Page 1

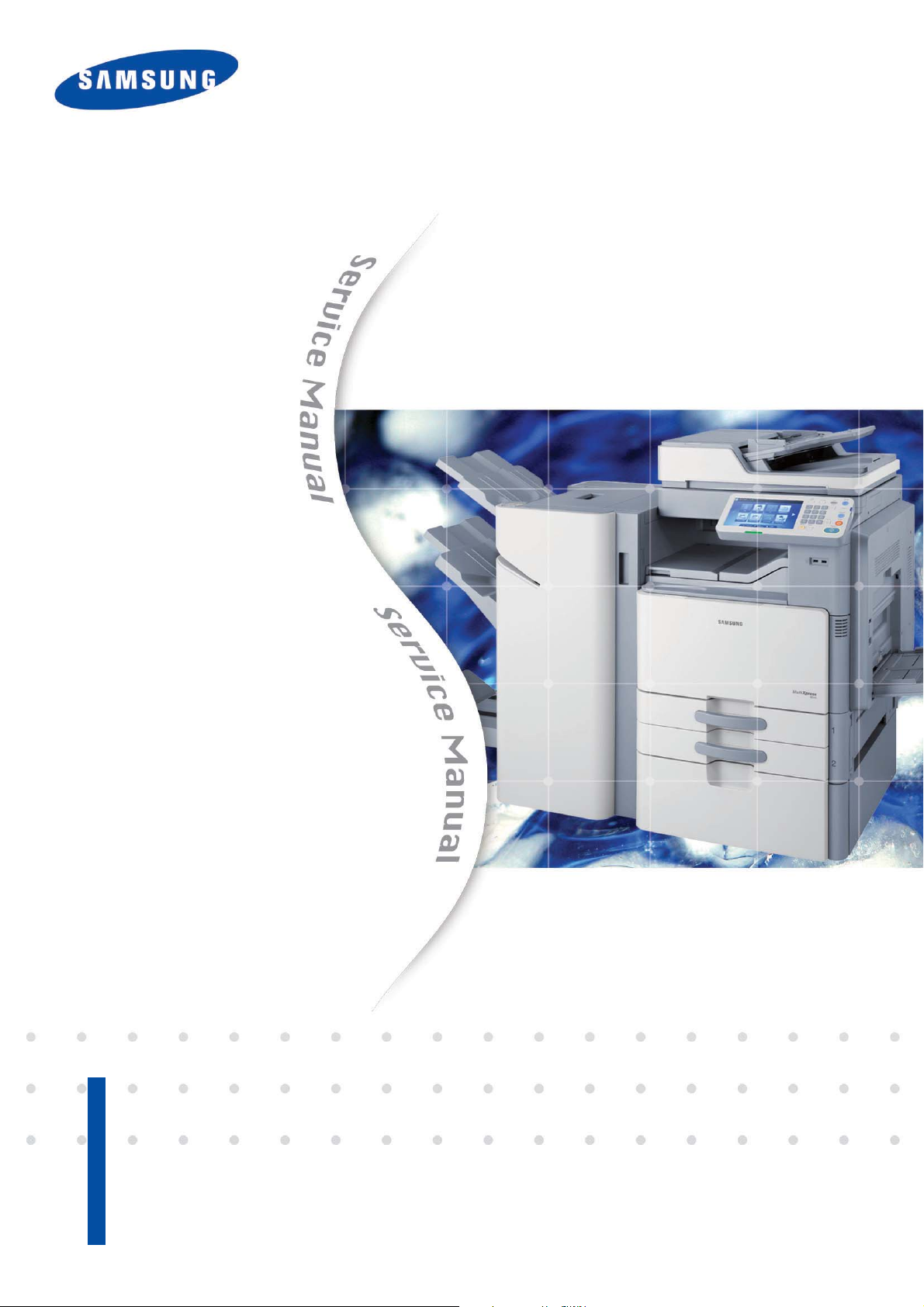

Service Manual

1. Print / Copy speed

• SCX-8030ND : 30 ppm (A4)

• SCX-8040ND : 40 ppm (A4)

2. 800 MHz CPU

3. 250GB HDD

4. 512 MB Memory (Max. 1GB)

The keynote of Product

Digital Laser MFP

SCX-8030ND / 8040ND series

5. 8.9 inch color graphic touch-screen LCD

6. Various option units

• 3K Booklet fi nisher, 1K Standard fi nisher

DCF, HCF, Punch unit , Multi fax etc.

Page 2

GSPN (Global Service Partner Network)

Area Web Site

Europe,MENA, CIS,

Africa

E.Asia, W.Asia,

China, Japan

N.America,

S.America

https://gspn1.samsungcsportal.com

https://gspn2.samsungcsportal.com

https://gspn3.samsungcsportal.com

ⓒ

Samsung Electronics Co.,Ltd. August. 2010

Printed in Korea.

VERSION NO.

: 0.04

CODE

: 80x0-00000E

Page 3

chapter 1 Precautions

1.1 Safety Warning …………………………………………………… 1-1

1.2 Caution for safety ………………………………………………… 1-2

1.3 ESD Precautions ………………………………………………… 1-5

chapter 2 Product decription

2.1 Specifi cations …………………………………………………… 2-1

2.2 System confi guration …………………………………………… 2-7

2.3 Sensor location …………………………………………………… 2-16

Contents

2.4 Paper handling section ………………………………………… 2-20

2.4.1 Overview……………………………………………………… 2-20

2.4.2 Components ………………………………………………… 2-23

2.4.3 Functions …………………………………………………… 2-24

2.4.4 Paper tray …………………………………………………… 2-25

2.4.5 Pick up unit …………………………………………………… 2-26

2.4.6 Registration unit …………………………………………… 2-27

2.4.7 MPF unit ……………………………………………………… 2-28

2.5 Image formation ………………………………………………… 2-29

2.5.1 Printing process overview ………………………………… 2-29

2.5.2 Imaging unit ………………………………………………… 2-30

2.6 Fuser unit ………………………………………………………… 2-34

2.6.1 Fuser unit overview ………………………………………… 2-34

2.6.2 Fuser unit components ……………………………………… 2-35

2.6.3 Fuser unit drive ……………………………………………… 2-36

2.6.4 Temperature control ………………………………………… 2-37

2.7 Laser scanning unit ……………………………………………… 2-38

2.7.1 Laser scanning unit overview ……………………………… 2-38

2.7.2 Laser scanning optical path ………………………………… 2-39

2.7.3 Laser synchronizing detectors …………………………… 2-40

2.8 Printer Drive system ……………………………………………… 2-41

Page 4

Contents

2.8.1 Drive Motors ………………………………………………… 2-41

2.8.2 Main drive unit (OPC, DEVE, MP, REGI, DUPLEX) …… 2-43

2.8.3 Pick-up Drive ………………………………………………… 2-44

2.8.4 Fuser /Exit Drive …………………………………………… 2-45

2.8.5 Toner Duct Drive …………………………………………… 2-46

2.8.6 Drive of Toner Supply ……………………………………… 2-46

2.8.7 WTB leveling drive ………………………………………… 2-46

2.8.8 PR Release drive …………………………………………… 2-47

2.9 Scanner system ………………………………………………… 2-48

2.9.1 Scannner system overview ………………………………… 2-48

2.9.2 Scanning System components …………………………… 2-49

2.10 DADF system …………………………………………………… 2-51

2.10.1 DADF systme overview …………………………………… 2-51

2.10.2 Electric parts layout ………………………………………… 2-52

2.10.3 Description of drive system operations …………………… 2-53

2.11 Printer Electronics confi guration ……………………………… 2-59

2.11.1 Video controller …………………………………………… 2-62

2.11.2 OPE controller …………………………………………… 2-70

2.11.3 Engine controller ………………………………………… 2-74

2.11.4 Scan controller …………………………………………… 2-77

2.11.5 DADF controller …………………………………………… 2-78

2.11.6 Interface part ……………………………………………… 2-79

2.11.7 Connection part …………………………………………… 2-79

2.11.8 SMPS board ……………………………………………… 2-80

2.11.9 HVPS board ……………………………………………… 2-82

2.11.10 Eraser PBA ……………………………………………… 2-83

2.11.11 DC Power PBA …………………………………………… 2-83

2.11.12 Cassette Joint PBA ……………………………………… 2-84

2.11.13 Side Joint PBA …………………………………………… 2-84

2.11.14 Toner Connector PBA …………………………………… 2-85

2.11.15 CRUM PBA ……………………………………………… 2-86

2.11.16 Development Crum Interface PBA ……………………… 2-86

2.11.17 Deve Crum Joint PBA …………………………………… 2-87

2.11.18 Toner Curm Joint PBA …………………………………… 2-87

Page 5

Contents

2.11.19 Fuser PBA ………………………………………………… 2-87

2.11.20 Waste Sensor PBA ……………………………………… 2-88

2.11.21 LED Panel PBA …………………………………………… 2-88

2.11.22 Scan Joint PBA …………………………………………… 2-89

2.11.23 CCDM PBA ……………………………………………… 2-90

2.11.24 Scan Cover Open Sensor PBA ………………………… 2-91

2.11.25 DADF Length Sensor PBA ……………………………… 2-91

2.11.26 DADF Width Sensor PBA ……………………………… 2-92

2.11.27 DADF Mixed Sensor PBA ……………………………… 2-92

2.11.28 DADF LED Panel PBA …………………………………… 2-93

2.11.29 Exit LED Panel PBA ……………………………………… 2-93

2.12 Heating cables ………………………………………………… 2-94

chapter 3 Replacement procedure

3.1 General Disassembly Procedure Precautions ………………… 3-1

3.2 Cover ……………………………………………………………… 3-2

3.2.1 Front cover …………………………………………………… 3-2

3.2.2 Left cover …………………………………………………… 3-3

3.2.3 Rear cover …………………………………………………… 3-3

3.2.4 Right cover …………………………………………………… 3-4

3.3 OPE unit …………………………………………………………… 3-5

3.4 Scan unit ………………………………………………………… 3-10

3.4.1 Scan glass …………………………………………………… 3-11

3.4.2 Scan main PBA ……………………………………………… 3-12

3.4.3 Lamp ………………………………………………………… 3-13

3.4.4 Original size detection sensor ……………………………… 3-15

3.4.5 Joint PBA …………………………………………………… 3-15

3.4.6 Joint sub PBA ……………………………………………… 3-16

3.4.7 Fan …………………………………………………………… 3-16

3.4.8 Pulley-belt …………………………………………………… 3-17

3.4.9 Scan motor and gear belt ………………………………… 3-18

Page 6

Contents

3.4.10 Home sensor ……………………………………………… 3-18

3.4.11 Scanner heating cable …………………………………… 3-19

3.4.12 Align set …………………………………………………… 3-23

3.5 Fuser unit ………………………………………………………… 3-24

3.6 Side Unit …………………………………………………………… 3-35

3.6.1 Duplex sensors ……………………………………………… 3-36

3.7.2 Transfer sensors …………………………………………… 3-37

3.7.3 MP unit ……………………………………………………… 3-39

3.7 Electrical components …………………………………………… 3-44

3.7.1 Engine controller …………………………………………… 3-44

3.7.2 Hard Disk Drive (HDD) ……………………………………… 3-45

3.7.3 Video controller ……………………………………………… 3-46

3.7.4 Joint PBA …………………………………………………… 3-47

3.7.5 Toner PBA …………………………………………………… 3-47

3.7.6 Toner motor ………………………………………………… 3-48

3.7.7 DC power PBA ……………………………………………… 3-49

3.7.8 HVPS PBA …………………………………………………… 3-50

3.7.9 Lift motor …………………………………………………… 3-51

3.7.10 SMPS PBA ………………………………………………… 3-52

3.7.11 SMPS FAN ………………………………………………… 3-53

3.7.12 Ozone Filter FAN ………………………………………… 3-55

3.7.13 Side joint PBA ……………………………………………… 3-56

3.7.14 Eraser Lamp ……………………………………………… 3-57

3.7.15 Waste sensor PBA ………………………………………… 3-58

3.7.16 Temperature sensor ……………………………………… 3-58

3.8 Main drive unit …………………………………………………… 3-60

3.8.1 Main drive motor …………………………………………… 3-62

3.8.2 Main drive clutch …………………………………………… 3-62

3.9 Exit drive unit …………………………………………………… 3-63

3.10 Toner Duct drive unit …………………………………………… 3-65

3.11 PR Release drive unit ………………………………………… 3-66

3.12 Pick-up drive unit ………………………………………………… 3-67

3.13 WTB leveling drive unit ………………………………………… 3-68

3.14 LSU (Laser Scanning Unit) …………………………………… 3-71

Page 7

Contents

3.15 Frame Duct …………………………………………………… 3-74

3.16 DADF Unit ……………………………………………………… 3-75

3.16.1 Width / Length sensor PBA ……………………………… 3-84

3.16.2 DADF Main PBA …………………………………………… 3-85

3.16.3 DADF Motors ……………………………………………… 3-87

3.16.4 DADF cover open sensor ………………………………… 3-90

3.16.5 Pick-Up Guide Sensor PBA ……………………………… 3-91

3.16.6 DADF Solenoid …………………………………………… 3-93

3.17 Exit Unit ………………………………………………………… 3-94

3.18 Regi. Unit ……………………………………………………… 3-96

3.19 Pick-Up Unit …………………………………………………… 3-98

3.20 Cassette Heating Cable ……………………………………… 3-100

chapter 4 Troubleshooting

4.1 Entering/Exiting Diagnostics Mode ……………………………… 4-1

4.2 Serive mode menu tree …………………………………………… 4-2

4.2.1 Information tab ……………………………………………… 4-2

4.2.2 Maintenance counts tab …………………………………… 4-4

4.2.3 Diagnostics tab …………………………………………… 4-5

4.2.4 Service Functions ………………………………………… 4-5

4.3 Information ………………………………………………………… 4-6

4.3.1 General ……………………………………………………… 4-6

4.3.2 Supply status ……………………………………………… 4-6

4.3.3 Software version …………………………………………… 4-8

4.3.4 Service Hours ……………………………………………… 4-8

4.3.5 Fault Log …………………………………………………… 4-8

4.3.5 Print reports ………………………………………………… 4-8

4.4 Maintenance Counts …………………………………………… 4-9

4.4.1 Fault count ………………………………………………… 4-9

4.4.2 Jam count …………………………………………………… 4-10

4.4.3 Part replacement count …………………………………… 4-12

4.5 Diagnotics ………………………………………………………… 4-13

Page 8

Contents

4.5.1 Engine diagnostics ………………………………………… 4-13

4.5.1.1 NVM Read/Write ……………………………………… 4-13

4.5.1.2 Engine Test Routines ………………………………… 4-13

4.5.2 Fax diagnostics …………………………………………… 4-14

4.5.2.1 Fax NVM Read/Write ………………………………… 4-14

4.5.2.2 Fax Test Routines ……………………………………… 4-15

4.5.3 Scanner diagnostics ……………………………………… 4-17

4.5.3.1 Shading Test ………………………………………… 4-17

4.5.3.2 Scanner/DADF NVM Read/Write …………………… 4-17

4.5.3.3 Scanner/DADF Test Routines ……………………… 4-18

4.5.4 Adjustment ………………………………………………… 4-20

4.5.4.1 Print Adjustment ……………………………………… 4-20

4.5.4.2 Copy Adjustment ……………………………………… 4-22

4.5.4.3 Scan Area Adjustment ………………………………… 4-23

4.5.4.4 DADF Adjustment ……………………………………… 4-25

4.5.4.5 Finisher Adjustment …………………………………… 4-27

4.5.5 ACS ………………………………………………………… 4-30

4.5.6 Color Management ………………………………………… 4-31

4.6 Sevice functions ………………………………………………… 4-32

4.6.1 Main Memory Clear ………………………………………… 4-32

4.6.2 Hard Disk Maintenance …………………………………… 4-32

4.6.3 Debug Log …………………………………………………… 4-32

4.6.4 Port …………………………………………………………… 4-33

4.6.5 Capture Log ………………………………………………… 4-33

4.6.6 Toner Save ………………………………………………… 4-33

4.6.7 Count Setting of Large Page ……………………………… 4-33

4.6.8 System Recovery …………………………………………… 4-33

4.6.9 User Data Management …………………………………… 4-34

4.6.10 TR Control Mode ………………………………………… 4-35

chapter 5 Updating Firmware

5.1 Updating from the Printer Control Panel ……………………… 5-2

5.2 Updating from the Network …………………………………… 5-8

Page 9

chapter 6 Preventive Maintenance (PM)

6.1 PM Supplies ……………………………………………………… 6-1

6.2. PM Procedures ………………………………………………… 6-5

6.2.1 Toner cartridge ……………………………………………… 6-5

6.2.2 Imaging unit ………………………………………………… 6-7

6.2.3 2nd Transfer roller ………………………………………… 6-11

6.2.4 Fuser Unit …………………………………………………… 6-12

6.2.5 Pick up/ Retard/ Forward roller …………………………… 6-13

6.2.6 Ozone Filter ………………………………………………… 6-13

6.2.7 DADF Rollers (Pick up /ADF/ Retard) …………………… 6-14

6.2.8 MP Pick up / Retard / Forward roller …………………… 6-19

6.2.9 Scanner Fan Filter ………………………………………… 6-21

Contents

6.3. Cleaning the PM parts ………………………………………… 6-22

6.3.1 Cleaning the charge scorotron …………………………… 6-22

6.3.2 Cleaning the pick up roller ………………………………… 6-22

6.3.3 Cleaning the Regi roller …………………………………… 6-23

6.3.4 Cleaning the tray1 feed roller ……………………………… 6-23

6.3.5 Cleaning the tray2 feed roller ……………………………… 6-24

6.3.6 Cleaning the DADF retard rubber pad …………………… 6-25

6.3.7 Cleaning the DADF rollers ………………………………… 6-26

6.3.7 Cleaning the ADF glass …………………………………… 6-27

chapter 7 Troubleshooting

7.1 Procedure of checking the symptoms ………………………… 7-1

7.2 Error code and troubleshooting ………………………………… 7-3

7.2.1 Error code and error message …………………………… 7-3

7.2.2 Error Code Details ………………………………………… 7-11

7.3 Image quality problems and solutions ………………………… 7-101

7.3.1 Vertical Lines ………………………………………………… 7-102

7.3.2 Horizontal Lines ……………………………………………… 7-103

7.3.3 White spot …………………………………………………… 7-104

7.3.4 Black background ………………………………………… 7-105

7.3.5 Blurred image ……………………………………………… 7-106

Page 10

7.3.6 Uneven pitch and jitter image ……………………………… 7-107

7.3.7 Skewed image ……………………………………………… 7-108

7.3.8 Low image density ………………………………………… 7-109

7.3.9 Blank copy, Black copys …………………………………… 7-110

7.3.10 Uneven density in sub scan direction …………………… 7-112

7.3.11 Uneven density in main scan direction ………………… 7-113

7.3.12 Poor fusing performance ………………………………… 7-114

7.3.13 Stain on the paper back side …………………………… 7-115

7.3.14 DADF skew testing ……………………………………… 7-116

7.4 Other Errors ……………………………………………………… 7-121

chapter 8 System Diagram

Contents

8.1 Engine 1 …………………………………………………………… 8-1

8.2 Engine 2 …………………………………………………………… 8-2

8.3 Main board & OPE ……………………………………………… 8-3

8.4 Scan & DADF …………………………………………………… 8-4

8.5 Bottle joint board & side joint board …………………………… 8-5

8.6 DC control board ………………………………………………… 8-6

8.7 Cassette joint board & Drive joint board ……………………… 8-7

8.8 Heater & Fuse …………………………………………………… 8-8

chapter 9 System Recovery

9.1 Entry Point ………………………………………………………… 9-1

9.2 USB ………………………………………………………………… 9-2

9.3 Network …………………………………………………………… 9-4

9.4 Confi rmation Page ……………………………………………… 9-5

9.5 Error Page ………………………………………………………… 9-6

9.6 Progress Page …………………………………………………… 9-7

9.7 Error List …………………………………………………………… 9-8

9.8 HDD Repair ……………………………………………………… 9-8

9.9 HDD Failure ……………………………………………………… 9-10

Page 11

Contents

chapter 10

Reference Information

10.1 Tools for troubleshooting ……………………………………… 10-1

10.2 Abbreviations …………………………………………………… 10-4

Page 12

1. Prec

a

n

o

(2) Use only Samsung replacement parts

t

e

s

f

IEC 825. Cl

n

t

o

-

o

utions

1. Warning and cautio

In order to prevent accidents and to prevent damage t

below carefully before servicing the printer and follow

1.1 Safety Warning

(1) Only to be serviced by appropriately qualified servi

High voltages and lasers inside this product are da

qualified service technician.

.

There are no user serviceable parts inside the prin

additions to the printer as these could cause the pr

fire hazards.

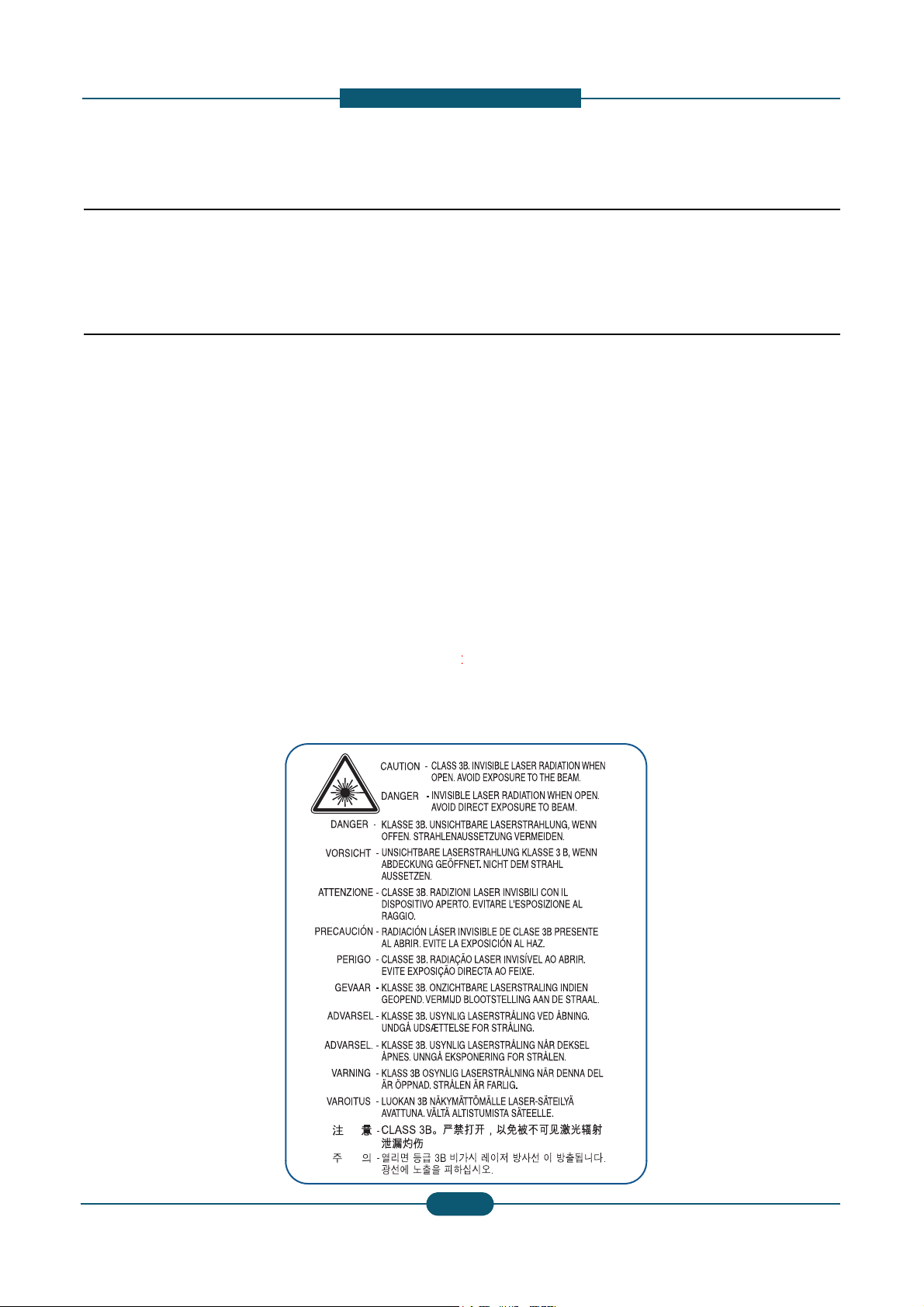

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to th

Subchapter J for Class 1(1) laser products, and el

orming to the requirements of

laser system and printer are designed so there is n

Class I level during normal operation, user mainte

ass I las

for s afety

the equipment please read the precautions listed

them closely.

ce technician.

ngerous. This printer should only be serviced by a

er. Do not make any unauthorized changes or

inter to malfunction and create an electric shock or

requirements of DHHS 21 CFR, chap ter 1

ewhere, it is certified as a Class I laser product coner products are not considered to be hazardous. The

ever any human access to laser radiation above a

ance, or prescribed service condition.

Warning >> Never operate or service the printer with

assembly. The reflected beam, although invisible, can

When using this product, these basic safety pre-cauti

electric shock, and personal injury.

he protective cover removed from Laser Scanner

damage your eyes.

ns should always be followed to reduce risk of fire,

Service Manual

SCX-8030/8040 series

1

1

SAMSUNG ELECTRONICS

Version 0.05

Page 13

a

1.2 Caution for safety

i

o

e

w

w

u

p

e

d

(2)

() y p pp p

o

(5)

a

() p g p

f

c

t

c

r

a

cable immediately, do not reuse or repair the dama

a

m

o

p

i

p

c

d

w

e

h

-

t

y sp

yp

cable. Some chemicals can attack the coating on

1.2.1 Toxic material

1. Prec

utions

This product contains toxic materials that could cause

(1) If the LCD control panel is damaged it is possible f

with the skin should be avoided. Wash any splash

doctor. If the liquid gets into the mouth or is swallo

(2) Please keep Drum cartridge and Toner cartridge a

Drum cartridge and Toner Cartridge may be harmf

1.2.2 Electric shock and fire safety

Failure to follow the following instructions could cause

(1) Use only the correct voltage, failure to do so could

electric shock.

Use only the power cable supplied with the printer.

cable to overheat and potentially cause a fire.

(3) Do not overload the power socket, this could lead t

lead to a fire.

(4) Do not allow water or other liquids to spill into the p

paper clips, pins or other foreign objects to fall into

to an electric shock or fire hazard.

Never touch the plugs on either end of the power c

When servicing the printer remove the power plug

(6) Use caution when inserting or removing the power

firmly and pull. The power connector must be inser

overheating possibly leading to a fire.

(7) Take care of the power cable. Do not allow it to be

damaged. Do not place objects on top of the powe

overheat and cause a fire. Exposed cables could c

the power cable, weakening the cover or exposing

(8) Ensure that the power sockets and plugs are not cr

should be repaired immediately. Take care not to c

the machine.

(9) Use caution during thunder or lightning storms. Sa

from the power source when such weather conditi

ower cord if it is still connected to the wall socket

(10) Avoid damp or dusty areas, install the printer in a

machine near a humidifier or in front of an air con

can lead to overheating and cause a fire or cause

(11) Do not position the printer in direct sunlight. This

possibly leading to the printer failing to work prop

(12) Do not insert any metal objects into the machine t

could make contact with a high voltage conductor

llness if ingested.

r the liquid inside to leak. This liquid is toxic. Contac

s from eyes or skin immediately and contact your

ed see a doctor immediately.

ay from children. The toner powder contained in the

l and if swallowed you should contact a doctor.

recautions

lectric shock or potentially cause a fire.

amage the printer and potentially cause a fire or

Use of an incorrectl

overheating of the cables inside the wall and could

rinter, this can cause electric shock. Do not allow

the printer these could cause a short circuit leading

ble with wet hands, this can cause electric shock.

rom the wall socket.

onnector. When removing the power connector, grip it

ed completely, otherwise a poor contact could cause

ome twisted, bent sharply around corners or wise

cable. If the power cable is damaged it could

use an electric shock. Replace the damaged power

cables causing fire and shock risks.

cked or broken in any way. Any such defects

ut or damage the power cable or plugs when moving

sung recommends that this machine be disconnected

ns are expected. Do not touch the machine or the

n these weather conditions.

lean well ventilated location. Do not position the

itioner. Moisture and dust built up inside the machine

parts to rust.

ill cause the temperature inside the printer to rise

rly and in extreme conditions could lead to a fire.

rough the ventilator fan or other part of the casing, it

inside the machine and cause an electric shock.

ecified cable could cause the

Service Manual

SCX-8030/8040 series

1

2

SAMSUNG ELECTRONICS

Version 0.05

Page 14

a

1.2.3 Handling Precautions

a

(1) Ensure the printer is installed on a level surface, ca

v

o

u

o

o

u

g

o

t

g

(3) Disconnect printer interface cables and power cabl

u

x

-

The OPC Drum can be irreparably damaged if it e

d

c

o

g

)

C

t

-

supporting its weight. Failure to do so could

p

light

1. Prec

utions

The following instructions are for your own personal s

product.

cause the printer to tip or fall.

(2) The printer contains many rollers, gears and fans.

fingers, hair or clothing in any of these rotating de

(3) Do not place any small metal objects, containers

which if spilled could get into the machine and ca

(4) Do not install the machine in areas with high dust

a humidifier or heater. Damage could be caused t

(5) Do not place candles, burning cigarettes, etc on th

(6) When reinstalling the imaging unit or ITB unit at p

1.2.4 Assembly / Disassembly Preca

Replace parts carefully and always use Samsung par

cable routing before dismantling any part of the machi

Please carry out the following procedures before dism

(1) Check the contents of the machine memory and m

if the main board or network card is replaced.

(2) Ensure that power is disconnected before servicin

(4) Only use approved spare parts. Ensure that part n

temperature rating are correct.

(5) When removing or re-fitting any parts do not use e

plastic.

(6) Take care not to drop any small parts into the mac

(7) Handling of the OPC Drum

Take care not to expose the OPC Drum either to

room lighting. Exposure for as little as 5 minutes

properties and will result in print quality degradati

Remove the OPC Drum and store it in a black ba

working with the Covers (especially the top cover

damage the OPC Drum.

- Take care not to scratch the green surface of OP

If the green surface of the Drum Cartridge is scra

compromised.

fety, to avoid injury and so as not to damage the

of

Take great care to ensure that you do not catch your

ices.

f water, chemicals or other liquids close to the printer

se damage, shock or fire hazard.

r moisture levels, beside on open window or close to

the printer in such areas.

e printer, These could cause a fire.

wer off, perform the OPC-ACR surely.

tions

s. Take care to note the exact location of parts and

ne. Ensure all parts and cables are replaced correctly.

antling the printer or replacing any parts.

ake a note of any user settings. These will be erased

or replacing any electrical parts.

.

mber, product name, voltage, current and

cessive force, especially when fitting screws into

hine.

to

irect sunlight or to fluorescent or incandescent

an damage the surface of the photoconductive

n. Take extra care when servicing the printer.

or other lightproof container. Take care when

open as light is admitted to the OPC area and can

Drum Unit.

ched or touched the print quality will be

.

Service Manual

SCX-8030/8040 series

1-1

3

3

SAMSUNG ELECTRONICS

Version 0.05

Page 15

1. Prec

a

u

r

o

w

v

quip

qp

e

h

s

o

-

e

utions

1.2.5 Disregarding this warning may

(1) Be careful with high temperature compone nts.

The fuser unit works at a high temperature. Use ca

cool down before disassembly.

(2) Do not put fingers or hair into the rotating parts.

When operating a printer, keep your hands and hai

motor, fan, etc.).

(3) When moving the printer :

- When transporting/installing the equipment, employ f

- Be sure not to hold the movable parts or units (e.g. th

equipment.

- Be sure to use a dedicated outlet with 110V/220V po

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessi

sunlight.

- Provide proper ventilation since the equipment emits

- The e

-Be sure to fix and plug in the power cable securely aft

-If you are moving the machine a short distance, you s

(e.g : same building through elevator)

- If you are moving the machine a long distance, you

& staple unit, tape and disassemble all trays. (e.g : m

ment must be installed near the socket outl

cause bodily injury

tion when working on the printer. Wait for the fuser to

away form the rotating parts (Paper feeding entrance,

ur people and be sure to hold the lifting handles.

e control panel, DADF) when transporting the

er input.

e heat, high humidity, dust, vibration and direct

a slight amount of ozone.

et and must be accessible.

r the installation so that no one trips over it.

ould separate the finisher.

hould remove toner & imaging unit, lock scan carrier

ved by truck or so)

1

Service Manual

SCX-8030/8040 series

4

SAMSUNG ELECTRONICS

Version 0.05

Page 16

a

1.3 ESD Precautions

d

integrated circuits, some field effect transistors, and se

h

p

n

o

h

m

d

4. Use only an anti

static solder removal device. Som

y

v

s

g

E

d

n

electricity sufficient to damage an ESD

-

chip components

solder removal devices not classified as anti

v

s

1. Prec

utions

Certain semiconductor devices can be easily damage

commonly called “Electrostatically Sensitive (ES) Dev

The techniques outlined below should be followed to

caused by static electricity.

Caution >>Be sure no power is applied to the chassis

1. Immediately before handling a semiconductor com

off any electrostatic charge on your body by touchi

commercially available wrist strap device, which sh

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped wit

such as aluminum or copper foil, or conductive foa

vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder or

“

”

-

static” can generate electrical charges sufficient to

5. Do not use Freon-propelled chemicals. When spra

damage ESDs.

6. Do not remove a replacement ESD from its protecti

Most replacement ESDs are packaged with all lead

or a comparable conductive material.

by static electricity. Such components are

ices” or ESDs. Examples of typical ESDs are:

“”

.

elp reduce the incidence of component damag e

or circuit, and observe all other safety precautions.

onent or semiconductor-equipped assembly, drain

g a known earth ground. Alternatively, employ a

uld be removed for your personal safety reasons

ESDs, place the assembly on a conductive surface ,

, to prevent electrostatic charge buildup in the

esolder ESDs.

“

-

damage ESDs.

ed, these can generate electrical charges sufficient to

e packaging until immediately before installing it.

shorted together by conductive foam, aluminum foil,

7. Immediately before removing the protective shortin

touch the protective material to the chassis or circui

8. Maintain continuous electrical contact between the

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackage

the brushing together of clothing fabric and lifting o

.

material from the leads of a replacement ESD,

t assembly into which the device will be installed.

SD and the assembly into which it will be installed,

replacement ESDs. Normal motions, such as

e’s foot from a carpeted floor, can generate static

Service Manual

SCX-8030/8040 series

1

5

SAMSUNG ELECTRONICS

Version 0.05

Page 17

2. Product

D

0

6

0

)

B

B

m

e

L

W

H

H

-

h

2. Product description

2.1 Specifications

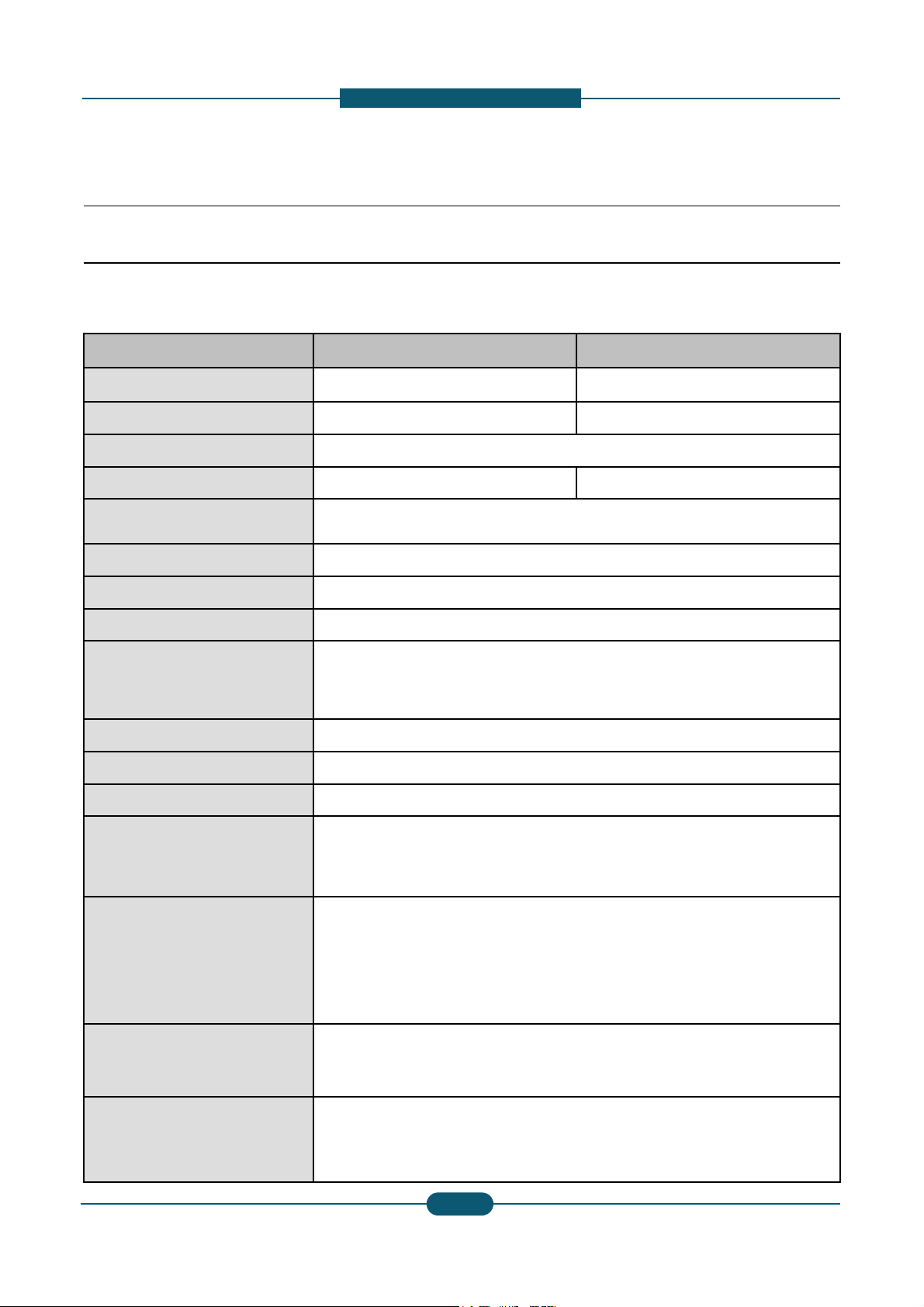

General Specifications

escription

Item SCX-8030ND

Printing Speed (A4) 30 ppm

FCOT < 7 sec

Warm-up Time < 25 sec

Duplex Printing Speed 30 ppm

Scanning Speed (A4) (Color)

Memory 512MB (Max.1GB )

HDD 250GB

CPU SPGPv4 800MHz

Resolution

Gradation 256

Size (W x D x H ) 677.5 x 742.8 x 924 m

Weight Approx. 113Kg (250lb

40 ipm @ 600 dpi

60 ipm @ 300 dpi

• Optical : 600 x 600 d

• Enhanced : Draft 60

Default

Up to 6

SCX-8040ND

40 ppm

< 5.5 sec

40 ppm

pi

x 600 x 1bit

00 x 600 x 2 bit

0 x 600 x 4 bit

m (26.7 x 29.2 x 36.4 inches)

(Including consumables and tray)

Noise (dB)

Power consumption

Power requirement

Power output rating for heating

wire in DCF/HCF

Service Manual

SCX-8030/8040 series

• Ready mode : 37 d

• Printing mode : 54 d

• Copying mode : 57 d

• Average operating

• Ready mode : Less t

• Low Power mode : L

• Power Save mode :

• Power off mode : 0

AC 110-127V , 50/60

Note - See the Rating

(hertz) and type of cur

AC 110-127V , 50/60

Note - See the Rating

and type of current.

The voltage rating of

(A)

(A)

B(A)

ode : Less than 1,100 W

han 250 W

ss than 40 W

ess than 7 W

z or AC 220-240V , 50/60 Hz

label on the machine for the correct voltage, frequency

rent.

z or AC 220-240V , 50/60 Hz

label on the machine for correct voltage, frequency (hertz)

eating wire is the same as the machine’s voltage rating.

2

1

SAMSUNG ELECTRONICS

Version 0.05

Page 18

D

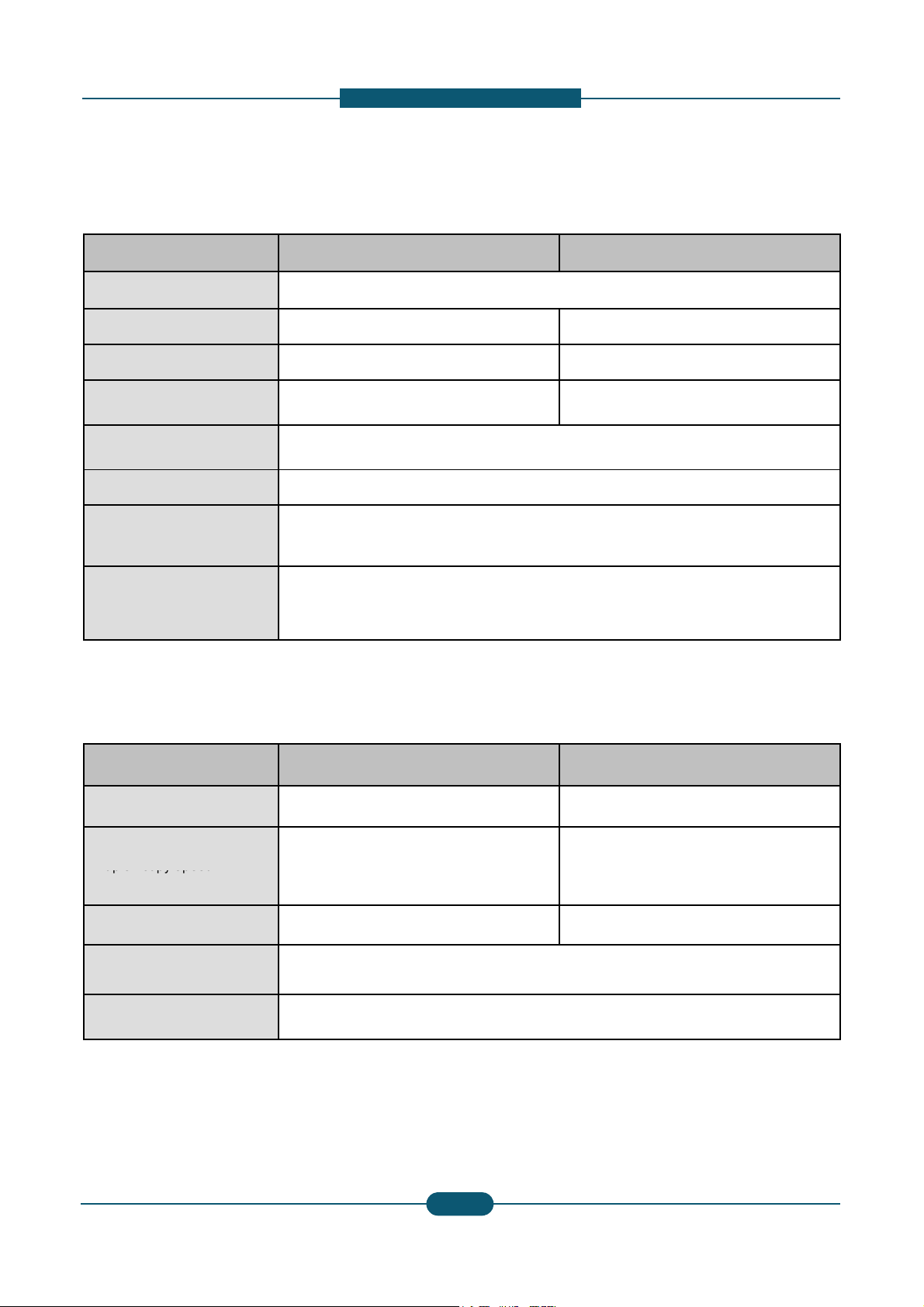

Printer Specifications

Printing method

laser beam printing

L

400

600

p

5

e

Duplex copy speed

Dupl

2)

0

Zoom range

4

-

t(600x600x2 dpi)

Dupl

2)

2. Product

escription

Item SCX-8030ND

Printing speed Up to 30 ppm (A4), 30 ppm

Duplex printing speed Up to 30 ipm (A4), 30 ipm (

First print out time

(from ready)

Print resolution

Printer language PCL5e, PCL6, PostScript 3,

OS compatibility

Interface

< 9 sec

•Default : Up to 2,

• Max : Up to 9,600 x 600 d

• Windows: 2000 ,XP,2003 ,

• Various Linux OS

• Macintosh: Mac OS X 10.

• High speed USB 2.0

• Ethernet 10/100/1000 Bas

• FDI (optional)

x

Copier specifications

SCX-8040ND

(Letter) Up to 40 ppm (A4), 40 ppm (Letter)

etter) Up to 40 ipm (A4), 40 ipm (Letter)

< 8 sec

dpi effective outpu

i effective output(600x600x2 dpi)

PDF 1.7+, TIFF, PJL

Vista ,2008 ,Win7

~10.6

TX (embedded type)

Item SCX-8030ND

Copy Speed Up to 30 cpm (A4), 30 cpm

Simplex to Duplex (1-1,1-2)

First copy out time < 7 sec

Copy resolution

Service Manual

SCX-8030/8040 series

: Up to 30 ipm in A4 (30 ipm

ex to Duplex (2-1.2-

: Up to 18 ipm in A4 (18 ipm

• Platen : 600 x 600 dpi

• Document feeder: Up to 6

• Platen : 25% to 400%

• Document feeder: 25% to

SCX-8040ND

(Letter) Up to 40 cpm (A4), 40 cpm (Letter)

Simplex to Duplex (1-1,1-2)

in Letter)

in Letter)

0 x 600 dpi

00%

2

2

: Up to 40 ipm in A4 (40 ipm in Letter)

ex to Duplex (2-1.2-

: Up to 24 ipm in A4 (24 ipm in Letter)

< 5.5 sec

SAMSUNG ELECTRONICS

Version 0.05

Page 19

D

0

t

Scanner specifications

0

8

Internal: 3

n

0

3

Applicable line

Public Sw

M

e

(

• Standar

0

F

n

c

-

bit

Telephone Network (PSTN) or behind PABX

203 x 98 dpi

2. Product

escription

Item SCX-803

Compatibility TWAIN s

Scanning method Color CC

TWAIN standard

Resolution

Network Scan File format PDF, TIF

Effective scanning length Max. 432

Effective scanning width Max. 297

Color bit depth

Mono bit depth

Scan to USB 100, 200,

Scan to Email 100, 200,

Scan to Server 100, 200,

Up to 60

(Up to 4,

External:

1 bit for li

8 bit for g

ND SCX-8040ND

andard (network)

D

x 600 dpi

00 x 4,800 dpi by software enhancement)

300, 400, 600 dpi

300, 400, 600 dpi

300, 400, 600 dpi

F, JPEG

mm (17 inches)

mm (11.7 inches)

24 bit

eart & halftone

ray scale

Fax Specifications

Item SCX-803

Compatibility Super G

Data coding MH/MR/

Modem speed 33.6kbps

Transmission speed Up to 3 s

Maximum document length 432 mm

Resolution

Memory HDD Ba

Auto dialer up to 500

Service Manual

SCX-8030/8040 series

• Fine : 2

• Super

• Ultra Fi

ND SCX-8040ND

MR/JBIG/JPEG

conds/page

17 inches)

:

3 x 196 dpi

ine : 300 x 300 dpi

e : 600 x 600 dpi

kup

numbers

2

3

SAMSUNG ELECTRONICS

Version 0.05

Page 20

D

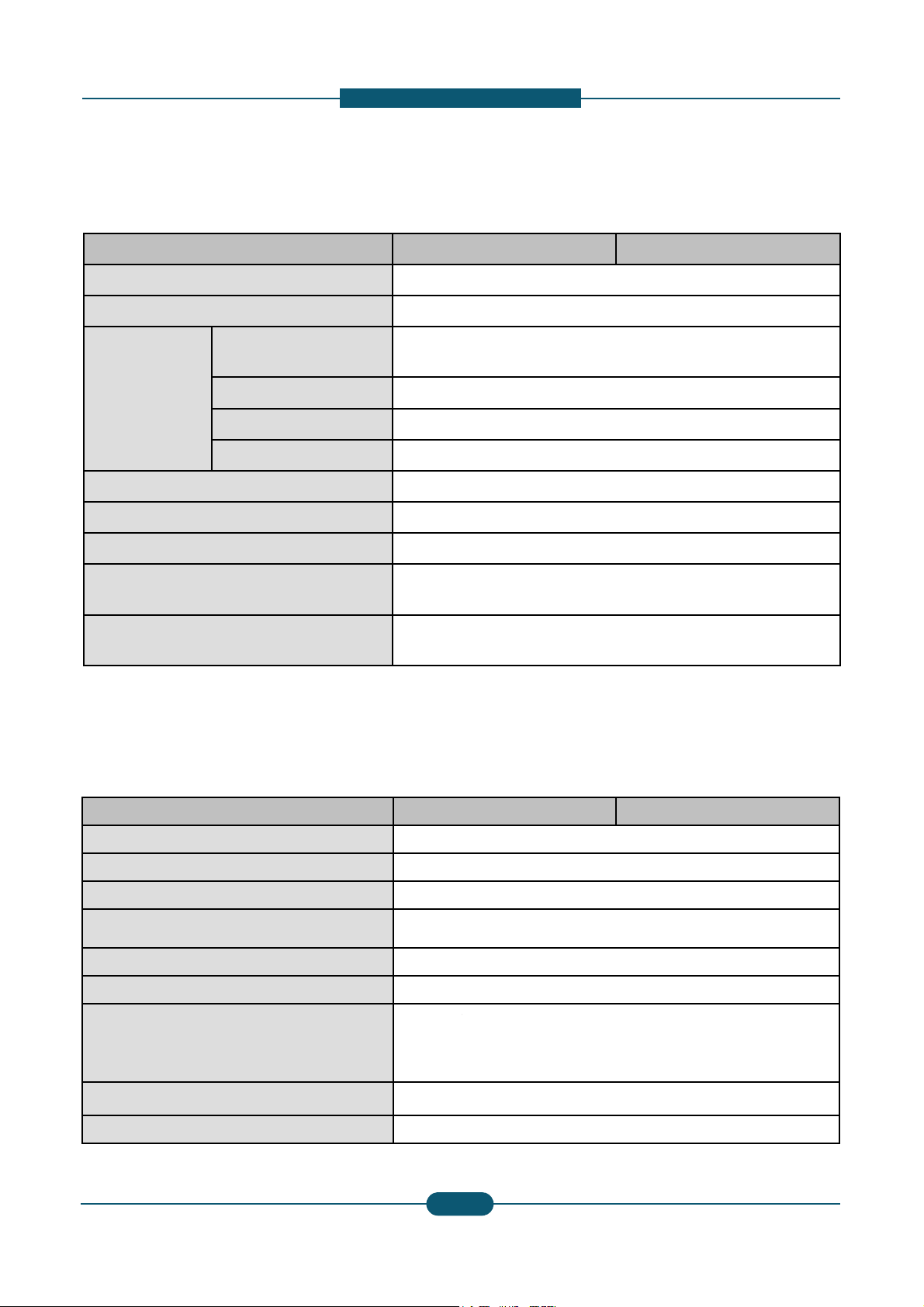

Paper Specifications

e

e

o

m

3

4

C

Plain Pap

Th

e

p

h

e

aPre

1

X

0

g

g

a

a

D

a

-

r

Thick Pap

2. Product

escription

Item SCX-8030ND

• Standard : 1,040 (Cassett

Input Paper Capacity

Output Paper Capacity

Paper Size

Paper Type

Paper Weight

• Maximum : 1,040 (Cassett

Note – The SCX-8025ND n

• Standard : 500 (Center Ou

• Maximum : 3,250 (Booklet

• Cassette :

•MP Tray :

• High Capacity Feeder :

assette :

•

• MP Tray :

• High Capacity Feeder :

• Cassette : 60 ~ 163 gsm (

• MP Tray : 60 ~ 216 gsm (1

• High Capacity Feeder : 60

148 x 210 m

98 x 148 mm(

A

er,

Recycled, Lett

Plain Pa

Recycled, Lett

Transparency,

er, T

Pl

SCX-8040ND

1 & 2) + 100 (MP Tray)

1 & 2) + 2,000 (High Capacity Feeder) + 100 (MP Tray)

t supports the Tray(DCF,HCF) and the Finishe

tput Tray)

Finisher) + 125 (Job Separator)

(5.83”x 8.27”) ~ 305 x 457 mm (12”x 18”)

.8”x 5.8”) ~ 305 x 1200 mm (12”47”)

/ Letter

n Paper,

rhead, Cotton, Colored, Archive, CardStock, Label

in Paper, Thick Paper, Bond, Punched, Pre-Printed,

rhead, Cotton, Colored, Archive, CardStock, Label,

Envelope

in Paper, Thin Paper, Thick Paper, Bond, Punched,

-Printed, Recycled, Cotton, Colored, CardStock

6lb Bond ~ 90lb Index)

6lb Bond ~ 90lb Cover)

~ 163 gsm (16lb Bond ~ 90lb Index)

er, Bond, Punched, Pre-Printed,

Original Capacity for DADF 100 sheets

Original Size for DADF

Original Weight for DADF

• Full supported Size : 140

• Auto-detected Size : A3, B

• Simplex : 42 ~ 163 gsm (3

• Duplex : 50 ~ 128 gsm (30

Consumables

Product Model name Life **

Toner Cartridge

Imaging unit MLT-R607K 100K p

Waste Toner Container MLT-W606 300K p

* American 35K Toner can be used for SCX-8030N

** Declared yield value in accordan ce with 6% cover

MLT-K606S 35K pa

MLT-K607S 20K pa

140mm ~ 297 x 432mm (5.5" x 5.5" ~ A3/Ledger)

4, B4 SEF, A4, A4 SEF, B5, B5 SEF, A5, A5 SEF

lb Book ~ 90lb Index)

lb Book ~ 34lb Bond)

SCX-8030ND SCX-8040ND

es X* O

es O O

ges O O

ges O O

ge.

Service Manual

SCX-8030/8040 series

2

4

SAMSUNG ELECTRONICS

Version 0.05

Page 21

D

m

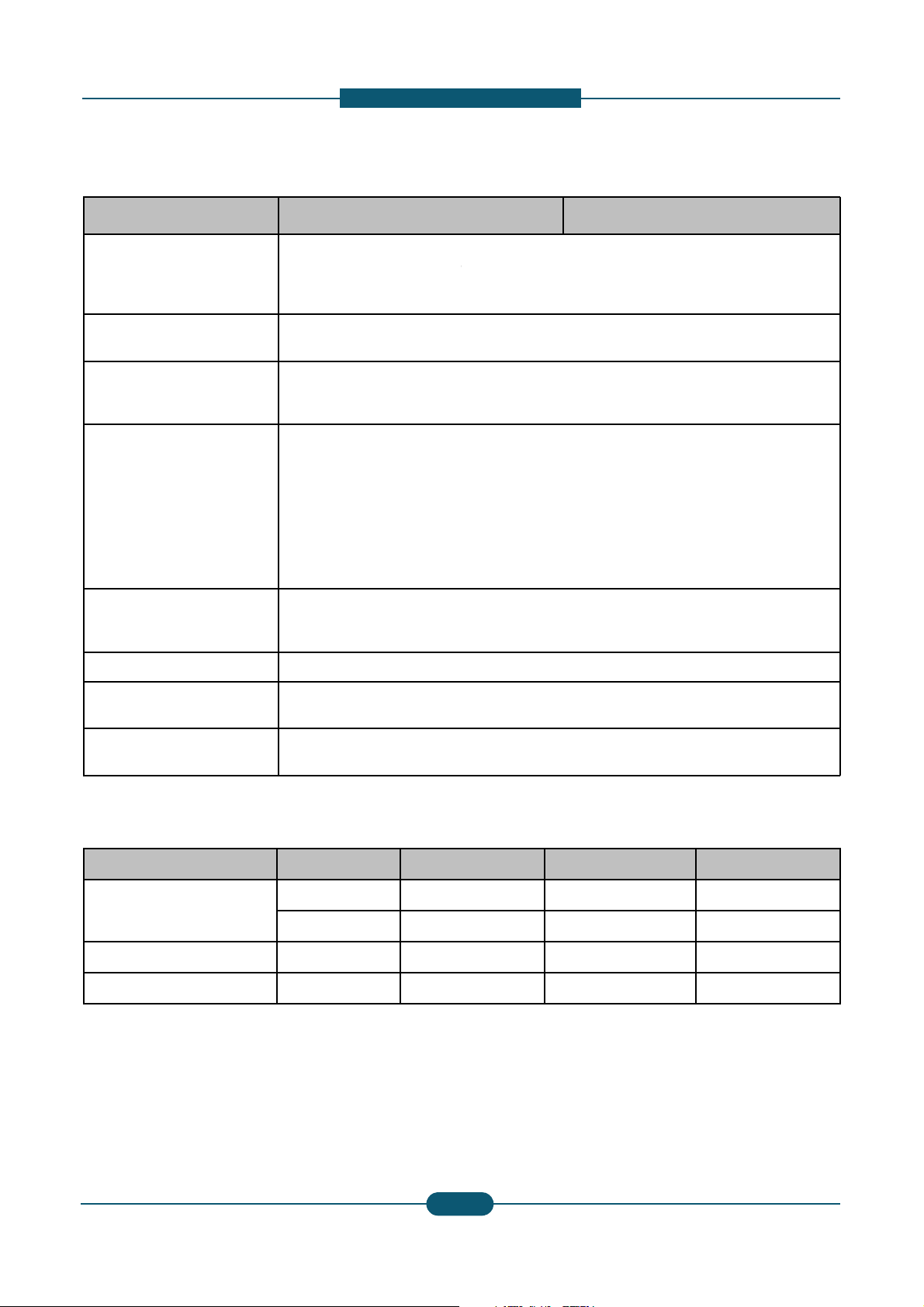

Option Unit

0

5

5

c

u

a

V

H

V

H

V

a

a

V

a

a

-

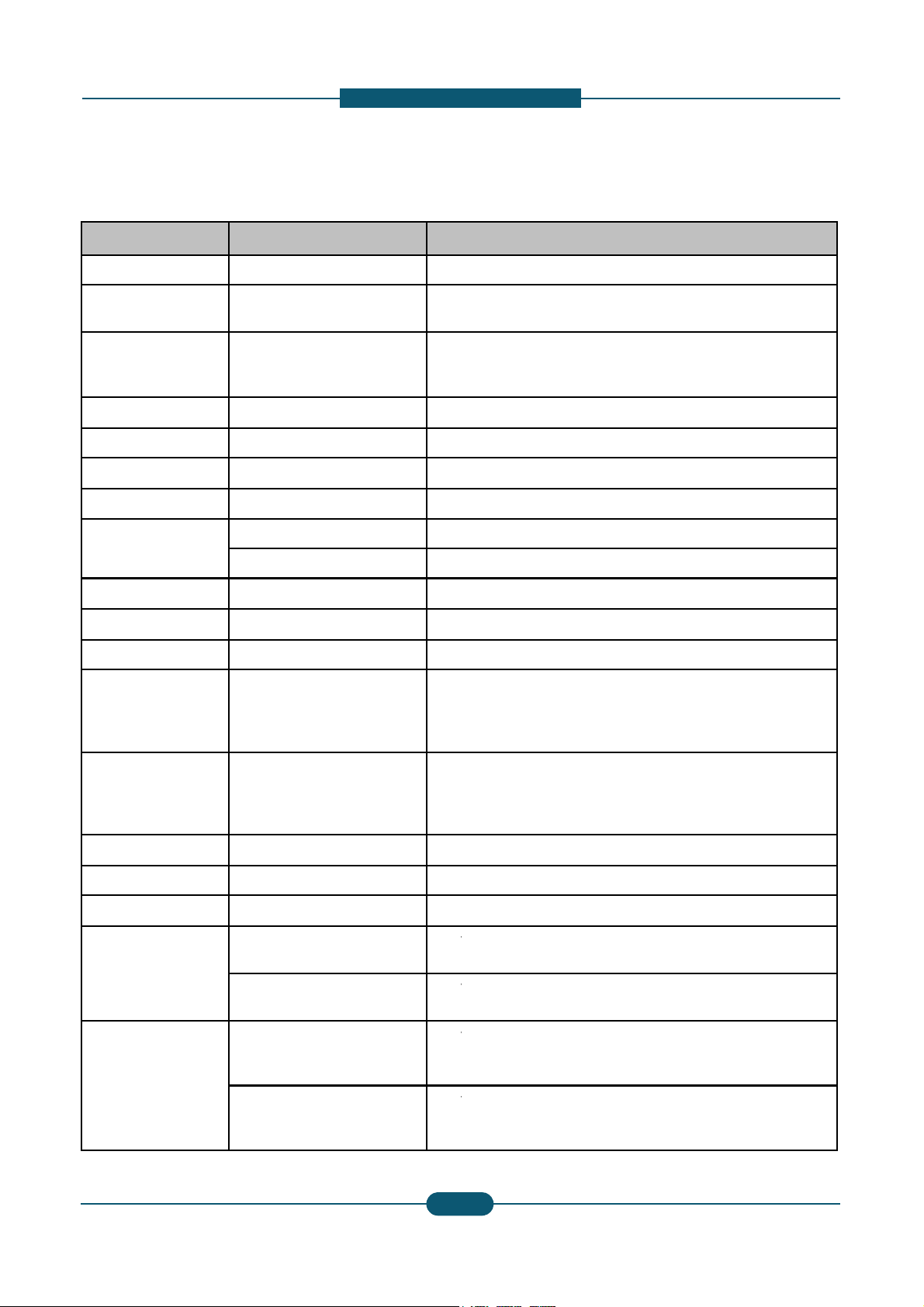

2. Product

escription

Option Unit Model name Re

Stand CLX-DSK10T/SEE

Dual Cassette

Feeder

HCF

(High Capacity

Feeder)

Job Separator SCX-JST000/SEE 125

Bridge Unit CLX-BRG200/SEE

Standard Finisher CLX-FIN40S/SEE 1,2

Booklet Finisher CLX-FIN40L/SEE 3,2

Punch Kit

Working Table CLX-WKT000/SEE

512MB Memory SCX-MEM300/SEE 512

FDI Kit CLX-KIT10F/SEE Seri

Fax Kit

CLX-PFP000/SEE 520

CLX-HCF102/SEE

CLX-HCF102/XAA

CLX-HPU000/XAA 2-3

CLX-HPU001/SEE 2-4

CLX-FAX150/SEE

CLX-FAX150/XEE

CLX-FAX150/XEG

CLX-FAX150/XEU

2,0

G3,

ark

Sheet Tray x 2

0 Sheets (LTR, A4)

Pages

0 Stacking, Stapling (5 Pos)

0 Stacking, Stapling (5 Pos), Booklet

Holes (NA)

Holes (EU)

MB

al Port

T.37/38, PC Fax SW, Fax Manual Softcopy

CLX-FAX250/SEE

Fax Multiline Kit

SmarThru Workflow Do

CounThru Co

Advanced Scan Kit CLX-KIT10D/SEE Se

Heating wire for

Cassette, HCF,

DCF

Heating wire for

Scan

Service Manual

SCX-8030/8040 series

CLX-FAX250/XEE

CLX-FAX250/XEG

CLX-FAX250/XEU

CLX-DHK11C

CLX-DHK12C

CLX-DHK11S

CLX-DHK12S

G3

ument Distribution Solution

nter/cost Management Solution

rchable PDF, Barcode, etc.

, 10W (equipped by service person at field, voltage rating

110

of

eating Wire is the same as the machine’s voltage rating)

220

, 10W (equipped by service person at field, voltage rating

of

eating Wire is the same as the machine’s voltage rating)

110

, 5W and 10W (equipped by service person at field,

volt

ge rating of Heating Wire is the same as the machine’s

volt

ge rating)

220

, 5W and 10W (equipped by service person at field,

volt

ge rating of Heating Wire is the same as the machine’s

volt

ge rating)

2

5

SAMSUNG ELECTRONICS

Version 0.05

Page 22

D

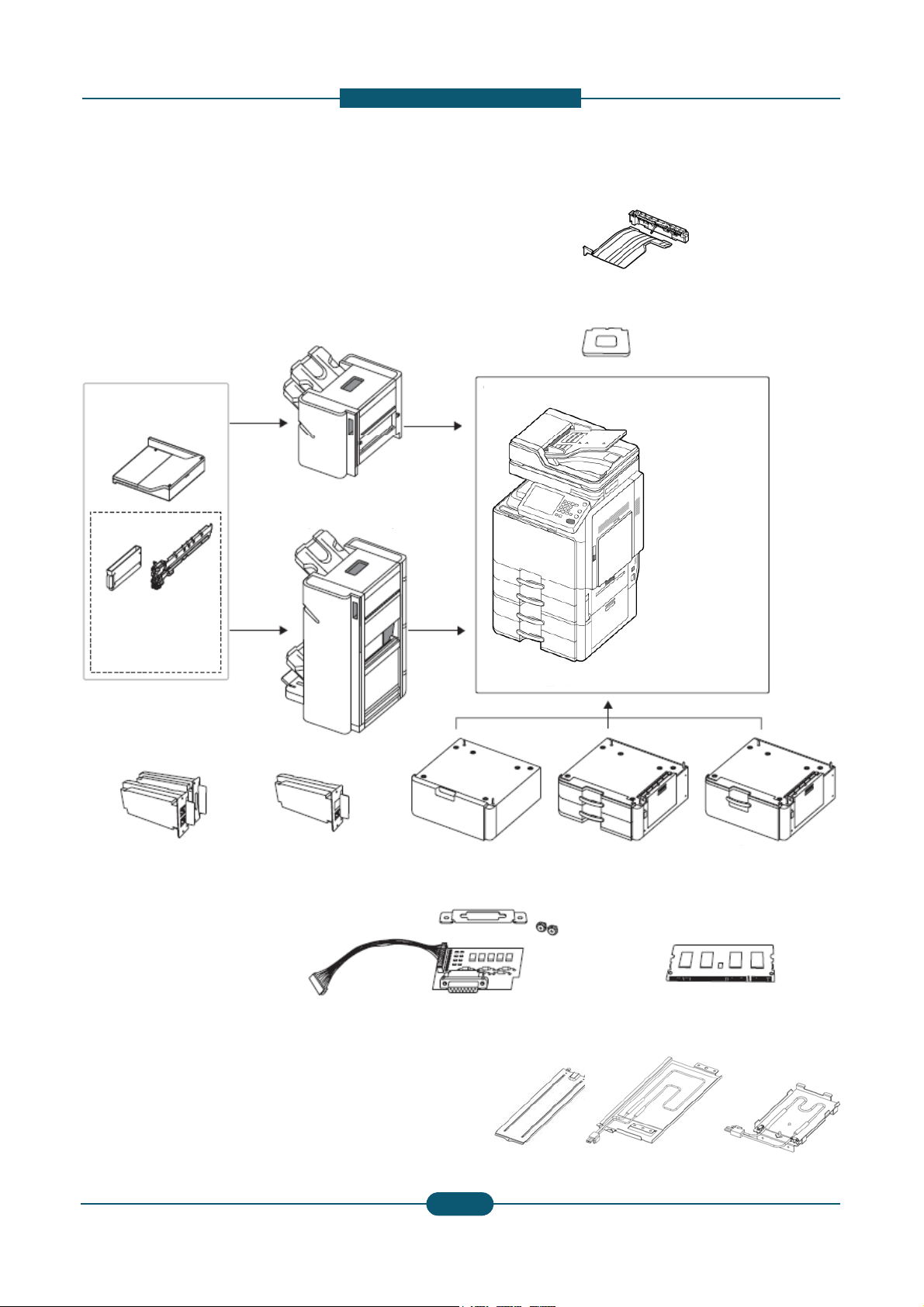

Option unit configuration

t

(CLX

D

(CLX

FAX150)

(CLX

FAX250)

F

X

-

(CLX

PFP000)

(CLX

HCF102)

kit

Expansion memory module 512M

1,250-sheet standard finisher

(CLX-FIN40S)

Bridge kit

(CLX-BRG200)

3,250-sheet booklet finisher

(CLX-FIN40L)

2. Product

escription

Job Separator

(SCX-JST000)

Working Table

(CLX-WKT000)

Duplex Automatic Document Feeder

2/3 hole Punch kit

(CLX-HPU000)

2/4 hole Punch kit

(CLX-HPU001)

Fax kit

-

Fax multi-line kit

-

(CL

S

and

-

I

-KIT10F)

Main unit

Optional tray

High capacity feeder

-

-

(SCX-MEM300)

Service Manual

SCX-8030/8040 series

Cassette / Scanner Heating cable

(CLX-DHK11C/12C/11S/12S)

2

6

SAMSUNG ELECTRONICS

Version 0.05

Page 23

2. Product

D

-

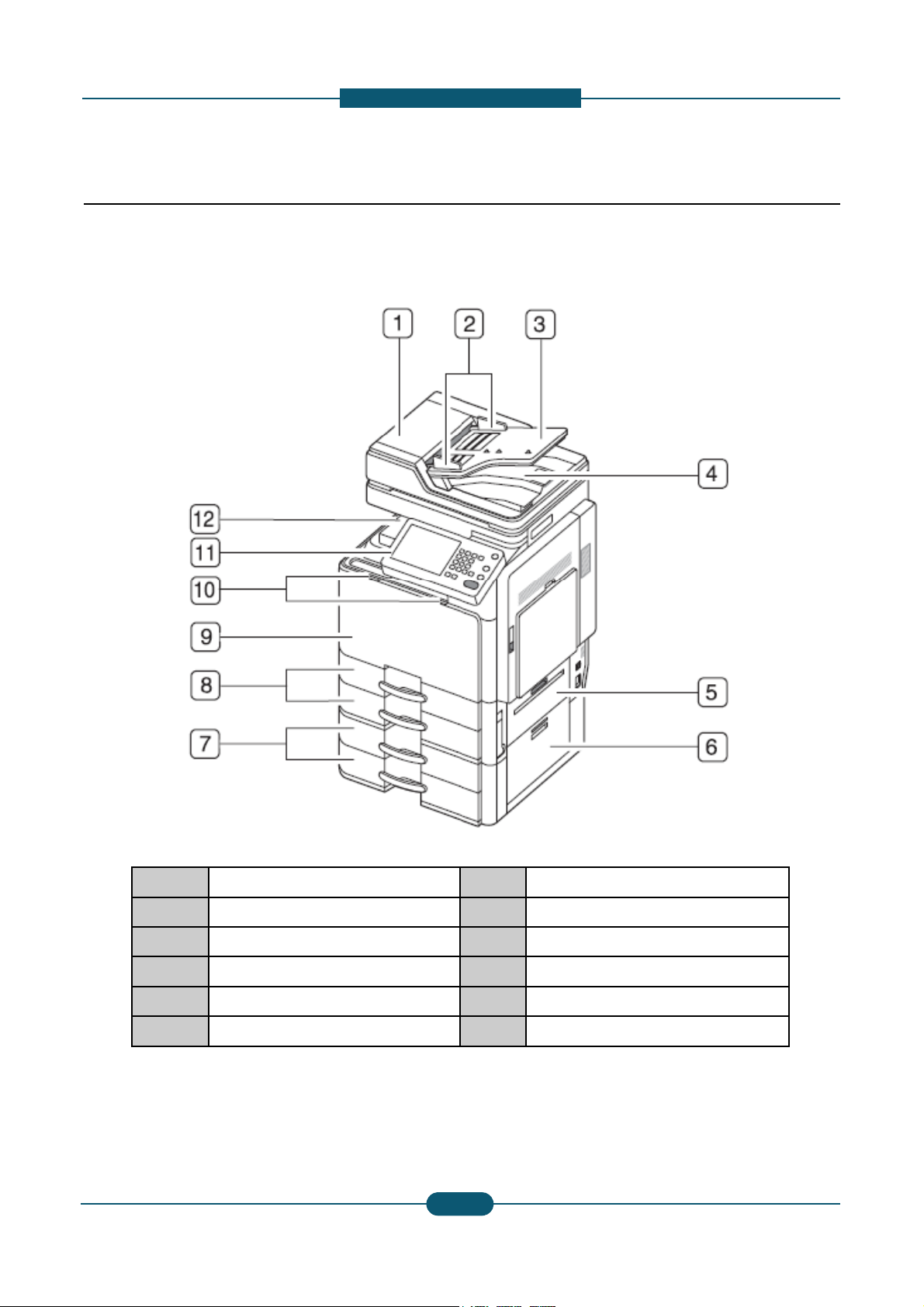

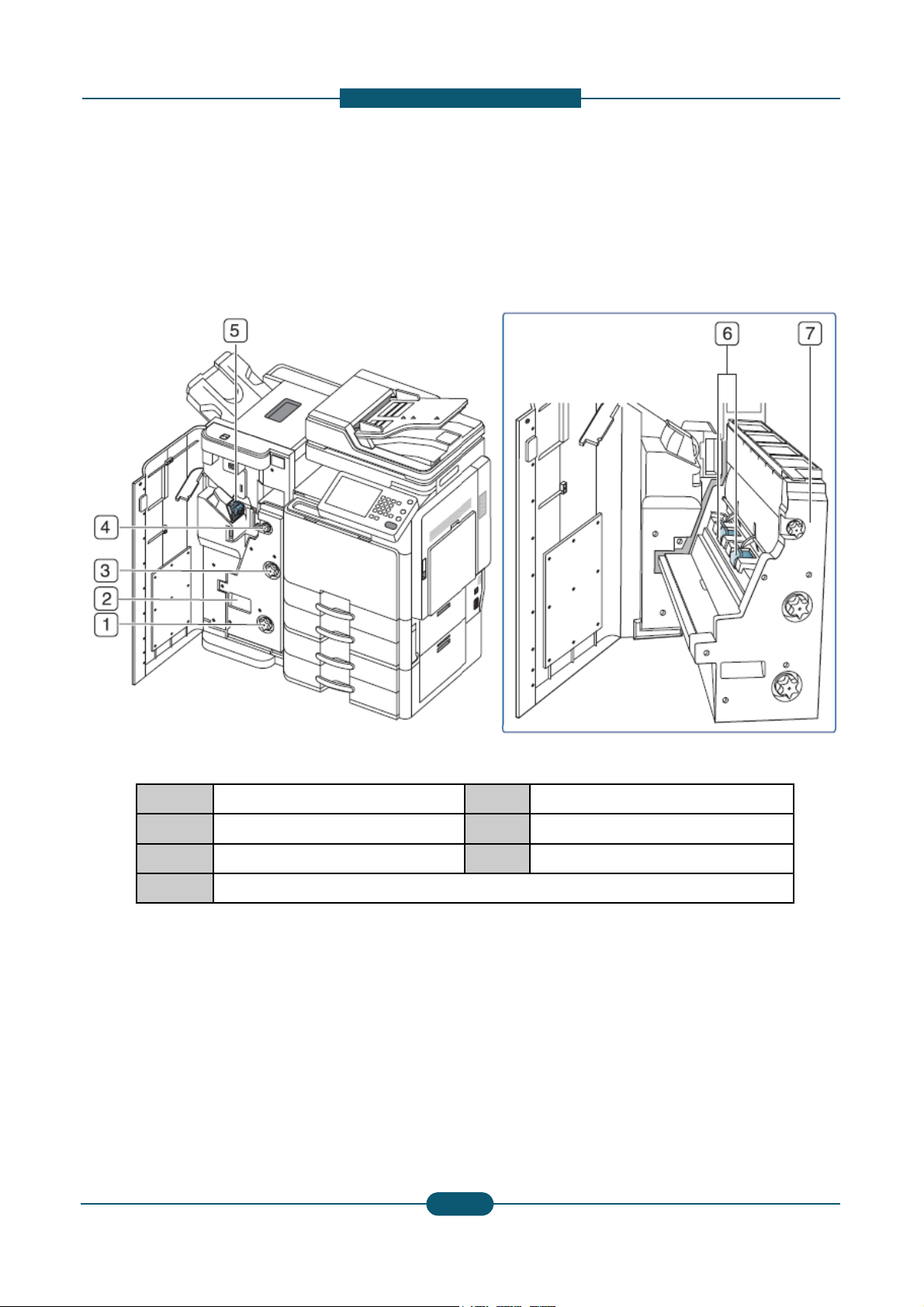

2.2 System configuration

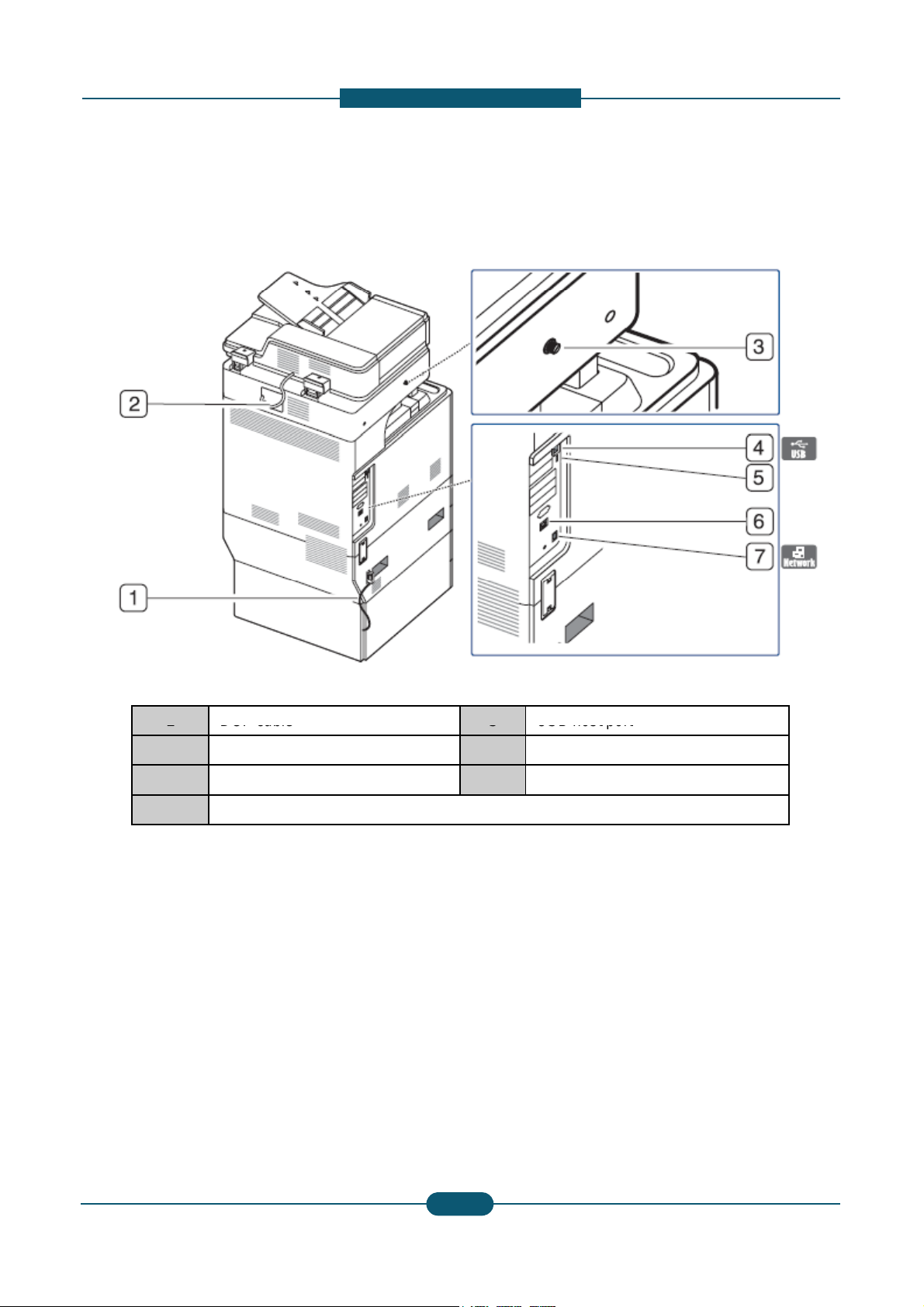

Front view 1

escription

1 DADF Cover

2 DADF width guides

3 DADF input tray

4 DADF output tray

5 Standard tray right bottom door

6 DCF right bottom door

7 DCF (tray3, tray4)*

8 Standard tray (tray1, tray2)

9 Front door

10 Front door handle

11 Control panel

12 Center tray

* Optional device

2

Service Manual

SCX-8030/8040 series

7

SAMSUNG ELECTRONICS

Version 0.05

Page 24

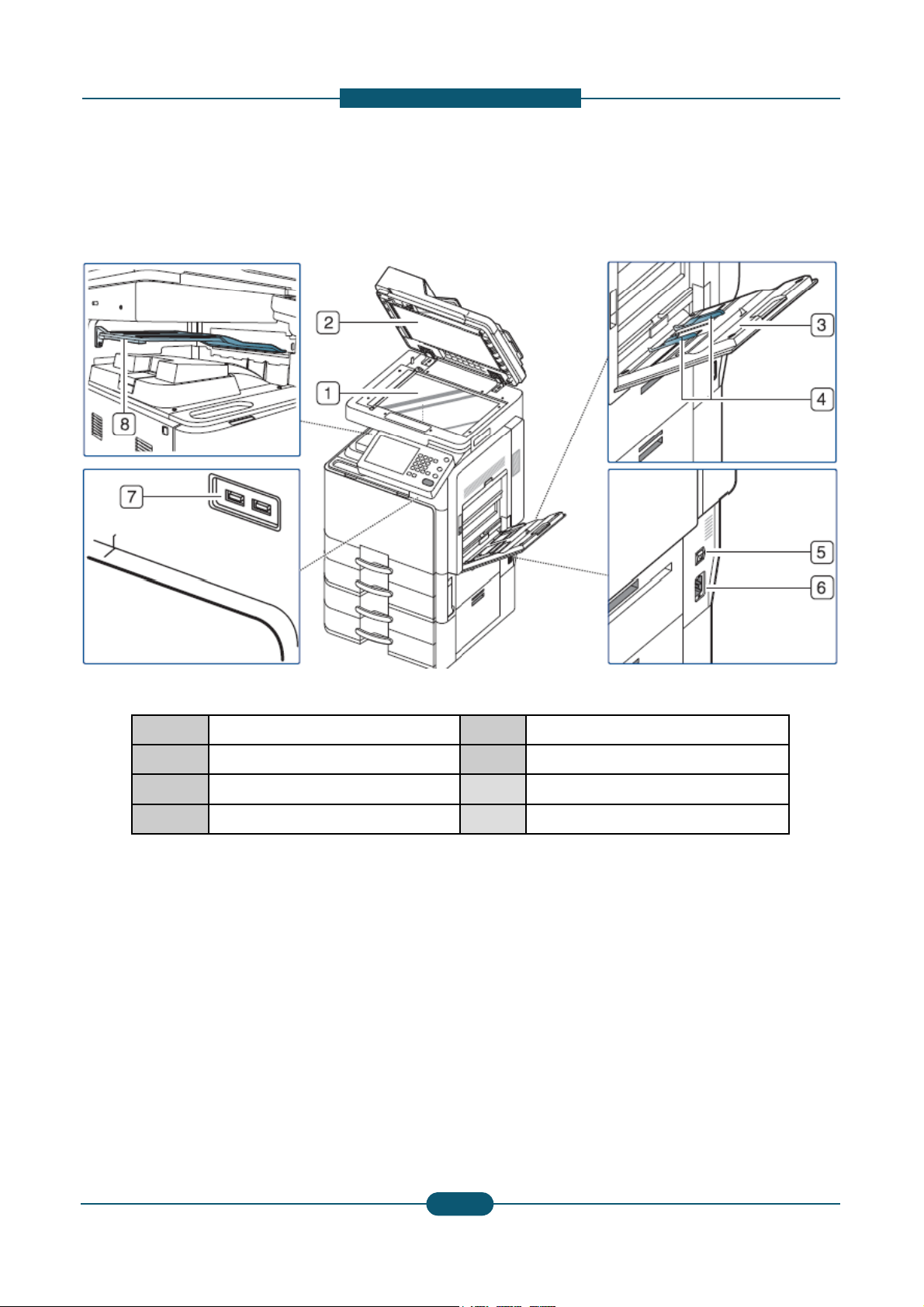

D

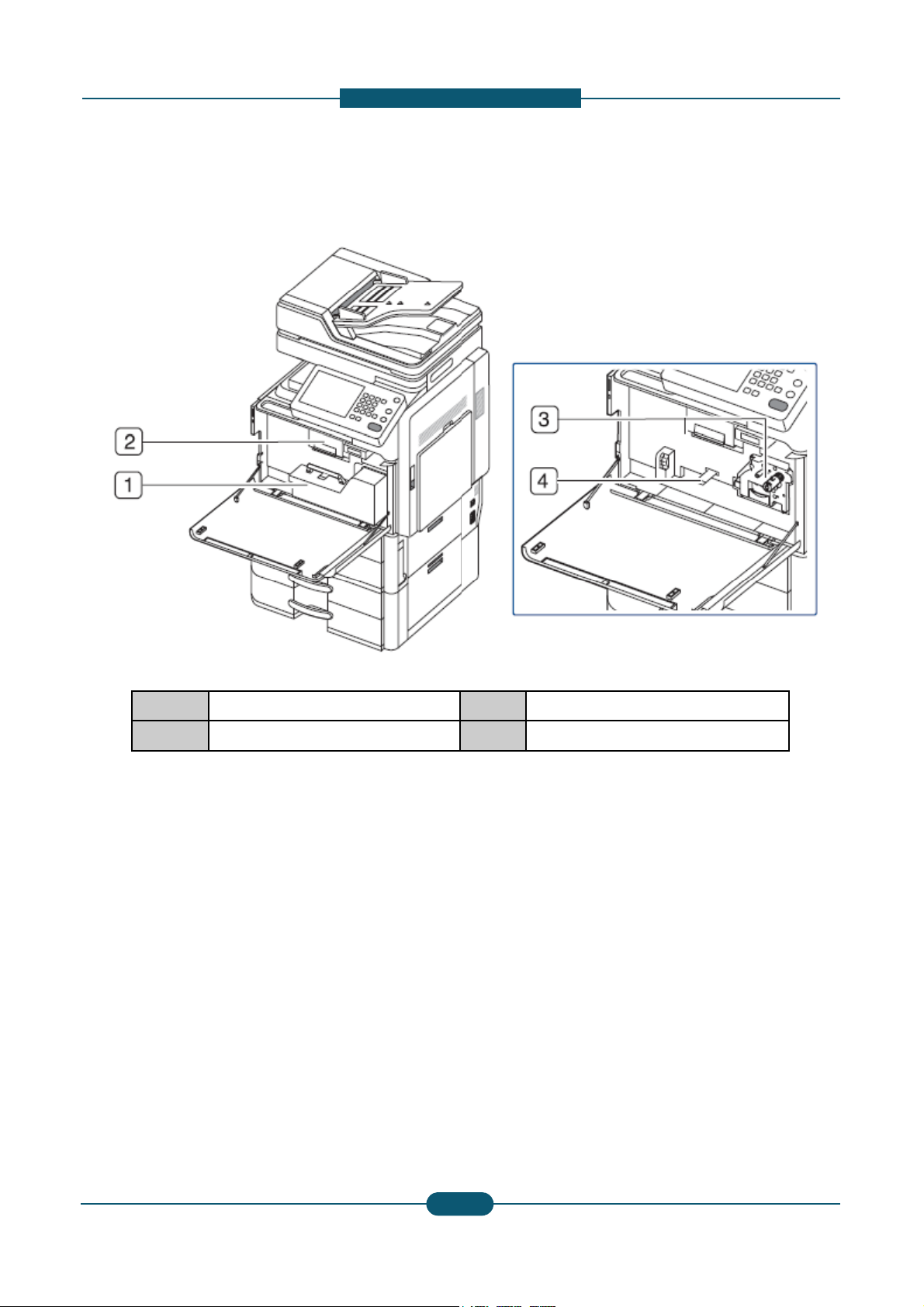

Front view 2

1

S

-

5

P

h

2. Product

escription

canner glass

2 White sheet

3 Multi-purpose tray

4 Multi-purpose tray width guide

* Optional device

ower-switc

6 Power receptacle

7 USB port (2 EA)

8 Job separator*

2

Service Manual

SCX-8030/8040 series

8

SAMSUNG ELECTRONICS

Version 0.05

Page 25

D

Rear view

1

DCF cable

u

-

5

USB host

port

2. Product

escription

2 DADF cable

3 Scanner locking screw

4 USB port (Connection port to comp

6 Finisher connector

7 Network port

ter)

Service Manual

SCX-8030/8040 series

2

9

SAMSUNG ELECTRONICS

Version 0.05

Page 26

D

Inner view

o

n

1

2. Product

escription

1 Waste toner container

2 Toner cartridge

NOTE

If you want to see the imaging unit, you need t

lever upward. Then remove the waste toner co

3 Imaging unit

4 Locking lever

remove the waste toner container. Lift the locking

tainer.

2-

Service Manual

SCX-8030/8040 series

0

SAMSUNG ELECTRONICS

Version 0.05

Page 27

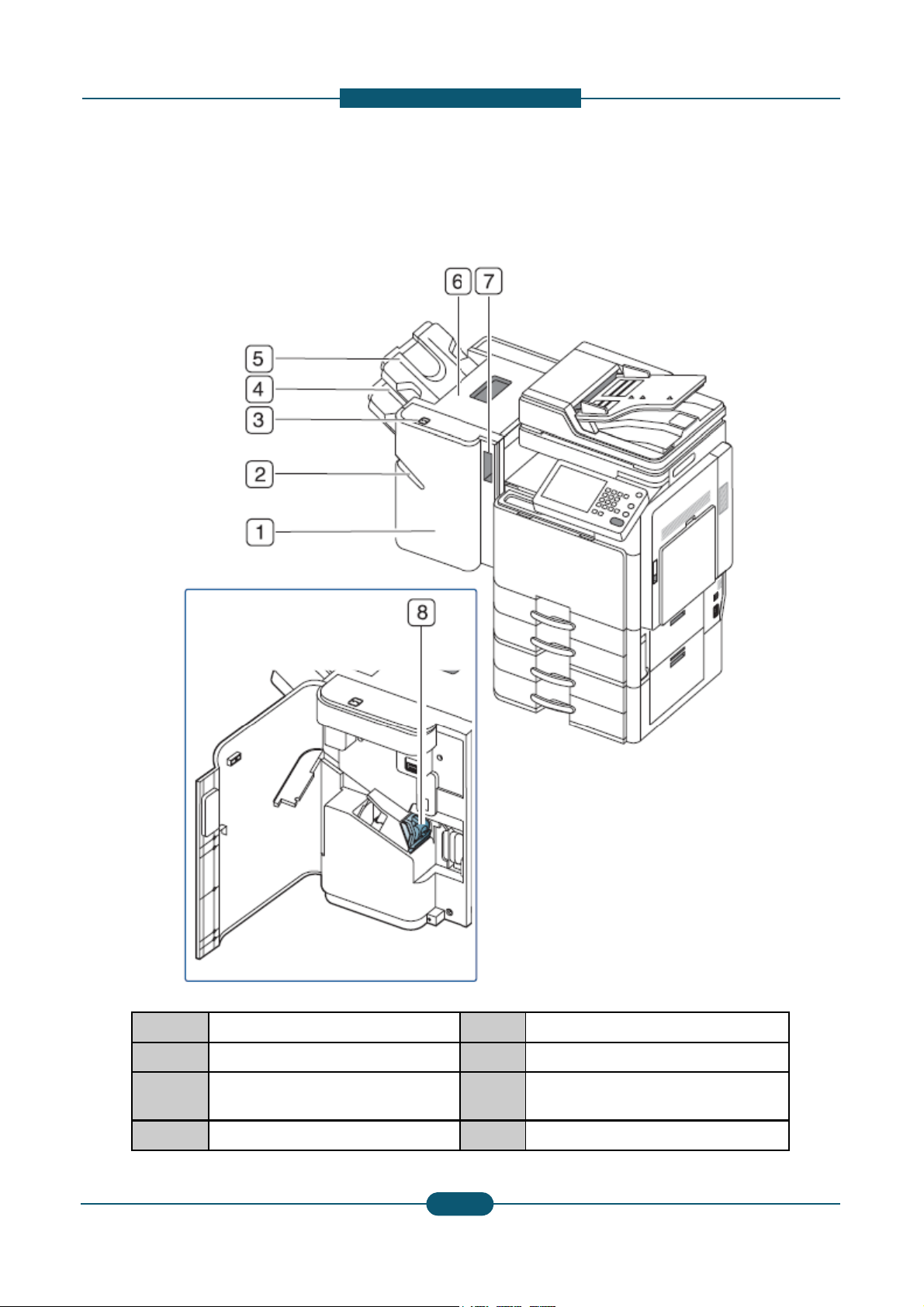

2. Product

D

V

1

escription

iew with standard finisher (option

al)

1 Standard finisher front door

2 Manual stapler

3 Manual stapler button

4 Finishing tray

Service Manual

SCX-8030/8040 series

5 Top tray

6 Top door

7 Standard finisher Front door

handle

8 Staple

2-

1

SAMSUNG ELECTRONICS

Version 0.05

Page 28

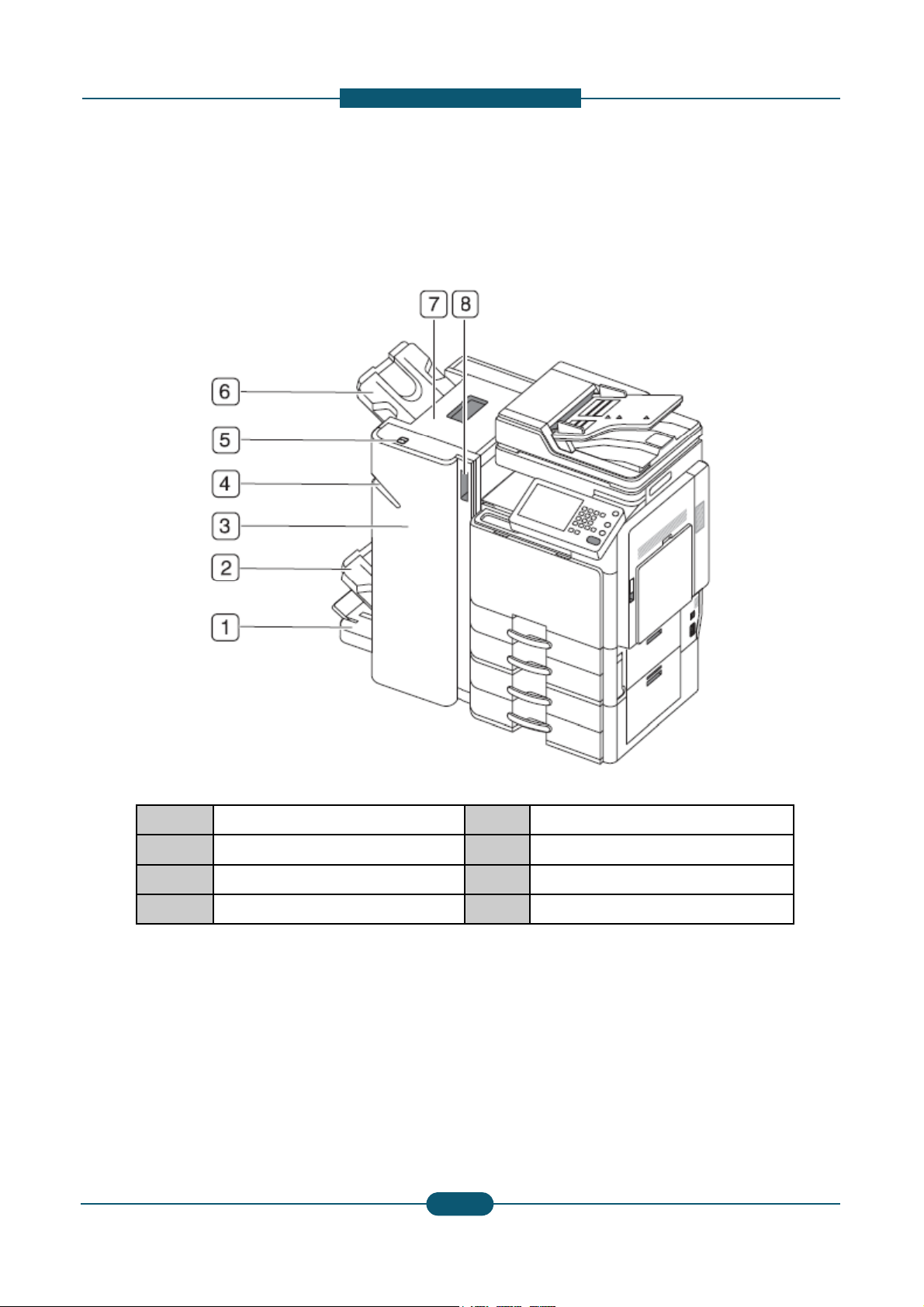

2. Product

D

a

1

escription

View with booklet finisher1 (option

l)

1 Booklet tray

2 Finishing tray

3 Booklet finisher front door

4 Manual stapler

Service Manual

SCX-8030/8040 series

5 Manual stapler button

6 Top tray

7 Top door

8 Booklet finisher front door handle

2-

2

SAMSUNG ELECTRONICS

Version 0.05

Page 29

2. Product

D

a

o

1

escription

View with booklet finisher2 (option

l)

1 Knife wheel

2 Booklet maker handle

3 Fold wheel

4 Booklet jam removal wheel

Note

If you want to open the booklet maker, hold the b

Service Manual

SCX-8030/8040 series

5 Staple

6 Booklet Staple (2 EA)

7 Booklet maker cover

oklet maker handle and pull it out.

2-

3

SAMSUNG ELECTRONICS

Version 0.05

Page 30

2. Product

D

1

r

1

16

escription

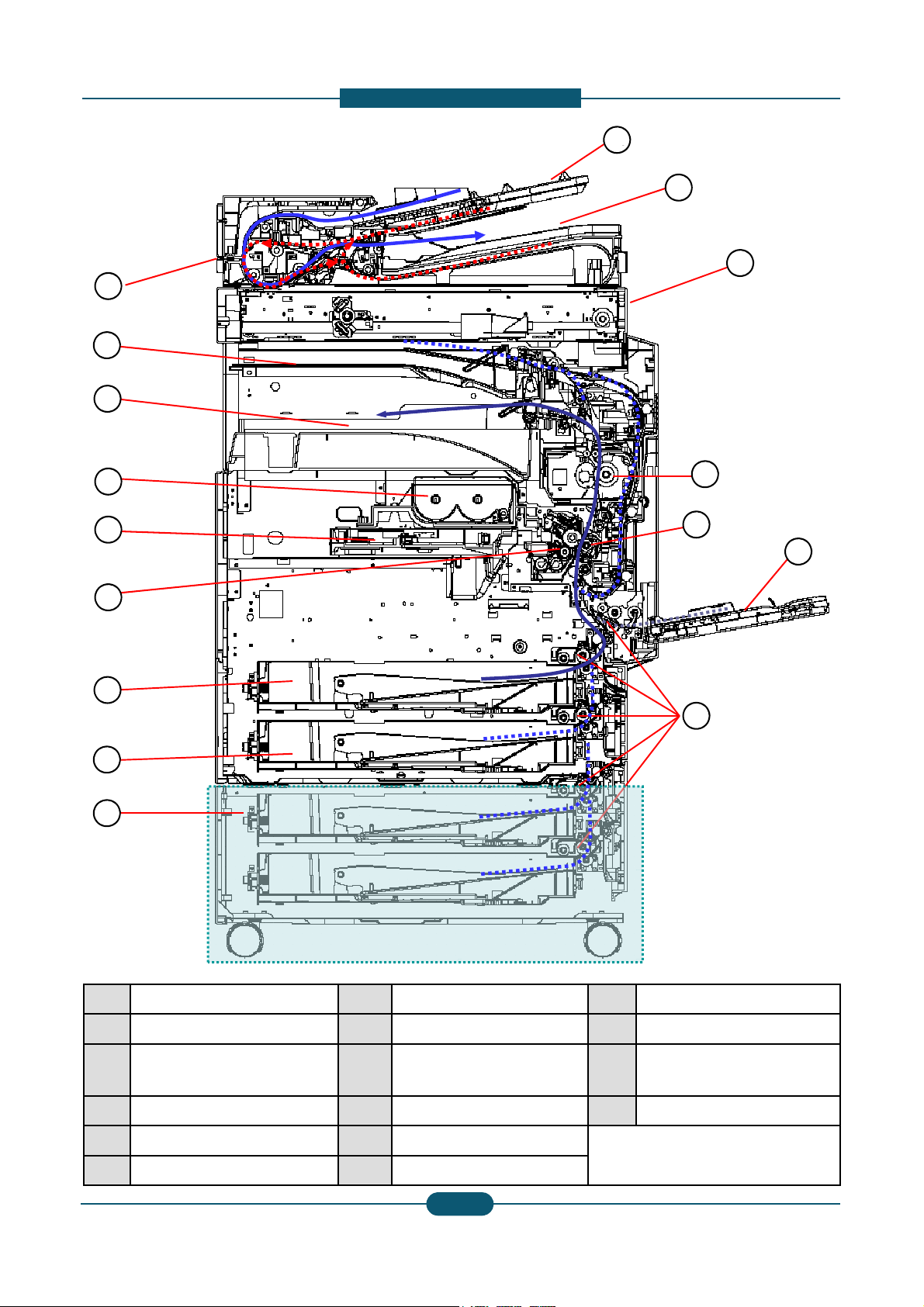

Layout

2

3

4

5

6

15

14

13

12

11

7

8

9

1 DADF 7 1sttray

2 Job separator output tray 8 2ndtray

3 Face down output tray 9 Optional

(Stand /

4 Toner cartridges 10 Pick up

10

13 Fuser unit

14 Flatbed scanner

tray

HCF / DCF)

ollers 16 Document input tray

15 Document output tray

5 Laser scanning unit 11 MP tray

6 Imaging units 12 Transfer

Service Manual

SCX-8030/8040 series

roller unit

2-

4

SAMSUNG ELECTRONICS

Version 0.05

Page 31

D

o

Paper Path

D

1

2. Product

escription

The following diagram displays the path the paper foll

Finisher

path

ws during the printing process.

ADF

path

Simplex

path

Duplex

path

Service Manual

SCX-8030/8040 series

2-

5

SAMSUNG ELECTRONICS

Version 0.05

Page 32

D

2.3 Sensor location

a

r

b

S1

SENSOR

HUMIDITY

JC32

00

2

0

0

0

0

0

0

0

0

1

0

r

A3

3211 / A3

3212

A

A

JC92

02302A

A

A

A

2. Product

escription

The following diagrams display the printer sensor loc

tions.

Ref. Description

S2 PBA-WASTE SENSOR RX JC92-0

S3 SWITCH FRONT COVER JC32-0

S4 PHOTO-INTERRUPTER 0604-0

S5 PHOTO-INTERRUPTER 0604-0

S6 PHOTO-INTERRUPTER 0604-0

S7 PHOTO-INTERRUPTER 0604-0

S8 PHOTO-INTERRUPTER 0604-0

S9 SENSOR-PAPER SIZE JC32-0

S10 SENSOR-PAPER SIZE JC32-0

S11 SENSOR-HUMIDITY JC32-0

Service Manual

SCX-8030/8040 series

Pa

Num

t

e

Controller PCB Relative Error Code

159

012

1393 M1-4111

1393 M1-4111

1393 M1-4211

1393 M1-4211

1393 C7-1311

PBA-ENGINE

SCX-8030ND

:

-

SCX-8040ND

: JC92-02221A

013

013

005

2-12-

6

6

A3-3311 / A3-3312

SAMSUNG ELECTRONICS

C7-1130

C7-1110

S2-4210

M1-4111

M1-4211

-

Version 0.05

Page 33

2. Product

D

3

9

7

7

5

8

Ref.Description

r

0

9

1

Controller PCB

Relative Error Code

: JC92

02221A

escription

Ref. Description

S12

PBA-COVER OPEN

SENSOR

Part

Number

JC92-0214

S13 PHOTO-INTERRUPTER 0604-0013

S14 PHOTO-INTERRUPTER 0604-0013

S15 PHOTO-INTERRUPTER 0604-0013

S16 CCD 0605-0011

S17 PHOTO-INTERRUPTER 0604-0013

Controller PCB Relative Error Code

Cover Open Sensor 1,

PBA-SCAN JOINT

2

(JC92-02144A)

3 Home Position Sensor

0

0 SCAN PAPER SIZE

8

PBA-SCAN

(JC92-02170A)

PBA-CCDM

(JC92-02171A)

SCAN PAPER SIZE

S3-3121

1 PBA-ENGINE U1-2115

S20

S21

Service Manual

SCX-8030/8040 series

Charger Clean SNR

Toner SNR

Part

Numbe

JC32-0001

3405-0010

2-12-

S21

S20

PBA-ENGINE

C3-5212

SCX-8030ND

: JC92-02302A

4 C3-5422

SCX-8040ND

-

7

7

SAMSUNG ELECTRONICS

Version 0.05

Page 34

2. Product

D

9

9

9

S34

PHOTO

INTERRUPTER

0604

00139

8

9

1

S43

PBA-ENGINE

M3-1413

M2-1334

escription

S34

S32

S49

S35

S38

S47

S53

S33

S44

S46

S51

S31

S37

S39

S48

S52

S36

S40

S41

S42

S45

S50

Ref. Description

Part

Number

S31 PHOTO-INTERRUPTER 0604-0013

S32 PHOTO-INTERRUPTER 0604-0013

S33 PHOTO-INTERRUPTER 0604-0013

-

-

S35 PHOTO-INTERRUPTER 0604-0013

S36 PHOTO-INTERRUPTER 0604-0013

Service Manual

SCX-8030/8040 series

Controller PCB Relative Error Code

3

M3-2230

M3-1211

3

M3-1213

M3-1214

3 M3-2430

M3-1411

(JC92-02221A)

M3-1414

M2-2411

1

M2-2413

M2-2414

M2-1331

3

2-12-

8

8

M2-1333

SAMSUNG ELECTRONICS

Version 0.05

Page 35

2. Product

D

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

r

M2-1324

M2-2213

PBA-ENGINE

M1-1113

Ref. Description

Pa

Num

S37 PHOTO-INTERRUPTER 0604-0

escription

rt

be

1393

Controller

PCB

Relative Error Code

M2-2111

M2-2113

M2-2114

S38 PHOTO-INTERRUPTER 0604-0

S39 PHOTO-INTERRUPTER 0604-0

S40 PHOTO-INTERRUPTER 0604-0

S41 PHOTO-INTERRUPTER 0604-0

S42 PHOTO-INTERRUPTER 0604-0

S43 PHOTO-INTERRUPTER 0604-0

S44 PHOTO-INTERRUPTER 0604-0

S45 VR-SLIDE 2102-0

S46 PHOTO-INTERRUPTER 0604-0

S47 PHOTO-INTERRUPTER 0604-0

S48 PHOTO-INTERRUPTER 0604-0

1393

M2-1325

M2-1321

1393 Curl Sensor 1

1393 Curl Sensor 2

1393 MP Long Size

1393

M2-2215

M2-2216

M2-1213

1381

M2-1214

M2-1211

1399 OHP Sensor

1020 MP Size Sensor

(JC92-02221A)

1393 M1-1610

M1-1113

1381

M2-1124

M2-1125

M2-1121

1393

M1-5112

S49 PHOTO-INTERRUPTER 0604-0

S50 PHOTO-INTERRUPTER 0604-0

S51 PHOTO-INTERRUPTER 0604-0

S52 PHOTO-INTERRUPTER 0604-0

S53 PHOTO-INTERRUPTER 0604-0

Service Manual

SCX-8030/8040 series

1393 M1-4111

1393 S2-4A10

M1-1213

1381

M2-1134

M2-1135

M2-1131

1393

M1-1213

M1-5212

1393 M1-4211

2-12-

9

9

SAMSUNG ELECTRONICS

Version 0.05

Page 36

2. Product

D

r

a

sensor, Tray Paper Stock sensor, MP Feed sensor, Tr

s

2

Feed sensor, Registration sensor, and Drive

DUPLEX

2.4 Paper handling section

escription

This section describes how the system picks up pape

transports it to the transfer position. The paper feedin

Forward roller, Retard roller, Transport roller, Registr

system for these components. The Transport motor i

2.4.1 Overview

The following diagrams display the positions of the pa

2NDEXIT

(OPTION)

from the Paper tray or Multi-Purpose (MP) tray and

g system mainly consists of the Pickup roller,

tion roller, MP Paper sensor, Paper Empty

used to drive all of these rollers.

per path rollers.

EXIT

SIDE

MPF

CASSETTE

Service Manual

SCX-8030/8040 series

PICKUP

2-22-

0

0

TAKEAWAY

TR

REGI

SAMSUNG ELECTRONICS

Version 0.05

Page 37

D

2NDExit tray paper

t

q

qy

MPF solenoid

e

t

2

yp

t

full detection

2NDEXIT (OPTION)

2NDExit tray jam detection

st

Exit tray paper

1

full detection

1stExit tray jam detection

Return path solenoid

Exit

2. Product

Re

escription

Return transport path

detection

urn

Duplex jam detection1

Paper jam detection

Paper regi. time detection

Transparency detection

Tray1 paper remaining

uantity detection

Tray1 paper

empty detection

Paper tray

Tray1 paper

size detection

Fuser

Paper curl detection

OPC

Regi

Tray1 upper limit detection

Tray1 lift

motor

Pick Up

Duplex

Duplex jam detection2

Duplex clutch

MPF

MPF

clutch

MPF media

MPF paper

empty

size detection

(Long media)

detection

MPF media size detection

Tray1 transport detection

Tray2 paper

empty detection

Tray2 paper

size detection

Service Manual

SCX-8030/8040 series

Tray2 lift

motor

Tray2 pap

quantity de

2-22-

r remaining

ection

1

1

Tray2 transport detection

Tray2 upper limit detection

SAMSUNG ELECTRONICS

Version 0.05

Page 38

2. Product

D

t

s

r

T

Detects t

e

i

p

e

s

Tray2 paper remaining quantity

r

e

i

p

e

T

y

o

a

1stExit tray paper full detection

Detect paper full

j

Duplex jam detection 2

Detects duplex jam 2

o

p

s

pp

s

e

2

y

ty

CN12@ C

PBA, 3Pi

y

y

CN7@ BOTTLE Joint

PBA, 3Pin

j

CN4 @ SIDE JOINT PBA, 3Pin

@,

y

escription

Name Func

Tray1 paper size detection Detects tray1 paper

Tray1 paper remaining quantity

detection

ray1 paper empty detection

Tray1 upper limit detection Detects tray1 upper l

Tray1 transport detection Detects tray1 paper

Tray1 Lift Motor Lifting knock up plat

Tray2 paper size detection Detects tray1 paper

detection

Tray2 paper empty detection Detects tray2 paper

Tray2 upper limit detection Detects tray2 upper l

Tray2 transport detection Detects tray2 paper

Tray2 Lift Motor Lifting knock up plat

Paper regi. time detection Detects paper regi.

Transparency detection Detects transparenc

Detects tray1 paper

Detects tray2 paper

ray1 paper

ion Connector & pin information

ize (installation) CN16@ Cassette Joint PBA, 4Pin

emaining quantit

mp

mit CN12@ Cassette Joint PBA, 3Pin

ass CN12@ Cassette Joint PBA, 3Pin

ize (installation) CN16@ Cassette Joint PBA, 4Pin

emaining quantit

mpt

mit CN13@ Cassette Joint PBA, 3Pin

ass CN13@ Cassette Joint PBA, 3Pin

ime CN10@ Engine PBA, 3Pin

CN11@ Cassette Joint PBA, 6Pin

assette Joint

CN15@ Cassette Joint PBA, 3Pin

CN11@ Cassette Joint PBA, 6Pin

CN13@ Cassette Joint PBA, 3Pin

CN15@ Cassette Joint PBA, 3Pin

CN10@ Engine PBA, 3Pin

n

Paper curl detection Detects paper positi

Paper jam detection Detects fuser jam

st

1

Exit tray jam detection

2ndExit tray jam detection

2ndExit tray paper full detection

Return transport path detection Detects return(2

Detects 1stexit tray j

Detects 2ndexit tray

Detects paper full

nd

ex

Return path solenoid Change paper path

Duplex jam detection 1 Detects duplex jam 1

Duplex clutch Duplex driving contr

MPF solenoid MPF pick up roller u

MPF clutch MPF driving control

MPF media size detection Detects MPF paper

MP media size detection

(Long media)

Detects MPF paper

MPF Paper empty detection Detects MPF paper

n CN3@ SIDE JOINT PBA, 6Pin

CN5 @ SIDE JOINT PBA, 3Pin

m CN7@ BOTTLE Joint PBA, 3Pin

am CN29 @ Engine PBA, 3Pin

CN29 @ Engine, 3Pin

it tray) paper pass CN7@ BOTTLE Joint PBA, 3Pin

CN7@ Engine PBA, 2Pin

CN5 @ SIDE JOINT PBA, 3Pin

l CN6 @ SIDE JOINT PBA, 2Pin

/down CN2 @ SIDE JOINT PBA, 2Pin

CN2 @ SIDE JOINT PBA, 2Pin

ize CN7 @ SIDE JOINT PBA, 3Pin

ize CN7 @ SIDE JOINT PBA, 3Pin

mpt

CN2 @ SIDE JOINT PBA, 3Pin

Service Manual

SCX-8030/8040 series

2-22-

2

2

SAMSUNG ELECTRONICS

Version 0.05

Page 39

D

2.4.2 Components

i

2

2

forward rollers

19

13

Tray 4 feed roller

full

2. Product

escription

The following diagrams display the positions of the pr

27

26

23

22

21

nter components

25

24

20

17

16

14

18

15

Tray 1 Paper tray

1

Tray 2 Paper tray

2

Tray 3 Paper tray

3

Tray 4 Paper tray

4

Tray 1 pick up / retard /

5

Tray 2 pick up / retard /

6

forward rollers

Tray 3 pick up / retard /

7

forward rollers

Tray 4 pick up / retard /

8

forward rollers

MP Tray pick up / retard

9

/ forward rollers

Tray 1 feed roller

10

Tray 2 feed roller

11

Tray 3 feed roller

12

Bypass feed roller

14

9

Sensor registration

13

15

Roller registration

16

Roller transfer

17

Sensor paper curl

18

Roller fuser

19

Sensor fuser out

20

Roller exit

21

Roller face down exit

22

Actuator face down bin

23

Sensor duplex return

24

Roller duplex return

25

Roller 2nd exit

26

Actuator 2nd Exit bin full

27

10

5

1

11

6

12

7

3

8

4

Service Manual

SCX-8030/8040 series

2-22-

3

3

SAMSUNG ELECTRONICS

Version 0.05

Page 40

D

2.4.3 Functions

d

Pickup Roller (paper tray and MP tray)

p

Retard

)

r

h

y)

p(ppy y)

e

a

e

This sensor detects whether paper is set in the bypass

o

a

d

c

Feed Sensor

e

r

r

2

tray

When it is, MP tray always comes

2. Product

escription

This section describes the functions of the paper han

This roller moves up and down and draws out the pap

the feed roller.

Forward Roller (paper tray and MP tray)

This roller is placed against the Retard roller. It trans

transport roller.

roller (paper tray and MP tray

This roller is placed against the feed roller. When two

pickup roller, the load of the torque limiter of the Reta

sheets. As a result, the Retard roller is stopped and t

only one sheet is transported from the pickup roller, th

roller.

Transport Roller (paper tray and MP tra

This roller transports the paper sent from the feed roll

Registration Roller

Paper transported from the transport roller is pushed

edge of the paper. Then, the registration rollers rotat

ling components.

er from the bypass tray or drawer and transports it to

orts the paper from the pickup roller to the

sheets of paper or more are transported from the

d roller is heavier than the frictional force between the

e lower paper does not advance any further. When

e Retard roller rotates following the feed

r to the registration roller.

gainst the registration roller which aligns the leading

to transport the paper to the transfer unit.

MP tray Paper Sensor

before drawer feeding.

Empty Sensor (Tray 1 / Tray 2)

This is a transmissive-type sensor and it detects the a

When there is no paper in the drawer, the actuator bl

determines that there is no paper.

Paper Stock Sensor

This is a transmissive-type sensor which detects the

actuator. When the remaining paper is consumed an

blocks

the light path for the transmissive-type sensor to dete

This sensor detects if the leading edge or trailing edg

detects jamming such as missfeeding.

Registration Sensor

This sensor detects that the leading edge of the pape

trailing edge of the paper has passed the registration

.

vailability of paper in the drawer by using an actuator.

cks the light path of the sensor, and the sensor

mount of remaining paper in the drawer using an

approximately 100 sheets remain, the actuator

t that there is less paper.

of the paper has passed the feed roller. It also

has reached the registration roller and that the

oller.

Service Manual

SCX-8030/8040 series

2-22-

4

4

SAMSUNG ELECTRONICS

Version 0.05

Page 41

D

2.4.4 Paper tray

e

p, pp

A

m

•

Paper

:

7

e

o

2

2. Product

escription

The paper trays consist of the Main trays, Optional tra

The MP tray is located on the right side of the machin

envelopes, and custom size paper.

Paper size is set using the Size Guides in each tray.

paper size.

ys (DCF,HCF), and one Multi-Purpose (MP) tray.

and allows feeding of specialty media stock,

djust the Front, Rear, and End Guides to match the

Specification

• Structure : Paper tray Type, Auto Paper Size

• Capacity : 520 Sheets ( 80g/㎡ standard Xerox Pre

-. Plain paper : A5, A4, A3, B5, B4, Letter, 11"×1

-. Special Paper : 12"×18", Label (Label : 50 she

• Weight : plain paper 60 ~ 163 g/㎡

• Plate knock up Lift type : Lift Motor + Up Limit Sens

Service Manual

SCX-8030/8040 series

inum)

"(Ledger), Statement, Legal

ts)

r

2-

5

SAMSUNG ELECTRONICS

Version 0.05

Page 42

D

2.4.5 Pick up unit

w

o

roller serve to make sure that a single sheet of paper i

c

2

s moved to the paper path, and the paper is moved

2. Product

escription

When pickup takes place, the pickup roller moves do

The pickup roller moves down when the pickup solen

as far as the registration roller by the work of the verti

pickup roller:

Actuator-Empty Sensor

n to come into contact with the surface of the paper.

id is activated. The forward roller and the separation

al path roller. The following is a diagram of the

Forward Roller

Retard Roller

Pick Up Roller

Service Manual

SCX-8030/8040 series

2-

6

SAMSUNG ELECTRONICS

Version 0.05

Page 43

D

t

l

2.4.6 Registration unit

roller in order to match paper and an image on the dru

R

G

Specification

m

m

m

Margin

C

2

the predetermined registration point

2. Product

escription

The registration roller is driven by the registratio n mul

between the registration roller and the registration mu

ROLLER-

JAM REMOVAL

LEVER

RE

i motor. The registration clutch (CL6) is located

ti motor, and it controls ON/OFF of the registration

at

.

SHAFT-REGI

EGI

I SENSOR

•Skewin Simplex

-. Top Skew : 2.0mm/241.3mm ( Option : 2.5m

-. Side Skew : 1.5mm/180.5mm ( Option : 2.0m

• Skew in Duplex

-. Top Skew : 3.0mm/241.3mm ( Option : 3.5m

-. Side Skew : 2.3mm/180.5mm ( Option : 2.5

• Dog Ear, Trees, Nicks, Wrinkling

-. Plain Paper : 1/5,000

-. Special Media : 1/1,000

•

-. Top Margin : 4.23 ± 2 mm ( Tray3, 4, HCF :

-. Left / Right Margin : 3 ± 2 mm ( Tray3, 4, H

-. Duplex Top Margin : 4.23 ± 2.5 mm ( Tray3

-. Duplex Side Margin : 3 ± 2.5 mm ( Tray3, 4

/241.3mm )

m/180.5mm )

/241.3mm )

m/180.5mm )

4.23 ± 2.5 mm )

F : 3 ± 2.5 mm )

, 4, HCF : 4.23 ± 3.0 mm )

, HCF : 3 ± 3.0 mm )

Service Manual

SCX-8030/8040 series

2-22-

7

7

SAMSUNG ELECTRONICS

Version 0.05

Page 44

D

2.4.7 MPF unit

P

C

Wh

[A]

n

2

MPF Clutch

The following is a diagram of the MFP unit:

MPF Pick up roller

2. Product

escription

Empty sensor

MPF

Tray

Specification

• Tray capacity : 100 sheets( 80g/㎡ standard Xerox

• Media Size : Max 12”×18” (305×457㎜) / Min 3.87

• Media weight : Plain paper 60 ~ 216 g/㎡

• Feeding speed : 40 ppm (SCX-8040ND), 30 ppm (S

•Auto size sensing : A6 SEF, Statement SEF, B5 S

LTR(Letter) LEF, A3, A4 LEF

Long paper sensor

reminum )

”×5.82” (98×148㎜)

X-8030ND) in Letter/A4 LEF (Long Edge Feeding)

EF, A4 SEF, A5 LEF, B4 B5(JIS) LEF, 11x17,

Paper Separation

en the by-pass paper detection

sensor detects

the by-pass solenoid [B] drops the pick-up roller [C] o

After that, the pick-up roller moves one

sheet of paper to the feed roller.

This machine uses an FRR (Feed and

Reverse Roller) system for feeding paper.

There is friction between the feed roller [E]

and Retard roller [D]. This friction separates

the top sheet of paper from the stack.

Service Manual

SCX-8030/8040 series

paper and the machine gets a by-pass printing job,

to the top of the paper stack on the by-pass tray.

2-

8

SAMSUNG ELECTRONICS

Version 0.05

Page 45

D

2.5 Image creation

v

e

s

Drum unit and Development unit. The Drum unit has a

m

b

a

n

m

e

r

u

v

g

2

g

gy

OPC drum, a scorotron (which charges the OPC)

v

g

g

2. Product

escription

This section describes the image creation process us

2.5.1 Printing process ov er

This mono printing system includes the LSU with a la

d by the printer.

iew

er beams, a imaging unit and transfer unit.

This machine uses single Imaging unit and dual laser

a light-guide ( which transfers the LED’s light in the

The OPC drum[A] is charged with a nega tive voltage

LSU (Laser Scanning unit)[B]. The light produced by

surface of the OPC drum. The negatively charged to

electric filed. The toners(real image) on the OPC dru

applied to the transfer roller[c].

1. Charging the OPC drum: The scorotron gives th

2. Laser exposure: Light produced by a laser diode i

mirrors .

3. Development: This machine uses a dual-compon e

negatively charged toner to the latent image on the dr

4. Transfer: The transfer rollers opposite the OPC dr

media (e.g. paper, OHP film, etc).

5. Cleaning for OPC drum: The cleaning blade remo

transfer to the paper.

6. Quenchin

lamps at the end of every job.

for OPC drum: Quenching is done by

beams for mono printing. The Imaging unit consists of

achine) and cleaning blade.

y the scorotron and is exposed by the light from the

laser creates a latent image by discha rgin g on the

ers are attracted to the latent image due to and

are moved to the transfer media by the positive bias

drum negative charges.

radiates the charged OPC through the lens and

nt development system . The magnetic roller carries

m surface.

ums transfer toner from the drums to the transfer

es remaining toners on the drum surface after image

illuminatin

the whole area of the drum with the LED

,

Service Manual

SCX-8030/8040 series

2-22-

9

9

SAMSUNG ELECTRONICS

Version 0.05

Page 46

D

2.5.2 Imaging unit

e

e

d

n

e diameter of the dru

ab

e d a ete o t e d u s 30 (c cu e e ce ab

o

r

u

Scorotron

3

2. Product

escription

2.5.2.1 Imaging unit ov ervi

The imaging unit consists of OPC drum unit and the d

drum, a scorotron which charges the OPC, a light-gui

and cleaning blade. The development unit has a mag

and a TC (Toner Concentration) sensor.

Th

The developing gap between a drum and the corresp

they assembled as one Imaging unit in the factory.

The cleaning blade removes remaining toner on the d

The CRUM chip in the image unit stores the data abo

m is 30 mm (circumference:

Light guide

w

velopment unit. The OPC drum unit has an OPC

e ( which transfers the LEDs light in the machine)

etic roller, two mixing augers, developer, a Dr-blade

94.2 mm).

nding magnetic roller cannot be adjusted becaus e

um surface after image transfer to the transfer belt.

t the Imaging unit.

Cleaning blade

Mixing Auger

OPC Drum

Magnetic Roller

Service Manual

SCX-8030/8040 series

2-32-

0

0

SAMSUNG ELECTRONICS

Version 0.05

Page 47

D

2.5.2.2 Drum drive

D

3

C

OPC

2. Product

escription

OPC and Mag Roller is driven by a motor. The OPC

coupling.

Drive motor BLDC

Coupling

Drum-K

rum and Mag roller are supplied with power from the

Drive transmission gear

BLDC motor

Service Manual

SCX-8030/8040 series

Gear-Drive OPC

oupling

Coupling Deve

2-32-

1

1

SAMSUNG ELECTRONICS

Version 0.05

Page 48

D

2.5.2.3 Development

y

the magnetic roller [A] by the two mixing augers [B] an

A

o

3

attracted onto the surface of the OPC drum. The

2. Product

escription

This machine uses a dual-component development s

drum unit and development unit). A new unit contains

diameter of the magnetic roller is 18mm.

n imaging unit has a TC (Toner concentration) sens

for controlling the operating range of toner density. Th

some information about the imaging unit is stored.

[A] Magnetic Roller

stem and has an imaging unit (which includes the

345g of toner. The developer in the unit is supplied to

is

r[C]. The TC sensor [C] in the imaging unit is used

e imaging unit is equipped with a CRUM in which

[C] TC

Sensor

[B]

Mixing

Auger

[B] Mixing Auger

Service Manual

SCX-8030/8040 series

2-32-

2

2

SAMSUNG ELECTRONICS

Version 0.05

Page 49

2. Product

D

a

a

h

e

3

escription

Two mixing augers [A] circulate the developers (which

backward to agitate the developer in order to mix the c

This occurs at the following times:

• During TC calibration

• During development.

Filters [B] on the top of the development unit ensure th

During the operating , this prevents contamination of t

[B] Filt

are mixtures of carriers and toners) forward and

rriers and toners well.

t the internal pressure does not become too high.

e imaging unit by the toner.

r

[A] Auger

2-32-

3

Service Manual

SCX-8030/8040 series

3

SAMSUNG ELECTRONICS

Version 0.05

Page 50

D

2.6 Fuser unit

d

A

a

2.6.1 Fuser unit overview

P

ili

f

a

e

e

th

r

t

u

3

Halogen L

htl

2. Product

escription

This section describes the image fusing process use

n instant fusing system is used. This has a faster wa

roller system.

The drum-fuser belt is made of 3 thin layers, so is he

ressure roller is made of soft s

cone rubber, which

The drum-fuser belt contains two fusing lamps (one la

other lamp, side heating lamp, heats the ends in the

NC sensors (non-contact type thermistors), located n

control the temperature of the drum-fuser belt at the c

ermistors and two thermostats, located at the cente

overheating by the heating lamps.

Temperature is normally controlled by turning on and

respectively, corresponding to predetermined target

by the printer.

rm-up time than a conventional fusing and pressure

ted quickly by halogen lamp inside.

attens slig

y, increasing the fusing nip.

mp, center heating lamp, heats the center and the

xial direction).

ar the center and the rear end of the drum-fuser belt,

nter and the ends, respectively. Two NTC

and the side, protect the fusing system from

off the center heating lamp and side heating lamp,

emperatures.

Pressure Roller

Dr

m-Fuser Belt

Thermistor

Center : 0.5mm-1.0mm distance

Side : Contact

Thermostat

NC Sensor

Service Manual

SCX-8030/8040 series

2-

4

SAMSUNG ELECTRONICS

Version 0.05

Page 51

2. Product

D

s

L

c

s

T

r

a

T

e

p

pp

p

e

i

e

h

e

f

3

2.6.2 Fuser unit component

The Fuser unit includes the following components:

escription

1. Center heater lamp (LAMP1) / Side heater lamp (

These halogen lamps heat the drum-fuser belt. The

lamp (LAMP2) are lit alternately to heat the drum-fu

Each heater lamp has its coil in a different location.

the center, those of the side heater lamp (LAMP2) a

the drum-fuser belt so that they will not rotate separ

2. Drum-fuser belt

It receives heat from halogen lamp inside and condu

reduces warming up time and mode changing time.

the surface of the fuser belt is fluorinated. Rigid ass

surface of the fuser belt at nip and is pressed on the

between fuser belt and pressure roller.

ni

3. Pressure roller

The pressure roller is a rubber roller which ensures

fuser belt. It is driven by external driving mechanism

4. NC sensors

NC sensors detect the surface temperature of the ce

the heater lamps.

AMP2)

enter heater lamp (LAMP1) and the side heater

er belt.

he coil of the center heater lamp (LAMP1) is in

e on both sides. The heater lamps are fixed inside of

tely.

cts heat to toner and paper. The thin fuser belt

o prevent the fuser belt from adhering to the toner,

mbly located inside the fuser belt contacts inner

pressure roller by springs in order to ensured proper

roper nip width between the pressure roller and

and drives fuser belt by pressure.

nter and the rear end of the fuser belt which controls

5. Thermistor (Center : 0.5mm-1.0mm distance, Sid

Thermistors, located at the center and rear end(non

overheating.

6. Thermostat

These thermostats cut off the power supply to the h

becomes abnormally hot as a result of problems suc

These thermostats are used to prevent abnormal op

replaced (as well as the other damaged parts in the

Service Manual

SCX-8030/8040 series

: Contact)

mage position), protect the fusing system from

ater lamps by opening the circuit when the fuser belt

as a NC sensor malfunction.

ration. When the thermostat is triggered, it must be

user unit).

2-

5

SAMSUNG ELECTRONICS

Version 0.05

Page 52

D

2.6.3 Fuser unit drive

e

dri

ith th

[B]

3

2. Product

escription

The fusing/paper exit motor [A] drives the pressure roll

ven by pressure w

e pressure roller

.

Fuser Belt [C]

r [B] through the gear train. The fuser belt [C] is

Exit Motor [A]

Pressure Roller [B]

2-

Service Manual

SCX-8030/8040 series

6

SAMSUNG ELECTRONICS

Version 0.05

Page 53

2. Product

D

detect the standby temperature. Then the CPU raises

e

g

o

o

h

h

e

h

3

the temperature to the

printing temperature

2.6.4 Temperature control

escription

When the main switch turns on, the CPU turns on the

Thermistor2

Thermistor1

NC Sensor2

NC Sensor1

Th

fusing lamp. The lamp stays on until the NC sensors

.

Lamp 1(700W) : Center heating

rmostat 1

Thermostat 2

Overheat Protection

The CPU cuts power to the fusing lamp in the followin

• The fuser belt temperature detected by the NC sens

• The fuser belt temperature detected by the thermist

The following components are used if thermistor over

• Two thermostats for the fuser belt get into line with t

• If one of the thermostat temperatures becomes high

lamp. If the other thermostat temperature becomes

fusing lamp.

Lamp 2(600W) :

Side heating

cases:

rs becomes higher than 198℃.

rs becomes higher than 210℃

eat protection fails.

e common ground line of the fusing lamp.

r than 170°C, it opens and cuts power to the fusing

igher than 170°C, it also opens and cuts power to the

Service Manual

SCX-8030/8040 series

2-

7

SAMSUNG ELECTRONICS

Version 0.05

Page 54

2. Product

D

O

n

1

5

1

3

2

P/Mirror Motor

2.7 Laser Scanning Unit

escription