Page 1

WASHING MACHINE

Technical Information

• Due to possibility of personal injury or property damage, always contact an authorized

technician for servicing or repair of this unit.

• Refer to Service Manual for detailed installation, operating, testing, troubleshooting, and

disassembly instructions.

CAUTION

All safety information must be followed as provided in Service Manual.

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

Code No. : DC68-02834A-03_EN

1

Techsheet-WF350AN-02834A-03_EN.indd 1 2011-09-28 �� 4:00:29

Page 2

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

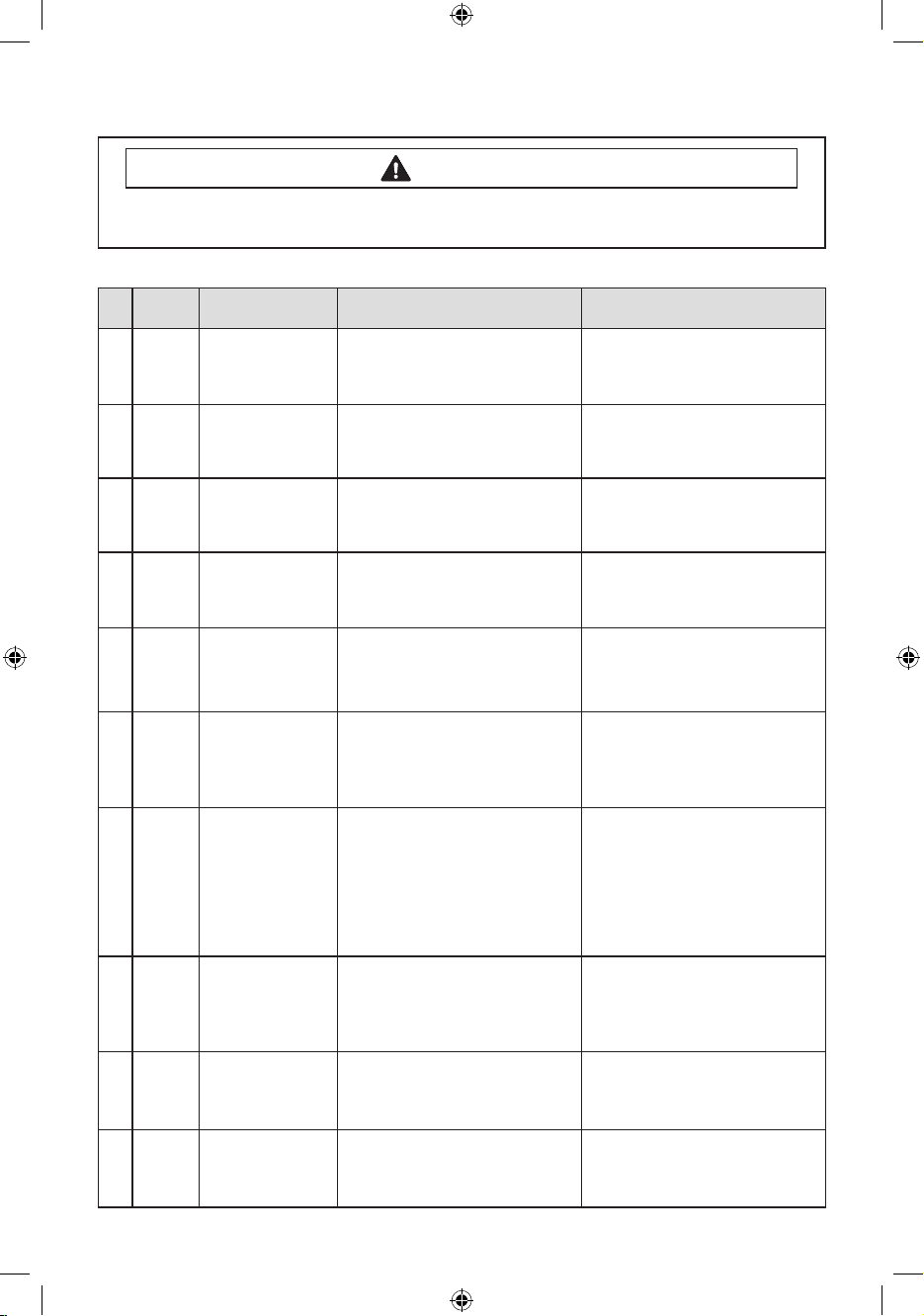

GENERAL ERROR FUNCTION

Error

NO

1 nd 1

Diagnostic Code

Code

Error Image

Description Corrective Action

The water level fails to drop below

the Reset Water Level within 15

minutes.

Go to “ Will Not Drain”

Troubleshooting Section.

2 LO 2

3 nF 3

4 FL 4

5 LE 8

6 LE 8

7 OE E

8 dc 10

9 E2 15

10 dL 18

Door fails to Unlock After 7

attempts.

When the lling Continues for

more than 40 minutes or there is no

change of water level for 6 minutes.

Door fails to lock after 7 attempts.

A water level lower than the Reset

water level (25.6Khz) is detected for

5 seconds during the Wash/Rinse

cycle.

Water Level Sensor Trouble. (When

the input signal from the water level

sensor is out of range, the unit will

send out beeping sounds and halts

the cycle.)

A fault is detected in the water level

sensor. Data (frequency) shows

the water level is at or above the

overow water level. (When this

condition is detected, the machine

will automatically starts draining

water until the water level falls

below the overow water level)

Unbalance or cabinet bump is

detected during nal spin, which

prevents the drum from spinning

over 150 rpm. (Never exceeds 150

RPM due to unbalanced load)

Jammed Key.(When key input

signals are coming out for more

than 30 seconds, it is regarded as

a jam.)

Door is detected as open when the

motor is operating.

Go to “ Will Not Unlock”

Troubleshooting Section.

Go to “ No Water Fill”

Troubleshooting Section.

Go to “ Will Not Lock”

Troubleshooting Section.

Go to “No Water Fill”

Troubleshooting Section.

Go to “No Water Fill”

Troubleshooting Section

First check to see that all of water

valves are not stuck. If water valves

are OK, check water level sensor.

Go to “Wet Clothes” Troubleshooting

Section.

Check all of keys. If A key is sensed

to be pressed, all keys will do not

respond.

Check for loose wire connections. Go

to “Quick Test Mode” and then do Door

lock/Unlock Test and Motor Test.

2

Techsheet-WF350AN-02834A-03_EN.indd 2 2011-09-28 �� 4:00:29

Page 3

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

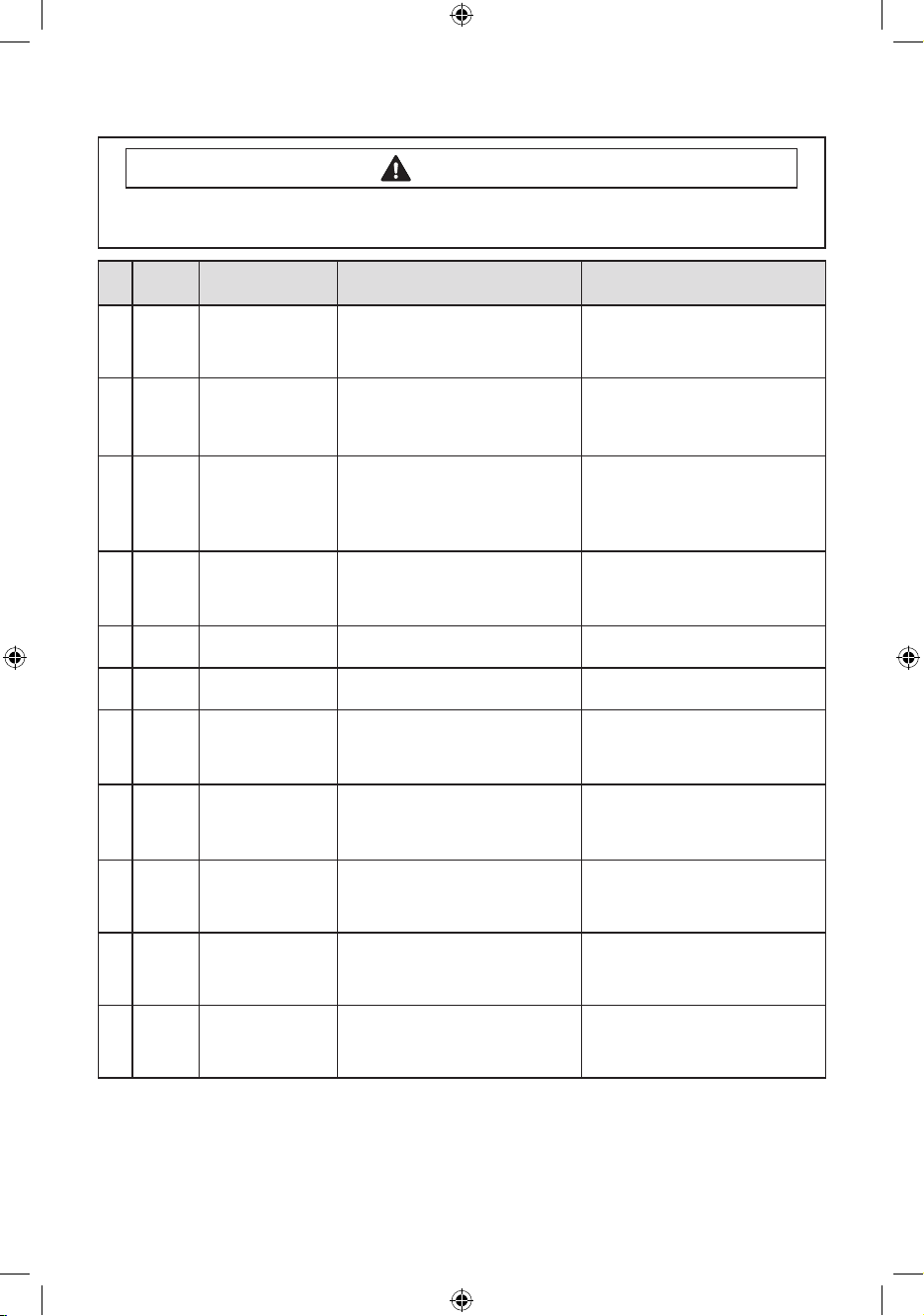

error

NO

Diagnostic Code

code

Error Image

Description Corrective Action

11 ds 22

12 tE 29

13

3E

14

Sr 34

15

Hr 36

16

nF1 5

2E

17 2E -

18 7E -

19 suds -

Door is detected as open while it is

trying to lock the door.

Abnormal high/low temperature or

resistance (Thermal sensor or PBA

resistance).

MICOM is attempting to drive the motor

but is not getting any response signals

from the hall sensor. Visual check shows

motor is not running. (Locked, Defective

Hall Sensor or Overload)

System Relay (Main Relay) Failure.

(PCB does not notice the relay

operation when there should be.)

Heater Relay Failure (No Heater

Relay Check Signal)

The hot/cold water hose connection

is not correct.

Voltage for motor control bus is

over or under specied limit.

Silver Care Kit (PCB) Failure.

Suds is detected during the washing

session. (“SUdS” is not an error. If the

washer is in suds period, “SUdS” will

light up instead of remaining time.)

Go to “Quick Test Mode” and then

do Door Lock/Unlock Test

Go to “ Board Input Test” and check

Water Temperature. Check loose

or pinched wires. Replace PCB or

thermistor.

Evaluate wire harness for loose or

unhooked connections. Go to “

Quick Test Mode” and test Motor.

Replace PCB.

Replace PCB

Please connect the hot/cold water

hose connection correctly.

Replace PCB

Check PCB ,Main PCB & Wireharness

Guide a user to reduce amount of

detergent usage.

20 AE

-

Communication error between SUB

PBA and MAIN PBA

Check Main PBA, SUB PBA & Wireharness. Replace PCB

SF1,

21

SF2,

-

System Error Replace PCB

SF3

3

Techsheet-WF350AN-02834A-03_EN.indd 3 2011-09-28 �� 4:00:29

Page 4

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

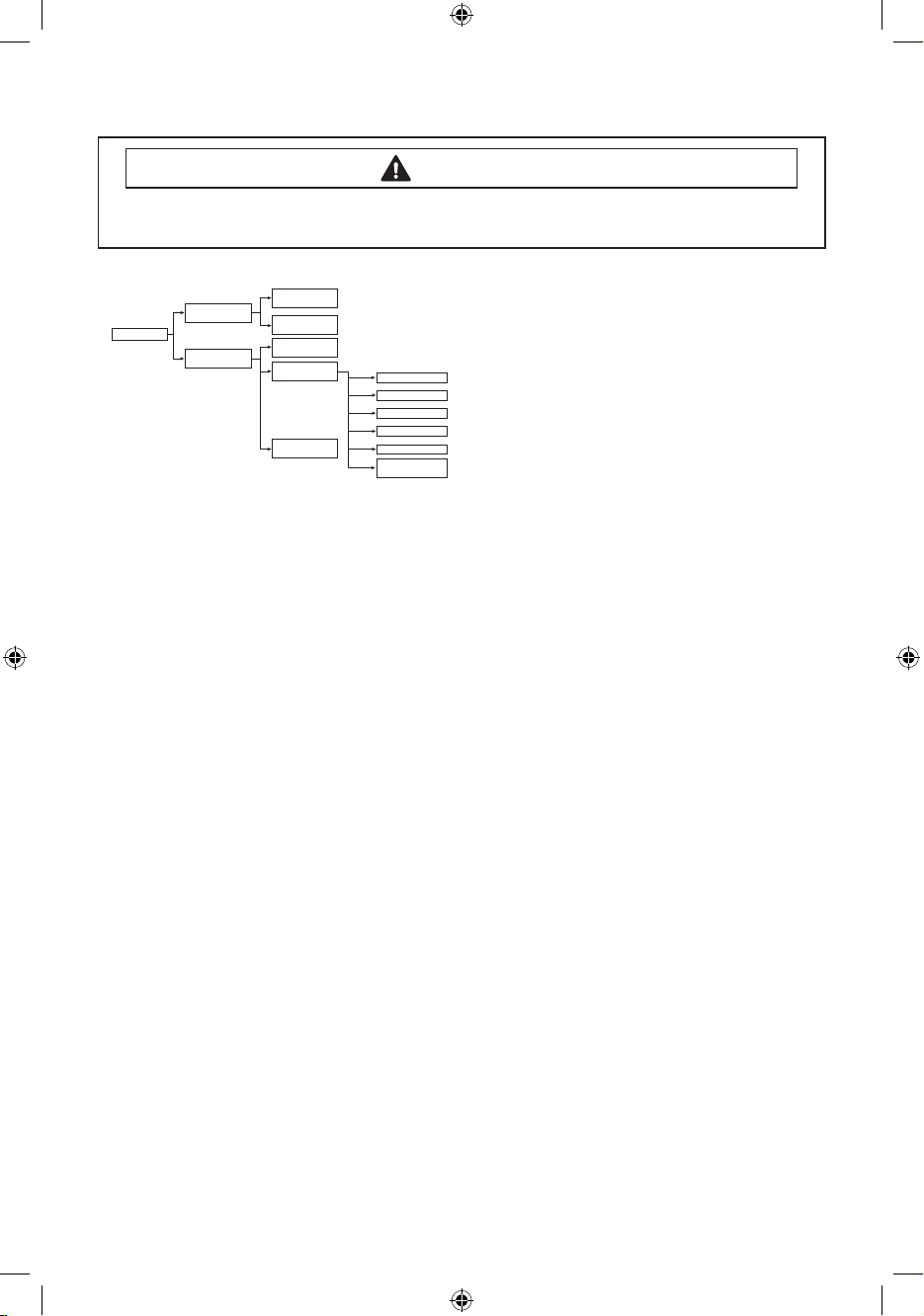

TEST MODE

Quick Test Mode

EEPROM Clear

Mode

Continuous Cycle

Mode

Service Mode

Demo Mode

Quick Spin Test Mode

Cycle Count Check Mode

S/W Version Check Mode

Fast Time Down Test Mode

Board Input Test Mode

Diagnostic Code

CheckMode

Special Test Mode

Power Off State

Power On State

(Normal User Mode)

Quick Test Mode

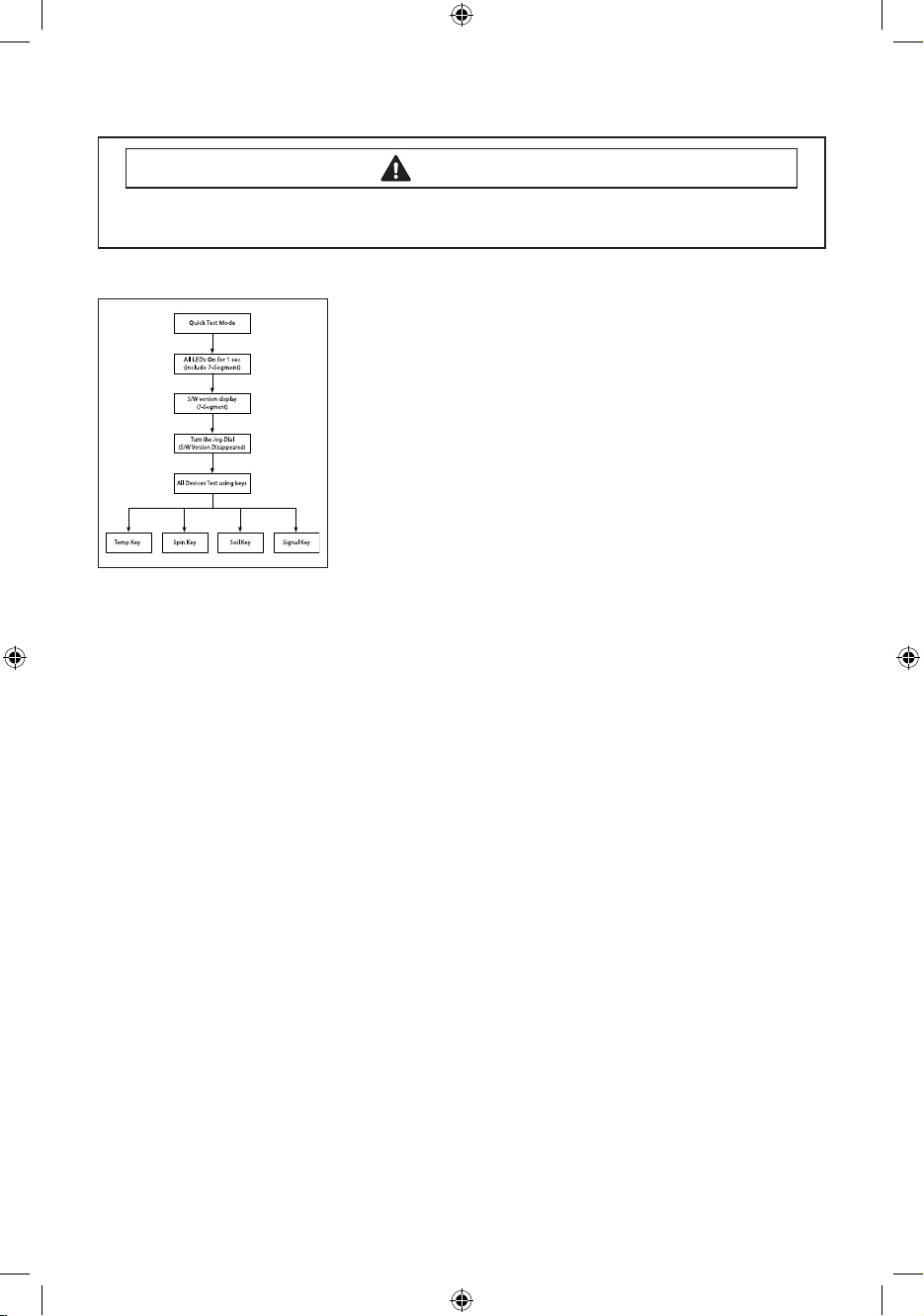

Denition of Quick Test Mode:

- Check operation of all LED’s (Verify faulty LED).

- Check model and software version.

- Check dierent operating modes (e.g. water valve, motor, door, drain pump, etc.).

How to Enter:

- Plug in the unit.

- Press Soil Level Key + Signal Key and Power Key at the same Time.

Important. Once test mode is performed, all data including the diagnostic code saved in the

EEPROM will be erased.

Test Mode:

Each Test Mode for the Squall is as follows in the

coming pages. The test modes indicated by the

red arrows are modes unable to get an access

once the washing cycle has started due to safety

resons.

4

Techsheet-WF350AN-02834A-03_EN.indd 4 2011-09-28 �� 4:00:29

Page 5

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

Quick Test Mode:

1. All LED’s light up and it sends out Beep Sound when it

enters into the Quick Test Mode. (Including 7-Segment)

2. Displays software version for a sec and Clear EEprom. (Ex. If

S/W Version is 49, 7-Segment will display E149)

3. When the version is displayed, turn the Jog-Dial so that

the version disappears. Press the following keys to test the

various components.

- Temp Key : Water Valve Test

- Spin Key : Door Lock/Unlock Test

- Soil Key : Water/Steam Heater Test(Steam Models)

Water Test(Non-Steam Models)

- Signal Key : Drain Pump Test

5

Techsheet-WF350AN-02834A-03_EN.indd 5 2011-09-28 �� 4:00:29

Page 6

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

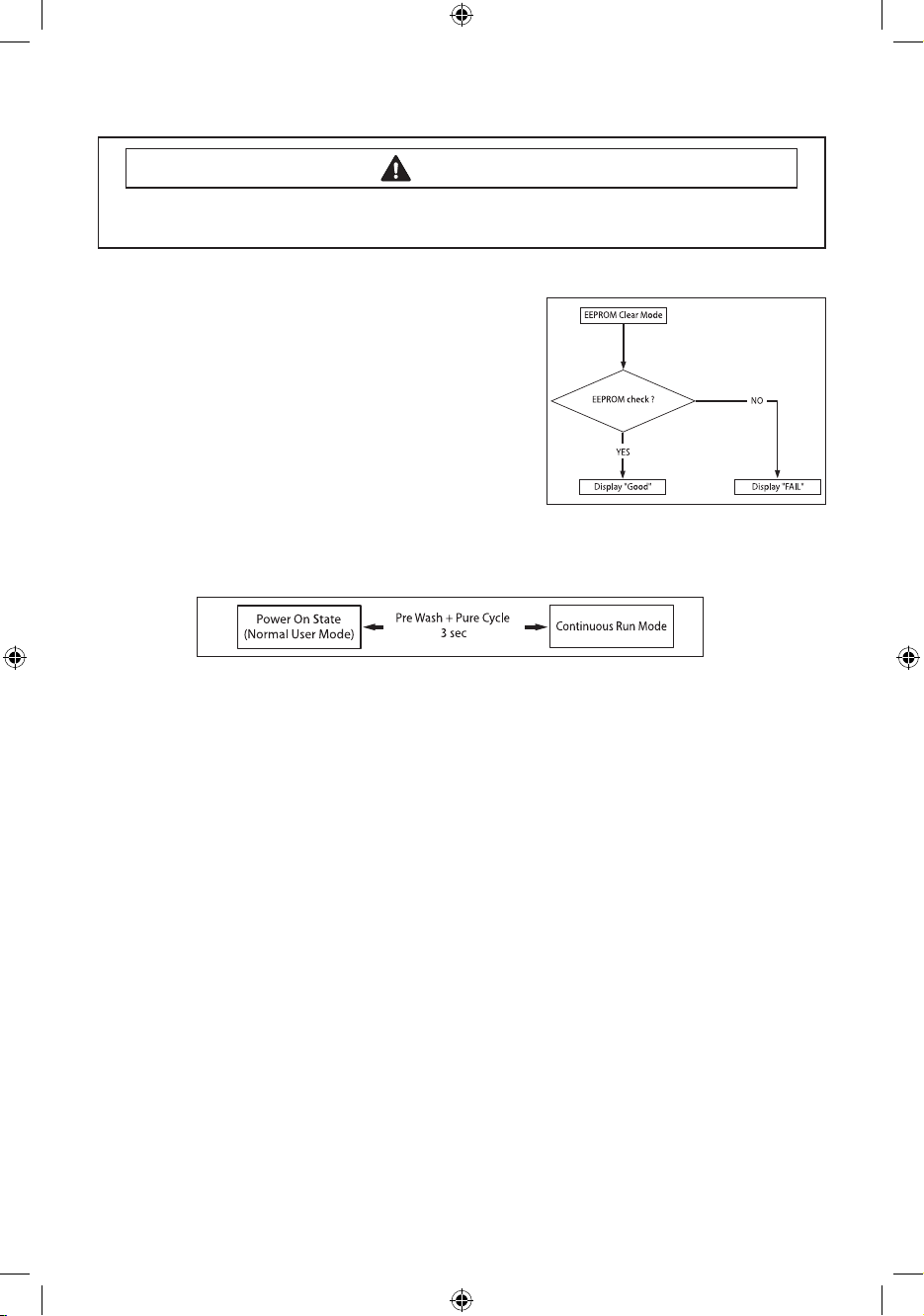

EEPROM Clear Check

Denition of EEPROM Clear Mode:

- EEPROM initialization.

- All course/option settings are to be reset to default values

after EEPROM initialization.

- When Service arises and it needs PCB replacement,

EEPROM should be reset.

How to Enter:

- The unit needs to be on.

-

Press Delay Start Key, Signal Key, and Power Key at the same time.

Continuous Run Mode

Denition of Continuous Run Mode:

- Will continuously repeat the current cycle until the Continuous Run Mode is cancelled.

How to Enter:

- Press Pre Wash Key and Pure Cycle Key together for 3 sec.

Continuous Run Mode:

1. Press

Pre Wash + Pure Cycle 3 sec

2.

Once in Continuous Run Mode, The seven segments will no longer display “0000” and will alternate

between displaying the number of cycles of the completed course and the remaining time of the course.

3. The Continuous Run Mode will repeat the previous cycle until continuous run mode is cancelled.

4.

During Continuous Run Mode, press Pre Wash + Pure Cycle 3 seconds to return to normal user

mode. The seven segments will no longer display the number of cycles and will display the

maintenance time only.

5. If you exit Service Mode after entering it from Continuous Mode, the washing machine returns

to Continuous Mode.

6. If power is lost in Continuous Run Mode (that is, when the power plug is disconnected or the

Power key is pressed turning the washing machine o), the mode is released when the washing

machine is turned on again.

during Power On State (Normal User Mode) .

6

Techsheet-WF350AN-02834A-03_EN.indd 6 2011-09-28 �� 4:00:30

Page 7

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

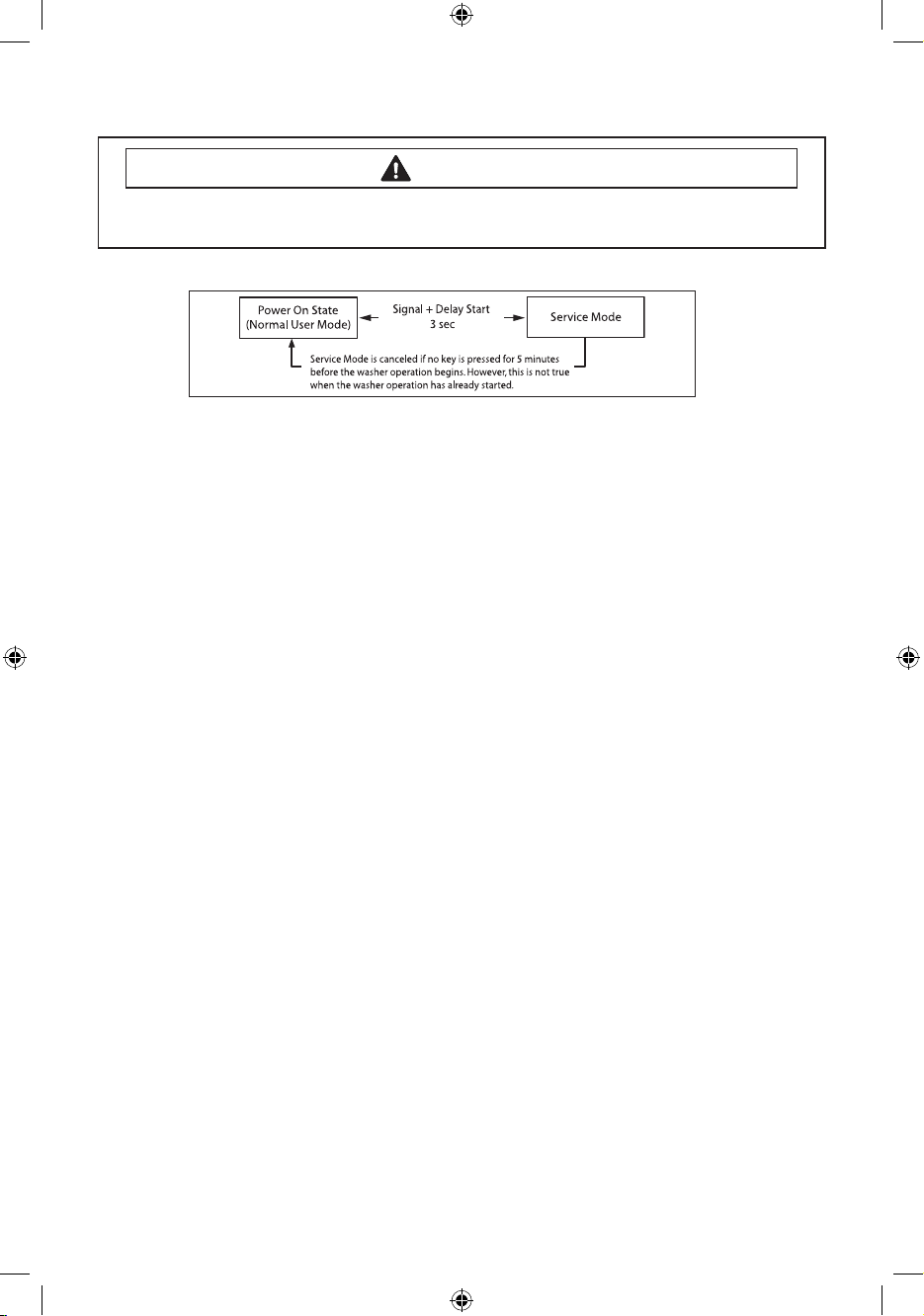

Service Mode

Denition of Service Mode:

- Service Mode enables service technicians to verify the operation of the washing machine and

do troubleshooting.

- Service Mode can be entered during all washing cycle without interrupting the cycle except

some of test modes.

- Various tests can be done with Service Mode. So, troubleshooting can be done based on the

resulting diagnostic codes.

How to Enter:

- To enter the Service Mode, press the Signal and Delay Start Keys for 3 seconds or until the unit

sends out beeping sounds.

Service Mode:

1. The washer must be on to go into the Service Mode.

2. The motor speed will be displayed when started (It displays 0 when the motor does not spin).

3. The present state of the machine will not be changed.

(i.e., the current cycle in progress will not be interrupted and only the display will change)

4. To exit Service Mode, press Signal and Delay Start Keys for 3 second again, or Power Key.If no key

is operated during Service Mode for 5 minutes, the machine will return to normal user mode.

7

Techsheet-WF350AN-02834A-03_EN.indd 7 2011-09-28 �� 4:00:30

Page 8

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

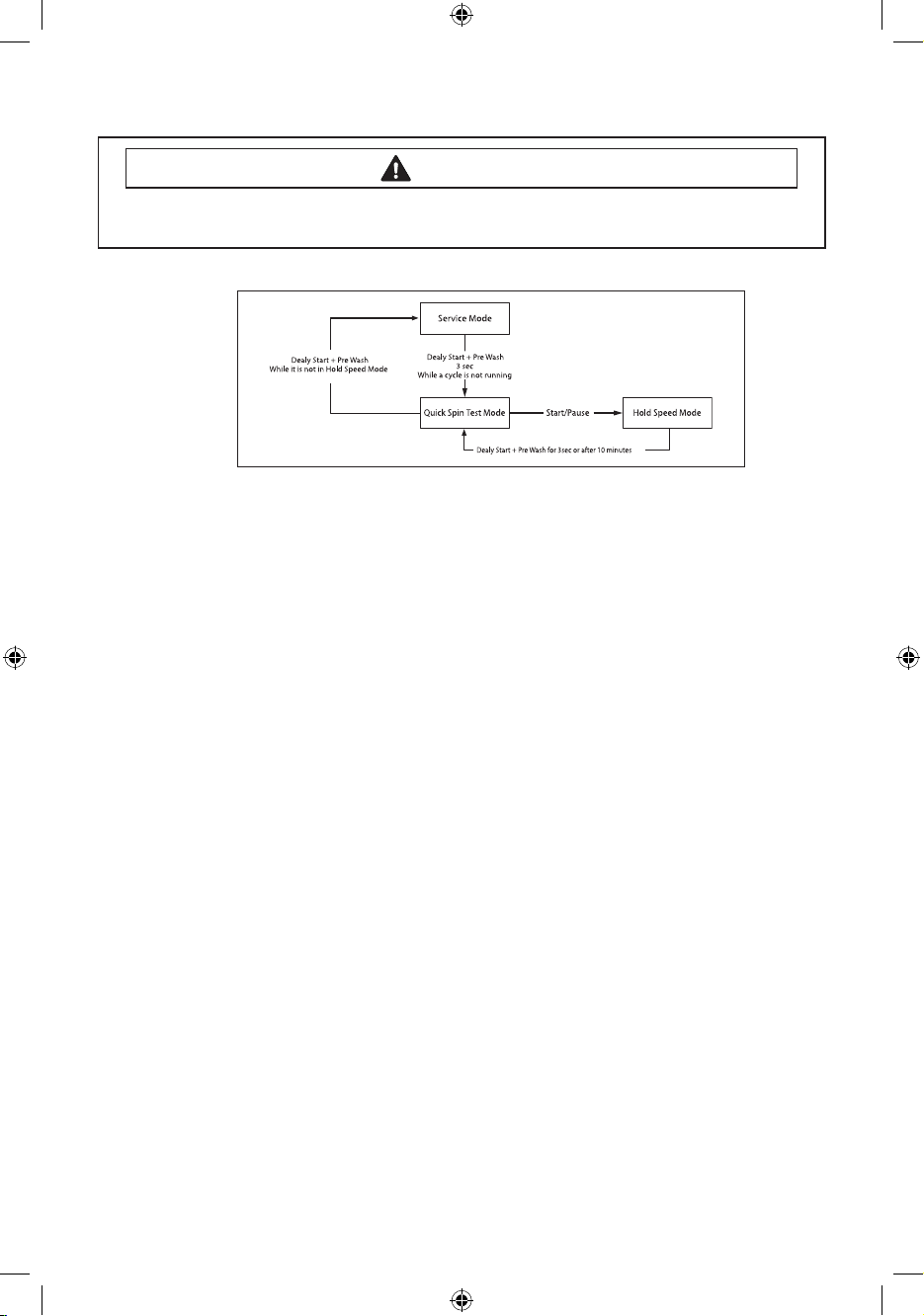

Quick Spin Test Mode

Denition of Quick Spin Test Mode:

- Quick Spin Test Mode is to do Spin Check. (High RPM)

How to Enter:

- During Service Mode, press the Dealy Start and Pre Wash Keys for 3 seconds to enter Quick Spin

Test Mode. (Same for all Frontier 2 models.)

- Cannot enter once the washing cycle has started.

Quick Spin Test Mode:

As it enters into the Quick Spin Test Mode, it starts spinning and reaches to its maximum RPM.

Once the Spin speed reaches the maximum RPM, the speed drops immediately.

To hold Quick Spin Test Mode (entering Hold Speed Mode), press the Start/Pause button. If the

Start/Pause button is pressed during Quick Spin Test Mode, it will stop accelerating and hold its

spinning speed for 10 minutes before going back to Quick Spin Test Mode.

Also, to cancel the hold and allow Quick Spin Test Mode to continue, press the Dealy Start and Pre

Wash Keys together for 3 seconds.

If you hold down the Dealy Start and Pre Wash keys for three (3) seconds when the washing

machine is not in Hold Speed Mode, Quick Spin Mode is exited and Service Mode is restored.

8

Techsheet-WF350AN-02834A-03_EN.indd 8 2011-09-28 �� 4:00:30

Page 9

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

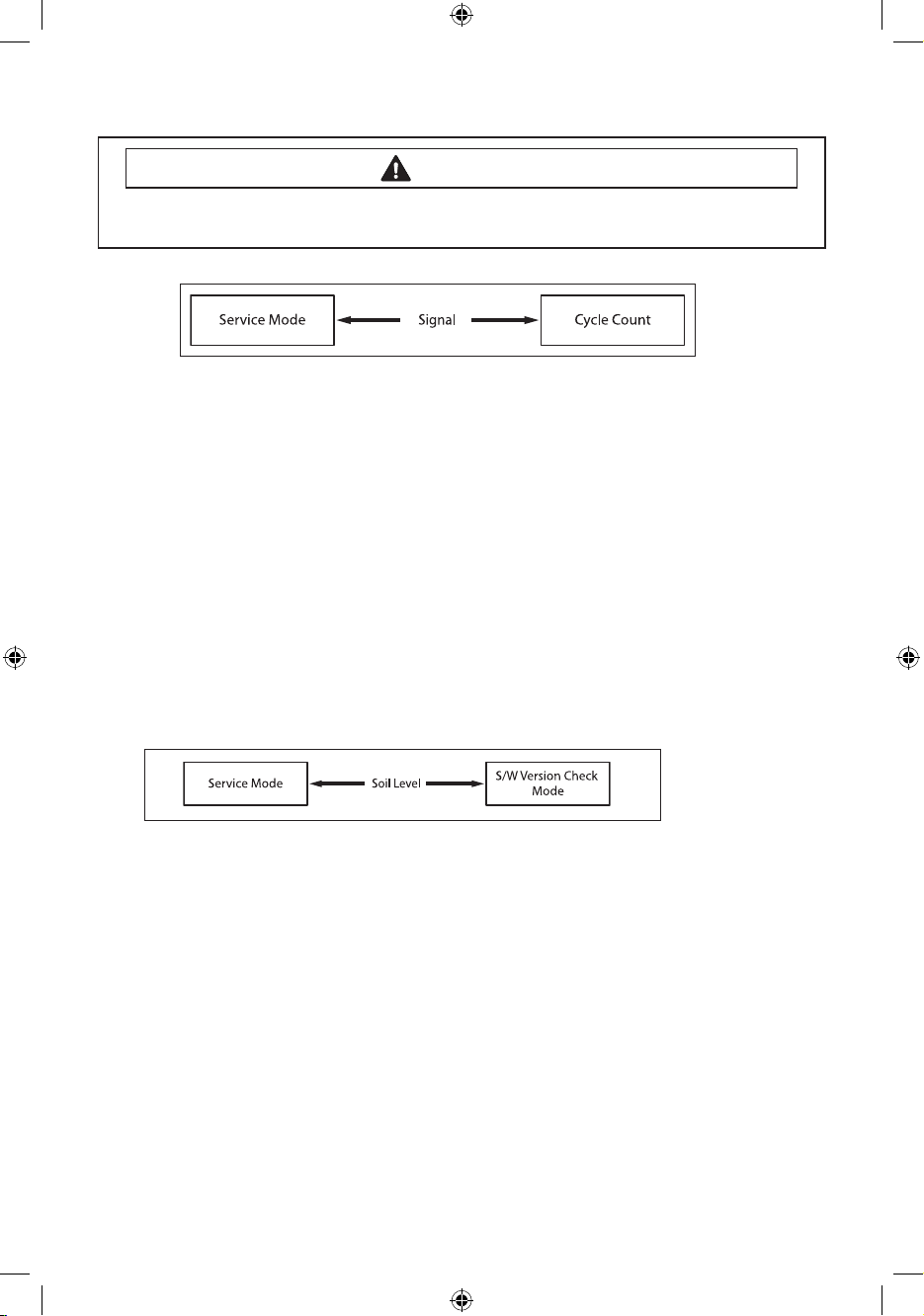

Cycle Count Check Mode

Denition of Cycle Count Check Mode:

- Cycle Count Check Mode is to tally up the number of washings.

How to Enter:

- To enter the Cycle Count Check Mode, press the Signal Key during Service Mode.

Cycle Count Check Mode:

1. Activate the Service Mode in advance.

2. When the Signal key is pressed, the total number of washings will light up and a signal LED will

glow.

3. The maximum number of cycles will be 9999.

The counter will roll over to 0 and start counting again after 9999.

4. The counting will be carried out at the end of the normal cycle.

(For normal and Continuous Run cycles, the count is carried out at the end of the cycles.

5. To exit the Cycle Count Check Mode, press the “Signal” key again.

S/W Version Check Mode

Denition of S/W Version Check Mode:

- S/W Version Check Mode is to bring up S/W Version information.

How to Enter:

- To enter the S/W Version Check Mode, press the Soil Level Key during Service Mode.

S/W Version Check Mode:

1. Activate the Service Mode in advance.

2. Press the Soil Level Key to bring up its software Version

EX) Generate AE49 at Version 49 (AE is Micom code, 49 is it’s software version)

3. To exit the S/W Version Check Mode, press the Soil Level S/W once again.

Then, it returns to the Service Mode with motor RPM illuminating.

9

Techsheet-WF350AN-02834A-03_EN.indd 9 2011-09-28 �� 4:00:31

Page 10

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

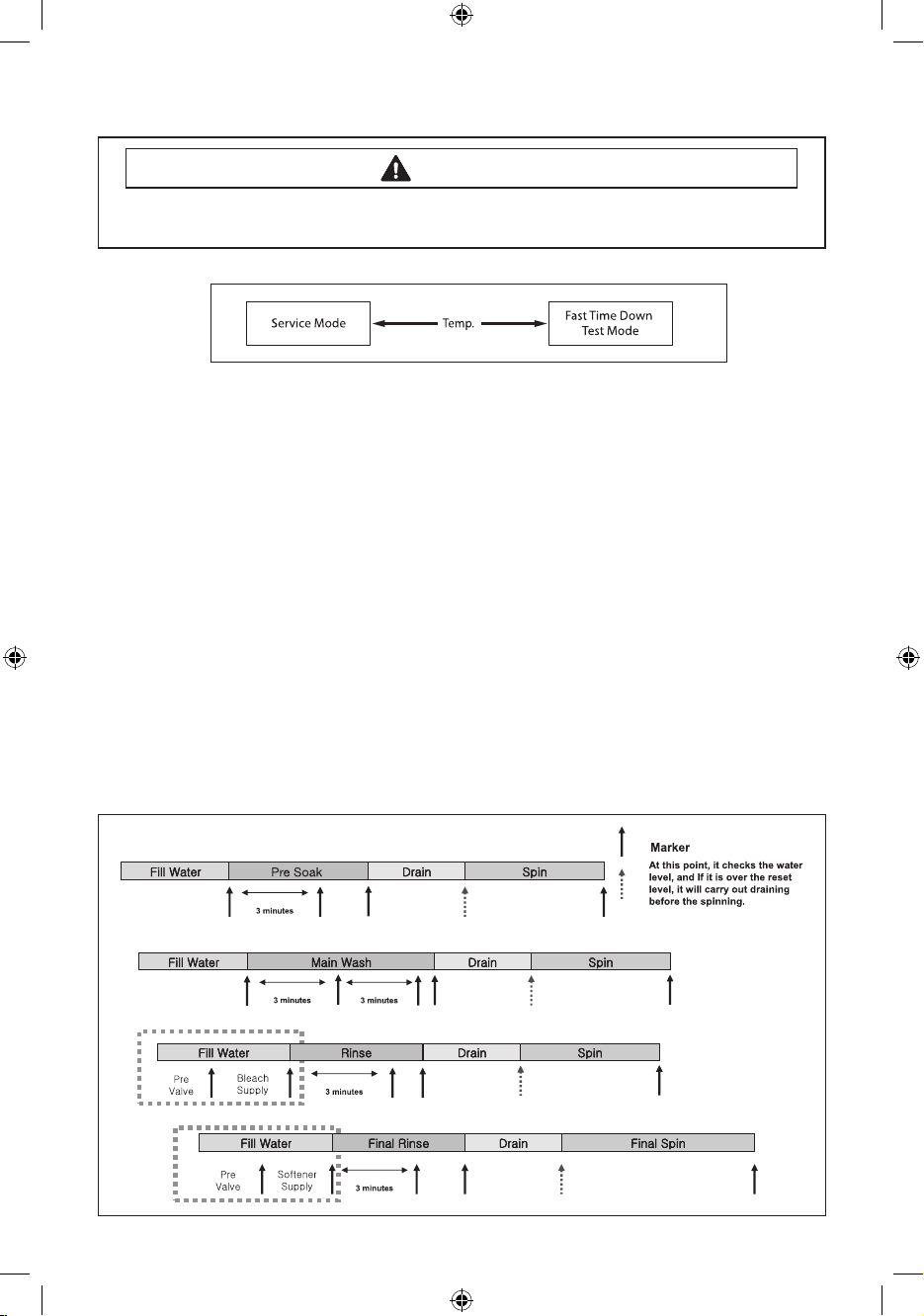

Fast Time Down Test Mode

Denition of Fast Time Down Test Mode:

- Fast Time Down Test Mode is to forward the program to the next cycle stage.

How to Enter:

- To enter the Fast Time Down Test Mode, press the Temp key during Service Mode.

Fast Time Down Test Mode:

1. Activate the Service Mode in advance.

2. To forward the program to the next cycle stage, press the Temp key.

Each stage is located at key points of a complete cycle as follows:

- End of Each Fill (Beginning of Wash or Rinse Tumble Session)

Caution: Check if the current water level is higher than the Reset water level and then perform

the Fast time down test.

- Beginning of Drain Session

- Beginning of Spin Session (Here, it checks the water level. So, if it is over the reset level, it carries

out draining before the spinning.)

- Beginning of Fill Session

- Beginning of Bleach Fill

- Beginning of Fabric Softener Fill

- Every 3 minutes during Wash and Rinse Tumble Session

10

Techsheet-WF350AN-02834A-03_EN.indd 10 2011-09-28 �� 4:00:31

Page 11

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

Board Input Test Mode

Denition of Board Input Test Mode:

- Board Input Test Mode is to displays a specied input after a key press.

How to Enter:

- To enter the Board Input Test Mode, press the Spin Key during Service Mode.

Board Input Test Mode:

1. Activate the Service Mode rst.

2. Press the Spin Key to start Board Input Test.

3. Turn the Jog-Dial so that the Pre Wash LED is turned on, and press the Start/Pause key. The Water

Temperature will be displayed in Celsius.

4. Turn the Jog-Dial so that the Extra Rinse(or Steam) LED is turned on, and press the Start/Pause

key. The Water Temperature will be displayed in Fahrenheit.

5. Turn the Jog-Dial so that the Cold/Cold LED is turned on, and press the Start/Pause key. The door

status will be displayed (OP if open, CL if closed).

6. Turn the Jog-Dial so that the No Spin LED is turned on, and press the Start/Pause key. The Door

Lock Switch status will be displayed (UL if unlocked, LO if locked).

7. Turn the Jog-Dial so that the Soil Level Light LED is turned on, and press the Start/Pause key. The

Water Frequency will be displayed.

8. Turn the Jog Dial so that the Signal O LED is turned on and press the Start/Pause button.

Within 3 seconds of pressing the button, the status of the Silver Nano kit is displayed.

1. Delayed: 0000

2. Normal: ---

3. Abnormal: ㅂE

11

Techsheet-WF350AN-02834A-03_EN.indd 11 2011-09-28 �� 4:00:31

Page 12

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

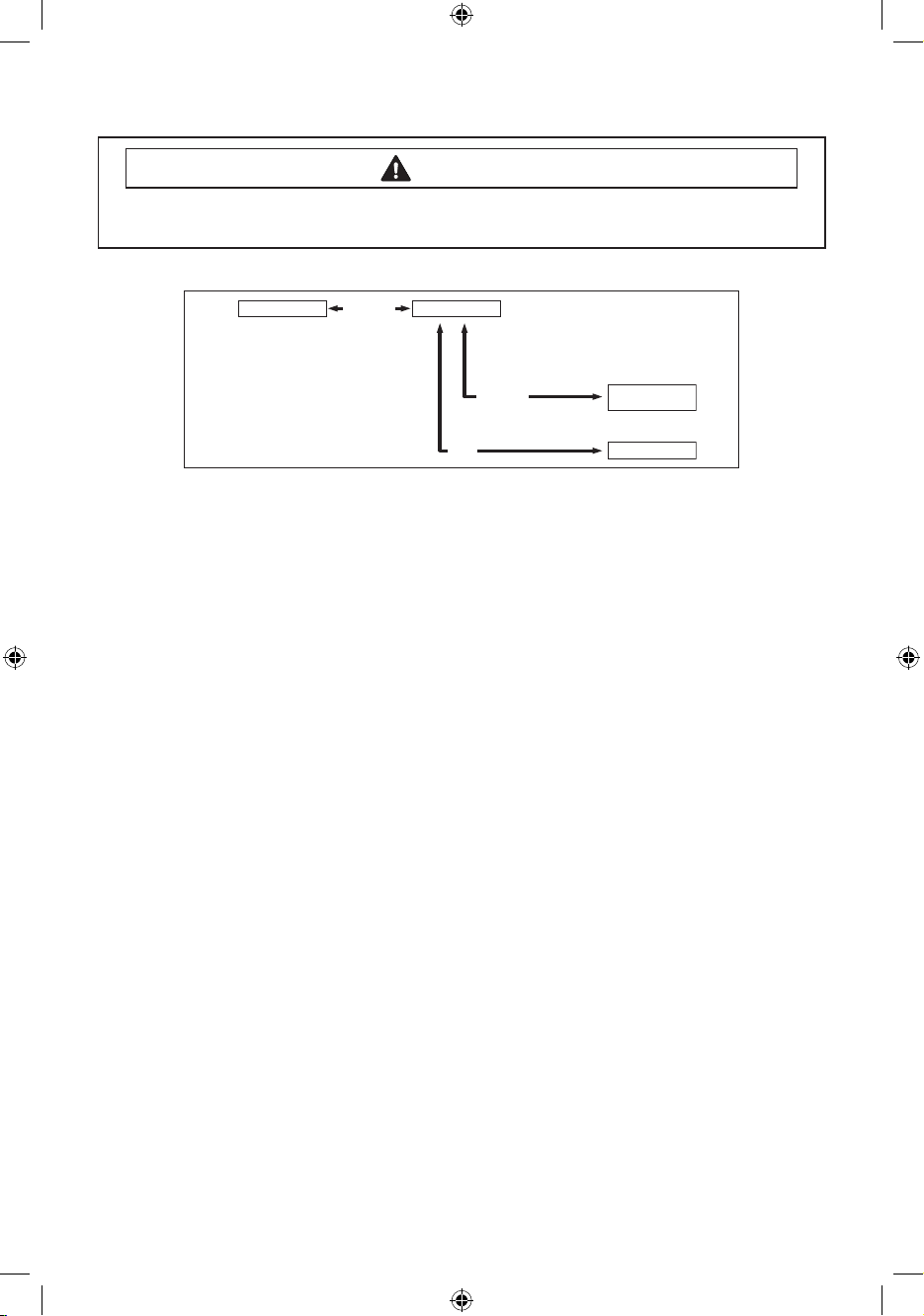

Diagnostic Code Check Mode

Service Mode

Pure Cycle

Diagnostic Code

Signal

Start/Pause

Pressing

Cycle No.

Before making Code

Cycle Count

Denition of Diagnostic Code Check Mode:

- Diagnostic Code Check Mode is to bring up the stored diagnostic codes (refere nce codes for

service technicians).

How to Enter:

- To enter the Diagnostic Code Check Mode with code “d” ashing, press the Pure Cycle key during

Service Mode.

Board Input Test Mode:

1. Activate the Service Mode rst.

2. Press the “Pure Cycle key” key to start Diagnostic Code Check Mode with Code “d” ashing.

3. To cycle through the diagnostic codes (d1,d2,d3~d9), turn the Rotary Cycle Selector in one

direction (either Clockwise or Counterclockwise).

4. Now, when turning the Rotary Selector Key in the same direction, it shows diagnostic codes

from the latest (d1).

5. When turning it in the opposite direction, it shows the diagnostic codes in the reverse order.

Ex) When it stops at d5 and turns backward, it shows from d4 down to “d”. Refer to Diagnostic

Code.

12

Techsheet-WF350AN-02834A-03_EN.indd 12 2011-09-28 �� 4:00:31

Page 13

ALIGNMENT AND ADJUSTMENTS

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

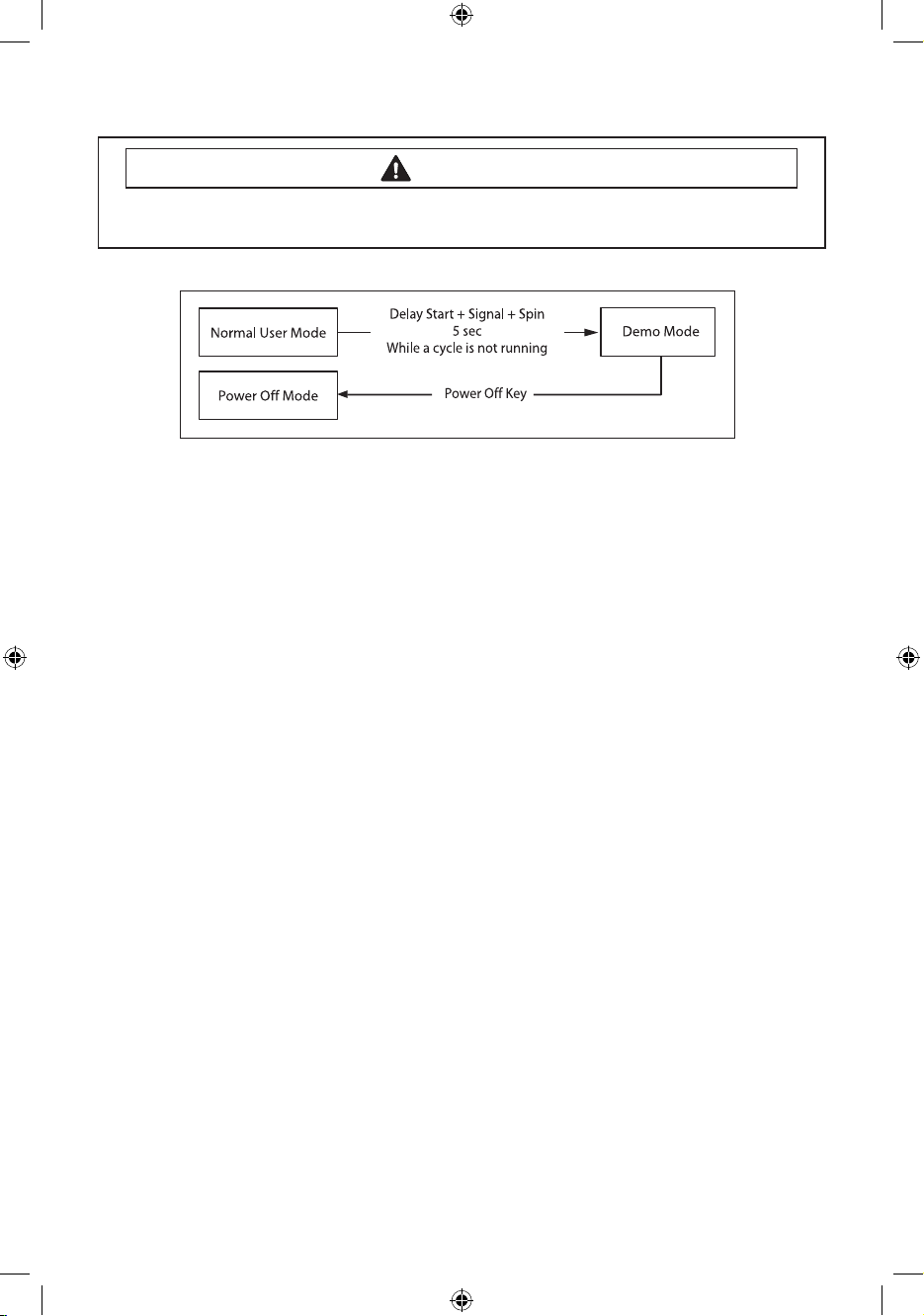

Demo Mode

- Demo mode is entered when the Delay Start + Signal + Spin buttons are held down for ve (5)

seconds simultaneously in the power on state.

- When entering Demo mode, the buzzer rings three (3) times and “- - - -” is displayed on the 7

segment display and all other LEDs are turned o. (Initial Demo mode)

- Demo mode consists of WASH, SPIN and LED modes.

- If the Temp button is pressed during the initial Demo mode, “WASH” blinks on the 7 segment

display and the washing machine enters WASH mode.

- If the Start/Pause button is pressed in WASH mode, the door is locked (Door Lock) and the motor

rotates left and right at 45 RPM in a 7 sec on and 3-sec o cycle.

- WASH mode continues up to ve (5) minutes once started. After the ve (5) minutes have

elapsed, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

- If the Start/Pause button is pressed during a WASH mode operation, “- - - -” is displayed on the 7

segment display and the initial Demo mode is maintained.

- If the Spin button is pressed in the initial Demo mode, “Spin” blinks on the 7 segment display

and the washing machine enters SPIN mode.

- If the Start/Pause button is pressed in the SPIN mode, the door is locked (Door Lock) and a spin

is operated at 1150 RPM. When the speed reaches 0 RPM, the No Spin, Low, Medium, High, and

Extra High LEDs are turned on.

- During a spin operation, the No Spin LED turns on when the speed is lower than 400 RPM. The

Low LED turns on between 400 RPM and 800 RPM. The Medium LED turns on between 800 RPM

and 1000 RPM. The High LED turns on at higher than 1000 RPM.

- SPIN mode continues up to four (4) minutes once started. After the four (4) minutes have

elapsed, “- - - -” is displayed on the 7 segment display and the initial Demo mode is maintained.

- If the Start/Pause button is pressed during a SPIN mode operation, “- - - -” is displayed on the 7

segment display and the initial Demo mode is maintained.

- If the Pure Cycle button is pressed during the initial Demo mode, “LED” is displayed on the 7

segment display and the washing machine enters LED mode.

- If the Start/Pause button is pressed in LED mode, all LEDs are turned on. The LED mode

continues up to thirty (30) seconds once started. After the thirty (30) seconds have elapsed, “- - -

-” is displayed on the 7 segment display and the initial Demo mode is entered.

- If the Start/Pause button is pressed during an LED mode operation, “- - - -” is displayed on the 7

segment display and the initial Demo mode is entered.

13

Techsheet-WF350AN-02834A-03_EN.indd 13 2011-09-28 �� 4:00:32

Page 14

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

- As the micom wash machine is congured of the complicate structure, there might be the

service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

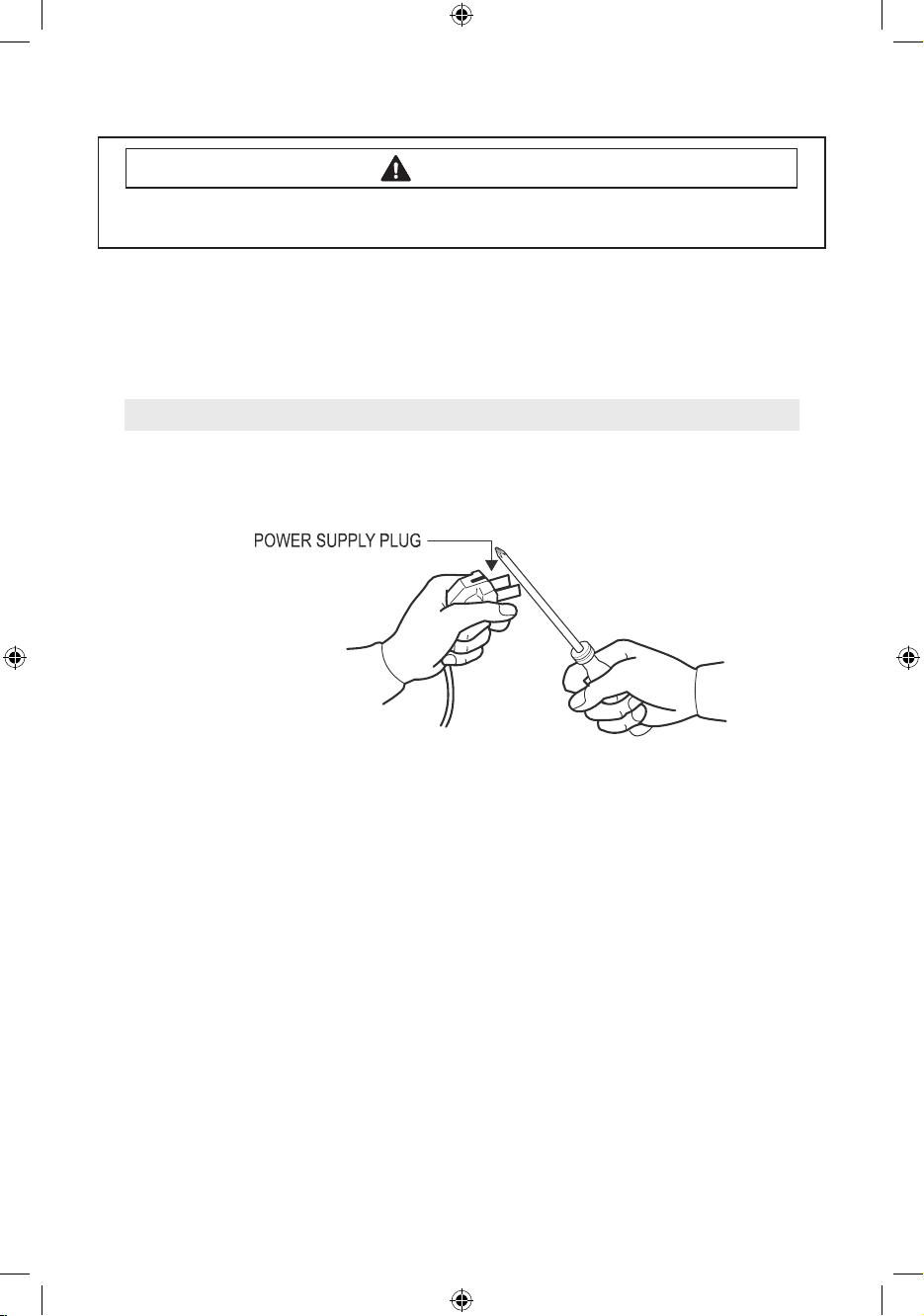

1) As some electronic components are damaged by the charged static electricity from the resin

part of machine or the human body, prepare the human body earth or remove the potential

dierence of the human body and machine by contacting the power supply plug when the

work contacting to PCB is executed.

2) Since AC120V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by touching

and be careful that the strong and weak electricity are mixed.

3) As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong

diagnosis and follow the procedure of the trouble diagnosis when the micom is not operated

normally.

14

Techsheet-WF350AN-02834A-03_EN.indd 14 2011-09-28 �� 4:00:32

Page 15

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Will Not Start

• Plug the unit into the wall outlet. Check for proper voltage.

• Check fuse or reset circuit breaker.

• Push any key to turn on the washer and press the Start/Pause key to run the washer.

• Close door and push the Start/Pause key to run the washer.

• Check if washer is in a pause, soak or suds process. Wait briey and it may start. (If the washer is in suds

period, Suds will light up instead of remaining time.)

• Check for restricted drain system. (If there is electrical problem in drain system, “nd” error will occur after 15

minutes.)

• Check Water Supply.

• Check the line or water valve screen lter.

• Check if PCB connectors are assembled properly.

• Check if CN2 terminals on PCB are in good condition. (Refer to PCB Connector Check.)

• Replace PCB.

Leaking

• Make sure inlet hose connections are not leaking. Check for rubber gasket damage due to over tightening.

• Check standpipe for leak. Wrap a dry rag around the standpipe opening.

If rag becomes wet, leak is fault of home plumbing.

Be sure the standpipe is capable of accepting the ow of water from the washer.

• Make sure end of drain hose is correctly inserted and secured to drain standpipe.

• Check internal hose connections (ll, drain systems, dispenser hoses & clamps).

• Check rubber boot. Remove, reposition and reinstall, if necessary.

• Check for possible kinked dispenser to outer tub hose. Hot water pressurization may force door open.

No Tumble

• Start normal cycle with an empty machine and allow a ll to check tumble.

• Perform Quick Spin Test. (Before test, make sure that the tumbler is empty.)

• Check for loose connections at Machine Control Board, Pressure Switch, Motor, Tach Harness and Motor

Control. (Refer to the component testing procedure)

• Check motor windings resistance.

CN5 pins 1 & 3 = 11.6ohms ±7%,

Pins 1 & 2 = 11.6ohms ±7%,

Pins 2 & 3 = 11.6 ohms ±7%

• Faulty Main Control Board.

• Faulty motor.

Will Not Spin

• Make sure to close the door completely.

• Check for water left inside the washer. If so, go to “Will Not Drain”.

• Perform Quick Test Mode or Quick Spin Test. Does the washer spin? (Before the test, empty the unit inside.)

If it doesn’t tumble after the above, change PCB. When the problem persists, change the motor.

• Perform Quick Test Mode or Quick Spin Test. Does the washer spin? If it does, Check Possible unbalanced

load scenario in normal mode.

• Check for loose connections at PCB, Water Level Sensor, Motor, Hall Sensor Wire Harness. (CN7,CN5,CN6)

(Refer to the Component Testing Procedure.)

• Check motor windings resistance. (CN5 Pin1&3 = 11.6 ohms (at ±7% 20°C/68°F),

Pin1&2 = 11.6ohms (at ±7% 20°C),

Pin2&3 = 11.6 ohms (at ±7% 20°C))

15

Techsheet-WF350AN-02834A-03_EN.indd 15 2011-09-28 �� 4:00:32

Page 16

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

No Water Fill

• Perform Quick Test Mode. Check all of Water Valves visually.

(Pre Wash Valve, Cold Water Valve, Bleach Water Valve, Softener dispenses using Cold & Bleach Water Valve,

and Hot Water Valve.)

• Check if water taps are turned on fully.

• Check Water Valves and Water Level Sensor (Refer to PCB Connector Check)

• Check if there is any kink in inlet hoses.

• Check if inlet screens are clogged up.

• Check if water has enough pressure. If so, nd out its contributors.

• Check if there is any frozen area in the unit (Drain Hose, etc)

• Measure the resistance of Water Valve Coil.

(It should read 1.18K ohms. Check Pin#1 of CN2 and PIN#1,2,7,8,9 of CN3)

• Check Pressure S/W and PCB for loose connections. (Refer to PCB Connector Check.)

Tub Full of Suds

• Go to “Will Not Drain” and “Will Not Spin” and check the draining.

• Check PCB and Drain Pump for any loose wire connection.

• Perform Quick Test Mode or Board Output Test to drain.

• Use HE (High-Eciency) or low sudsing detergent specially formulated for front load washers.

• Reduce the amount of detergent for that specic load size and soil level. Keep in mind that towel creates

more suds generally.

• Reduce the amount of detergent when water is soft, or laundry is small or lightly soiled.

• Do one more washing cycle with cold water and a table spoon of salt without detergent.

16

Techsheet-WF350AN-02834A-03_EN.indd 16 2011-09-28 �� 4:00:32

Page 17

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Wet Clothes

• Unbalance due to not enough load. Put additional load.

•

Due to excessive suds by using general detergent. Use HE (High-Eciency) or reduce its quantity.

• Low Spin Speed or Drain Only was selected.

• Go to “ Will Not Spin”.

Will Not Lock

• Door is not aligned or closed properly.

• Perform Quick Test Mode. Check Door Lock.

Check the output voltage of Door Lock Coil.

If it reads 120V, change Door Lock Switch, and if not, change PCB. (Refer to PCB Connector Check.)

• Read Lock Switch and PCB (CN3). (Refer to PCB Connector Check.)

• Try Door Lock and check for 120V to Door Lock Connector. If 120V present, change Main Control Board and

if not, change Door Lock switch.

Will Not Unlock

• Check if the door is being pushed out, which may keep it from unlocking.

• Door locks itself when the water level is too high. Opening door will result in water draining from door

opening.

• Check the following with Board Input Test Mode.

Water Level (frequency): Over 23.80 KHz.

If so, refer to “Will Not Drain”.

Temperature (Inside Drum): Higher than 60ºC/140ºF.

If so, wait until it drops.

When everything is normal, check PCB connectors and Door Lock Switch.

• Drain manually after removing the plastic drain hose holder.

• Display shows “LO”. Turn o and on the unit. If “LO” keeps illuminating, check PCB and Door Lock Switch.

17

Techsheet-WF350AN-02834A-03_EN.indd 17 2011-09-28 �� 4:00:32

Page 18

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

• Read Lock Switch and PCB (CN2 & CN3). (Refer to PCB Connector Check.)

• Perform Quick Test Mode. Check Door Lock. Check the output voltage of Door Lock Coil.

If it reads 120V, change Door Lock Switch, and if not, change PCB. (Refer to PCB Connector Check.)

No Key Operation

• Option and Function buttons respond dierently according to each cycle.

• Child Lock is being activated. To exit, hold down Soil Level Key and Signal Key simultaneously until it sends

out a beeping sound.

• When “End“ illuminates on the display, only Power button works. Press Power button and make new cycle

selections.

Will Not Drain

• Check for any kink on the drain hose. If any, straight it out.

• Check for any restriction in the drain hose.

• Close the door and press the Start/Pause Button. For safety reasons, the washer does not tumble or spin with

the door open.

• When it is freezing outside, check if it is frozen inside the drain hose.

• Check if the water level signal input is correct. Go to Board Input Test Mode.

• Go to Quick Test Mode and do Drain Pump Test.

• Check if there is any twist in the hose (the one between Tub and Drain Pump).

• Check if it reads AC 120V at the pump when a spin cycle is selected.

• Read the winding resistance of the pump motor. (14.2±7% Ohms)

• Check the pump at CN3(PIN3) on PCB. It should read AC 110~120V. (Refer to PCB Connector Check)

18

Techsheet-WF350AN-02834A-03_EN.indd 18 2011-09-28 �� 4:00:32

Page 19

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

Wrong Water Temperature

• Check if both of the water taps are fully open.

• Make sure the domestic water heater is set to deliver water lower than 120°F (49°C) hot water at the tap.

Also check water heater capacity and recovery rate.

• If the water heater is located far from the washer, screw out the hot water tap and let its water pass until you

get hot water.

• Too Hot/Too Cold: Reduced amount of water is supplied while PCB controls the inux to regulate the actual

temperature of the water in the tub. This may appear to be signicantly hotter/colder than expected.

• Check if the temperature selection is correct.

• Disconnect inlet hoses from the Water Valve and remove any residue in the inlet screens.

Noisy and/or Vibration/Walking

• Check if the washer is leveled and the lock nuts are tightened up on the bottom plate.

• Check if all of the shipping bolts and spacers are removed from the back panel.

•

Check if load is big enough and there is no unbalance.If there is not enough load, put in a few towels to balance it.

• Check if the motor is fastened enough.

• Remove various trouble contributors (such as dust coat on the oor).

Rubber Feet Leaving Marks on Floor

• Use a pencil eraser to remove mark.

• Walk washer into location, do not drag.

Additive Cups Full of Water

• Small amount of water in bottom of additive cups is normal.

• Remove and wash Dispenser Tray, removable Cup, and Rinse Cap.

• Level washer.

Buttons do not Respond

• Option and Function buttons respond dierently according to each cycle.

• Child Lock feature has been selected. To disable feature press and hold Temp and Spin simultaneously until a

beep is heard.

• When display shows “End”, only the Power button will function. Press Power and make new cycle selections.

19

Techsheet-WF350AN-02834A-03_EN.indd 19 2011-09-28 �� 4:00:32

Page 20

TROUBLE SHOOTING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

PROBLEM CHECKING AND METHOD OF PCB

- If you plug in the power cord and turn Power S/W on, memorized data is displayed.

If any data is not displayed, check the followings.

Thermistor Check

Check Voltage at Pin #4 and #5 of CN7

Tester Check = DC 2.5V

If it reads 5V, Check if its connector is engaged

properly

Door Switch Check

Check Voltage at Pin #1 and #3 of CN4

When Door Open = DC 25V

When Door Close = DC 0V

Water Sensor Check

Check Voltage and Frequency at Pin #5 and #6

of CN7

Reset water level = DC2.5V, 25.8KHz

Check Voltage and Frequency at Pin #5 and #7

of CN7

Reset water level = DC2.5V, 25.8KHz

Hall Sensor Check

Check Voltage at Pin #4 and #2 of CN6

Tester Check = DC 0V or 3.75V

Check Voltage at Pin #4 and #3 of CN6

Tester Check = DC 0V or 3.75V

Motor Check

Resistance at Pin #1 and #2 of CN5 = 12Ω

Resistance at Pin #1 and #3 of CN5 = 12Ω

Resistance at Pin #2 and #3 of CN5 = 12Ω

Door Lock Check

Check Voltage at Pin #3 of CN2 and Pin #1 of CN3

When Door Lock = AC 120V

Door Unlock Check

Check Voltage at Pin #3 of CN2 and Pin #2 of

CN3

When Door Unlock = AC 120V

Drain Motor Check

Check Voltage at Pin #3 of CN2 and Pin #3 of

CN3

When Drain Motor operates = AC 120V

Water Valve Check

Check Voltage at Pin #3 of CN2 and Pin

#1,2,7,8,9 of CN3

When each valve operates = AC 120V

AC Power Check

Check Voltage at Pin #1 and #2 of CN2

Tester Check = AC 120V

Wash Heater Relay Check

Check Voltage at Pin #3 of CN2 and PIN #2 of

RY3

When Heater Relay operates = AC 120V

Steam Heater Relay Check(Only Steam Models)

Check Voltage at Pin #3 of CN2 and PIN #2 of

RY4

When Heater Relay operates = AC 120V

20

Techsheet-WF350AN-02834A-03_EN.indd 20 2011-09-28 �� 4:00:33

Page 21

WIRING DIAGRAM

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

21

Techsheet-WF350AN-02834A-03_EN.indd 21 2011-09-28 �� 4:00:33

Page 22

WATER FLOW DIAGRAM

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer

before servicing, unless testing requires power.

22

Techsheet-WF350AN-02834A-03_EN.indd 22 2011-09-28 �� 4:00:33

Page 23

MEMO

Techsheet-WF350AN-02834A-03_EN.indd 23 2011-09-28 �� 4:00:33

Page 24

Techsheet-WF350AN-02834A-03_EN.indd 24 2011-09-28 �� 4:00:33

Page 25

LAVE-LINGE

Informations techniques

• En raison des risques de blessure ou de dommages matériels existants, demandez toujours à un

technicien qualié d'eectuer les opérations d'entretien ou de réparation de l'appareil.

• Reportez-vous au manuel de réparation pour connaître les consignes d'installation, d'utilisation,

de test, de dépannage et de démontage détaillées.

ATTENTION

Toutes les consignes de sécurité gurant dans le manuel de réparation doivent être respectées.

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Code n°: DC68-02834A-03_CFR

1

Techsheet-WF350AN-02834A-03_CFR.indd 1 2011-09-28 �� 3:52:25

Page 26

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

PROBLÈMES PRINCIPAUX

Code

N°

d'erreur

1 nd 1

2 LO 2

3 nF 3

4 FL 4

5 LE 8

6 LE 8

7 OE E

8 dc 10

9 E2 15

10 dL 18

Achage

du code de

diagnostic

Description Action corrective

Le niveau d'eau ne descend pas sous le

niveau d'eau de réinitialisation dans les

15minutes.

Le hublot ne se déverrouille pas après

sept tentatives.

Le remplissage se poursuit pendant

plus de 40minutes ou le niveau d'eau

ne change pas pendant 6minutes.

Le hublot ne se verrouille pas après

sept tentatives.

Un niveau d'eau inférieur au niveau

d'eau de réinitialisation (25,6Khz) est

détecté durant 5secondes pendant le

cycle de lavage/rinçage.

Problème au niveau du capteur

de niveau d'eau. (Lorsque le signal

d'entrée émis par le capteur de niveau

d'eau se situe en dehors de la plage,

l'appareil émet des signaux sonores et

le programme s'interrompt.)

Une erreur a été détectée sur

le capteur de niveau d'eau. Les

données (fréquence) indiquent que

le niveau d'eau atteint ou dépasse

le niveau de trop-plein. (Lorsque cet

état est détecté, la machine lance

automatiquement un cycle de vidange

jusqu'à ce que le niveau d'eau passe

sous le niveau de trop-plein.)

Un déséquilibre ou un choc au niveau

du châssis est détecté pendant

l'essorage nal, ce qui empêche

le tambour de tourner à plus de

150tr/min. (Jamais d'essorage à

plus de 150tr/min en cas de charge

déséquilibrée)

Bouton bloqué. (L'activation des

signaux d'entrée de bouton pendant

plus de 30secondes est considéré

comme un blocage.)

Le hublot est détecté comme étant

ouvert alors que le moteur tourne.

Consultez la section Dépannage «Pas

de vidange».

Consultez la section Dépannage «Le

hublot ne se déverrouille pas».

Consultez la section Dépannage «Pas

de remplissage».

Consultez la section Dépannage «Le

hublot de se déverrouille pas».

Consultez la section Dépannage «Pas

de remplissage».

Consultez la section Dépannage

«Pas de remplissage».

Vériez tout d'abord que les vannes ne

sont pas grippées. Si elles ne le sont

pas, vériez le capteur de niveau d'eau.

Consultez la section Dépannage

«L'essorage n'a pas fonctionné».

Vériez tous les boutons. Si UN SEUL

bouton est considéré par l'appareil

comme étant enclenché, aucun autre

bouton ne répond.

Vériez que les câbles sont bien

connectés. Consultez la section «Mode

de test rapide», puis eectuez un test

de verrouillage/déverrouillage du

hublot et un test du moteur.

2

Techsheet-WF350AN-02834A-03_CFR.indd 2 2011-09-28 �� 3:52:25

Page 27

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

code

N°

d'erreur

11 ds 22

12 tE 29

13

14

15

16

17 2E -

3E 2E

Sr 34

Hr 36

nF1 5

Achage

du code de

diagnostic

Description Action corrective

Le hublot est détecté comme étant

ouvert alors que le système tente de le

verrouiller.

Température ou valeur de la résistance

anormalement haute/basse (capteur

thermique ou carte de circuit imprimé).

Le MICOM essaie d'entraîner le moteur

mais n'obtient aucun signal de réponse

de la part du capteur à eet Hall. Un

contrôle visuel conrme que le moteur

ne fonctionne pas. (Verrouillage,

Capteur à eet Hall défectueux ou

Surcharge)

Échec du relais du système (relais

principal). (La carte de circuit imprimé

ne détecte pas le fonctionnement en

relais quand il le faudrait.)

Échec du relais de la résistance (pas

de signal de contrôle du relais de la

résistance)

Le tuyau d'eau chaude/d'eau froide n'a

pas été raccordé correctement.

La tension du jeu de barres de la

commande du moteur est supérieure

ou inférieure à la limite spéciée.

Consultez la section «Mode de test

rapide», puis eectuez un test de

verrouillage/déverrouillage du hublot.

Consultez la section «Test des entrées

au niveau de la carte» et vériez la

température de l'eau. Vériez que les

câbles sont bien connectés et qu'ils ne

sont pas pincés. Remplacez la carte de

circuit imprimé ou la thermistance.

Vériez que le faisceau électrique n'est

pas desserré ou débranché. Consultez

la section «Mode de test rapide» et

eectuez un test du moteur.

Remplacez la carte de circuit imprimé.

Remplacez la carte de circuit imprimé.

Veuillez procéder au raccordement

correct du tuyau.

Remplacez la carte de circuit imprimé.

18 7E -

19 suds -

20 AE

SF1, SF2,

21

SF3

Échec du kit Silver Care (carte de circuit

imprimé).

La présence de mousse est détectée

pendant le cycle de lavage. («SUdS»

n'est pas une erreur. Si le lave-linge se

trouve dans une phase de lessivage, le

message «SUdS» s'ache au lieu du

temps restant.)

-

-

Erreur de communication entre la carte

de circuit imprimé secondaire et la

carte de circuit imprimé principale

Erreur système Remplacez la carte de circuit imprimé.

Vériez la carte de circuit imprimé, la

carte de circuit imprimé principale et le

faisceau électrique.

Conseillez à l'utilisateur de réduire la

quantité de lessive.

Vériez la carte de circuit imprimé

principale, la carte de circuit imprimé

secondaire et le faisceau électrique.

Remplacez la carte de circuit imprimé

3

Techsheet-WF350AN-02834A-03_CFR.indd 3 2011-09-28 �� 3:52:25

Page 28

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

MODE DE TEST

Quick Test Mode

EEPROM Clear

Mode

Continuous Cycle

Mode

Service Mode

Demo Mode

Quick Spin Test Mode

Cycle Count Check Mode

S/W Version Check Mode

Fast Time Down Test Mode

Board Input Test Mode

Diagnostic Code

CheckMode

Special Test Mode

Power Off State

Power On State

(Normal User Mode)

Mode de test rapide

Dénition du mode de test rapide:

- Vérier le bon fonctionnement de toutes les DEL (Contrôler les DEL défectueuses).

- Vérier le modèle et la version du logiciel.

- Vérier les diérents modes de fonctionnement (ex.: vanne d'eau, moteur, hublot, pompe de

vidange, etc.).

Pour sélectionner ce mode:

- Branchez l'appareil.

- Appuyez simultanément sur les boutons Degré de salissure, Signal et Mise en marche.

Important: Une fois le mode de test réalisé, toutes les données, y compris le code de diagnostic,

enregistrées dans le circuit EEPROM seront eacées.

Mode de test:

Chaque mode de test concernant le Squall est

décrit dans les pages suivantes. Les modes de

test indiqués par les èches rouges sont des

modes qui, pour des raisons de sécurité, ne

sont plus accessibles une fois le cycle de lavage

commencé.

4

Techsheet-WF350AN-02834A-03_CFR.indd 4 2011-09-28 �� 3:52:25

Page 29

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de test rapide:

1. Toutes les DEL s'allument et un signal sonore retentit lors de

l'entrée en mode de test rapide (y compris l'écran).

2. La version du logiciel s'ache pendant une seconde et le

circuit EEprom s'eace. (ex.: si la version du logiciel est 49,

l'écran ache E149)

3. Lorsque la version s'ache, tournez la molette de sélection

pour la faire disparaître. Appuyez sur les boutons suivants

pour vérier les diérents composants.

- Bouton Température: Test de la vanne d'arrivée d'eau

- Bouton Essorage: Test de verrouillage/déverrouillage du

hublot

- Bouton Degré de salissure: Test du chaue-eau et de la

résistance vapeur (modèles vapeur)

Test de l'eau (modèles sans vapeur)

- touche Signal Test de la pompe de vidange

(S/W Version Disappeared)

All Devices Test using keys

Temp Key Soil Key Signal KeySpin Key

Quick Test Mode

All LEDs On for 1 sec

(include 7-Segment)

S/W version display

(7-Segment)

Turn the Jog-Dial

5

Techsheet-WF350AN-02834A-03_CFR.indd 5 2011-09-28 �� 3:52:25

Page 30

ALIGNEMENTS ET RÉGLAGES

EEPROM Clear Mode

EEPROM check ?

Display "FAIL"Display "Good"

NO

YES

Pre Wash + Pure Cycle

3 sec

Power On State

(Normal User Mode)

Continuous Run Mode

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Vérication de l'eacement du circuit EEPROM

Dénition du mode d'eacement du circuit EEPROM:

- initialisation du circuit EEPROM.

- Les valeurs par défaut de tous les paramètres de

programme/d'option doivent être rétablies après

l'initialisation du circuit EEPROM.

- Lorsque le message Réparation apparaît et que le

remplacement de la carte de circuit imprimé est

nécessaire, le circuit EEPROM doit être réinitialisé.

Pour sélectionner ce mode:

- L'appareil doit être sous tension.

-

Appuyez simultanément sur le bouton Départ diéré, le bouton Signal et le bouton Mise en marche.

Mode de fonctionnement en continu

Dénition du mode de fonctionnement en continu:

- permet de répéter le cycle en cours jusqu'à l'annulation du mode.

Pour sélectionner ce mode:

- Appuyez simultanément sur les boutons Prélavage et Pure Cycle pendant 3secondes.

Mode de fonctionnement en continu:

1. Appuyez sur les boutons

Prélavage

et Pure Cycle pendant 3secondes avec l'appareil sous

tension (mode d'utilisation normale).

2.

Une fois en mode de fonctionnement en continu, l'écran n'ache plus «0000» et alterne entre

l'achage du nombre de cycle du programme eectué et le temps restant du programme.

3. Le mode de fonctionnement en continu répète le cycle précédent jusqu'à l'annulation du mode.

4.

En mode de fonctionnement en continu, appuyez simultanément sur les boutons Prélavage et

Pure Cycle pendant 3secondes pour revenir au mode d'utilisation normale. L'écran n'ache plus le

nombre de cycles et ache uniquement la durée de maintenance.

5. Si vous êtes passé en mode de réparation à partir du mode de fonctionnement en continu,

l'appareil revient en mode de fonctionnement en continu lorsque vous sortez du mode de

réparation.

6. Si l'alimentation est coupée alors que l'appareil se trouvait en mode de fonctionnement en

continu (c'est-à-dire, si la prise d'alimentation est débranchée ou si l'appareil est mis hors

tension via le bouton de mise en marche), ce mode ne sera plus activé lors de la remise en

marche du lave-linge.

6

Techsheet-WF350AN-02834A-03_CFR.indd 6 2011-09-28 �� 3:52:26

Page 31

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de réparation

Power On State

(Normal User Mode)

Service Mode is canceled if no key is pressed for 5 minutes

before the washer operation begins. However, this is not true

when the washer operation has already started.

Signal + Delay Start

3 sec

Service Mode

Dénition du mode de réparation:

- Le mode de réparation permet aux techniciens de maintenance de contrôler le fonctionnement

du lave-linge et de procéder au dépannage.

- Le mode de réparation est accessible pendant n'importe quel cycle de lavage (sans interruption

de ce dernier), à l'exception de quelques modes de test.

- Plusieurs tests peuvent être menés grâce au mode de réparation. Le dépannage peut donc être

eectué à partir des codes de diagnostic découlant de ces tests.

Pour sélectionner ce mode:

- Pour passer en mode de réparation, appuyez simultanément sur les boutons Signal et Départ

diéré pendant 3secondes ou jusqu'à ce que l'appareil émette un signal sonore.

Mode de réparation:

1. Le lave-linge doit être en marche pour pouvoir passer en mode de réparation.

2. La vitesse du moteur s'ache lors du démarrage (l'écran ache 0 lorsque le moteur ne tourne

pas).

3. Le mode dans lequel se trouvait l'appareil à ce moment-là reste inchangé.

(c'est-à-dire que le cycle en cours n'est pas interrompu et que seul l'achage change).

4. Pour sortir du mode de réparation, appuyez à nouveau simultanément sur les boutons Signal et

Départ diéré pendant 3secondes ou sur le bouton de mise en marche. Si aucun bouton n'est

actionné pendant 5minutes alors que l'appareil est en mode de réparation, le mode d'utilisation

normale est rétabli.

7

Techsheet-WF350AN-02834A-03_CFR.indd 7 2011-09-28 �� 3:52:26

Page 32

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de test de l'essorage rapide

Service Mode

Dealy Start + Pre Wash

While it is not in Hold Speed Mode

Dealy Start + Pre Wash

3 sec

While a cycle is not running

Dealy Start + Pre Wash for 3sec or after 10 minutes

Start/PauseQuick Spin Test Mode

Hold Speed Mode

Dénition du mode de test de l'essorage rapide:

- Le mode de test de l'essorage rapide permet de procéder à un contrôle de l'essorage (vitesse

élevée).

Pour sélectionner ce mode:

- En mode de réparation, appuyez sur les boutons Départ diéré et Prélavage pendant 3secondes

pour passer en mode de test de l'essorage rapide (Identique pour tous les modèles Frontier2.)

- Ce mode devient inaccessible une fois que le cycle de lavage a démarré.

Mode de test de l'essorage rapide:

Une fois que l'appareil est passé en mode de test de l'essorage rapide, le tambour commence à

tourner et atteint la vitesse maximale.

Lorsque la vitesse d'essorage maximale est atteinte, la vitesse baisse immédiatement.

Pour maintenir le mode de test de l'essorage rapide (passage en mode de maintien de la vitesse),

appuyez sur le bouton Démarrer/Pause. Si vous appuyez sur le bouton Démarrer/Pause en mode

de test de l'essorage rapide, l'appareil arrête d'accélérer et maintient sa vitesse de rotation pendant

10minutes avant de revenir en mode de test de l'essorage rapide.

De même, pour annuler l'arrêt cuve pleine et permettre au mode de test de l'essorage rapide

de se poursuivre, appuyez simultanément sur les boutons Départ diéré et Prélavage pendant

3secondes.

Si vous maintenez les boutons Départ diéré et Prélavage enfoncés pendant 3secondes lorsque

le lave-linge n'est pas en mode de maintien de la vitesse, le mode de test de l'essorage rapide est

désactivé et le mode de réparation est rétabli.

8

Techsheet-WF350AN-02834A-03_CFR.indd 8 2011-09-28 �� 3:52:26

Page 33

ALIGNEMENTS ET RÉGLAGES

Soil Level

Service Mode

S/W Version Check

Mode

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de comptage de cycle

Service Mode Cycle Count

Signal

Dénition du mode de comptage de cycle:

- Le mode de comptage de cycle permet de compter le nombre de lavages eectués.

Pour sélectionner ce mode:

- Pour passer en mode de comptage de cycle, appuyez sur le bouton Signal en mode de

réparation.

Mode de comptage de cycle:

1. Activez tout d'abord le mode de réparation.

2. Lorsque le bouton Signal est activé, le nombre total de lavages s'ache et une DEL témoin

s'allume.

3. Le nombre maximum de cycles est de 9999.

Le compteur revient à0 et reprend le comptage après 9999.

4. Le comptage s'eectue à la n du cycle normal.

(Pour le cycle normal et le cycle de fonctionnement en continu, le comptage s'eectue à la n

du cycle.)

5. Pour quitter le mode de comptage de cycle, appuyez à nouveau sur le bouton Signal.

Mode de contrôle de la version du logiciel

Dénition du mode de contrôle de la version du logiciel:

- Le mode de contrôle de la version du logiciel permet d'obtenir des informations sur la version

du logiciel.

Pour sélectionner ce mode:

- Pour passer en mode de contrôle de la version du logiciel, appuyez sur le bouton Degré de

salissure en mode de réparation.

Mode de contrôle de la version du logiciel:

1. Activez tout d'abord le mode de réparation.

2. Appuyez sur le bouton Degré de salissure pour acher la version du logiciel.

Ex.: AE49 Version 49 (AE correspond au code Micom et 49 à la version du logiciel)

3. Pour désactiver le mode de contrôle de la version du logiciel, appuyez à nouveau sur le bouton

Degré de salissure.

Le mode de réparation est rétabli et la vitesse du moteur s'ache.

9

Techsheet-WF350AN-02834A-03_CFR.indd 9 2011-09-28 �� 3:52:27

Page 34

ALIGNEMENTS ET RÉGLAGES

Temp.

Service Mode

Fast Time Down

Test Mode

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de test rapide de décompte du temps restant

Dénition du mode de test rapide de décompte du temps restant:

- Le mode de test rapide de décompte du temps restant permet de forcer le programme à passer à l'étape suivante du

cycle.

Pour sélectionner ce mode:

- Pour passer en mode de test rapide de décompte du temps restant, appuyez sur le bouton Température en mode de

réparation.

Mode de test rapide de décompte du temps restant:

1. Activez tout d'abord le mode de réparation.

2. Pour forcer le programme à passer à l'étape suivante du cycle, appuyez sur le bouton Température.

Chaque étape se situe aux moments clés de la n d'un programme:

- Fin de chaque remplissage (début des cycles de lavage ou de rinçage machine)

Attention: vériez si le niveau d'eau actuel est supérieur au niveau d'eau de réinitialisation puis eectuez le test rapide

de décompte du temps restant.

- Début du cycle de vidange

- Début du cycle d'essorage (À ce moment, le niveau d'eau est contrôlé; si celui-ci se situe au-delà du niveau de

réinitialisation, une vidange est eectuée avant l'essorage.)

- Début du cycle de remplissage

- Début du remplissage en agent de blanchiment

- Début du remplissage en adoucissant

- Toutes les 3minutes pendant les cycles de lavage et de rinçage machine

10

Techsheet-WF350AN-02834A-03_CFR.indd 10 2011-09-28 �� 3:52:27

Page 35

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de test des entrées au niveau de la carte

Service Mode Board Input Test

Dénition du mode de test des entrées au niveau de la carte:

- Le mode de test des entrées au niveau de la carte permet d'acher une entrée spécique après

avoir appuyé sur un bouton.

Pour sélectionner ce mode:

- Pour passer en mode de test des entrées au niveau de la carte, appuyez sur le bouton Essorage

en mode de réparation.

Mode de test des entrées au niveau de la carte:

1. Activez tout d'abord le mode de réparation.

2. Appuyez sur le bouton Essorage pour lancer le test des entrées au niveau de la carte.

3. Tournez la molette de sélection an que la DEL Prélavage s'allume et appuyez sur le bouton

Démarrer/Pause. La température de l'eau s'ache en degrés Celsius.

4. Tournez la molette de sélection an que la DEL Rinçage plus (ou Vapeur) s'allume et appuyez sur

le bouton Démarrer/Pause. La température de l'eau s'ache en degrés Fahrenheit.

5. Tournez la molette de sélection an que la DEL Froid/Froid s'allume et appuyez sur le bouton

Démarrer/Pause. L'état du hublot s'ache (OP s'il est ouvert et CL s'il est fermé).

6. Tournez la molette de sélection an que la DEL Pas d'essorage s'allume et appuyez sur le

bouton Démarrer/Pause. L'état du commutateur de verrouillage du hublot s'ache (UL s'il est

déverrouillé, LO s'il est verrouillé).

7. Tournez la molette de sélection an que la DEL Degré de salissure s'allume et appuyez sur le

bouton Démarrer/Pause. Le niveau d'eau s'ache.

8. Tournez la molette de sélection an que la DEL Signal désactivé s'allume et appuyez sur le

bouton Démarrer/Pause. Après avoir maintenu le bouton appuyé pendant 3secondes, l'état du

kit Silver Nano s'ache.

1. Diéré: 0000

2. Normal: ---

3. Anormal: ㅂE

Spin Key

11

Techsheet-WF350AN-02834A-03_CFR.indd 11 2011-09-28 �� 3:52:28

Page 36

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de contrôle du code de diagnostic

Service Mode

Pure Cycle

Diagnostic Code

Signal

Start/Pause

Pressing

Cycle No.

Before making Code

Cycle Count

Dénition du mode de contrôle du code de diagnostic:

- Le mode de contrôle du code de diagnostic permet d'acher les codes de diagnostic

enregistrés (codes de référence pour les techniciens de maintenance).

Pour sélectionner ce mode:

- Pour passer en mode de contrôle du code de diagnostic avec le code «d» clignotant, appuyez

sur le bouton Pure Cycle en mode de réparation.

Mode de test des entrées au niveau de la carte:

1. Activez tout d'abord le mode de réparation.

2. Appuyez sur le bouton «Pure Cycle» pour lancer le mode de contrôle du code de diagnostic

avec le code «d» qui clignote.

3. Pour naviguer d'un code à un autre (d1,d2, d3~d9), tournez la molette du sélecteur de

programme dans un sens (sens des aiguilles d'une montre ou sens inverse des aiguilles d'une

montre).

4. Si vous tournez alors la molette dans le même sens, les codes s'achent en partant du dernier

aché (d1).

5. Si vous la tournez dans le sens opposé, les codes de diagnostic s'achent dans l'ordre inverse.

Ex.: si le code aché est d5 et que la molette est tournée dans le sens opposé, l'achage passe

de d4 à «d». Reportez-vous à la section Code de diagnostic.

12

Techsheet-WF350AN-02834A-03_CFR.indd 12 2011-09-28 �� 3:52:28

Page 37

ALIGNEMENTS ET RÉGLAGES

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

Mode de démonstration

Normal User Mode

Power O Mode

Delay Start + Signal + Spin

While a cycle is not running

5 sec

Power O Key

Demo Mode

- Pour passer en mode de démonstration, maintenez enfoncés les boutons Départ diéré + Signal +

Essorage pendant cinq(5) secondes (appareil sous tension).

- Lorsque l'appareil passe en mode de démonstration, le signal sonore retentit à trois(3) reprises et le

message «- - - -» apparaît sur l'acheur; toutes les autres DEL sont éteintes (mode de démonstration

initial).

- Le mode de démonstration est composé des modes WASH, SPIN et LED (LAVAGE, ESSORAGE et DEL).

- Si le bouton Température est activé en mode de démonstration initial, le message «WASH» clignote sur

l'acheur et le lave-linge passe en mode LAVAGE.

- Si le bouton Démarrer/Pause est activé en mode LAVAGE, le hublot est verrouillé (Verrouillage du

hublot) et le moteur tourne vers la gauche et vers la droite à 45tr/min pendant des cycles de 7secondes

entrecoupés de pauses de 3secondes.

- Le mode LAVAGE se poursuit pendant cinq (5) minutes après son démarrage. Une fois les cinq (5) minutes

écoulées, le message «- - - -» apparaît sur l'acheur et le mode de démonstration initial est maintenu.

- Si le bouton Démarrer/Pause est activé au cours du mode LAVAGE, le message «- - - -» apparaît sur

l'acheur et le mode de démonstration initial est maintenu.

- Si le bouton Essorage est activé en mode de démonstration initial, le message «Spin» clignote sur

l'acheur et le lave-linge passe en mode ESSORAGE.

- Si le bouton Démarrer/Pause est activé en mode ESSORAGE, le hublot est verrouillé (Verrouillage du

hublot) et un essorage est eectué à 1150tr/min. Lorsque la vitesse descend à 0tr/min, les DEL Sans

essorage, Faible, Moyenne, Élevée et Très élevée s'allument.

- Pendant l'essorage, la DEL Sans essorage s'allume lorsque la vitesse est inférieure à 400tr/min. La DEL

Faible s'allume lorsque la vitesse de rotation est comprise entre 400 et 800tr/min. La DEL Moyenne

s'allume lorsque la vitesse de rotation est comprise entre 800 et 1000tr/min. La DEL Très élevée s'allume

lorsque la vitesse est supérieure à 1000tr/min.

- Le mode ESSORAGE se poursuit pendant quatre (4) minutes après son démarrage. Une fois les quatre

(4) minutes écoulées, le message «- - - -» apparaît sur l'acheur et le mode de démonstration initial est

maintenu.

- Si le bouton Démarrer/Pause est activé au cours du mode ESSORAGE, le message «- - - -» apparaît sur

l'acheur et le mode de démonstration initial est maintenu.

- Si le bouton Pure Cycle du lave-linge est activé en mode de démonstration initial, le message «LED»

clignote sur l'acheur et le lave-linge passe en mode DEL.

- Si le bouton Démarrer/Pause est activé en mode DEL, toutes les DEL s'allument. Le mode DEL se poursuit

pendant trente (30) secondes après son démarrage. Une fois les trente (30) secondes écoulées, le message

«- - - -» apparaît sur l'acheur et le mode de démonstration initial est activé.

- Si le bouton Démarrer/Pause est activé pendant le fonctionnement en mode DEL, le message «- - - -»

apparaît sur l'acheur et le mode de démonstration initial est activé.

13

Techsheet-WF350AN-02834A-03_CFR.indd 13 2011-09-28 �� 3:52:28

Page 38

DÉPANNAGE

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

DIAGNOSTIC DES PROBLÈMES

- Le micom du lave-linge est conguré pour une structure complexe, c'est pourquoi il est

conseillé de contacter le service après-vente.

Les informations suivantes répondent à un diagnostic précis et constituent un guide de

réparation adapté.

Consignes à respecter pendant les opérations de réparation et de remplacement

Respectez les consignes ci-dessous pour le diagnostic des problèmes et le remplacement

1) Certains composants électroniques risquant d'être endommagés par l'électricité statique

recouvrant la partie en résine de la machine ou le corps humain, veillez à ce que votre corps soit

toujours relié à la terre ou éliminez la diérence de potentiel de votre corps et du lave-linge en

touchant la prise d'alimentation avant de travailler sur la carte de circuit imprimé.

2) Un courant de 120V CA étant appliqué au triac T1 et T2 de la carte de circuit imprimé, vous

risquez de vous électrocuter si vous touchez cet élément. Soyez également prudent, car il s'agit

de courant alternatif.

3) La carte de circuit imprimé étant un composant résistant, ne la remplacez pas suite à un

diagnostic erroné et respectez la procédure de diagnostic des problèmes lorsque le micom ne

fonctionne pas correctement.

des pièces.

14

Techsheet-WF350AN-02834A-03_CFR.indd 14 2011-09-28 �� 3:52:28

Page 39

DÉPANNAGE

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

DIAGNOSTIC DES PROBLÈMES

Votre lave-linge ne démarre pas.

• Branchez l'appareil sur la prise murale. Vériez que la tension est adaptée.

• Vériez les fusibles ou réinitialisez le disjoncteur.

• Appuyez sur n'importe quel bouton pour mettre en marche le lave-linge et appuyez sur le bouton Démarrer/Pause pour faire

fonctionner l'appareil.

• Fermez le hublot et appuyez sur le bouton Démarrer/Pause pour faire fonctionner le lave-linge.

• Vériez que le lave-linge n'est pas dans une phase de pause, de trempage ou de lessivage. Il se peut que la machine se remette

en marche après quelques minutes. (Si le lave-linge se trouve dans une phase de lessivage, le message Suds s'ache au lieu du

temps restant.)

• Vériez que le système de vidange n'est pas obstrué. (En cas de problème électrique dans le système de vidange, le message

«nd» s'ache au bout de 15minutes.)

• Vériez l'arrivée d'eau.

• Vériez le tuyau ou le tamis du ltre de la vanne d'arrivée d'eau.

• Vériez que les connecteurs de la carte de circuit imprimé sont bien en place.

• Vériez que les bornes CN2 de la carte de circuit imprimé sont en bon état. (Reportez-vous à la partie Contrôle des connecteurs

de la carte de circuit imprimé.)

• Remplacez la carte de circuit imprimé.

Fuite

• Assurez-vous que les raccordements des tuyaux d'arrivée d'eau ne fuient pas. Vériez que le joint en caoutchouc n'a pas été

endommagé lors du serrage.

• Vériez l'absence de fuite au niveau de la conduite d'évacuation. Enroulez un chion sec autour de l'ouverture de la conduite

d'évacuation.

Si le chion devient humide, la fuite provient de la plomberie de l'habitation.

Assurez-vous que la conduite d'évacuation peut recevoir le ux d'eau provenant du lave-linge.

• Assurez-vous que l'extrémité du tuyau de vidange est correctement insérée dans la conduite d'évacuation et xée à celle-ci.

• Vériez les raccordements des tuyaux internes (remplissage, systèmes d'évacuation, tuyaux de distribution et colliers de serrage).

• Vériez l'état de la manchette en caoutchouc. Si nécessaire, retirez-la, repositionnez-la et réinstallez-la.

• Vériez que le distributeur du tuyau à l'extérieur du tambour n'est pas emmêlé. La mise sous pression de l'eau chaude peut

forcer l'ouverture du hublot.

Pas de mouvement de rotation

• Lancez un cycle normal à vide et laissez se dérouler un cycle de remplissage pour vérier le mouvement de rotation.

• Eectuez un test de l'essorage rapide. (Avant le test, assurez-vous que le tambour est vide.)

• Vériez les connexions au niveau du panneau de commande de la machine, du pressostat, du moteur, du faisceau électrique du

tachymètre et de la commande du moteur. (Reportez-vous à la procédure de test des composants)

• Vériez la résistance des bobines du moteur.

CN5 Broches 1 et 3 = 11,6ohms ±7%,

Broches 1 et 2 = 11,6ohms ±7%,

Broches 2 et 3 = 11,6ohms ±7%

• Panneau de commande général défectueux.

• Moteur défectueux.

Pas d'essorage

• Assurez-vous que le hublot est bien fermé.

• Vériez qu'il ne reste pas d'eau dans le lave-linge. S'il reste de l'eau, consultez la partie «Pas de vidange».

• Lancez le mode de test rapide ou le test de l'essorage rapide. Le lave-linge procède-t-il à l'essorage? (Avant de procéder au test,

videz l'intérieur du tambour.) En cas d'absence de rotation après les étapes ci-dessus, changez la carte de circuit imprimé. Si le

problème persiste, changez le moteur.

• Lancez le mode de test rapide ou le test de l'essorage rapide. Le lave-linge procède-t-il à l'essorage? Si oui, vériez s'il s'agit d'un

problème de déséquilibre en mode normal.

• Vériez les connexions au niveau de la carte de circuit imprimé, du capteur de niveau d'eau, du moteur et du faisceau électrique

du capteur à eet Hall. (CN7, CN5, CN6) (Reportez-vous à la procédure de test des composants)

• Vériez la résistance des bobines du moteur. (CN5 Broches 1 et 3 = 11,6ohms (à ±7% 20°C/68°F),

broches 1 et 2 = 11,6ohms (à ±7% 20°C),

broches 2 et 3 = 11,6ohms (à ±7% 20°C))

15

Techsheet-WF350AN-02834A-03_CFR.indd 15 2011-09-28 �� 3:52:28

Page 40

DÉPANNAGE

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

DIAGNOSTIC DES PROBLÈMES

Pas de remplissage d'eau

• Lancez le mode de test rapide. Procédez à un contrôle visuel de l'état de toutes les vannes d'arrivée d'eau.

(Vanne de prélavage, vanne d'eau froide, vanne d'agent de blanchiment; l'adoucissant est distribué par la

vanne d'eau froide et d'agent de blanchiment et par la vanne d'eau chaude.)

• Vériez que les robinets sont complètement ouverts.

• Vériez les vannes d'arrivée d'eau et le capteur de niveau d'eau (Reportez-vous à la partie Contrôle des

connecteurs de la carte de circuit imprimé.).

• Vériez qu'aucun tuyau d'arrivée d'eau n'est emmêlé.

• Vériez que les tamis d'arrivée d'eau ne sont pas obstrués.

• Vériez que la pression de l'eau est susante. Si ce n'est pas le cas, recherchez la cause du problème.

• Vériez qu'aucun élément de l'appareil n'est gelé (tuyau de vidange, etc.).

• Mesurez la résistance de la bobine de la vanne d'arrivée d'eau.

(Elle doit être de 1,18KOhms. Vériez la broche 1 du CN2 et les broches 1, 2, 7, 8 et 9 du CN3)

• Vériez les connexions au niveau du commutateur de pression et de la carte de circuit imprimé. (Reportez-

vous à la partie Contrôle des connecteurs de la carte de circuit imprimé.)

Le tambour est plein de mousse

• Consultez les parties «Pas de vidange» et «Pas d'essorage» et vériez que la vidange s'eectue

correctement.

• Vériez que les connexions au niveau de la carte de circuit imprimé ou de la pompe de vidange sont bonnes.

• Lancez le mode de test rapide ou un test des sorties au niveau de la carte pour procéder à la vidange.

• Utilisez une lessive haute ecacité ou à faible pouvoir moussant conçue spécialement pour les lave-linge à

chargement frontal.

• Adaptez la quantité de lessive à la charge et au degré de salissure. N'oubliez pas que les éponges produiront

davantage de mousse.

• Réduisez la quantité de lessive lorsque l'eau de lavage est douce ou lorsque le linge est de petite taille ou

peu sale.

• Eectuez un cycle de lavage supplémentaire à froid en ajoutant une cuillère à soupe de sel (pas de lessive).

16

Techsheet-WF350AN-02834A-03_CFR.indd 16 2011-09-28 �� 3:52:28

Page 41

DÉPANNAGE

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

DIAGNOSTIC DES PROBLÈMES

L'essorage n'a pas fonctionné

• Déséquilibre dû à une charge trop faible. Augmentez le chargement.

•

Mousse trop importante avec utilisation d'une lessive normale. Utilisez une lessive haute ecacité (HE) ou

réduisez la quantité de lessive.

• L'option Essorage à faible vitesse ou Vidange seule a été sélectionnée.

• Consultez la section «Pas d'essorage».

Le hublot ne se verrouille pas

• Le hublot n'est pas aligné ou est mal fermé.

• Lancez le mode de test rapide. Vériez le verrouillage du hublot.

Vériez la tension de sortie de la bobine de verrouillage du hublot.

Si elle est de 120V, remplacez le commutateur de verrouillage du hublot; sinon, remplacez la carte de circuit

imprimé. (Reportez-vous à la partie Contrôle des connecteurs de la carte de circuit imprimé.)

• Lisez la partie Commutateur de verrouillage et carte de circuit imprimé (CN3). (Reportez-vous à la partie

Contrôle des connecteurs de la carte de circuit imprimé.)

• Essayez le verrouillage du hublot et vériez que la tension du connecteur de verrouillage du hublot est

de 120V. Si la tension est de 120V, remplacez le panneau de commande général; sinon, remplacez le

commutateur de verrouillage du hublot.

Le hublot ne se déverrouille pas.

• Vériez que le hublot n'a pas dévié de sa position initiale; ce qui pourrait empêcher son déverrouillage.

• Le hublot est automatiquement verrouillé lorsque le niveau d'eau est trop élevé. Dans le cas contraire, toute

l'eau de vidange s'écoulerait par celui-ci à l'ouverture.

• Vériez les éléments suivants en mode de test des entrées au niveau de la carte.

Niveau d'eau (fréquence): supérieure à 23,80KHz.

Si c'est le cas, consultez la partie «Pas de vidange».

Température (intérieur du tambour): supérieure à 60ºC/140ºF.

Si c'est le cas, attendez qu'elle baisse.

Lorsque tous ces éléments sont normaux, vériez les connecteurs de la carte de circuit imprimé et le

commutateur de verrouillage du hublot.

• Eectuez la vidange manuellement après avoir retiré le support en plastique du tuyau de vidange.

• Le message «LO» s'ache. Éteignez, puis rallumez l'appareil. Si le message «LO» est toujours aché,vériez

la carte de circuit imprimé et le commutateur de verrouillage du hublot.

17

Techsheet-WF350AN-02834A-03_CFR.indd 17 2011-09-28 �� 3:52:29

Page 42

DÉPANNAGE

AVERTISSEMENT

An d'éviter tout risque d'électrocution légère ou mortelle, débranchez le lave-linge avant

de procéder aux réparations (sauf si le test nécessite sa mise sous tension).

DIAGNOSTIC DES PROBLÈMES

• Lisez la partie Commutateur de verrouillage et carte de circuit imprimé (CN2 et CN3). (Reportez-vous à la

partie Contrôle des connecteurs de la carte de circuit imprimé.)

• Lancez le mode de test rapide. Vériez le verrouillage du hublot. Vériez la tension de sortie de la bobine de

verrouillage du hublot.

Si elle est de 120V, remplacez le commutateur de verrouillage du hublot; sinon, remplacez la carte de circuit

imprimé. (Reportez-vous à la partie Contrôle des connecteurs de la carte de circuit imprimé.)

Aucun bouton ne fonctionne

• Les boutons d'option et de fonction réagissent diéremment selon les programmes.

• La sécurité enfant est activée. Pour le désactiver, appuyez simultanément sur les boutons Degré de salissure

et Signal jusqu'à ce qu'un signal sonore soit émis.

• Lorsque le message «End» (Fin) s'ache, seul le bouton Mise en marche répond. Appuyez sur le bouton

Mise en marche et faites de nouvelles sélections de programme.

Pas de vidange

• Vériez que le tuyau de vidange n'est pas emmêlé ou entortillé. Si c'est le cas, démêlez-le.

• Vériez que le tuyau de vidange n'est pas obstrué.

• Fermez le hublot et appuyez sur le bouton Démarrer/Pause. Pour des raisons de sécurité, le lave-linge ne