Page 1

Colour Television

Service Manual

Model CE25DN4-C

Service Ref.No.: CE25DN4-C-01

PRODUCT CODE: 111339716

ORIGINAL VERSION: Chassis No. EB4-A(MKII)

CE25DN4-C

Give complete "SERVICE REF.NO." for parts

order or servicing, it is shown on the rating sheet

on the cabinet back of the TV set.

Note

This TV receiver will not work properly in foreign

countries where the television transmission

system and power source differ from the design

specifications. Refer to the specifications for the

design specifications

Contents

Safety precautions/Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cabinet Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Service control adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Circuit alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Important notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Special Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cabinet Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electric Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

Part No. SKSM0309 F7VVV APRIL 1999

Page 2

-2-

F7VVV

SAFETY PRECAUTION

X-RADIATION PRECAUTION

The primary source of X-RADIATION in the television receiver is the picture tube. The picture tube is specially

constructed to limit X-RADIATION emissions. For continued X-RADIATION protection, the replacement tube must

be the same type as the original including suffix letter. Excessive high voltage may produce potentially hazardous

X-RADIATION. To avoid such hazards, the high voltage must be maintained within specified limit. Refer to this

service manual, high voltage adjustment for specific high voltage limit. If high voltage exceeds specified limits,

take necessary corrective action. Carefully follow the instructions for +B1 volt power supply adjustment, and high

voltage adjustment to maintain the high voltage within the specified limits.

PRODUCT SAFETY NOTICE

PRODUCT SPECIFICATIONS

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is particularly recommended that only parts designated on the parts list in

this manual be used for component replacement designated by mark . No deviations from resistance wattage

or voltage ratings may be made for replacement items designated by mark .

!!!

1: An isolation transformer should be connected in the

power line between the receiver and the AC line

when a service is performed on the primary of the

converter transformer of the set.

2: Comply with all caution and safety-related notes

provided on the cabinet back, inside the cabinet, on

the chassis or the picture tube.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, isolation resistor-capacitor

networks etc.Before returning any television to the

customer, the service technician must be sure that it

is completely safe to operate without danger of

electrical shock.

Power source AC 220~240V, 50Hz

Television system System B/G, D/K

Colour system PAL/NTSC 4.43/SECAM

Receiving channel VHF: E2~E12, R1~R12

CATV: X, Y, Z, S1~S41

UHF: #21~69

Aerial input impedance 75 ohm

AV terminal

21 Pin socket AV1: CENELEC standard (RGB/S-Video inputs)

AV2: CENELEC standard

AV2: RCA Terminal, video and audio (L/R) inputs

Sound output(Music) 12 watts x 2

Picture tube 63cm diagonal, 110 degree

(Visible picture diagonal) 59cm

Dimensions (WxHxD) 680 x 543 x 442mm

Weight 26.6 Kg

Page 3

-3-

F7VVV

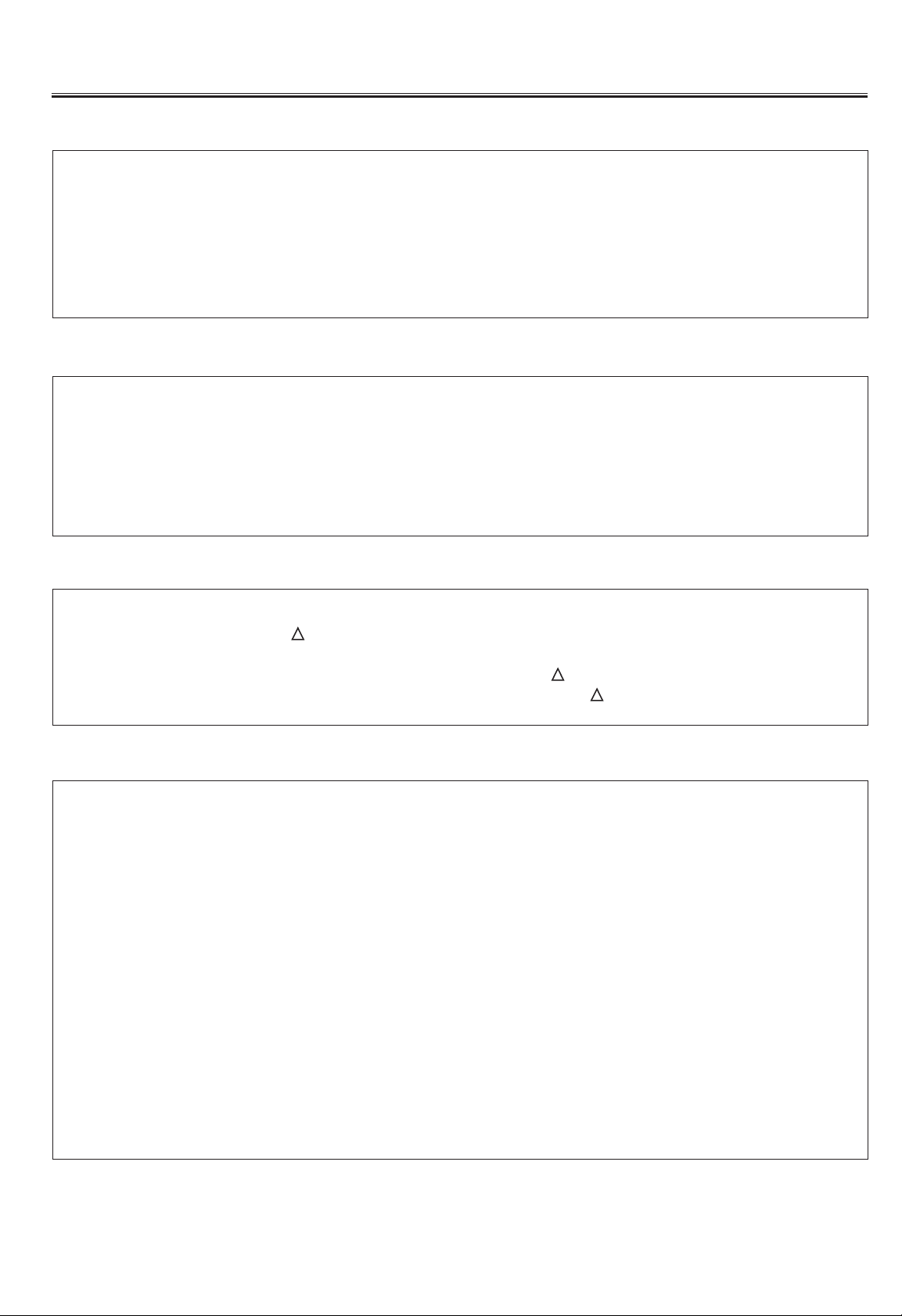

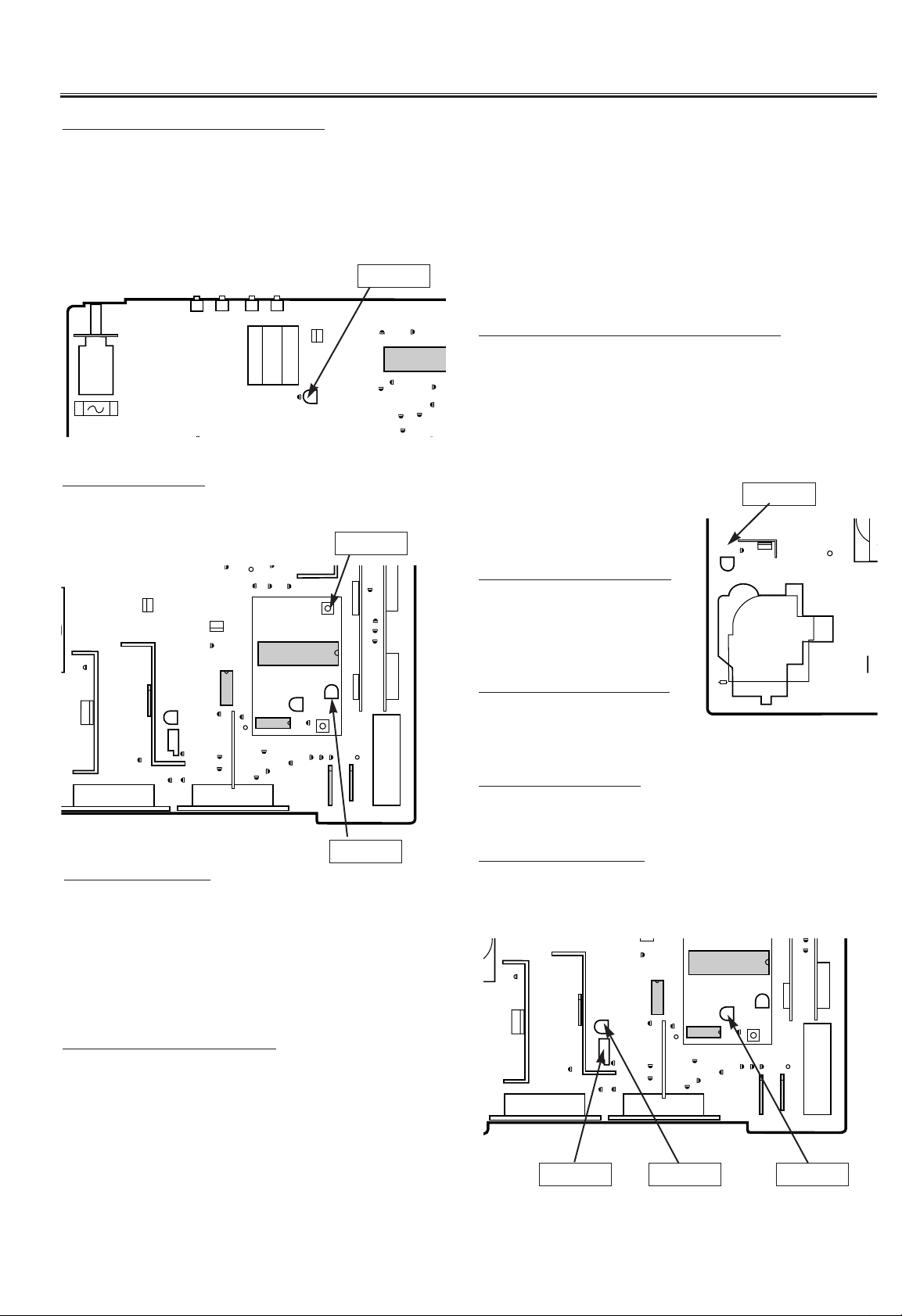

BLOCK DIAGRAM

This is a diagram for all models and therefore differs slightly from the actual block diagram.

IC801

CPU

21P Scart: AV1

21P Scart: AV2

IC201

IF/Video/Chroma/Def.

IC1202

CVBS int/ext sw.

IC1201

CVBS AV2 sw.

CRT Unit

FBT

DY

IC001

Audio Output

IC501

Vert. Output

T611

Converter Transformer

Power Supply Circuit

SIF Unit

Audio Unit

Tuner

IC802

Memory

47

49

50

SCL

SDA

RC Pre.amp

6

5

51

52

IC810

Band sw.

14

24

17

18

234

5

2: Bright 3: Contranst

4: Colour 5: Sharpness

Control Keys

10

VL

VH

U

IF

TU

1

16

45/46

28/29

30/31

41

48

37

18

19

20

7

13

15

21

22

23

24

X131

SAW Filter

IC271

1H Delay

R-Y/B-Y

R-Y/B-Y

CVBS In

Functuin In(AV1/AV2)

11/12

14/16

B

G

R

BLK

External CVBS in

Internal CVBS in

Q151 Q152/Q154

H-Drive

Q431

Q432

H-Outpit

V-Drive

V-Feedback

Audio In

Speakers

VR501

C512

H

V

HV

Q2601

Q2611

Q2621

Video In

Audio In

L R

Q171

1

6

3

8 Out

4 Out

2

7

Audio I/O

Audio I/OVideo I/O

Video I/O

RGB/BLK In

B1: 150V

B2: 25V

B3: 15V

B4: 24V

IC651

IC652

B6: 12V

B8: 5V

L, R

L, R

1/ 5

10/ 8

AC In

Q612

Q613

V-In

V-In

R

G

B

CVBS In

AV1 I/O

SIF In

Audio Out L, R

4

2

IC653

B6: 12V

B7: 8V

3D Surround

Decoder

Nicam & Stereo

Decoder

AV2 I/O

Front In

Audio

Page 4

-4-

F7VVV

1. POWER SUPPLY

The power supply circuit of the EB4-A chassis is

composed of a rectifier smoothing circuit, an oscillation

circuit, a control circuit and an output rectifier circuit. The

AC input voltage is full-wave rectified by the rectifier

smoothing circuit, and an unstable DC voltage is

generated at both terminals of the smoothing capacitor

C607. This voltage is input to the oscillation circuit. The

oscillation circuit is provided with a blocking oscillator

circuit that switches the switching transistor Q613 ON

and OFF, and an oscillation frequency and a duty square

wave pulse are generated in the input windings

according to operation of the control circuit. A squarewave pulse whose size is dependent on the turn ratio of

the input and output windings is obtained in the output

winding. This is rectified in the output rectifier circuit, and

the desired DC voltage is obtained.

2. IF & DEFLECTION (TDA8361)

The IF output signal from the tuner passes through the

SAW filter, and it is input to pin45 and pin46 of IC201.

The signal input to the IC passes through the IF

amplifier, video detection and video amplifier circuits and

is output from pin7 as a composite video signal. And

after this signal is converted to impedance at Q151,

supplies to the video and chroma amplifier stages.

The sync.-separation circuit separates the video signals

applied to pin13(internal video signal) or pin15(external

video signal) to vertical- and horizontal-sync. signals

respectively. The horizontal oscillator requires no

external components and is fully integrated. The

oscillator is always running when the start-pin36 is

supplied with 8V. Horizontal drive signal is output from

pin37. VR361 is for adjustment of the horizontal centring.

The separated vertical-sync. signal from sync. separation

circuit passes through the vertical-separation circuit, and

applied to trigger divider circuit. The horizontal oscillation

pulse and input vertical sync. pulse are monitored by the

trigger divider circuit, and switching 50Hz and 60Hz

system, the vertical amplitude automatically adjusted for

50Hz and 60Hz. The output signal from the trigger

divider is triggered vertical oscillation circuit consisting of

C351, R352 and pin42, and vertical drive pulse is output

from pin43. VR501 is for changing the amount of AC

feedback applied to pin41 and for adjustment of the

vertical amplitude.

3. VIDEO CHROMA & R.G.B. (TDA8361)

The composite video signal output from the pin7 of

IC101 passes through Q151-Q154, and it is supplied to

pin13. The external video signal output from SCART is

supplied to pin15. The video signal input to pin13 or

pin15 is separated to luminance (Y) signal and chroma

signal in IC201. These pins are used in common with

H/V-sync. separation input. The peaking of Y signal is

adjusted by DC voltage of pin14. (“SHARPNESS”

control) The chroma signal is divided into R-Y and B-Y

chroma signals, demodulated in IC201, and output from

pin30 (R-Y) and pin31 (B-Y). These chroma signals pass

through the 1H delay line circuit (IC271), and they are

input to pin29 (R-Y) and pin28 (B-Y). These R-Y/B-Y

signals pass through RGB matrix circuit and RGB

selector circuit of IC101. The internal RGB signals are

generated in RGB matrix circuit and the RGB selector,

consisting linear amplifiers, clamps and selects either the

internal RGB signals or the external RGB signals input

from pin22(R), pin23(G), pin24(B). Selection is controlled

by the voltage at the RGB switch control (pin21) and

mixed RGB modes are possible since RGB switching is

fast. The RGB switch also functions as a fast blanking

pin by blanking the RGB output stages; here internal and

external RGB signals are overruled. The colour gain is

controlled by DC voltage of pin26. (“COLOUR” control)

The contrast control voltage present at pin25, and the

brightness control voltage present at pin17 controls DC

level of RGB signals. The RGB signals are finally

buffered before being available at the RGB output pins

[pin20 (R), pin19 (G), pin18 (R)].

4. AUDIO OUTPUT(TDA7263M)

The audio signals output from the audio unit are input to

pin1(L) and 5(R) of IC171 and passes through the preamplifier circuit and drive circuit, after which it is input to

the audio amplifier. The audio amplifier is an SEPP

(single-ended, push-pull) OTL type and output to pin8(R)

and 10(L) to directly drive the speakers.

5. VERTICAL OUTPUT (LA7832/LA7832)

An IC (LA7832/LA7833) is used for the vertical output

circuit in this chassis. The vertical drive pulse from pin43

of IC201 is input to pin4 of IC501. This pulse drives

IC501, and vertical scanning is performed. In the first half

of scanning a deflecting current is output from pin2 and

passes through the following path:

Vcc(B4) ➞ D501 ➞ pin3 ➞ pin2 ➞ DY ➞ C512 ➞

VR501/R509. An electric charge is then stored in C512.

In the last half of scanning the current path is C512 ➞

DY ➞ pin2 ➞ pin1 ➞ VR501/R509 ➞ C512. In this way,

an amplifying sawtooth waveform current flows directly to

DY to perform electron beam defection. Next, in the first

half of the banking period the vertical drive pulse

suddenly becomes OFF, and in order to reduce the

current flowing to DY, the current path becomes as

follows by the inductance of DY:

DY ➞ pin2 ➞ pin1 ➞ VR501/R509 ➞ C512 ➞ DY. Also,

when the charge of DY has dissipated, the current path

becomes Vcc24V ➞ pin6 ➞ pin7 ➞ C502 ➞ pin3 ➞

pin2➞ DY ➞ C512 ➞ VR501/R509, and when the

prescribed current value is reached, the vertical drive

pulse becomes ON. This completes one cycle.

CIRCUIT DESCRIPTION

Page 5

-5-

F7VVV

6. HORIZONTAL OUTPUT

A horizontal oscillation signal is output from pin37 of

IC201 and switches the drive transistor Q431. This

switching signal is current amplified by the drive

transformer T431 and drives the output transistor Q432.

When Q432 becomes ON, an amplifying current flows

directly to DY through C441 ➞ DY ➞ 0432 ➞ GND, and

defection is performed in the last half of the scanning

period. Next, when Q432 becomes OFF, the charge that

had been stored in DY up to that point releases a

resonance current to the resonant capacitors C421/C423

and charges them. The current stored in C421/C423 is

then flowed back to DY, and an opposite charge is then

stored in DY. This opposite charge then switches the

dumper diode in Q432 ON, the resonance state is

completed, and an amplifying current is then flowed

again directly to DY through the dumper diode. By this

means, deflection in the first half of the scanning period

is performed, and when Q432 becomes ON at the end of

the first half of the scanning period, deflection during the

last half is begun, thus completing one cycle.

In the PCC circuit consisting of Q461 and Q462, the

parabola signal supplied from the vertical circuit is added

at the horizontal output stage and pincushion

compensation is performed by varying the DC voltage

bias. Further, the ABL voltage is feedback to the base of

Q462 to compensate for width variations due to

variations in the beam current.

7. CPU <System and Teletext Control>

Pin description

Pin1: Tuning voltage output

Pin2: Brightness control output (6-bit DAC)

Pin3: Contrast control output (6-bit DAC)

Pin4: Colour control output (6-bit DAC)

Pin5: Sharpness control output(6-bit DAC)

Pin6: Not used (GND)

Pin7: Not used (GND)

Pin8: Power ON/OFF output (H:ON)

Pin9: AFT signal input

Pin10: Option SW1 & Keyboard scan input (DC)

Pin11: Option SW2

Pin12: 50/60Hz switch input (50Hz: Hi)

Pin13: GND

Pin14: TV/AV switch output (TV: Hi)

Pin15: S-VHS switch output (S-VHS: Hi)

Pin16: Option SW3 (2AV: Hi)

Pin17: Function signal input for SCART1

Pin18: Function signal input for SCART2

Pin19: Power LED drive output1

Pin20: Option SW4 & Power LED drive output2

Pin21: Ignore output

Pin22: GND

Pin23: CVBS input0 (Internal)

Pin24: CVBS input1 (Internal/External)

Pin25: Black

Pin26: IREF

Pin27: Odd/Even output

Pin28: GND

Pin29: Pin30: V-deflection stop output

Pin31: RGB REF

Pin32: Blue output for OSD

Pin33: Green output for OSD

Pin34: Red output for OSD

Pin35: Blanking output for OSD

Pin36: H-sync. input (Horizontal pulse for OSD)

Pin37: V-sync. input (Vertical pulse for OSD)

Pin38~39: Supply (+5V)

Pin40: OSC GND

Pin41: Oscillator input for CPU

Pin42: Oscillator output for CPU

Pin43: Reset input

Pin44: Supply (+5V)

Pin45: Protect signal input (L:Power circuit defects)

Pin46: Ident. signal input

Pin47: R/C signal input

Pin48: Mute output in no picture

Pin49: I2C bus SCL (Serial clock)

Pin50: I2C bus SDA (Serial date)

Pin51: Option SW5 & Band select output1

Pin52: Band select output2

Page 6

-6-

F7VVV

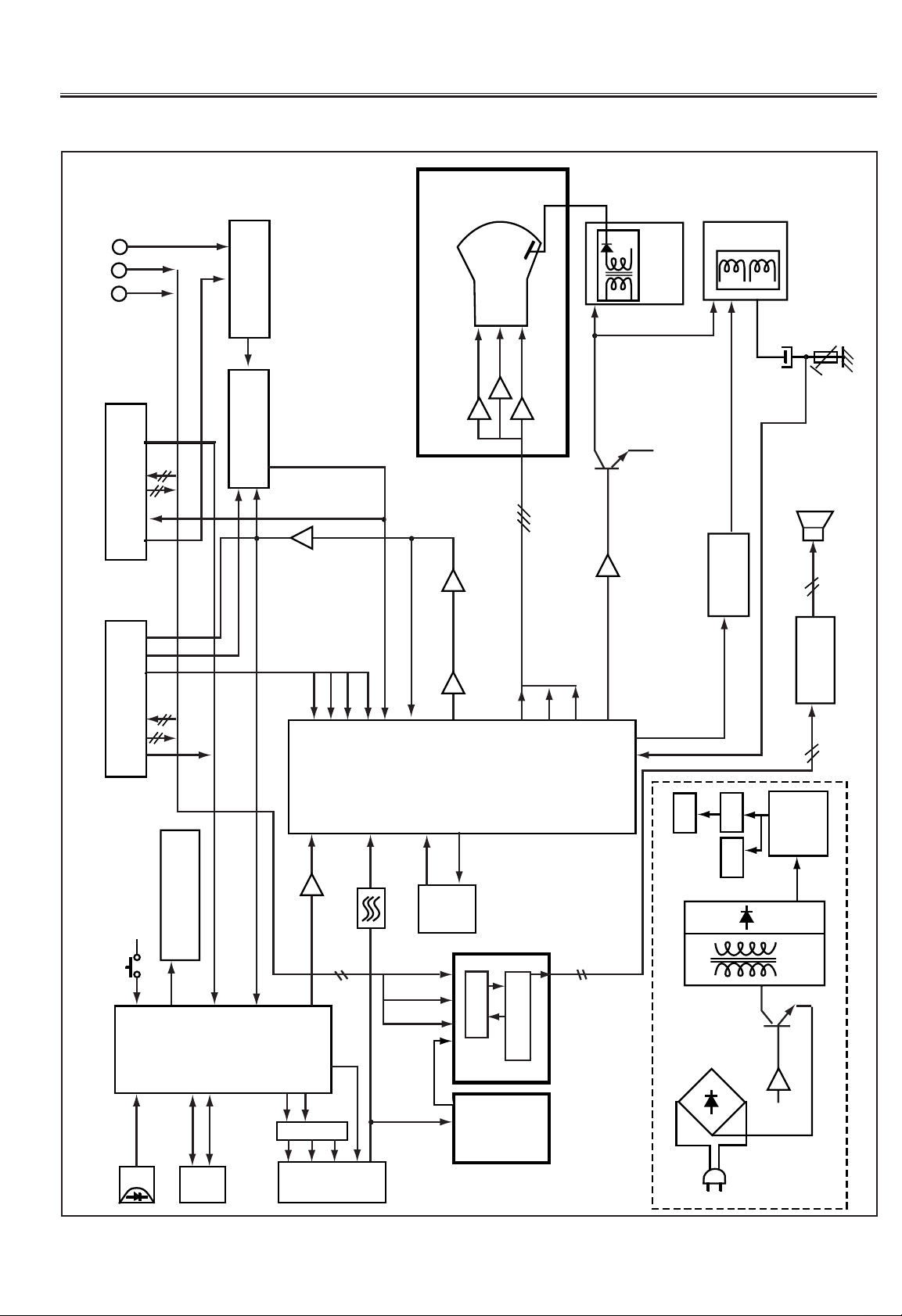

CABINET DISASSEMBLY

CABINET BACK DISASSEMBLY

1. Remove 10 screws(A).

2. Pull out the cabinet back.

PLACING THE CHASSIS TO SERVICE

POSITION

1. Pullout the chassis and put it to the rails on the

side cabinet.

2. Fix main board with hook on the top rail.

(A)

(A)

(A)

(A)

(A)

(A)

(A)

(A)

(A)

(A)

Page 7

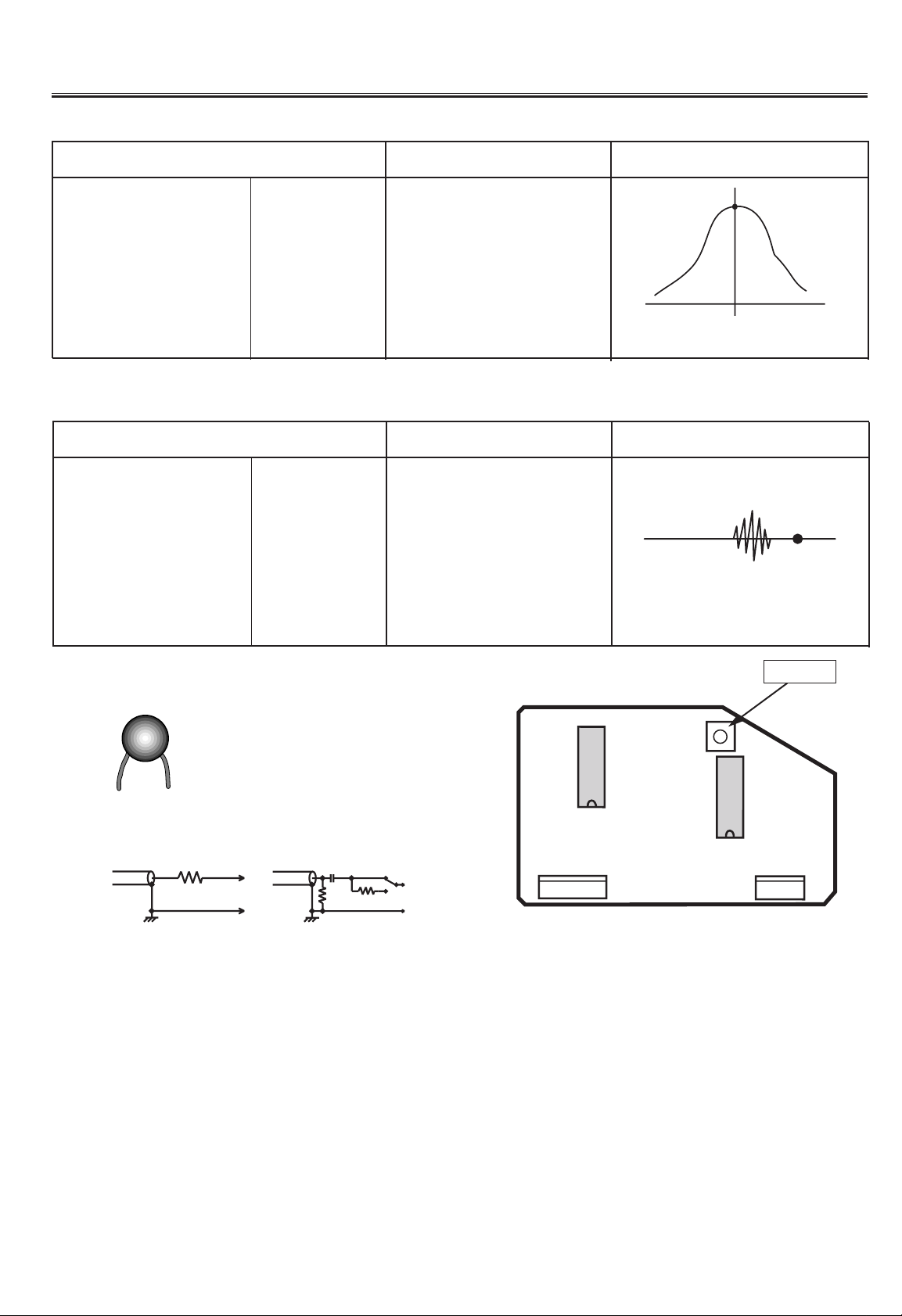

B1 POWER SUPPLY ADJUSTMENT

1. Set VR641 to be mechanical centre before pressing

the main switch.

2. Tune the receiver to PAL circular pattern.

3. Set brightness and contrast controls to normal.

4. Connect digital V-meter to test point "TP-B".

5. By using VR641, adjust voltage to 150 ± 0.5 V.

AFT ADJUSTMENT

1. Tune the receiver to the clearest station.

2. By using T141, adjust AFT to obtain the best picture.

AGC ADJUSTMENT

NOTE:

Do not attempt this adjustment with weak

signal.

1. Tune the receiver to the clearest station.

2. Set AGC VR(VR131) in direction which causes snow

noise to appear, then in the opposite direction until

snow noise just disappears.

GREY SCALE ADJUSTMENT

[SCREEN VR ADJUSTMENT]

1. Tune the receiver to the white pattern.

2. Set brightness and contrast controls to normal.

3. Set VR602and VR612 to be mechanical centre.

4. Turn VR601, VR611 and VR621 fully counter-

clockwise.

5. Set mode to one horizontal scanning line, how to set

refer to "service mode"

6. Set screen VR for one colour to be just visible.

[BIAS VR ADJUSTMENT]

7. By using VR601, VR611 or VR621, adjust line to be

white.

8. Set screen mode OFF, how to set refer to "service

mode"

[DRIVE VR ADJUSTMENT]

9. By using VR602 and VR612, adjust white balance.

HIGH VOLTAGE & WIDTH ADJUSTMENT

[HIGH VOLTAGE ADJUSTMENT]

1. Tune the receiver to circular pattern.

2. Set brightness and contrast controls to maximum.

3. Connect digital V-meter to both terminals of R224, and

high voltage meter to CRT anode.

4. Confirm high voltage to be 26.0 ± 1 KV at beam

current 1.3, and less than 29.0 KV at 0 beam current.

[H-WIDTH ADJUSTMENT]

5. Adjust VR462 to obtain proper

H- width.

6. Reconfirm high voltage.

H-CENTRE ADJUSTMENT

1. Tune the receiver to circular

pattern.

2. Adjust H-centre by using

VR361.

V-CENTRE ADJUSTMENT

1. Tune the receiver to circular

pattern.

2. Adjust V-centre by using SW501.

V-SIZE ADJUSTMENT

1. Tune the receiver to circular pattern.

2. Adjust V-size by using VR501.

FOCUS ADJUSTMENT

By using FOCUS VR, adjust focus control for good

scanning lines.

SERVICE CONTROL ADJUSTMENT

-7-

F7VVV

SW601

Main switch

F601

Fuse

T481

RC Transformer

SW1901

Prog.+

SW1902

Prog.-

SW1903

Vol.+

SW1904

Vol.-

Q641

VR641

+B ADJ.

Q681

IC801

CPU

Q501

Q432

H-Output

IC501

V-Outout

IC651

+12V

Scart 2

SW501

V-Centre

VR501

V-Size

IC271

1H Delay

IC652

+8V

Scart 1

IC201

IF/Video/Croma/Def.

IC281

VR361

H-Centre

VR131

AGC

T101

T141

SIF Board

A101 Tuner

IC1202

Int./Ext. SW.

IC1201

AV2 SW.

TP-E

TP-

Q-SOUND Board

T611

Converter Trans

TP-B

VR462

H-Width

Q461

Q462

T451

Flyback

Transformer

R224

J213

Q501

Q432

H-Output

IC501

V-Outout

Scart 2

SW501

V-Centre

VR501

V-Size

IC271

1H Delay

Scart 1

IC201

IF/Video/Croma/Def.

IC281

VR361

H-Centre

VR131

AGC

T101

SIF Board

A101 Tuner

IC1202

Int./Ext. SW.

IC1201

AV2 SW.

TP-E

Q-SOUND Board

T141

VR641

VR642

VR361VR501SW501

VR131

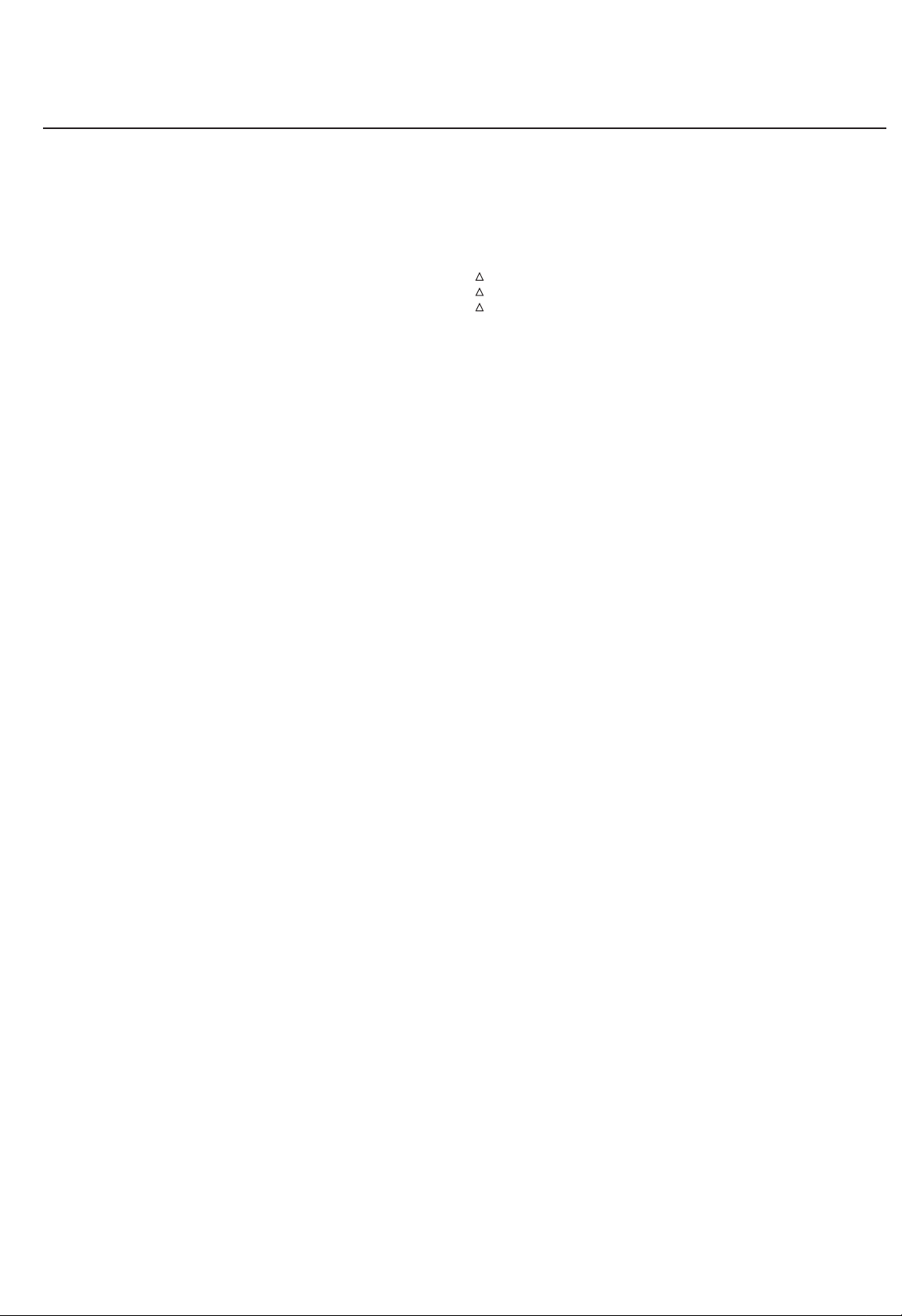

Page 8

-8-

F7VVV

DC 15.5V

AGC voltage (4.3-4.5V)

Output probe

Input probe

Marker frequency

Sweep ATT

0dB=176mVrms/75

SETTING

C644 +

IC201-pin48

IC201-pin45

(Side b)

IC201-pin7

38.9MHz

20dB

Adjustment

By using T141, adjust "P" to

be maximum amplitude.

Waveform

CIRCUIT ALIGNMENT

VIF alignment

P

P

0.002µF

75Ω

1kΩ

a

b

10kΩ

Input probe

Output probe

SIF alignment

SIF BOARD

DC 12V

AGC voltage(5V DC)

Output probe

Input probe

Sweep ATT

Marker Frequency

Tool-A

SETTING

IC3801-pin9

IC3801-pin13

IC3801-pin5

(Side b)

IC3801-pin17

10dB

38.9MHz

IC3801-pin6

and ground

Adjustment

1. By using T3801, adjust the

VCO oscillation to be "P".

Waveform

0.01

Tool-A

IC3811

IC3801

K38H2

K38H1

T3801

Page 9

-9-

F7VVV

When you replace a memory IC (IC802), it is

necessary to initialise the IC as following step.

A. Initialization

Press and hold the ( ) normalization button on the

remote control handset and press the ( )

programme + button on the TV set.

The IC will be initialised automatically to set the

following data.

User control data

Colour : Centre

Brightness : Centre

Contrast : Maximum

Sharpness : Centre

Text. Bright : Centre

Bass : Centre

Treble : Centre

Balance : Centre

Volume : Step 12

B. Service Mode

1. To enter the service mode, press and hold the ( )

Function button on the remote control handset and

press the ( )programme + button on the TV set.

The following OSD appears on the screen.

2. Select desired service item by using the ( )

Function button on the remote control handset.

3. Change date by using the ( )Level + or ()button.

4. To return to TV mode press the ( )Recall button

on the remote control handset.

Service mode description

SCREEN: For screen adjustment

To make one horizontal scanning line.

ADJUST DATA

System +000

SCREEN VOL

CPU MK2 1.0

P

P

INITIALIZATION (Important Notice)

Page 10

-10-

F7VVV

This TV set allows you to set up the following special functions.

■ Maximum volume setting and prohibition of presetting

ITEM-1

Sets the current volume as the maximum volume level and prohibition of

presetting.

SET➞ 0 NO

SET➞ 1 YES

■ Start up programme position

ITEM-2

Presets the programme position when the set is switched on.

SET -> 0 Last programme position start

SET -> 1 Programme position "1" start

SET -> 2 Programme position "2" start

SET -> 3 Programme position "3" start

SET -> 4 Programme position "4" start

SET -> 5 Programme position "5" start

SET -> 6 Programme position "6" start

SET -> 7 Programme position "7" start

SET -> 8 Programme position "8" start

SET -> 9 "AV1" start

SETTING PROCEDURE

1

Press and hold the button on the Remote control handset

and then press the Ps button on the TV set.

2

To select the "Item" number, press the button on the remote

control handset.

3

To select the "Set" number, press the or button

repeatedly.

4

To return to the normal TV mode, press the button.

✐The setting conditions of all items can be confirmed.

✐Special functions are not cancelled if the TV set is switched off or the

mains disconnected.

ITEM-1 SET -> 0

SPECIAL FUNCTION

Page 11

F7VVV

-11-

CABINET PARTS LIST

CABINET PARTS

1 610 278 4800 ASSY,CABINET FR-F7VT

2 610 276 5618 BUTTON POWER-F7WC

3 610 278 4886 CABINET BACK -F7VA-A

4 610 278 4923 DOOR-F7WV

5 610 276 5656 DEC IND-F7WC

6 SKZZ0072 DEG COIL CLIP-F4AC

7 610 253 2449 AC CORD HOLDER-U-D4VA

8 SKZZ0041-A SPRING-E7GC

9 645 030 7355 BADGE,SANYO*53.5X12 GRAY

10 610 104 2505 LATCH PUSH,7.9X6.9BK\

11 610 224 5721 CRT CUSHION-B3MY-UK

12 411 076 1004 SCR TPG BRZ 4X12

13 411 076 1301 SCR TPG BRZ 4X14

14 1AA2HLM0146A- HOLDER DC GBR-F3SC

15 412 009 3003 SPECIAL SCREW

ACCESSORIES

16 JXMCA RC TRANSMITTER

SKP10174 INST MANUAL - F7WV (1)

SKP10175 INST MANUAL - F7WV (2)

SKP10178 INST MANUAL - F7WV (3)

645 000 6708 BATTERY,MANGAN,COMPOSITE

Note: Parts order must contain Service Ref. No., Part No., and descriptions.

1

2

3

4

5

6

7

89

0

-/--

P▲

▼

P

P

F

P

MENU

i

SURROUND

BASS

TV

TXT

?

X

AB

TV

2

12

11

5 14 15

104

1

9

8

16

Ref. No. Part No. Description Ref. No. Part No. Description

SERVICE REF. NO. CE25DN4-C-01

3

7

Page 12

CHASSIS ELECTRICAL PARTS LIST

Product safety should be considered when a component replacement is made in any area of a receiver.

Components indicated by a mark in this parts list and the circuit diagram show components whose value have

special significance to product safety. It is particularly recommended that only parts specified on the following parts

list be used for components replacement pointed out by the mark.

Note: Parts order must contain Service Ref. No., Part No., and descriptions.

!

!

Ref.No. Part No. Description

Read description in the Capacitor and Resistor as follows:

CAPACITOR

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

Less than 10PF

A:Not specifiedB:±0.1PF C:±0.25PF

D:±0.5PF F: ±1PF G:±2PF

R:±0.25-0PF S:±0-0.25PFE: +0-1PF

More than 10PF

A:Not specifiedB:±0.1% C:±0.25%

D:±0.5% F: ±1% G:±2%

H:±3% J:±5% K:±10%

L:±15% M:±20% N:±30%

P:+100-0% Q:+30-10% T:+50-10%

U:+75-10% V:+20-10% W:+100-10%

X:+40-20% Y:+150-10%Z:+80-20%

Rated value: P=pico farad, U=Micro farad

Material:

CERAMIC............Ceramic

MT-PAPER..........Metallized Paper

POLYESTER........Polyester

MT-POLYEST......Metallized Polyester

POLYPRO............Polypropylene

MT-POLYPRO......Metallized Polypropylene

COMPO FILM......Composite film

MT-COMPO........Metallized Composite

STYRENE............Styrene

TA-SOLID............Tantalum Solid

AL-SOLID............Aluminium Solid

ELECT..................Electrolytic

NP-ELECT............Non-polarised Electrolytic

OS-SOLID............Aluminium Solid with Organic Semiconductive Electrolytic

DL-ELECT............Double Layered Electrolytic

RESISTOR

CARBON 4.7K J A 1/4W

Rated Wattage

Performance Symbols:

A: General B: Non flammable Z:Low noise

Other:Temperature coefficient

Tolerance Symbols:

A:±0.05% B:±0.1% C:±0.25%D:±0.5%

F:±1% G:±2% J:±5% K:±10%

M:±20% P:+5-15%

Rated value, ohms:

K:1,000, M: 1,000,000

Material:

CARBON............Carbon

MT-FILM..............Metal Film

OXIDE-MT..........Oxide Metal Film

SOLID..................Composition

MT-GLAZE..........Metal Glaze

WIREWOUND....Wire Wound

CERAMIC RES....Ceramic

FUSIBLE RES....Fusible

Chassis construction CE25DN4-C-01

OUT OF CIRCUIT-F7VVV (Page 12)

ASSY,PWB,CRT-MK2 F3SSY1AA0B10H03500 (Page 12)

ASSY, TEMPSIF-POLISH.2 1AA0B10H030EA (Page 13)

ASSY, TEMP AUDIO-POLISH.21AA0B10H030EB (Page 13)

ASSY,PWB,MAIN F2VVV 1AA0B10H026Q0 (Page 14~19)

OUT OF CIRCUIT-F7VVV

PICTURE TUBE

!

Q901 414 009 7104 CRT A59EHJ43X38

COIL

!

L901 645 025 6530 25DEG.COIL OREGA 47320234

MISCELLANEOUS

SP901 610 232 3986 SPEAKER

SP902 610 232 3986 SPEAKER

!

W901 645 012 7632 EURO PLUG +2P HOUSE @ 2.1

W902 610 204 6083 GROUNDING CONNECTOR-D8CD

ASSY,PWB,CRT-MK2 F3SSY1AA0B10H03500

TRANSISTOR

Q701 405 041 6507 TR 2SC2621-D-RA

Q711 405 041 6507 TR 2SC2621-D-RA

Q721 405 041 6507 TR 2SC2621-D-RA

Q740 406 007 1901 TR JC556A

Q751 406 007 1901 TR JC556A

CAPACITOR

C701 403 073 2910 CERAMIC 390P K 50V

C711 403 073 2910 CERAMIC 390P K 50V

C721 403 073 2910 CERAMIC 390P K 50V

C731 403 077 2728 CERAMIC 1000P P 2K

C735 403 055 8401 ELECT 22U M 250V

C751 403 248 1608 ELECT 47U M 16V

RESISTOR

R701 401 026 3925 CARBON 330 JA 1/6W

R702 401 026 7022 CARBON 3K9 JA 1/6W

R703 401 025 4220 CARBON 1K8 JA 1/6W

!

R704 401 065 4604 OXIDE-MT 12K JA 2W

R705 401 009 6622 CARBON 3.3K JA 1/2W

R711 401 026 3925 CARBON 330 JA 1/6W

R712 401 026 7022 CARBON 3K9 JA 1/6W

R713 401 026 1020 CARBON 2K7 JA 1/6W

!

R714 401 065 4604 OXIDE-MT 12K JA 2W

R715 401 009 6622 CARBON 3.3K JA 1/2W

R721 401 026 3925 CARBON 330 JA 1/6W

R722 401 026 7022 CARBON 3K9 JA 1/6W

R723 401 025 4220 CARBON 1K8 JA 1/6W

!

R724 401 065 4604 OXIDE-MT 12K JA 2W

R725 401 009 6622 CARBON 3.3K JA 1/2W

R727 401 026 9620 CARBON 470 JA 1/6W

F7VVV

-12-

Page 13

R741 401 026 9927 CARBON 4K7 JA 1/6W

R742 401 026 4328 CARBON 3K3 JA 1/6W

R744 401 026 0627 CARBON 270 JA 1/6W

R752 401 024 7430 CARBON 10K JA 1/6W

R753 401 024 7430 CARBON 10K JA 1/6W

VARIABLE RESISTOR

VR701 645 003 5722 VR,SEMI,4.7K N

VR702 645 003 5647 VR,SEMI,1K N

VR711 645 003 5722 VR,SEMI,4.7K N

VR712 645 003 5647 VR,SEMI,1K N

VR721 645 003 5722 VR,SEMI,4.7K N

COIL

L701 645 007 9856 PEAKING COIL 220UH K

L711 645 007 9856 PEAKING COIL 220UH K

L721 645 007 9856 PEAKING COIL 220UH K

DIODE

D701 407 012 4416 DIODE 1SS133-T-77

D711 407 012 4416 DIODE 1SS133-T-77

D721 407 012 4416 DIODE 1SS133-T-77

D751 407 012 4416 DIODE 1SS133-T-77

MISCELLANEOUS

K7M 645 008 4058 TERMINAL PLUG

K7P 645 008 7288 HOUSING PLUG 5P

K7Q 645 008 7264 HOUSING PLUG 3P

K701 645 031 7699 CRT SKT. HPS-014103

ASSY, TEMP SIF-POLISH.2 1AA0B10H030EA

TRANSISTOR

Q3811 405 014 4519 TR 2SC2412KT146/R

INTEGRATED CIRCUIT

IC3801 409 310 8407 IC LA7577N

CAPACITOR

C3805 403 023 4414 CERAMIC 330P J 50V

C3806 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3807 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3808 403 049 4204 ELECT 10U M 50V

C3809 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3810 403 051 0607 ELECT 4.7U M 50V

C3811 403 018 0513 CERAMIC 22P J 50V

C3812 403 048 6308 ELECT 0.47U M 50V

C3813 403 074 6610 CERAMIC 560P K 50V

C3814 403 069 1712 CERAMIC 1000P K 50V

C3815 403 069 9510 CERAMIC CHIP 0.01 Z 50V

RESISTOR

R3811 401 038 7512 MT-GLAZE 56 JA 1/10W

R3812 401 037 5618 MT-GLAZE 10K JA 1/10W

R3815 401 037 5410 MT-GLAZE 1K JA 1/10W

R3816 401 038 3514 MT-GLAZE 330 JA 1/10W

R3817 401 037 9210 MT-GLAZE 1.8K JA 1/10W

R3818 401 038 9011 MT-GLAZE 680K JA 1/10W

TRANSFORMER

T3801 610 037 4539 S COIL

MISCELLANEOUS

J3801 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3802 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3811 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3813 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3816 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3818 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

K38H1 645 027 0185 PLUG,4P

K38H2 645 027 0185 PLUG,4P

X3801 421 007 2208 SAW F TSB5393

ASSY, TEMPAUDIO-POLISH.2 1AA0B10H030EB

TRANSISTOR

Q1252 405 014 4519 TR 2SC2412KT146/R

Q1253 405 014 4519 TR 2SC2412KT146/R

Q3452 405 014 4519 TR 2SC2412KT146/R

Q3453 405 014 4519 TR 2SC2412KT146/R

Q3501 405 014 4519 TR 2SC2412KT146/R

Q3502 405 014 4519 TR 2SC2412KT146/R

Q3503 405 014 4519 TR 2SC2412KT146/R

INTEGRATED CIRCUIT

IC1251 409 009 2501 IC HD14052BP

IC3451 409 445 1403 IC TDA9875A/V2

IC3500 409 367 2809 IC BA178M09T

IC3501 409 398 9204 IC MM1369AD

CAPACITOR

C1251 403 248 1618 ELECT 47U M 16V

C3452 403 314 5915 SMD CAP GRM40X5R474K16

C3453 403 026 2813 CERAMIC 47P J 50V

C3454 403 068 0419 CERAMIC 0.1U Z 25V

C3455 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

C3458 403 026 2813 CERAMIC 47P J 50V

C3461 403 248 1410 ELECT 1U M 50V

C3462 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

C3468 403 248 1410 ELECT 1U M 50V

C3469 403 248 1410 ELECT 1U M 50V

C3473 403 279 4312 CERAMIC 0.33U K 16V

C3474 403 279 4312 CERAMIC 0.33U K 16V

C3476 403 314 5915 SMD CAP GRM40X5R474K16

C3477 403 248 1618 ELECT 47U M 16V

C3480 403 248 1618 ELECT 47U M 16V

C3481 403 248 1618 ELECT 47U M 16V

C3482 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3483 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3484 403 248 1618 ELECT 47U M 16V

C3485 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C3486 403 248 1410 ELECT 1U M 50V

C3487 403 248 1410 ELECT 1U M 50V

C3490 403 009 5718 CERAMIC 100P J 50V

C3492 403 069 5611 CERAMIC 0.01U K 50V

C3493 403 069 5611 CERAMIC 0.01U K 50V

C3500 403 248 1618 ELECT 47U M 16V

C3501 403 049 4204 ELECT 10U M 50V

C3502 403 075 0716 CERAMIC 6800P K 50V

C3503 403 010 1112 CERAMIC 100

C3504 403 192 5915 CERAMIC 0.1U K 25V

C3505 403 248 1618 ELECT 47U M 16V

C3506 403 248 2813 ELECT 2.2U M 50V

C3507 403 069 5611 CERAMIC 0.01U K 50V

C3508 403 069 5611 CERAMIC 0.01U K 50V

C3509 403 069 5611 CERAMIC 0.01U K 50V

C3510 403 069 5611 CERAMIC 0.01U K 50V

C3511 403 010 1112 CERAMIC 100

C3512 403 192 5915 CERAMIC 0.1U K 25V

C3513 403 075 0716 CERAMIC 6800P K 50V

C3514 403 049 4204 ELECT 10U M 50V

C3515 403 248 2813 ELECT 2.2U M 50V

C3516 403 049 4204 ELECT 10U M 50V

C3517 403 269 5916 CERAMIC 0.22U K 16V

C3518 403 248 1618 ELECT 47U M 16V

C3520 403 248 1618 ELECT 47U M 16V

C3521 403 279 4312 CERAMIC 0.33U K 16V

C3522 403 279 4312 CERAMIC 0.33U K 16V

RESISTOR

R1251 401 038 9318 MT-GLAZE 68K JA 1/10W

R1252 401 038 9318 MT-GLAZE 68K JA 1/10W

R1253 401 038 9318 MT-GLAZE 68K JA 1/10W

R1254 401 038 9318 MT-GLAZE 68K JA 1/10W

!

Ref. No. Part No. Description Ref. No. Part No. Description

-13-

F7VVV

Page 14

R1255 401 038 9318 MT-GLAZE 68K JA 1/10W

R1256 401 038 9318 MT-GLAZE 68K JA 1/10W

R1257 401 038 9318 MT-GLAZE 68K JA 1/10W

R1258 401 038 9318 MT-GLAZE 68K JA 1/10W

R1261 401 038 6317 MT-GLAZE 470 JA 1/10W

R1262 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1263 401 038 6317 MT-GLAZE 470 JA 1/10W

R1264 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R3451 401 037 5212 MT-GLAZE 100 JA 1/10W

R3452 401 037 5212 MT-GLAZE 100 JA 1/10W

R3453 401 037 5618 MT-GLAZE 10K JA 1/10W

R3454 401 037 5212 MT-GLAZE 100 JA 1/10W

R3455 401 037 5618 MT-GLAZE 10K JA 1/10W

R3456 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R3459 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R3462 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R3464 401 037 5212 MT-GLAZE 100 JA 1/10W

R3465 401 037 5618 MT-GLAZE 10K JA 1/10W

R3466 401 037 5410 MT-GLAZE 1K JA 1/10W

R3467 401 038 2111 MT-GLAZE 2.7K JA 1/10W

R3468 401 037 5410 MT-GLAZE 1K JA 1/10W

R3469 401 038 2111 MT-GLAZE 2.7K JA 1/10W

R3471 401 038 2012 MT-GLAZE 270 JA 1/10W

R3472 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R3473 401 038 6317 MT-GLAZE 470 JA 1/10W

R3474 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R3475 401 038 6317 MT-GLAZE 470 JA 1/10W

R3476 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R3477 401 038 5310 MT-GLAZE 39K JA 1/10W

R3478 401 038 5310 MT-GLAZE 39K JA 1/10W

R3479 401 037 8015 MT-GLAZE 15K JA 1/10W

R3480 401 037 8015 MT-GLAZE 15K JA 1/10W

R3501 401 180 0416 MT-GLAZE 7.5K FA 1/10W

R3502 401 037 5212 MT-GLAZE 100 JA 1/10W

R3503 401 037 5410 MT-GLAZE 1K JA 1/10W

R3504 401 037 5410 MT-GLAZE 1K JA 1/10W

R3505 401 039 0512 MT-GLAZE 82K JA 1/10W

R3506 401 037 9319 MT-GLAZE 18K JA 1/10W

R3507 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R3508 401 037 5410 MT-GLAZE 1K JA 1/10W

R3509 401 038 9219 MT-GLAZE 6.8K JA 1/10W

R3510 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R3511 401 038 0919 MT-GLAZE 220K JA 1/10W

R3512 401 038 7819 MT-GLAZE 56K JA 1/10W

R3513 401 038 7819 MT-GLAZE 56K JA 1/10W

R3514 401 038 5112 MT-GLAZE 3.9K JA 1/10W

R3515 401 037 5410 MT-GLAZE 1K JA 1/10W

R3516 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R3517 401 037 5410 MT-GLAZE 1K JA 1/10W

R3518 401 038 0711 MT-GLAZE 2.2K JA 1/10W

COIL

L3450 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

L3452 645 011 0252 INDUCTOR,2.2U K

L3456 645 011 0252 INDUCTOR,2.2U K

L3457 645 011 0252 INDUCTOR,2.2U K

L3459 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

MISCELLANEOUS

J1251 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3459 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3463 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3465 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3469 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3474 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3486 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3489 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J3501 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

K12B 645 008 7288 HOUSING PLUG 5P

K34A 645 027 0192 PLUG,10P

K34B 645 027 0192 PLUG,10P

K34C 645 027 0178 PLUG,3P

X3451 645 024 7484 OSC,CRYSTAL 24.576MHZ

ASSY,PWB,MAIN F2VVV 1AA0B10H026Q0

TRANSISTOR

Q001 406 007 2106 TR JC546A

Q1001 406 007 1901 TR JC556A

Q1002 406 007 2106 TR JC546A

Q1003 406 007 2106 TR JC546A

Q1004 406 007 2106 TR JC546A

Q1005 406 007 2106 TR JC546A

Q1041 406 007 2106 TR JC546A

Q1042 406 007 1901 TR JC556A

Q1043 406 007 2106 TR JC546A

Q1201 406 007 2106 TR JC546A

Q1202 406 007 2106 TR JC546A

Q1203 406 007 2106 TR JC546A

Q121 406 007 2106 TR JC546A

Q151 406 007 1901 TR JC556A

Q152 406 007 2106 TR JC546A

Q153 406 007 1901 TR JC556A

Q154 406 007 1901 TR JC556A

Q171 406 007 2106 TR JC546A

Q2001 406 007 2106 TR JC546A

Q201 406 007 2106 TR JC546A

Q202 406 007 2106 TR JC546A

Q431 405 018 0616 TR 2SC3332-S

Q432 406 015 2501 ON5111 (BU2708DX) PH.

Q432-1 610 252 1108 H HEAT SINK E7LC

Q461 405 064 7307 TR 2SB1274-Q-RA

Q461-1 610 251 5916 HEAT SINK PCC E7LC

Q462 406 007 2106 TR JC546A

Q501 406 007 2106 TR JC546A

Q611 406 007 1901 TR JC556A

Q612 405 058 0208 TR 2SC3807-R-CTV-YA

Q613 405 095 0407 TR 2SC4429-L-YB

Q613-1 610 251 5893 POW HEAT SINK E7LC

Q641 406 007 2106 TR JC546A

Q681 405 059 9804 TR 2SD1913-Q-RA

Q682 406 007 1901 TR JC556A

Q801 405 118 4217 TR PH2369

Q835 406 007 2106 TR JC546A

Q861 406 007 1901 TR JC556A

Q871 406 007 2106 TR JC546A

Q872 406 007 2106 TR JC546A

Q873 406 007 2106 TR JC546A

Q874 406 007 2106 TR JC546A

INTEGRATED CIRCUIT

IC001 409 301 4906 IC TDA7263M

IC001-1 610 251 4186 AUDIO HEATSINK ASSY E7PC

IC1201 409 018 7603 IC LA7016

IC1202 409 120 3401 IC LA7221

IC201 409 380 8703 IC TDA8361/N5

IC271 409 404 0201 IC U3665M

IC501 409 192 5709 IC LA7833

IC501-1 610 251 5909 V HEAT SINK E7LC

IC651 409 365 2900 IC BA178M12T

IC652 409 365 2801 IC BA178M08T

IC653 409 241 5407 IC BA178M05T

IC654 409 367 2809 IC BA178M09T

IC801 410 342 3308 IC SAA5296ZP/***

IC802 409 333 3700 IC 24LC02B/P

IC810 409 019 6209 IC LA7910

CAPACITOR

C001A 403 068 0419 CERAMIC 0.1U Z 25V

C002 403 070 9813 CHIP CERAMIC 0.015U K 50V

C003A 403 068 0419 CERAMIC 0.1U Z 25V

C004 403 070 9813 CHIP CERAMIC 0.015U K 50V

Ref. No. Part No. Description Ref. No. Part No. Description

-14-

F7VVV

Page 15

C005 403 258 3619 ELECT 33U M 25V

C006 403 258 3619 ELECT 33U M 25V

C007 403 237 7941 MT-COMPO 0.22U J 50V

C008 403 237 7941 MT-COMPO 0.22U J 50V

C009 403 237 7941 MT-COMPO 0.22U J 50V

C010 403 237 7941 MT-COMPO 0.22U J 50V

C011 403 218 8101 ELECT 1000U M 25V

C012 403 218 8101 ELECT 1000U M 25V

C013 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C014 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C015 403 047 3100 ELECT 47U M 25V

C016 403 152 4702 NP-ELECT 10U M 16V

C017 403 152 4702 NP-ELECT 10U M 16V

C020 403 069 0517 CERAMIC 1000P K 50V

C021 403 154 1917 ELECT 1000U M 35V

C023 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C024 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C100 403 248 1618 ELECT 47U M 16V

C1001 403 069 1712 CERAMIC 1000P K 50V

C1002 403 049 4204 ELECT 10U M 50V

C1003 403 009 5718 CERAMIC 100P J 50V

C1004 403 130 3119 CERAMIC 0.047U K 50V

C1005 403 069 1712 CERAMIC 1000P K 50V

C1006 403 049 4204 ELECT 10U M 50V

C1007 403 009 5718 CERAMIC 100P J 50V

C1008 403 130 3119 CERAMIC 0.047U K 50V

C1009 403 049 4204 ELECT 10U M 50V

C101 403 194 4609 ELECT 470U M 16V

C102 403 248 1618 ELECT 47U M 16V

C1021 403 069 1712 CERAMIC 1000P K 50V

C1022 403 049 4204 ELECT 10U M 50V

C1023 403 009 5718 CERAMIC 100P J 50V

C1024 403 189 2425 ELECT 10U M 16V

C1025 403 069 1712 CERAMIC 1000P K 50V

C1026 403 049 4204 ELECT 10U M 50V

C1027 403 009 5718 CERAMIC 100P J 50V

C1028 403 189 2425 ELECT 10U M 16V

C1029 403 049 4204 ELECT 10U M 50V

C103A 403 069 1712 CERAMIC 1000P K 50V

C1031 403 033 4510 CERAMIC 82P J 50V

C104B 403 248 1618 ELECT 47U M 16V

C1041 403 049 4204 ELECT 10U M 50V

C106 403 248 1410 ELECT 1U M 50V

C106A 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C107A 403 069 1712 CERAMIC 1000P K 50V

C107B 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C108 403 027 1211 CERAMIC 5P J 50V

C109 403 027 1211 CERAMIC 5P J 50V

C110 403 033 4510 CERAMIC 82P J 50V

C1101 403 049 4204 ELECT 10U M 50V

C1103 403 069 1712 CERAMIC 1000P K 50V

C1104 403 049 4204 ELECT 10U M 50V

C1106 403 069 1712 CERAMIC 1000P K 50V

C1107 403 049 4204 ELECT 10U M 50V

C1108 403 033 4510 CERAMIC 82P J 50V

C1109 403 008 7416 CERAMIC 10P D 50V

C114 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

C117 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

C1200 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C1201 403 049 4204 ELECT 10U M 50V

C1202 403 049 4204 ELECT 10U M 50V

C1203 403 069 8315 CERAMIC 0.01U Z 50V

C121 403 068 0419 CERAMIC 0.1U Z 25V

C131 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

C132 403 069 1712 CERAMIC 1000P K 50V

C133 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C134 403 050 6600 ELECT 3.3U M 50V

C135 403 068 0419 CERAMIC 0.1U Z 25V

C136 403 194 4609 ELECT 470U M 16V

C137 403 068 0419 CERAMIC 0.1U Z 25V

C138 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C141 403 028 4419 CERAMIC 56P J 50V

C142 403 068 0419 CERAMIC 0.1U Z 25V

C143 403 027 1211 CERAMIC 5P J 50V

C146 403 010 8517 CERAMIC 18P J 50V

C151 403 024 2112 CERAMIC 39P J 50V

C162 403 068 2512 CERAMIC 0.22U Z 25V

C171 403 237 8057 MT-COMPO 0.1U J 50V

C1901 403 069 1712 CERAMIC 1000P K 50V

C200 403 068 0419 CERAMIC 0.1U Z 25V

C2001 403 068 0419 CERAMIC 0.1U Z 25V

C2002 403 068 0419 CERAMIC 0.1U Z 25V

C2003 403 068 0419 CERAMIC 0.1U Z 25V

C201 403 014 3419 CERAMIC 1

C202 403 237 8057 MT-COMPO 0.1U J 50V

C203 403 073 9117 CERAMIC 4700P K 50V

C204 403 068 0419 CERAMIC 0.1U Z 25V

C205 403 068 0419 CERAMIC 0.1U Z 25V

C206 403 068 0419 CERAMIC 0.1U Z 25V

C207 403 068 0419 CERAMIC 0.1U Z 25V

C208 403 068 0419 CERAMIC 0.1U Z 25V

C209 403 069 1712 CERAMIC 1000P K 50V

C212 403 248 2813 ELECT 2.2U M 50V

C215 403 067 7895 MT-COMPO 0.47 J 50V

C222 404 045 6605 NP-ELECT 2.2U M 50V

C226 403 054 4909 ELECT 1U M 100V

C231 403 068 0419 CERAMIC 0.1U Z 25V

C232 403 033 4510 CERAMIC 82P J 50V

C233 403 068 0419 CERAMIC 0.1U Z 25V

C234 403 033 4510 CERAMIC 82P J 50V

C235 403 008 7416 CERAMIC 10P D 50V

C271 403 069 1712 CERAMIC 1000P K 50V

C272 403 069 1712 CERAMIC 1000P K 50V

C273 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C274 403 049 4204 ELECT 10U M 50V

C351 403 237 8057 MT-COMPO 0.1U J 50V

C352 403 179 1015 POLYESTER 0.047U J 50V

C353 403 073 9117 CERAMIC 4700P K 50V

C354 403 248 1410 ELECT 1U M 50V

C361 403 072 5615 CERAMIC 2700P K 50V

C362 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C363 403 195 8804 ELECT 100U M 16V

C421 404 046 8806 MT-POLYPRO 6200P J 1.5K

C422 403 299 3210 POLYPRO 0.027U J 400V

C423 404 061 0601 MT-POLYPRO 5100P J 1.5K

C424 403 299 3111 POLYPRO 0.022U J 400V

C430 403 075 9719 CERAMIC 1800P K 500V

C431 403 068 5612 CERAMIC 0.056U Z 25V

C432 403 075 7111 CERAMIC 1000P K 500V

C433 403 076 3112 CERAMIC 3900P K 500V

C434 403 054 0703 ELECT 47U M 35V

C437 403 066 6106 MT-POLYEST 0.47U J 250V

C438 403 178 9319 POLYESTER 0.01U J 50V

C441 403 083 5106 POLYPRO 0.27U J 400V

C445 403 049 4204 ELECT 10U M 50V

C462 403 248 1410 ELECT 1U M 50V

C463 403 237 8057 MT-COMPO 0.1U J 50V

C464 403 255 8934 MT-COMPO 0.39U J 50V

C465 403 066 0104 MT-POLYEST 2.2U K 100V

C467 403 241 3817 ELECT 220U M 10V

C468 403 217 1103 ELECT 22U M 50V

C470 403 069 8315 CERAMIC 0.01U Z 50V

C481 403 076 1415 CERAMIC 2700P K 500V

C482 403 066 2009 MT-POLYEST 0.1U K 250V

C501 403 054 1502 ELECT 470U M 35V

C502 403 217 1103 ELECT 220U M 35V

C503 403 024 2112 CERAMIC 39P J 50V

C504 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C505 403 075 7111 CERAMIC 1000P K 500V

C506 403 102 8408 MT-POLYEST 0.UUF K 100V

C511 403 256 4806 ECQU1104JM3 0.1U J 100V

C512 403 148 0701 ELECT 2200U M 25V

Ref. No. Part No. Description Ref. No. Part No. Description

-15-

F7VVV

Page 16

C513 403 049 4204 ELECT 10U M 50V

C514 403 049 4204 ELECT 10U M 50V

C600 403 076 4010 CERAMIC 4700P K 500V

C601 404 060 7205 MT-POLYEST 0.1U M 250V

C602 404 060 7205 MT-POLYEST 0.1U M 250V

C603 403 076 7130 CERAMIC 1000P M 1K

C604 403 076 7130 CERAMIC 1000P M 1K

C605 403 076 7130 CERAMIC 1000P M 1K

C606 403 076 7130 CERAMIC 1000P M 1K

C607 404 047 1608 ELECT 270U M 385V

C613 403 179 1213 POLYESTER 4700P J 50V

C614 403 237 8057 MT-COMPO 0.1U J 50V

C615 403 179 3217 POLYESTER 0.015U J 50V

C616 403 246 8708 CERAMIC 1000P K 2K

C617 403 179 2418 POLYESTER 0.022U K 50V

C631 404 060 6505 CERAMIC 2200P M 400V

C632 404 044 2806 CERAMIC 470P K 400V

C640 403 069 8315 CERAMIC 0.01U Z 50V

C641 403 165 9335 CERAMIC 680P K 1K

C642 404 055 9801 ELECT 220U M 200V

C643 403 214 4404 ELECT 470U M 35V

C644 403 148 0701 ELECT 2200U M 25V

C645 403 161 2607 ELECT 2200U M 35V

C651 403 148 0305 ELECT 470U M 16V

C652 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C653 403 248 1618 ELECT 47U M 16V

C655 403 126 4400 ELECT 100U M 10V

C661 403 051 0607 ELECT 4.7U M 50V

C681 403 190 4702 ELECT 1000U M 25V

C682 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C683 403 039 9004 ELECT 1000U M 10V

C684 403 050 6600 ELECT 3.3U M 50V

C802 403 237 8057 MT-COMPO 0.1U J 50V

C812 403 248 1410 ELECT 1U M 50V

C814 403 248 1410 ELECT 1U M 50V

C816 403 051 0607 ELECT 4.7U M 50V

C818 403 051 0607 ELECT 4.7U M 50V

C841 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C861 403 179 0810 POLYESTER 0.0056U J 5

C871 403 068 0419 CERAMIC 0.1U Z 25V

C872 403 248 1618 ELECT 47U M 16V

C873 403 018 0513 CERAMIC 22P J 50V

C874 403 018 0513 CERAMIC 22P J 50V

C875 403 068 0419 CERAMIC 0.1U Z 25V

C878 403 073 9117 CERAMIC 4700P K 50V

C879 403 068 0419 CERAMIC 0.1U Z 25V

C881 403 069 9510 CERAMIC CHIP 0.01 Z 50V

C882 403 049 4204 ELECT 10U M 50V

C883 403 018 0513 CERAMIC 22P J 50V

C884 403 018 0513 CERAMIC 22P J 50V

C892 403 069 9510 CERAMIC CHIP 0.01 Z 50V

RESISTOR

R001 401 037 5410 MT-GLAZE 1K JA 1/10W

R002 401 037 9210 MT-GLAZE 1.8K JA 1/10W

R003 401 037 5410 MT-GLAZE 1K JA 1/10W

R004 401 037 9210 MT-GLAZE 1.8K JA 1/10W

R005 401 019 9640 CARBON 47 JA 1/4W

R006 401 014 4145 CARBON 1K5 JA 1/4W

R007 401 019 9640 CARBON 47 JA 1/4W

R008 401 014 4145 CARBON 1K5 JA 1/4W

R009 401 010 1514 CARBON 4.7 JA 1/2W

R010 401 010 1514 CARBON 4.7 JA 1/2W

R011 401 007 7641 CARBON 150 JA 1/2W

R012 401 007 7641 CARBON 150 JA 1/2W

R013 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R014 401 016 2644 CARBON 220 JA 1/4W

R015 401 037 5410 MT-GLAZE 1K JA 1/10W

R016 401 038 6515 MT-GLAZE 47K JA 1/10W

R017 401 037 5618 MT-GLAZE 10K JA 1/10W

R100 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1001 401 038 7611 MT-GLAZE 560 JA 1/10W

R1002 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1003 401 038 7611 MT-GLAZE 560 JA 1/10W

R1004 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1005 401 027 6628 CARBON 75 JA 1/6W

R1006 401 038 5310 MT-GLAZE 39K JA 1/10W

R1007 401 038 3712 MT-GLAZE 33K JA 1/10W

R1008 401 027 6628 CARBON 75 JA 1/6W

R1009 401 027 6628 CARBON 75 JA 1/6W

R101 401 038 6218 MT-GLAZE 47 JA 1/10W

R1010 401 027 6628 CARBON 75 JA 1/6W

R1011 401 037 5212 MT-GLAZE 100 JA 1/10W

R1012 401 027 6628 CARBON 75 JA 1/6W

R1013 401 012 4543 CARBON 100 JA 1/4W

R1014 401 027 6628 CARBON 75 JA 1/6W

R1015 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R1016 401 019 1040 CARBON 390 JA 1/4W

R1017 401 024 7430 CARBON 10K JA 1/6W

R1018 401 038 3514 MT-GLAZE 330 JA 1/10W

R1021 401 038 7611 MT-GLAZE 560 JA 1/10W

R1022 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1023 401 038 7611 MT-GLAZE 560 JA 1/10W

R1024 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1025 401 038 5310 MT-GLAZE 39K JA 1/10W

R1026 401 038 3712 MT-GLAZE 33K JA 1/10W

R1027 401 027 6628 CARBON 75 JA 1/6W

R1028 401 027 6628 CARBON 75 JA 1/6W

R1029 401 017 0847 CARBON 270 JA 1/4W

R1031 401 038 0612 MT-GLAZE 220 JA 1/10W

R1032 401 038 0612 MT-GLAZE 220 JA 1/10W

R1033 401 038 0612 MT-GLAZE 220 JA 1/10W

R1041 401 038 2210 MT-GLAZE 27K JA 1/10W

R1042 401 037 5618 MT-GLAZE 10K JA 1/10W

R1043 401 039 0314 MT-GLAZE 820 JA 1/10W

R1044 401 039 0314 MT-GLAZE 820 JA 1/10W

R1045 401 037 5410 MT-GLAZE 1K JA 1/10W

R1046 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1047 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R1051 401 037 8114 MT-GLAZE 150K JA 1/10W

R1052 401 037 5717 MT-GLAZE 100K JA 1/10W

R1053 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R1054 401 037 8114 MT-GLAZE 150K JA 1/10W

R1055 401 037 5717 MT-GLAZE 100K JA 1/10W

R1056 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R108 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R110 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1101 401 027 6628 CARBON 75 JA 1/6W

R1102 401 038 2012 MT-GLAZE 270 JA 1/10W

R1103 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1104 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1105 401 037 5717 MT-GLAZE 100K JA 1/10W

R1106 401 037 5717 MT-GLAZE 100K JA 1/10W

R1111 401 037 5618 MT-GLAZE 10K JA 1/10W

R1200 401 022 1935 CARBON 680 JA 1/4W

R1201 401 038 6515 MT-GLAZE 47K JA 1/10W

R1202 401 038 6515 MT-GLAZE 47K JA 1/10W

R1203 401 037 5618 MT-GLAZE 10K JA 1/10W

R1204 401 038 2210 MT-GLAZE 27K JA 1/10W

R1205 401 038 2210 MT-GLAZE 27K JA 1/10W

R1208 401 038 0810 MT-GLAZE 22K JA 1/10W

R1209 401 012 7049 CARBON 10K JA 1/4W

R121 401 020 2944 CARBON 47K JA 1/4W

R131 401 038 0919 MT-GLAZE 220K JA 1/10W

R132 401 038 0919 MT-GLAZE 220K JA 1/10W

R133 401 037 9111 MT-GLAZE 180 JA 1/10W

R134 401 039 0413 MT-GLAZE 8.2K JA 1/10W

R135 401 038 0810 MT-GLAZE 22K JA 1/10W

R136 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R137 401 037 5212 MT-GLAZE 100 JA 1/10W

R138 401 038 7710 MT-GLAZE 5.6K JA 1/10W

R141 401 038 9219 MT-GLAZE 6.8K JA 1/10W

!!!

!

Ref. No. Part No. Description Ref. No. Part No. Description

-16-

F7VVV

Page 17

R150 401 024 7024 CARBON 1K JA 1/6W

R151 401 022 1935 CARBON 680 JA 1/4W

R152 401 025 3827 CARBON 180 JA 1/6W

R153 401 037 5410 MT-GLAZE 1K JA 1/10W

R154 401 038 7611 MT-GLAZE 560 JA 1/10W

R155 401 037 5410 MT-GLAZE 1K JA 1/10W

R156 401 037 5410 MT-GLAZE 1K JA 1/10W

R157 401 039 0918 MT-GLAZE 910 JA 1/10W

R158 401 037 5410 MT-GLAZE 1K JA 1/10W

R159 401 022 1935 CARBON 680 JA 1/4W

R163 401 038 6515 MT-GLAZE 47K JA 1/10W

R171 401 038 6317 MT-GLAZE 470 JA 1/10W

R172 401 016 2644 CARBON 220 JA 1/4W

R173 401 025 7429 CARBON 220 JA 1/6W

R1901 401 037 8015 MT-GLAZE 15K JA 1/10W

R1901A 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1902 401 039 0413 MT-GLAZE 8.2K JA 1/10W

R1902A 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1903 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R1903A 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1904 401 038 2111 MT-GLAZE 2.7K JA 1/10W

R1905 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R1906 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R1907 401 037 5618 MT-GLAZE 10K JA 1/10W

R1908 401 038 3514 MT-GLAZE 330 JA 1/10W

R1909 401 037 7919 MT-GLAZE 1.5K JA 1/10W

R1911 401 038 6317 MT-GLAZE 470 JA 1/10W

R1921 401 037 6615 MT-GLAZE 120 JA 1/10W

R1922 401 038 5013 MT-GLAZE 390 JA 1/10W

R1924 401 022 3147 CARBON 6K8 JA 1/4W

R2001 401 038 2210 MT-GLAZE 27K JA 1/10W

R2002 401 037 5618 MT-GLAZE 10K JA 1/10W

R2004 401 037 7810 MT-GLAZE 150 JA 1/10W

R2005 401 019 1941 CARBON 3K9 JA 1/4W

R201 401 039 0413 MT-GLAZE 8.2K JA 1/10W

R202 401 037 5717 MT-GLAZE 100K JA 1/10W

R203 401 024 6720 CARBON 100 JA 1/6W

R204 401 024 6720 CARBON 100 JA 1/6W

R205 401 024 6720 CARBON 100 JA 1/6W

R206 401 037 5212 MT-GLAZE 100 JA 1/10W

R207 401 037 5212 MT-GLAZE 100 JA 1/10W

R208 401 037 5212 MT-GLAZE 100 JA 1/10W

R212 401 017 1844 CARBON 2K7 JA 1/4W

R213 401 038 7710 MT-GLAZE 5.6K JA 1/10W

R214 401 037 5212 MT-GLAZE 100 JA 1/10W

R215 401 038 3712 MT-GLAZE 33K JA 1/10W

R216 401 016 4836 CARBON 22K JA 1/4W

R217 401 016 4836 CARBON 22K JA 1/4W

R218 401 038 7819 MT-GLAZE 56K JA 1/10W

R223 401 014 9506 CARBON 160K JA 1/4W

R224 401 024 7024 CARBON 1K JA 1/6W

R226 401 026 7428 CARBON 39K JA 1/6W

R227 401 012 7049 CARBON 10K JA 1/4W

R231 401 038 2012 MT-GLAZE 270 JA 1/10W

R232 401 038 2012 MT-GLAZE 270 JA 1/10W

R271 401 024 6720 CARBON 100 JA 1/6W

R272 401 024 9028 CARBON 120 JA 1/6W

R351 401 037 5212 MT-GLAZE 100 JA 1/10W

R353 401 038 0919 MT-GLAZE 220K JA 1/10W

R354 401 024 7727 CARBON 100K JA 1/6W

R355 401 012 9904 CARBON 10M JA 1/4W

R356 401 037 5212 MT-GLAZE 100 JA 1/10W

R357 401 037 5618 MT-GLAZE 10K JA 1/10W

R361 401 038 5419 MT-GLAZE 390K JA 1/10W

R363 401 038 0810 MT-GLAZE 22K JA 1/10W

R364 401 037 5212 MT-GLAZE 100 JA 1/10W

R365 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R431 401 038 3514 MT-GLAZE 330 JA 1/10W

R432 401 037 5410 MT-GLAZE 1K JA 1/10W

R433 401 007 1134 CARBON 1K JA 1/2W

R434 401 067 9003 OXIDE-MT 390 JA 2W

R435 402 075 2307 WIRE WOUND 10 JA 5W

R436 401 012 7049 CARBON 10K JA 1/4W

R441 401 058 3706 OXIDE-MT 1K JA 1W

R447 401 026 9927 CARBON 4K7 JA 1/6W

R448 401 009 5843 CARBON 330 JA 1/2W

R451 401 064 5305 OXIDE-MT 1.5 JA 2W

R462 401 014 4145 CARBON 1K5 JA 1/4W

R463 401 025 4220 CARBON 1K8 JA 1/6W

R467 401 025 8723 CARBON 220K JA 1/6W

R468 401 025 4220 CARBON 1K8 JA 1/6W

R469 401 027 5928 CARBON 68K JA 1/6W

R470 401 027 0329 CARBON 47K JA 1/6W

R471 401 025 1625 CARBON 1K5 JA 1/6W

R472 401 027 0329 CARBON 47K JA 1/6W

R473 401 027 5225 CARBON 680 JA 1/6W

R474 401 009 0927 CARBON 270 JA 1/2W

R481 401 015 4738 CARBON 180K JA 1/4W

R482 401 027 2620 CARBON 5K6 JA 1/6W

R501 401 020 2053 CARBON 4.7K JA 1/4W

R502 402 002 2004 FUSIBLE RES 4.7 J- 1/2W

R504 401 027 3023 CARBON 56K JA 1/6W

R505 401 026 7022 CARBON 3K9 JA 1/6W

R506 401 026 9927 CARBON 4K7 JA 1/6W

R507 401 027 5027 CARBON 68 JA 1/6W

R508 401 025 7825 CARBON 2K2 JA 1/6W

R509 401 057 7507 OXIDE-MT 0.82 JA 1W

R511 401 061 6404 OXIDE-MT 390 JA 1W

R513 401 058 3706 OXIDE-MT 1K JA 1W

R521 402 037 1805 FUSIBLE RES 4.7 J- 1W

R602 402 072 4403 WIRE WOUND 3.9 KA 7W

R611 401 027 2620 CARBON 5K6 JA 1/6W

R615 401 025 8228 CARBON 22K JA 1/6W

R617 401 024 7024 CARBON 1K JA 1/6W

R619 401 016 1538 CARBON 22 JA 1/4W

R620 401 007 5815 CARBON 120K JA 1/2W

R621 401 007 5815 CARBON 120K JA 1/2W

R622 401 014 5241 CARBON 15K JA 1/4W

R623 401 025 4220 CARBON 1K8 JA 1/6W

R624 401 068 6902 OXIDE-MT 56 JA 2W

R625 401 065 9609 OXIDE-MT 18 JA 2W

R626 401 016 3344 CARBON 2.2K GA 1/4W

R631 402 000 8602 SOLID 5.6M KA 1/2W

R632 402 000 8602 SOLID 5.6M KA 1/2W

R641 401 014 6149 CARBON 150K JA 1/4W

R642 401 027 4327 CARBON 6.2K JA 1/6W

R643 401 015 4738 CARBON 180K JA 1/4W

R644 401 011 2718 CARBON 68K JA 1/2W

R645 401 025 8228 CARBON 22K JA 1/6W

R646 402 069 9800 WIRE WOUND 2.7 KA 5W

R647 402 076 0609 WIRE WOUND 8.2 KA 7W

R648 401 026 9927 CARBON 4K7 JA 1/6W

R651 401 064 3806 OXIDE-MT 1 JA 2W

R652 401 065 1801 OXIDE-MT 12 JA 2W

R653 401 067 8204 OXIDE-MT 39 JA 2W

R655 401 065 5809 OXIDE-MT 15 JA 2W

R661 401 068 4700 OXIDE-MT 4.7K JA 2W

R662 401 068 8807 OXIDE-MT 5.6K JA 2W

R681 401 008 1628 CARBON 1K8 JA 1/2W

R682 401 069 1708 OXIDE-MT 68 JA 2W

R684 401 023 2842 CARBON 8K2 JA 1/4W

R685 401 025 8228 CARBON 22K JA 1/6W

R800 401 016 3849 CARBON 2.2K JA 1/4W

R801 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R802 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R803 401 037 9418 MT-GLAZE 180K JA 1/10W

R804 401 024 7430 CARBON 10K JA 1/6W

R806 401 024 7430 CARBON 10K JA 1/6W

R807 401 024 7430 CARBON 10K JA 1/6W

R808 401 019 1941 CARBON 3K9 JA 1/4W

R811 401 016 3849 CARBON 2.2K JA 1/4W

!!!!!!!!!!!!!!!!!!!!!

!

Ref. No. Part No. Description Ref. No. Part No. Description

-17-

F7VVV

Page 18

R812 401 038 5112 MT-GLAZE 3.9K JA 1/10W

R813 401 018 4933 CARBON 33K JA 1/4W

R815 401 012 4543 CARBON 100 JA 1/4W

R816 401 038 9219 MT-GLAZE 6.8K JA 1/10W

R817 401 016 3849 CARBON 2.2K JA 1/4W

R817A 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R818 401 038 9318 MT-GLAZE 68K JA 1/10W

R819 401 016 3849 CARBON 2.2K JA 1/4W

R820 401 037 5618 MT-GLAZE 10K JA 1/10W

R821 401 038 0810 MT-GLAZE 22K JA 1/10W

R822 401 038 6515 MT-GLAZE 47K JA 1/10W

R823 401 013 5341 CARBON 1K2 JA 1/4W

R824 401 038 5112 MT-GLAZE 3.9K JA 1/10W

R825 401 038 3613 MT-GLAZE 3.3K JA 1/10W

R831 401 037 5618 MT-GLAZE 10K JA 1/10W

R838 401 037 8015 MT-GLAZE 15K JA 1/10W

R839 401 018 4933 CARBON 33K JA 1/4W

R840 401 020 0841 CARBON 470 JA 1/4W

R841 401 038 0810 MT-GLAZE 22K JA 1/10W

R842 401 020 2053 CARBON 4.7K JA 1/4W

R843 401 037 5618 MT-GLAZE 10K JA 1/10W

R844 401 037 9210 MT-GLAZE 1.8K JA 1/10W

R845 401 037 5618 MT-GLAZE 10K JA 1/10W

R846 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R847 401 037 5618 MT-GLAZE 10K JA 1/10W

R848 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R851 401 037 5410 MT-GLAZE 1K JA 1/10W

R852 401 037 5410 MT-GLAZE 1K JA 1/10W

R853 401 038 0810 MT-GLAZE 22K JA 1/10W

R861 401 038 2111 MT-GLAZE 2.7K JA 1/10W

R862 401 038 0810 MT-GLAZE 22K JA 1/10W

R863 401 038 0810 MT-GLAZE 22K JA 1/10W

R864 401 038 9011 MT-GLAZE 680 JA 1/10W

R865 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R866 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R867 401 038 0711 MT-GLAZE 2.2K JA 1/10W

R868 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R869 401 038 2210 MT-GLAZE 27K JA 1/10W

R870 401 016 4836 CARBON 22K JA 1/4W

R870A 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

R871 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R872 401 038 3712 MT-GLAZE 33K JA 1/10W

R873 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R874 401 037 5618 MT-GLAZE 10K JA 1/10W

R875 401 038 7710 MT-GLAZE 5.6K JA 1/10W

R876 401 037 5618 MT-GLAZE 10K JA 1/10W

R877 401 039 0413 MT-GLAZE 8.2K JA 1/10W

R878 401 037 7919 MT-GLAZE 1.5K JA 1/10W

R879 401 037 5618 MT-GLAZE 10K JA 1/10W

R880 401 038 6515 MT-GLAZE 47K JA 1/10W

R884 401 037 7810 MT-GLAZE 150 JA 1/10W

R885 401 038 5112 MT-GLAZE 3.9K JA 1/10W

R886 401 037 7810 MT-GLAZE 150 JA 1/10W

R887 401 038 5112 MT-GLAZE 3.9K JA 1/10W

R888 401 037 5212 MT-GLAZE 100 JA 1/10W

R889 401 037 5212 MT-GLAZE 100 JA 1/10W

R891 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R892 401 038 6416 MT-GLAZE 4.7K JA 1/10W

R893 401 037 5410 MT-GLAZE 1K JA 1/10W

R894 401 037 5410 MT-GLAZE 1K JA 1/10W

R895 401 037 6714 MT-GLAZE 1.2K JA 1/10W

R897 401 012 5748 CARBON 1K JA 1/4W

R898 401 012 5748 CARBON 1K JA 1/4W

VARIABLE RESISTOR

VR131 645 003 5531 VR 10K ALPS

VR361 645 003 5531 VR 10K ALPS

VR462 645 003 5616 VR 4.7K ALPS

VR501 645 006 5231 VR 100 ALPS

VR641 645 003 5579 VR 2.2K ALPS

TRANSFORMER

TP-A 645 008 4058 TERMINAL PLUG

TP-B 645 008 4058 TERMINAL PLUG

TP-D 645 008 4058 TERMINAL PLUG

TP-E 645 008 4058 TERMINAL PLUG

T101 610 037 4508 S COIL

T141 610 037 4522 S COIL

T431 610 223 1656 DRIVE TRANS

T451 645 027 9317 F.B.T. SAMSUNG FSM-28A001

T611 645 015 7653 TRANS,POWER,PULSE

T681 610 033 3758 POWER TRANS

COIL

L001 645 008 5635 INDUCTOR,12U K

L002 645 008 5635 INDUCTOR,12U K

L003 645 002 4511 CORE,PIPE

L1002 645 002 4511 CORE,PIPE

L1003 645 001 4550 PEAKING COIL 10UHK

L1004 645 001 4550 PEAKING COIL 10UHK

L1005 645 001 4550 PEAKING COIL 10UHK

L1006 645 001 4550 PEAKING COIL 10UHK

L101 645 001 4710 PEAKING COIL 10UH J

L102 645 001 5656 PEAKING COIL 4.7UH K

L1022 645 002 4511 CORE,PIPE

L1023 645 001 4550 PEAKING COIL 10UHK

L1024 645 001 4550 PEAKING COIL 10UHK

L1025 645 001 4550 PEAKING COIL 10UHK

L1026 645 001 4550 PEAKING COIL 10UHK

L1027 645 001 5656 PEAKING COIL 4.7UH K

L1101 645 001 4550 PEAKING COIL 10UHK

L1102 645 001 4550 PEAKING COIL 10UHK

L1103 645 001 5656 PEAKING COIL 4.7UH K

L141 645 001 4550 PEAKING COIL 10UHK

L151 645 002 1534 PEAKING COIL 8.2UHK

L152 645 002 1459 PEAKING COIL

L201 645 001 4710 PEAKING COIL 10UH J

L202 645 001 4710 PEAKING COIL 10UH J

L203 645 001 4710 PEAKING COIL 10UH J

L231 645 001 5656 PEAKING COIL 4.7UH K

L232 645 003 8518 PEAKING COIL

L431 645 008 5628 INDUCTOR,1U M

L432 645 002 4511 CORE,PIPE

L441 610 000 0964 LINEARITY COIL

L442 610 221 3348 COIL

L461 645 005 5645 INDUCTOR 222UH K

L462 610 000 0261 COIL 349UH

L501 645 008 5642 INDUCTOR,3.3U K

L601 645 017 1260 ELF 18D431F LINE FILTER

L607 610 237 1000 PIPE CORE

L608 610 237 1000 PIPE CORE

L641 645 002 4511 CORE,PIPE

L642 645 002 4511 CORE,PIPE

L643 645 002 4511 CORE,PIPE

L871 645 008 2962 PEAKING COIL 5.6UH K

L881 645 012 8707 PEAKING COIL 1.5UH M

DIODE

D1005 407 063 8319 ZENER DIODE MTZJ11C

D1007 407 063 8319 ZENER DIODE MTZJ11C

D1008 407 063 8319 ZENER DIODE MTZJ11C

D1010 407 063 8319 ZENER DIODE MTZJ11C

D1011 407 063 8319 ZENER DIODE MTZJ11C

D1021 407 063 8319 ZENER DIODE MTZJ11C

D1022 407 063 8319 ZENER DIODE MTZJ11C

D1023 407 063 8319 ZENER DIODE MTZJ11C

D1024 407 063 8319 ZENER DIODE MTZJ11C

D1026 407 063 8319 ZENER DIODE MTZJ11C

D1027 407 063 8319 ZENER DIODE MTZJ11C

D1101 407 063 8319 ZENER DIODE MTZJ11C

D1201 407 053 6803 ZENER DIODE MTZ5.6C

!!!

Ref. No. Part No. Description Ref. No. Part No. Description

-18-

F7VVV

Page 19

D135 407 063 8319 ZENER DIODE MTZJ11C

D1901-1 610 269 4710 HOLDER LED A-G2CA

D1901A 407 116 6504 LED SLP-181B-51

D1903 407 063 8319 ZENER DIODE MTZJ11C

D1905 407 012 4416 DIODE 1SS133-T-77

D201 407 063 8319 ZENER DIODE MTZJ11C

D202 407 063 8319 ZENER DIODE MTZJ11C

D203 407 063 8319 ZENER DIODE MTZJ11C

D210 407 012 4416 DIODE 1SS133-T-77

D221 407 012 4416 DIODE 1SS133-T-77

D222 408 007 8607 DIODE 1N4148

D271 407 053 6209 ZENER DIODE MTZ5.1A-T-77

D352 407 053 8401 ZENER DIODE MTZ8.2B-T-77

D361 407 063 8319 ZENER DIODE MTZJ11C

D431 407 162 2703 ZENER DIODE UZ-9.1BCB

D432 407 005 7328 DIODE EM01Z

D438 407 095 8001 DIODE ERD07-15L

D439 407 006 4128 DIODE ERB44-04V1

D442 408 007 8607 DIODE 1N4148

D445 407 012 4416 DIODE 1SS133-T-77

D446 407 151 9003 ZENER DIODE UZ-7.5BCC

D464 407 053 6803 ZENER DIODE MTZ5.6C

D465 407 012 4416 DIODE 1SS133-T-77

D466 407 077 9705 ZENER DIODE MTZ20A

D469 407 007 7415 DIODE EU1

D481 407 007 7415 DIODE EU1

D482 407 012 4416 DIODE 1SS133-T-77

D501 407 005 7328 DIODE EM01Z

D502 407 118 2217 ZENER DIODE 1Z75

D603 407 009 6921 DIODE RM11C

D604 407 009 6921 DIODE RM11C

D605 407 009 6921 DIODE RM11C

D606 407 009 6921 DIODE RM11C

D614 408 007 8607 DIODE 1N4148

D615 408 009 8407 PHOTO COUPLE CNY17GF-3

D616 408 007 8607 DIODE 1N4148

D617 407 007 6616 DIODE ES1

D618 408 007 8607 DIODE 1N4148

D619 407 053 3000 ZENER DIODE MTZ11C

D641 407 009 8816 DIODE RU3AM

D642 407 007 7613 DIODE EU2

D643 407 166 2303 DIODE ERC-91-02L

D644 407 166 2303 DIODE ERC-91-02L

D645 407 053 7206 ZENER DIODE MTZ6.2C

D647 407 012 4416 DIODE 1SS133-T-77

D648 407 099 8601 ZENER DIODE MTZJT77-24A

D651 407 005 7328 DIODE EM01Z

D654 407 012 4416 DIODE 1SS133-T-77

D661 409 026 8005 IC L5630

D681 407 005 7328 DIODE EM01Z

D682 407 053 6803 ZENER DIODE MTZ5.6C

D683 407 005 7328 DIODE EM01Z

D684 408 007 8607 DIODE 1N4148

D685 407 012 4416 DIODE 1SS133-T-77

D831 408 007 8607 DIODE 1N4148

D861 407 012 4416 DIODE 1SS133-T-77

D871 407 012 4416 DIODE 1SS133-T-77

D872 407 055 7927 ZENER DIODE RD3.6EL

MISCELLANEOUS

A101 645 023 4118 TUNER,U/V

A1901 645 020 9277 UNIT,REMOCON RECEIVER

F601 423 022 2102 FUSE 250V 4.0A

F601A 645 000 5077 HOLDER,FUSE

F601B 645 000 5077 HOLDER,FUSE

J025 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J130 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J151 401 037 5816 MT-GLAZE 1M JA 1/10W

J194 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J225 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J226 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J231 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J232 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J233 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J234 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J235 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J236 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J237 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J238 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J239 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J240 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J241 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J242 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J245 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J247 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

J248 401 037 5014 MT-GLAZE 0.000 ZA 1/10W

KDY-1 645 008 4058 TERMINAL PLUG

KDY-3 645 008 4058 TERMINAL PLUG

KDY-5 645 008 4058 TERMINAL PLUG

KDY-6 645 008 4058 TERMINAL PLUG

KE-1 645 008 4058 TERMINAL PLUG

KE-2 645 008 4058 TERMINAL PLUG

KF-1 645 008 4058 TERMINAL PLUG

KF-2 645 008 4058 TERMINAL PLUG

KL 645 004 2881 PLUG,2P

KP 645 008 7288 HOUSING PLUG 5P

KQ 645 008 7264 HOUSING PLUG 3P

KR-1 645 008 4058 TERMINAL PLUG

KR-2 645 008 4058 TERMINAL PLUG

K001 645 005 5706 PHONE JACK HTJ-035-10AB

K10B 645 008 7288 HOUSING PLUG 5P

K1001 645 005 5867 21-PIN SOCKET

K1001Z 610 261 2813 MOUNTING BRKT-F2WV

K1002 645 005 5867 21-PIN SOCKET

K1002Z 610 261 2813 MOUNTING BRKT-F2WV

K1101 645 016 6433 JACK,RCA-3

PB101 610 275 0539 PWB,MAIN F3SS

PS601 408 013 3801 TH PTH451C262BF140M270

SW1901 610 011 4432 SWITCH,PUSH

SW1902 610 011 4432 SWITCH,PUSH

SW1903 610 011 4432 SWITCH,PUSH

SW1904 610 011 4432 SWITCH,PUSH

SW501 610 011 2728 SWITCH,LEVER 1P-3T

SW601 645 024 0607 PUSH SW POWER SDDFC3

X131 421 002 2609 SAW F TSF5315

X151 610 015 3547 EFC-S5R5MW3AS (5.5B)

X152 645 000 4490 TRAP, CERAMIC (6.5W3)

X201 645 025 2631 OSC,CRYSTAL 4.43MHZ

X871 645 018 9593 OSC,CRYSTAL 12MHZ

Y01 645 008 4058 TERMINAL PLUG

Y02 645 008 4058 TERMINAL PLUG

Y04 645 008 4058 TERMINAL PLUG

Y05 645 008 4058 TERMINAL PLUG

Y06 645 008 4058 TERMINAL PLUG

Y07 645 008 4058 TERMINAL PLUG

Y08 645 008 4058 TERMINAL PLUG

Y09 645 008 4058 TERMINAL PLUG

Y10 645 008 4058 TERMINAL PLUG

Y11 645 008 4058 TERMINAL PLUG

Z101 610 259 7813 SHIELD CASE-A-F2RC

Z102 610 259 7820 SHIELD CASE-B-F2RC

!!!!!!!

Ref. No. Part No. Description Ref. No. Part No. Description

-19-

F7VVV

All information in this manual is correct at the start of

production. Sanyo reserves the right to modify

components and procedures in order to comply with

their continuous improvement policy.

Page 20

Sanyo Industries (UK) Ltd

Printed in UK

Page 21

Part No. SKP20221 F7VVV (SHEET 1/2)

COLOUR TELEVISION

EE

EE

BB

BB4444

MMMMKKKKIIIIII

II

SERVICE REF.NO.

MODEL NUMBER

CHASSIS SERIES

CE25DN4-C-01

CE25DN4-C

The service Precaution:

The area enclosed by this line

( ) is directly connected with

AC mains voltage. When servicing the

area, connect an isolating transformer

between TV receiver and AC line to

eliminate hazard of electric shock.

NOTIZIE SULLA SICUREZZA DI FUNZIONAMENTO

Ogni sotituzione di componenti va fatta

tenendo conto della sicurezza di funzionamento. I componenti indicati sollo

schema con il simbolo /!\ hanno particolare importanza per il sicuro funzionamento del TV.

I suddetti componenti devono essere

sostituti esclusivamente con quelli indicati nell'elenco.

PRECAUZIONE DI SERVIZIO

L'area inclusa in questa linea ( )

è collegata direttamente con la tensione

della rete CA quando si serve l'area collegare un trasformatore isolante tra il

ricevitore TV e la linea CA per eliminare

il pericolo di scossa elettrica.

Product safety notice:

Product safety should be considered

when a component replacement is

made in any area of a receiver.

Components indicated by a mark /!\ in

this circuit diagram show components

whose values have special significance to product safety. It is particularly recommended that only parts

specified on the part service manual

be used for components replacement

pointed out by the mark.

Note sul diagramma di circuito :

1. Tutte i valori di resistenza sono in ohm,

K=1,000, M=1,000,000.

2. Tutte le resistenze nominali watt sono di

1/6 a meno che sia specificato altrimenti.

3. Eccetto per i condensatori elettrolitici, tutti

i valori di capacitanza di meno di sono

espressi in µF, e di piu di 1 sono in pF. I

varoli di capacitanza elettrolitici sono in

µF.

4. Tutti volt di capacitanza nominali sono di

50V a meno cha sia indicato altrimenti.

5. Tutti valori di inductanza sono in µH.

6. I valori letti del voltaggio presi con un

"VTVM" proven gono dal punto indicato

sulla massa del chassis, i valori di voltaggio presi usando un segnale di barre colore sono con tutti i controlli alle loro

posizioni normali ed il commutatore AFC in

posizione "OFF". Il voltaggio puo variare

con l'intensita del segnale.

7. Le forme di onda furono prese con il segnale di barre colore e i controlli regolati

oppure le forme di onda di immagine normale furono prese usando un oscillatore a

larga banda ed una sonda bassa capasità.

8. Rispetto a quando indicato su questo

schema possono essere state introdotte

delle modifiche.

9.■ I diodo 1S1555 possono essere sostitutti

con 1S2473, 1S2076 oppure DS472 a

meno che sia specificato altrimenti.

■ I transistori possono essere sostitutti con

2SC536(Q,R,S), 2SC1740(Q,R,S),

2SC945A(Q,R,P) oppure

2SC1815(G,O,Y) a meno che sia specificato altrimenti.

■ Il transistore 2SA608(E,F) puo essere

sostituito con 2SA933(Q,R),

2SA564(QA,RA), oppure 2SA1015(O,Y)

a meno che sia specificato altrimenti.

Circuit diagram notes :

1. All resistance values are in ohms,

K=1,000, M=1,000,000.

2. All resistance rated wattages are 1/6W

unless otherwise noted.

3. Excepting electrolytic capacitors, all

capacitance values of less than 1 are

expressed in µF and more than 1 are pF.

4. All capacitance rated voltages are 50V

unless otherwise noted.

5. All inductance values are in µH.

6. Voltage readings taken a digital voltmeter

are from point indicated chassis ground.

Voltage readings taken by using a colour

bar signal are with all controls at normal

position. Some voltages may vary with

signal strength.

7. Waveforms were taken with colour bar

and controls adjusted for normal picture.

Waveforms were taken by using a wide

band oscilloscope and a low capacity

probe.

J1EK1745-

K1001

L IN

V IN

C1109

CD10CA

R1111

1/10GJ

10K

(E-NP:F-NP

:QT0378(A:B)

Q1202

2SC536

:G-NP)

R1101

75

C1101

16EM

10

B6

12V

R1209

10K

0V

AV2

TV/AV

SHARP

NESS

CONT

BRIGHT

COLOUR

R803

1/10GJ

180K

PH2369

R818

1/10GJ

68K

R822

1/10GJ

47K

TP-D

J30B0250N

3.3V

C121

R121

25KZ0.1FA

47K

:KZ0.1FA

Q121

2SC536

(E-NP:F-NP

:G-NP)

:QT0378(A:B)

R1906

1/10GZ

0.0

R1905

1/10GJ

2.2K

R1904

1/10GJ

2.7K

SW1901/.../SW1904

VOL -

SW1904

SW1903

SW1902

SW1901

R1903

VOL +

1/10GJ

4.7K

R1902

POS -

1/10GJ

8.2K

R1901

POS +

1/10GJ

15K

R1924

6.8K

B6

12V

D1903

MTZJ11C

:UZ-11

BSC

Q801

C812

EM1

C814

EM1

C816

25EM

4.7

C818

25EM

4.7

8.0V

1/10GJ

1.5K

S10B1170NS10B1170NS10B1170NS10B1170N

R1922

1/10

GJ390

1AA2HLM0066--

1/10GJ22K

R825

1/10GJ

3.3K

2.8V

D1901A

LN28RPL

D1901-1

R802

2.0V

1/10GJ

2.2K

0.6V

0V

R812

1/10GJ

3.9K

R813

R816

1/10GJ

33K

6.8K

R817

R820

1/10GJ

2.2K

10K

R821

R824

1/10GJ

3.9K

R831

1/10GJ

B7

10K

8V

R838

1/10GJ

15K

R1908R1909

1/10GJ

330

R1907

1/10GJ

10K

TV/AV

S-VHS