SCC2600A

SCC 2600A

1

SANY CRAWLER C RANE

SCC2600A

1

SCC2600A

CONTENTS

SCC2600A Crawler Crane

Outline Dimensions

Main Technical Features

Main Performance Data

Transport Dimensions

Transporting scheme

Assembly and disassembly diagram

Specifi cations

Superstructure

Undercarriage

Operation Devices

Safety Devices

Operating Condition Combination

Operating Condition Combination

H Operating Condition

Fixed Jib Combination

Luffi ng Jib Combination

Shield Operating Condition Load Charts

P2

P16

P23

02 Outline Dimensions

03 Main Technical Features

04 Main Performance Data

05 Transport Dimensions

10 Transporting scheme

12 Assembly and disassembly diagram

CRAWLER CRANE

SANY CRAWLER C RANE

SCC2600A

3

2

Main technical featuresOUTLINE dimensions

1. Safety Control System:

There are two convenient a nd reliable operation modes, wor king

and assembly. The electronic level indicator and bubble level

indicator are equippe d to ensure dual protection for real- time

display. It has the leaving-machine stop action, emergency

electrical c ontrol, lightning protection, walkin g automatically

steering and closed circuit monitoring functions, with the

complete safety and mo nitoring system;

2. New Lift Operating Condition De sign:

The operating condition of 20m boom + 12m heavy fixed jib is

adopted, to meet the lift ing requirement of shield machine used

for subway construction and similar products. The turning-over

operation of shield mac hine can be automatically done, without

the auxiliary cra ne. The auxiliary hook is larger enou gh to lift the

heavy object up to 96T. The load moment limiter indicator can

dynamically reflect the loading capacities of main and auxiliary

hooks;

3. Beautiful and Comfortable Cab:

The cab is beautiful, c omfortable and safe;

4. Superior Operating Performance:

The load sensor, limit load regul ation and electronic- over-

hydraulic control can ens ure the best all actions excellent action

and stability.;

5. Reliable Function Assurance:

The designed safety margin for structures and mechanisms are

sufficient; and th e control system can operate stably in the cold,

high temperature, plateau, and l arge sand harsh environment;

6. Convenient Maintenance Technology:

It takes approx imately no more than 10m in/person to adjust;no

more than 30min/person for daily maintenance;no more than 2h/

person to repair.GPS remote monitor ing system is optional for

maintenance and management.;

7. Powerful Lifting Capacity:

The maximum boom lif ting moment is 183.8t × 8m = 1470.4t

• m and the longest boom length is 86m; th e maximum lifting

capacity of luffing jib is 62.5t × 18m = 1125t • m and the longest

boom combination length is 62 m+6 3m;

8. High Efficient Self-Handling Technology:

A button can be coc ked to easily lift the mast, to ensure the

clutch traction wi nch reeving operation. It can suppor t the

machine self-dis mounting operation; and the quick-cha nge rope

connectors and win ch rope head are can be used;

9. Large Chassis Design:

The chassis wi th the track gauge of 6.7m is ado pted, to ensure

the excellent operation sta bility within the range of 360°

rotation;

10. Globalization of Transportation Standards:

The transport wei ght of main machine is limited within 45 tons,

the transport wi dth is less than 3m and the transpor t height is

less than 3.2m, thus saving the transport cost significantly;

11. Powerful Traveling Capacity with Load:

The powerful travelin g traction and walking stabilit y can make

the best advantage of craw ler crane;

12. Reliable Transmission System:

The use of advanced hydraulic co mponents and of load

feedback control technology with independent property rights

can ensure the stable an d reliable operation of hydraulic system;

13. Large Fuel Tank Design:

The fuel tank capaci ty is 1050L, which is greatly incr eased

compared with the o ld models (400L), thus avoid the frequent

refueling;

14. Broad Adaptability:

In accordance with Europe and America non-road phase III

emission standards a nd has a wide application in boat building,

subway constructio n, metallurgy and infrastructure.

9145

8003

1200

1200

7980

7504

3164

10000

4622

1800

2350

1400

1550

369

3033

SANY CRAWLER C RANE

SCC2600A

5

4

Main Performance Data Tr a ns p o rt Dimensi o ns

L

H

L

H

L

L

L

L

L

H

H

H

H

H

Basic Machine ×1

Length 13.32 m

Width 3.0m

Height 3.20m

Weight 45t

Track Assembly ×2

Length 9.15 m

Width 1.20 m

Height 1.4 0m

Weight 22t

Boom Head (inclu ding pulley block) ×1

Length 3.24m

Width 2.0 7m

Height 1.6 2m

Weight 3.5t

Boom Base (inclu ding winch) ×1

Length 10.35m

Width 2.60m

Height 2.99m

Weight 13.58t

3m Boom Inser t ×1

Length 3.18 m

Width 2.65m

Height 2.66m

Weight 1. 3t

6m Boom Inser t ×1

Length 6 .18m

Width 2.65m

Height 2.66m

Weight 2.0t

12m Boom Insert ×5

Length 1 2.18m

Width 2.65m

Height 2.66m

Weight 3.6t

Main Performanc e Parameters of SCC2600A Crawler Cran e

Performance index Unit Parameters

Boom operating

condition

Maximum lifting capacity

t 260

Maximum rated lif ting moment

t•m

1470.4

Boom length m 20~86

Boom luffing angl e ° 30~85

Fix jib operating jib

Longest boom + longest fi xed jib m 62+42

Fixed jib offset angle ° 10, 30

Heavy fixed jib

operating condition

Boom + fixed jib (shield operating

condition)

m 20+12

Angle between boo m and jib ° 20

Luffing jib operat ing

condition

Maximum liftin g moment t•m 62.5×18 =1125

Longest boom + longest l ufffing jib m 62+63

Jib luffing angle ° 65~88

Speed

Boom ( jib) winch line speed (outmost

working layer)

m/min 0~124

Main luf fing winch lin e speed (outmost

working layer)

m/min 0~108

Auxiliary luf fing winch line speed

(outmost working layer)

m/min 0~14 4

Swing speed rpm 0~1. 25

Traveling speed km/h 0~1.2/0~0.53 (double speed)

Gradeability % 30

Engine

Output power kW 242

Rated speed rpm 2100

Transportation data

Max. transpor t weight of single part

(including boom and jib li fting winches)

t 45

Transport dimension (L * W * H) mm 13320×3000×3200

Average ground pressure MPa 0.14

SANY CRAWLER C RANE

SCC2600A

7

6

Tr a ns p o rt Dimensi o nsTr a ns p o rt Dimensi o ns

6m Transitional Boo m Insert ×1

Length 6.20m

Width 2.65m

Height 2.66m

Weight 2.0t

Luffing Jib Tip ×1

Length 6.46m

Width 2.12m

Height 2.1 0m

Weight 2.4t

3m Luffing Jib In sert ×1

Length 3 .17m

Width 2 .12m

Height 1. 91m

Weight 0.63t

6m Luffing Jib I nsert ×1

Length 6.17 m

Width 2.12m

Height 1. 91m

Weight 1.04t

6m Luffing Jib I nsert ×1

Length 6.17 m

Width 2.12 m

Height 1. 91m

Weight 1.05t

12m Luffing Jib Inse rt ×3

Length 12.1 7m

Width 2.12 m

Height 1. 91m

Weight 1.95t

Boom Extens ion ×1

Length 2.2m

Width 0.9 5m

Height 1. 44m

Weight 0.42t

Jib Base, Luffing Front and Rear Masts ×1

Length 11. 49m

Width 2 .11m

Height 3.26m

Weight 5.5 t

6m Fixed Jib Inser t ×1

Length 6.11 m

Width 1.50 m

Height 1. 42m

Weight 0.75t

11.5m Fixed Jib Insert ×2

Length 11.67m

Width 1.5 0m

Height 1.42m

Weight 1.3 t

Fixed Jib Base and Ma st ×1

Length 6.70 m

Width 1. 42m

Height 2.00m

Weight 1.75t

Fixed Jib Tip ×1

Length 7.1 0m

Width 1. 42m

Height 1. 43m

Weight 1.75t

Carbody Counterweight ×2

Length 5.48m

Width 1.72 m

Height 0.60m

Weight 15t

Counterwe ight Tray ×2

Length 7. 50 m

Width 1.9 6m

Height 0 .70m

Weight 16t

L

L

L

L

L

L

L

W

H

H

H

H

H

H

L

H

W

H

H

H

H

W

L

L

L

L

L

L

SANY CRAWLER C RANE

SCC2600A

9

8

Tr a ns p o rt Dimensi o nsTr a ns p o rt Dimensi o ns

16t Hook ×1

Length 0.53m

Width 0 .57m

Height 1.10 m

Weight 0.9 t

6t Counter weight Block ×14

Length 2.17 m

Width 1.9 6m

Height 0. 51m

Weight 6t

Dolly ×1

Length 2.56 m

Width 1.74m

Height 1.00 m

Weight 1t

260t Hook ×1

Length 1.04m

Width 1.02 m

Height 2.93m

Weight 5.2t

160t Hook ×1

Length 0.59m

Width 1.02 m

Height 2.64m

Weight 3.2t

100t Hook ×1

Length 0 .51m

Width 1.02 m

Height 2.48m

Weight 2.3t

50t Hook ×1

Length 0.45m

Width 1. 02m

Height 2.30m

Weight 1.7t

H

H

H

H

H

W

L

L

L

L

L

L

W

W

W

W

H

L

W

Notes: 1. The transp ort dimensions of t he parts are marked o n schematic

diagrams, but not d rawn by scale; the dime nsions indicated ar e

the design value s excluding packag e.

2. The weight is the d esign value and th ere may be differe nce due

to the manufactu ring error.

SANY CRAWLER C RANE

SCC2600A

11

10

Transporting schemeTransporting scheme Transporting scheme

Platform lorry 498-16165 Rated load:49. 8t

Transport part Basic crane

Transport weight 45t

Quantity 1

Platform lorry 395-16165 Rated load:3 9.5t

Transport part Left track fra me assembly

Transport weight 22t

Quantity 1

Platform lorry 395-16165 Rated load:39.5t

Transport part Right track fra me assembly

Transport weight 22t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part

Counterweight tray × 1, 6m luffing jib inter mediate

section Ⅰ and 6m luffing jib intermedi ate section

Transport weight 17.7t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part

Central ballast frame × 1, 6m boom intermediate secti on

× 1 and 3m luffing jib intermed iate section × 1

Transport weight 18t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part

Transport part : Counterweig ht block × 2 and 12m boom

intermediate section × 1

Transport weight 15.7t

Quantity 5

Platform lorry 20-146 30 Rated load: 20t

Transport part

Counterweight block × 2, 12m luffing jib int ermediate

section × 1 and 50T hook × 1

Transport weight 15.2t

Quantity 1

4117

2460

2460

4346

4844

4619

3916

859

9146

9146

6000

6000

13115

13115

3227

3227

18018

18018

14630

14630

14630

14630

2840

6480

8500

13320

13115

3450

18341

1000

1060

1060

1500

1500

1500

1500

1000

500

1000

1000

1000

1000

1840

3800

3860

1023

Platform lorry 20-146 30 Rated load:20t

Transport part Basic crane

Transport weight 13.5t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part

Central ballast frame × 1, 12m luffing jib intermediate

section × 1 and 16T ball hook × 1

Transport weight 18t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part Fixed jib 11.5m and intermediate se ction × 1

Transport weight 1.3t

Quantity 2

Platform lorry 20-146 30 Rated load:20t

Transport part Fixed jib base and mast × 1, fixed jib top × 1

Transport weight 2.6t

Quantity 1

Platform lorry 20-146 30 Rated load:20t

Transport part

160T hook × 1 and boom tape red insert ×1, Boom head

(with pulley bloc k) × 1 and luffing jib top × 1

Transport weight 13t

Quantity 1

Platform lorry 20-16140 Rated load:20t

Transport part

Luffing jib base and front and rear mast assembly × 1, 100T hook

× 1, 260t hook × 1 and fixed jib 6m int erme diat e sect ion × 1

Transport weight 13.5t

Quantity 1

Platform lorry 20-1614 0 Rated load: 20t

Transport part

Boom base × 1, boom 3m int ermediate sect ion × 1,

boom extensio n × 1 and dolly × 1

Transport weight 16.7t

Quantity 1

3916

3916

3454

3768

4062

4214

3932

1500

1500

1500

1500

990

990

990

1000

1000

1000

500

500

500

2950

7440

600

16140

16140

16140

3390 1000

1840

6590

9500

14630

14630

14630

14630

7717

SANY CRAWLER C RANE

SCC2600A

13

12

Assembly and disassembly diagram Assembly and disassembly diagram

1) Basic crane self-assembly

2) Track frame self-assembly

3) Counterweight self-assembly

4) Boom/jib base self-assembly

1) Basic boom installation

Main/Auxiliary winch wire rope

2) Jib frame installation under luffing jib operat ing condition

Boom frame installation diagram

SANY CRAWLER C RANE

SCC2600A

15

14

15

SCC2600A

Superstructure 16

Undercarriage 18

Operation Devices 19

Safety Devices 20

3) Jib frame installation under fi xed jib operating condition

Assembly and disassembly diagram

SANY CRAWLER C RANE

SCC2600A

17

16

NO.1 Main lifting device

Outermost working layer rope speed 0~ 110 m/ min

Diameter of wire rop e 28 mm

Length of wire rope of b oom winch 480m

Rated single line pul l 17t

NO.2 Auxiliar y lifting device

Outermost working layer rope speed 0~ 110 m/ min

Diameter of wire rop e 28 mm

Length of wire rope of b oom winch 390m

Rated single line pul l 17t

1)Engine

■

Diesel engine with r ated power of 242kw (324hp)/2100rpm

and rated torque output 1424N·m/1500rpm.

■

Emission standard: Tier I II .

2)Electrical Control System

■

Advanced central co ntrol unit, load moment indicator,

display, sensor and closed-circuit monitoring system are

adopted.

■

Reliability: Advanced main electrical devices are

adopted to ensure the stabl e operation in the cold,

high temperature, plateau an d large sand storm harsh

environment.

■

Security: Elect rical design fully compli es with the CE

standard; the multi- level safety limit control is adopted

and all safety signal indi cators are complete.

■

Comfortable ness: The electrical paramete rs of all points

can be seen through the c ombination instruments in the

cab, to monitor all operati ng parameter and working state

in real time.

■

Advancement: The vehicl e electrical system adopts

the CAN bus system; the load power lim it load

control is adopted, wit h the calibration of redundant

communications and with the optional GPS.

3)Hydraulic System

■

The hydraulic system includes: Mai n valve hydraulic

system, main lifting hydraulic st ructure, boom luffing

hydraulic structure, jib luffing hydraulic structure, and

auxiliary hydraulic structure. .

■

Features: The main system is of open cir cuit, widely

adopting the electronic proportional control components.

The system adopts the load sen sitive LUDV system,

which can achieve the f low distribution irrelevant wit h

load. The hydraulic propor tional pilot control is adopted,

which is character ized by the sensitive operation and

good micro- mobility.

■

The system pressure is 32M Pa.

4)Main and Auxiliary Hoisting Devices

■

The bo om and jib winch mech anisms can be driven

separately, which is characte rized by the compact

structure, easy installa tion, and low wear. The

maintenance-fr ee built-in wet brake can ensure the

safety of winch.

■

The displacement of vari able hydraulic motor of lifting

mechanism can be automatically adjusted according

to the load, to achieve the maxi mum winch speed.

■

The high-quali ty anti-rotation wire rop e is adopted, to

ensure the high lifti ng safety and long life.

■

The pouch socket with swag ed sleeve is adopted to

ensure the convenient and quic k dismounting of wire

rope.

SUPERSTRUCTURE

NO.3 Boom luffing device

Outermost working layer rope speed 0~121m/m in

Diameter of wire rop e 28mm

Length of boom luffing wire ro pe 310m

Rated single line pull 17t

5)Boom Luffing Device

The boom luffing drum is equipped w ith the ratchet pawl

locking device, to ensur e the parking safety of boom

under non-working state.

NO.4 Jib luffing device

Outermost working layer rope speed 0~72m/min

Diameter of wire rop e 20mm

Length of jib luffing wire rope 410m

Rated single line pull 8t

6)Jib luffing Device

The ji b luffing drum is equipped wit h the r atchet pawl

locking device, to ensur e the parkin g safety of jib under

non-working st ate.

7)Swing Mechanism

■

It adopts the three- row roller slewing ring and is driven

by the large-displacement single motor reducer, with

the slewing speed of 0 -1.1r/min; it has the median

free s lipping function, with 36 0° rotation provided.

When the handle is at middl e position and there is no

slewing speed, the brake is at t he closed position and

the slewing is at the lock ing state through the locking

device. If the traveling or tr ansportation is done with

load, the upper rotar y impact should be prevented.

8)Counterweight

■

Carbody counter weight: 2; total weight: 30t (15t × 2)

■

Rear c ounterweight: 6t counterweight block, with a

total of 14; a counter weight tray of 16t, with a total of

100t.

9)Cab

■

The full-enc losed and wide-vision ca b having a

smooth shape and the Sany uni que style is adopted,

with the tempered glas s equipped at front and sides.

The GE structural s heet material is adopted at the

top, which is character ized by a good transparency,

high strength and high wear r esistance; the indoor

noise is low (less than 8 5dB). Air-conditioning, control

devices, instrumentation, fire alarms and closed circuit

monitoring system are installed indoors, in accordance

with the ergonomic design.

■

The cab can pitching 25 d egrees upwards, expanding

the vision of driver’s operation, improving the

operational safety, with the transport width reduced

due to its rotatable characteristics.

10)Control Operation

■

The track traveling oper ation can be controlled

through the handle or the t raveling pedal, having the

control automatic ally forward direction fun ction. With

the function of automat ic change of the direction of

steering, no matter th e superstructure rotates to no

matter the superstr ucture rotates to any direction,

the forward direc tion refers to the operator’s for ward

direction.

■

The boo m winch, jib winch, luf fing and rotar y actions

can be controlled by swi tching the handle function;.

■

There are all operatio n buttons and control switches

as well as the air conditio ning control panel on the left

and right armrest box, to ac hieve the different control

function.

11)Alar m Display

All alarm information, including the wind speed, water

temperature, oil temperature, oil level, oil pressure,

working hours time an d engine rotation errors, can be

shown on the display in the c ab, while giving the audible

and visual alarm.

SANY CRAWLER C RANE

SCC2600A

19

18

1)Traveling Drive

Each track part has a n independent travel drive device,

The traveling motor drives th e machine to achieve

independent traveling and turning through drive wheel

and planetary gear r educer if travelling motor.

2)Traveling Brake

The travelling brake is a norma lly closed, built-in brake

with automatic compensation function. When the control

pedal valve is pressed dow n, the brake will be released to

achieve travelling operation.

3)Track Shoe

The track shoe is made of hi gh-strength and high wear-

resistance materia l, with its tension regulated by the

hydraulic jacks afte r installation. The ideal tensi on can be

achieved through adjustin g the position of gaskets.

UNDERCARRIAGE

1)Boom

■

The main chord pipe is mad e of high-strength material.

And the boom frame is of l attice the space truss

structure with the c onstant cross section at mi ddle of

boom and with the varia ble cross-section at two ends.

■

Factory standard sec tions include: Boom base 10m,

transition insert 6 m, boom head 1m, intermediate

section 3m×1, intermediate section 6m×1 a nd

intermediate section 12m×5.

■

The boom length can be va riable between the basic

boom (20m) and longest length (86m), which is

increased by 3m.

■

The 2.0m boom extensi on can be installed not only on

the boom head but also on th e luffing jib head.

2)Fixed Jib

■

The main chord pipe is mad e of high-strength material.

And the boom frame is of l attice the space truss

structure with the c onstant cross section at mi ddle of

boom and with the varia ble cross-section at two ends.

■

Jib top 6 .5m, jib base 6.5 m, intermediate section 6m × 1

and 11.5 m × 2; the usable fixed jib length includes 13m,

19m, 24.5m, 30.5 m, 36m and 42m and the fixed jib can be

mounted on the boom of the length of 29~62m.

3)Luffing Jib

■

The main chord pipe is mad e of high-strength material.

And the boom frame is of l attice the space truss

structure with the c onstant cross section at mi ddle of

boom and with the varia ble cross-section at two ends.

■

Jib top 6m, jib base 6m, intermediate section 3m × 1, 6m×2

and 12m × 3; the us able fixed jib length includes 21m,

24m, 27m, 30m, 33m, 36m, 39m, 42m, 45m, 48m,

51m, 54m, 57m, 60m and 63m the luffing j ib can be

mounted on the boom of the le ngth of 26~62m.

4)Hook Block

■

16t hook

■

50t hook

■

100t ho ok

■

160t hook

■

260t hook

Operation Dev ices

SANY CRAWLER C RANE

SCC2600A

21

20

1)Load moment Indicator

■

The SCC2600A-type load mo ment indicator is a

overload protection system specially designed for

the Sany SCC series boom c rawler crane, with the

performance structure parameters of all Sany series

crawler cranes store d directly in it, such as load curve,

boom weight, center of gravit y and other geometric

parameters. The moment c alculation adopts the

targeted optimized mod el with tailor-made advantage,

integrating Sany’s technology ac cumulated over

years in the area of crawler c rane. It ensures lifting

safety, maximizes the utiliz ation efficiency by

avoiding technology disjunction and after-sale service

difficulti es caused by different manufacture rs of the

crane and LMI, so as to enhanc e quality of the whole

machine.

■

As an independent safet y control system completely

controlled by a comput er, the load moment limiter can

automatically detect t he load weight, working radius

and lifting boom an gle, and compare them with the

rated load capacity a nd actual load, rated working

radius and rated boom angl e. Under normal operating

condition, it can intelligently judge and automatica lly

cut off the crane movi ng towards danger direction, It is

also equipped with blac k box to record the overloading

information.

■

Its main components i nclude display, controller, angle

sensor and force senso r.

2)Three-color Load Alarm Light

Its correspondi ng moment limiter display can show the

load progress bar state, r eflecting the safety status of

lifting load.

3)Main and Auxiliary Hoisting Limiter

When the lifting ho ok is raised to the height limit, it can

send produce the alar m message and while cut off the

lifting action of h ook.

4)Lowering Limit er of Main and Auxiliary

Winch

When the wire rope rele ases to the last three loops, it

can send produce th e alarm message, so the electr ical

control system can automat ically cut off the lowering

action.

5)Switch between Assembly/Operation

Mode

In assembly mode, over hoisti ng limiter, boom angle

limiter and load moment indi cator will be bypassed for the

assembly of the crane. In o peration mode, all safety limit

devices will function.

6)Lifting Boom Limit Detection Device

Under different operating conditions, through the

detection of the limit swi tch and the boom angle signal of

force limiter system, t he crane b oom or jib can operate

within the safety angl e.

7)Lifting Boom Back-stop Device

■

The boom adopts the cyli nder back-stop structure,

with the larger compr ession and amount, the greater

back-stop force. The ma ximum output force of back-

stop cylinder is 38t.

■

There is a pair of mechanic al back-stop device on the

rear mast of luffing jib, to pr event the mast overturn roll

backward and to tensio n the rear mast pendant bar.

■

If the angle bet ween jib and boom is too sm all, the

cylinder back-stop devic e can prevent it overturn roll

backward, with the ma xim output force of back-stop

cylinder of 50t.

Safety Devices

8)Winch Brake

All winch brakes adopt th e spring-loaded normally close d

disc brakes, which are cha racterized by the larger braking

force, free maintenanc e, safe and reliable operation and

long service life.

9)Monitoring System

With the high-definition camera adopted, the operator in

the cab can monitor the real-t ime states of luffing dr um,

lifting winch dr um and vehicle rear through the monitor.

10)Self- diagnosis System

It can automatically give the fault alarm message, and

check the work powere d state of electrical circuit , to

quickly eliminate the el ectrical fault.

11)Phraos

It is mounted on the top of boom, to g ive the boom

altitude lighting, so th e boom lowering at night is not

needed.

12)Anemometer

It is installed at the top of bo om, to measure the wind

speed in real time, and to tra nsfer the data to the monitor

display in the cab.

13)Level Gauge

The bubble level gauge is adopte d as the validation basis

and the electric al level indicator is adopted to give the

high-precision display in real time, showing the crane

tilting angle and infor ming the crane safety working

ground environment.

14)Hook Latch Device

There are baffle on the hook to prevent the wire rope fall

off.

15)O perating Alarm

Before any operation, pre ss the horn to give an alarm,

informing the crane w ill start work operation don e now

and other staff to pay at tention to danger.

16)Traveling or Swing Alarm Message

In traveling or slewing oper ation, the working alarm lamps

flashes, accompani ed by a buzzer sound.

17)Function Lock

If the operator leaves the se at or the function locking

handle is not at the proper po sition, all other functional

control handles will n ot be working so as to are invalid,

thus effectively avoid ing misuse.

18)Automatic Reverse Traveling

No matter what the relati ve position of superstructure

and chassis is pulled fo rwarded, the vehicle will travel

forward; if pulled bac kwards, the vehicle will travel

backward.

19)Monitor Display

The high-preci sion true color display with that is t he

vehicle electrical man-machine dialogue display terminal

can show the working st ate and real-time parameters of

engine system, hydraulic system and electrical system.

SANY CRAWLER C RANE

SCC2600A

23

22

SANY CRAWLER C RANE

SCC2600A

SCC2600A

23 Operating Condition Combination

24 H Operating Condition

28 Fixed Jib Combination

38 Luffi ng Jib Combination

56 Shield Operating Condition Load Charts

Operating condit ion combination

21m-63m

26m-62m29m-62m

13m-42m

20m-86m

H operating

condition (H)

Fixed jib operating

condition (FJ)

Luffing jib operating

condition (LJ)

Shield operating

condition (FJh)

20m

12m

SANY CRAWLER C RANE

SCC2600A

25

24

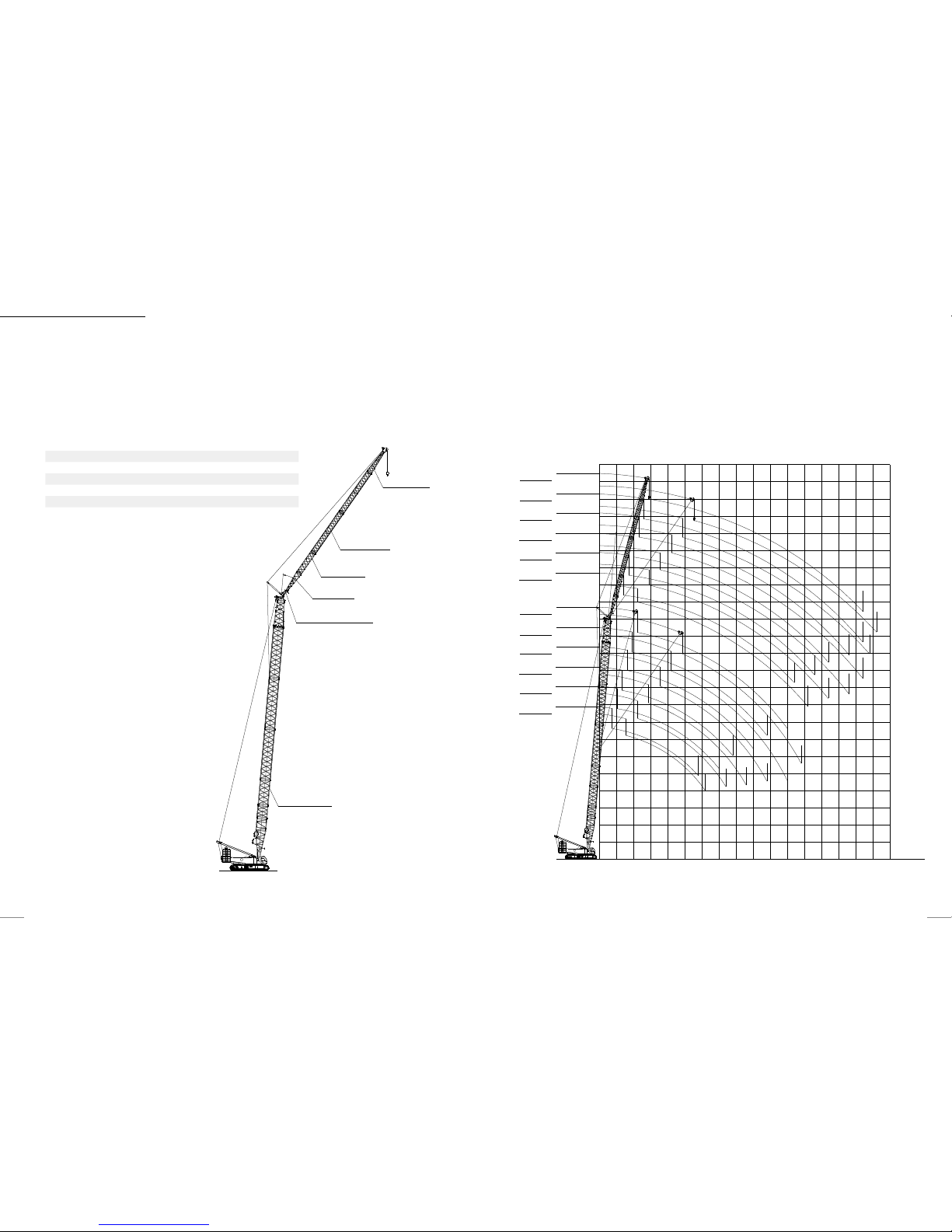

H operating condition

Boom length Insert

m 3 m 6 m 12m

20 1 - -

23 1 -

26 1 1 -

29 - - -1

32 1 - 1

35 - 1 1

38 1 1 1

41 - - 2

44 1 - 2

47 - 1 2

50 1 1 2

53 - - 3

56 1 - 3

59 - 1 3

62 1 1 3

65 - - 4

68 1 - 4

71 - 1 4

74 1 1 4

77 - - 5

80 1 - 5

83 - 1 5

86 1 1 5

Boom head(1m)

Transitional insert(6m)

12m boom insert(5 pieces)

6m boom insert(1 pieces)

3m boom insert(1 pieces)

Boom base(10m)

64

60

68

72

76

92

96

84

88

80

56

48

52

44

40

36

28

32

20

24

12

16

8

5

0

85°

30°

68

62

65

71

74

77

80

86

89

92

83

59

53

56

47

50

44

38

41

29

32

35

23

26

20

0 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64 68

Working radius (m)

Lifting height(m)

H operating condition working radius diagram

H operating condition

SANY CRAWLER C RANE

SCC2600A

27

26

H OPERATIng CONDITION LOAD CHARTS H OPERATIng CONDITION LOAD CHARTS

Unit:(t)

SCC2600A Crawler Crane – H Operating Condition Load Charts

Boom length 2 0-86m Rear coun terweight 100t Car body counterwei ght 30t

Boom length (m)

Radius(m)

56 59 62 65 68 71 74 77 80 83 86

Boom length (m)

Radius(m)

8

8

9

114.0 114. 0 98.9 98.9

9

10

92.0 9 0.0 9 0.0 90.0 89.0 83.3 83.3 83.3

10

12

91.0 87. 2 85.6 76.3 72.8 67. 0 63.7 60.4 60.0 5 9.0 59.0

12

14 79.1 77.7 74 .9 73 .1

71.8 65 .1 60.3 5 4.9 51.8 51.2 50.0

14

16 68.1 6 7.0 65.6 64.4 63.0 62.0 54.8 52.1 48.2 47. 5 46.0 16

18 59.4 58.5 57. 3 56.2 55.1 54.2 53.0 47.4 4 5.5 44.9 39.0 18

20 52.4 51. 6 50.5 49.6 48.6 47. 8 46.8 45.9 42.9 39.4 35.9 20

22 46.6 45.9 44.9 44.1 43.2 42.5 41.5 40.8 39.8 36.6 3 2.1 22

24 41.8 41.1 40.2 39.5 38.6 38.0 37.1 36.4 35.6 35.0 31.1 24

26 37.6 37.1 36.2 35.6 34.7 34.2 33.4 32.7 31.9 31.4 28.7 26

28 33.7 33.6 32.8 32 .1 31.4 30.9 30.1 29.5 28.7 28.2 27.4 28

30 30.2 3 0.1 29.8 29.2 28.4 28.0 27. 2 26.6 25.9 25.4 24.7 30

32 27.2 27.1 26.8 26.5 25.8 25.4 24.7 24 .1 23.4 23.0 22.3 32

34 24.6 24.5 24.2 24.0 23.5 23.1 22.4 21.9 21.2 20.8 20.1 34

36 22.3 22.2 21.9 21.7 21.3 2 1.1 20.4 19.9 19.2 18.8 18.2 36

38

20.3

20.2 19.8 19.6 19.3 19.1 18. 6 18.1 17. 4 1 7.1 16.4 38

40

19.0

18.4 18.2 17.8 17.4 17.3 16.9 16.5 15.8 15.5 14.8 40

42

17.5

17.1 16.9 16.3 16.0 15.7 15. 3 15.0 14.3 14.0 13.4 42

44

16.2

15.9 15.5 14.9 14.7 14.5 13. 8 13.6 13.0 12.7 12 .1 44

46

15.0

14.5 14.0 13.7 13.4 13. 2 12.5 12.3 11.8 11.5 10.8 46

48

13.4

13.5 13 .1 12.6 12.5 12.3 11. 3 11.1 10.6 10.3 9.7 48

50

12.5

12.5 12.0 11. 7 11.5 11.2 10.2 9.9 9.6 9.3 8.7 50

52 11.5 11 .0 10.5 10.3 10.0 9.2 8.9 8.5 8.3 7.7 52

54 10.2 10.0 9.5 8.6 8.2 8.0 7.6 7.4 6.8 54

56 9.0 8.8 8.7 7.3 7.1 6.7 6.6 6.0 56

58 7.9 7.8 6.5 6.3 5.9 5.8 5.2 58

60 7.0 7.0 5.8 5.5 5.1 5.0 4.5 60

62 6.0 5.0 4.8 4.4 4.3 3.8 62

64 5.4 4.4 4.1 3.8 3.6 3 .1 64

66 3.7 3.5 3.1 3.0 2.5 66

68 2.9 2.5 2.4 68

SCC2600A Crawler Crane – H Operating Condition Load Charts

Boom length 2 0-86m Rear coun terweight 100t Car body counterwei ght 30t

Boom length (m)

Radius(m)

20 23 26 29 32 35 38 41 44 47 50 53

Boom length (m)

Radius(m)

5

260.0

5

6

238.4 224.9 223.6 204.2 194.0

6

7

207. 9 2 07.6 202.2 191.4 174 .4 1 69.1 165.0 158.0

7

8

183.8 178 .3 174. 4 170. 6 166.3 15 7.9 156.5 1 41.8 126 .3 125.0 12 4.0 122.0

8

9 15 6.1 153 .4 149.4 145 .4

142.7 142.7 141.3 130.2 122.1 11 7.6 115. 0 113 .0

9

10 141. 2 13 7.8 135.7 132 .2 13 0.1 129 .2 128.0 12 5.8 115 .5 11 5.5 10 7.1 104. 9 10

12 11 0.1 10 8.2 107.7 1 07.4 10 7.1 107.7 105.5 102.4 10 2.4 100.0 9 7.8 95.8 12

14 89.6 88.8 88 .1 8 7.7 87.2 87.2 8 6.9 86.8 85.8 84.2 82.4 80.9 14

16 74. 6 74. 2 73.8 73.5 72.8 72.6 73.8 72.3 72.3 72.3 70.8 69.5 16

18 63.8 63.3 62.8 62.5 62.5 62.6 62.0 62.3 61. 6 61.5 61.7 60.7 18

20 60.7 5 5.1 5 4.7 54.4 54.3 54.6 54.5 54.3 54.2 54 .1 53.8 53.5 20

22 49.5 48.8 48.3 48.2 48.2 48 .1 48.0 47. 8 47.7 4 7.5 47.6 22

24 43.8 43.5 43.1 43.0 42 .8 42.7 42.6 42.5 42.3 42 .7 24

26 39.1 39.0 39.1 38.9 38.9 38.0 38.3 38.2 38.1 26

28 37.0 35.0 35.1 34.9 3 4.8 3 4.5 34.5 34.2 34.0 28

30 31.4 31.6 31.4 31.3 31.1 31.0 30.7 30.5 30

32 28.6 28.4 28.3 28 .1 28.0 27. 7 2 7.5 32

34 25.8 25.7 25.5 25.4 25 .1 24.9 34

36 24.6 23.4 23.4 23.1 22.8 22 .7 36

38 22.3 21.7 22.0 20.8 20.6 38

40 20.0 20.2 19.5 19.2 40

42 17.8 17.7 17.6 42

44 16.9 16.8 16.5 44

46 16.5 15.2 46

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

29

28

Fixed jib combination

Jib length

(m)

Insert

Boom length

(m)

Angle between boo m

and jib

6 m 11.5 m

13 - - 29~62 10°, 30°

19 1 - 29~62 10°, 30°

24.5 - 1 29~62 10°,30°

30.5 1 1 29~62 10°, 30°

36 - 2 29~62 10°, 30°

42 1 2 29~62 10°, 30°

Fixed jib working range dia gram

Jib tip(6.5m)

11.5m jib insert(2 pieces)

6m jib insert(1 pieces)

Jib base(6.5m)

Angle between boom and jib(10°,30°)

30°

Boom(29m-62m)

Fixed jib (jib angle: 10° +30°)

Lifting height(m)

Working radius (m)

80

75

85

90

95

115

105

110

100

70

60

65

55

50

45

35

40

25

30

15

10

20

5

5 1510 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Boom (62m)

Jib (+42m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Boom (62m)

Jib (+36m)

Jib (+30.5m)

Jib (+24.5m )

Jib (+19m )

Jib (+13m)

Jib (+36m)

Jib (+30.5m)

Jib (+24.5m )

Boom (62m)

Jib (+19m )

Boom (62m)

Jib (+42m)

Boom (29m)

Jib (+42m )

Boom (29m)

Jib (+36m)

Boom (29m)

Jib (+30.5m )

Boom (29m)

Jib (+24.5m)

Boom (29m)

Jib (+19m )

Boom (29m)

Jib (+13m )

Boom (29m)

Jib (+42m )

Boom (29m)

Jib (+36m)

Boom (29m)

Jib (+30.5m )

Boom (29m)

Jib (+24.5m)

Boom (29m)

Jib (+19m )

Boom (29m)

Jib (+13m )

SANY CRAWLER C RANE

SCC2600A

31

30

Unit:(t)

Fixed jib load CHARTS

SCC2600A Fixed Jib Load Charts (Without Jib Head Pulley Block)

Without mai n hook; jib angle: 10°

Boom length (m) 29 35 Boom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

9

64.1 9

10

64.4 64.4

10

12

59.3 52. 9 62 .7 54. 2

12

14

53.1 4 9.7 44. 4 34.7 56.6 51.5 45.2

14

16 47.9 4 4.7 38.9 31.9

24.5 51.4 47.3 41 .6 32.8 24.1

16

18 4 3.7 40.6 3 4.1 28 .1 23.7 17.4 47.1 43.2 36.5 29.9 23.4 17.2 18

20 4 0.1 37. 2 30.4 25.0 2 1.8 16.8 42.5 39. 8 32.6 26.8 2 2.7 16.7 20

22 3 7.1 34.4 27. 5 22.7 19.7 16.2 38.0 3 6.9 29.8 24.2 20.9 16.1 22

24 3 4.1 31.8 24.9 20.5 17. 9 15.7 33.8 3 4.0 26.9 22 .1 19.0 15.6 24

26 30.5 29.3 22.9 18.8 16. 3 14. 4 34. 2 30.8 24.8 20.1 17.5 15. 2 26

28 29.2 26.9 20.9 17.3 1 5.1 13.2 30.6 27. 6 23.0 18.7 16.1 14.0 28

30 28.0 25.0 19 .4 16.0 13.9 12.2 29.3 25.0 21. 4 17.3 14.9 13 .0 30

32 26.9 23.0 18.1 14. 9 12 .8 11.3 26.6 22.7 19.9 16 .1 14.0 11. 9 32

34 24.5 22.5 17.0 13 .9 12.0 10.5 24.9 22.1 18 .6 15.1 12 .9 11.1 34

36 21.8 16 .7 13.1 11 .8 9.8 23.3 21.4 1 7.4 14.2 12.1 10.4 36

38 2 0.1 16.2 12.2 11 .6 9.7 21.3 19.6 16.4 13.3 11.4 9.8 38

40 18.5 15. 8 11.5 11.1 9.1 19.5 18 .1 15.5 12.6 10.7 9.2 40

42 15.0 11. 3 10.5 9.0 16.7 15.4 11. 9 10.5 9.0 42

44 14.3 10.7 9.9 8.5 15.4 14. 5 11.3 10.2 8.5 44

46 10.3 9.4 8.0 13.5 10.7 9.7 8.0 46

48 9.8 8.9 7.7 12.6 10.2 9.1 7.6 48

50 9.4 8.4 7.1 11.6 9.7 8.7 7.2 50

52 8.0 6.8 9. 3 8.4 6.8 52

54 6.8 6.5 8.9 7.9 6.5 54

56 6.1 7.5 6.2 56

58 5.9 7.2 5.9 58

60 5.5 7.0 5.6 60

62 5.4 62

64 5.1 64

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Fixed jib load CHARTS

Unit:(t)

SCC2600A Fixed Jib Load Charts (Without Jib Head Pulley Block)

Without mai n hook; jib angle: 10°

Boom length (m) 41 47 Boom le ngth (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

10

10

12

63.3 53.0 64.1

12

14

57.3 47.7 42.5 59.3 53.1

14

16

52.6 43.7 38.5 30.5 51.1 50.4 42.8 30.7

16

18 46.4 40.4 35.5 29.7

22.1 4 4.6 4 4.3 40.9 30.1 22.5

18

20 41.0 37.8 32.9 27.8 21.5 16.6 39.5 39.2 37.2 2 9.4 2 2.0 16.3 20

22 36.5 35.2 30.8 25.4 20.9 16.1 35.2 35.0 3 3.8 27.0 21.4 15.8 22

24 32.8 32.7 29.0 23.3 20.0 15. 6 33.6 31.5 31.0 24.7 20.9 15.5 24

26 29.6 29.6 26.4 21.5 18 .2 15 .1 32.2 28.5 28.5 22.8 19.4 15.0 26

28 30.2 26.9 24.5 20.0 17. 0 14 .7 31.0 25.9 26.0 21. 3 17. 9 14.6 28

30 2 7.1 24.5 22.9 18.4 15.7 14.2 2 8.1 23.6 23.7 19.9 16.8 14.3 30

32 27. 5 22.3 21. 4 17. 2 14.6 13.2 27. 0 21.6 21.8 18.5 15 .7 13.5 32

34 24.9 23.0 20.0 16 .1 13.8 12.4 24.4 21 .1 20.0 1 7.5 14.6 12.5 34

36 22.7 20.9 18. 8 15.2 12.9 11.5 22.2 20.5 18 .4 16.4 13.9 11.9 36

38 21.8 19 .2 17. 4 14.3 12.1 10.8 21.3 18.7 17.0 15.5 13.1 11.2 38

40 20 19 .0 16.0 13.6 11.5 10 .2 19.5 18.2 15.5 14.6 12. 4 10.5 40

42

18.3

17.7 15.7 12.9 10 .8 9.7 17.8 16.7 15.3 13 .9 11.7 9.9 42

44

16.8

16.3 14.5 12 .2 10.3 9.0 16.3 16.2 15.0 13.2 11.1 9.4 44

46 15.1 13.4 11. 6 9.8 8.7 15 15.6 13.8 12.5 10.5 8.9 46

48 14.9 12. 4 11.0 9. 3 8.2 13.7 14 .4 13.4 11.5 1 0.1 8.5 48

50 13.7 11 .4 10.6 8.8 7.7 13.2 12.4 10.6 9.6 8.0 50

52 10.6 1 0.1 8.5 7.3 12.2 11.4 9.8 9.2 7. 7 52

54 10.5 10.2 8.0 7.0 11.2 10 .5 9.7 8 .7 7.4 54

56 9.4 7.7 6.7 9.7 9.5 8.4 7.0 56

58 8.7 7.4 6.4 9.0 8.8 8.0 6.8 58

60 8.6 7.1 6.1 8.2 7. 4 6.4 60

62 6.8 5.9 7. 9 6.9 6.2 62

64 6.5 5.5 7.6 6.4 5.9 64

66 5.3 5.9 5.6 66

68 5.1 5.4 5.4 68

70 4.9 5.1 70

72 4.7 72

74 4.4 74

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

SANY CRAWLER C RANE

SCC2600A

33

32

Fixed jib load CHARTS

SCC2600A Fixed Jib Load Charts (Without Jib Head Pulley Block)

Without mai n hook; jib angle: 10°

Boom length (m) 53 56 Boom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

10

10

12

58.8 58.8

12

14

56.9 52.7 55.7 49.5

14

16

49.1 48.5 39.8 48.2 47. 6 38.2

16

18 43.0 42.6 39.2 28.8

21.8 42 .1 41. 8 37. 7 2 8.1

18

20 38.0 37. 7 3 7.6 28.3 21. 4 16.0 3 7.2 37.0 3 6.8 27.6 22.4 16 .9 20

22 33.8 33.7 33.6 2 7.8 20.9 15 .6 35.3 33.0 32.9 27. 2 22.0 16.5 22

24 32.3 30.3 30.2 25.9 20.5 15.2 31.6 29.6 29.6 26.6 21.5 16.1 24

26 29 .1 2 7.3 27.4 24.1 20.0 14.9 30.2 26.7 26.8 24.5 21.0 15.8 26

28 28.3 24.8 24.9 22.4 18.8 14 .5 28.9 24.2 24.3 22.8 20.6 15.4 28

30 26.9 22.6 22.7 20.9 1 7.7 14 .2 27. 6 23.4 2 2.1 21. 5 19.2 15.0 30

32 27. 2 22.0 20.8 19. 6 16.5 13.8 26. 5 22.8 20.3 20.2 18.1 14. 6 32

34 24.8 21.3 19.1 18 .5 15.6 13. 3 24.1 22.7 18.5 18 .6 17. 0 14.3 34

36 22.7 20.7 17.5 17.3 14.6 12.5 22 22.4 17.0 17.1 15.9 13. 7 36

38 20.7 1 9.1 16.1 16. 2 13.9 11. 9 20.2 20.5 16. 6 15.7 15 .1 12. 9 38

40 18.9 18. 5 15.8 14.9 13.2 11.1 18.4 18. 8 16.3 14.5 14.4 12.2 40

42

17.2

17.9 15.5 13.8 12.5 10.6 16.9 17.3 15.0 13.4 13 .7 11.5 42

44

15.7

16.4 14.3 12 .8 11. 9 10 .1 15. 4 15.9 14.6 12.3 13.0 11.0 44

46

14.4

15 13.3 11.8 11.2 9.5 14 14.6 14. 0 11.4 12.2 10.5 46

48

13.1

13.8 12. 2 11.0 10.8 9.1 12. 7 13.4 13. 8 10.5 11. 4 9.9 48

50

12

12.6 11.1 10 .1 10.2 8.6 11. 6 12.2 12.7 10.3 10.5 9.4 50

52

10.9

11.5 10.9 10.0 9.5 8.2 10.5 11.2 11.7 1 0.1 9.7 9.0 52

54

9.9

10.6 10.0 9.8 8.8 7.9 9.6 10.2 10.7 9.4 9.0 8.6 54

56 9.7 9.4 9.3 8.2 7. 5 8.7 9.3 9.8 9.4 8.2 8.2 56

58 8.8 9.3 9.0 7. 5 7.2 8.4 9 9.3 7.6 7. 7 58

60 8.6 8.9 7.0 6.9 7.7 8.2 8.5 7.0 7.1 60

62 7.8 8.2 6.4 6.5 7. 5 7.8 6.4 6.5 62

64 7.1 7. 5 5.9 6 .0 6.8 7.1 5.9 6.0 64

66 6.8 5.4 5.6 6.1 6.5 5.4 5.4 66

68 6.2 5.0 5.1 5.9 4.9 5.0 68

70 4.5 4.7 5.3 4.5 4.6 70

72 4.1 4.2 4.0 4.1 72

74 3.7 3.8 3.6 3.7 74

76 3.5

3.2 3.3 76

78 3.2 3.0 78

80 2.6 80

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Fixed jib load CHARTS

SCC2600A Fixed Jib Load Charts (Without Jib Head Pulley Block)

Without mai n hook; jib angle: 10°

Boom length (m) 59 62 B oom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

10

10

12 12

14

54.7 46.5 53.6

14

16

47.3 46.0 36.5 46.4 43.5 35.0

16

18 41. 4 41.1 36 .1 27. 3

40.5 40.3 3 4.7 26.6

18

20 36.5 36.4 35.6 26.9 20.7 35.8 35.6 34.2 26.3 20.3 20

22 34.7 32.5 32.4 26.5 20.3 15.3 36.0 31. 8 31.7 25.8 20.0 15. 2 22

24 31.0 29.1 29.1 26.0 19.9 15.0 32.3 28.5 28.5 25.4 19.6 14.9 24

26 30.7 26.3 26.3 25.2 19.5 14. 6 30.7 25.7 25.8 25.0 19. 3 14.6 26

28 29.9 23.8 23.9 23.6 19.1 14.3 30.8 24.8 23.3 23.3 18.9 14.2 28

30 28.6 23.0 21.8 21.8 18.5 14.0 2 7.9 23.9 2 1.2 21.2 18 .5 14.0 30

32 26 22.9 19.9 19.9 17.3 13.8 25.3 23.8 19.4 19 .4 17.7 13.7 32

34 23.7 22.1 18.2 18.2 16. 3 13.4 23 23.3 17.7 17.8 16.7 13.4 34

36 21.6 2 1.9 16.7 16.7 15 .5 13 .1 20.9 21.3 17.3 16.3 15.8 13 .1 36

38 19.7 2 0.1 16. 3 15.4 14.6 12.4 19.1 19.4 16.8 14. 9 14.9 12. 7 38

40 18 18.4 15.9 14. 2 13.9 11.7 1 7.4 17.8 16 .3 13.7 13. 8 11.9 40

42

16.5

16.9 14.6 13.1 13.1 11 .2 15. 9 16.3 14.9 12 .6 12.8 11.4 42

44

15.1

15.5 13.4 12.0 12.2 10. 5 14.5 14.9 13.8 11.6 11.7 10.7 44

46

13.8

14.2 12.4 11.1 11.2 10. 0 13.2 13.6 12.9 11. 4 10.8 10. 3 46

48

12.6

13 11. 4 10.9 10 .4 9.5 12 12. 4 12.8 1 1.1 10.0 9.8 48

50

11.4

11.9 11.1 10 .6 9.5 9.2 10.9 11 .3 11.8 10.6 9.2 9.2 50

52

10.4

10.9 10.7 10.4 9.4 9.3 9.9 10.3 10.8 10 .1 8.4 8.5 52

54

9.4

10 10.4 9.9 8.6 8 .7 9 9. 4 9.8 10 .1 7.7 7.8 54

56

8.5

9.1 9.5 9.7 8.0 8.0 8.1 8.5 9 9.2 7.1 7.1 56

58

7.7

8.3 8.7 8.9 7.4 7.4 7.3 7.7 8.1 8.4 6.5 6.5 58

60 7.5 7.9 8.2 6.7 6.8 6.5 6.9 7.4 7.6 5.9 6.0 60

62 6.7 7. 2 7.4 6.2 6.2 6.2 6.7 6.9 5.4 5.5 62

64 6.1 6.5 6.8 5.6 5 .7 5. 5 6 6.2 4.9 5.0 64

66 5.9 6.1 5.1 5.2 4.9 5.3 5.6 4.4 4.5 66

68 5.3 5.5 4.6 4 .7 4.7 5 4.0 4.1 68

70 4.9 4. 2 4.2 4.2 4.4 3.5 3.6 70

72 4.4 3.8 3.8 3.9

3.2 3.2 72

74 3.9 3.4 3.4 3.4 2.8 2.9 74

76 3.0 3.0 2.9 2.4 2.5 76

78 2.6 2.6 2.0 2 .1 78

80 2.3 1.7 1.8 80

82 2.0 1. 5 82

84 1.7 1.2 84

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

35

34

SCC2600A Fixed Jib Load Charts (Without Jib Head Pulley Block)

Without mai n hook; jib angle: 30°

Boom length (m) 29 35 Boom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

12

12

14

27.8 28.4

14

16

26.2 26.9

16

18

24.7 20.6 25.5 21

18

20 23.4 19.4 1 7.5

24.3 19.9

20

22 22.3 18.4 16.5 23.2 19 16.8 22

24 21.3 17.5 15.7 13.9 22.3 18 .1 16 14 .1 24

26 20.5 16.7 14. 9 13.2 21.4 17.3 15.3 13.5 26

28 19.7 16 14.2 12 .6 11. 8 20.7 16.7 14.7 12.9 12 28

30 19 15.3 13.6 12 11 .2 20 16 14.1 12 .3 11. 5 30

32 18.4 14 .8 13 11.5 10.7 10 19. 4 15.5 13. 5 11.8 11 10.3 32

34 17. 9 14.3 12.5 11 10.3 9.5 18.8 14.9 13.1 11.4 10 .5 9.8 34

36 17. 5 13. 8 12.1 10.5 9.8 9.1 18.3 14.5 12.6 10.9 10.1 9.4 36

38 13.4 11 .7 10. 2 9.4 8.7 17. 9 14.1 12 .3 10.6 9.8 9 38

40 13 11. 3 9.8 9.1 8.4 17. 6 13 .7 11.9 10.2 9.4 8 .7 40

42 12.7 11 9.5 8.7 8.1 17.3 13.3 11. 5 9.9 9.1 8.4 42

44 10.7 9.2 8.4 7. 8 13 11.2 9. 6 8.8 8.1 44

46 10.5 8.9 8. 2 7. 5 12.8 10.9 9.3 8.5 7.8 46

48 10.2 8.6 7.9 7. 2 10.7 9 8.2 7.6 48

50 8.4 7.7 6.9 10.5 8.8 8 7.3 50

52 8.2 7.4 6.6 10.3 8.6 7.8 7 52

54 8 7.2 6.4 8.4 7.6 6.8 54

56 7.1 6.2 8.2 7.4 6.5 56

58 6.9 5.9 8.1 7.2 6.3 58

60 6.8 5.7 7.1 6 60

62 5.5 6.9 5.9 62

64 5.3 6.8 5.7 64

66 5.5 66

68 5.4 68

70 5.2 70

Fixed jib load CHARTS Fixed jib load CHARTS

SCC2600A Fixed Jib Load Charts (Without Boom Hook and Counterweight 100+30t)

Without mai n hook; jib angle: 30°

Boom length (m) 41 47 Boom le ngth (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

14

14

16

26.9 2 7.9

16

18

25.7 20.9 26.7

18

20

24.6 19.9 25.6 20.7

20

22 23.6 19 16.7

24.7 19.8 17.4

22

24 22.7 18 .2 16 23.8 19.1 16.7 24

26 21.9 17.5 15.3 13.3 23 18.4 16 13.9 26

28 21 .1 16.9 14.7 12.8 11 .8 22.2 17. 7 15. 4 13.3 28

30 20.4 16.3 14. 2 12.3 11 .4 21.6 17.1 14.9 12.8 11.8 30

32 19.8 15 .7 13.7 11.8 10.9 10 20.9 16.6 14.4 12.4 11 .4 10. 4 32

34 19.3 15. 2 13.2 11 .4 10. 5 9.6 20.4 16.1 13 .9 12 11 10 34

36 18.8 14. 8 12.8 11 1 0.1 9.3 19.9 15 .6 13.5 11.6 10.6 9.7 36

38 18.3 14. 3 12.4 10. 5 9.8 8.9 19.4 15.2 13.1 11.2 10. 3 9.4 38

40 17. 9 14 12 .1 10 .1 9.4 8.6 18.9 14.8 12 .7 10.9 9.9 9 40

42 17. 6 13 .6 11. 7 9.6 9.1 8.3 18.5 14.4 12.4 10.6 9.6 8.7 42

44 17. 3 13. 3 11.4 9.2 8.8 8 16.9 14.1 12.1 10.3 9.3 8.5 44

46

15.8

13 11 .1 8.9 8.6 7. 8 15.5 13 .8 11. 8 10 9.1 8.2 46

48 12.8 10.9 8.5 8.3 7.5 14. 2 13.5 11. 5 9.7 8.8 8 48

50 12.5 10.6 8.3 8.1 7.3 12.9 13. 3 11.3 9.5 8.6 7.7 50

52 12.3 10.4 8 7.9 7.1 12.8 11.1 9.3 8.4 7. 5 52

54 10.2 7.8 7.7 6.9 11.7 10.8 9.1 8.2 7.3 54

56 10 .1 7.7 7.5 6.7 10.7 10.6 8.9 8 7.1 56

58 7.5 7.3 6.5 10. 5 8.7 7.8 6.9 58

60 7.4 7.1 6.3 9.8 8.5 7.6 6.8 60

62 7.3 7 6 .1 8.9 8.4 7. 5 6.5 62

64 6.9 5.9 8.2 7.3 6.3 64

66 6.7 5. 8 8.1 7.2 6. 2 66

68 6.6 5.6 7.4 7 6 68

70 5.4 6.9 5.8 70

72 5.3 6 .7 5 .7 72

74 5.2 5.5 74

76 5.3 76

78 5.3 78

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

unit:(t)

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

37

36

SCC2600A Fixed Jib Load Charts (Without Boom Hook and Counterweight 100+30t)

Without mai n hook; jib angle: 30°

Boom length (m) 53 56 Boom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

14

14

16

28.3 28.5

16

18

27.2 27.4

18

20

26.2 21 26.4 21.1

20

22 25.2 20.2

25.5 20.3

22

24 24.4 19.4 16.9 24.6 19.6 17 24

26 23.6 18.8 16.3 14 23.9 19 16.4 26

28 22.9 18.2 15. 7 13.5 23.2 18.3 15 .9 13.6 28

30 22.2 17. 6 15.2 13.1 12 22.5 1 7.8 15.4 13.2 1 2.1 30

32 21.6 17.1 14.7 12.6 11.6 21.9 17.3 14.9 12.7 11.7 32

34 21 16 .6 14.3 12. 2 11.2 10.2 21.4 16 .8 14.4 12. 3 11.3 10.2 34

36 20.5 16 .1 13.9 11.8 10.8 9.8 20.8 16. 3 14 12 10.9 9.9 36

38 20 15 .7 13.5 11.5 10.5 9.5 20.4 15.9 13.6 11.6 10.6 9.6 38

40 19.6 15. 3 13.1 11.2 10.2 9.2 19.5 15.5 13. 3 11.3 10.3 9.3 40

42 18 14.9 12. 8 10.9 9.9 8.9 17.7 15 .2 12.9 11 10 9 42

44 16.4 14.6 12.4 10.6 9.6 8.7 16.1 14.8 12.6 10.7 9.7 8 .7 44

46

15

14.3 12. 2 10.3 9.3 8.4 14.7 14.5 12.3 10. 4 9.4 8.5 46

48

13.7

14 11. 9 10 9.1 8.2 13.4 14.2 12.1 10 .2 9.2 8.3 48

50

12.5

13.5 11 .7 9.8 8.9 7.9 12.2 13.2 11. 9 9.9 9 8 50

52

11.4

12.3 11 .4 9.6 8.6 7.7 1 1.1 12 11. 6 9.7 8.8 7.8 52

54

10.3

11.3 11.2 9.4 8.4 7.5 10 11 11. 4 9.5 8.5 7. 6 54

56 10.3 11 9.2 8.2 7.3 9.1 10 10.8 9.3 8.4 7.4 56

58 9.4 10.2 9 8 7. 2 8.1 9.1 9.9 9 .1 8.2 7.3 58

60 8.5 9.3 8.8 7. 9 7 8.2 9 8.9 8 7.1 60

62 8.5 8.6 7.7 6.8 7.4 8.2 8.8 7.8 6.9 62

64 7.7 8.4 7.6 6.6 6.6 7.4 8 .1 7.7 6. 8 64

66 7 7.7 7.4 6.4 6.7 7. 4 7.5 6.6 66

68 7 7.3 6.2 6 6.7 7.3 6.3 68

70 6.3 6.9 6 6 6.6 6.2 70

72 5.7 6.3 5.9 5.4 6 6 72

74 5.7 5.8 4.8 5.4 5.8 74

76 5.1 5.6 4.8 5.3 76

78 4.5 5 4.3 4.7 78

80 4.5 3 .7 4.2 80

82 4 3.7 82

84 3.5 3. 2 84

86 2.7 86

Fixed jib load CHARTS

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

SCC2600A Fixed Jib Load Charts (Without Boom Hook and Counterweight 100+30t)

Without mai n hook; jib angle: 30°

Boom length (m) 59 62 Boom length (m)

Jib length (m)

Radius(m)

13 19 24.5 30.5 36 42 13 19 24.5 30.5 36 42

Jib length (m)

Radius(m)

16

16

18

27.6 27.7

18

20

26.6 21.2 26.8

20

22

25.7 20.5 25.9 20.6

22

24 24.9 19.8 17.1

25.1 19.9 17. 2

24

26 24 .1 1 9.1 16. 5 24.4 19.3 16.7 26

28 23.5 18.5 16 13.7 23.7 18.7 16.1 13 .8 28

30 22.8 18 15 .5 13.3 12.1 23.1 18.2 15 .6 13.4 30

32 22.2 17. 5 15 12.8 11.7 22.5 17. 7 15. 2 12.9 11. 8 32

34 21.6 17 14.6 12.5 11. 4 10.3 2 1.9 17. 2 14.7 12.6 11. 4 10.3 34

36 21 .1 16.5 14 .2 12 .1 11 10 21.4 16.7 14. 3 12.2 11.1 10 36

38 20.6 16 .1 13.8 11.7 10.7 9.7 20.3 16. 3 14 11.9 10 .8 9.7 38

40 19 .1 15.7 13.5 11.4 10.4 9.4 18.5 15.9 13 .6 11. 5 10.5 9.4 40

42 17. 5 15 .4 13 .1 11 .1 1 0.1 9.1 16.9 15.6 13 .3 11. 2 10.2 9.2 42

44 16 15 12.8 10.8 9.8 8.8 15.4 15.2 13 11 9.9 8.9 44

46 14.6 14.7 12.5 10.6 9.6 8.6 14.1 14.9 12.7 10.7 9.7 8 .7 46

48

13.3

14.2 12. 3 10.3 9.3 8.4 12.8 13.7 12.4 10 .4 9.4 8.4 48

50

12.1

13 12 10.1 9.1 8 .1 11.6 12.5 12.2 10.2 9.2 8.2 50

52

10.9

11.9 11.8 9.9 8.9 7.9 10.6 11.4 12 10 9 8 52

54

9.9

10.8 11. 6 9.6 8.7 7.7 9.9 10.4 11.1 9.8 8.8 7. 8 54

56

9

9.9 10.7 9.4 8.5 7.5 8.6 9.4 10.2 9.6 8.6 7. 6 56

58

8.1

9 9.8 9.3 8.3 7.4 7. 7 8.5 9. 3 9.4 8.4 7.5 58

60

7.2

8.1 8.9 9.1 8 .1 7.2 6.9 7.7 8.4 9 8.2 7.3 60

62 7.3 8.1 8 .7 8 7 6.1 6.9 7.6 8.2 8.1 7.1 62

64 6.5 7.3 7.9 7.8 6.8 6.1 6.9 7. 5 7.9 6.9 64

66 5.8 6.6 7.2 7. 6 6.6 5.4 6.2 6.7 7.3 6.8 66

68 5.9 6.5 7 6.5 4.7 5.5 6.1 6.6 6.6 68

70 5.3 5.8 6.4 6.3 4.8 5.4 6 6.4 70

72 5.2 5.8 6.2 4.2 4.8 5.3 5.8 72

74 4.6 5.2 5 .6 3.6 4.2 4.7 5.2 74

76 4 4.6 5 3.6 4.2 4.6 76

78 4 4.5 3.1 3.6 4.1 78

80 3.5 3.9 3.1 3.5 80

82 3 3.4 2.6 3 82

84 2.9 2 .1 2.5 84

86 2.5 2.1 86

88 2 1.6

88

Fixed jib load CHARTS

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condition that the heav y object is lifted slowly and stably from the level and hard soil grou nd.

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

39

38

Jib length

(m)

Insert

Boom length

(m)

Angle between boo m and jib

3m 6m 12m

21 1 1 - 26~62 65°~88°

24 - 2 - 26~62 65°~88°

27 1 1 -- 26~62 65°~88°

30 -- 1 1 26 ~62 65°~88°

33 1 1 1 26~62 65°~88°

36 - 2 1 26~ 62 65°~88°

39 1 2 1 26~62 65°~88°

42 -- 2 2 26~62 65°~88°

45 1 1 2 26~62 65°~88°

48 -- 2 2 26 ~62 65°~88°

51 1 2 2 26~ 62 65°~88°

54 -- 1 3 26~ 62 65°~88°

57 1 1 3 26~62 65°~88°

60 2 3 26~ 62 65°~88°

63 1 2 3 26~62 65°~88°

Luffing jib combination Luffing jib opera ting condition

w ork ing r a nge di agram

Jib top(6m)

Jib 12m section(3pieces)

Jib 6m section(2pieces)

Jib 3m section(1pieces)

Boom section(6m)

Boom section(26m-62m)

Lifting height(m)

Working radius (m)

Boom angle: 88′

63m

60m

57m

54m

51m

48m

45m

42m

39m

36m

33m

30m

27m

24m

21m

0 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

75°

62m

15°

15°

26m

63m

60m

57m

54m

51m

48m

45m

42m

39m

36m

33m

30m

27m

24m

21m

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

135

SANY CRAWLER C RANE

SCC2600A

41

40

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 26 Boom length (m)

Jib length (m) 21 24 27 30 J ib length (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

90 89.1 10

12

88 89.8 84. 8 83.8 78.9

12

14

77 84.3 73. 9 82.6 73. 5 81.1 73.4

14

16

67

72.4 71. 9 64.6 71.4 64.3 70.9 63.6 69.8

16

18

59

62.9 63.8 56.9

62.7 62 .7 56.6 62 .4 61.6 56.7 62 .2

18

20

50

54.7 5 7.4 55.4 51. 2 55.2 56.4 50.9 55.4 55.3 50.5 55. 2 54.0 20

22

38

45.5 51. 7 5 0.1 4 4.8 49.6 51 .2 49.4 45.9 4 9.7 50.2 46.1 49.4 49.0 22

24 3 4.2 46.3 44. 9 43.5 3 7.0 43.1 46.2 4 4.7 41. 3 45.3 45.9 43.9 42 .0 45.2 44. 9 43.0 24

26 41. 9 40.6 39.3 35.4 41.9 40.5 39.2 34.7 40.8 41.7 39.8 38.3 41.1 41.1 39.5 26

28 37.0 35.9 34.7 38 .1 36 .9 35.7 27.7 33.8 37.9 36.3 35.1 32 .1 3 7.6 37. 5 3 6.1 28

30 32.9 31.9 35. 0 33.9 32.8 31.7 26. 4 34.9 33.3 32.2 26.4 32 .3 34.4 3 3.1 31.8 30

32 2 9.4 31.2 30.2 29. 2 32.1 30.7 29.7 28.9 25.9 31.7 30.5 29 .3 32

34 28.0 2 7.1 28.4 2 7.5 26.9 29. 4 28.3 27.1 26.4 34

36 25.1 25.6 24.9 26.3 25.2 24.6 36

38 23. 3 24.5 23.6 22. 9 38

40 22.0 21. 4 40

42 20.1 42

44 44

46 46

48 48

50 50

52 52

54 54

56 56

58 58

60 60

62 62

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 26 Boom length (m)

Jib length (m) 33 36 39 42 Jib leng th (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

10

12 12

14

72.7 70. 2 62.6

14

16

63.2

68.6 62. 9 61.9 54.1

16

18

55.8

61.1 55.8

60.1 55.4 59.1 53.5

18

20

50.3

55.0 50. 0 54.1 49.4 53.3 48.3 52.4 20

22

45.5

49.2 48.6 45.4 4 9.1 47. 4 4 4.7 48.4 43.7 4 7.7 22

24

41.7

44.5 44.5 41.4 44.3 4 3.4 40.7 44.3 42.7 39.9 4 3.7 41 .1 24

26

38.4

40.8 41. 0 38. 3 37. 9 40.6 39.9 3 7.5 40.7 3 9.3 36.5 40.1 37. 9 26

28

33.3

37.6 3 7.7 35.2 3 5.1 37.4 3 7.0 34.8 34.8 37.3 36.3 3 4.2 34.0 37.0 35 .1 28

30

28.3

33.1 34.6 32 .3 31.1 30.8 34.5 34.0 32.1 32 .1 34. 3 33.9 31.8 31.5 34.2 32.7 31.1 30

32

23.6

28.2 31. 9 29.8 2 8.7 26.8 30. 9 31.4 29.6 28.5 28 .7 32.0 31. 2 29.3 2 9.3 32.0 30 .4 28.9 32

34

18.9

23.3 29.6 2 7.5 26.6 22. 3 26.6 2 9.1 27.5 26.4 25 .0 29.0 28. 9 27. 2 2 6.1 26.6 29 .7 28 .1 26.8 34

36 26.0 25.7 24.8 2 4.3 18.4 22.0 2 7.0 25.5 24.6 2 1.9 25.2 26.9 25.3 24 .3 23.2 27. 2 26.1 24.8 23.9 36

38 20.6 23.9 23.0 22.7 1 7.9 25.2 23.8 22. 9 22.0 1 7.5 20.9 25.0 23.6 22.6 21.7 20.3 23.8 24.4 23.1 22.3 38

40 22.3 21.6 21. 3 23.6 22.2 21.4 20 .6 14.2 17.3 23.4 2 2.1 21.2 20 .3 16.3 2 1.0 22.8 21.7 20. 8 19.9 40

42 20. 3 19.9 2 0.9 20 .1 19. 3 22.0 2 0.7 19.9 19.1 13.6 16.7 21. 4 20.3 19.5 18.7 42

44 18 .7 18.9 18.1 20.6 19.4 18. 6 17. 9 13 .5 18 .1 19.1 18.3 17.5 44

46 17.7 17.1 18.3 17. 6 16. 8 14.9 18.0 1 7.3 16.6 46

48 16.1 16.6 15.8 17.0 16. 3 15.6 48

50 15.0 15.4 14 .7 50

52 13.9 52

54 13.2 54

56 56

58 58

60 60

62 62

64 64

66 66

68 68

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

43

42

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 26 Boom length (m)

Jib length (m) 45 48 51 54 Jib l ength (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

10

12 12

14 14

16

48.2

16

18

47.7

42.8

38.4 31.9

18

20

47.1

46.7 42.1 41.9 3 7.9 31.5 20

22

43.7

45.9 41 .6 41.3 37. 4 3 7.2 3 1.1 3 0.9 22

24

39.9

42.1 39.4 4 0.8 36.8 3 6.6 30.6 3 0.4 24

26

36.6

38.8 3 7.3 3 6.1 3 8.2 36.0 36.1 30.2 30.1 26

28

33.6

35.9 34.5 33.5 35 .4 33.9 33 .2 34.8 33. 4 29.8 29. 6 28

30

31.3

33.4 32.0 31 .1 32. 9 31.6 30.9 32. 4 31.1 29. 3 29.3 28.5 30

32

29.1

31.1 30.0 28 .7 28.8 30 .7 29.4 2 8.7 30.2 2 9.0 28.4 2 9.0 28.2 32

34

27.2

28.9 2 7.9 26.8 27.1 28.7 27.6 26.5 26.9 28.3 27.1 25.9 26.4 2 7.9 26.7 34

36

24.7

26.9 25.9 24.9 25.4 2 6.8 25.7 24.7 25.2 26.6 25.5 24. 4 23.7 26.2 25.1 24.0 36

38

22.0

25.1 24.2 23.2 23.0 23.4 24.9 24.0 23.0 22 .1 23.7 24.8 23.8 22.8 21. 4 24.3 23.6 2 2.6 38

40 19.4 22 .1 22.6 21.7 21.5 20.6 23.3 22.4 21.5 20.6 21. 9 23.1 22.2 21.2 20. 3 19.3 21. 8 2 2.1 21.2 40

42

15.6

19.6 21. 2 20.3 2 0.2 18.6 18.5 21. 0 21.0 20.2 19.3 19.4 21.7 20. 8 19.9 19.1 17. 4 19.6 20.7 19.8 18. 9 42

44

13.0

15.4 19 .9 19 .1 18 .9 17. 6 16.4 18.6 19.7 18 .9 18 .1 17.3 17. 5 19.9 19.5 18.7 17.8 15.7 17. 6 19 .4 18.5 17.7 44

46

10.4

12.8 17.4 18.0 17.8 16.5 12.2 14.7 18. 6 17. 8 17.0 16.3 15.6 17.7 18.4 17.6 16.8 16.0 1 4.1 15.9 18. 3 17. 5 16.7 46

48 14.3 16.9 16 .7 15.6 10.0 12. 2 17. 6 16 .8 16.0 15.3 11 .5 15.7 17.4 16.6 15 .8 15 .1 12.6 14. 3 17. 2 16.5 15.7 14.9 48

50 16.0 15.8 14 .7 9.7 16.6 15 .8 15 .1 14.5 9.5 11.5 16.4 15.7 14 .9 14.2 11.3 13. 0 15.8 15.5 14. 8 14.0 50

52 15.1 15.0 13 .9 15.7 15.0 14.3 13. 7 9.5 13.1 14.8 14.1 13. 4 7.3 11 .5 14.2 14. 7 14.0 13.3 52

54 14 .1 13.1 14. 2 13.6 13.0 10.7 14. 0 13.3 12.7 5 .3 7. 4 12. 8 13.9 13.2 12.5 54

56 12 .4 12. 9 12.2 13. 2 12.6 12.0 5.5 8.5 13.1 12.5 11. 9 56

58 11.6 12. 5 12.0 11.3 6. 8 9.6 11.9 11. 3 58

60 11.3 10.8 7.9 11. 3 10.6 60

62

10.3 10 .6 10 .1 62

64 9.5 64

66 66

68 68

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 26 Boom length (m

Jib length (m) 57 60 63 Ji b length (m

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m

10

10

12 12

14 14

16 16

18 18

20

31.0 28.2

20

22

30.5 27.7 25. 3

22

24

30.1 29.9 27. 3 2 7.2 24.9

24

26

29.5 29.4 26.9 26 .7 24.6 24.5

26

28

29.1 29.0 26.6 26.5 24 .1 24.0

28

30

28.8 28.5 28.0 26.1 26.0 23.8 23.7

30

32

28.3 28.3 27.7 25.7 25.7 25.2 23.3 23.3

32

34

26.6 2 7.5 26.3 2 5.3 25.2 24.8 23.0 23.0 2 2.6

34

36

24.9 25.7 24.7 24.6 24.8 24. 2 2 2.6 22.6 22. 2

36

38

23.3 24.2 23.1 2 2.1 23.0 23.9 22.8 21.7 22.2 22.2 21.9

38

40

21.9 22. 9 21.9 20 .8 21.8 2 2.5 21.4 20.4 21.6 21.9 21.0 20.0

40

42

20.5

21.4 20. 4 19.5 20. 5 21.2 20 .3 19.3 20 .3 20.8 19.8 18.9

42

44

19.4

20.1 19.2 18 .4 17. 5 19.4 19. 9 19.0 18.1 19.3 19.7 18.7 17. 8

44

46

17.5

18.9 1 8.1 17.2 16.4 18.3 18.7 17.8 17.0 16.2 18 .1 18. 5 17. 6 16. 8

46

48

15.8

17.8 17. 0 16 .2 15.4 16.6 17.6 16.8 16.0 15 .2 17.3 17.5 16.6 15.8 14.9

48

50

14.2

16.0 16.0 15.3 14.6 13.9 14. 9 16.7 15 .8 15 .1 14 .3 15.6 16.5 15.7 14.9 14.1

50

52

10.2

14.5 15.1 14.4 13.8 13.1 13.4 15. 2 14.9 14.2 13.5 12.8 14.1 15.5 14.8 14.0 13 .3

52

54

8.5

10.2 14. 3 13.7 13.0 12.3 12.1 13. 8 14 .1 13. 5 12.8 12.1 12.9 14. 5 14.0 13.2 12.5 11.9

54

56

6.8

8.6 13.6 13.0 12. 2 11.6 7.7 9.4 13. 4 12.8 12.1 11.4 11.5 13.1 13.2 12.5 11.9 11.2

56

58

6.8 12.9 12.2 11. 6 11.0 6.3 7.9 12.7 12.1 11.4 10.8 7.2 11.8 12.5 11.9 11.2 10.5

58

60

12.2 11.6 11.0 10.4 4.9 6.4 8.8 11.4 10.8 10.3 5. 9 7.3 11.9 11. 3 10. 6 10.0

60

62

11.6 11.0 10.4 9.9 7. 5 10.9 10.3 9.7 4.5 5 .9 7.7 10.6 10. 0 9.5

62

64

10.4 9.9 9.4 5 .8 10.3 9.7 9.2 4.5 6 .9 10.1 9.5 8.9

64

66 9.4 8.9 9.7 9.2 8.7 5.4 9.5 9.0 8.5 66

68 8.4 8.7 8.3 9.1 8.6 8.0 68

70 7.8 8.6 8.1 7. 6 70

72 7.7 7. 2 72

74 6.8 74

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

45

44

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 38 Boom length (m)

Jib length (m) 21 24 27 30

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

89.8 10

12

87.4 83. 0 82.6 75.6

12

14

78.2 75.7 76.8 74.3 75.3 74.1

14

16

68.9

66.6

67.7

65.4 66 .4 64.3 65. 4 63.3

16

18

61.6

59.5 56.3 60.5

58.5 59. 4 57. 4 5 8.5 56.6

18

20

52.8

53.6 50.8 54.6 52 .7 49.9 5 3.6 51.8 52.9 51.1 20

22

37.4

49.0 46.2 49.9 4 8.1 45.5 49.0 47. 3 44.6 48.2 4 6.6 44.0 22

24 4 5.0 42.3 40. 0 45.8 44.2 41.7 39.3 44.9 43.4 40.9 44.3 42.8 40.3 24

26 41.4 39.2 36.9 40.1 40.9 3 8.4 36.3 41.6 40.1 3 7.7 35.6 41. 0 39.5 37.2 26

28 36.0 3 4.2 32.2 37. 8 35.7 33.6 3 7.8 37. 3 35. 0 32.9 3 8.1 36.7 34.6 32.5 28

30 31.4 29.7 32.9 31. 2 29.5 34 .6 32.7 3 0.7 35.6 34. 3 32.2 30.2 30

32 28.9 27. 5 25.9 30.3

28.8

27.3 30. 2 28.6 2 7.0 30.6 31. 9 30.2 2 8.3 32

34 25.4 24.0 26.6 25.2 23.8 28.0 26.5 25.0 2 9.4 28.0 26. 4 24.8 34

36 22 .3 23.5 2 2.1 24.7 23.2 21.9 26.0 24.6 23.1 36

38 20. 8 21.9 20.6 23.0 21.7 20.3 24.2 23.0 21.6 20.3 38

40 19.3 20. 3 19.1 2 1.4 20.2 18.9 40

42 17. 8 18.9 17.7 42

44 16.7 17.7 16.7 44

46 15.7 46

48 48

50 50

52 52

54 54

56 56

58 58

60 60

62 62

64 64

66 66

68 68

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 38 Boom length (m)

Jib length (m) 33 36 39 42 Jib leng th (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

10

12 12

14

66.8

59.6

14

16

64.3 59 .1

52.9 47.6

16

18

57.5

55.5 56 .6

54.7 52 .5 47. 2

18

20

52.0

50.2 51 .2 49.4 50.3 48 .6 46.7 4 6.5 20

22

47.4

45.8 46 .7 45 .1 45 .9 44.3 45. 3 43.7 22

24

43.6

42.0 39.6 42.8 41.4 3 9.0 42.2 40.7 41. 6 4 0.1 24

26

40.2

38.8 36.5 39.6 38 .2 35.9 3 9.0 37. 5 3 5.3 38.4 37.1 34.8 26

28

37.4 36.0

33.8

36.8

35.5 33.3 36.2 3 4.8 32.7 35.6 34.4 32.2 28

30

34.9 33.6 31.6

29.6

34.3 33.0

31.1 29.2

33.8

32.5 30.4 33.3 32 .0 30 .1 30

32

31.7 31.5 29.5

27.7

32.1 31.0

29.0

27.2 31.6 30. 3

28.4 26.6 31.1 30.0 28.1 32

34

29.3 27. 7 26.0

24.4

29.3 29 .1 27. 3

25.6

29.6 28.5

26.7 25.0

29.3

28.1 26.4 2 4.7 34

36

27.3 25.8 24.3

22.9

22.1 27.2 25.7 24.0

22.4

27.8 26.8 25.1

23.5

27.5 26.5

24.8 23.1 36

38

24.0 22.7 21.3 25 .3 23.9 22. 5

21.1

25.1 25.1 23.7

22.1 20.6

25.9 25.0

23.3 21.8 38

40

22.5 21.2 19.9

18.6

23.7 22 .4 21.1 19.7 22.2 23.5 22.1 20.8

19.4

23.8 23.5 2 2.1

20.6 19.2 40

42

19.9 18.6 17. 5 21.0 19.7 18.5 17. 3 2 2.1 20.8 19.5 18. 2 21.3 22.0 20.7 19. 4

18.1 42

44

18.6 17. 6 16.4 18.5 17. 4 16.2 19. 5 18.3 17.1

15.9

18.6 20.7 19.4 18. 2

17.0 44

46

16.5 15.5 17.5 16.4 15.2 18. 4 17.3 16.1 14.9 1 9.1 18.3 17.1 15.9

14.9 46

48

14.6 15.4 14.4 16.3 15. 2 14.1 17.3 16 .2 15.0 14.0

48

50

13.7 14. 5 13.6 14.3 13.3 15.3 14 .2 13.1

50

52

12.8 13. 5 12.6 14. 4 13.4 12.4

52

54

11.9 12.7 11. 8

54

56

11.3 12.0 11. 2

56

58

10.5

58

60 60

62 62

64 64

66 66

68 68

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Notes: 1. The actual we ight is a value that t he rated weight in t his table is subt racted by the weig hts of the hooks, ha ngers, and wir e ropes winding o n the hooks and on th e boom head.

2. The rated load in this table is measured under the condi tion that the heavy object is lifted slowl y and stably from the level and hard soil ground.

Unit:(t)

Unit:(t)

SANY CRAWLER C RANE

SCC2600A

47

46

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 38 Boom length (m)

Jib length (m) 45 48 51 54 Jib l ength (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65

Boom angle(°)

Radius(m)

10

10

12 12

14 14

16

42.9

16

18

42.5

38.3

34.7

18

20

42.0

38.0 34 .4 28.7 20

22

41.6

41.4 37. 5 37.4 34.0 3 3.8 28.4 22

24

41.0

39.4 3 7.2 36.9 3 3.6 33.4 28.1 27. 9 24

26

37.8

36.5 3 6.7 35.8 3 3.2 33.0 27.7 2 7.6 26

28

35.1 33.8

31.7

34.6

33.3 32. 8 32.6 27.5 2 7.3 28

30

32.7 31.5 29.5 3 2.2 31.0

29.0

31.7

30.4 28.4 27. 3 27.1 30

32

30.6 29.4 27. 5 30. 2 29 .0

27.1

29.6 28.4

26.6 26. 9 26.8 25.9 32

34

28.7 27. 6 25.8 24 .1 28.3 2 7.2 25 .4 27. 8 26.6

24.8

26.6

26.3 24.5 34

36

27.0 26.0 24.3 22.6 26.6 25.6 23.9 22.2 2 6.1 2 5.1 23.4 25.7 24.8

23.0 36

38

25.6 24.5 22.9 21.3 25.1 24 .1 22.5 20.9 24.7 23.7 22.0

20.4

24.3 23.3

21.7 38

40

24.0 23.2 21.6 20 .1 23.8 22.8 21.2 19.7 23. 3 22. 3 20 .8 19.3 23.0 22.0 20.4

18.9 40

42

22.4

21.8 20.4 19.0 1 7.6 2 2.4 21.6 20 .1 18.6 2 2.1 21. 2 19.6 18.2 2 1.7 20.8 19.4 17. 9

42

44

20.3

20.5 19.3 17. 9 16.7 21.1 20. 3 19.0 17.6 16.3 20.9 2 0.1 18.6 17.2 15.8 20.5 19.7 18. 3 16.9

44

46

18.0

19.4 18 .1 16.9 15.7 19 .2 19.2 17. 9 16.7 15.5 19.7 19.0 17. 6 16.3 15. 0 18 .5 18.7 17. 4 16.0 14. 8

46

48 18. 2

17.1 15 .9 14.8 13.7 17.2 18.1 16.9 15.8 14.6 18.1 17.9 16.7 15.5 14. 2 16 .6 17.7 16.5 15.2 14.0

48

50 16 .1

15.0 14.0 12. 9

15.1

17.1 15 .9 14.9 13.8 12 .7 16.4 16.9 15.8 14. 6 13.5 14.7 16.7 15.7 14.4 13. 2

50

52 15. 2

14.2 13 .1 12.2

15.6

15.1 14.0 13.0 12. 0

14.6

16.0 14.9 13.8 12.7 11.7 13.1 15.6 14.8 13 .7 12.6

52

54 13.4

12.5 11. 5

14.3

13.3 12.2 11.3

15.0

14.1 13.1 12.1 11.0 13.8 14.0 12 .9 11.9 10.9

54

56 11. 8

10.9

12.6

11.6 10 .7

13.3

12.3 11. 3 10.4 13. 2 12.2 11. 3 10.3

56

58 11. 2 10.3 11 .9 11.0

10.1

12.6

11.7 10. 8 9 .8 12.5 11.6 10.6 9.7

58

60 9.7 10.4 9.5 11.1

10.2 9.3

11.9

11.0 10.1 9.2

60

62 9.2 9 .1 9.6

8.8

10.4

9.5 8.6

62

64 8.6 9 .2 8.4 9.9 9.0

8.2

64

66 7.9 8.6 7.7 66

68

7.4

68

70 6.9 70

Unit:(t)

Luffing jib load CHARTS

SCC2600A Luffing Jib Load Charts (Without Jib Head Pulley Block)

Boom length (m) 38 Boom length (m)

Jib length (m) 57 60 63 Jib length (m)

Boom a ngle (°)

Radius(m)

88 85 80 75 70 65 88 85 80 75 70 65 88 85 80 75 70 65