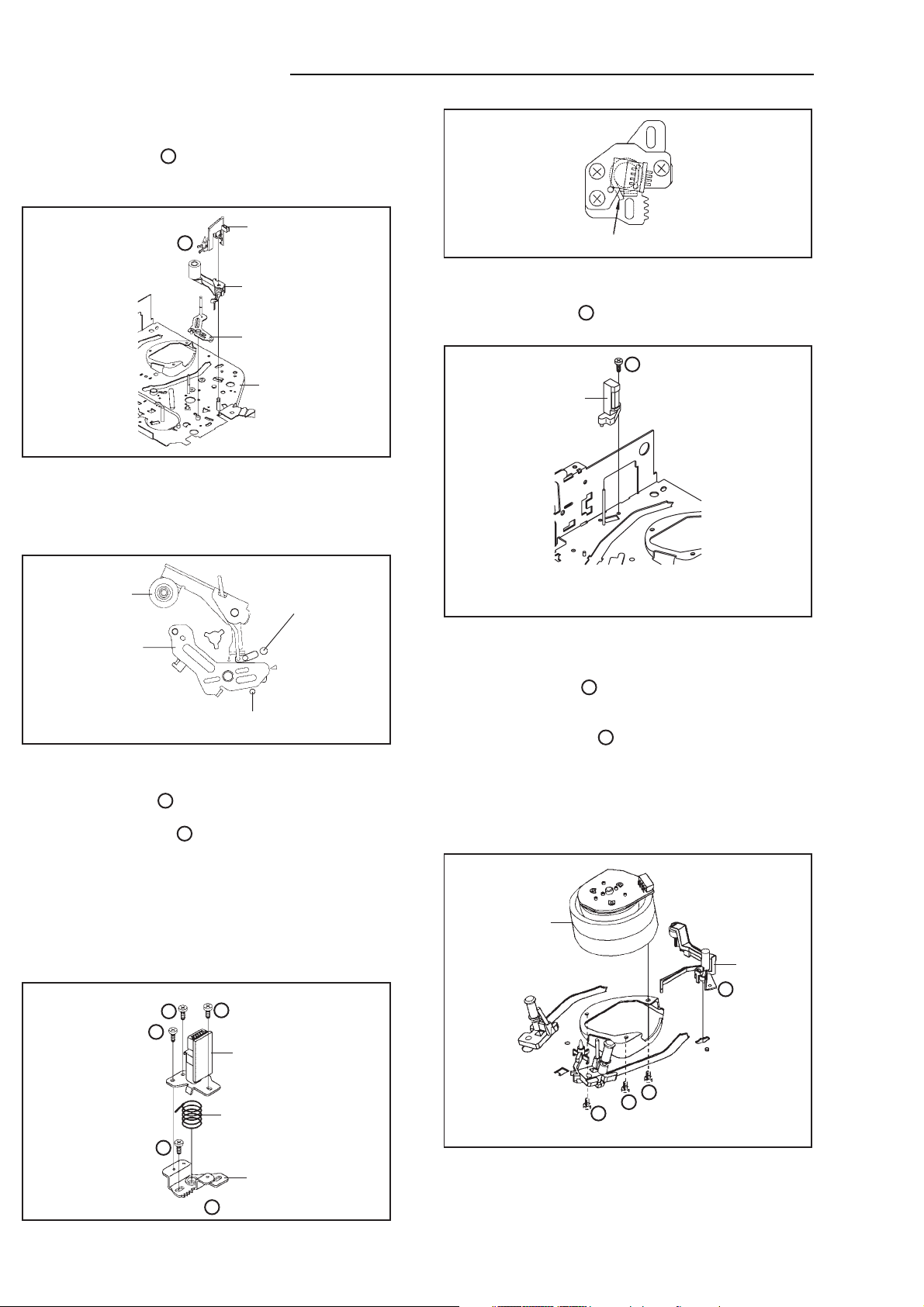

DISASSEMBLY INSTRUCTION

2-8: T BRAKE ARM/T BRAKE BAND (Refer to Fig. 2-8-A)

Remove the T Brake Spring.

1.

Turn the T Brake Arm clockwise and bend the hook

2.

section to remove it.

3.

Unlock the 2 supports and remove the T Brake

Band.

1

Idler Gear

S Reel

Idler Arm Ass'y

(B)

T Brake Band

Hook section

1

1

T Brake Arm

T Brake Spring

Fig. 2-8-A

NOTE

1. In case of the T Brake Band installation, install correctly

as Fig. 2-8-B.

[OK]

T Brake Band

[NG]

T Brake Band

T Brake Arm

T Brake Arm

(A) T Reel

(A)

1

Fig. 2-9-A

NOTE

1.2.In case of the S Reel and T Reel installation, check if the

correct parts are installed. (Refer to Fig. 2-9-B)

In case of the Idler Arm Ass'y installation, install correctly

as Fig. 2-9-C. And also set it so that the section "B" of

Fig. 2-9-A is placed under the Main Chassis tab.

Fig. 2-8-B

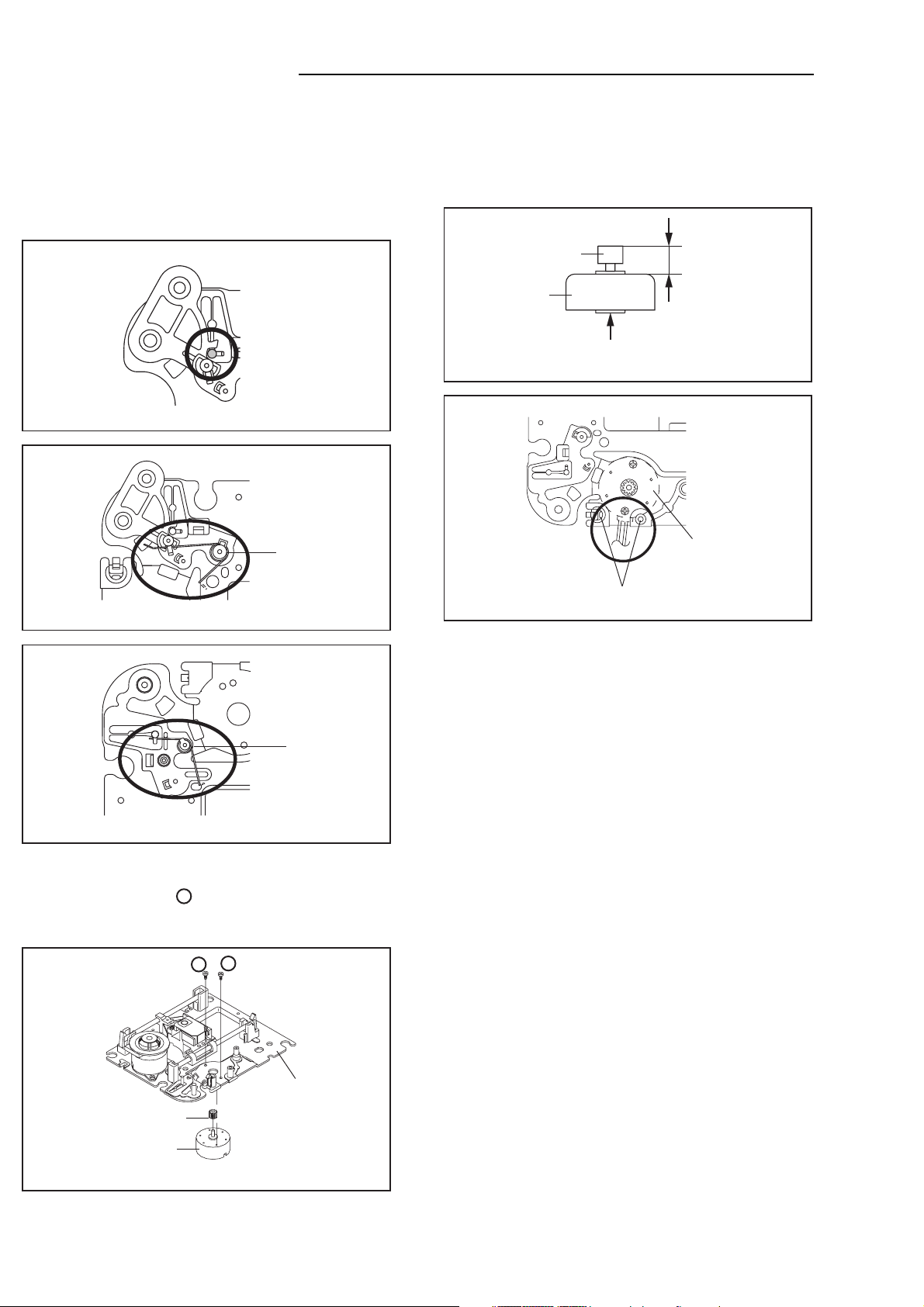

2-9: S REEL/T REEL/IDLER ARM ASS'Y/IDLER GEAR

(Refer to Fig. 2-9-A)

Remove the S Reel and T Reel.

1.

Remove the 2 Polyslider Washers .

2.

Remove the Idler Arm Ass'y and Idler Gear.

3.

1

NOTE

Take care not to damage the gears of the S Reel and T

1.

Reel.

The Polyslider Washer may be remained on the back of

2.

the reel.

3.

Take care not to damage the shaft.

4.

Do not touch the section "A" of S Reel and T Reel. (Use

gloves.) (Refer to Fig. 2-9-A) Do not adhere the stains

on it.

When you install the reel, clean the shaft and grease it

5.

(FG-84M). (If you do not grease, noise may be heard in

FF/REW mode.)

After installing the reel, adjust the height of the reel.

6.

(Refer to MECHANICAL ADJUSTMENT)

[OK]

[NG]

Clutch Gear

Clutch Gear

Big Hole

(S Reel)

Small Hole

(T Reel)

Fig. 2-9-B

Idler Arm Ass'y

Idler Arm Ass'y

Fig. 2-9-C

- 6 -

Page 8

DISASSEMBLY INSTRUCTION

2-10: CASSETTE OPENER/PINCH ROLLER BLOCK/

P5 ARM ASS'Y (Refer to Fig. 2-10-A)

Unlock the support and remove the Cassette

1.

Opener.

2.

Remove the Pinch Roller Block and P5 Arm Ass'y.

1

1

Cassette Opener

Pinch Roller Block

P5 Arm Ass'y

Main Chassis

Fig. 2-10-A

NOTE

Do not touch the Pinch Roller. (Use gloves.)

1.

In case of the Pinch Roller Block and the Pinch Roller

2.

Cam installation, install correctly as Fig. 2-10-B.

Pinch Roller Block

P5 Arm Ass'y

Can be seen the hole of the

Main Cam.

Can be seen the hole of

the Pinch Roller Cam.

Fig. 2-10-B

2-11: A/C HEAD (Refer to Fig. 2-11-A)

Remove the screw .

1.

Remove the A/C Head Base.

2.

Remove the 3 screws .

3.

Remove the A/C Head and A/C Head Spring.

4.

1

2

NOTE

1.

Do not touch the A/C Head. (Use gloves.)

2.

When you install the A/C Head Spring, install as shown in

Fig. 2-11-B.

3.

When you install the A/C Head, tighten the screw (1) first,

then tighten the screw (2), finally tighten the screw (3).

(3)

(1)

2

2

(2)

1

2

A/C Head

A/C Head Spring

Spring Position

Fig. 2-11-B

2-12: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-12)

Remove the screw .

1.

2.

Remove the FE Head.

• Screw Torque: 5 ± 0.5kgf•cm

• The FE Head is not installed on the Video Cassette Player.

FE Head

1

1

Fig. 2-12

2-13: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-13)

Unlock the support and remove the AHC Ass'y.

1.

2.

Disconnect the following connector:

1

(CD2001)

Remove the 3 screws .

3.

Remove the Cylinder Unit Ass'y.

4.

2

NOTE

When you install the Cylinder Unit Ass'y, tighten the

1.

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

Cylinder Unit Ass'y

AHC Ass'y

1

(3)

(2)

(1)

• Screw Torque: 3 ± 0.5kgf•cm

2

2

2

Fig. 2-13

• Screw Torque: 5 ± 0.5kgf•cm (Screw )

1

A/C Head Base

Fig. 2-11-A

- 7 -

Page 9

DISASSEMBLY INSTRUCTION

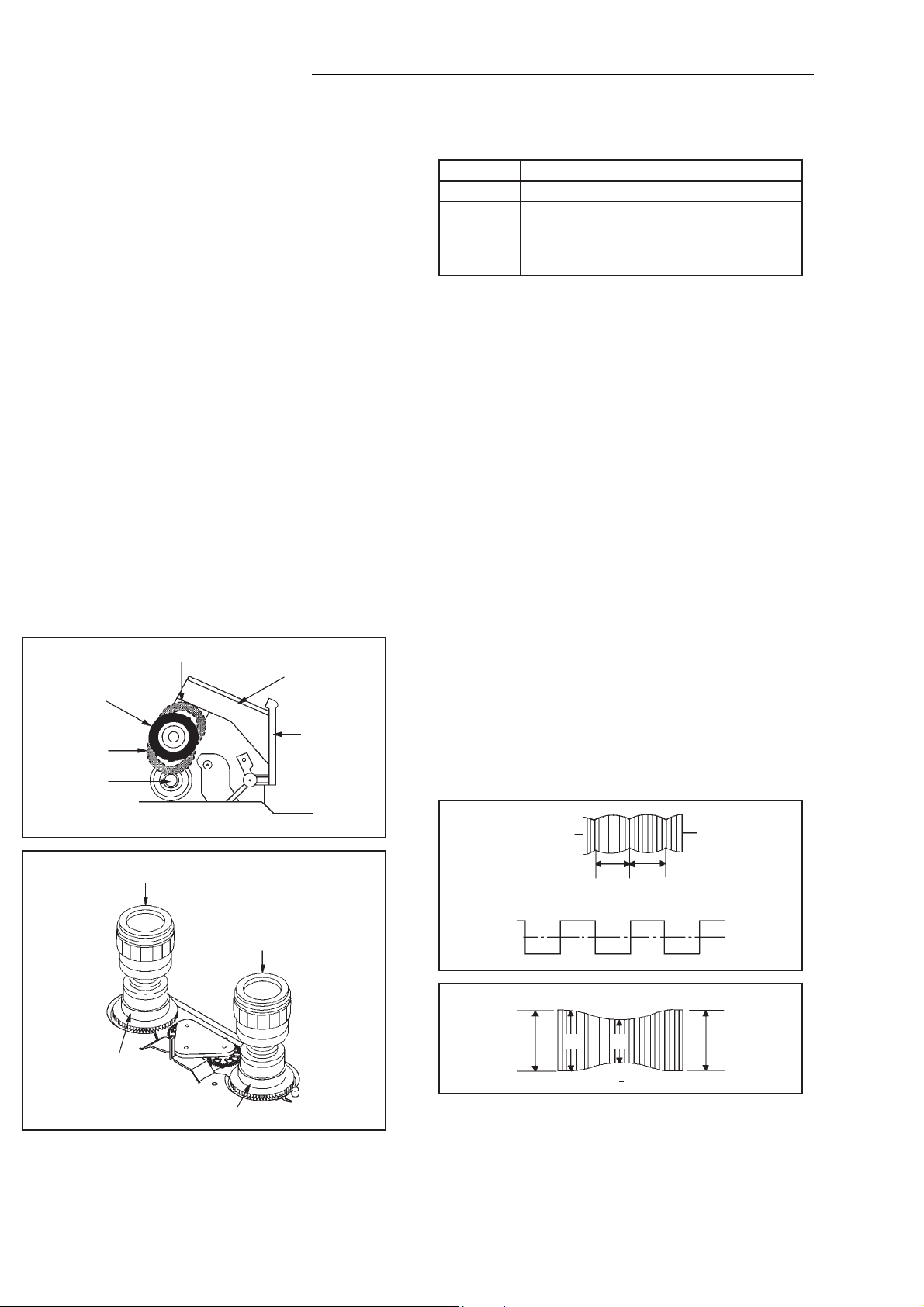

2-14: CAPSTAN DD UNIT (Refer to Fig. 2-14-A)

Remove the Capstan Belt.

1.

Remove the 3 screws .

2.

3.

Remove the Capstan DD Unit.

1

2-15:

MAIN CAM/PINCH ROLLER CAM/JOINT GEAR

(Refer to Fig. 2-15-A)

Remove the E-Ring , then remove the Main Cam.

1.

Remove the E-Ring , then remove the Pinch Roller

2.

1

2

Cam and Joint Gear.

1

Capstan Belt

Capstan DD Unit

1

1

• Screw Torque: 4 ± 0.5kgf•cm

1

Fig. 2-14-A

NOTE

In case of the Capstan DD Unit installation, apply the

1.

silicon bond (TSE3843-W) on the position Fig. 2-14-B

correctly. (If no silicon bond applied, abnormal noise will

be heard on the deck operation.)

(Refer to Fig. 2-14-B, C)

Applied position of

silicon bond

Main Cam

2

Pinch Roller Cam

Joint Gear

Fig. 2-15-A

NOTE

In case of the Pinch Roller Cam and Main Cam

1.

installation, install them as the circled section of Fig. 215-B so that the each markers are met. (Refer to Fig.

2-15-B)

Pinch Roller Cam

Marker

Capstan DD Unit

Be careful not to apply the silicon

bond to the Pinch Roller.

Fig. 2-14-B

Silicon Bond

Main Chassis

Fig. 2-14-C

Main Cam

Fig. 2-15-B

2-16: LOADING GEAR S/T UNIT (Refer to Fig. 2-16-A)

1.2.Remove the E-Ring and remove the Main Loading

1

Gear.

Remove the Main Rod, Tension Lever, Loading Arm S

Unit and Loading Arm T Unit.

1

Main Rod

Tension Lever

Main Loading Gear

Loading Arm T Unit

Loading Arm S Unit

- 8 -

Fig. 2-16-A

Page 10

DISASSEMBLY INSTRUCTION

NOTE

When you install the Loading Arm S Unit, Loading Arm

1.

T Unit and Main Loading Gear, align each marker.

(Refer to Fig. 2-16-B)

Marker

Main Loading Gear

Marker

CASSETTE GUIDE POST/INCLINED BASE S/T

2-18:

UNIT/P4 CAP/LED REFLECTOR

(Refer to Fig. 2-18-A)

Remove the P4 Cap.

1.

Unlock the support and remove the Cassette Guide

2.

1

Post.

Remove the Inclined Base S/T Unit.

3.

Remove the screw .

4.

5.

Remove the LED Reflector.

2

Cassette Guide Post

1

Loading Arm T Unit

2-17:

CLUTCH ASS'Y/RING SPRING/CLUTCH LEVER/

Loading Arm S Unit

CLUTCH GEAR (Refer to Fig. 2-17-A)

Remove the Polyslider Washer .

1.

Remove the Clutch Ass'y and Ring Spring.

2.

Remove the Clutch Lever.

3.

4.

Remove the Coupling Gear, Coupling Spring and

1

Clutch Gear.

1

Clutch Ass'y

Ring Spring

Coupling Gear

Coupling Spring

Clutch Gear

Clutch Lever

Fig. 2-16-B

Inclined Base S

Unit

LED Reflector

• Screw Torque: 5 ± 0.5kgf•cm

2

Inclined Base T

Unit

P4 Cap

Fig. 2-18-A

NOTE

Do not touch the roller of Guide Roller.

1.

In case of the P4 Cap installation, install it with parallel

2.

for "A" and "B" of Fig. 2-18-B.

3.

In case of the Cassette Guide Post installation, install

correctly as the circled section of Fig. 2-18-C.

"A"

"B"

Fig. 2-17-A

NOTE

1.

In case of the Clutch Ass'y installation, install it with

inserting the spring of the Clutch Ass'y into the dent of

the Coupling Gear.

(Refer to Fig. 2-17-B)

Clutch Ass'y

Coupling Gear

Fig. 2-17-B

- 9 -

P4 Cap

[OK]

Cassette Guide Post

[NG]

Cassette Guide Post

Cassette Opener

Fig. 2-18-B

Fig. 2-18-C

Page 11

DISASSEMBLY INSTRUCTION

3. REMOVAL OF DVD DECK PARTS

NOTE

1. Do not disassemble the DVD DECK PARTS except

listed parts here. Minute adjustments are needed if the

disassemble is done. If the repair is needed except

listed parts, replace the DVD MECHA ASS'Y.

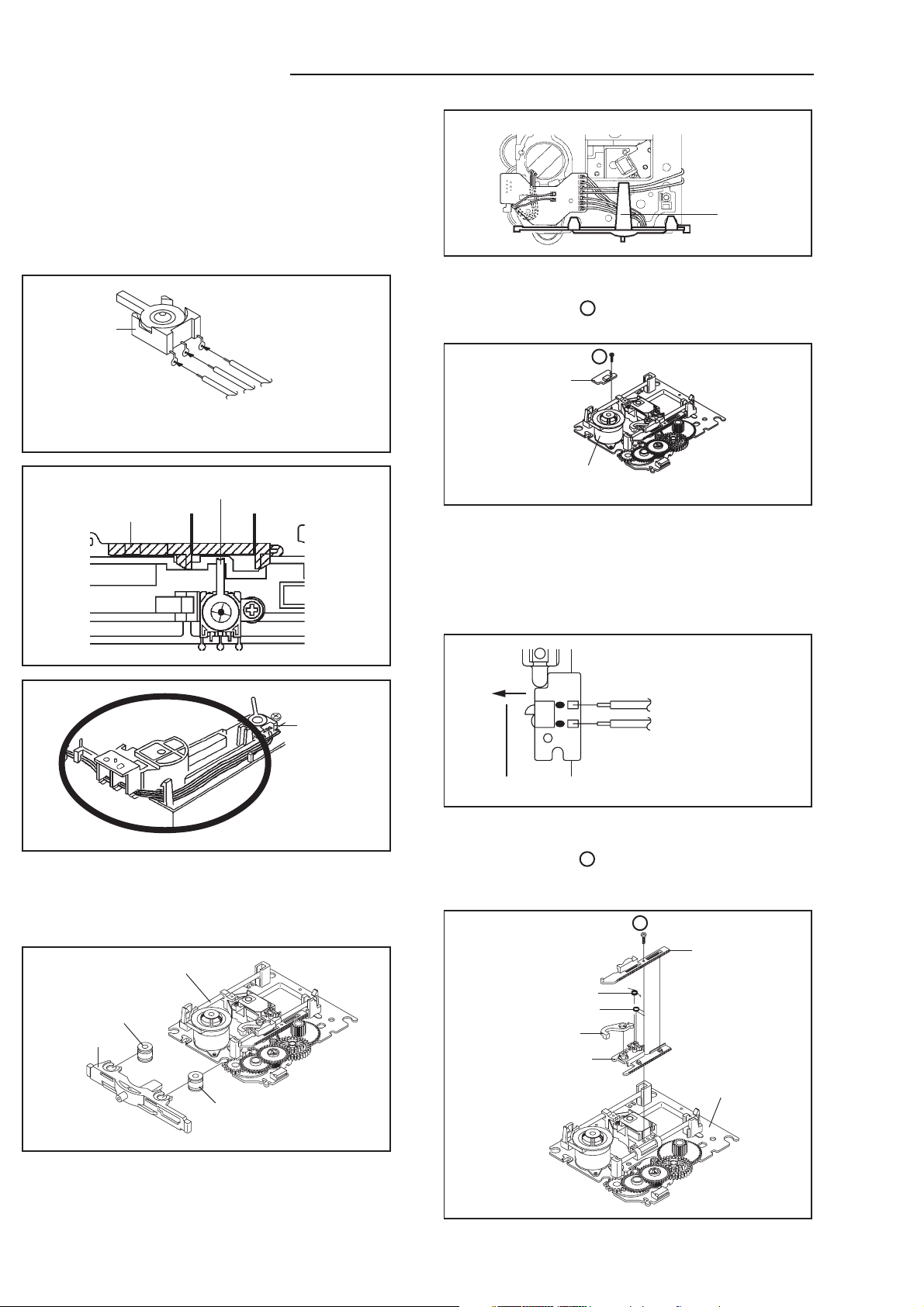

3-1: TRAY (Refer to Fig. 3-1-A)

Set the Tray opened. (Refer to the DISC REMOVAL

1.

METHOD AT NO POWER SUPPLY)

2.

Unlock the support and remove the Tray.

Tray

NOTE

In case of the Tray installation, install them as the

1.

circled section of Fig. 3-1-B so that the each markers

are met.

1

Main Frame Ass'y

1

Fig. 3-1-A

NOTE

In case of the Main Chassis Ass'y, install it from (1) to

1.

(6) in order.

Move it to the direction

of the arrow.

(Refer to Fig. 3-2-B)

Rack Loading

1

Main Frame Ass'y

Main Chassis Ass'y

2

3

5

6

4

6

Check Lock

4

Fig. 3-2-B

3-3: RACK LOADING/MAIN GEAR/ RACK LOADING

SPRING (Refer to Fig. 3-3)

1.

Remove the Rack L Spring.

2.

Press down the catcher and slide the Rack Loading.

3.

Remove the Rack Loading, Rack Loading Spring and

Main Gear

.

1

5

Tray

Main Frame Ass'y

Fig. 3-1-B

3-2: MAIN CHASSIS ASS'Y (Refer to Fig. 3-2-A)

Remove the Main Chassis Ass'y from the Insulator (R).

1.

Unlock the support .

2.

3.

Remove the Main Chassis Ass'y.

Main Frame Ass'y

1

Insulator (R)

(Green)

1

Rack Loading

Rack Loading Spring

Rack L Spring

1

3-4:

CLAMPER ASS'Y/INSULATOR(R)/LEVER SWITCH

Main Gear

Main Frame Ass’y

(Refer to Fig. 3-4-A)

Remove the screw .

1.

Remove the Lever Switch.

2.

Remove the 2 Insulator (R).

3.

Press the Clamper and rotate the Clamper Plate

4.

clockwise, then unlock the 3 supports .

5.

Remove the Clamper Plate, Clamper Magnet and

1

2

Clamper.

Clamper Plate

Clamper Magnet

Insulator (R)

(Green)

Insulator (R)

(Green)

Fig. 3-3

Main Chassis Ass'y

Fig. 3-2-A

- 10 -

Lever Switch

Main Frame

2

2

1

Clamper

2

Fig. 3-4-A

Page 12

DISASSEMBLY INSTRUCTION

NOTE

1.

When installing the Clamper Magnet, install it with the

green face up.

2.

When installing the wire of the Lever Switch, install it

correctly as Fig. 3-4-B.

3.

When installing the Lever Switch, install it correctly as

Fig. 3-4-C.

4.

In case of the Lever Switch installation, hook the wire

on the Main Frame as shown Fig. 3-4-D.

Lever Switch

Red

White

Blue

From DVD PCB

Fig. 3-4-B

The Lever should be position

between A and B.

Rack Loading

AB

Main Chassis Ass'y

Traverse Holder

Fig. 3-5-B

3-6: SWITCH PCB ASS'Y (Refer to Fig. 3-6-A)

Remove the screw .

1.

Remove the Switch PCB Ass'y.

2.

Switch PCB Ass'y

• Screw Torque: 4±

1

1

Main Chassis Ass'y

0.5kgf•cm

Fig. 3-6-A

NOTE

1.2.When installing the wire of the Switch PCB, install it

correctly as Fig. 3-6-B.

When installing the wire of the Switch PCB, while

pressing it in the direction of the arrow as shown Fig. 36-B, then instal it.

3-5:

TRAVERSE HOLDER/INSULATOR (F)

(Refer to Fig. 3-5-A)

Remove the Traverse Holder.

1.

Remove the 2 Insulator (F).

2.

Main Chassis Ass'y

Insulator (F)

(Black)

Traverse Holder

Insulator (F)

(Black)

Fig. 3-4-C

Lever Switch

Fig. 3-4-D

Fig. 3-5-A

Switch PCB Ass'y

Black

From Relay PCB

White

Main Chassis Ass'y

Fig. 3-6-B

3-7: RACK FEED ASS'Y (Refer to Fig. 3-7-A)

Remove the screw .

1.

2.

Remove the Rack Feed 1/2 Spring, Rack Feed 1/2 and

1

Rack Feed Lever.

1

Rack Feed 2

Rack Feed 1 Spring

Rack Feed 2 Spring

Rack Feed Lever

Rack Feed 1

Main Chassis Ass'y

NOTE

1. After the installing of the Traverse Holder, check if the

wire is like Fig. 3-5-B.

- 11 -

• Screw Torque: 3.5± 0.5kgf•cm

Fig. 3-7-A

Page 13

DISASSEMBLY INSTRUCTION

NOTE

1.2.After the assembly of the Rack Feed, check if the Rack

Feed 1/2 is moving smoothly. (Refer to Fig. 3-7-B)

In case of the Rack Feed Ass'y installation, install

correctly as Fig. 3-7-C.

Moving smoothly

Moving smoothly

Check the position of

the Rack Feed Lever.

Should not be engaged.

Fig. 3-7-B

Fig. 3-7-C

3-8: RELAY PCB ASS'Y (Refer to Fig. 3-8-A)

Remove the screw .

1.

2.

Remove the Relay PCB Ass'y.

1

Main Chassis Ass'y

3-9: GEAR (Refer to Fig. 3-9-A)

Unlock the support .

1.

2.

Remove the Middle Gear 1/2/3, Idler Gear and Feed

1

Gear.

Middle Gear 2

Middle Gear 1

Middle Gear 3

Idler Gear

Feed Gear

1

Main Chassis Ass'y

Fig. 3-9-A

NOTE

1.2.In case of the Idler Gear installation, install correctly as

Fig. 3-9-B.

When installing the Middle Gear 2, check if the Middle

Gear 2 is locked correctly as Fig. 3-9-C.

[OK] [NG]

Idler Gear

Idler Gear

Relay PCB Ass'y

1

Fig. 3-8-A

NOTE

1. When installing the wire of the Relay PCB, install it

correctly as Fig. 3-8-B.

Idler Arm

Check Lock

Middle Gear 2

Idler Arm

3-10: IDLER ARM (Refer to Fig. 3-10-A)

Remove the Idler Arm Spring.

1.

Remove the Chassis Spring.

2.

3.

Remove the Idler Arm.

Idler Arm Spring

Idler Arm

Main Chassis Ass'y

Fig. 3-9-B

Fig. 3-9-C

Fig. 3-8-B

Chassis Spring

Fig. 3-10-A

- 12 -

Page 14

DISASSEMBLY INSTRUCTION

NOTE

1.

In case of the Idler Arm installation, install as the circled

section of Fig. 3-10-B.

2.

In case of the Idler Arm Spring installation, install as the

circled section of Fig. 3-10-C.

3.

In case of the Chassis Spring installation, install as the

circled section of Fig. 3-10-D.

Idler Arm

Main Chassis Ass'y

Fig. 3-10-B

Idler Arm Spring

NOTE

1.2.In case of the Motor Gear installation, check if the value

of the Fig. 3-11-B is correct.

When installing the Feed Motor, check if the cable is

positioned as Fig. 3-11-C.

Motor Gear

Feed Motor

Safety surface for pressing

of the insert.

Main Chassis Ass'y

6.1 0.1mm

Fig. 3-11-B

Feed Motor

Main Chassis Ass'y

Main Chassis Ass'y

3-11: FEED MOTOR (Refer to Fig. 3-11-A)

Remove the 2 screws .

1.

Remove the Feed Motor.

2.

Remove the Motor Gear.

3.

1

1

1

Fig. 3-10-C

Chassis Spring

Fig. 3-10-D

Pass the cable

between 2 pins.

Fig. 3-11-C

Motor Gear

Feed Motor

• Screw Torque: 1 ± 0.5kgf•cm

Main Chassis Ass'y

Fig. 3-11-A

- 13 -

Page 15

MECHANICAL ADJUSTMENTS

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTES before starting work.

•Place an object which weighs between 450g~500g on

the Cassette Tape to keep it steady when you want to

make the tape run without the Cassette Holder. (Do not

place an object which weighs over 500g.)

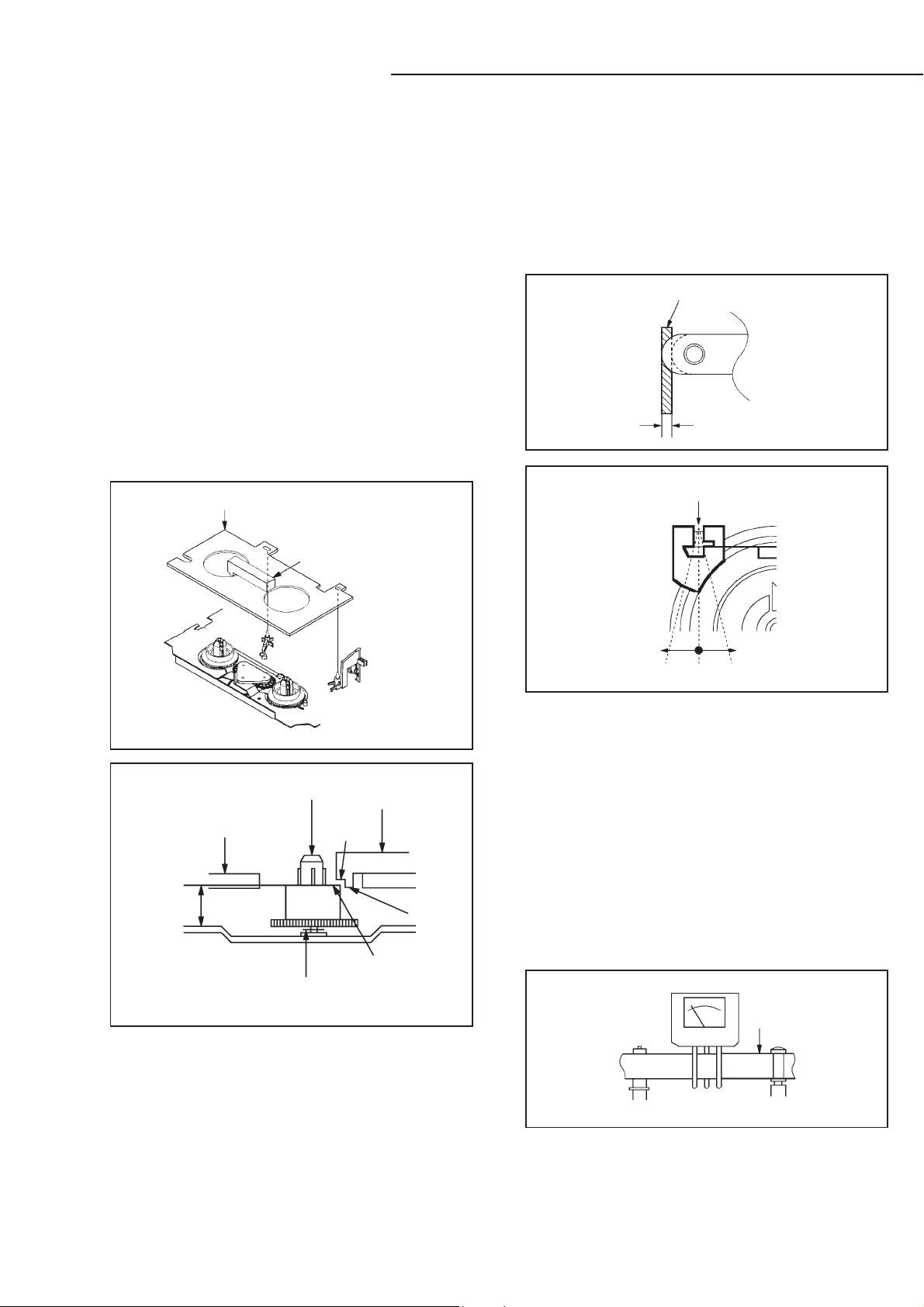

1-1: CONFIRMATION AND ADJUSTMENT OF REEL

DISK HEIGHT

1.

Turn on the power and set to the STOP mode.

2.

Set the master plane (JG022) and reel disk height

adjustment jig (JG024A) on the mechanism framework,

taking care not to scratch the drum, as shown in Fig. 1-

1-A.

3.

While turning the reel and confirm the following points.

Check if the surface “A” of reel disk is lower than the

surface “B” of reel disk height adjustment jig (JG024A)

and is higher than the surface “C”. If it is not passed,

place the height adjustment washers and adjust to

10(+2, -0)mm.

4.

Adjust the other reel in the same way

Master Plane (JG022)

Reel Disk Height Adjustment Jig

(JG024A)

.

1-2: CONFIRMATION AND ADJUSTMENT OF TENSION

POST POSITION

1.

Set to the PLAY mode.

2.

Adjust the adjusting section for the Tension Arm

position so that the Tension Arm top is within the

standard line of Main Chassis.

3.

While turning the S Reel clockwise, confirm that the

edge of the Tension Arm is located in the position

described above.

Standard line of Main Chassis

Tension Arm

0.5mm (Adjusting range)

Fig. 1-2-A

Adjusting section for the

Tension Arm position

Tension Band

Master Plane (JG022)

10(+0.2, -0)mm

Reel Disk

(B)

Height Adjustment Washer

2.6x4.7xT0.13

2.6X4.7xT0.25

Fig. 1-1-A

Reel Disk Height

Adjustment Jig

(JG024A)

(C)

(A)

Fig. 1-1-B

The Tension Arm top will

move to the inside direction

of the Main Chassis.

Bend

The Tension Arm top will

move to the outside direction

of the Main Chassis.

Fig. 1-2-B

1-3: CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK

1.2.Load a video tape (E-180) recorded in standard speed

mode. Set the unit to the PLAY mode.

Install the tentelometer as shown in Fig. 1-3. Confirm that

the meter indicates 20 2gf in the beginning of playback.

• USING A CASSETTE TYPE TORQUE TAPE (JG100A)

1.

After confirmation and adjustment of Tension Post

position (Refer to item 1-2), load the cassette type

torque tape (JG100A) and set to the PLAY mode.

2.

Confirm that the right meter of the torque tape indicates

50~90gf•cm during playback in SP mode.

Confirm that the left meter of the torque tape indicates

3.

25~40gf•cm during playback in SP mode.

Tentelometer

Video Tape

- 14 -

P1 Post Guide Roller

Fig. 1-3

Page 16

MECHANICAL ADJUSTMENTS

1-4: CONFIRMATION OF VSR TORQUE

1.2.Install the Torque Gauge (JG002F) and Adapter (JG002B)

on the S Reel. Set to the Picture Search (Rewind) mode.

(Refer to Fig.1-4-B)

Then, confirm that it indicates 120~180gf•cm.

NOTE

Install the Torque Gauge on the reel disk firmly. Press the

REW button to turn the reel disk.

1-5: CONFIRMATION OF REEL BRAKE TORQUE

(S Reel Brake) (Refer to Fig. 1-4-B)

1.

Once set to the Fast Forward mode then set to the Stop

mode. While, unplug the AC cord when the Pinch Roller

Block is on the position of Fig. 1-4-A.

2.

Move the Idler Ass’y from the S Reel.

3.

Install the Torque Gauge (JG002F) and Adapter

(JG002B) on the S Reel. Turn the Torque Gauge

(JG002F) clockwise.

4.

Then, confirm that it indicates 60~100gf•cm.

(T Reel Brake) (Refer to Fig. 1-4-B)

1.

Once set to the Fast Forward mode then set to the Stop

mode. While, unplug the AC cord when the Pinch Roller

Block is on the position of Fig. 1-4-A.

2.

Move the Idler Ass’y from the T Reel.

3.

Install the Torque Gauge (JG002E) and Adapter

(JG002B) on the T reel. Turn the Torque Gauge

(JG002E) counterclockwise.

4.

Then, confirm that it indicates 30~50gf•cm.

Stop at this position.

The position at

STOP mode.

Capstan DD Unit

The position at FF mode.

Pinch Roller Block

Cassette Opener

NOTE

If the torque is out of the range, replace the following parts.

Check item

1-4

1-5

S Reel side:

Replacement Part

Idler Ass’y/Clutch Ass’y

S Reel/Tension Band/Tension

Connect/Tension Arm Ass’y

T Reel side:

T Reel/T Brake Band//T Brake

Spring/T Brake

Arm

2. CONFIRMATION AND ADJUSTMENT

OF TAPE RUNNING MECHANISM

Ta pe Running Mechanism is adjusted precisely at the

factory. Adjustment is not necessary as usual. When you

replace the parts of the tape running mechanism because

of long term usage or failure, the confirmation and adjustment are necessary.

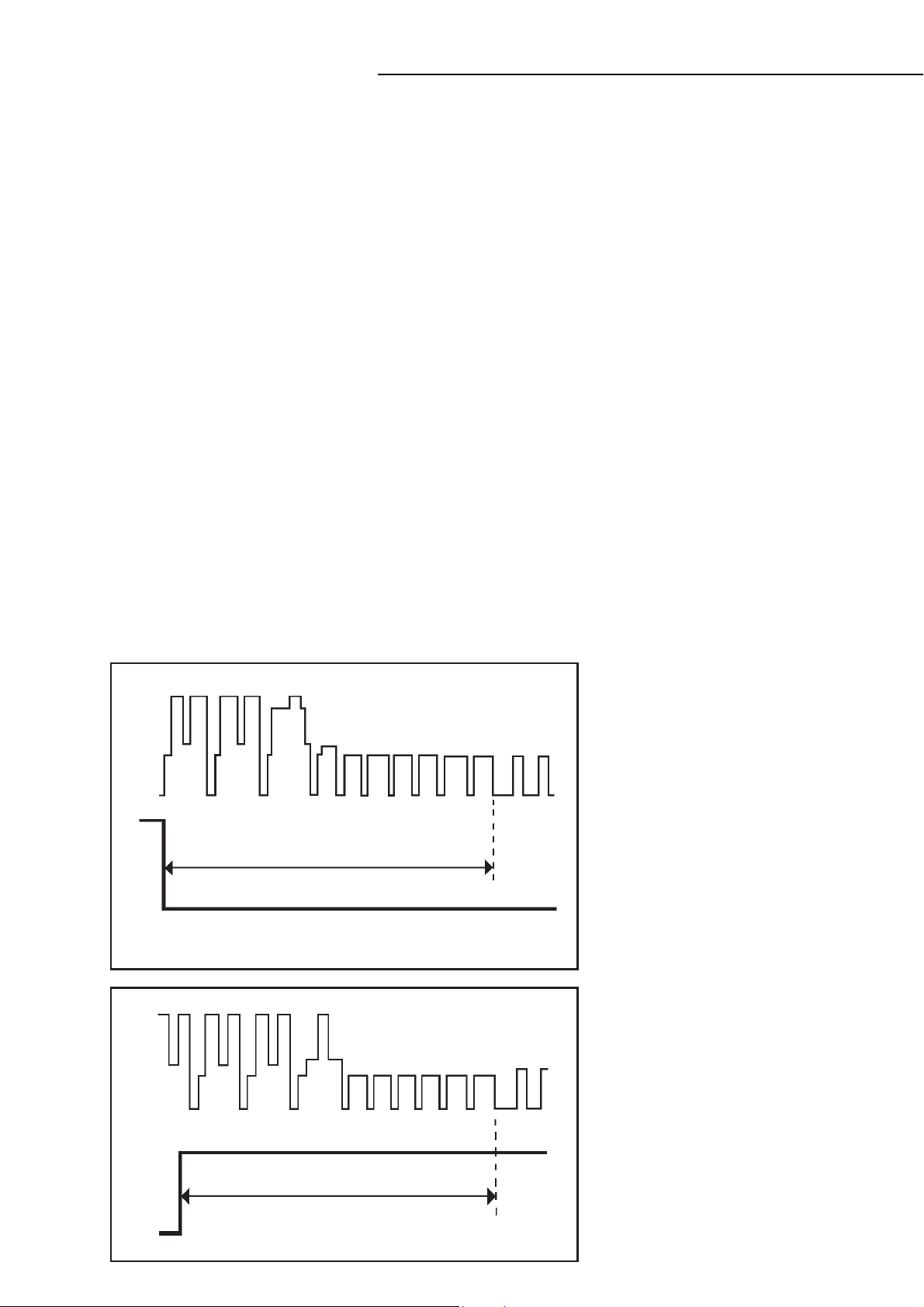

2-1: GUIDE ROLLER

1.

Playback the VHS Alignment Tape (JG001C or JG001E).

(Refer to SERVICING FIXTURE AND TOOLS)

2.

Connect CH-1 of the oscilloscope to TP103 (Envelope)

and CH-2 to TP102 (SW Pulse).

Trigger with SW Pulse and observe the envelope. (Refer

3.

to Fig. 2-1-A)

4.

When observing the envelope, adjust the Adjusting

Driver (JG005) slightly until the envelope will be flat.

Even if you press the Tracking Button, adjust so that

flatness is not moved so much.

Adjust so that the A : B ratio is better than 3 : 2 as shown

5.

in Fig. 2-1-B, even if you press the Tracking Button to

move the envelope (The envelope waveform will begin to

decrease when you press the Tracking Button).

6.

Adjust the PG shifter during playback.

(Refer to the ELECTRICAL ADJUSTMENTS)

NOTE

After adjustment, confirm and adjust A/C head.

(Refer to item 2-2)

Cassette Holder Ass’y

Torque Gauge/Adapter

(JG002F/JG002B)

S Reel

Torque Gauge/Adapter

(JG002E/JG002B)

T Reel

Fig. 1-4-A

Fig. 1-4-B

CH-1

Envelope

(TP103)

CH-2

SW Pulse (TP102)

Entrance

Max

A B

CH-1

Track

A : B

3 : 2

CH-2

Trac k

Fig. 2-1-A

Exit

Max

Fig. 2-1-B

- 15 -

Page 17

MECHANICAL ADJUSTMENTS

2-2: CONFIRMATION AND ADJUSTMENT OF AUDIO/

CONTROL HEAD

When the Tape Running Mechanism does not work well,

adjust the following items.

1.

Playback the VHS Alignment Tape (JG001C or JG001E).

(Refer to SERVICING FIXTURE AND TOOLS)

2.

Confirm that the reflected picture of stamp mark is

appeared on the tape prior to P4 Post as shown in Fig.

2-2-A.

a)

When the reflected picture is distorted, turn the screw

1 clockwise until the distortion is disappeared.

b)

When the reflected picture is not distorted, turn the

screw counterclockwise until little distortion is

1

appeared, then adjust the a).

3.

Turn the screw to set the audio level to maximum.

4.

Confirm that the bottom of the Audio/ Control Head and

2

the bottom of the tape is shown in Fig. 2-2-C.

c)

When the height is not correct, turn the screw to

adjust the height.

Then, adjust the 1~3 again.

Audio/Control Head

Reflected picture of

Stamp Mark

P4 Cap

3

2-3: TAPE RUNNING ADJUSTMENT

(X VALUE ADJUSTMENT)

1.

Confirm and adjust the height of the Reel Disk.

(Refer to item 1-1)

2.

Confirm and adjust the position of the Tension Post.

(Refer to item 1-2)

3.

Adjust the Guide Roller. (Refer to item 2-1)

4.

Confirm and adjust the Audio/Control Head.

(Refer to item 2-2)

5.

Connect CH-1 of the oscilloscope to TP102, CH-2 to

TP103 and CH-3 to pin 19 of J8004.

6.

Playback the VHS Alignment Tape (JG001U or JG001V).

(Refer to SERVICING FIXTURE AND TOOLS)

7.

Set the X Value adjustment driver (JG153) to the of

Fig. 2-2-B. Adjust X value so that the envelope waveform

output becomes maximum. Check if the relation between

Audio and Envelope waveform becomes (1) or (2) of Fig.

.

2-3

Envelope

(1)

CH-3

Audio

(2)

4

3

2

Audio/Control Head

Tap e

Stamp Mark

Audio/Control Head

1

4

Fig. 2-2-A

Fig. 2-2-B

0.25± 0.05mm

Fig. 2-3

2-4: CONFIRM HI-FI AUDIO (Hi-Fi model only)

1.

Connect CH-1 of the oscilloscope to TP103 and CH-2 to

the pin 19 of J8004.

2.

Playback the VHS Alignment Tape (JG001R).

(Refer to SERVICING FIXTURE AND TOOLS)

3.

Press the Tracking Up button and count number of steps

which the audio output is changed from Hi-Fi (10KHz) to

MONO (6KHz).

4.

Press the Tracking Down button and count number of

steps which the audio output is changed from Hi-Fi

(10KHz) to MONO (6KHz).

5.

If the difference are more than 3 steps, set the X Value

adjustment driver (JG153) to of Fig. 2-2-B. Change the

4

X Value and adjust it so that the value becomes within 2

steps.

Fig. 2-2-C

- 16 -

Page 18

MECHANICAL ADJUSTMENTS

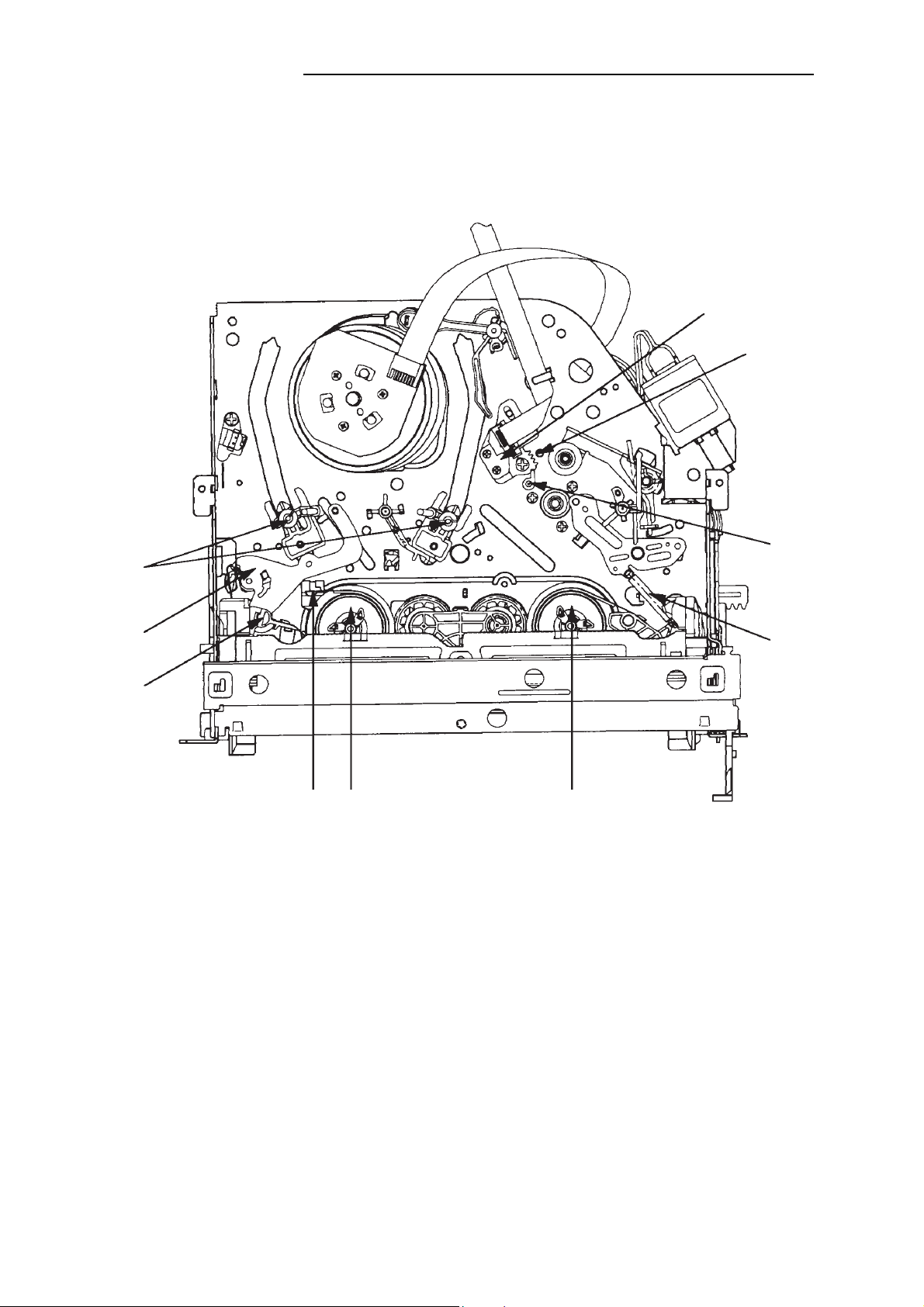

3. MECHANISM ADJUSTMENT PARTS LOCATION GUIDE

4

5

6

3

2

1

8910

1. Tension Connect

2. Tension Arm

3. Guide Roller

4. Audio/Control Head

5. X value adjustment driver hole

6.

P4 Post

7.

T Brake Spring

8.

T Reel

S Reel

9.

10.

Adjusting section for the Tension Arm position

7

- 17 -

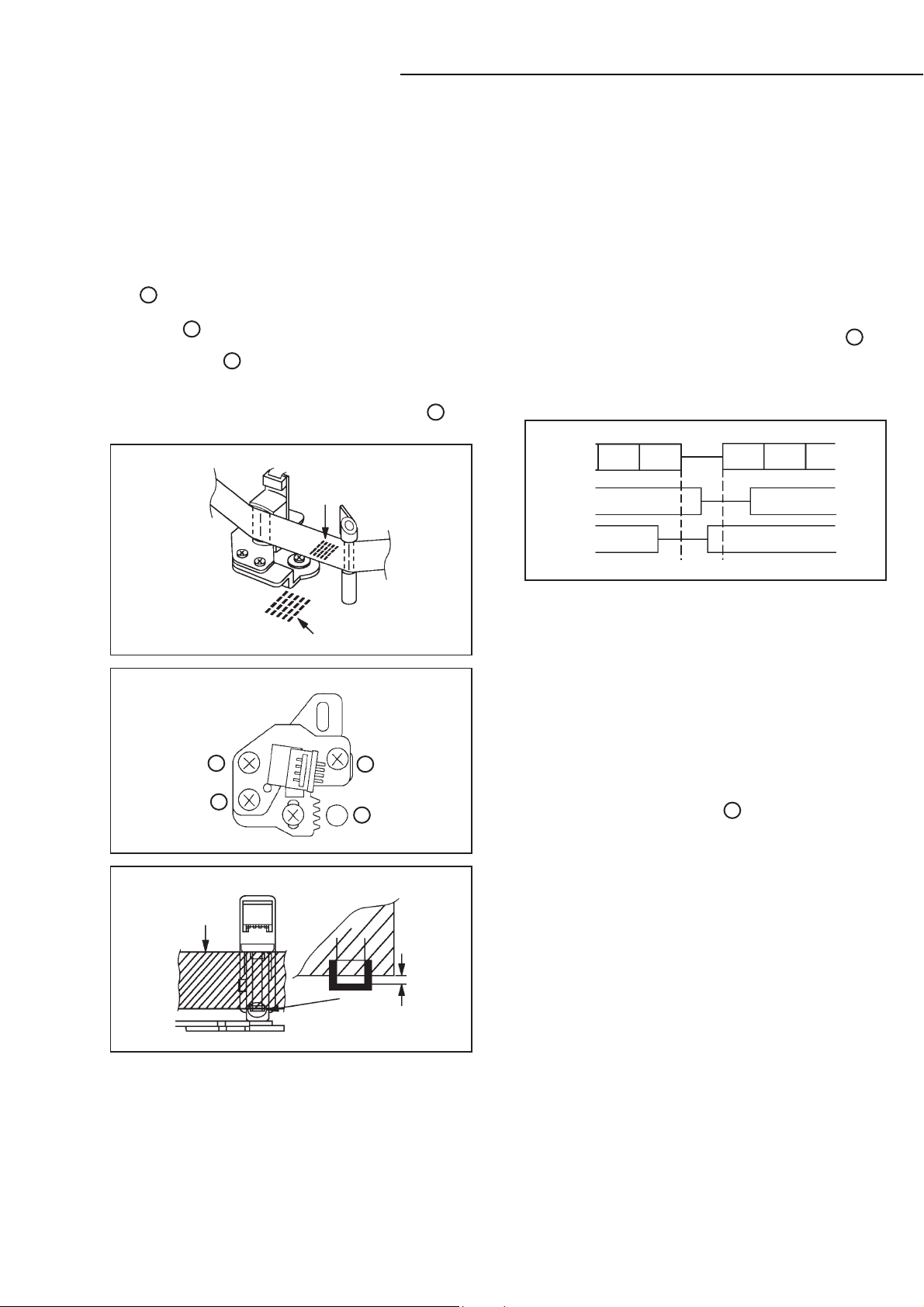

Page 19

SERVICING FIXTURES AND TOOLS

(For 2 head 1 speed model,

4 head model)

VHS Alignment Tape

JG001E

JG001F

JG001R

JG001U

(VP S-LI6 )

(VP S-CO1 )

(VP S-LI6 H)

(VP S-X6 )

3

1

3

1

3

1

3

1

Screwdriver

JG154 Cable

(For 2 head 2 speed model)

VHS Alignment Tape

JG001C

JG001D

JG001V

(VP S-LI6 )

(VP S-CO1 )

(VP S-X6 )

3

2

3

2

3

2

JG002B

JG002E

JG002F

JG024AJG022 Master PlaneJG153 X Value Adjustment

TentelometerJG176 Up-Date Disc

Adapter

Dial Torque Gauge

(10~90gf•cm)

(60~600gf•cm)

Reel Disk Height

Adjustment Jig

JG005 Post Adjustment

Screwdriver

Part No. SV-TG0-030-000

(small)

JG100A Torque Tape

(VHT-063)

Ref. No.

JG001E

JG001F APJG001F00

JG001R

JG001U

JG001C

JG001D

JG001V

JG002B

JG002E

JG002F

JG005

JG153

JG022

JG024A

JG100A

JG154

Part No.

APJG001E00

APJG001R00

APJG001U00

APJG001C00

APJG001D00

APJG001V00

APJG002B00

APJG002E00

APJG002F00

APJG005000

APJG153000

APJG022000

APJG024A00

APJG100A00

APJG154000

Parts Name

VHS Alignment Tape

VHS Alignment Tape

VHS Alignment Tape

VHS Alignment Tape

VHS Alignment Tape

VHS Alignment Tape

VHS Alignment Tape

Adapter

Dial Torque Gauge (10~90gf•cm)

Dial Torque Gauge (60~600gf•cm)

Post Adjustment Screwdriver

X Value Adjustment Screwdriver

Master Plane

Reel Disk Height Adjustment Jig

Torque Tape (VHT-063)

Cable

Remarks

Monoscope, 6KHz (For 2 head 1 speed model, 4 head model)

Color Bar, 1KHz (For 2 head 1 speed model, 4 head model)

Hi-Fi Audio (For Hi-Fi model)

X Value Adjustment (For 2 head 1 speed model, 4 head model)

Monoscope, 6KHz (For 2 head 2 speed model)

Color Bar, 1KHz (For 2 head 2 speed model)

X Value Adjustment (For 2 head 2 speed model)

VSR Torque, Brake Torque (S Reel/T Reel Ass'y)

Brake Torque (T Reel Ass'y)

VSR Torque, Brake Torque (S Reel)

Guide Roller Adjustment

X Value Adjustment

Reel Disk Height Adjustment

Reel Disk Height Adjustment

Playback Torque, Back Tension Torque During Playback

Used to connect the test point of SERVICE and GROUND

JG176 APJG176034 Up-Date Disc Up-Date of the Firmware

PREPARATION FOR SERVICING

How to use the Servicing Fixture

1.

While pressing the POWER button on the set for more than 2 seconds, press the CH DOWN button on the set

simultaneously at the Power OFF. Although the DVD is connected, the DVD mode cannot be selected.

2.

Short circuit between TP3001 and Ground with the cable JG154.

(The BOT, EOT, and the Reel Sensor do not work and the VCR deck can be operated without a cassette tape.)

In case of using a cassette tape, press the TAPE EJECT button to insert or eject a cassette tape.

3.

Turn on the power and re-check the cable before checking the trouble points.

When you servicing with connection of DVD, perform the operations above step 2 to step 3.

- 18 -

Page 20

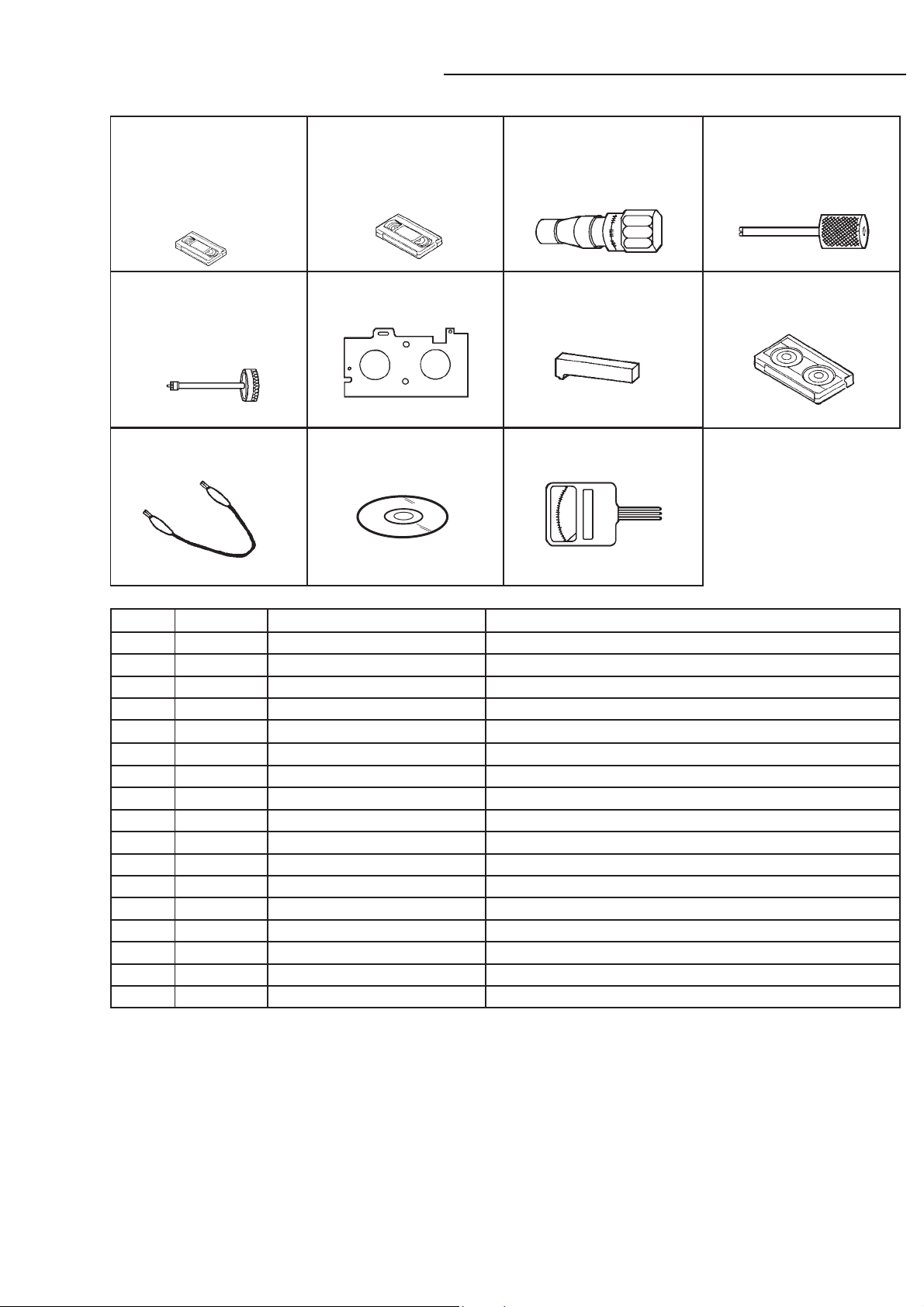

PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage.

Parts replacing time does not mean the life span for individual parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

The following list means standard hours, so the checking hours depends on the conditions.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

T Brake Band

Clutch Ass’y

Idler Arm Ass’y

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

: Clean

: Check it and if necessary

500

hours

1,000

hours

, replace it.

1,500

hours

2,000

hours

2,500

hours

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

CONFIRMATION OF HOURS USED

PLAY/REC total hours can be checked on the screen.

Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is reset to “0”.

1.

Connect the set to TV Monitor.

2.

Turn on the POWER.

3.

Press both CH UP button on the set and the FF button on the set for more than 2 seconds.

The Fig. 1 screen will appear on TV Monitor.

4.

After the confirmation of using hours, turn off the power.

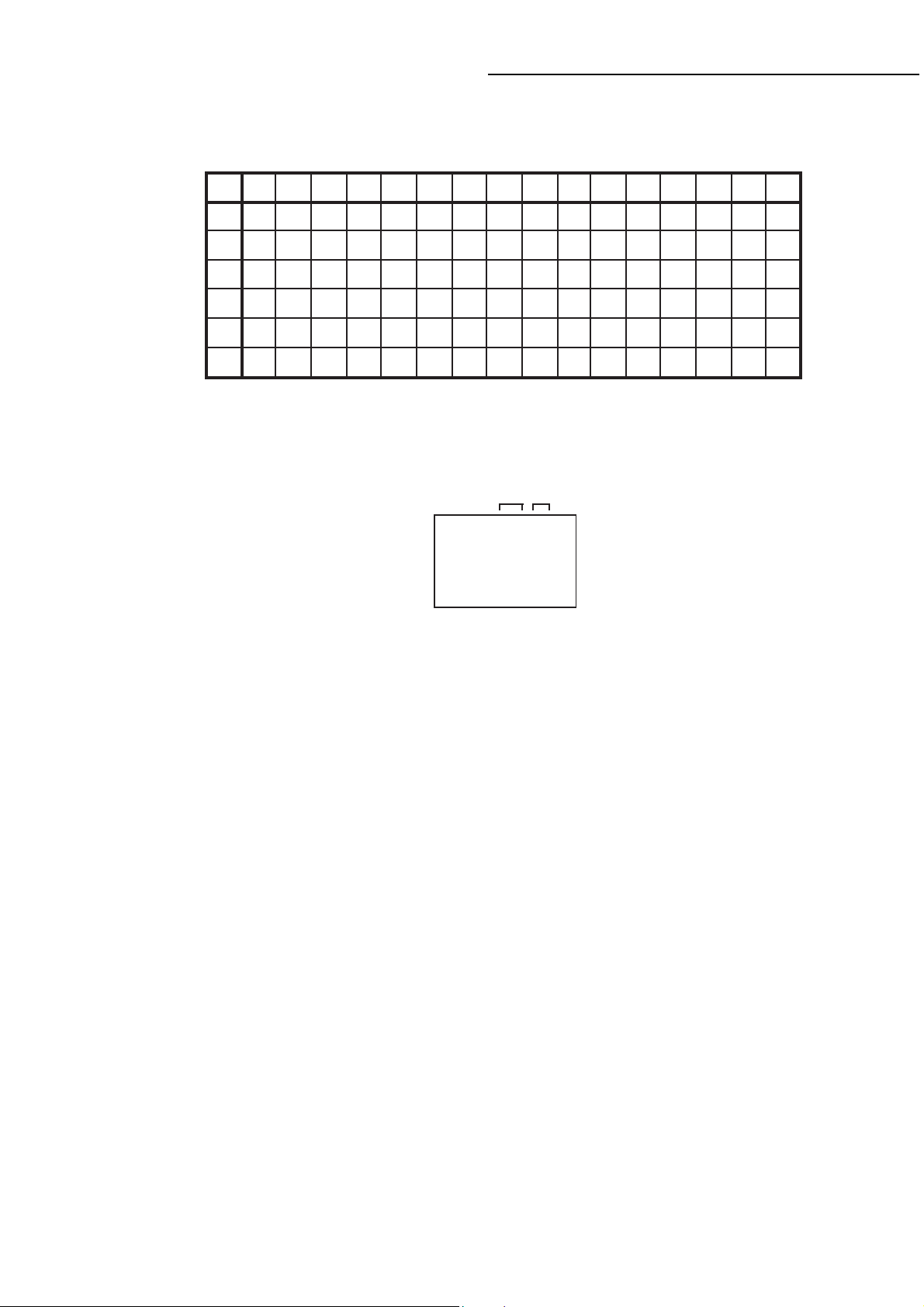

INIT 0C6 06

PLA

Y/REC 0010

Fig. 1

Initial setting content of MEMORY IC.

PLAY/REC total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

- 19 -

Page 21

PREVENTIVE CHECKS AND SERVICE INTERVALS

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads

are not completely dry and alcohol gets on the tape,

damage may occur.

1. AUDIO CONTROL HEAD

Clean the Audio Control Head with the cotton stick

soaked by alcohol. Clean the full erase head in the

same manner. (Refer to the figure below.)

Audio Control Head

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the

gauze moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in

the direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Cylinder Head

- 20 -

Page 22

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit or on the main unit

and on the remote control for more than a standard time (second).

Set Key

CH UP

CH UP STOP 2

CH UP PLAY 2

CH DOWN POWER 2

Set Key

REC 4 2

Set Key

FF 2

Standard Time

(seconds)

Standard Time

(seconds)

Operations

PLAY/REC total hours are displayed on the TV Monitor.

Refer to the “PREVENTIVE CHECKS AND SERVICE INTERVALS”

(CONFIRMATION OF HOURS USED).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the “WHEN REPLACING EEPROM (MEMORY) IC”.

Adjust the PG SHIFTER automatically.

Refer to the “ELECTRICAL ADJUSTMENT” (PG SHIFTER).

Initialization of the factory on VCR.

NOTE:

VCR operation mode at no connection of DVD.

Refer to the “PREPARATION FOR SERVICING”

NOTE:

Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such as

the clock setting, the channel setting, and PLAY/REC total hours.

Although the DVD is connected, the DVD mode cannot be

selected.

OperationsRemocon Key

Initialization of the factory on DVD.

NOTE: Do not use this for the normal servicing.

The function will only work without the setting of DVD disc at

DVD mode.

While pressing the Remocon Key for more than the Standard

Time, press the Set Key simultaneously

.

REC 6 2

STOP 1 3

STOP 7 3

Method Operations

Make the short circuit

between the test point of

SERVICE and the GND.

The BOT, EOT, and the Reel Sensor do not work and the VCR deck can be operated

without a cassette tape.

Refer to the “PREPARATION FOR SER

DVD Write mode.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE:

Check for the firmware version.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE:

Releasing of PARENTAL LOCK.

Refer to the “PARENTAL CONTROL - RATING LEVEL”.

NOTE:

Do not use this for the normal servicing.

The function will only work at the DVD stop mode.

Do not use this for the normal servicing.

The function will only work at the DVD stop mode.

The function will only work without the setting of DVD disc at

DVD mode.

VICING”

- 21 -

Page 23

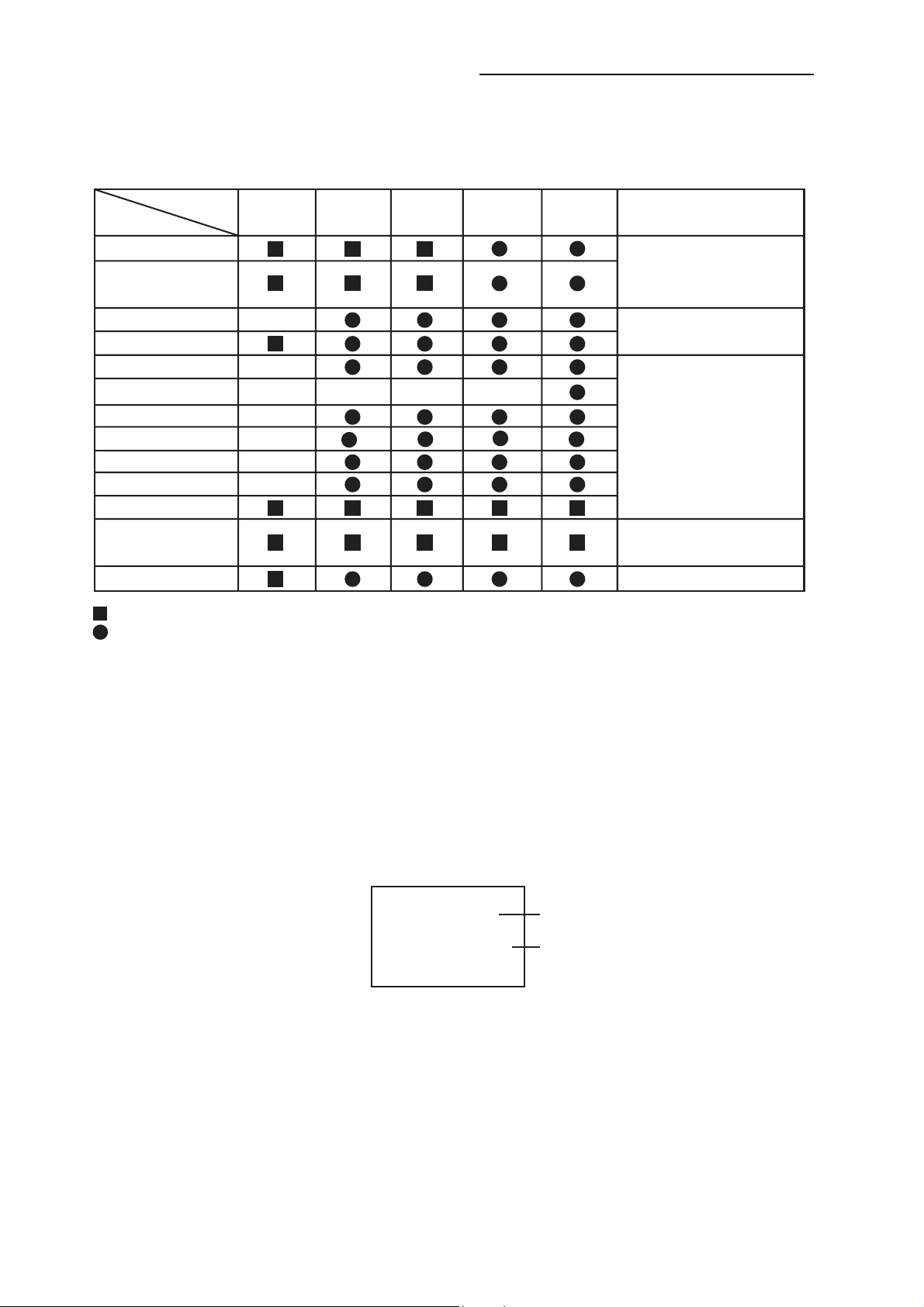

WHEN REPLACING EEPROM(MEMORY)IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to T

Note: No need setting due to the adjustment value except the list below.

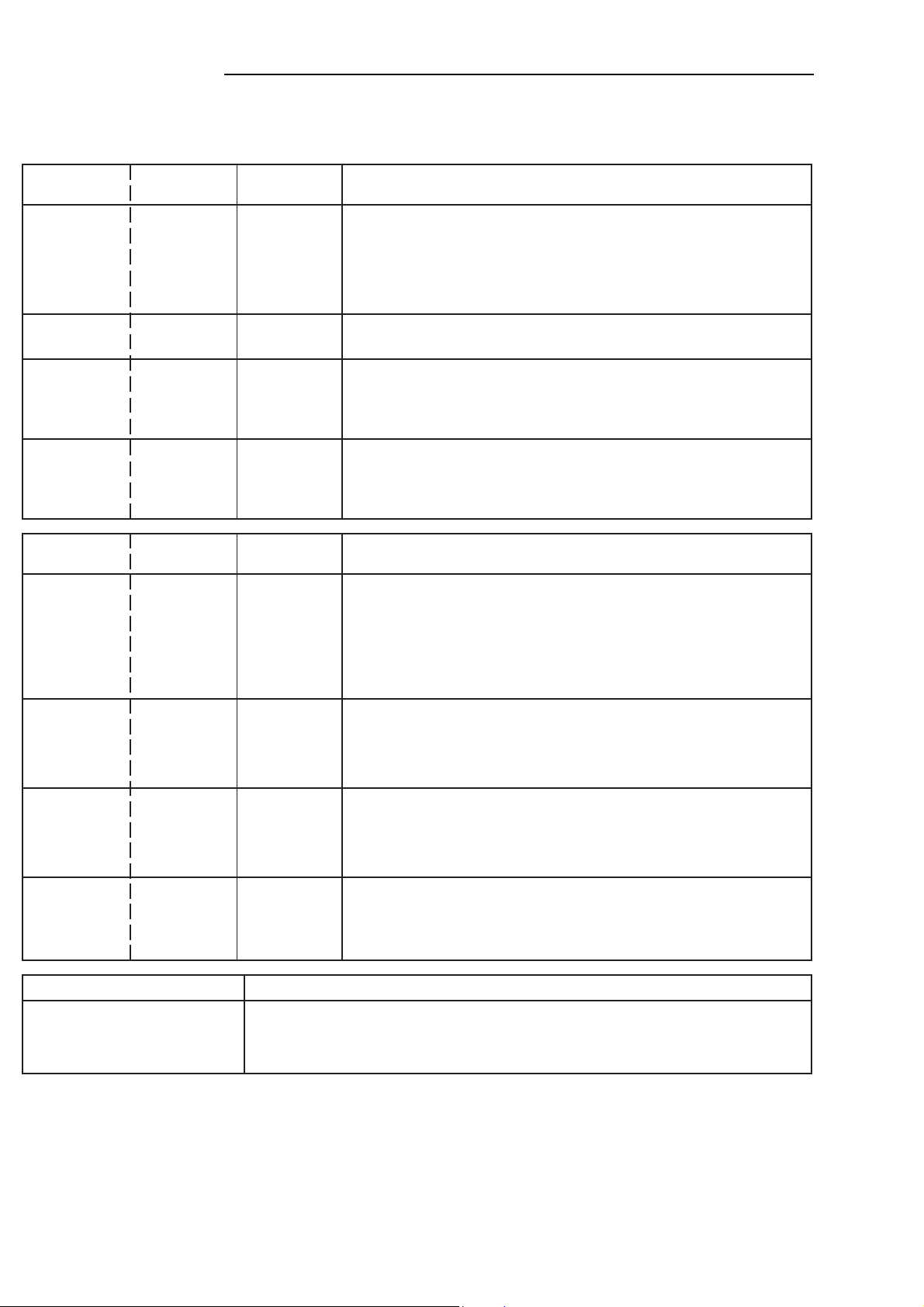

INIT

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

0B0

--- --- --- --- --- --- --- --- --- 1D 07 AD 20 00 02 38

0C0

44 18 00 99 9F 05 10 B7 89 AD AD 96 93 88 00 00

ABLE 1.

0D0

00 89 42 30 60 56 65 5F 80 97 2C FA 5F 00 00

0E0

00 00 00 00 00 00 00 00 00 00 00 5F 00 97 2C FA

0F0

5F CD C8 02 21 55 80 3D 68 08 89 3A 99 --- --- ---

100

06 06 D9 00 99 01 D9 00 99 01 03 00 66 F2 00 00

00

Table 1

1.

Connect the set to TV Monitor.

2.

Turn on the POWER.

3.

Press both CH UP button on the set and the FF button on the set for more than 2 seconds.

ADDRESS and DATA will appear on TV Monitor as Fig 1.

ADDRESS

INIT 0B9 1D

Y/REC 0010

PLA

DAT

A

Fig. 1

4.

ADDRESS is now selected and should “blink”. Using the Tracking + or - button on the remote, step through the ADDRESS

until required ADDRESS to be changed is reached.

5.

Press ENTER to select DATA. When DATA is selected, it will “blink”.

6.

Again, step through the DATA using Tracking + or - button until required DATA value has been selected.

7.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

8.

Repeat steps 4 to 7 until all data has been checked.

9.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

After the data input, set to the initializing of shipping.

10.

Turn POWER on.

11.

Press both CH UP button on the set and the PLAY button on the set for more than 2 seconds.

After the finishing of the initializing of shipping, the unit will turn off automatically.

12.

The unit will now have the correct DATA for the new MEMORY IC.

- 22 -

Page 24

RE-WRITE FOR DVD FORMWARE

Turn on the power, and set the DVD mode.

1.

Confirm that the “No Disc” will be appeared on the screen.

2.

Open the DVD tray.

3.

Press both Channel button (6) on the remote control and the REC button on the set for more than 2 seconds.

4.

Press OPEN/CLOSE button on the unit to check if all the keys on the unit do not function.

5.

NOTE: To check if DVD Write mode is set.

Up-Date can be done at Non DVD Write mode. But the read error may occur.

Place the Up-Date Disc and close the tray by hand. (Refer to SERVICING FIXTURE AND TOOLS)

6.

Automatic read will start and "Firmware upgrade" will be displayed on the screen.

7.

Approxi. 60 seconds later, the tray will open automatically. Remove the Up-Date Disc.

8.

Then, Approxi. 50 seconds later, the above indication will disappear and the tray will close automatically.

9.

When the "No Disc" appears on the screen, the write will end.

NOTE: Do not turn off the unit on the way or push the tray by hand to close it.

Up-Date error will happen and can not be done with the Up-Date of Up-Date Disc.

Unplug the AC cord, then plug it in.

10.

After the write, set to the initializing of shipping.

11.

Set to the DVD mode, press both Channel button (4) on the remote control and the REC button on the set for more than 2

seconds.

The "INITIALIZE 7 ---> COMPLETE" will appear on the screen.

Then unplug the AC cord, and plug it in.

12.

CHECK FOR THE FIRMWARE VERSION

13.

Set to the DVD mode, press both Channel button (1) on the remote control and the STOP button on the set for more than 3

seconds.

Firmware version will be displayed on the top left of the screen.

When the changed version displays, the Re-write will be completed.

14.

Turn off the power

No Disc

GMJ36101

G M J 3 6 1 0 1

Fixed

Released times on the same date

Release date (Example: 2003.6.10)

When the changed version displays, the Re-write will be completed.

A = October

B = November

C = December

- 23 -

Page 25

ELECTRICAL ADJUSTMENTS

Read and perform this adjustment when repairing the

circuits or replacing electrical parts or PCB assemblies.

1. BASIC ADJUSTMENT

CAUTION

When you exchange IC and Transistor for a heat sink,

•

apply the silicon grease (YG6260M) on the contact

section of the heat sink. Before applying new silicon

grease, remove all the old silicon grease. (Old grease

may cause damages to the IC and Transistor.)

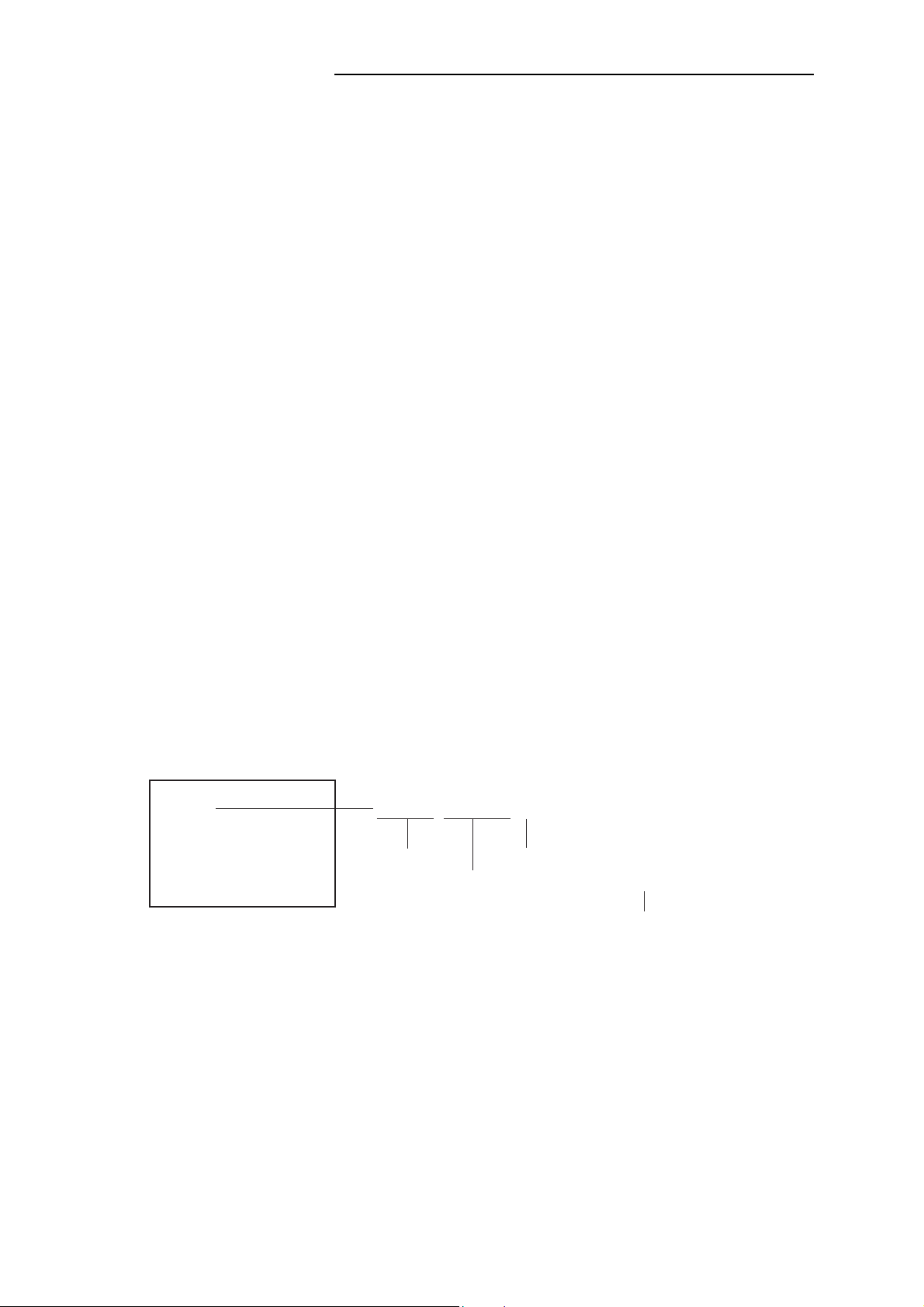

1-1: PG SHIFTER

CONDITIONS

MODE-PLAYBACK

Input Signal-Alignment Tape (JG001B)

INSTRUCTIONS

Connect CH-1 on the oscilloscope to TP102 and CH-2

1.

to the Pin 19 of J8004.

Playback the alignment tape. (JG001B)

2.

Press and hold the Tracking-Auto button on the remote

3.

control more than 2 seconds to set tracking to center.

Press both CH UP button on the set and the STOP

4.

button on the set for more than 2 seconds.

6.5H

CH-2

CH-1

Fig. 1-1-A

CH-2

CH-1

6.5H

Fig. 1-1-B

- 24 -

Page 26

ELECTRICAL ADJUSTMENTS

2. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

POWER PCB

TU301

TP3001

TP103

CP103

TP102

J653

J652

FE HEAD

J651

CP102

CD102

AC HEAD

VCR PCB

OS651

J8004

V651

TU302

CP8002

CP1701

CP8001

CP1702

CP651

CD8002

CD8001

CD502

CP8102

CP4002

DVD PCB

S503

S502

CP2601

CP2603

CP2602

AC IN

CD501

J8101

CP8101

CD2001

CP601

OPERATION PCB

CD651

DVD DECK

CD2301

CD2302

- 25 -

Page 27

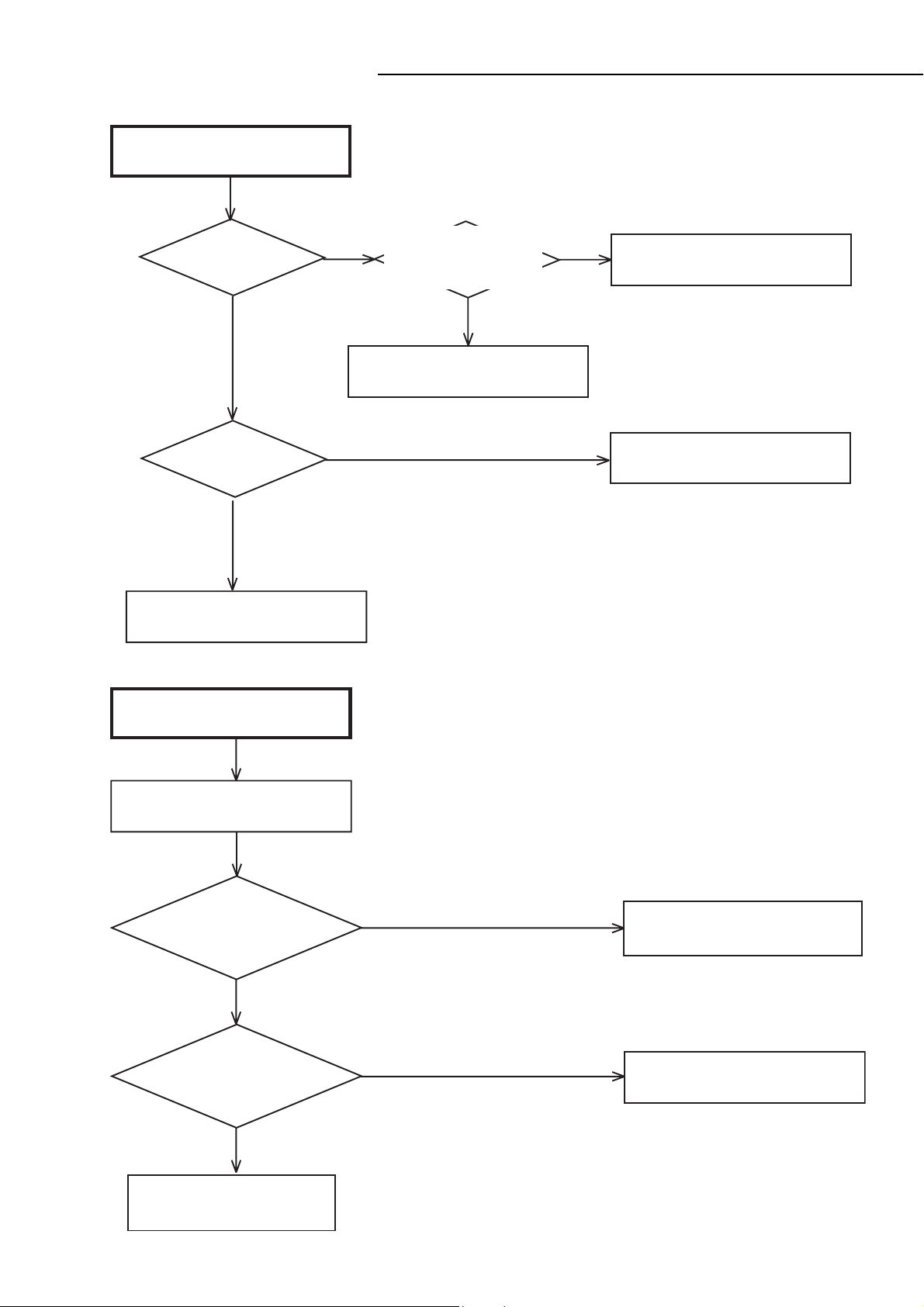

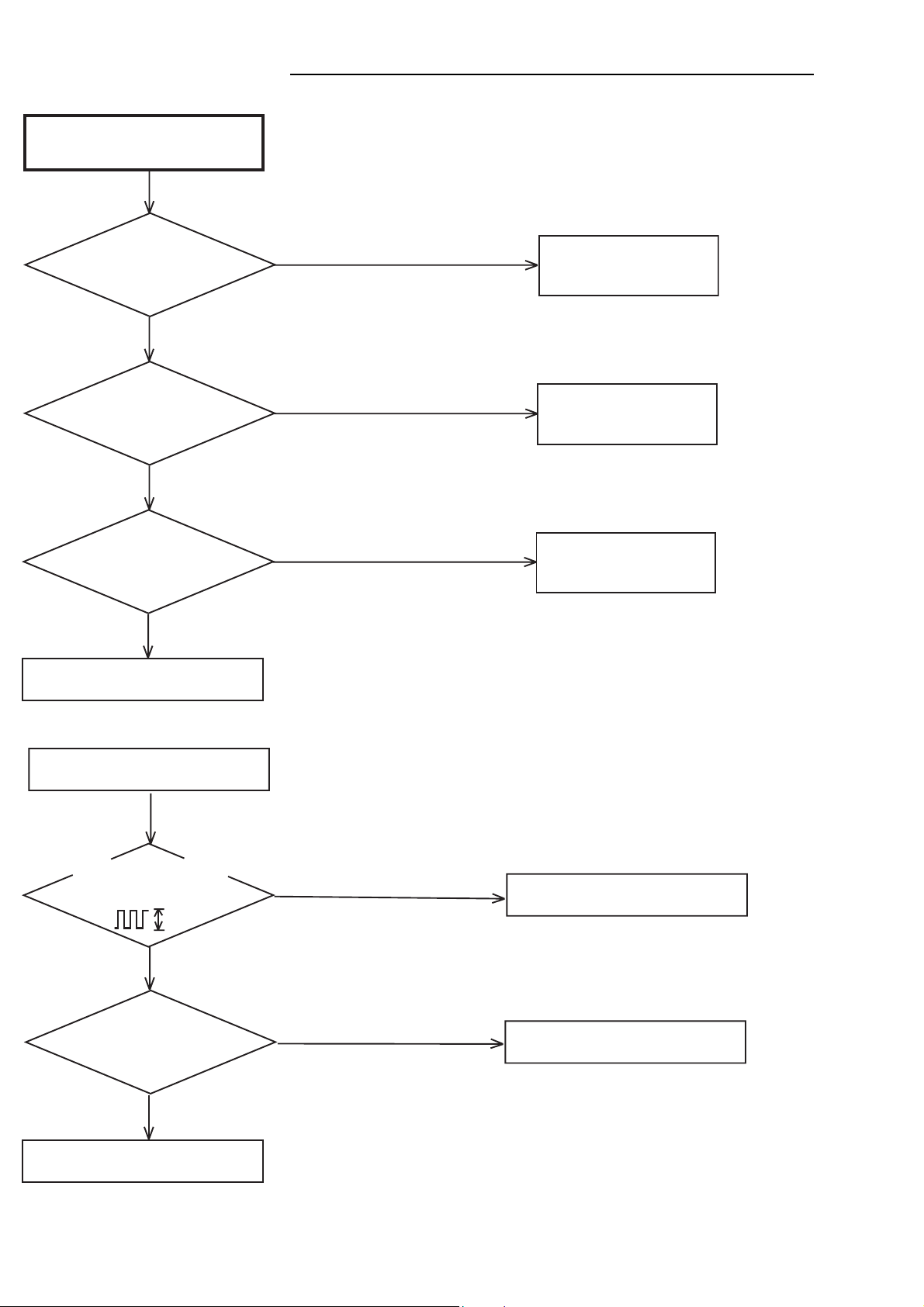

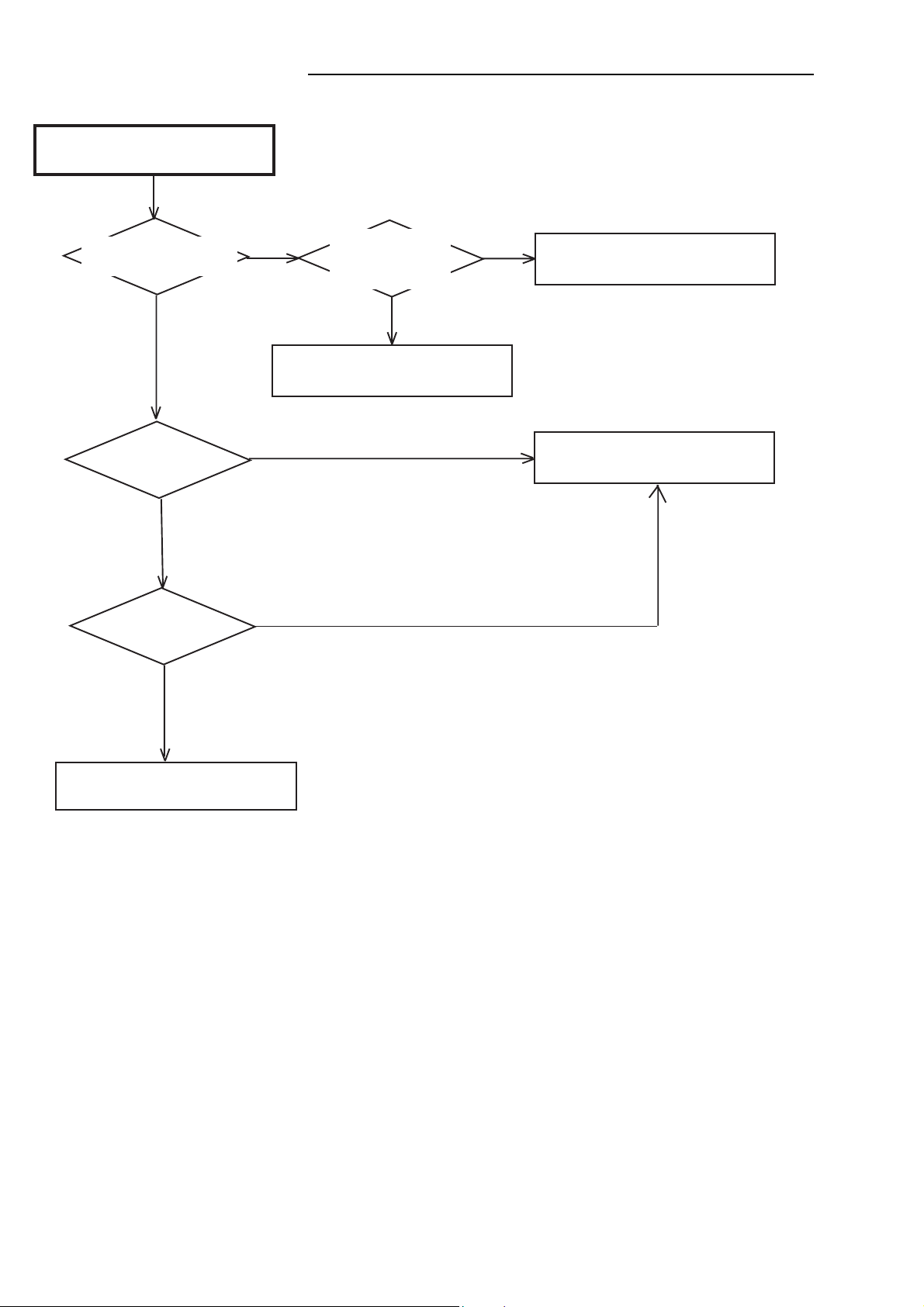

TROUBLE SHOOTING GUIDE

(VCR SECTION)

POWER DOES NOT TURN ON

Does display light?

YES

Is there voltage at

pin 16 of IC 3001?

YES

Check of T501

and peripheral circuit.

NO

NO

Is the voltage

linked to 1, 2, 3, 8 pin

of CP502?

YES

Check IC651.

NO

Check of T501

and peripheral circuit.

Check IC3001.

THE POWER SUPPLY CUT

Inserting a casette

and push play button.

Does the power cut

after 3 seconds?

NO

Does the power cut

after about 6 seconds?

NO

YES

YES

Check CAPSTAN DD UNIT

and CYLINDER UNIT.

Check Q3001,Q3002

and CAPSTAN BELT.

Check the POWER BLOCK.

- 26 -

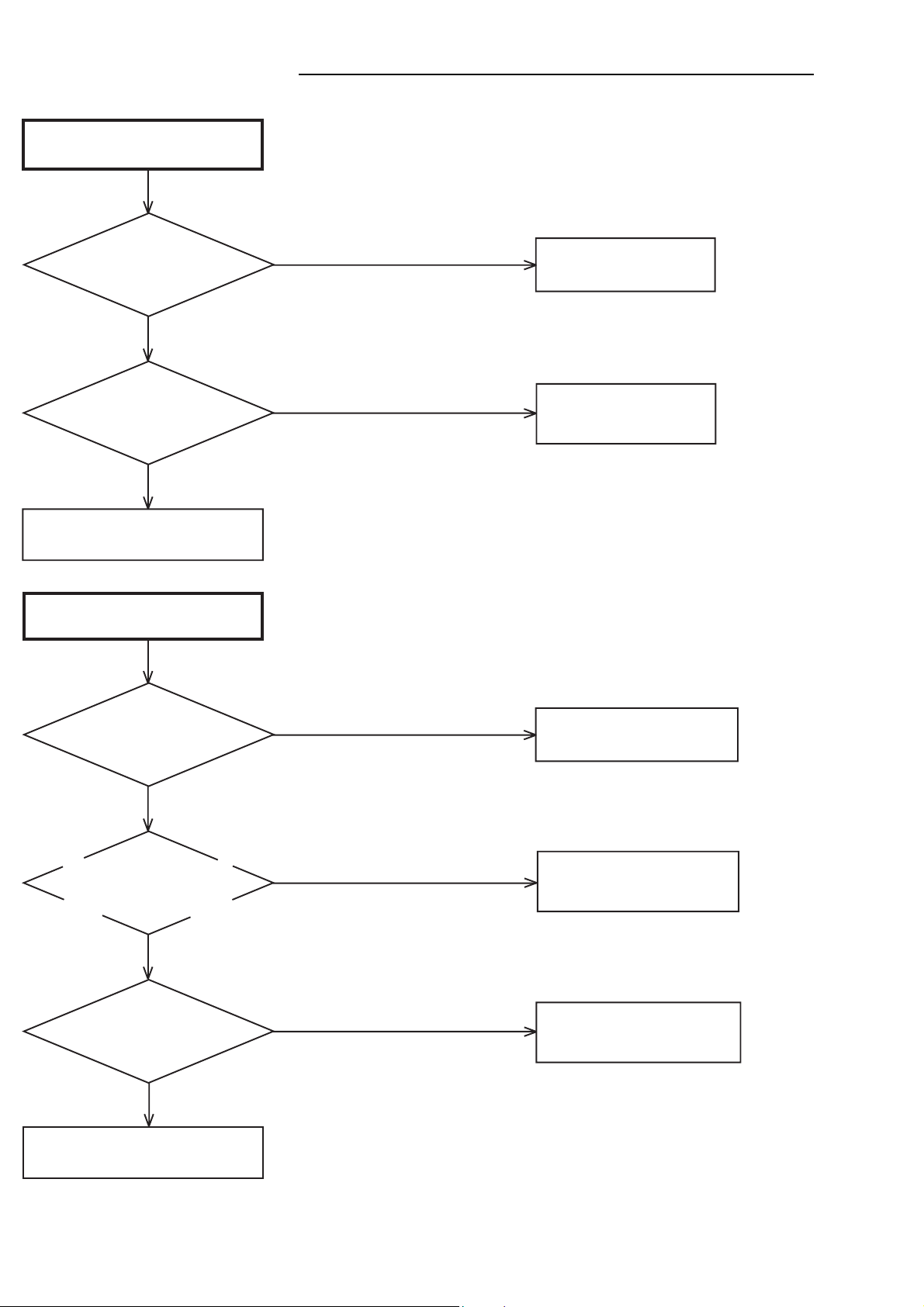

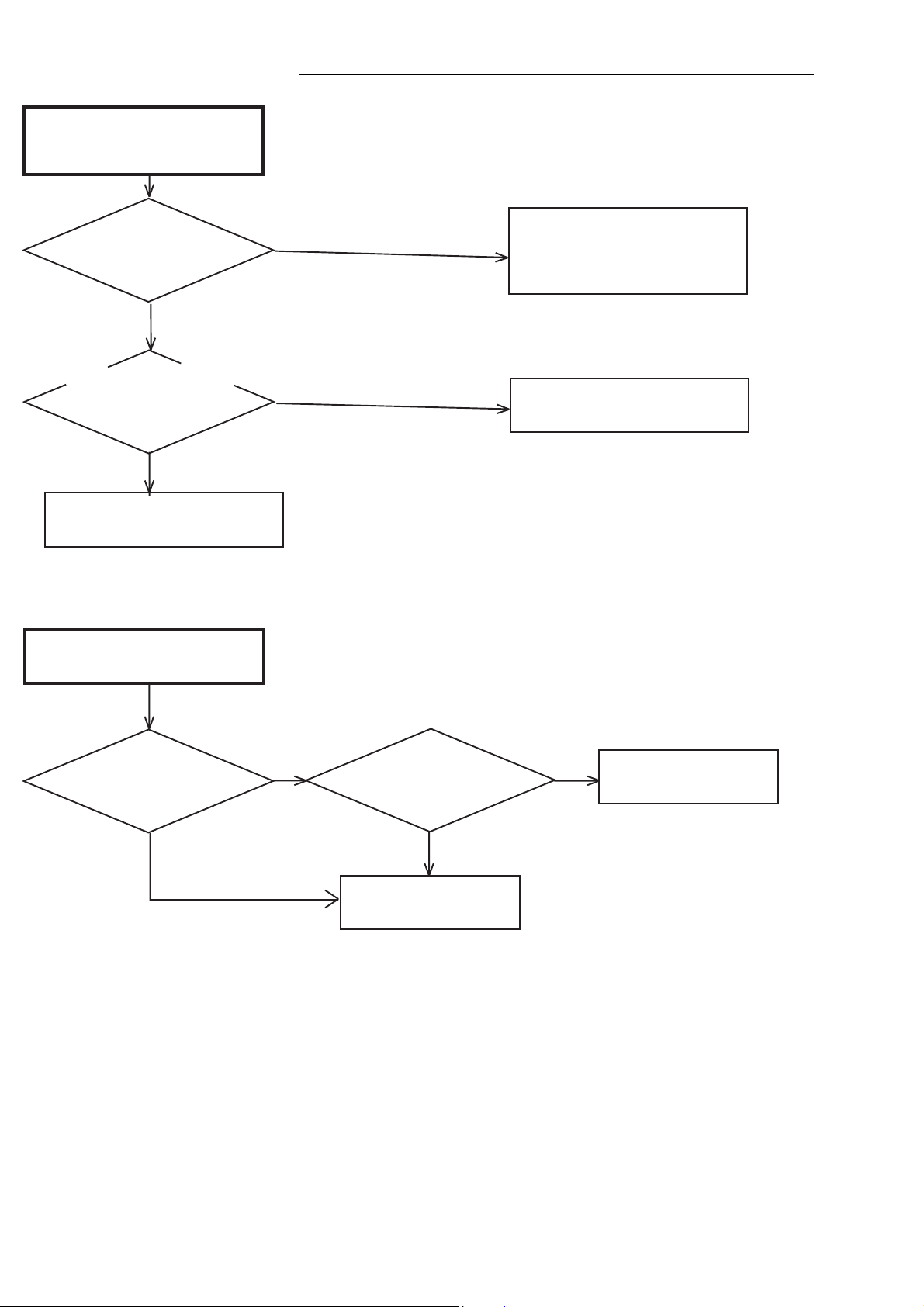

Page 28

TROUBLE SHOOTING GUIDE

AT PLAYBACK AND RECORDING,

CYLINDER MOTOR UNLOAD

Is the voltage at pin 8 of

CP3001 about DC12.6V?

YES

In playback,is at pin 12 of

CP3001 about DC2.6V?

YES

Check the DECK BLOCK.

AUDIO SHAKES

NO

NO

Check T501.

Check IC3001.

Is AUDIO HEAD

scratched?

NO

At playback,is input about

4.5Vp-p of a rectangular

wave at pin 87 of IC3001?

YES

At playback,is pin 5 of

CP3001 3.5V?

YES

Check AUDIO BLOCK.

YES

NO

NO

Change AUDIO HEAD.

Change CAPSTAN DD UNIT.

Check IC3001.

- 27 -

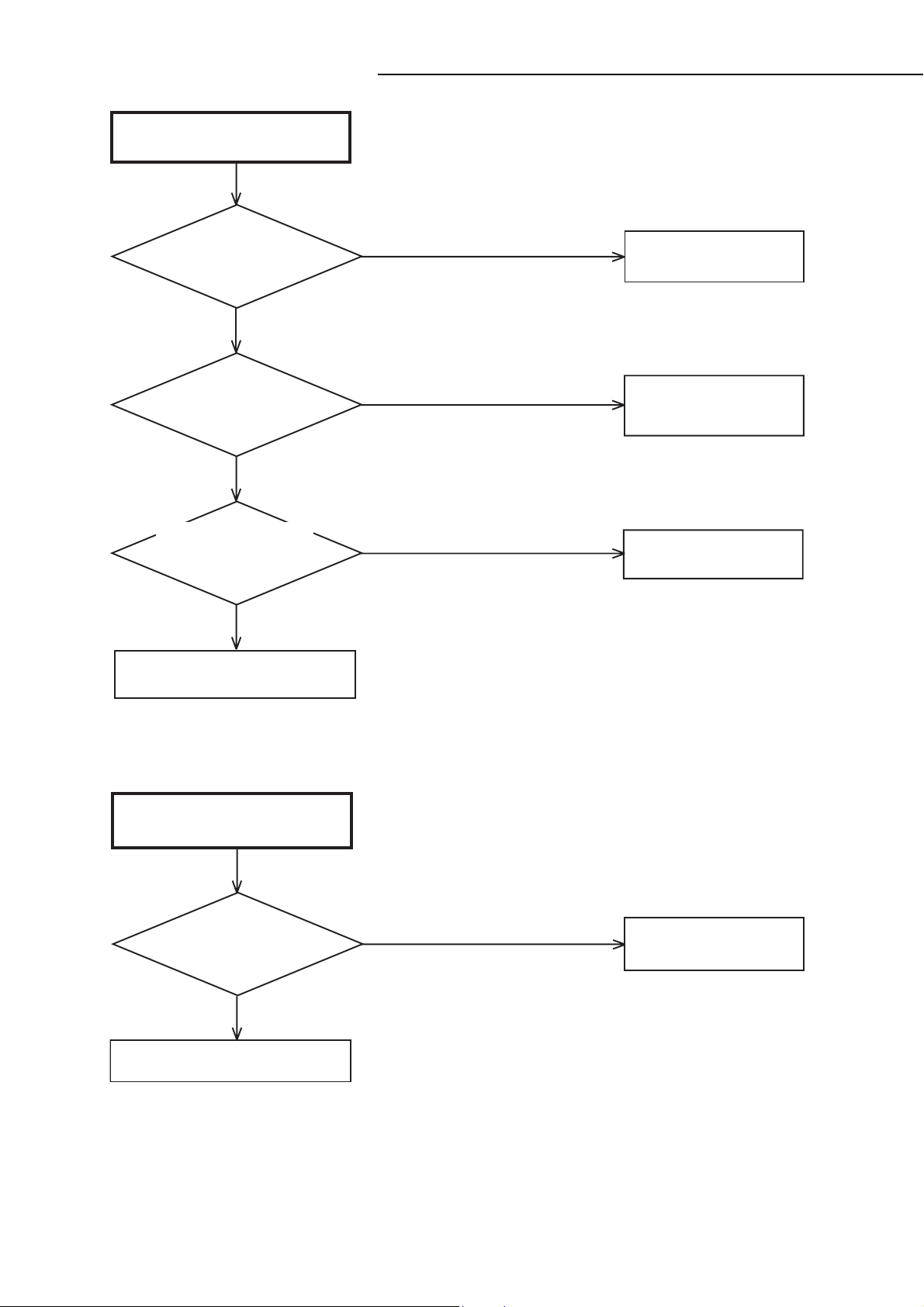

Page 29

TROUBLE SHOOTING GUIDE

The CASSETTE TAPE

CAN NOT BE INSERTED

Does WORM GEAR of

cassette loading block

move?

YES

When a CASSETTE can

not inserted, is pin 4 of

IC3001 5V ?

YES

When a CASSETTE is

inserted, is pin 8 of

CP3001 12.6V ?

NO

Check circuit of POWER BLOCK.

NO

NO

YES

Check WORM GEAR

of cassette loading block.

Check LED of DECK,

PHOTO SENSOR.

Change

LOADING MOTOR.

CAN NOT FF/REW

At FF/REW, does voltage

at pin11 of IC3001

change?

YES

Check DECK MECHANISM.

NO

Check of IC3001.

- 28 -

Page 30

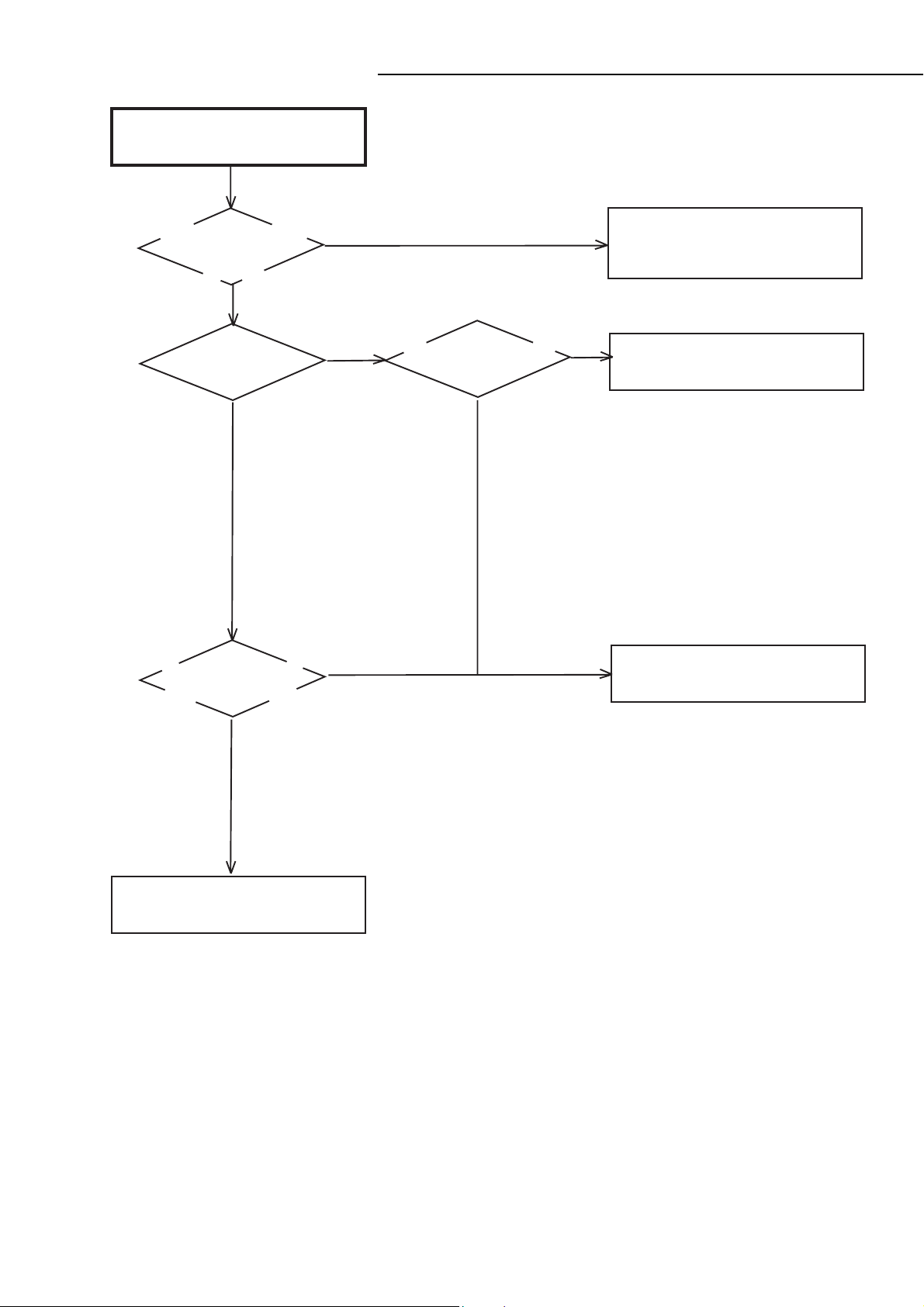

TROUBLE SHOOTING GUIDE

WHEN INSERTING A CASSETTE,

IT EJECTS IMMEDIATELY

Does another CASSETTE

insert?

YES

Does SW3001 and

REC LEVER

correctly set ?

YES

After inserting

CASSETTE, is pin 84

of IC3001 0V ?

YES

Check IC3001.

NO

NO

NO

Defective CASSETTE

or cassette loading block.

Correctly SW3001

and REC LEVER set.

Check SW3001.

AT PLAY, THE PICTURE

JITTERS VERTICAL MINUTELY

Is FG wave of CP3001

at pin 11 5V ?

5V

YES

Is pin 12 of CP3001 2.6V ?

YES

Change CYLINDER MOTOR.

NO

NO

Change

CYLINDER MOTOR.

Change IC3001.

- 29 -

Page 31

TROUBLE SHOOTING GUIDE

TAPE LOADING IS OK, BUT

UNLOADS IMMEDIATELY

Does CYLINDER

rotate?

YES

Is there HEAD SW

PULSE at TP102.

YES

NO

NO

Is the voltage

at pin 10 of CP502

13V ?

YES

At play, is the voltage

at pin 12 of CP3001 2.6V ?

YES

Change CYLINDER unit.

NO

Is PG PULSE signal

inputted to pin 90

of IC3001 ?

YES

NO

NO

Check POWER BLOCK.

Check Q3001 and Q3002.

AUTO TRACKING

DOES NOT OPERATE

In auto tracking, is the

voltage at pin 6 of IC3001

more than DC 0.2V?

YES

NO

Change IC3001.

Does the CTL pulse

signal (about 2.5Vp-p)

appear at pin 97 of IC3001.

2.5Vp-p

YES

NO

Check CONTROL HEAD.

Change IC3001.

- 30 -

Page 32

TROUBLE SHOOTING GUIDE

WHEN PLAYBACK, FF OR REW

MODE IS ACTIVE, UNIT STOPS

IMMEDIATELY

Does CAPSTAN DD

MOTOR rotate?

YES

Is there REEL SENSOR

PULSE signal at pin 79

and pin 80 of IC3001.

YES

Change IC3001.

AT PLAYBACK, THE COLER DOES

NOT APPEAR

NO

NO

Refer to section "CAPSTAN

DD MOTOR NOT

ROTAING".

Check Q3008 and Q3009.

Is there color signal in

video signal at pin 29 of

IC101.

YES

NO

Is there video signal at pin

29 of IC101.

YES

Change IC101.

NO

Change X'tal.

- 31 -

Page 33

TROUBLE SHOOTING GUIDE

AT PLAY, PICTURE JITTERS

HORIZONTALLY

NO

Does a noise on the picture

appear?

YES

By adjusting the MANUAL

TRACKING UP/DOWN

BUTTONS, will the line

disappear?

YES

Is a height of GUIDE POST

maximum?

YES

Is PG SHIFTER

adjustment 6.5H?

NO

NO

NO

Check P/B ENVELOPE.

The height of GUIDE POST

readjust.

Adjust PG SHIFTER.

YES

Is a wave of PB-Y unusual?

YES

Change IC101.

NO

Change IC101

and peripheral circuit.

- 32 -

Page 34

TROUBLE SHOOTING GUIDE

AT PLAYBACK, THE PICTUER

DOES NOT APPEAR

Does E-E picture

appear?

YES

Is there video signal

of IC101 at pin 29?

YES

Is there video signal

of IC3001 at pin 52?

YES

Is there video signal

of IC8001 at pin 25?

NO

NO

NO

NO

Is the voltage of IC101 at

pin 4, 22, 47, 59, 60,and 84

5V?

YES

NO

Check POWER BLOCK.

Change IC101.

Change IC3001.

Change IC8001.

YES

Check J8004.

NO COLER DURING SELF

RECORDING AND PLAYBACK

Is there CHROMA signal at

pin 17, 19 and 21 of IC101.

YES

Is there CHROMA signal at

pin 29 of IC101.

NO

NO

Check TU301, J653,J8004

IC8001 circuit around it.

Change IC101.

YES

Check circuit around of J8004.

- 33 -

Page 35

TROUBLE SHOOTING GUIDE

PLAYBACK PICTURE IS NOISY

(EVEN AFTER CLEANING HEADS)

Is noisy a wave of video

signal at pin 29 of IC101?

YES

Is noisy a wave of video

signal at pin 25 of IC8001?

NO

Check J8004.

CAPSTAN DD MOTOR NOT

ROTATING

NO

YES

Check CYLINDER.

Check IC8001.

In playback,is there voltage at

pin 2 of IC3001 12V?

YES

In playback,is there voltage at

pin 78 of IC3001 2.5V?

YES

DD MOTOR rotate now?

If not, replace it.

NO

NO

Check POWER BLOCK.

Change IC3001.

- 34 -

Page 36

TROUBLE SHOOTING GUIDE

AT PLAY, AUDIO DOES NOT

APPEAR

At E-E, does audio appear?

YES

Is the voltage at pin 97 of

IC101 about 2.5V?

YES

Is there audio signal at pin

6 of IC101?

YES

Is there audio signal at pin

24, 27 of IC701?

NO

NO

NO

YES

Refer to section"E-E DOES

NOT APPEAR".

Check A/C HEAD.

Check circuit around at pin

6 of IC101.

Check circuit around at pin

24, 27 of IC701.

NO

Check whether there are not a

damage, dirt in AUDIO HEAD.

- 35 -

Page 37

TROUBLE SHOOTING GUIDE

THE AUDIO CAN NOT RECORD

Is bias level at L102 OK?

YES

Is there audio signal at

pin 1 of IC101?

YES

Is there voltage of

base of Q101 about

5V?

YES

NO

NO

In starting recording,

is there sine wave at

pin 98 of IC101?

Check disconnection and short

of L102.

YES

NO

Check POWER BLOCK and

voltage of base of Q101.

Check IC701 and

the circuit from TUNER

or audio input juck to IC01.

Change Q101.

Is there Asin wave at

pin 5 of L101?

YES

Check lead wire of A/C HEAD

and CONNECTOR.

NO

Change L102.

- 36 -

Page 38

TROUBLE SHOOTING GUIDE

THE CASSETTE INSERT, BUT

THE TAPE DOES NOT MOVE

Does the mode

appear at display?

YES

Does operate with

remote control?

YES

Check operation PCB.

NO

NO

Check LOADING MOTOR and

MODE SENSOR

RELATION DEPARTMENT.

Check IC3001.

- 37 -

Page 39

TROUBLE SHOOTING GUIDE

RECORDING MECHANISM WORKS,

BUT NO VIDEO RECORD FROM

INPUT JACK OR TUNER

Is there video signal at

pin 17, 19 and 21 of

IC 101?

YES

Is the BASE of

Q101 5V?

YES

Is there video signal

at pin 29 of IC101?

NO

NO

NO

Is the voltage at pin 41

of IC3001 5V?

YES

Check cricuit of video signal from

VIDEO IN or

TUNER to IC101.

NO

Change IC3001.

Change IC101.

YES

Check CYLINDER UNIT and

circuit around of CP101.

- 38 -

Page 40

TROUBLE SHOOTING GUIDE

E-E DOES NOT APPEAR

(THE PICTURE DOES NOT

APPEAR FROM TUNER)

Does normality AUDIO JACK

CONNECT?

YES

Are there thevoltage

of MB(5V), PB(5V),

TU(32V) of TU301?

YES

Check the picture.

Is there video signal at

pin 24 of TU301?

NO

NO

NO

Connection is done over again.

Check POWER BLOCK.

Change TU301.

YES

Is there video signal

at pin 29 of IC101?

YES

Is there video signal at

pin 52 of IC3001?

YES

Check J8004.

NO

NO

Change IC101.

Change IC3001.

- 39 -

Page 41

TROUBLE SHOOTING GUIDE

E-E AUDIO (MONO)

DOES NOT APPEAR

Does E-E AUDIO

(STEREO) appear?

YES

Is the voltage at pin 98

of IC101 5V?

YES

Is the voltage at pin 74

of IC3001 5V?

NO

Is there audio signal at

pin 11, 73 of IC701?

NO

NO

YES

NO

Refer to section "E-E AUDIO

(STEREO) DOES NOT APPEAR".

Check POWER BLOCK.

Change IC3001.

Check J651, J652.

YES

Is there audio signal at

pin 6 of IC701?

YES

Check circuit around of J8004.

NO

Change IC701.

- 40 -

Page 42

TROUBLE SHOOTING GUIDE

E-E AUDIO (STEREO)

DOES NOT APPEAR

Is the voltage at pin 5,32

of IC701 5V?

YES

Is the voltage at pin

3 of IC701 9V?

YES

Is there Audio signal at

pin 11, 73 of IC701?

YES

Is there Audio signal at

pin 78, 80 of IC701.

NO

NO

NO

NO

Check POWER BLOCK.

Check POWER BLOCK.

Check J651, J652.

Change IC701.

YES

Check circuit around of J8004.

- 41 -

Page 43

TROUBLE SHOOTING GUIDE

TUNER AUDIO (MONO)

DOES NOT APPEAR

Does E-E AUDIO

(MONO) appear?

YES

Is there signal at pin

38 of IC801?

YES

Is there audio signal at

pin 78, 80 of IC701?

YES

Is there audio signal at

pin 41, 44 of IC8001?

NO

NO

NO

NO

Refer to section "E-E AUDIO

(MONO) DOES NOT APPEAR".

Check circuit around of TU301

at pin 22.

Change IC701.

Check IC8001.

YES

Check circuit around of J8004.

- 42 -

Page 44

TROUBLE SHOOTING GUIDE

TUNER AUDIO (STEREO)

DOES NOT APPEAR

Does TUNER AUDIO

(MONO) appear?

YES

Does E-E AUDIO

(STEREO) appear?

YES

At the time of channel

change,does the display of a

stereo come out to the screen?

YES

Is there audio signal at

pin 38 of IC801?

NO

NO

NO

NO

Refer to section "TUNER AUDIO

(MONO) DOES NOT APPEAR".

Refer to section "E-E AUDIO

(STEREO) DOES NOT APPEAR".

Change IC701.

Check ciruit around of TU301.

YES

Is there audio signal at

pin78, 80 of IC701?

YES

Is there audio signal at

pin 41, 44 of IC8001?

YES

Check circuit around of J8004.

NO

NO

Change IC701.

Check IC8001.

- 43 -

Page 45

TROUBLE SHOOTING GUIDE

PB AUDIO (Hi-Fi)

DOES NOT APPEAR

Does E-E AUDIO

(STEREO) appear?

YES

Does NORMAL PB

AUDIO appear?

YES

Is there audio signal at

pin 24, 27 of IC701?

YES

Is there audio signal at

pin 78, 80 of IC701?

NO

NO

NO

NO

Refer to section "E-E AUDIO

(STEREO) DOES NOT APPEAR".

Refer to section "AT PLAY,

AUDIO DOES NOT APPEAR".

Check circuit of HEAD AMP

and CYLINDER UNIT.

Change IC701.

YES

Check circuit around of J8004.

- 44 -

Page 46

TROUBLE SHOOTING GUIDE

Hi-Fi AUDIO

CAN NOT RECORD

Does E-E AUDIO appear?

YES

AT state of video recording,

is there audio signal at

pin 11 and 73 of IC701?

YES

Is there audio signal at

pin 78, 80 of IC701?

YES

At recording and play,is

there signal at pin 7, 8

and 9 of CP101?

NO

NO

NO

NO

Refer to section "E-E AUDIO

(MONO) DOES NOT APPEAR".

Check circuit arounf of J651,

J652 and TU301.

Change IC701.

Check CYLINDER UNIT.

YES

Check IC701.

- 45 -

Page 47

TROUBLE SHOOTING GUIDE

(RADIO SECTION)

NO SOUND OF RADIO

Is the voltage linkd to

8,10 pin of CP8003?

Yes

Is there a waveform at

65,67 pin of IC701

Yes

Check of IC701 and

perpheral circuit.

(DVD SECTION)

DECK DOES NOT ACCEPT

OPEN/CLOSE

No

No

Check of POWER BLOCK.

Check of RADIO PACK

and peripheral circuit.

Is the voltage at pin 3 and

14 of IC2301 about DC9V ?

Yes

Is the lose connection

at CD2602 & CD2603 to

DECK ?

No

Check loader block.

No

Yes

Check P.CON 9V line of

POWER BLOCK.

Check CD2602 & CD2603

connection to DECK.

- 46 -

Page 48

TROUBLE SHOOTING GUIDE

NO PLAYBACK PICTURE

OF AV JACK

Is there a oltage

(beam current) at

TP40 and TP42?

No

Is there a signal at

pin 9,10,11 and 12

of IC2601?

No

Is there a signal at

pin 9,10,11 and 12

of IC2601?

No

Yes

Yes

Yes

Check loader block

Check CP2601

and peripheral circuit.

Check IC2601

and peripheral circuit.

.

Is there video signal

at pin 159 of IC4001?

No

Change IC4001.

NO AUDIO ON PLAYBACK

Is there AUDIO signal at

pin 9,10,11,12,13 and 14

of IC7302 ?

No

Yes

Yes

Check IC8001

and peripheral circuit.

Check IC7302 and

peripheral circuit.

Change IC4001.

- 47 -

Page 49

TROUBLE SHOOTING GUIDE

NO PLAYBACK PICTURE OF

S-VIDEO JACK

Is there Y signal at

pin 161 of IC4001 ?

No

Is there VIDEO signal

at pin 162 of IC4001 ?

Yes

Change IC4001.

NO COLOR PLAYBACK PICTURE

OF S-VIDEO JACK

Yes

No

Check J8101 and peripheral

circuit.

REFER TO "NO PLAYBACK

PICTURE OF AV JACK ".

Is there C signal at

pin 162 of IC4001 ?

No

Is there Y signal at

pin 161 of IC4001?

Yes

Is there VIDEO signal

at pin 162 of IC4001?

No

Is the voltage at pin 25,

64, 93,123,140 and 192

of IC4001 about 1.8V?

Yes

No

Yes

No

Check J8101 and peripheral

circuit.

REFER TO "NO PLAYBACK

PICTURE OF S-VIDEO JACK".

REFER TO "NO PLAYBACK

PICTURE OF AV JACK" .

Check P.CON+3.3V line on

POWER BLOCK.

Yes

Change IC4001.

- 48 -

Page 50

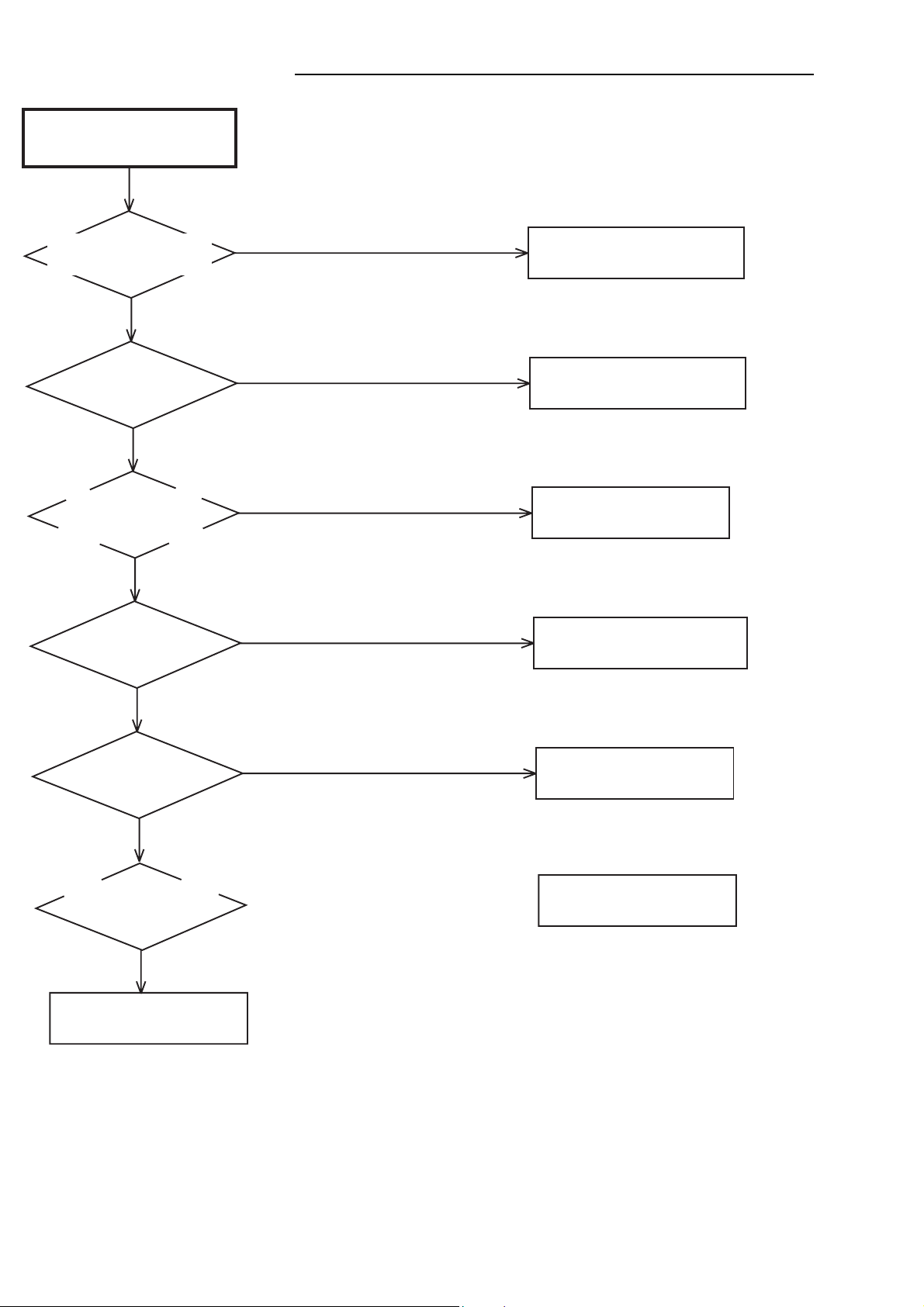

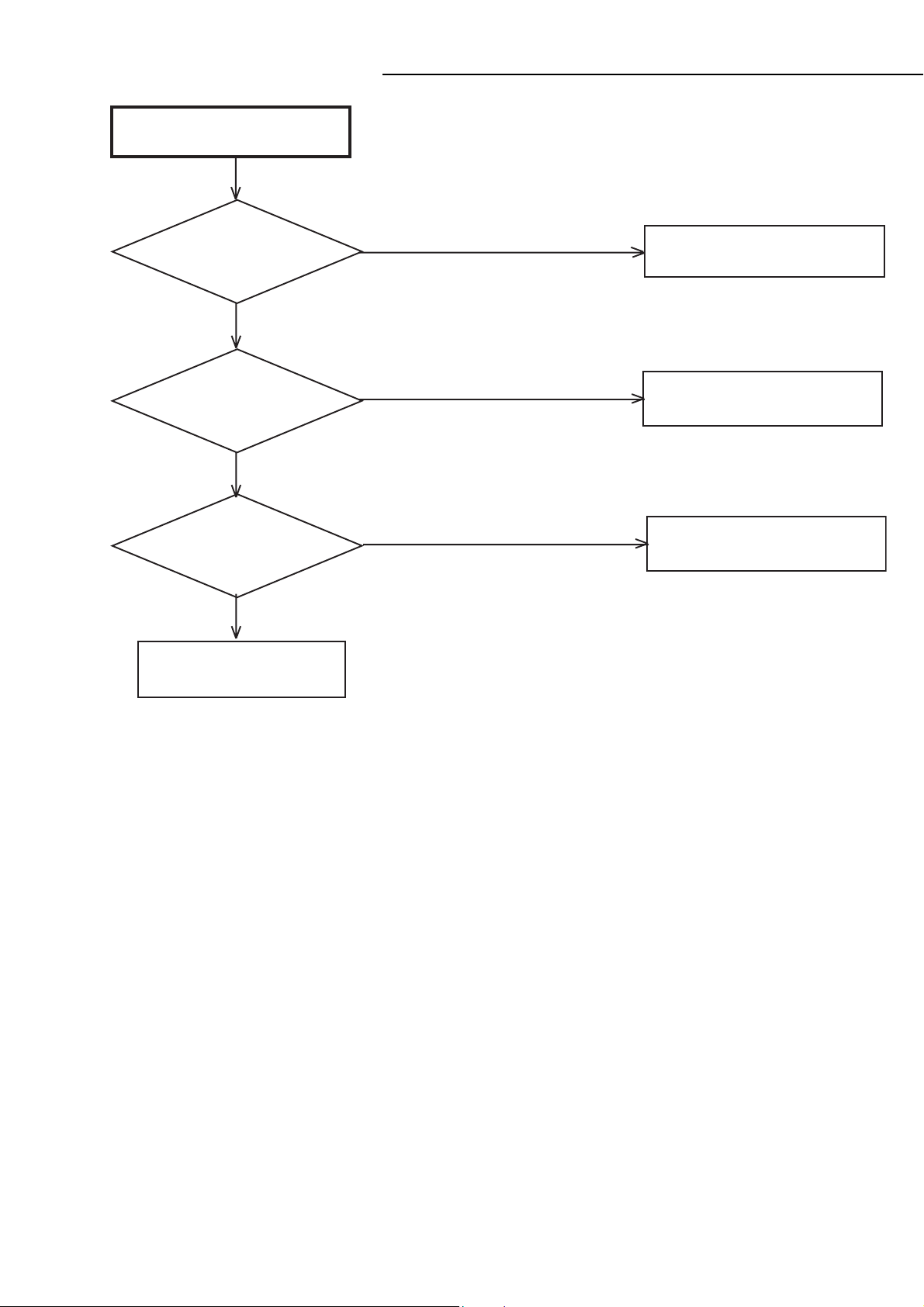

TROUBLE SHOOTING GUIDE

(SPEAKER SECTION)

ALL SPEAKER NO SOUND

Is there voltage at

CP5502 and CP5503?

YES

Is there voltage at

pin 9 of J5501?

YES

Is there voltage at

pin 8 of J5501?

NO

Check SPEAKER MAIN PCB.

NO

YES

Check of fuse.

F5402 ~ F5404

(Open?)

YES

NO

Check of CD5403

and CD5404.

Check DVD/VR SET.

Check of mute circuit.

- 49 -

Page 51

TROUBLE SHOOTING GUIDE

FRONT SPEAKER NO SOUND.

Is there waveform at

pin 6 and 7 of J5501?

YES

Is there voltage at

pin 1,3,6 of IC5501?

YES

Is there voltage at

pin 5 of IC5501?

Check of IC5501.

YES

NO

NO

NO

Check DVD/VR SET.

Check of DIODE.

D5502 ~ D5509

Check Q5515.

- 50 -

Page 52

TROUBLE SHOOTING GUIDE

SURROUND SPEAKER NO SOUND.

Is there waveform at

pin 4 and 5 of J5501?

YES

Is there voltage at

pin 1,3,6 of IC5502?

YES

Is there voltage at

pin 5 of IC5502?

YES

Check of IC5502.

NO

NO

NO

Check DVD/VR SET.

Check of DIODE.

D5502 ~ D5509

Check Q5517.

- 51 -

Page 53

TROUBLE SHOOTING GUIDE

CENTER SPEAKER NO SOUND.

Is there waveform at

pin 3 of J5501?

YES

Is there voltage at

pin 7,8,13,15 of IC5503?

YES

Is there voltage at

pin 9,10 of IC5503?

YES

Check of IC5503.

NO

NO

NO

Check DVD/VR SET.

Check of DIODE.

D5502 ~ D5509

Check Q5512.

SUB WOOFER SPEAKER

NO SOUND.

Is there waveform at

pin 2 of J5501?

YES

Is there voltage at

pin 7,8,13,15 of IC5504?

YES

Is there voltage at

pin 9,10 of IC5504?

NO

NO

NO

Check DVD/VR SET.

Check of DIODE.

D5501

Check Q5513.

YES

Check of IC5504.

- 52 -

Page 54

RE-WRITE FOR DVD FIRMWARE

Turn on the power, and set the DVD mode.

1.

Confirm that the “No Disc” will be appeared on the screen.

2.

Open the DVD tray.

3.

Press both Channel button (6) on the remote control and the REC button on the set for more than 2 seconds.

4.

Press OPEN/CLOSE button on the unit to check if all the keys on the unit do not function.

5.

NOTE: To check if DVD Write mode is set.

Up-Date can be done at Non DVD Write mode. But the read error may occur.

Place the Up-Date Disc and close the tray by hand. (Refer to SERVICING FIXTURE AND TOOLS)

6.

Automatic read will start and "Firmware upgrade" will be displayed on the screen.

7.

Approxi. 60 seconds later, the tray will open automatically. Remove the Up-Date Disc.

8.

Then, Approxi. 50 seconds later, the above indication will disappear and the tray will close automatically.

9.

When the "No Disc" appears on the screen, the write will end.

NOTE: Do not turn off the unit on the way or push the tray by hand to close it.

Up-Date error will happen and can not be done with the Up-Date of Up-Date Disc.

Unplug the AC cord, then plug it in.

10.

After the write, set to the initializing of shipping.

11.

Set to the DVD mode, press both Channel button (4) on the remote control and the REC button on the set for more than 2

seconds.

The "INITIALIZE 7 ---> COMPLETE" will appear on the screen.

Then unplug the AC cord, and plug it in.

12.

CHECK FOR THE FIRMWARE VERSION

13.

Set to the DVD mode, press both Channel button (1) on the remote control and the STOP button on the set for more than 3

seconds.

Firmware version will be displayed on the top left of the screen.

When the changed version displays, the Re-write will be completed.

14.

Turn off the power

No Disc

GMJ36101

G M J 3 6 1 0 1

Fixed

Released times on the same date

Release date (Example: 2003.6.10)

When the changed version displays, the Re-write will be completed.

A = October

B = November

C = December

- 53 -

Page 55

EXPLODED VIEW (CABINET & CHASSIS)

205

205

205

126

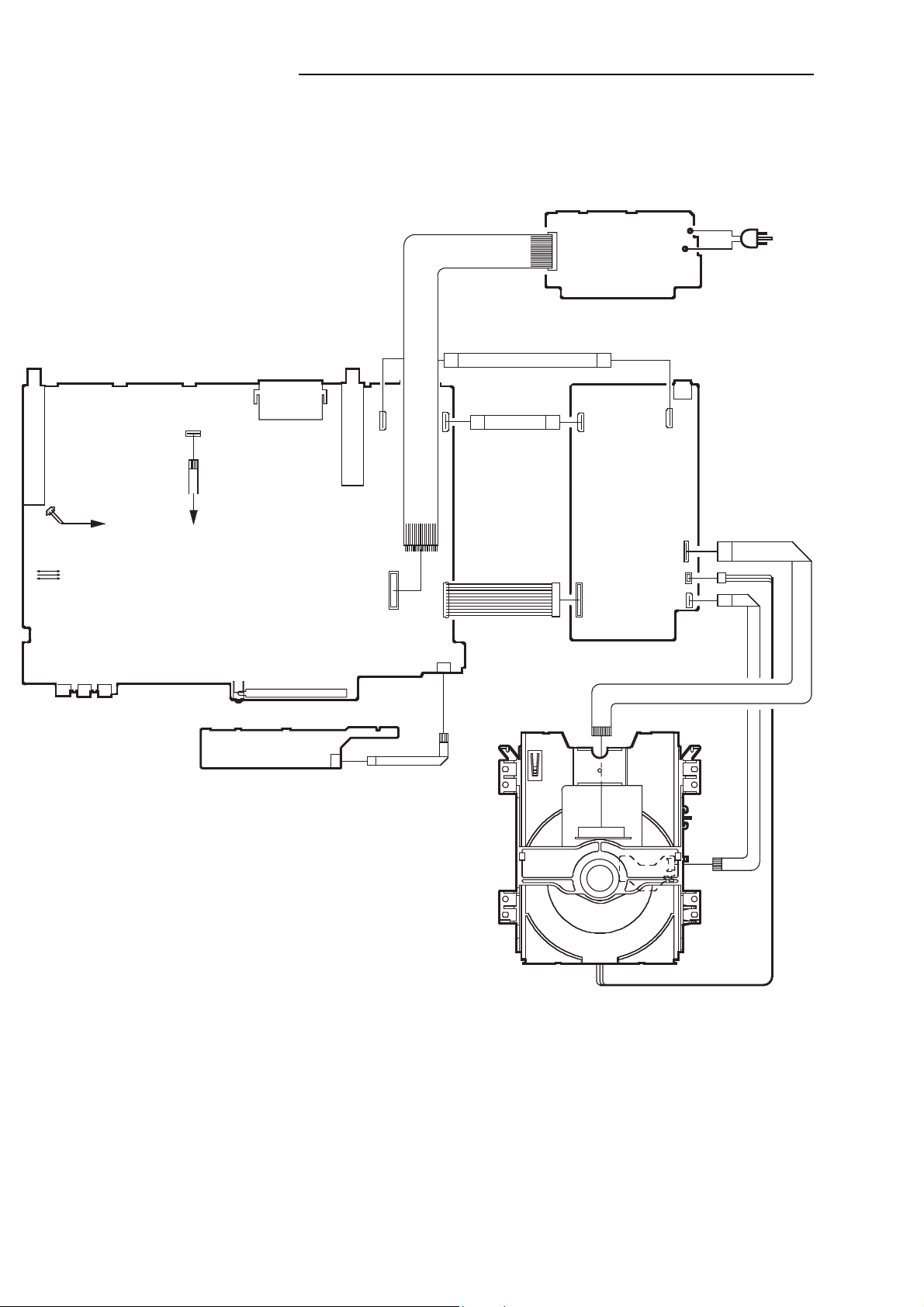

132

201

118

130

202

201

115

105

104

103

109

102

CD102

109

125

CD8002

103

203

107

CP1702

PCB010

(VCR PCB ASS'Y)

127

208

123

108

CD8001

CD502

204

202

116

106

204

110

124

209

208

208

PCB240

117

(POWER PCB ASS'Y)

203

202

206

123

205

CD501

204

119

PCB130

(DVD PCB ASS'Y)

202

112

205

101F

101K

101H

101B

128

101G

129

101C

101A

101D

101G

101F

101H

101E

101K

101C

101I

101J

101

101I

202

207

CD651

207

PCB270

(OPERATION PCB ASS'Y)

120

- 54 -

202

111

131

202

121

114

204

113

206

204

122

208

Page 56

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH THE

!!

IEC SYMBOL

BE OF SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED BY

DESIGNATED, OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT ARE DESIGNATED IN

THE PARTS LIST IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST BE MADE TO DETERMINE

THAT EXPOSED PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT BEFORE RETURNING THE PRODUCT TO

THE CUSTOMER.