Page 1

FACSIMILE

SF150T

CONTENTS

1. Precautions

2. Specification

3. Operating Instructions

4. Disassembly and Reassembly

5. Circuit Description

6. Troubleshooting

7. Electrical Parts List

8. Exploded Views and Parts List

9. PCB Diagrams

10. Block Diagram

11. Wiring Diagram

12. Schematic Diagrams

FACSIMILE

SERVICE

Manual

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 2

Samsung Electronics Co.,Ltd. Mar. 1998.

Printed in Korea.

JF68-60936A

Page 3

SF150T 1-1

1. Be sure that all built-in protective devices are

in place. Restore any missing protective

shields.

2. Make sure there are no cabinet openings

through which people- particularly childrenmight insert fingers or objects and contact

moving parts or dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this equipment, such as

auxiliary connectors, etc. Such alterations and

modifications will void the manufacturer's

warranty.

5 Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct

any potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-ofplace, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

provide could be lost if a replacement

component differs from the original. This

holds true, even though the replacement may

be rated for higher voltage, wattage, etc.

8. Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. A replacement part

that does not have the same safety

characteristics as the original may create

shock, fire, or other safety hazards.

1 Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

Page 4

1. Immediately before handling a semiconductor

component or semiconductor-equipped

assembly, drain off any electrostatic charge on

your body by touching a known earth ground.

Alternatively, employ a commercially

available wrist strap device, which should be

removed for your personal safety reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly

equipped with ESDs, place the assembly on a

conductive surface, such as aluminum or

copper foil, or conductive foam, to prevent

electrostatic charge buildup in the vicinity of

the assembly.

3. Use only a grounded-tip soldering iron to

solder or desolder ESDs.

4. Use only an "anti-static" solder removal device.

Some solder removal devices not classified as

"anti-static" can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective

shorting material from the leads of a

replacement ESD, touch the protective material

to the chassis or circuit assembly into which

the device will be installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal

motions, such as the brushing together of

clothing fabric and lifting one's foot from a

carpeted floor, can generate static electricity

sufficient to damage an ESD.

Precautions

1-2 SF150T

1. Exercise caution when replacing a Lithium

battery. There could be a danger of explosion

and subsequent operator injury and/or

equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Lithium batteries contain toxic substances and

should not be opened, crushed, or burned for

disposal.

1-3 Lithium Battery Precautions

1-2 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called "Electrostatically Sensitive (ES) Devices", or ESDs. Examples of typical ESDs are: integrated circuits,

some field effect transistors, and semiconductor "chip" components.

The techniques outlined below should be followed to help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

Page 5

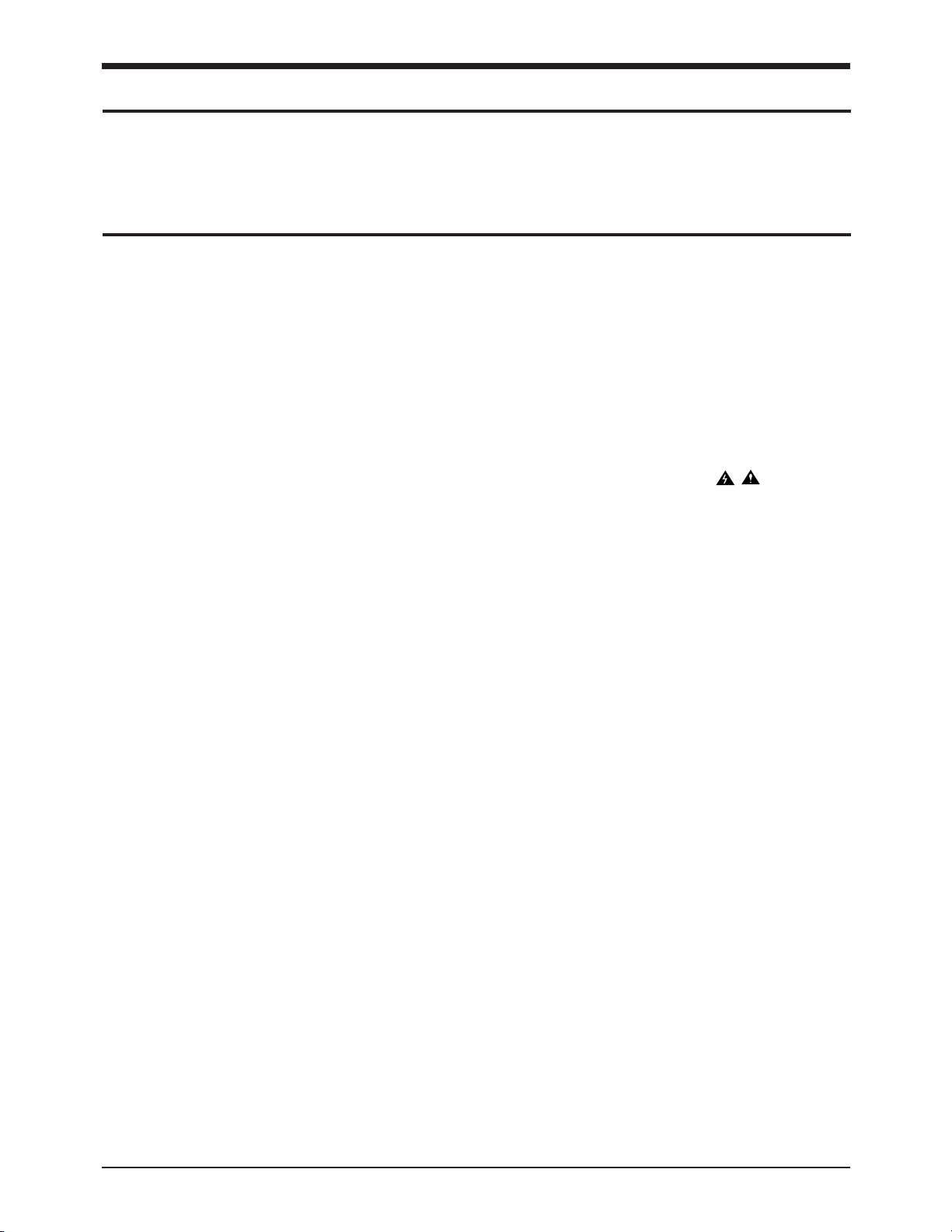

Parameter Specification

Coding Scheme MH (Modified Huffman)/MR (Modified READ)

Recording Paper Size 216 mm x 30 m; core diametre: 12.7 mm

Effective Recording Width 210 mm

Recording Method Solid state Thermal Printing Head

Horizontal 8 dots/mm

Resolution

Standard: 3.85 lines/mm

Vertical Fine: 7.7 lines/mm

Super Fine: 15.4 lines/mm

Parameter Specification

Normal 210 x 297 mm

Document Size Max. 216 x 1500 mm

Min. 152 x 76 mm

Document Thickness 0.085 x 0.115 mm

Scan Line Length Horizontal A4 paper,1728 scan elements along 216 line length

Effective Scanning Width Vertical 216 mm

Scanning Method Horizontal Flat-bed scanning using CIS

Vertical Stepping motor

Horizontal 8 dots/mm

Resolution

Standard: 3.85 lines/mm

Vertical Fine: 7.7 lines/mm

Super Fine: 15.4 lines/mm

SF150T 2-1

2 Specification

2-1 Transmitter

2-2 Receiver

Page 6

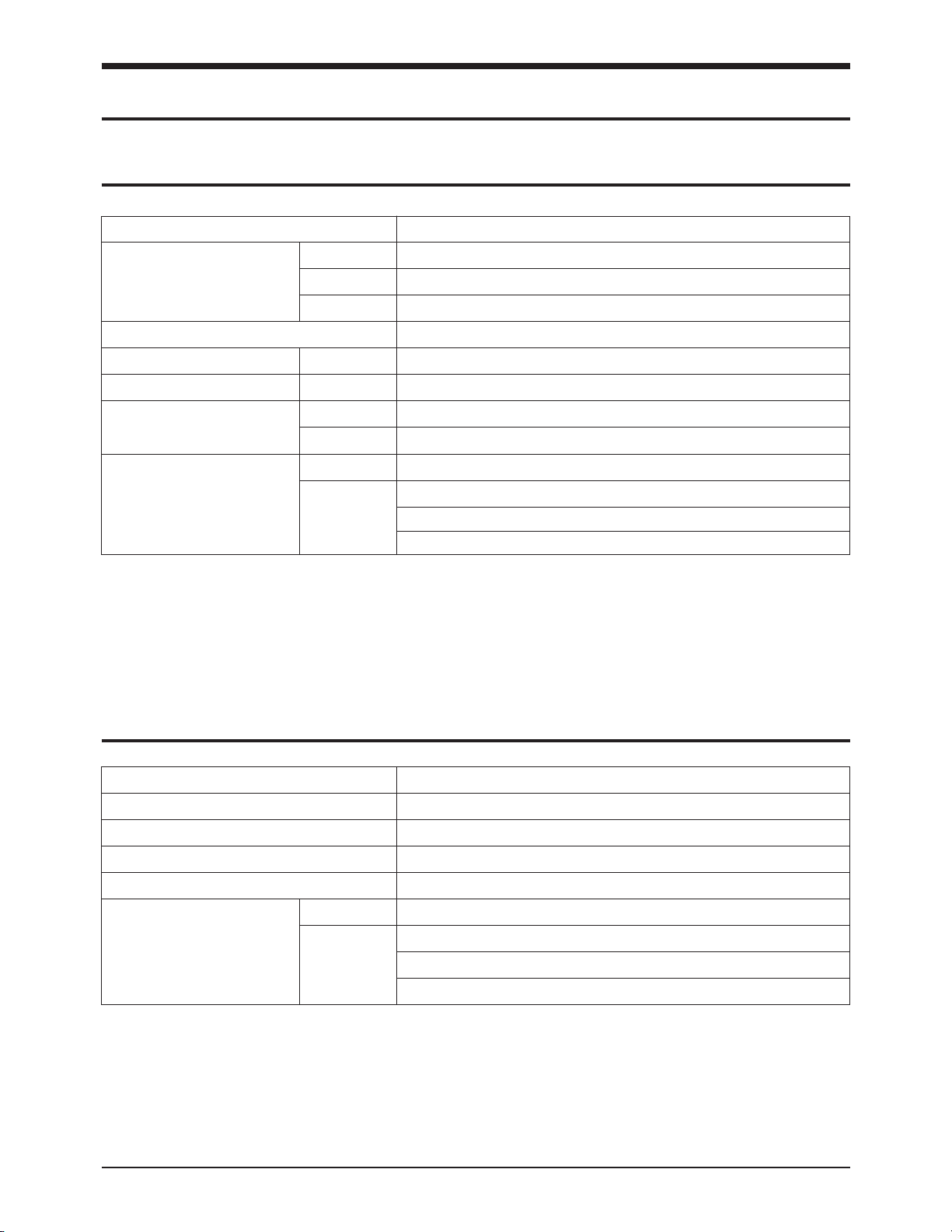

Specifications

2-2 SF150T

Parameter Specification

Dialling Signal DP/DTMF

Dialling Method Manual; Memory dialling; Last Number Redialling

Memory Capacity 34 memory dial (power on)

Power Requirement Check power label attached near the power cord connection.

Power Consumption

Stand-by 7 Watt

In use Max. 115 Watt

Temperature 5 °C to 45 °C

Relative Humidity 20 to 80 % RH (Non-Condensing)

Width 278 mm

Dimension

Depth 211 mm

Height 107 mm

Weight 2.5 kg

Parameter Specification

Communication Facility Public Switched Telephone Network (PSTN)

Line Coupling Direct

Transmission Speed 9600, 7200, 4800, 2400 bps

Modem QAM, DPSK and FSK

(V.29, V.27ter with fall back function and V.21)

Carrier Frequency 1700 Hz (9600/7200 bps)

1800 Hz (4800/2400 bps)

Control Signal 1100 Hz (CNG)

2100 Hz (CED)

300 bps (FSK)

Output Level 0 dBm to - 15 dBm +0.0 / -3 dBm, adjustable in 1 dB steps

Input Sensitivity 0 dBm to - 48 dBm in two ranges

Input & Output Impedance 600 ohm

2-3 Line Control Blockk

2-4 Others

Page 7

SF150T 3-1

3. Operating Instructions

3-1 Service Mode

In Service Mode, the technician can check the machine and perform various tests to isolate a machine

malfunction.

To enter Service Mode, press ÔMENU, #, 1, 9, 3, 4Õ in sequence, and ' ' will be displayed in the LCD to

confirm that the machine has entered Service Mode. While in Service Mode, the machine still performs all

normal operations. To return to normal User Mode, press 'MENU, #, 1, 9, 3, 4' in sequence again, or turn

the power off, then on by unplugging and replugging the power cord.

3-2 Changing Options

3-2-1 Selectable Options

CONFIRMATION REPORT

Select whether a confirmation report prints each

time a user sends a fax.

YES: The machine prints a report automatically

after each fax sent.

ERROR : The machine prints a report only when

there is an error.

NO: The machine does not print a report

automatically. User can print the list on

demand.

DIAL TYPE

Select the type of dial system to which the machine

is connected.

Select MF if connected to a tone dial system.

Select DP if connected to a pulse dial system.

Use ^ or v buttons to select, then press Start.

RING COUNT

Select the number of rings the machine allows

before it answers a call in automatic receiving

mode.

CALLER ID

This is the number of the person faxing you.

Choose YES to turn on Caller ID display.

Choose NO to disable.

REMOTE RECEIVE CODE

This code can be used only with a phone extension

connected to the FAX machine. The user can

initiate FAX receive mode by entering a remote

receiving code on the extension phone. The code is

factory preset to 9 , and the middle character

may be changed to any digit between 0 and 9.

AUTO PRINT

The machine prints a TX/RX journal automatically

after every 20 fax sessions.

MODEM SPEED

Select baud rate of 9600, or 4800 bps. The lower the

baud rate, the larger the acceptable error rate. T30

protocol has a fixed speed of 300 bps in the

protocol mode. When the TX speed is set to 9600

bps, the RX speed will be V.29. When the TX

speed is set to 4800 bps, the RX speed will be V.27

ter.

T

Page 8

Operating Instructions

3-2 SF150T

CALL TRANSFERRING

This feature allows the fax machine to transfer

incoming caller's message to a specified remote

location.

Choose YES to turn on this feature. The LCD

display asks to enter the telephone number you

want to be transferred.

Choose NO to turn off the feature.

CALL MONITORING

This feature enables you to hear callers leaving

messages on the machine.

Choose YES to turn on this feature.

Choose NO to turn off this feature.

CHARGE SAVER

This feature lets the user dial into this machine

from a remote phone and check whether anyone

has left a message without being charged for a

charge call. When toll saver is on and there are

messages waiting to be heard, the machine

answers on the number of rings you specify in the

ring count option. If there are no messages, the

machine answers on the second ring after the

number specified. This gives the user time to hang

up the phone before the machine answers - and

saves the price of the call.

Choose YES to turn on charge saver.

Choose NO to turn off charge saver.

MESSAGE RECORDING TIME

You can select the maximum time allowed for

caller messages and memos.

If you choose YES, the LCD display shows you the

time limits available : 0 second, 30 seconds, 60

seconds or 90 seconds. Choose the proper time. If

you choose 0, it allows callers to hear the greeting

message but doesn't permit them to leave

messages.

REMOTE PASSWORD

You can change the three-character password used

to access your machine from a remote phone. The

password is preset to "#139#" (pound one three

nine pound) at the factory. The first and the last #'s

are fixed, but you can change the middle numbers

from 0 to 9.

Enter the characters you want to use, then press

Start.

BATTERY ALARM

You can turn on the battery alarm feature. With

this feature on, the machine displays the low

battery message in the LCD and sounds beeps to

alert you low battery condition.

Choose YES to turn on the battery alarm feature.

Choose NO to turn off the battery alarm feature.

TAD SILENCE CHECK

In TAD mode, The machine decides the next

action when detected a silence of 10 seconds.

The actions are:

RX : Swiches to receive mode.

REC : Keeps the recording the silence.

CUT : Disconnect the line and returns to standby

mode.

TX LEVEL

From -9 dBm to -15 dBm is acceptable. You can set

the transmission level to between 0 and -15 dBm

in 1dB steps using the control panel keypad.

Accuracy is + 0 / -3 dBm.

CABLE EQUALIZER

Copper telephone wire attenuates low frequencies

less than high frequencies. The longer a cable is,

the more pronounced the effect. To compensate for

this attenuation you may need to set the machine

to match the cable length currently used. Select

short or long.

Page 9

Operating Instructions

SF150T 3-3

LINE MONITOR

Allows you to monitor line signals through the

speaker.

RX LEVEL

Reception level may be too low due to cable losses.

If set to - 43 dBm, reception sensitivity will be

between 0 and - 43 dBm.

If set to - 48 dBm, reception sensitivity will be

between -5 and -48 dBm.

BUSY TONE DETECTION LEVEL

While checking tone in ANS/FAX mode, If any

signal which is great than set level is detected for a

few seconds the machine will disconnect the line.

BUSY ON DROP OUT TIME

While checking busy on time, if any signal noise is

detected, the machine will ignore the signal noise

unless it is greater than a specified time.

BUSY OFF DROP OUT TIME

While checking busy off time, if any signal noise is

detected, the machine will ignore the signal noise

unless it is greater than a specified time.

PAUSE TIME

Adjust the period of pause time to wait for a

second dial tone in a PABX or mobile paging

system. You can adjust the time from 0 sec to 9 sec

(0 to 9).

RECALL TIME

When a call comes in and you want to connect it to

another party, you can transfer the call by using a

timed-break recall funtion.

This funtion must make a properly timed break

authorized by the country. The machine can select

times of 100, 280, or 600 msat an accuracy of ± 10

ms of the setting.

MH/MR CODING

Selection the coding method used for picture

detail

MR = Use MR and MH coding.

MH = Use only MH coding.

RING ON CHECK TIME

The machine must receive a ring signal with a

specified active time from a telephone exchange in

automatic reception mode. The detection time that

the machine considers valid is adjustable via this

option. If the active time of the ring signal is less

than the set value of the Ring On Check Time, the

machine will not consider it a ring signal.

RING OFF CHECK TIME

The machine must receive a ring signal with a

specified inactive time, as well as an active time. If

the inactive time of the ring signal is longer than

the value of the Ring Off Check Time, the machine

will not consider it a valid ring signal.

3-2-2 Changing Options

Press ÔMENU, 3, Start/COPYÕ in sequence. Press

^ or v to select the desired option item.

When the desired item appears, press Start and

use ^ or v to change the status of the selected

option.

Page 10

3-4 SF150T

Operating Instructions

3-3 Test Mode

Test Mode is used to test machine functions. To enter Test Mode, press ÔMENU, 0, START/COPYÕ in

sequence.

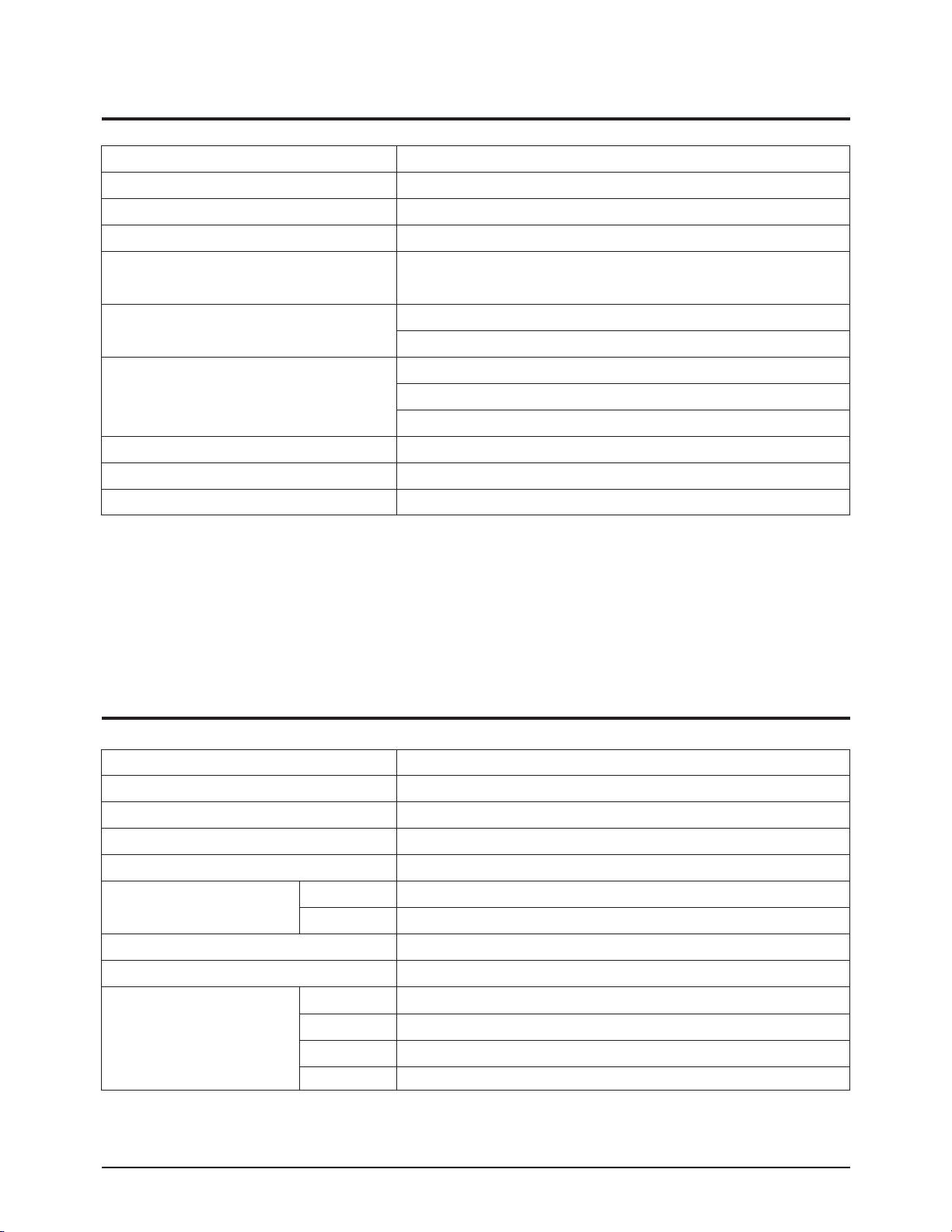

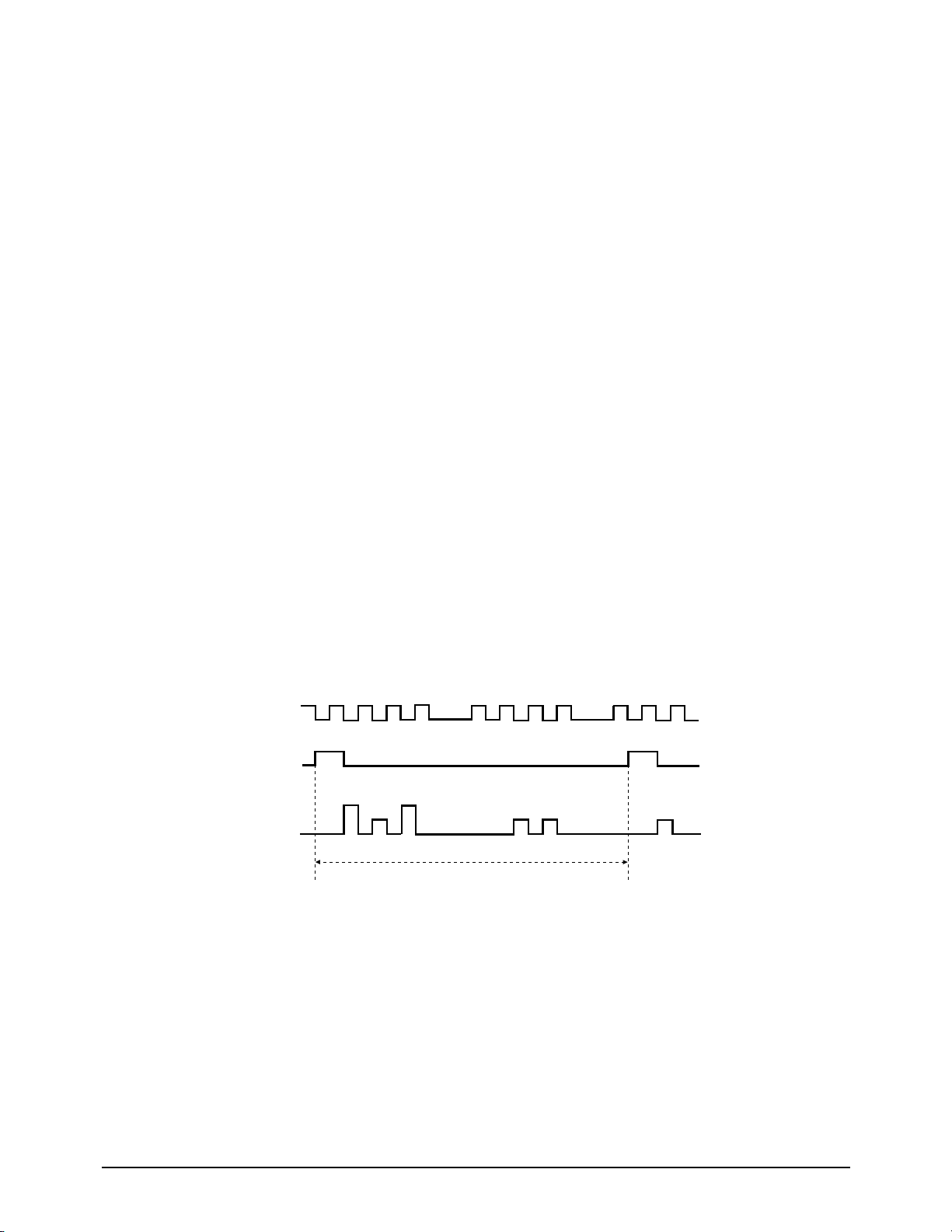

TPH TEST

The TPH test pattern checks the heating element of the TPH. Figure 3-1 is a sample test pattern.

Figure 3-1: TPH Test Pattern

Page 11

Operating Instructions

SF150T 3-5

3-4 Report Printout

A number of useful reports can be printed in Service Mode. One of these lists is the protocol list, which

contains detailed information which may be required when contacting technical support. To print this list,

press MENU, 4, START/COPY in sequence.

When a report name appears in the display, scroll through the list of reports by pressing ^ or v. When a

desired report is selected, press START/COPY.

CONFIRMATION REPORT

Shows the last transmission result.

TX/RX JOURNAL

Shows information about faxes sent and received.

SYSTEM DATA LIST

Shows all option settings.

TEL. NUMBER LIST

Lists all numbers stored in the machine's OneTouch and Speed-Dialling memory.

PROTOCOL LIST

This list is available in Service Mode only, and

shows the sequence of the CCITT group 3 T.30

protocol during the most recent TX or RX

operation. You can check for send and receive

errors with this list.

If a communication error occurs while the machine

is in Service Mode, the protocol list will print

automatically.

HELP LIST

This report illustrates the machine's basic

functions and commands. Use as a quick reference

guide.

To print this list, press HELP (#).

MODEM TEST

The modem will transmit send various signals on

the telephone line to check the following:

¥ FSK Test

¥ Tone Test: 1100 Hz, 1650 Hz, 1850 Hz, 2100 Hz

¥ G3 training: 9600, 4800 bps

¥ RX Loop Test

¥ DTMF Test

ROM TEST

Tests machine ROM (Read Only Memory). The

result and the software version appear in the LCD

in the following format:

CHKSUM= VXX/XX, OK

ALL MEMORY CLEAR

Erases contents of RAM. When memory is cleared,

the machine returns to default settings.

Page 12

Operating Instructions

3-6 SF150T

3-5 LCD Display

3-5-1 During communication

In User Mode, the LCD shows the remote

machine's TTI number, communication type, (send

or receive), and page number.

In Service Mode, the display shows the

communication type, abbreviations for the CCITT

Group 3 T.30 protocol as they occur, the protocol

type (G3), coding type (MH), baud rate in kbps,

and line time.

3-5-2 If a communication problem

occurs:

In User Mode, the display shows one of the

following reasons: CAM JAM, COMM. ERROR,

CHECK DOCUMENT.

In Service Mode, the display shows all error

messages available in User Mode, as well as

additional error messages not available in User

Mode.

Error messages shown only in Service Mode are:

PRE-MESSAGE ERROR:

problem occurred during phase B of session

MESSAGE ERROR:

problem occurred during phase C of session

POST-MESSAGE ERROR:

problem occurred during phase D of session

LINE ERROR:

machine cannot connect or has lost connection

with the remote machine

Additional messages, not shown above, will

appear in the TX/RX journals printed in Service

Mode.

Page 13

SF150T 4-1

4. Disassembly and Reassembly

Note: Make sure power is OFF by removing the power cord from the wall outlet.

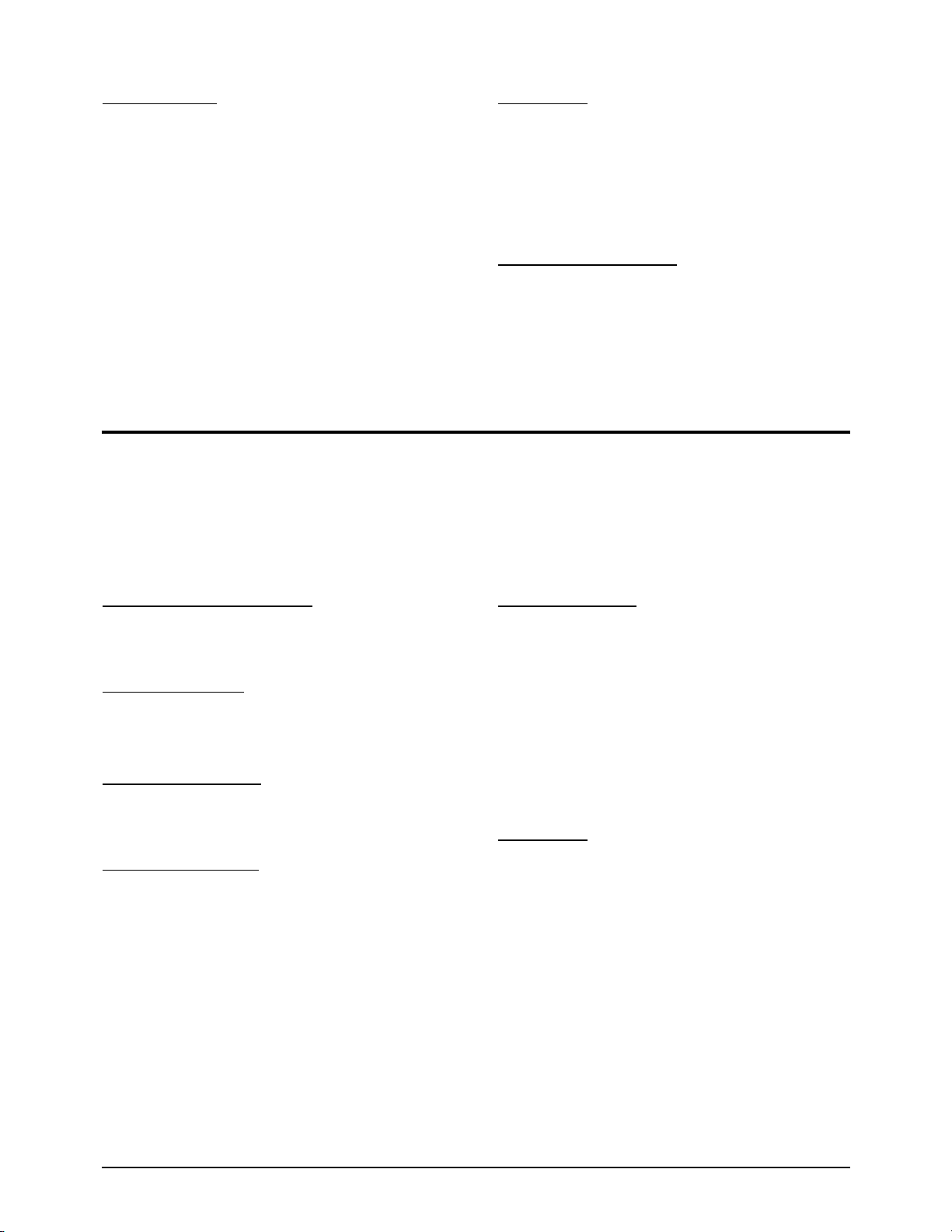

4-1 Tx Guide

¥ Open the operating panel assembly.

¥ Carefully lift the TX guide, as shown in the figure.

OPE Cover

TX Guide

Figure 4-1

Figure 4-2

4-2 Top Cover

¥ Loosen the 5 screws fastening the top cover.

¥ Carefully lift the top cover.

¥ Remove the wire harness from the base, as

shown in the figure.

2

1

1

3

3

3

3

3

Page 14

Disassembly Instruction

4-2 SF150T

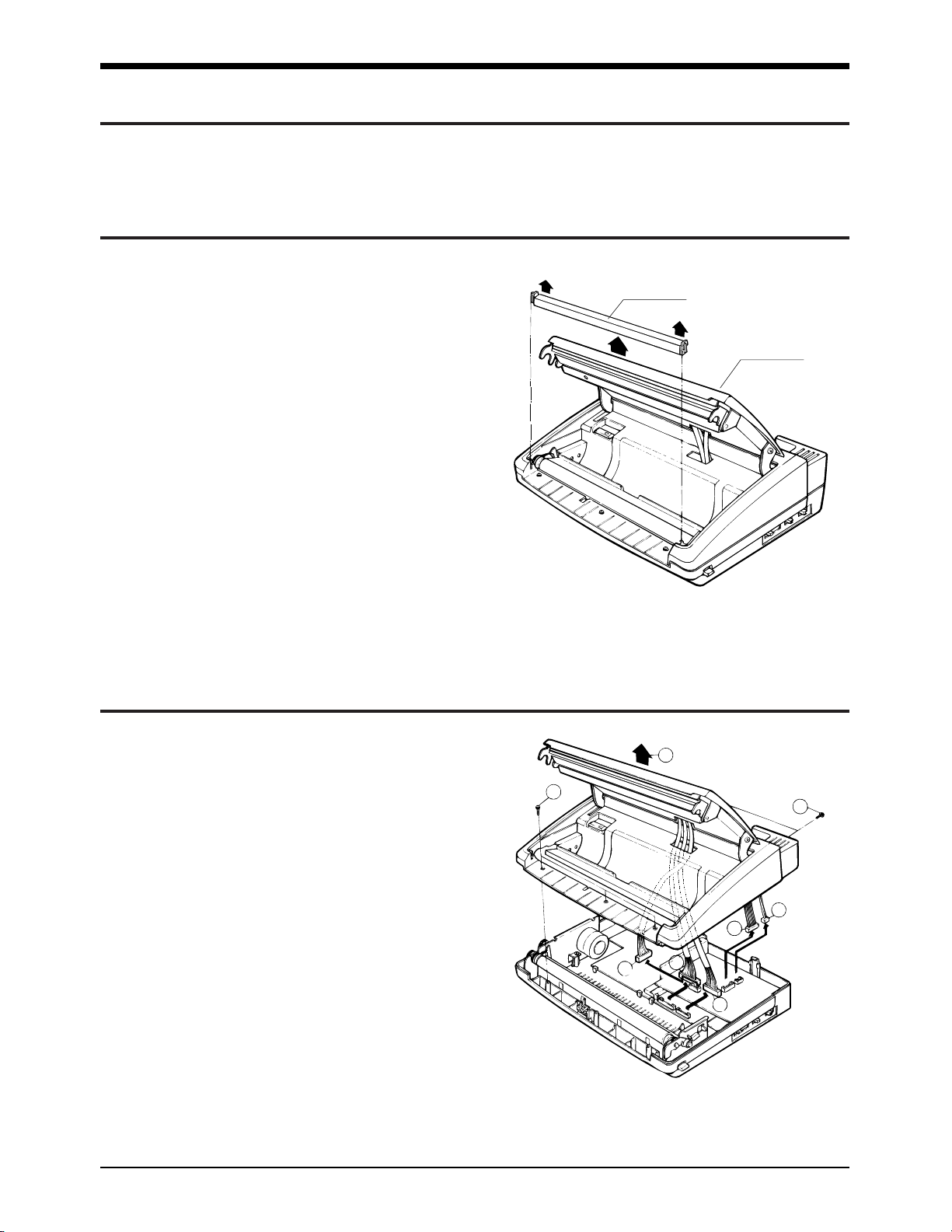

4-3. OPE Unit

4-4.

OPE Cover

¥ Loosen the 2 screws fastening the top cover.

¥ Carefully lift the OPE assembly, as shown by

the arrow.

¥ Loosen the 2 screws fastening the OPE chassis.

¥ Remove the Paper Empty sensor connector

from the OPE board.

¥ Remove the OPE unit from the OPE chassis, as

shown by the arrows.

Top Cover

OPE Unit

OPE Cover

OPE Chassis

Figure 4-3

Figure 4-4

Page 15

Disassembly Instruction

SF150T 4-3

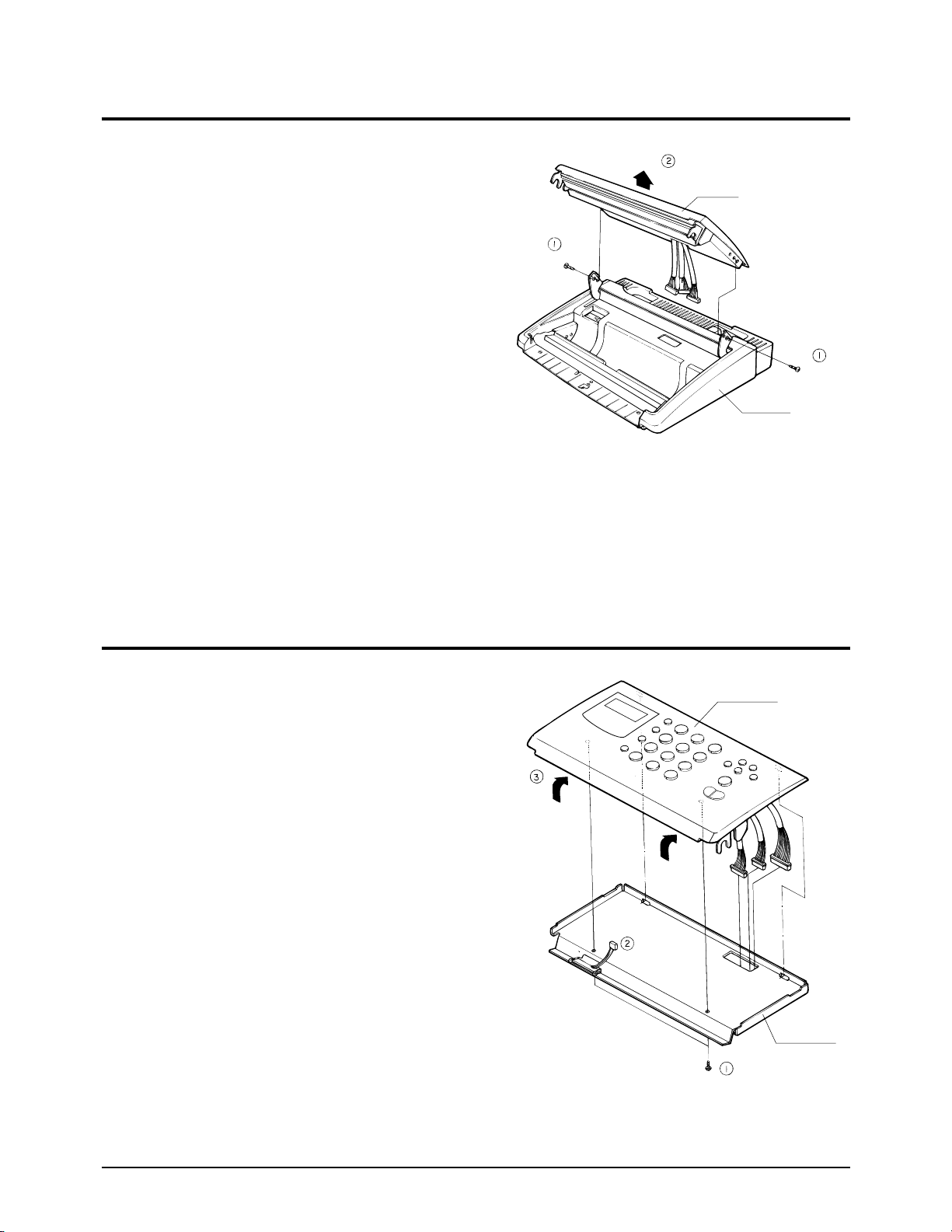

4-5. TPH

¥ Remove the TPH assembly from the OPE unit.

¥ Remove the TPH from the TPH assembly.

¥ Remove the TPH harness from the TPH

connector.

¥ Remove the TPH guide from the TPH.

¥ Lift the white roller assembly.

¥ Loosen the 2 E-rings fastening the main chassis

assembly.

¥ Remove the spring-lock.

¥ Loosen the 2 screws fastening the main chassis

assembly.

¥ Lift the CIS assembly.

¥ Remove the document guide from the CIS

assembly (2 screws).

¥ Remove the CIS guide from the CIS (2 screws).

OPE Cover

TPH Bracket

TPH Guide

TPH

Base Ass'y

Main chassis Ass'y

4-6. Main Frame

Figure 4-5

Figure 4-6

Page 16

Disassembly Instruction

4-4 SF150T

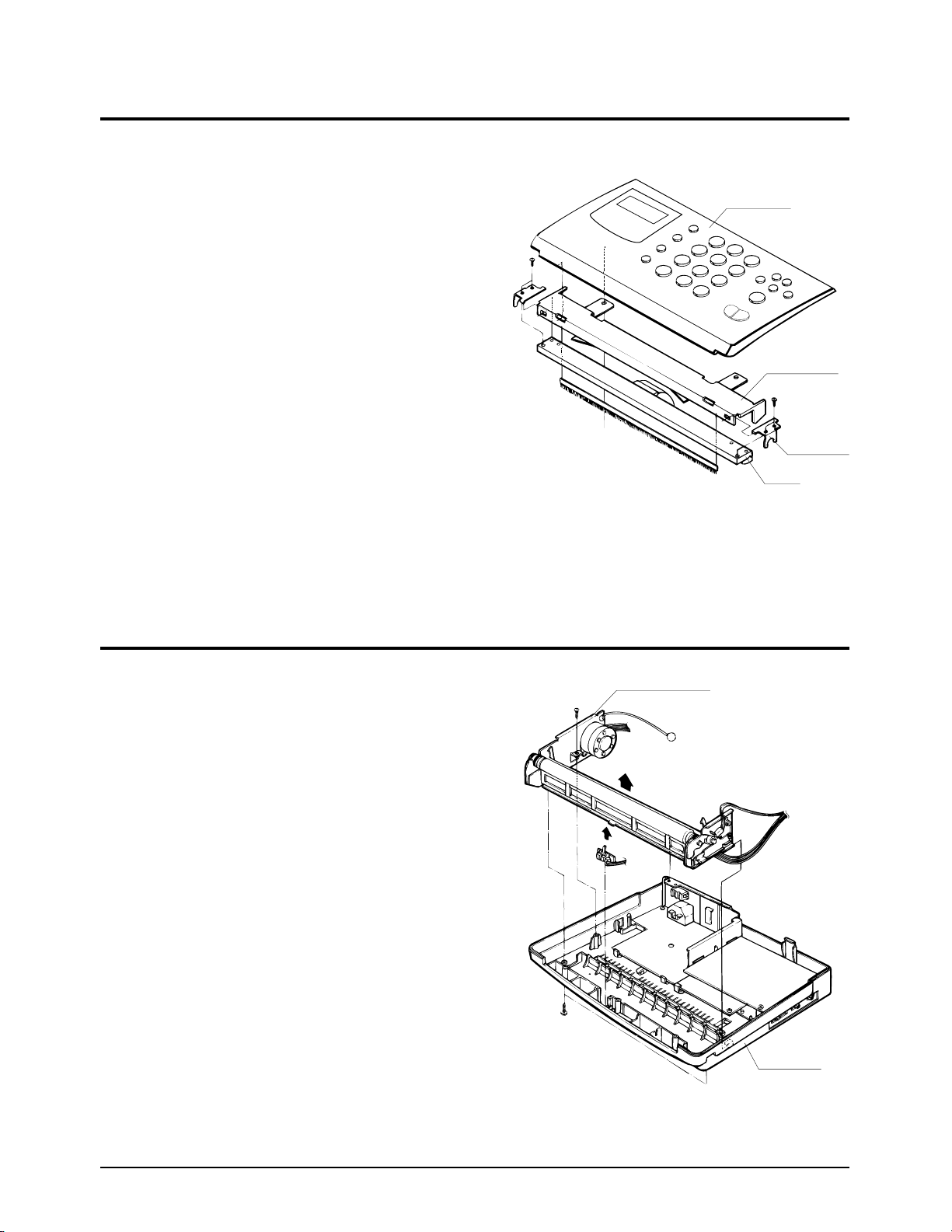

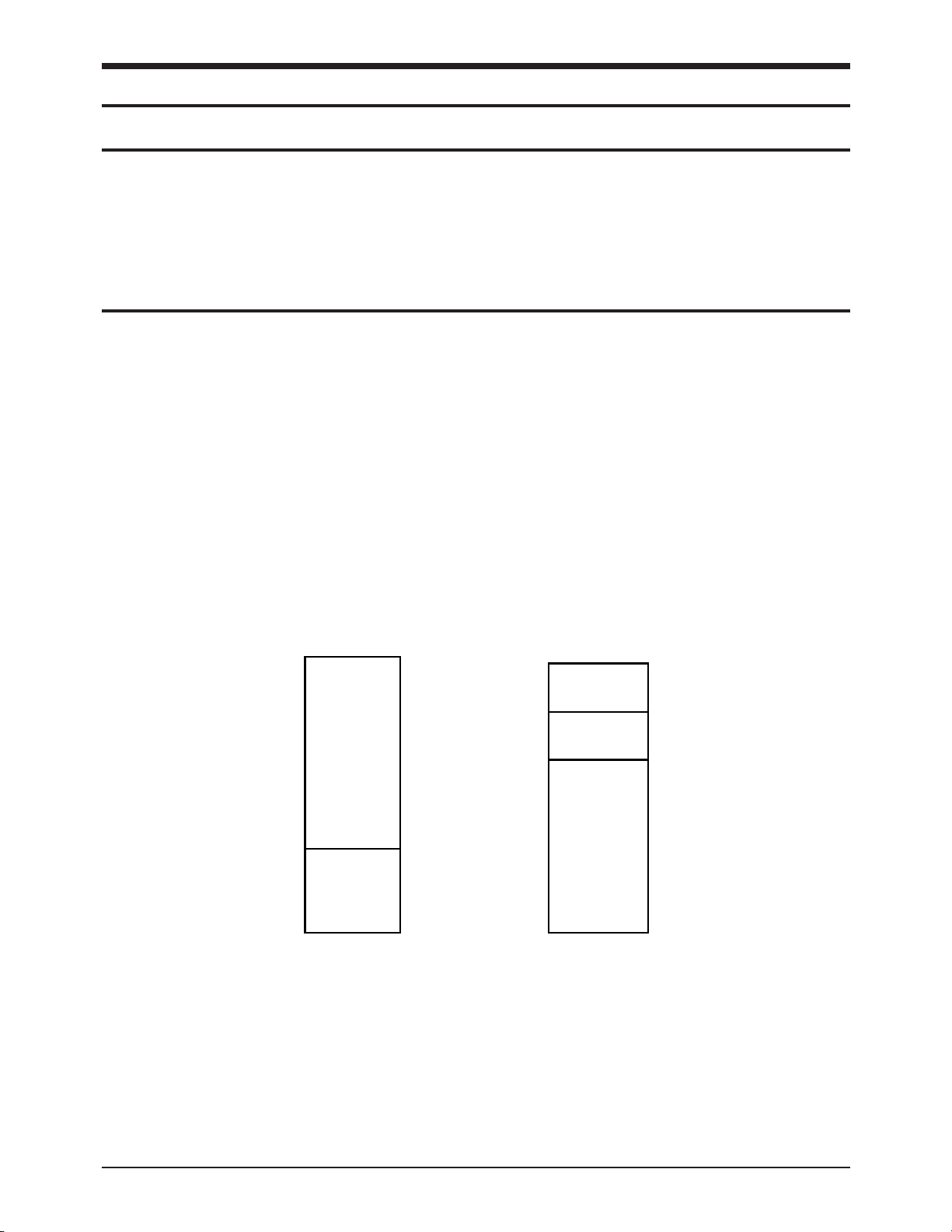

4-8. BOARDS & POWER SUPPLY

LIU PBA

MAIN PBA

BASE

POWER

¥ Remove the handset modular harness from the

LIU board.

¥ Loosen the screw fastening the LIU board and

carefully lift the LIU board as shown by the

arrow.

¥ Loosen the 3 screws connecting the main and

daughter boards. Lift the rear bracket.

¥ Loosen the screw fastening the daughter board

to the base. Lift the daughter board.

¥ Loosen the 2 screws fastening the power supply

to the base. Lift the power supply and the main

board to remove them.

¥ Lift the modular jack and the earth spring.

¥ Lift the white roller assembly.

¥ Loosen the 2 E-rings fastening the main chassis

assembly.

¥ Remove the spring-lock.

¥ Loosen the 3 screws fastening the main chassis

assembly.

¥ Lift the CIS assembly.

¥ Remove the document guide from the CIS

assembly (2 screws).

¥ Remove the CIS guide from the CIS (2 screws).

4-7. CIS

Figure 4-7

Figure 4-7

Page 17

SF150T 5-1

5. Circuit Description

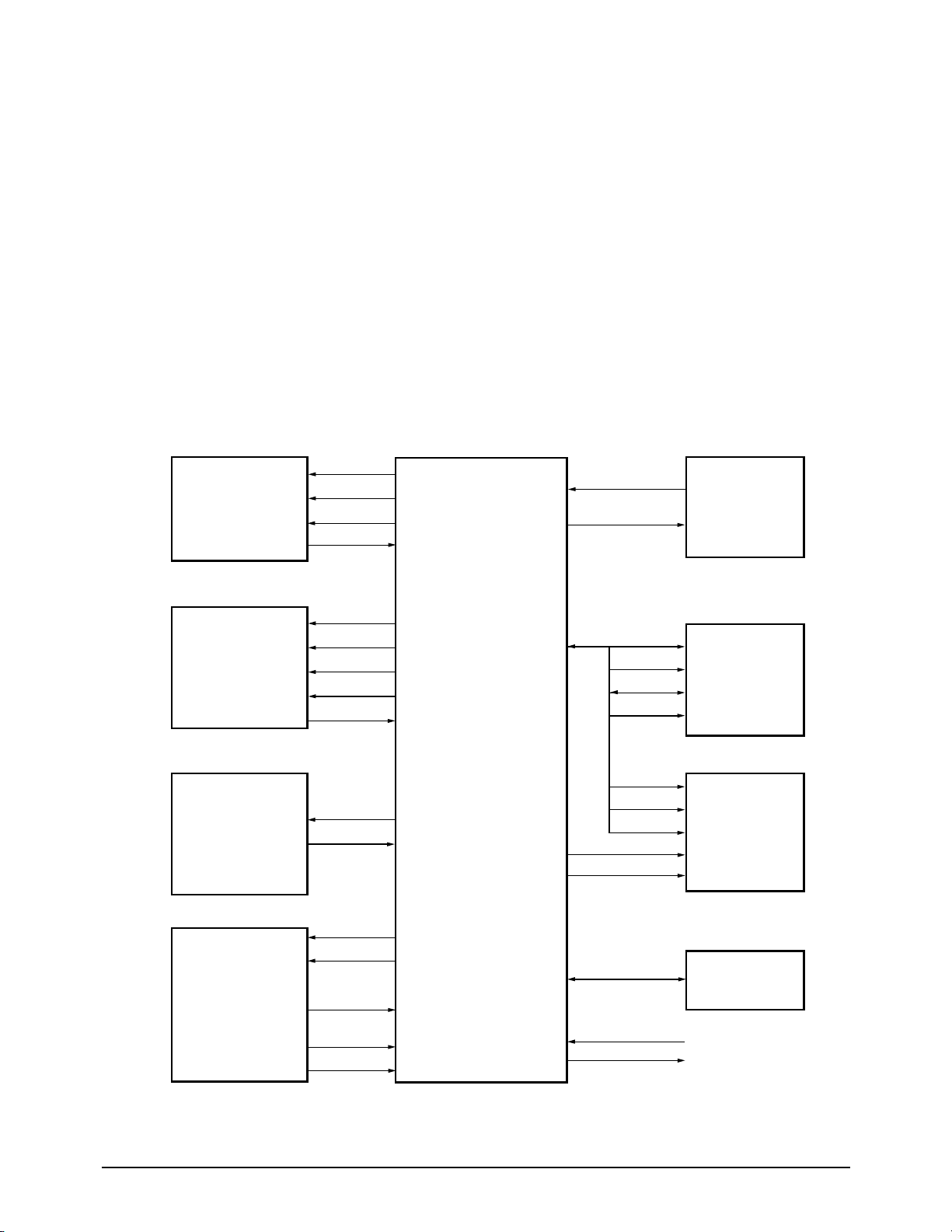

5-1 General

The main circuit board controls the machine, and consists of Super Fax Chip (KS16118), External memory,

CODEC circuit with modem-TX and RX signal path and some parts of the Line Interface Unit, Digital TAD

circuit with DSP amd DRAM, witch controls the system.

5-2 System Control Section

This circuit consists of the EP-ROM and SRAM, external Real Time Clock crystal, RTC and memory back-up

circuitry, and the Super Fax Chip (KS16118).

The KS16118 Super Fax Chip is an integrated 9600 bps modem, image processor, 8-bit MPU, peripheral

controller, and analog front end circuit on a single-chip.

Peripheral functions inculde 2-channel SI0, 3-channel DMA, 6-bit Half flash A/D converter, scanner and

video processor units, TPH interface, CODEC unit, and tone generator.

Modem is a 9600 bps, half duplex monolithic device incorporating digital filters, a Samsung SSP1600 digital

signal processor and CPU-Interface logic.

Figure 5-1: KS16118 External Memory Map

1FFFH

0100H

00FFH

0000H

0000H

FFFFH

FF80H

FF7FH

FF00H

FEFFH

/DMS

(SRAM)

Peripheral

PCS0

DSP /CS

PCS1

Interrupt

Vectors

/PMS

(EP-ROM)

[ Program Memory ]

[ Data Memory ]

5-2-1 Memory Map

The external memory of the CPU is devided into, 1 byte(FF00H) DSP chip select, 32kbyte SRAM (0000H

through 7FFFH) and 128kbyte EP-ROM (0100H through 1FFFH).

Page 18

Circuit Description

5-2 SF150T

Figure 5-2: XFC Hardware Interface Signals

5-2-2 lExternal Chip Control

KS16118 internal logic generates chip select signals for both memory chips and peripherals.

To support external access, from one to three wait cycles can be inserted under program control during

external access.

A chip select signal line goes active (low) whenever its corresponding device is accessed over the external

interface. The peripheral addresses are located in data memory space.

/DMS : SRAM chip select active (low)

/PMS : EP-ROM chip select active (low)

/PCSn : Peripheral chip select active (low)

D0 - D7 : 8 bit data bus

A0 - A15 : address bus

5-2-3 System Clock

The 12 MHz internal system clock frequency is generated by dividing the 24 MHz clock.

OPERATING

PANEL

PRINTER DATA

CONTROL AND

SENSORS

MOTOR

DRIVER

(MOTOR)

SCANNER

CONTROL

AND

PROCESSING

RTC

CRYSTAL

DATA

MEMORY

PROGRAM

MEMORY

GENERAL

PURPOSE I/ 0

OP00-OP06

LED_CTL

LCD_EN

OPI0-OPI3

STB 0-3

PDAT

PCLK

PLAT

THADI

SM0-SM3

MODE

SI

CLK1

Vin

+Vref

-Vref

XIN

XOUT

/DMS

/RD /WR

D0~D7

A0~A14

/RD

D0~D7

A0~A15

A16

/PMS

RESTOUT

/RESET

KS16118

Page 19

Circuit Description

SF150T 5-3

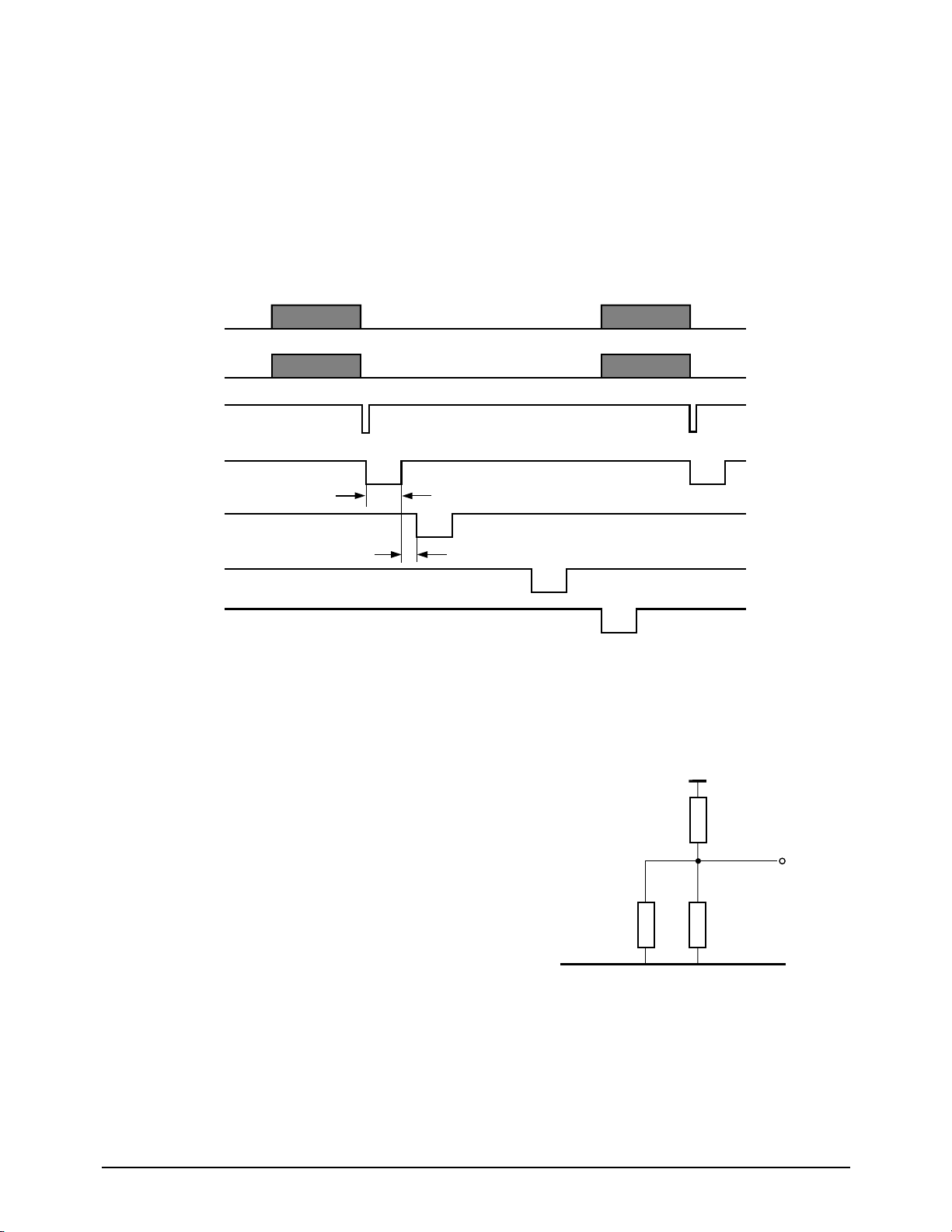

Figure 5-4: Printer Timing

5-2-4 Real Time Clock (RTC)

This circuit receives clock pulses from an external

32.768 kHz crystal, which it divides into hours,

minutes, seconds, year, month, and day.

A battery maintains operation when power is off.

KS16118 can up-track 100 years, begining with

1992.

5-2-5 Print Control

The PCLK and PDATA signals synchronize serial

print data to the TPH.

PLAT latches TPH serial print data to the TPH

from a shift register through PDATA.

STB0 - STB3 enable TPH printing in four steps.

This system has a 10ms/line printing format and

sets STB High/Low enable status

according to the STBPOL signal.

PDATA

PCLK

PLAT

STB0

STB1

STB2

STBWID

[0:11]

STB0FF

[0:11]

STB3

Figure 5-6: THD Connection Circuit

GND5

THD1

+5V

R5

R4

Rth

(T)

TPH

Thermistor

5-2-6. A/D Converter (Scanner & TPH

Temperature)

Using a half-flash conversion technique, the 6-bit

A/D converter supports a 0.8µs peak conversion

time and dissipates only 7mA, maximum.

The half-flash unit uses 16 comparators, a most

significant 3-bit ADC, and a least significant 3-bit

ADC.

If the analog input voltage is greater than +Vref,

the A/D conversion result is 3FH.

If the analog input voltage is less than -Vref, the

A/D conversion result is 00H.

A/D conversion register, ADCON (19H), is used

to select an internal or external source for the A/D

converter, to enable or disable the converter, and

to select the operating mode (H: ADin 1 (Scanner),

L: ADin 0 (TPH)).

Page 20

Circuit Description

5-4 SF150T

5-2-7 Operation Panel Control

Communication

The Operation Panel is controlled by the Port 1,

Port2, and Port 5 registers.

Port 1 (E2H) is a 4-bit general output port for LCD

display data.

This port can be configured for normal data (P1.4P1.7) or alternately as internal MODEM V.24

interface output signals (P1.0-P1.3).

Port 2 (E4H) is an 8-bit port with both input and

I/O pins.

P2.0-P2.3 are input ports for OPE key scan data,

and P2.6-P2.7 are not used for SF150T.

Port 5 (EAH) is an 8-bit port with both output and

I/O pins.

P5.0 and P5.4 are used for LED control and LCD

enable.

5-2-8 Image Sensor

The shading wave is formed by scanning the white

roller prior to a document.

The slice level is determined by the shading wave,

and compensates for shading distortion according

to the CIS characteristics.

The wave format from the CIS is converted into a 6

bit digital value in the KS16118 image processor,

and processed in B/W or intermediate mode.

5-2-9 CIS Input Processor

To process the B/W input signal, maximum (+Vref)

and minimum (-Vref) values of the CIS input signal

are adjusted by calibrating KS16118 in the high state

for maximum level, and setting them to earth for

minimum level.

Shading correction uses a multiplier composed of a

9-bit sequential adder for simple H/W Logic.

5-2-10 CIS Driver

The CIS driver clock (CLK1) frequency is 250 kHz.

A 75% low duty cycle lengthens the charging time.

A start signal (SI) is provided every 10 ms to

match the line scanning time.

Actual image signal (VIN) is provided in less than

6.8 ms, based on A4 paper size using the 250 kHz

clock.

Figure 5-10: CIS Driver Clock Timing

250 KHZ (L:DUTY 75%)

SI

CLOCK

SIG

1 LINE

Page 21

Circuit Description

SF150T 5-5

5-2-11 I/O Port Table

High Bank Memory

DSP Inactive

DATA = 1

DATA = 1

Active

Active

Active

Active

-

Active

Active

DSP Reset

DSP High Byte

Normal

Normal

CIS LED On

High

OPE LED On

Normal

Normal

-

Open

No Paper

No Document

Normal

Normal

CODEC Serial Clock

CODEC Serial Data

CODEC Enable

-

Closed

Paper Exist

Document Exist

Incomming Ring

Active DSP Data Transfer

Low Bank Memory

DSP Active

DATA = 0

DATA = 0

Inactive

Inactive

Inactive

Inactive

-

Inactive

Inactive

Normal

DSP Low Byte

Low Battery

DSP Response Mode

Off

Low

OPE LED Off

No Barttery

Circuit Symbol

I/O

Pin No.

Port Name

High Low

A16

/DSP_CS

IRXD

ITXD

MOTOR A

MOTOR /A

MOTOR B

MOTOR /B

/CML2

/CML1

/24VCTL

DSPRST

DSPHL

/LOWBAT

DSPACK

/GLED

-

LEDCTL

/NOBAT

SCLK

SDATS

/SDEN

/HOOK DET2

MODE

P_EMPTY

D_DET

RING_DET

/DSPFLAG

P0.0

P0.1

P2.4

P2.5

P3.0

P3.1

P3.2

P3.3

P3.4

P3.5

P3.6

P4.1

P4.2

P4.4

P4.5

P4.6

P4.7

P5.0

P5.3

P5.5

P5.6

P5.7

P6.1

P6.2

P6.3

P6.4

P6.5

P6.6

O

PCS

I

O

O

O

O

O

O

O

O

O

O

I

O

O

O

O

I

O

O

I

I

I

I

I

I

I

34

35

45

46

49

50

51

52

53

54

55

93

92

90

89

87

88

126

96

137

138

139

59

60

61

62

63

116

Page 22

5-2-12 Motor Controller

This facsimile machine perform sending, receving,

and printing functions utilising a single 24 volt

motor with a 120 ohm winding resistance.

Four drive strobe pulses operate the motor.

5-2-13 Serial communication Signals

The KS16118 have two full-duplex serial

communication port.

One port is used for I-LIU communication on LIU

PBA, and is a standart UART (Universal

Asynchronous Receiver/Transmitter).

Another port, not used, may be configured for

UART or SRT (Synchronous

Receiver/Transmitter) operation.

5-2-14 Reset

To initialize the chipÕs internal logic, the reset

input (/RESET) must be held to 0 Volt for at least

22 CPU clocks. During this time, Vdd must be

greater than 3 Volt.

The watchdog timer can also invoke a system

reset.

When the reset input is released, the reset

condition continues for about 209.7 ms.

While the KS16118 is in this state, 0 Volt is applied

to the /RSTOUT pin.

[ +5V Power Monitoring ]

If 5 volt power to MX93000AFCÕs pin 6 (VPOW)

drops to between 4.6V and 4.4V (typically 4.5V),

power failure is indicated and the output of

MX93000AFCÕs pin 5 (/POWB) will go `lowÕ(GND5).

This causes the KS16118 to become active (low=reset).

The KS16118 reset causes the /REST0 terminal to be

reset.

Circuit Description

5-6 SF150T

Table 5-1: Motor Functions

Motor Function

Swing Gear Control

Document Out

100 pps

100pps

Drive Strobe Pulse

Phase

2

2

Other 100pps

2

Super Fine Mode 100pps

1-2

5-3 Memory

System memory consists of 128 kB EP-ROM and 32 kB SRAM. All of SRAM is backed up.

ROM and SRAM are selected by chip select lines, and data is accessed by the units position of the byte.

ROM has two banks. One Bank is as low bank that address range is 0100H-FFFFH.

Another bank is as high bank 10000H-1FFFFH. ROMÕs bank is selected port 0 (bit 0) of the KS16118.

5V power is applied to SRAM through VB. This model facsimile machine uses a Lithium battery.

A 1 kohm resistor in series with the positive battery terminal is for battery protection.

5-4 CODEC circuit with Modem-TX and RX signal path

This has PCB CODEC which has ablity that converts voice signal to A/D and is able to store is DRAM and convert

to voice signal passing through D/A transmission after scanning from voice digital stored in DRAM by DSP.

This has PRE-PGA(Programmable Gain Amplifier) that is able to amplift selectively among Mic input, remot

signal, rx signal.

This has ALC(Automatic Level Control) circuit has maximum 42dB gain to be convenient for recording using Mic.

This have two comparator having 1.25V reference voltage and two universal opamp.

This has 1 W speaker drive amplifir that is able to drive 8 ohm speaker.

Because MX93000AFCÕs control uses synchronous communication port, that is fast in action is convenient.

Page 23

Circuit Description

SF150T 5-7

5-5-1 DSP

This circuit consists of host interface, memory

interface, CODEC interface.

receives data to the compressed voice data to and

from KS16118.

Memory interface sends and receives data to the

compressed voice data to and from DRAM to play

back and record voice data.

DSP communicates with host KS16118 through host

interface.

5-5-2 Recording Path

The voltage is supplied with MIC as using the

MX93000AFC's Vref Voltage (2.25V), and the voltage

entering into MIC is trasmitted to electric signal and

enters into MX93000AFC's MIC terminal.

Input signal is amplified by MX93000AFC's ALC

until maximum 26dB (Max. 3VP-P) according to

signal size.

The signal enters into PCM CODEC that converts to

D/A and compresses in the DSP Chip and stores in

DRAM.

5-5-3 Play Path

The signal stored in DRAM is decomressed in DSP

and enters into MX93000AFC.

Input signal is converted to D/A again and is

amplified by LIU-DRV amplifier and comes into

LOUT terminal through or comes into terminal

after being attanuated by ATT (Electronic Volume)

or SPK-DRV.

5-5-4 Voice Backup

+5V is supplied for DSP or voice memory through

VBT when power is on.

When power is off, +5V is supplied from the 9V

backup battery.

When supply voltage is "ON", U9(5V Voltage

Regulator) makes 5V Supply Voltage.

The signal is supplied with DSP or DRAM and it

caused that the data is protected.

When supply voltage is "OFF", U9 makes 5V Voltage

as using the 9V Battery.

And then the voltage is used to "backup supply

voltage" in DSP or DRAM.

If the supply voltage were "OFF" as using the full

charged 9V Battery, voice data is usually protected

for twenty hours.

5-5 TAD

TAD circuit consists of a voice coprocessor to record and play voice messages and voice memory.

1) TX CIRCUIT

The output signal coming from internal modem

KS16118 enters MX93000AFC through AUX2

terminal after amplfied by OP AMP U1.

That signal passes through internal switch, is

amplified by LIN-DRV amplfier and is sent to LIU

board through LOUT terminal.

2) RX CIRCUIT

The signal goming into LIU terminal through LIU

board is amplified by MX93000AFC's PRE-PGA,

passes through internal switch and goes into FILT

terminal.

After the singal is diminished by OP AMP U1, it

enters internal modem of KS16118.

Page 24

Circuit Description

5-8 SF150T

5-6-1 FAX section

MODEM/LINE INTERFACE

This is the path for data and control signals.

¥ CML201 relay: switches telephone line between

FAX and telephone circuits.

¥ U201 pin 3 TIT: single-ended input for

transformer T202.

¨ TIT: Transmit Input from Transformer

¥ U201 pin 40 ROT : Output for driving a

transformer T203 with an AC impedance

exceeding 10Kohm.

¨ ROT: Receive Output Transformer

¥ C212: DTMF and CNG detect path to T201

20Kohm winding under idle conditons; and DC

blocking for 20Kohm winding.

¥ AC impedance: the AC impedance of U201 (I-

LIU) is set at 1000ohm by external capacitor

C228 at U201 pin 8 CI (Complex Impedance

input) port. With an external resistor (R244) at

U201 pin 34 ACI port it can be programmed to

600ohm. And U201 pin 35 CS (Current Shunt

control output) port is N-channel open drain

output to control the external high power shunt

transistor for synthesizing AC and DC

impedance.

¥ DC conditions : normal operating mode is from

15mA to 100mA. An operating mode with

reduced performance is from 5mA to 15mA. In

the line hold range from 0mA to 5mA the device

is in a power down mode and the voltage at

U201 pin 37 LI (Line Input) port is reduced to a

maximum of 3.5V. The DC characteristic is

determined by the voltage at U201 pin 37 LI port

and a R215 resistor between U201 pin 37 LI and

pin 39 LS port. It can be calculated by the

following equation : VLS = VLI + ILINE X R215.

RING DETECT

¥ U201 pin 28(MO) is ring melody output port and

this signal drive the Q207 which drive the

FET201 which drive Photo coupler U204 for

artificial ring.

MF DIAL (Same as telephone section)

¥ U201 pin 2 DMS(Dial Mode Selection) port is set

to VDD by R227 It is M/B ratio 33:66, and no

power operation mode conducts only DP.

¥ MF signal appears (tone level of low group :

typical -14dBm) at U201 pin 4 MFO(DTMF

Generator Output). This signal is leveled by

R226, R225 and C239, then to amplier U201 pin 9

MFI(DTMF Amplier Input).

¥ Line dial signals appear at U201 pin 39 LS(Line

Current Sense Input).

DP DIAL (Same as Telephone section)

¥ U201 pin 2(DMS) is set to Vdd(33/67) or

VSS(40/60) by R227 or R228 resistor.

¥ Dial pulses originate at U201 pin 27(DPn), which

toggles Q205, which drives Q201. The resulting

intermittent voltage interrupts the telephone

line.

¥ Pulse M/B ratio is set by U201 pin 2 MDS port.

Vdd = 33/66, and Vss = 40/60.

¥ U201 pin 35 CS port : Modulation of line voltage

and shorting the line during make period of

pulse dialling.

LLC (Line Loss Compensation) / LOOP

CURRENT DETECT

¥ When the LLC pin option. it is activated, the

transmit and receive gains for both I/O are

decreased 6dB at line currents above 20mA

when the U201 pin 31 LLC is connected to

AGND, and from 75mA when this pin is

connected to VDD. The LLC is deactivated

when LLC pin is connected to VSS.

¥ When CML201 or Hook Switch switches to

telephone line, U201 on the LIU board and CPU

(U1) on the Main board begin communication.

U201 sends an <Ack> message containing the

line current information to recognize a parallel

phone.

5-6 LIU PBA

The LIU (Line Interface Unit) interfaces the MODEM and telephone to the telephone line. The FAX and

telephone portions of the LIU are active with machine power on. When machine power is off, only the

telephone circuitry operates, powered by telephone line voltage. The FAX portion of LIU consists of the

interface between MODEM and telephone line; and the circuits for DC loop feeding, DP signal, loop current

and ring detect. The telephone portion is divided into ringer, dialling, and speech circuits. Refer to the

schematic and connection diagram sections of this manual.

Page 25

Circuit Description

SF150T 5-9

Serial interface

¥ U201 pin 11 RXD: Schmitt trigger input

(threshold = 2.5V) to serial interface.

¥ U201 pin 29 TXD: Open drain output from serial

interface.

¥ The communication is standard UART :

Baud Rate 9600

Start Bit 1

Stop Bit 1

Data Bits 8

Parity Bit None

LSB is transferred prior to MSB.

5-6-2 Telephone Section

RINGER CIRCUIT

¥ When a ringing signal is applied to the line, Vdd

of U201 (I-LIU) is charged via an external path.

After Vdd has reached the operating voltage the

oscillator starts and U201 detects the ring

frequency.

After a valid ring frequency is applied to the

U201 pin 25 RFD (Ring Frequency

Discrimination) port, the ring melody generator

of U201 sends out a 3-tone melody via U201 pin

28 MO (Ring Melody Output) port.

¥ U201: I-LIU and associated components.

¥ Ring frequency passes through DC blocking

capacitor C206 (C205 for Switzerland or Austria)

and Zener-diode ZD205 (ZD209 for Switzerland

or Austria) to U201 pin 25 RFD port.

¥ Line ring voltage passes through DC blocking

capacitor C201, current limit resistor R205,

bridge diode BD201, CML relay, and Hook

Switch to FET201 (BS170) pin 3, C214, ZD203

and R246.

¥ The ring frequency discriminator of U201

assures that only signals with a frequency

between 13Hz and 70Hz are regarded as valid

ring signals.

¥ When a valid ring signal is present for at least

73ms, the ring melody generator (pin 28, MO) is

activated and remains active as long as a valid

ring signal is present.

¥ U201 filters the ring signals and output is pin 28

(MO).

¥ The 3 basic melody frequencies are : F1 = 880 Hz,

F2 = 1067 Hz, and F3 = 1333 Hz. The repetition

rate is set to 4 which means that the sequence of

F!, F2, F3, F1, F2, F3 is repeated 4 times within a

second.

Speech Circuit

¥ U201 (STI9510) and associated components.

¥ Handset transmitting circuit: Handset

transmitter audio (Condensor MIC.) is filtered

by R240, C232, C224, C225, C226, C227, C229 and

C230, and then amplified by U201 pin 32 and 33

(M1, M2).

¥ Handset receiving circuit: Handset receiver

(Dynamic unit) is filtered by R229, C241, C209,

C203 and C231, and then applied to U201 pin 1

(ROH) and VSS.

¥ U201 pin 39 (LS) is audio output to telephone

line.

Sidetone Circuit

¥ Sidetone audio characteristics are controlled by

R238, R235, R237, R239, and C202 connected to

U201 pin 7 STB.

Page 26

5-7 OPE PBA

OPE PBA serves as the Machine-User interface.

The OPE operates on a time-sharing basis. As shown below, OPE keys and LED control are divided into

key scanning, LED displaytime and display time. On each 2ms interrupt rising edge, OPE line turns off

after 125µsec initial delay, and after 1 CPUCLK cycle, LEDCTL-LOW makes LED turn off. During the next

128 CPUCLK cycles, OPE KEY STROBE is maintained and during the next 1 CPUCLK KEY, INPUT is

scanned and stored in KEY buffer.

After key scanning, through the OPO0-3 port the upper and lower nibble data are transferred to the LCD

module as LCDCTL goes high.

After key displaying DATA on LCD, LED lamps turn on with LEDCTL-ON.

OPO0-4 : Used as key board strobe or LCD, LED driver

OPO5-7 : Used as key board strobe.

OPI0-3 : Key scanning ports from key matrix.

7

01

2345

67

0

LED0

LED0

LED0 LED0 LED0

LED0 LED0 LED0 LED0

LED0

LED1

LED1

LED1 LED1 LED1

LED1 LED1 LED1 LED1

LED1

LED2

LED2

LED2 LED2 LED2

LED2 LED2 LED2 LED2

LED2

LED7

LED7

LED7 LED7 LED7

LED7 LED7 LED7 LED7

LED7

C2MS

125µsec

LEDCTL

LEDCTL

LED

OFF

LED

ON

LCDCS

LCDCS

LCD HI

LCD H

LCD LO

LCD L

KB STROBE

[X] = Time Interval of TSTCLK's

IRQ2MS

IRQ2MS

OPO0

OPO1

OPO2

OPI0

OPI1

OPI2

OPI7

OPI[3:0]

OPO7

(7)

(7)

(128)

(12)

(16)

(1) (1)

(3)

(1) (7) (1)

LED0

LED1

LED2

LED7

LCD DB0H LCD DB0L

LCD DB1L

LCD DB2L

LCD DB1H

LCD DB2H

5-10 SF150T

Page 27

Y

Y

Y

Y

Y

YY

Y

N

N

NN

YY Y

NN N N

N

N

6. Troubleshooting

6-1. Initial Checkout and Overall Troubleshooting Flow

SF150T 6-1

Plug in the power

cord

Load document in

feeder

Copy OK ?

OGM play back ?

Call machine from

another phone

Auto Answer

OK ?

ICM Recording ?

Manual

operation OK ?

OGM Recording

RX OK ?

Document feed ? Push 'START' Key CIS ON ?

System

initialized ?

See Section 6-3 See Section 6-2

See Section 6-5See Section 6-4

See Section 6-5

See Section 6-8

See Section 6-7

See Section 6-6

See Section 6-9 See Section 6-10

A

Power Supply

OK ?

Start

Page 28

Troubleshooting

6-2 SF150T

YY

N N

Lift Handset

off hook

Dial tone OK ? TX OK ?

See Section 6-11

End

See Section 6-12

A

Page 29

Troubleshooting

SF150T 6-3

6-2. Check Power Supply

N

N

Check AC socket

voltage

Power cord

connected ?

Start

220 - 240 VAC?

Y

Y

END

Connect as required Notify customer

N N

N

Check

Power Cord

Continuity

Replace Cord Replace Fuse Replace Q1

YY

Fuse OK ?

Q1 OK ?

Y

N

R5 changed

value ?

Remove short

End

Page 30

Troubleshooting

6-4 SF150T

6-2-1 No + 5 V

Y

NN

output shorted ?Start

N

Y Y

N

Remove short

Y

Replace D4

Check PCB Pattern Replace U2

Check CON 1

Check

U2 Input voltage

D4 Open or

Shorted ?

DC 6 V Check U2 ?

End

6-2-2 No -12 V

YY

N N

output shorted ?

Start

N

Y Y

N

Remove short Replace D5

Check PCB Pattern Replace U1

Check CON1

Check

U1 Input voltage

D5 Open or

Shorted ?

-15 VDC U1 Output ?

End

Page 31

Troubleshooting

SF150T 6-5

Y

Y

N

N

output shorted ?

Start

N

Y Y

N

Remove short

Replace D3

OVP operation

Restart Replace Q3

Check CON1

D3 Open or

Shorted ?

Check

OVP operation

Q3 OK ?

End

6-2-3 No + 24 V

6-2-4 + 24 V TPH Doesn't output

YN

Check

C/S port short ?

Start

N

Y

Remove short Replace Q5

Check CON1

Q5 OK ?

End

Page 32

Troubleshooting

6-6 SF150T

6-3. System Not Initialized

N

NG

N

N

NG

OK

N

N

N

Step motor driving

Start

Y

Y

Y

Y

OK

NG

Y

Y

See Section 6-2-2

Replace P5 Harness

or OPE PBA

Replace U3

Replace U7

Fax Engine IC

Replace U7

Fax Engine IC

Replace Main PBA

Replace U14

Motor Driver

Replace

X2 XTAL

Check

U3 Pin 5

= "High"

Check U3 Pin 6

(above +2.25 V)

Check

P5 Harness or OPE

PBA

Check 12 MHz

Clock U7-37

Check 24 MHz

Clock U7-129

O.K ?

O.K ?

Check

Vcc ³ 4.75 V

P1-4 (+5V)

P1-3 (GND5)

End

End

Page 33

Troubleshooting

SF150T 6-7

6-4 Document Not Loading

Start

P7-1 "L" ?

Check 24 V

P6-5, 6 ?

Insert Document

Replace Motor

END

Replace U14

Replace U7

Replace D-DET PBA

or P7 Harness

See Section 6-2

P6-1, 2, 3, 4

Motor Strobe

U7-49, 50, 51, 52

Motor Strobe

Y Y

OK

OK

NG

NG

N

N

Page 34

Troubleshooting

6-8 SF150T

6-5 No Copy Mode Operation

Start

TPH Test O.K ? CIS Test O.K ? Is Memory Clear ? Reload Document

Check U7-55

"H"

Check P1-10

"L"

Check +24 V

P1-8, 9 ?

Replace Main PBA

P2-4, 6, 8, 10

TPH strobe

Replace U7 Replace U5 See Section 6-2 Replace U7

P2-7, 11, 12 Replace TPH

Restart

Restart

Replace U5

Replace U7

Replace Main PBA

O.K ?

O.K ?

B

Y

Y

Y

Y Y Y Y

Y

N

N N N N

N

N

N

N N

Y Y

Page 35

Troubleshooting

SF150T 6-9

6-5 Continued

B

CIS LED on ?

Check P3-9

CLED ² 1 V

U7-87

"H"

Check P3-8

CLK1: 300 kHz

Check P3-6

START Signal

P3-4

- 12 V ?

Replace U7 Replace U7

Replace CIS Replace CIS

Replace U7

Replace Q2

See Section 6-2

Y

Y

H

Y

N

L

N

NG NG

OKOK

Page 36

Troubleshooting

6-10 SF150T

6-6. OGM Not Playing Back

Y

Y

Y

Y

Y

Y

N

N

NN

N

N

Start End

End

OGM Play Back ?

Speaker On

Check

Mic signal from

P7-4, 5

Check

signal from

U3-16 ?

Replace main

board

End

Replace U3

Check

signal from

U3-29, 31 ?

Replace speaker

Replace Mic.

End

Check

P7 Harness ?

Page 37

Troubleshooting

SF150T 6-11

6-7. ICM Not Recording

Y

Y

Y

N

N

N

Start

End

Call machine

from other phone

ICM

Recording

mode ?

Check LIU board

OK ?

Replace LIU

board

Replace main

board

ICM Playback ?

Page 38

Troubleshooting

6-12 SF150T

6-8. Malfunction in Auto Answer

Y

N

Y

N

Start

Call machine from

another phone

Auto answer ?

Check signal

P4-16

Replace LIU board

END

Replace U7

+5V

0V

?

Page 39

Troubleshooting

SF150T 6-13

6-9. Malfunction in Manual Receiving

N

Y

Y

Y

N

N

Start

Lift handset

Press START

Machine goes

on-line ?

Check U7-45

(Hook Event)

OK ?

Replace U7

Replace main

board

End

Check LIU board

OK ? Replace LIU board

Page 40

Troubleshooting

6-14 SF150T

6-10. Automatic Receive Malfunction

Y

Y

Y

Y

N

N

N

N

Start

Call fax machine

Rings exceed

ÒRings To AnswerÓ

Setting ?

Auto Answer ?

Replace:

Main Board

Replace LIU Board

Go To 6-9

ÒManual Receive

MalfunctionÓ

Main Board

P4-18, 19

TX/RX

Receiving Data ?

Return

Machine to

Customer

Page 41

Troubleshooting

SF150T 6-15

6-11. No Dial Tone

NG

OK

OK

Y

H

OK

NG

NG

OK

N

L

NG

Start

Request

Telephone

Service

Check/Replace:

Speaker

Main Board U14

P4, 205, 206

Replace U3

Lift Handset

Dial tone ?

Service OK ?

Main PCB

U7-54

CML1

Main PCB

U3-29, 31

SPK_OUT

Dial tone ?

Return

machine to

Customer

Press

OHD/V.REQ.

Replace

Telephone Cord

Use a phone to check

service at wall jack

Test

Telephone

Cord

Check / Replace:

Handset cord

Handset

Hook Switch

LIU U201

LIU Board

Page 42

Troubleshooting

6-16 SF150T

6-12. Transmit Failure

Y

Y

N

N

Start

Load document

Feed OK ?

Dial Receiving

Machine

Transmit

Begin ?

Replace:

LIU board

Main Board

Return

Machine to

Customer

Chart 6-4

Document

Not Loading

Page 43

8-1SF150T

1

2

S4

4

8

10

11

S2

S2

S3

5

S1

S1

6

7

12

9

3

8. Exploded Views and Parts Lists

8-1. Total Assembly

Page 44

8-2 SF150T

Exploded Views and Parts Lists

Total Assembly Parts Lists

Location No. Description SEC. Code Q'ty Remark

1 ASS'Y-OPE UNIT JF96-01296A 1

2 ASS’Y-TOP COVER JF96-01297A 1

3 SPACER JF72-40611A 1

4 GUIDE-TX JF72-41122Z 1

5 PBA-LIU JF92-00843Q 1

6 REAR-BRKT JF70-10681A 1

7 PBA-MAIN JF92-00842E 1

8 SMPS-V2, AC/DC JF44-10059A 1

9 ASS’Y-BASE UNIT JF96-01298A 1

10 ASS’Y-MAIN CHASSIS UNIT JF96-01253A 1

11 ASS’Y-HANDSET JF96-01262A 1

12 CURL-CORD JF39-60075A 1

S1 SCREW, TAPTITE, BH, +, M3, L8 6003-000015 11

S2 SCREW, TAPTITE, BH, +, M3, L6 6003-000261 2

S3 SCREW, TAPTITE, BH, +, M3, L6 6003-000115 2

Page 45

Exploded Views and Parts Lists

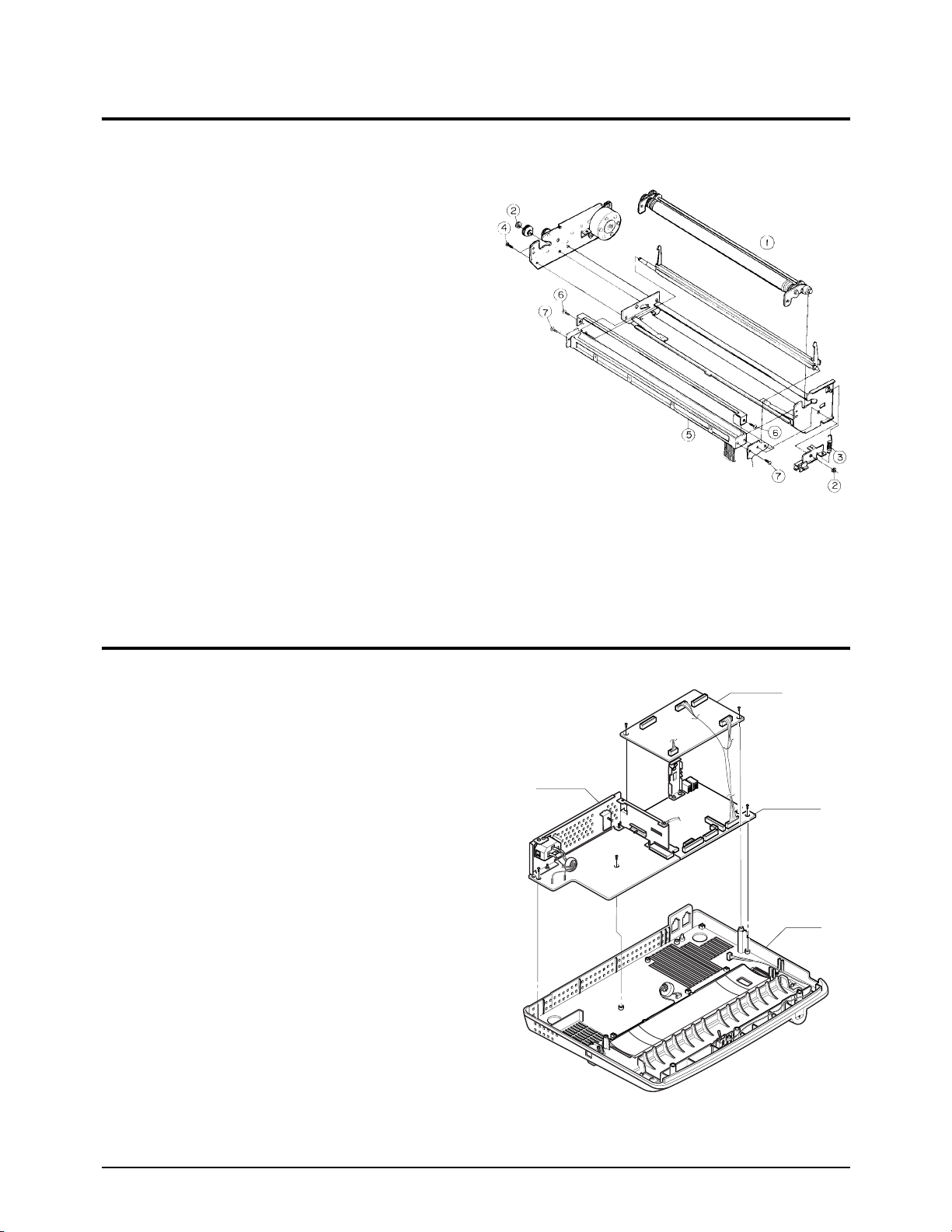

8-2. Ass'y OPE Unit

SF150T 8-3

2

1

3

4

5

6

7

10

11

9

13

14

15

16

17

18

19

20

21

22

23

24

25

S1

S2

S3

26

8

12

27

Page 46

Ass'y OPE Unit Parts Lists

Exploded Views and Parts Lists

8-4 SF150T

Location No. Description SEC. Code Q'ty Remark

ASS'Y-OPE UNIT JF96-01296A 1

1 OPE COVER JF72-42016Z 1

2 LCD-WINDOW JF75-11004F 1

3 KEY-ONETOUCH JF72-42021A 1

4 KEY-OHD JF72-42022A 1

5 KEY-STOP JF72-42029A 1

6 KEY-START JF72-42028A 1

7 KEY-TEL JF72-42026A 1

8 KEY-TAD(A) JF72-42056A 1

9 KEY-TAD(B) JF72-42057A 1

10 KEY-MENU JF72-42020A 1

11 KEY-RESOLUTION JF72-42018B 1

12 KEY-RECEIVE JF72-42017B 1

13 KEY-ANSWER JF72-42019M 1

14 RUBBER-CONTACT JF73-40521A 1

15 DISPLAY-LCD JF07-20061A 1

16 CBF-WIRE, MAIN-OPE, 18 P JF39-41081A 1

17 CBF-WIRE, LIU-OPE, 7 P JF39-40957A 1

18 PBA-OPE JF92-00844B 1

19 CHASSIS OPE UNIT JF70-10863A 1

20 BRKT-TPH UNIT JF70-10861B 1

21 GUIDE-TPH(R) JF70-10679A 1

22 PRINT HEAD-THERMAL JF47-30069B 1

23 PBA-P.EMPTY JF92-00704B 1

24 GUIDE-TPH(L) JF70-10679B 1

25 CBF-WIRE, MAIN-TPH, 14P JF39-40955A 1

26 BRUSH-ANTISTATIC JF75-10650A 1

27 FLAT CABLE, OPE-LCD JF39-41018A 1

S1 SCREW, TAPTITE, PWH, +, B, M2. 6003-000193 11

S2 SCREW-MACHINE, BH, +, M3, L4 6001-000125 4

S3 SCREW, TAPTITE, BH, +, B, M3, L 6003-000015 2

Page 47

Exploded Views and Parts Lists

SF150T 8-5

8-3. Ass'y COVER TOP

1

2

3

4

6

7

8

S1

9

10

S2

S3

S3

11

12

5

Page 48

Exploded Views and Parts Lists

8-6 SF150T

Location No. Description SEC. Code Q'ty Remark

ASSEMBLY-COVER TOP JF96-01297A 1

1 TOP COVER JF72-42015A 1

2 HINGE-OPE(R) JF70-10676A 1

3 COVER-SPRING(R) JF70-40562A 1

4 HINGE-BRKT(R) JF70-10677A 1

5 BATTERY-COVER JF72-42027A 1

6 HINGE-BRKT(L) JF70-10677B 1

7 COVER-SPRING(L) JF70-40562B 1

8 HINGE-OPE(L) JF70-10676B 1

9 SWITCH-HOOK, 48 V, 200 mA 3409-000117 1

10 PBA-HOOK JF92-00845C 1

11 SPEAKER, 1 W, 8 OHM, 83dB 3001-001044 1

12 UNIT-FIXING BRKT GB70-10500A 1

S1 SCREW, TAPTITE, BH, +, M3, L6 6003-000261 3

S2 SCREW, TAPTITE, BH, +, M3, L8 6003-000015 2

S3 SCREW, TAPTITE, PWH, +, B, M2.5, L6 6003-000193 2

Ass'y COVER TOP Parts Lists

Page 49

Exploded Views and Parts Lists

SF150T 8-7

8-4. Ass’y Handset

3

2

S1

1

4

5

6

7

8

9

Page 50

Exploded Views and Parts Lists

8-8 SF150T

Ass’y Handset Parts Lists

Location No. Description SEC. Code Q'ty Remark

ASS'Y-HANDSET JF96-01262A 1

1 HANDSET-LOWER JF72-42014A 1

2 AUDIO-RECEIVER, 160 OHM 3009-001001 1

3 HOLD-DUMMY GB72-40792A 1

4 RUBBER-MIC JF73-40501A 1

5 PBA-H/S MIC JF92-00625A 1

6 CBF-HARNESS JF39-40834A 1

7 WEIGHT-BALANCE JF70-10864A 1

8 HANDSET-UPPER JF72-42013A 1

9 RING-OP, ID17, OD35 6044-000138 1

S1 SCREW, TAPTITE, PH, +, B, M3, 6003-000168 1

Page 51

Exploded Views and Parts Lists

SF150T 8-9

8-5. Ass'y Base

5

6

7

8

S1

2

1

3

4

10

9

Page 52

Exploded Views and Parts Lists

8-10 SF150T

Ass'y Base Parts Lists

Location No. Description SEC. Code Q'ty Remark

ASS'Y-BASE JF96-01298A 1

1 CBF-WIRE, MAIN-CIS/MODE JF39-41062A 1

2 MICRO-SWITCH 3405-000166 1

3 STEP-MOTER, 7.5 DEG, 24 V 3101-000171 1

4 ASS’Y-MAIN CHASSIS UNIT JF96-01253A 1

5 BASE JF72-42025A 1

6 PBA-D’DET JF92-00888A 1

7 CBF-WIRE, HANDSET-LIU JF39-41066A 1

8 RUBBER-FOOT JF73-10002A 2

9 MIC-CONDENSOR 3003-000120 1

10 MIC-ADAPTER GB72-40770A 1

S1 SCREW, TAPTITE, BH, +, M3, L6 6003-000261 2

Page 53

Exploded Views and Parts Lists

SF150T 8-11

8-6. Harness

1

2

3

11

3'

5

9

4

4'

6

8'

8

1'

2'

15

6'

4''

10'

11'

10

12

5'

7'

13

14

7

14'

Page 54

Exploded Views and Parts Lists

8-12 SF150T

Harness Parts Lists

Location No. Description SEC. Code Q'ty Remark

1 CBF-WIRE, MAIN-TPH, 14 P JF39-40955A

2 CBF-WIRE, MAIN-OPE, 18 P JF39-41081A

3 CBF-WIRE, LIU-OPE, 7 P JF39-40957A

4 CBF-WIRE, MAIN-LIU, 22 P JF39-41063A

5 CBF-WIRE, LIU-HANDSET JF39-41066A

6 CBF-WIRE, MAIN-CIS/MODE JF39-41062A

7 CBF-WIRE, MAIN-D.DET, MIC, 5 P JF39-41078A

8 STEP-MOTER, 7.5 DEG, 24 V 3101-000171

9 CBF-WIRE, LIU-HOOK JF39-41080A

10 CBF-WIRE, POWER-MOTOR JF39-40963B

11 CBF-WIRE, POWER-TOP COVER JF39-40962B

12 CURL CORD JF39-60075A

13 CABLE CLAMP 6502-001026

14 CBF-WIRE, MAIN-BATTERY, 2 P JF39-41082A

15 CBF-WIRE, MAIN-SPEAKER, 2 P JF39-41079A

Page 55

SF150T 7-1

Ref. No. Description SEC Code Remark

PBA, PCB Assembly, MAIN JF92-00842E

- Capacitors -

C1 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C2 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C3 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C4 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C5 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C7 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C8 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C9 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C10 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C11 Ceramic, Chip, 33 nF, K, 50 V, 2012 2203-000802

C12 Ceramic, Chip, 33 nF, K, 50 V, 2012 2203-000802

C13 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C14 TA, Chip, 1 µF, M, 10 V, 3216 2404-000291

C15 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C16 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C17 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C18 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C19 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C20 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C21 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C22 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C23 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C24 Ceramic, Chip, 10 pF, 0.05 pF, 50 V 2203-000281

C25 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C26 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C27 Ceramic, Chip, 18 pF, J, 50 V, 2012 2203-000429

C28 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C29 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C30 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C31 Ceramic, Chip, 39 pF, J, 50 V, 2012 2203-000858

C32 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C33 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C34 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

7 Electrical Parts List

7-1 MAIN PBA

Capacitor / Resistor tolerance:

D: 0.5 %, F: 1 %, G: 2 %, J: 5 %, K: 10 %, M: 20 %, Z: +80 %, -20 %

Page 56

Electrical Parts List

SF150T7-2

Ref. No. Description SEC Code Remark

C35 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C36 Ceramic, Chip, 18 pF, J, 50 V, 2012 2203-000429

C37 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C38 TA, Chip, 1 µF, M, 10 V, 3216 2404-000291

C39 TA, Chip, 1 µF, M, 10 V, 3216 2404-000291

C40 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C43 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C44 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C45 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C46 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C47 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C48 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C49 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C50 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C51 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C52 Ceramic, Chip, 10 pF, 0.5 pF, 50 V, 2012 2203-000281

C53 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C54 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C55 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C56 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C57 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C58 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C59 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C60 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C62 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C63 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C64 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C65 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C66 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C67 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C68 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C69 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C70 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C71 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C72 Ceramic, Chip, 1 nF, K, 50 V, 2012 2203-000444

C73 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C74 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C75 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C76 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C77 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C78 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C79 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

Page 57

Electrical Parts List

SF150T 7-3

Ref. No. Description SEC Code Remark

C80 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C81 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C82 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C83 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C84 Ceramic, Chip, 100 pF, J, 50 V, 2012 2203-000239

C85 Ceramic, Chip, 100 nF, Z, 50 V, 2012 2203-000192

C87 Electrolytic, 10 µF, M, 25 V 2401-000448

C88 Electrolytic, 10 µF, M, 25 V 2401-000448

C89 Electrolytic, 22 µF, M, 25 V 2401-000943

C90 Electrolytic, 10 µF, M, 25 V 2401-000448

C91 Electrolytic, 10 µF, M, 25 V 2401-000448

C93 Electrolytic, 3.3 µF, M, 50 V, BP 2401-001014

C94 Electrolytic, 10 µF, M, 25 V 2401-000448

C95 Electrolytic, 10 µF, M, 25 V 2401-000448

C97 Ceramic, Chip, 220 nF, K, 50 V, 2012 2203-000609

- Connectors -

P1 Header, 1 Wall, 10 P, 1R, 2.5 mm, STR 3711-002034

P2 Header, Box, 14 P, 1R, 2 mm, STR 3711-002815

P3 Header, Box, 12 P, 1R, 2 mm, STR 3711-002813

P4 Header, 22 P, 2R, 2 mm, STR 3711-002002

P5 Header, 18 P, 2R, 2 mm, STR 3711-002000

P6 Header, 3 Wall, 6 P, 1R, 2 mm, STR 3711-000496

P7 Header, 3 Wall, 5 P, 1R, 2 mm, STR 3711-000484

P8 Header, 3 Wall, 2 P, 1R, 2 mm, STR 3711-000444

P9 Header, 3 Wall, 2 P, 1R, 2 mm, STR 3711-000443

SOK1 Socket-IC, 32 P, DIP, 2.54 mm 3704-000255

- Diodes -

D3 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

D4 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

D5 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

D6 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

D7 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

D8 Switching, 100 V, 200 mA, 225 mW, 4 ns 0401-000116

ZD1 Zener, PTZ5.1B, 5.1V-5.7V, 1W 0403-000464

ZD2 Zener, PTZ12B, 5.1 V, 12.0V-13.5V, 1W 0403-001142

ZD3 Zener, 3.9 V, 5 %, 1 W, 1N4730 0403-000521

ZD4 Zener, 3.9 V, 5 %, 1 W, 1N4730 0403-000521

- ICs -

U1 4558, SOP, 8P 1201-000189

U2 74HC32, OR Gate, SOP, 14 P 0801-000410

U3 MX93000A, QFP, 44 P 1205-001333

U4 SRAM, 62256, 32k x 8 bit, DIP, 28 P 1106-001037

Page 58

Electrical Parts List

SF150T7-4

Ref. No. Description SEC Code Remark

U5 EPROM, 27010, 128k x 8 bit, DIP, 32 P 1102-000191

U6 44C1000, 1M x 4 bit, SOJ, 20 P 1105-000133

U7 Micro Computer JF09-10053A

U8 6305, 16 bit, QFP, 80 P 0904-001068

U9 Reset, 78L05, SOT-89, 3 P 1203-001037

U10 74HC245, Transceiver, SOP, 20 P 0801-000696

U11 Photo-Coupler, PC817, 200 mW, DIP-4 0604-000119

U12 Photo-Coupler, PC817, 200 mW, DIP-4 0604-000119

U14 TR-Array, UL2003L, NPN, SOP-16, ST 0506-000182

- Resistors -

R1 Chip, 20 kohm, J, 1/10 W, 2012 2007-000546

R2 Chip, 205 kohm, F, 1/10 W, 2012 2007-007434

R3 Chip, 15 kohm, J, 1/10 W, 2012 2007-000409

R4 Chip, 75 kohm, J, 1/10 W, 2012 2007-000002

R5 Chip, 46.4 kohm, F, 1/10 W, 2012 2007-000917

R6 Chip, 18 kohm, J, 1/10 W, 2012 2007-000457

R8 Chip, 390 kohm, F, 1/10 W, 2012 2007-001663

R9 Chip, 150 kohm, F, 1/10 W, 2012 2007-000392

R10 Chip, 2.2 kohm, J, 1/10 W, 2012 2007-000493

R11 Chip, 330 kohm, J, 1/10 W, 2012 2007-000757

R12 Chip, 4.7 kohm, J, 1/10 W, 2012 2007-000872

R13 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R14 Chip, 330 kohm, J, 1/10 W, 2012 2007-000757

R15 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R16 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R17 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R18 Chip, 100 ohm, J, 1/10 W, 2012 2007-000290

R19 Chip, 100 ohm, J, 1/10 W, 2012 2007-000290

R20 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R21 Chip, 100 ohm, J, 1/10 W, 2012 2007-000290

R22 Chip, 51 ohm, J, 1/10 W, 2012 2007-007162

R23 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R24 Chip, 1 kohm, J, 1/10 W, 2012 2007-000468

R25 Chip, 118 kohm, F, 1/10 W, 2012 2007-000325

R26 Chip, 86.6 kohm, F, 1/10 W, 2012 2007-001220

R27 Chip, 86.6 kohm, F, 1/10 W, 2012 2007-001220

R28 Chip, 34.8 kohm, G, 1/10 W, 2012 2007-000784

R29 Chip, 34.8 kohm, G, 1/10 W, 2012 2007-000784

R30 Chip, 86.6 kohm, F, 1/10 W, 2012 2007-001220

R31 Chip, 300 ohm, J, 1/10 W, 2012 2007-000728

R32 Chip, 787 kohm, F, 1/10 W, 2012 2007-002888

R33 Chip, 300 ohm, J, 1/10 W, 2012 2007-000728

Page 59

Electrical Parts List

SF150T 7-5

Ref. No. Description SEC Code Remark

R34 Chip, 46.4 kohm, F, 1/10 W, 2012 2007-000917

R35 Chip, 1 kohm, J, 1/10 W, 2012 2007-000468

R36 Chip, 150 ohm, J, 1/10 W, 2012 2007-000401

R38 Chip, 1 Mohm, J, 1/10 W, 2012 2007-000477

R39 Chip, 3 kohm, J, 1/10 W, 2012 2007-000844

R40 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R41 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R42 Chip, 100 kohm, J, 1/10 W, 2012 2007-000282

R43 Chip, 20 ohm, J, 1/10 W, 2012 2007-001289

R44 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R45 Chip, 4.7 kohm, J, 1/10 W, 2012 2007-000872

R46 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R47 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R48 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R49 Chip, 4.7 kohm, J, 1/10 W, 2012 2007-000872

R50 Chip, 34.8 kohm, G, 1/10 W, 2012 2007-000784

R51 Chip, 0 ohm, J, 1/10 W, 2012 2007-000029

R52 Chip, 34.8 kohm, G, 1/10 W, 2012 2007-000784

R53 Chip, 0 ohm, J, 1/10 W, 2012 2007-000029

R54 Chip, 10 kohm, J, 1/10 W, 2012 2007-000300

R55 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R56 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R57 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R58 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R59 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R60 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R61 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R62 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R63 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R64 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R65 Chip, 470 ohm, J, 1/10 W, 2012 2007-000931

R68 220 ohm, J, 1/4 W 2001-000034

R69 Chip, 15 kohm, J, 1/10 W, 2012 2007-000409

- Miscellaneous -

Q1 Small Signal, KSA1182, PNP, 150mW 0501-000279

Q2 Small Signal, KSC5019, NPN, 750mW 0501-000385

Q3 Small Signal, KSC1623, NPN, 200mW 0501-000342

ARR2 Varistor, 600 V, 500 A, 7.0 x 3.3 mm, TP 1405-001009

ARR3 Varistor, 600 V, 500 A, 7.0 x 3.3 mm, TP 1405-001009

L1 Inductor, Chip, 3.3 µH, 5 % 2703-000185

L2 Inductor, Chip, 3.3 µH, 5 % 2703-000185

L3 Coil-Filter, 60 µH, 50 Mohm, 18 T JF27-60051A

Page 60

Electrical Parts List

SF150T7-6

Ref. No. Description SEC Code Remark

L4 Coil-Filter, 60 µH, 50 Mohm, 18 T JF27-60051A

L7 Coil-Filter, 60 µH, 50 mohm, 18 T JF27-60051A

L8 Coil-Filter, 60 µH, 50 mohm, 18 T JF27-60051A

L9 Coil-Filter, 60 µH, 50 mohm, 18 T JF27-60051A

MJ1 Modular-Jack, 6P/6C, Ivory 3722-000255

X1 Crystal, 32.768 kHz, 5 ppm 2801-001498

X2 Crystal, 24.00014 MHz, 50 ppm 2801-001528

X3 Crystal, 29.4912 MHz, 50 ppm 2801-001530

BAT Battery-LI, 3V, 210mAH, Button 4301-000108

BUZ1 Buzzer, 81 dB, 1.5 V, 70 mA, 2.731kHz 3002-000126

JP1 Wire, Jumper, 52 mm, AWG22

JP6 Wire, Jumper, 52 mm, AWG22

PCB PCB, MAIN, Blank

Page 61

Electrical Parts List

SF150T 7-7

Ref. No. Description SEC Code Remark

PBA, PCB Assembly, LIU JF92-00843A

- Capacitors -

C201 Electrolytic, 1 µF, M, 50 V, GP 2401-000597

C202 Electrolytic, 100 µF, M, 25 V, GP 2401-000310

C203 Electrolytic, 330 nF, M, 50 V, GP 2401-001087

C206 Film, MPEF, 1 µF, K, 250 V 2305-000505

C207 Electrolytic, 100 µF, M, 25 V, GP 2401-000310

C208 Electrolytic, 470 µF, M, 16 V, GP 2401-001368

C209 Electrolytic, 22 µF, M, 50 V, GP 2401-000966

C210 Electrolytic, 10 µF, M, 50 V, GP 2401-000486

C212 Film, MPEF, 15 nF, M, 630 V 2305-000199

C214 Electrolytic, 10 µF, M, 50 V, GP 2401-000486

C216 Film, PEF, 47 nF, K, 50 V 2301-000278

C217 Electrolytic, 1 µF, M, 50 V, GP 2401-000597

C218 Electrolytic, 100 nF, M, 50 V, GP 2401-000217

C220 Ceramic, Chip, 2.2 nF, K, 50 V 2203-000499

C221 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C222 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C223 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C225 Ceramic, Chip, 33 nF, K, 50 V 2203-000805

C226 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C227 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C228 Ceramic, Chip, 15 nF, K, 50 V 2203-000376

C229 Ceramic, Chip, 33 nF, K, 50 V 2203-000805

C230 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C231 Ceramic, Chip, 100 nF, K, 50 V 2203-001450

C232 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C233 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C234 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C235 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C236 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C239 Ceramic, Chip, 3.3 nF, K, 50 V 2203-000717

C240 TA, Chip, 1 µF, M, 10 V 2404-000291

C241 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C242 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C243 Ceramic, Chip, 15 nF, K, 50 V 2203-000376

C244 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C247 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C248 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C249 Ceramic, Chip, 68 nF, K, 50 V 2203-001145

7-2. LIU PBA

Page 62

Electrical Parts List

SF150T7-8

Ref. No. Description SEC Code Remark

PBA, PCB Assembly, LIU JF92-00843A

- Capacitors -

C201 Electrolytic, 1 µF, M, 50 V, GP 2401-000597

C202 Electrolytic, 100 µF, M, 25 V, GP 2401-000310

C203 Electrolytic, 330 nF, M, 50 V, GP 2401-001087

C206 Film, MPEF, 1 µF, K, 250 V 2305-000505

C207 Electrolytic, 100 µF, M, 25 V, GP 2401-000310

C208 Electrolytic, 470 µF, M, 16 V, GP 2401-001368

C209 Electrolytic, 22 µF, M, 50 V, GP 2401-000966

C210 Electrolytic, 10 µF, M, 50 V, GP 2401-000486

C212 Film, MPEF, 15 nF, M, 630 V 2305-000199

C214 Electrolytic, 10 µF, M, 50 V, GP 2401-000486

C216 Film, PEF, 47 nF, K, 50 V 2301-000278

C217 Electrolytic, 1 µF, M, 50 V, GP 2401-000597

C218 Electrolytic, 100 nF, M, 50 V, GP 2401-000217

C220 Ceramic, Chip, 2.2 nF, K, 50 V 2203-000499

C221 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C222 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C223 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C225 Ceramic, Chip, 33 nF, K, 50 V 2203-000805

C226 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C227 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C228 Ceramic, Chip, 15 nF, K, 50 V 2203-000376

C229 Ceramic, Chip, 33 nF, K, 50 V 2203-000805

C230 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C231 Ceramic, Chip, 100 nF, K, 50 V 2203-001450

C232 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C233 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C234 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C235 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C236 Ceramic, Chip, 100 pF, J, 50 V 2203-000242

C239 Ceramic, Chip, 3.3 nF, K, 50 V 2203-000717

C240 TA, Chip, 1 µF, M, 10 V 2404-000291

C241 Ceramic, Chip, 1 nF, J, 50 V 2203-000457

C242 Ceramic, Chip, 10 nF, K, 50 V 2203-000262

C243 Ceramic, Chip, 15 nF, K, 50 V 2203-000376

C244 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C247 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C248 Ceramic, Chip, 100 pF, K, 50 V 2203-000242

C249 Ceramic, Chip, 68 nF, K, 50 V 2203-001145

Ref. No. Description SEC Code Remark

C250 Ceramic, Chip, 100 pF, K, 50 V 2203-000242