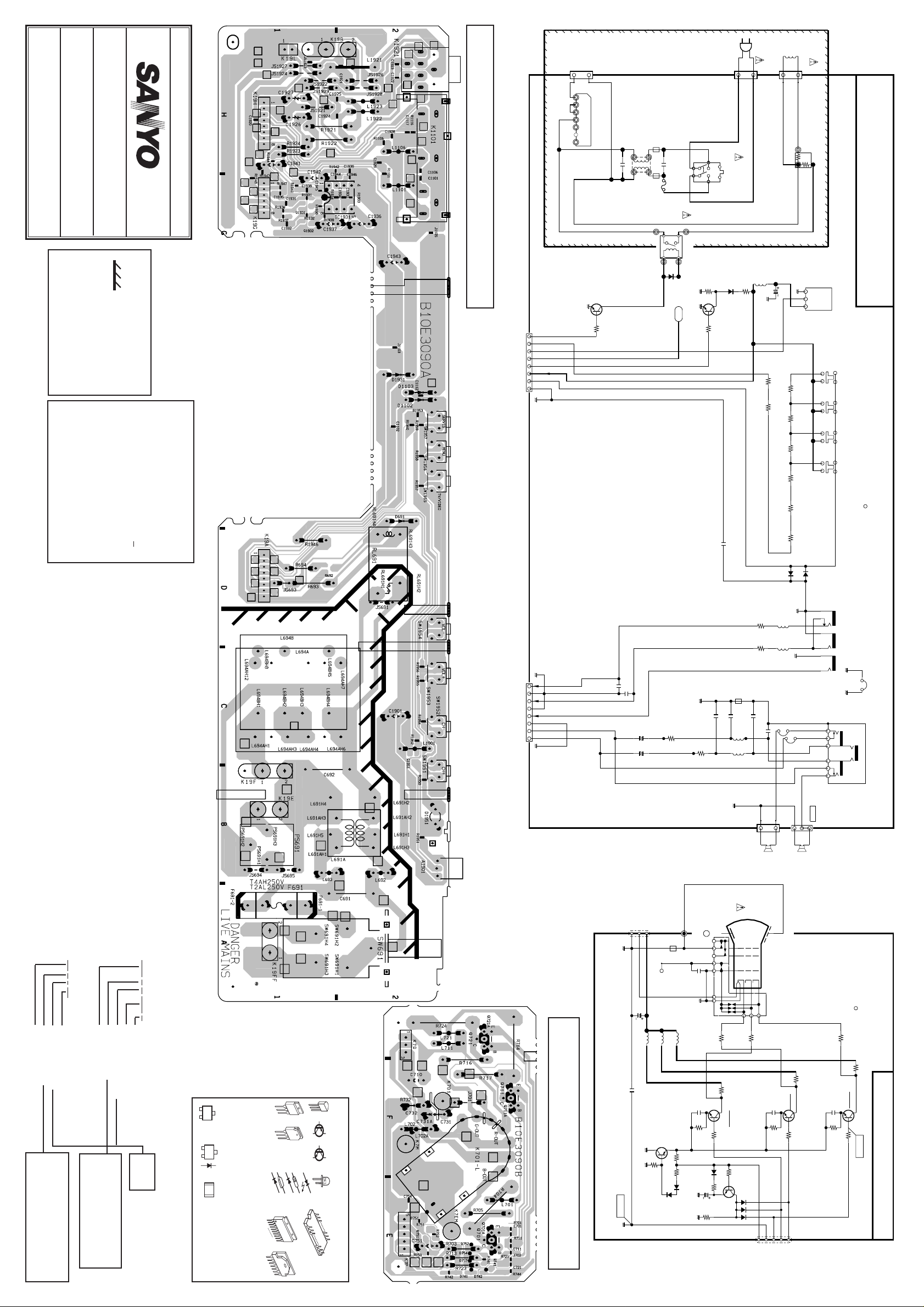

Page 1

Part No. SKP20370 C3YFV (SHEET 1-3)

COLOUR TELEVISION

EE

EE

BB

BB

77

77

--

--

AA

AA

SERVICE REF.NO.

MODEL NUMBER

CHASSIS SERIES

CE32WN5F-C-04

CE32WN5F-C

The service Precaution:

The area enclosed by this line

( ) is directly connected

with AC mains voltage. When

servicing the area, connect an

isolating transformer between

TV receiver and AC line to elim-

inate hazard of electric shock.

Product safety notice:

Product safety should be considered

when a component replacement is

made in any area of a receiver.

Components indicated by a mark /!\ in

this circuit diagram show components

whose values have special significance

to product safety. It is particularly rec-

ommended that only parts specified on

the part service manual be used for

components replacement pointed out

by the mark.

Circuit diagram notes :

1. All resistance values are in ohms, K=1,000, M=1,000,000.

2. All resistance rated wattages are 1/6W unless otherwise noted.

3. Excepting electrolytic capacitors, all capacitance values of less

than 1 are expressed in µF and more than 1 are pF.

4. All capacitance rated voltages are 50V unless otherwise noted.

5. All inductance values are in µH.

6. Voltage readings taken a digital voltmeter are from point indi-

cated chassis ground. Voltage readings taken by using a colour

bar signal are with all controls at normal position. Some volt-

ages may vary with signal strength.

7. Waveforms were taken with colour bar and controls adjusted

for normal picture. Waveforms were taken by using a wide

band oscilloscope and a low capacity probe.

8. This circuit diagram covers a basic or

representative chassis only. There

may be some components or partial

circuit differences between the actual

chassis and the circuit diagram.

9.■ Diode 1S1555 may be replaced with

1S2473,1S2076 or DS472 unless

otherwise noted.

■ Transistor 2SC536(Q,R,S),

2SC1740(Q,R,S), 2SC945A(Q,R,P)

or 2SC1815(G,O,Y) unless other-

wise noted.

■ Transistor 2SA608(E,F) may be

replaced with 2SA933(Q,R),

2SA564(QA,RA), or 2SA1015(O,Y)

unless otherwise noted.

Expression of capacitance and resistance in circuit diagram.

Capacitance (Example)

1000 C M 2000 D

Characteristic

Capacitance value (220pF)

Tolerance (±20%)

Kind(Ceramic)

Rated voltage (1,000V)

Resistance (Example)

1/2 N J 1.2

Resistance value (1.2Ω)

Tolerance (±5%)

Kind (M.carbon)

Rated wattage(1/2W)

D : Carbon

N : Metallized carbon

S : Oxide metallized

W : Wire wounding

C : Solid

T, A, U, D : Electrolytic

C, K, B : Ceramic

F : Mylar film

M, N : Polypropylene

Z : Metallized paper

J= ± 5%

K= ± 10%

M= ± 20%

FRONT BOARD

CRT BOARD

Terminal guide

C : Collector

B : Base

E : Emitter

A : Anode

K : Kathode

Chip Components

AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3

AT3

AT3AT3AT3AT3

AT3

AT3

L26B4480N

L694B

AT3

AT3

J30B0250N

J30B0250N

AT3

AT3

TO_MAIN

KF

K19F-1

K19F-2

123

2400030

L694BH1

2400030

L694BH2

2400030

L694BH3

4

2400030

L694BH4

5

2400030

L694BH5

78

2400030

L694BH8

AT3

AT3

AT3

AT3

250HM0.1XD

:250GM0.1XBJ

:250MK0.1VA

AT3

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

AT3

2400030

L691AH2

2400030

L691AH3

F35B1020N

C692

AT3

AT3

Q1951/Q692

2SC2812NL6P:

2SC2412KR:

AT3

Z20103---

L692

2400030

L691AH1

2400030

L691H3

F35B0570N:

L691A

L693

Z20103---

J3EZ0333-

2400030

RL691H2

AT3

AT3

1SS133

D691

AT3

:250GM0.1XBJ

:250MK0.1VA

F691-2

F691-1

J20B00100:

J20B0170J:

2400030

RL691H3

RL691H4

AT3

AT3

250HM0.1XD

C691

2400010

SW691H3

SW691H4

2400010

4A250

VTCSL

F691

RL691H1

2400030

S20B0460N

RL691

2400030

AT3

SW691H1

2400010

2400010

SW691H2

AT3

1/16GJ

2.2KC

AT3

AT3

R1951

AT3

W10B00100

W901

K19FF-1

J30B0250N

SW691

S10B5560N:

S10B5750N

AT3

AT3

1/16GJ

390C

AT3

R1950

K19FF-2

J30B0250N

AT3

L1901

J

AT3

L81B23500

16EM

100CD

AT3

AT3

L901

K19E-2

J30B0250N

J30B0250N

2400030

PS691H3

PS691H1

2400030

PS691

DHXAAEV0065

AT3

AT3

C1901

AT3

K19E-1

AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3 AT3

ASSY,PWB,FRONT C3YFV (1AA0B10E661BA)

PWB,FRONT C3AC (1AA4B10E3090A)

AT3AT3AT3AT3

AT3

AT3

AT3

TO_MAIN

KA

J11EH080N

K19A

1

8

POWER&

RL

KEY

RC

9V

LED 1

RC5V

GND

Q692

8.2K

R694

D1951

DLXRB0001653C

9V

Q1951

R1952

1/16GJ

47KC

1/16GJ

1.5KC

R1953

C1102

KK1000GQ

R1101

1/16GJ

2.2KC

330C

1/16GJ

R1960

1/16GJ

15KC

1/16GJ

8.2KC

1/16GJ

4.7KC

1/16GJ

2.7KC

1/16GJ

2.2KC

1/16GZ

0C

R1954

R1955

R1956

R1957

R1958

R1959

1SS133

D1103

AMP

RC

D1102

1SS133

A1901

U20B20900

SW1951

1170N

S10B

SW1952

1170N

S10B

- ++-

SW1953

1170N

S10B

VOLCH

SW1954

1170N

S10B

A4B10E30900

:A4B10E3090A

PB1901

TO_MAIN

KH

KK1000

GQ

C1929

GND

8

AV3-R

GND

AV3-L

GND

AV3-V

GND

L-IN

1

R-IN

J11EH080N

K19H

J10EA030N

K7Q

250EM22

CY

3

C710

KK1000

GQ

16PM

10P

16PM

10P

TO_MAIN

KQ

C1928

C1926

C1927

1

0250N

L721

J

J30B

K7D1

KK0.01

GQ

1/2

DJ150

R1922

1/2DJ150

1AA0W31B07300

W902

L702A

Z20103---

K7M

J30B0250N

C731

2000KZ

1000HE

L701

L711

J

J

C1925

R1921

GQ

275

-41

9

10

KK0.01

2.7K

2.2KC

L1921

Z21B0040N:

Z21B0710B

KK0.01GQC1923

C1924

L1922

L2C1120JN

L1923

L2C1120JN

:A10B15000

AT1

R717

1/2DJ

1/2DJ

2.7K

R716

1/16GJ

R1106

KK0.01GQC1922

J30B0250N

1

SP902

A10B22200

11

8

6

9100

L1101

L2B

KN

9100

L1106

L2B

KN

JS1928

J

K19R-2

J30B0250N

K19R-1

L-OUT

R-OUT

(W76EGV023X115)

BXXAVB114VIU

Q901

J11B3090N

K701-L

J31B01000

K1101

LRV

JS1929

J

J10EA020N

K19L

1

:A10B15000

A10B22200

SP901

A4B10E30900:

A4B10E3090B

1/2DJ

2.7K

R705

PB701

2SJ

12K

R704

1/16GZ0C

JS1923

J12B05400:

J12B04901

K1921

Q701/Q711/Q721

QT0392

QT0392

QT0392

R714

2SJ

220C

D752

1/16GJ

D753

KP

Q711

R711

D754

TO_MAIN

R-OUT

470

1

12K

R713

050N

K7P

J10EA

GQ

220C

KK560

1/16GJ

R701C701

470

R703

C732

KK1200

Transistor

B

C

E

Diode

A

123

12 x 10

3

= 12k

K

Resistor

B

C

E

B

C

E

K

1

2

3

9

10

1

2

3

4

5

6

7

K

A

A

N

E

C

B

B

C

B

E

A

K

1

E

C

N/2

N/2 + 1

Q741/Q751

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

TP-7E

680C

1/16GJ

R744

0C

0C

1/16GJ

1.2KC

Q741

1/16GZ

D741

D742

1/16GZ

GQ

R741

C721

KK560

1/16GJ

5.6KC

330CD

1/16GJ

10KC

R742

16EM

R753

220C

C751

1/16GJ

0C

R721

1/16GZ

R751

12K

Q721

470

R723

1SS355

D751

Q751

R724

2SJ

G-OUT

1/16GJ

10KC

R752

KK560GQC711

5

1SS3551SS355

1SS355

1AA4B10E3090B PWB,SOCKET,C3AC

1AA0B10E661BB ASSY,PWB,SOCKET,C3YFV

B-OUT

Q701

TP-7B

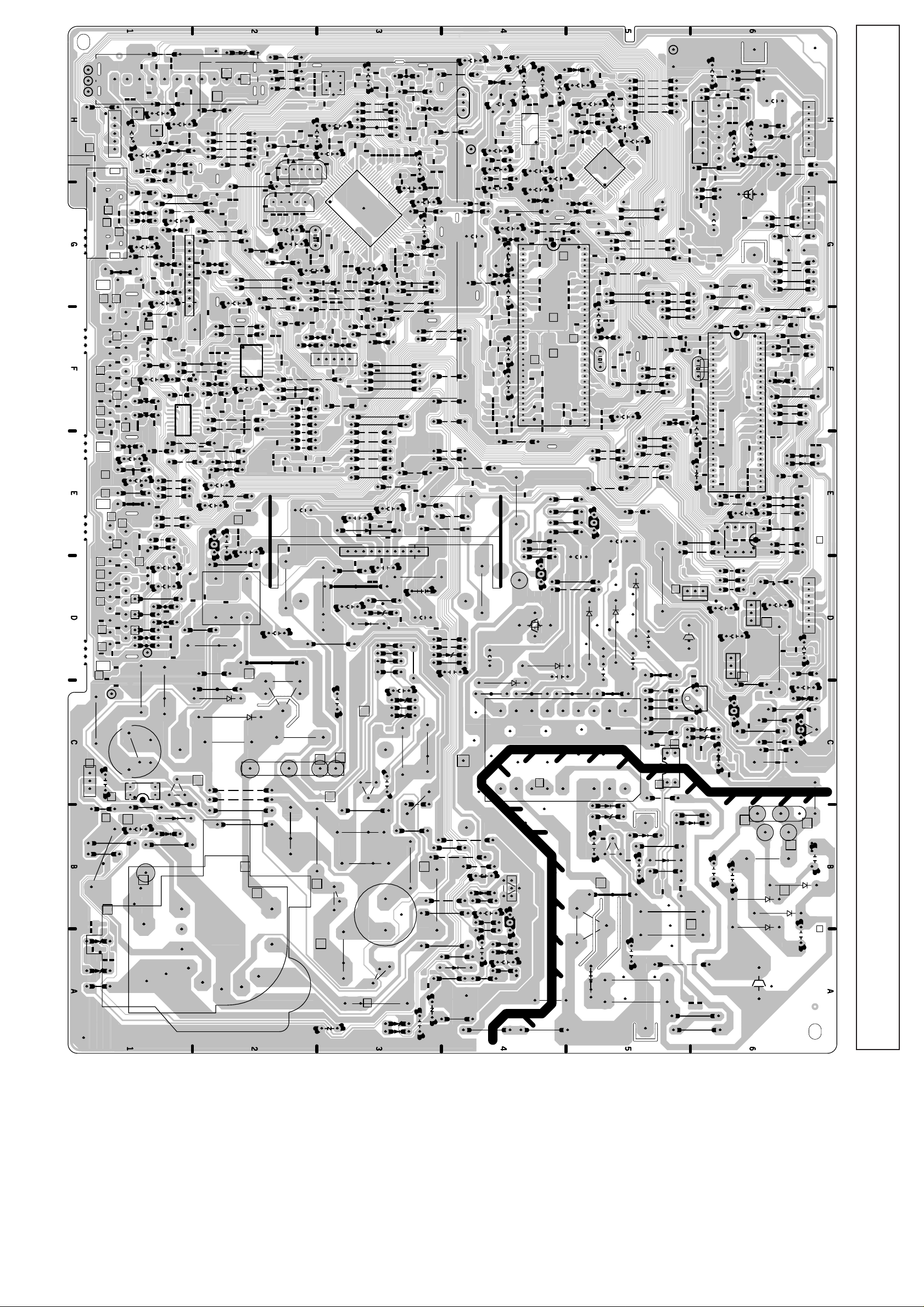

Page 2

MAIN BOARD

JW11

JW12

JW13

C3132

10

R625

R627

C3122

12

11

R3129

R3128

J603

C614

R024

J609

C639

C3123

J544

J607

D633

R3417

J546

C3133

L3469

J538

J653

J655

J654

J656

J657

R874

R875

J620

D615

C635

J536

J537

Q611

J517

R646

L641

R645

C823

J434

R642

J407

1

J406

Z13

D616

R611

L861

R647

J601

JW18

R644

4

R624

R628

R864

R626

Z31

R002

R001

C015

R021

2

IC001

10

C009

C013

C007

Q001

R013

R023

J554

Q044

J542

J541

R821

R822

R830

R829

C834

J533

X801

C833

R832

R831

R840

R852

R853

R860

C811

J630

C810

C861

C826

C824

29

J633

R885

J616

Q808

D646

IC641

C637

R641

VR641

Q641

R689

2

Q686

R688

3

R622

D614

R619

D617

JS611

L611

R014

R016

J651

C002

C001

1

C005

11

C011

J649

R003

C003

R004

C004

R008

C006

R007

F001

R005

R006

C008

C021A

R010

C021

R009

C012

R022

J652

J644

PB1

1

KH

J648

J647

1

KG

J623

Z32

R018

J646

R827

R826

J641

56

49

Q879

10

R879

IC801

40

C819C818 R839

C803

C822 R842

C807

C817

R838

C816

J635

C802

8

5

R872

C801

IC803

R871

JS617

1

4

J617

D641

R884

J618

IC643

C648

C649

IC642

R643

E

Q661

R661

D645

D685

C685

Q685

R637-1

R687

KF

R602-2

C604

C606

J622

J621

R824

R823

R817

J643

J637

R815

1

C827

J642

R863

Q807

J639

R862

R861

R819

D826

R818

R808

J636

R881

R653

R654

R880

20

C835

D637

D638

J634

R809

28

L803

L802

J632

R870

L801

R873

J615

J631

D647

J619

1

C650

KA

R681

R648

R659

C682

Q645

R660

Q682

C666

R667

J610

R686

R637

Q666

R666

D666

E

R637-2

Q666A

C636

X

D683

R663

JS637

12

KF-2

KF-1

XX

XX

KGG-2KGG-1

C603

R602-1

R602

D603

D604

D605

C605

C607

R620

R621

1

D606

HT

HT

C612

C613

C607-2C607-1

D1002

R1201

C305

Q1043

E

L432

D439

T451

L102

J236

J233

J237

L1204

J224

J223

C1043

R440

T451-6

30V

JS105

Q1205

C1042

R1219

R1220

Q431

J201

5

R138

L1202

JS301

J312

R1224

R153

C1214

C306

J205

J311

D438

C421

NC

J242

J241

J246

C432

J202

T451-5

J244

8

J217

J240

1

Q1203

T431

JS107

D101

Q153

IF

R137

C1202

T451-4

R308

R307

Q1206

C433

R152

R214

R215

R1215

D1041

D1042

R434

R432

C431

X

KDY-1

T451-3

Q1202

R1218

R1216

R1225

C1201

J218

T451-1

R146

D132

R147

R145

C138

R144

R157

Z04

C421-2

R443

1

2

JS132

1

C136

R139

R149

Z03

R143

IC301

C1217

R859

C815

C423-2

R466

R148

J340

JS202

10

9

JS806

R1034

R858

C434

Q432-C

J336

16

Q432-E

KDY

R150

C145

J323

Q141

JS131

C123

L201

R855

Q432

C446A

T451-2

J245

J243

D131

J355

R1217

J308

R302

Q806

Q805

R510

C137

J322

JS111

C124

L431

C446

C131

C208

J328

R301

KDY-3

X

JS108

C140

C1207

X

R158

L243

J203

R140

C132

C133

R141

C238

C232

C215

J326

Q301

C814

C423

3

C446-1

C446-2

C446A-2

C106

Q133

R142

C127

L103

Q152

C144

C239

C230

R256

R257

L242

R854

C501

IC501H3

X131A

Q151

X132

C207

R303

J307

Q432-B

Q132

C134

JS104

C128

R135

T131

J335

R136

C120

C135

C146

C203

R201

C209

C201

C202

65

C125

X131

C121

70

80

110 2024

X231

C231

C126

R233

R238

R230

C235

R234

C233

C236

J327

R240

R239

Q242

C237

R242

J325

R243

R241

J324

Q243

Q244

R848

J344

J343

R258

J247

L244

KP

J248

1

J314

R849

R304

R309

J351

J313

J310

J309

J305

J304

J303

R857

R856

J423

J424

R217

J425

Q804

J301

R437

C527

R514

D501

R537

10

C503

R534

R512

R503

L501

C529

D449

R449

R459

R467

R476

R475

C511

C423-1

KDY-5

KDY-6

X

X

6

5

Q425

R461

R442

L443A

C443-1

C441-1

C443-2

C441

X

C441-2

L443

C443

X

X

C442

C442A

X

C451

J334

J333

64

IC201

C234

R462

R464

C528

R511

L441

R134

C130

R161

L124

Q424

D464

R487

D465

C161

R209

C210

R251

D463

R847

D503

D422

R460

D423

C443A

C443A-1

C437A

C437

R132

R264

C223

25

R247

R246

C242

L231

R843

R844

R845

R851

C502

R518

R513

C504

R516

D502

C441A

C441A-1

L461

J302

R133

C206

5060

30

C214

Z10

C428

L461A

Q131

C301

R542

C261

C243

IC501

C505

D504

L122

C222

R248

C429

R477

L442-1

C139

X121

JW19

C3402

R3411

J524

R523

C217

C212

J522

R3486

R3476

Q3453

R3474

C3441

R3441

C3442

R3442

R491

R657

C427-1

J504

C483

Z21Z22

R632

R473

Q3455

C3443

C3444

Q491

R469

C3417

Q3452

C463

C3419

R3488

L643

D3418

C3416

C3413

JS3503

R3413

L3457

C3484

L3456

D461

C462

C3418

C3421

C3485

Q3454

R3473

C686

J527

R3412

R3414

R3475

D648

C486

C3408

C3490

C3488

R3487

R3485

D3441

R3443

R3444

R103

Z01

R656

R650

R655

Z02

TP-B

C642A-1

Q461A

D460

13 20

24

C3481

C3480

C3477

D3442

T611-8

E

C113

C3401

C3129

J516

X

T611-11

Q462

C3403

IC3401

C3415

R3133

64

60

R3471

40

33

R492

C642

Q461

R471

D466

C468

R468

50

L632

C3414

C3126

D3121

Q642

C642A

T611-12

C3406

C3409

C3404

R3127

C3405

12

C3407

10

J553

C3411

C3412

R3134

1

R3403

C3128

C3420

C3127

R3132

L3121

J548

C3456

J549

C3452

R3453

C3453

C3454

J547

C3462

C3489

C3493

C3492

C3494

C3495

C3483

C3482

IC3451

D041

C3476

C3431

C3432

D3443

C3433

R3415

C3436

D3444

C3434

R3416

J515

R658

R652

R651

R636

Q643

C633

E

R649

J306

C642A-2

D630

C646

L642

T611-13

T611-5

LIVE MAINS

Q613-B

C631

R631

R048

C010

Q043

J521

C3131

C3121

C3124

J552

L3122

J551

30

33

34

22

23

20

PB

PB

40

IC3121

1

44

R3131

R3121

JS3452

1

JS3451

J543

C3458

R3452

C3461

10

20

C3435

32

C3459

C3467

C3446

C3447

L3459

J608

J606

X3451

L3452

R3451

C3460

R3126

R3123

R3122

C651

J605

Q651

E

C640

D643

D635

D642

D644

C641

L635

T611-17

T611

C647

T611-2

T611-3

DANGER

C615

D618

D619

R623

Q612

R615

R617

L612

Q613

Q613-C

Q613-E

C617

X

C616B

C616A

C616

R3124

Z16

R130

C129

R129

R128

R123

JS109

Q121

L121

R124

R127

Q162

R163

C263

C262

R165

C216

R213

C221

C241

C219

41

R263

J341

C213

40

R231

J339

Q122

R131

R126

R164

J338

R162

Q161

C224

R216

C218

JS3504

J342

R219

C220

J332

R212

J331

Q211

R232

Q231

R218

R254

R202

R255

C251

J329

J416

J414

R253

J330

R250

J418

J421

J422

J512

J431

J510

J435

R546

J316

R515

R483

R547

Q532

J436

J432

1

R502

C506

C506A

C687

R517

JS501

J433

D431

C426

R436

IC501H2

J200

C436

C427

X

L442-2

JS114

R455

R441

R454

R435-1

L442

J506

J503

R435

J502

R486

R435-2

R472

R470

R474

R463

D469

R465

R488

C450

C470

R450

J114

C112

C1031

C108

TU

AGC

ADR

R101

C057

C056

J113

D1051

1

KCPA

C101

X

KEM2

C102

K1003

R1015

C1038

5

R1014

R1049

L1012

C1017

5

R1031

R1032

L1003

K1001

D1019

20

C1016

J104

J102

L1019

L1018

R1207

C1200

J105

L1205

C1044

20

R1002

D1003

R1005

R1007

R1009

10

R1011

R1012

C1034

C1013

C1014

D1018

R1018

D1021

L1017

R1017

R1048

R1019

D1044

D1047

D1046

R1050

10

R1020

R1021

J110

J111

C1046

C1047

15

C1033

K1002

15

C1037

L1022

C1036

1

C1035

R1022

R1023

J109

C053

C435

C466

R1206

J230

C1213

C1011

R1013

C1111

D1043

C1045

D1007

D1008

L1010

C1010

C1012

C1015

JW16

R102

SCL

C104

X

J106

J103

R1042

D1010

R1016

J221

R1047

L1020

L1023

C1212

J232

C1204

R1043

L1013

J211

C1029

C1027

R1001

SDA

J108

TP-A

C1218

D1203

L1201

Q1041

1

L1011

IC1401

8

R1226

D1026

D1025

X

C424A

J107

R1203

C052

C1215

J214

J213

J212

J215

J216

C1021

J225

C1024

C1028

C109

L101

J337

R835

R834

C1205

L1206

R1230

Q1042

J226

J222

C424

C107

MB

C103

R1003

J220

C1026

Q802

C149

Q1044

L1021

J219

A101

R154

R1041

J229

J227

X

BP

NC

C110

J239

IC1201

9

C1203

C1211

J231

1

Z33

R1227

L301

D1202

C303

J228

16

D1022

C1020

10

9

R1046

R1044

R433

D1052

J206

C438

R445

C422A

C422

JW17

C465

L462-1

L462

L462A

L462-2

KQ

3

C482

R482

2

1

1

R452

R448

D442

R451

T451-11A

R456

C447

Q447

D441

R481

C445

KSC

X

T451A-11

T451-11

D446

D445

R447

R458

R457

D448

R453

PB

T451-11B

C421-1

Z09

Q451

3

4

R444

D481

D482

R480

T451-10

T451A

T451-7

7

T451A11A

Page 3

TO

Part No. SKP20370 C3YFV (SHEET 2-3)

FRONT

K19H

KH

J10EF080N

1

2

3

4

5

6

7

8

R SP

L SP

27V

C021A

35EM

1000CD

R014

DJ680

AV3-V

AV3-L

AV3-R

R016

DJ680

C012

25EM

2200CD

C011

25EM

2200CD

PB101

A4B10E30800

-

P_

+

R SP AMP

+

R_

L SP AMP

VCC

1110987654321

F001

J

C009

25KZ

0.1GQF

C013

Z31

25KZ

2400010

0.1GQF

Z32

R010

2400010

4.7

C008

25KZ

0.1GQF

C007

25KZ

0.1GQF

R009

4.7

PW

GND

R006

1.5K

R008

1.5K

C003

16KK0.47

(BA:GMB)

-

R004

1/16GJ

1KC

R003

1/16GJ

3.3KC

C006

25EM

33CD

KK0.012

Q043

R007

47

C004

GQ

25EM47CD

C010

16EM

100CD

1/16GJ

560C

C015

D041

1SS133

R023

1AA0HEA0100--

pre

GND

C005

25EM

33CD

R005

47

R001

1/16GJ

3.3KC

R013

1/16GJ

2.7KC

+9V

IC001-1

R048

1/16GJ

10KC

Q044

TDA7263M

C002

C001

16KK0.47

(BA:GMB)

Q001

R024

2.2K

IC001

KK0.012

GQ

R002

1/16GJ

1KC

R018

1/16GJ

10KC

R022

1Q001/Q044

2SC2412KR:

2SC2412KR:

2SC2812NL6P:

2SC2812NL6P:

TXXKBB004P:

TXXKBB004P:

TXXKBB005P:

TXXKBB005P:

TXXKBB006P

TXXKBB006P

1/16GJ

47KC

C3401

25EM4.7CD

Q043

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

C3409

25EM4.7CD

JS3503

J

JS3504

L3456L3457

MOL

SCL

C3485

KK0.01

GQ

C3484

6.3EM

47CD

C3493

KK0.01

GQ

MOR

SDA

R3452

100

L2B9

2R2KN

C3494

25KZ

0.1GQF

DDA3SSA1

V

V

C3452

16KK

0.47BA:

16KK

0.47GMB

AUXOL

DDA1

V

1/16

GJ10KC

C3495

25KZ

0.1GQF

R3453

AUXOR

Iref

C3483

KK0.01

GQ

DDA3

V

P1

C3453

CJ

47

CGQ

Q3454/Q3455

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

C3482

KK0.01

GQ

PCAPL

PCAPR

SIF2

Vref1

C3454

25KZ

0.1GQF

R3487

1/16GJ

470C

C3481

6.3EM

47CD

Vref3

SIF1

C3458

CJ

47

CGQ

Q3455

R3488

1/16GJ

2.2KC

R3485

1/16GJ

470C

SCOL2

SCOR2

SSD1

ADDR2

V

L3459

1/16GZ

0C

C3459

6.3EM47CD

R3486

1/16GJ

2.2KC

SSA4

V

DDD1

V

L3452

L2B9

2R2KN

SSD2

V

CRESET

C3461

16KZ1FA

Q3454

6.3EM

47CD

SCOL1

SCOR1

XTALO

XTALI

X3451

V10B

2830N

24.576MHz

C3480

5V-1

R3475

1/16

GJ470C

Vref2

Vtune

Q3453

CAPR1

P2

R3476

1/16

GJ2.2KC

CAPR2

SYSCLK

43444546474849505152535455565758596061626364

SSA2

V

SCK

L2B9

2R2KN

C3489

KK0.01GQ

R3411

1/16GZ

0C

R3413

1/16GZ

0C

C3492

KK0.01

GQ

LOL

DDD2

LOR

V

IC3451

TDA9875A/V2

PCLK

NICAM

ADDR1

12345678910111213141516171819202122

R3451

100

J

TO

FRONT

K19A

KA

J10EF080N

RELAY

1

2

3

+9V

4

5

SPARK

6

7

8

IC803

CAT24WC08P:

M24C08-BN6:

24LC08B/P

1

2

3

45

R861

1/16GJ

680C

D826

MTZJ4.3B

8

7

6

Q807

R862

1/16GJ

8.2KC

R863

1/16GJ

15KC

L801

L2B95R6KN

16KZ2.2FA:

16KZ2.2GWF

R809

1/16GJ

10KC

C801

KK0.01

GQ

Q807

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

C827

R873

1/16GJ

3.9KC

R847

1/16GJ

4.7KC

R848

1/16GJ

4.7KC

R849

1/16GJ

4.7KC

R872

1/16GJ

3.9KC

5R6KN

L802

L2B9

R871

1/16GJ10KC

C802

10EM47CD

L803

L2B95

R6KN

R843

2.7K

R844

2.7K

R845

2.7K

R875

R870

1/16GJ

100C

470

R874

C803

25KZ0.1

GQF

C807

C816

KK4700

GQ

R880

470

1/16G

J39KC

R881

1K

R851

J

25KZ

0.1GQF

C817

CJ22

CGQ

KK1000

R808

100

C821

R815

100

R824

100

R823

100

C835

KK4700

GQ

R838

1/16GJ

5.6KC

IC801

QXXAVC007---N

1

RC IN

RESET

2

OUT

3

50/60

4

H-BLK

5

V-BLK

6

AV SW2

7

AV SW1

8

KEY IN

9

H-P

RELAY

10

11

Protect

12

HP-MUTE

13

BBE

14

15

B-OUT

16

G-OUT

17

R-OUT

18

FB-OUT

19

SDA

20

SCL

21

VDD

22

23

24

25

AVDD3

26

TEST0

27

MCFM

28 29

8Pin

(SC1)

8Pin

(SC2)

POWER&RL

P-TTARI

AGC

H-PHASE

S-VHS SW

LED

Mute

IGNOR

STATUS

ACK

V-SYNC

H-SYNC

VDDA

PXFM

AVDD2

TXCF

L/L'

56

55

54

53

52

51

50

X801

EX0046XC:

EX0046SC

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

1/16GJ

33KC

R884

47K

R842

1/16GJ

15KC

R829

Q808

C834

CJ27

CGQ

R817

100

1/16GJ

33KC

C824

R830

CJ82

CGQ

D1051

UDZS10BG

R826

220

C833

CJ27

CGQ

Q808

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

C819

CJ22

CGQ

C826

PM

0.47P

C861

CJ150

CGQ

C822

KK2200

GQ

R831

1/16GJ

10KC

R839

1/16GJ

5.6KC

C818

KK4700

GQ

R860

1/16GJ

270C

R852

1/16GJ

27KC

R832

1/16GJ

10KC

1/16GJ

1KC

R853

1/16GJ

22KC

R840

R885

1K

KCPA

J10AN050N

1

R821

J

R822

J

R834

47K

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

L861

L2B95R6KN

Q802

+5V

JS806

1/16GZ

R835

3.9K

0C

R859

1/16GZ

0C

R143

1/16GZ

0C

R144

1/16GJ

220C

C138

KK0.01

GQ

R145

1/16GJ

68KC

C131

KK0.01

GQ

1SS356

R147

1/16GJ

10KC

R148

1/16GJ

10KC

R149

56

Q152

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

Q121/Q162

2SC2412KR:

2SC2412KR:

2SC2812NL6P:

2SC2812NL6P:

TXXKBB004P:

TXXKBB004P:

TXXKBB005P:

TXXKBB005P:

TXXKBB006P

TXXKBB006P

1/16GZ0C

R146

1/16GJ

22KC

D132

JS109

Q141

2SC

2814F4P:

2SC

2814-F5

R139

1/16GJ

27C

D131

1SS356

R150

1/16GJ

33KC

+5V

DJ27B

1/16GJ

47C

1/16GJ

5.6KC

R142

1/16GJ

1KC

Q151

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

Q152

16EM47CD

R164

1/16GJ

1KC

Q121

R127

1/16GJ

560C

R123

C106

KK0.01

GQ

R140

R141

C136

KK0.01

GQ

L103

C120

J

Q162

R163

1/16GJ

2.7KC

R124

1/16GJ

2.7KC

+9V

C132

CC5CGQ

C133

CC5CGQ

C143

1/16GZ

0C

R152

27K

T131

SL0004XV

X131

SB6315T

C127

KK0.01

GQ

L124

J

C146

16EM47CD

1/16GZ0C

C134

CJ82

CGQ

X132

SF5315

:SF5315U

C121

KK0.01

GQ

C125

16EM10CD

C203

16KK0.47BA:

16KK0.47GMB

R201

1/16GJ

C202

470C

KK22

00GQ

KK0.01

GQ

C130

JS104

1/16GZ0C

Q133

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

C135

R154

1/16GJ

10KC

R158

1/16GJ

39KC

1/16GJ

100C

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

R136

+5V

R157

1/16GJ

10KC

C123

KK

0.01GQ

C144

16KZ1

FA

C140

C124

FK0.01BE

16EM10CD

12345678910

IF-AGC

PIFVCO

FIL

C232

CC10

CGQ

RIPPLE

C238

CC1

CGQ

1/16GJ

33KC

PIF-IN

PIF-IN

RF-AGC

NC

SIF-IN

SIF-IN

IF-VCC-5V

SIF-IN

IF-GND

SIF-OUT

DC-NF

LOOP-FILTER

IF-DET-OUT

IF-VCC-9V

DAC3

C128

10EM

220CD

R137

1/16GJ

470C

R138

1/16GJ

470C

AU-TV-OUT

DE-EMP

R153

1/16GJ

470C

Q133

R209

1/16GZ0C

C209

16KZ

1FA

Q153

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

DC-RESTOR

Y/CVBS1-IN

C210

16KZ1FA

R264

1/16GJ

100C

R230

X231

V10B

2961N

X-TAL

YS

KK22

00GQ

C231

C230

16KK0.22BA

APC

FILTER

C-IN

KK0.01

GQ

C206

C126

16KK0.47

(BA:GMB)

R-IN

25KZ0

S-FILTER

B-IN

.1GQF

C261

25KZ0

.1GQF

C262

G-IN

55565758596061626364

1FA

16KZ

C263

2

C614

HJ0.1G

R619

1/2DJ

47

D617

ES1(:Z)

1/16GJ

22KC

34

R626

DG

2.2K

R615

1

R622

DJ

15K

L611

L2E9220KN:

L2E7220KN:

L2J4220KN

TO

FRONT

K19F

KF-1

J30B

0250N

KF-2

J30B

0250N

Q611

R602

5WK1.8V:

5WK1800K

R602-1

2400010

1000KK

1000

(CBB:HB)

1000KK

1000

(CBB:HB)

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

D603/.../D606

R602-2

2400010

C603

C604

D616/D618

1SS133

1SS133

ERC05-10B

:RM11C

D605

D603

D604

R611

1/16GJ

5.6KC

Q611

D619

MTZJ

11B

R623

1/16GJ

1.5KC

D606

D618

D616

1/16GJ

1.2KC

D615

PC123F2

C607

400EM220

R617

(XD:XN)

C607-2

2400010

C607-1

2400010

:ERA18-04

R628

2SJ56

Q612

2SC3807

RYA

C615

FJ0.015

(BE:D)

R620

1/2DJ

120K

R621

1/2DJ

120K

D614

1SS133

R624

2SJ47

L612

L3004

R625

2SJ22

C616

2000KK

2200

(CTB:NH)

Q613

2SC4429LYB

:2SC4429MYB

2400010

Q613-B

C617

FK0.033

(BE:D)

R627

2SJ22

Q613-1

0HEA0099--

Q613-C

2400010

2400010

Z13

2400010

Q613-E

Z16

2400010

R631

1/2CK

5.6MXG

:1/2XJ

5.6MVA

T611-3

2400030

T611

L51B4850N

T611-2

2

17

2400030

3

16

15

T611-5

5

2400030

18

6

14

7

13

12

11

T611-8

2400030

810

R632

1/2CK

5.6MXG

:1/2XJ

5.6MVA

C631

400KM2200XS

:400KK2200XP

:250KK2200XH

C682

R681

R660

10K

1/16GJ10KC

R651

DJ10K

145V

R689

1/16GJ22KC

R688

1/16GJ

10KCQ686

D685

MTZJ6.2B

R658

10K

16EM

33CD

Q645

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

Q661

2SB764E:

2SA1020Y

R661

R637

5WK2.2V

R637-1

2400010

Q651

2SB985(S:T):

2SA1707(S:T)

Q685

C685

EM1CD

Q682

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

R663

1/2DJ

390

R637-2

2400010

R652

DJ3.9K

D683

1SS355

R686

1/16GJ

220KC

R687

1/16GJ

560KC

Q685

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

R653

1/16GJ

22KC

R654

1/16GJ

6.8KC

27V

D637

1SS133

R644

2SJ18

R648

2SJ22

R643

J

IC642

BA178M09T

:MC78M09CT

:UPC78M09AHF

123

C649

16EM

100CD

IC641

BA178M05T

:MC78M05CT

:UPC78M05AHF

:L78M05CV

321

C648

6.3EM

100CD

IC643

BA178M05T

:MC78M05CT

:UPC78M05AHF

:L78M05CV

123

C651

6.3EM

1000CD

C650

6.3EM100CD

1SS355

D646

1SS355

C139

6.3EM47CD

D647

1SS355

L3469

J

D641

+9V

+5V

C137

KK

0.01GQ

5V-1

TECT

PRO

R646

DJ

150K

R659

1/2DJ

68K

R645

DJ22K

C687

25EM

1000T

1/16GJ

10KC

R647

1/16GJ10KC

Q666

R666

2SC3807RYA

1/2DJ18

R667

D635

RU4YXLF-L1

D630

EU2(:Z):

D642

ERB44-02

RU4AMLF-L1

C642A-2

2400010

C642A-1

2400010

C642

200EM220XD

D648

RU3YX

R649

10K

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

560

C666

16EM47CD

D633

ERC91-02L

C637

35EM

2200CD

R642

NF150K

R641

1/16GJ

6.2KC

C686

25EM

470CD

R650

100K

MTZJ5.6B

C640

25EM

2200CD

R636

10K

C633

25EM

470CD

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

VR641

R3L1202NJ

:R3D7222NJ

R656

100K

D666

1SS355

Q643

D644

1SS355

D643

Q641

D645

MTZJ6.2B

Q642

2SC4487(S:T):

2SD1347(S:T)

R655

DJ2.2K

R657

1SJ3.3

C647

KK680GQ

T611-17

2400030

L635

ZZ0122

L641

J

L632

J

L642

J

T611-13

2400030

T611-12

C641

2400030

1000KK1500

(NH:CTB)

T611-11

2400030

L643

J

Q643/Q686

Page 4

Q3452/Q3453

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

Q3452

D3441

UDZS10BG

DDA2

V

SCIL2

SDI1

TEST1

+9V

R165

1/16GJ

1KC

R162

1/16GJ

2.2KC

R257

1/16GJ

1KC

Q243

TXXKBB006P

C3431

CJ100

CGQ

D3442

UDZS

10BG

SCIR2

MONO_IN

R3415

1/16GJ

15KC

C3467

16KZ1FA

AM

C3447

16KK

0.33BA:

16KK

0.33GMB

R258

1/16GJ

1KC

Q242/Q243/Q244

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

Q244

YC-GND

1/16GJ15KC

C3432

UDZS

10BG

SSG

V

TEST2

C3435

CJ100

CGQ

1/16GJ

10KC

VM-OUT

R3441

D3443

1/16GJ

100C

R233

SCIL1

EXTIR

DAC1

CJ100CGQ

C3433

CJ100CGQ

33343536373839404142

SCIR1

EXTIL

R234

YSM

D3444

UDZS10BG

R3416

1/16GJ

15KC

C3436

CJ100

CGQ

C3446

16KK

0.33BA:

16KK

0.33GMB

R3442

1/16GJ15KC

C3434

CJ100

CGQ

25KZ0.1

C235

R-IN-CPU

C3441/3442/

C3443/3444

16KK0.33BA:

16KK0.33GMB

R3443

1/16GJ15KC

R3444

1/16GJ15KC

GQF

25KZ0.1

GQF

C236

G-IN-CPU

B-IN-CPU

C3129

KK

0.01GQ

R3473

1/16

GJ470C

R3474

1/16

GJ2.2KC

C3476

16KK0.47BA:

16KK0.47GMB

R3471

C3477

1/16

6.3

GJ

EM47

270C

CD

Vref(n)

CAPL1

SDO2

R240

1/16GJ

2.2KC

R242

1/16GJ

2.2KC

R-OUT

1/16GJ

1KC

R239

1/16GJ

100C

Vref(p)

SDO1

SDI2

Q161

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

R161

100

C161

KK

0.01GQ

R256

Q242

R241

1/16GJ

100C

R243

1/16GJ

100C

G-OUT

B-OUT

CAPL2

WS

23 24 25 26 27 28 29 30 31 32

R238

1/16GJ

2.2KC

L201

J

C207

KK0.01

GQ

C208

16EM

47CD

11 12 13 14 15 16 17 18 19 20 21 22 23 24

YC-VCC-5V

IC201

TB1262FM

Y/MON-OUT

BLACK-DET

R213

1/16GJ

100KC

2SA1037AKR:2SA1179NM6P:

TXXKBB001P:TXXKBB002P:

1/16GJ

1KC

C216

16EM10CD

Q211

TXXKBB003P

IC501

LA7846N

VCC

OUT

GND

IC501H3

2400010

IC501H2

2400010

0HEA0072--

CB-OUT

R218

IN

IC501-1

CR-OUT

Q211

C501

10

9

8

7

6

5

4

3

2

1

DIG-GND

C223

KK0.01

GQ

JS107

1/16GZ

0C

25EM

1000T

L26B0800N:

L26B4410N:

L2G33R3KN:

L2PC3R3KN

C511

100FK

0.033AD:

100FK

0.033BE

CR3-IN

R515

1FJ3.3

C502

35EM220CD

D501

EM01Z:

ERA15-02

C505

L501

CB3-IN

C222

+5V

500CD

8GAA

R512

1SJ470

KDY-6

J30B

0250N

KK0.01

GQ

JS501

R513

1/16

GZ0C

V-OUT

J

R542

1/16GJ

10KC

KDY-5

J30B

0250N

R503

1/16GJ

56KC

V-RAMP

C241

HJ0.47

R514

1/16GJ

6.8KC

J30B

0250N

R502

1/2FJ1.5

C506

HJ0.47

KDY-3

H-VCC

C221

KK0.01

GQ

R492

1/16GJ

10KC

R518

1/16GJ

47KC

16KK

0.33

(BA:GMB)

R510

1SJ

0.68

KDY-1

J30B

0250N

Y3/CVBS3-IN

C219

KK5600

GQ

Q491

R534

1/6NF

5.6K

C504

C528

25KZ

0.1GQF

H-AFC

R491

1/16GJ

2.7KC

R516

6.8K

SYNC^OUT

C220

EM1CD

VD

1/16GJ

10KC

D502

1SS355

C237

25KZ0.1

RGB-VCC-9V

HD-SCP

4142434445464748495051525354

R216

1/16GJ

4.7KC

R523

J

R537

D503

MTZJ

6.8B

GQF

C3441

C3443

SCL

SDA

EHT-IN

ABCL-IN

BED-PIN

EW-OUT

CW-OUT

DIG-VCC

DAC2

FBP-IN

H-OUT

R263

1/16GJ

10KC

1/16GJ

4.7KC

Q804

C503

KK0.01

GQ

R517

1/16GJ

27KC

C3442

C3444

L231

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

VD

40

C212

KK1000

GQ

P-TTARI

Q491/Q804/Q805

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

R856

1/16GJ

4.7KC

R855

1/16GJ

10KC

C814

KK3300GQ

D504

1SS355

C529

16EM10CD

J

C242

16KZ

1FA

R212

270

C224

KK1000

GQ

R854

C233

16EM47CD

R215

R214

C251

16KZ

1FA

R247

1/16GZ0C

R248

1/16GJ

82KC

C218

KK0.01

GQ

CJ330CGQ

+9V

Q805

D449

EM01Z:

ERA15-02

100

100

1/16GJ

120KC

R202

1/16

GJ

27KC

C243

16KK

0.47

(BA:GMB)

C213

16EM47CD

C141

PRO

TECT

C234

25KZ

0.1GQF

R251

R253

100K

R246

1/16GJ

39KC

R254

100K

R857

1/16GJ

33KC

D463

1SS133

C438

KK1000GQ

R255

1/16GJ

56KC

R250

4.7K

ABCL IN

R464

J

J10EA050N

KP

1/16GJ

5.6KC

R486

1/2DJ47K

C486

160EM

0.47CY

TO_SOCKET_K7P

+9V

FBP

H OUT

R437

330

R434

R217

10K

R432

1/16

GJ1KC

C431

16KK

0.47

(BA:GMB)

12345

L244

L2B92R2KN

D431

MTZJ9.1B

1/2DJ

1K

Q431

2SC

3332

(R:S)

C467

16KZ

1FA

L243

L2B92R2KN

L242

L2B92R2KN

A101

F1BEB0250

TUNER(WITH PLL & BAND SW)

13 14

GND

12

IF1

BT

N.C

BP

MB

DATA

CLOCK

C102

6.3EM

470CD

R445

100

R436

DJ10K

R433

C433

500KK

3900A

145V

Y IN

1

2 3

R462

J

R488

1/16GJ

470KC

R103

1SJ33K

JS202

1/16GZ0C

D441

L18B0600N

C432

500KK

1000A

R487

J

R463

330

PC817(C:D):

TLP521-1

R449

1/2DJ47

C113

KZ

0.01F

1/16GZ

T431

D465

1SS133

Q1202

R1217

1/16GJ

470C

JS301

0C

1/2DJ

100K

4

D101

MTZJ36B

R1215

1/16GJ

100C

Q1206

R1227

1/16

GJ

270C

C1214

CJ82

CGQ

250MJ

0.22

(AT:UAP:AV)

R443

R444

10K

L431

L26B2790N:

L26B4400N:

L2G31R0MN:

L2PC1R0KN

S2055N--3E

C434

35EM

47CD

Q461-1

2HEA0127--

C470

FK

0.022

2SB1274

BE

(Q:R:S):

2SB1565

(E:F)

EM10CD

C446

C446A-2

2400030

Q461

C104

L1204

L2B94

Z22

C103

6.3EM

470CD

C110

KK0.01

GQ

L102

+5V

2SC2412KR:

2SC2412KR:

2SC2812NL6P:

2SC2812NL6P:

TXXKBB004P:

TXXKBB004P:

TXXKBB005P:

TXXKBB005P:

TXXKBB006P

TXXKBB006P

R7KN

C1020

1/16GZ

0C

L441

L71B0160N:

L71B0530N

C446-2

2400030

C446-1

2400030

Q451

TXXGA0

00868N

Q432-1

0HEA

0099--

Q432-B

2400010

Q432

L432

J

Z21

2400010

2400010

J

C1200

16EM10CD

R1207

75

R1226

1/16GJ

1KC

C443A-1

2400030

C443-2

2400030

C443-1

2400030

C443

250MJ

0.18(AT:UAP:AV)

Q432-C

2400010

Q432-E

2400010

Z10

2400010

Z09

2400010

D461

1SS133

R102

1/16GJ

100C

R101

1/16GJ

100C

L101

J

C109

KK

0.01

GQ

+9V

IC1201

LA7954

OUT

A

B

123456789

L1201

L2B94

R7KN

R1206

1/16GJ

270C

C1206

CJ22

CGQ

10

11

12

13

14

G

15

16

+5V

R

G

B

JS114

J

R441

1SJ1K

C442

250MJ

0.12

C441A-1

(AT:UAP:AV)

2400030

C441-2

2400030

C441-1

2400030

Q462

2SC3114

(R:S:T)

C441

250MJ

0.2

(AT:UAP

:AV)

1500MH

9800XK

D438

ERD07

D439

ERB44

R473

680

-15L

L443

LM0016D:

L26B0180N

R442

2SJ120

C421

C423

1500MH

C421-2

C423-2

8200XK

2400030

2400030

C421-1

C423-1

2400030

2400030

C424

630NJ

0.015EAQ

-04

C422

630NJ

0.015EAQ

R470

56K

R472

J

R471

1.5K

ADDRESSTUAGC

AV3

2400030

Z33

C1211

CJ82

CGQ

L1205

L2B94

R7KN

R1203

1/16

GJ

270C

C1204

16EM10CD

D1203

UDZS10BG

0X

1X

VCC

RGB_SW

IC1401

TC4053BF

Q1043

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

Q1044

2SA1179NM6P:

R466

1/2DJ

2.7B

C468

25EM

22CD

GND

1234567891011

C101

16EM47CD

SC1

C1202

16EM47CD

C1215

CJ82

CGQ

D1202

UDZS10BG

0Z

1Z

0Y

1Y

2SC2412KR:

TXXKBB006P

2SA1037AKR:

TXXKBB001P:

TXXKBB002P:

TXXKBB003P

L462-1

2400010

L462

AA0017:

L26B0790N

L462-2

C466

2400010

100GJ

2.2P

C465

100GJ2.2P

L461

L26B0170N

:L26B0260N

:LM0045

:LM0045D

C463

100FK

6800

(BE:D)

EU1:

R469

ERA22-04

12K

R468

J

D466

MTZJ20B

15

TP-A

J30B0250N

SC2

89

7

6

5

B

4

3

2

1

R474

1/2DJ

820

D469

1AA0B10E662G0 ASSY,PWB,MAIN C3YFV

1AA4B10E30800 PWB,MAIN C3AC

C053

CJ180CGQ

TV

C1203

KK0.01

GQ

C1212

CJ82

CGQ

R1201

1/16

GJ

270C

L1202

L2B94

R7KN

C1213

16EM10CD

R1230

1/16GJ

270C

L1206

L2B94

R7KN

C1205

16EM10CD

R480

1/2DJ

2.2B

EU1:

ERA22-04

C1218

CJ82

CGQ

D481

T451-4

2400010

R435

R435-2

2400010

7WK4.7

(I:VC)

R435-1

2400010

145V

TP-B

J30B0250N

C482

250GK

0.1P

2SA1037AKR:

2SA1179NM6P:

TXXKBB001P:

TXXKBB002P:

D1042

1SS133

R1017

1/16GJ

75C

R1050

1/16GJ

75C

R1034

1/16GJ

10KC

D1025

UDZS10BG

D1026

UDZS10BG

D1052

UDZS10BG

T451

L40B10000

T451-6

2400010

6

T451-5

2400010

5

T451-3

2400010

3

4

T451-1

2400030

1

T451-10

2400010

10 7

T451-2

2400030

2

C437

250GJ0.47:

250GJ0.47PA

R450

15K

R455

R454

DJ39K

DJ56K

R481

DJ

270K

R482

8.2K

D482

1SS133

TECT

R1043

1/16GJ

4.7KC

1SS133

TXXKBB003P

R1003

75

D1002

UDZS10BG

+5V

Q1044

UDZS10BG

R453

1K

PRO

D445

1SS355

D1041

Q1042

L1004

UDZS10BG

UDZS10BG

UDZS10BG

C1015

16EM10CD

KK1000GQ

R1044

1/16GJ

4.7KC

Q1043

UDZS10BG

D1047

C1027

16EM10CD

KK1000GQ

C1029

16EM10CD

KK1000GQ

C1042

16EM10CD

KK1000GQ

C1043

16EM10CD

KK1000GQ

C450

100PM

2.2X

+5V

J

D1003

UDZS10BG

D1007

D1008

D1010

L1010

L2B9

100KN

C1010

CJ100

CGQ

C1012

CJ100

CGQ

C1014

C1017

16EM10CD

R1046

1/16GJ

22KC

R1047

100

D1043

UDZS10BG

D1046

UDZS10BG

C1024

CJ100

CGQ

C1026

C1028

C1044

C1045

T451-11

2400010

11

T451-7

2400010

R447

1/16GJ

4.7KC

Q1041

2SC2412KR:

2SC2812NL6P:

TXXKBB004P:

TXXKBB005P:

TXXKBB006P

R1042

100

L1011

L2B9

100KN

L1012

L2B9

100KN

C1016

KK1000GQ

D1044

L1020

L2B9

100KN

C1021

CJ100

CGQ

L1021

L2B9

100KN

L1022

L2B9

100KN

L1023

L2B9

100KN

L1018

L2B9

100KN

100KN

R451

2SJ2.7

C451

100PM

2.2X

MTZJ8.2B

VIDEO OUT

R1002

1/16GJ

75C

R1005

1/16GJ

75C

R1009

1/16GJ

75C

R1011

1/16GJ

75C

R1012

1/16GJ

2.2KC

C1034

CJ100

CGQ

R1021

2.2K

R1022

1/16GJ

560C

R1023

1/16GJ

560C

L1019

L2B9

R1032

1/16GJ

560C

D446

R1013

1/16GJ

2.2KC

R1014

1/16GJ

560C

L1013

L2B9

100KN

UDZS10BG

R1048

1/16GJ

75C

R1019

1/16GJ

75C

R1049

1/16GJ

75C

R1020

2.2K

R1001

39K

R1031

1/16GJ

560C

R1041

1/16GJ

22KC

1/16GJ

75C

D1021

R

R1007

G

B

R1016

39K

L1017

ZZ0122

R448

DJ330

L1003

ZZ0122

R1015

1/16GJ

560C

R1018

75

C IN

L-OUT

KQ

J10EA030N

J30B0250N

D442

1SS355

C445

EM10CD

R

G

B

R-OUT

KSC

21

19

17

15

13

11

9

7

5

3

1

21

19

17

15

13

11

9

7

5

3

1

J12B2821N

3

2

1

20

18

16

14

12

10

8

6

4

2

K1001

J1EK1745B

:J11B0490N

20

18

16

14

12

10

8

6

4

2

K1002

J1EK1745B

:J11B0490N

K1003

3

TO

SOCKET

2

K7Q

1

HV

SCREEN

VIDEO IN

L-IN

R-IN

DY1

X

Page 5

MAIN BOARD

BLOCK DIAGRAM (OUTLINE)

Part No. SKP20370 C3YFV (SHEET 3-3)

C607

R602

R637

IC643

KA KH

IC642

IC801

IC803

IC001

Q613

Q641

T451

T611

Q432

VR641

IC641

IC501

TP-B

C502

C501

IC3451

KP

IC201

T131

X131

X132

SPEAKER

SP902

SP901

D603-D606

C607

SW901

AC

Q613

Q611

8/10

IC001

AUDIO-OUT

<TDA7263M>

T611

CONVERTER

5

8

2

3

D615

15

18

11

14

13

10

1 5

12

-27V

Q666

Q661

Q642

L462

25V

Q651

Q641

KEY SW

I2C BUS

CONTROL

IC803

MEMORY

5V

IC641

IC642

IC643

27V

145V

Reg.

Q643

RC RECEIVER

SDA

SCL

5V

D646

9V

5V-1

Q645

T431

K1002

A1901

RC-IN

KEY-IN

SDA

SCL

PROTECT

D641

D647

D637

Q685

Q686

IC801

CPU

1

8

19

20

21

11

Q682

MUTE

45

BLK

18

R

17

G

16

B

15

H-BLANK

4

34

33

53

54

SCREEN

POWER

WIDTH

CONTROL

D441

IC501

V-OUTPUT

<LA7846>

IC1201

A101

K1001

TP-A

K1003

KCPA

Video-IN

R/G/B-IN

Video/

R/G/B-IN

B

R

PICTURE

G

AERIAL

SCL

SDA

C-IN

Y-IN

19

C-IN

TUBE

19

SCART SC1

20

11/7/15

15

20

SCART SC2

15

7/11/15

K1001

K1002

IC3451

71

26

27

20

21

22

23

33

47

39

R

12

G

13

B

14

R/G/B-OUT

NICAM/

STEREO

IF-IN

80

79

SIF-IN

75

76

IF/VIDEO/CHROMA/DEF

X131

<TB1251>

IC201

54

48

46

58

61

51/53

57

56

55

Video-Out

C-IN

Y-IN

M-OUT

R

G

B

T451 FLYBACK

CRT

HEATER

A101

TUNER

C-OUT

13

12

1/3/13

2/5/12

IF

X132

AV-VIDEO-SW <LA7954>

IC1201

9816

Video/Y-Out

4

14

15

IC1401

RGB-SW

<TC4053BF>

Q701

Q711

Q721

60 61

5

SDA

Q462

Q461

12

SIF-OUT

SCL

SDA

EW-OUT

V-OUT

H-OUT

L461

L462

4

SCL

6

3

Q432

H-OUTPUT

Q431

H.V

D.Y

200V

FOCUS/SCREEN

Page 6

OPTION SETTING

[After replacing the Memory IC (IC803)]

The memory IC, IC803, stores the option data of TV set and service adjustments data for each circuit, therefore,

when the memory IC is replaced, it should be performed following setting and “SERVICE ADJUSTMENT” on next

page.

To enter to the Option Mode

+ Press and hold the F/OK button on the remote control and P▼ button on the front panel of the TV. The option

window will appear on the screen.

OPTION

ON-TIMER ON

SORT MODE SORTING

P&P ON

WEL. TEXT ON

COMB FILTER OFF

BBE OFF

AUTO VOLUME OFF

HEADPHONE OFF

COUNTRY BG/DK/I/LL'

WIDE ON

ADJUST : EXIT : RECALL

OPTION MODE FOR CE32WN5F-C-04

To set the option mode

+ Highlight the desired option item by using the P▲ or P▼ button .

+ To switch the option mode, use the Volume - (LEFT) or Volume + (RIGHT) button.

+ The data which is set in the option mode is stored into the memory IC automatically.

Following table shows the available option items and default setting mode.

Option Mode Mode Description & Note

ON-TIMER ON or OFF On-timer available, default “ON”

SORT MODE SORTING or Tuning mode, default “SORTING”

TUNING

P & P ON or OFF Plug & Play mode, default “ON”

WEL. TEXT ON or OFF Display message when first set up, default “ON”

COMB FILTER OFF or ON For factory use, default “OFF”

BBE ON or OFF BBE sound mode, default “OFF”

AUTO VOLUME ON or OFF Default “OFF”

HEADPHONE ON or OFF Headphone control , default “OFF”

COUNTRY UK, IRE TV system, default “UK”

BG/DK / I / LL’

WIDE ON or OFF Wide mode, default ON

Exit from the Service Mode

+ Press the RECALL button.

?

SERVICE ADJUSTMENTS

Note: Some items of the service adjustments for this chassis are controlled by the CPU, IC801, and the

adjustments are carried out by using the RC handset.

[After replacing the Memory IC (IC803)]

The memory IC, IC803, stores the service adjustments data for each circuit, therefore, when the memory IC is

replaced, it should be programmed by using “OPTION SETTING” on previous page and the following adjustments.

ADJUSTABLE SERVICE ADJUSTMENT

REGULAR

Item No. OSD Description

1 AGC AGCAdjustment

2 -- Cut-Off Drive Adjustment

3 GR Y G-Drive Adjustment (white balance)

4 GR Y B-Drive Adjustment (white balance)

5 CTR Contrast Adjustment (use factory setting)(for factory use)

6 -- Screen Adjustment mode

8 OSD OSD Positioning Adjustment

IMAGE

ADJUSTMENTS

IMPORTANT NOTICE

Do not attempt to adjust the following service adjustments except when adjustments are required in servicing

otherwise it may cause loss of performance and product safety.

ADJUSTMENT

+ B VOLTAGE

1. Receive white raster pattern.

2. Set controls to normal.

3. Connect digital voltmetre to test point TP-B and GND.

4. Adjust voltage to 145 ±0.5V by using VR641.

ADJUSTMENT

AGC ADJUSTMENT

1. Input and tune an RF signal which is UHF to the clearest station.

2. Connect digital voltmetre to test point TP-A and GND.

4. Enter to the service mode and select mode “REGU-

LAR”, and select item no.1 “REGULAR 1, AGC”.

5. Press the LEVEL+ or LEVEL - button to adjust volt-

age to be 3.2Vdc.

FOCUS ADJUSTMENT

By using FOCUS VR, adjust focus control for well

defined scanning lines.

GREY SCALE ADJUSTMENT

SCREEN

ADJUSTMENT

1. Receive black & white pattern.

2. Enter to the service mode and select mode “REGU-

LAR”, and select item no. 2 “REGULAR 2, CUT”. The

horizontal line will appear on the screen.

3. Set the SCREEN VR for one colour to be just visible.

4. Using the numeric buttons shown set each colour to

minimum by decreasing to the point where any further

decrease resets the adjustment to maximum value.

ADJUSTMENT

BIAS

5. By using the buttons 1, 2, 4, 5, 7, 8 on the remote

control, adjust the line to be white.

The key allocation is as follows;

Button No. Operation

1 Increase Red

2 Decrease Red

4 Increase Green

5 Decrease Green

7 Increase Blue

8 Decrease Blue

CORNER ADJUSTMENT

1. Receive cross hatch pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item no. 11 “IMAGE 11.P ECT” for top corner adjustment OR item no. 12 “IMAGE 12.P ECB for

bottom corner adjustment.

3. Press the LEVEL+ or LEVEL - button to correct the

distortion of the vertical line around the corners.

HORIZONTAL ADJUSTMENT

HORIZONTAL CENTRING ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item no. 2 “IMAGE 2.P H-P”.

3. Press the LEVEL+ or LEVEL - button to adjust the

horizontal centre.

HORIZONTAL WIDTH ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item 6 “IMAGE 6.P H-S”.

3. Press the LEVEL+ or LEVEL - button to adjust the

horizontal width.

DRIVE

6. Select item no.3 “REGULAR 3, GRY” (G-Drive) or 4

“REGULAR 4, GRY” (B-Drive) and adjust both initially

to 40.

7. Change data value of each item by using LEVEL + or

LEVEL - button to obtain the proper white balance.

PCC ADJUSTMENT

PCC

ADJUSTMENT

1. Receive cross hatch pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item no. 7 “IMAGE 7.P E-P”.

3. Press the LEVEL+ or LEVEL - button to adjust the

vertical line to be straight.

TRAPEZOID

1. Receive cross hatch pattern and set screen mode to

2. Enter to the service mode and select mode “IMAGE”,

3. Press the LEVEL+ or LEVEL - button to correct the

ADJUSTMENT

“FULL”.

and select item no. 8 “IMAGE 8.P E-T”.

trapezum distortion of the vertical line.

VERTICAL ADJUSTMENT

CENTRING ADJUSTMENT

VERTICAL

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item no. 1 “IMAGE1.P V-C”.

.3 Press the LEVEL+ or LEVEL - button to adjust the

vertical centre.

VERTICAL HEIGHT ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select mode “IMAGE”,

and select item no. 5 “IMAGE 5.P V-A.

3. Press the LEVEL+ or LEVEL - button to adjust the

vertical height.

Item No. OSD Description

1 PV-C P Vertical Position Adjustment

2 PH-P P Horizontal Position Adjustment

3 PV-L P Vertical Linearity Adjustment

4 PVSC P Vertical S-Correction Adjustment

5 PV-A P Vertical Size Adjustment

6 PH-S P Horizontal Size Adjustment

7 PE-P P Pin Cushion Adjustment

8 PE-T P Trapezoid Distortion Adjustment

11 P ECT P Top Corner Correction Adjustment

12 P ECB P Bottom Corner Correction Adjustment

13 P HPA P Parallelogram Distortion Adjustment

IMPORTANT NOTICE

Do not attempt to adjust service adjustments not listed on the above otherwise it may cause

loss of performance and product safety.

To enter to the Service Mode

+ Press and hold the GREEN button on the remote control and then press the P▼ button inside of the door. Press

the P▼ button to highlight the mode required (Regular, Image, others and TB12**). Then press the F/OK button to

select the mode.

The available adjustment items are as follows;

Image : This can be adjusted for picture images/shapes.

Regular : This can be adjusted for the service adjustment.

other : This is for factory setting. DO NOT ADJUST.

TB1251 : This is for the factory setting. DO NOT

To select the mode and service item and change data value

+ Highlight the desired adjustment mode by using the P▲ or P▼ button and then press the F/OK button.

+ To select the adjustment item, use the P▲ or P▼ button.

+ To change the service data, use the Volume -(LEFT) or Volume + (RIGHT) button.

+ The data which is set in the service mode is stored into the memory IC automatically.

REGULAR mode

REGULAR

1, AGC 38

Adjustment No.

and Item name

Adjustment Data

ADJUST

.

Adjustment No.

and Item name

IMAGE mode

IMAGE

1. P V-P 1F

Adjustment Data

Exit from the Service Mode

+ Press the RECALL button or turn off the TV set by using the Mains switch.

?

INITIALISATION OF MEMORY IC

To initialise the memory IC (IC803), press and hold the NORMAL button on the remote control, then press

the P▼ button on the front panel of the TV set and then turn the Mains switch Off and On. The initialisation is now

completed.

When initialised the memory IC and all of the setting data (option data and service adjustment data) stored in the IC

are reset to the default value. It is necessary to set the option settings and readjust the service adjustments listed on

page 6 and to re-tune all the channels.

OSD POSITIONING ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

HIGH-VOLTAGE CONFIRMATION

1. Receive circular pattern and set screen mode to

“FULL”.

2. Set controls for brightness and contrast to maximum.

3. Connect high-voltage meter to the anode of CRT and

GND.

4. Confirm that voltage is:

26.5±1.0kV,1.1mA for 24” Wide model

29.5±1.0kV,1.15mA for 28” Wide model.

30.5±1.0kV,1.4mA for 32” Wide model.

29.5±1.0kV,1.35mA for 28” Flat wide model.

30.5±1.0kV,1.45mA for 32” Flat wide model.

2. Enter to the service mode and select mode “REGULAR”, and select item no. 8 “REGULAR 8 OSD”. The

OSD test bar will appear on the top of screen.

3. Press the LEVEL+ or LEVEL - button to adjust prop-

er OSD positioning.

❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚❚

CPU PORT FUNCTIONS

Pin No. Function Name Function IN/OUT

1 RC IN RC Signal Input IN

2 RESET Reset Input IN

3 50/60 50/60Hz output 50Hz:H OUT

4 H-BLK H-Blank (on/off?) OUT

5 V-BLK -6 AV-SW2 Option SW2 -7 AV-SW1 Option SW1 -8 KEY IN Key switch signal input IN

9 H-P

10 RELAY To operate degauss circuit OUT

11 PROTECT Power failure detect input “L” error IN

12 HP-MUTE OUT

13 BBE OUT

14 ? OUT

15 B-OUT Blue output OUT

16 G-OUT Green output OUT

17 R-OUT Red output OUT

18 FB-OUT Fast Blanking output OUT

19 SDA SDA IN/OUT

20 SCL SCL OUT

21 VDD Power -22 Not used -23 Not used -24 Not used -25 AVDD3 Analogue VDD of PLL -26 TEST0 Test -27 MCFM Test -28 -29 TXCF Analogue pin for Teletext slicerline PLL -30 -31 AVDD2 Analogue power supply -32 Not used -33 Video input (H.F) IN

34 Video input (L.F.) IN

35 Not used -36 Not used -37 Not used -38 PXFM Analogue pin for the Display Pixel Frequency Multiplier -39 VDDA -40 H-SYNC Horizontal Sync. Input IN

41 V-SYNC Vertical Sync. Input IN

42 ACK Answer for status OUT

43 STATUS Request for BUS open IN

44 INGNOR Not Used -45 MUTE Sound Mute on/off switch OUT

46 L/L’ Not used OUT

47 LED Led drive OUT

48 S-VHS-SW Not used -49 H-PHASE Not used -50 OSC Clock oscillator

51 OSC Clock oscillator IN

52 AGC Auto gain control IN

53 P-TTAR1 Pittari switch (Natural wide) OUT

54 POWER & RL Power & relay On/Off control OUT

55 8PIN (SC2) AV2 Scart function input IN

56 8PIN (SC1) AV1 Scart function input IN

IN

Loading...

Loading...