Samsung SF4300C Service manual

SF4300C

INKJET PRINTER COMPOUND CONTENTS

1. Precaution

2. Referential Information

3. Specifications

4. Disassembly & Assembly

5. Circuit

6. Repair

7. Exploded View

8. Packing

9. Circuit Diagram & Parts List

10. Block Diagram

11. PCB Layout

12. Wiring Diagram

SER VICE

Manual

ELECTRONICS

Samsung Electronics 1-1

1. Precautions

1-1 Safeguards

Please read these instructions carefully and completely.

1. Unplug this product from the wall outlet before

you disassemble it.

2. Replace defective parts with the same parts as

them.

3. Check the insulation of electricity-conducting

parts (metal plate or input terminal) that can easily contact AC plug blades.

4. How to check insulation: Pull the AC plug out of

the outlet and measure insulation resistance of

each blade.

5. Insulation resistance of AC plug blades against

electricity-conducting parts should be 1 megaohm

or over.

6. Always use it after connecting the ground of measuring instruments to the ground of chassis. And

after you use it, separate the ground of the

measuring instruments lastly.

1. Do not use this product in a humid place nor outdoor.

2. Do not place this product on an unstable stand or

table. The product may fall, causing serious damage to the product.

3. Use this product in a well-ventilated place.

4. Slots are provided for ventilation. Never push

objects of any kind into this product through

these slots as they may result in a fire or electric

shock. Never spill liquid of any kind on the product.

5. Power-supply cords should be routed so that

they are not likely to be walked.

6. Use this product in a place big enough to support

printers.

7. Install this product within 180cm from the computer and 150cm from the power outlet.

8. This product should be operated only from the

type of power source indicated on the marking

label.

9. If you use extension cords, be sure they have

three-wire grounding-type power outlets. Do not

overload wall outlets and extension cords. Never

load one wall outlet with over 15 ampere.

10. Unplug this product from the wall outlet before

cleaning. Do not use liquid cleaners or aerosol

cleaners. Use a dry cloth for cleaning.

11. Use only standard paper, OHP film, andapproved envelopes.

1-2 Servicing Precautions

Please read these instructions carefully and completely.

1-2 Samsung Electronics

1-3 Static Electricity Precautions

Semi-conductors are easily damaged by static electricity. They are usually called electrostatically

sensitive devices (ESD). For example, there are IC,

FET, and semi-conductor chips.

1) Before you handle semi-conductor parts, be sure

to discharge electricity by touching earth connection or putting on a wristband. (Before you turn

on the product, put off the wristband to prevent

electric shock.)

2) Remove the static electricity protective device

and then place the assembly on the surface of

electric conductors such as aluminum foil to

prevent static electricity from accumulating.

3) Do not use chemicals like Freon. These chemicals

produce static electricity that may damage parts.

4) Solder ESD parts with a grounded soldering iron.

5) Use static electricity protective solder. Solder not

marked Ôstatic electricity protectiveÕ may accumulate static electricity that damages ESD parts.

6) Do not get rid of the static electricity protective

cover of ESD parts until you are ready to replace

them. Most of ESD parts are packed, with electricity conducting materials in contact with ESD

parts leads.

7) Make static electricity protective materials contact the chassis or the circuit where parts will be

mounted, before you remove the materials from

ESD parts to be replaced.

8) Minimize your motion when you handle the ESD

parts from which static electricity protective

materials have been removed. Static electricity is

generated when your clothes are frictionized or

you walk on the carpet.

9) Be careful not to bend pins when you handle IC.

10) Pay attention to directions when you mount

parts on PCB.

11) Overheat during soldering may damage the

parts completely. Heat affects all the parts.

Samsung Electronics 2-1

2. Referential Information

2-1 Abbreviations & Acronyms

Abbreviations Definition

MFP Multi Function Peripheral

I/F INTERFACE

UART Universal Asynchronous Receiver/Transmitter

ECP Expended Capasilities port : 8bits Data

CR Carriage Return

LF LINE FEED

CIP COLOR IMAGE PROCESSOR

CCD Charge Coupled Device

A/D ANALOG TO DIGITAL

D/A DIGITAL TO ANALOG

LIU Line Interface Unit

TIT Transformer Input from Transformer

ROT Receive Output Transformer

LI Line Input

2-2 Samsung Electronics

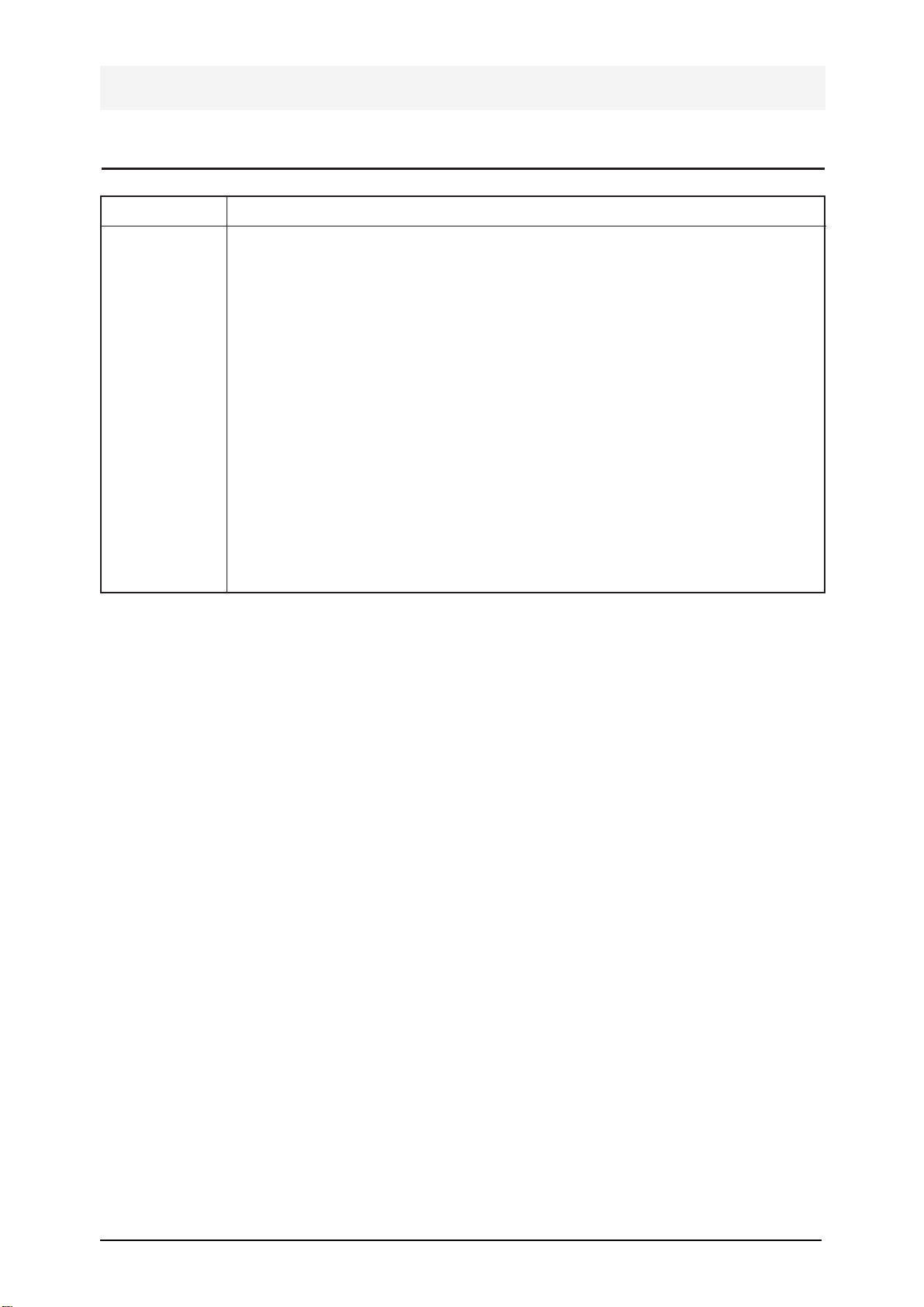

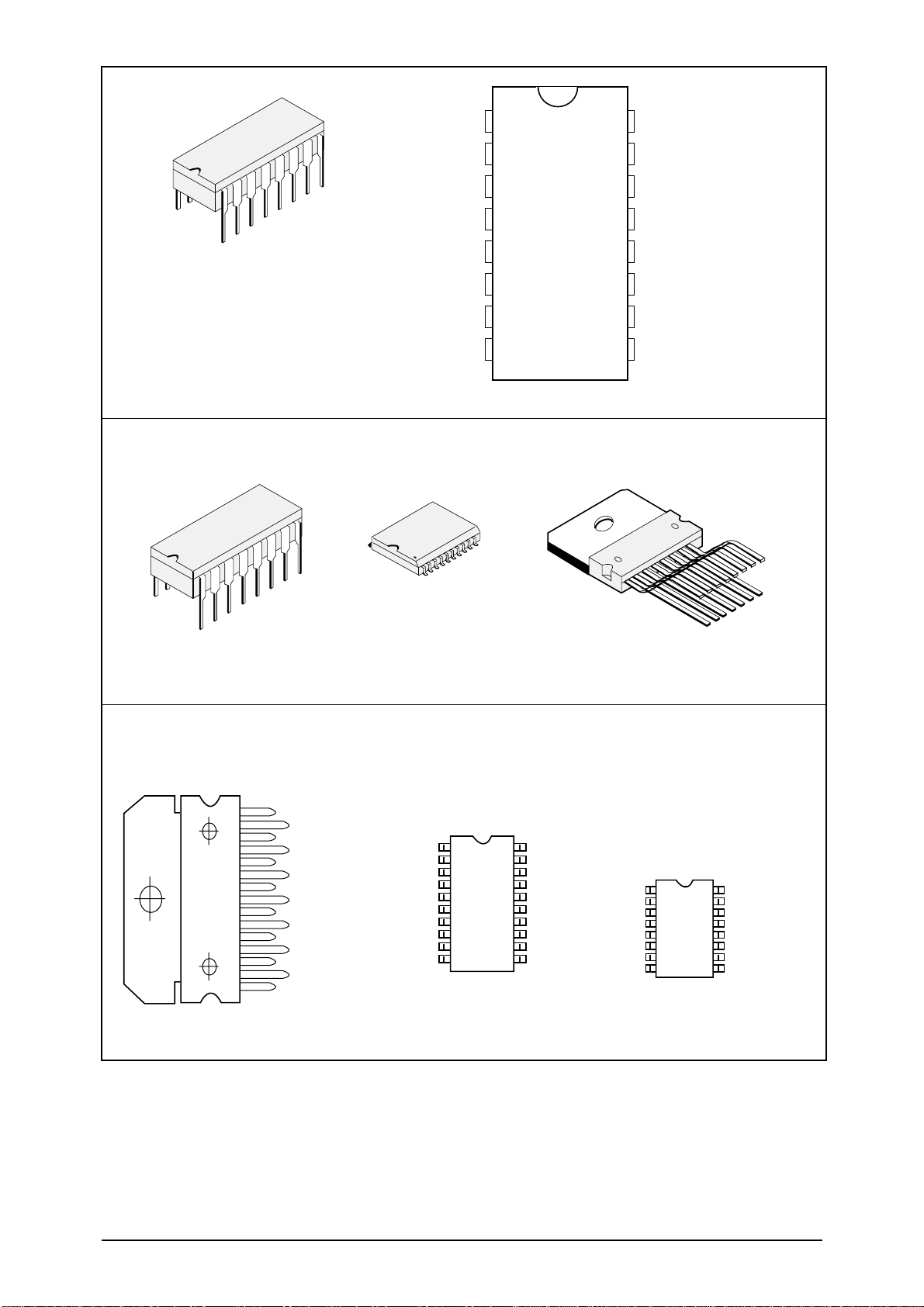

2-2 Location & Outline of Pins of Electrical Parts

1. Gate 2. Drain 3. Source

1

2

3

C

E

B

R1 R2

R1=10KΩ

R2=0.6KΩ

.

.

.

.

TO-220

1. Base 2. Emitter 3. Collector

1

3

2

SOT-23

1. Base 2. Collector 3. Emitter

1

2

3

SOT-89

LOGIC AND CONNECTION

DIAGRAMS DIP (TOP VIEW)

Vcc

EB1

20 19 18 17 16 15 14 13 12 11

12345678910

DIR

A1 A2 A3 A4 A5 A6 A7 A8 GND

B2 B3 B4 B5 B6 B7 B8

20

20

20

J SUFFIX

CERAMIC

CASE 732-03

1

N SUFFIX

PLASTIC

CASE 738-03

1

DW SUFFIX

SOIC

CASE 751D-03

1

Samsung Electronics 2-3

BLOCK DIAGRAM

8 DIP

8 SOP

Vcc

Q6 Q6

OUT 1

IN1(- )

IN1(+ )

Q12

GND

Q17

1

2

_

+

3

4

Q19

8

Vcc

OUT 2

7

6

_

+

IN2 (- )

IN2 (+)

5

IN(-)

IN(+)

Q1

Q8

Q2

Q3

Q4

Q9

C1

Q11

Q10

Q13

Q14

Q15

Q18

Q20

R1

R2

OUT

Q21

2-4 Samsung Electronics

PIN CONNECTIONS

Block Diagram Simplified Application

Audio

Input

Cj

0.1

Ri

3.0k

C2*

5.0uF

C1

1.0uF

Rf

75k

Vin

FC1

4

3

6

5

8

7

#2

_

+

#1

_

+

2

50k

This device contains 45 active transistors.

Rf

Rj

*=Optional

Differential Gian=2 x

50k

125k

FC2

1

Vcc

Vo1

Vo2

Speaker

CD

GND

Bias

Circuit

MC34119

Chip

Disable

8

1

8

8

1

1

P SUFFIX

PLASTIC PACKAGE

CASE 626

D SUFFIX

PLASTIC PACKAGE

CASE 751

(SO-8)

DTB SUFFIX

PLASTIC PACKAGE

CASE 948J

(TSSOP)

14DIP

BLOCK DIAGRAM

14SOP

1

1

OUT2

OUT1

Vcc

IN1(-)

IN2(-)

IN1(+)

+

_

+

_

+

_

+

_

IN2(+)

1

2

3

4

5

6

7

14

13

12

11

10

9

8

18

CD

27

FC2

FC1

36

45

Vin

(Top View)

Vo2

Gnd

Vcc

Vo1

Samsung Electronics 2-5

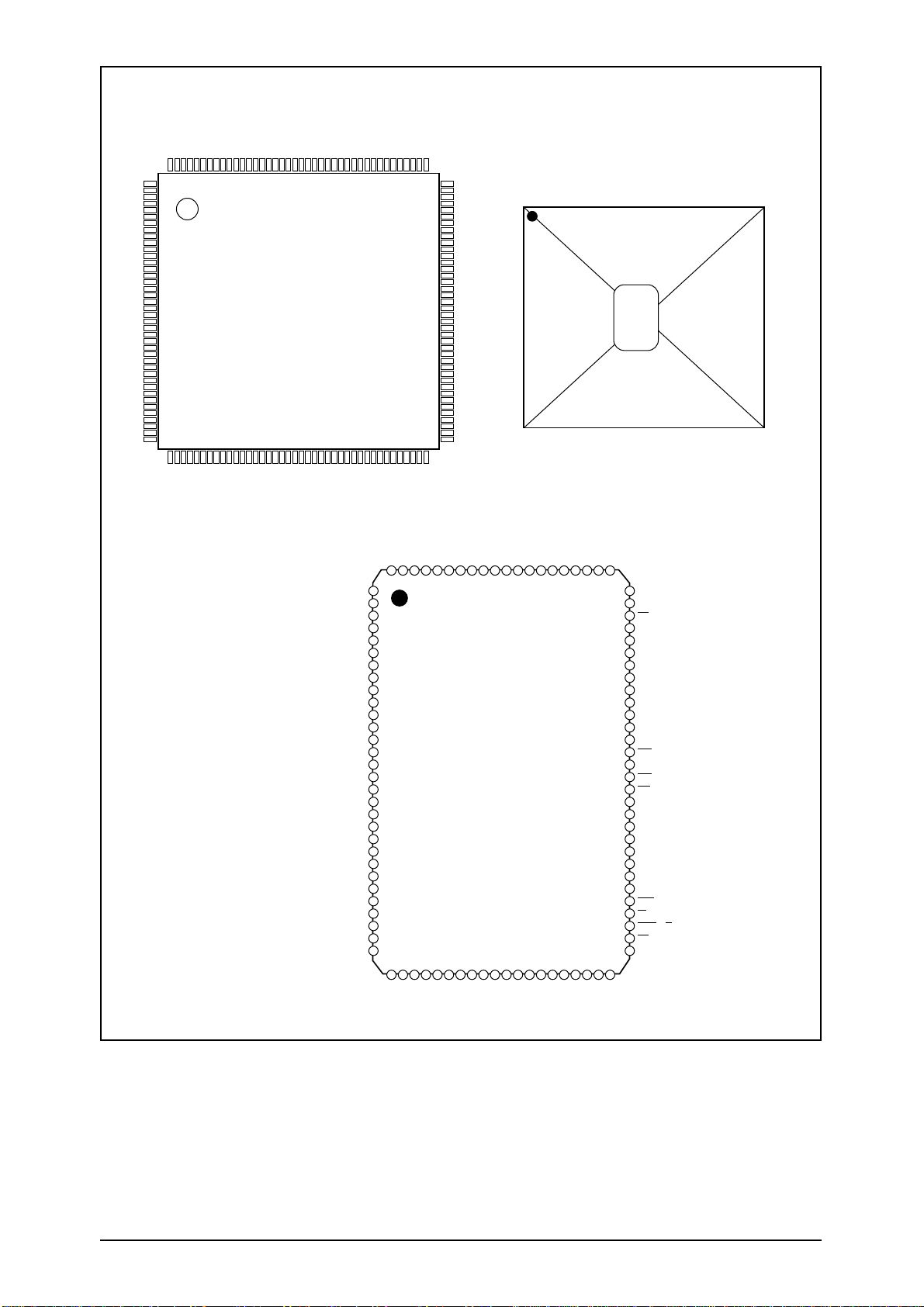

PIN CONFIGURATION (Top Views)

S

KM416C/V10(2)00BJ KM416C/V10(2)00BT

TO-92

1

VCC

2

DQ0

3

DQ1

DQ2

4

DQ3

5

6

VCC

7

DQ4

8

DQ5

9

DQ6

10

DQ7

11

N.C

12

N.C

13

W

14

RAS

*A11(N.C)

*A10(N.C)

15

16

17

A0

18

A1

19

A2

20

A3

21

VCC Vss

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

Vss

DQ15

DQ14

DQ13

DQ12

Vss

DQ11

DQ10

DQ9

DQ8

N.C

UCAS

UCAS

OE

A9

A8

A7

A6

A5

A4

Vcc

DQ0

DQ1

DQ2

DQ3

Vcc

DQ4

DQ5

DQ6

DQ7

N.C

N.C

N.C

W

RAS

*A11(N.C)

*A10(N.C)

A0

A1

A2

A3

Vcc

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE

RESET

NC

NC

RY/BY

NC

A17

A7

A6

A5

A4

A3

A2

A1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

Vss

DQ15

DQ14

DQ13

DQ12

Vss

DQ11

DQ10

DQ9

DQ8

N.C

N.C

UCAS

UCAS

OE

A9

A8

A7

A6

A5

A4

Vss

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE

Vss

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

Vcc

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE

Vss

CE

A0

1

2

3

1.Emitter 2.Base 3.Collector

A16

BYTE

Vss

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

Vcc

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

Vss

OE

CE

A0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE

RESET

NC

NC

RY/BY

NC

A17

A7

A6

A5

A4

A3

A2

A1

2-6 Samsung Electronics

OUTPUT B

1

16

SENSE RESISTOR

Powerdip 12+2+2

(Plastic Package)

ORDER CODE:PBL3717A

Powerdip

12+2+2

PULSE TIME

Vs(B)

GND

GND

Vss

INPUT 1

PHASE

SO-20

2

3

4

5

6

7

8

15

OUTPUT A

14

Vs(A)

13

GND

12

GND

11

REFERENCE

10

COMPARATOR INPUT

9

INPUT

MULTIWATT-15

ORDERING NUMBERS:

ORDERING NUMBERS:

TEA3718SDP

TEA3718DP

TEA3718SP

(Multiwatt-15)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Note:HEATSINK SURFACE CONNECTED TO PIN B

Us

DUT B

SENSE

DUT A

PULSE TIME

Us

N.C.

GND

ALARM OUTPUT

REFERENCE

COMPARATOR INPUT

IN0

PHASE

IN1

Uss

TEA3718SFP

TEA3718SFP

OUT B

PULSE TIME

Us Us

N.C.

GND

GND

N.C.

Uss

IN1

PHASE

(SO-20)

1

2

3

4

5

6

7

8

9

10

ORDERING NUMBER : TEA3718SP

TEA3718DP

TEA3718SDP

(Powerdip 12+2+2)

20

SENSE

19

OUT A

18

17

N.C.

16

GND

15

GND

14

PRE-ALARM OUT

13

REFERENCE

12

COMPARATOR INPUT

11

IN0

PULSE TIME

OUT B

GND

GND

Uss

PHASE

1

2

3

Us

4

5

6

7

IN1

8

16

SENSE

15

OUT A

14

Us

13

GND

GND

12

11

REFERENCE

10

COMPARATOR INPUT

9

IN0

Samsung Electronics 2-7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

nECS2

nECS1

nECS0

nWBE1

nWBE0

nWE

nOE

nCAS1

nCAS0

nRAS1

nRAS0

nRCS2

nRCS1

nRCS0

VCC6

GND6

ADDR21

ADDR20

ADDR19

ADDR18

ADDR17

ADDR16

ADDR15

ADDR14

ADDR13

ADDR12

ADDR11

ADDR10

ADDR9

ADDR8

ADDR7

ADDR6

ADDR5

ADDR4

ADDR3

ADDR2

ADDR1

ADDR0

VCC5

GND5

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

GND1

NC

NC

NC

NC

NC

NC

NC

NC

VCC1

NC

NC

NC

NC

NC

NC

NC

NC

GND2

GOP12

NC

NC

NC

NC

NC

NC

GPIO0/TCK

GPIO1/TMS

GPIO2/TDI

GPIO3/nTRST

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

VCC4

DATA15

DATA14

DATA13

DATA12

DATA11

DATA10

DATA9

DATA8

GND4

DATA7

DATA6

DATA5

DATA4

DATA3

DATA2

DATA1

DATA0

VCC3

245CLK

PPD0

PPD1

PPD2

PPD3

PPD4

PPD5

PPD6

PPD7

GND3

nSTROBE

nAUTOFD

nSLCTIN

nINIT

SELECT

nACK

BUSY

PERROR

nFAULT

VCC2

GPIO4/TDO

807978777675747372717069686766656463626160595857565554535251504948474645444342

41

nECS3

GOP0/TXD1

GIP0/RXD1

GOP1/TXD2

GIP1/RXD2

TEST1

TEST2

GIP5/UCLK

CLKSEL

nRESET

GND7

MCLK

GND8

GOP5/nIOWR1

VCC7

GIP2/nEINT1

GIP3/nEINT2

GIP4/nXDREQ

GOP2/nXDACK

NCNCNCNCNC

NC

EEDATA

EECLK

GND9

GOP3/TONE

GOP4/nRSTO

GOP8/nIORD2

GOP9/CLKOUT

GOP10/FIREPULSE

GOP11

GOP6/nIOWR2

GOP7/nIORD1

VCC8

NCNCNC

KS32C6200

160 TQFP

(Top View)

KS16116/7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

D11

D10

D9

D8

VSS

D7

D6

D5

D4

VDD

D3

D2

D1

D0

VSS

ADDR4

ADDR3

ADDR2

ADDR1

ADDR0

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

VDD

GPO0

GPO1

GPO2

GPO3

VSS

GPO4

GPO5

GPO6

GPO7

VDD

GPI0

GPI1

GPI2

GPI3

VSS

GPI4

GPI5

GPI6

GPI7

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

VSS

Xin

Xout

VSS

VDD

nXDREQ

TEST

nXDACK

nRESET

nCIPCS

nRD

nWR

ADCDG

ADCDP

pVref

Vin

nVref

ADCAP

ADCAG

VSS

CLR-SCANSHCLK1

CLK2

CLK-M

VSS

VDD

VSS

D15

D14

D13

D12

212223 2425262728 29 3031323334 353637383940

807978 7776757473 72 7170696867 666564636261

CIP1

V2.1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

GP03

GP04

GP05

GP06

GP07

GNDD

GNDD

D7

D6

D5

D4

D3

D2

D1

D0

GNDD

GNDA

RXAMPI

NC

NC

GNDA

V

DD

GNDD

SWGAINI

ECLKIN1

SYNCIN1

NC

NC

NC

GNDA

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

NCNCNC

DAIN

ADOUT

BYPASS

RCVI

TXATT3

TXATT2

TXATT1

NC

VREFN

VSSG

TXAO

RXAI

Vcc

GNDA

VC

AOUT

GNDD

GP02

SWGAINO

RCVO

GNDD

RLSD

RXDO

GP19

GP20

GNDD

GP21

SEPYO

GNDD

DAOUT

ADIN

SEPXO

SEPCLK

SEPCLKX

SEPWCLK

DCLK

GNDD

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

NC

IRQ

WRITE-R/W

CS

READ-ø2

RS4

RS3

RS2

RS1

RS0

GP13

NC

GP11

RTS

EN85

DGND

PORI

XTALI

XTALO

XCLKO

YCLKO

DVDD

DCLK

SYNCIN2

GP16

GP17

DGND

CTS

TXDI

GNDD

81828384858687888990919293949596979899100

2-8 Samsung Electronics

2-3 Chip Replacement (SMD parts)

2-2-1. Precautions for Chip Replacement

1. See to it that the soldering iron does not touch

parts directly. In particular, TSOP may be easily

damaged by heat.

2. Handle the soldering iron with care and avoid

using the same many times. Some parts can be

damaged by sudden heat. Preheat parts for minutes at about 100¡c before soldering them.

3. The temperature of the soldering iron should

remain at about 240¡c Use a 280¡c iron for

bigger parts.

4. Thin (0.3mm) solder used for chip parts does not

contain enough flux. Use additional flux.

* For computers and OA systems, water-soluble flux

is used. Water-soluble flux and solder are also

good for replacing parts and repairing this product. Improper flux may corrode the soldered part

and cause serious defects to the system.

5. Be careful not to damage the circuit pattern when

you disjoin soldering. The pattern should be clean

because there are a lot of pins close together on IC.

6. Be careful not to cause a short circuit between

close pins.

7. Locate parts in place. It has a great influence on

soldering.

8. Do not use repaired parts again.

9. Check the soldered part.

10. Defective variable resistors are not adjustable. Be

sure to replace them.

11. After finishing the job, check if there are cold soldered parts.

2-2-2. Tools to Replace Chips

The following tools are used to replace chip parts.

¥ iron with thin tip

¥ iron with small and flat tip

¥ solder remover

¥ ventilation device

¥ tools to lift flat parts

¥ flux that can be cleaned with water

¥ 0.3mm thin solder that can be cleaned with water

¥ wire to remove solder

¥ tweezers

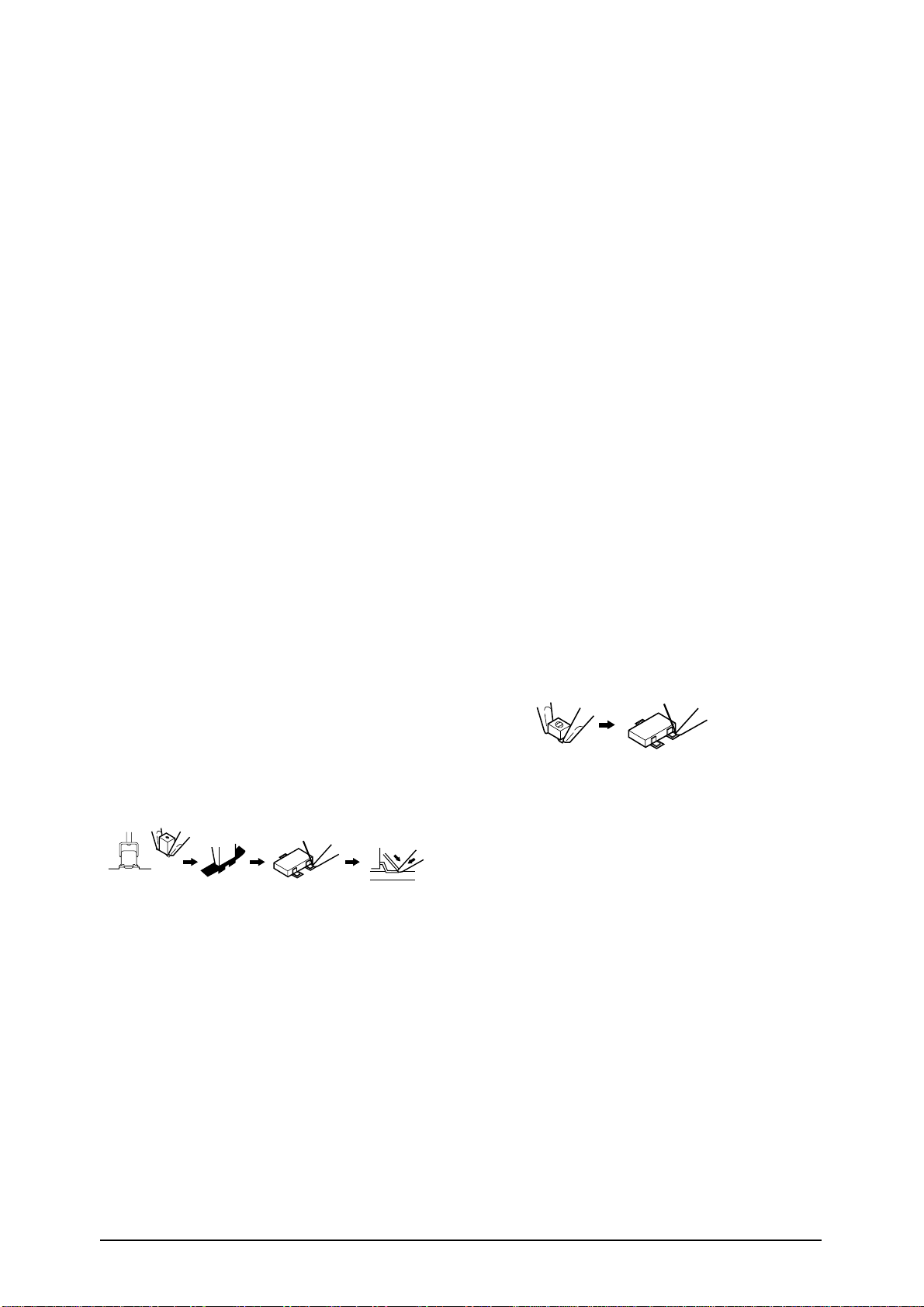

2-2-3. Chip Resistance & Chip Condenser

2-2-3 (a) Type

There are the following types of chip resistance and

chip condensers.

¥ There are the following types of thin film and chip

condensers.

¥ Carbon Film chip resistance

¥ Metal Film chip resistance

¥ Chip ceramic condenser

¥ Chip variable resistance

2-2-3 (b) Removal

Use 2 soldering irons.

a. Use a thin-tip iron.

b. Keep about 280¡c

c. Apply heat to both ends of a part at the same time.

d. Remove it with the tip of the iron while heating.

e. Remove the remaining solder on PCB completely

with solder removing wire. It should be done to

install a new part.

Samsung Electronics 2-9

2-2-3 (c) Installation

a. Clean the place where a new part will be located.

b. Apply water-soluble flux.

c. Set a part correctly in place. Prevent it from shift-

ing.

d. Stick the part fast without contacting it directly

with the soldering iron. Put 0.3mm solder between

the iron and the part so that it can melt into the

part.

e. Check the soldered part with a magnifier.

2-2-4. Chip Tantalum Condenser and Chip Filter

2-2-4 (a) Type

There are the following types of chip tantalum condenser and chip filter.

¥ Chip coil

¥ Chip tantalum condenser

¥ Chip tantalum electrolysis condenser

¥ Chip aluminum electrolysis condenser

¥ Chip transformer

¥ Chip filter

2-2-4 (b) Remoral

1. Use a special solder-removing iron.

a. Choose an iron tip that suits the size of the part.

b. Put the iron tip to the part to be soldered.

c. Remove the part when solder melts.

d. Remove the remaining solder completely with

solder-removing wire.

2. Use two irons.

a. Use an iron with small flat tip.

b. Apply heat to both ends of the part at the same

time.

c. Remove the part with the tip of the iron while

melting.

d. Remove the remaining solder completely with

solder removing wire.

2-2-4 (c) Installation

1. Clean the place where new parts will be installed.

2. Apply water-soluble flux.

3. Locate a part exactly in place. Be careful not to shift

it.

4. Stick the part fast with a soldering iron not contacting it directly. Put 0.3mm solder between the

iron and the part so that it can melt into the part.

5. Check the soldered part with a magnifier.

2-2-5. Chip Variable Resistance, Chip

Variable Condenser, Diode &

Transistor

Chip Variable Resistance, Chip Variable Condenser,

Diode & Transistor

2-2-5 (a) Type

There are the following types.

¥ Chip Variable Resistance

¥ Chip Variable Condenser

¥ Diode

¥ Transistor

2-2-5 (b) Removal

Use two soldering irons.

a. Use an iron with small flat tip.

b. Apply heat to both ends of a part at the same time.

c. Remove the part with the tip of the iron while sol-

der melts.

d. Remove the remaining solder completely with sol-

der removing wire.

2-10 Samsung Electronics

2-2-5 (c) Installation

1. Clean the place where new parts will be installed.

2. Apply water-soluble flux.

3. Locate a part exactly in place. Be careful not to shift

it.

4. Stick the part fast with a soldering iron not contacting it directly. Put 0.3mm solder between the

iron and the part so that it can melt into the part.

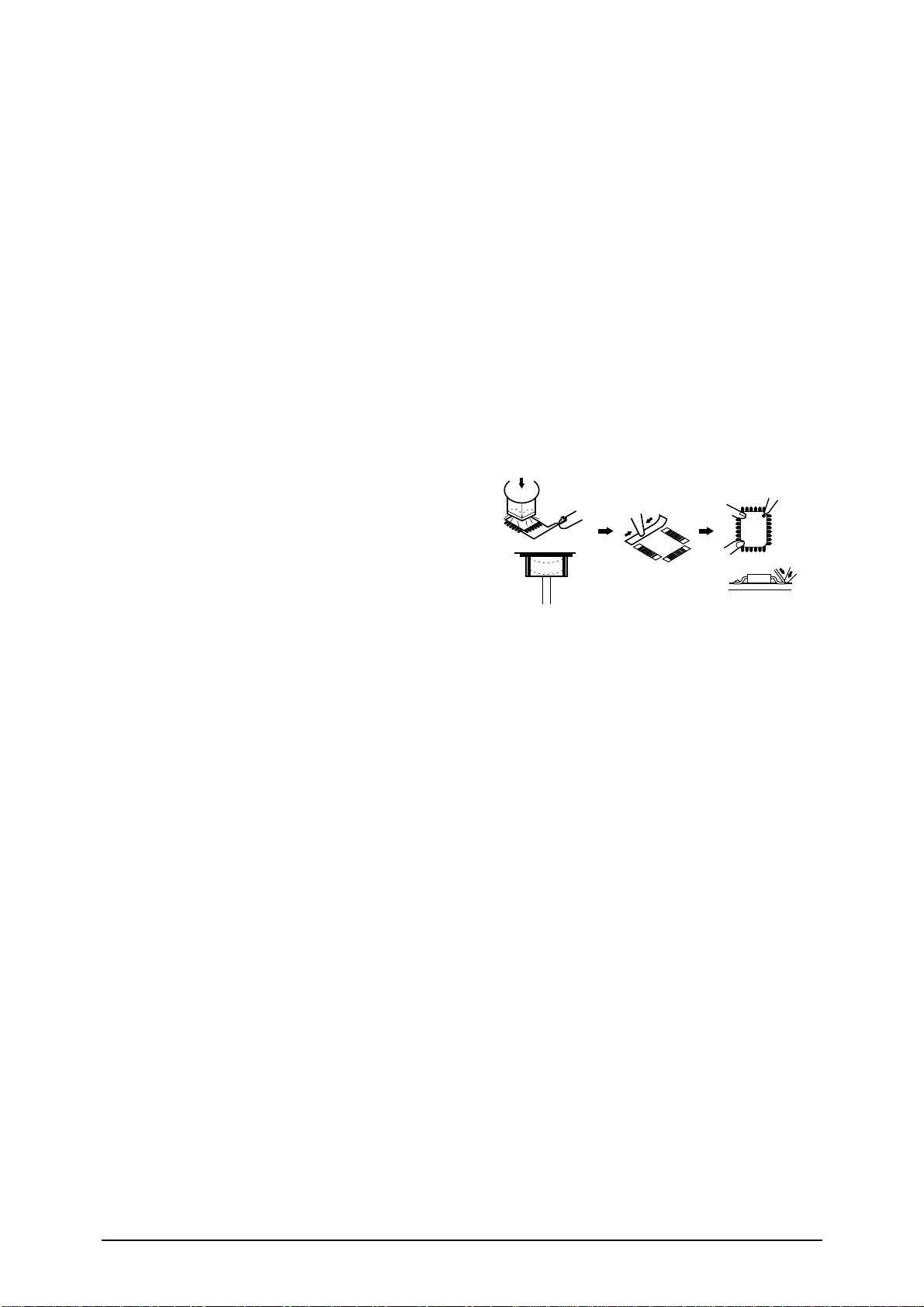

2-2-6. Chip IC

2-2-6 (a) Type

There are the following types of chip IC.

1. SOP (Small Outline Package) IC

2. SSOP (Shrink Small Outline Package) IC

3. VSOP (Very Small Outline Package) IC

4. QFP (Quad Flat Package) IC

5. VQFP (Very Quad Flat Package) IC

6. PLCC (Plastic Leaded Chip Carrier) IC

7. TSOP (Thin Small Outline Package) IC

2-2-6 (b) Removal

1. Use a special solder-removing iron.

a. Choose an iron tip that suits the shape and the

size of IC.

b. Use ÔthinÕ tip to contact legs of IC.

c. Put the tip right in front of the legs of IC.

d. Twist the iron carefully when solder melts.

e. Raise and remove IC.

2. Use a ventilation device.

a. Choose an injector that suits IC.

b. Choose the temperature and the ventilation

speed. (normal: temperature - 7, speed - 4)

c. Use IC-removing tools.

d. Preheat it for about 5 seconds with the ventila-

tion device. And apply heat with the injector

until IC can be removed from the board with IC

removing tools.

2-2-6 (c) Installation

1. Remove the remaining solder completely with solder-removing wire.

2. Clean the place to be soldered.

3. Apply water-soluble flux.

4. Put IC in place and solder the legs of opposite

direction.

5. Solder each leg carefully with thin tip.

6. Remove solder with solder-removing wire if there

is a short circuit.

7. Check the soldered part with a magnifier.

IC

Samsung Electronics 3-1

3. Specifications

3-1 Specifications

Specification & Features

1. Printer

1-A. Set

1-B. Ink Cartridge Supply

Technology

Thermal Inkjet

1-pen & print head swapping type

Speed

Color 3PPM at draft mode (6005300 DPI)

Mono 7PPM at draft mode (6005300 DPI)

Resolution

Color 600 5 600DPI (120051200 DPI addressable)

Mono 600 5 600DPI (120051200 DPI addressable)

Printing Width 8 Inch

Feeding

Automatic 100 sheets for normal cut sheets, coating paper

Method

Manual Recommended for thick media, fashion paper, envolope,

postcard, Banner paper

Emulation Host Based Printing (GDI)

Printer Driver Window 3.1/3.11 and Windows 95 drivers

Interface IEEE 1284 Compatible Parallel Interface (ECP)

Mono Ink Color Ink

Print Head 208 nozzles 192 nozzles

Ink Type Pigment Dye

Ink Color Black Color

Ink Yield About 600 sheets About 200 sheets

3-2 Samsung Electronics

2. Scanner

Technology CCD

Scanner Type Color/Mono

TWAIN Compatible Yes

Pre-Scan Using Carrier Sheet

Speed Color about 1 PPM

Mono about 2 PPM

Resolution Color 300 X 300 DPI (for SmartJet-C only)

Mono 300 X 300 DPI

Gray Scale 256 Level

Printing Width 8 lnch

Feeding Manual Yes

Interface IEEE 1284 Compatible Parallel Interface (ECP)

Samsung Electronics 3-3

3-1. Facsimile

Compatibility ITU-G3

Scan Method CCD Shuttle Scanning Method

Scan Width Max. 8.5 Inch, Effective : 8 Inch

Document Feeding Method Manual Feeding Method

Guide Document In-put Guide

Stacker None

Handset None

Keys on OPE 4EA (Ready, Cartridge, FF/STOP, START/COPY))

LEDs on OPE 3EA (Ready, Busy, Scan/Fax)

Real Time Clock None

Fax Monitoring Speaker Yes

Ring Volume Control Switch None

Paper Tray BIN Type, up to 100 sheets

Modem Speed Max 9600 bps

Coding Method MH, MR, MMR, Error Correction Mode

LCD None

Answering Machine I/F None

Extension Phone I/F 1-Jack, Extension Phone Transfer

PC Interface IEEE 1284 Parallel Interface (ECP)

Fax Send Resolution - Standard : 200 x 100 dpi

- Fine : 200 x 200 dpi

- Superfine : 300 x 300 dpi

3-4 Samsung Electronics

3-2. Facsimile

Feature Use Ext. Telephone Use PC

Gray Scale - Auto Contrast - Auto Contrast

- 256 level with

Error diffusion

Memory Transmission None Yes

Memory Rx Yes Yes

Receive Mode - Tel, Fax - Fax

- PC Rx

One Touch Dial *No 70 Numbers

Speed Dial *No

Chain Dial *No No

On Hook Dial *No No

Last Number Redial *No No

Telephone Auto Busy Redial *No No

No Power Operation *No No

Hold & Mute *No No

Pause *No Yes

Ring Volume Control *No No

Flash *No No

Tone/Pulse Switch *No Yes

Sensors No paper sensor, Paper jam sensor

Error Indicator Yes (On LED) Yes (On PC Screen)

Voice Request No No

Others TTI Yes

Rx Terminal ID No No

Polling No No

DRPD U.S.A : Yes, Other countries : No

Mercury No No

* The marked “No” can be provided by telephone’s feature.

Samsung Electronics 3-5

Feature Use Ext. Telephone Use PC

Tx/Rx Journal No Yes

Report & List

Delayed Dial List No No

Print out System Data No Yes

Tel Number List No Yes

Help List No No

Copy Yes (1-Page) Yes (99-Page)

Copy Gray Scale No Yes

Reduction Copy No Yes

Enlargement Copy No No

4. Electrical & Environment

Power Source AC 220~240V, 0.3A, 50~60Hz

Dimension (W5D5H) 422(mm) 5 237(mm) 5 180(mm)

Weight 3.7kg

5. Accessories

Tel Handset No

Curl Cord No

Tel Line Yes

Power Cord Yes

Software 1 CD-ROM

(Manual, Printer Driver, PC-Fax)

Manual 1EA

Ink Mono Ink Yes

Cartridge Color Ink Yes

* Xerox’s OCR S/W and scanner editor are recommended for its own use.

Samsung Electronics 4-1

4. Disassembly & Assembly

4-1 Taking Off Front Cover

This section explains with illustrations how to disassemble the printer.

It does not explain how to assemble it, because it is the very reverse of disassembly.

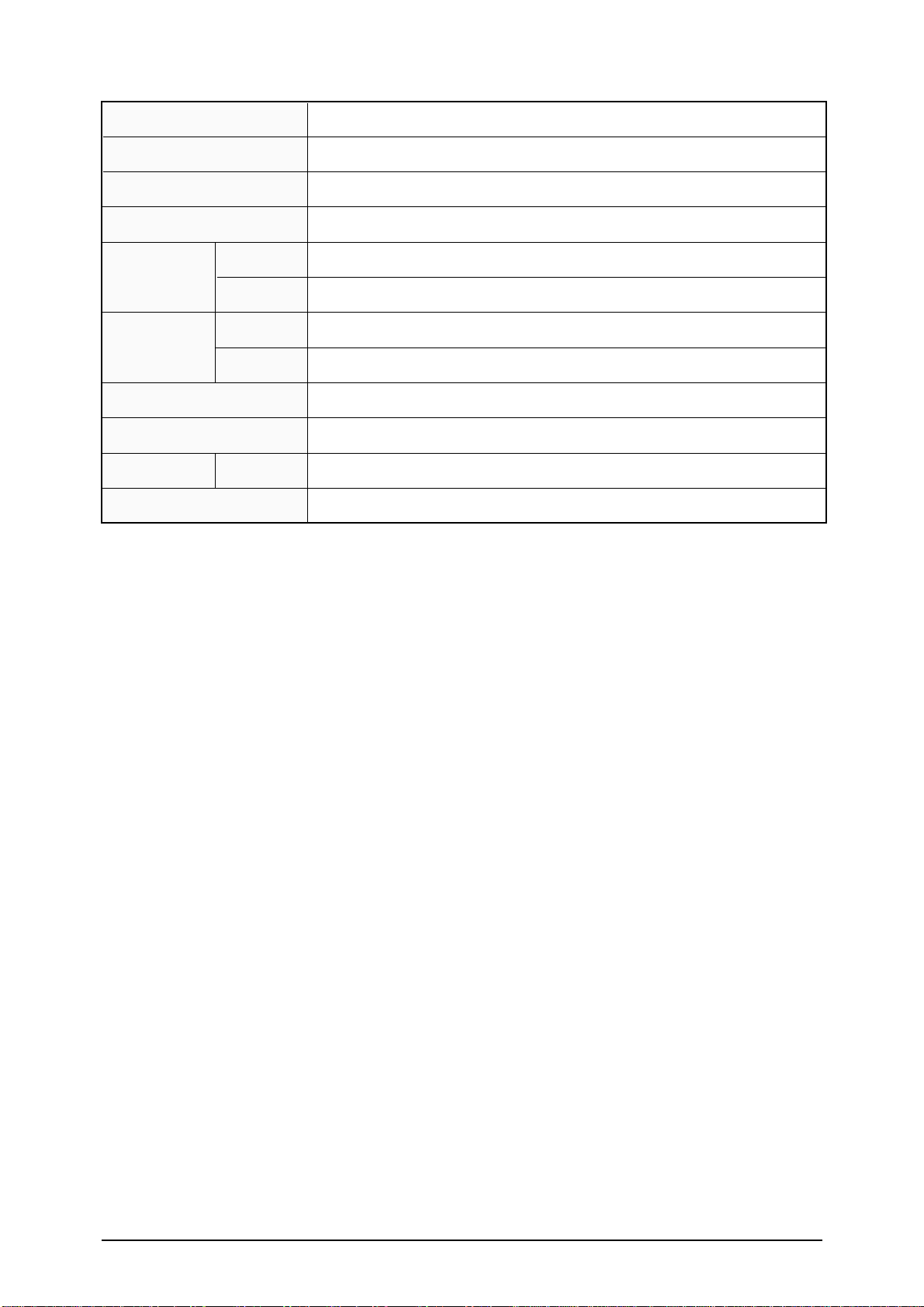

Fig.4-1. Taking Off Front Cover -1 Fig.4-1. Taking Off Front Cover -2

Disconnect power cords and printer cable from

the printer.

Unscrew 1 screws on rear cover to separate ink

cartridge storage.

Push Guide Extension in the direction of the

arrow symbol.

Remove 2 screws between front cover and bottom cover.

▲▲▲▲

Hold the upper part of front cover with both

hands and lift the front cover, holding

down rear cover.

Separate front cover from rear cover in the

direction of the arrow symbol.

▲▲

4-2 Samsung Electronics

4-2 Taking off Rear Cover

4-3 Separating Automatic Sheet Feeder

Fig.4-2. Taking Off Rear Cover

Push in the paper guide (ÒCÓ) of automatic

sheet feeder and place it inside of A4 line.

Push the guide manual(L) (ÒDÓ) left.

Unhook right and left hooks(ÒAÓ) on the upper

part of rear cover.

Unhook right and the left hooks of bottom

cover by pushing them in.

Separate rear cover in the same direction that

the automatic sheet feeder is mounted.

▲▲▲▲▲

Fig.4-3. Separating Automatic Sheet Feeder

Remove various wires fixed on the side of automatic sheet feeder.

Unscrew 2 screws on automatic sheet feeder.

Push slightly and disconnect the hook (ÒAÓ) fixed to the main frame.

Separate automatic sheet feeder by pulling it in the direction of the arrow symbol.

▲▲▲▲

“A”

Samsung Electronics 4-3

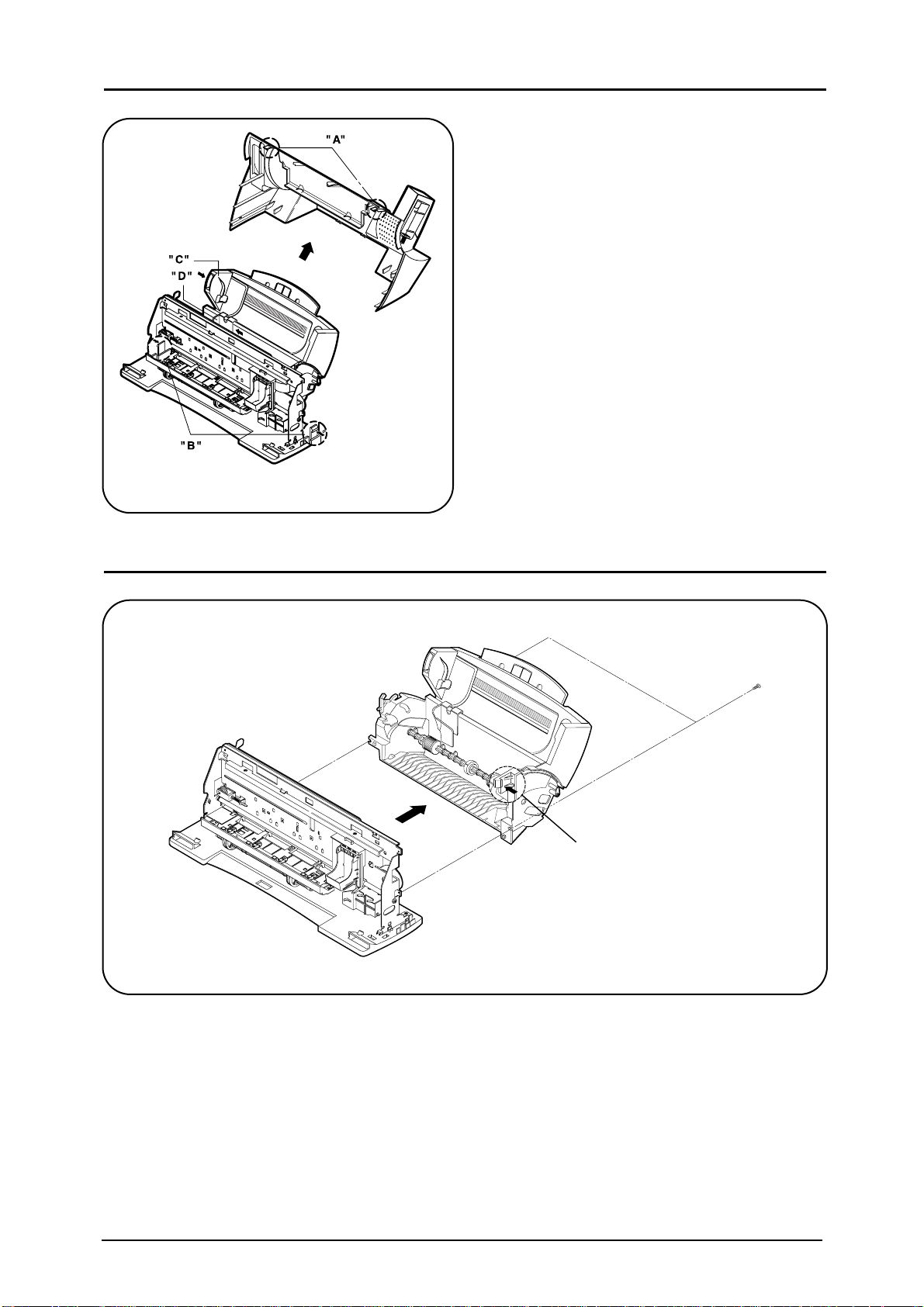

4-4 Separating Main Circuit Board

Separate various connectors connected with the main board.

Separate head cable connected with the main board.

Unscrew 3 screws fixed to the main board and separate the main board in the

direction of the arrow symbol.

Fig.4-4. Separating Main Circuit Board

4-5 Separating Power Circuit Board

Fig.4-5. Separating Power Circuit Board

▲▲▲

Unscrew 2 screws that fix the right and left ground wire.

Press the hook (ÒAÓ) on the middle of the housing and separate power circuit board.

▲▲

4-4 Samsung Electronics

4-6. Separating Printer Engine

Fig.4-6. Separating Printer Engine

Remove 2 screws fixed to printer engine unless

you unscrewed them at the previous

stage.

Push outside right and left hooks on the side of

the engine, unhook them, and

separate the engine in the direction of the arrow

symbol.

▲▲

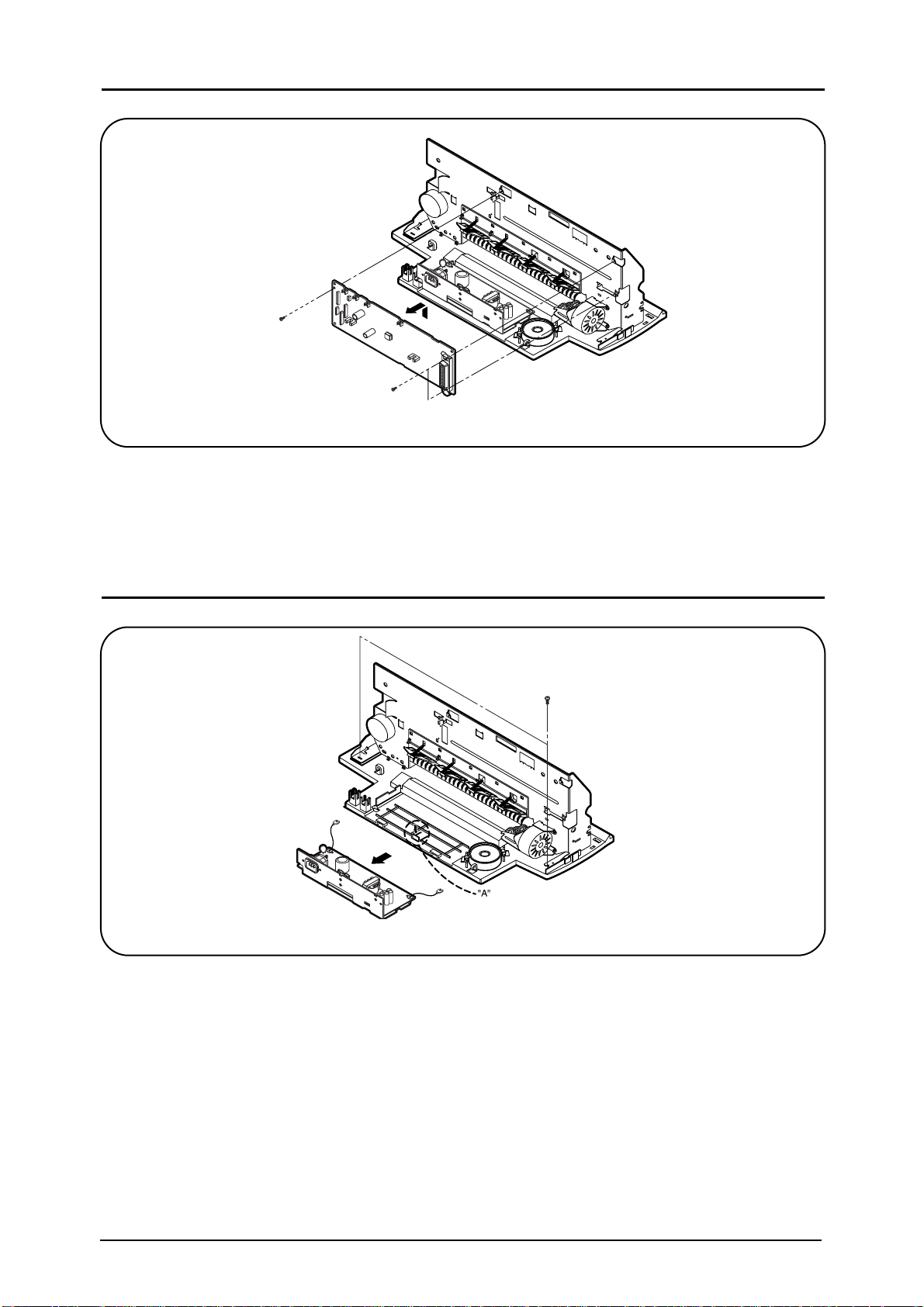

4-7. Separating Home Assembly

Fig.4-7. Separating Home Assembly

Unscrew 1 screw fixed to the back of the engine

and separate home assembly from the

engine.

Pull out the wiper and the cap in the direction

of the arrow symbol to separate them.

▲▲

Samsung Electronics 4-5

4-8. Separating Carrier Assembly

Fig.4-8. Separating Carrier Assembly

Separate FPC cable connected with the main

board.

Separate the holder cable fixed to the main

frame.

Remove 1 screw on the right of the engine and

spring on the left of the engine.

Push the left idle pulley in and separate the

right part of the timing belt from motor

pulley.

Pull out carrier shaft and separate carrier

Assembly.

▲▲▲▲ ▲

Holder

Cable

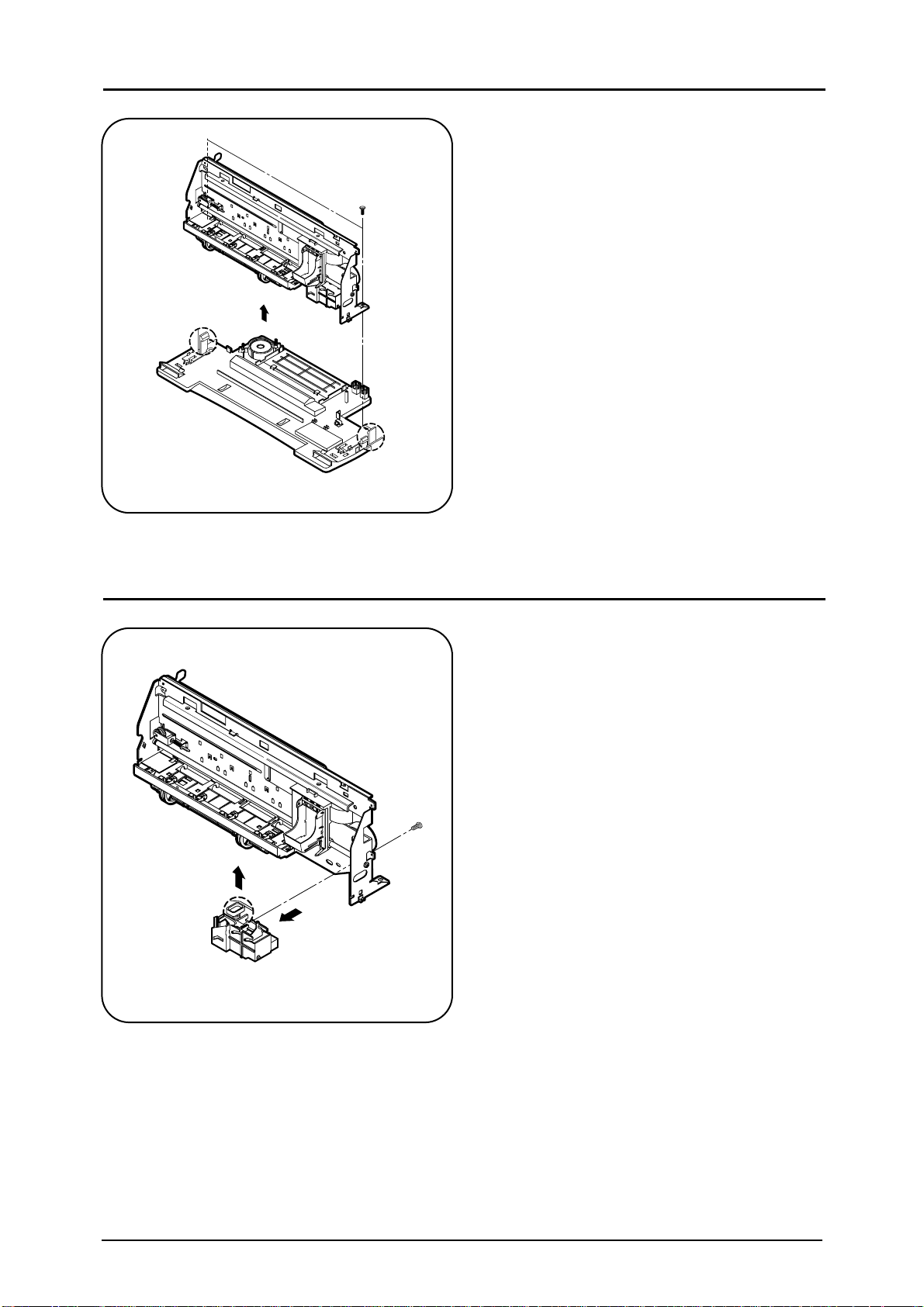

4-9. Separating Frame Base Assembly

Fig. 4-9. Separating Frame Base Assembly

Refer to 4-8 to separate carrier Assembly first.

Separate 4 roller friction Assembly on the back

of the engine and then actuator feed.

Separate frame base Assembly by lifting the

back.

▲▲ ▲

Frame Base Assembly

Actuator Feed

Roller Friction Assembly

Idle Pulley

Carrier Shaft

Head Cable

4-6 Samsung Electronics

4-10 Separating Feed Roller Assembly

1

2

Fig.4-10. Separating Feed Roller Assembly

Refer to 4-9 to separate frame base Assembly

first.

Unscrew 1 screw fixed to the back of the engine

and separate frame support from the

engine.

Turn the bearing feed (R) in the direction of the

arrow symbol to separate it from

the main frame.

Push feed roller on the right to separate it from

the main frame.

▲▲ ▲ ▲

Bearing Feed (R)

4-11 Separating Bracket Line Feed Assembly

Fig.4-11. Separating Bracket Line Feed Assembly

Refer to 4-10 to separate feed roller Assembly.

Unscrew 2 screws and separate bracket line

feed Assembly.

▲▲

Bracket Line Feed

Feed Roller

Frame Support

Samsung Electronics 4-7

4-12 Separating Automatic Sheet Feeder

Fig.4-12. Separating Automatic Sheet Feeder

Separate the manual plate from frame ASF.

Separate the cam pickup on the right and then unscrew the right screw to separate

the finger part.

Pull out the clutch and then unscrew 1 left screw to separate the clutch part.

Separate the guide finger from shaft pickup.

Push shaft pickup to the right to separate.

Bend plate-knockup slightly and then separate it from the frame ASF.

▲▲ ▲▲▲▲

4-8 Samsung Electronics

4-13. Separating LIU board

Fig.4-13. Separating LIU board

Refer to 4-12 to separate automatic sheet feeder from the engine.

Separate the connector.

Unscrew 2 screws fixed to LIU board.

Separate LIU board from the engine in the direction of the arrow symbol.

▲▲▲▲

Samsung Electronics 4-9

4-14. Separating Scan Assembly

Fig.4-14. Separating Scan Assembly

Unscrew 1 screw.

Push up scan Assembly in the direction of the arrow symbol to separate it from the carriage.

▲▲

4-15. Separating White Reference Sheet

Fig.4-15. Separating White Reference Sheet

Remove contaminated white reference sheet completely from the frame base.

Ask for new white reference sheet.

▲▲

White Reference Sheet

Frame Base

Loading...

Loading...