Page 1

Part No. SKSM0711 C5VRL JUNE 2004

Colour Television

Service Manual

Model CE25DN9-B

Service Ref. No. CE25DN9-B-01

PRODUCT CODE: 111360913

ORIGINAL VERSION: Chassis No. EB8-A

Give complete "SERVICE REF. NO." for parts

order or servicing, it is shown on the rating sheet

on the cabinet back of the TV set.

Note

This TV receiver will not work properly in foreign

countries where the television transmission

system and power source differ from the design

specifications. Refer to the specifications for the

design specifications

CE25DN9-B

Contents

Safety precautions/Specifications ..................................................................................................................2

Block diagrams ..............................................................................................................................................3

Cabinet Disassembly......................................................................................................................................4

Adjustment and Repair Procedures............................................................................................................5~9

CPU Functions..............................................................................................................................................................................10~1 1

Component Locations ..................................................................................................................................12

IC Block Diagrams..................................................................................................................................13~15

Pin description of semiconductors................................................................................................................16

Part Description and reading of schematic diagram ....................................................................................17

Cabinet Parts List/TV Stand parts list ..........................................................................................................18

Electric Parts List....................................................................................................................................19~24

Please use Schematic Diagram SKP20435

inserted with this Service Manual.

Page 2

Part No. SKSM0720 C7WAS JULY 2004

Colour Television

Service Manual

Model CE28DN9-B

Service Ref. No. CE28DN9-B-01

PRODUCT CODE: 111373100

ORIGINAL VERSION: Chassis No. EB8-A

Give complete "SERVICE REF. NO." for parts

order or servicing, it is shown on the rating sheet

on the cabinet back of the TV set.

Note

This TV receiver will not work properly in foreign

countries where the television transmission

system and power source differ from the design

specifications. Refer to the specifications for the

design specifications

CE28DN9-B

Contents

Safety precautions/Specifications ..................................................................................................................2

Block diagrams ..............................................................................................................................................3

Cabinet Disassembly......................................................................................................................................4

Adjustment and Repair Procedures............................................................................................................5~9

CPU Functions..............................................................................................................................................................................10~1 1

Component Locations ..................................................................................................................................12

IC Block Diagrams..................................................................................................................................13~15

Pin description of semiconductors................................................................................................................16

Part Description and reading of schematic diagram ....................................................................................17

Cabinet Parts List ........................................................................................................................................18

Electric Parts List....................................................................................................................................19~24

Please use Schematic Diagram SKP20443

inserted with this Service Manual.

Page 3

-2-

C7WAS

SAFETY PRECAUTION

X-RADIATION PRECAUTION

The primary source of X-RADIATION in the television receiver is the picture tube. The picture tube is specially

constructed to limit X-RADIATION emissions. For continued X-RADIATION protection, the replacement tube

must be the same type as the original including suffix letter. Excessive high voltage may produce potentially

hazardous X-RADIATION. To avoid such hazards, the high voltage must be maintained within specified limit.

Refer to this service manual, high voltage adjustment for specific high voltage limit. If high voltage exceeds

specified limits, take necessary corrective action. Carefully follow the instructions for +B1 volt power supply

adjustment, and high voltage adjustment to maintain the high voltage within the specified limits.

PRODUCT SAFETY NOTICE

SPECIFICATIONS

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is particularly recommended that only parts designated on the parts list in

this manual be used for component replacement designated by mark . No deviations from resistance wattage

or voltage ratings may be made for replacement items designated by mark .

1: An isolation transformer should be connected in the

power line between the receiver and the AC line

when a service is performed on the primary of the

converter transformer of the set.

2: Comply with all caution and safety-related notes

provided on the cabinet back, inside the cabinet, on

the chassis or the picture tube.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, isolation resistor-capacitor networks

etc. Before returning any television to the customer,

the service technician must be sure that it is completely

safe to operate without danger of electrical shock.

Power source AC 220~240V, 50Hz

Television system System I

Colour system PAL/NTSC4.43 (PAL/NTSC4.43/NTSC3.58 IN AV MODE)

Receiving channel UHF: #21~69

Aerial input impedance 75ohm

Rear AV terminal

AV1: CENELEC standard

INPUT: Composite video, RGB and Audio L/R

OUTPUT: TV-output with composite video and audio L/R

AV2: CENELEC standard

INPUT: Composite video, RGB, S-VHS and Audio L/R

OUTPUT: Monitor output with composite video and Audio L/R

Front AVterminal

AV3: RCA jacks

INPUT: Composite video and Audio L/R

Sound output(Music) 5 x 2

Dimensions (WxHxD) 736 x 597 x 494mm

Weight 30.7Kg

!

!

!

Page 4

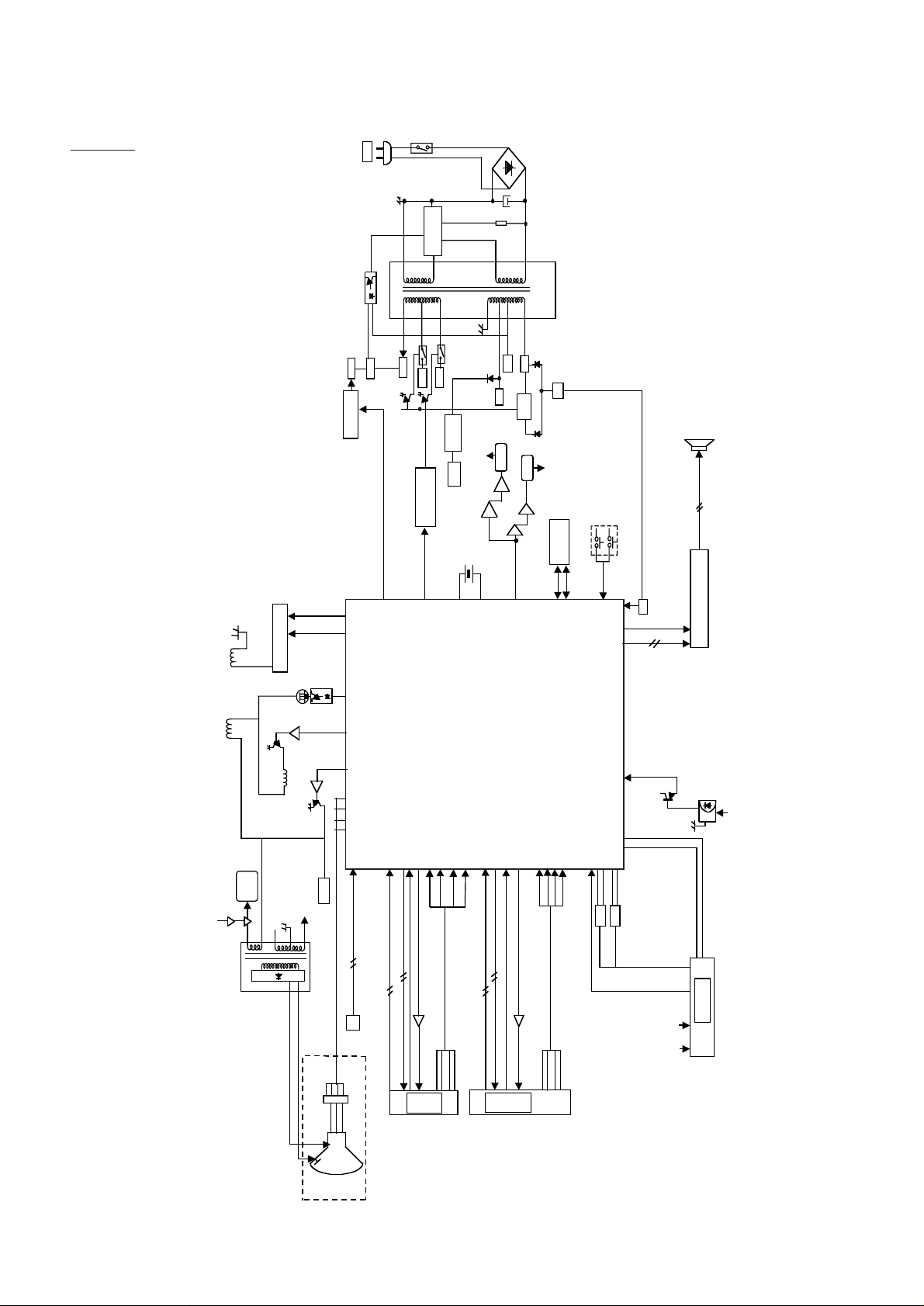

-3-

C7WAS

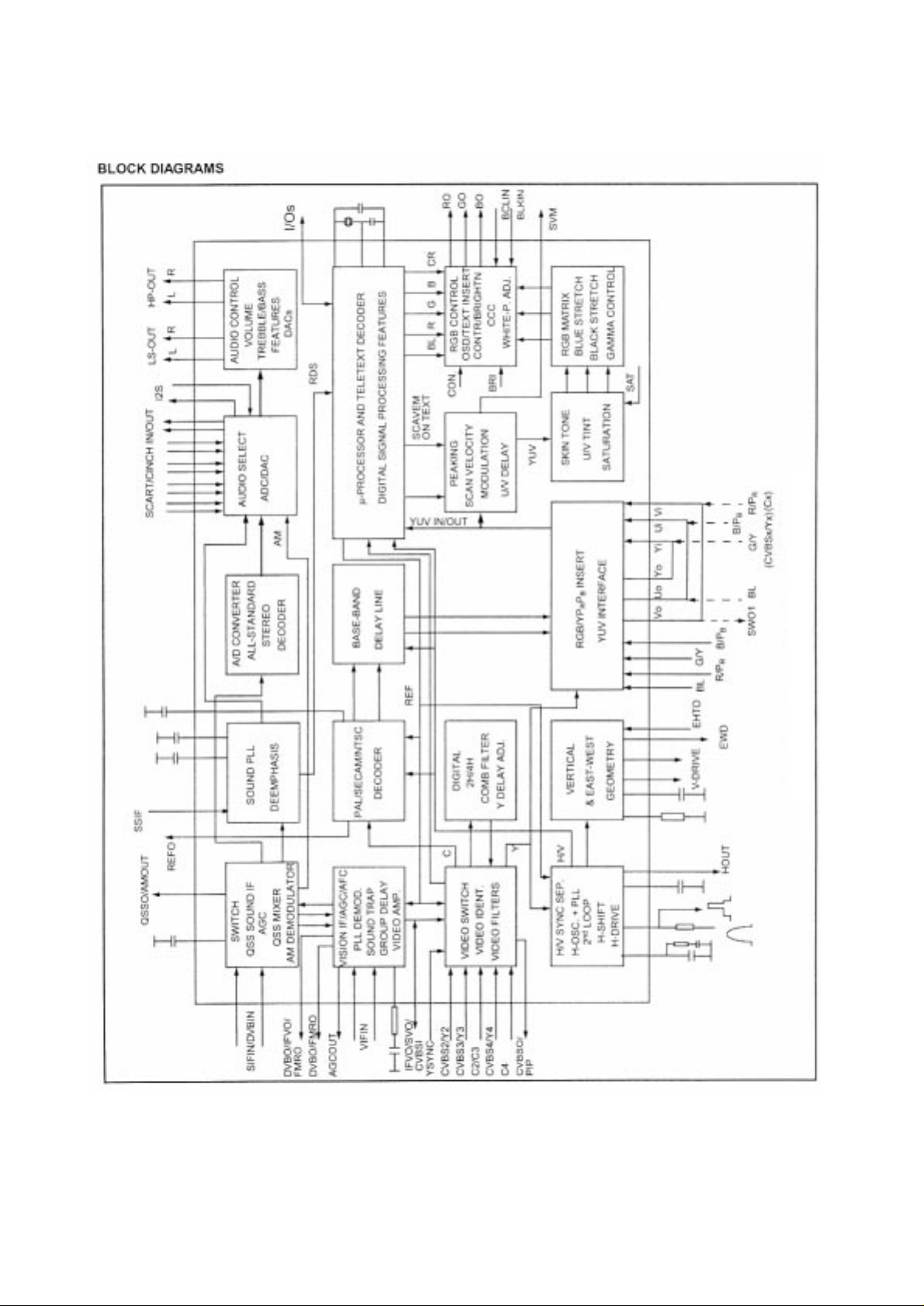

BLOCK DIAGRAM

This is a diagram for all models and therefore differs slightly from the actual block diagram.

Outline

SW601

AC

C609

TN6Q04

IC601

SCAN COIL

VERTICAL

HORIZONTAL

SCAN COIL

V-OUTPUT

LA78045

Q461

IC501

Q462

L462

L461

Q432

D441

Q431

PIN 106

22 23

128

2

Q439

D610

Q675

Q641

St-BY UOC

106

6

84 85 86

Q642

Q625

145v

Q651

+14v

-14v

Q682

IC666

3v3

ON/OFF

UOC PIN 107

107

D671

3v3 St-By

TO UOC PINS

93 & 96

X201

10

11

UOC

7v

1V8_2

Q203

25v

4

Q204

14

14v

1

5v

2

IC645

1V8_1

Q202

Q201

CONVERTER

T611

P.F

3,100,117,118,124

TO UOC PINS

I

IC801

MEMORY

2

C BUS CONTROL

9

9

12031127

60 61

97

108 109

KEY SW

SPEAKER

SP901

SP902

IC001

AUDIO AMPLIFIER

PF

Q866

5

A1901

RC RECEIVER

ON/OFF CONTROL

CPU PIN 106

Q402

Q403

To CRT

200v

Q401

145V

CRT

Heater

T451 FLYBACK

SCREEN & FOCUS

H.V

IK

K1101

BOUT

IC7 01

515354

AV3 AUDIO L/R & VIDEO IN

GOUT

R OUT

PICTURE TUBE

49

50

58

62

63

SCART 2 AUDIO L/R OUT

SCART 2 AUDIO L/R IN

48

SC_2 VIDEO IN

K1002

SCART 2

75

72

71

70

SC_2 VIDEO OUT

SC_2 R-IN

SC_2 B- IN

SC_2 G -IN

SC_2 FB -IN

Q1003

Q1004

553435

36

37

SCART 1 AUDIO L/R IN

SCART 1 AUDIO L/R OUT

K1001

SCART 1

SC_1 VIDEO IN

43

SC_1 VIDEO OUT

Q1001

Q1002

807978

77

SC1 FB IN

SC_1 R-IN

SC_1 G-IN

SC_1 B-IN

30

29

X122

25

X121

SIF IN

24

IF IN

TUNER

A101

5v30v

Page 5

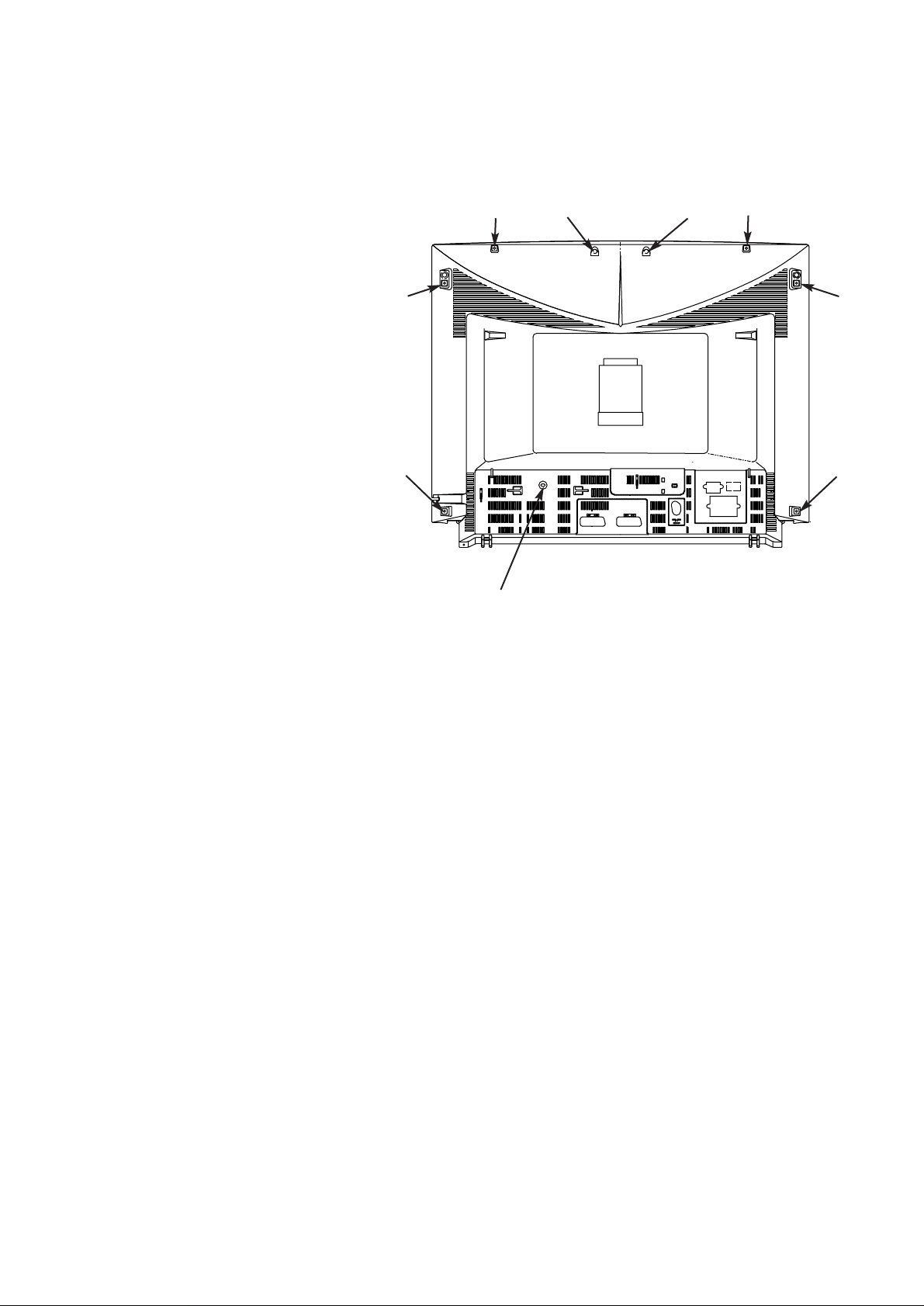

-4-

C7WASÍ

(A)

(A)

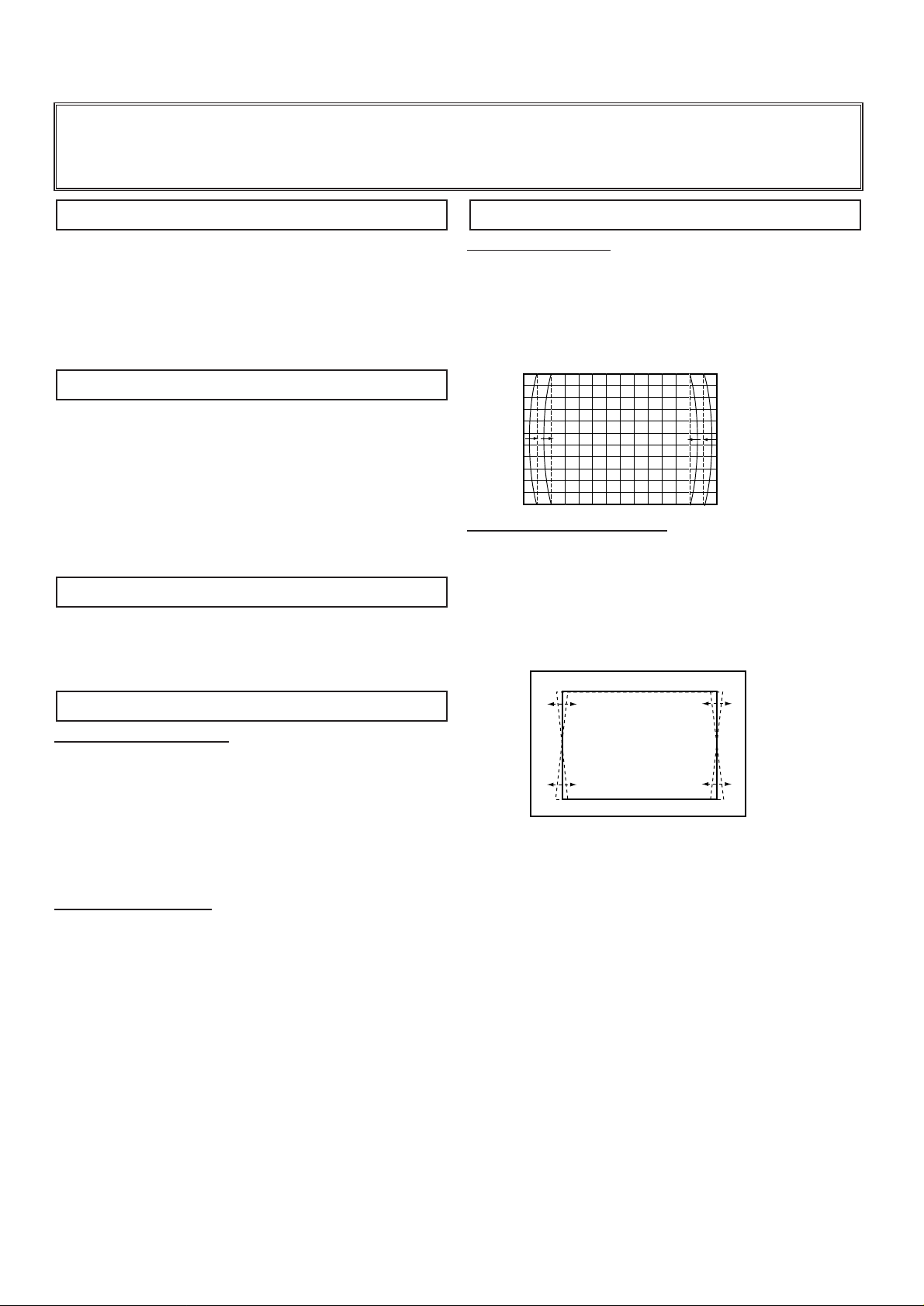

CABINET DISASSEMBLY

CABINET BACK DISASSEMBLY

1. Remove 9 screws(A) for 28”

2. Pull out the cabinet back.

(A)

(A)

(A)

(A)

(A)

(A)

(A)

Page 6

-5-

C7WAS

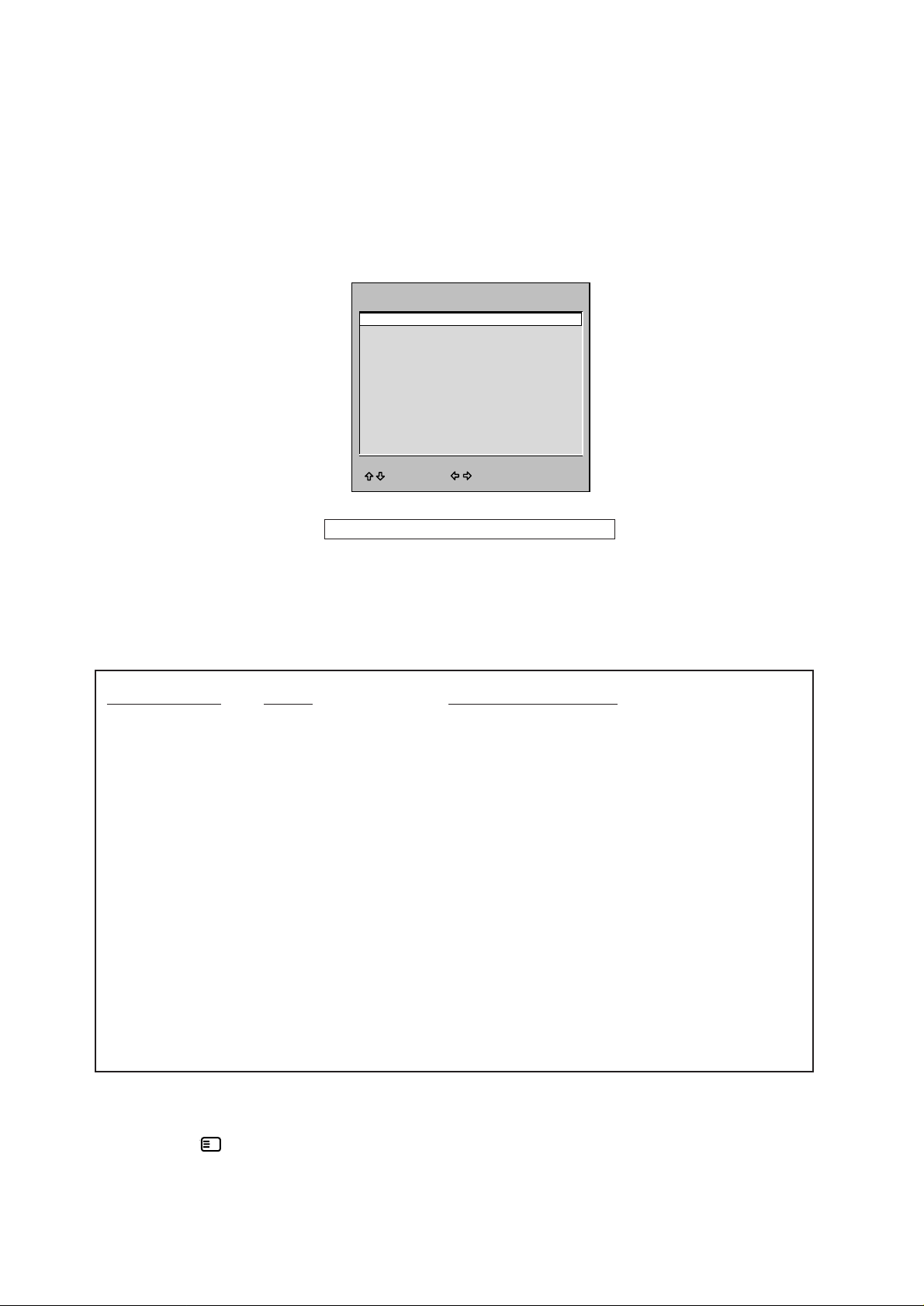

OPTION SETTING

[After replacing the Memory IC (IC801)]

The memory IC, IC801, stores the option data of TV set and service adjustments data for each circuit, therefore,

when the memory IC is replaced, it should be programmed to the following settings and “SERVICE ADJUSTMENT”

on pages 6 to 9.

To enter to the Option Mode

+ Press and hold the F/OK button on the remote control and P▼ button on the front panel of the TV. The option

window will appear on the screen.

To set the Option Mode

+ Highlight the desired option item by using the P▲ or P▼ button .

+ To switch the option mode, use the Volume - (LEFT) or Volume + (RIGHT) button.

+ The data which is set in the option mode is stored into the memory IC automatically.

The following table shows the available option items and default setting mode.

Exit from the Service Mode

+ Press the MENU button.

Option Mode Mode Description & Note

SORT MODE SORTING or Tuning mode, default “SORTING”

TUNING

P & P ON or OFF Plug & Play mode, default “ON”

WEL. TEXT ON or OFF Display message when first set up, default “ON”

AUTO VOLUME ON or OFF Auto volume default “OFF”

SURROUND ON or OFF Surround sound default “ON”

VIRT SUB WOOFER ON or OFF Virtual Sub Woofer default “ON”

COUNTRY UK or IRE or TV system, default “UK”

BG/DK / I / LL’

WIDE ON or OFF Wide mode, default ON

AV3 ON or OFF Front AV disable, default “ON”

TEXT NO SIGNAL ON or OFF Disables Text when no signal, default “ON”

AFC ON or OFF Auto Frequency Control default “OFF”

OPTION MODE FOR CE28DN9-B-01

i

OPTION

SORT MODE SORTING

P&P ON

WEL. TEXT ON

AUT O VOLUME OFF

SURROUND ON

VIRT SUB WOOFER ON

COUNTRY UK

WIDE ON

AV3 ON

TEXT NO SIGNAL ON

AFC OFF

ADJUST : EXIT : RECALL

Page 7

-6-

C7WAS

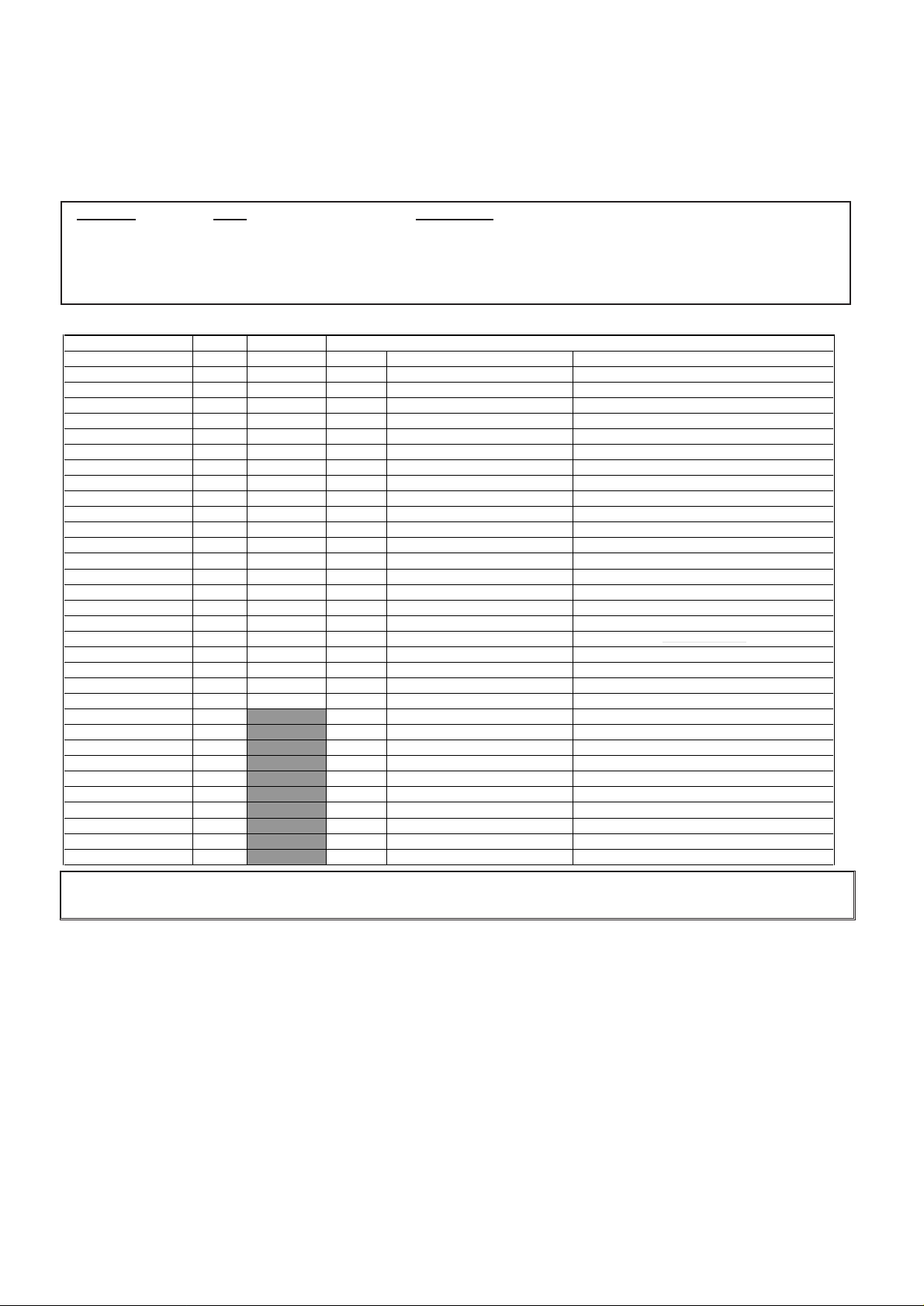

SERVICE ADJUSTMENTS

After replacing the Memory IC (IC801)]

The memory IC, IC801, stores the service adjustments data for each circuit, therefore, when the memory IC is

replaced, it should be programmed by using “OPTION SETTING” on previous page and the following adjustments.

ADJUSTABLE SERVICE ADJUSTMENT

Item No. OSD Description

7 VG2 Screen adjustment

151 WPR - N R - Drive adjustment

152 WPG - N G - Drive adjustment

304 AGC Take Over AGC adjustment

314 TXT - H - POS OSD Positioning adustment

IMPORTANT NOTICE

Do not attempt to adjust service adjustments not listed above otherwise it may cause loss of performance and product safety.

GEOMETRY SERVICE DATA

Service Item Number. Symbol 1 Symbol 2

13

14 A02

15 A03

16 A04

17 A05

18 A06

19 A07

20 A08

21 A09

22 A10

23 A11

24 A12

25 A13

26 A14

27 A15

28 A16

29 A17

30 A18 H BLK SW

31 A19 H BLK L

32 A20 H BLK R

33 A21 OSVE

34 A22 EVB

35 B02

36 B09

37 B10

38 B11

39 B12

40 B13

41 B14

42 B15

43 B16

44 B17

A01

Track. mode 50Hz Full

Vert. Zoom 50Hz Full

Vert. Slope 50Hz Full

Vert. Shift 50Hz Full

Vert. Ampl. 50Hz Full

S-Corr. 50Hz Full

V.Lin.Ctrl. 50Hz Full

V.Linearity 50Hz Full

EW Width 50Hz Full

Hor. Shift 50Hz Full

EW Parabola 50Hz Full

Trapezium 50Hz Full

UC Parabola 50Hz Full

LC Parabola 50Hz Full

Hor. Bow 50Hz Full

Parallel 50Hz Full

Vert. Scroll 50Hz Full

Vert. Zoom 50Hz Natural / or 4:3 squeeze mode

EW Width 50Hz Natural / or 4:3 squeeze mode

Hor. Shift 50Hz Natural / or 4:3 squeeze mode

EW Parabola 50Hz Natural / or 4:3 squeeze mode

Trapezium 50Hz Natural / or 4:3 squeeze mode

UC Parabola 50Hz Natural / or 4:3 squeeze mode

LC Parabola 50Hz Natural / or 4:3 squeeze mode

Hor. Bow 50Hz Natural / or 4:3 squeeze mode

Parallel 50Hz Natural / or 4:3 squeeze mode

Vert. Scroll 50Hz Natural / or 4:3 squeeze mode

Frequency Wide Mode

50Hz Full

50Hz Full

50Hz Full

50Hz Full

50Hz Full

Explanation

Track. Mode(HCO)

Vertical zoom

Vertical slope

Vertical shift

Vertical amplitude

S-correction

V.Lin.Ctrl.

V.Linearity

EW width

Horizontal shift

EW parabola/width

EW trapezium

EW upper corner parabola

EW lower corner parabola

Horizontal bow

Horizontal parallelogram

Vertical Scroll

RGB blanking mode

Timing of wide blanking front(WBF)

Timing of wide blanking rear(WBR)

Black current measuring lines in overscan

Extended vertical blanking

Vertical zoom

EW width

Horizontal shift

EW parabola/width

EW trapezium

EW upper corner parabola

EW lower corner parabola

Horizontal bow

Horizontal parallelogram

Vertical Scroll

Page 8

-7-

C7WAS

To enter to the Service Mode

+ Press and hold the GREEN button on the remote control and then press the P▼ button on the cabinet.

To select the service item and change data value

+ To select the adjustment item, use the P▲ or P▼ button.

+ To change the service data, use the Volume -(LEFT) or Volume + (RIGHT) button.

+ The data which is set in the service mode is stored into the memory IC automatically.

SERVICE MODE

SERVICE SERVICE SOFTWARE

ITEM ITEM VERSION

NUMBER DESCRIPTION

Exit from the Service Mode

+ Press the MENU button or turn off the TV set by using the Mains switch.

INITIALISATION OF MEMORY IC

To initialise the memory IC (IC801), press and hold the NORMAL button on the remote control, then press

the P▼ button on the front panel of the TV set. The tv set will switch into standby mode. Turn the Mains switch Off

and On, then switch on from standby. The initialisation is now completed.

When initialised the memory IC and all of the setting data (option data and service adjustment data) stored in the IC

are reset to the default value. It is necessary to set the option settings and readjust the service adjustments listed in

this manual and to re-tune all the channels.

SERVICE

000 EB8A 3_52

Page 9

-8-

C7WAS

ADJUSTMENTS

IMPORTANT NOTICE

Do not attempt to adjust the following service adjustments except when adjustments are required in servicing

otherwise it may cause loss of performance and product safety.

1. Receive white raster pattern.

2. Set controls to normal.

3. Connect digital voltmetre to test point TP-B and GND.

4. Adjust voltage to 150 ±0.5V by using VR641.

1. Input and tune an RF signal which is UHF to the clearest station.

2. Connect digital voltmetre to test point TP-A and GND.

4. Enter the service mode and select item no. 304. AGC

TAKE OVER

5. Press the LEVEL+ or LEVEL - button to adjust volt-

age to be 3.2Vdc.

By using FOCUS VR, adjust focus control for well

defined scanning lines.

SCREEN ADJUSTMENT

1. Receive black and white pattern.

2. Enter the service mode and select item no. 7. VG 2

3. Turn screen VR from min to max. OSD will change

from below to above. Turn back until below appears

and then stop turning.

DRIVE ADJUSTMENT

6. Select item no.151. WPR - N (R-Drive) or 152. WPG -

N (G-Drive) and adjust both initially to 20.

7. Change data value of each item by using LEVEL + or

LEVEL - button to obtain the proper white balance.

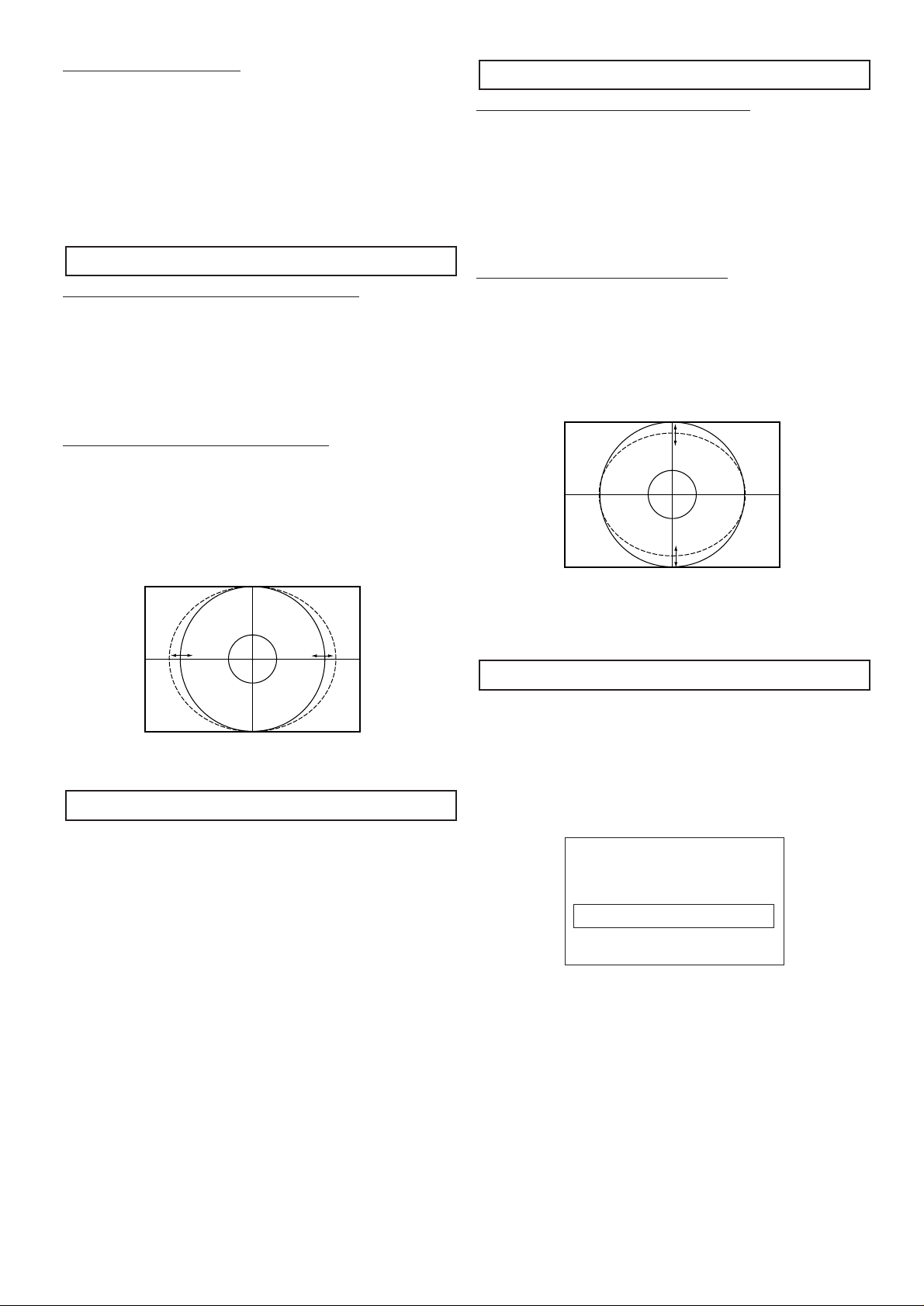

PCC ADJUSTMENT

1. Receive cross hatch pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 23. EW

PARABOLA

3. Press the LEVEL+ or LEVEL - button to adjust the

vertical line to be straight.

TRAPEZOID ADJUSTMENT

1. Receive cross hatch pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 24.

TRAPEZIUM

3. Press the LEVEL+ or LEVEL - button to correct the

trapezum distortion of the vertical line.

PCC ADJUSTMENT

GREY SCALE ADJUSTMENT

FOCUS ADJUSTMENT

AGC ADJUSTMENT

+ B VOLTAGE ADJUSTMENT

Page 10

-9-

C7WAS

CORNER ADJUSTMENT

1. Receive cross hatch pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 25. UC

PARABOLA for top corner adjustment OR item no.

26. LC PARABOLA for bottom corner adjustment.

3. Press the LEVEL+ or LEVEL - button to correct the

distortion of the vertical line around the corners.

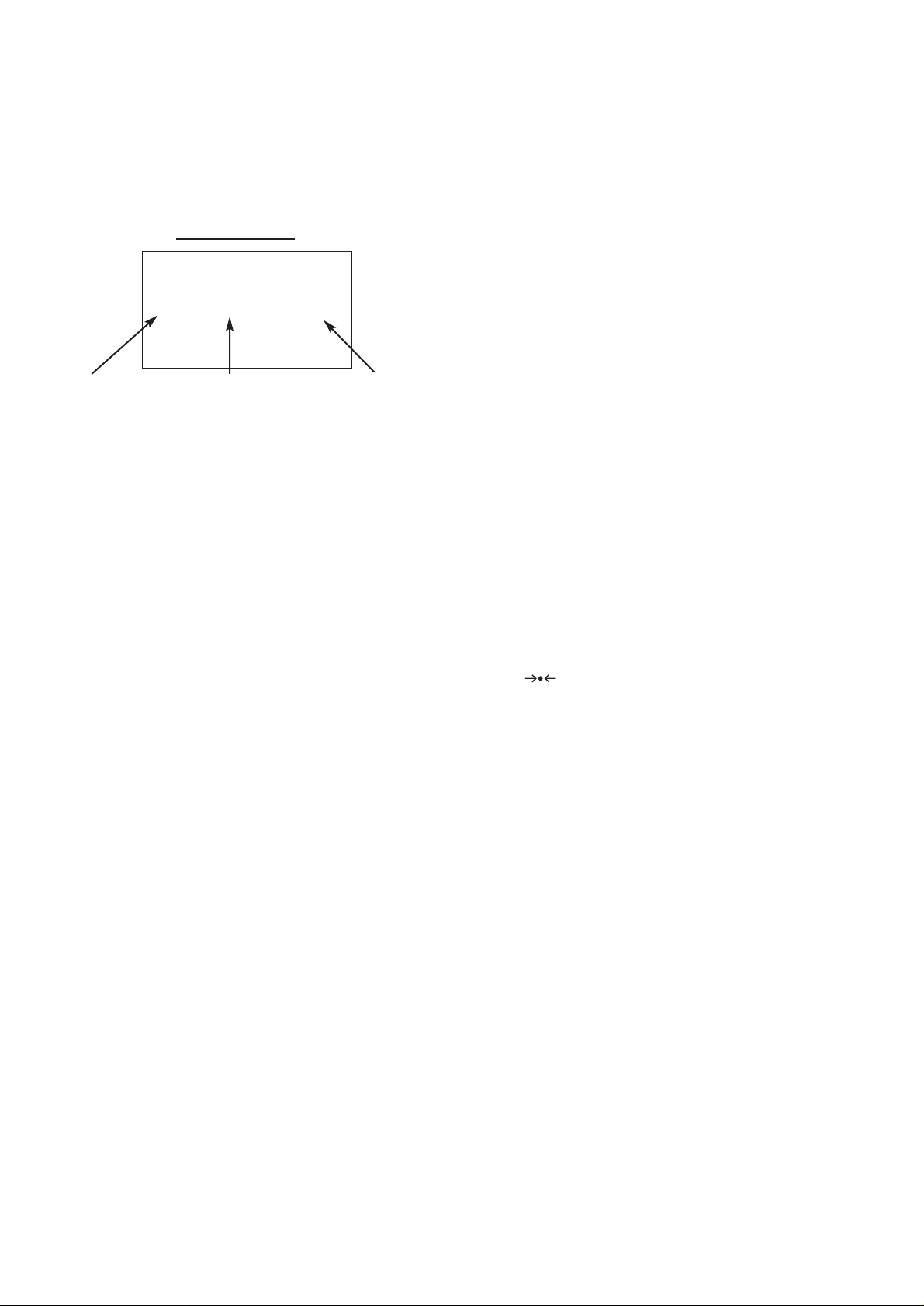

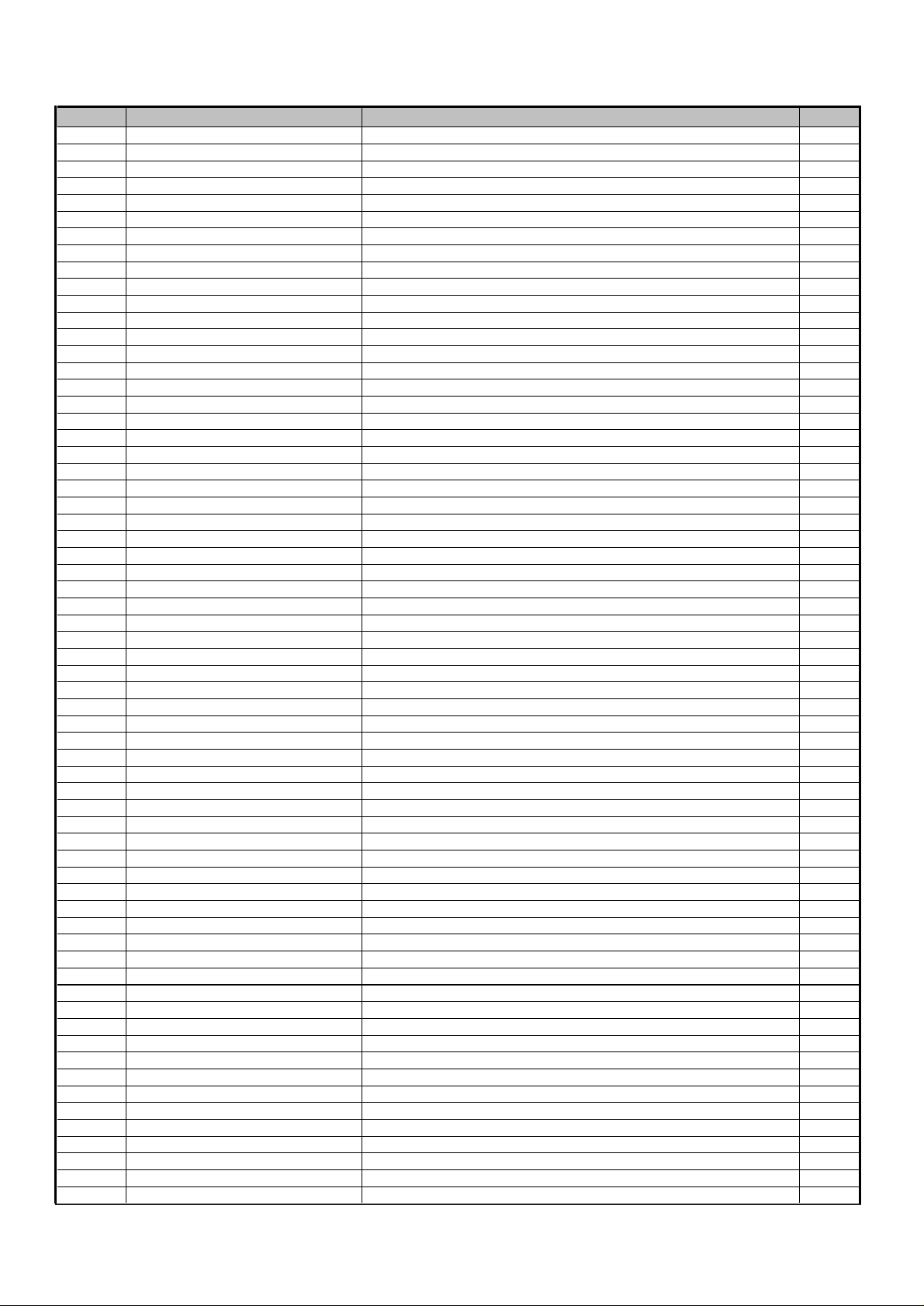

HORIZONTAL CENTRING ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 22. HOR.

SHIFT.

3. Press the LEVEL+ or LEVEL - button to adjust the

horizontal centre.

HORIZONTAL WIDTH ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter to the service mode and select item 21. EW

WIDTH.

3. Press the

LEVEL+ or LEVEL - button to adjust the

horizontal width.

1. Receive circular pattern and set screen mode to

“FULL”.

2. Set controls for brightness and contrast to maximum.

3. Connect high-voltage meter to the anode of CRT and

GND.

4. Confirm that voltage is 26 kV ±1.0kV at maximum

beam current 1.2mA ± 0.05

VERTICAL CENTRING ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no.16.VERT

SHIFT.

.3 Press the LEVEL+ or LEVEL - button to adjust the

vertical centre.

VERTICAL HEIGHT ADJUSTMENT

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 17. VERT

AMPL.

3. Press the LEVEL+ or LEVEL - button to adjust the

vertical height.

1. Receive circular pattern and set screen mode to

“FULL”.

2. Enter the service mode and select item no. 314. TXT H - POS.

3. Press the

LEVEL+ or LEVEL - button to adjust

proper OSD positioning.

OSD POSITIONING ADJUSTMENT

VERTICAL ADJUSTMENT

HIGH-VOLTAGE CONFIRMATION

HORIZONTAL ADJUSTMENT

314 TXT - H - POS 7

Page 11

-10-

C7WAS

CPU PORT FUNCTIONS

Pin No Function Name Function In/Out

1 VSS Gnd -2 VSS Gnd

3 1v8_1 1.8v Supply -4 3v3 3.3v Supply -5 Vref 3.3v Reference -6 Vref V Ref Gnd -7 Vref 3.3v Reference -8 Vref V Ref Gnd --

9 Vref 3.3v Reference -10 XTAL IN Clock Oscillator In

11 XTAL OUT Clock Oscillator Out

12 Vss Gnd -13 Vguard sw -14 Dec Dig 1.8v source supply Out

15 5v 5v Supply -16 Phi 2 Phi 2 -17 Phi 1 Phi 1 -18 Gnd Gnd -19 Sec pii -20 Dec BG -21 EW Drive parabola out Out

22 VdrB Vertical drive B Out

23 VdrA Vertical drive A Out

24 Vif 1 Vision IF 1 In

25 Vif 2 Vision IF 2 In

26 Vsc -27 I Ref Reference current -28 Gnd Gnd -29 Sif 1 Sound IF 1 In

30 Sif 2 Sound IF 2 In

31 Agc Auto matic gain control In

32 Eht Eht In

33 SSif/Ref Iin/Avl/Ref Out -34 Audio in Scart L In

35 Audio in Scart R In

36 Audio Out Scart L Out

37 Audio Out Scart R Out

38 -39 Qsso/Amo/AudioEm -40 Gnd -41 PLL IF Phase Lock Loop If -42 SifAgc SifAgc -43 IFVo Scart 1 Video Out

44 FmRo -45 V8Audio Switches -46 AgcsSif -47 V5P2 5v Supply -48 Svo/IfVo/Cbvs1 Scart 2 Video Out

49 Audio4 L In Scart 2 Audio L In

50 Audio4 R In Scart 2 Audio R In

51 Y4/Cvbs4 Av3 Video In

52 C4 -53 Audio2InL Av3 Audio L In

54 Audio2InR Av3 Audio R In

55 Cvbs2/y Scart 1 Video In

56 Audio3InL -57 Audio3InR -58 Y3/Cvbs Scart 2 Video In

59 C3 Scart 2 Chroma In In

60 Audio Out L SL Audio out Left Speaker Out

61 Audio Out L SR Audio Out Right Speaker Out

62 Audio Out HPL Scart Audio L Out 2 / monitor Out Out

63 Audio Out HPR Scart Audio R Out 2 / monitor Out Out

64 Pip --

Page 12

-11-

C7WAS

CPU PORT FUNCTIONS (continued)

Pin No Function Name Function In/Out

65 SVM Scan Velocity Modulation Out

66 FbiSo Flyback In SandCastle Out In/out

67 Hout Horizontal Drive Out Out

68 VssComb Gnd

69 V5Comb 5v Supply -70 Vin/R2/Pr Scart 2 R-In In

71 Uin/B2/Pb Scart 2 B-In In

72 Yin/G2/Y Scart 2 G-In In

73 Y Sync Y Sync In

74 Y out Yout Out

75 Uout/Fb in Scart 2 Fast Blanking In

76 Vout/Sw01 -77 Fbl3 Scart 1 Fast Blanking In

78 R3/Pr Scart 1 R-In In

79 G3/Y Scart 1 G-In In

80 B3/Pb Scart 1 B-In In

81 Gnd 3 Gnd -82 V5P3 5vSupply -83 BCL Beam Current Limiting In

84 Iblack -85 Rout Red Drive Out

86 Gout Green Drive Out

87 Bout Blue Drive Out

88 V3.3A1 3.3v Supply -89 RefAdn Ref Gnd -90 V3.3RefAdp 3.3v Supply -91 RefAd -92 GndA Gnd -93 V1.8A 1.8v Supply -94 V3.3A2 3.3v Supply -95 VssAdc Gnd -96 V1.8Adc 1.8v Supply -97 Into Remote control In In

98 P10/Int1 SCl In/out

99 P121/TO SDA In/out

100 V1.8C2 1.8v Supply -101 VssC2 Gnd -102 P04/I2Sws -103 P03/I2SCLk -104 P02/I2SDOC -105 P01/I2SDOC -106 P00/I2SDi1 StandBy Out

107 P13/T1 On/Off Out

108 P16/SCL SCL In/out

109 P17/SDA SDA In/out

110 V3.3P 3.3v Supply -111 P20/Tpwm Relay On/Off Out

112 P21/Pwmo LED Drive Out

113 STATUS Status In/out

114 ALK Alk In/out

115 P30/Adco Scart 1 Pin8 Function In

116 P31/Adc1 Scart 2 Pin8 Function In

117 V1.8C1 1.8v Supply -118 DecV1v8 1.8v Supply -119 P32/Adc2 AGC In

120 P33/Adc2 Key scan in In

121 VssC1+P1 Gnd -122 P24/Pwm3 Audio Mute Out

123 P25/Pwm4 L/L’ switch (Export only) Out

124 V1.8C3 1.8v Supply -125 Vssc3 Gnd -126 P12/Int2 -127 P14/Rx Power Fail In

128 P:15/Tx Natural Wide Switch

Page 13

-12-

C7WAS

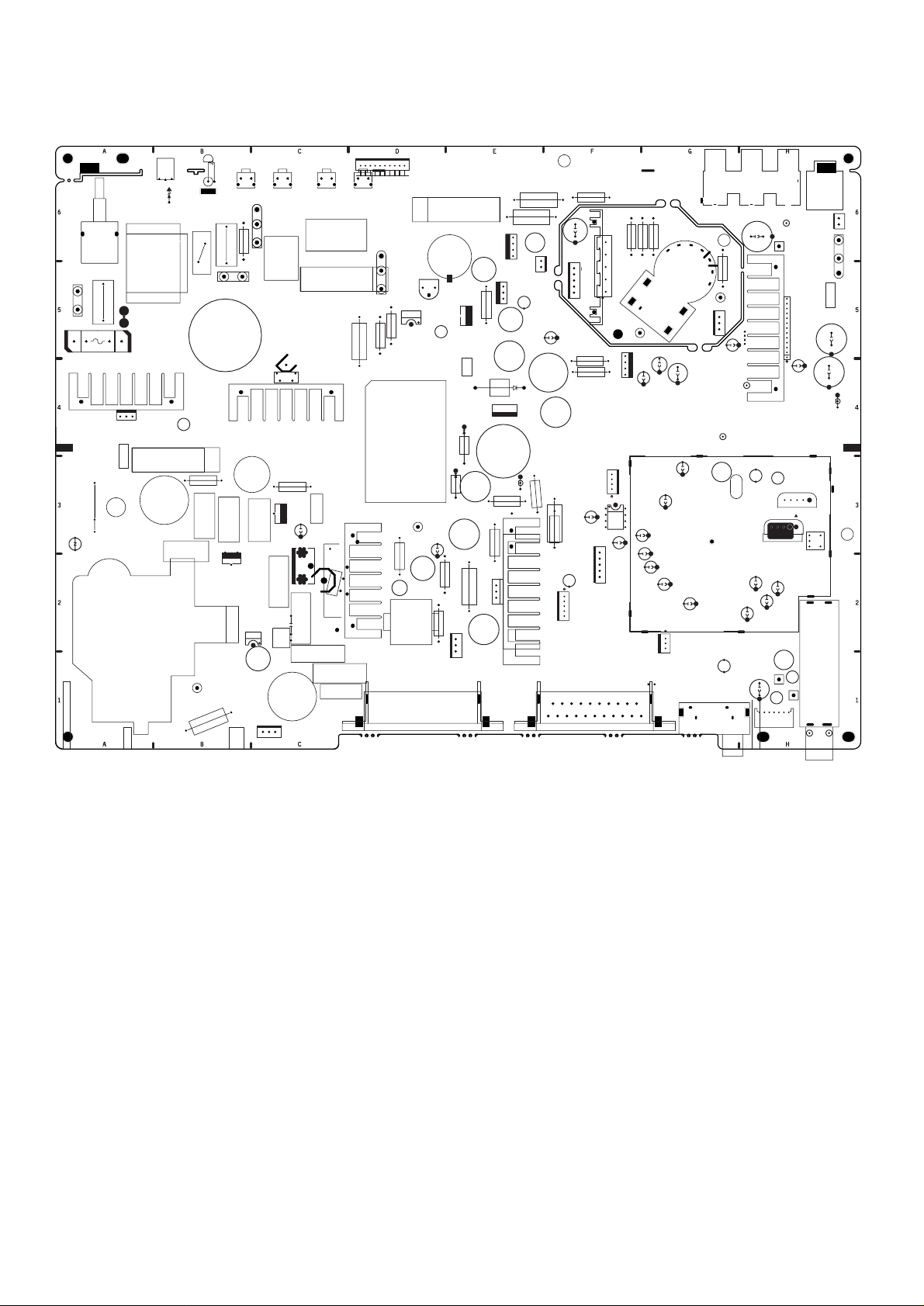

COMPONENT LOCATIONS

MAIN BOARD / FRONT BOARD / CRT BOARD

DANGER

LIVE MAINS

SW601

KFF-1

KFF

1

2

KFF-2

F601-1 F601-2

F601

R474

C437

L461

C451

EB8A

C601

Q461

L601

L608

T4AH250V

T4AL250V

Q461-1

A1901

R435

L441

D1901

C446

D1911

C486

C441

KSC

R451

VA601

R441

T451

SW1901 SW1902

C602

R601

KE

KE-2KE-1

2

C609

L442

C443

Q451

KF-2

C427

C481

KF

KF-1

KF

D441

PS601

Q425

C423

IC601

R477

L462

KQ

C429

C421

C422

SW1903

C426

K4A

RL601

R602A

Q432

C424

C466

SW1904

R614

3

KA

R606

KGG

R449

R607

C434

T611

D610

C503

T431

K1002

TP-B

C529

C655

R511

R637

VR641

R433

K4B

C637

D648

D633

D630

D639

C501

R512

C682

D642

C686

R502

IC501

C502

B10E33300

R692

R691

IC643

C650

C685

IC666

R667

C667

C643

D635

C642

Q642

C640

R501

K2

C691

C633

K5

C271

A

1

R515

C710

R699

K7P

R648

C205

R644

KP

K4

1

K1001

IC701

IC801

IC641

C206

8

5

R715

K7V

R705

C645

C288

R725

C283

C648

C281

C268

K701

C803

C210

K3

B10E3330B

***

K7Q

C841

C256

C1001

K1003

C022

JW2

C203

A

R742

K7Y

3

1

K1101

K1101

C023

J006

JW1

C214

X201

C229

C236

C233

C239

TP-A

C102

17

X122

C101

KCPA

JW3

KEM1

X121

C103

KEM2

IC001

C209

C104

K031

T131

A101

JWA

12

KR-2

21

KRKL

KR-1

R031

C009

C010

Q202

B10E3330A

DB=KG_PCB

CELL=B10E33300

A

***

JWB

Page 14

-13-

C7WAS

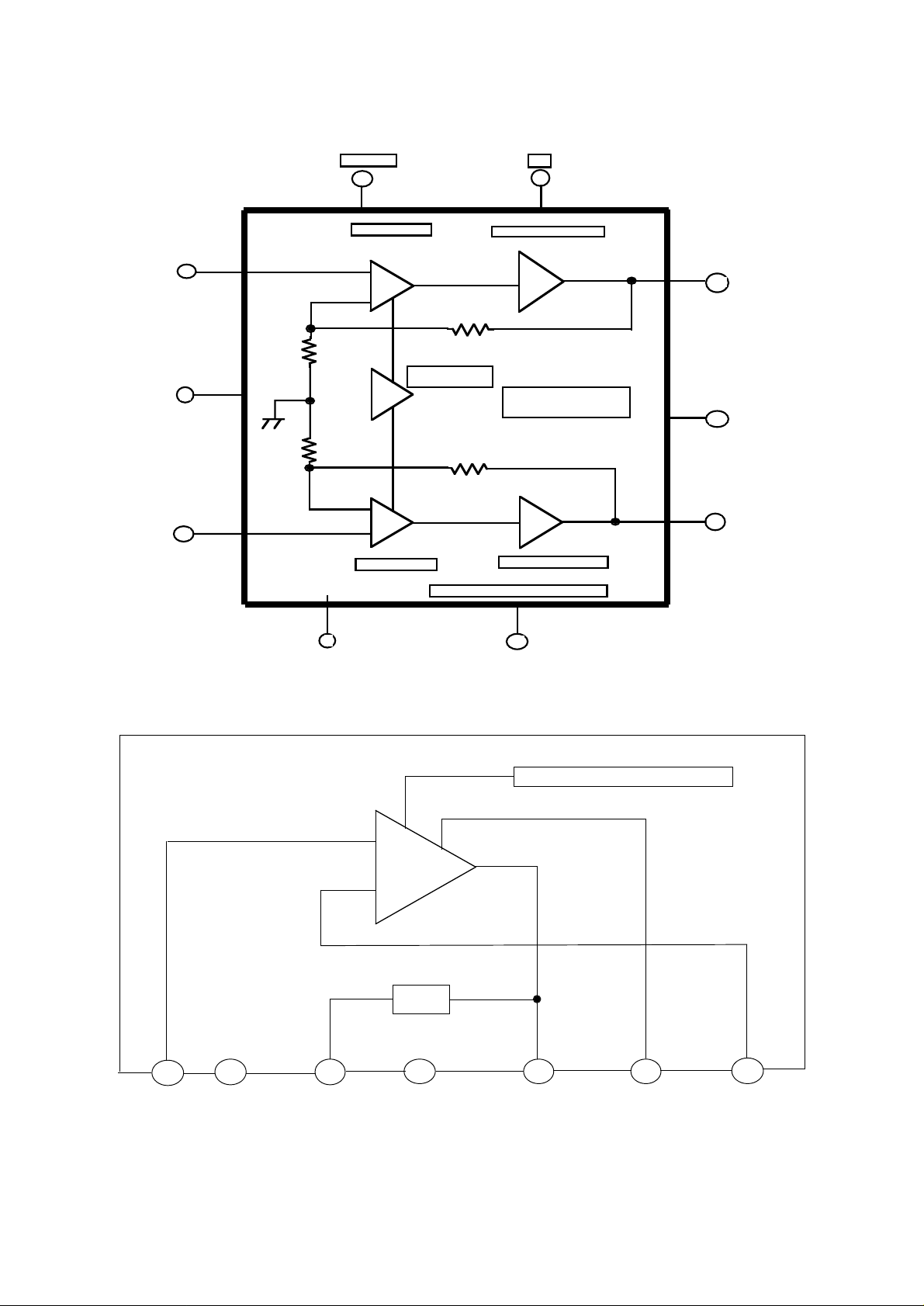

IC BLOCK DIAGRAMS

IC001 LA42052 <Audio Output>

Vcc

IC501 LA78041 <Vertical Output>

STAND BY

5 7

IN 2

IN 1

INPUT AMPLIFIER

REFERENCE

AMPLIFIER

3

4

INPUT AMPLIFIER

RIPPLE FILTER

1

RIPPLE FILTER

POP NOISE PREVENTION BLOCK

OUTPUT AMPLIFIER

THERMAL PROTECTION CIRCUIT

OUTPUT AMPLIFIER

6

P.P

12

OUT 1

POWER

10

GND

OUT 2

8

1

INVERTING

2

Vcc

INPUT

3

OUT

PUMP UP

-

AMPLIFIER

+

PUMP

UP

4

GND

THERMAL PROTECTION CIRCUIT

5

6

VER

OUTPUT

OUTPUT STAGE Vcc

7

NON INV. INPUT

Page 15

-14-

C7WAS

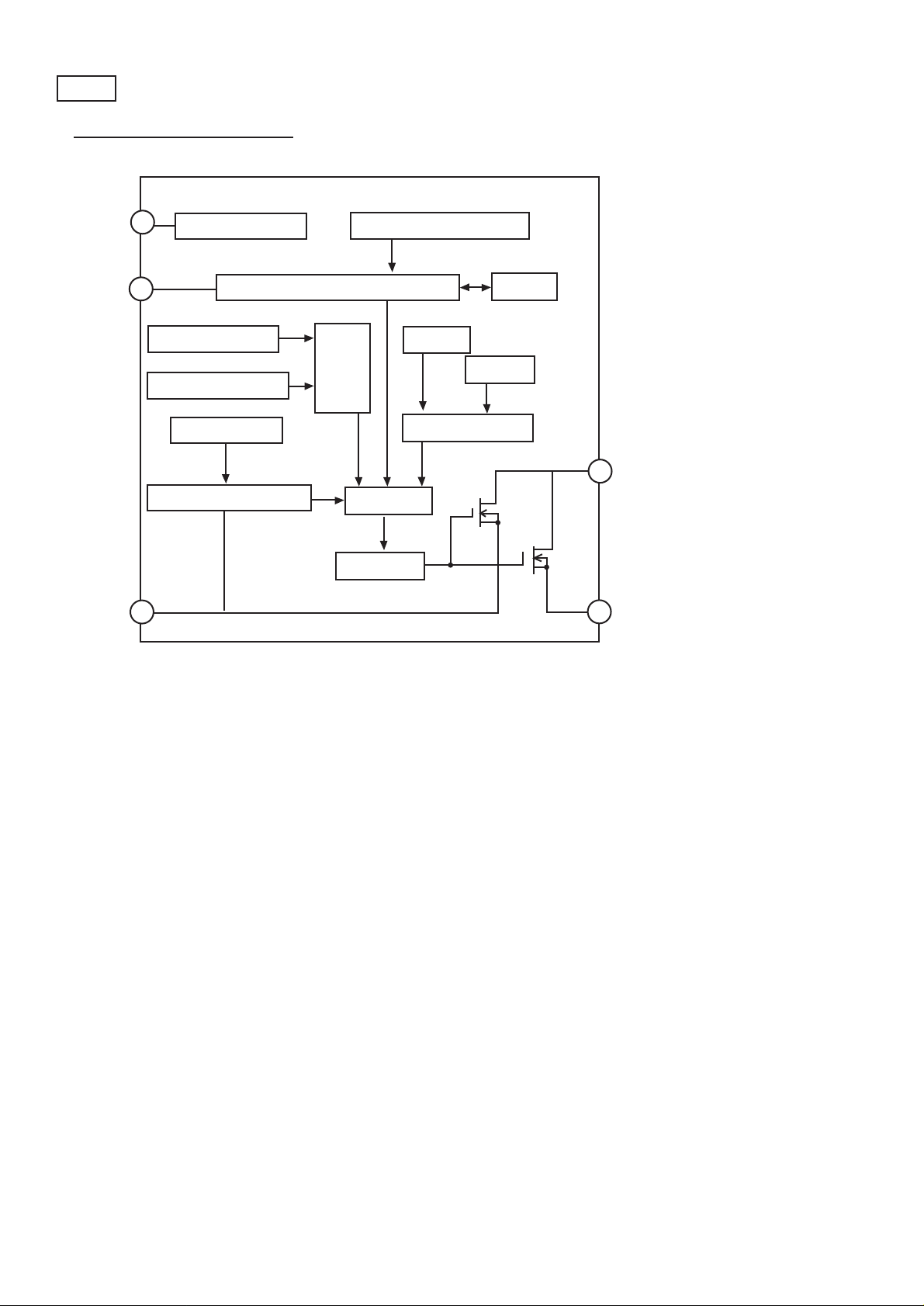

IC601

Block Diagram TN6Q03/04

VDD pin

EDGE pin

FB pin

4

Internal power supply

2

Over heat protection

Over voltage protection

Reference Voltage

Over current/FB comparator

1

Input Under voltage protection

Falling edge detection

Latch

Circuit

Logic

Driver

Oscillator

Burst On

Burst Off

Latch for Burst circuit

3

DRAIN pin

5

SOURCE (GND) pin

Page 16

-15-

C7WAS

Page 17

-16-

C7WAS

PIN DESCRIPTION OF SEMICONDUCTORS

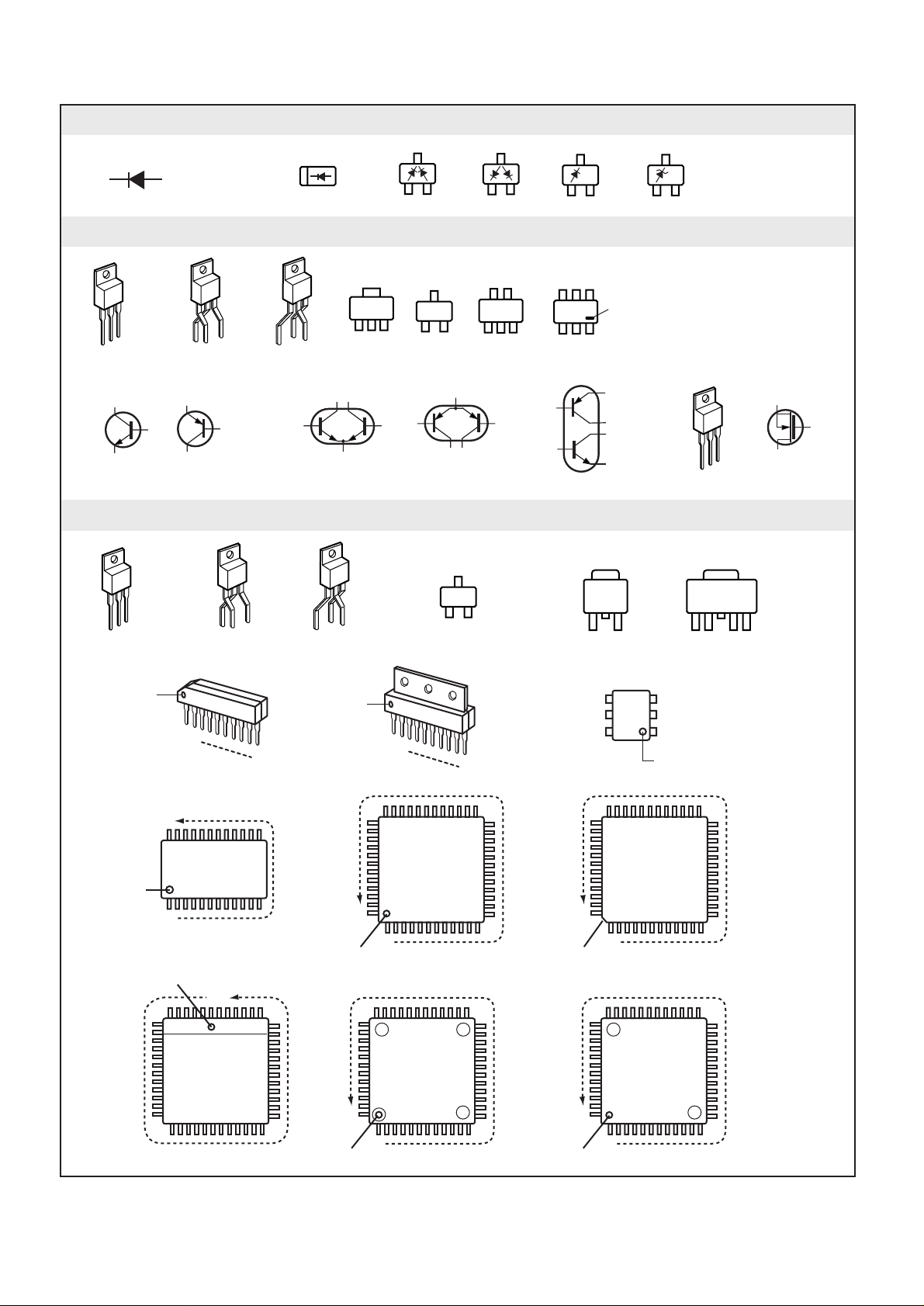

● Diode

● Transistor/FET

● IC

FET

● Diode

K

● Transistor/FET

A

K

A

K

AA

KK

A

K

K

K: Cathode

A: Anode

A

A

C

B

C

E

● IC

1

E

3

2

Index

C1

3

E

C2

Vdd

2

1

C1

C2

B1 B2

E

B2

GND

C

C

E

B

C

E

B

B

2

3

1

E

C1

CBE

C2

B2

E

3

2

C

B

B1

1

C

BE

B1

RESET

Index

1

2

N

1

2

N

C2

E2 C1

B1

B2

B1

B2

(IN)

E1

1

(GND)

2

4

5

6

Index

E1

C1

C2

E2

3

(OUT)

C: Collector

B: Base

E: Emitter

G

3

2

1

Index

D: Drain

G: Gate

S: Source

S

G

D

S

D

3

21

5

4

Index

N

1

Index

Index

Index

N

1

N

1

N

1

Index

N

1

N

1

Index

Page 18

-17-

C7WAS

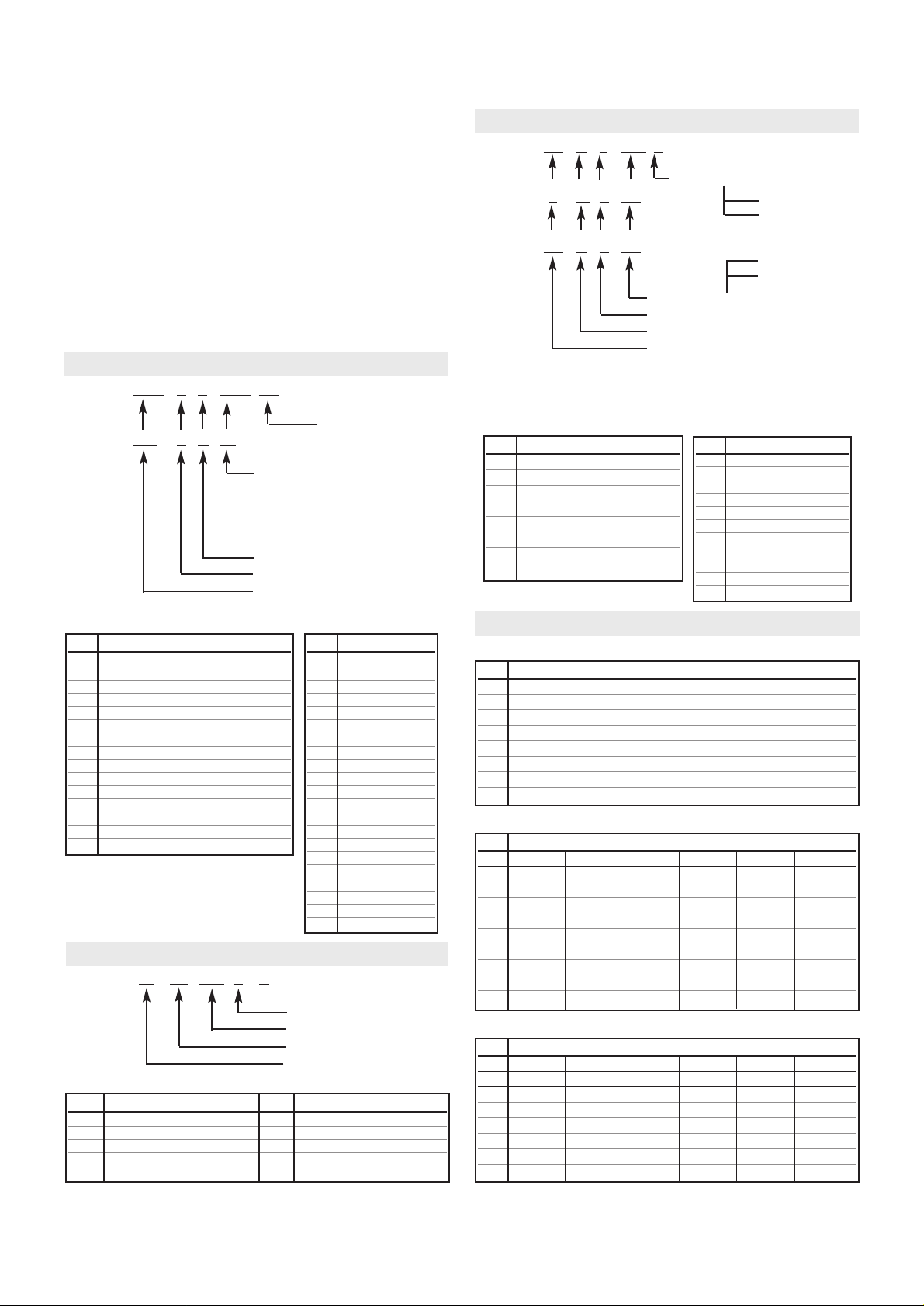

PARTS DESCRIPTION AND READING IN SCHEMATIC DIAGRAM

1. The parts specification of resistors, capacitors and

coils are expressed in designated code. Please

check the parts description by the following code

table.

2. Some of transistors and diodes are indicated in

mark for the substitution of parts name. Please

check the parts name by the following code table.

3. Voltages and waveforms were taken with a video

colour bar signal(1Vp-p at 75 ohms terminated) and

controls to normal.

4. Voltages were taken with a high-impedance digital

voltmetre.

Example 2000 K K 1000 BG

Characteristic

Example 160 E M 10

Capacitance value

Tolerance

Type

Rated voltage

Excepting electric capacitors, all

capacitance values of less than 1

are expressed in µF and more

than 1 are in pF.

Example L2

C1 4R7 K N

Tolerance

Inductance value

Manufacture code

Unique code

Mark Material

E Electrolytic

P Electrolytic (non-Polarised)

C Ceramic (temperature compensation)

K Ceramic

F Polyester

N Polypropylene

M Metalised polypropylene

H Metalised polypromylar

B Ceramic (semiconductor)

G Metalised polyester

Y Composite film

S Styrol

T Tantalum oxide solid electrolytic

U Organic semiconductive electrolyte

D Electric double layer electrolytic

Mark Tolerance

A not specified

B ±0.1

C ±0.25

D ±0.5

F±1

G±2

E ±2.5

H±3

J±5

K±0

M±20

N±30

P +100 -0

Q +30 -10

T +50 -10

U +75 -10

V +20 -10

W +100 -10

X +40 -20

Y +150 -10

Z +80 -20

Mark Tolerance (nH) Mark Tolerance (%)

C ±0.25 G ±2

D ±0.5 J ±5

S ±0.3 K ±10

A ±0.2 L ±15

M±20

Coil Reading

Capacitor Reading

Example 1/2 D J 10K B

Example 6 W K 8.2

Example 1/2 C K 1M

Resistor Reading

Characteristic

Z (Carbon fuse)

B (Non-burnable)

Resistance value

Tolerance (see below table)

Material (see below table)

Rated wattage (W)

K indicates in KΩ

M indicate in MΩ

Note: Resistor which is indicated with resistance value only are

1/6W carbon resistor. Resistor which is indicated with material, tolerance and value are 1/4W rated wattage.

Mark Material

D Carbon

N Metal film

S Oxide metal film

C Solid

G Metal glaze

W Wire wounding or cement

H Ceramic

F Fusible

Mark Tolerance

A ±0.05

B ±0.1

C ±0.25

D ±0.5

F±1

G±2

J±5

K±10

M±20

P +5 -15

Z used in 0 ohm

● Material table

● Tolerance table

● Material table

● Tolerance table

Mark Type number

-- 1S1555,1S2473,1S2076,1SS133,DS442,1SS176

K 1S1555,1S2473,1S2076,DS442

L 1S1555,1S2076A,1S2471

M 1SS133,1SS176,GMA01

N 1S1555,1S2473,1S2076,1SS133,DS442,1SS176,1N4148

P 1S1555,1S2076A,1S2471,1N4148

R 1S1555,1S2076,1S2473,DS442,1N4148

AA 1S1555,1S2076,1S2473,1SS133,DS442,1SS176,1N4148,GMA01

● Diode

Mark Type number

-- 2SC536 2SC945A 2SC1815 2SC1740 2SC1740S KSC945C

A E, F, G P, Q, R O, Y, G Q, R, S Q, R, S

B E, F, G P, Q, R O, Y, G Q, R, S

D F, G P, Q Y, G Q, R, S

F F, G P G R, S

H F, G P, Q Y, G Q, R, S Y, G

I E, F, G P, Q, R O, Y, G Q, R, S Y, G

G F, G P G R, S G

AD F, G Q, R Y, GR Q, R, S

AE E, F, G Q, R O, Y, GR Q, R, S

● Transistor (NPN type)

Mark Type number

-- 2SA608 2SA564A 2SA1015 2SA933 2SA933S KSA733C

Y E, F Q, R O, Y, G Q, R

WF R Y, GR

V E, F Q, R O, Y, G Q, R Y, G

U F R Y, G R G

Z E, F Q, R O, Y, G Q, R Q, R

AB F R Y Q, R

AE E, F Q, R O, Y R

● Transistor (PNP type)

Diode/Transistor Type Reading

Page 19

-18-

C7WAS

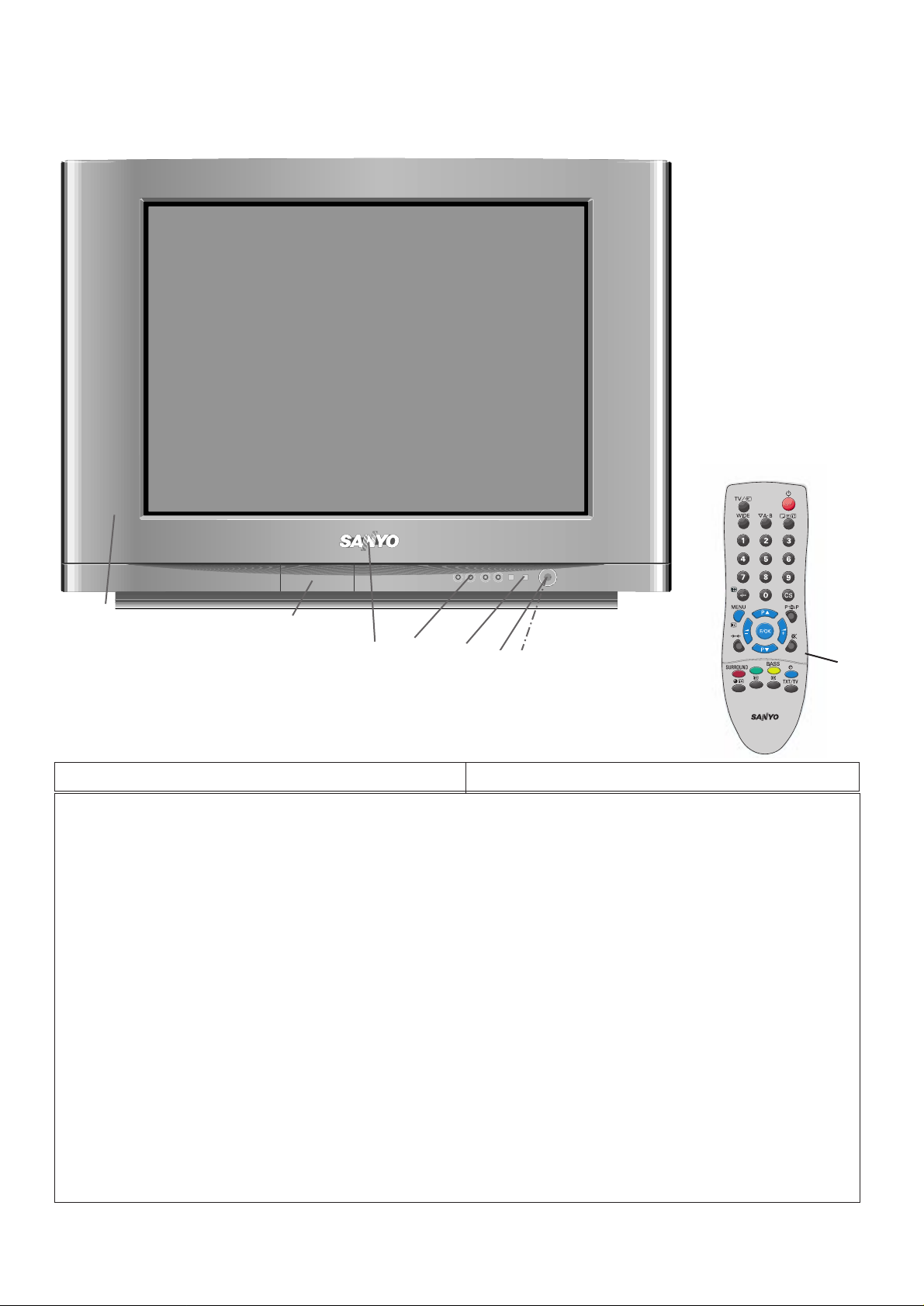

CABINET PARTS LIST FOR MODEL CE28DN9-B-01

CABINET PARTS

1 610 310 7387 CABINET FRONT-C7WA

2 610 301 6665 BUTTON POWER-C6AA

3 610 301 6672 BUTTON UNITED-C6AA

4 610 310 7394 CABINET BACK C7WA

5 610 301 6689 DOOR-C6AA

6 665 000 2654 DEC IND-C7WA

7 610 253 2449 AC CORD HOLDER-U-D4VA

8 610 261 3032 COIL SPRING-E7GCS

9 645 043 5058 BADGE,SANYO*53.5X12L53.3

10 610 265 4202 HOLDER DC GBR-F3SC

ACCESSORIES

11 JXPLA RC TRANSMITTER

645 054 9533 BATTERY ENERGIZER R6SH2VP

665 000 2647 INST MANUAL - C7WA

665 000 2463 QUICK GUIDE - C7WA

Item Part No. Description

Note: Parts order must contain Service Ref. No., Part No., and descriptions.

11

9

1

3

2

8

5

6

JXPLB

Page 20

C7WAS

-19-

CHASSIS ELECTRICAL PARTS LIST

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by a mark in this parts list and the circuit diagram show components whose value have

special significance to product safety. It is particularly recommended that only parts specified on the following

parts list be used for components replacement pointed out by the mark .

013C7WAS ELECTRICAL PARTS DIRECTOR

COIL

L901 645 060 9855 PRE-FORM,D-COIL,28-TOTOKU

PICTURE TUBE

Q901 414 012 4404 CRT A66QEW13X49 SAM BERL.

MISCELLANEOUS

SP901 652 000 0663 SPEAKER 8 OHM 3 WATT 5*9

SP902 652 000 0663 SPEAKER 8 OHM 3 WATT 5*9

W901 645 011 8838 3P AC CORD +2P HOUSE @2.1

W902 665 000 2159 GND CON.EB8A 28" 2P C7WLS

1AA0B10H0690A ASSY,PWB,MAIN C7WAS

CAPACITOR

C-R534 403 067 6274 POLYESTER 0.15U J 50V

C003 403 314 5915 GRM21BR71C474KA01L PT297

C004 403 314 5915 GRM21BR71C474KA01L PT297

C005 403 215 2310 GRM188R71H123KA01D PT115

C006 403 215 2310 GRM188R71H123KA01D PT115

C009 403 047 5065 ELECT 470U M 25V

C010 403 047 5065 ELECT 470U M 25V

C021 403 218 8101 ELECT 100U M 25V

C022 403 051 0627 ELECT 4.7U M 50V

C023 403 218 8151 25 YK 1000 M TA 1020

C030 403 113 3815 GRM188R71H102KA01D PT115

C031 403 086 3802 NP-ELECT 10U M 50V

C032 403 086 3802 NP-ELECT 10U M 50V

C033 403 215 2211 GRM188R71H103KA01D PT115

C034 403 215 2211 GRM188R71H103KA01D PT115

C035 403 215 2211 GRM188R71H103KA01D PT115

C036 403 215 2211 GRM188R71H103KA01D PT115

C040 403 113 4119 GRM188R71H222KA01D PT115

C057 403 113 3815 GRM188R71H102KA01D PT115

C1001 403 248 1618 16 YK 47 M TA 0511

C1003 403 157 3611 GRM1885C1H101JZ01D PT115

C1005 403 113 3815 GRM188R71H102KA01D PT115

C1006 403 157 3611 GRM1885C1H101JZ01D PT115

C1007 403 113 3815 GRM188R71H102KA01D PT115

C101 403 233 1111 ELECT 22U M 50V

C1011 403 248 1618 16 YK 47 M TA 0511

C1013 403 157 3611 GRM1885C1H101JZ01D PT115

C1014 403 157 3611 GRM1885C1H101JZ01D PT115

C1016 403 113 3815 GRM188R71H102KA01D PT115

C1017 403 113 3815 GRM188R71H102KA01D PT115

C102 403 039 3507 ELECT 470U M 6.3V

C1038 403 323 8815 GRM21BF51C225ZA01K PT115

C1039 403 323 8815 GRM21BF51C225ZA01K PT115

C104 403 233 0817 ELECT 10U M 50V

C106 403 215 2211 GRM188R71H103KA01D PT115

C107 403 215 2211 GRM188R71H103KA01D PT115

Ref. No.

Part No.

Description

Chassis construction

CE28DN9-B-01

013C7WAS ELECTRICAL PARTS DIRECTOR (PAGE 19)

1AA0B10H0690A ASSY,PWB,MAIN C7WAS (PAGE 19-24)

1AA0B10H0690B ASSY,PWB,SOCKET C7WAS (PAGE 24)

Read description in the Capacitor and Resistor as follows:

CAPACITOR

CERAMIC 100P K 50V

Tolerance Symbols:

Less than 10PF

A: Not specified B: ±0.1PF C:±0.25PF

D: ±0.5PF F: ±1PF G:±2PF

R: ±0.25-0PF S: ±0-0.25PF E: +0-1PF

More than 10PF

A: Not specified B: ±0.1% C: ±0.25%

D: ±0.5% F: ±1% G:±2%

H: ±3% J: ±5% K: ±10%

L: ±15% M: ±20% N: ±30%

P: +100-0% Q: +30-10% T: +50-10%

U: +75-10% V: +20-10% W:+100-10%

X: +40-20% Y: +150-10% Z: +80-20%

Material:

CERAMIC............Ceramic

MT-PAPER ..........Metallized Paper

POLYESTER ......Polyester

MT-POLYEST......Metallized Polyester

POLYPRO............Polypropylene

MT-POLYPRO ....Metallized Polypropylene

COMPO FILM......Composite film

MT-COMPO ........Metallized Composite

STYRENE............Styrene

TA-SOLID............Tantalum Solid

AL-SOLID............Aluminium Solid

ELECT ................Electrolytic

NP-ELECT ..........Non-polarised Electrolytic

OS-SOLID ..........Aluminium Solid with Organic Semiconductive Electrolytic

DL-ELECT ..........Double Layered Electrolytic

RESISTOR

CARBON 4.7K J A 1/4W

Rated Wattage

Performance Symbols:

A: General B: Non flammable Z: Low noise

Other: Temperature coefficient

Tolerance Symbols:

A: ±0.05% B: ±0.1% C:±0.25% D: ±0.5%

F: ±1% G: ±2% J: ±5% K: ±10%

M:±20% P: +5-15%

Rated value, ohms:

K: 1,000, M: 1,000,000

Material:

CARBON ............Carbon

MT-FILM..............Metal Film

OXIDE-MT ..........Oxide Metal Film

SOLID..................Composition

MT-GLAZE ..........Metal Glaze

WIRE WOUND....Wire Wound

CERAMIC RES....Ceramic

FUSIBLE RES ....Fusible

Rated Voltage

Rated value: P=pico farad, U=Micro farad

Note: Parts order must contain Service Ref. No., Part No., and descriptions.

!

!

!

!

!

!

!

Page 21

C109 403 113 3815 GRM188R71H102KA01D PT115

C110 403 113 4119 GRM188R71H222KA01D PT115

C1101 403 113 3815 GRM188R71H102KA01D PT115

C1106 403 113 3815 GRM188R71H102KA01D PT115

C121 403 067 6274 POLYESTER 0.15U J 50V

C122 403 215 2211 GRM188R71H103KA01D PT115

C123 403 113 3815 GRM188R71H102KA01D PT115

C126 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

C1901 403 195 8824 ELECT 100U M 16V

C1902 403 195 8824 ELECT 100U M 16V

C200 403 215 2211 GRM188R71H103KA01D PT115

C201 403 269 5916 GRM219R71C224KC01D PT115

C202 403 269 5916 GRM219R71C224KC01D PT115

C203 403 308 3409 ELECT 1000U M 6.3V

C204 403 164 0214 GRM188F51E104ZA01D PT115

C205 403 241 3817 10 YK 220 M TA 0511

C206 403 241 3817 10 YK 220 M TA 0511

C207 403 269 5916 GRM219R71C224KC01D PT115

C208 403 323 8815 GRM21BF51C225ZA01K PT115

C209 403 195 8804 ELECT 100U M 16V

C210 403 241 3817 10 YK 220 M TA 0511

C211 403 164 0214 GRM188F51E104ZA01D PT115

C212 403 215 2211 GRM188R71H103KA01D PT115

C213 403 157 7312 GRM188R71H682KA01D PT115

C214 403 248 1410 50 YK 1R0 M TA 0511

C215 403 157 1914 GRM1885C1H100JZ01

C216 403 269 5916 GRM219R71C224KC01D PT115

C217 403 284 4314 CERAMIC 0.022U K 50V

C218 403 323 8815 GRM21BF51C225ZA01K PT115

C219 403 113 3815 GRM188R71H102KA01D PT115

C220 403 157 1914 GRM1885C1H100JZ01

C221 403 113 3815 GRM188R71H102KA01D PT115

C222 403 323 8815 GRM21BF51C225ZA01K PT115

C223 403 314 5915 GRM21BR71C474KA01L PT297

C224 403 314 5915 GRM21BR71C474KA01L PT297

C225 403 314 5915 GRM21BR71C474KA01L PT297

C226 403 323 8815 GRM21BF51C225ZA01K PT115

C227 403 323 8815 GRM21BF51C225ZA01K PT115

C228 403 164 0214 GRM188F51E104ZA01D PT115

C229 403 233 0817 ELECT 10U M 50V

C231 403 155 2210 GRM188R71H332KA01D PT115

C232 403 164 0214 GRM188F51E104ZA01D PT115

C233 403 248 2813 50 YK 2R2 M TA 0511

C234 403 164 0214 GRM188F51E104ZA01D PT115

C235 403 157 3611 GRM1885C1H101JZ01D PT115

C236 403 233 0817 ELECT 10U M 50V

C237 403 323 8815 GRM21BF51C225ZA01K PT115

C238 403 164 0214 GRM188F51E104ZA01D PT115

C239 403 233 0817 ELECT 10U M 50V

C240 403 157 3611 GRM1885C1H101JZ01D PT115

C241 403 314 5915 GRM21BR71C474KA01L PT297

C242 403 314 5915 GRM21BR71C474KA01L PT297

C243 403 164 0214 GRM188F51E104ZA01D PT115

C244 403 314 5915 GRM21BR71C474KA01L PT297

C245 403 157 3611 GRM1885C1H101JZ01D PT115

C246 403 314 5915 GRM21BR71C474KA01L PT297

C247 403 164 0214 GRM188F51E104ZA01D PT115

C251 403 164 0214 GRM188F51E104ZA01D PT115

C252 403 215 2211 GRM188R71H103KA01D PT115

C256 403 233 0817 ELECT 10U M 50V

C257 403 164 0214 GRM188F51E104ZA01D PT115

C258 403 164 0214 GRM188F51E104ZA01D PT115

C259 403 164 0214 GRM188F51E104ZA01D PT115

C261 403 164 0214 GRM188F51E104ZA01D PT115

C262 403 164 0214 GRM188F51E104ZA01D PT115

C263 403 164 0214 GRM188F51E104ZA01D PT115

C264 403 164 0214 GRM188F51E104ZA01D PT115

C266 403 164 0214 GRM188F51E104ZA01D PT115

C267 403 164 0214 GRM188F51E104ZA01D PT115

C268 403 233 0817 ELECT 10U M 50V

C269 403 164 0214 GRM188F51E104ZA01D PT115

C271 403 258 3619 25 YK 33 M TA 0511

C272 403 215 2211 GRM188R71H103KA01D PT115

C276 403 256 5011 CERAMIC 560P J 50V

C280 403 269 5916 GRM219R71C224KC01D PT115

C281 403 042 4875 ELECT 1000U M 16V

C282 403 269 5916 GRM219R71C224KC01D PT115

C283 403 042 4875 ELECT 1000U M 16V

C284 403 164 0214 GRM188F51E104ZA01D PT115

C286 403 269 5916 GRM219R71C224KC01D PT115

C287 403 164 0214 GRM188F51E104ZA01D PT115

C288 403 042 4875 ELECT 1000U M 16V

C289 403 269 5916 GRM219R71C224KC01D PT115

C293 403 207 0317 GRM21BF51C105ZA01L PT297

C401 403 215 2211 GRM188R71H103KA01D PT115

C402 403 215 2211 GRM188R71H103KA01D PT115

C422 403 299 3210 POLYPRO 0.027U J 400V

C423 403 343 7713 MT-POLYPRO 12000P H 1.5K

C424 403 299 3012 POLYPRO 0.015U J 400V

C432 403 075 7111 DD07-959B102K500 P333

C433 403 076 3112 DD11-959B392K500 P333

C434 403 054 0703 ELECT 47U M 35V

C436 403 036 2513 CERAMIC 47P J 500V

C437 403 066 6106 MT-POLYEST 0.47U J 250V

C439 403 314 5915 GRM21BR71C474KA01L PT297

C441 403 349 3125 ECWF2124N583 MT-POLY PANA

C443 403 358 7220 ECWF2154N583 MT-POLY PANA

C445 403 233 0817 ELECT 10U M 50V

C451 404 056 5208 NP-ELECT 100NA2R2MTA-5X11

C463 408 173 8208 POLYESTER 6800P K 100V

C466 403 188 0818 MT-POLYEST 2.2U J 100V

C467 403 207 0317 GRM21BF51C105ZA01L PT297

C468 403 233 1111 ELECT 22U M 50V

C470 403 284 4314 CERAMIC 0.022U K 50V

C481 403 281 9302 ELECT 10U M 250V

C501 403 148 0424 ELECT 1000U M 25V

C502 403 148 0424 ELECT 1000U M 25V

C503 403 225 2505 ELECT 220U M 50V

C505 403 036 0816 CERAMIC DD05-SL390J500

C506 403 067 7895 MT-COMPO 0.47 J 50V

C507 403 179 2319 POLYESTER 2700P K 50V

C521 403 113 4119 GRM188R71H222KA01D PT115

C529 403 233 0817 ELECT 10U M 50V

C531 403 113 4119 GRM188R71H222KA01D PT115

C601 403 360 5706 B81130-C1104M-000 M.POLYE

C602 403 360 5706 B81130-C1104M-000 M.POLYE

C603 403 076 6727 DEBB33A102KP3A P335

C604 403 076 6727 DEBB33A102KP3A P335

C605 404 088 3104 DE1E3KX102MB5BM37

C609 404 098 2609 ELECT LLU2G271MHLB

C611 403 157 2911 GRM1885C1H470JZ01D PT115

C612 403 275 8106 CERAMIC TDK 470P 2K TAPE

C614 403 233 1507 ELECT 47U M 50V

C616 403 067 0905 MT-POLYEST 0.01U K 630V

C618 403 178 9210 POLYESTER 1000P J 50V

C621 404 088 3104 DE1E3KX102MB5BM37

C631 404 088 3104 DE1E3KX102MB5BM37

C633 403 199 9718 25 YK 470 M TA K1012

C635 403 076 3617 DD05-989B471K500 P333

C637 403 194 3800 ELECT 2200U M 25V

C640 403 194 3800 ELECT 2200U M 25V

C641 403 165 6215 DEHR33D102KN3A P335

C642 404 085 6900 200YXF100MCA 100U M 200V

C643 403 054 1502 ELECT 470U M 35V

C645 403 248 1410 50 YK 1R0 M TA 0511

C647 403 157 6810 GRM188R71H681KD01D PT115

C648 403 241 3817 10 YK 220 M TA 0511

C655 403 248 1410 50 YK 1R0 M TA 0511

C667 403 218 8151 25 YK 1000 M TA 1020

C682 403 308 3409 ELECT 1000U M 6.3V

Ref. No.

Part No.

Part No.

Description

Ref. No.

Description

-20-

C7WAS

!

!

!

!

!

Page 22

-21-

C7WAS

Ref. No.

Part No.

Part No.

Description

Ref. No.

Description

C685 403 195 8824 ELECT 100U M 16V

C686 403 199 9718 25 YK 470 M TA K1012

C691 403 209 4709 ELECT 22U M 50V

C801 403 269 5916 GRM219R71C224KC01D PT115

C802 403 269 5916 GRM219R71C224KC01D PT115

C803 403 248 2813 50 YK 2R2 M TA 0511

C804 403 269 5916 GRM219R71C224KC01D PT115

C806 403 164 0214 GRM188F51E104ZA01D PT115

C809 403 269 5916 GRM219R71C224KC01D PT115

C811 403 155 2319 GRM188R71H472KA01D PT115

C812 403 164 0214 GRM188F51E104ZA01D PT115

C841 403 195 8824 ELECT 100U M 16V

DIODE

D021 407 149 0817 DIODE 1SS355-TE-17

D1002 407 206 5618 ZENER D. UDZS-TE-1710B

D1003 407 206 5618 ZENER D. UDZS-TE-1710B

D1004 407 206 5618 ZENER D. UDZS-TE-1710B

D1006 407 206 5618 ZENER D. UDZS-TE-1710B

D1007 407 206 5618 ZENER D. UDZS-TE-1710B

D1008 407 206 5618 ZENER D. UDZS-TE-1710B

D1009 407 206 5618 ZENER D. UDZS-TE-1710B

D1012 407 206 5618 ZENER D. UDZS-TE-1710B

D1013 407 206 5618 ZENER D. UDZS-TE-1710B

D1014 407 206 5618 ZENER D. UDZS-TE-1710B

D1016 407 206 5618 ZENER D. UDZS-TE-1710B

D1017 407 206 5618 ZENER D. UDZS-TE-1710B

D1018 407 206 5618 ZENER D. UDZS-TE-1710B

D1019 407 206 5618 ZENER D. UDZS-TE-1710B

D102 407 100 0333 Z DIODE MTZJ36B 52MM

D1101 407 149 0817 DIODE 1SS355-TE-17

D1102 407 149 0817 DIODE 1SS355-TE-17

D1901 407 063 8626 ZENER DIODE MTZJ-T72-5.1A

D1911 408 039 4400 SLZ-981B-09H-AB-T1 LED

D231 407 206 5618 ZENER D. UDZS-TE-1710B

D232 407 206 5618 ZENER D. UDZS-TE-1710B

D261 407 099 5422 Z DIODE MTZJ6.2B 52MM

D262 407 099 5422 Z DIODE MTZJ6.2B 52MM

D263 407 099 5422 Z DIODE MTZJ6.2B 52MM

D264 407 149 0817 DIODE 1SS355-TE-17

D265 407 149 0817 DIODE 1SS355-TE-17

D266 407 149 0817 DIODE 1SS355-TE-17

D281 407 012 4426 DIODE 1SS133-T-72

D293 407 149 0817 DIODE 1SS355-TE-17

D431 407 099 5224 ZENER DIODE MTZJ-T72-5.1B

D438 407 095 8001 DIODE ERD07-15L

D439 407 007 7613 DIODE EU2

D442 407 149 0817 DIODE 1SS355-TE-17

D445 407 149 0817 DIODE 1SS355-TE-17

D446 407 099 6122 Z.DIODE MTZJ-T72-10B

D463 407 012 4426 DIODE 1SS133-T-72

D464 407 099 6924 ZENER DIODE MTZJ-T72-15A

D465 407 149 0817 DIODE 1SS355-TE-17

D466 407 099 7921 Z DIODE MTZJ20B 52MM

D469 407 007 7415 DIODE EU1 52MM

D481 407 007 7415 DIODE EU1 52MM

D482 407 012 4426 DIODE 1SS133-T-72

D501 407 005 8632 DIODE ERA15-02-V1

D502 407 149 0817 DIODE 1SS355-TE-17

D503 407 063 9128 Z.DI0DE MTZJ-T72-6.8B

D504 407 149 0817 DIODE 1SS355-TE-17

D506 407 005 8632 DIODE ERA15-02-V1

D601 407 149 0817 DIODE 1SS355-TE-17

D603 407 006 6310 DIODE ERC05-10B

D604 407 006 6310 DIODE ERC05-10B

D605 407 006 6310 DIODE ERC05-10B

D606 407 006 6310 DIODE ERC05-10B

D610 407 231 7707 PHOTO COUPLE TLP421F

D611 407 006 0130 DIODE ERA91-02

D612 407 200 7806 DIODE RB441Q-40

D613 407 099 5224 ZENER DIODE MTZJ-T72-5.1B

D614 407 091 6724 DIODE AP01C

D615 407 099 7624 ZENER DIODE MTZJ-T72-18B

D616 407 200 7806 DIODE RB441Q-40

D630 407 007 7613 DIODE EU2

D633 407 166 2303 DIODE ERC-91-02L

D635 407 129 6706 DIODE RU4YX LF-L1

D637 407 149 0817 DIODE 1SS355-TE-17

D639 407 007 7415 DIODE EU1 52MM

D641 407 149 0817 DIODE 1SS355-TE-17

D642 407 009 8816 DIODE RU3AM

D645 407 099 5422 Z DIODE MTZJ6.2B 52MM

D648 407 007 7613 DIODE EU2

D671 407 011 3014 DIODE S5277B

D676 407 099 5224 ZENER DIODE MTZJ-T72-5.1B

D681 407 012 4426 DIODE 1SS133-T-72

D682 407 012 4426 DIODE 1SS133-T-72

D841 407 149 0817 DIODE 1SS355-TE-17

INTEGRATED CIRCUIT

IC001 409 569 1907 IC LA42052

IC001-1 610 298 8475 HEAT SINK

IC201 409 586 2010 IC TDA12020 N1

IC501 409 453 5905 IC LA78041

IC501-1 610 309 3338 HEAT SINK-PCC C6BLL

IC601 409 606 0306 IC TN6Q04-E—-N

IC601-1 610 313 8510 HEAT SINK C7WLV 30*47*15

IC641 409 414 3001 IC PQ05RD11

IC666 409 559 9203 IC BA33BC0T

IC801 409 459 4506 IC 24LC16B/P

COIL

L031 645 007 9566 LAL03TB120K P/COIL 52MM

L032 645 007 9566 LAL03TB120K P/COIL 52MM

L035 645 033 2722 BEAD CORE TAIYO YUDEN 52M

L1001 652 000 1718 PIPE CORE

L1002 652 000 1718 PIPE CORE

L1107 645 002 7420 P COIL LAL02TB100K 52MM

L1108 645 002 7420 P COIL LAL02TB100K 52MM

L201 645 008 2887 P.COIL LALO2TB5R6K 52MM

L202 645 008 2887 P.COIL LALO2TB5R6K 52MM

L203 401 027 2135 CARBON 56 JA 1/6W 52MM

L206 645 008 2887 P.COIL LALO2TB5R6K 52MM

L207 645 008 2887 P.COIL LALO2TB5R6K 52MM

L208 645 008 2887 P.COIL LALO2TB5R6K 52MM

L209 645 008 2887 P.COIL LALO2TB5R6K 52MM

L211 645 008 2887 P.COIL LALO2TB5R6K 52MM

L212 645 008 2887 P.COIL LALO2TB5R6K 52MM

L213 645 008 2887 P.COIL LALO2TB5R6K 52MM

L214 645 008 2887 P.COIL LALO2TB5R6K 52MM

L216 645 008 2887 P.COIL LALO2TB5R6K 52MM

L217 645 008 2887 P.COIL LALO2TB5R6K 52MM

L431 645 052 5940 C9HB-1R0K-R INDUCT 1.0UH

L441 645 036 7380 COIL,LINEARITY

L442 610 219 0342 COIL

L461 645 005 5645 AR635LY-1038K 2200UHK

L462 610 000 0261 COIL 349UH

L601A 645 019 3873 LINE FILTER-SAMWHA TECOM

L607 652 000 1817 PIPE CORE BF2030RTM TAPED

L608 652 000 1817 PIPE CORE BF2030RTM TAPED

L632 401 011 9014 CARBON 1R JB 1/4W FLAMPRO

L635 652 000 1718 PIPE CORE

L639 401 011 9014 CARBON 1R JB 1/4W FLAMPRO

L642 401 011 9014 CARBON 1R JB 1/4W FLAMPRO

L801 645 008 2887 P.COIL LALO2TB5R6K 52MM

L802 645 008 2887 P.COIL LALO2TB5R6K 52MM

L803 645 008 2887 P.COIL LALO2TB5R6K 52MM

L804 645 008 2887 P.COIL LALO2TB5R6K 52MM

!

!

!

!

!

Page 23

TRANSISTOR

Q001 405 014 4519 TR BC847B,235 10000/REEL

Q1001 405 134 5925 TR BC857B,235 10000/REEL

Q1002 405 014 4519 TR BC847B,235 10000/REEL

Q1003 405 134 5925 TR BC857B,235 10000/REEL

Q1004 405 014 4519 TR BC847B,235 10000/REEL

Q201 405 014 4519 TR BC847B,235 10000/REEL

Q202 405 006 6514 TR 2SA984-E-AA

Q203 405 014 4519 TR BC847B,235 10000/REEL

Q204 405 006 6514 TR 2SA984-E-AA

Q208 405 134 5925 TR BC857B,235 10000/REEL

Q281 405 014 4519 TR BC847B,235 10000/REEL

Q282 405 014 4519 TR BC847B,235 10000/REEL

Q293 405 014 4519 TR BC847B,235 10000/REEL

Q401 405 003 9013 TR 2SA1371-D AE TAPE

Q402 405 013 6217 TR 2SC2271-D-CTV-AE TAPED

Q403 405 014 4519 TR BC847B,235 10000/REEL

Q431 405 018 0616 TR 2SC3332-S

Q432 405 157 1304 TR 2SD2634-YB

Q432-1 610 308 7658 HEAT SINK C2ST

Q439 405 014 4519 TR BC847B,235 10000/REEL

Q461 405 052 8002 TR 2SB1274-R

Q461-1 610 313 8527 HEAT SINK C7HAL 50*47*15

Q462 405 019 1909 TR 2SC536-E-NP

Q491 405 134 5925 TR BC857B,235 10000/REEL

Q602 406 017 2400 TR BC847B,215 3000/REEL

Q641 405 014 4519 TR BC847B,235 10000/REEL

Q642 405 089 3001 TR 2SC4487S-AN TAPING

Q643 405 134 5925 TR BC857B,235 10000/REEL

Q645 405 014 4519 TR BC847B,235 10000/REEL

Q651 405 009 7003 TR 2SB985-T

Q671 405 014 4519 TR BC847B,235 10000/REEL

Q672 405 009 7003 TR 2SB985-T

Q676 405 014 4519 TR BC847B,235 10000/REEL

Q682 405 014 4519 TR BC847B,235 10000/REEL

Q683 405 014 4519 TR BC847B,235 10000/REEL

Q691 405 014 4519 TR BC847B,235 10000/REEL

Q692 405 134 5925 TR BC857B,235 10000/REEL

Q841 405 134 5925 TR BC857B,235 10000/REEL

Q861 405 014 4519 TR BC847B,235 10000/REEL

Q866 405 134 5925 TR BC857B,235 10000/REEL

RESISTOR

R001 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R002 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R003 401 105 0514 MT-GLAZE 1K JA 1/16W

R004 401 105 0514 MT-GLAZE 1K JA 1/16W

R011 401 105 0415 MT-GLAZE 100 JA 1/16W

R012 401 105 0613 MT-GLAZE 10K JA 1/16W

R013 401 105 0613 MT-GLAZE 10K JA 1/16W

R015 401 105 5410 MT-GLAZE 47K JA 1/16W

R016 401 105 0613 MT-GLAZE 10K JA 1/16W

R017 401 024 7440 CARBON 10K JA 1/6W 52MM

R031 401 007 7641 CARBON 150 JA 1/2W

R032 401 007 7641 CARBON 150 JA 1/2W

R1001 401 105 1412 MT-GLAZE 150 JA 1/16W

R1002 401 105 1412 MT-GLAZE 150 JA 1/16W

R1003 401 027 6638 CARBON 75 JA 1/6W 52MM

R1004 401 105 0514 MT-GLAZE 1K JA 1/16W

R1006 401 105 0514 MT-GLAZE 1K JA 1/16W

R1007 401 016 1548 CARBON 22 JA 1/4W 52MM

R1009 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R101 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R1011 401 105 0613 MT-GLAZE 10K JA 1/16W

R1012 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R1013 401 105 2716 MT-GLAZE 220 JA 1/16W

R1014 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R1017 401 105 2716 MT-GLAZE 220 JA 1/16W

R102 401 105 1115 MT-GLAZE 12K JA 1/16W

R1021 401 105 1412 MT-GLAZE 150 JA 1/16W

R1022 401 105 1412 MT-GLAZE 150 JA 1/16W

R1023 401 027 6638 CARBON 75 JA 1/6W 52MM

R1024 401 105 0514 MT-GLAZE 1K JA 1/16W

R1026 401 105 0514 MT-GLAZE 1K JA 1/16W

R1027 401 016 1548 CARBON 22 JA 1/4W 52MM

R1028 401 025 7835 CARBON 2K2JA 1/6W 52MM

R1029 401 025 7835 CARBON 2K2JA 1/6W 52MM

R103 401 105 0415 MT-GLAZE 100 JA 1/16W

R1031 401 105 0613 MT-GLAZE 10K JA 1/16W

R1032 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R1033 401 025 7439 CARBON 220 JA 1/6W 52MM

R1034 401 025 7439 CARBON 220 JA 1/6W 52MM

R1036 401 113 4412 MT-GLAZE 75 JA 1/16W

R1037 401 113 4412 MT-GLAZE 75 JA 1/16W

R1038 401 113 4412 MT-GLAZE 75 JA 1/16W

R1039 401 113 4412 MT-GLAZE 75 JA 1/16W

R104 401 105 0415 MT-GLAZE 100 JA 1/16W

R1041 401 024 6730 CARBON 100 JA 1/6W 52MM

R1042 401 024 6730 CARBON 100 JA 1/6W 52MM

R1043 401 024 6730 CARBON 100 JA 1/6W 52MM

R1044 401 024 6730 CARBON 100 JA 1/6W 52MM

R1046 401 113 4412 MT-GLAZE 75 JA 1/16W

R1047 401 113 4412 MT-GLAZE 75 JA 1/16W

R1048 401 113 4412 MT-GLAZE 75 JA 1/16W

R1049 401 113 4412 MT-GLAZE 75 JA 1/16W

R1051 401 024 6730 CARBON 100 JA 1/6W 52MM

R1052 401 024 6730 CARBON 100 JA 1/6W 52MM

R1053 401 024 6730 CARBON 100 JA 1/6W 52MM

R1054 401 024 6730 CARBON 100 JA 1/6W 52MM

R106 401 060 9307 OXIDE-MT 27K JA 1W

R108 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R1101 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R1106 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R111 401 105 3416 MT-GLAZE 27K JA 1/16W

R112 401 105 3416 MT-GLAZE 27K JA 1/16W

R121 401 026 7438 CARBON 39K JA 1/6W 52MM

R122 401 027 5235 CARBON 680 JA 1/6W 52MM

R123 401 024 6730 CARBON 100 JA 1/6W 52MM

R127 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R128 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R1901 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R1910 401 105 4512 MT-GLAZE 390 JA 1/16W

R1913 401 105 7315 MT-GLAZE 820 JA 1/16W

R1914 401 105 5212 MT-GLAZE 470 JA 1/16W

R1915 401 105 3218 MT-GLAZE 270 JA 1/16W

R1916 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R201 401 027 0339 CARBON 47K JA 1/6W 52MM

R203 401 027 0339 CARBON 47K JA 1/6W 52MM

R209 401 105 1115 MT-GLAZE 12K JA 1/16W

R211 401 024 6730 CARBON 100 JA 1/6W 52MM

R212 401 024 6730 CARBON 100 JA 1/6W 52MM

R213 401 024 6730 CARBON 100 JA 1/6W 52MM

R216 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R217 401 105 1115 MT-GLAZE 12K JA 1/16W

R218 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R219 401 105 1115 MT-GLAZE 12K JA 1/16W

R221 401 105 0415 MT-GLAZE 100 JA 1/16W

R222 401 105 0415 MT-GLAZE 100 JA 1/16W

R223 401 105 4512 MT-GLAZE 390 JA 1/16W

R224 401 024 6730 CARBON 100 JA 1/6W 52MM

R226 401 105 0415 MT-GLAZE 100 JA 1/16W

R227 401 105 1412 MT-GLAZE 150 JA 1/16W

R228 401 105 1412 MT-GLAZE 150 JA 1/16W

R229 401 024 6730 CARBON 100 JA 1/6W 52MM

R231 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R232 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R233 401 105 1115 MT-GLAZE 12K JA 1/16W

R234 401 105 1115 MT-GLAZE 12K JA 1/16W

R236 401 027 5532 CARBON 6K8 JA 1/6W 52MM

R237 401 105 1115 MT-GLAZE 12K JA 1/16W

Ref. No.

Part No.

Part No.

Description

Ref. No.

Description

-22-

C7WAS

!

Page 24

-23-

C7WAS

Ref. No.

Part No.

Part No.

Description

Ref. No.

Description

R238 401 027 5532 CARBON 6K8 JA 1/6W 52MM

R239 401 105 1115 MT-GLAZE 12K JA 1/16W

R246 401 024 6730 CARBON 100 JA 1/6W 52MM

R247 401 024 6730 CARBON 100 JA 1/6W 52MM

R248 401 024 6730 CARBON 100 JA 1/6W 52MM

R249 401 024 6730 CARBON 100 JA 1/6W 52MM

R251 401 024 6730 CARBON 100 JA 1/6W 52MM

R252 401 024 6730 CARBON 100 JA 1/6W 52MM

R253 401 024 9731 CARBON 12K JA 1/6W 52MM

R254 401 105 0514 MT-GLAZE 1K JA 1/16W

R256 401 105 0415 MT-GLAZE 100 JA 1/16W

R261 401 105 0514 MT-GLAZE 1K JA 1/16W

R262 401 105 0415 MT-GLAZE 100 JA 1/16W

R263 401 105 0415 MT-GLAZE 100 JA 1/16W

R264 401 105 0415 MT-GLAZE 100 JA 1/16W

R266 401 105 2013 MT-GLAZE 1.8K JA 1/16W

R267 401 026 4932 CARBON 330K JA 1/6W 52MM

R268 401 105 3010 MT-GLAZE 220K JA 1/16W

R269 401 105 3416 MT-GLAZE 27K JA 1/16W

R271 401 105 5410 MT-GLAZE 47K JA 1/16W

R272 401 105 4314 MT-GLAZE 330K JA 1/16W

R282 401 105 0514 MT-GLAZE 1K JA 1/16W

R283 401 105 0514 MT-GLAZE 1K JA 1/16W

R284 401 105 5311 MT-GLAZE 4.7K JA 1/16W

R285 401 026 9937 CARBON 4K7 JA 1/6W 52MM

R293 401 105 0712 MT-GLAZE 100K JA 1/16W

R401 401 027 5532 CARBON 6K8 JA 1/6W 52MM

R402 401 027 0537 CARBON 470K JA 1/6W 52MM

R403 401 105 4314 MT-GLAZE 330K JA 1/16W

R404 401 105 0613 MT-GLAZE 10K JA 1/16W

R405 401 027 2630 CARBON 5K6 JA 1/6W 52MM

R406 401 105 0613 MT-GLAZE 10K JA 1/16W

R433 401 007 1134 CARBON 1K JA 1/2W

R434 401 105 0514 MT-GLAZE 1K JA 1/16W

R435 402 068 0204 WIRE WOUND 10 JA 5W

R436 401 012 7059 CARBON 10K JA 1/4W 52MM

R437 401 105 0514 MT-GLAZE 1K JA 1/16W

R438 401 018 2850 CARBON 330 JA 1/4W 52MM

R439 401 105 5212 MT-GLAZE 470 JA 1/16W

R441 401 058 3706 OXIDE-MT 1K JA 1W

R447 401 105 5311 MT-GLAZE 4.7K JA 1/16W

R448 401 018 2850 CARBON 330 JA 1/4W 52MM

R449 401 061 2505 OXIDE-MT 330 JA 1W

R450 401 027 5532 CARBON 6K8 JA 1/6W 52MM

R451 401 066 3002 OXIDE-MT 2.2 JA 2W

R453 401 024 7034 CARBON 1K JA 1/6W 52MM

R454 401 021 4155 CARBON 56K JA 1/4W 52MM

R455 401 017 2841 CARBON 27K JA 1/4W 52MM

R462 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R463 401 024 7034 CARBON 1K JA 1/6W 52MM

R468 401 027 8335 CARBON 820 JA 1/6W 52MM

R469 401 027 8632 CARBON 8K2 JA 1/6W 52MM

R470 401 025 8238 CARBON 22K JA 1/6W 52MM

R471 401 027 5235 CARBON 680 JA 1/6W 52MM

R472 401 105 6516 MT-GLAZE 680 JA 1/16W

R474 401 009 0927 CARBON 270 JA 1/2W

R480 401 015 6613 CARBON 2.2 JB 1/4W FLAME

R481 401 020 3941 CARBON 470K JA 1/4W 52MM

R482 401 027 8632 CARBON 8K2 JA 1/6W 52MM

R488 401 105 1719 MT-GLAZE 150K JA 1/16W

R489 401 105 4819 MT-GLAZE 390K JA 1/16W

R491 401 105 5311 MT-GLAZE 4.7K JA 1/16W

R492 401 105 1115 MT-GLAZE 12K JA 1/16W

R493 401 105 5915 MT-GLAZE 560 JA 1/16W

R501 402 002 4206 FUSIBLE RES 3.3 J- 1W

R502 402 022 2008 FUSIBLE RES 1 J- 1/2W

R510 401 269 1508 OXIDE-MT 0.56 JA 2W

R511 401 006 9329 CARBON 10 JA 1/2W

R512 401 066 6102 OXIDE-MT 220 JA 2W

R515 402 079 5106 FUSIBLE RES 2.2 J- 1W

R516 401 027 5532 CARBON 6K8 JA 1/6W 52MM

R517 401 105 1610 MT-GLAZE 15K JA 1/16W

R521 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R522 401 083 8321 MT-FILM 1.2K FA 1/6W 52MM

R526 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R527 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R534 401 083 8321 MT-FILM 1.2K FA 1/6W 52MM

R601 401 008 8627 CARBON 220K JA 1/2W

R602A 402 067 7709 WIRE WOUND 3.9 KA 7W

R604 401 027 8632 CARBON 8K2 JA 1/6W 52MM

R606 401 008 8627 CARBON 220K JA 1/2W

R607 401 008 8627 CARBON 220K JA 1/2W

R608 401 017 0857 CARBON 270 JA 1/4W 52MM

R610 401 016 2654 CARBON 220 JA 1/4W 52MM

R611 401 019 9650 CARBON 47 JA 1/4W 52MM

R612 401 021 3059 CARBON 5.6K JA 1/4W 52MM

R613 401 007 2319 CARBON 100K JA 1/2W

R614 401 068 5509 OXIDE-MT 47 K JA 2W

R631 402 088 1106 RESISTER 5.6M JA 1/2W

R632 402 088 1106 RESISTER 5.6M JA 1/2W

R636 401 024 7440 CARBON 10K JA 1/6W 52MM

R641 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R642 401 043 2014 MT-FILM 150K FA 1/4W 52MM

R646 401 014 5251 CARBON 15K JA 1/4W 52MM

R647 401 019 1951 CARBON 3K9 JA 1/4W 52MM

R649 401 105 0613 MT-GLAZE 10K JA 1/16W

R650 401 105 0712 MT-GLAZE 100K JA 1/16W

R651 401 105 0613 MT-GLAZE 10K JA 1/16W

R652 401 105 2013 MT-GLAZE 1.8K JA 1/16W

R653 401 105 2914 MT-GLAZE 22K JA 1/16W

R654 401 105 6615 MT-GLAZE ERJ 3GEYJ682V

R655 401 016 3859 CARBON 2.2K JA 1/4W 52MM

R656 401 105 0712 MT-GLAZE 100K JA 1/16W

R658 401 024 7440 CARBON 10K JA 1/6W 52MM

R659 401 105 6011 MT-GLAZE 5.6K JA 1/16W

R660 401 105 4611 MT-GLAZE 3.9K JA 1/16W

R665 401 105 0613 MT-GLAZE 10K JA 1/16W

R667 401 060 0403 OXIDE-MT 2.7 JA 1W

R668 401 105 3416 MT-GLAZE 27K JA 1/16W

R670 401 014 2943 CARBON 150 JA 1/4W 52MM

R671 401 105 0613 MT-GLAZE 10K JA 1/16W

R672 401 025 4230 CARBON 1K8 JA 1/6W 52MM

R673 401 105 0613 MT-GLAZE 10K JA 1/16W

R675 401 027 8335 CARBON 820 JA 1/6W 52MM

R676 401 105 0613 MT-GLAZE 10K JA 1/16W

R681 401 105 6011 MT-GLAZE 5.6K JA 1/16W

R682 401 105 0514 MT-GLAZE 1K JA 1/16W

R683 401 105 0613 MT-GLAZE 10K JA 1/16W

R684 401 105 0514 MT-GLAZE 1K JA 1/16W

R685 401 105 6011 MT-GLAZE 5.6K JA 1/16W

R691 401 065 1801 OXIDE-MT 12 JA 2W

R692 401 065 1801 OXIDE-MT 12 JA 2W

R693 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R694 401 105 0613 MT-GLAZE 10K JA 1/16W

R695 401 105 2013 MT-GLAZE 1.8K JA 1/16W

R696 401 105 0613 MT-GLAZE 10K JA 1/16W

R697 401 027 8335 CARBON 820 JA 1/6W 52MM

R801 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R802 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R803 401 105 0415 MT-GLAZE 100 JA 1/16W

R807 401 024 6433 CARBON 10 JA 1/6W

R808 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R809 401 024 6433 CARBON 10 JA 1/6W

R810 401 024 6730 CARBON 100 JA 1/6W 52MM

R811 401 105 4116 MT-GLAZE 3.3K JA 1/16W

R812 401 024 6730 CARBON 100 JA 1/6W 52MM

R813 401 024 6730 CARBON 100 JA 1/6W 52MM

R814 401 024 6730 CARBON 100 JA 1/6W 52MM

R817 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

R818 401 024 9335 CARBON 1K2 JA 1/6W 52MM

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 25

-24-

C7WAS

Ref. No.

Part No.

Description

Ref. No.

Part No.

Description

R821 401 024 6730 CARBON 100 JA 1/6W 52MM

R826 401 105 4710 MT-GLAZE 39K JA 1/16W

R829 401 024 7034 CARBON 1K JA 1/6W 52MM

R832 401 105 0415 MT-GLAZE 100 JA 1/16W

R840 401 105 6011 MT-GLAZE 5.6K JA 1/16W

R841 401 105 0613 MT-GLAZE 10K JA 1/16W

R861 401 105 5410 MT-GLAZE 47K JA 1/16W

R862 401 105 2815 MT-GLAZE 2.2K JA 1/16W

R866 401 105 0613 MT-GLAZE 10K JA 1/16W

R867 401 105 0415 MT-GLAZE 100 JA 1/16W

TRANSFORMER

T431 652 001 2400 TRANS DRIVE

T451 645 038 7616 TRANS,FLYBACK EB6 4X3 28

T611 645 067 2880 TRANS,POWER,PULSE 25&28”

MISCELLANEOUS

A101 645 068 0700 TUNER,U TEDBX303A

A1901 645 028 1044 REMO REC SPS-443-1-E

F601 423 024 8409 FUSE 250V 4.0A GLASS S/B

F601-1 645 040 3576 HOLDER,FUSE EYF-52BC PANA

F601-2 645 040 3576 HOLDER,FUSE EYF-52BC PANA

JS121 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS122 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS123 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS201 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS248 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS249 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

JS401 401 105 5519 MT-GLAZE 470K JA 1/16W

J116 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J137 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J154 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J155 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J164 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J165 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J166 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J182 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J183 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J187 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J210 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J225 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J240 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J259 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J307 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J404 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J408 645 017 6944 491-01.5T52 ICPROTECT.

J511 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J512 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J513 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

J662 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

KCPA 645 006 0946 PLUG,7P

KEM2 645 008 4058 TERMINAL PLUG

KE-1 645 008 4058 TERMINAL PLUG

KE-2 645 008 4058 TERMINAL PLUG

KFF-1 645 008 4058 TERMINAL PLUG

KFF-2 645 008 4058 TERMINAL PLUG

KL 645 004 2881 PLUG,2P

KP 645 008 7288 HOUSING PLUG 5P

KQ 645 008 7264 HOUSING PLUG 3P

KR-1 645 008 4058 TERMINAL PLUG

KR-2 645 008 4058 TERMINAL PLUG

K031 645 027 8761 PHONE JACK HTJ-035-10ABT

K1001 645 005 5867 21-PIN SOCKET

K1002 645 005 5867 21-PIN SOCKET

K1101 652 001 1380 RCA JACK

K4A 645 010 9683 PLUG, 2P B2B-VT JST

K4B 645 008 7264 HOUSING PLUG 3P

PS601 408 046 4301 PTDAA1BF4R5Q200 MURATA

RL601 645 028 2713 RELAY

SW1901 610 011 4432 SWITCH,PUSH

SW1902 610 011 4432 SWITCH,PUSH

SW1903 610 011 4432 SWITCH,PUSH

SW1904 610 011 4432 SWITCH,PUSH

SW601 645 061 3111 SWITCH,PUSH POWER 1P-2T

TP-A 645 008 4058 TERMINAL PLUG

TP-B 645 008 4058 TERMINAL PLUG

VA601 407 130 2902 VARISTOR

VR641 645 003 5579 VR, RH063MCJ3R 2K2 ALPS

X121 421 010 5609 SAW F TSF5425U

X122 421 003 9102 SAW F TSB5318U

X201 645 058 9898 XTAL 24.576MHZ TAPED KSS

Z101 610 282 9693 SHD.CASE EB6 6 CUTT+5HOLE

Z102 610 282 9709 SHIELD CASE C2HC-B

1AA0B10H0690B ASSY,PWB,SOCKET C7WAS

CAPACITOR

C710 403 275 6904 ELECT 10U M 160V

C741 403 247 2101 CERAMIC 2200P K 2K

C745 403 159 7409 MT-POLYEST 0.1U K 250V

DIODE

D702 407 006 3913 DIODE ERB43-04-V1 52MM

D712 407 006 3913 DIODE ERB43-04-V1 52MM

D722 407 006 3913 DIODE ERB43-04-V1 52MM

INTEGRATED CIRCUIT

IC701 409 592 0205 IC TDA6107AJF/N1B

IC701-1 610 313 0590 HEAT SINK RGB C6ARL

RESISTOR

R701 401 105 1412 MT-GLAZE 150 JA 1/16W

R704 401 024 6730 CARBON 100 JA 1/6W 52MM

R705 401 007 1134 CARBON 1K JA 1/2W

R711 401 105 1412 MT-GLAZE 150 JA 1/16W

R714 401 024 6730 CARBON 100 JA 1/6W 52MM

R715 401 007 1134 CARBON 1K JA 1/2W

R721 401 105 1412 MT-GLAZE 150 JA 1/16W

R724 401 024 6730 CARBON 100 JA 1/6W 52MM

R725 401 007 1134 CARBON 1K JA 1/2W

R731 401 105 0514 MT-GLAZE 1K JA 1/16W

R732 401 105 8213 MT-GLAZE ERJ 3GEYJ683V

MISCELLANEOUS

JS701 401 105 7919 MT-GLAZE 0.000 ZA 1/16W

K7P 645 008 7288 HOUSING PLUG 5P

K7Q 645 008 7264 HOUSING PLUG 3P

K7V 645 008 4058 TERMINAL PLUG

K7Y 645 008 4058 TERMINAL PLUG

K701 645 026 2005 HPS1521-015103 CRT.SKT

Sanyo Industries (UK) Ltd

Printed in UK

All information in this manual is correct at the start of

production. Sanyo reserves the right to modify components

and procedures in order to comply with their continuous

improvement policy.

!

!

!

!

!

!

!

Page 26

Part No. SKP20443 C7WAS (SHEET 1-4)

COLOUR TELEVISION

EEEEBBBB8888----AA

AA

SERVICE REF.NO.

MODEL NUMBER

CHASSIS SERIES

CE28DN9-B-01

CE28DN9-B

The service Precaution:

The area enclosed by this line

( ) is directly connected

with AC mains voltage. When

servicing the area, connect an

isolating transformer between

TV receiver and AC line to eliminate hazard of electric shock.

Product safety notice:

Product safety should be considered

when a component replacement is

made in any area of a receiver.

Components indicated by a mark /!\ in

this circuit diagram show components

whose values have special significance

to product safety. It is particularly recommended that only parts specified on

the part service manual be used for

components replacement pointed out

by the mark.

Circuit diagram notes :

1. All resistance values are in ohms, K=1,000, M=1,000,000.

2. All resistance rated wattages are 1/6W unless otherwise noted.

3. Excepting electrolytic capacitors, all capacitance values of less

than 1 are expressed in µF and more than 1 are pF.

4. All capacitance rated voltages are 50V unless otherwise noted.

5. All inductance values are in µH.

6. Voltage readings taken a digital voltmeter are from point indicated chassis ground. Voltage readings taken by using a colour

bar signal are with all controls at normal position. Some voltages may vary with signal strength.

7. Waveforms were taken with colour bar and controls adjusted

for normal picture. Waveforms were taken by using a wide

band oscilloscope and a low capacity probe.

8. This circuit diagram covers a basic or

representative chassis only. There

may be some components or partial

circuit differences between the actual

chassis and the circuit diagram.

9.■ Diode 1S1555 may be replaced with

1S2473,1S2076 or DS472 unless

otherwise noted.

■ Transistor 2SC536(Q,R,S),

2SC1740(Q,R,S), 2SC945A(Q,R,P)

or 2SC1815(G,O,Y) unless otherwise noted.

■ Transistor 2SA608(E,F) may be

replaced with 2SA933(Q,R),

2SA564(QA,RA), or 2SA1015(O,Y)

unless otherwise noted.

Expression of capacitance and resistance in circuit diagram.

Capacitance (Example)

1000 C M 2000 D

Characteristic

Capacitance value (220pF)

Tolerance (±20%)

Kind(Ceramic)

Rated voltage (1,000V)

Resistance (Example)

1/2 N J 1.2

Resistance value (1.2Ω)

Tolerance (±5%)

Kind (M.carbon)

Rated wattage(1/2W)

D : Carbon

N : Metallized carbon

S : Oxide metallized

W : Wire wounding

C : Solid

T, A, U, D : Electrolytic

C, K, B : Ceramic

F : Mylar film

M, N : Polypropylene

Z : Metallized paper

J= ± 5%

K= ± 10%

M= ± 20%

Terminal guide

C : Collector

B : Base

E : Emitter

A : Anode

K : Kathode

Chip Components

BLOCK DIAGRAM

SPEAKER

SP901

SP902

IC001

AUDIO AMPLIFIER

PF

5

A1901

RC RECEIVER

Q866

A101

TUNER

5v30v

C609

IC601

TN6Q04

AC

SW601

T611

CONVERTER

D610

I2C BUS CONTROL

P.F

TO UOC PINS

3,100,117,118,124

IC801

MEMORY

Q202

2

TO UOC PINS

93 & 96

1V8_1

1V8_2

3v3

Q204

ON/OFF

UOC PIN 107

Q203

Q651

Q642

14v

25v

145v

+14v

-14v

1

7v

D671

Q682

IC645

5v

4

3v3 St-By

Q625

IC666

Q641

Q675

St-BY UOC

PIN 106

KEY SW

Q201

X201

127

120

9

9

14

10

11

107

106

22 23

V-OUTPUT

60 61

LA78045

SCAN COIL

IC501

VERTICAL

97

108 109

24

25

29

30

31

80

79

78

77

43

55

34

35

36

37

SC1 FB IN

SC_1 VIDEO OUT

SC_1 VIDEO IN

SCART 1 AUDIO L/R OUT

SCART 1 AUDIO L/R IN

75

UOC

128

D441

72

71

70

48

58

49

50

62

63

51

84 85 86

2

6

Q439

Q431

53

54

Q432

L461

Q462

L462

SC_2 G -IN

SC_2 B- IN

SC_2 R-IN

SC_2 VIDEO OUT

SC_2 VIDEO IN

SCART 2 AUDIO L/R OUT

SCART 2 AUDIO L/R IN

AV3 AUDIO L/R & VIDEO IN

145V

CRT

Heater

Q461

200v

To CRT

HORIZONTAL

SCAN COIL

ON/OFF CONTROL

IF IN

X121

SIF IN

X122

SC_1 B-IN

SC_1 G-IN

SC_1 R-IN

Q1001

Q1002

SC_2 FB -IN

Q1003

Q1004

T451 FLYBACK

Q401

Q402

Q403

CPU PIN 106

R OUT

GOUT

K1101

BOUT

IK

SCREEN & FOCUS

K1001

SCART 1

K1002

SCART 2

PICTURE TUBE

IC7 01

H.V

B

B

C

E

E

C

B

Transistor

C

E

B

C

E

B

E

C

E

C

B

Diode

K

A

K

K

A

K

A

A

Resistor

123

1

12 x 103= 12kΩ

N/2

N/2 + 1

N

10

9

3

2

1

7

6

5

4

3

2

1

Page 27

MAIN / CRT BOARD

K031

J001

R272

21

Q202

C110

R202

D102

X

KR-2

2

X

KR-1

JS003

J230

C040

J151

J156

J311

C030

1

C009

C141

R031

C010

E

JS122

JS121

Q113

C132

C106

JWB

KL

C035

L031

KR

JS005

J233

C131

C105

T131

J152

30V

NC

BP

TU

C016

C018

J239

R108

MB

J002

C011

C012

R494

Q201

R104

AGC

L035

C013

R201

Q112

C107

C055

J144

C031

JS004

C014

R493

R847

L206

R271

SCL

ADR

C033

R285

R137

SDA

R103

1

J141

K1101

J143

J142

J138

C032

J139

JW3

J137

J136

C036

L032

KEM1

X

C034

JS006

R009

131

IC001-1

R012

C017

IC001

R010R008

J003

R007

R032

J004

R013

C021

R011

R014

R015

J005

R653

R654

Q282

R491

D637

Q491

R492